Page 1

I OPERAToR’s MANUAL I

,|, ......................

i i i in it

- i li I I I II I

~ "- i~_.

MODEL 9100 SERIES

April 1993

Page 2

[ TABLE OF CONTENTS

1 General Information

Purpose

Unpacking and Inspection

Warranty

Product Asskmnce

Maintenance Agreements

Documentation Discrepancies

Software Licensing Agreement

Service Procedure

2 Product Description

9100 System Description 2-1

9100 Waveform Generation Concept

91 O0 Architecture 2-3

Front Panel Controls, Connections and Indicators 2-11

Rear Panel Controls, and Connections 2-13

Specifications 2-15

$ Operations

Preparation For Use 3-1

Standard Functions 3-3

Arbitrary Waveforms and File Conventions

Defining An Arbitrary Waveform In Terms

OfA Waveform File

Transferring Waveform Data Files Into the

AFG RAM Disk Via GPIB 3--6

Loading the Waveform Files From RAM Disk

Into the Waveform Generator Circuit 3-9

Control Settings Summnry-(amplitude, dock, ...) 3-12

Specifying How the Data Values Are

Convened to Voltage Levels 3-13

Spedfying the Time Per Point 3-14

Specifying The Trigger Mode 3-14

Specifying the Trigger Delay 3-27

Specifying External Triggering 3-27

Using the Filters to Smooth the Waveform 3-27

Disconnecting the Output While the Generator

is Running 3-28

Inverting Channel 1 or 2

Summing Channel 1 and Channel 2 Signals

Using the External Sum Input

Using an External Clock Reference 3-29

Using an External Clock Source 3-29

Synchronizing with Another 9100 Series AFG 3-29

Starting and Stopping the Waveform

1-1

1-I

1-1

1-2

1-9

1-2

1-2

1-3

2-2

3--4

3-5

3-28

3-28

3-28

3-30

Page 3

I TABLE OF CONTENTS I

Automating the Setup and Loading of Waveforms 3-30

4 Operating Instructions

Control Panel Operation 4-1

Basic Description 4-1

Main Menu Keys

Understanding the 9100/CP Menus 4-11

Entry Changes 4-19

Controlling the Arbitrary Function Generator

with the 9100/CP

Selecting an Arbitrary Waveform 4-23

Selecting a Standard Waveform

Selecting Attributes of Standard Sine 4-26

Selecting Attributes of Standard Square 4--27

Selecting Attributes of Standard Triangle 4-28

Selecting Attributes of Standard Ramp 4-28

Selecting Attributes of Standard Pulse 4-29

Selecting Attributes of Standard DC

Channel 1 Waveform Attributes 4-30

Channel 2 Waveform Attributes 4-33

Controlling the Tunebase 4--33

Trigger Control

Arming and Firing Trigger

Working with Setup Files

Working with Sequence Files

Loading and Linking Waveforms ~ ~3

Executing Waveforms

Aborting Waveforms

Accessing the State of the AFG

4-5

’ 4-22

4-25

4-30

4--37

~ ~0

~ ".0

~ ~2

~ ~5

~ ~5

~ ~5

5 Operating over the GPIB

Genera]

Introduction

Remote Mode

Local Mode

Addressing

Messages

Device Dependent Messages

Message Input Format

Command Format

Command Parameters

General Rules for Commands

IEEE-488 Standard Messages

Receiving the Device Clear Message

Receiving the Trigger Message

5-1

5-1

5-1

5-1

5-2

5-2

5-2

5-3

5-3

5--4

5-5

5-5

5-5

Page 4

l TABLE OF CONTENTS

Receiving the Remote Message

Receiving the Local Message

Receiving the Local Lockout Messages

Sending Messages

Sending the Require Service Message (SRQ)

Sending the Serial Poll Status Byte

Sending the Secondary Status Bytes

Operation of the Status Bytes

Acronym Guidelines

Programming Command Reference Section

Command Summary

File Handling Commands

File Structures

Setup and Sequence Files

Setup Files

Executing Setup Files

Sequence Files

Executing Sequence Files

Single Waveform Files

Dual Waveform Files

Executing Waveform Files

File Handling Commands

DELETE

END

LEARN_SETUP

LINK

LOAD

RECAIJ~

SEQUENCE

SETUP

STORE

Action Commands

ABORT

ARBITRARY

ARM

CALIBRATE

CI.FAR

GO

NEXT

SELFTEST

STOP

TRIGGER

Channel Parameter Commands

CH 1 AMPLITUDE (CH2_AMPLITUDE)

CH I"FILTER (CH2_FILTER)

5-5

5-5

5-5

5-6

5-6

5-6

5-7

5-7

5-14

5-15

5-18

5-18

5-19

5-19

5-20

5-20

5-21

5-22

5-22

5-23

5-24

5-25

5-26

5-27

5-29

5-30

5-31

5-32

5-33

5-34

5-35

5-36

5-37

5-38

5-39

5-40

5-41

5-42

5-43

5-44

5-45

Page 5

TABLE OF CONTENTS

CH l_I NVERT (CH2_I NVERT)

CHI OFFSET (CH2_OFFSET)

CHI__.OLrI~UT (CH2_OUTPUT)

CH I_ZERO_REF (CH I_ZERO_REF)

EXTERNAL SUM

SUM_MODI~

Timebase Commands

CLOCK_SOURCE

CLOCK_LEVEL

CLOCK_MODE

CLOCX_RA~

CLOCK_SLOPE

CLOCKPERIOD

CLOCKREFERENCE

Trigger Commands

DELAY MODE

MARKI~R DELAY

TRIGGEI~ ARM SOURCE

TRIGGER_-DELAY

TRIGGER_LEVEL

TRIGGER_MODE

TRIGGER_SLOPE

TRIGGER_SOURCE

Standard Function Commands

STANDARD

SINE

SINE_MODE

SINE_FREQUENCY

SINE CHI PHASE

SINE_-CH2-_PHASE

SQUARE

SQUARE_MODE

SQUARE_FREQUENCY

SQUARE_PHASE

SQUARE_P.ELATIVE_PHASE

TRIANGLE

TRLkNGLE_MODE

TR/ANGLE FREQUENCY

TRIANGLE_PHASE

TRIANGLE_RELATIVE_PHASE

RAMP

RAMP_MODE

RAMP_PERIOD

RAMP_PHASE

5--46

5-47

5-48

5-49

5-50

5-51

5-52

5-53

5-54

5-55

5-56

5-57

5-58

5-59

5-60

5-61

5-62

5--63

5--64

5-65

5--66

5-68

5-69

5-70

5-71

5-72

5-73

5-74

5-75

5-76

5-77

5-78

5-79

5-80

5-81

5-82

5-83

5-84

5-85

5-86

5-87

Page 6

TABLE OF CONTENTS I

RAMP_RELATIVE_PHASE

PULSE

PULSE_WIDTH

PULSE_PERIOD

PULSE DELAY

PULSE-OPTIMIZE

DC

DC_MODE

Query Type Commands

ACTIVE FILES

FUNCTION

EXIST

DIRECTORY

IDENTIFY

MEMORY

VIEW

Communication Commands

COMM_FORMAT

COMM_HEADER

MASK

STB

TSTB

COMMAND SUMMARY

Figure 5.1 - Heirarchical Structure Of The 9100

Status Bytes

Table 5.1 -Status Byte Bit Assignments

Table 5.2 - Error Codes

Table 5.3 - 9100 GPIB Acronyms

5--88

5-89

5-90

5-91

5-92

5-93

5-94

5-95

5-96

5-97

5--98

5-99

5-101

5-102

5-103

5-105

5-106

5-107

5-108

5-109

5-110

5-9

5-10

5-11

5-14

6 RS--232-Interface

Selecting the RS-232C Interface

Configuring the RS--232C Interface

Using RS-232

Typical RS-232C Dialog

RS-232 Commands

COMM_RS_CONF

COMM_PROMPT

COMM_RS_SRQ

6-1

6-1

6-2

6-3

6--4

6--6

6-7

Page 7

]TABLE OF CONTENTS I

7 Model 9109

General Description

High Speed Memory

Digital Output Specifications

Reconfiguring the Digital Output

Interconnection Information

Application InformatiOn

9109 Front Panel Diagram

7-1

7-1

7-1

7-4

7-6

7-10

7-12

8 Model 9101

Introduction

Differences Between 9101 and 9100

9101 Front Panel Diagram

9 9100/MM, /MM1,/MM2

Description

U.ing The Memory Expamion Option

Using The Control Memory Image Functions

Learning A CMI File

Deleting A CMI File

Reviewing The Contents ofA CMI File

10 9100/RT

Introduction

Verifying Installation

Functional Description

9100/RT LOAD and LINK Comands

FIFO Memory Commands

External FIFO Loading

FIFO Reading

F..yamples of Operation

External Real-Time Port

Using the 9100/RT Option

Using the External Real-Time Port

Waveform Selection Using BASICA

Specifications

8-1

8-1

8-4

9..-1

9--2

9--3

9-3

9--5

9-6

10-I

10-1

10-2

10-4

1 0-5

10--6

10--8

10-9

10-10

10-11

10-15

10-17

10-19

Appendix I

Index

Page 8

1

GENERAl, INFORMATION

"

PURPOSE

UNPACKING AND

INSPECTION

WARRANTY LeCroy warrants its instrument products to operate within speci-

This manual is intended to provide instruction regarding the

setup and operation of the covered instruments. In addition, it

describes the theory of operation and presents other information

regarding its functioning and application.

The Service Documentation, packaged separately, should be

consulted for the schematics, parts lists and other materials that

apply to the specific version of the instrument as identified by

its ECO number.

LeCroy recommends that the shipment be thoroughly inspected

immediately upon delivery. All material in the container(s)

should be checked against the enclosed Packing List and shortages reported to the carrier promptIy. If the shipment is damaged in any way, please notify the carrier. If the damage is due

to mishandling during shipment, you must file a damage claim

with the carrier. The LeCroy field service office can help with

this. LeCroy tests all products before shipping and packages all

products in containers designed to protect against reasonable

shock and vibration.

fications under normal use and service for a period of one year

from the date of shipment. Component products, replacement

parts, and repairs are warranted for 90 days. This warranty ex-

tends only to the original purchaser. Software is thoroughly

tested, but is supplied "as is" with no warranty of any kind cov-

ering detailed performance. Accessory products not manufac-

tured by LeCroy are covered by the original equipment manu-

facturers warranty only.

In exercising this warranty, LeCroy will repair or, at its option,

replace any product returned to the Customer Service Depart-

ment or an authorized service facility within the warranty pe-

riod, provided that the warrantor’s examination discloses that

the product is defective due to workmanship or materials and

has not been caused by misuse, neglect, accident or abnormal

conditions or operations.

The purchaser is responsible for the transportation and insur-

ance charges arising from the return of products to the servicing

facility. LeCroy will return all in-warranty products with trans-

portation prepaid.

This warranty is in lieu of all other warranties, express or im-

plied, including but not limited to any implied warranty of mer-

1-1

Page 9

General Information

chantability, fitness, or adequacy for any particular purpose or

use. LeCroy shall not be liable for any special, incidental, or

consequential damages, whether in contract, or otherwise.

PRODUCT ASSISTANCE

MAINTENANCE

AGREEMENTS

DOCUMENTATION

DISCREPANCIES

SOFTWARE LICENSING

AGREEMENT

Answers to questions concerning installation, calibration, and

use of LeCroy equipment are available from the SSD Customer

Services Department, 700 Chestnut Ridge Road, Chestnut

Ridge, New York 10977-6499, (914) 578-6020, or your local

field service office.

LeCroy offers a selection of customer support services. For example, Maintenance agreements provide extended warranty that

allows the customer to budget maintenance costs after the initial

warranty has expired. Other services such as installation, training, on-site repair, and addition of engineering improvements

are available through specific Supplemental Support Agreements.

Please contact the Customer Service Department or the local

field service office for details.

LeCroy is committed to providing state-of-the-art instrumenta-

tion and is continually refining and improving the performance

of its products. While physical modifications can be imple-

mented quite rapidly, the corrected documentation frequently

requires more time to produce. Consequently, this manual may

not agree in every detail with the accompanying product and the

schematics in the Service Documentation. There may be small

discrepancies in the values of components for the purposes of

pulse shape, timing, offset, etc., and, occasionally, minor logic

changes. Where any such inconsistencies exist, please be assured that the unit is correct and incorporates the most up-todate circuitry.

Software products are licensed for a single machine. Under this

license you may:

1-2

¯ Copy the software for backup or modification purposes in sup-

port of your use of the software on a single machine.

¯ Modify the software and/or merge it into another program for

your use on a single machine.

¯ Transfer the software and the license to another party if the

other party accepts the terms of this agreement and you relin-

Page 10

General Information 1

quish all copies, whether in printed or machine readable form,

including all modified or merged versions.

SERVICE PROCEDURE Products requiring maintenance should be returned to an

authorized service facility. If under warranty, LeCroy will repair

or replace the product at no charge. The purchaser is only responsible for the transportation charges arising from return of

the goods to the service facility.

For all LeCroy products in need of repair after the warranty

period, the customer must provide a Purchase Order Number

before any inoperative equipment can be repaired or replaced.

