Page 1

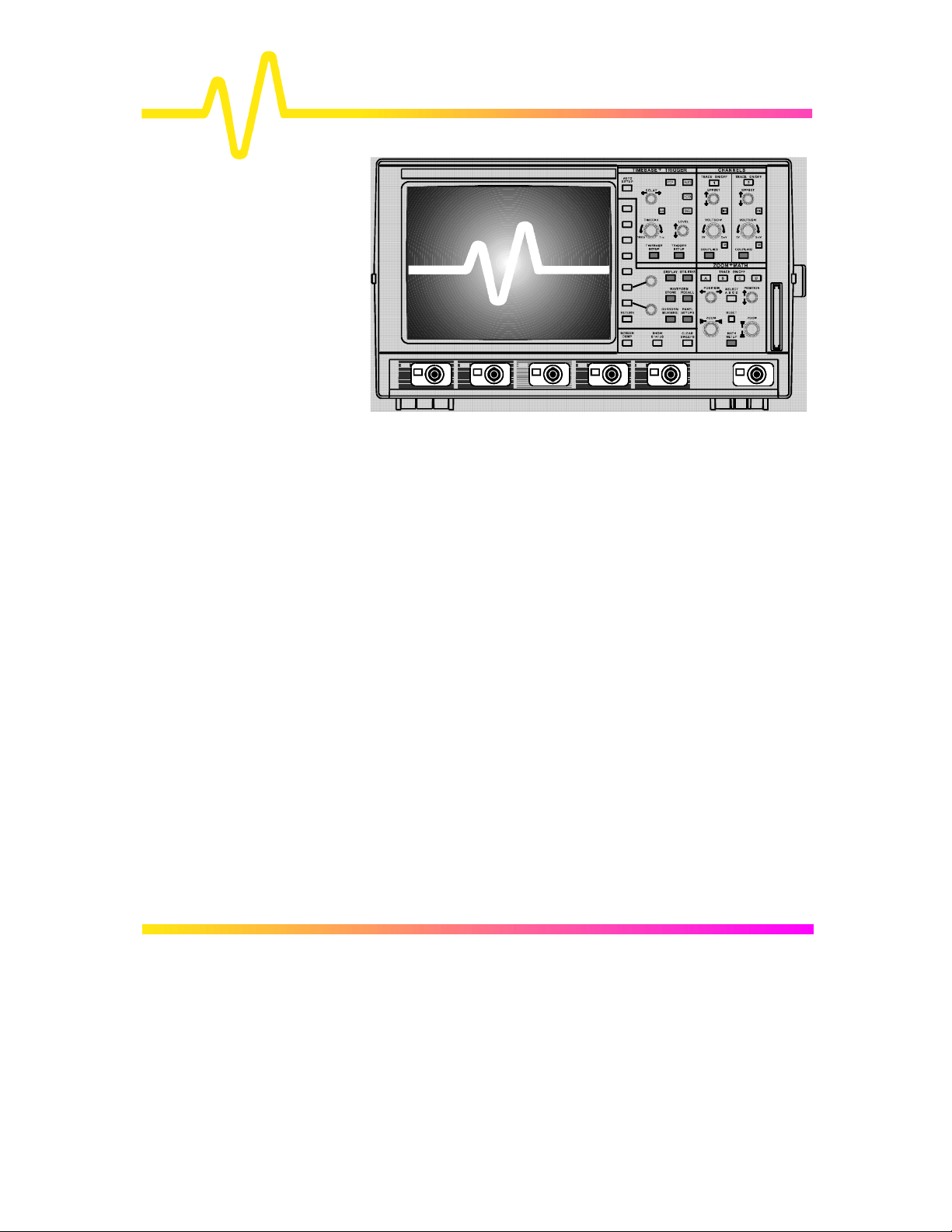

Operator’s Manual

LeCroy

9300C Series

Digital Oscilloscopes

Revision A — January 1998

Page 2

LeCroy Corporation

700 Chestnut Ridge Road

Chestnut Ridge, NY 10977–6499

Tel: (845) 578 6020, Fax: (845) 578 5985

LeCroy SA

2, rue du Pré-de-la-Fontaine

1217 Meyrin 1/Geneva, Switzerland

Tel: (41) 22 719 21 11, Fax: (41) 22 782 39 15

Internet: www.lecroy.com

Copyright © January 1998, LeCroy. All rights reserved. Information in this publication supersedes all

earlier versions. Specifications subject to change.

LeCroy, ProBus and SMART Trigger are registered trademarks of LeCroy Corporation. MathCad is

a registered trademark of MATHSOFT Inc. Centronics is a registered trademark of Data Computer

Corp. Epson is a registered trademark of Epson America Inc. PowerPC is a registered trademark of

IBM Microelectronics. MATLAB is a registered trademark of The MathWorks, Inc. DeskJet,

ThinkJet, QuietJet, LaserJet, PaintJet, HP 7470 and HP 7550 are registered trademarks of HewlettPackard Company. I

Manufactured under

an ISO 9000

Registered

Quality Management

System

Visit www.lecroy.com

to view the certificate.

2

C is a trademark of Philips.

This electronic product is

subject to disposal and

recycling regulations that

vary by country and

region. Many countries

prohibit the disposal of

waste electronic

equipment in standard

waste receptacles.

For more information

about proper disposal

and recycling of your

LeCroy product, please

visit

www.lecroy.com/recycle.

93XXC-OM-E Rev A 0198

Page 3

Chapter 1 — Read This First!

Product and Client Care..............................................................1–1

Chapter 2 — Instrument Architecture

General Designed Capabilities................................................2–1

Block Diagrams.................................................................................2–4

Chapter 3 — Installation and Safety

Installation for Safe and Efficient Operation...................3–1

Chapter 4 — Introduction to the Controls

The Front Panel.................................................................................4–1

The Main Controls.......................................................................... 4–3

Choosing and Navigating in Menus.......................................4–4

System Setup and Menu Controls..........................................4–6

Screen Topography ........................................................................4–8

Contents

Chapter 5 — CHANNELS, Coupling and Probes

Channel Controls..................................................................... 5–1

Coupling...............................................................................................5–3

Probes and Probe Calibration ..................................................5–4

Chapter 6 — TIMEBASE + TRIGGER

TIMEBASE + TRIGGER Controls..............................................6–1

Chapter 7 — Timebase Modes and Setup

Timebase Sampling Modes........................................................7–1

Timebase Setup ...............................................................................7–5

iii

Page 4

Chapter 8 — Triggers and When to Use Them

Choosing the Right Trigger .......................................................8–1

Edge or SMART? ..............................................................................8–2

Edge Trigger ......................................................................................8–3

TRIGGER SETUP: Edge................................................................8–9

SMART Triggers.............................................................................8–10

TRIGGER SETUP: SMART ........................................................ 8–29

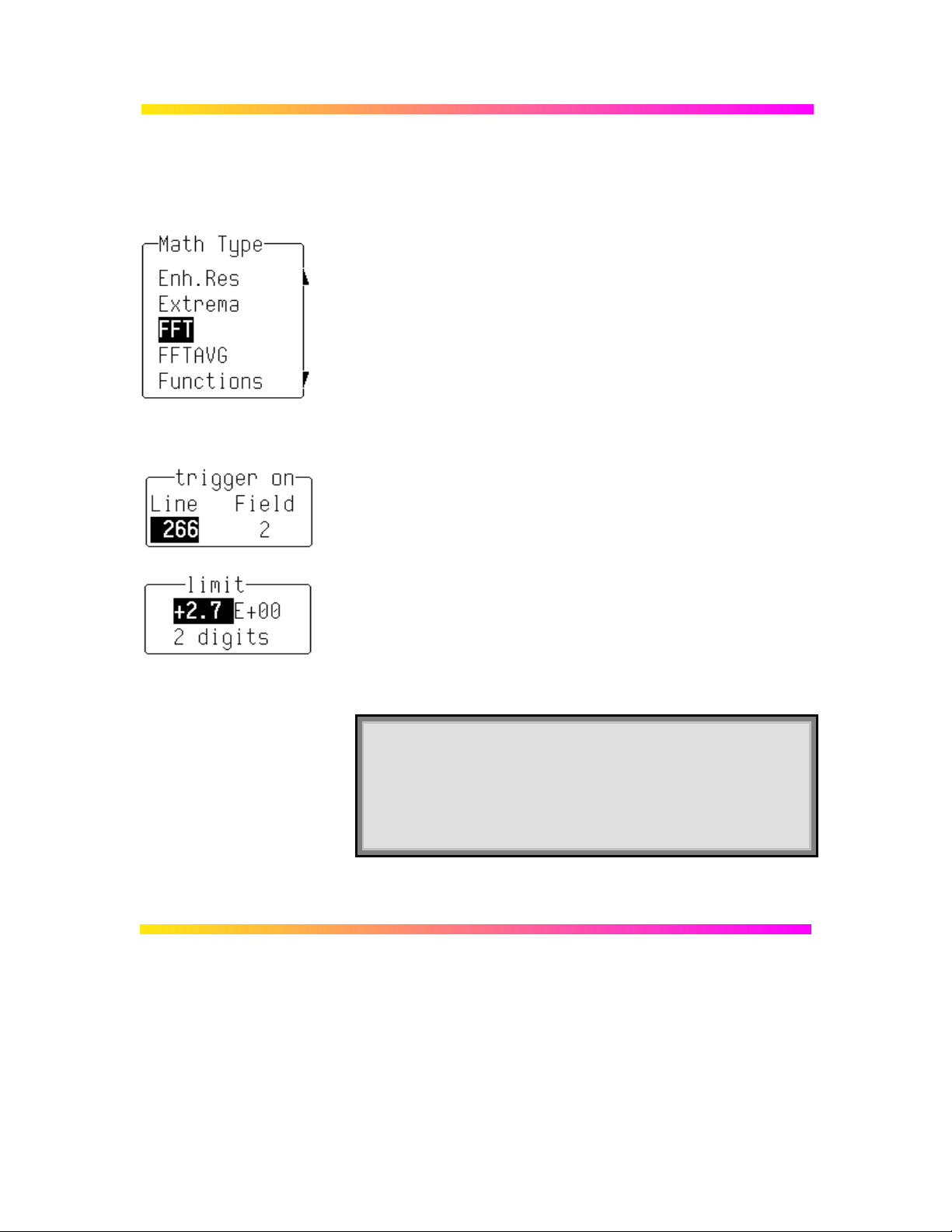

Chapter 9 — ZOOM + MATH

Zoom and Math Controls............................................................. .9–1

Chapter 10 — Zoom, Mathematics and Math Setup

Zooming for Precise Waveform Measurements...........10–1

Math Functions and Options ..............................................10–2

Using Waveform Mathematics...........................................10–5

Configuring for Zoom and Math.........................................10–6

Setting Up FFT Span and Resolution .............................10–17

Contents

Chapter 11 — Display

Chapter 12 — UTILITIES

Setting Up the Display........................................................ 11–1

Printing, Storing, Using Special Modes ........................... 12–1

Hardcopy Setup............................................................................12–2

Time/Date Setup...........................................................................12–4

GPIB/RS232 Setup.......................................................................12–5

Mass Storage Utilities .............................................................. 12–7

Special Modes ........................................................................ 12–19

CAL BNC Setup.............................................................................12–21

iv

Page 5

Chapter 13 — WAVEFORM STORE & RECALL

Waveform Store......................................................................13–1

Waveform Recall....................................................................13–4

Chapter 14 — CURSORS/MEASURE & Parameters

Cursors: Tools for Measuring Signal Values.................14–1

Parameters: Automatic Measurements ..........................14–4

Pass/Fail Testing...................................................................14–13

Chapter 15 — PANEL SETUPS

Saving and Recalling Panel Setups...............................15–1

Chapter 16 — SHOW STATUS

The Complete Picture — Summarized............................ 16–1

Appendix A — Specifications

Appendix B — Enhanced Resolution

Appendix C — Fast Fourier Analysis (FFT)

Appendix D — Parameter Measurement

Appendix E — ASCII-Stored Files

v

Page 6

1

Read This First!

Product and Client Care

We recommend you thoroughly inspect the contents of the

scope packaging at once. Check all the contents against

the packing list/invoice copy shipped with the instrument

and the list on page 1–3 of this manual. Unless LeCroy is

notified promptly of a missing or damaged item, we cannot

accept responsibility for its replacement. Contact your

national LeCroy Customer Service Department or local

office immediately (contact numbers follow index).

Warranty LeCroy warrants its oscilloscope products for normal use and

operation within specifications for a period of three years from

the date of shipment. Calibration each year is recommended to

ensure in-spec performance. Spares, replacement parts and

repairs are warranted for 90 days. The instrument's firmware has

been thoroughly tested and is thought to be functional, but is

supplied without warranty of any kind covering detailed

performance. Products not made by LeCroy are covered solely

by the warranty of the original equipment manufacturer.

In exercising its warranty, LeCroy will repair or, at its option,

replace any product returned within the warranty period to the

Customer Service Department or an authorized service center.

However, this will be done only if the product is determined by

LeCroy’s examination to be defective due to workmanship or

materials, and the defect has not been caused by misuse,

neglect or accident, or by abnormal conditions or operation.

