Page 1

Table of Contents

General Information

Manuals .......................................................... i

Using This Manual ................................................. i

Warranty ......................................................... iii

Product Assistance ................................................. iv

Maintenance Agreements ............................................ iv

Service Procedure .................................................. iv

Table of Contents

Safety Precautions ..................................................

ESD Precaution ........................................... ’ ......... viii

Plug-in Module Installation and Removal ............................... x

Section 1: Product Description 1-1

Block Diagram .................................................... I-4

Section 2: Installation 2-1

Attach Line Cord ................................................... 2-1

Operate in Proper Environment ........................................ 2-1

Apply Power ...................................................... 2-2

Selecting the Computer Port .......................................... 2-2

Setting the GPIB Address ............................................ 2-2

GPIB Host and Hardcopy Operation ....................................

RS-232-C Configuration ............................................. 2-7

Install the Plug-in(s) ................................................

Section 3: Operation

Overview ......................................................... 3-1

vii

2-3

2-12

3-1

7200A Mainframe Front Panel ........................................ 3-10

Acquisition Keys .................................................. 3-11

TOC-1

Page 2

Table of Contents

Waveform Display and Measurement ..................................

Panel Settings Storage ............................................... 3-51

Hardcopy ........................................................

Programming ......................................................

Using Setup Screens ................................................

Configure System ..................................................

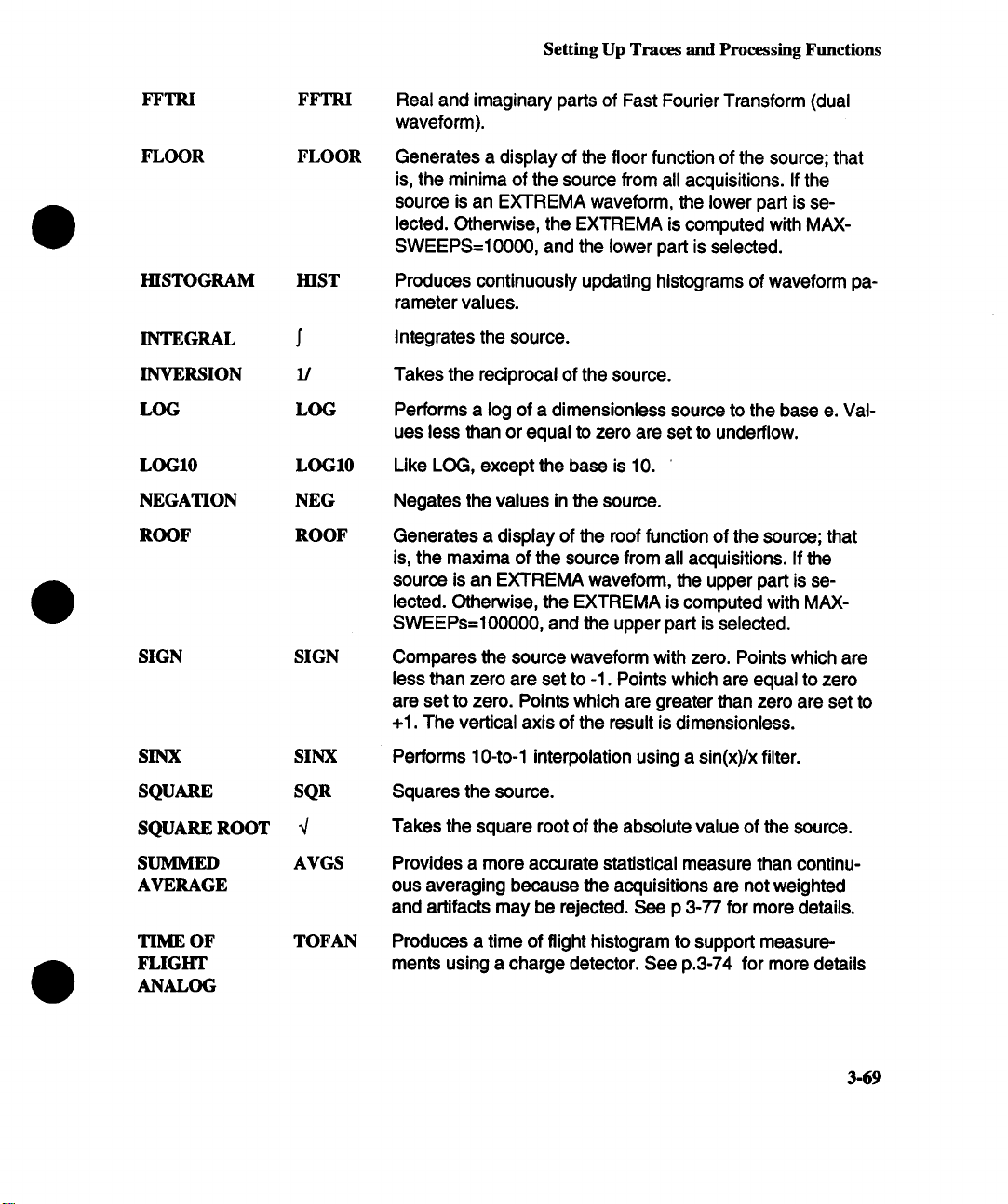

Setting Up Traces and Processing Functions .............................

Extended Parameter Setup ............................................ 3-89

Persistence Setup Screen .............................................

Multi Zoom Setup Screen ............................................

Hardcopy Setup ....................................................

Waveform Storage Setup ............................................. 3-112

Waveform Recall Setup .............................................. 3-115

Disk Utilities ......................................................

Configure System ..................................................

Program Setup .....................................................

3-15

3-51

3-51

3-53

3-54

3-56

3-99

3-101

3-103

3-118

3-127

3-139

7242 Series Operator’s Manual

The 7242 Series ....................................................

Accessories and Options .............................................

Specifications .....................................................

Installation ........................................................

Install the Plug-in(s) ................................................ 4-3

Operation .........................................................

Probes ...........................................................

Control Layout .................................................

Display of Acquisition Settings ......................................

7242 Series Plug-in Front Panel Controls ................................ 4-8

TOC~

4-1

4-1

4-1

4-1

4-3

4-4

4-4

4-5

4-6

Page 3

Table of Contents

Index to Controls ...................................................

Vertical Controls ...................................................

Timebase Controls .................................................. 4-12

Trigger Controls ...................................................

VERTICAL Status .................................................

TIMEBASE Status ................................................. 4-20

TRIGGER Status .................................................. 4-25

Standard Trigger ................................................... 4-27

Smart Trigger ...................................................... 4-27

Single Source ......................................................

Pattern .................................................. ......... 4-34

State Qualified .................................................... 4-39

Time Qualified .....................................................

TV ..............................................................

Plug-in Status .................................................... 4-51

4-9

4-10

4-14

4-17

4-30

4-45

4-50

7234 Plug-in Operator’s Manual 4-53

Installation ........................................................ 4-55

Install the Plug-in(s) ................................................

Operation ......................................................... 4-57

Probes ........................................................... 4-57

Control Layout ....................................................

Display of Acquisition Settings ...................................... 4-59

7234 Plug-in Front Panel Controls: ..................................... 4-61

Vertical Controls ................................................... 4-63

Timebase Controls .................................................. 4-66

Trigger Controls ................................................... 4-67

VERTICAL Status ................................................. 4-71

4-55

4-58

TOC-3

Page 4

Table of Contents

TIMEBASE Status ................................................. 4-74

TRIGGER Status .................................................. 4-79

Standard Trigger ...................................................

Smart Trigger

TM

................................................... 4-81

Single Source ...................................................... 4-84

Pattern ........................................................... 4-88

State Qualified .................................................... 4-93

Time Qualified ..................................................... 4-99

Plug-in Status .................................................... 4-104

Appendix A

Summary of Waveform Processing, Display, and Storage ................... A-I

Appendix B

Raekmount Installation ............................................. B-1

Appendix C

Accessories ....................................................... C-1

Appendix D - 7291 2GS/sec Adaptor

Features .......................................................... D-1

4-81

A-I

B-I

C-I

D-1

Calibration ........................................................ D-2

Operation ......................................................... D-4

Appendix E - 7200ARCLK Installation, Test and Cal Procedure E-1

How to Use This Manual ............................................

Installation ........................................................ E-3

Calibration ........................................................

Test .............................................................

TOC4

E-1

E-5

E-6

Page 5

Table of Contents

Appendix F - 7200A-IF2 Installation & System Test Manual

How To Use This Manual ............................................

Product Description .................................................

Specifications .....................................................

PC Utilities Operation and Description .................................

PC Utility Software Installation .......................................

Utility Program Definition ...........................................

7200A-IF2 Installation Procedure ......................................

F-1

F-1

F-1

F-3

F-3

F-4

F-7

F-10

Appendiz G - 7200A Version 2.2.0, Keyboard and SCSI Support G-1

Keyboard Support ..................................................

Additional Keyboard Support ................................ . ......... G-2

New Display Options ...............................................

SCSI Sequence ....................................................

Software Installation

7200A Install / Archive Utility ........................................

With the 7200A powered off: .........................................

Gol

G-3

G-3

Install-1

1

1

7200A Installation of New Software ...................................

MS-DOS Copy ....................................................

7200A Back Up / Restore Utility ...................................... 5

7200A Back Up/Restore Utility .......................................

Setup Screen Selections ..............................................

Restrictions .......................................................

Back Up and Restore Operation .......................................

Progress Display ...................................................

2

4

6

6

7

8

9

TOC-5

Page 6

General Information

~,~. :.

Four manuals are included with the LeCroy 7200A Modular Oscilloscope System:

¯ LeCroy 7200 Series Modular Oscilloscope System Operator’s Manual explains

front-panel operation~ ~:

LeCroy 7200 Set)’ies Modular Oscilloscope System Programmer’s Manual

¯

e xp!a|ns programming protocol for controlling the 7200 Series from a host

computer, R~bte command descriptions for the 7200 Series and 7242/34 Series

plug,ins areialso included.

Getting SMrtedWith the LeCroy 7200 Modular Oscilloscope System and 7242/34

¯

Sede$ P, lug-in Modules helps a new user to quickly operate the instrument.

NEW -

LeCro.y¯7200 Series Technical Reference Manual, explaining the Pulse

P’arameters for the 7200 Series Oscilloscope.

Note

A/I Controls and Operation for the 7200 and 7200A Modular Oscilloscope

Mainframes are the same except for the following:

Time of Flight processing functions

Persistence setup Screen

1.44 MByte Floppy Format

Trace Annotation.Setup

Display Opi~0ns Setup

Display Options

Using, Manual

This operator’s manual cbntains installation and operating instructions for the 7200A

Modular Oscilloscope.,.. System:

Section 1: Product Description

Section 2: Im~latie.

... ,... ~.’ ’,.~

Overviews the 7200A’s major features. It also contains a

simple block diagram.

Describes the proper operating environment, setup pro-

cedures, and plug-in installation.

p. 3-74

p. 3-99

p. 3-122

p. 3-123

p. 3-125

p 3-128

Page 7

Using This Manual

Section 3: Operation

Section 4:7200 Series

Plug-in Operation

Introduces concepts which are fundamental to operating

the 7200A. Then, =Using Front Panel Controls" details

manual operation. The remainder of the section explains

how to use setup screens to configure controls.

Explains the Operation and Control of all 7200 Series

Plug-in modules.

ii

Page 8

Warranty

LeCroy warrants operation under normal use for a period of two years from the date of shipment. Replacement parts and repairs are warranted for 90 days. Accessory products not

manufactured by LeCroy are covered by the original equipment manufacturers’ warranties.

LeCroy provides software code error corrections at no charge.

USA

EAST

LeCmy Corporation

690 Chestnut Ridge Road

Chestnut Ridge, New York 10977-6449

TEL: (914) 578-6091

FAX: (914) 578-5999

FARWF.3T

LeCroy Corporation

5912 Stoneridge Mall Road, Suite 150

Pleasanton, California 94566

TEL: (415) 463-2600

FAX: (415) 463-9179

SOUTHWEST

LeCroy Corporation

14800 Central Avenue, S.E.

Albuquerque, New Mexico 87123

TEL: (505) 293-6100

FAX: (505) 293-9617

CANADA

LeCroy Canada Inc.

2751 Jacques Cartier est

Suite 200

Longueull, PQ, J4N IL7

TEL: 514.928.4707

FAX: 514.928.0969

EUROPE

WEST GERMANY

LeCroy GmbH

Postfach 10-37-67

Manhelmer Str. 177

D.6900 Heidelberg

West Germany

TEL: 011.49.6221.831001

FAX: 011.49.6221.834655

FRANCE

LeCroy SARL

B.P. 214

Avenue du Parana

F-91941 Les Ulis Cedex

France

TEL: 011.33.16.907.3897

FAX: 011.33.16.907.4042

SWITZERLAND

LeCroy SA

2, CheminPre-de-ia-Fontaine

P.O. Box 341

CH-1217 Meyrin 1 Geneva,

Switzerland

TEL: 011.41.22.719.21.11

LeCroy SA

Bahnhofstrasse 18

CH - 5600 Lenzburg

Switzerland

TEL: 011.41.64.519.181

FAX: 011.41.64.519.192

ENGLAND

LeCmy LTD

28 Blacklands Way

Abingdon Business Park

Abingdon, Oxon OX14 1DY

Great Britain

TEL: 011.44.23.553.31.14

FAX: 011.44.23.552.87.96

ITALY

LeCroy S.r.I.

Via Roccaporena 58

1-00191 Roma

Italy

TEL: 011.39.6.33.13.146

FAX: 011.39.6.327.92.21

LeCroy S.r.l.

Via Pinturricchio, 9

I - 20133 Milano

Italy

TEL: 011.39.220.47.082

FAX: 011.39.220.47.026

JAPAN

LeCroy OS

Esaka Sansho Bldg - 3rd Floor

16-3, 3-Chome

Tarumicho, Suite City

Osaka 564 Japan

TEL: 011.816.330.0961

FAX: 011.816.330.8096

LeCroy TK

Zaiken Bldg 6th Floor

Sasazuka, Shibuya-ku

Tokyo 151 Japan

TEL: 011.813.3376-9400

FAX: 011.813.3376.9587

BENELUX

LeCroy BV

Waalreseweg 17

NL-5554 HA Valkenswaard

The Netherlands

TEL: 011.31.4902.8.9285

FAX: 011.31.4902.42628

m

Page 9

Service Procedure

In exercising this warranty, LeCroy will repair or, at its option, replace any product returned

to the factory or an authorized service facility within the warranty period only if the warrantor’s examination discloses that the product is defective due to workmanship or materials

and the defect has not been caused by misuse, neglect, accident, or abnormal conditions or

operations.

The purchaser is responsible for transportation and insurance charges. LeCroy will retum all

in-warranty products with transportation prepaid.

This warranty is in lieu of all other warranties, express or implied, including but not limited to

any implied warranty of merchantability, fitness, or adequacy for any particular purpose or

use. LeCroy Corporation shall not be liable for any special, incidental, or consequential damages, whether in contract, or otherwise.

Product Assistance

LeCroy Corporation will gladly answer your questions. Write or call your regional field serv-

ice office (see next page) or Test & Measurement Division, 700 Chestnut Ridge Road, Chestnut Ridge, New York 10977-6499. TEL: (914) 425-2000, ext. 6011.

Maintenance Agreements

LeCroy offers a choice of customer support services to meet your individual needs. Annual

software maintenance contracts, ensures your 7200A always features the latest processing

enhancements and extensions. Extended warranty maintenance agreements let you budget

maintenance costs after the initial warranty has expired. Other services such as installation,

training, calibration, enhancements and on-site repair are available through specific Supple-

mental Support Agreements. Contact your regional field service office for details:

Service Procedure

Refer any servicing requiring removal of exterior enclosure panels to qualified LeCroy service personnel. Be prepared to describe the problem in detail.

WARNING: Do not remove chassis panels. Removing the

ax~rlor covers exposes parts which could cause electric [

Jl

ahock.

If the product is under warranty, LeCroy will, at its option, repair or replace the 7200A at no

charge. For repairs after the warranty period, the customer must provide a Purchase Order

iv

Page 10

Service Procedure

Number before the service engineer can initiate repairs. The customer will be billed for the

parts, labor, and shipping.

Shipping Guidelines

First, attach a tag to the instrument which indicates:

Purchase Order Number

Owner’s name and complete address

The service required including detailed operational problems

Person to contact for confirmation (include phone number)

Ship the unit in its original packaging. If not possible, provide a 275 lb. strength double wall

corrugated cardboard box with inside dimensions at least eight inches greater than the

instrument dimensions. The extra space will provide adequate room for cushioning.

Protect the finish by carefully wrapping the unit in polyethylene sheeting.

Place adequate dunnage or urethane foam in the container (approximately 4 inch depth) and

place the wrapped unit on it. Allow approximately four inches of space on all four sides and

the top of the unit.

Fasten the container with packaging tape and/or industrial staples. Address the container to

LeCroy’s service location and include your return address.

Page 11

Safety Precautions

This manual describes how to maintain the LeCroy 7200 Series Precision Digital Oscilloscope. For ease of reference, this equipment is referred to as the 7200 Mainframe throughout this manual.

The general Safety precautions listed below must be followed during all phases of operation and service of the LeCroy 7200 Series Precision Digital OscoUoscope. These wamings and other specific safety notices may be repeated

elsewhere in this manual. LeCroy Corporation assumes no liability for the operator who fails to comply with these

precautions.

AC POWER SOURCE

This product Is designed to operate from an AC

power soume that will supply not more than 250

volts rms, between the two supply conductors (line

and neutral), or between either supply conductor

and ground.