The customer will be billed for the parts and labor for the repair as well as for shipping.

All products returned for repair should be identified by the

model and serial numbers and include a description of the defect or failure; name and phone number of the user. In the

case of products returned, a Return Authorization Number is

required and may be obtained by contacting the Customer gerv-

ice Department in your area.

New York Corporate Headquarters

East Coast Regional Service

New Hampshire

Virginia

New Mexico

California

(914)

(914)

(603)

(703) 368-1033

(505)

(415) 463-2600

425-2000 or

578-6059

627-6303

293-8100

1-3

Page 11

2

9100 SYSTEM

DESCRIPTION

9100, 9101, 9109

9100R

9100/CP

9100/SW

9100GPIB2

PRODUCT DESCRIPTION

The LeCroy 9100 Series Arbitrary Function Generators (AFG)

are high performance ATE or benchtop instruments which can

generate either standard or user-defined, complex waveforms

with unparalleled point-to-point resolution. They are fully programmable via either GPIB or RS-232. Wavef6rm creation and

editing software is offered for PC-DOS compatible computers.

The products in the 9100 Series are:

9100 high speed dual channel Arbitrary Function Generator

9101 high speed single channel Aribitrary Function Generator

9109 high speed dual channel Arbitrary Function Generator

with digital outputs.The common elements of the 9100 Series

are described in the early chapters of this manual. Product spe-

cific information for the 9109 and 9101 is located in Chapter 7

and 8 respectively.

The 9100 Series instruments are part of a complete custom

waveform generation system. The main products which support

this system are listed below.

ARBITRARY FUNCTION GENERATOR MAINFRAME. This

is the basic mainframe unit. The standard unit is remotely programmable over GPIB. This unit has local control ONLY

through use of the optional 9100/CP control panel.

9100 REAR PANEL CONNECTOR MAINFRAME. Same as

9100 except all signal input and output connectors are brought

to the rear panel.

9100 HAND-HELD CONTROL PANEL. This is the control

panel which adds local operation of all features of the 9100 with

the exception of waveform file creation, editing and downloading. Metal brackets are included to allow control panel to be

free-standing or attached to side of the 9100 mainframe.

The EASYWAVE® Operating Manual covers the following

products:

EASYWAVE SOFTWARE. An optional software package for

PC-DOS compatible computers which provides easy waveform

creation and editing. This includes creating waveforms from a

simple waveform element library, equations, tabular editing, or

direct acquisition from LeCroy Oscilloscopes. Without this

package waveform files must be created on a host computer

either with a text editor or a user written program and then

downloaded either over GPIB or RS-232.

IBM PC COMPATIBLE GPIB CARD AND SOFTWARE. This

GPIB card and driver software are required to run EASYWAVE

2-1

Page 12

Product Description

from an IBM XT/AT compatible. Manuals are included with

this for detailed operation of GPIB without EASYWAVE.

Operation of the 9100 AFG via the EASYWAVE software package provides full capability without compromise. All waveforms

may be edited at any time and the 9100 can be operated via a

full-screen interface on the host IBM XT/AT.

NOTE: Waveform editing capability has not been provided in

the 9100 Series mainframe.

Some applications may not need to have waveform creation or

editing facilities on hand at all times. In these cases, after the

waveforms have been created with EASYWAVE (or other user

supplied program) and downloaded to the AFG non-volatile

RAM disk the host computer may be disconnected and the

AFG can be used as a "custom" waveform generator with all

control accessible via the 9100/CP control panel.

Some users may need to use other host computers to operate

their test systems. In this case the basic waveform shapes

needed for testing may be edited using EASYWAVE and downloaded into the 9100 or transferred to the test system host computer.

9100 WAVEFORM

GENERATION CONCEPT

2-2

The 9100 is a signal source whose output voltage as a function

of time .can be programmed via an array of data values and

various control settings. The instrument generates the waveform

by sequentially steppir~g through the array and outputting a volt-

age proportional to each data value for a fixed time interval or

sample period (point). Selecting or specifying the contents

the data array are performed separately from entering the con-

trol settings commands so the user has a great deal of flexibility

in modifying a waveform without having to change its basic

shape (the waveform data array).

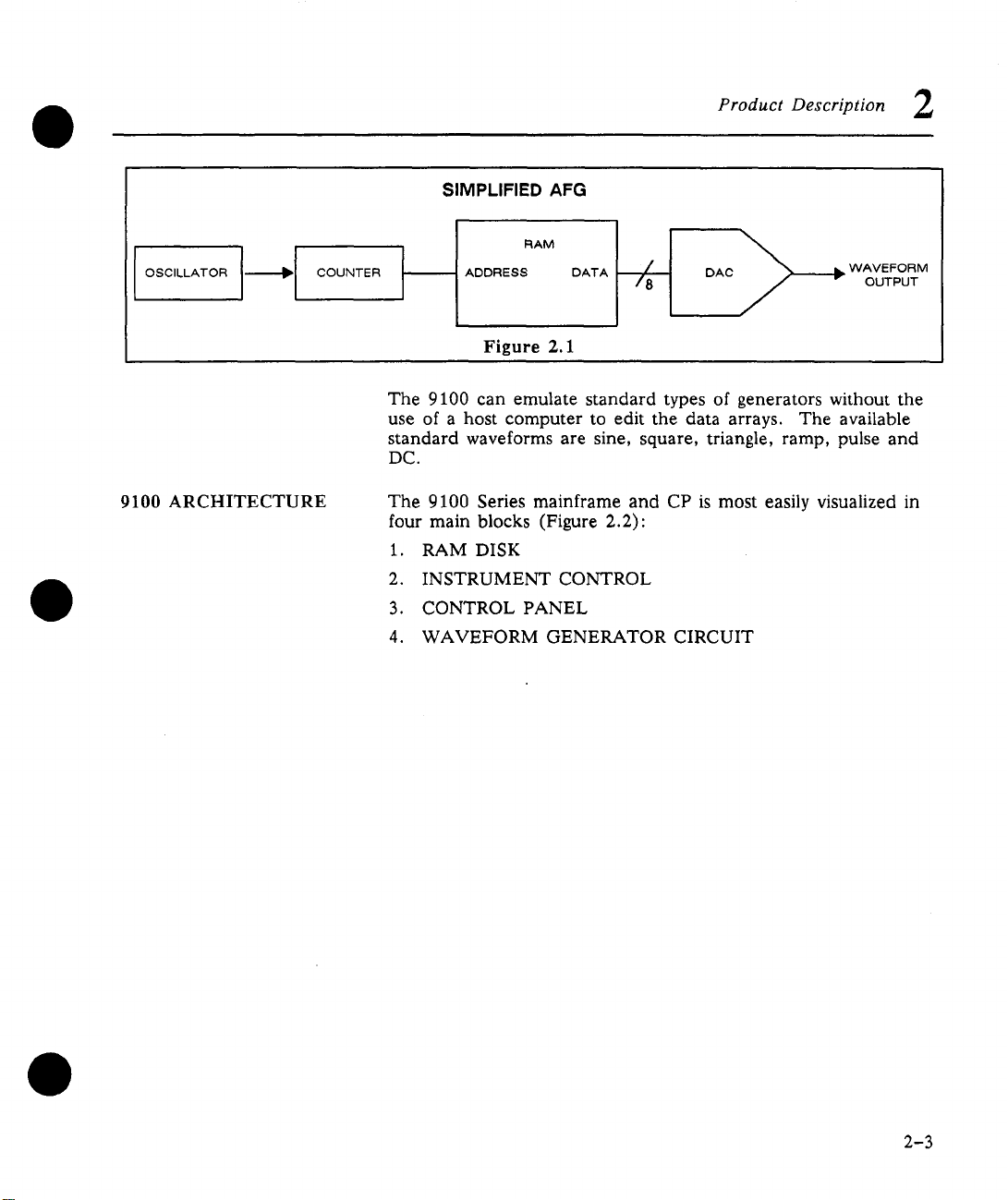

A simple way of thinking about the operation of an AFG is

shown in Figure 2.1. Basically, an oscillator clocks a counter

which in turn advances the address applied to a memory. The

memory data value which is stored in the next sequential loca-

tion is then output to the digital-to-analog converter (DAC).

Finally the DAC converts the data value to an analog level. As

the counter steps through the memory addresses, the associated

data values are converted by the DAC. This results in a voltage

waveform being output which is proportional to the data array

which resides in the memory.

Page 13

COUNTER

Product Description 2

SIMPLIFIED AFG

RAM

ADDRESS DATA

DAC

~

Figure 2.1

The 9100 can emulate standard types of generators without the

use of a host computer to edit the data arrays. The available

standard waveforms are sine, square, triangle, ramp, pulse and

DC.

WAVEFORM

OUTPUT

9100 ARCHITECTURE

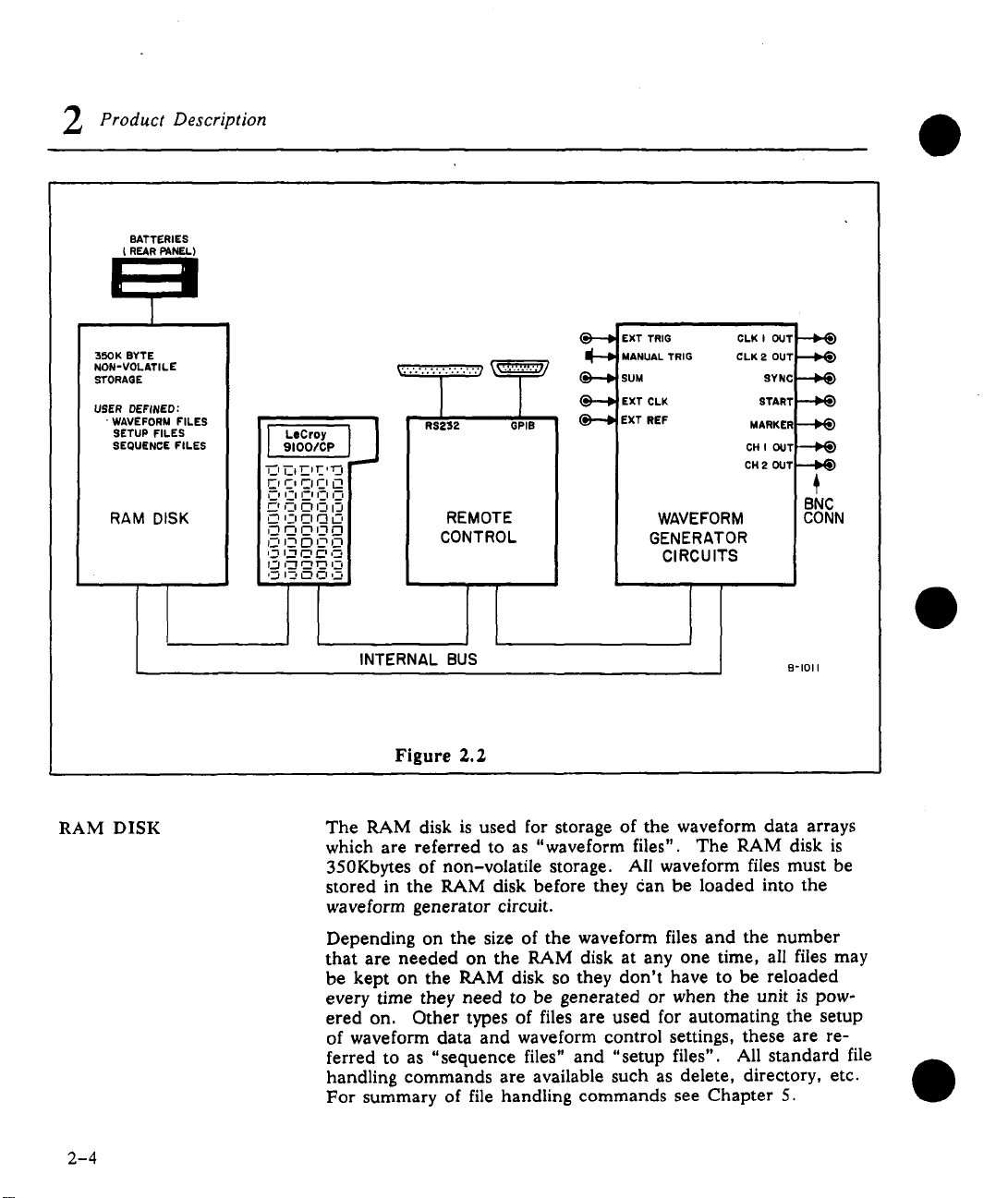

The 9100 Series mainframe and CP is most easily visualized in

four main blocks (Figure 2.2):

1. RAM DISK

2. INSTRUMENT CONTROL

3. CONTROL PANEL

4. WAVEFORM GENERATOR CIRCUIT

2-3

Page 14

Product Description

BATTERIES

( REAR PANEL)

35OK BYTE

NON’VOLATILE

STORAGE

USER DEFINED:

¯ WAVEFORM FILES

SETUP FILES

SEQUENCE FILES

RAM DISK

RAM DISK

LeCroy

91001CP

r-, CI D I~ I’~

0 rZ_, 0 ,D ,_-I

, ~ I:l i’ll_ I=l 1:7

:

i_~ ,~ ~_ ~_ ,-,

,..~ I-, O. Ci ,-,

1

The RAM disk is used for storage of the waveform data arrays

which are referred to as "waveform files". The RAM disk is

350Kbytes of non-volatile storage. All waveform files must be

stored in the RAM disk before they (~an be loaded into the

waveform generator circuit.