Note: This warranty replaces all other warranties,

expressed or implied, including but not limited to any

implied warranty of merchantability, fitness, or adequacy

for any particular purpose or use. LeCroy shall not be liable

for any special, incidental, or consequential damages,

whether in contract or otherwise. The client will be

responsible for the transportation and insurance charges

for the return of products to the service facility. LeCroy will

return all products under warranty with transport prepaid.

1–1

Page 7

Read This First!

Product Assistance Help on installation, calibration, and the use of LeCroy

equipment is available from the LeCroy Customer Service

Department in your country (see contact numbers following the

index).

Maintenance Agreements We provide a variety of customer support services. Maintenance

agreements give extended warranty and allow our clients to

budget maintenance costs after the initial three-year warranty

has expired. Other services such as installation, training,

enhancements and on-site repairs are available through special

Supplemental Support Agreements.

Staying Up to Date LeCroy is dedicated to offering state-of-the-art instruments,

continually refining and improving the performance of our

products. Because of the speed with which physical

modifications may be implemented, this manual and related

documentation may not agree in every detail with the products

they describe. For example, there might be small discrepancies

in the values of components affecting pulse shape, timing or

offset, and — infrequently — minor logic changes.

However, be assured the scope itself is in full order and

incorporates the most up-to-date circuitry.

We frequently update firmware or software during servicing to

improve scope performance, free of charge during warranty. We

will keep you up to date with such changes, through new or

revised manuals and other publications.

But you should retain this, the original manual, for future

reference to your scope’s unchanged hardware

specifications.

Service and Repair Please return products requiring maintenance to the Customer

Service Department in your country or to an authorized service

facility. LeCroy will repair or replace any product under warranty

free of charge. The customer is responsible for transportation

charges to the factory, whereas all in-warranty products will be

returned to you with transportation prepaid. Outside the warranty

period, you will need to provide us with a purchase order

number before we can repair your LeCroy product. You will be

1–2

Page 8

billed for parts and labor related to the repair work, and for

shipping.

1–3

Page 9

Read This First!

How to Return a ProductContact your country’s Customer Service Department or local

field office to find out where to return the product. All returned

products should be identified by model and serial number. You

should describe the defect or failure, and provide your name

and contact number. And in the case of products returned to the

factory, a Return Authorization Number (RAN) should be used.

The RAN can be obtained by contacting the Customer Service

Department.

Return shipments should be made prepaid. We cannot accept

COD (Cash On Delivery) or Collect Return shipments. We

recommend air-freighting.

It is important that the RAN be clearly shown on the outside of

the shipping package for prompt redirection to the appropriate

LeCroy department.

What Comes with Your Scope The following items are shipped

together with the standard configuration of this oscilloscope:

Ø Front Scope Cover

Ø 10:1 10 MΩ Passive Probe — one per channel

Ø ProBus Single-Channel Adapter (9354C, 9374C, 9384C

SERIES ONLY)

Ø Two 250 V T-rated Fuses (5 A or 6.3 A depending on model

— see Chapter 3)

Ø AC Power Cord and Plug

Ø Operator’s Manual (this manual)

Ø Remote Control Manual

Ø Hands-On Guide

Ø Performance Certificate

Ø Declaration of Conformity

Ø Warranty

Note: Wherever possible, please use the original shipping

carton. If a substitute carton is used, it should be rigid and

packed so that that the product is surrounded by a minimum

of four inches or 10 cm of shock-absorbent material.

1–4

Page 10

2

Instrument

Architecture

General Designed Capabilities

Your oscilloscope is the newest

version of a series that set the

standard for monochrome DSOs

(Digital Storage Oscilloscopes).

Each of the scope’s channels has an

8-bit ADC (Analog–to–Digital Converter).

On the higher-range models, combining two channels doubles

the scope’s sampling rate. While on high-range, four-channel

models, combining all channels increases the original rate by

four times.

Processors The central microprocessor performs the scope’s computations and

controls its operation. A wide range of peripheral interfaces allow

remote control, storage and printing. A support processor constantly

monitors the front-panel controls, rapidly reconfiguring setups. Data

processing is also rapid, with data being transferred to the display

memory for direct waveform display or stored in the reference

memories (see below).

Note: Wherever a feature is specific to a particular model,

or not included with a model, it is indicated thus:

9314C ONLY, for example.

For the complete list of specifications for each

model, see the section on that model or its series in

Appendix A.

ADCs The instrument’s multiple-ADC architecture ensures absolute

amplitude and phase correlation, maximum ADC performance for

multi-channel acquisitions, large record lengths and excellent time

resolution.

Memories The copious acquisition memories simplify transient capture by

producing long waveform records that capture even when triggertiming or signal-speed is uncertain. Combining channels also

increases the acquisition memory length. There are four memories

for temporary storage, and four more for waveform zooming and

processing.

2–1

Page 11

Instrument

Architecture

RIS Repetitive signals can be acquired and stored at a Random

Interleaved Sampling (RIS) rate of 10 GS/s. RIS is a highprecision digitizing technique that enables measurement of

repetitive signals to the instrument's full bandwidth, with an

effective sampling interval of 100 ps and measurement

resolution of 10 ps. (See Chapter 7).

Trigger System The Trigger System offers an extensive range of capabilities,

selected according to the character of the signal, using onscreen menus and front-panel controls. In standard trigger mode

these menus and controls enable the selection and setting of

parameters such as pre- and post-trigger recording, as well as

special modes. The trigger source can be any of the input

channels, line (synchronized to the scope’s main input supply) or

external. The coupling is selected from AC, LF REJect, HF

REJect, HF, and DC; the slope from positive and negative. (See

Chapter 8.)

Automatic Calibration The oscilloscope’s automatic calibration ensures an overall

vertical accuracy of typically 1% of full scale. Vertical gain and

offset calibration take place each time the volts/div setting is

modified. In addition, periodic calibration is performed to ensure

long-term stability at the current setting.

Display System The display’s interactive, user-friendly interface is controlled by

push-buttons and knobs (see Chapter 4).

The large, 12.5 × 17.5 cm (nine-inch diagonal) screen shows

waveforms and data with enhanced resolution on a variety of

grid styles (see Chapter 11). Up to four waveforms can be

displayed at once, while the parameters controlling signal

acquisition are simultaneously reported. The screen presents

internal status and measurement results, as well as operational,

measurement, and waveform-analysis menus.

Printing or copying the screen on plotter, printer or to a

recording medium is done by pressing the front-panel SCREENDUMP button(See Chapter 12).

2–2

Page 12

Manual or Remote

Control

Despite being a truly digital instrument, the scope has a frontpanel layout and controls that will be familiar to users of analog

oscilloscopes. Rapid instrument response and instant

representation of waveforms on the high-resolution screen add

to this impression.

Four front-panel setups can be stored internally and recalled

either manually or by remote control, thus ensuring rapid frontpanel configuration. When the power is switched off, the current

front-panel settings are automatically stored for subsequent

recall at the next power-on.

The oscilloscope has also been designed for remote control

operation in automated testing and computer-aided

measurement applications — operations described in the

Remote Control Manual. The entire measurement process,

including cursor and pulse-parameter settings, dynamic

modification of front-panel settings, and display organization, is

controlled through the rear-panel GPIB (IEEE-488) and

RS-232-C ports (see Chapter 12).

