Page 1

L

L

E

E

C

C

R

R

O

O

Y

Y

W

W

A

A

V

V

E

E

R

R

U

U

N

N

N

N

E

E

R

R

®

®

6600000

0

SSE

E

R

RII

E

ESS

O

O

SSC

CII

L

L

L

L

O

OSS

C

C

O

O

P

P

E

ESS

O

OPPEERRAATT

O

ORR’’SS

M

MAANNUUAALL

O

O

CCTTOOBBEERR

22000033

Page 2

LeCroy Corporation

700 Chestnut Ridge Road

Chestnut Ridge, NY 10977 –6499

Tel: (845) 578 6020, Fax: (845) 578 5985

Internet: www.lecroy.com

© 2003 by LeCroy Corporation. All right s reserved.

LeCroy, ActiveDSO, ProBus, SMART Trigger, JitterTrack, WavePro, and Waverunner are

registered trademarks of LeCroy Corporation. WaveMaster and X-Stream are trademarks of

LeCroy Corporation. Information in this publication supersedes all earlier versions. Specifications

subject to change without notice.

WR6K-OM-E Rev A

901769-00

Page 3

INTRODUCTION.................................................................................................14

HOW TO USE ON-LINE HELP....................................................................................................14

Type Styles ............................................................................................................................. 14

Instrument Help....................................................................................................................... 14

Windows Help ................................................................................................................................ 15

RETURNING A PRODUCT FOR SERVICE OR REPAIR ........................................................... 15

TECHNICAL SUPPORT................................................................................................................ 15

STAYING UP-TO-DATE................................................................................................................ 16

SPECIFICATIONS ........................................................................................................................ 17

Horizontal System .......................................................................................................................... 18

Acquisition System.........................................................................................................................19

Acquisition Modes ..........................................................................................................................19

Acquisition Processing ................................................................................................................... 20

Triggering System .......................................................................................................................... 20

Basic Triggers ................................................................................................................................20

SMART Triggers.............................................................................................................................20

SMART Triggers with Exclusion Technology.................................................................................. 21

Automatic Setup.............................................................................................................................21

Probes............................................................................................................................................21

Color Waveform Display.................................................................................................................21

Analog Persistence Display ...........................................................................................................22

Zoom Expansion Traces ................................................................................................................ 22

Rapid Signal Processing................................................................................................................22

Internal Waveform Memory............................................................................................................ 22

Setup Storage ................................................................................................................................22

Interface ......................................................................................................................................... 22

Auxiliary Input................................................................................................................................. 22

Auxiliary Output..............................................................................................................................23

Math Tools (standard).....................................................................................................................23

Measure Tools (standard) ..............................................................................................................24

Pass/Fail Testing ............................................................................................................................24

Master Analysis Package (XMAP) ................................................................................................. 24

Advanced Math Package (XMATH) ...............................................................................................25

Advanced Customization Package (XDEV)................................................................................... 25

Intermediate Math Package (XWAV) .............................................................................................25

Jitter and Timing Analysis Package (JTA2) .................................................................................... 26

Value Analysis Package (XVAP) ....................................................................................................26

Disk Drive Measurement Package (DDM2) ................................................................................... 27

General...........................................................................................................................................27

WR6K-OM-E Rev A ISSUED: October 2003 1

Page 4

Operator's Manual

Warranty and Service.....................................................................................................................28

Environmental Characteristics .......................................................................................................28

Temperature ...........................................................................................................................28

Humidity .................................................................................................................................. 28

Altitude ....................................................................................................................................28

Random Vibration ................................................................................................................... 28

Shock ......................................................................................................................................28

Certifications ........................................................................................................................29

CE Declaration of Conformity .................................................................................................29

Warning................................................................................................................................ 29

WARRANTY................................................................................................................................... 30

COPYRIGHT ..................................................................................................................................31

SAFETY REQUIREMENTS...........................................................................................................39

Safety Symbols and Terms..................................................................................................... 39

Operating Environment ..................................................................................................................40

Cooling Requirements....................................................................................................................41

AC Power Source........................................................................................................................... 41

Power and Ground Connections....................................................................................................41

On/Standby Switch.........................................................................................................................42

Calibration ......................................................................................................................................42

Cleaning .........................................................................................................................................42

Abnormal Conditions......................................................................................................................43

FRONT PANEL CONTROLS.........................................................................................................43

Front Panel Buttons and Knobs.............................................................................................. 43

Trigger Knobs: ........................................................................................................................45

Trigger Buttons: ......................................................................................................................45

Horizontal Knobs:.................................................................................................................... 45

Vertical Knobs:........................................................................................................................ 46

Channel Buttons: ....................................................................................................................46

Wavepilot Control Knobs: ......................................................................................................46

Special Features Buttons:......................................................................................................46

General Control Buttons: .......................................................................................................46

ON-SCREEN TOOLBARS, ICONS, AND DIALOG BOXES......................................................47

Dialog Boxes ..................................................................................................................................48

ALTERNATE ACCESS METHODS ...............................................................................................48

Mouse and Keyboard Operation............................................................................................. 48

Tool Bar Buttons ..................................................................................................................... 49

TRACE DESCRIPTORS................................................................................................................ 50

Trace Annotation ............................................................................................................................50

To Annotate a Waveform........................................................................................................ 51

To Turn On a Channel Trace Label ................................................................................................52

2 ISSUED: October 2003 WR6K-OM-E Rev A

Page 5

SCREEN LAYOUT.........................................................................................................................53

INSTALLATION..................................................................................................55

Hardware........................................................................................................................................ 55

External Monitor ............................................................................................................................. 55

WRITABLE CD DRIVE OPTION.......................................................................................... 56

Software .........................................................................................................................................59

Checking the Scope Status .................................................................................................... 59

DEFAULT SETTINGS ...................................................................................................................60

WaveMaster and WavePro 7000 Series DSOs...................................................................... 60

DDA, SDA, and WaveRunner DSOs..............................................................................................60

ADDING A NEW OPTION ........................................................................................................... 61

RESTORING SOFTWARE............................................................................................................ 62

Restarting the Application....................................................................................................... 62

Restarting the Operating System............................................................................................ 62

REMOVABLE HARD DRIVE ........................................................................................................ 62

EXTERNAL MONITOR ................................................................................................................. 64

CONNECTING TO A SIGNAL ............................................................................66

PROBUS INTERFACE...................................................................................................................66

AUXILIARY OUTPUT SIGNALS.................................................................................................. 67

To Set Up Auxiliary Output .............................................................................................................67