~........................../

1

RS232 GPIS

REMOTE

CONTROL

INTERNAL BUS

Figure 2.2

EXT TRIG

MANUAL TRIG

SUM

EXT CLK

EXT REF

WAVEFORM

GENERATOR

CIRCUITS

CLK I OUT

CLK2 OUT

8YNC

START

MARKER

CH I OU1

CH 2 OUT

BNC

CONN

B-IOI I

2-4

Depending on the size of the waveform files and the number

that are needed on the RAM disk at any one time, all files may

be kept on the RAM disk so they don’t have to be reloaded

every time they need to be generated or when the unit is pow-

ered on. Other types of files are used for automating the setup

of waveform data and waveform control settings, these are re-

ferred to as "sequence files" and "setup files". All standard file

handling commands are available such as delete, directory, etc.

For summary of file handling commands see Chapter 5,

Page 15

Product Description 2

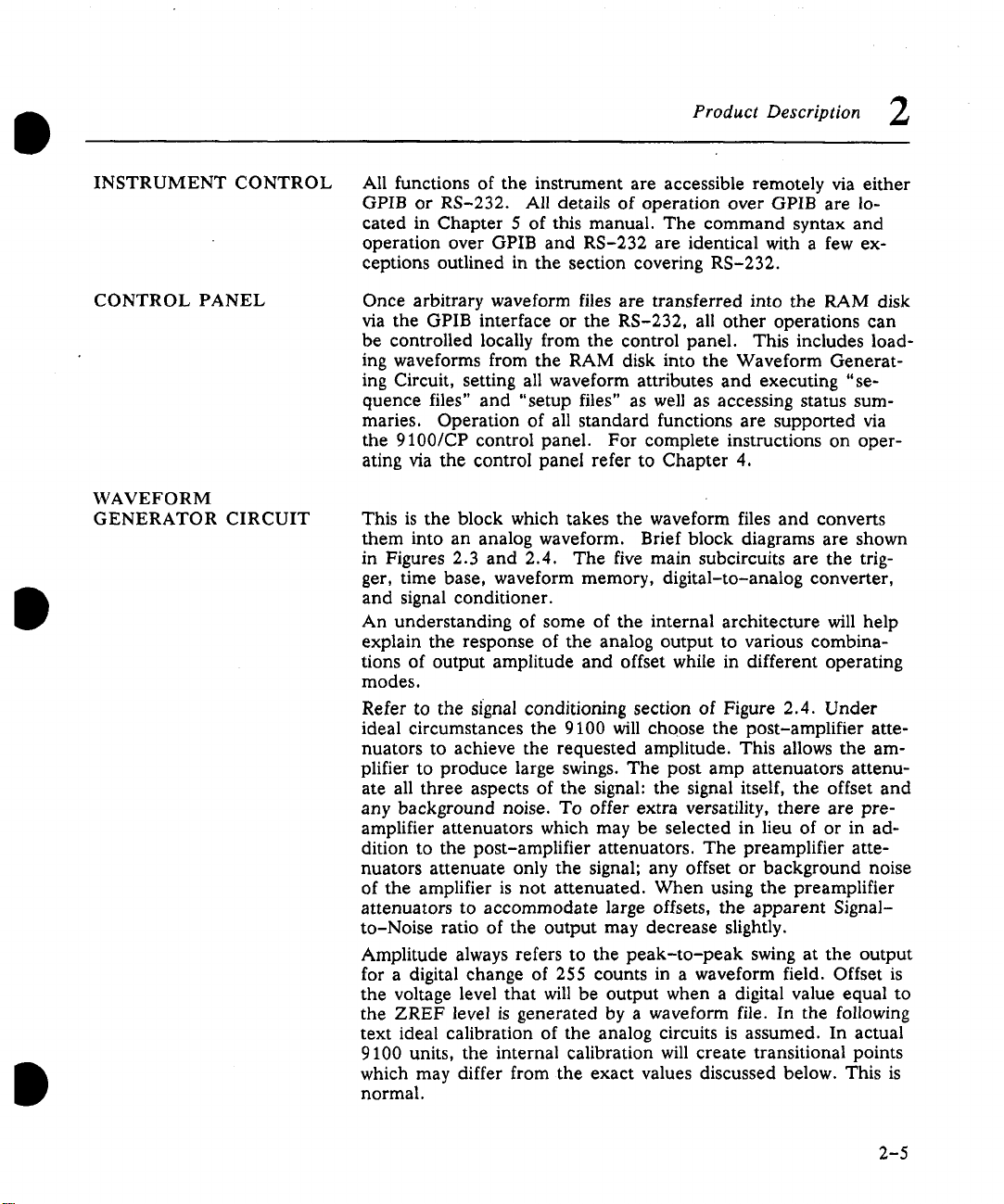

INSTRUMENT CONTROL

CONTROL PANEL

WAVEFORM

GENERATOR CIRCUIT

All functions of the instrument are accessible remotely via either

GPIB or RS-232. All details of operation over GPIB are located in Chapter 5 of this manual. The command syntax and

operation over GPIB and RS-232 are identical with a few exceptions outlined in the section covering RS-232.

Once arbitrary waveform files are transferred into the RAM disk

via the GPIB interface or the RS-232, all other operations can

be controlled locally from the control panel. This includes loading waveforms from the RAM disk into the Waveform Generat-

ing Circuit, setting all waveform attributes and executing "sequence files" and "setup files" as well as accessing status sum-

maries. Operation of all standard functions are supported via

the 9100/CP control panel. For complete instructions on operating via the control panel refer to Chapter 4.

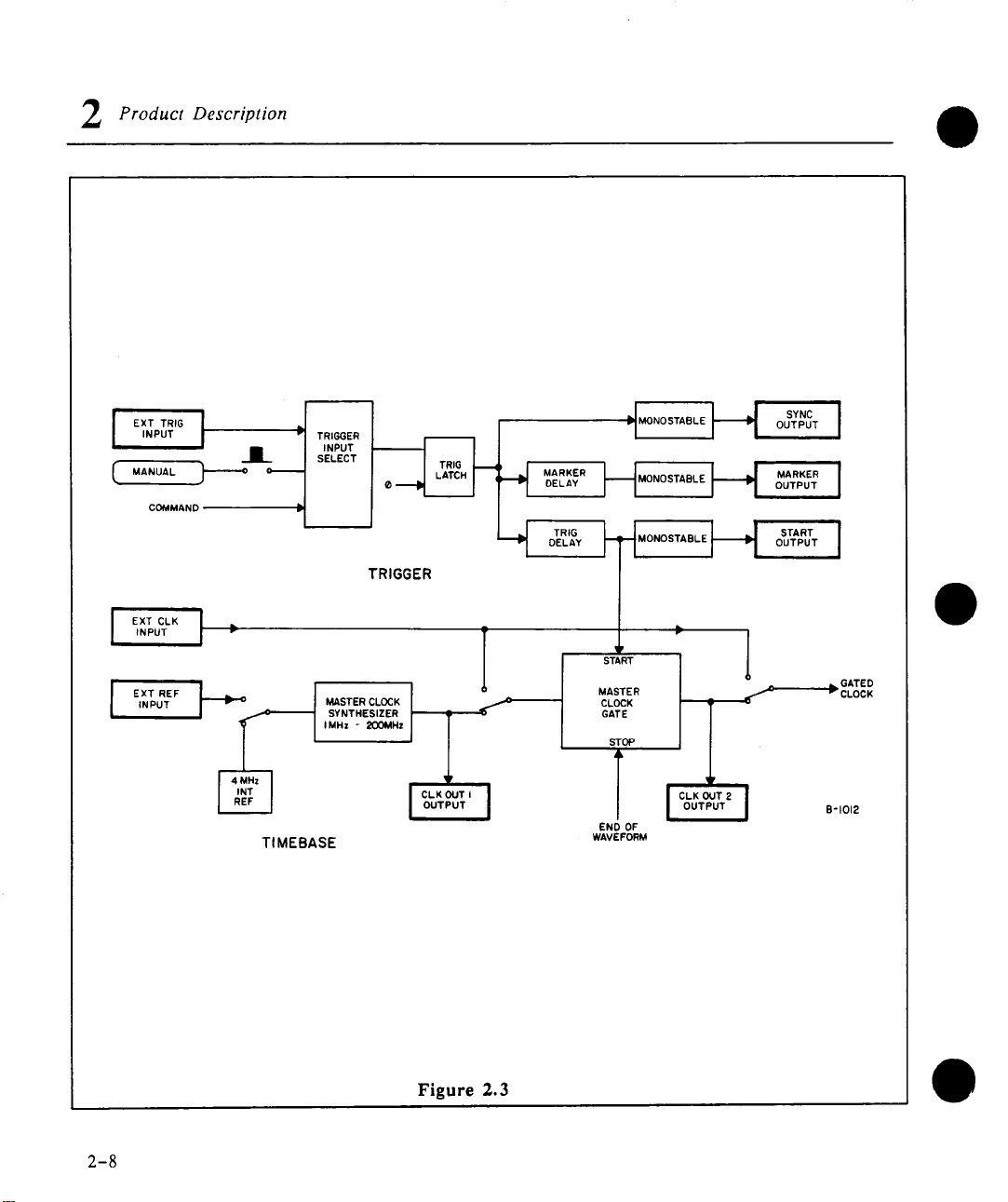

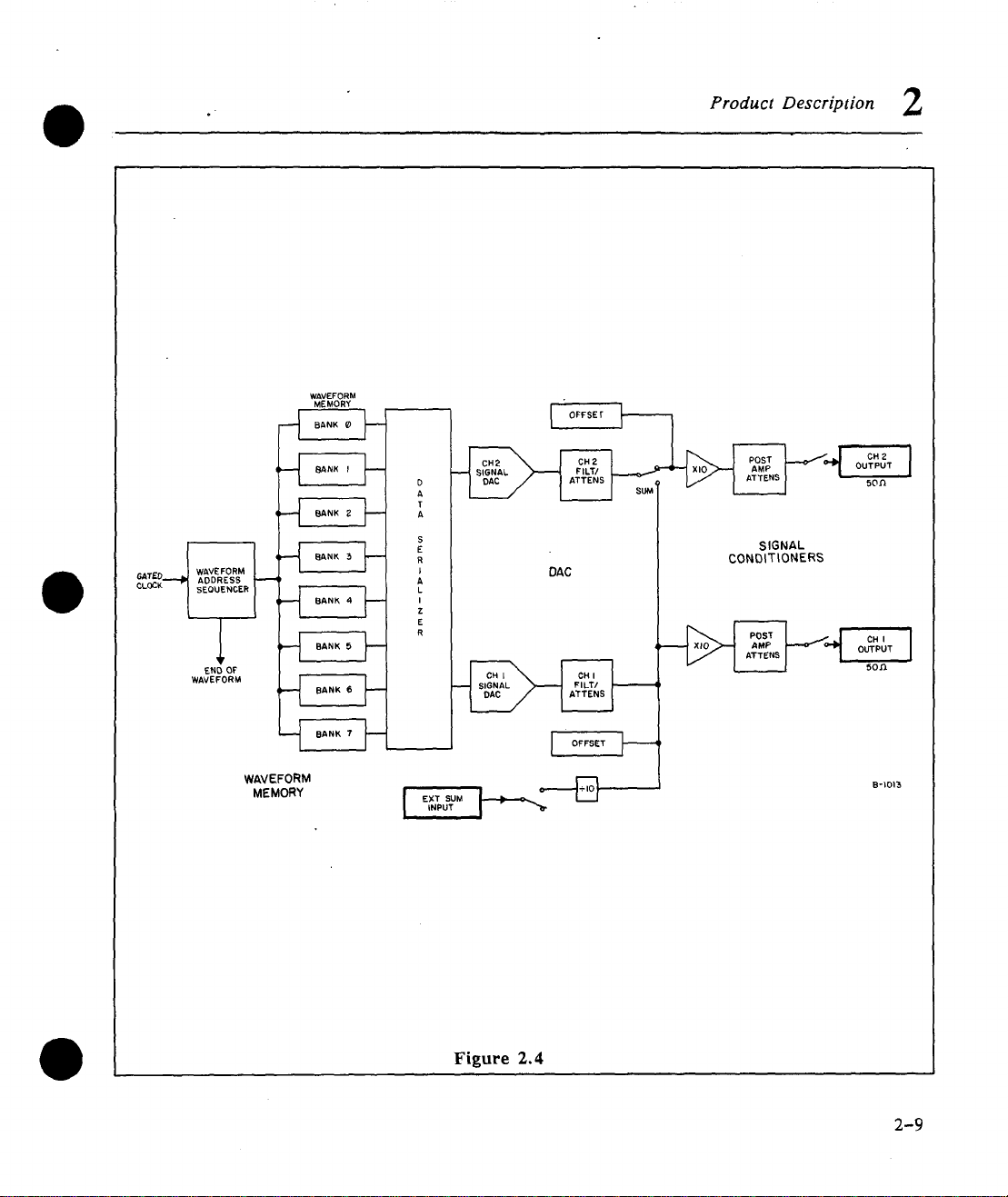

This is the block which takes the waveform files and converts

them into an analog waveform. Brief block diagrams are shown

in Figures 2.3 and 2.4. The five main subcircuits are the trigger, time base, waveform memory, digital-to-analog converter,

and signal conditioner.

