Page 1

Operating In struc tions

freezers

CU 357

CU 357S

Page 2

2

GB/IE

The freezer was developed taking the different storage requirements of food items

into consideration. The freezer is equipped with freezing drawers in various sizes

giving room to all the little things as well as a big turkey.

To ensure that you get as much joy out of your freezer as possible, it is important

that you become familiar with the freezer functions and know how to use the accessories. Please read the instructions for use carefully before setting up and using

your freezer.

As these instructions apply to several freezer models, the equipment may vary from

model to model.

Before using the freezer

On receipt, check to ensure that the freezer has not become damaged in transport.

Transport damage should be reported to the local supplier before the freezer is put

to use.

Before lling the freezer with items of food, the freezer interior should be cleaned

with lukewarm water containing a mild detergent. Use a soft cloth. If the freezer has

been stored in cold surroundings (colder than +5°C), it must be allowed to stabilise

for at least 2 hours before being switched on.

Read more about setting up, building in, and installation on pages 12 and 13.

Page 3

3

GB/IE

Contents

Important information

Transporting and moving the freezer 4

If the freezer is to remain unused for a time 4

Old refrigerators/freezers 4

Disposal 4

Product description 5

Using the freezer 6

Using the freezer and accessories 7

Defrosting and cleaning

Manual defrosting 8

Cleaning 8

Setting up and installation

Where to place the freezer 9

Electrical connection 10

Mainstenace and Service 11

Changing the door hinging 12

Spare parts 13

Page 4

4

The freezer contains the environment-friendly, non-ozone-depleting refrigerant

R600a. As R600 is a ammable gas, it is important to avoid damage to the refrigerating circuit during transport and installation. If the refrigeration circuit is damaged,

avoid using a naked ame in the vicinity of the freezer and connecting power to

the cabinet. Also make sure that there is good ventilation in the room. If you are in

doubt, please con¬tact your supplier.

Transporting and moving the freezer

The freezer must always be moved in the vertical position. The freezer must not be

tilted more than approx. 40°. If the freezer has been tilted more than 40°, the power

supply must not be con¬nected until the appliance has stood upright for at least two

hours.

If the freezer is to remain unused for a time

If the freezer is to remain unused for a period of time, e.g. during refurbishment

work, switch it off by pressing the switch O (1) and disconnecting the power

supply to the cabinet and possibly pulling the plug out of the wall socket.

Empty, defrost and clean the freezer. Leave the freezer door slightly ajar. This will

prevent bad smells in the cabinet.

Warning

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Old refrigerators and freezers are often tted with complicated latches that can only

be opened from the outside. If you have an old unit like this stored away somewhere, or if you scrap it, remember to destroy the latch to prevent chil¬dren from

being exposed to danger by getting locked inside the unit.

Note! Please also observe the environ¬mental rules on disposal.

Disposal

If a freezer is to be disposed of, this must be done in an environmentally correct

way, in accordance with current rules on disposal.

Please observe the environmental rules on disposal. There might be special requirements/conditions to be observed.

Information on disposal can be obtained from:

- Your supplier

- Authorities (the local council, Ministry of the Environment, etc.)

GB/IE

Important information

Page 5

5

GB/IE

Product description

The freezer is intended for use in a working kitchen environment. It is designed for

temperature class SN in accordance with European standard EN 153. The appliance

is equivalent to a four-star freezer approved for freezing down and storing frozen items

of food. a room temperature of +10°C to +32°C.