SAMPLING MODES ...........................................................................................68

SAMPLING MODES .....................................................................................................................68

To Select a Sampling Mode.................................................................................................... 68

SINGLE-SHOT SAMPLING MODE.............................................................................................68

Basic Capture Technique ....................................................................................................... 68

SEQUENCE SAMPLING MODE WORKING WITH SEGMENTS.............................................. 69

To Set Up Sequence Mode .................................................................................................... 70

Sequence Display Modes ....................................................................................................... 71

To Display Individual Segments .............................................................................................72

To View Time Stamps.............................................................................................................72

RIS SAMPLING MODE -- FOR HIGHER SAMPLE RATES ......................................................73

ROLL MODE.................................................................................................................................. 74

VERTICAL SETTINGS AND CHANNEL CONTROLS .......................................75

ADJUSTING SENSITIVITY AND POSITION ............................................................................75

To Adjust Sensitivity................................................................................................................ 75

To Adjust the Waveform's Position......................................................................................... 75

COUPLING ....................................................................................................................................75

Overload Protection ................................................................................................................ 75

To Set Coupling ...................................................................................................................... 76

PR OBE ATTENUATION ................................................................................................................76

WR6K-OM-E Rev A ISSUED: October 2003 3

Page 6

Operator's Manual

To Set Probe Attenuation ....................................................................................................... 76

BANDWIDTH LIMIT.....................................................................................................................76

To Set Bandwidth Limiting ......................................................................................................76

LINEAR AND (SINX)/X INTERPOLATION................................................................................77

To Set Up Interpolation........................................................................................................... 77

Inverting Waveforms............................................................................................................... 77

QUICKZOOM ................................................................................................................................77

To Turn On a Zoom ................................................................................................................77

FINDING SCALE ..........................................................................................................................77

To Use Find Scale ..................................................................................................................77

VARIABLE GAIN...........................................................................................................................77

To Enable Variable Gain.........................................................................................................78

CHANNEL DESKEW.....................................................................................................................78

To Set Up Channel Deskew ................................................................................................... 78

TIMEBASE AND ACQUISITION SYSTEM.........................................................79

TIMEBASE SETUP AND CONTROL ...........................................................................................79

DUAL CHANNEL ACQUISITION ................................................................................................79

Combining of Channels...........................................................................................................79

To Combine Channels ............................................................................................................79

AUTOSETUP..................................................................................................................................80

TRIGGERING .....................................................................................................81

TRIGGER SETUP CONSIDERATIONS....................................................................................... 81

Trigger Modes.........................................................................................................................81

Trigger Types..........................................................................................................................81

Determining Trigger Level, Slope, Source, and Coupling..............................................................82

Trigger Source................................................................................................................................83

Level...............................................................................................................................................83

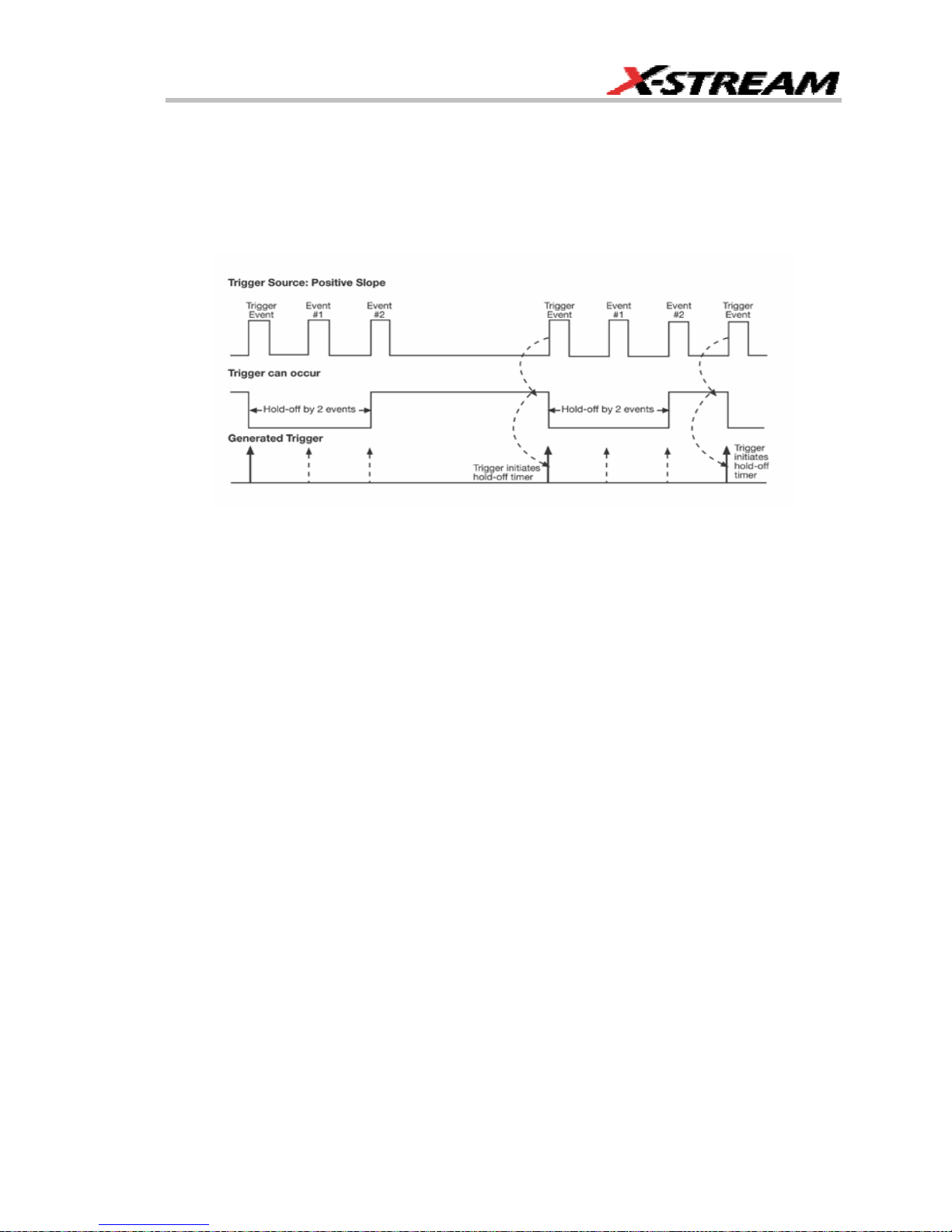

Holdoff by Time or Events ..............................................................................................................84

