LEAKWISE

®

Oil on Water Detection & Monitoring

ID-220 SERIES MODEL

SLC-220 Smart Leakwise Controller

&

SLR-220 Smart Leakwise Receiver

for Remote SLC-220’s

Connected to

Any ID-220 Sensor

USER GUIDE

Rev. 2.0 June 2018

With 2

nd

Generation of Main and Outputs Boards

And Firmware Version 4.1 and later

SLC-220 User Guide Rev 2.0 June 2018

2

SLC-220 User Guide Rev 2.0 June 2018

3

Important notes for using a Leakwise system

• Refer to the relevant Sensor User Guide for specific information about

sensor certification, installation and operation.

• Consider the following during operation:

1. Beware of high voltage 100 - 240 ±10% VAC inside the enclosure of the

controller unit! Only qualified personnel may service the system.

2. For a controller in a NEMA 7 or Exd enclosure installed in a Hazardous

Area: The enclosure may be opened for service only when the

surrounding atmosphere is known to be non-explosive! Consult your

local Safety Officer!

3. For a controller in a NEMA 4 (IP65) enclosure: Close the cover properly

to attain the weatherproof properties of the enclosure.

For safety: Install a padlock on each quick release latch of enclosure cover!

4. Ambient operating temperature: -20 to +67°C (-4 to +152°F)

5. Maximum relative humidity inside enclosure: 95%, non-condensing.

6. Maximum altitude: 2000 m.

SLC-220 User Guide Rev 2.0 June 2018

4

SLC-220 User Guide Rev 2.0 June 2018

5

Contents

Important notes for using a Leakwise system ................................................................................................................. 3

Warnings ........................................................................................................................................................................... 7

1 General Description .............................................................................................................................................. 9

2 Installation ............................................................................................................................................................ 13

2.1 Sensor Installation ............................................................................................................................................. 13

2.2 Mounting and Wiring the SLC-220 ................................................................................................................... 13

2.2.1 Connecting the Power Cable ................................................................................................................... 14

2.2.2 Connecting Sensor Cables to SLC-220 .................................................................................................... 15

2.2.3 Connecting the Analog 4-20 mA / 0-5 V Outputs .................................................................................... 17

2.2.4 Connecting the Relay Outputs ................................................................................................................. 19

2.2.5 Adding / Removing Outputs boards, and Selt-Test .................................................................................. 21

2.2.6 Front Panel Status Lights, On-Board Buzzer .......................................................................................... 23

2.2.7 Connecting the RS-485 SCADA Serial Port ............................................................................................ 26

2.2.8 Connecting the RS-485 SLC-220 Interconnect Serial Port ..................................................................... 27

2.2.9 Connecting a PC to RS-232 Serial Port .................................................................................................. 28

2.3 Maximum Cable Length between Sensor and SLC-220 .................................................................................... 29

3 Sensor signals, processing & Calibration ........................................................................................................... 31

Status Description ....................................................................................................................................................... 34

Parameters Description ............................................................................................................................................... 34

4 Using the SLC-Manager Program ...................................................................................................................... 37

4.1 Program Installation ............................................................................................................................................ 37

4.2 Entry Screen ........................................................................................................................................................ 37

4.3 Main Sensors View Screen ................................................................................................................................. 39

4.4 Sensor Settings Screen ........................................................................................................................................ 40

4.5 SLC-220 Settings Screen .................................................................................................................................... 46

5 Using the optional front panel LCD ................................................................................................................... 51

6 Using the optional GSM MODEM ..................................................................................................................... 55

6.1 Configuration Messages ....................................................................................................................................... 57

6.1.1 User Configuration ...................................................................................................................................... 57

6.1.2 Active Sensors .............................................................................................................................................. 57

6.1.3 Sensor Name ................................................................................................................................................ 58

6.1.4 Update Interval ............................................................................................................................................ 58

6.1.5 Sensor Sample Interval ................................................................................................................................ 59

6.2 Calibration Messages ........................................................................................................................................... 60

6.2.1 Set-Points Setting ......................................................................................................................................... 60

6.2.2 Season Setting .............................................................................................................................................. 60

6.2.3 Automatic Calibration .................................................................................................................................. 61

6.2.4 Write Calibration ......................................................................................................................................... 61

6.2.5 Calibration Confirmation............................................................................................................................. 61

6.3 Inquiry Messages ................................................................................................................................................. 62

6.4 Testing the GSM MODEM .................................................................................................................................. 63

7 SLR-220/SGM ...................................................................................................................................................... 64

8 Troubleshooting Guide ........................................................................................................................................ 67

9 Appendix A: Installation in Hazardous Area .................................................................................................... 71

10 Appendix B: Connecting a PC to SLC-220 ........................................................................................................ 71

11 Appendix C: Updating SLC-220 Firmware ....................................................................................................... 75

12 Appendix D: Ferrites for EMC Compatibility................................................................................................... 79

13 Appendix E: SLC-220 Drawings ......................................................................................................................... 82

SLC-220 User Guide Rev 2.0 June 2018

6

SLC-220 User Guide Rev 2.0 June 2018

7

Warnings

English

This is a Class A product. In a domestic environment, this product may cause electromagnetic

interference in which case the user may be required to take adequate measures to correct the

interference.

This is a measurement CAT I device. Do not use in CAT II, CAT III or CAT IV measurement

circuits.

An external switch or circuit breaker (5 Amp) must be installed on the power input line of

the instrument. This switch must disconnect both poles of the supply voltage. It should be

rated, labeled and located appropriately.

INSTALLATION IN HAZARDOUS AREAS:

Do not open the controller enclosure when an explosive gas atmosphere may be present!

Keep enclosure cover tight while circuits are alive.

Seals are required within 3 inches of enclosure threaded holes.

Comply with local norms and regulations during installation and operation.

The power input, sensor input/s and system output connections should be installed by a qualified

electrician.

SLC-220 controller:

For personnel safety and to avoid damage to the instrument:

Disconnect AC/DC supply power before removing the Main board frame.

The On-Off switch is wired in series with the 12VDC internal supply.

Set On-Off switch to Off before connecting / disconnecting any wires!

Leakwise sensors are floating devices.

The installation must allow their free floatation and avoid submergence.

Leakwise sensors are delicate instruments. Handle with care!

Do not drop.

Avoid damages to the cable/s during installation and operation, as this will void the IP67 sealing.

Installation: Follow mechanical and wiring instructions as detailed in the User Guide.

Do not use the system beyond its specifications.

If installed or used in a manner not specified in this User Guide, the protection provided by

the instrument may be impaired.

The sensor is constructed of a plastic material that constitutes a potential electrostatic

hazard. Do not rub! Clean only with a damp cloth.

SLC-220 User Guide Rev 2.0 June 2018

8

Français

Ceci est un produit de classe A. Dans un environnement domestique, ce produit peut provoquer

des interférences électromagnétiques. Dans ce cas l'utilisateur peut être tenu de prendre des

mesures adéquates pour corriger l'interférence.

Ceci est un dispositif de mesure CAT I. Ne pas utiliser dans CAT II, CAT III ou CAT IV circuits de

mesure.

Un interrupteur externe ou disjoncteur (5 Amp) doivent être installés sur la ligne de

l'instrument d'entrée de puissance. Cet interrupteur doit déconnecter les deux pôles de la

tension d'alimentation. Il devrait être classé, étiqueté et situé de manière appropriée.

INSTALLATION DANS DES ZONES DANGEREUSES:

Ne pas ouvrir le boîtier du contrôleur quand une atmosphère explosive de gaz peut être présente!

Gardez le couvercle du boîtier étanche tandis que les circuits sont actifs.

Des joints sont nécessaires dans les 3 pouces de l'enceinte des trous filetés.

Se conformer aux normes et réglementations locales lors de l'installation et de l'exploitation.

Les entrées d'alimentation, entrée du détecteur/s et le système de sortie des connexions doivent

être installés par un électricien qualifié.

Contrôleur SLC-220:

Pour la sécurité du personnel et pour éviter tout dommage à l'instrument:

Déconnectez d'alimentation AC / DC avant de retirer le cadre de la carte principale.

L'interrupteur On-Off est câblé en série avec l'alimentation interne 12VDC.

Réglez l'interrupteur On-Off Off avant de brancher/débrancher tous les fils!

Les détecteur Leakwise sont des dispositifs flottants.

L'installation doit permettre leur flotation libre et éviter toute submersion.

Les détecteur Leakwise sont des instruments délicats a manipuler avec soin!

Ne pas lacher!

Tout dommage créé au câble/s lors de l'installation et de l’utilisation, annulerait automatiquement

l'étanchéité IP67.

Installation: Suivre les instructions mécaniques et le câblage comme détaillé dans le Guide

Utilisateur.

Ne pas utiliser le système au-delà de ses spécifications.

Si installé ou utilisé d'une manière non spécifiée dans ce Guide de l'utilisateur, la

protection fournie par l'instrument peut être altérée.

Le détecteur est constitué d'un matériau plastique qui constitue un danger potentiel

électrostatique. Ne pas frotter! Nettoyer uniquement avec un chiffon humide.

SLC-220 User Guide Rev 2.0 June 2018

9

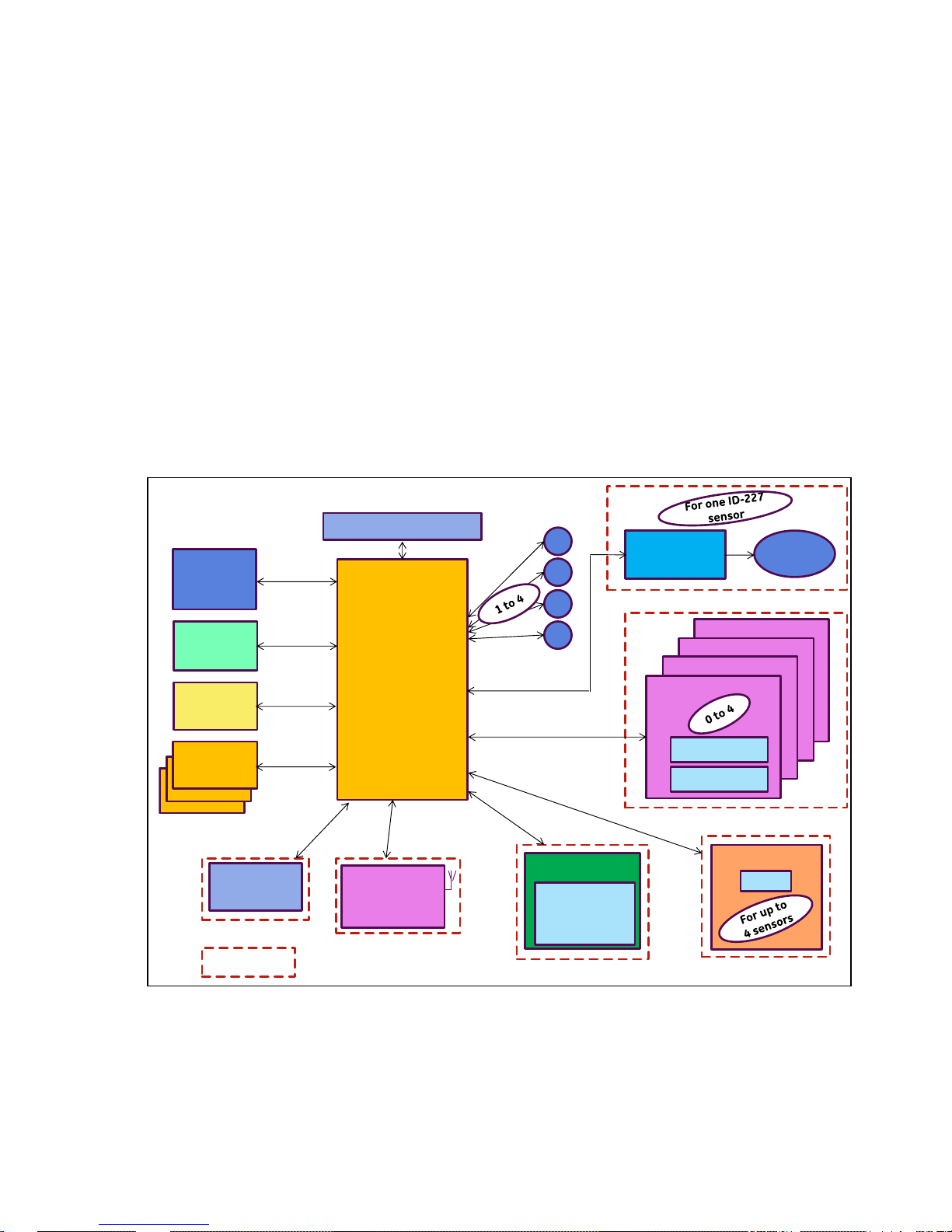

1 General Description

The SLC-220 Smart Leakwise Controller is a digital signal processor that interfaces with Leakwise