2–3

Page 13

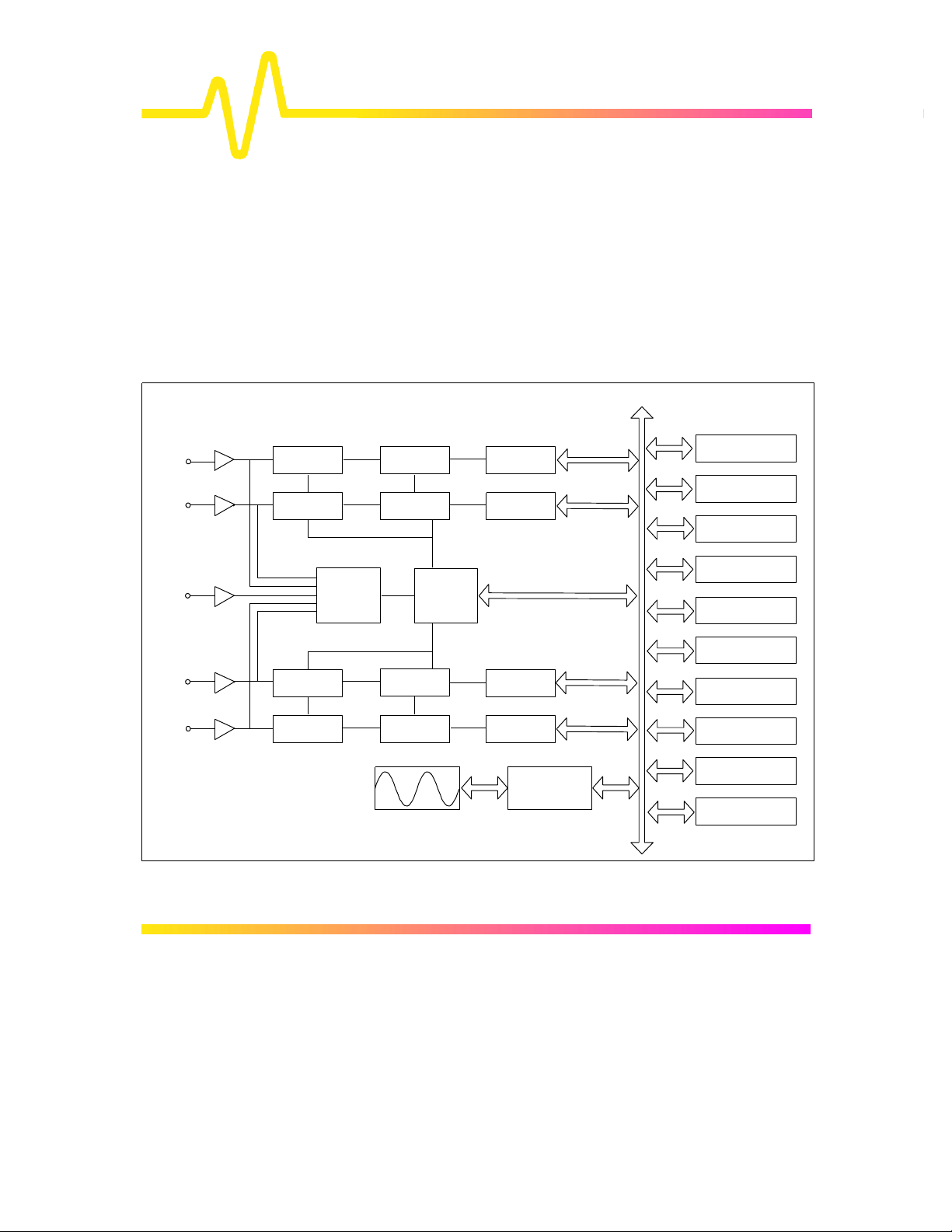

Block Diagrams

Program memory

Microprocessor

Storage devices

Ø 9304C, 9310C, 9314C

Instrument

Architecture

Series

Hi-Z, 50 Amplifiers + Attenuators

CH1

CH2

External

trigger

CH3

CH4

W

Sample

& Hold

Sample

& Hold

Sample

& Hold

Sample

& Hold

Trigger

logic

8-bit

Flash ADC

8-bit

Flash ADC

Timebase

8-bit

Flash ADC

8-bit

Flash ADC

Fast

memory

Fast

memory

Fast

memory

Fast

memory

processor

Display

Centronics

RS-232-C

GPIB

Coprocessor

Front-panel

processor

Real-time

clock

Data memories

2–4

Page 14

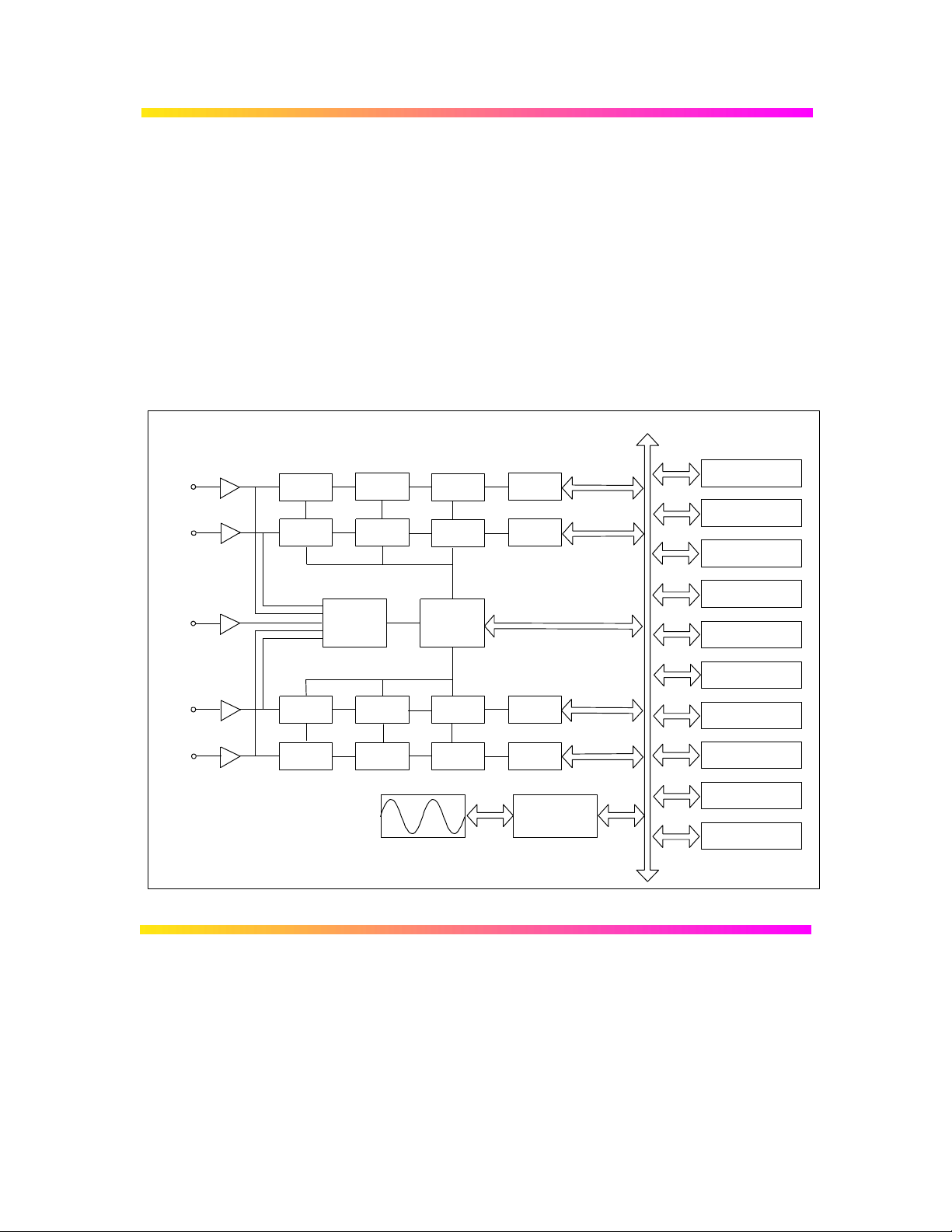

Ø 9344C, 9350C, 9354C

Program memory

Microprocessor

Series

Ø 9370C, 9374C Series

Ø 9384C Series

Hi-Z, 50 Amplifiers + Attenuators

CH1

CH2

External

trigger

CH3

CH4

W

Sample

& Hold

Sample

& Hold

Sample

& Hold

Sample

& Hold

8-bit ADC

8-bit ADC

Trigger

logic

8-bit ADC

8-bit ADC

Peak

detect

Peak

detect

Timebase

Peak

detect

Peak

detect

Fast

memory

Fast

memory

Fast

memory

Fast

memory

Display

processor

Storage devices

Centronics

RS-232-C

GPIB

Coprocessor

Front-panel

processor

Real-time

clock

Data memories

2–5

Page 15

3

Installation and Safety

Installation for Safe and Efficient Operation

The oscilloscope will operate to its specifications if the

operating environment is maintained within the following

parameters:

Operating Environment

Safety Symbols Where the following symbols or indications appear on the

Symbol Meaning

Ø Temperature..........................5 to 40 °C (41 to 104 °F) rated.

Ø Humidity................................Maximum relative humidity 80 % RH

(non-condensing) for temperatures up

to 31 °C decreasing linearly to 50 %

relative humidity at 40 °C

Ø Altitude ..................................< 2000 m (6560 ft)

The oscilloscope has been qualified to the following EN61010-1

category:

Ø Protection Class.........................................I

Ø Installation (Overvoltage) Category...........II

Ø Pollution Degree.........................................2

instrument’s front or rear panels, or elsewhere in this manual, they

alert the user to an aspect of safety.

CAUTION: Refer to accompanying documents (for Safetyrelated information).

See elsewhere in this manual wherever the symbol is present,

as indicated in the Table of Contents.

CAUTION: Risk of electric shock.

x

On (Supply).

3–1

Page 16

Installation and Safety

Symbol Meaning

Off (Supply)

Earth (Ground) Terminal

Protective Conductor Terminal

Chassis Terminal

Earth (Ground) Terminal on BNC Connectors

Denotes a hazard. If a WARNING is indicated on the

WARNING

WARNING Any use of this instrument in a manner not specified by the

Power RequirementsThe oscilloscope operates from a 115 V (90 to 132 V) or 220 V (180

instrument, do not proceed until its conditions are

understood and met.

manufacturer may impair the instrument’s safety

protection. The oscilloscope has not been designed to

make direct measurements on the human body. Users who

connect a LeCroy oscilloscope directly to a person do so at

their own risk. Use only indoors.

to 250 V) AC power source at 45 Hz to 66 Hz.

3–2

Page 17

No voltage selection is required, since the instrument automatically

adapts to the line voltage present.

Fuses The oscilloscope’s power supply is protected against short-circuit and

overload by means of two “T”-rated fuses of type according to scope

model:

Ø 6.3 A/250 V AC 9344C, 9350C, 9354C, 9370C, 9374C, 9384C Series

Ø 5 A/250 V AC 9304C, 9310C, 9314C Series.

The fuses are located above the mains plug. Disconnect the power

cord before inspecting or replacing a fuse. Open the fuse box by

inserting a small screwdriver under the plastic cover and prying it open.

For continued fire protection at all line voltages, replace only with fuses

of the specified type and rating (see above).

Ground The oscilloscope has been designed to operate from a single-phase

power source, with one of the current-carrying conductors (neutral

conductor) at ground (earth) potential. Maintain the ground line to

avoid an electric shock. None of the current-carrying conductors

may exceed 250 V rms with respect to ground potential. The

oscilloscope is provided with a three-wire electrical cord containing a

three-terminal polarized plug for mains voltage and safety ground

connection. The plug's ground terminal is connected directly to the

frame of the unit. For adequate protection against electrical hazard,

this plug must be inserted into a mating outlet containing a safety

ground contact.

Cleaning and Maintenance Maintenance and repairs should be carried out exclusively by a LeCroy

technician (see Chapter 1). Cleaning should be limited to the exterior of

the instrument only, using a damp, soft cloth. Do not use chemicals or

abrasive elements. Under no circumstances should moisture be allowed

to penetrate the oscilloscope. To avoid electric shocks, disconnect the

instrument from the power supply before cleaning.

CAUTION Risk of electrical shock: No user-serviceable parts inside. Leave

repair to qualified personnel.

Power On Connect the oscilloscope to the power outlet and switch it on by pressing

the power switch located on the rear panel. After the instrument is

switched on, auto-calibration is performed and a test of the

oscilloscope's ADCs and memories is carried out. The full testing

procedure takes approximately 10 seconds, after which time a display

will appear on the screen.

3–3

Page 18

4

Two-Channel Front Panel

Introduction to the

Controls

4–1

Page 19

Four-Channel Front Panel

Introduction to the

Controls

4–2

Page 20

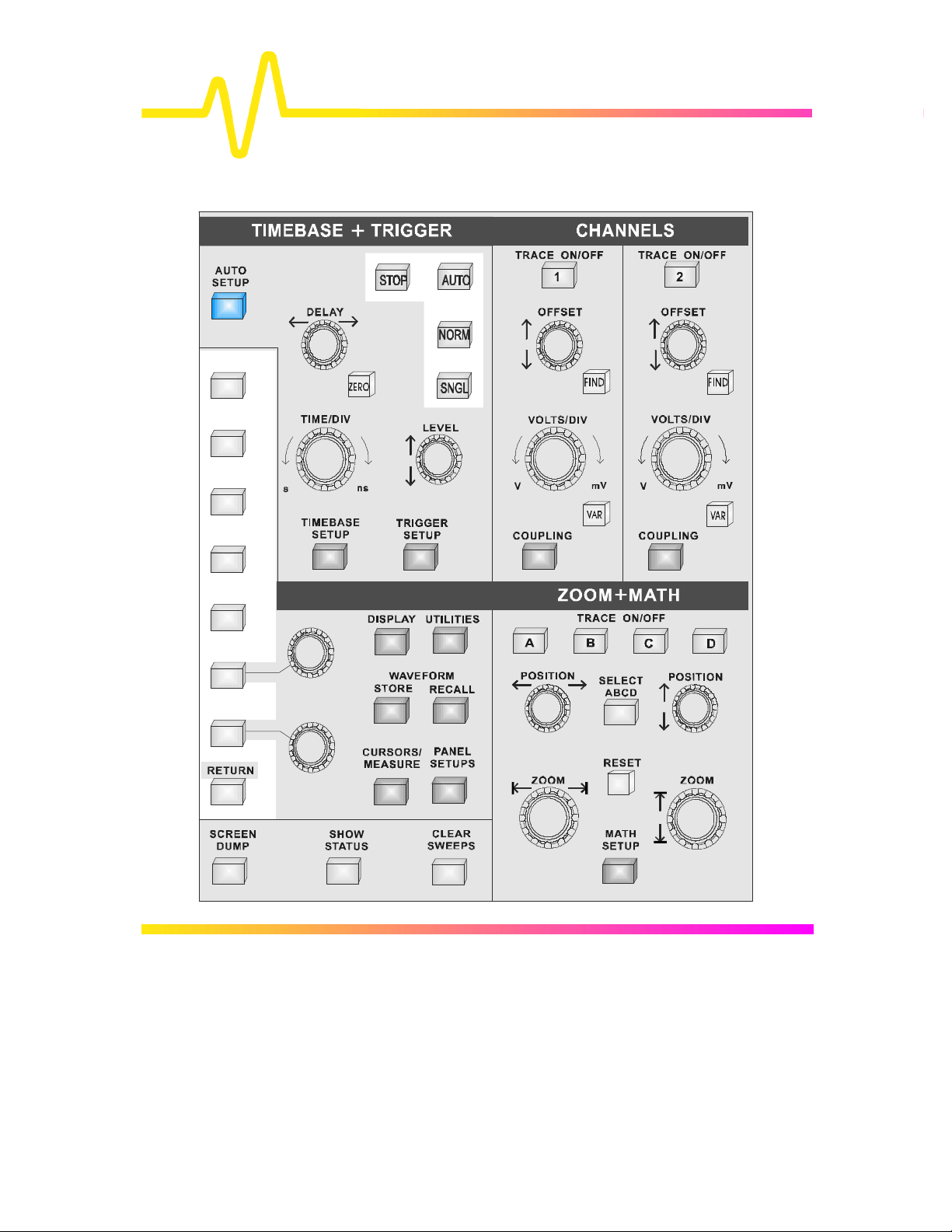

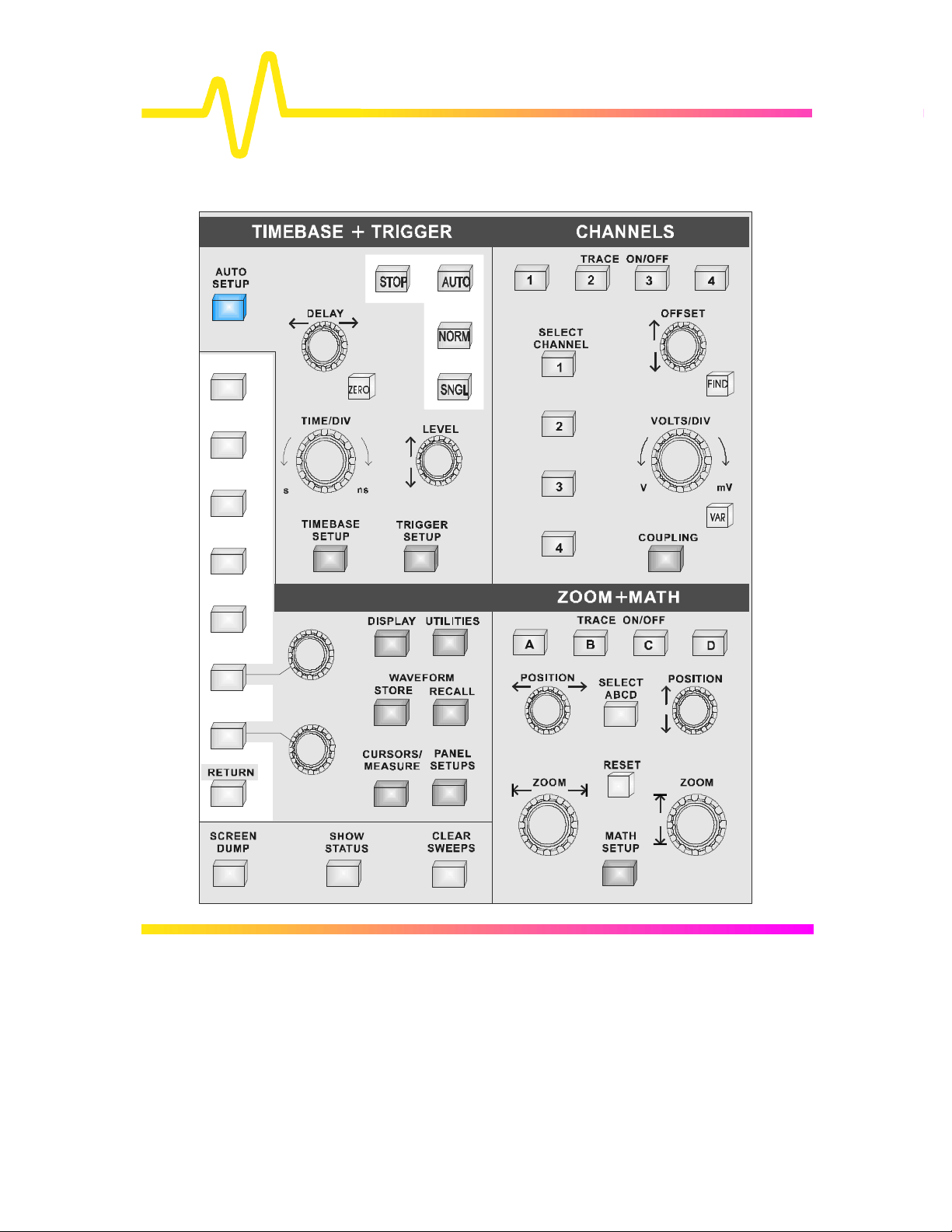

The Main Controls

The front panel controls are divided into four main groups

of buttons and knobs: the System Setup and menu

controls, CHANNELS, TIMEBASE + TRIGGER and ZOOM +

MATH.