Hold Off by Time ..................................................................................................................... 84

Hold Off by Events .................................................................................................................. 85

SIMPLE TRIGGERS .....................................................................................................................85

Edge Trigger on Simple Signals ............................................................................................. 85

Control Edge Triggering.......................................................................................................... 85

To Set Up an Edge Trigger..................................................................................................... 86

SMART TRIGGERS ......................................................................................................................89

WIDTH TRIGGER........................................................................................................................ 89

GLITCH TRIGGER....................................................................................................................... 90

INTERVAL TRIGGER ................................................................................................................... 92

QUALIFIED TRIGGER .................................................................................................................. 96

STATE TRIGGER ........................................................................................................................ 99

DROPOUT TRIGGER................................................................................................................. 100

LOGIC TRIGGER ...................................................................................................................... 101

4 ISSUED: October 2003 WR6K-OM-E Rev A

Page 7

DISPLAY FORMATS........................................................................................104

DISPLAY SETUP.........................................................................................................................104

Sequence Mode Display....................................................................................................... 104

PERSISTENCE SETUP............................................................................................................... 105

Saturation Level.................................................................................................................... 105

3-Dimensional Persistence ................................................................................................... 106

Show Last Trace .......................................................................................................................... 107

Persistence Time..........................................................................................................................108

Locking of Traces.........................................................................................................................108

To Set Up Persistence..................................................................................................................108

SCREEN SAVER ......................................................................................................................... 109

MOVING TRACES FROM GRID TO GRID .............................................................................. 109

ZOOMING WAVEFORMS .......................................................................................................... 110

To Zoom a Single Channel ................................................................................................... 111

To Zoom by Touch-and-Drag ...............................................................................................111

To Zoom Multiple Waveforms Quickly.................................................................................. 112

Multi-Zoom ............................................................................................................................ 112

XY DISPLAY................................................................................................................................114

To Set Up XY Displays .........................................................................................................114

SAVE AND RECALL ........................................................................................115

SAVING AND RECALLING SCOPE SETTINGS ...................................................................... 115

To Save Scope Settings .......................................................................................................115

To Recall Scope Settings ..................................................................................................... 115

To Recall Default Settings .................................................................................................... 115

SAVING SCREEN IMAGES....................................................................................................... 116

SAVING AND RECALLING WAVEFORMS............................................................................... 116

Saving Waveforms................................................................................................................ 116

Recalling Waveforms............................................................................................................ 118

DISK UTILITIES ........................................................................................................................ 118

To Delete a Single File .........................................................................................................118

To Delete All Files in a Folder............................................................................................... 119

To Create a Folder................................................................................................................ 119

PRINTING AND FILE MANAGEMENT.............................................................120

PRINT, PLOT, OR COPY.............................................................................................................120

PRINTING ...................................................................................................................................120

To Set Up the Printer ............................................................................................................ 120

To Print .................................................................................................................................120

Adding Printers and Drivers.................................................................................................. 120

Changing the Default Printer ................................................................................................ 121

MANAGING FILES .....................................................................................................................121

Hard Disk Partitions .............................................................................................................. 121

WR6K-OM-E Rev A ISSUED: October 2003 5

Page 8

Operator's Manual

100BASE-T ETHERNET CONNECTION .........................................................122

CONNECTING TO A NETWORK...............................................................................................122

COMMUNICATING OVER THE NETWORK .............................................................................123

Windows Setups ................................................................................................................... 123

Windows Repair Disk............................................................................................................123

TRACK VIEWS.................................................................................................124

CREATING AND VIEWING A TREND......................................................................................124

CREATING A TRACK VIEW ......................................................................................................125

HISTOGRAMS..................................................................................................126

CREATING AND VIEWING A HISTOGRAM............................................................................126

To Set Up a Single Parameter Histogram ............................................................................126

To View Thumbnail Histograms............................................................................................ 127

Persistence Histogram..........................................................................................................127

Persistence Trace Range .....................................................................................................128

Persistence Sigma ................................................................................................................ 128

HISTOGRAM PARAMETERS ..................................................................................................... 128

HISTOGRAM THEORY OF OPERATION..................................................................................143

DSO Process ........................................................................................................................ 144

Parameter Buffer................................................................................................................... 145

Capture of Parameter Events ............................................................................................... 145

Histogram Parameters (XMAP and JTA2 Options) ...................................................................... 146

Histogram Peaks..........................................................................................................................147

Binning and Measurement Accuracy ........................................................................................... 147

WAVEFORM MEASUREMENTS .....................................................................149

MEASURING WITH CURSORS ................................................................................................ 149

Cursor Measurement Icons .................................................................................................. 149

CURSORS SETUP ...................................................................................................................... 149

Quick Display ........................................................................................................................ 149

Full Setup.............................................................................................................................. 150

OVERVIEW OF PARAMETERS..................................................................................................150

To Turn On Parameters........................................................................................................ 150

Quick Access to Parameter Setup Dialogs........................................................................... 150

Status Symbols ..................................................................................................................... 151

Using X-Stream Browser to Obtain Status Information ........................................................ 152

Statistics .......................................................................................................................................153

To Apply a Measure Mode............................................................................................................154

Measure Modes ...........................................................................................................................154

Standard Vertical Parameters............................................................................................... 154

Standard Horizontal Parameters ..........................................................................................155

My Measure .......................................................................................................................... 155

Parameter Math (XMATH or XMAP option required) ................................................................... 155

6 ISSUED: October 2003 WR6K-OM-E Rev A

Page 9

Logarithmic Parameters........................................................................................................ 155

Excluded Parameters ........................................................................................................... 156

Parameter Script Parameter Math........................................................................................ 156

Param Script vs. P Script...................................................................................................... 157

To Set Up Parameter Math................................................................................................... 158

To Set Up Parameter Script Math......................................................................................... 158

Measure Gate ..............................................................................................................................159

To Set Up Measure Gate...................................................................................................... 161

Help Markers................................................................................................................................162

To Set Up Help Markers .......................................................................................................163

To Turn Off Help Markers ..................................................................................................... 164

To Customize a Parameter...........................................................................................................164

From the Measure Dialog ..................................................................................................... 164

From a Vertical Setup Dialog................................................................................................ 164

From a Math Setup Dialog.................................................................................................... 165

PARAMETER CALCULATIONS ..................................................................................................166

Parameters and How They Work.......................................................................................... 166

Determining Time Parameters.............................................................................................. 168

Determining Differential Time Measurements ...................................................................... 169