ID-220 Series Sensors to report hydrocarbons spill/leak alerts, including layer buildup and

thickness, to users via a wide variety of outputs and communication interfaces for local or remote

reporting. The SLC-220’s modular design and flexible configuration provides solutions for all

specific customer needs. It can be AC or DC line powered or battery powered, and it operates in

wired and/or wireless applications. The SLC-220 supports up to four (4) Leakwise Sensors per

unit. Multiple SLC-220 Controllers can be interconnected to provide a cost-effective, multi-sensor

network (up to 40 sensors).

Block Diagram:

µC Main Board

1

2

3

4

Leakwise

Sensor #

AutoCleaner

Control

Auto

Cleaner

Wireless

Communication:

GSM / Satellite /

Point-to-Point

Indicates

optional feature

Outputs Board # 4

Outputs Board # 3

Outputs Board # 2

Outputs Board # 1

()

1 x 4-20 mA

5 x Relay, SPDT

PC

Connectivity

(Setup &

Calibration)

Power Supply

SCADA

Connectivity

(Modbus)

Status Lights

6 Lights

Display

4.3” Graphic

Color LCD

480*272 Dots +

Touch Panel

Additional

SLC-220

Units (up to 9)

HART

Connectivity

(future)

Hardware

Enhancement

Options

RS-232

RS-485

RS-485

RS-232

RS-232

RS-232

SLC-220 User Guide Rev 2.0 June 2018

10

The SLC-220 is designed for low-power consumption in onshore and offshore applications without

an available power source. Therefore, the operating software extensively uses a “sleep mode”

algorithm that turns off unnecessary hardware. Each monitored sensor is powered on for a short

duration for sampling and decision making, and then turned off. This off interval is userprogrammable. Careful selection and programming of optional features will enable operation for

months from a single battery charge.

All SLC-220 settings and calibrations can be changed locally or remotely through:

• Local LCD & touch screen or RS-232 connection to a PC with the SLC-Manager program

(program supplied with a cable)

• Remote RS-485 connection to the control room through Modbus

• Remote cellular phone messaging if a Cellular modem is installed (SIM card required,

supplied by customer)

The Status of the system is available to the user locally on the LCD or with the SLC-Manager on

the PC, or remotely at the control room through wires connectivity (Modbus) or wireless

connectivity (Cellular / Satellite / Point-to-Point radio).

There are three types of SLC-220:

1. SLC-220/Multi, which supports up to four Leakwise sensors.

2. SLC-220/Basic, which supports up to two Leakwise sensors.

3. SLR-220, which supports up to four local sensor and multiple remote sensors connected to

remote SLC-220 controllers.

SLC-220 User Guide Rev 2.0 June 2018

11

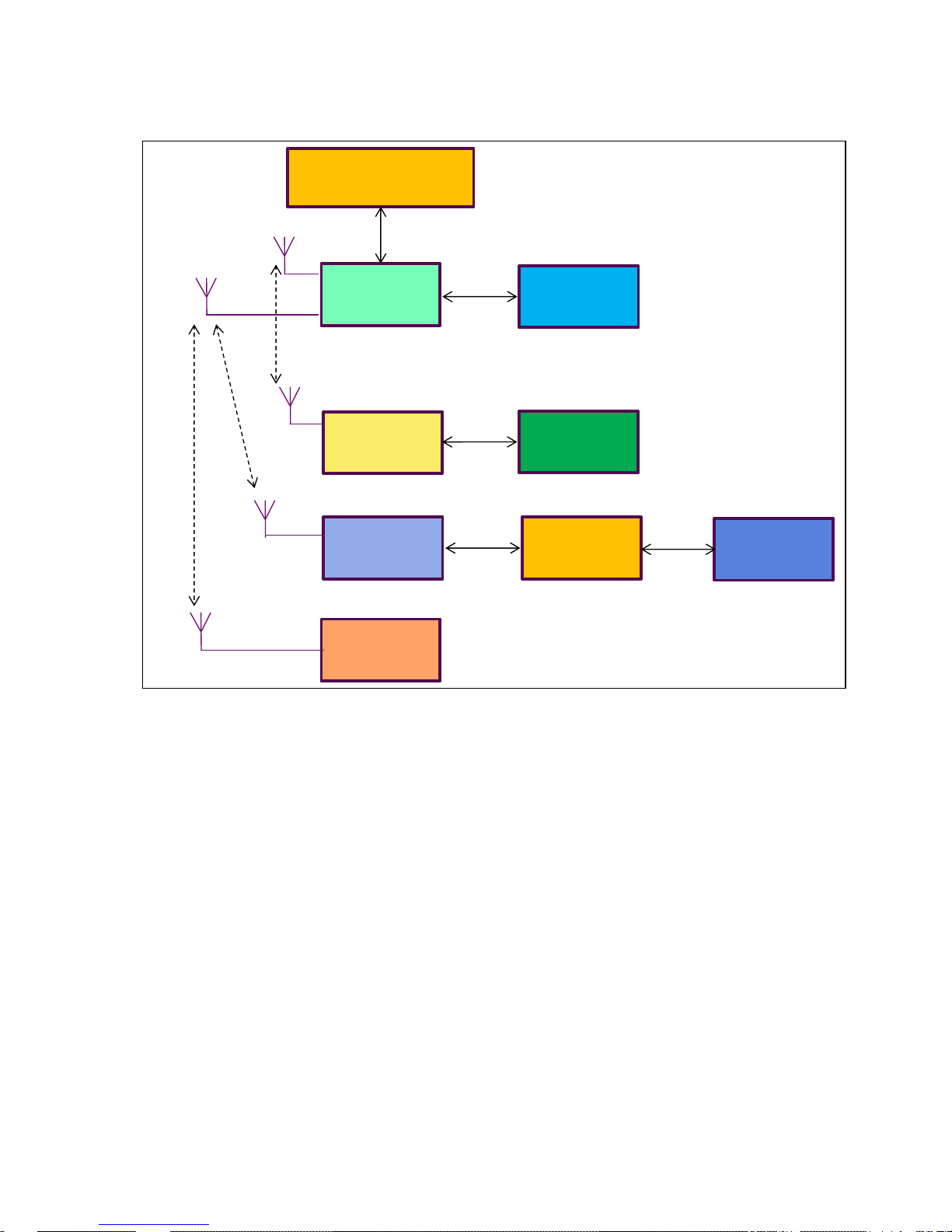

Multiple SLC-220 units as a big system with a single connection to a SCADA:

The main unit is SLC-220 #1, also called SLR-220 (Smart Leakwise Receiver). It collects

information from other SLC-220 units by wired or wireless connectivity.

SCADA (Modbus)

SLC #2

SLC #7

SLR (SLC #1)

SLC #8

SLC #4

SLC #6

SLC #3

SLC #5

RS-485

RS-485

RS-485

RS-485

RS-485

PTP

PTP

GSM

GSM

GSM

SLC-220 User Guide Rev 2.0 June 2018

12

SLC-220 User Guide Rev 2.0 June 2018

13

2 Installation

Installation of the SLC-220 system includes three major steps. First, the sensors and the

SLC-220 unit must be installed in their respective locations. Then, the interconnecting cables

should be wired. Finally, configuration and calibration of the system components should be

performed.

Prior to the calibration procedure, fully install the sensor that has to be calibrated. Instructions and

procedures for system configuration and calibration are described in the next chapters.

NOTE: For EMC compatibility, ferrites should be installed on the power and sensor/s cables.

Refer to Appendix D.

2.1 Sensor Installation

The sensors should be placed and installed in accordance with installation instructions specific to

each type of sensor. Please refer to the appropriate Sensor User Guide.

2.2 Mounting and Wiring the SLC-220

The SLC-220 unit should be mounted in a dry, shaded location, and should have the inside of the

enclosures easily accessible when opening the cover.

For a 100 - 240 VAC system, refer to the following SLC-220 Wiring Diagram: DWGW SLC 003 5.

For a 12 / 24 VDC system, refer to the following SLC-220 Wiring Diagram: DWGW SLC 004 2.

Refer also to mechanical drawings A SLC 0020, A SLC 0021 and A SLC 0030, and when

applicable refer to the NEMA 7 / Exd enclosure drawing/s.

If Safety Barriers are required (hazardous Area installation) refer also to Appendix B in Sensor

User Guide, to drawing DWGV2200012 that shows the summary of ITS certificate No.

Ex01E2023.

The IP65 / NEMA 4 enclosure has a transparent cover with two latches on the right side and

hinges on the left side. After opening the transparent cover there is access to the LCD with touch

screen (if installed), installed on the front panel. Access to the boards and wiring connections is

easy: Lift the front panel with a finger inserted into the hole on the right side of its edge (the

hinges are on the left side).

SLC-220 User Guide Rev 2.0 June 2018

14

2.2.1 Connecting the Power Cable

Make sure that there is no power connected to the cable. Pass the cable through the electrical

conduit that goes from the power source to the SLC-220. Pass the cable through the input gland

on the bottom side of the enclosure.

For 100 - 240 VAC:

Connect the cable to the power-supply terminal block inside the enclosure as follows:

Power Line Contact of Power Supply

Terminal Block

AC PHASE 1 (L)

AC NULL 2 (N)

FRAME GROUND 3 (FG)

NOTE:

Use wires of minimum 18AWG, specified to at least 90°C and 300V.

An external switch or circuit breaker (5 Amp) must be installed on the power input line

of SLC-220. This switch, located near SLC-220, must disconnect both poles of the

supply voltage. It should be rated appropriately and must be marked as the

disconnecting device for SLC-220.

For 12 or 24 VDC:

Connect the cable to the power-supply terminal block inside the enclosure as follows:

Power Line Contact of Power Supply

Terminal Block

+12 or + 24 V 1 (+)

12 V or 24 V RETURN 2 (-)

FRAME GROUND 3 (FG)

Power consumption is 24 Watts maximum.