An understanding of some of the internal architecture will help

explain the response of the analog output to various combina-

tions of output amplitude and offset while in different operating

modes.

Refer to the signal conditioning section of Figure 2.4. Under

ideal circumstances the 9100 will choose the post-amplifier attenuators to achieve the requested amplitude. This allows the am-

plifier to produce large swings. The post amp attenuators attenu-

ate all three aspects of the signal: the signal itself, the offset and

any background noise. To offer extra versatility, there are pre-

amplifier attenuators which may be selected in lieu of or in addition to the post-amplifier attenuators. The preamplifier atte-

nuators attenuate only the signal; any offset or background noise

of the amplifier is not attenuated. When using the preamplifier

attenuators to accommodate large offsets, the apparent Signalto-Noise ratio of the output may decrease slightly.

Amplitude always refers to the peak-to-peak swing at the output

for a digital change of 255 counts in a waveform field. Offset is

the voltage level that will be output when a digital value equal to

the ZREF level is generated by a waveform file. In the following

text ideal calibration of the analog circuits is assumed. In actual

9100 units, the internal calibration will create transitional points

which may differ from the exact values discussed below. This is

normal.

2-5

Page 16

Product Description

If there is a conflict in requested amplitude and offset settings,

the 9100 always tries to achieve the requested amplitude in pref-

erence to the requested offset. A general guideline relating

maximum offset to requested amplitude is that you can always

achieve an offset of between 8 and 16 times the requested amplitude as long as all points of the waveform are within the

4-5 V limitation (assuming a 50 12 load) of the output amplifier.

To calculate the exact value of maximum offset achievable for a

given amplitude you first divide the requested amplitude into

10 V. This gives you the total attenuation factor that is re-

quired. If this value is less than 32 then the achievable output

levels will be anywhere within the 4-5 V range. For attenuation

factors greater than or equal to 32, divide the required attenu-

ation factor by 32 and choose the next higher power of 2 than

the result. For example, if the division yields a result of 11.32

the next higher power of 2 would be 16. This power of 2 is the

least amount of post-amplifier that will be utilized up to a maxi-

mum of 64 (2^6). The maximum achievable output level

4-5 V divided by post-amplifier attenuation.

In requesting an offset value you should be aware that any point

of the output waveform which exceeds the achievable output

levels due to the combination of amplitude, offset and ZREF

will generate an error message. A clipped or distorted output

may also result from exceeding the maximum output levels.

NOTE: The amplifier will appear to operate, with reduced performance, for levels up to 125% of the calculated maximum

levels.

When the 9100 detects an output programming which exceeds

the maximum levels an warning code of 202 is set into STB4

and bit 4 of STB7 (a warning) is set. The facts described above

can be quickly understood with the following example. Start by

generating any convenient waveform with the 9100 and set the

offset to 4.8 V and ZREF to 127.5. Set the amplitude to 10 V.

Clearly the top half of the waveform is cutoff or clipped due to

the limitation of the amplifier and an error message has been

generated. Reduce the amplitude to 1 V. The output will appear

correct since the amplifier has some usable range beyond the

5 V limitation described above, but an error message will again

be generated. Further reduce the amplitude to 330 inV. At this

point the offset to amplitude ratio is near the maximum achiev-

able value of 16.

A reduction in the requested amplitude to 300 mV requires additional post-amplifier attenuation. As a result, the 300 mV am-

plitude request will allow for only a 2.5 V offset even though

the unit has been requested to generate a 4.8 V offset. An error

2-6

Page 17

Product Description 2

"

message will be generated. Also at this point the amplifier is

being driven well above its 25% safety margin and the output is

fully saturated; no visible signal appears, only insufficient offset

is perceived. The unit will not indicate the erroneous offset

value if queried, but instead returns the requested offset value.

If the requested amplitude is changed back to 330 mV, then the

9100 will again generate 4.8 V of offset. As a final example, if

the requested amplitude is 40 mV, then the maximum achievable offset is 625 mV.

Similar concerns apply to attenuator selection when sum modes

are utilized. When external sum mode is selected, the sum signal is injected at the input of the output amplifier. To avoid

attenuating the external sum signal, the 9100 chooses to use the

preamplifier attenuators in preference to the post-amplifier atte-

nuators. This tends to cause a slight reduction in signal-to-noise

ratio. However, when the requested amplitude for the internal

generated signal is less than 312 mV, some post-amplifier atte-

nuators are required. This causes the external portion of the

summed signal to be attenuated.

NOTE: No error message is generated.

The 312 mV comes from the fact that the pre-amp attenuators

offer an attenuation factor of 16 and the fine gain control of

the Signal DAC offers a factor of 2 for a total attenuation of 32

without using the post-amplifier attenuators. 10 V divided by 32

equals 312.5 mV.

When the two channels are summed, the summing is dgne at

the preamplifier point of the circuit. To be certain that the cor-

rect gain will be applied to each channel’s contribution to the

summed’ signal you should verify that both channels’ amplitudes

can be generated with the same amount of post-amplifier attenuation. This typically limits the ratio of the two channels’

amplitudes to a value between 16 and 32. A safe method is to

limit the ratio of the two channels’ amplitudes to less than or

equal to 16. If this is not done, then the amplitude contribution

of the lower amplitude channel will be greater than pro-

grammed.

2-7

Page 18

Product Description

EXT TRIG

I

INPUT

(MANUAL

EXT CLK I

INPUT

tN PUT

COMMAND

~

I

_1__

oo

~..

I INPUT ~ I

sELEcT

I

, [ TRIG I z

TRIGGER

MASTER CLOCK

SYNTHESIZER -’

IMHz - 20OMHz

I 1

TI MEBASE

i

~

I CLKOUT, I

I O~TPOT I

~H ~1

OUTPUT

/

~~

START

MASTER

CLOCK

GATE

STOP

T

END OF

WAVEFORM

CLK OUT 2

OUTPUT I

I

OUTPUT

]

1

GATED

v CLOCK

B-IOI2

2-8

Figure 2.3

Page 19

Product Description 2

Figure 2.4

2-9

Page 20

Product Description

LaCroy 9100 ARBITRARY FUNCTION GENERATOR

2-10

"