Please nd on the product nameplate the interval of ambient temperature for which

this product is designed to have the best performances

Class Symbol Ambient Temperature

Range °C

Extended

Temperate SN + 100C to + 320C

Temperate N + 160C to + 320C

Subtropical ST +180C to + 380C

Page 6

6

GB/IE

Using the freezer

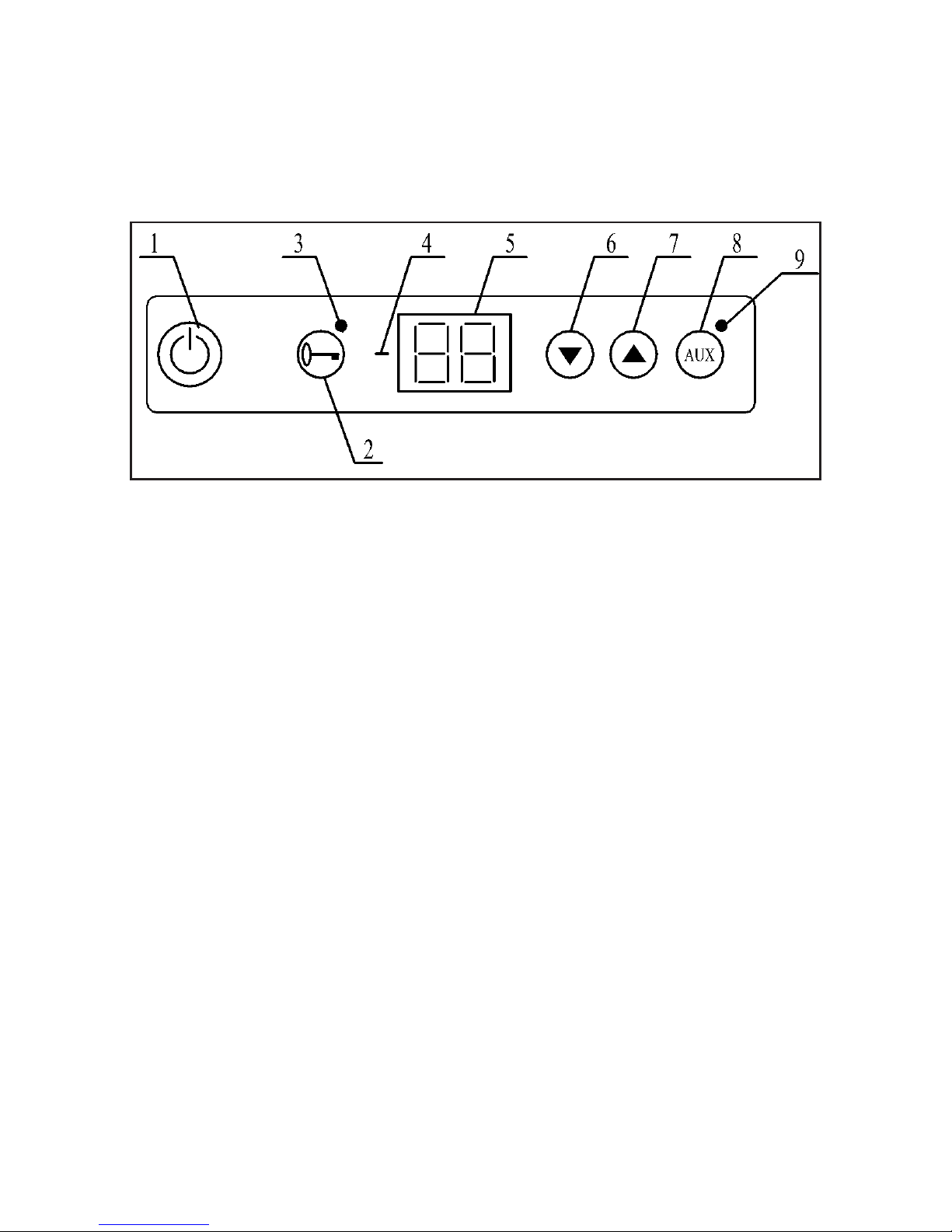

4

1. User interface

1.1 Button (1) ‘ I ’ (ON /OFF) – pressed for about 2-3sec – switches on and switches

off whole product's controlling,

1.2 Button (2) ‘lock’ – pressed for about 2-3sec – blocks the keypad – does not refer

to button (1) driver switch off,

1.3 Green LED diode (3) – indicates active blockade function,

1.4 ‘-‘ minus diode (4) – indication of temperatures below zero,

1.5 LED display (5) –temperatures, service parameters and alarm symbols display,

1.6 Button (6) ‘▼’ - minimum temperature preview or parameter value decrease,

1.7 Button (7) ‘▲’ – maximum temperature preview or parameter value increase,

1.8 Button (8) AUX – functional button,

1.9 Green LED diode (9) – indication of temperature programming mode – manual

switch of AUX output.