Level and Slope .................................................................................................................... 169

LIST OF PARAMETERS .............................................................................................................170

WAVEFORM MATH..........................................................................................194

INTRODUCTION TO MATH TRACES AND FUNCTIONS ......................................................194

MATH MADE EASY.....................................................................................................................194

To Set Up a Math Function................................................................................................... 194

RESAMPLING TO DESKEW...................................................................................................... 195

To Resample......................................................................................................................... 195

RESCALING AND ASSIGNING UNITS ...................................................................................196

To Set Up Rescaling............................................................................................................. 196

AVERAGING WAVEFORMS.......................................................................................................196

Summed vs. Continuous Averaging .....................................................................................196

To Set Up Continuous Averaging ......................................................................................... 198

To Set Up Summed Averaging ............................................................................................. 198

ENHANCED RESOLUTION .......................................................................................................199

How the Instrument Enhances Resolution ........................................................................... 199

To Set Up Enhanced Resolution (ERES)..................................................................................... 201

WAVEFORM COPY .....................................................................................................................202

WAVEFORM SPARSER ..............................................................................................................202

To Set Up Waveform Sparser............................................................................................... 202

INTERPOLATION........................................................................................................................203

To Set Up Interpolation......................................................................................................... 203

FFT...............................................................................................................................................203

WHY USE FFT? ................................................................................................................... 203

WR6K-OM-E Rev A ISSUED: October 2003 7

Page 10

Operator's Manual

Improving Dynamic Range...........................................................................................................206

Record Length.............................................................................................................................. 207

FFT ALGORITHMS.............................................................................................................. 207

GLOSSARY .......................................................................................................................... 209

FFT SETUP........................................................................................................................... 212

ANALYSIS........................................................................................................214

PASS/FAIL TESTING.................................................................................................................214

COMPARING PARAMETERS ...................................................................................................... 214

MASK TESTS........................................................................................................................... 215

Actions .................................................................................................................................. 215

Setting Up Pass/Fail Testing ........................................................................................................216

Initial Setup ........................................................................................................................... 216

Comparing a Single Parameter ............................................................................................217

Comparing Dual Parameters ................................................................................................ 218

Mask Testing......................................................................................................................... 219

UTILITIES.........................................................................................................221

STATUS .......................................................................................................................................221

To Access Status Dialog....................................................................................................... 221

REMOTE COMMUNICATION..................................................................................................... 221

To Set Up Remote Communication. ..................................................................................... 221

To Configure the Remote Control Assistant Event Log........................................................222

HARDCOPY .................................................................................................................................222

PRINTING................................................................................................................................ 222

CLIPBOARD ............................................................................................................................. 222

FILE........................................................................................................................................ 222

E-MAIL ...................................................................................................................................223

AUX OUTPUT..............................................................................................................................224

DATE & TIME..............................................................................................................................224

To Set Time and Date Manually ........................................................................................... 224

To Set Time and Date from the Internet ............................................................................... 224

To Set Time and Date from Windows................................................................................... 224

OPTIONS.....................................................................................................................................225

PREFERENCES ...........................................................................................................................225

Audible Feedback ................................................................................................................. 225

Auto-calibration ..................................................................................................................... 226

Offset Control........................................................................................................................226

Delay Control ........................................................................................................................ 226

Performance Optimization ....................................................................................................226

E-mail.................................................................................................................................... 227

ACQUISITION STATUS.............................................................................................................227

SERVICE ..................................................................................................................................... 228

SHOW WINDOWS DESKTOP...................................................................................................228

8 ISSUED: October 2003 WR6K-OM-E Rev A

Page 11

TOUCH SCREEN CALIBRATION .............................................................................................. 228

CUSTOMIZATION ............................................................................................229

CUSTOMIZING YOUR INSTRUMENT .....................................................................................229

Introduction ........................................................................................................................... 229

Solutions ............................................................................................................................... 229

Examples .............................................................................................................................. 230

What is Excel? ...................................................................................................................... 235

What is Mathcad? ................................................................................................................. 235

What is MATLAB?................................................................................................................. 235

What is VBS?........................................................................................................................235

What can you do with a customized instrument? ................................................................. 237

CALLING EXCEL FROM YOUR INSTRUMENT........................................................................238

Calling Excel Directly from the Instrument............................................................................ 238

How to Select a Math Function Call.............................................................................................239

How to Select a Parameter Function Call .................................................................................... 239

The Excel Control Dialog .............................................................................................................239

Entering a File Name ...................................................................................................................239

Organizing Excel sheets ..............................................................................................................241

Setting the Vertical Scale.............................................................................................................242

Trace Descriptors.........................................................................................................................242

Multiple Inputs and Outputs .........................................................................................................243

Simple Excel Example 1 ....................................................................................................... 243

Simple Excel Example 2 ....................................................................................................... 247

Examples of Excel Parameter Functions ..................................................................................... 250

Examples of Excel Waveform Functions......................................................................................251

Exponential Decay Time Constant Excel Parameter (Excel Example 1).....................................251

Gated Parameter Using Excel (Excel Example 2) .......................................................................253

How Does this Work? ...........................................................................................................254

Correlation Excel Waveform Function (Excel Example 3) ........................................................... 255

Multiple Traces on One Grid (Excel Example 4).......................................................................... 257

Using a Surface Plot (Excel Example 5) ...................................................................................... 260

WRITING VB SCRIPTS ............................................................................................................. 262

Types of Scripts in VBS ........................................................................................................262

Loading and Saving VBScripts ............................................................................................. 262

The default parameter function script: explanatory notes .................................................... 266

Scripting with VBScript .........................................................................................................267

Variable Types...................................................................................................................... 268

Variable Names ............................................................................................................................ 268

Arithmetic Operators ....................................................................................................................270

VBS Controls................................................................................................................................ 272

IF . . . Then . . . Else . . . End If ............................................................................................. 272

Summary of If . . . . Then . . . . Else ...................................................................................... 274

Select Case........................................................................................................................... 275

WR6K-OM-E Rev A ISSUED: October 2003 9

Page 12

Operator's Manual

Summary of Select Case . . . . End Select ........................................................................... 276

Do . . . Loop ..........................................................................................................................276

While . . . Wend..................................................................................................................... 277

For . . . Next .......................................................................................................................... 277

VBS keywords and functions .......................................................................................................278

Other VBS Words .................................................................................................................280

Functions......................................................................................................................................280

Hints and Tips for VBScripting .....................................................................................................281

ERRORS......................................................................................................................................283