PROPER GROUNDING

The 7200A Is a Safety Class 1 instrument. This

means that the instrument enclosure is connected

to protective earth ground through the three-conductor power supply cord, and properly grounded AC

power outlet. This protective grounding minimizes

shock hazard and is essential for safe opera-

tion. Any interruption of the protective earth connection will cause a potential shock hazard, as all

accessible conductive parts, (even knobs and con-

trois which may appear to be non-conductive) may

render an electric shuck.

FUSES

To avoid fire hazard, use only fuses of the same

type, current rating, and voltage rating, as speclfl-

caUy called out in this manual.

DO NOT OPERATE IN AN EXPLOSIVE

ATMOSPHERE

Do not operate the 7200A In an atrnosphere of explosive gases of flammable gases.

DO NOT REMOVE COVERS OR

PANELS

To avoid personal Injury, the operator should not re.

move the protective covers, or attempt internal servicing or adjustment of any kind. Refer this servicing

to qualified LeCroy service personnel. Do not oper-

ate this instrument with any protective panels or cov-

ers removed.

DEFINITION OF TERMS

In Manuals: CAUTION statement, signifies condi-

tions or practices which may result in damage to

EQUIPMENT or PROPERTY. This differs from the

WARNING statement, which signifies a condition or

pratlce which could result in PERSONAL INJURY or

LOSS OF LIFE.

When these terms are encountered in the text, the

reader should not proceed further until the specific

notice is fully understood.

On Equipment: CAUTION statement, indicates a

personal injury hazard which is not immediately ac-

cessible to the person reading the marking, it may

also signify a hazard to the equipment or property.

DANGER statement, signifies a personal

injury hazard which is immediately acces-

sible to the person reading the marking.

SAFETY SYMBOLS

As marked on equipment:

DANGER - Hazardous voltages

Protective ground (earth) terminal

®

//~ A’I-I’ENTION - refer to the manual

vii

Page 12

Section 1: Product Description

The LeCroy 7200A Precision Digital Oscilloscope offers high accuracy waveform measurement and analysis with full IEEE-488 (GPIB) and RS-232-C support. Using different plug-ins,

you can customize waveform acquisition parameters to match a specific application. These

parameters include sample rate, resolution, bandwidth, triggering, waveform memory, and

number of channels.

Key Features of the 7200A Precision Digital Oscilloscope

Modular Digitizing Plug-in

1 or 2 plug-ins per 7200A mainframe, with independent or slaved timebase and

¯

trigger.

Display

¯ High resolution color display.

¯ Up to 8 traces, simultaneously displayed.

¯ Vertical and horizontal expand and position for all traces.

¯ Hardcopy to plotters, dot matrix printers, laser printers and floppy disk

(compatible with desktop publishing systems).

Manual, Remote, and Automatic Control

Familiar analog controls for timebase, sensitivity, offset, etc.

¯

¯ On-line HELP for all controls.

¯ Autosetup to set the trigger, gain, offset, and timebase to display a repetitive input

signal.

¯ Full remote control from IEEE-488 (conforming to IEEE-488.2) and RS-232-C.

¯ Program mode for automated measurement sequences and test applications.

Waveform Measurements

¯ 14 basic waveform parameters on any trace.

¯ Up to 20 waveform parameters (choose from more than 70) on any combination

of 8 traces.

Any parameter on any trace available from remote control or Program mode.

¯

¯ Simple vertical and horizontal measurements using cursors.

1-1

Page 13

ESD Precaution

The 7200 Mainframe contains electrostatic discharge (ESD) sensitive devices. For this reason, it is necessary to work on the 7200 Mainframe in an environment that minimizes exposure of the circuit board assemblies and components to conditions that could be

destructive. Servicing of the 7200 Mainframe and its ancillary devices requires an awareness

of the potentially destructive effects of ESD. Depending upon the relative humidity of the

maintenance shop, seemingly simple and unrealted acts such as walking across vinyl floor

or picking up an ordinary polyethylene bag from a workbench can generate thousands of

volts of electricity. If proper grounding practices are not used, accidental contact with one of

the CMOS devices on a circuit can result in its destruction.

The maintenance shop must be free of sources of static electricity. This means that neither

the 7200 mainframe nor any of its acillary devices should be disassembled on a work surface of melamine or finished wood unless a properly grounded electrostatic mat is underneath.

A work chair padded with urethane foan can generate 18 thousand volts of static electricity If

humidity is low. Chairs of finished wood, vinyl, and fiberglass should not be used and metal

work chairs may be used only if properly grounded.

Personell should not wear common clean room smocks, non-conductive shoes, or garments

made of any material other than virgin cotton.

Common plastic bags, wraps, envelopes, bubble pack, foam, trays, tote boxes, vials, and

parts bins should not be in the shop. All board assemblies should be placed in ESD-protective bags Immediatley upon removal and all new boards should not be removed from their

ESD-protective bags until immedlaltely before installation.

In addition, common spray cleaners, solder suckers, and soldering irons should not be

used. Brushes with synthetic bristles should not be used for solvent cleening, e.g., removal

of rosin residue from circuit board assemblies.

Heat guns and blowers are potential sources of static electricity and all cleaning and drying

operations are potential sources as well.

Increased ESD awareness has four major effects:

¯ All electronic components are assumed to be ESD-sensitive

¯ Sensitive components are not touched unless a properly grounded wrist strap is

worn

¯ Sensitive components are transported, stored, and handled only in ESD-frae

environments

¯ ESD-sensltive components are tested only in a static-free environment

viii

Page 14

As a general approach to servicing the 7200 Mainframe and its ancillary devices, do the following:

Disconnect power from the 7200 Mainframe except when required for voltage checks and

.

adjustments.

Be sure the multimeter is properly grounded before checking power supply output levels.

.

3.

Wear a properly grounded wrisy strap or touch the properly grounded 7200 Mainframe

before removing any board, the hard disk drive, or the floppy drive.

°

Wear a properly grounded wrist strap to remove any board from a plug-in

5.

Ground the ESD-protective package containing replacement devices before opening to

dissipate its static charge.

°

Remove ESD-sensitive devices from their packaging immediately before installation. Avoid

touching other parts, connections, and circuitry.

Use only anti-static spray for troubleshooting.

.

ix

Page 15

Plug-in Module Installation and Removal

Installation

CAUTION: Plug-in modules should not be installed with 7200 Mainframe power on.

To install a plug-in module, use the following procedure:

a.)

b.)

Align groove on bottom of plug-in module (Figure 1) with guide on bottom of plug-in

compartment of 7200 mainframe.

Slide plug-in module into compartment until latched in place.

Removal

CAUTION: Plug-in modules should not be removes with 7200 Mainframe power on.

To remove a plug-in module, use the following procedure:

a.) At bottom front of plug-in module, pull latch to release, then slide out of compartment

Figure 1

Page 16

Waveform Processing

¯ Extensive processing possible for each of 8 traces including addition, subtraction,

multiplication, division, differentiation, integration, smoothing, averaging, FFT,

square, square-root, log, histograming, trending, etc.

¯ Engineering units used for all processing.

Data Storage and Portability

¯ MS-DOSe compatible 3.5" floppy for waveform storage and portability.

¯ 8 non-volatile memories available for individual waveform storage.

¯ Store and recall front-panel setups to intemal or floppy disk.

¯ Optional external hard drive available for increased security

Software Support

¯ Updates via floppy disk.

Future plug-in drivers supplied on floppy disk without firmware Updates.

¯

The LeCroy 7200A Precision Digital Oscilloscope provides high accuracy waveform measurement, analysis, and built-in mass storage with full IEEE-488 (GPIB) and RS-232-C sup-

port. Its modular amhitecture accepts plug-ins with integral digitizers and recording

memories.

Different plug-ins allow you to customize acquisition parameters, such as sample rate, bandwidth, and number of channels, to match specific applications. Because each plug-in contains its own digitizing circuitry, you can add channels without losing performance. The

system is truly Integrated, permitting cable-free synchronization of timebases and triggers

between plug-ins.

The 7200A can perform extensive waveform processing and measurements, either manually, automatically, or under remote control. Waveform processing includes addition, subtrac-

tion, multiplication, division, differentiation, integration, smoothing, averaging, FFT, square,

square-root, log,histogram, trend, etc.

Using custom digital signal processing circuitry, the 7200A rapidly analyzes large waveforms

to produce accurate waveform parameters based on the IEEE standard for pulse characterization. A comprehensive set of automatic waveform parameters is provided. Custom pa-

ramaters can be added (contact LeCroy).

A built-in hard disk and 3.5" MS-DOSe floppy disk drive provide mass storage and data portability. Waveforms, front-panel setups, and user Programs can be stored on either disk. In

Record Traces mode, thousands of waveforms can be stored at high speed to the hard disk

for later recall, analysis, or processing. The hard disk also contains the operating system and

1-2

Page 17

the comprehensive on-line HELP manual. The MS-DOS® floppy disk provides convenient

data portability and long-term storage. Software upgrades and new plug-in drivers are han-

dled economically by using floppies rather than by changing firmware.

The 7200A _supports a wide variety of hardcopy devices, using GPIB, RS-232-C, and parallel

(Centronics

ing graphic output with a desktop publishing system.

Another powerful feature of the 7200A is its ability to execute user programs, making it ideally suited for automated test applications. Programs are closely tied to the 7200A’s remote

control syntax with simple control-flow structures. The "Learn" mode records a sequence of

front-panel keystrokes as a program, providing the basis for automating measurements. Off-

line editing on a PC can produce more powerful programs involving looping and decision

making for sophisticated automatic tests.

The 7200A’s extensive waveform processing and measurement capabilities, coupled with decision making, make it a complete stand-alone automatic test system for producing answers,

not just data.

~)

communication standards. It also supports HPGL output to floppy for integrat-

1-3

Page 18

Block Diagram

The Cenb’al Processor co-ordinates the activities of the other units. Commands are received

from the front-panel subsystem, which constantly monitors all the front-panel keys and

knobs, or from a host computer. Alternately, the CenVal Processor can execute a previously

saved sequence of commands, interpreting and directing them to the appropriate subsystem

to perform tasks. All control settings are saved in non-volatile memory. The front panel con-

trol setup can also be saved on the Internal disk or the floppy diskette.

The C, enVal Processor also oversees data acquisition. The Master Timebasa Reference syn-

chronizes data acquisition between plug-ins. When acquisition completes, the Central Processor receives the data and performs any requested waveform processing and automatic

measurements. Some processing can also be done in the plug-in itself. The results can be

sent to the display, floppy diskette, and the I/O port. If Record Traces is enabled, the data

can also be stored on the internal disk for later review.

digital bus

1-4

I

analog bus

i ::::~: MASTSR .......... iiii

TIMEBA8E : i

i REFERENCE i

L.......~.: ...........,.;. .......................; ...........

..[+++~~+®+++

~1+ "+++ +~:+

Figure 1.1: 7200A Block Diagram

~~

I IEEE-488 I Plotters,

[ RS.232-C ] Printers and

[ Centronlcs [ Remote Control

External Reference IN/OUT

Analog Inputs

External Sample Clock

Analog Inputs

Floppy Disk

Hard Disk

External Sample Clock

Trigger IN/OUT

Page 19

Section 2: Installation

The 7200A runs over the full line voltage range of 90 Volt to 250 Volt AC rms and source frequencies of 47 to 63 Hertz.

The 7200A is shipped with the fuse drawer and fuses most common to its destination already installed in the line cord connector (rear panel).

Attach Line Cord

The AC input receptacle (CEE-22 style) located in the line cord connector (rear panel)

three recessed male pins which accept the detachable line cord. To obtain an AC line cord

other than the one supplied, please contact the factory.

Operate in Proper Environment

WARNING: To avoid explosion, do not operate the 7200A in an

atmosphere of explosive gases.

To ensure proper operation and long instrument life, the 7200A should be operated within

the following environmental conditions:

Temperature

Ambient air temperatures between 0° to +40° C. Storage temperatures can range between

-40 to +75 C.

Ventilation

The Model 7200A is cooled by air drawn from the bottom front and exhausted through the

rear. Operate the instrument on a hard flat surface, or carpeting of very low pile. Allow at

least one half inch clearance under the bottom and 2" behind the rear fans and along the

side panels.

Grounding

Ensure a good ground. The Model 7200A is a Safety Class 1 instrument. Its exposed metal

chassis is directly connected to earth via the power supply cord.

2-1

Page 20

Setting the GPIB Address

WARNING: To avoid possible shock hazard, ground the 7200A

chassis by connecting the power supply cord to an earth grounded

AC power receptacle. Do not make any connections to the

instrument’s input or output terminals until the 7200A is properly

grounded.

Apply Power

CAUTION: Use correct power source. The Model 7200A is

designed to operate from a single-phase power source. The voltage

to ground (earth) from either pole of the power source must not

exceed the maximum rated operating voltage, 250 Volts AC rms.

To supply power to the 7200A, set its rear panel ON/OFF switch to the ON (I) position.

Selecting the Computer Port

CAUTION: Before connecting external equipment to the 7200A, set

its front panel power switch to the OFF (0) position.

The 7200A provides three interfaces: the General Purpose Interface Bus (GPIB), an RS-232-

C Sedal Port, and a Centronics Port. The GPIB end RS-232-C ports can be used to connect

the 7200A to a host computer or to connect to a printer or plotter for hardcopy output. The

Centronics port is used for hardcopy output only. The advantage of GPIB is high transmission rates. The advantage of RS-232-C is that it is a lower cost interface which can generally

be used over longer distances. If the 7200A will be used in conjunction with a host computer,

set the =Remote Control from" field in the Communications screen to either GPIB or RS232.

CAUTION: If the same port is selected for both Remote Control

and Hardcopy, when the hardcopy key is pressed, no plot is

produced and only the User Request (URQ) bit in the Standard

Event Status register (’ESR) is saL This is so the Remote

Controller can synchronously initiate the hardcopy remotely once all

the connected devices are properly set up. If a Remote Controller

is not used, then the "Remote Control from" field in the

Communications Setup screen must be set to a port that is different

from the Hardcopy Port in order to enable the hardcopy key.

Setting the GPIR Address

The GPIB address is set in the Communications Setup screen. From the Main Screen, press

the Configure System softkey to display the Configure System setup screen. Then press the

Communication Setup softkey to display the Communications Setup screen. Move the box

2-2

Page 21

GPIB Host and Hardcopy Operation

onto the =Remote Contol from" field and select GPIB. Then move the box onto the =GPIB Ad-

dress" field and select an address from 0 to 30. Note that these controls are preserved in battery backed up memory and are NOT reset by pressing the Default Settings softkey.

GPIB Host and Hardcopy Operation

The 7200A can communicate across GPIB as a talker or a listener with a remote host controller to receive remote commands/queries and send responses. Alternately, it can operate

over GPIB with a controller as a Talk Only device. The use of each of these modes is described below.

Remote Control Operation over GPIB

The 7200A enters Talk/Listen mode when the =Remote Control from" field in the Communications Setup screen is set to GPIB. In this mode, the 7200A can both receive commands and

setups from the remote host computer and send data and measurement results.

Plotting/Printing over GPIB with a Controller

If the HARDCOPY command is sent to the 7200A when in this mode, the 7200A will wait to

be addressed to talk before sending the hardcopy data. The host computer then has three

options in generating the hardcopy:

1) The host computer may read the data into internal memory

and then send the data to a printer/plotter. This is exactly the

same as reading a query response.

2) The host computer may send the =HARDCOPY" remote command and then address the printer/plotter to listen and the

7200A to talk and read the data from the 7200A. As the data is

read into the computer’s internal memory, it is also printed/plot-

ted to the printer/plotter which is a Listener.

3) The host computer may send the =HARDCOPY" remote command and then address the printer/plotter to listen, the 7200A to

talk, and the controller to go into stand-by mode waiting for EOI.

Altematively, the Data Processing Status Register (DPR) could

be programmed to issue an SRQ when hardcopy is complete so

that the host computer can perform other tasks while the hard-

copy is performed.

If the local HARDCOPY key is pressed when both the Remote

Control port and the Hardcopy port are set to GPIB, then a hardcopy is not generated. This is so the hardcopy data does not dis-

2-3

Page 22

GPIB Host and Hardcopy Operation

rupt controller activity on the GPIB bus. Instead, pressing the

HARDCOPY key sets the User Request (URQ) bit in the Stand-

ard Event Status register (*ESR). The Remote Controller can

monitor this bit and when it is set, it can initiate the hardcopy remotely In one of the three ways discussed previously.

Printing/Plotting over GPIB without a Controller

To output hardcopy data over GPIB, the "Hardcopy Port" field in the Hardcopy screen must

be set to GPIB and the Remote Control port must be RS-232-C. Talk Only is a special GPIB

mode where there is no controller allowed on the bus; the 7200A is the only talker and all

connected devices must be listeners (ie., printers/plotters must be in Listen Only mode).

Note: Since some printers/plotters do not properly enter Listen Only mode,

the 7200A will address the device at address 30 to listen before sending the

hardcopy data. ff your GPIB printer/p/offer does not work with the 7200A, set

Its GPIB address to 30 and the 7200A will force/t to listen.