Note:

1. A Power On-Off switch is installed near the Power Supply terminal block for easier

maintenance when power should be turned off before making wiring changes.

The switch disconnects the 12VDC supply to the boards, not the Mains power!

2. When the SLC-220 is powered up, it goes through a self-test procedure of a few seconds

which turns on all status lights. Only then the sensors are sampled normally and the lights,

relays and 4-20mA outputs are updated to real values.

NOTE for SLC-220/Multi:

If one or more Outputs Boards are provided, they are installed on a separate metallic

mounting plate above the Main board. The mounting plate can be easily removed since

it is fastened by four quick-disconnect nylon studs, giving access to the Main board.

The nylon suds should be used gently to avoid break!

SLC-220 User Guide Rev 2.0 June 2018

15

2.2.2 Connecting Sensor Cables to SLC-220

Up to four sensors may be connected to the SLC-220. Each sensor is connected individually. The

sensor wires are passed through the proper sensor cable gland in the external wall of the

enclosure. Then they are connected to the respective contacts in terminal block TB10 (on Main

Board) as follows:

Wire Color TB10 Contact Contact Function

Red or Brown or Black#1 + Sensor +12 VDC (DET+)

Black or Yellow or Black#2 - Sensor GROUND (DET-)

Blue, or Black#3 SIG Sensor SIGNAL (Iout)

Note: For EMC compatibility, a small EMC Filter board is installed as an extension to TB10.

Refer to Appendix D.

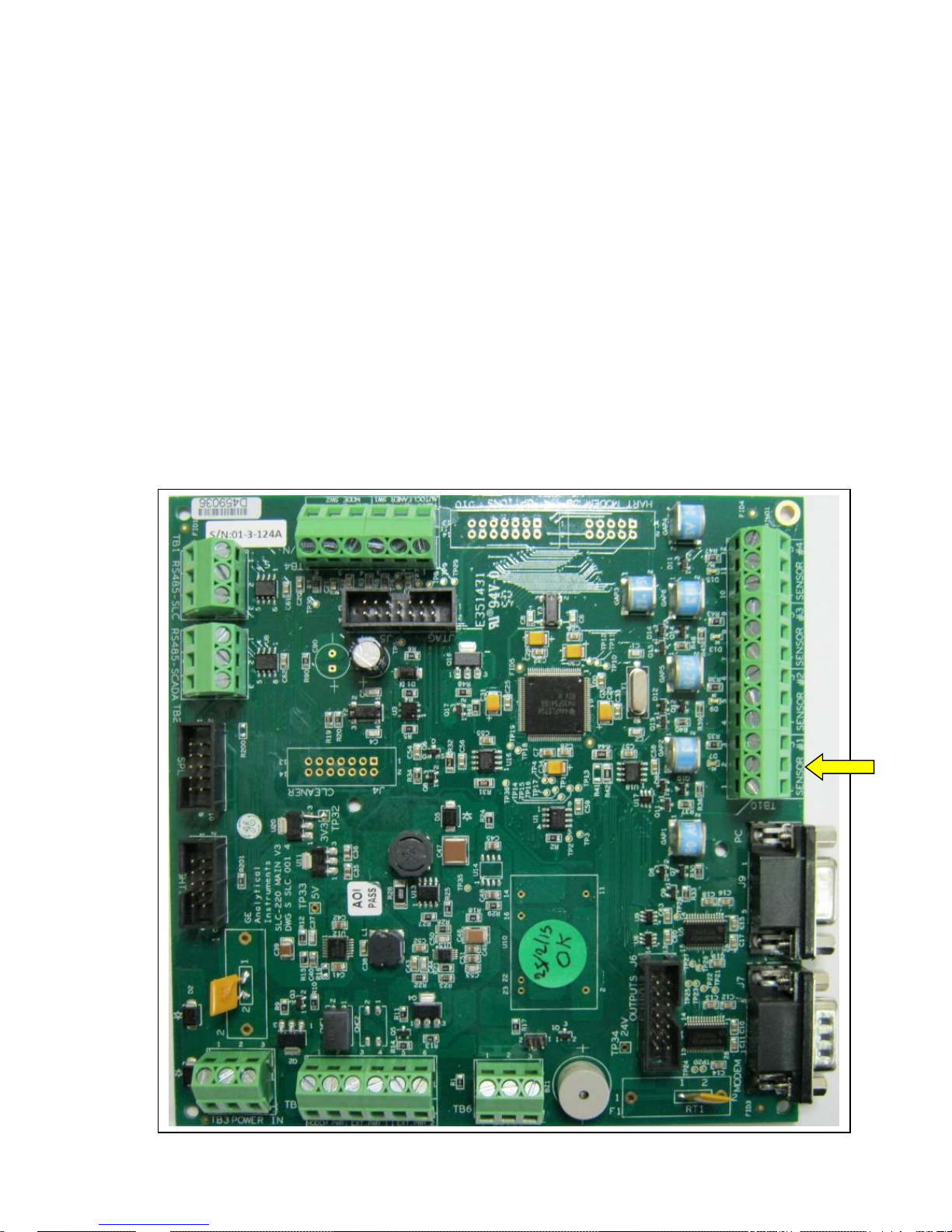

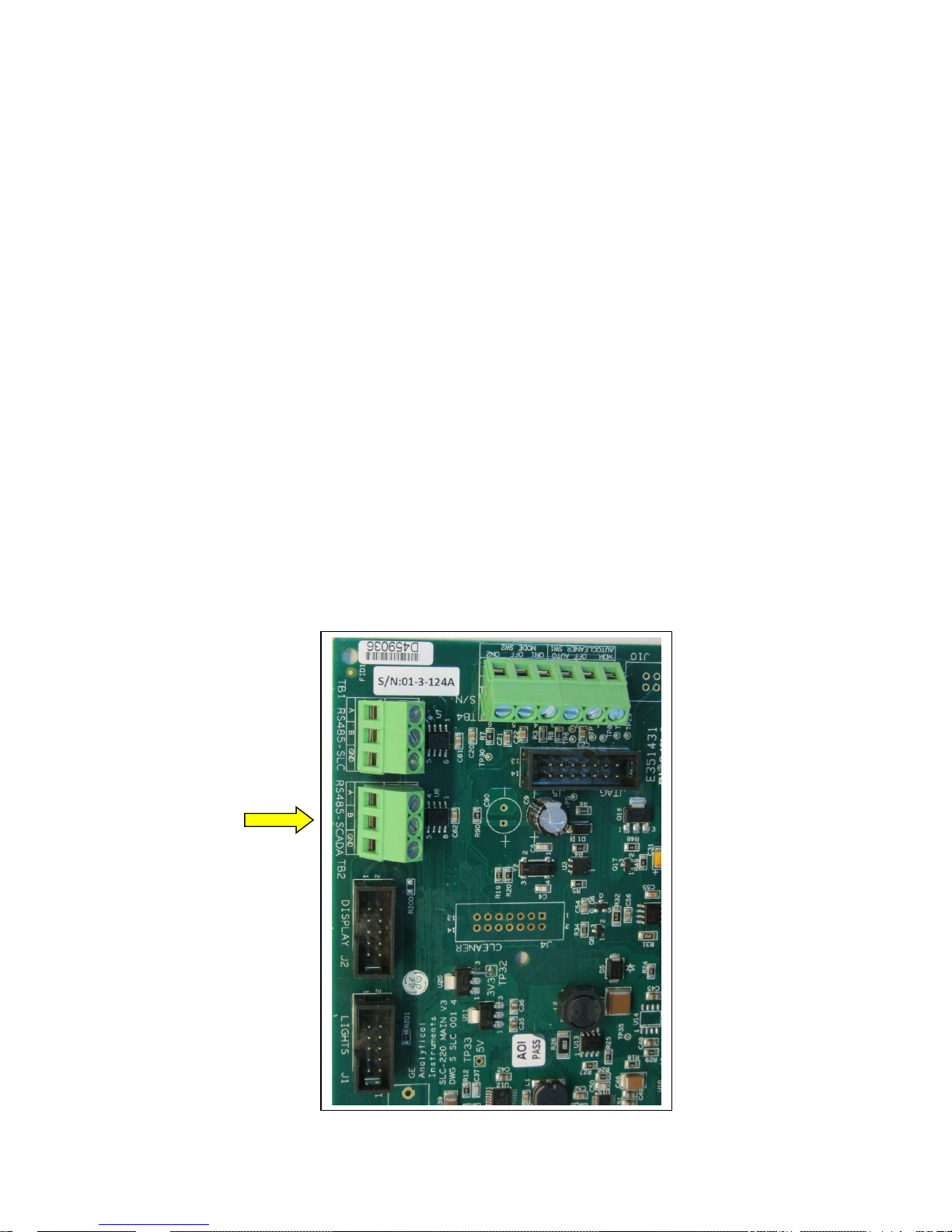

Main Board picture:

TB10 is on the right side

SLC-220 User Guide Rev 2.0 June 2018

16

Each sensor input has an indicating red LED on the board to indicate when it is energized. The

LEDs are located on the left side of TB10.

For Hazardous-Area installation, connect the sensor through Zener Safety Barriers which are

installed on an isolated DIN rail inside the enclosure. If the safety barriers are supplied with the

controller, their Safe-Area side is already wired to TB10. Connect the sensors to the HazardousArea side of the safety barriers:

Wire Color Safety Barrier Contact Contact Function

Red or Brown or Black#1 MTL 7715+ point 3 Sensor +12 VDC (DET+)

Black or Yellow or Black#2 MTL 7715+ point 4 Sensor GROUND (DET-)

Blue, or Black#3 MTL 7710+ point 3 Sensor SIGNAL (Iout)