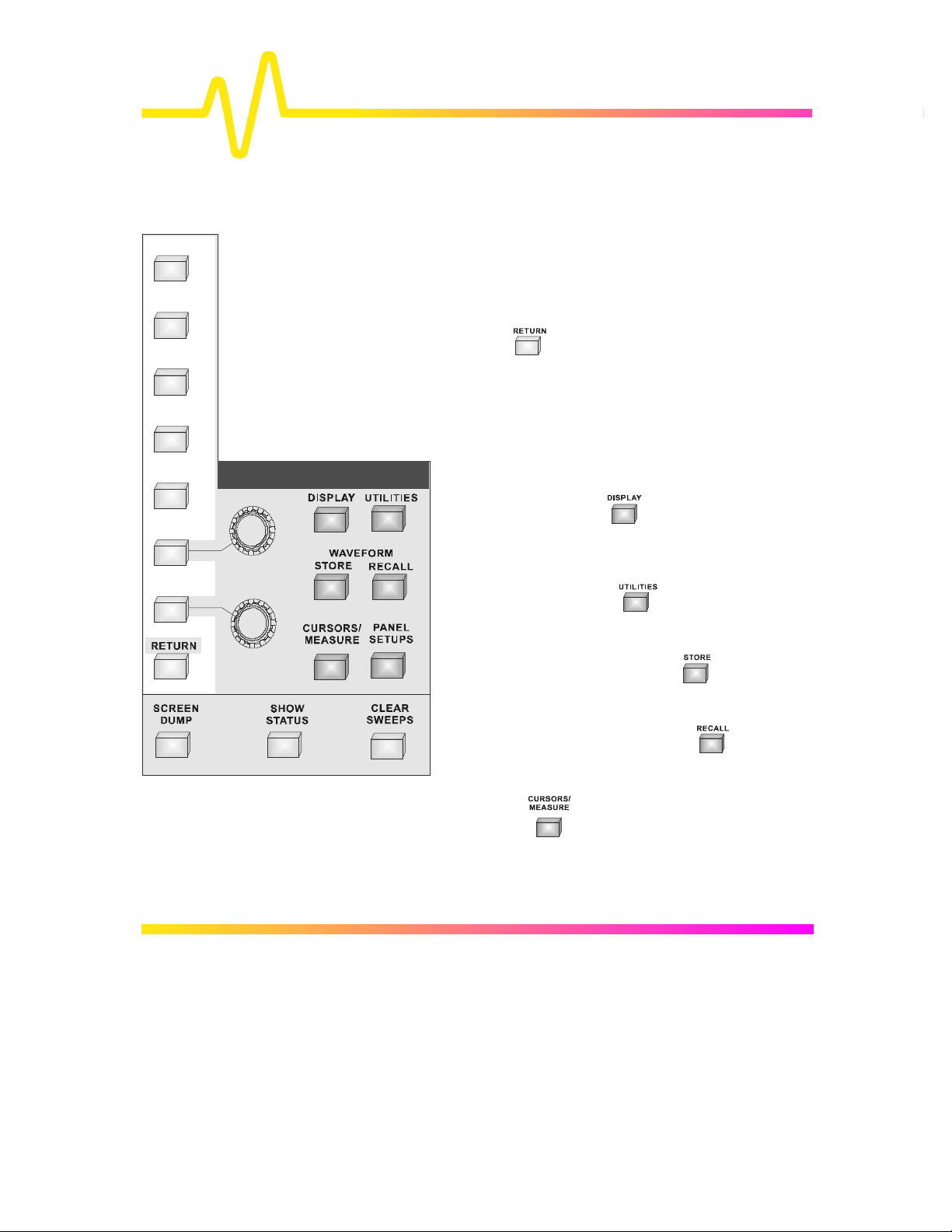

System Setup Dark-gray, menu-entry buttons, also represented in the other

groups of controls, provide access to the main on-screen menus

and the acquisition, processing and display modes of the

instrument.

The SCREEN DUMP, SHOW STATUS and CLEAR SWEEPS

buttons, respectively: copy or print the screen display, show onscreen summaries of the scope’s status, and restart operations that

require several acquisitions. See page 4–6.

Menu Buttons & Knobs The seven untitled buttons vertically aligned beside the screen,

RETURN and the two linked rotary knobs enable on-screen menu

selection. See following pages.

CHANNELS This group offers selection of displayed traces and adjustment of

vertical sensitivity and offset. See Chapter 5.

AUTO SETUP This singular blue button automatically adjusts the scope to acquire

and display signals on the input channels. See Chapter 6.

TIMEBASE + TRIGGER These controls allow direct adjustment of time/division, trigger level

and delay, as well as access to the “TIMEBASE” and “TRIGGER”

menu groups. See Chapters 6, 7 and 8.

ZOOM + MATH And this group controls trace selection, movement, definition, and

expansion with Zoom and Math functions. See Chapters 9 and 10.

See also “ Getting Started”, Part 2 of the

Hands-On Guide , for more on the front-panel

and a complete run-through of the controls…

4–3

Page 21

Introduction to the

entry

Choosing and Navigating in Menus

On-screen menus — the panels running down the righthand side of the screen — are used to select specific scope

actions and settings. All other on-screen text is for

information only. The menus are broadly grouped

according to function. The name of each menu group is

shown at the top of the column of menus. Individual menus

also have names in the top of their frames.

Each menu either contains a list of items or options — functions

to be selected or variables modified — or when selected

performs a specific action. Menus that perform certain actions

are indicated by capitalized text, as in the example shown at left.

Controls

Going to Menus and

Selecting from them

When a menuconfiguration for its particular group of functions is immediately

displayed on-screen as a menu group. Once accessed, these

menus are controlled using the menu buttons and the two menu

knobs (illustrated at left).

A menu button is active and can be pressed to make

selections whenever a menu is visible beside it on-screen.

The two menu knobs work together with the two menu

buttons to which they are joined by lines. Both control the

menus currently shown beside them. Buttons and knobs are

used either for selecting entire menus, particular items from

menus, for moving up or down through menu lists, or for

changing the values listed in menus.

Some menus, referred to as primary, have secondary menus

beneath them whose existence is indicated by a heavy outline or

shadow, as illustrated at left. Pressing the corresponding menu

button reveals and activates these ‘hidden’ menus. Pressing the

RETURN button again displays the top, or primary, menu.

Changing a menu value normally changes the screen, because the

new value is immediately used in acquisition settings, processing or

display.

button is pressed, the set-up

4–4

Page 22

Setting Menu Options The activated selection is highlighted in the menu. Press the

corresponding menu button and the field will advance to

highlight and select the next item on the menu. However, if

there is only one item on a menu, pressing its button will have

no effect.

Where a menu is associated with one of the two menu knobs,

turning this knob in one direction or the other will cause the

selection to move either up or down the list in the menu.

Menus that extend along the length of two menu buttons can be

operated using both buttons. Pressing the lower of the two will

move the highlighting forward — down the list — while pushing

the upper will move the selector back up the list.

An arrow on the side of a menu frame indicates that by pressing

the button beside this arrow, the selection can be moved further

up or down the list. The arrow’s direction shows whether the

highlighting selector will move up or down. Arrows may also

indicate items that are not visible, either above or below on the

list. The respective arrow will disappear when the selection is at

the very beginning or end of the list.

As in the examples at left, some menu button and knob

combinations control the value of a continuously adjustable

variable. The knob is then used to set its value, while the button

either selects a value or makes a simple change in it.

Still other menu button and knob combinations control the value

of several continuously adjustable variables, with the knob used

to set the value and the button to highlight it.

Note: When the oscilloscope is placed in a remote state,

the REMOTE ENABLE menu will be displayed. It will

contain the command “GO TO LOCAL”, activated by menu

button if the action is possible. This is the only manual

way to turn off the REMOTE ENABLE menu. The scope

need not be in remote state to accept remote commands.

4–5

Page 23

Introduction to the

System Setup and Menu Controls

As well as the menu buttons and knobs described on the

previous pages, the System Setup controls include the menuentry buttons and others for copying displays, reporting

instrument status and restarting multiple-acquisition

operations.

The RETURN button is used to go back to the preceding

displayed menu group. Or it returns the display to a higher-level, or

primary menu. But when the display is at the highest possible menu

level, the button switches off that menu.

Each of the dark-gray menu-entry buttons activates a major set of

on-screen menus (those represented in the other control groups are

described in the following chapters, along with the other

elements in the groups).

The DISPLAY button provides entry to the

“DISPLAY SETUP” group of menus, controlling display

mode, grids, intensities, Dot Join and Persistence menus.

See Chapter 11.

Controls

The UTILITIES button gives access to the

“UTILITIES” menus, controlling hardcopy setups, GPIB

addresses and special modes of operation. Chapter 12.

The WAVEFORM STORE button

“STORE W’FORM” menus, used for storing waveforms

to internal or external memory. Chapter 13.

Whereas, WAVEFORM RECALL

“RECALL W’FORM”: menus for retrieving waveforms

stored in internal or external memory. Chapter 13.

CURSORS/MEASURE

menus, used for making precise cursor measurements on traces,

and “MEASURE”, for precise parameter measurements. Chapter

14.

4–6

offers up the “CURSORS” Setup

accesses the

calls up

Page 24

And PANEL SETUPS gives access to the “PANEL SETUPS”

menus for saving and recalling a configuration of the instrument.

See Chapter 13.

SCREEN DUMP — prints or plots the screen display to an on-line hardcopy device,

via the GPIB, RS-232-C or Centronics interface ports, or directly to

an external thermal graphics printer. Hardcopies can also be

generated as data files onto floppy, memory card or portable hard

disk.

Once SCREEN DUMP is pressed, all displayed information will be

copied. However, it is possible to copy the waveforms without the

grid by turning the grid intensity to 0 with the “Display Setup” menu.

While a screen dump is taking place — indicated by the on-screen

“PRINTING” or “PLOTTING” message — it can be aborted by

pressing SCREEN DUMP a second time. It will take a certain

amount of time for the buffer to empty before copying stops.

CLEAR SWEEPS — restarts operations requiring several acquisitions, or sweeps,

including averaging, extrema, persistence and pass/fail testing, by

resetting the sweep counter(s) to zero.

SHOW STATUS — menu entry to “STATUS”, which shows summaries of the

instrument’s status for acquisition, system and other aspects. See

Chapter 16.