2.4

Page 23

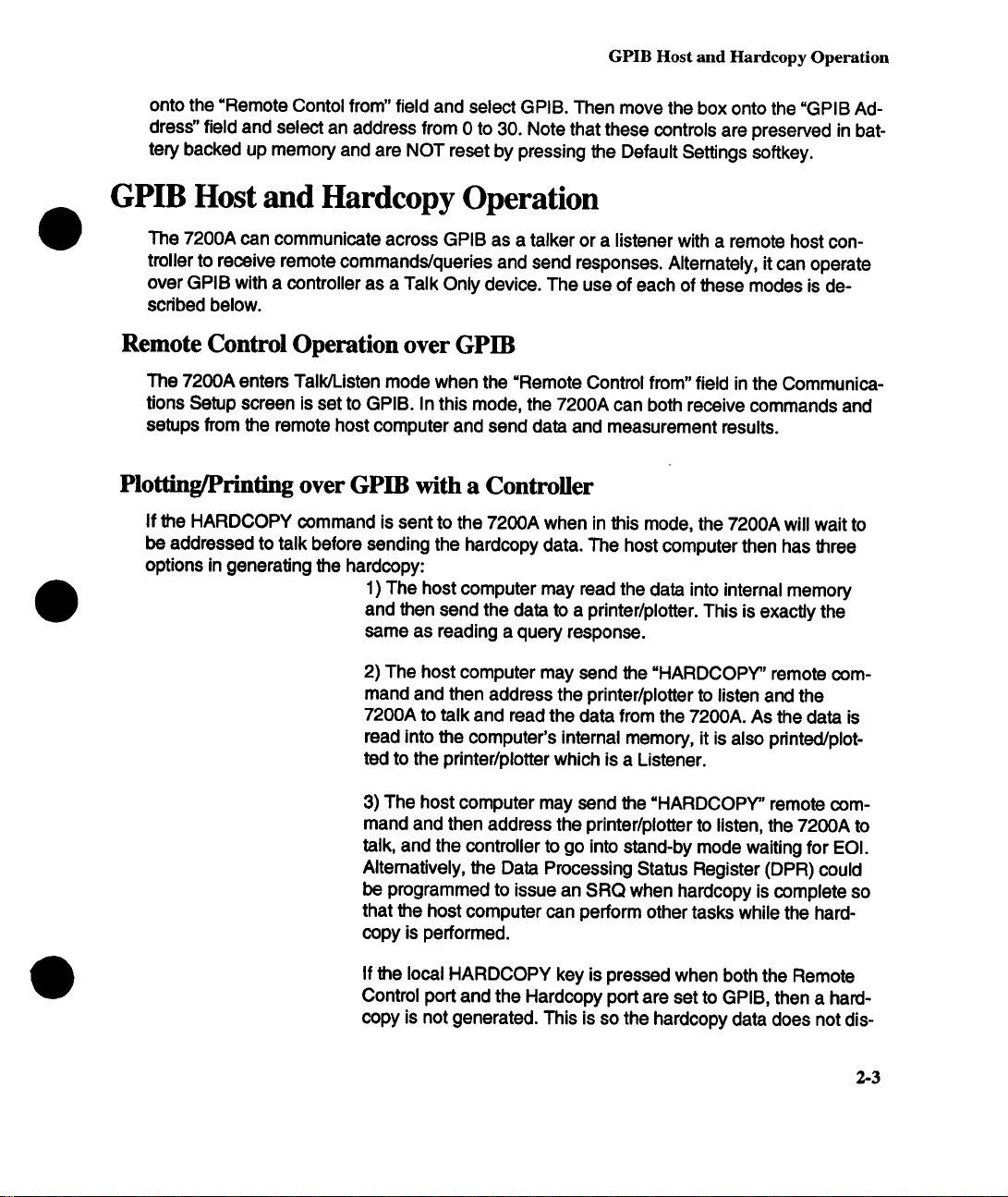

GPIB Interconnection

The devices on the GPIB network can be connected in any combination of star or linear arrangements. Standard IEEE 488.2 cables must be used to connect all the devices and total

length must not exceed 20 meters. Attach the 7200A’s rear panel connector to the network

using the cable provided with the 7200A.

The devices must conform to these rules:

¯ At least half of the devices on the network must be turned on.

¯ One network can connect no more than 15 devices (including the controller).

¯ One device must be connected for every two meters of cable, assuming one

device represents one standard device load. The 7200A’s GPIB connector is

located on its rear panel.

¯ Each device must have a unique bus address.

DEVlCE D

DEVICE 8

STAR CONFIGURATION

LINEAR CONFIGURATION

Figure 2.1: Examples of GPIB Network Arrangements

2-5

Page 24

GPIB Host and Hardcopy Operation

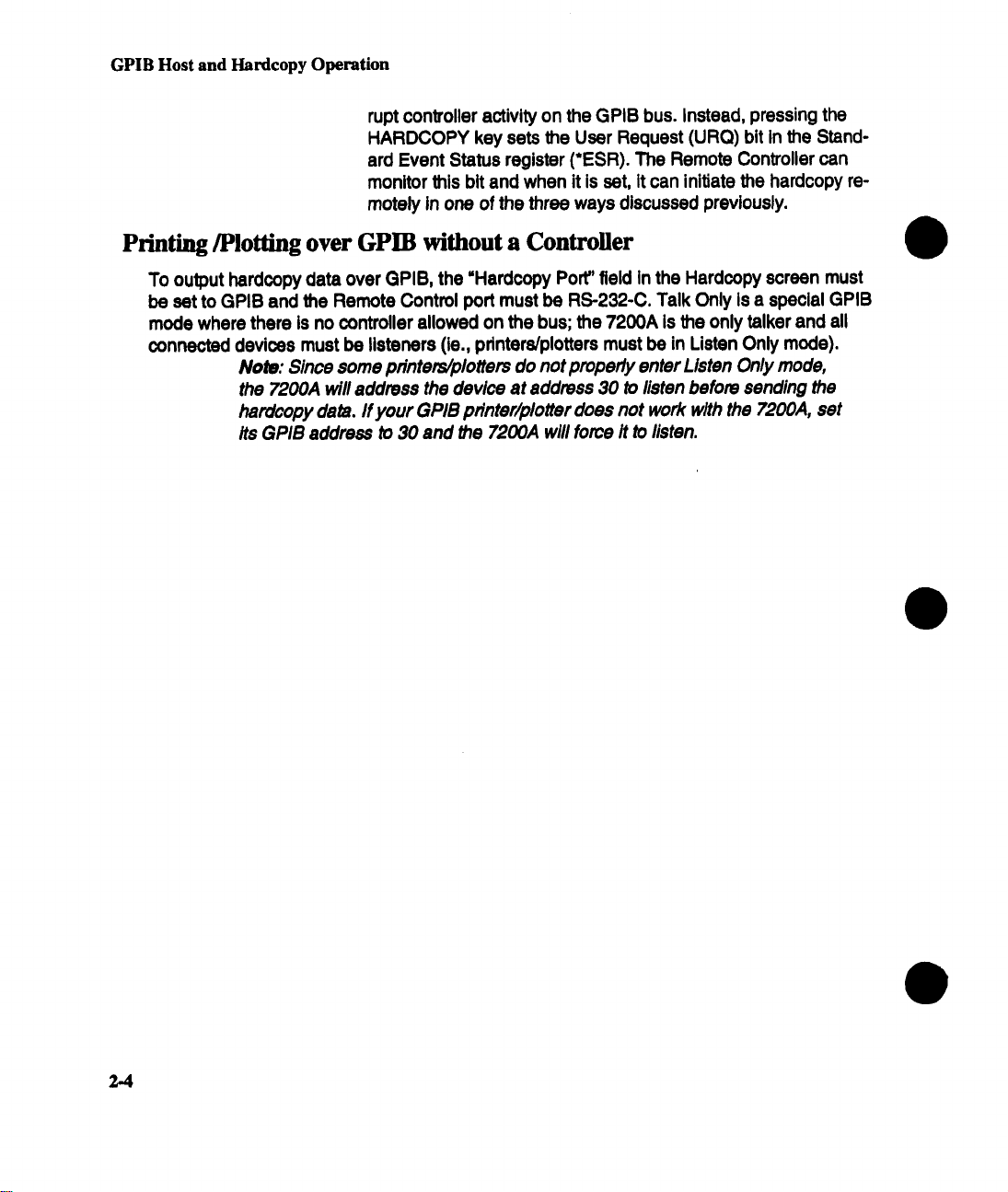

Connect the Printer / Plotter

When operating in Talker Only mode, set the GPIB printer/plotter to Listen Only, and the

7200A to Talk only.

GPIB

7200A

Figure 22.: Talk Only mode GPIB output

When operating in Talk/Listen mode, a GPIB controller is required. The conVoller directs the

7200A to output data to the printer or plotter.

Controller

Figure 2.3: Talk/Listen mode GPIB output

Plotter

2-6

Page 25

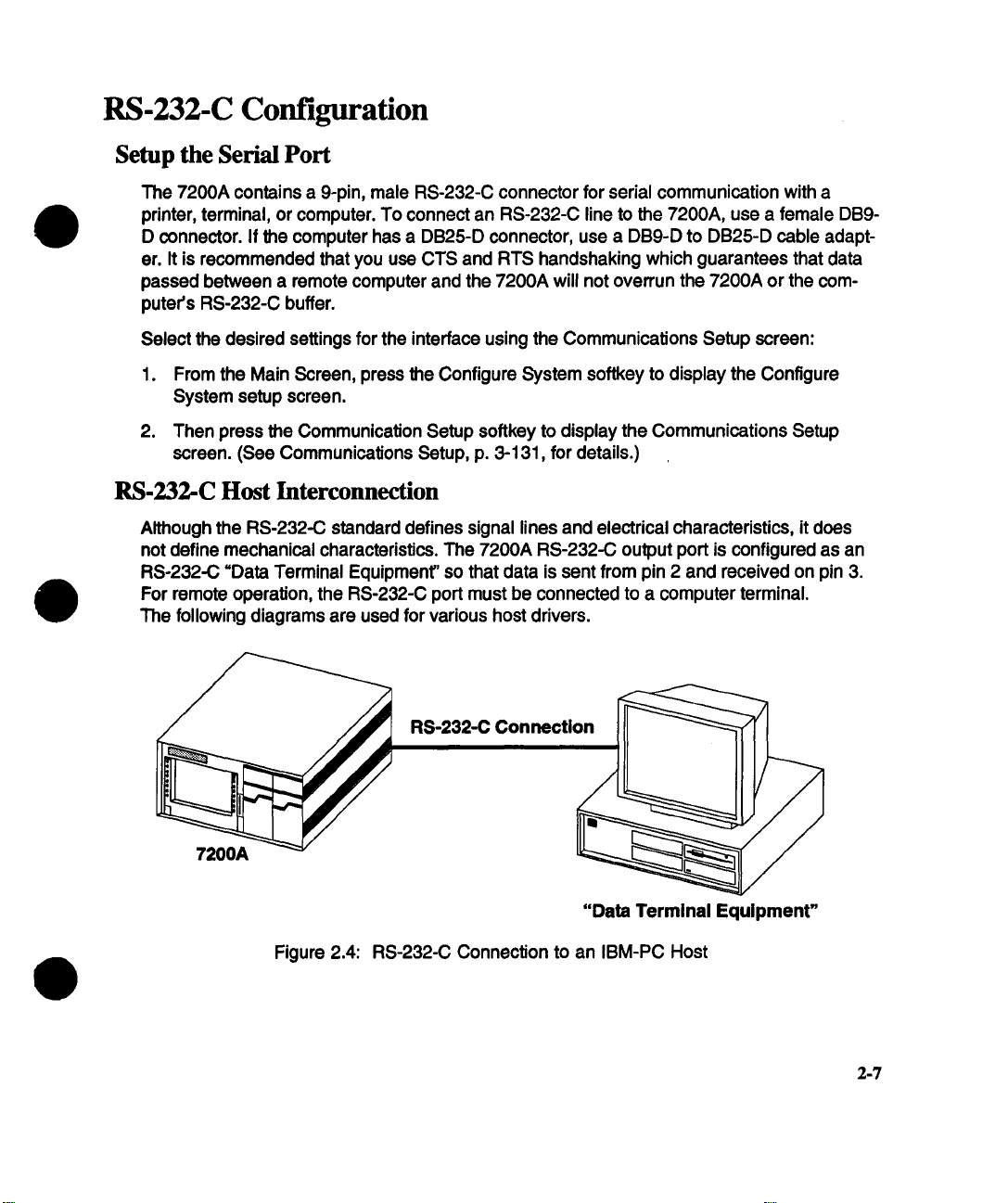

RS-232-C Configuration

Setup the Serial Port

The 7200A contains a 9-pin, male RS-232-C connector for serial communication with a

printer, terminal, or computer. To connect an RS-232-C line to the 7200A, use a female DB9D connector. If the computer has a DB25-D connector, use a DB9-D to DB25-D cable adapter. It is recommended that you use CTS and RTS handshaking which guarantees that data

passed between a remote computer and the 7200A will not overrun the 7200A or the computer’s RS-232-C buffer.

Select the desired settings for the interface using the Communications Setup screen:

1. From the Main Screen, press the Configure System softkey to display the Configure

System setup screen.

2. Then press the Communication Setup softkey to display the Communications Setup

screen. (See Communications Setup, p. 3-131, for details.)

RS-232-C Host Interconnection

Although the RS-232-C standard defines signal lines and electrical characteristics, it does

not define mechanical characteristics. The 7200A RS-232-C output port is configured as an

RS-232-C =Data Terminal Equipment" so that data is sent from pin 2 and received on pin 3.

For remote operation, the RS-232-C port must be connected to a computer terminal.

The following diagrams are used for various host drivers.

"Data Terminal Equipment"

Figure 2.4: RS-232-C Connection to an IBM-PC Host

2-7

Page 26

DB9 to DB25 Wiring

This wiring configuration is used for IBM-PCs and compatibles with DB25-D connectors

configured as Data Terminal Equipment. Note that for XON-XOFF communication protocol,

only pins 2, 3, and 5 on the DB9-D connector are needed. Also, commercially available DB9-

to-DB25 adapter cables for the IBM-PC swap pins 2 and 3 and pins 7 and 8.

DB9 to DB9 Wiring

For IBM PC-AT types with DBg-D connectors configured as Data Terminal Equipment.

2-8

Page 27

DTE to DCE Wiring

For non-IBM types with DB9-D connectors configured as Data Communications Equipment.

Page 28

RS-232-C Configuration

RS-232-C Interconnections for Hardcopy

When connecting an RS-232-C serial printer/plotter to the 7200A, the printer/plotter configuration must match the 7200A RS-232-C port settings. To modify the 7200A’s settings, use

the Communications Setup screen (see page 3-131 ).

RS-232-C Connection

"Data Terminal Equipment"

"Data Terminal Equprnent"

(7200A)

DB9 to DB25 Wiring

NOTE: The 7200A RS-232-C interface is a DB9-D connector. Use

an adapter cable to connect to an RS-232-C DB25-D connector.

Figure 2.5:

RS-232-C Connection to an RS-232-C

Serial Plotter

2-10

Page 29

RS-232-C Configuration

Parallel-Centronics Wiring

The 7200A uses a standard DB25-D female connector as the Centronics parallel output port.

An adaptor cable is required to adapt the 7200A DB25-D connector to the standard 36-pin

bail lock connector used on most Centronics printers.

7200A

Figure 2.6: Output to Centronics type Printer/Plotter

Printer

2-11

Page 30

Install the Plug-in(s)

The plug-in manual contains instructions for operating the front panel controls. Plug-in functions controlled by the 7200A mainframe front panel are detailed in Section 3 of this manual.

CAUTION: Do not Install or remove a plug-In while the 7200A

mainframe is powered on.

To install, align the plug-in’s bottom grooves with the guides at the bottom of the mainframe’s plug-in compartment. Next, slide in the plug-in until it latches into place. Move the

latch on the 7200 Series plug-in until it is flush with the plug-in body. Remove the plug-in by

pulling out its latch and sliding it out.

2-12

/LATCH

Rgure 2.7: Plug-in Installation

Page 31

Section 3: Operation

Section 3 first introduces concepts which are fundamental to operating the 7200A. Next, "Using Front Panel Controls" details manual operation. The remainder of the section explains

how to use the setup screens to configure controls.

Overview

Controls

The 7200A’s controls are keys, softkeys, and knobs.

Keys have front panel labels (upper case) which identify their functions.

Softkeys have screen labels (initial capitals) which identify their functions. The softkeys are

arranged vertically to the left and right of the screen. Softkey labels change to suit specific

operations.