SLC-220 User Guide Rev 2.0 June 2018

17

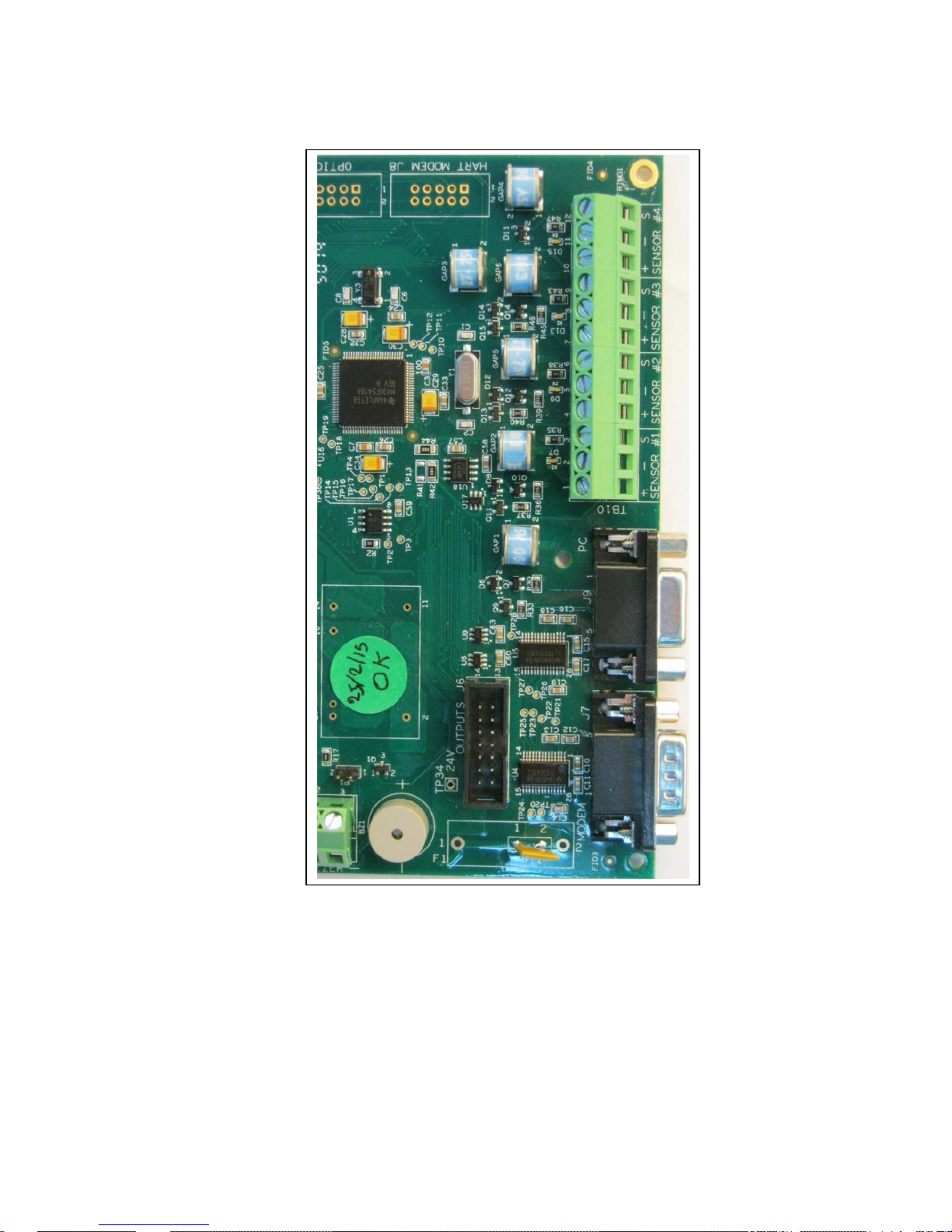

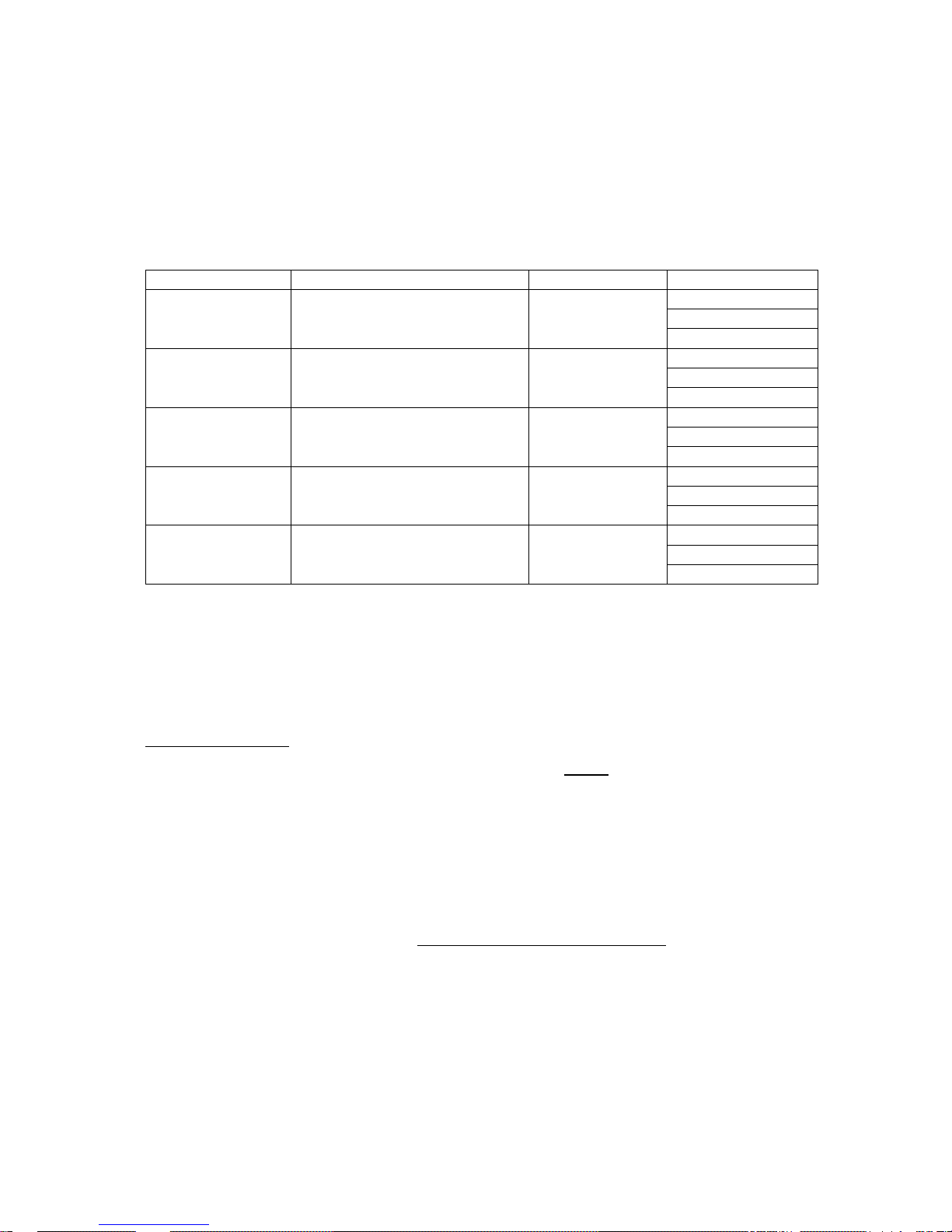

2.2.3 Connecting the Analog 4-20 mA / 0-5 V Outputs

Up to four Outputs boards may be installed in one SLC-220/Multi, up to two in SLC-220/Basic.

The first board on SLC-220/Multi, located rightmost, is associated with sensor #1; the second

board from the right is associated to sensor #2, etc. For SLC-220/Basic, the lower board is

associated with sensor #1; the upper board is associated with sensor #2.

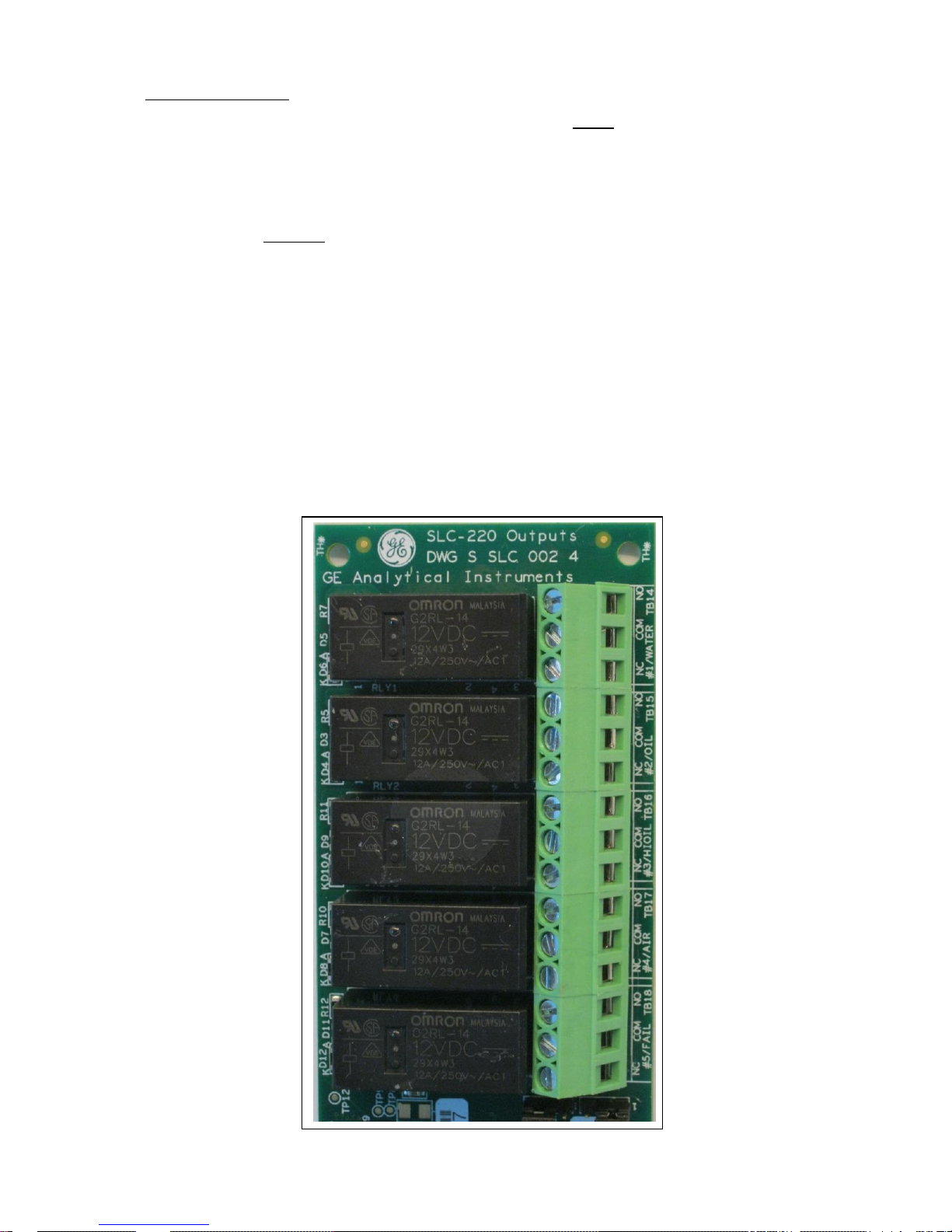

Outputs Board picture:

SLC-220 User Guide Rev 2.0 June 2018

18

If the SLC-220 unit is equipped with Outputs board/s, pass the 4-20mA cable through the proper

cable gland in the external wall of the enclosure. Then connect the two wires to the contacts of

terminal block TB19 as follows:

TB19 Contact Contact Function

Iout 4-20 mA + (Current source, non-isolated)

GND 4-20 mA - (Current return, non-isolated)

If 0-5 V output is required (instead of 4-20 mA), connect each of the two wires to TB19 as follows:

TB19 Contact Contact Function

Vout 0-5 V + (non-isolated)

GND 0-5 V return (non-isolated)

Note: At this point, the current / voltage output is not galvanically isolated.

Setting the functionality / range of the output is done by jumpers on the Outputs board:

JP5 position JP6 position Range at TB19

2-3 2-3 0-5 V

1-2 2-3 4-20 mA < This is the default setting

2-3 1-2 0-20 mA

1-2 1-2 0-24 mA

SLC-220 User Guide Rev 2.0 June 2018

19

Arranging the wires:

For SLC-220/Multi, there is one white plastic wire saddle below each Outputs board. Insert the

wires into the saddles and guide them to the left of the enclosure, then down and to the cable

gland.