4–7

Page 25

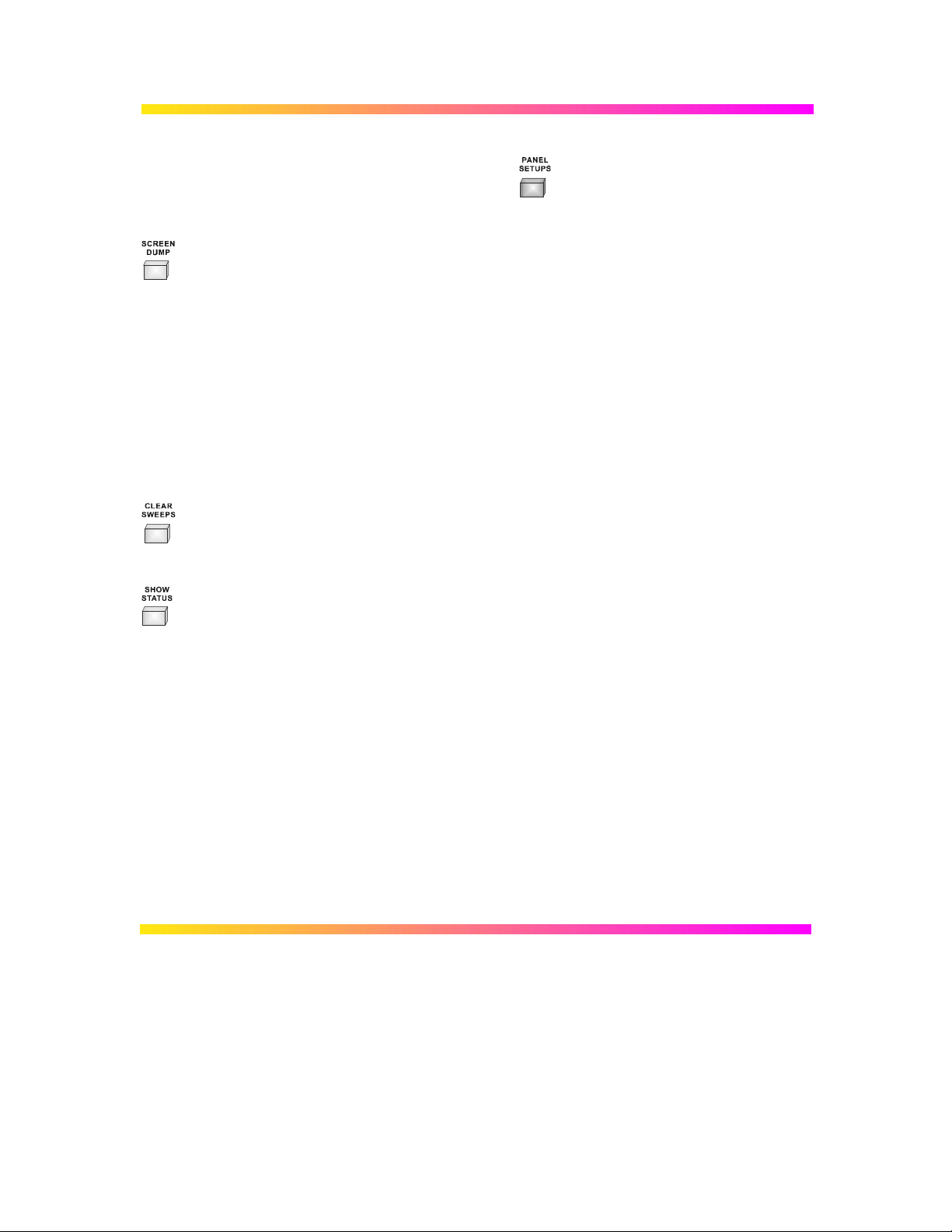

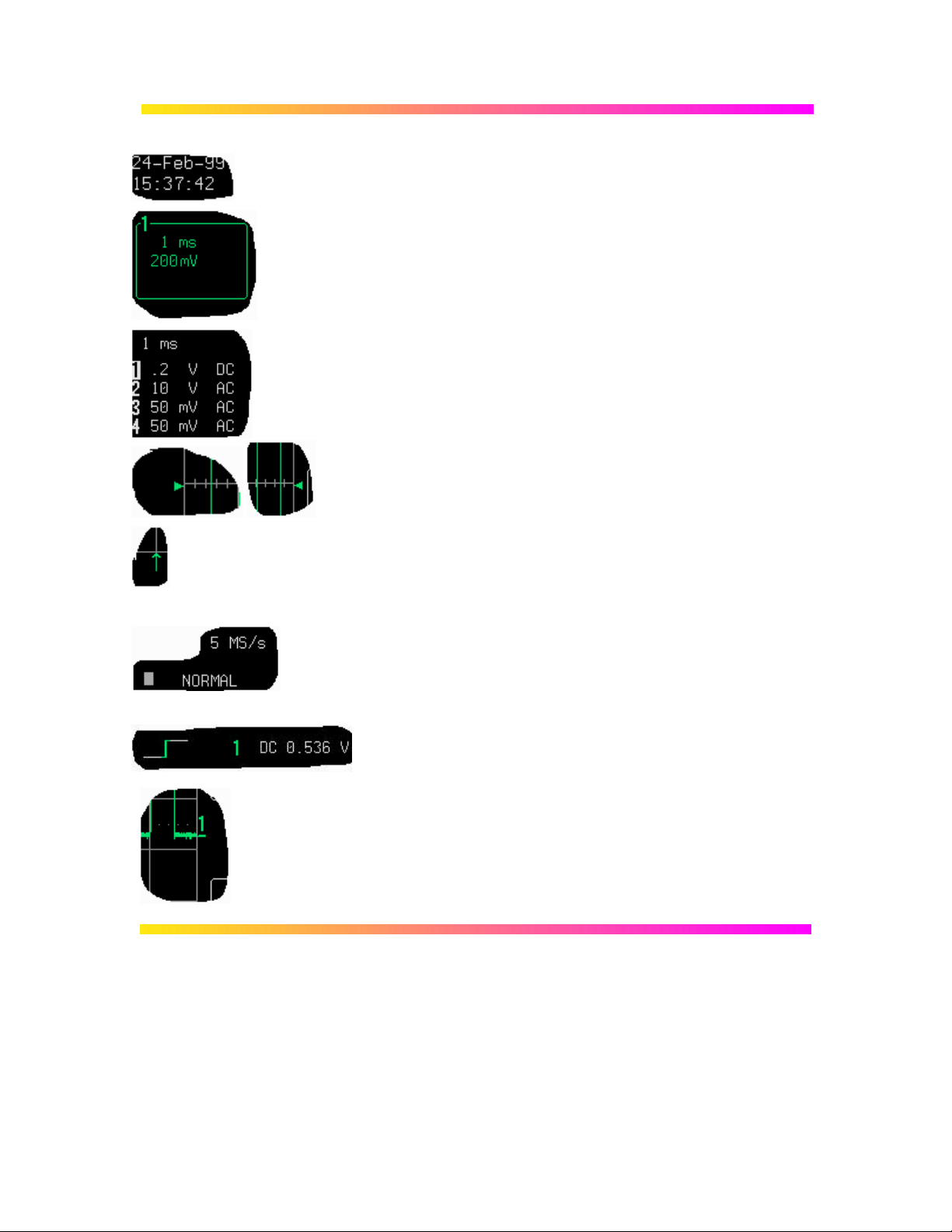

Screen Topography

Introduction to the

Controls

The sections of the screen shown here and described below, which surround the grid,

contain a variety of useful information as well as accessing specific commands and functions.

4–8

Page 26

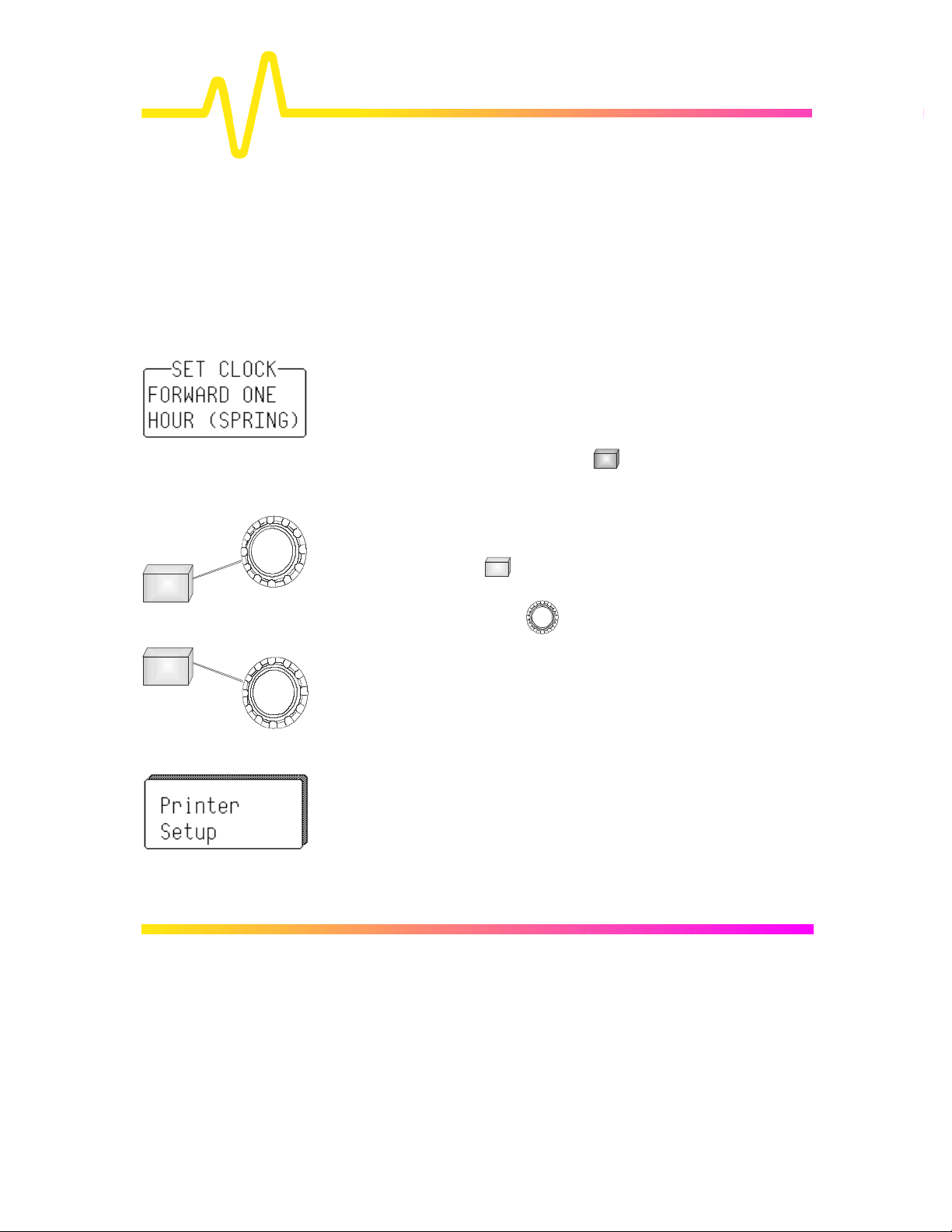

Real-Time Clock field: powered by a battery-backed real-time

clock, it displays the current date and time.

Displayed Trace Label indicates each channel or channel

displayed, the time/div and volts/div settings, and cursor

readings where appropriate. It indicates the acquisition

parameters set when the trace was captured or processed, while

the Acquisition Summary field (below) indicates the present

setting.

Acquisition Summary field: timebase, volts/div, probe

attenuation and coupling for each channel, with the selected

channel highlighted. It indicates the present setting, while the

acquisition parameters set when the trace was captured or

processed are indicated in the Displayed Trace label (above).

Trigger Level arrows on both sides of the grid that mark the

trigger voltage level relative to ground level.

Trigger Delay: an arrow indicating the trigger time relative to

the trace. The delay can be adjusted from zero to ten grid

divisions (pre-trigger), or zero to −10 000 (post-trigger) offscreen. Pre-trigger delay appears as the upward-pointing arrow,

while post-trigger is given as a delay in seconds.

Trigger Status field shows sample rate and trigger re-arming

status (AUTO, NORMAL, SINGLE, STOPPED). The small

square icon flashes to indicate that an acquisition has been

made.

Trigger Configuration field: icon indicating type of trigger, and

information on the trigger’s source, slope, level and coupling,

and other information when appropriate.

Trace and Ground Level: trace number and ground-level

marker.

4–9

Page 27

Introduction to the

AUTO

SETUP

Controls

Other Fields

(not illustrated here)

Time and Frequency field: displays time and frequency relative

to cursors beneath the grid. For example, when the absolute

time cursor (the cross-hair) is activated by selection from the

“MEASURE” menu group, this field displays the time between

the cursor and the trigger point.

Message field: used to display a variety of messages, above

the grid, including warnings, indications and titles showing the

instrument’s current status.

General Instrument Reset: Simultaneously

press the AUTO SETUP button, the top menu

button, and the RETURN button. The scope will

revert to its default power-up settings.

Press:

!

+ +

4–10

Page 28

5

Channel Controls

These enable selection

of displayed traces and

adjustment of vertical

sensitivity and offset.