All knobs have front panel labels (upper case) which identify their functions except the outer

and inner knobs beneath the center of the screen. Labels on the screen indicate their current

functions. See Figure 3.1:

The label above the left arrow

indicates the outer (detented) indicates the inner (continuous)

knob’s current func, on. knob’s current function,

Figure 3.1: Outer and Inner knobs beneath center

of screen

The label above the right arrow

3-1

Page 32

Overview

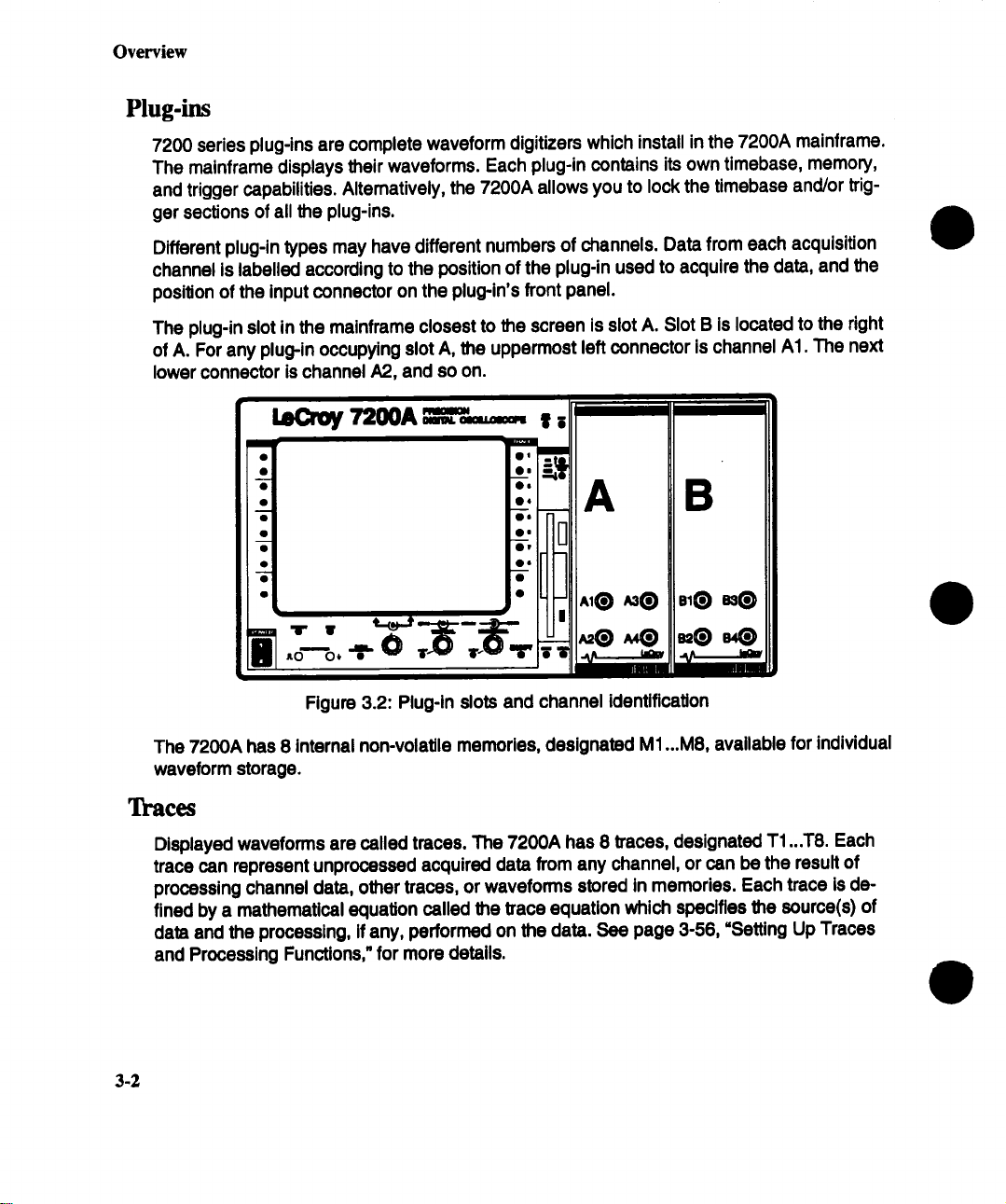

Plug-ins

7200 series plug-ins are complete waveform digitizers which install in the 7200A mainframe.

The mainframe displays their waveforms. Each plug-in contains its own timebase, memory,

and trigger capabilities. Alternatively, the 7200A allows you to lock the timebase and/or trigger sections of all the plug-ins.

Different plug-in types may have different numbers of channels. Data from each acquisition

channel is labelled according to the position of the plug-in used to acquire the data, and the

position of the input connector on the plug-in’s front panel.

The plug-in slot in the mainframe closest to the screen is slot A. Slot B is located to the right

of A. For any plug-in occupying slot A, the uppermost left connector is channel AI. The next

lower connector is channel A2, and so on.

A B

I’"

I

Figure 3.2: Plug-in slots and channel identification

The 7200A has 8 internal non-volatile memories, designated M1 ...M8, available for individual

waveform storage.

Traces

Displayed waveforms are called traces. The 7200A has 8 traces, designated T1 ...T8. Each

trace can represent unprocessed acquired data from any channel, or can be the result of

processing channel data, other traces, or waveforms stored in memories. Each trace is defined by a mathematical equation called the trace equation which specifies the source(s)

data and the processing, if any, performed on the data. See page 3-56, =Setting Up Traces

and Processing Functions," for more details.

3.2

Page 33

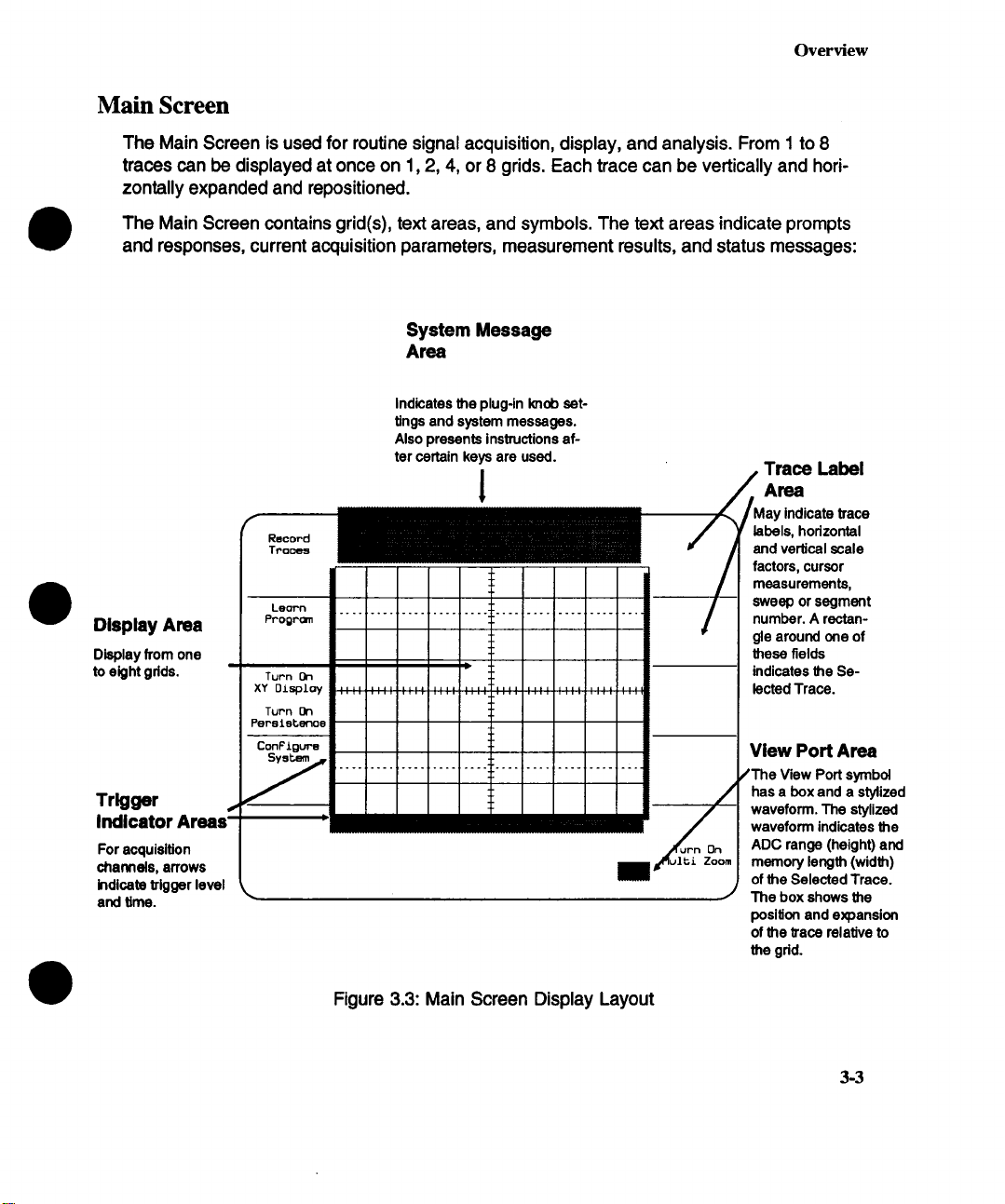

Main Screen

The Main Screen is used for routine signal acquisition, display, and analysis. From 1 to 8

traces can be displayed at once on 1,2, 4, or 8 grids. Each trace can be vertically and horizontally expanded and repositioned.

The Main Screen contains grid(s), text areas, and symbols. The text areas indicate prompts

and responses, current acquisition parameters, measurement results, and status messages:

System Message

Area

Indicates the plug-in knob set-

tings and system messages.

Also presents instructions af-

Display Area

Display from one

to eight gdds.

Trigger

For acquisition

charlrlels, arrows

indicate trigger level

and time.

ter certain keys are used.

Record

Troce. end vertical scale

Lech’n

Pr’ogr~n ............................. ’ " number. A rectan-

Turn On

xY o~spzoy lected Trace.

Turn On

Peps lete~’3oe

’

CooF~g~,-s

Trace Label

~lay indicate trace

185OIs, horizontal

factors, cursor

measurements,

sweep or segment

gle around one of

these fields

indicates the Se-

View Port Area

View Port symbol

has a box and a stylized

waveform. The stylized

waveform indicates the

ADC range (height) and

memory length (width)

of the Selected Trace.

The box shows the

position and expansion

of the trace relative to

the grid.

Overview

Figure 3.3: Main Screen Display Layout

3-3

Page 34

Overview

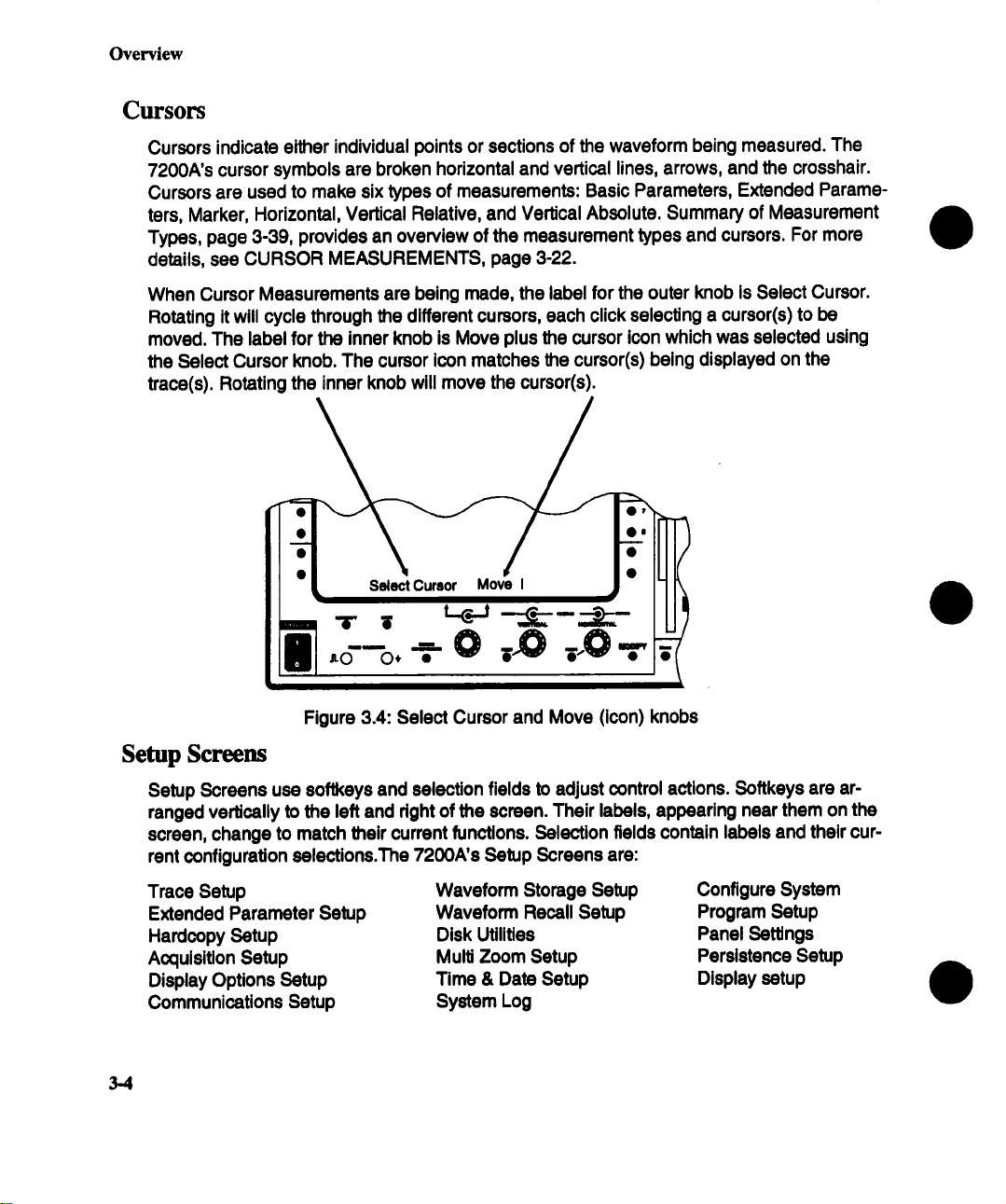

Cursors

Cursors indicate either individual points or sections of the waveform being measured. The

7200A’s cursor symbols are broken horizontal and vertical lines, arrows, and the crosshair.

Cursors are used to make six types of measurements: Basic Parameters, Extended Parameters, Marker, Horizontal, Vertical Relative, and Vertical Absolute. Summary of Measurement

Types, page 3-39, provides an overview of the measurement types and cursors. For more

details, see CURSOR MEASUREMENTS, page 3-22.

When Cursor Measurements are being made, the label for the outer knob is Select Cursor.

Rotating it will cycle through the different cursors, each click selecting a cursor(s) to

moved. The label for the inner knob is Move plus the cursor icon which was selected using

the Select Cursor knob. The cursor icon matches the cursor(s) being displayed on the

trace(s). Rotating the inner knob will move the cursor(s).

Figure 3.4: Select Cursor and Move (icon) knobs

Setup Screens

Setup Screens use softkeys and selection fields to adjust control actions. Softkeys are arranged vertically to the left and dght of the screen. Their labels, appearing near them on the

screen, change to match their current functions. Selection fields contain labels and their current configuration selections.The 7200A’s Setup Screens are:

Trace Setup

Extended Parameter Setup

Hardcopy Setup

Acquisition Setup

Display Options Setup

Communications Setup

3-4

Waveform Storage Setup

Waveform Recall Setup

Disk Utilities

Multi Zoom Setup

Time & Date Setup

System Log

Configure System

Program Setup

Panel Settings

Persistence Setup

Display setup

Page 35

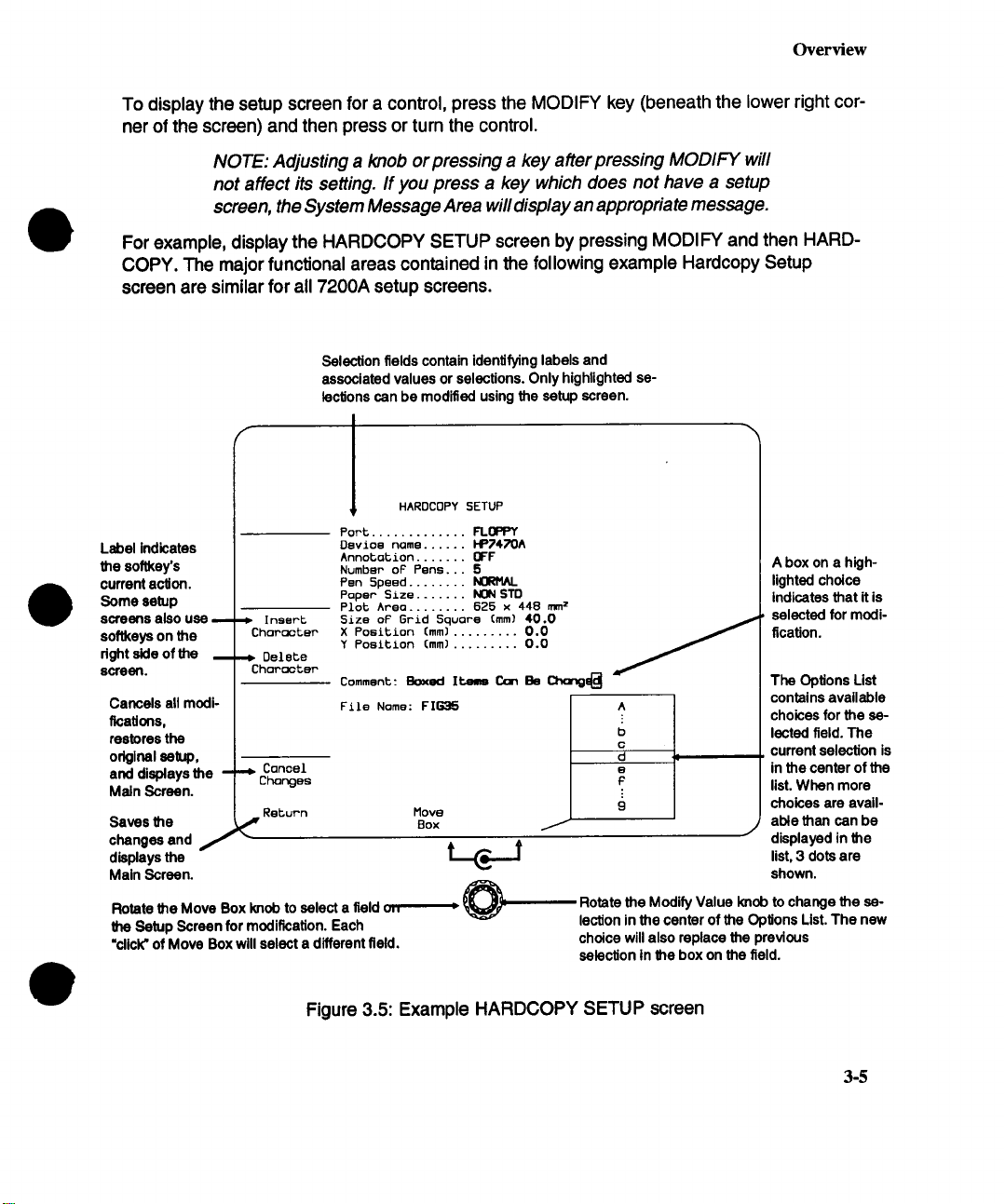

Overview

To display the setup screen for a control, press the MODIFY key (beneath the lower right cor-

ner of the screen) and then press or turn the control.

NOTE: Adjusting a knob or pressing a key after pressing MODIFY will

not affect its setting, ff you press a key which does not have a setup

screen, the System Message Area will display an appropriate message.