Error Handling ..............................................................................................................................285

Speed of Execution ...................................................................................................................... 285

Scripting Ideas..............................................................................................................................286

Example Waveform Script............................................................................................................286

Example Parameter Scripts .........................................................................................................287

Debugging Scripts........................................................................................................................287

Horizontal Control Variables.........................................................................................................287

Vertical Control Variables .............................................................................................................288

List of Variables Available to Scripts ............................................................................................288

Communicating with Excel from a VBScript................................................................................. 290

CALLING MATLAB FROM THE INSTRUMENT........................................................................291

Calling MATLAB.................................................................................................................... 291

How to Select a Waveform Function Call.....................................................................................292

The MATLAB Waveform Control Panel........................................................................................293

MATLAB Waveform Function Editor -- Example..........................................................................293

MATLAB Example Waveform Plot................................................................................................297

How to Select a MATLAB Parameter Call.................................................................................... 298

The MATLAB Parameter Control Panel .......................................................................................299

The MATLAB Parameter Editor....................................................................................................300

MATLAB Example Parameter Panel ............................................................................................ 301

Further Examples of MATLAB Waveform Functions....................................................................303

Creating your own MATLAB function ...........................................................................................306

CUSTOMDSO...................................................................................................307

CUSTOM DSO ............................................................................................................................307

Introduction – What is CustomDSO?.................................................................................... 307

Invoking CustomDSO ...........................................................................................................307

CustomDSO Basic Mode...................................................................................................... 308

Editing a CustomDSO Setup File .........................................................................................308

Creating a CustomDSO Setup File....................................................................................... 310

CustomDSO PlugIn Mode ....................................................................................................310

Creating a CustomDSO PlugIn............................................................................................. 310

Properties of the Control and its Objects.............................................................................. 312

Removing a PlugIn................................................................................................................ 316

First Example PlugIn – Exchanging Two Traces on the Grids ............................................. 316

10 ISSUED: October 2003 WR6K-OM-E Rev A

Page 13

Second Example PlugIn – Log-Log FFT Plot ....................................................................... 319

Control Variables in CustomDSO ......................................................................................... 322

JTA2 OPTION...................................................................................................323

ACCESSING JTA2...................................................................................................................... 323

TIMING FUNCTIONS.................................................................................................................323

TIMING PARAMETERS.............................................................................................................. 324

Statistical Tools..................................................................................................................... 324

HOW JITTERTRACK WORKS ................................................................................................... 324

Using “Clock” or “Data” .........................................................................................................324

WHEN TO USE JITTERTRACK .................................................................................................327

JitterTrack or Trend? ............................................................................................................ 327

CLOCK OR DATA?...................................................................................................................... 329

SETTING UP JITTER MEASUREMENTS ..................................................................................331

Jitter Math Setup................................................................................................................... 331

Jitter Parameters Setup ........................................................................................................331

WHEN TO USE PERSISTENCE HISTOGRAMS......................................................................331

SETTING UP PERSISTENCE HISTOGRAMS .......................................................................... 332

Selecting the Math Function ................................................................................................. 332

Setting Up the Histogram...................................................................................................... 333

HOW TO TRACE PERSISTENCE.............................................................................................. 334

An Innovative Visual and Processing Tool ...........................................................................334

To Set Up Trace Persistence........................................................................................................335

CHOOSING A TIMING PARAMETER....................................................................................... 337

HOW TO USE THE TREND TOOL............................................................................................ 337

The Basic Idea ...................................................................................................................... 337

To Set Up and Configure Trend............................................................................................ 338

Math Setup............................................................................................................................ 341

HISTOGRAM AND TREND CALCULATION............................................................................. 341

Acquisition Sequence ........................................................................................................... 341

Parameter Buffer................................................................................................................... 342

Parameter Events Capture ................................................................................................... 342

Zoom Traces and Segmented Waveforms...................................................................................343

Histogram Peaks................................................................................................................... 343

Example ................................................................................................................................ 343

Binning and Measurement Accuracy.................................................................................... 344

DFP2 OPTION ..................................................................................................347

INTRODUCTION ........................................................................................................................ 347

The Need .............................................................................................................................. 347

The Solution..........................................................................................................................347

Enhanced Solutions .....................................................................................................................348

KINDS OF FILTERS..................................................................................................................... 349

Communications Channel Filters ................................................................................................. 351

WR6K-OM-E Rev A ISSUED: October 2003 11

Page 14

Operator's Manual

IIR Filters ......................................................................................................................................353

FILTER SETUP............................................................................................................................354

To Set Up a DFP Filter.......................................................................................................... 354

MULTIRATE FILTERS .................................................................................................................355

Description ............................................................................................................................ 355

CUSTOM FILTERS......................................................................................................................356

Custom Filter Setup .............................................................................................................. 356

Example 1: Creating an FIR Filter Coefficient File Using Mathcad ......................................356

Example 2: Creating an IIR Filter Coefficient File Using Mathcad ....................................... 358

SPECIFICATIONS ...................................................................................................................... 359

PMA2 OPTION .................................................................................................360

INTRODUCTION TO PMA2....................................................................................................... 360

The Tools and What They Do............................................................................................... 360

Equipment Required ............................................................................................................. 360

DESKEWING VOLTAGE AND CURRENT.................................................................................361

Matching the Time Delay in Your Measurement System .....................................................361

Initial Setup ........................................................................................................................... 363

Clearing the Deskew Setup .................................................................................................. 367

USING POWER DEVICE ANALYSIS ........................................................................................ 368

Setup and Configuration for Power Device Analysis ............................................................ 368

Initial Setup (Optional Event Trigger).................................................................................... 369

Initial Setup (Main Trigger) ...................................................................................................370

Setup for Power Device Analysis.......................................................................................... 371

Power Device Analysis Measurements ................................................................................373

Saturation Voltage and Dynamic On-resistance Measurement ...........................................377

Fine DC Level Adjustment ....................................................................................................379

Effects of Probe Compensation on Saturation Voltage Measurements.......................................379

Example: ............................................................................................................................... 380

Clearing the Power Device Analysis Setup .................................................................................. 382

Measuring Device dv/dt................................................................................................................382

To Access dv/dt ....................................................................................................................383

USING MODULATION ANALYSIS............................................................................................384

How Modulation Analysis Works ..........................................................................................384

The Modulation Analysis Display .................................................................................................387

Configuration for Modulation Analysis..........................................................................................387

Setup for Modulation Analysis Measurements.............................................................................388