II

HAN I CHAN

¯ UM 1"2

I I Ill

B-1004

Figure 2.5

Page 21

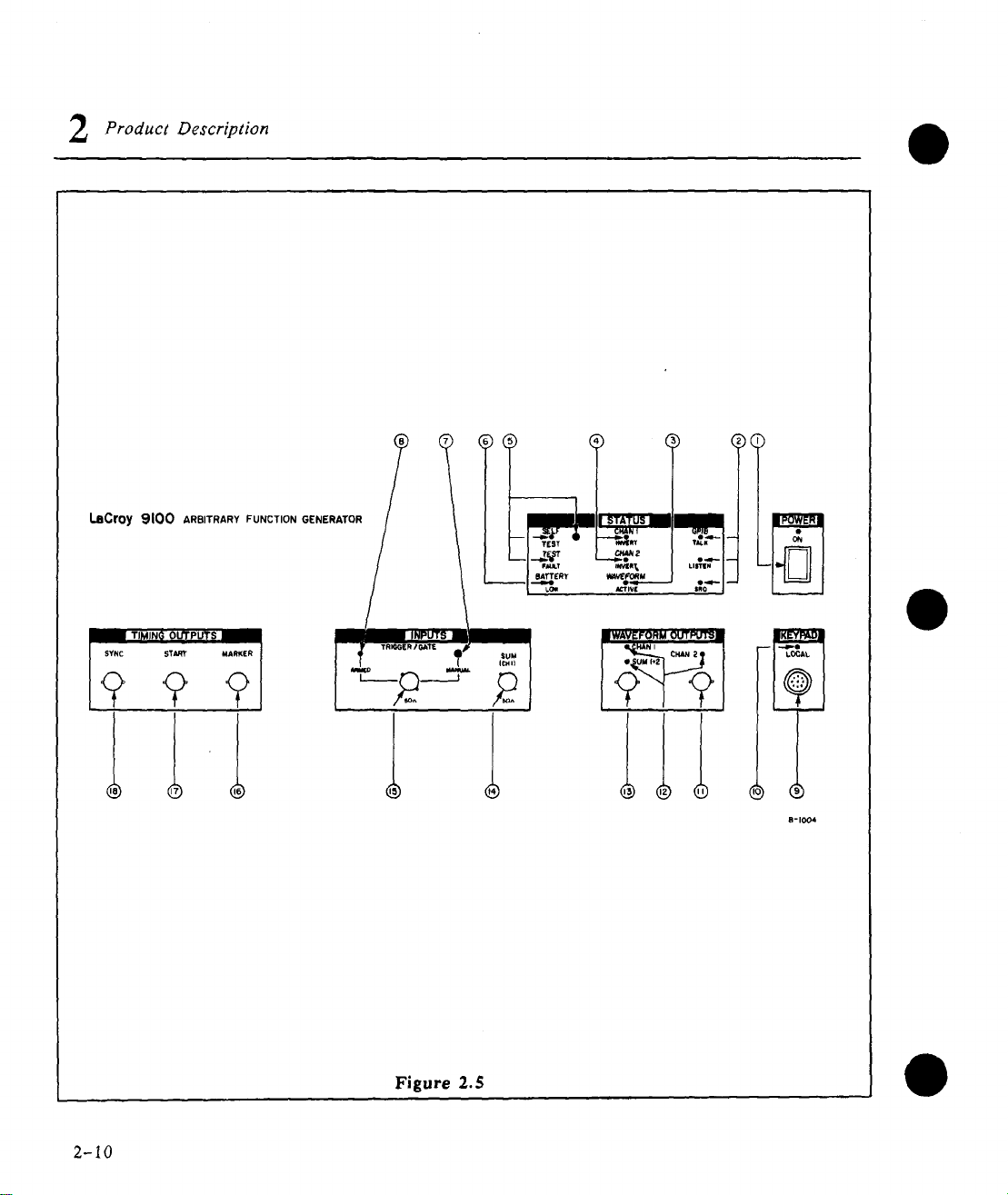

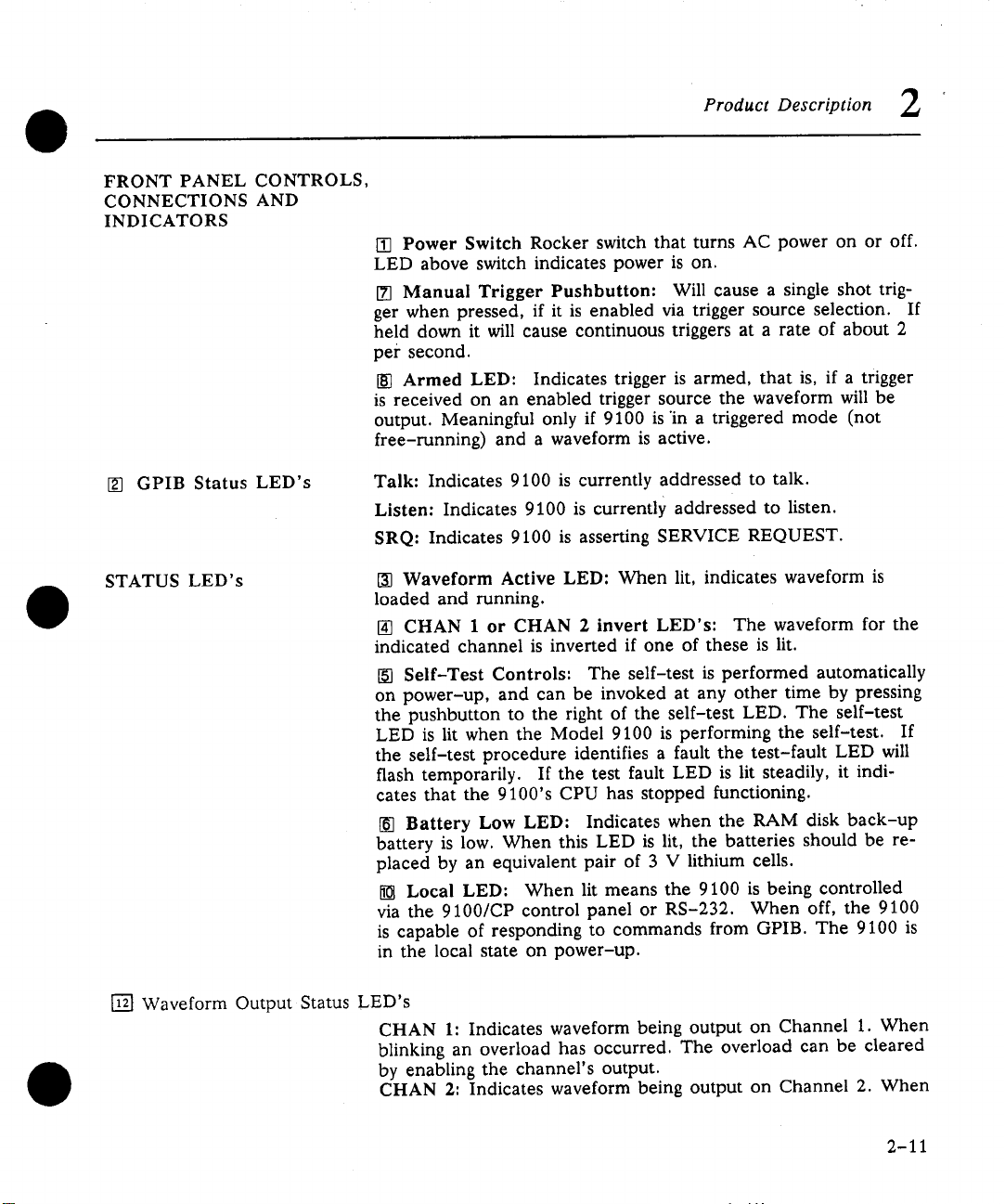

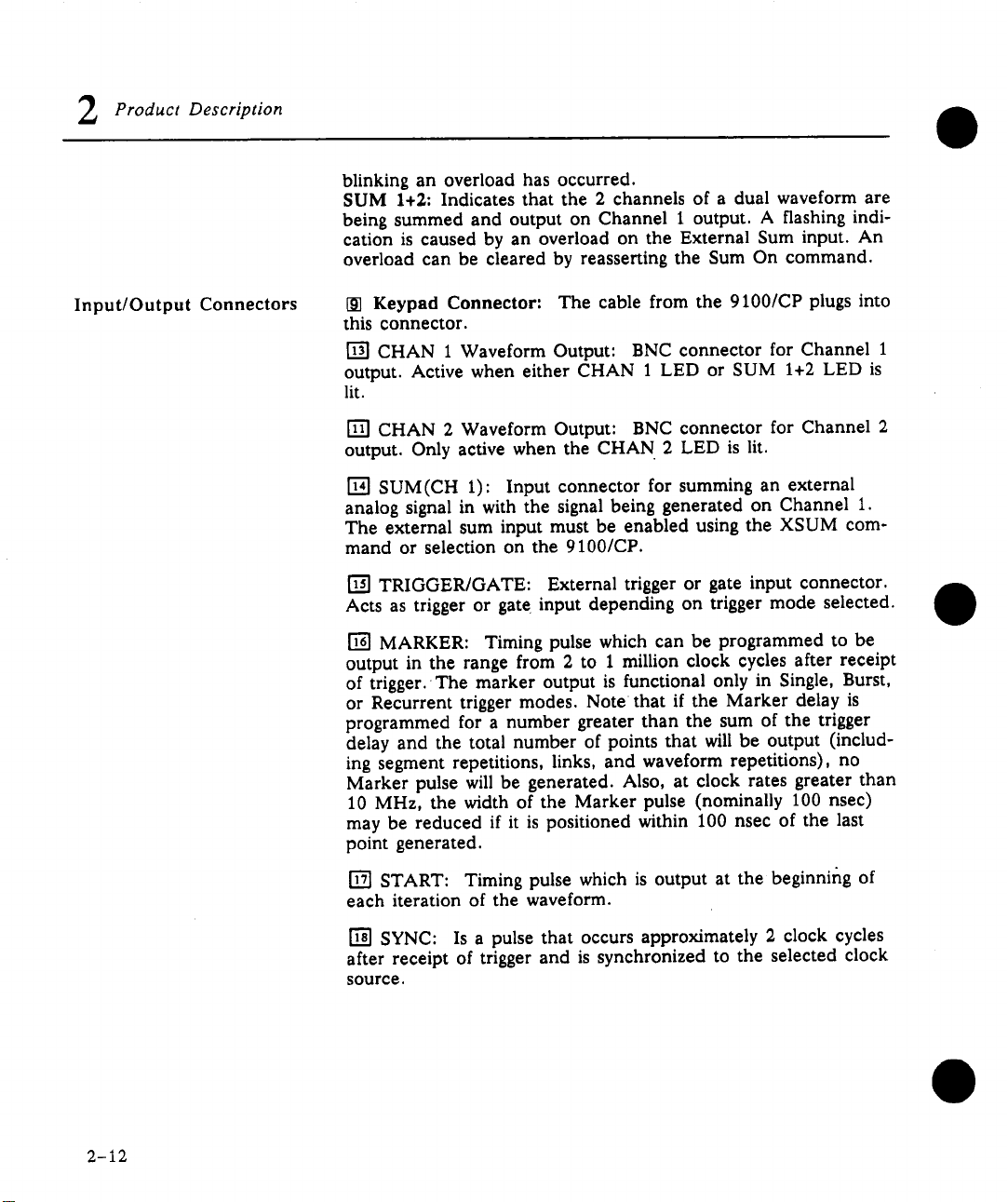

FRONT PANEL CONTROLS,

CONNECTIONS AND

INDICATORS

Product Description 2

[] Power Switch Rocker switch that turns AC power on or off.

LED above switch indicates power is on.

[] Manual Trigger Pushbutton: Will cause a single shot trig-

ger when pressed, if it is enabled via trigger source selection. If

held down it will cause continuous triggers at a rate of about 2

per second.

[] Armed LED: Indicates trigger is armed, that is, if a trigger

is received on an enabled trigger source the waveform will be

output. Meaningful only if 9100 is "in a triggered mode (not

free-running) and a waveform is active.

[] GPIB Status LED’s

STATUS LED’s

[] Waveform Output Status LED’s

Talk: Indicates 9100 is currently addressed to talk.

Listen: Indicates 9100 is currently addressed to listen.

SRQ: Indicates 9100 is asserting SERVICE REQUEST.

[] Waveform Active LED: When lit, indicates waveform is

loaded and running.

[] CHAN 1 or CHAN 2 invert LED’s: The waveform for the

indicated channel is inverted if one of these is lit.

[] Self-Test Controls: The self-test is performed automatically

on power-up, and can be invoked at any other time by pressing

the pushbutton to the right of the self-test LED. The self-test

LED is lit when the Model 9100 is performing the self-test. If

the self-test procedure identifies a fault the test-fault LED will

flash temporarily. If the test fault LED is lit steadily, it indicates that the 9100’s CPU has stopped functioning.

[] Battery Low LED: Indicates when the RAM disk back-up

battery is low. When this LED is lit, the batteries should be replaced by an equivalent pair of 3 V lithium cells.

[] Local LED: When lit means the 9100 is being controlled

via the 9100/CP control panel or RS-232. When off, the 9100

is capable of responding to commands from GPIB. The 9100 is

in the local state on power-up.

CHAN 1: Indicates waveform being output on Channel 1. When

blinking an overload has occurred. The overload can be cleared

by enabling the channel’s output.

CHAN 2: Indicates waveform being output on Channel 2. When

2-11

Page 22

Product Description

blinking an overload has occurred.

SUM 1+2: Indicates that the 2 channels of a dual waveform are

being summed and output on Channel 1 output. A flashing indi-

cation is caused by an overload on the External Sum input. An

overload can be cleared by reasserting the Sum On command.

Input/Output Connectors

[] Keypad Connector: The cable from the 9100/CP plugs into

this connector.

[] CHAN 1 Waveform Output: BNC connector for Channel 1

output. Active when either CHAN 1 LED or SUM 1+2 LED is

lit.

[] CHAN 2 Waveform Output: BNC connector for Channel 2

output. Only active when the CHAN 2 LED is lit.

[] SUM(CH 1): Input connector for summing an external

analog signal in with the signal being generated on Channel 1.

The external sum input must be enabled using the XSUM command or selection on the 9100/CP.

[] TRIGGER/GATE: External trigger or gate input connector.

Acts as trigger or gate input depending on trigger mode selected.

[] MARKER: Timing pulse which can be programmed to be

output in the range from 2 to 1 million clock cycles after receipt

of trigger. The marker output is functional only in Single, Burst,

or Recurrent trigger modes. Note that if the Marker delay is

programmed for a number greater than the sum of the trigger

delay and the total number of points that will be output (includ-

ing segment repetitions, links, and waveform repetitions), no

Marker pulse will be generated. Also, at clock rates greater than

10 MHz, the width of the Marker pulse (nominally 100 nsec)

may be reduced if it is positioned within 100 nsec of the last

point generated.

2-12

[] START: Timing pulse which is output at the beginning of

each iteration of the waveform.

[] SYNC: Is a pulse that occurs approximately 2 clock cycles

after receipt of trigger and is synchronized to the selected clock

source.

Page 23

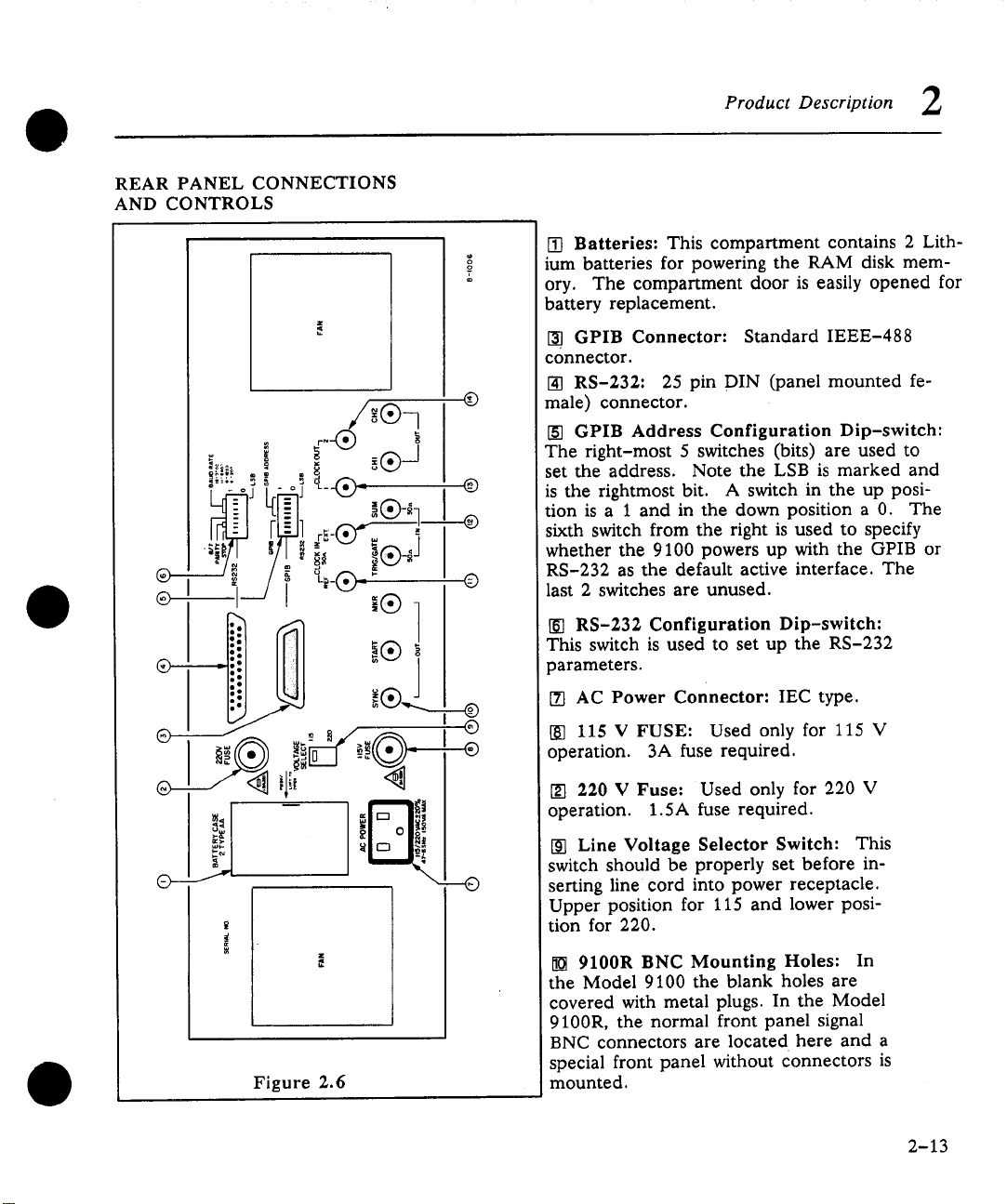

REAR PANEL CONNECTIONS

AND CONTROLS

Product Description 2

[] Batteries: This compartment contains 2 Lith-

ium batteries for powering the RAM disk memory. The compartment door is easily opened for

battery replacement.

[] GPIB Connector: Standard IEEE-488

connector.

[] RS-232: 25 pin DIN (panel mounted fe-

male) connector.

[] GPIB Address Configuration Dip-switch:

The right-most 5 switches (bits) are used

set the address. Note the LSB is marked and

is the rightmost bit. A switch in the up posi-

tion is a I and in the down position a 0. The

sixth switch from the right is used to specify

whether the 9100 powers up with the GPIB or

RS-232 as the default active interface. The

last 2 switches are unused.