For example, display the HARDCOPY SETUP screen by pressing MODIFY and then HARDCOPY. The major funcUonal areas contained in the following example Hardcopy Setup

screen are similar for all 7200A setup screens.

Selection fields contain identifying labels and

associated values or selections. Only highlighted se-

lecfions can be modified using the setup screen.

HARDCOPY 5ETUP

Box

t_c._J

FLOPPY

NORMAL

z

A box on a highlighted choice

indicates that it is

selected for modi-

fication.

The Opfions List

contains available

b

C

-~ current selection is

9

t

Rotate the Modify Value Imob to change the selection in the center of the Options List. The new

choice will also replace the previous

selection in the box on the field.

choices for the se-

lected field. The

in the center of the

list. When more

choices are avail-

able than can be

J displayed in the

list, 3 dots are

shown.

Port .............

Label indicates

the softkey’s

current action.

Some setup

screens aiso use

soflkeys on the

right side of the

screen.

Cancels all modificafions,

restores the

original setup,

and displays the

Main Screen.

Saves the

changes and J

displays the

Main Screen.

Rotate the Move Box I~ob to select a field v,,

the Setup Screen for modification. Each

"dick" of Move Box will select a different field.

, ! I nssrt

Character

, Delete

Character

i Cancel

Changes

Re~urn

~"

Dsvioe name ..... HP7470A

Annotation ..... OFF

Number oF Pens. 5

Pen 5peed ......

Paper Size ..... NON STO

Plot Area ...... 6Z5 x 448 mm

Size of Grid Square (mm) 40.0 ~,

X Position (mm) .........0.0

Y Position (mm) .........0.0

Comment: Boxed Items Can Be Change~

File Name: FIG35 J ^

Move

Figure 3.5: Example HARDCOPY SETUP screen

3-5

Page 36

Overview

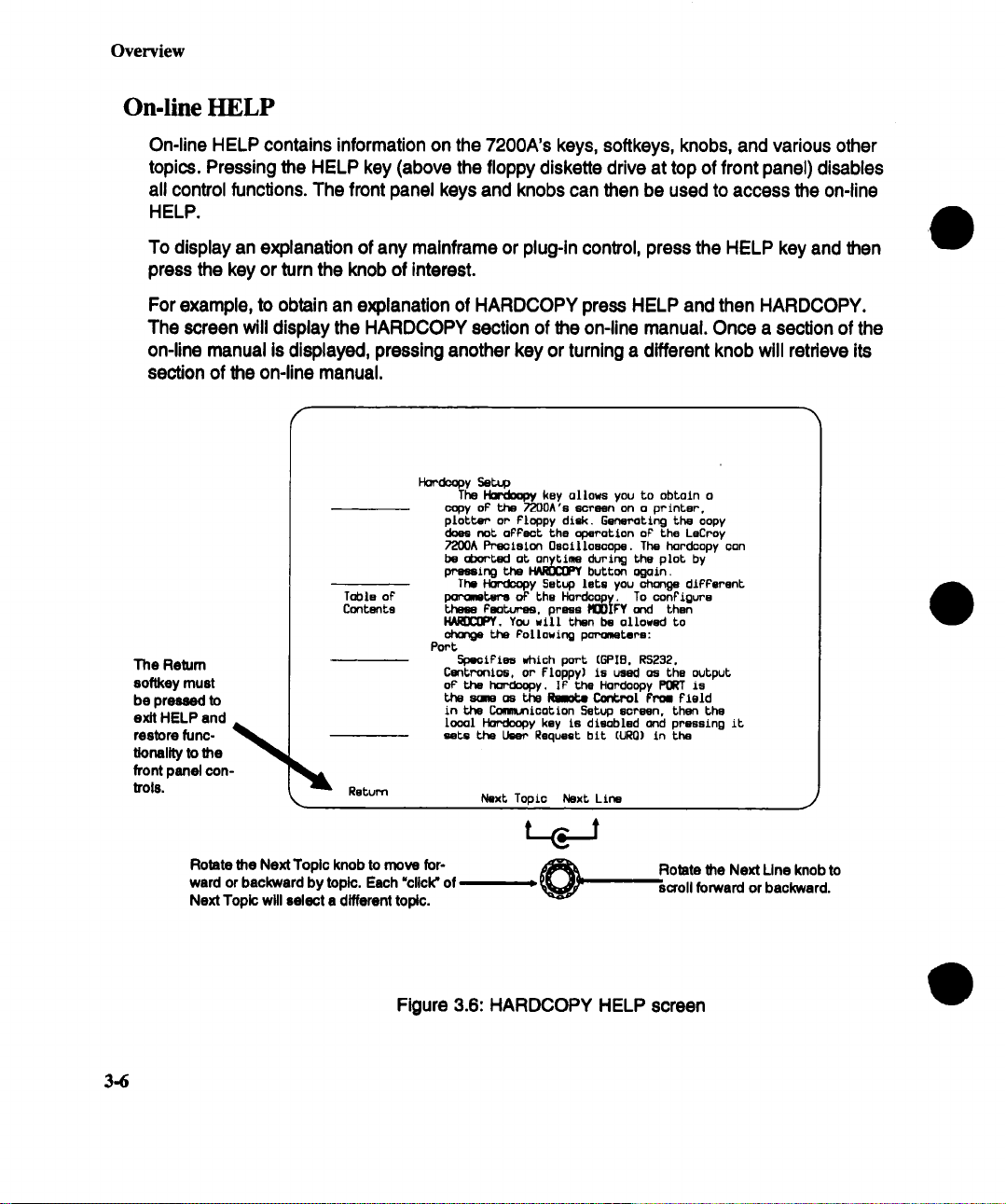

On-line HELP

On-line HELP contains information on the 7200A’s keys, softkeys, knobs, and various other

topics. Pressing the HELP key (above the floppy diskette drive at top of front panel) disables

all control functions. The front panel keys and knobs can then be used to access the on-line

HELP.

To display an explanation of any mainframe or plug-in control, press the HELP key and then

press the key or turn the knob of Interest.

For example, to obtain an explanation of HARDCOPY press HELP and then HARDCOPY.

The screen will display the HARDCOPY section of the on-line manual. Once a section of the

on-line manual is displayed, pressing another key or turning a different knob will retrieve its

section of the on-line manual.

H=-~py Seep

The HordooW key allows you to obtain o

coW oF the 7200A’e 6croon on a printer,

piot~P or Floppy disk. Generating the oopy

does not oPPect the operation of’ the LsCroy

7200A Prectsion Oscilloscope, The hordoopy con

be aborted at, anytime during the plot by

pressing the H/~ button again.

The ~y Setup lets you change dlFPsrsnt

poromter’s oF the Hordoopy. To configure

these Features, press flOOIFY and then

~, You sill then be allowed to

ohonge tJne Pollowing pm-omtsrs:

Port,

SpeciFies which port (GPI8. R5232,

CentPonlos, or Floppy] is used as the output

oF" the hor’doopy. IP the Hordoopy PORT is

the some as the ~ CofCPol FPOll Field

in the Communication 5etup screen, then the

local Hordoopy key Is disabled and pressing it,

sets the User Request bit (URQ] in the

Next Topic Next Line

The Return

eoftkey must

be pressed to

exit HELP and

restore rune- ~

flonallty to the

front panel controis.

Table oF

Cantante

Return

3.6

Rotate the Next Topic knob to move for-

ward or backward by topic. Each "click" of

Next Topic will select a different topic.

Figure 3.6: HARDCOPY HELP screen

Rotate the Next Line knob to

scroll forward or backward.

Page 37

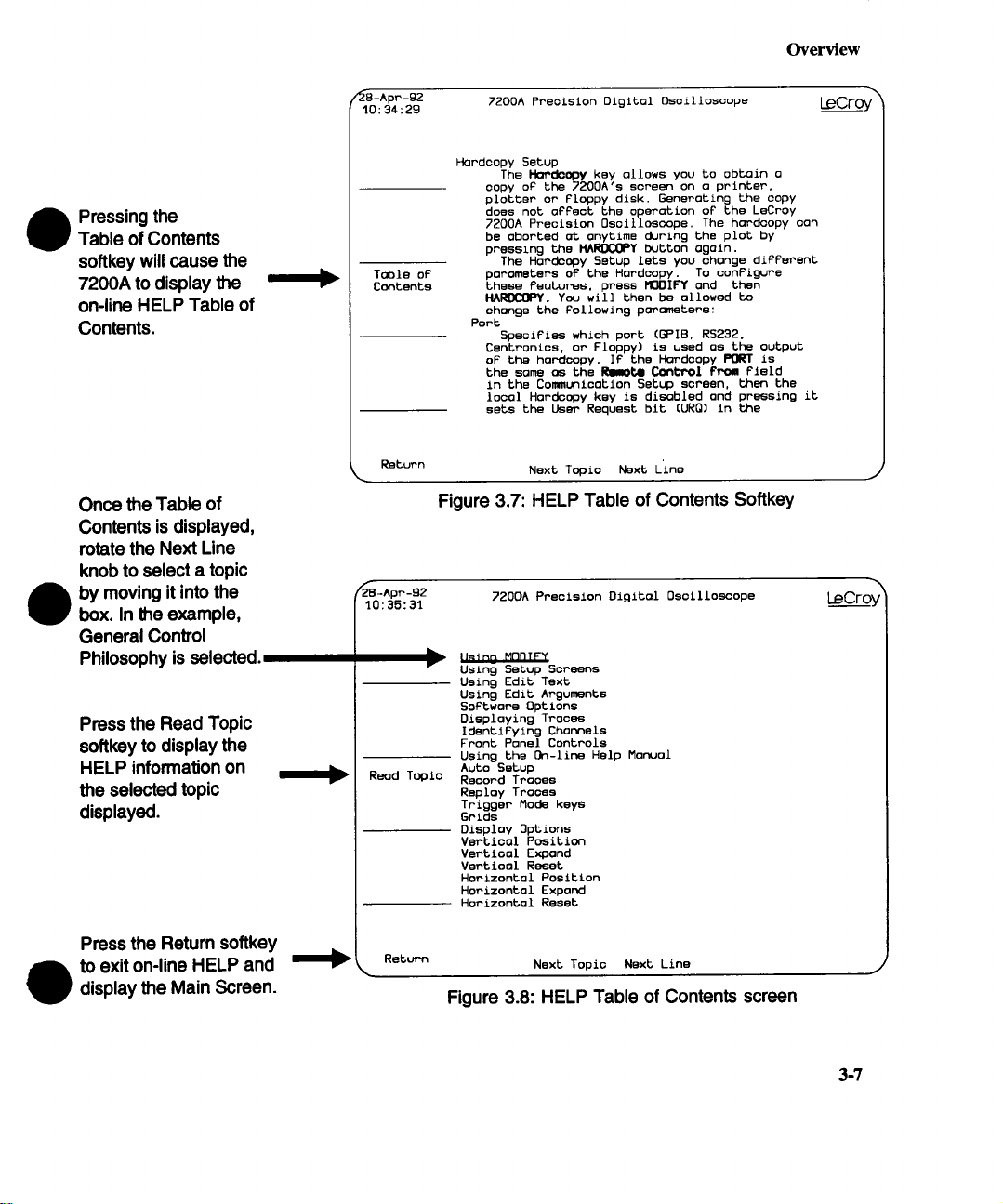

Overview

Pressing the

Table of Contents

softkey will cause the

7200A to display the

on-line HELP Table of

Contents.

Once the Table of

Contents is displayed,

rotate the Next Line

knob to select a topic

by moving it into the

box. In the example,

General Control

Philosophy is selected.

Press the Read Topic

softkey to display the

HELP information on

the selected topic

displayed.

~El-Apr-92

10:34 : 29

Toble of

Contents

~2B-Apr-g2

10:35:31

Reod Topic

7200A Preoision Olglbul Oscilloscope

Hordoopy Setup

The HoP~opy key ollows you to obtoin o

copy of the 7200A’s screen on o printer,

plotter or Floppy disk. Generoting the copy

does not offsct the operotion of the LeCroy

7200A Precision Oscilloscope. The hordoopy con

be oborted o~ onytime during the plot by

pressing the HAROCOPY button ogoin.

The Hordcopy Setup lets you chonge different

poromsters of the Hordcopy. To configure

these lectures, press MODIFY ond then

HAROCOPY. You will then be o[Iowed to

chunge the Following po~ometere:

Port

Specifies which pore (BPIB, R5232.

Csntronics, or Floppy) is used oS the output

of b~ hordcopy. If the Hordcopy PORT is

the some os the I~41 Control PPoll field

in the Communicotlon Setup screen, then the

Io0oi Hordoopy key is disobled ond pressing it

sets the User Request bib (URQ) in the

Next Topic Next L’ins

Figure 3.7: HELP Table of Contents Softkey

7200A Precision Digital Osoillomcope

===

Ilminn MnRIFY

r

Using Setup Screens

Using Edit Text

Using Edit Arguments

Softwore Options

Dieploying Trooes

Identifying Chonnels

Front Ponel Controls

Using the On-line Help Monuol

Auto Setup

Record Traces

Reploy Trooes

Trigger Mode keys

Grids

Disploy Options

Vertlcol Position

VertlooL Expond

Vsrtiool Reset

Horizontol Position

Horizontol Expond

Hor£zontol Reset

~

LeCroy

J

LeCroy

Press the Return softkey

to exit on-line HELP and

display the Main Screen.

I1~ Return

Next Topic Next Line

Figure 3.8: HELP Table of Contents screen

J

3-?

Page 38

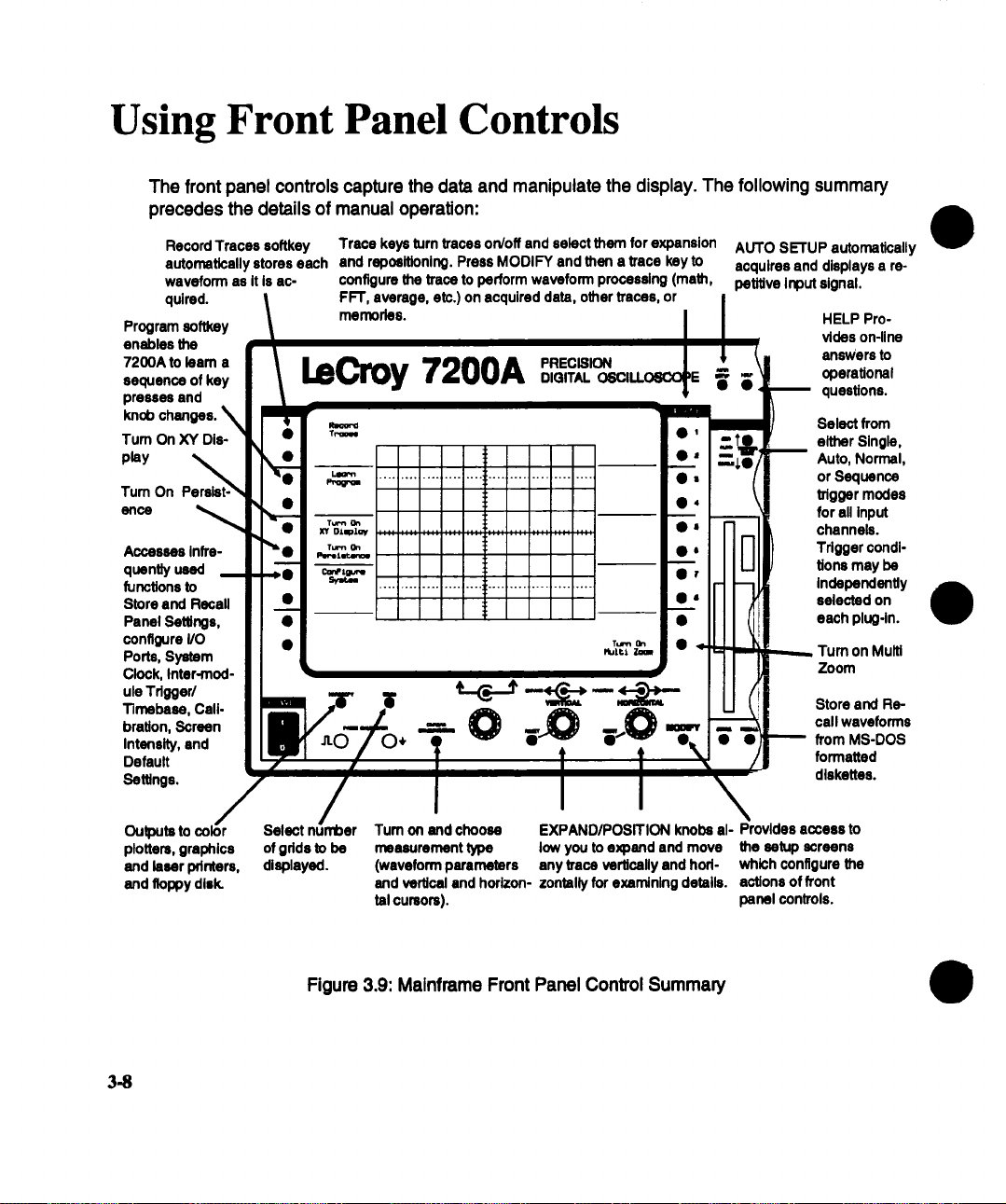

Using Front Panel Controls

The front panel controls capture the data and manipulate the display. The following summary

precedes the details of manual operation:

Record Traces acftkey Trace keys turn traces on/off and select them for expansion

automatically stores each and rspceltionlng. Press MODIFY and then a trace key to

weveforrn as it Is ac*

qulrsd.

Program softkey

enables the

7200A to learn a

sequence of key

presses and

knob

Tum On XY Display

Tum On

ence

Accesses Infrequen~ used

functions to

Store end Recall

Panel Settings,

configure I/O

Ports, System

Clock, Inter-module Tdggar/

"rimabase, Cali-

bration, Screen

Intensity, and

Default

Settings.

configure the trace to perform waveform processing (math,

FFT, average, etc.) on acquired data, other traces, or

memories.