Modulated Signal and Trigger Setup .................................................................................... 388

Trigger Setup – The Event Trigger ....................................................................................... 389

Initial Setup – The Modulated Signal.................................................................................... 390

Finishing the Setup and Making Modulation Measurements................................................ 390

Activating the Modulation Analysis Menu ............................................................................. 390

Modulation Analysis Controls .......................................................................................................391

Optimizing the Display .................................................................................................................392

12 ISSUED: October 2003 WR6K-OM-E Rev A

Page 15

Clearing the Modulation Analysis Setup ......................................................................................392

USING LINE POWER ANALYSIS ............................................................................................. 393

Line Power Analysis Overview .............................................................................................393

EN 61000-3-2, Harmonic Current Emissions .......................................................................393

Configuration for Line Power Analysis ......................................................................................... 394

Setting Up the Line Voltage and Current Signals.........................................................................396

Activating the Line Power Analysis Menu............................................................................. 397

Line Harmonics Measurement .....................................................................................................398

USING NON-PROBUS PROBES...............................................................................................401

PMA2 Dialog Overview......................................................................................................... 401

Current Input Setup Menus................................................................................................... 402

Voltage Input Setup Menus ..................................................................................................403

PROCESSING WEB.........................................................................................404

PROCESSING WEB ................................................................................................................... 404

To Use the Web Editor ......................................................................................................... 404

WR6K-OM-E Rev A ISSUED: October 2003 13

Page 16

Operator's Manual

INTRODUCTION

HOW TO USE ON-LINE HELP

Type Styles

Activators of pop-up text and images appear as green, underlined, italic: Pop-up

text and images after opening them, touch the pop-up text again.

Links jump you to other topics, URLs, or images. They take you out of the current Help screen.

Link text appears blue and underlined: Link

icon in the toolbar at the top of the Help window to return to the Help screen you just left. With

each touch of the Back icon, you return to the preceding Help screen.

Instrument Help

When you press the front panel Help button

button

found for you automatically or to search for information yourself.

If you want context-sensitive Help, that is, Help related to what was displayed on the screen when

you requested Help, touch

control (or front panel button or knob) that you need information about. The instrument will

automatically display Help about that control.

If you want information about something not displayed on the screen, touch one of the buttons

inside the drop-down menu to display the on-line Help manual:

, you will be presented with a menu: you can choose either to have information

. After making a jump, you can touch the Back

(if available), or touch the on-screen Help

in the drop-down menu, then touch the on-screen

. To close pop-up

Contents displays the Table of Contents.

Index displays an alphabetical listing of keywords.

Search locates every occurrence of the keyword that you enter.

www.LeCroy.com connects you to LeCroy's Web site where you can

find Lab Briefs, Application Notes, and other useful information. This

feature requires that the instrument be connected to the internet through

14 ISSUED: October 2003 WR6K-OM-E Rev A

Page 17

the Ethernet port on the scope's rear panel. Refer to Remote

Communication for setup instructions.

About opens the Utilities "Status" dialog, which shows software version

and other system information.

Once opened, the Help window will display its navigation pane: the part of the window that shows

the Table of Contents and Index. When you touch anywhere outside of the Help window, this

navigation pane will disappear to reveal more of your signal. To make it return, touch the Show

icon at the top of the Help window or touch inside the Help information pane.

Windows Help

In addition to instrument Help, you can also access on-line Help for Microsoft® Windows®. This

help is accessible by minimizing the scope application, then touching the Start button in the

Windows task bar at the bottom of the screen and selecting Help.

RETURNING A PRODUCT FOR SERVICE OR REPAIR

If you need to return a LeCroy product, identify it by its model and serial numbers. Describe the

defect or failure, and give us your name and telephone number.

For factory returns, use a Return Authorization Number (RAN), which you can get from customer

service. Write the number clearly on the outside of the shipping carton.

Return products requiring only maintenance to your local customer service center.

If you need to return your scope for any reason, use the original shipping carton. If this is not

possible, be sure to use a rigid carton. The scope should be packed so that it is surrounded by a

minimum of four inches (10 cm) of shock absorbent material.

Within the warranty period, transportation charges to the factory will be your responsibility.

Products under warranty will be returned to you with transport prepaid by LeCroy. Outside the

warranty period, you will have to provide us with a purchase order number before the work can be

done. You will be billed for parts and labor related to the repair work, as well as for shipping.

You should prepay return shipments. LeCroy cannot accept COD (Cash On Delivery) or Collect

Return shipments. We recommend using air freight.

TECHNICAL SUPPORT

You can get assistance with installation, calibration, and a full range of software applications from

your customer service center. Visit the LeCroy Web site at http://www.lecroy.com for the center

nearest you.

WR6K-OM-E Rev A ISSUED: October 2003 15

Page 18

Operator's Manual

STAYING UP-TO-DATE

To maintain your instrument’s performance within specifications, have us calibrate it at least once

a year. LeCroy offers state-of-the-art performance by continually refining and improving the

instrument’s capabilities and operation. We frequently update both firmware and software during

service, free of charge during warranty.

You can also install new purchased software options in your scope yourself, without having to

return it to the factory. Simply provide us with your instrument serial number and ID, and the

version number of instrument software installed. We will provide you with a unique option key that

consists of a code to be entered through the Utilities' Options dialog to load the software option.

16 ISSUED: October 2003 WR6K-OM-E Rev A

Page 19

SPECIFICATIONS

Note: Specifications are subject to change without notice.