2. First start up

After switching on, the driver activates the auto-test procedure. During the rst second, it displays dots, program version during next second, dots during the third

second and then switches to normal work mode.

During normal work mode, the display shows cooler temperature. In case of an alarm,

it displays E with alarm number.

If the driver is switched off, LED diodes are turned off and the display shows two

horizontal lines.

The display indicates temperature of the cooler-freezer within the range of –30oC to

+30oC.

3. SET UP

3.1 Temperatures programming (set range : from -18’C to -25’C) :

- short pressing of (8) AUX button – entering/leaving set temperature programming

Page 7

7

GB/IE

mode. Buttons (6)‘▼’ and (7)‘▲’ are used to adjust settings. Diode (9) blinking indicates active function of set temperature programming; if button (6)‘▼’ or (7)‘▲’ is not

pressed, after 10 seconds since the last pressing of (6)‘▼’ or (7)‘▲’ the driver will

leave the described mode.

3.2 Deleting recorded exceedance (MIN / MAX) :

- pressing buttons (6)‘▼’ and (7)‘▲’ for about 2-3sec results in deleting saved min/

max temperatures and saving current temperature in the driver’s memory.

4. Alarms

A displayed alarm should be saved even if the reason of the alarm does not exist

anymore. Alarms are not saved after switch off (lack) of energy.

E1 – cooler sensor malfunction – if the reason of the alarm still exists, it can not be

deleted,

Hi – maximum set temperature of the product

Lo – minimum set temperature of the product exceeded

Pressing a random button deletes the sound signal as well as Hi and Lo indications.

E1 deletion by means of turning off the on/off driver after prior elimination of a malfunction.

Using the freezer and accessories

The whole of the freezer can be used for freezing down and for the long-term storage

of frozen items of food. In addition, the freezer comes equipped with a freezing tray

for berries, etc.