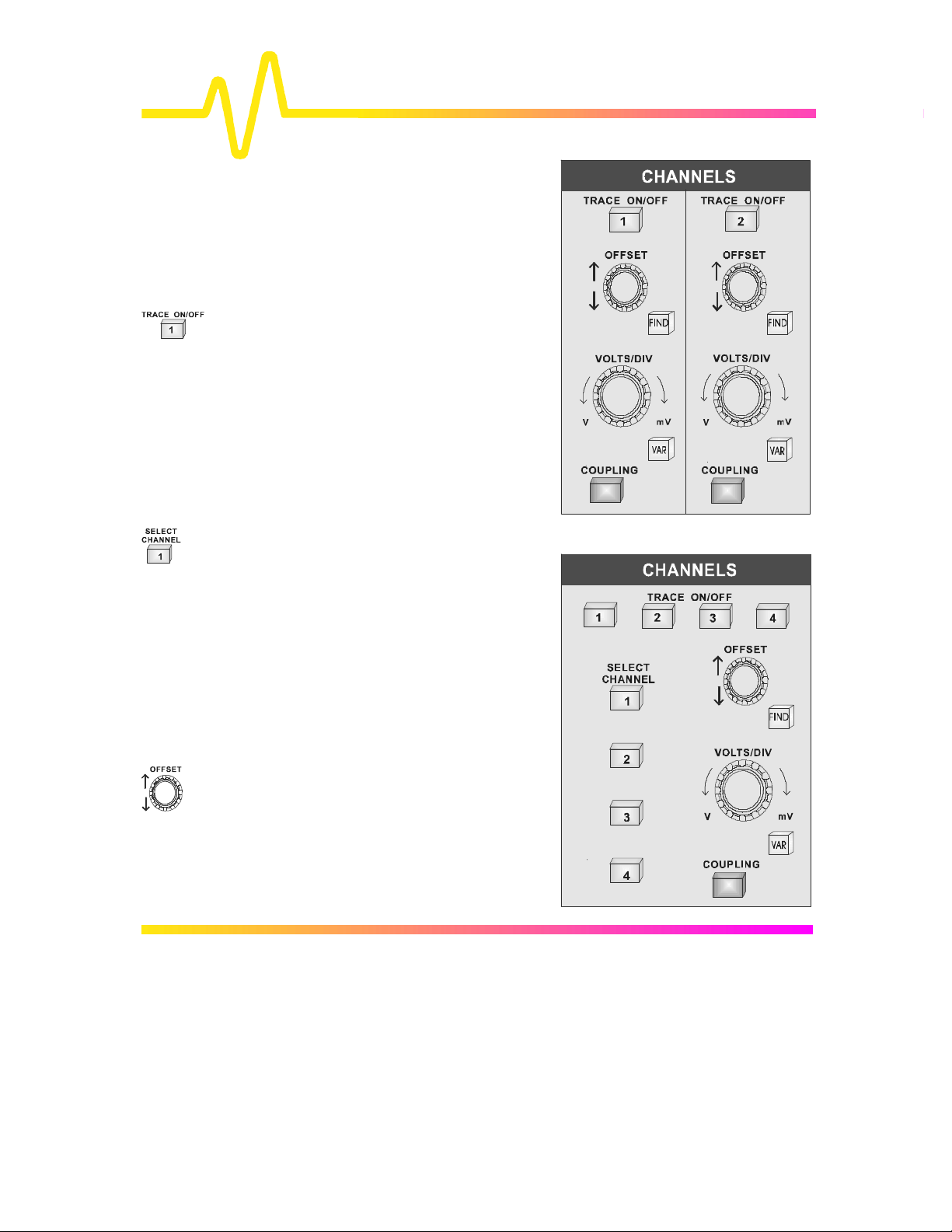

TRACE ON/OFF Pressing these buttons either

displays or switches off the

corresponding channel trace.

When a channel is switched

on, the OFFSET and

VOLTS/DIV controls will

then be attributed to this, the

active channel. On twochannel models (right), each

channel has its own set of

unique, dedicated controls.

CHANNELS, Coupling & Probes

SELECT CHANNEL On four-channel models

(right), these buttons are

used to attribute all the

vertical controls to one

channel, independent of

whether or not it is the

channel displayed. The

selected channel number

is highlighted in the

Acquisition Summary

field (see previous

chapter).

OFFSET — vertically positions the

active channel.

5–1

Page 29

CHANNELS, Coupling & Probes

FIND — automatically adjusts offset and volts/div to match the active

channel’s input signal.

VOLTS/DIV — selects the vertical sensitivity factor either in a 1–2–5 sequence

or continuously (see VAR, below ). The effect of gain changes on the

acquisition offset can be chosen from the “SPECIAL MODES”

menu.

VAR — allows the user to determine whether the VOLTS/DIV knob will

modify the vertical sensitivity in a continuous manner or in discrete

1–2–5 steps.

The format of the vertical sensitivity in the Acquisition Summary

field (bottom left of screen) shows whether the VOLTS/DIV knob is

operating in continuous or stepping mode.

COUPLING — menu-entry button that accesses the “Coupling” menus (see next

section).

5–2

Page 30

Coupling

Coupling Menus Press for access to selection of:

Ø Coupling and grounding of each input channel

Ø ECL or TTL gain, offset and coupling preset for the

channel shown

Ø Bandwidth limiter for all channels

Ø Probe attenuation of each input channel.

Coupling

Used to select the input channel’s coupling. If an overload is

detected, the instrument will automatically set the channel to the

grounded state: the menu can then be reset to the desired coupling.

V/div Offset

When NORMAL is highlighted, pressing the corresponding menu

button sets the offset, Volts/div, and input coupling to display ECL

signals. Press the button a second time and the settings for TTL

signals are given. And a third time returns the settings to those used

at the last manual setup of the channel.

Global BWL

To turn the bandwidth limit “OFF” or “ON”. The bandwidth can be

reduced from 500 MHz or 1 GHz, to either 200 MHz or 25 MHz, or

30 MHz (–3dB), depending on the model (see Appendix A).

Bandwidth limiting can be useful in reducing signal and system

noise or preventing high-frequency aliasing, reducing — for

example — any high-frequency signals that may cause aliasing in

single-shot applications.

Note: This command is global and affects all input channels.

Probe Atten

Sets the probe attenuation factor related to the input channel (see

following for probe details).

5–3

Page 31

CHANNELS, Coupling & Probes

In the AC position, signals are coupled capacitively, thus

blocking the input signal’s DC component and limiting the

In the DC position, all signal frequency components are

allowed to pass through, and 1

MΩ or 50

Ω may be chosen as

The maximum dissipation into 50

Ω is 0.5

W and inputs will

automatically be grounded whenever this is attained. An

overload message will be displayed in the Acquisition

Summary Field and “Grounded” will be indicated in the

the signal from the input and again selecting the 50

Ω input

Probes and Probe Calibration

Probe Calibration To calibrate the probe supplied, connect it to one of the input

channels’ BNC connectors. Connect the probe’s grounding

alligator clip to the CAL BNC ground and touch the tip to the

inner conductor of the CAL BNC. The CAL signal is a 1 kHz

square wave, 1 V p-p.

Set the channel coupling to DC 1 MΩ, turn the trace ON and

push AUTO SETUP to set up the oscilloscope. If over- or

undershoot of the displayed signal occurs, the probe can be

adjusted by inserting the small screwdriver, supplied with the

probe package, into the trimmer on the probe’s barrel and

turning it clockwise or counter-clockwise to achieve the optimal

square-wave contour.

More On Coupling

signal frequencies below 10 Hz.

the input impedance.

“Coupling” menu. The overload condition is reset by removing

impedance from the menu.

5–4

Page 32

ProBus System LeCroy’s ProBus system provides a complete measurement

solution from probe tip to oscilloscope display. This intelligent

interconnection between LeCroy oscilloscopes and a growing range

of accessories is achieved via a six-wire bus following Philips’ I2C

protocol. It provides major benefits over standard BNC or even

probe-ring connections:

Ø Autosensing the probe type, eliminating all the guesswork —

and the errors — from manually setting attenuation or

amplification factors, and ensuring proper input coupling.

Ø Transparent gain and offset control right from the front panel

— particularly useful for FET (FET menus shown here) and

current probes.

Ø Gain and offset correction factors are uploaded from the

ProBus EPROMS on FET probes and automatically

compensated to achieve fully calibrated measurements.

Coupling

Used to select the input channel’s coupling. If an overload is

detected, the instrument will automatically set the channel to the

grounded state: the menu can then be reset to the desired coupling.

V/div Offset

When NORMAL is highlighted, pressing the corresponding menu

button sets the offset, Volts/div, and input coupling to display ECL

signals. Press the button a second time and the settings for TTL

signals are given. And a third time returns the settings to those used

at the last manual setup of the channel.

Global BWL

To turn the bandwidth limit “OFF” or “ON”. The bandwidth can be

reduced from 500 MHz or 1 GHz, to either 200 MHz or 25 MHz, or

30 MHz (–3dB), depending on the model (see Appendix A).

Bandwidth limiting can be useful in reducing signal and system

noise or preventing high-frequency aliasing, reducing — for

example — any high-frequency signals that may cause aliasing in

single-shot applications.

When a FET probe is used, “Probe sensed…”, automatically

appears to indicate settings. When other ProBus probes are

used, this is redefined.

5–5

Page 33

6

TIMEBASE + TRIGGER

TIMEBASE + TRIGGER Controls

These controls allow direct adjustment of time/division,

trigger level and delay, and access the “TIMEBASE” and

“TRIGGER” menu groups.

AUTO SETUP The blue button

automatically scales

the timebase, trigger

level, offset, and

volts/div to provide a

stable display of

repetitive signals.

AUTO SETUP operates only on

channels which are active. If no

channels are on, then AUTO

SETUP will operate on all

channels, switching them all on.

Signals detected must have an

amplitude between 5 mV and

40 V, a frequency greater than

50 Hz, and a duty cycle greater

than 0.1 %.

If signals are detected on several channels, the channel with the

lowest number will determine the selection of the timebase and

trigger source.

STOP This button halts the acquisition in any of the three re-arming

modes: Auto, Normal or Single.

Pressing the STOP button prevents the oscilloscope acquiring a

new signal.

Press STOP while a single-shot (see next chapter) acquisition is

under way and the last acquired signal will be kept.

6–1

Page 34

TIMEBASE + TRIGGER

Press STOP after an RIS acquisition has been started (next

chapter) and the acquisition will be halted and a partial

waveform reconstruction will be performed.

Press STOP when the acquisition is in Roll Mode (see next

chapter) and the incomplete acquisition data will be shown as if

a trigger had occurred.

In Sequence Mode (next chapter), the action will stop the

timebase and show all new segments.

AUTO Pressing this button places the instrument in Auto Mode: the

scope automatically displays the signal if no trigger occurs within

60 ms.

If a trigger does occur within this time, the oscilloscope behaves

as in Normal Mode.

Press AUTO in RIS Mode and the acquisition will be terminated

and shown each second (some required segments may be

missing).

Press the button in Roll Mode and the oscilloscope will sample

the input signals continuously and indefinitely. The acquisition

will have no trigger condition but can be stopped as desired.

Press AUTO in Sequence Mode and the acquisition will be

terminated if the time between two consecutive triggers exceeds

a timeout that can be selected. The next acquisition is then

started from Segment 1.

NORM Pressing this button will continuously update the screen as long

as a valid trigger is present. If not, the last signal is preserved

and the warning “SLOW TRIGGER” is displayed in the Trigger

Status Field.

Press NORM in Roll Mode and the acquisition will be terminated

when the last needed data after a trigger have been taken. The

display will pause to show the entire waveform. It then goes

back into Roll Mode while it waits for the next trigger.

Press this button in Sequence Mode and the acquisition will be

terminated after the last segment is acquired. The next

acquisition will start immediately. Sequence WRAP in Normal is

the same as in Single-Shot Mode.

6–2

Page 35

SNGL Pressing this button places the scope in Single-Shot Mode,

where it waits for a single trigger to occur, then displays the

signal and stops acquiring. If no signal occurs, the button can be

pressed again to show the signal being observed without a

trigger.

Press SNGL when in RIS Mode and the instrument will wait for

all the trigger events required to build up one signal on screen

before it stops. This may require as many as 4000 trigger

events.

Single-Shot Roll Mode behavior is the same as standard SingleShot but without the need to press the button a second time to

show the signal.

DELAY — is used to adjust the pre- or post-trigger delay. Pre-trigger

adjustment is available from zero to 100 % of the full time-scale

in steps of 1 %. The pre-trigger delay is illustrated by the vertical

arrow symbol at the bottom of the grid. Post-trigger adjustment

is available from 0 to 10 000 divisions in increments of 0.1 of a

division. The post-trigger-delay value is labeled in seconds and

is located in the on-screen Trigger Delay field.

ZERO — sets the trigger delay at zero, the trigger instant at the left-

hand edge of the grid.

TIME/DIV — selects the time per division in a 1–2–5 sequence. The

time/div setting is displayed in the Acquisition Summary field.

LEVEL — adjusts the trigger threshold. The amplitude of trigger signals

and the range of trigger levels is limited: ± 5 screen divisions

with a channel as trigger source; ± 0.5 V with EXT as trigger

source; ± 5 V with EXT/10 as trigger source; and Inactive with

Line as trigger source. The trigger sensitivity is better than a

third-of-a-screen division.

6–3

Page 36

TIMEBASE + TRIGGER

TIMEBASE SETUP — menu-entry button that calls up the “TIMEBASE” menus

described in the next chapter.

TRIGGER SETUP — menu-entry button that calls up “TRIGGER SETUP” detailed

in Chapter 8.

6–4

Page 37

7

Timebase Modes and Setup

Timebase Sampling Modes

Depending on the timebase, any of three sampling modes

can be chosen: Single-Shot, Random Interleaved Sampling

(RIS) or Roll Mode. Furthermore, for timebases suitable for

either Single-Shot or Roll Mode, the acquisition memory

can be subdivided into user-defined segments to give

Sequence Mode. Channels can also be combined to boost

sample rate and record length.

Single-Shot Single-Shot is the digital oscilloscope’s basic acquisition

technique and other timebase modes make use it.

An acquired waveform consists of a series of measured voltage

values sampled at a uniform rate on the input signal. The

acquisition, a single series of measured data values associated

with one trigger event, is typically stopped at a fixed time after

the arrival of the event, this being determined by the trigger

delay. The time of the trigger event is measured using the

timebase clock. The horizontal position of a waveform is

determined using the trigger event as the definition of time zero.

Waveform display is also carried out using this definition.

Because each channel has its own ADC, the voltage on each

input channel is sampled and measured at the same instant.

This allows very reliable time measurements between different

channels.

Trigger delay can be selected anywhere within a range that

allows the waveform to be sampled from well before the trigger

event up to the moment it occurs (100 % pre-trigger), or at the

equivalent of 10 000 divisions (at the current time/div) after the

trigger.