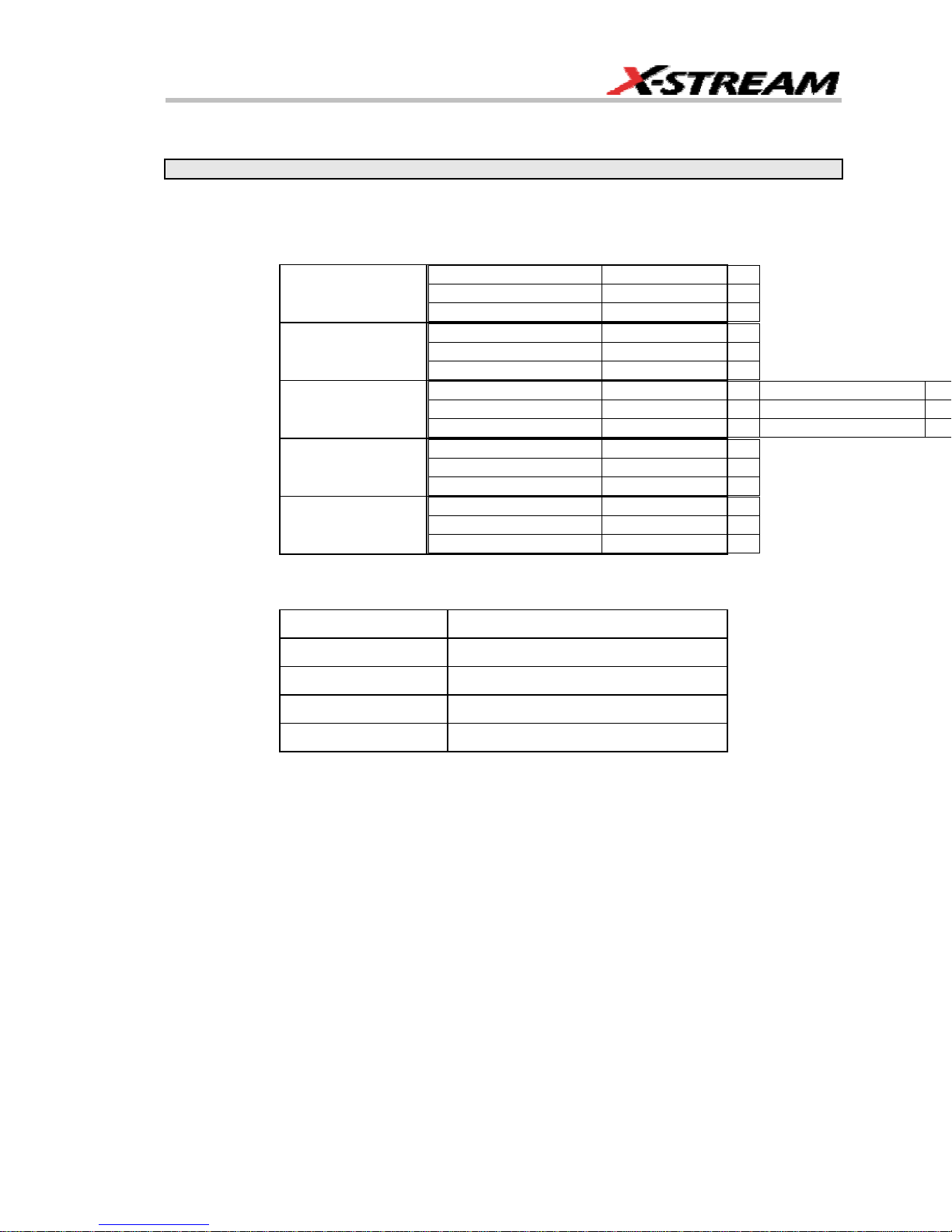

Vertical System

Bandwidth @ 50 ohms (-3 dB):

10 mV/div to 1 V/div 350 MHz

WaveRunner 6030

WaveRunner 6050

WaveRunner 6051

WaveRunner 6100

WaveRunner 6200

Input Channels: 4 (model 6051: 2)

5 mV/div to 9.95 m/div 350 MHz

2 mV/div to 4.99 m/div 300 MHz

10 mV/div to 1 V/div 500 MHz

5 mV/div to 9.95 m/div 500 MHz

2 mV/div to 4.99 m/div 350 MHz

10 mV/div to 1 V/div 500 MHz

5 mV/div to 9.95 m/div 500 MHz

2 mV/div to 4.99 m/div 350 MHz

10 mV/div to 1 V/div 1 GHz

5 mV/div to 9.95 m/div 800 MHz

2 mV/div to 4.99 m/div 350 MHz

10 mV/div to 1 V/div 2 GHz

5 mV/div to 9.95 m/div 1 GHz

2 mV/div to 4.99 m/div 350 MHz

Rise Time (typical):

WaveRunner 6030 1 ns

WaveRunner 6050 750 ps

WaveRunner 6051 750 ps

WaveRunner 6100 400 ps

WaveRunner 6200 225 ps

Bandwidth Limiters:

• Full

• 200 MHz

• 20 MHz

Input Impedance: 1 Mohms // < 20 pF (10 // 9.5 pF using PP007 probe)