Note: If there is only one Outputs board and more than one sensor, and the Common functionality

of the Outputs board is selected by setup, then the Analog output will be associated with

sensor#1.

Note: For a disabled sensor associated with an Outputs board, the 4-20mA output will default to

4.33 mA.

2.2.4 Connecting the Relay Outputs

Up to four Outputs boards may be installed in one SLC-220/Multi. The first board, located

rightmost, is normally associated with sensor #1; the second board from the right is normally

associated to sensor #2, etc. (See note 3 in 2.2.5 for exceptions).

SLC-220 User Guide Rev 2.0 June 2018

20

For SLC-220/Basic, the lower board is associated with sensor #1; the upper board (if installed) is

associated with sensor #2.

Pass the cable through the proper cable gland in the external wall of the enclosure. Then connect

the wires of this cable to the contacts of terminal blocks TB14 till TB18 of the appropriate Outputs

board as follows:

Relay number

Indicated Status

Terminal Block

Contacts

#1

Water or

Oil / High Oil for sensor #1

TB14

NO

COM

NC

#2

Oil or

Oil / High Oil for sensor #2

TB15

NO

COM

NC

#3

High Oil or

Oil / High Oil for sensor #3

TB16

NO

COM

NC

#4

Air or

Oil / High Oil for sensor #4

TB17

NO

COM

NC

#5

Fail or

Common Fail for all sensors

TB18

NO

COM

NC

NO: Normally Opened contact,

COM: Common point,

NC: Normally Closed contact.

Arranging the wires:

In SLC-220/Multi, there is one white plastic wire saddle above every Outputs board. Insert the

wires into the saddles and guide them to the left of the enclosure, then down and to the cable

gland.

Each relay has an indicating LED on the board to indicate when it is energized.

The relays can be set to operate in normal mode or in fail-safe mode. Changing the setting is

done in SLC-220 Settings (chapter 4.5).

SLC-220 User Guide Rev 2.0 June 2018

21

There are two modes to use the relays, depending on the setup:

1. Normal mode: Each sensor activates five relays on the relevant Outputs board. There is

one relay associated with each status: Water, Oil, High Oil, Air and Fail.

2. Common mode: If only one Outputs board is installed, relay #1 will alarm on Oil / High Oil

for sensor #1, relay #2 will alarm on Oil / High Oil for sensor #2, etc., and relay #5 will

alarm on Fail in any of the enabled sensors. This results in individual Oil / High Oil

indication and a common Fail indication.

Changing between the modes is done in SLC-220 Settings (chapter 4.5).

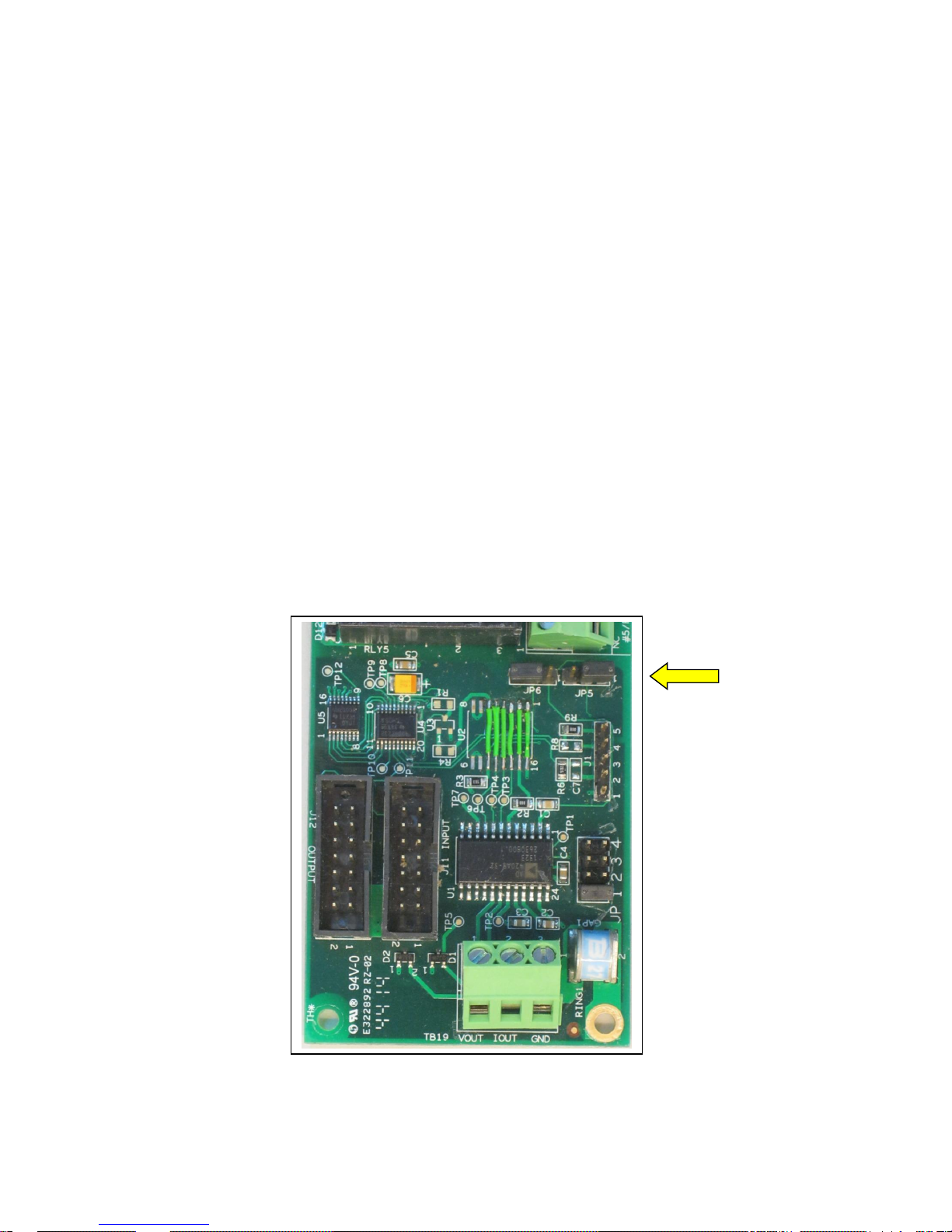

2.2.5 Adding / Removing Outputs boards, and Selt-Test

Up to four Outputs boards may be installed in one SLC-220/Multi. The first board, located

rightmost, is associated with sensor #1; the second board from the right is associated to sensor

#2, etc. The Outputs boards are connected in a series chain to the Main board which sends

updated data to the relays and to the Analog output.

Outputs board #1 is connected by a flat cable from header J11 to header J6 on the Main board.

Outputs board #2 is connected by a flat cable from J11 to J12 on Outputs board #1.

Outputs board #3 is connected by a flat cable from J11 to J12 on Outputs board #2.

Outputs board #4 is connected by a flat cable from J11 to J12 on Outputs board #3.

Note 1: Headers J11 and J12 on each board are actually in parallel; therefore, they may be

interchanged in cases where it is more convenient, for example in SLC-220/Basic.

There are four jumpers on each Outputs board which must be set properly to ensure correct

operation of the outputs. The setting depends on the total number of sensors and Outputs boards,

and their position in the chain:

For SLC-220/Multi, where additional Outputs board/s (up to 4) may be added at any time, the

rightmost Outputs board in the chain will be associated with sensor #1 and will have address #1

(JP1 shorted, JP2, JP3, JP4 disconnected).

Second Output board in the chain will be associated with sensor #2 and will have address #2 (JP2

shorted, JP1, JP3, JP4 disconnected), etc.

SLC-220 User Guide Rev 2.0 June 2018

22

Associating an Outputs board with sensor #1:

Note 2: Update the number of installed Outputs boards in SLC-220 Settings (chapter 4.5).

Note 3: In principle it is not important to associate a certain Outputs board in the chain to a certain

sensor in a rigid order.

Note 4: It is also possible to associate more than one Outputs board to the same sensor! By

doing this, for example, two relays on different Outputs boards will give indications in parallel for

the specific sensor status, and two 4-20mA outputs will give the same information for this sensor.

Note 5: An Outputs board associated to a disabled sensor will not operate: All relays will be deenergized, and all 4-20mA outputs will be set to 4.33 mA.

Outputs board self-test:

1. Power down the controller.

2. Remove the jumper from JP1 / JP2 / JP3 / JP4 of the Outputs board to be tested.

3. Power up the controller.

4. The relays will be energized and de-energized in sequence one after the other.

5. The 4-20mA output will change between 5mA and 10mA when a complete sequence cycle

of the relays in finished.

6. Power off the controller.

7. Insert the jumper back to JP1 / JP2 / JP3 / JP4 (where it was before).

8. Power on. The Outputs board will operate normally.

SLC-220 User Guide Rev 2.0 June 2018

23

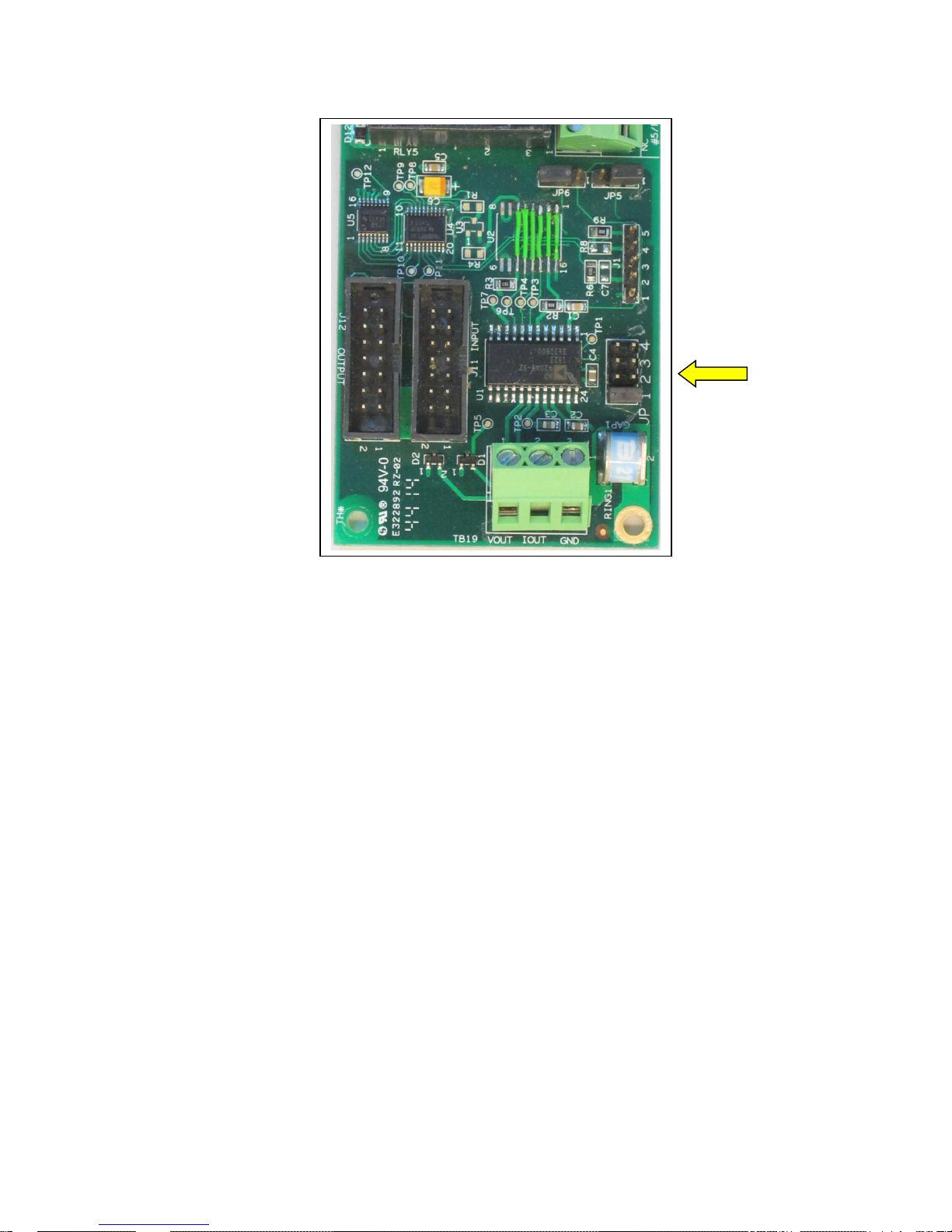

2.2.6 Front Panel Status Lights, On-Board Buzzer

There are six status lights on the front panel.