[] RS-232 Configuration Dip-switch:

This switch is used to set up the RS-232

parameters.

[] AC Power Connector: IEC type.

Figure 2.6

@

[] 115 V FUSE: Used only for 115 V

operation. 3A fuse required.

[] 220 V Fuse: Used only for 220 V

operation. 1.5A fuse required.

[] Line Voltage Selector Switch: This

switch should be properly set before in-

serting line cord into power receptacle.

Upper position for 115 and lower posi-

tion for 220.

[] 9100R BNC Mounting Holes: In

the Model 9100 the blank holes are

covered with metal plugs. In the Model

9100R, the normal front panel signal

BNC connectors are located here and a

special front panel without connectors is

mounted.

2-13

Page 24

Product Description

[] CLOCK IN REF: A 4 MHz reference oscillator, amplitude

between 1 and 4 V p-p, may be used as the 9100 reference

oscillator instead of the internal crystal. It is input here and the

signal is AC coupled.

[] CLOCK IN EXT: The internal synthesizer may

be bypassed altogether and the 9100 can be driven by a clock

signal that is input to this connector. This input is selected via

the CLOCK SOURCE command.

m

[] CLOCK OUT 1: Ungated clock output at the point rate for

single channel waveforms, or twice the point rate for dual channel waveforms.

[] CLOCK OUT 2: Gated clock output for master-slave op-

eration.

2-14

Page 25

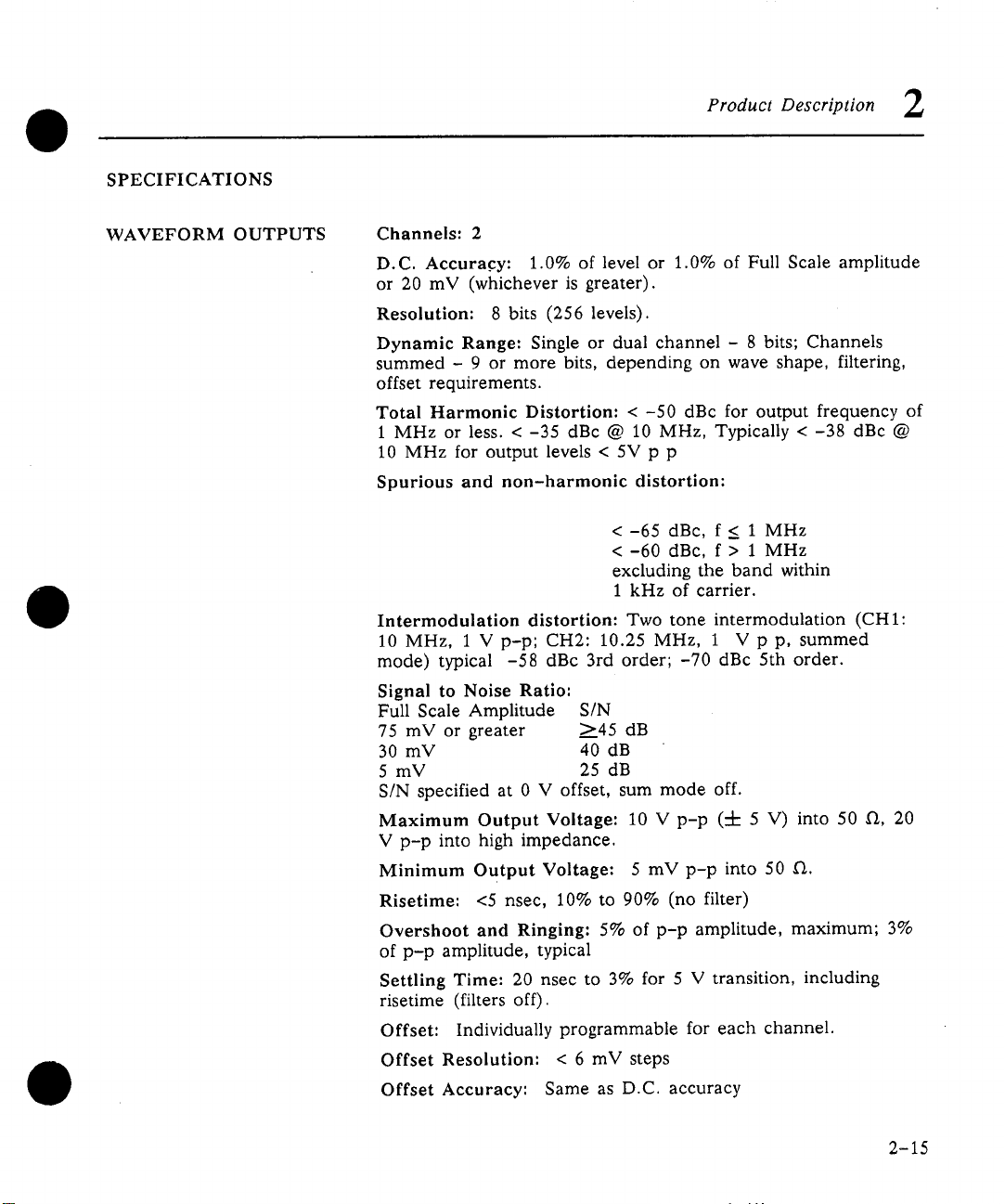

SPECIFICATIONS

WAVEFORM OUTPUTS Channels: 2

D.C. Accura.cy: 1.0% of level or 1.0% of Full Scale amplitude

or 20 mV (whichever is greater).

Resolution: 8 bits (256 levels).

Dynamic Range: Single or dual channel - 8 bits; Channels

summed - 9 or more bits, depending on wave shape, filtering,

offset requirements.

Total Harmonic Distortion: < -50 dBc for output frequency of

1 MHz or less. < -35 dBc @ 10 MHz, Typically < -38 dBc @

10 MHz for output levels < 5V p p

Spurious and non-harmonic distortion:

Intermodulation distortion: Two tone intermodulation (CHI:

10 MHz, 1 V p-p; CH2:10.25 MHz, 1 Vp p, summed

mode) typical -58 dBc 3rd order; -70 dBc 5th order.

Signal to Noise Ratio:

Full Scale Amplitude

75 mV or greater

30 mV

5 mV 25 dB

S/N specified at 0 V offset, sum mode off.

Maximum Output Voltage: 10 V p-p (4- 5 V) into 50 11,

V p-p into high impedance.

Minimum Output Voltage: 5 mV p-p into 50 fl.

Risetime: <5 nsec, 10% to 90% (no filter)

Overshoot and Ringing: 5% of p-p amplitude, maximum; 3%

of p-p amplitude, typical

Settling Time: 20 nsec to 3% for 5 V transition, including

risetime (filters off).

Offset: Individually programmable for each channel.

Offset Resolution: < 6 mV steps

Offset Accuracy: Same as D.C. accuracy

Product Description 2

<-65 dBc, f < 1 MHz

<-60 dBc, f > 1 MHz

excluding the band within

1 kHz of carrier.

S/N

~45 dB

40 dB

2-15

Page 26

Product Description

STANDARD FUNCTIONS

(WAVEFORMS)

Maximum Offset Voltage:

External Load: Max. Offset V:

50 n 4-5 V

Open Circuit 4-10 V

Output Smoothing: Built-in filters with programmable cutoff

frequencies: bypassed, 1, 3, 10, 30, 100 MHz; 18 riB/octave

(Bessel)

Crosstalk between channels: < I%

Ch I to Ch 2 Phase Accuracy:

Sinewave - Frequency Range: 0.01 Hz to 25 MHz

Frequency Resolution: 0.035%

Squarewave - Frequency Range: 0.01 Hz to 100 MHz

(50 MHz dual channel)

Frequency Resolution: 0.035%

Triangle -

Pulse - (single channel only) Period: 40 nsec to 10 sec; Width:

variable, 5 nsec to 10 sec (not to exceed period); Orientation:

selectable, positive or negative going.

Ramp - Period: 40 nsec to 100 sec; Resolution: 0.035%;

Linearity:--1-1%; Orientation: selectable, positive or negative going.

DC - Generates a D.C. level, the value of which is the offset

level. Accuracy: the greater of 1% or 20 mV.

Frequency Range: 0.01 Hz to 25MHz

Frequency Resolution: 0.035%

Linearity: 4-1%

Internal Summing -I-.5 nsec

Dual Outputs 4-1 nsec

TIME BASE (Clock Rate)

TRIGGER

Modes

2-16

Range: 5 nsec to 20 sec per point

Resolution: 0.035%

Accuracy: 5 ppm, at achievable set points, 230 C,

115 VAC/60 Hz, after 30 minute warmup

Stability: < 0.5 ppm/° C

Continuous: The generator runs continuously at the selected

frequency.

Page 27

Product Description 2

Recurrent: The waveform is cycled with a programmable delay

of up to 1 million points (1/2 million in dual channel) between

cycles. Number of waveforms per cycle is programmable up to

65,535.

Single: Upon receipt of a trigger, the selected waveform is generated only once. The start of the waveform can be delayed

from the trigger point by up to 1 million points (1/2 million in

dual channel).

Burst: Upon receipt of a trigger, the selected waveform is generated the number of times set into the burst counter, up to

65,535. The start of the burst can be delayed up to 1 million

points (1/2 million in dual channel).

Gated (uses the trigger threshold): Uses a triggered start and

stops at the completion of the current waveform cycle after the

gate closes.

External Trigger Threshold:

Source

Arm Source:

WAVEFORM MEMORY

Slope + or Range-4-2.5 V

Resolution 20 mV (8 bits)

Manual

External

Bus

Auto - Automatically rearms itself.

Bus - Rearmed from the GPIB, RS-232 or the

Control Panel.

Trigger sources and arm sources may be individually enabled or

disabled.Internal triggering is automatically selected in continuous or recurrent trigger modes

Delay: Variable, from four to one million points (2 to 1/2 million in dual channel).

Fast Memory Length: Single Channel - 64 Kpoints; Dual

Channel - 32 kpoints each channel.

Storage Memory Length (RAM Disk): > 350 Kpoints for

waveforms, setup and sequence files.

RAM Disk to Fast Memory Load Rate: 250 msec +0.7 l~sec/

byte.

Front-panel button

External trigger applied via a front panel BNC

Trigger from GPIB, RS-232 or Control Panel

Control Panel Trigger Key

2-17

Page 28

Product Description

Battery back-up:>3 years (non-rechargable Lithium cells).

Minimum Waveform Length: Nonlinked waveform segment, no

looping - 8 points (4 points for each channel in dual mode);

linked waveforms - Single channel operation - 72 points, Dual

channel operation - 36 points for each channel.

Waveform Length Resolution: Single channel operation - 8

point blocks, Dual channel operation - 4 point blocks.

Waveform Loop Counter: One counter per linked waveform

maximum repetitions - 4095.

OUTPUTS:

Front Panel:

Rear Panel:

INPUTS

Front Panel

Protection: Waveform outputs are protected against applied

voltages to 4-40 V. If an externally applied overvoltage condition is detected, the output relay is opened, the LED for that

channel is flashed and, if enabled, an SRQ is generated on the

GPIB. The condition can be cleared by reconnecting the channel’s output.

Waveform Outputs - Output impedance, 50 12; All Timing

Outputs - Output impedance, 50 12, source 1.5 V peak into

50 12, approximately 75 nsec duration.

Time Marker Output - Settable from two up to one million

clock cycles, referenced to the trigger point.

Sync Output - Occurs at the next Sample Clock edge after

receiving a trigger.

Waveform Start Output - Occurs at the start of the waveform.

Clock Outputs - 0 to -0.8 V into 50 12. Approximately a

square wave. Present in all modes including External Clock.

Protection: The maximum input voltage level for all inputs

should not exceed 5 V.

External Gate/Trigger Input - Impedance: 50 12

Sum Input - Impedance: 50 12. Overload is indicated by flash-

ing Sum 1 + 2 LED. Gain: X 1, 4-5% for >350 mV full scale

output ranges. Bandwidth: >80 MHz at 3 dB

Hand-Held Keypad (Control Panel) Input - DIN connector is provided for attaching the hand-held control panel and

display.

Rear Panel

2-18

External Clock Input - When this input is selected, the inter-

nal clock is deselected and the waveform is generated using the

Page 29

Product Description 2

external clock. Impedance: 50 12 Threshold: Variable -4-2.5 V,

8 bits resolution.

External Reference Input: Selection of this input causes the

internal clock to phase lock to it. It requires a 4 MHz signal

with 1 to 4 V p-p amplitude into 50 12, AC coupled.

2-19

Page 30

Product Description

FRONT-PANEL

INDICATORS AND

CONTROLS

Controls

Indicators

Power ON/OFF

Manual Trigger Button

Manual Self Test Button

Hand-held Control Panel (optional)

Power on LED - ON when power is applied to the instrument.

Trigger Armed LED - ON when awaiting a trigger signal.

Waveform Output LED’s: Chan 1: ON when Channel 1 is

turned on; Chan 1 & 2: ON when Channel 1 is being summed

with channel 2. Chan 2: ON when Channel 2 is turned on.

Waveform Active LED: ON when a waveform is being clocked

out of the fast memory to one or both waveform outputs or if

the unit is armed and waiting for a trigger.