LeCroy 7200A

! ....

-- !!

.... ; .................i l .....................

i

¯

’~ "~ "--" ~ Store and Re-

"- 0 ~0 ~-0

AUTO SETUP automatically

acquires and displays a re-

petitive Input signal.

HELP Pro-

vldes on-line

answers to

operational

questions.

Select from

either Single,

Auto, Normal,

or Sequence

trigger modes

for ell Input

channels.

Trigger conditions may be

independently

selected on

each plug-in.

Turn on Multi

Zoom

call waveforms

from MS-DOS

formatted

diskettes.

Outputs to

plotters, gmphlce

and laser printers,

and floppy disk.

3.8

Select

of gdds to be

displayed.

Figure 3.9: Mainframe Front Panel Control Summary

Tum on and choose

measurement type low you to expand and move

(waveform parameters any trace vertically and hodand vertical and horizon- zontslly for exarnlnlng details,

tel cursors),

EXPAND/POSITION knobs al- Provides access to

the setup screens

which configure the

actions of front

panel controls.

Page 39

7200A Mainframe Front Panel Illustration

Page 40

7200A Mainframe Front Panel

LeCroy 7200A

11 12 13

14 15 16

17 18 19 20 21 22 23 24

31

PRECISION

DIGITAL OSCILLOSCOPE

32

33~

34~

35m

3O

25 26

29 28

27

Index to Controls

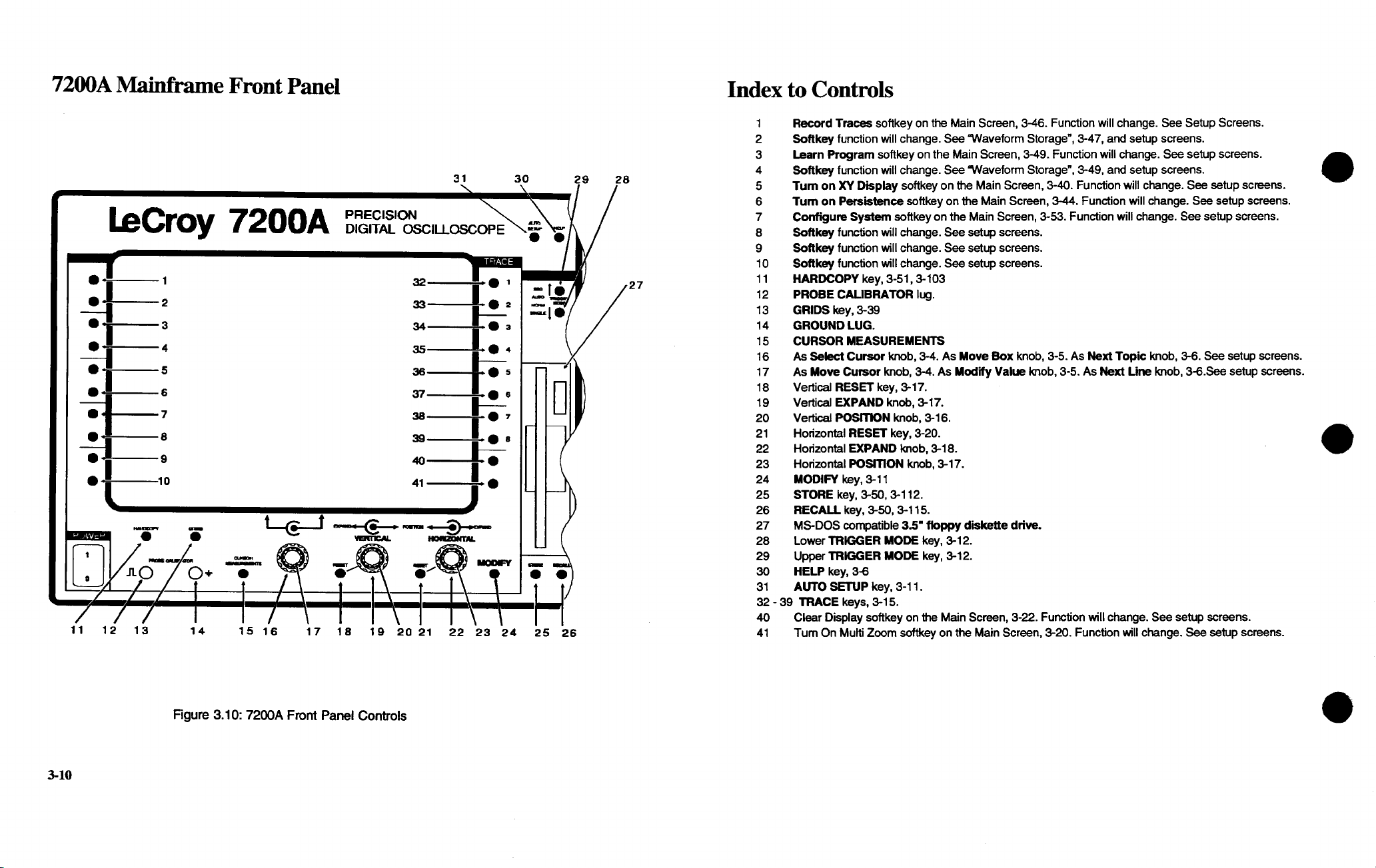

1 Record Traces softkey on the Main Screen, 3-46. Function will change. See Setup Screens.

2 Softkey function will change. See =Waveform Storage", 3-47, and setup screens.

3 Learn Program softkey on the Main Screen, 3-49. Function will change. See setup screens.

4 Softkey function will change. See =Waveform Storage", 3-49, and setup screens.

5 Turn on XY Display softkey on the Main Screen, 3-40. Function will change. See setup screens.

6 "rum on Persistence softkey on the Main Screen, 3-44. Function will change. See setup screens.

7 Configure System softkey on the Main Screen, 3-53. Function will change. See setup screens.

8 Softkey function will change. See setup screens.

9 Soltkey function will change. See setup screens.

10 Soltkey function will change. See setup screens.

11 HARDCOPY key, 3-51,3-103

12 PROBE CALIBRATOR lug.

13 GRIDS key, 3-39

14 GROUND LUG.

15 CURSOR MEASUREMENTS

16 As Select Cursor knob, 3-4. As Move Box knob, 3-5. As Next Topic knob, 3-6. See setup screens.

17 As Move Cursor knob, 3-4. As Modify Value knob, 3-5. As Next Line knob, 3-6.See setup screens.

18 Vertical RESET key, 3-17.

19 Vertical EXPAND knob, 3-17.

20 Vertical POSITION knob, 3-16.

21 Horizontal RESET key, 3-20.

22 Horizontal EXPAND knob, 3-18.

23 Horizontal POSITION knob, 3-17.

24 MODIFY key, 3-11

25 STORE key, 3-50, 3-112.

26 RECALL key, 3-50, 3-115.

27 MS-DOS compatible 3.5" floppy diskette drive.

28 Lower TRIGGER MODE key, 3-12.

29 Upper TRIGGER MODE key, 3-12.

30 HELP key, 3-6

31 AUTO SETUP key, 3-11.

32 - 39 TRACE keys, 3-15.

40 Clear Display softkey on the Main Screen, 3-22. Function will change. See setup screens.

41 Tum On Multi Zoom softkey on the Main Screen, 3-20. Function will change. See setup screens.

3-10

Figure 3.10: 7200A Front Panel Controls

Page 41

Following are descriptions of the mainframe front panel controls. The number in parentheses

locates the control on the 7200A front panel drawing (Figure 3.10, page 3-10).

MODIFY (24)

The MODIFY key (beneath the lower right corner of the screen)

provides access to the 7200A’s setup screens. When MODIFY is

pressed, PRESS KEY TO MODIFY ITS SE’I-I’INGS is displayed

in the System Message Area. Pressing a key or turning a knob

will then cause the control’s setup screen to appear. Modifying

the selection fields on the setup screen will change the control’s

actions.

For example, pressing MODIFY and then HARDCOPY will

cause the 7200A to display the HARDCOPY SETUP screen.

Modifying the HARDCOPY SETUP selection fields will change

the HARDCOPY key’s actions.

NOTE: If you press MODIFY and then select a control

which does not have a setup screen, the System Mes-

sage Area will display NO SETUP SCREEN FOR and

the name of the control (e.g., NO SETUP SCREEN FOR

GRIDS). Adjusting a control after pressing MODIFY

does not change the control’s setting.

Acquisition Keys

AUTO (31)

SETUP

Press this key to have the 7200A display a repetitive input signal

by automatically adjusting the acquisition control settings of each

plug-in for the "best" display. Pressing the key while in progress

will abort AUTO SETUP. The acquisition controls may then be

further adjusted if desired.

3-11

Page 42

Input signals must have an amplitude between 2 mV and 8 V, fre-

quency above 50 Hz, and a duty cycle greater than 0.1%. AUTO

SETUP time depends on the signal frequency. It is generally

under 20 seconds.

¯ The TRIGGER MODE (as described below) is set

AUTO, and timebase and trigger settings are automatIcally adjusted as follows:

If AUTO SETUP is performed on a single channel that

has a valid signal, the timebase and trigger controls

adjust to best display the signal. If no signal or a DC

signal is found, timebase for the channel is set to

10 psec.

If more than one channel is used by a trace(s) that

turned on, the lowest numbered channel with a valid

signal is used to setup the timebase and trigger

controls for all plug-in channels. If no signal or a DC

signal is found, the timebase for all channels is set to

10 IJ~ec.

¯ AUTO SETUP does not change the input’s vertical

coupling.

¯ Vertical settings for all channels are selected Inde-

pendently.

TRIGGER MODE

((28) and (29))

3-12

Selects from either Single, Normal, Auto, or Sequence trigger

modes for all input channels. Trigger conditions can be Inde-

pendently selected on each plug-in. As these keys are pressed

to step through each trigger mode, LEDs Indicate the mode selected.

A READY LED on each plug-in indicates that the tdgger circuit

has been armed and the plug-in is currently acquiring input

signals. The plug-in’s TRIG’D LED is lit whenever a valid trigger

has been received and waveform acquisition completed. In RIS

or SEQuence mode, the TRIG’D LED is not lit until a complete

waveform has been constructed after sufficient triggers have occurred.

If an acquisition key is changed while acquiring data, the acquisi-

tion stops and acquisition restarts using the new setting. If the

Page 43

key is changed between acquisitions, it affects the next acquisi-

tion.

NOTE: When the 7200A is in SINGLE or SEQuence

mode and has finished acquiring data, changes to the

plug-in acquisition settings will not affect the currently

displayed trace, but will affect the acquisition of the next

trace (initiated by pressing the TRIGGER MODE key to

re-select the mode).

The Trigger modes operate as follows:

SINGLE

NORMAL

Arms the trigger circuit. When a valid tdgger signal is detected,

acquisition occurs and the waveform is displayed.

To arm the circuit again for another sweep, press the lower

TRIGGER MODE key again to re-select SINGLE. (The READY

LED is lit.) When a valid trigger is detected (TRIG’D LED lit),

acquisition completes and the new waveform then replaces the

one previously displayed. This mode is useful for capturing transient events.

If TRIGGER MODE is pressed a second time prior to detecting a

valid trigger, the 7200A will manually trigger all plug-ins.

When the 7200A is in the Random Interleaved Sampling (RIS)

mode (as indicated by the LED on the plug-in front panel), the

waveform is constructed and displayed after sufficient triggers

have occurred. The 7200A must then be re-armed by pressing

TRIGGER MODE again to re-select SINGLE before acquisition

of the next RIS waveform begins.

The 7200A acquires data and updates the display for each valid

trigger. The trigger circuit is automatically re-armed after each

acquisition.

Select NORMAL mode by pressing either TRIGGER MODE key

until the NORM LED is lit.

This mode is useful for capturing signals correlated in time with a

repetitive trigger signal.

3-13

Page 44

When the plug-in is in the RIS mode, as indicated by an LED on

the plug-in front panel, each waveform is displayed after sufficient triggers have occurred to construct it.

AUTO

SEQUENCE

AUTO and NORMAL Trigger Modes are identical, except that in

AUTO the 7200A automatically generates an internal trigger signal If a valid trigger Is not detected within 100 msec during single

shot mode and 200 msec in RIS mode.

This mode is useful for obtaining a trace on the screen for Initial

adjustment of acquisition settings. It is also used for capturing

signals not having a reliable, detectable, or time-correlated trigger signal. Select AUTO mode by pressing either TRIGGER

MODE key until the AUTO LED is lit.

In this trigger mode the acquisition memory is partitioned Into

segments as selected from within a Plug-in Status screen.

Select SEQuence mode by pressing the upper TRIGGER MODE

key until the SEQ LED is lit.

Each time a trigger occurs, the current segment is acquired and

the ~gger circuit is re-armed for acquisition of the next segment.

When all segments are completed, the result is displayed. Some

plug-ins will optionally average the successive segments, If desired, (see plug-in manuals for details).

There are 2 types of Sequence Triggers: Single and Normal. Sequence Trigger Types are selectable in the Acquisition Setup

screen. This may be accessed either from the Configure System

screen or by pressing the MODIFY key and then a TRIGGER

MODE key.

3-14

Single Sequence acquires the requested number of segments

and displays the sequence waveform. To arm the circuit again

for another sweep, press TRIGGER MODE again to re-select

Sequence.

If SEQuence Mode is selected again prior to acquiring all

segments, acquisition halts and those segments which have

been acquired so far are displayed. If SEQuence Mode is

selected a third time, acquisition is restarted from the beginning.

Page 45

Normal Sequence will keep acquiring and displaying

sequence waveforms until the TRIGGER MODE key

is pressed again to re-select Sequence.

In SEQuence mode the total duration of each segment is equal

to the time/div x 10. Changing the number of required segments

does not change the time per division; it only affects the number

of data points (record length) per segment, and the time/point

(sampling rate).

Waveform acquisition in this mode is particularly useful for shortlived or echoed signals, such as those in RADAR, SONAR, LI-

DAR and NMR.

Waveform Display and Measurement

TRACE

((32) through (39))

Turns the trace on, selects the trace, or turns the race off. If a

TRACE key is pressed while its corresponding trace is not dis-

played, the trace is turned on and becomes the Selected Trace.

The Selected Trace is indicated by a rectangle around its trace

label. If the trace is already on, pressing its TRACE key makes it

the Selected Trace. If the TRACE key of the Selected Trace is

pressed, the trace is turned off and the next trace becomes the

Selected Trace.

While a trace is displayed, the area on the screen next to the

TRACE key indicates the trace label and the horizontal and verti-

cal scale factors for that trace (i.e., time per division and volts

per division for unprocessed waveforms). The trace label indi-

cates either: the source(s) and any processing of the trace data,

or the user selected name for the trace. If cursor measurements

are tumed on, certain cursor values are displayed under the

trace label. If the trace contains an average, extrema, histogram

or trend function, the number of acquisition sweeps or parameter

values accumulated is indicated. If the trace consists of a se-

quence waveform, the number of segments is indicated. If one

segment of a sequence waveform is displayed, the segment

number is indicated. When "l’race Colors" is set to 8 in the Dis-

play Setup Screen (see p. 3-128), this text is displayed in the

same color that the trace is drawn for easy identification.

3-15

Page 46

Waveform Display and Measurement

The following six controls affect the display of the Selected Trace, indicated by a rectangle

around Its trace label on the right side of the screen. These controls adjust the trace’s posi-

tion and magnification. As the trace is being altered, refer to the View Port which appears as

a stylized waveform within a box below the lower right corner of the grid. The View Port

graphically shows the trace location and expansion with respect to the display grid. The

width of the stylized waveform represents the total record length of the trace; the height represents the full range of the Analog to Digital Converter (ADC). If the Selected Trace is positioned or expanded to accentuate some points and not display others, the View Port

identifies the displayed section (boxed-in area) relative to the entire trace. That is, the section of the stylized waveform within the rectangle corresponds to the displayed section of the

Selected Trace. Also, when a trace Is expanded vertically or re-positioned, a two headed vertical arrow is positioned next to its’ trace label. For horizontal expansion or position a two

headed horizontal arrow is positioned next to its’ trace label.

VERTICAL (2O)

POSITION

This knob moves the Selected Trace vertically anywhere on the

screen. This allows traces to be overlaid for comparisons or

separated for easy viewing. As the Selected Trace is positioned

a two headed vertical arrow is positioned next to the trace label.

The position knob does not affect the vertical offset of the acquisition channel(s).

The View Port shows the position of the trace relative to the grid.

See Figure 3.11.

3.16

Page 47

Waveform Display and Measurement

VERTICAL (19)

EXPAND

Record

Trocee

Leorn

Progrom

Turn On

XY Oisploy

Turn On

Persistenoe

ConFigure

5ystem

~B1

5 ns 20 mV

=

Figure 3.11: Trace Vertically reposiUoned. View Port

indicates location of trace.

This knob vertically expands the Selected Trace around the center of its home grid. As the Selected Trace is expanded, the

View Port shows only a portion of the trace inside the View Port

box to indicate that part of the data range is off the screen. The

vertical scale factor indication under the trace label is automat-

ically adjusted. The expansion knob does not affect the amplifier

settings of the acquisition channel(s).

VERTICAL (18)

RESET

HORIZONTAL (23)

POSITION

The waveform can be expanded or contracted vertically in steps

that are multiples of one, two, and five.

Toggles the vertical display of the Selecte.d Trace between the

selected expansion and position and the reset vertical state (unexpanded on the center of the home grid). When the Selected

Trace is expanded or re-positioned, a two headed vertical arrow

appears next to its’ trace label.