Page 8

8

GB/IE

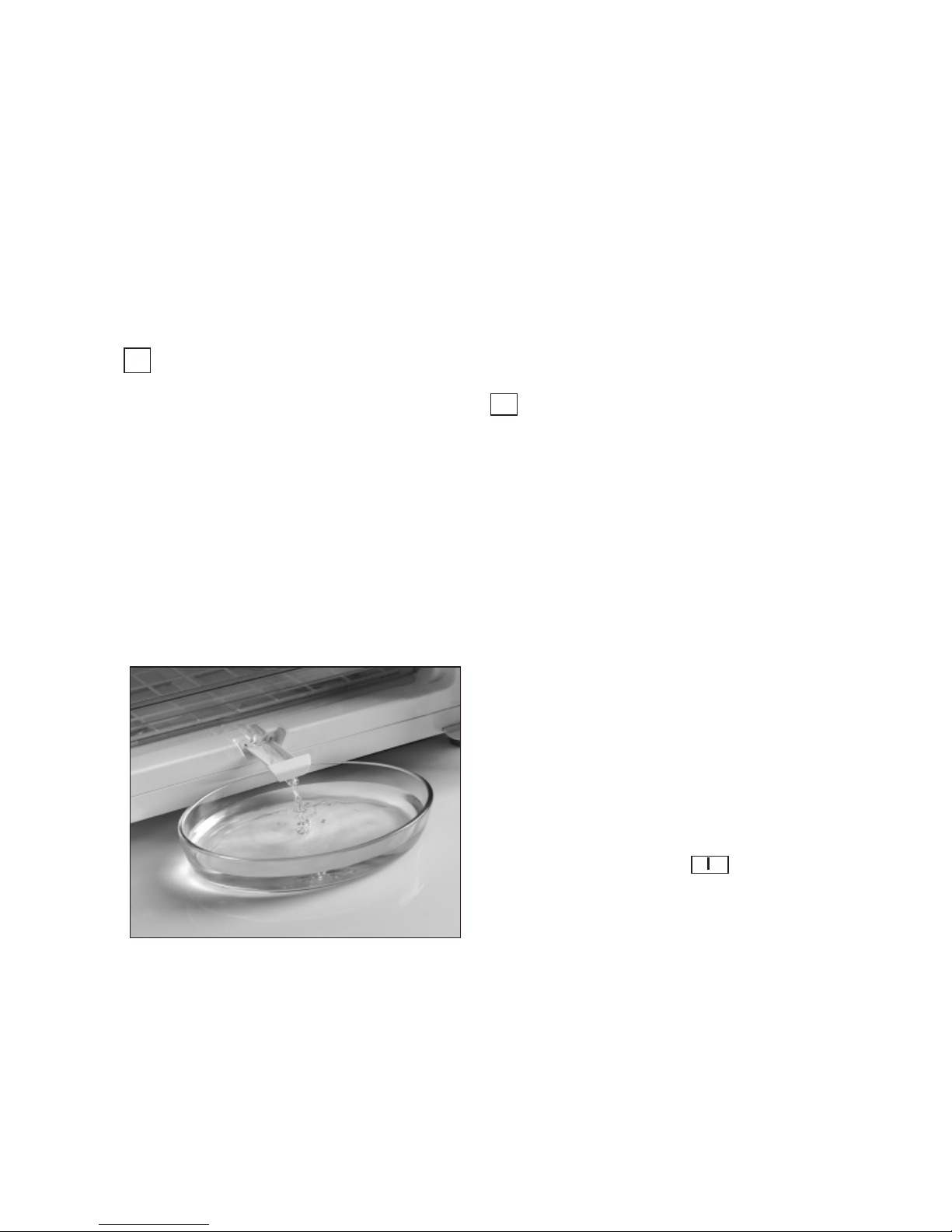

Manual defrosting

It is recommended to defrost the freezer

at least once a year.

Stop the compressor by pressing button

O (1) and disconnecting the power supply

to the freezer.

Remove all items from the freezer. To

keep them as cold as possible during defrost, they can be placed in the

re¬frigerator. Place a bowl containing hot

water (not boiling) in the freezer.

Pull out the drain spout (10) and place

a bowl under it to receive defrost water.

When the ice has melted, clean out the

freezer using water and a mild washing-up

liquid. Dry the freezer with a soft cloth.

Warning

10

Defrosting and cleaning

It is dangerous to use electrical apparatus, knives or sharp objects to accelerate

defrost.

Cleaning

Stop the compressor by pressing button

O (1) and disconnecting the power sup-

ply to the freezer.

The freezer is best cleaned using a weak

soap solution and a soft cloth. Never use

cleaning agents that scour. Clean the

sealing strip around the door regularly

to prolong its life. Use only clean water

for cleaning the sealing strip. The plastic

parts of the cabinet cannot withstand

boiling water (max. 85°C). It is important

to prevent water from getting into the

control panel.

Remove dust and threads from the

compressor compartment at the back of

the freezer with a vacuum cleaner. Connect the current and restart the freezer

by pressing start button (1).

Cleaning of doors in stainless steel or aluminium

Stainless steel or aluminium doors on Lec products can, with advantage, be

cleaned with a spray and a soft cloth. There are a number of different spraying

agents for this purpose on the market.

Page 9

9

GB/IE

Setting up and installation

Where to place the freezer

For safety reasons the freezer must not be installed outdoors; it must be placed in a dry

room. Never place the appliance close to sources of heat such as cookers or radiators,

and avoid placing it in direct sunlight. The surface on which the appliance is placed must

be plane. Do not use a frame or similar. The small wheels mounted at the rear of the

freezer make it easy to place it in the required position.

The freezer can stand freely on the oor or be built into a kitchen element or a refrigerator element.