For fast timebase settings the ADCs’ maximum single-shot

sampling rate is used (on one and each channel, with higher

sampling rates achieved by combining channels — see page

7–4). For slower timebases, the sampling rate is decreased and

the number of data samples maintained. (See Appendix A for

details).

7–1

Page 38

Timebase Modes and Setup

Peak Detect

NOT AVAILABLE WITH

9304C, 9310C, 9314C

SERIES

RIS: Random

Interleaved Sampling

When using slow timebases, sample-rate decreases and very

short events such as glitches can be missed if they occur

between two samples. To prevent this, a special circuitry called

the Peak Detect system can be switched on (see “Channel Use”

menu, page 7–5) to capture the signal envelope with a

resolution of 2.5 ns. This is done without destroying the

underlying, simultaneously captured data, on which a wide range

of advanced processing can be performed.

RIS is an acquisition technique that allows effective sampling

rates higher than the maximum single-shot sampling rate. It is

used on repetitive waveforms with a stable trigger.

The maximum effective sampling rate of 10 GS/s can be

achieved by acquiring 100 single-shot acquisitions, or bins, at

100 MS/s using the 9304C, 9310C, 9314C Series oscilloscopes;

20 bins at 500 MS/s when using the other models. These bins

are positioned approximately 0.1 ns apart. The process of

acquiring this number of bins and satisfying the time constraint

is random. The relative time between ADC sampling instants

and the event trigger provides the necessary variation,

measured by the timebase to 10 ps accuracy.

7–2

Page 39

On average, 104 trigger events are needed to complete an

acquisition. But sometimes many more are needed. These

segments are interleaved to provide a waveform covering a time

interval that is a multiple of the maximum single-shot sampling

rate. However, the real-time interval over which the waveform

data are collected is orders of magnitude longer and depends on

the trigger rate and the desired level of interleaving. The

oscilloscope is capable of acquiring approximately 40 000 RIS

segments per second.

Roll Single-shot acquisitions at timebase settings slower than

0.5 s/div (10 s/div for traces with more than 50 000 points) have

a sufficiently low data rate to allow the display of the incoming

points in real time. The oscilloscope shows the incoming data

continuously, “rolling” it across the screen, until a trigger event is

detected and the acquisition completed. The latest data is used

to update the trace display in the same manner as a strip-chart

recorder. Waveform Math and Parameter calculations are done

on the completed waveforms.

Note: The behavior of , ,

and

is modified in

Roll Mode and Sequence Modes (refer to previous chapter

and pages 7–8 and 7– 9).

Sequence Sequence Mode is an alternative to single-shot acquisition that

offers many unique features. The complete waveform consists

of a number of fixed-size segments acquired in Single-Shot

Mode (see Appendix A for the limits), which are able to be

selected. .

The dead time between the trigger events for consecutive

segments can be kept to under 50 µs — in contrast to the

hundreds of milliseconds normally found between consecutive

single-shot waveforms. Complicated sequences of events

covering a large time interval can be captured in fine detail,

Note: to ensure low deadtime between segments,

button-pushing and knob-turning is to be avoided during

sequence acquisition.

ignoring uninteresting periods between events. And time

measurements can be made between events on different

7–3

Page 40

Timebase Modes and Setup

segments of a sequence waveform using the full precision of the

acquisition timebase.

Trigger-time stamps are given for each of the segments in the

“Text & Times Status” menu. Each individual segment can be

displayed by Zoom, or used as input to the MATH functions.

Sequence Mode can be used in remote operation to take full

advantage of the scope’s high data-transmission capability:

overlapping transmission of one waveform with its successor’s

acquisition (see the Remote Control Manual for details).

The timebase setting in Sequence Mode is used to determine

the acquisition duration of each segment, which will be 10 x

TIME/DIV.

Timebase setting, desired number of segments, maximum

segment length and total available memory are used to

determine the actual number of samples/segment and

time/point. The display of the complete waveform with all its

segments may not entirely fill the screen.

Sequence Mode is normally for acquiring the desired number of

segments and terminating the waveform acquisition. It can also

be used to acquire the segments continuously, overwriting the

oldest ones as needed, with a manual STOP order or timeout

condition being used to terminate the waveform acquisition.

Combining Channels

NOT AVAILABLE WITH

9304C, 9310C, 9314C

SERIES

The ADCs can be interleaved to boost standard sampling rate

and record length considerably.

When channels are combined on two-channel models, both

channels are paired on Channel 2, while Channel 1 is disabled.

On four-channel models, the two pairs of channels are enabled

on Channels 2 and 3, while Channels 1 and 4 are disabled. Both

maximum sampling rate and record length are doubled using

this function, activated by menu selection (see page 7–9).

On fast timebases it is even possible to again double the

sampling rate by means of a special adapter. With this adapter

in place, the oscilloscope interleaves the four ADCs and the

acquisition memory to achieve the maximum sampling rate and

up to four times the initial record length (see Appendix A for

details).

7–4

Page 41

Timebase Setup

TIMEBASE Press

Ø Single-Shot or Interleaved (RIS) sampling

Ø External clock

Ø Channel pairing (combining) and Peak Detect ..

Ø Sequence Mode

Ø Number of segments in Sequence Mode

Ø Maximum record length.

The “TIMEBASE” menus also show the number of points acquired,

the sampling rate and the total time span.

Sampling

For selecting either of the two principal modes of acquisition:

Ø “Single Shot” — displays data collected during successive

single-shot acquisitions from the input channels. This mode

allows the capture of non-recurring or very low repetition-rate

events simultaneously on all input channels.

Ø “RIS” (Random Interleaved Sampling) — achieves a higher

effective sampling rate than Single-Shot, provided the input

signal is repetitive and the trigger stable.

Sample Clock

To select “Internal” or External (“ECL”, “OV ”, “TTL”) clock modes

(see next page).

Channel Use (NOT AVAILABLE WITH 9304C, 9310C, 9314C

SERIES)

To select for channel pairing and, on models with this feature, to

control Peak Detect Mode (refer page 7–2).

Sequence

For turning “Off” or selecting “Sequence” or “Wrap ” Mode. See

page 7–10.

Record up to

to access and choose:

7–5

Page 42

Timebase Modes and Setup

For selecting the maximum number of samples to be acquired,

using the associated menu knob. See Appendix A for model

maximums.

7–6

Page 43

TIMEBASE EXTERNAL — appears when an External clock mode is chosen.

Sampling

This menu is inactive when the external sample clock is being used.

Only single-shot acquisition is available (see below ).

Sample Clock

For selecting a description of the signal applied to the EXT BNC

connector for the sample clock up to 100 MHz. The rising edge of the

signal is used to clock the ADCs of the oscilloscope. The effective

thresholds for sampling the input are*:

ECL..................................... −1.3 V

0V ....................................... 0.0 V

TTL................................ ...... +1.5 V

(With CKTRIG Option ONLY) RP (Rear Panel) specifies that

the 50–500 MHz external clock connected to the rear panel be

used as the sample clock (see CKTRIG Manual for details).

External

To select the input coupling for the external clock signal.

Sequence

Offers Sequence Mode. The corresponding knob is used to adjust the

number of segments. Neither the trigger time stamps nor the AUTO

sequence time-out feature are available when the external clock is in

use. Nor is the inter-segment dead time guaranteed.

Record

To select the desired number of samples for the single-shot

acquisition. See Appendix A for model maximums.

*

External clock modes are available only if the EXT trigger is not

the trigger source.

7–7

Page 44

Timebase Modes and Setup

ger and the external

Notes for using External Clock

Ø The time/div is expressed in s/div, to be understood to be samples/div.

Ø The trigger delay is also expressed in samples and can be adjusted as normal.

Ø No attempt is made to measure the time difference between the trig

clock. Therefore, successive acquisitions of the same signal can appear to jitter on the

screen.

Ø The oscilloscope will require a number of pulses (typically 50) before it recognizes the

external clock signal. The acquisition is halted only when the trigger conditions have

been satisfied and the appropriate number of data points have been accumulated.

Ø Any adjustment to the time/division knob automatically returns the oscilloscope to

normal (internal) clock operation.

7–8

Page 45

TIMEBASE — Sequence — for operating in Sequence Mode

Sampling

This menu is inactive when the external sample clock is being used.

Only single-shot acquisition is available (see pages 7–7, 7– 1).

Sample Clock

For selecting a description of the signal applied to the EXT BNC

connector for the sample clock (7–7).

Channel Use (NOT AVAILABLE WITH 9304C, 9310C, 9314C

SERIES)

For combining or pairing channels to achieve more memory and a

greater sampling rate by interleaving the ADCs in time. When “2” is

selected on two-channel models both channels are combined, or

paired. While when the same selection is made on four-channel

models either Channels 1 and 2 or 3 and 4 may be combined. But

when “1” on two-channel models or “4” on four-channel scopes is

selected, none of the channels is combined.

Sequence

When either “On” or “Wrap” are activated, the menu changes to the

one shown here. The associated menu knob is used to choose the

desired number of segments, here given in example as “100

segments”..

Also, when “Sequence“ is “On”:

If the trigger mode is Single

the oscilloscope fills the segments

and stops.

But it will wait until is pressed if there are not enough trigger

events to fill the segments.

If the trigger mode is Normal the oscilloscope fills the segments

and then, if more trigger events occur, the acquisition is restarted

from Segment 1.

7–9

Page 46

Timebase Modes and Setup

If the trigger mode is Auto and if the time between two

consecutive triggers exceeds a time-out that can be selected, the

acquisition is restarted from Segment 1. The time-out is selected in

“SPECIAL MODES” “UTILITIES”.

However, when “Wrap” is selected, the segments are filled

continuously until the STOP button is pressed. The last n segments

will be displayed. An alterna tive way to stop the WRAP sequence is

through AUTO mode; if the time between two consecutive triggers

exceeds a time-out that can be selected, the acquisition will stop.

Max. segment

To select using the corresponding button or associated knob the

maximum record length for each segment. See Appendix A for

model maximums.

Note: A summary of the acquisition conditions is

displayed above the “TIMEBASE” menus, indicating

number of segments, available record length per segment,

sampling rate, and timebase setting.

7–10

Page 47

8

Triggers and When to Use Them

Choosing the Right Trigger

Your oscilloscope offers many distinctive and useful

techniques for triggering on and capturing data. These

range from the simple Edge triggers to the advanced

SMART Trigger types, which trigger on multiple inputs.

Three triggering modes are available: AUTO, NORM and SNGL.

Additionally, STOP enables the acquisition process to be

aborted. All are directly accessible by pressing the respective

front-panel buttons. (See Chapter 6.)

Modifying Trigger Settings Trigger adjustments are made directly using the front-panel controls

and with the trigger menus.

Rotating — for example — causes the scope to adjust the

trigger level of the highlighted trace.

Pressing accesses advanced trigger operations, such as

changing the glitch width or the hold-off timeout, which are

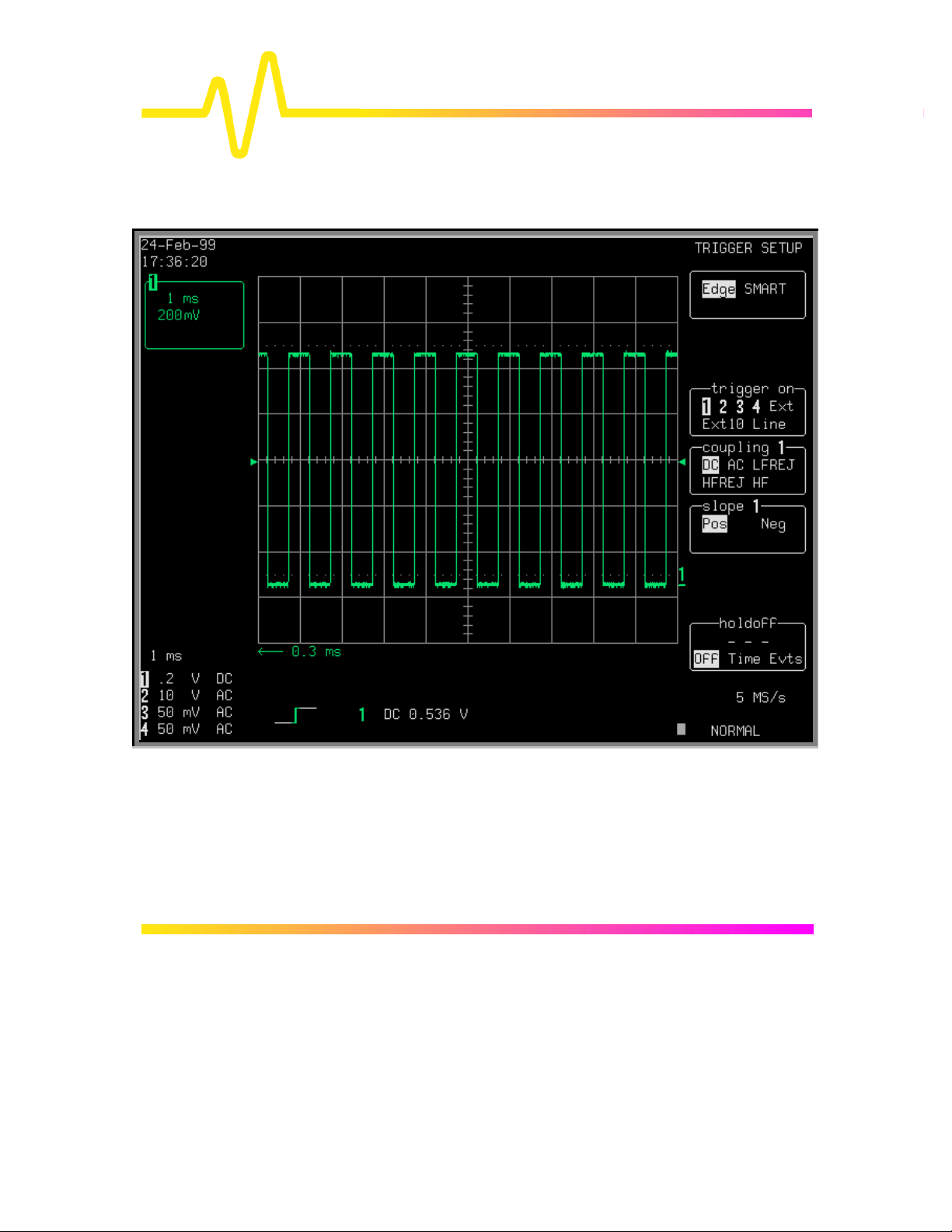

changed via the TRIGGER SETUP menu group (Fig. 8–1). Once

the trigger configuration has been modified, changes are stored

internally in a non-volatile memory.