This knob moves the Selected Trace horizontally anywhere on

the screen. As the Selected Trace is positioned a two headed

horizontal arrow is positioned next to the trace label. The posi-

3-17

Page 48

Waveform Display and Measurement

tion knob does not affect the trigger delay of the acquisition chan-

nel.

If part of the waveform is positioned off the display grid, the View

Port and horizontal arrows can help determine the position of the

displayed section relative to the entire trace.

If displaying one segment of a trace acquired with SEQuence

Mode, rotate the knob to display other segments. When a seg-

ment boundary is reached, an extra turn of the knob is required

to display the next segment. The segment number is indicated

next to the trace label.

HORIZONTAL (22)

EXPAND

This knob horizontally expands (i.e., magnifies) the Selected

Trace around the center of the grid. As the Selected Trace is expanded, the View Port shows a shorter portion of the trace inside

the View Port box to indicate that there is data which is not currentiy on the screen. The horizontal scale factor indication under

the trace label Is automatically adjusted. The expansion knob

does not affect the timebase settings of the acquisition chan-

nel(s).

The waveform can be expanded or contracted horizontally in

steps that are multiples of one, two, and five.

When a trace is horizontally expanded so that the number of

data points is less than the number of display pixels across the

screen, linear interpolation is used to connect the data points.

The actual data points are displayed with greater intensity in order to distinguish them.