It is important that the appliance stands completely level and that there is good air

circulation over, under and around it. The freezer can be adjusted by turning the four

adjusting screws on the plinth. After adjustment, the feet and the two rear wheels must

be in contact with the surface on which the appliance stands.

Page 10

10

GB/IE

Electrical connection

The appliance is intended for connection to alternating current. The connection values

for voltage (V) and frequency (Hz) are given on the nameplate in the cabinet.

Power must be connected via a wall socket with switch. The wall socket should be

easily accessible.

All earthing requirements stipulated by the local electricity authority must be observed.

The cabinet plug and wall socket should then give correct earthing. If in doubt, contact

your local supplier or an authorised electrician.

WARNING – This appliance must be earthed

The exible cord (mains lead) tted to this appliance has three cores for use with a

3-pin 13-amp plug. If a BS 1363 (13-amp) fused plug is used, it should be tted with

a 13-amp fuse.

IMPORTANT

The cores in this mains lead are coloured in accordance with the following code:

GREEN-AND-YELLOW: EARTH

BLUE: NEUTRAL

BROWN: LIVE

These colours might not correspond with the colour markings identifying the terminals

in your plug.

Note:

First connection to the mains.

The appliance provides information about the higher temperature (Hi alarm ) till the

moment of cooling.

The alarm is signalised by a sound signal and “Hi” caption on the display.

To cancel the alarm, press any push button.

Until the moment of cooling, the alarm is repeated every 15 minutes.

Such an operating mode is normal until the required temperature settings are

reached.

Page 11

11

GB/IE

Maintenance and Service

The sounds that can be heard during normal operation:

• clicks - heard when the control activates or deactivates the compressor

• buzz - the sound of the compressor intensely working shortly after its activation

• crackles and clatter - coming from the cooling system, caused by expansion and shrin-

king of parts due to temperature differences before and after compressor activation

• rustle, gurgle, whistle - coming from the cooling system piping, caused by the coolant owing inside.

● Expanding and shrinking of parts caused by temperature changes causes crackling

sounds that may be heard

Easily corrigible sources of noise:

● noise caused by the appliance positioned not level - adjust the position with the

adjustable turn-in front feet.

● rubbing the adjacent piece of furniture - move the refrigerator a bit.

● creaking of the drawers and shelves - take out and put back the drawer or shelf.