The Power (green) light indicates operation of the unit.

The other five lights can be used in either of two operating modes:

1. Common mode: Water (green), Oil (red), High Oil (red), Air (yellow) and Fail (yellow)

lights will turn on if any of the enabled sensors (up to four sensors) generates the

appropriate status. Therefore, it is possible that more than one light is turned on.

2. Individual mode: Oil 1 (red), Oil 2 (red), Oil 3 (red), Oil 4 (red) and Fail (yellow) lights will

be operated as follows:

• Oil 1 will turn on when sensor #1 generates Oil or High Oil status.

• Oil 2 will turn on when sensor #2 generates Oil or High Oil status.

• Oil 3 will turn on when sensor #3 generates Oil or High Oil status.

• Oil 4 will turn on when sensor #4 generates Oil or High Oil status.

• Fail light is common to all enabled sensors. It will turn on if any of the four sensors

is in Fail status.

Therefore, it is possible that more than one light is turned on.

Note: Status of a disabled sensor will not be reflected in the status lights.

SLC-220 User Guide Rev 2.0 June 2018

24

The system is supplied in Common mode for systems supplied with a single sensor, and in

Individual mode for systems supplied with more than one sensor. In order to change between

modes, if required, do the following:

1. Remove the existing Lights board from the front panel.

2. Remove the aluminum black Lights panel.

3. Install the black Lights panel inverted with the correct legends facing the user.

4. Install another Lights board (DWG S SLC 003 1) that has correct LEDs colors for the

required mode (should be ordered separately). The serial number of a Common mode

board end with a "C", while the serial number of an Individual mode board end with a "I".

5. Make the correct mode setting in SLC-220 Settings (chapter 4.5).

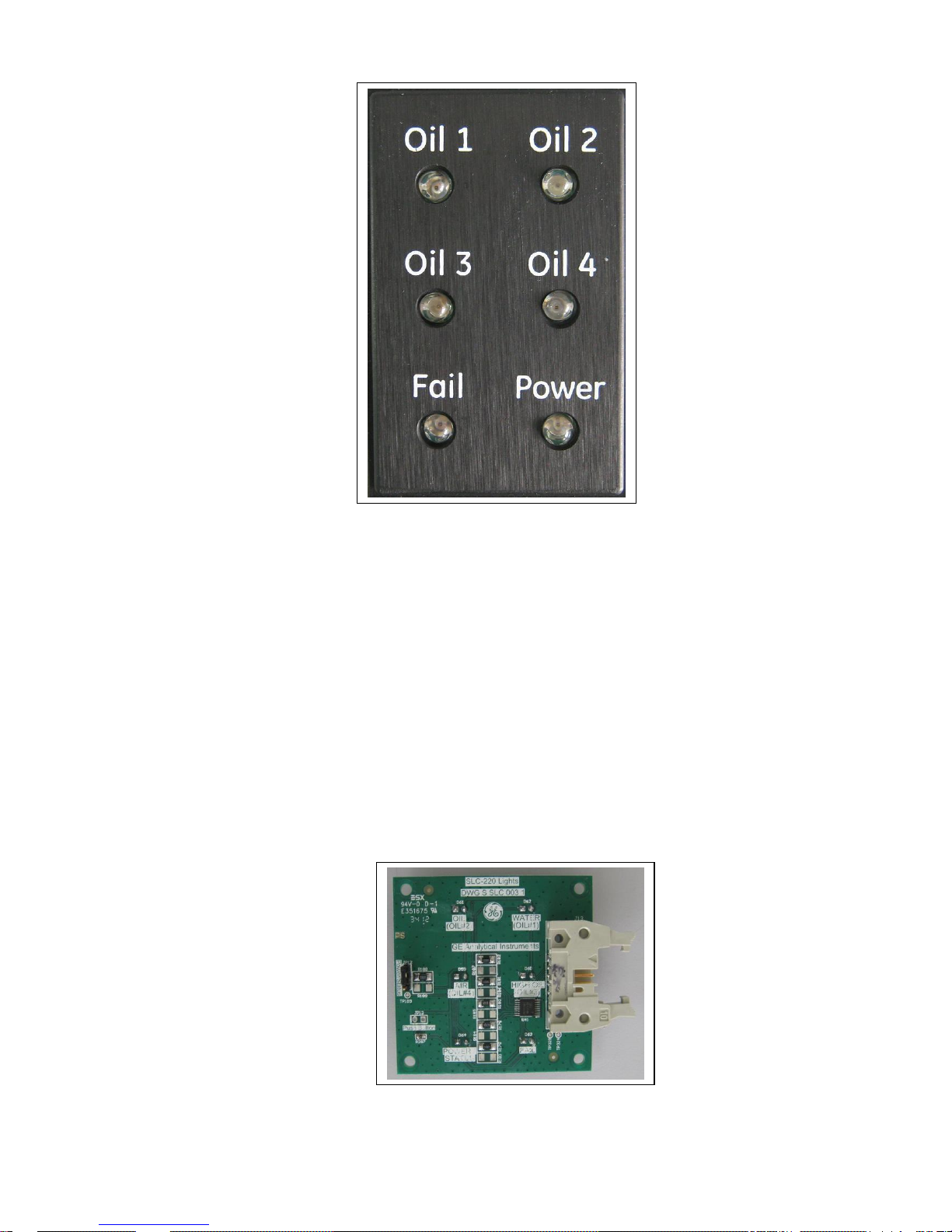

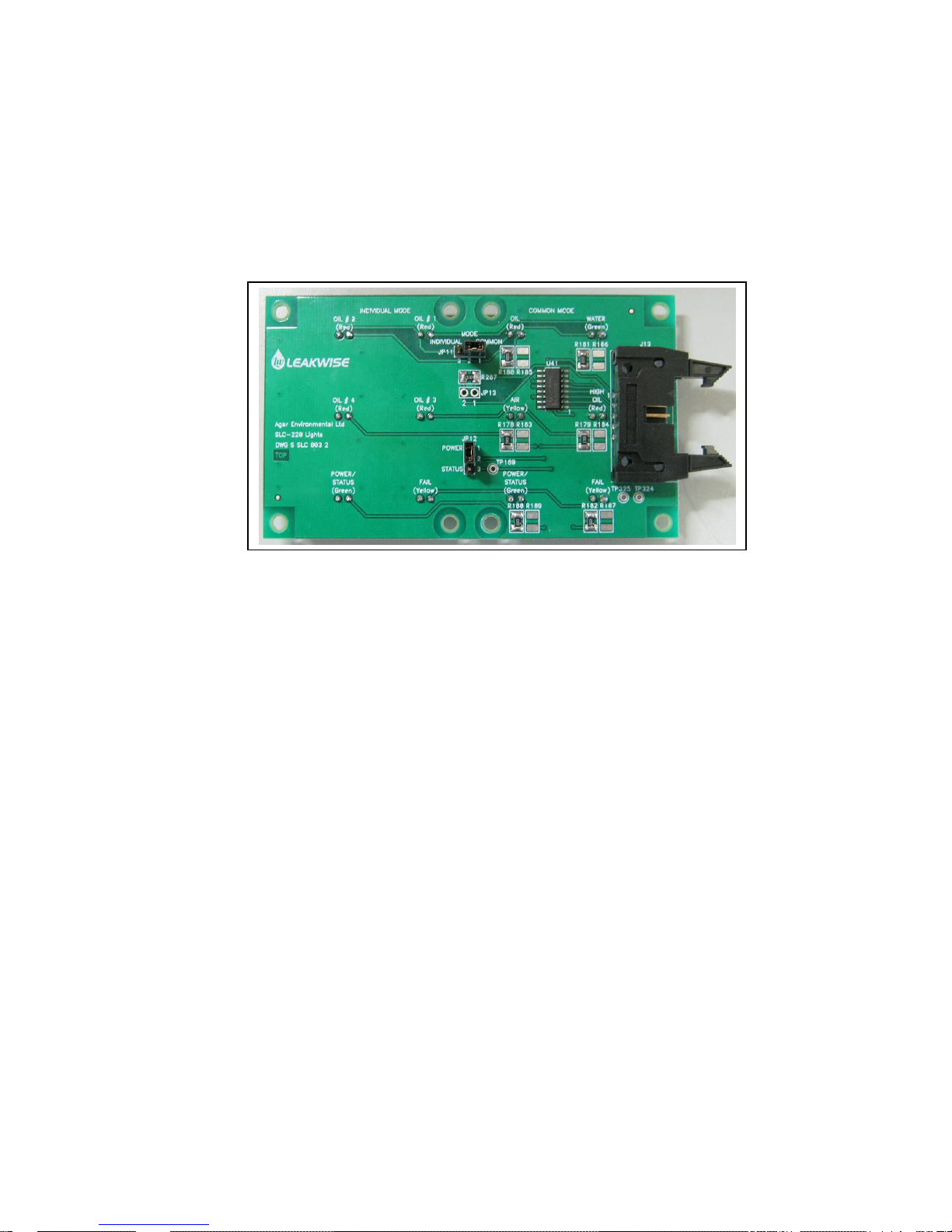

Lights Board picture:

SLC-220 User Guide Rev 2.0 June 2018

25

A new type of Lights board (DWG S SLC 003 2) will be installed during 2018. It supports both

Common and Individual modes, therefore mode change will be very quick and easy. The board

has JP11 MODE jumper to select between the modes.

To use the Common mode, install the board with its’ right side above the black Lights panel.

To use Individual mode, install the board with its’ left side above the black Lights panel.

New Type of Lights Board:

On-Board Buzzer:

Shoring jumper JP1 near the on-board buzzer (and TB6) enables the buzzer.

The buzzer will beep one after a successful parameters update done through the LCD display or

through the SLC-Manager PC program. It will beep multiple times if there are problems in the

parameters, which will then be rejected.

SLC-220 User Guide Rev 2.0 June 2018

26

2.2.7 Connecting the RS-485 SCADA Serial Port

This port can be used only for connecting a SCADA or any other unit using Modbus protocol to

the SLC-220 for setup, calibration and status interrogation. The specifics of using the protocol with

SLC-220 are detailed in a separate document.