GPIB: Talk LED - ON when the instrument is in the talk

mode.

Listen LED - ON when the instrument is in the listen

mode.

SRQ LED - ON when the SRQ line is asserted and the

instrument is awaiting action from a GPIB controller.

Remote - This word is spelled out in the hand-held

control panel display whenever the instrument is put into

remote by a GPIB controller.

Local LED - Located with the keypad input connector,

it indicates when the instrument is in the LOCAL mode

and the hand-held control panel is operative. When it

is not ON, the instrument is in the GPIB remote state.

Self Test LED - ON when a self test or calibrate is in progress.

Test Fault LED - Flashes for 10 seconds when a self test or

calibrate determines there is a fault or steady ON in the event

of a microprocessor failure.

Battery Low LED - ON when the RAM Disk memory backup

battery is too low.

Chan 1, Invert LED - ON when Ch 1 output is inverted.

Chan 2, Invert LED - ON when Ch 2 output is inverted.

2-20

Page 31

REAR PANEL

CONNECTORS AND

SWITCHES

WAVEFORM CREATION

AND EDITING

A

Product Description 2

Connectors: GPIB: IEEE 488-1978 compatible; RS-232 Port:

DB 25 S Connector.

Switches: GPIB Address Switch; RS-232 Port Configuration

Switch, Line voltage selector and fuses.

LeCroy’s EASYWAVE® software package is available for PCDOS compatible computers*. It provides for waveform creation

and editing in a menu driven environment. Waveform creation

can be accomplished by any of the following methods:

1. Equation entry.

2. Selecting and combining simple waveform elements.

3. Waveforms can be acquired over the GPIB from

LeCroy Oscilloscopes and then edited.

Editing may be accomplished as follows:

1. Modifying individual points from the keyboard.

2. Modifying the equation describing the waveform.

3. Deleting, moving and rescaling blocks of data.

* Minimum hardware configuration of host computer 640K

RAM, 10 Mbyte Hard Disk, Graphics (CGA,HGA, or EGA)

Display.

Other GPIB Compatible Controllers: Waveforms can be created and edited on other controllers using user supplied software.

INSTRUMENT CONTROL

GENERAL

PC-DOS Compatibles: The same software package used for

waveform editing also can be used for controlling the 9100.

Local Control Panel: Once the waveforms have been loaded to

RAM Disk, an optional, detachable control panel with a four

line LCD display may be used for controlling the 9100.

Other GPIB or RS-232 Compatible Controllers: Other com-

puters or terminals may be used to control the instrument using

the remote commands.

GPIB Interface Functions: IEEE 488-1978 compatible. SH1,

AH1, T5, TE0, L3, LEO, SR1, RL1, PP0, DC1, DT1, CO

GPIB DMA Rates: Typically >__200 kbytes/sec

RS-232C: Implemented as data communications Equipment

(DCE).

2-21

Page 32

Product Description

Baud Rates: 300, 600, 1200, 2400, 4800, and 9600.

Data Bits: 7 or 8.

Stop Bits: 1 or 2.

Parity: None, Even, or Odd.

Protocol: Full Duplex, Xon/Xoff (DC1/DC3) handshake,

Data Formats: #I Arbitrary length ASCII #L ASCII HEX "00"

to "FF" (double the length of internally stored binary data files)

Commands: Full Conversational same as GPIB plus: RS_SRQ,

Define character equivalent to SRQ in GPIB. Default is "Bell",

ESC commands ECHO on/off Trig remote/local

Temperature Range: 15o C. to 35o C., full specification; 0° C.

to 40o C., operating.

Humidity: 40o C., 10% to 95% relative, non-condensing.

Power: 115/220 +/- 20% VAC,47-63 Hz. approximately

147 watts

Size: 5-1/4" H X 19" W X 15" D.

Weight: 26 lbs. (approximately).

STANDARD ACCESSORIES I each Operator’s Manual

r

ORDERING INFORMATION 9100

9100R

9101

9109

OPTIONAL ACCESSORIES

EASYWAVE® is a trademark of LeCroy Corp

IBM XT/AT® is a registered trademark of International Business

Machines Corp

2-22

9100/CP

9100/EC

9100/OM

9100/SM

9100/SW

9100/SP

9100/MM

9100/MM1

9100/MM2

9100/RT

9100 GPIB2

DC/GPIB-2

Dual Channel Arbitrary Function Generator

Dual Channel Arbitrary Function Generator with

Rear Panel Connectors

Single Channel Arbitrary Function GeneratOr

Dual Channel Arbitrary Function Generator with

Digital Word Outputs

Detachable Hand-held Control Panel

6’ Extender Cable (Control Panel)

Operator’s Manual

Service Manual

EASYWAVE Software

Advanced Waveform Creation Software

Waveform Memory Expansion - 1/2 Mbyte

Waveform Memory Expansion - 1 Mbyte

Waveform Memory Expansion - 2 Mbyte

Real-Time Waveform Selection

GPIB Interface Card and Software (National

Instruments PCII Card and GPIB-PC Software)

GPIB Cable, 2 meters

Page 33

3

PREPARATION FOR USE

OPERATING

ENVIRONMENT

Voltage Selection and

Fuse Check

[OPERATIONS

The Model 9100 should be operated only within the following

environmental limits:

Temperature: 15°C to 35° C, in spec;

0°C to 40° C, in operating.

Humidity: 40° C, 10% to 95% relative, non-condensing.

Specifications are rated from +15° C to +35° C.

The Model 9100 has been designed to operate from either a

115 V or 220 V nominal power source. On the rear panel of

the instrument, a switch permits user selection of either voltage.

Also on the rear panel, separate fuses are provided for each

voltage.

Prior to powering up the Model 9100, make certain that the

voltage selector switch is set to whichever of those two voltages

corresponds to the available power supply and that the fuse for

that voltage is intact and properly installed.

CAUTION: The Model 9100 will fail to operate and could be

damaged if plugged into a voltage other than that which the

voltage selector switch on the rear panel is set. Thus, correct

line voltage selection MUST be made before plugging the

instrument in or turning it on.

Power Cable

GPIB Address Selection

The Model 9100 has been designed to operate from a

single-phase power source with one of the current-carrying

conductors (neutral conductor) at ground (earth) potential.

Operation from power sources in which both current-carrying

conductors are live with respect to ground (such as

phase-to-phase on a tri-phase system) is not recommended.

The instrument is provided with a three-wire electrical cable

containing a three-terminal polarized plug for line voltage and

safety ground connection. The plug’s ground terminal is

connected directly to the frame of the unit. For adequate

protection against electrical hazard, this plug must be inserted

into a mating outlet containing a safety ground contact.

The Model 9100’s 8-segment GPIB address switch is located on

the instrument’s rear panel. Segments 1 and 2 are unused.

Segment 3 selects the communication source. A "1" selects

GPIB and "0" selects RS-232.

3-1

Page 34

Operations

Segments 4 through 8 on the switch are used for GPIB address

selection as shown in Figure 3.1.

1 = GPIB, 0 = RS-232

GPIB Address

¯

O OOOOOO 0 o

r

16 8 4 2 1 Binary Equivalent

For Example:

0 0 0 0 0 = 0

0 0 0 0 1 = 1 The default address

1 0 0 0 1 = 17 Typical Address

1 1 1 1 1 = 31 automatically defaults to 1

Valid Addresses are 1 through 30

Not a valid address

automatically defaults to 1

Not a valid address

RS-232 Switch Setup

Power-On Procedure

3-2

Figure 3.1

GPIB Selection and Addresses

Refer to Chapter 6.

As described in the preceding sections, the first steps in

operating the Model 9100 is to be sure that it is properly

connected to line power, that it is properly fused, and that the

selector switch on the rear panel is set to the same voltage as

line power.

Once those steps are complete, press the power switch (in the

upper right corner of the front panel) to the ON position. The

LED above that switch will light to indicate that power is on.

Also on will be the SELF-TEST light in the STATUS rectangle

to the left of the power switch. This light indicates that the

instrument is undergoing calibration, which is part of self-test.

When the calibration is complete the self-test LED will no

longer be lit.

Page 35

Operations

NOTE: It is normal for all front-panel lights to flash on prior

to self-test.

After calibration, the instrument initializes all control settings,

which takes several seconds. During this time the LOCAL LED

will be on. The remote interfaces are ignored until initialization

is complete, to avoid any possible conflicts. After initialization

the message "LECROY 9100" appears on the 9100/CP, if it is

attached. If a GPIB controller places the instrument in the

REMOTE state during initialization, this will be recognized at

the end of initialization. If the communications source is

RS-232, a prompt "AFG\>" is sent over RS-232 at the end of

initialization.

The instrument is now ready to use in its power-up mode. All

instrument settings will be at their default values and only the

POWER and LOCAL LED’s will remain lit (the Model 9100

powers up in LOCAL mode, which means it is at that point set

to be controlled by the 9100/CP).

When settings are changed to meet the needs of specific

operations, and/or if appropriate commands are given to invoke

REMOTE (computer) control of the instrument, different

front-panel LED’s will light up accordingly.

3

OPERATING THE 9100

STANDARD FUNCTIONS

In the following sections the general format of remote

commands will be given to show how certain operations are

invoked. The argument descriptor will often be shown as the

argument name or explanation enclosed in angular brackets.

For example:

Command: CLOCK_PERIOD,<desired period>;

The type of argument is not to be entered literally when the

command is used. The angular brackets and text enclosed

should be replaced by the properly formatted argument in

accordance with the rules specified in Chapter 5. The argument

is typically a number with a unit appended to it with no

embedded spaces.

All commands except for those that transfer files into and out

of the 9100 can also be given using the 9100/CP via its

menu-driven command entry. See Chapter 4 for the 9100/CP

menu description.

Standard functions may be generated with the 9100 using the

9100/CP or by command over the bus without loading or using

any waveform files. The standard function modes completely

emulate the usual function generator operation by automatically

generating the waveforms needed in the waveform memory. In

3-3

Page 36

Operations

all these modes the user simply enters the parameters needed

(for example, frequency and phase for sine generation) and the

rest is done automatically.

The standard functions are accessed under the FUNC main

menu key on the 9100/CP. For detailed instructions on the

menu driven operation of the standard functions see Chapter 4.

To operate standard functions under remote control, first send

the command which forces the 9100 into the particular standard

function mode (a single word command which is usually the

name of the function, e.g., sine, pulse, ..) and then give the

GO command. The function will then be output. For a detailed

explanation of the operation of all related commands see

Chapter 5.

Listed below are the commands for setting up dual channel

I MHz sine waves with 20° phase difference between Channel 1

and Channel 2,

SINE;

SINE_MODE,DUAL;

SINE FREQUENCY, 1MHZ;

SINE_CH2_PHASE,20;

In standard function modes the clock is set automatically and

cannot be controlled independently as with arbitrary functions.

For this reason all clock related commands are disabled when in

a standard function mode. When using a 9100/CP, if an

external clock reference is needed in standard function mode it

must be selected when in arbitrary mode and then it will be

active when using standard functions. It cannot be selected

when in standard mode.

ARBITRARY WAVEFORMS

AND FILE CONVENTIONS

3-4

The LeCroy EASYWAVE software running on an IBM XT/AT

computer is the recommended method of creating and

transferring arbitrary waveform files to the 9100. The next

section carefully explains how to format and transfer waveform

files to the 9100, and Chapter 5 summarizes all the commands

and formats used. All arbitrary waveforms are handled as files

in the 9100. Once the files exist on the 9100 RAM disk all

control can be accomplished via the 9100/CP control panel.

All files in the AFG have an extension which is necessary and

significant. Below is a summary of the different types of files

you will encounter. The file name, represented by xxxxxxxx, is

the alphanumeric name that the user gives when creating the

file.

Page 37

Defining an Arbitrary

Waveform in Terms

of a Waveform File

Operations

xxxxxxxx.WAV - SINGLE CHANNEL WAVEFORM FILE

Contains the data to generate a single channel waveform. May

only be output on Channel 1.

xxxxxxxx.WAD - DUAL CHANNEL WAVEFORM FILE

Contains the data to generate a dual channel waveform.

xxxxxxxx.SET - SETTINGS FILE Used to automatically

establish all settings of the 9100 in conjunction with the SETUP

command. The LEARN command automatically generates a

setup file.

xxxxxxxx.SEQ - SEQUENCE FILE Used to contain a

sequence of 9100 commands that may be executed

automatically by giving the SEQUENCE command. This

command is most necessary when defining a complex waveform

using the LINK command.

Two types of waveform file formats are used by the 9100, one

for single channel waveforms and one for dual channel

waveforms. Both single channel and dual channel waveform files

contain a single sequence of bytes which define the waveform

data array to be generated. The bytes should be UNSIGNED, in

other words range from 0 to 255. In general, when you

calculate your waveform using your computer you will probably

be using floating point numbers to represent the voltage values

which you wish to generate. In order to convert these into 8-bit

waveform data values and maintain the maximum amplitude

resolution you should, in most cases, scale your waveform so

that the minimum value corresponds to 0 and your maximum

value corresponds to 255.