This chapter describes

the triggering operations

and offers hints on how

to perform them. Along

with the standard menu

descriptions, schematics

show the trigger-menu

structure, and diagrams

explain how the main

triggers work.

TRIGGER SETUP

Edge

SMART

Figure 8–1. Main Trigger Menu.

8–1

Page 48

Triggers and When to Use Them

Edge or SMART

A variety of triggers for different applications can be

chosen from the two main trigger groups, the Edge and

SMART trigger types.

Edge Triggers In the Edge group of menus trigger conditions are defined by the

vertical trigger level, coupling, and slope. Edge triggers use simple

selection criteria to characterize a signal. They are most useful for

triggering on simple signals (see page 8–3).

SMART Trigger The SMART Trigger types allow additional qualifications to be

set before a trigger is generated. These qualifications can be

used to capture rare phenomena such as glitches or spikes,

specific logic states, or missing bits. A qualification might

include trigger generation only on a pulse wider or narrower than

a user-specified limit. Or it might require — to take but another

example — three trigger sources exceeding specific levels for a

minimum time.

Generally speaking, SMART Trigger offers various trigger

qualifications based on three basic abilities:

1. To count a specified number of events

2. To measure time intervals

3. To recognize a pattern input.

SMART explanations start on page 8–10 and on page menus 8–

29.

Trigger Symbols, illustrated throughout this chapter,

allow immediate on-screen recognition of the current

trigger conditions. There is a symbol for each Edge and

SMART Trigger type, with the more heavily-marked

transitions on the symbols indicating where a trigger will be

generated.

8–2

Page 49

Edge Trigger

Selecting Edge and its menus (Fig. 8–2) causes the scope

to trigger whenever the selected signal source meets the

trigger conditions. The trigger source is defined by the

trigger level, coupling, slope or hold-off.

Edge

Trigger on

Coupling

Slope Pos|Neg|Window

Holdoff

Figure 8–2. Edge Trigger Menu (see page 8–9).

1|2|3|4|Ext|Ext10|Line

DC|AC|LFREJ|HFREJ|HF

Off|Time (10 ns to 20 s)

|Events (1to 99 999 999)

8–3

Page 50

Triggers and When to Use Them

Trigger Source The trigger source may be:

Ø The acquisition channel signal (CH 1, CH 2 or CH 3, CH 4

on four-channel models) conditioned for the overall voltage

gain, coupling, and bandwidth.

Ø The line voltage that powers the oscilloscope (LINE). This

can be used to provide a stable display of signals

synchronous with the power line. Coupling and level are not

relevant for this selection.

Ø The signal applied to the EXT BNC connector (EXT). This

can be used to trigger the oscilloscope within a range of

± 0.5 V, or ± 5 V with EXT/10 as trigger source.

Level Level defines the source voltage at which the trigger circuit will

generate an event (a change in the input signal that satisfies the

trigger conditions). The selected trigger level is associated with

the chosen trigger source. Note that the trigger level is specified

in volts and is normally unchanged when the vertical gain or

offset is modified.

The Amplitude and Range of the trigger level are limited as

follows:

Ø ± 5 screen divisions with a channel as trigger source

Ø ± 0.5 V with EXT as trigger source

Ø ± 5 V with EXT/10 as trigger source

Ø None with LINE as trigger source (zero crossing is used).

Note: Once specified, Trigger Level and Coupling are

the only parameters that pass unchanged from mode

to mode for each trigger source.

Coupling This is the particular type of signal coupling at the input of the

trigger circuit. As with the trigger level, the coupling can be

independently selected for each source. Thus changing the

trigger source can change the coupling. The types of coupling

able to be selected are:

8–4

Page 51

Ø DC: All the signal's frequency components are coupled to

the trigger circuit. This is used in the case of high-frequency

bursts, or where the use of AC coupling would shift the

effective trigger level.

Ø AC: Here the signal is capacitively coupled. DC levels are

rejected and frequencies below 50 Hz attenuated.

Ø LF REJ: The signal is coupled via a capacitive high-pass

filter network. DC is rejected and signal frequencies below

50 kHz attenuated. This mode is used when stable triggering

on medium- to high-frequency signals is desired.

Ø HF REJ: Signals are DC-coupled to the trigger circuit and a

low-pass filter network attenuates frequencies above

50 kHz. The HF REJ trigger mode is used to trigger on low

frequencies.

Ø HF: Used for triggering on high-frequency repetitive signals

in excess of 300 MHz. Maximum trigger rates greater than

500 MHz are possible. HF triggering should be used only

when needed. It will be automatically overridden and set to

AC when incompatible with other trigger characteristics —

as is also the case for SMART Trigger. Only one slope is

available, indicated by the trigger symbol.

Slope Slope determines the direction of the trigger voltage transition

used for generating a particular trigger event. Like coupling, the

selected slope is associated with the chosen trigger source.

Hold-off Hold-off disables the trigger circuit for a given period of time or

a number of events after a trigger event occurs. It is used to

obtain a stable trigger for repetitive, composite waveforms. For

example, if the number or duration of sub-signals is known they

can be disabled by choosing an appropriate hold-off value.

Without Hold-off, the time between each successive trigger

event would be limited only by the input signal, the coupling, and

the oscilloscope's bandwidth. Sometimes a stable display of

complex repetitive waveforms can be achieved by placing a

condition on this time. This hold-off is expressed either as a time

or an event count, described on the following pages.

8–5

Page 52

Triggers and When to Use Them

Hold-off by Time This is the selection of a minimum time for triggers (Fig. 8–

3). A trigger is generated when the trigger condition is met

after the selected delay from the last trigger. The timing for

the delay is initialized and started on each trigger. The holdoff timeout should exceed the duration of the signal

displayed on screen. For instance, at a timebase setting of 1

ms/div, the time-out hold-off should at least exceed 10 ms.

Trigger Source: Positive Slope

Trigger

Event

Trigger can occur

Hold-off time Hold-off time

Generated Trigger

Trigger

Event

Trigger initiates

hold-off timer

Figure 8–3. Edge Trigger with Hold-off by Time.

Trigger

Event

Trigger initiates

hold-off timer

8–6

Page 53

Hold-off by Events Hold-off by events is initialized and started on each trigger

(Fig. 8–4 ). A trigger is generated when the trigger condition is met

after the selected number of events from the last trigger. Event here

refers to the number of times the trigger condition is met after the

last trigger. For example, if the number selected is two, the trigger

will occur on the third event.

Trigger Source: Positive Slope

Trigger

Event

Event

#1

Event

#2

Trigger

Event

Trigger can occur

Holdoff by 2 events Holdoff by 2 events

Generated Trigger

Trigger initiates

hold-off timer

Figure 8–4. Edge Trigger with Hold-off by Events.

Event

#1

Event

#2

Trigger initiates

hold-off timer

Trigger

Event

8–7

Page 54

Triggers and When to Use Them

Window Trigger

AVAILABLE ONLY WITH

9304C, 9310C, 9314C

SERIES

Trigger Level

On some scope models a “Window” Edge Trigger is also

available (Fig. 8–5). Two trigger levels are defined and a trigger

event occurs when the signal leaves the window region in either

direction.

Upper Region

WINDOW REGION

Lower Region

Time

Triggers

Figure 8–5. Edge Window Trigger.

8–8

Page 55

TRIGGER SETUP: Edge

Press to access menu selection of:

Ø Trigger source

Ø Coupling for each source

Ø Slope (positive or negative), and

Ø Hold-off by time or events.

Edge/SMART To select “Edge”

trigger on

For selecting the Edge trigger source (four-channel menu

shown).

coupling

To select the trigger coupling for the current source.

slope

To place the trigger point on either the “Pos ”-itive or “Neg”-ative slope of

the selected source. On those models featuring Window Trigger (9304C,

9310C, 9314C SERIES), this menu will also include a “Window” option,

which allows triggering whenever the input signal leaves a specified

voltage window, defined in the “window size” menu. The “window size”

menu becomes available on models featuring Window Trigger. It allows

adjustment of the window around a level defined using the Trigger

LEVEL knob.

holdoff

To allow the disabling of the oscilloscope's trigger circuit for a definable

period of time or number of events after a trigger event occurs. When

activated, “holdoff” can be defined as: a period of “Time”, or a number

of “Evts ” (an event being a change in the input signal that satisfies the

trigger conditions). The menu knob is used to vary the “holdoff” value.

Time hold-off values in the range 10 ns–20 s may be entered. Event

counts in the range 1–109 are allowed.

8–9

Page 56

Triggers and When to Use Them

SMART Trigger

SMART Trigger allows the setting of additional qualifications

before a trigger is generated. Depending on the oscilloscope

model, this can include triggers adapted for glitches, intervals,

abnormal signals, TV signals, state- or edge-qualified events,

dropouts and patterns.

Glitch Trigger Glitch Trigger (Fig. 8–6) is used to capture narrow pulses

inferior to or exceeding a given time limit. In addition, a width

range can be defined to capture any pulse that is comprised

within or outside the specified range — an Exclusion Trigger.

Glitch

Trigger on

Coupling

At end of Neg|Pos|Pulse

Width: l

than or equal

greater than

or equal to

Figure 8–6. Glitch Trigger Menu (see page 8–30).

ess

to

Width:

1|2|3|4|Ext|Ext10|Pattern

DC|AC|LFREJ|HFREJ|HF

Off|Time (2.5 ns to 20 s)

Off|Time (2.5 ns to 20 s)

8–10

Page 57

Applications In digital electronics circuits normally use an internal clock, and for

testing purposes a glitch can be defined as any pulse of width smaller

than the clock- or half-period. But generally speaking a glitch is a pulse

much faster than the waveform under observation. Glitch Trigger thus

has a broad range of applications in digital and analog electronic

development, ATE, EMI, telecommunications, and magnetic media

studies.

Pulse Smaller than

Selected Pulse Width

This Glitch Trigger selects a maximum pulse width (Fig. 8–7). It is

generated on the selected edge when the pulse width is less than the

selected width. The timing for the width is initialized and restarted on the

slope opposite to the edge selected. Widths of between 2.5 ns and 20 s

can be selected, but typically triggering will occur on glitches 1 ns wide.

Trigger Source

Glitch

Glitch width

width

Trigger can occur

Selected width

Generated Trigger

Figure 8–7. Glitch Trigger on pulse width < selected width.

8–11

Page 58

Triggers and When to Use Them

Exclusion Trigger Exclusion Trigger enables the exclusion of events over a

determined time interval. Exclusion Trigger is generated on the

selected edge when the pulse width is within or outside the

selected width range. For example (Fig. 8–8), only pulses

smaller than 25 ns or longer than 27.5 ns will generate the

trigger. The timing for the width is initialized and restarted on the

slope opposite to the edge selected. Widths of between 2.5 ns

and 20 s can be selected.

Figure 8–8. Exclusion Trigger. Only pulses within or outside the

boundaries of the width range are captured.

Applications Exclusion Triggers allow a signal’s normal width or period to be

specified, with the scope instructed to ignore the normally

shaped signals and trigger only on abnormal ones. Circuit

failures, for instance, can be looked for all the time.

8–12

Page 59

Interval Trigger Whereas Glitch Trigger performs over the width of a pulse,

Interval Trigger (Fig. 8–9) performs over the width of an

interval. An interval corresponds to the signal duration

separating two consecutive edges of the same polarity. Interval

Trigger is used to capture intervals that are inferior to or exceeding

a given time limit. In addition, a width range can be defined to

capture any interval that is comprised within or outside the specified

range — an Exclusion Trigger by Interval.

Interval

Trigger on

Coupling

Between

Interval: l

than or equal

greater than

or equal to

Figure 8–9. Interval Trigger Menu (see page 8–32).

ess

to

Interval:

1|2|3|4|Ext|Ext10|Pattern

DC|AC|LFREJ|HFREJ|HF

Pos|Neg

edges