The port is set to 115,200 Baud as default, 8 data bits, 1 stop bit, no parity and no flow control.

The baud rate can be changed by the SLC-Manager program through the PC serial port.

Pass the cable through the proper gland in the external wall of the enclosure. Then connect the

wires to the contacts of terminal block TB2 on the Main board as follows:

TB2 Contact Contact Function (SLC-220 side)

1 A (non-inverting input)

2 B (inverting input)

3 Ground / shield of Cable

Note: Operating mode is Half Duplex. Full duplex is not supported.

Note: See also the note in 2.2.9.

Main Board top-left corner:

SLC-220 User Guide Rev 2.0 June 2018

27

2.2.8 Connecting the RS-485 SLC-220 Interconnect Serial Port

This port can be used only for future connection of a SLC-220 unit to a network of multiple SLC220 units and a SLR-220. No other device should be connected to this port.

Pass the cable through the proper gland in the external wall of the enclosure. Then connect the

wires to the contacts of terminal block TB1 on the Main board as follows:

TB1 Contact Contact Function (SLC-220 side)

1 A (non-inverting input)

2 B (inverting input)

3 Ground / shield of Cable

Note 1: Operating mode is Half Duplex. Full duplex is not supported.

Note 2: Functionality of this port is not implemented yet.

SLC-220 User Guide Rev 2.0 June 2018

28

2.2.9 Connecting a PC to RS-232 Serial Port

A PC can be connected to the SLC-220 for setup, calibration and monitoring the sensors when

required. The PC should have the SLC-Manager program installed to do this.

A RS-232 cable is supplied: Male to female, non-crossed Rx & Tx. Connect the 9-pin male DSubminiature connector to connector J9 on the Main board, as follows:

J9 Contact Contact Function (SLC-220 side)

2 RxD (Data input to SLC-220)

3 TxD (Data output from SLC)

4 DTR (Input, Data Terminal Ready from PC)

5 GND (and shield of RS-232 Cable)

Connection of PC DTR to pin 4 is essential to enable automatic detection of a device connected to

this port.

For a PC without a RS-232 connector, a RS-232 to USB adaptor is also supplied.

For IP65 / NEMA 4 enclosure of SLC-200/Multi: Connect the PC to an extension connector

located at the top-left of the opened enclosure, and marked "PC".

For IP65 / NEMA 4 enclosure of SLC-200/Basic: Connect the PC to an extension connector

located at the right of the opened enclosure, and marked "PC".

For Exd / NEMA 7 enclosure: There is a "PC" connector located under the glass window. This

enables easy connection of a PC without the need to open the screws of the enclosure.

The communication through this port is in Modbus protocol with a fixed address 1. Therefore, a

SCADA can be connected to the RS-232 port if required.

The port is set to a fixed 115,200 Baud, 8 data bits, 1 stop bit, no parity, and no flow control.

Note: The PC and the SCADA share the same serial port on the SLC-220 Main board. When a

PC or any other terminal is connected to the RS-232 port, the RS-485 SCADA port is disabled

within 10 seconds after the SCADA confirms this event. This is required since the SLC-220 acts

as a slave device, and can handle only one master device at a time: PC or SCADA.

SLC-220 User Guide Rev 2.0 June 2018

29

2.3 Maximum Cable Length between Sensor and SLC-220

The integral cable supplied with the sensor can be extended with another cable after a connection

inside an IP65 junction box.

ID-221 and all ID-223 sensors:

1. For Gas Group IIC hazardous area (Hydrogen):

150 meters maximum if 20 AWG wires (or thicker wires) are used.

1100 meters maximum if 22 AWG wires are used.

2. For Gas Groups IIA or IIB hazardous area (Ethylene and Propane):

1800 meters maximum if 20 AWG wires (or thicker wires) are used.

1100 meters maximum if 22 AWG wires are used.

3. For non-hazardous area:

1800 meters maximum if 20 AWG wires (or thicker wires) are used.

ID-225 sensors:

1. For Gas Group IIC hazardous area (Hydrogen):

150 meters maximum if 20 AWG wires (or thicker wires) are used.

550 meters maximum if 22 AWG wires are used.

2. For Gas Groups IIA or IIB hazardous area (Ethylene and Propane):

1300 meters maximum if 18 AWG wires (or thicker wires) are used.

900 meters maximum if 20 AWG wires are used.

3. For non-hazardous area:

1300 meters maximum if 18 AWG wires (or thicker wires) are used.

ID-227 sensors:

1. For Gas Group IIC hazardous area (Hydrogen):

150 meters maximum if 20 AWG wires (or thicker wires) are used.

1000 meters maximum if 22 AWG wires are used.

2. For Gas Groups IIA or IIB hazardous area (Ethylene and Propane):

1600 meters maximum if 20 AWG wires (or thicker wires) are used.

1000 meters maximum if 22 AWG wires are used.

3. For non-hazardous area:

1800 meters maximum if 20 AWG wires (or thicker wires) are used.

The above maximum cable lengths refer to connecting the sensor to Safety Barriers. Safety

Barriers are usually installed close to the signal processor in a safe area. A safe area may be an

Explosion Proof enclosure installed in a hazardous area. The Safety Barriers may be installed in a

longer distance from the signal processor, and the connecting cable between them and signal

processor should have 16 AWG wires (or thicker).

SLC-220 User Guide Rev 2.0 June 2018

30

If the installation is not in hazardous area (safety barriers are not used):

The cable should be a simple cable used for power purposes, for example 3 times 1 or 1.5 mm².

Do not use a communication cable with twisted wires or a coaxial type.

If the installation is in hazardous area (safety barriers are used):

Use a cable of 3 conductors (gauge as described above), non-twisted inside outer jacket

(communication cables are not good).

The jacket should withstand 500 V RMS.

The capacitance between each two wires should not exceed 200 pF/meter.

The inductance of each wire should not exceed 0.7 uH/meter.

Select such a cable from a catalog or test its capacitance and inductance.

A shielded cable is not required in most cases.

Zener Safety Barriers for installation in hazardous area:

Note: MTL 715+ and 710+ are obsolete. Use MTL 7715+ and 7710+.

SLC-220 User Guide Rev 2.0 June 2018

31

3 Sensor signals, processing & Calibration

Each Leakwise sensor has a cable with three wires named: DET+, DET-, DET Sig.

DET+ : +12VDC supply in reference to DET-. Supplied current is the sum of the currents through

the other two wires.

DET- : Power and signal ground. Returning current between 6 to 9mA, no matter if the sensor is in

air or in water.

DET Sig. : Sensors' current output signal, value depends on sensor model and on liquid condition

around the sensor, typically as follows:

Typical signal values are:

ID-221: In Air: 0.65 to 0.85 mA

In clean Water: 1.00 to 1.30 mA

ID-223 (all models): In Air: 0.90 to 1.10 mA if the sensor is 20 mm or more above bottom flange.

In Air: 0.65 mA when the sensor is resting on bottom flange.

In Oil layer of 30 mm or more: 0.97 to 1.10 mA

In clean Water: 1.60 to 1.90 mA

ID-225/100: In Air: 1.00 mA.

In Oil layer of 110 mm or more: 1.20 mA

In clean Water: 3.20 to 3.40 mA

ID-225/200: In Air: 1.10 mA.

In Oil layer of 230 mm or more: 1.44 mA

In clean Water: 4.30 to 4.50 mA

ID-227: In Air: 0.80 to 1.00 mA.

In clean Water: 1.35 to 1.80 mA

The signal gets lower below Water signal as oil layer increases.

SLC-220 User Guide Rev 2.0 June 2018

32

The following diagram reflects the relation between sensor output signal, set-points, calibration

points and possible status messages that are shown on the front panel Lights, on optional LCD

display, on the PC screen, and the information sent to the SCADA.

The shown µA signal values are typical to ID-223 sensors. Signal decrease means a thicker oil

layer.

Set Points & Calibration Points (µA) Sensor Status

1700µA

1600µA

1570µA

1480µA

900µA

800µA

600µA

0µA

Water Cal. + 100

Water Calibration (Cal. Point = 1600)

Over Range Delta (Value = 100)

Oil Delta (Value = 30)

High Oil Delta (Value = 120)

Water Cal. - 120

Water Cal. - 30

Air Cal. + 100

Air Delta (Value = 100)

Air Calibration (Cal. Point = 800)

Under Range Set Point (Set Point = 600)

SLC-220 User Guide Rev 2.0 June 2018

33

The SLC-220 processor is responsible for status/warning decision-making based on comparing

the existing sensor signal to the calibration and set point parameters that were programmed by

the user.

For example, “Oil Alarm” will be determined when sensor’s signal is more than Water Calibration

minus High Oil Delta set point, and also less than Water Calibration minus Oil Delta set point.

Only one status is possible at a given time.

Calibration parameters Water Calibration and Air Calibration are the basic reference for every

decision-making. These two parameters should be entered once after seeing the measured

sensor signal when the sensor is dry (Air Calibration) and when the sensor is floating in clean site

water (Water Calibration).

All calibration parameters are positive numbers, in µA.

The following set points are in reference to Water Calibration:

• Over range Delta: Sensor signal above Water Calibration + Over Range Delta is

abnormal and indicates that the sensor either went under water or failed.

• Oil Delta: Sensor signal below Water Calibration – Oil Delta means oil detection. This is

the first oil alarm setting, for relatively thin oil layer detection.

• High oil Delta: Sensor signal below Water Calibration – High Oil Delta means high-oil

detection. This is the second oil alarm setting, for relatively thick oil layer detection.

Air Delta is in reference to Air Calibration. This parameter ensures that when the sensor is not

floating on water or on oil, the indicated status will be AIR even if the sensor is not 100% dry.

Under Range Set Point is an absolute parameter. It defines a minimum signal which is normally

expected from the sensor. If sensor signal is lower than this value, it the sensor failed.

In addition to the above parameters, there is a Hysteresis parameter that influences each

comparison of sensor’s signal to the other parameters and calibration points. The default value is

5 µA, and it adds a hysteresis of ±5 µA around each crossing point between two adjacent status

decisions.

SLC-220 User Guide Rev 2.0 June 2018

34

Status Description

1. WATER: The most normal indication when no oil is detected, and the sump is not dry.

2. OIL alarm: Small oil layer was detected.

3. HIGH OIL alarm: A thick oil layer was detected, thicker than Oil 1 Alarm.

4. AIR: The sensor is out of water or oil (the sump is dry).

5. SIGNAL TOO HIGH: Indicated a possible sensor failure or an improper floatation (too

deep or submerged).

6. SIGNAL TOO LOW: Indicated a possible sensor failure.

The Lights on the front panel will show FAIL status for any fail indication. The details about the

nature of the failure can be seen through the PC, Modbus, LCD or wireless communication,

whatever option implemented.

Parameters Description

•

Water Calibration

A value (in μA) that is equal to sensor output when floating properly in clean water. If the

measured signal is more than Water Calibration - Oil Delta + Hysteresis, then the status is

WATER.

•

Oil Delta

A value (in μA) below Water Calibration.

If sensor's signal is less than Water Calibration - Oil Delta - Hysteresis then the status is OIL

alarm.

•

High Oil Delta

A value (in μA) below Water Calibration.

If sensor's signal is less than Water Calibration - High Oil Delta - Hysteresis then the status is

HIGH OIL alarm.