Problem

a break in the operation of the freezer

the freezer compressor

operates

continuously

Reason

A gap in the electric system

circuit

The compressor hardly ever

activates

The ambient temperature is

above +32°C

the freezer door is opened to

often

Air circulation at the back of the

appliance hampered

Solution

make sure there is electricity

in the socket by plug ging in

another electric device, such as

a night lamp,

make sure the ambient temperature is not below +10°C

the appliance is designed for

operation in temperatures from

+10°C to +32°C,

dec r ease t he f r eque n cy o f

opening the door

place the appliance according to

the recommendations

Page 12

12

GB/IE

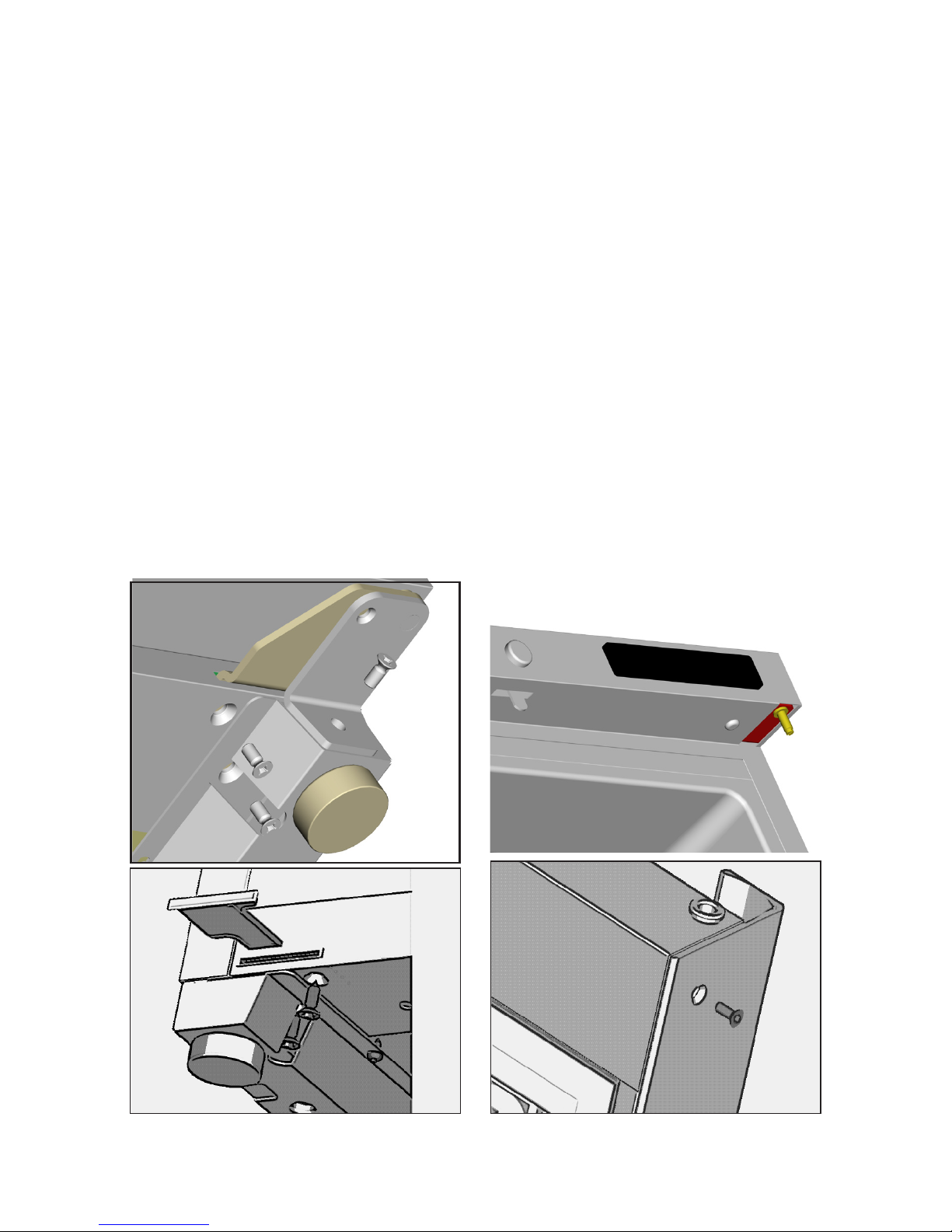

See gures 11-14 for instructions on how to change the door hinging.

The fridge must be off and empty.

- tilt the appliance by 45 degrees backward. Thereby, the lower hinge becomes accessible.

- use cross screw driver to unscrew the three lower hinge bolts (see g. 11).

- remove the door and set aside. Make sure the door cannot fall.

- use screw driver to remove the pin below the control panel at the right side of the

fridge. Screw it fully into the hole at the left side (see g. 12).

- unscrew the two lower bolts. Remove the plug from the lower hinge socket with a

screw driver (see g. 13).

- t the fridge door back, insert the top pin into the door slat.

- insert the hinge pin into the lower slat. Screw the hinge fully with a cross screw driver.

- unscrew the door handle (see g. 14).

- t the handle to the opposite side of the door.

- start the appliance according to the relevant instructions.

12

13

14

11

Changing the door hinging

Page 13

13

GB/IE

Spare parts

Glen Dimplex Professional Appliances

(A division of GDHA)

Stoney Lane

Prescot

Merseyside

L35 2DX

Customer service

Telephone number: 0870 458 4386

Fax : 0870 458 4192

Service

Page 14

14

GB/IE

Page 15

15

GB/IE

Page 16

IOAL-723

(11.2007/2)

Loading...

Loading...