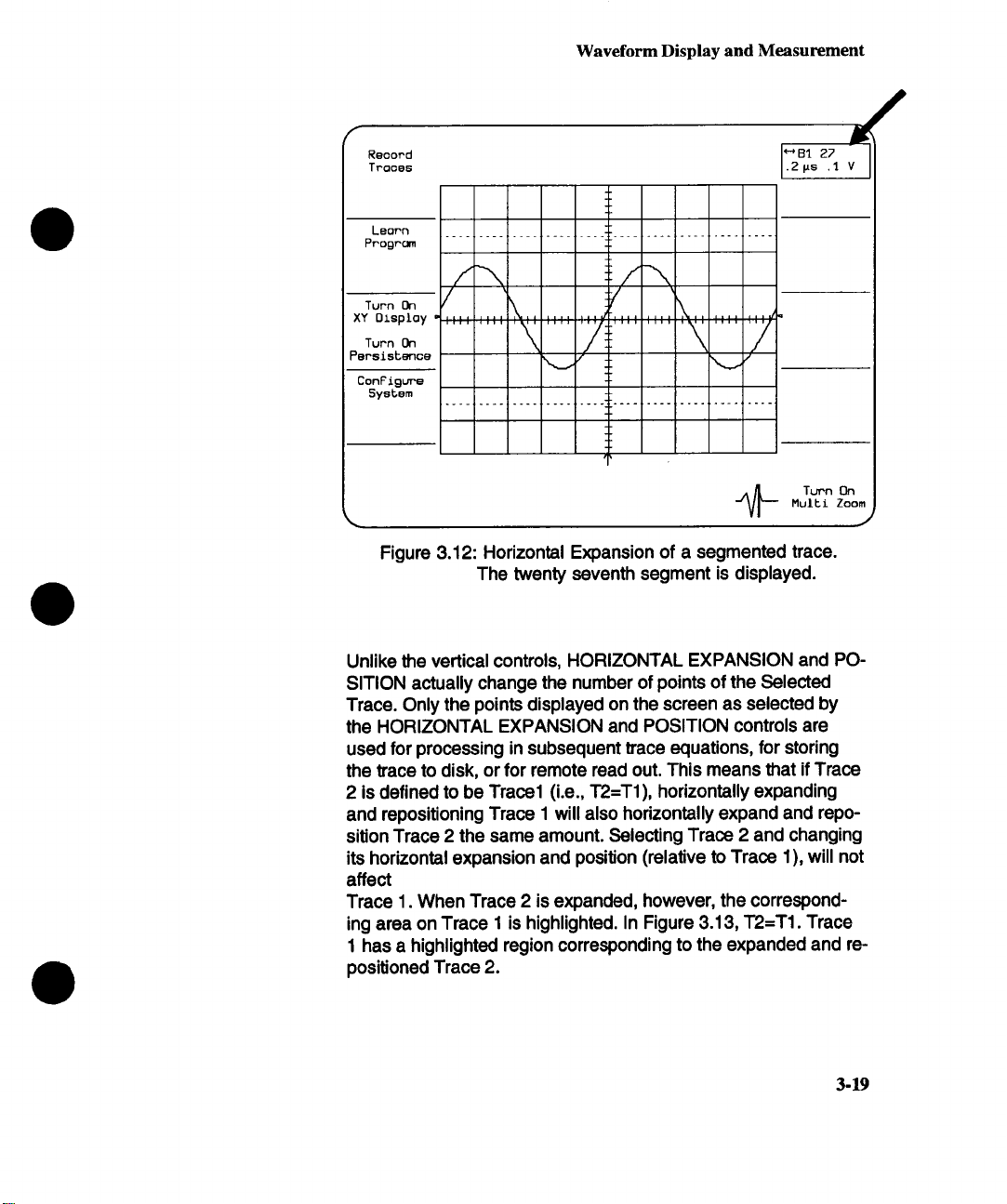

When displaying a trace acquired with SEQuence Mode, rotating

the HORIZONTAL EXPANSION knob clockwise by one position

displays a single segment of the trace. Additional rotations will

expand that segment. Rotating the HORIZONTAL POSITION

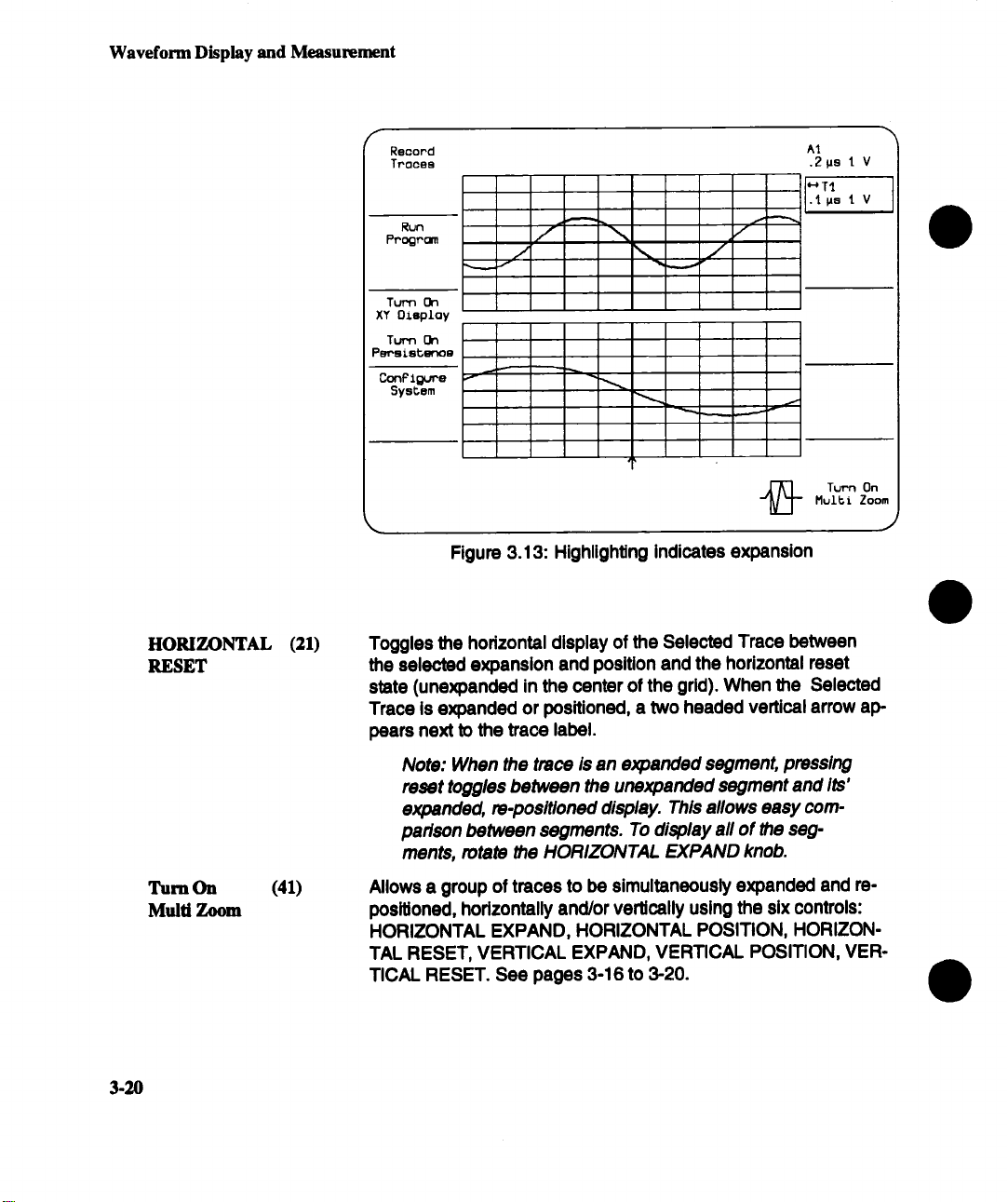

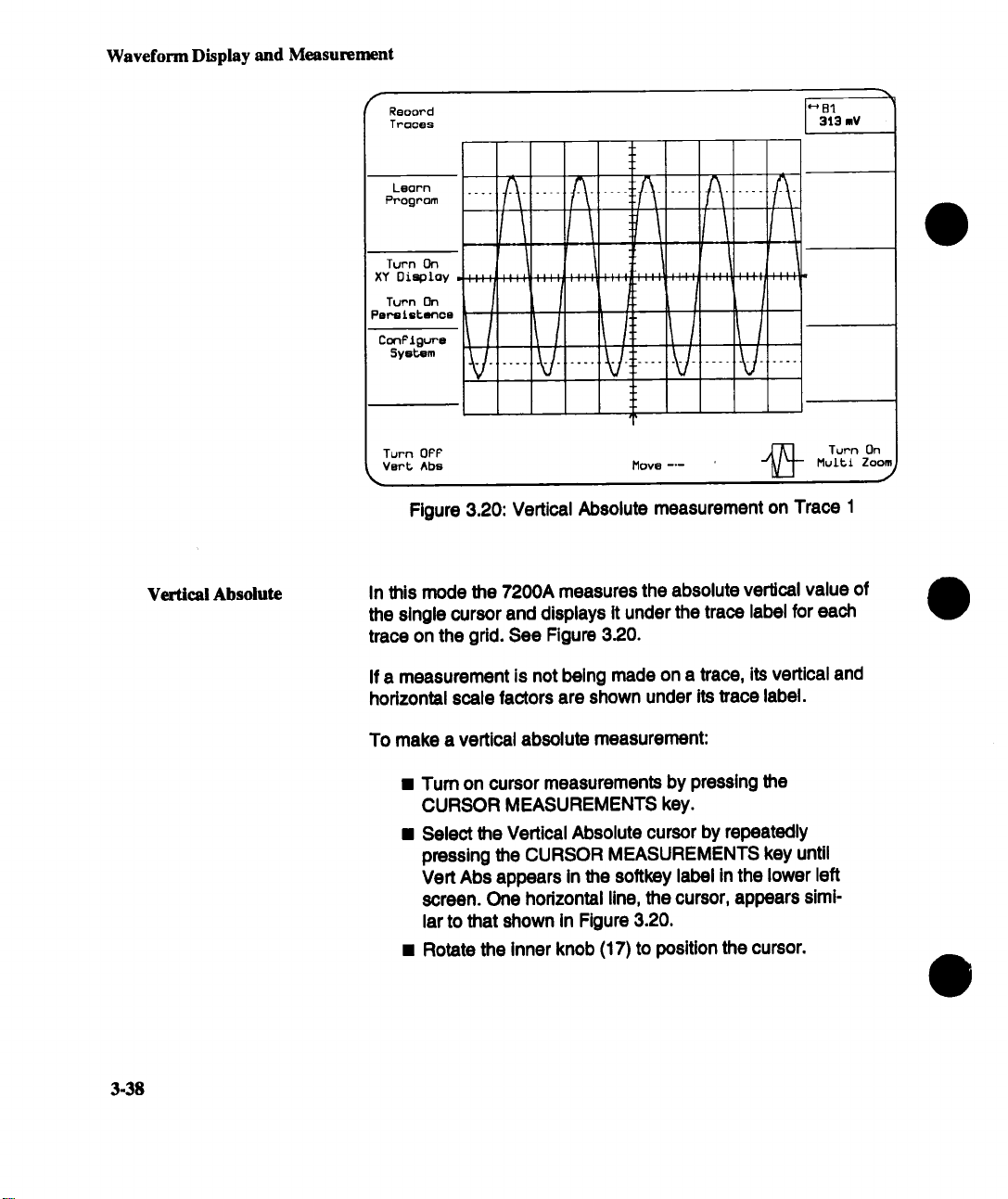

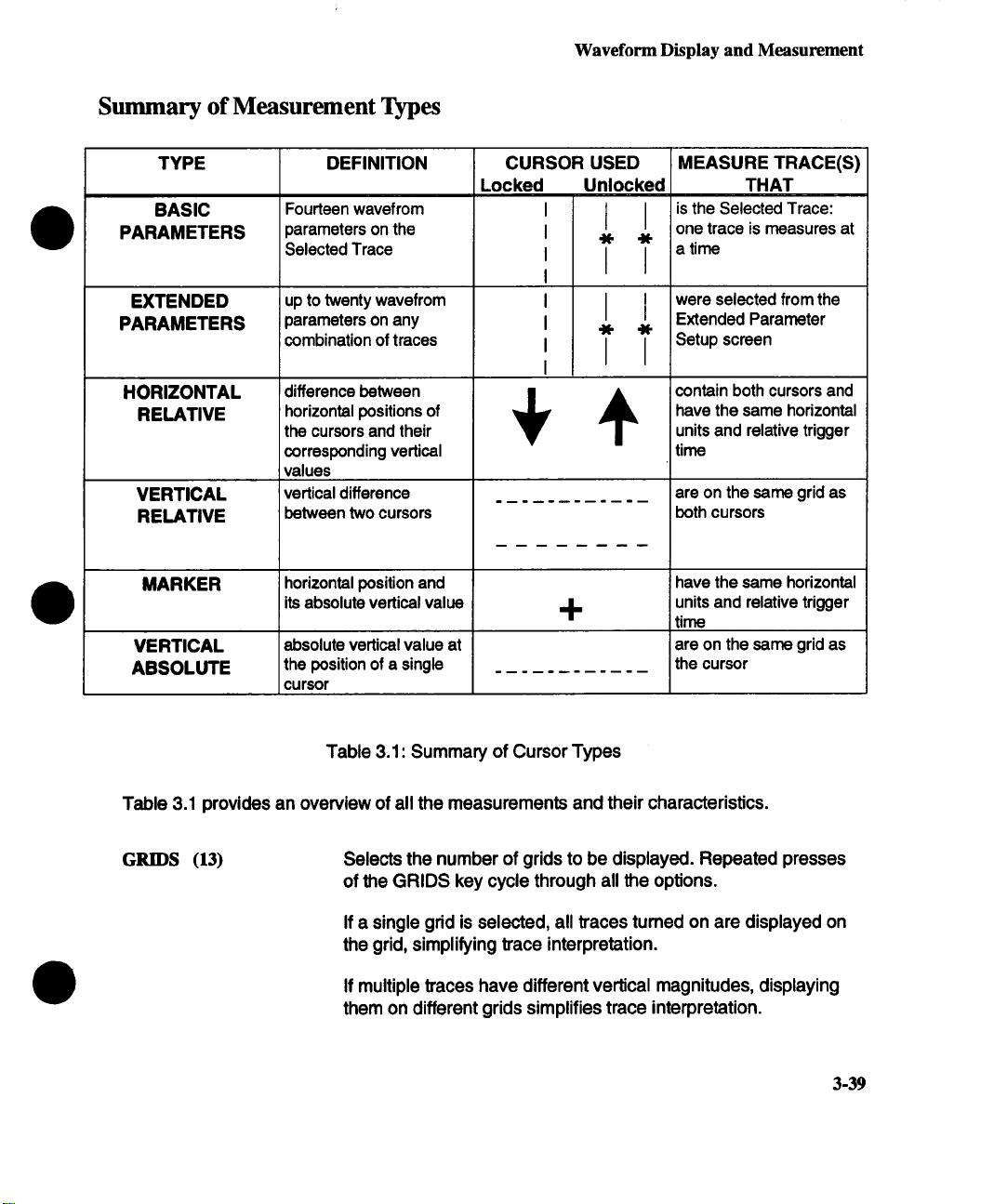

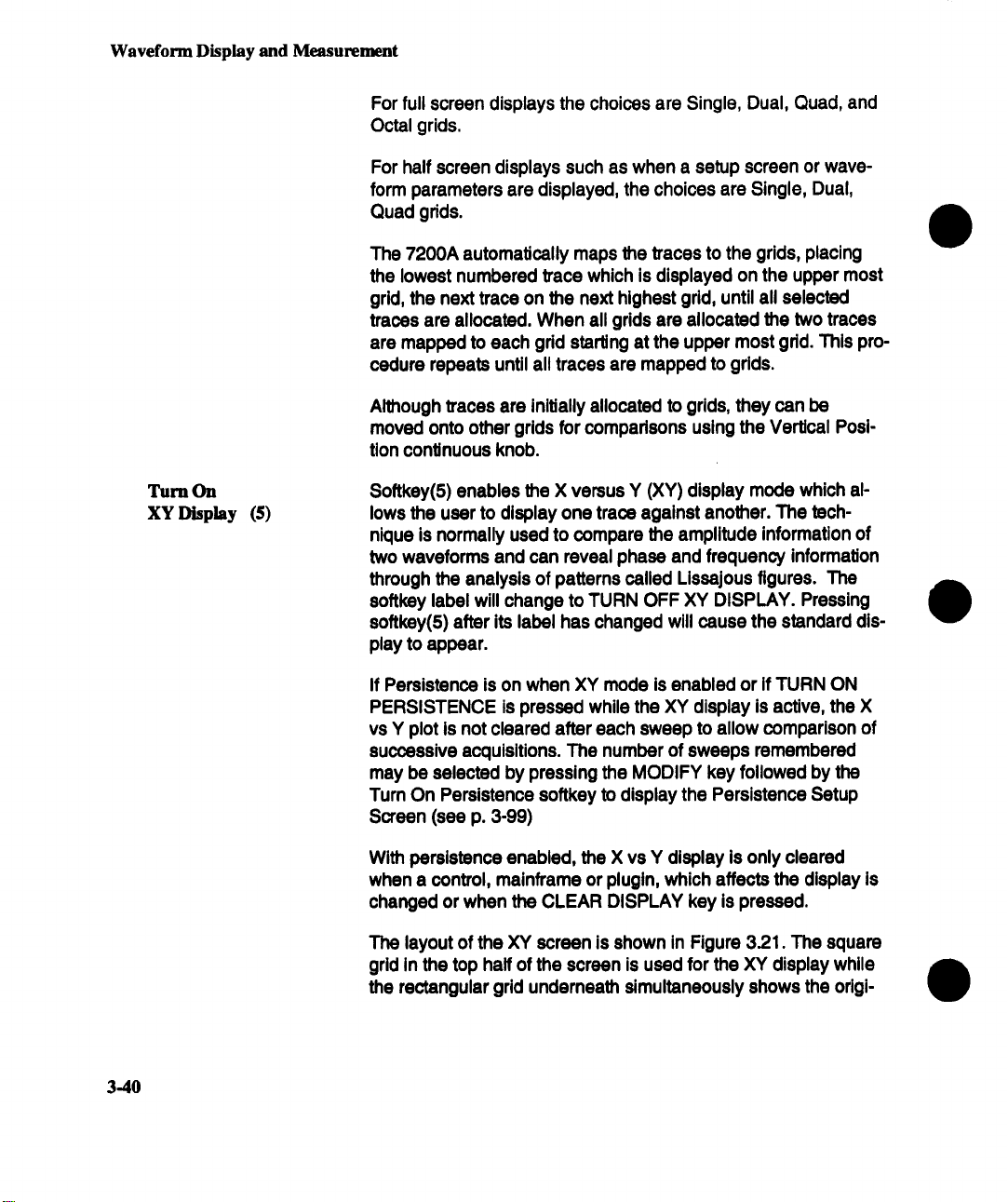

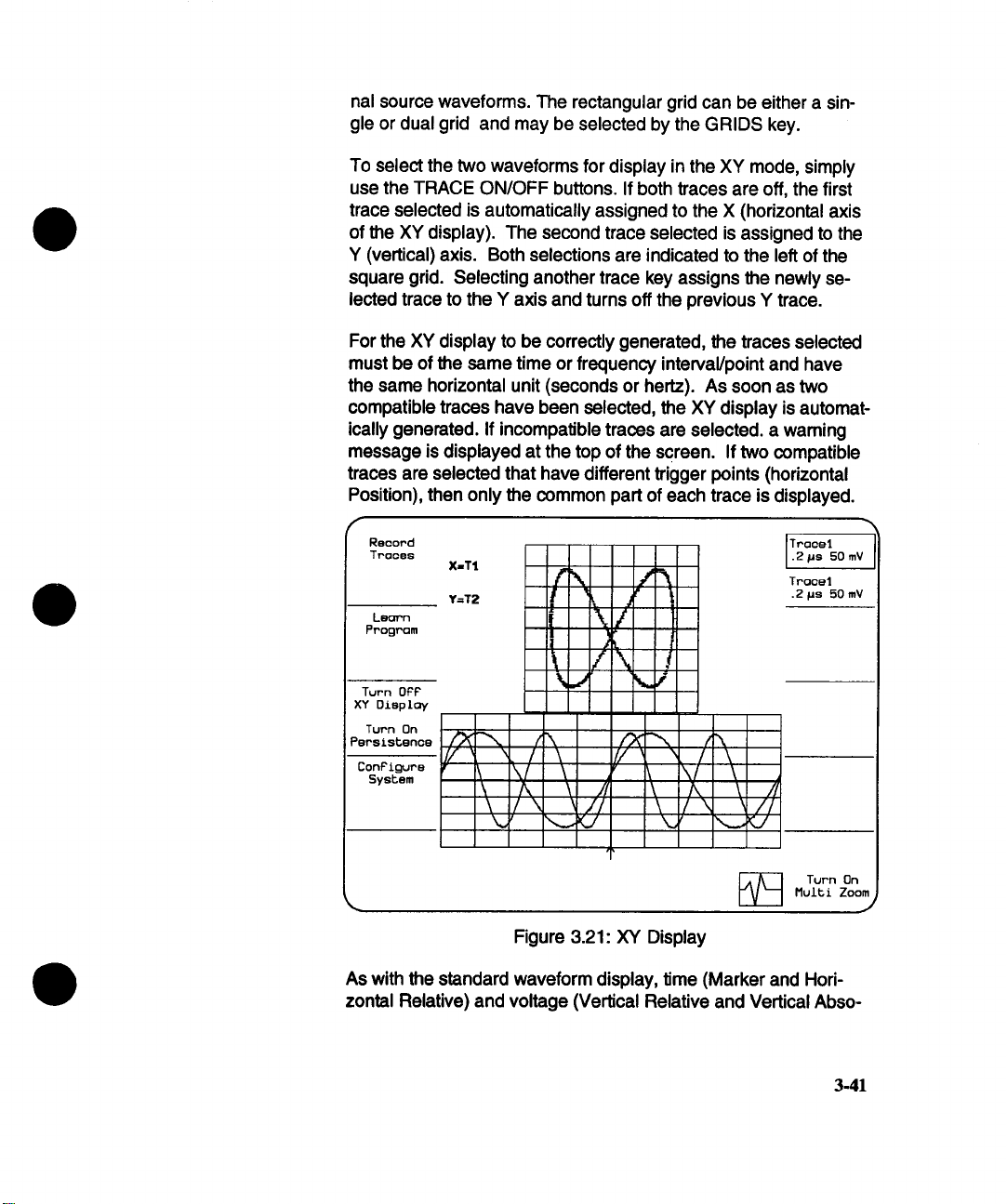

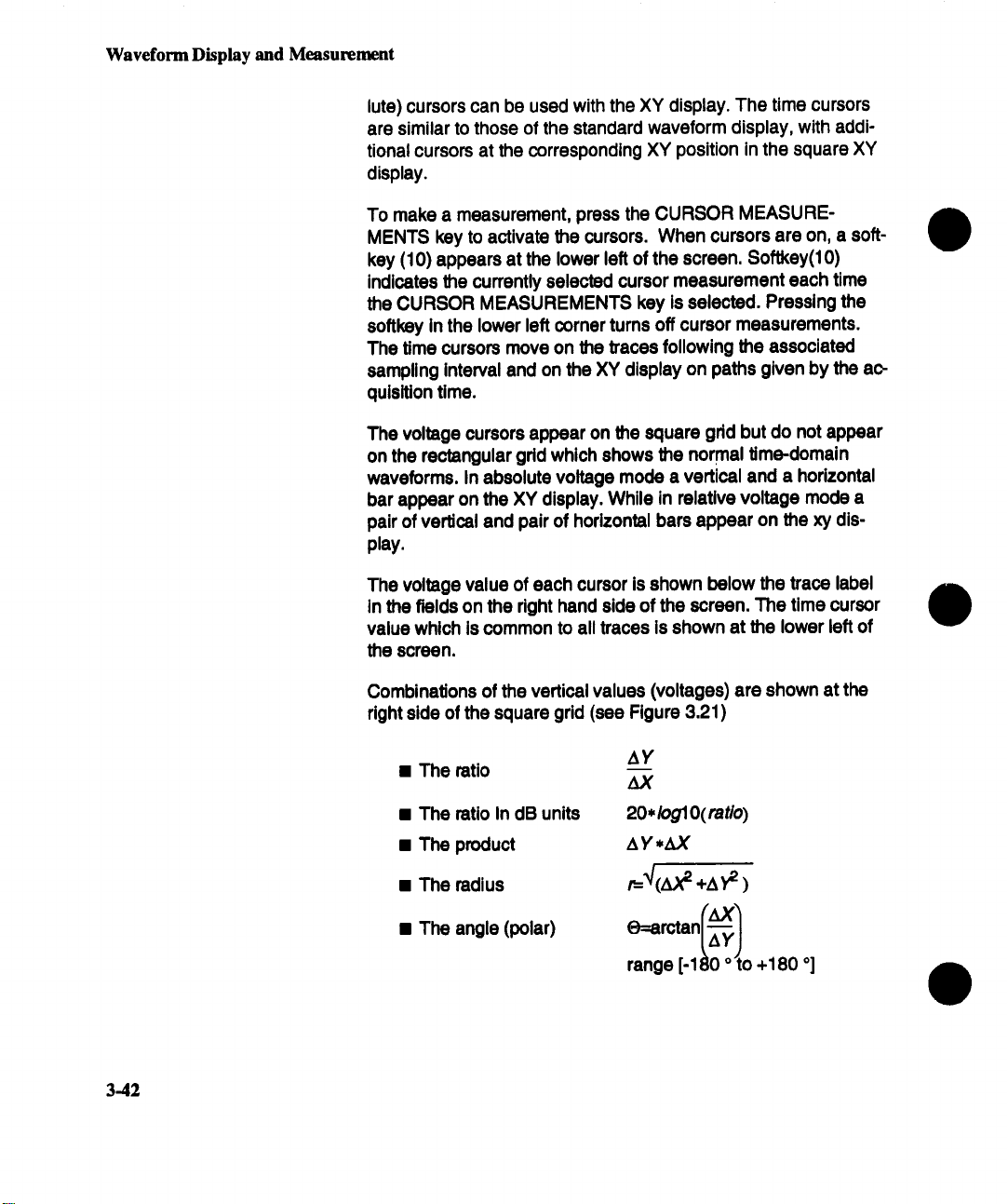

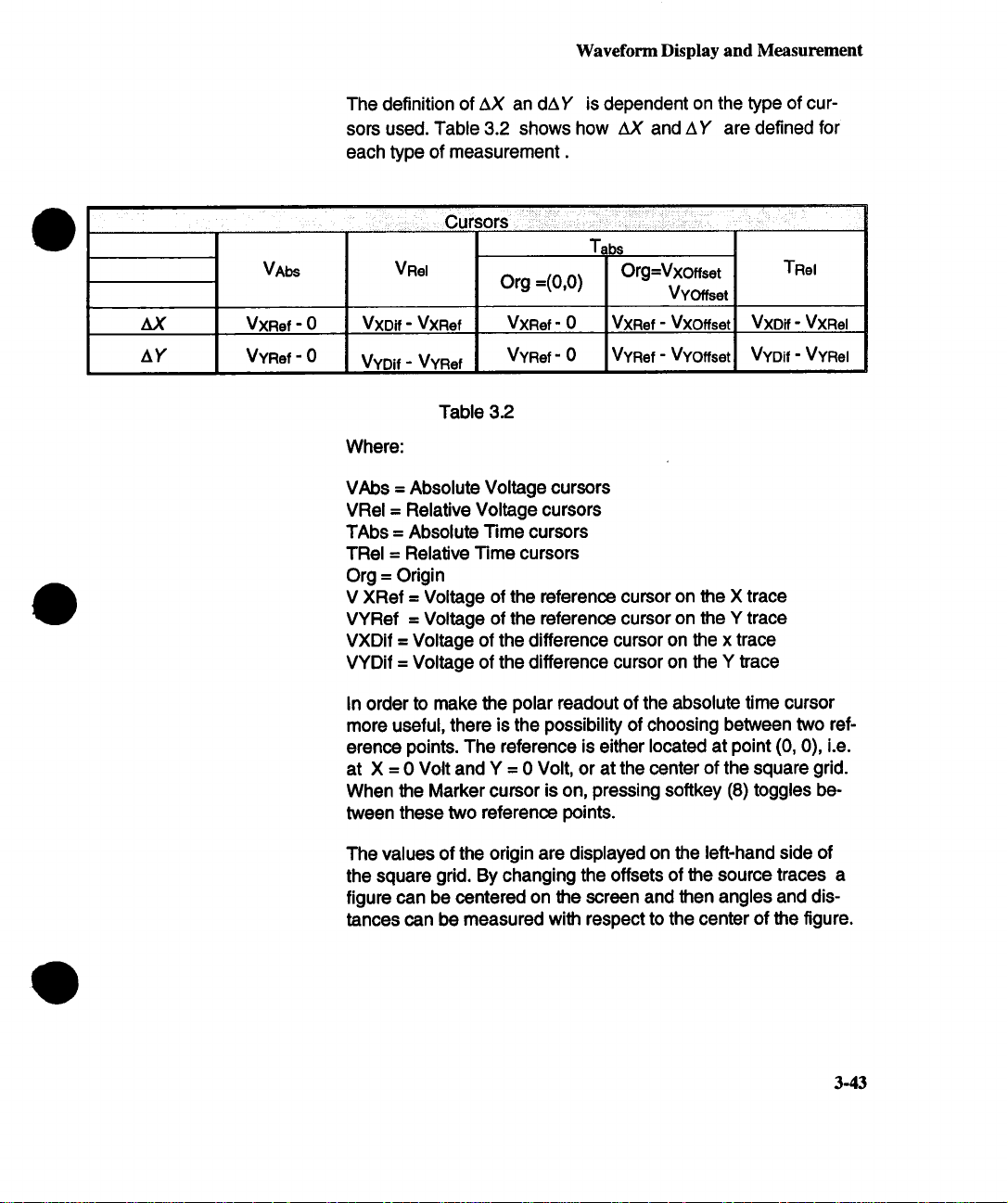

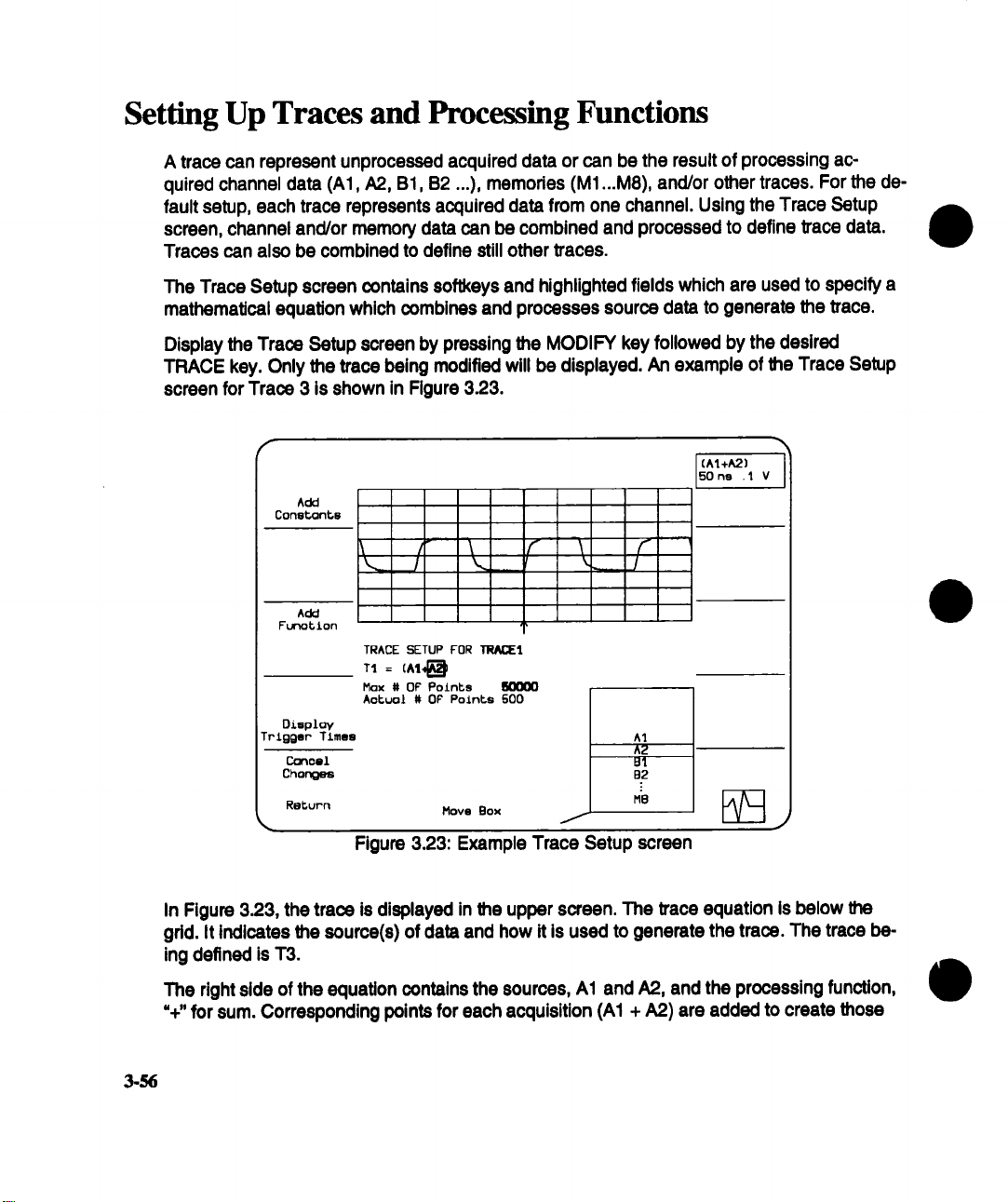

knob moves to the other segments. The displayed segment num-