The basic constraints on the waveform files are:

1. The maximum number of bytes is 65536.

2. The number of bytes must be a multiple of 8. This is due to

a hardware constraint in the waveform memory.

The number of bytes must be greater than or equal to 8 for

3.

a waveform file that will not be "linked" with other

waveform files when loaded into the WAVEFORM

GENERATOR CIRCUIT from the RAM DISK. (See page

3-9, for an explanation of waveform file linking.)

4. The number of bytes must be greater than or equal to 72

for a single-channel waveform file that will be "linked" with

other single channel waveform files. Dual channel files that

are to be linked must contain at least 36 bytes per channel.

3

3-5

Page 38

Operations

TRANSFERRING WAVEFORM

DATA FILES INTO THE

AFG RAM DISK VIA GPIB

NOTE: If you are using the EASYWAVE Program to create and

NOTE: The extension on the waveform is significant and lets

the 9100 know what type of waveform will be contained in the

file. Filename represents the name by which you will refer to

5, Minimum data value is 0,

Maximum data value is 255.The single channel waveform file

simply contains a series of bytes in the exact order in which you

want them to be generated. The single channel waveform will

always be output on Channel 1. The format is given below

where the index specifies the interval (point in time) during

which that value will be generated. The waveform file contains

N data bytes.

a(1) a(2), a(3) a(4) a(5) a(6) ...........

The dual channel waveform file consists of interleaved pairs of

data values which will be routed to Channel l(a) and Channel

2(b). Below we designate bytes for Channel 1 as a and bytes for

Channel 2 as b and the index specifies the interval during which

that value will be generated starting with 1. This waveform file

contains 2N data bytes and when run will result in N points

being output on channel 1 and N points being output on

Channel 2.a(1)

a(2) b(1) b(2) a(3) a(4) b(3) a(N-1)

a(N)b(N-1)

load your waveform files, you may skip this section.

After you have defined the data array which will become your

waveform file, you need to transfer it to the 9100. We do this

with the STORE command.

First send the command to transfer the file.

For single channel waveforms: STORE filename.wav

For dual channel waveforms~ STORE filename.wad

the waveform file.

Next, send the file. The stream of bytes that you send consists

of either a single block of bytes or a series of blocks. If the file

is being sent in multiple blocks EOI must be asserted only with

the last byte of the last block to indicate the end of the file.

The waveform files may be transferred to the 9100 in either of

two block formats; binary (called #A format) or hex-ASCII

(called #L format). Each individual block consists of a block

3-6

Page 39

Operations

preamble, a count (the number of data bytes in #A and the

number of data values in the #L case). Below are the block

formats for the binary and hex ASCII file block transfers. In

the table, each row corresponds to a byte sent over the GPIB to

the 9100.

3

3-7

Page 40

Operations

FOR BINARY TRANSFER:

Byte Number

1

2

3

4

5

6

7

N+4 <data byte N> (with EOI, if last block)**

* Data byte count is an unsigned integer which in this case

equals N. It contains the number of bytes being transferred in

the block. In this binary representation there is 1 data value per

byte.

**EOI, if sent, must be sent with the last byte. EOI terminates

the file transfer. If EOI is not sent, the 9100 will accept another

block as part of the same file. The last block of a file transfer

must be sent with EOI on the last byte.

Byte Value

#

A (ASCII uppercase A)

<data byte count, most significant byte>*

<data byte count, least significant byte>*

<data byte 1>

<data byte 2>

<data byte 3>

(ASCII #)

FOR HEX ASCII TRANSFER:

3-8

Byte Number

1

2

3

4

5

6

7

8

9

10

2N+5

2N+6 <lsb hex digit of data byte N> (with EOI,

* Value count is the number of data bytes you are sending over

in this block. In this hex ascii representation there are 2 bytes

per data value.

Byte Value

#

L

<value count, 4th hex digit, most significant >*

<value count, 3rd hex digit>*

<value count, 2nd hex digit>*

<value count, ist hex digit, least significant>*

<most significant hex digit of data byte i>

<least significant hex digit of data byte i>

<most significant hex digit of data byte 2>

<least significant hex digit of data byte 2>

<msb hex digit of data byte N>

if no last block)

(ASCII .#)

(ASCII uppercase L)

Page 41

Operations

**EOI, if sent, must be sent with the last byte. EOI terminates

the file transfer. If EOI is not sent, the 9100 will accept another

block as part of the same file. The last block of a file transfer

must be sent with EOI on the last byte.

NOTE: When transferring files over the RS-232 interface, the

last byte must be followed by the character defined by

COMM RS CONF as simulting EOI; see Chapter 6.

LOADING THE WAVEFORM

FILES FROM RAM DISK

INTO THE WAVEFORM

GENERATOR CIRCUIT The simplest type of waveform that we can generate is based on

a single waveform file. To generate the waveform described by a

single waveform file, simply load it and go by issuing the

following commands:

LOAD filename.ext; GO;

Where ext is either WAV or WAD, if single or dual channel

respectively.

NOTE: The commands shown in this screen are remote

commands valid over GPIB or RS-232. All functions are also

accessible from the 9100/CP. Operation with the 9100/CP is

covered in Chapter 4.

If you are using only simple waveforms composed of single

waveform file, skip the rest of this section of the operation

procedure. The procedure for building up more complicated

waveforms which utilize the linking and looping capabilities of

the 9100 will now be described.

The waveform data memory length of the 9100 is 64 Kbytes.

This means that if you are using only a single waveform file the

upper limit on a single channel waveform is 64 Kpoints and for

a dual channel waveform is 32 Kpoints per channel. The 9100

provides a way to effectively generate much longer waveforms if

any parts of the waveform are repetitive in nature.

You may link together waveform files when loading into the

waveform memory to define what can be thought of as a

waveform program. Lets look at an example. Suppose you want

to generate the waveform shown in Figure 3.2. It consists of

several pieces each of which are repeated several times:

3

3-9

Page 42

Operations

1 sine cycle

I DC section

4 since cyles

2 DC sections

2 Gaussian pulses

6 DC sections

WA VEFORM LINKING

(SF.OJZ~.E_EU.E)

WA VEFORM

LOAD. SINE

LINK - T COMP

-"LINK - SINE

V

IF--LINK- r COMP

IIr"-LINK-aAus

I[I ILINK - T COMP

You could simply generate a single data file which contained all

the data as a single array or we provide another method which

will use less waveform memory. We may define three waveform

files as follows:

REPETITIONS

1

I

4

2

2

6

Figure 3.2

SINE L

T COMP - OV (10 POINTS)

GAU~L,_

3-10

Page 43

Operations

3

GAUS.WAV

SINE.WAV

T.WAV

We can then load the waveform using the following sequence of

commands:

LOAD SINE.WAV, 1;

LINK TCOMP.WAV, 1;

LINK SINE.WAV,4;

LINK TCOMP.WAV,2;

LINK GAUS.WAV,2;

LINK TCOMP.WAV,6;

GO; (when you want to start it running)

The load command always comes first and tells the 9100 that

we are loading a new waveform into the waveform memory. In

this waveform the 9100 will generate one repetition of

SINE.WAV, then one repetition of TCOMP.WAV, then four

repetitions of SINE.WAV, then two repetitions of

TCOMP.WAV, then two repetitions of GAUS.WAV, and finally

six repetitions of TCOMP.WAV. When the waveform is loaded

in this manner, as a multi-file waveform, the amount of

waveform data memory used is conserved since each unique file

has to reside in the waveform memory only once. Therefore,

the amount of waveform memory used by this waveform is the

sum only of the number of data values in the three files.

Main constraints in making linked waveforms:

1. Minimum size of each file must be 72 bytes, as opposed to

8 for a single file waveform.

2. A Maximum of 1 Load + 681 sequential Link commands

can be used to generate a linked waveform.

3. The maximum number for the repetition argument in the

load or link is 4095.

The LINK command also accepts an additional argument. The

purpose of this argument is to permit each trigger cause output

of different waveform segments.

The format of the command is:

LINK argl [arg2] [arg3];

where optional items are contained in brackets, and items to be

replaced are in lower case.

argl: filename to link, with extension, such as A.WAD.

arg2: Number between 1 and 4095, inclusive, representing the

segment repetition count. Default if not present is 1.

contains 1 Gaussian pulse

contains 1 cycle of a sine wave

contains a constant data array

3-11

Page 44

Operations

arg3: WAIT.

The "WAIT" argument, if present, tells the 9100 Series AFG to

wait for trigger before executing this segment. More precisely, it

tells the AFG to act as if the entire waveform ended with the

segment before this one, and this segment is the first one in the

next waveform repetition. A detailed discussion of the effect of

this argument will be found under "Specifying the Trigger

Mode", page 3-15.

3-12

Page 45

CONTROL SETTINGS

SUMMARY

(amplitude, clock ....

Operations

Specifying the 9100 control settings gives the user control over

the various waveform characteristics. All attributes can be

controlled from the Control Panel as well as by GPIB

commands. The values of the settings determine when a

particular waveform data point will be output and at what

voltage level. The settings can be grouped into the following

major categories shown below.

3

Channel Parameter Settings

Timebase Settings

Trigger Settings

Settings which control the signal conditioning applied to the

Channel 1 and Channel 2 signals.

CH1 AMPLITUDE CH2 AMPLITUDE

CH 1-OFFSET

CH1 ZERO REF

CH 1-FILTER CH2-FILTE-R

CH I_INVERT

CH1 OUTPUT

EXTERNAL SUM

SUM_MODI~

Settings that affect the main clock, which determines the data

point period (i.e., determines rate at which the waveform is

output).

CLOCK_RATE

CLOCK_PERIOD

CLOCK_SOURCE

CLOCK_REFERENCE

CLOCK_LEVEL

CLOCK_MODE

CLOCK_SLOPE

Settings that affect when and how the waveform is triggered.

TRIG_MODE

TRIGDELAY

TRIG SOURCE

m

TRIG ARM SOURCE

TRIG-SLOP-’E

TRIG LEVEL

MARKER DELAY

DELAY_I~ODE

A detailed explanation of every command is contained in the

command reference in Chapter 5.

CH2-OFFSET

CH2 ZERO REF

CH2 INVERT

CH2-OUTPUT

3-13

Page 46

Operations

SPECIFYING HOW THE

DATA VALUES ARE

CONVERTED TO

VOLTAGE LEVELS AMPLITUDE, OFFSET AND ZERO REF determine the output

voltage as a function of data point vaiue, V(n) where n is the

data point value.

NOTE: All voltages are for the output terminated in 50 £). If

the output load is a high impedance, then all voltages at the

output will be 2 × higher than set.

The AMPLITUDE command sets the full scale voltage range,

that is, the voltage swing obtained when the data point value

changes from 0 to 255. For example the commands to set both

channel amplitudes to 2.3 V would be:

CH1 AMPLITUDE 2.3V;

m

CH2 AMPLITUDE 2.3V;

ZERO REF sets the data point value whose output voltage does

not change when the amplitude is changed (think of it as the

fixed point or baseline). This is also the data point value which

when output from the AFG will correspond to the offset voltage.

This value must fall between 0 and 255 but need not be

constrained only to integer values (127.5 is a valid value and is

the default value for this parameter). The commands to set

zero_ref to 0 (for unipolar positive operation) are:

CH1 ZERO REF 0;

CH2 ZERO REF 0;

For unipolar positive operation zref is typically set to 0. For

unipolar negative operation zref is typically set to 255.

NOTE: For an autoscaled waveform (i.e., one that is

normalized so that the maximum value is 255 and minimum is

O) to be generated symmetrically about 0 V ZREF should be set

to 127.5, and the offset should be set to 0 V.

OFFSET sets the output voltage obtained when the data point

value is equal to zref. The following commands set the offset

on channel 1 to 1 V and the offset on channel 2 to 2 V.

CH1 OFFSET 1V;

CH2 OFFSET 2V;

To summarize:

V(n=zref) = Voffset

V(255) - V(0) = Vamplitude

so for a general data point value n:

V(n) = Voffset + Vamplitude*(n-zref)/255

3-14

Page 47

SPECIFYING THE TIME

PER POINT

SPECIFYING THE

TRIGGER MODE

Operations

Where

V(n) is the voltage output for data value n. n is the

waveform data value between 0 and 255. Voffset is the

programmed offset voltage. Vamplitude is the selected

amplitude voltage. Zref is the selected zero reference point.

The clock period attribute controls the amount of time each

waveform point is output.

CLOCK_PERIOD < time value with optional units>;

The TRIG_MODE specifies the overall running mode of the

waveform. The 9100 has five different trigger modes:

1. Continuous - On receipt of the GO command the generator

outputs the loaded waveform. When it reaches the end of the

waveform it immediately starts over at the beginning with no

interruption between the last point and the first point. The

generator will continue to cycle the loaded waveform until

receipt of an ABORT or STOP. A pulse will be output from the

START output at the beginning of each cycle. The SYNC and

MARKER outputs are not available in this mode.

COMMAND: TRIG MODE CONTINUOUS;

2. Single (triggered) - This is a single sweep triggered mode.

In general, for each receipt of a trigger the generator will

output one sweep of the loaded waveform.

a GO command the generator waits for an ARM command

(if ARM SOURCE=BUS) before it proceeds. Usually (and