WR6K-OM-E Rev A ISSUED: October 2003 17

Page 20

Operator's Manual

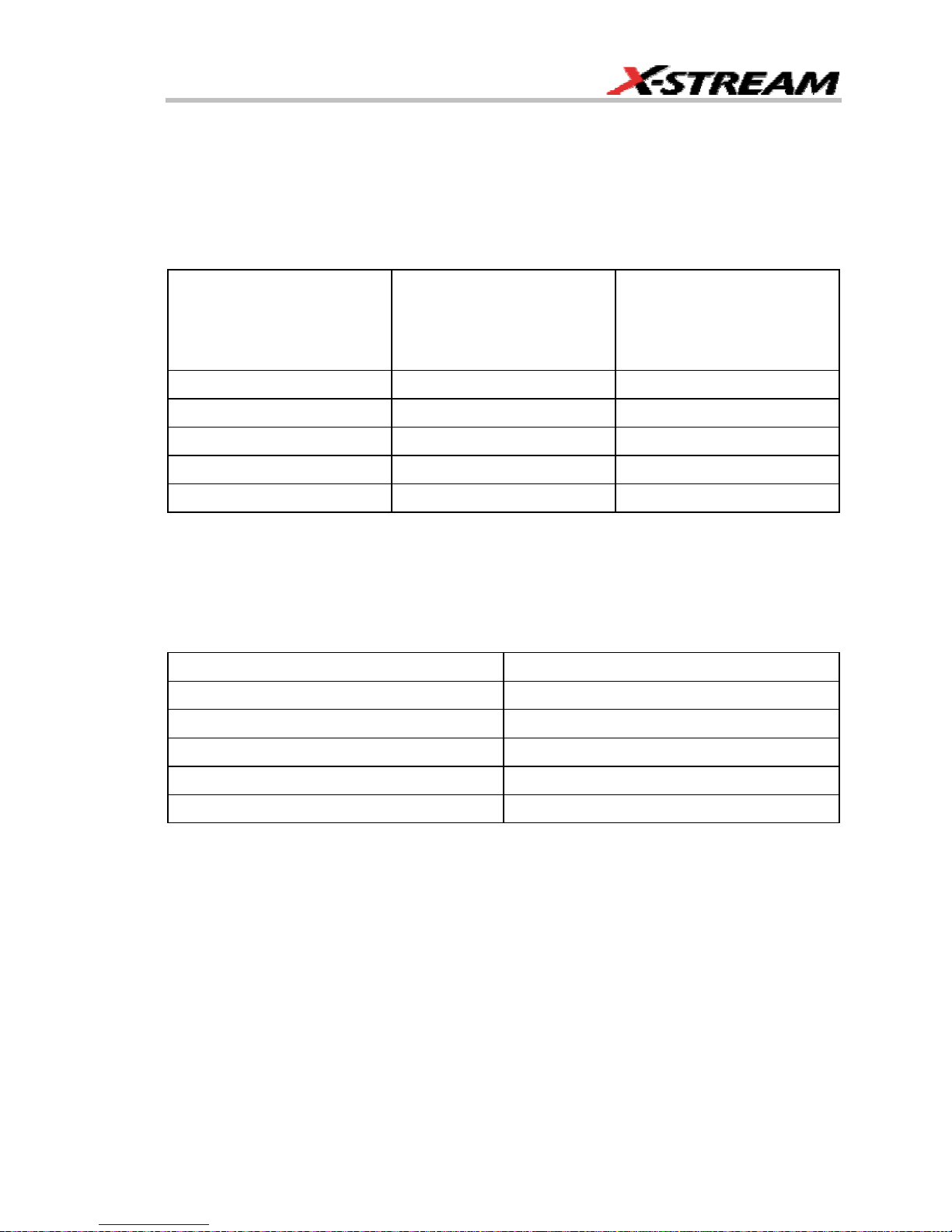

Input Coupling: 50 ohms: DC; 1 Mohms: AC, DC, GND

Max Input Voltage: 50 ohms: 5 V

Installation (Overvoltage) Category: CAT I

Channel to Channel Isolation: > 40 dB @ < 100 MHz (> 30 dB @ full bandwidth)

Vertical Resolution: 8 bits; up to 11 bits with enhanced resolution (ERES)

Sensitivity: 50 ohms: 2 mV to 1 V/div fully variable; 1 Mohms: 2 mV to 10 V/div fully variable

DC Gain Accuracy: ±1.5% of full scale

Offset Range:

50 ohms ±400 mV @ 2.0 to 4.99 mV/div

1 Mohms ±500 mV @ 2.0 to 4.99 mV/div

Offset Accuracy: ±(1.5% of full scale value + 0.5% of offset value + 1 mV)

Probing System: BNC or ProBus

; 1 Mohms: 250 V

rms

±1.0 V @ 5 to 99 mV/div

±10 V @ 0.100 to 1 V/div

±1.0 V @ 5 to 99 mV/div

±10 V @ 0.100 to 1 V/div

±100 V @ 1 to 10 V/div

(Peak AC: ≤ 10 kHz + DC)

max

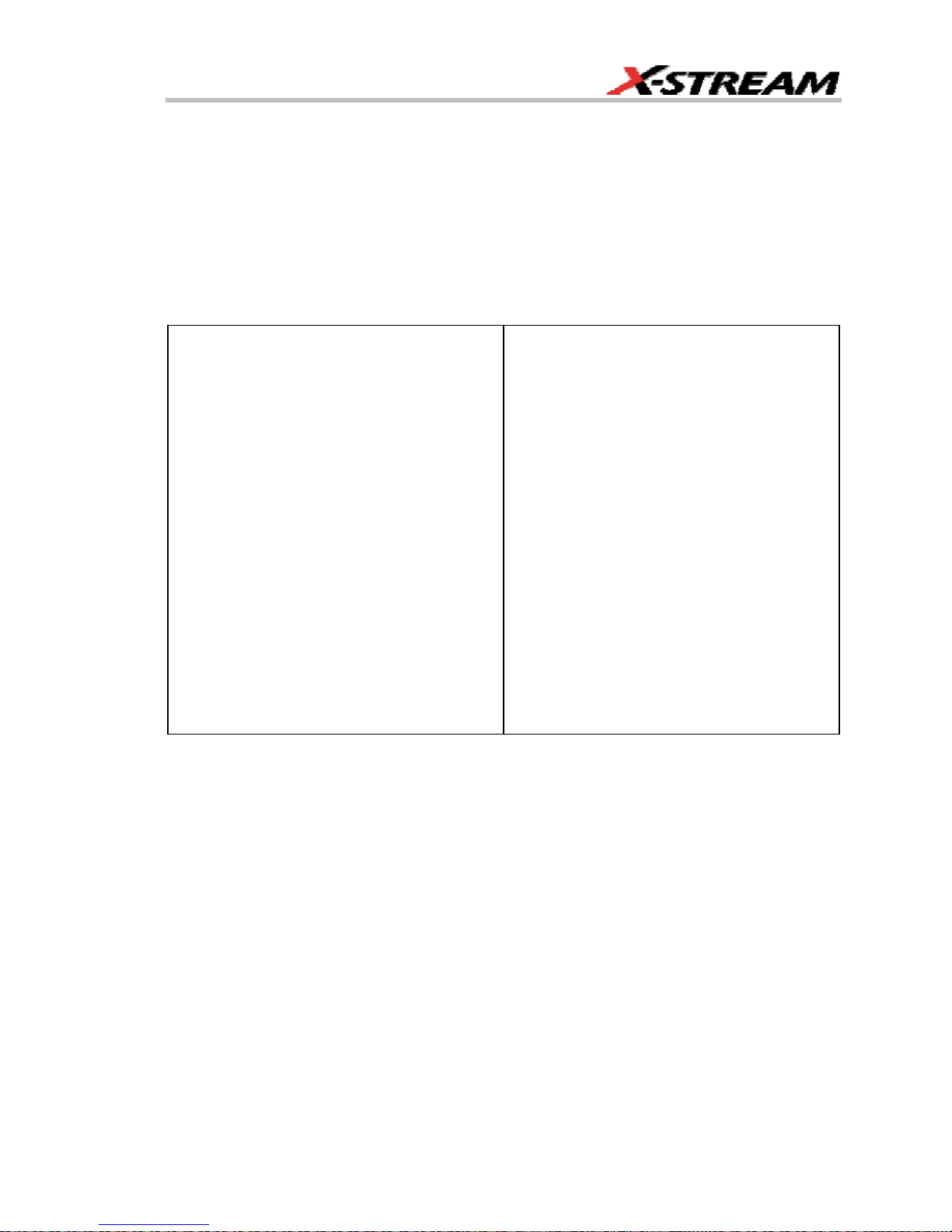

Horizontal System

Timebases: Internal timebase common to all input channels; an external clock can be applied at

the auxiliary input