•

Air Calibration

A value (in μA) that is equal to sensor output in Air, without any liquid around.

Note: For ID-223, this is the value when the sensor is held by a non-metallic spacer at least

2 cm above the bottom flange of the cage.

•

Air Delta

A value (in μA) above Air Calibration. It is used for ensuring Air status even if the sensor is a bit

wet or doesn’t sit correctly on the bottom flange.

If measured sensor's signal is less than Air Calibration + Air Delta – Hysteresis then the status is

AIR.

SLC-220 User Guide Rev 2.0 June 2018

35

•

Hysteresis for all Thresholds

This is a value (in μA) above and below each of the crossing points between adjacent

status indications. This value introduces a Hysteresis window around each crossing point

to prevent bouncing between two status changes and unstable operation of relay outputs.

This value if 5 μA as default, but can be changed (see SLC-220 Advanced Settings).

•

Over range Delta

This is a value (in μA) above Water Calibration. If measured sensor's signal is higher than

Water Calibration + Over Range Delta + Hysteresis, the status will be FAIL:

SIGNAL TOO HIGH.

•

Under Range Set Point

This is an absolute value (in μA) that indicates an abnormal low sensor signal value limit. If

measured sensor's signal is lower than Under Range Set Point - Hysteresis, the status will

be FAIL: SIGNAL TOO LOW.

Note:

The SLC-220 is factory set and calibrated according to the supplied sensors or to typical values of

the supplied sensors. The minimum settings that should be done after installation are: Water

calibration, Air calibration, Oil Delta and High Oil Delta.

NOTE:

Refer to sensor User Guide for specific notes related to floatation and calibration.

Important Note:

All the following calibration rules must always be valid to enable the system to perform

correctly:

• Water Calibration > Air Calibration

• Oil Delta < High Oil Delta

• (Water Calibration - High Oil Delta - Hysteresis) >

(Air Calibration + Air Delta + Hysteresis + 10 μA)

• Under Range Set Point < Air Calibration

The SLC-220 will give a feedback if the rules are violated and will reject such wrong settings.

SLC-220 User Guide Rev 2.0 June 2018

36

SLC-220 User Guide Rev 2.0 June 2018

37

4 Using the SLC-Manager Program

4.1 Program Installation

The SLC-Manager Program is supplied on a CD. It will work on MS Windows XP, 7 and 10

operating systems. A RS-232 cable is also supplied. The PC needs a RS-232 serial port or a USB

port with USB to RS-232 adaptor.

Simple installation of the SLC-Manager Program is required from the Installation folder in the CD;

run setup.exe. SLC-Manager (and SLC-Manager OFFLINE for versions before 2.0.0.1) will be

created in the Start menu and on the desktop. Use SLC-Manager to start the program when a

SLC-220 unit is connected to the PC. SLC-Manager OFFLINE can be used to work on settings

without a connection to the SLC-220 unit.

4.2 Entry Screen

SLC-220 User Guide Rev 2.0 June 2018

38

Unit Type:

Currently it is SLC-220. In the future SLR-220 central controller will be available for selection.

About/Info button:

Optional access to documentation.

Offline Mode (Not Connected) check box:

For version 2.0.0.1 and later. If the Check Box is marked, the program enables loading a

parameters file from PC, editing the parameters and then saving them to PC. No communication

with the SLC-220 controller can be done.

Communication Settings button:

Selecting and setting of the PC serial port. Default setting is 115,200 baud, 8 data bits, no parity,

one stop bit. If the SLC-Manager doesn’t connect to the SLC-220, press the Advanced button

and then Save.

Optionally, MODBUS registers access is possible for the integration phase with a SCADA.

Change User Authorization Level button:

There are three available system access levels:

View Level:

Default entry level when the program is launched. It enables only viewing the settings

without the ability to change them.

Technician Level:

Allowed to view all parameters and can also change most practical parameters.

Initial password is 1234. It can be changed in the SLC-220 Settings screen.

Administrator Level:

Allowed to view all parameters and can also change all parameters (including advanced).

Initial password is 5678. It can be changed in the SLC-220 Settings - advanced screen.

If the correct Password is not accepted by the SLC-220, reset both SLC-220 and SLC-Manager.

The current active User Level is displayed at the bottom of the screen, below the Date/Time.

Connected / Disconnected indication:

Indicates if the SLC-220 is communicating with SLC-Manager. A Green dot indicated Connected;

a Red dot indicates Disconnected.

SLC-220 Main board serial number: Displayed below the Connected/Disconnected indication.

SLC-220 Main board firmware version: Displayed below the serial number and above

Date/Time.

Date and Time: Taken from the controller. It will be updated to PC time during the next “Save to

SLC” operation – see section 4.5.

Enter button: Enter to the Main Sensors View screen.

Exit button: Exit SLC-Manager.

SLC-220 User Guide Rev 2.0 June 2018

39

4.3 Main Sensors View Screen

This screen shows the current status of all four sensors.

For each sensor the data includes:

Sensor / Installation site name,

Status,

Raw sensor signal in µA

A color bar graph that indicates the signal visually within the calibration range.

Sensor 1 / Sensor 2 / Sensor 3 / Sensor 4 buttons:

Pressing one of these buttons continues to a detailed specific Sensor Settings screen.

Entry Screen button: Return to the Entry Screen.

SLC-220 Menu button: Continue to the SLC-220 Settings screen.

The lower area of the screen is for SLC-220 special status / error Messages.

SLC-220 User Guide Rev 2.0 June 2018

40

4.4 Sensor Settings Screen

This screen enables viewing and changing the parameters of a specific sensor, and also view the

status in the corresponding Outputs board.

The number of the selected sensor is shown on the top-left.

The default view is View Parameters as shown on next page.

SLC-220 User Guide Rev 2.0 June 2018

41

The parameters can be changed after pressing the Change Parameters button by a Technician

or by an Administrator user level:

The parameters are (see also chapter 3):

1. Sensor name: A text field with up to 13 characters.

2. Sensor model: As defined. It is important to select the correct model since the typical

signal ranges are selected by the system and used to derive self-test results.

3. Air Calibration: A value (in μA) that is equal to sensor output in Air, without any liquid

around.

Note: When the Calibrate button is pressed (on this line while in the Change mode), a

measuring cycle is performed, and the sensor signal is taken as Air Calibration. This

means that the sensor must be in dry condition when doing this.

4. Oil Delta: A value (in μA) below Water Calibration. If sensor's signal is less than Water

Calibration - Oil Delta - Hysteresis, then the status is OIL alarm.

5. High Oil Delta: A value (in μA) below Water Calibration. If sensor's signal is less than

Water Calibration - High Oil Delta - Hysteresis, then the status is HIGH OIL alarm.

SLC-220 User Guide Rev 2.0 June 2018

42

6. Water Calibration: A value (in μA) that is equal to sensor output when floating properly in

clean water. If the measured signal is more than Water Calibration - Oil Delta +

Hysteresis, then the status is WATER.

Note: When the Calibrate button is pressed (on this line while in the Change mode), a

measuring cycle is performed, and the sensor signal is taken as Water Calibration. This

means that the sensor must be in clean water when doing this.

7. Current Season, Winter Offset: Either Summer or Winter. In winter, the parameter

Winter Offset is subtracted from Water Calibration for compensating the influence of water

icing.

8. AutoCleaner Installed: Future feature. Relevant for a ID-227 sensor connected as sensor

number 1. If Yes is selected, the automatic sensor cleaning will be enabled.

9. Alarm at Air: If Yes is selected, Air status will be treated as an Alarm condition. Select

Yes for ID-221 or ID-225 or ID-227. For ID-223 it depends on the application.

10. Sample Interval: Relevant for firmware versions before 4.1. Determines how often the

system will take a signal sample from the sensor for validating / updating the status. This is

important for battery operated systems. The interval can be between 30 seconds and 15

minutes, or it can be sampling Continuously.

11. Delay Time (Filter): Relevant for firmware versions before 4.1. A delay window between 1

and 30 seconds on the reading from the sensor. This is important if the sensor is installed

in a non-stable liquid environment. Any alarm will have to be present enough readings

within the delay window to take effect as a valid status. See also Alarm Reading

Percentage Threshold.

12. Warm Up Time: Relevant for firmware versions before 4.1. A period letting the sensor

reach a stabilized output signal after it is turned on. The sampling is done after this period

has ended. This parameter should be correlated with the level of liquid instability in which

the sensor floats. This period can be set between 0.5 second and 15 seconds.

Save to SLC button: Writes the updated parameters to the SLC-220 unit, and updates the View

Parameters column on the left.

Load from SLC button: Reads the existing parameters from the SLC-220 unit for viewing and

changing if necessary.

Save to PC button: Writes the updated parameters to the PC as a xml file.

Load from PC button: Reads parameters from a xml file in the PC for viewing and changing if

necessary, and for saving to the SLC-220 if necessary.

Exit (Back) button: Return to the Main Sensors View screen.

SLC-220 User Guide Rev 2.0 June 2018

43

Notes:

1. In each screen where parameter where changed, press Save to SLC button or Save to

PC button (as appropriate) BEFORE changing to a different screen or exiting the

program. If a substantial sensor parameters change is done in the two screens related to

the sensor, press the Save to SLC button only after doing all such changes, to avoid

conflicts between parameters.

2. On versions before 2.0.0.1: After Load From PC, do a Save to SLC from each screen.

3. It is recommended to have the parameters saved also to the PC for future reference.

4. When a parameter is changed, it is colored red until it is saved to the SLC or to the PC.

5. If the Save operation is stuck or gives an error message, reset the SLC-220 and the SLCManager.

6. After the parameters are saved on the SLC-220 controller, the on-board Buzzer will

confirm it with a single beep, or reject the data by sounding multiple beeps.

Pressing the Advanced button enables an Administrator user to view and change additional

special parameters:

Pressing the View Parameters button returns the display to the basic Sensor parameters.

1. Alarm Reading Percentage Threshold: Relevant for firmware versions before 4.1. When

the Delay Time (Filter) opens a measurement window to filter out unstable readings, the

Alarm Reading Percentage Threshold (between 5% and 100%) defines the proportion

between the two alternating statuses for determining the "winning" status in unstable liquid

conditions. For example, if 70% is selected, and then 85% of the readings "vote" Oil status

while the other 15% "vote" Water status, then Oil status will be determined at the end of

the Delay Time.

SLC-220 User Guide Rev 2.0 June 2018

44

2. Sensor Filter Level: Signal digital filtering level on sensor measurements before reaching

the stage of determining the status. There are 16 levels of filtering, where level 15 is the

highest level and used when the sensor floats in a very non-stable liquid environment.

Level 0 doesn’t filter at all, and is used for calm water conditions. It is advised to check

Water Calibration after changing this parameter.

3. Alarm Cycles Wait Before Transmit: Relevant for firmware versions before 4.1. This

determines how many Sample Intervals will be performed from the moment that a new

status change is first detected, until the new status is accepted as valid. If the status

changed during one of the cycles, the new status is ignored, and the process starts again.

The number of cycles can be between 1 and 7. 1 means that one additional cycle is added

to the original cycle, so two consecutive cycles must "agree" on the same status change. If

Immediate is selected, then the status is determined at the end of each cycle.

4. Over Range Delta: This is a value (in μA) above Water Calibration. If measured sensor's

signal is higher than Water Calibration + Over Range Delta + Hysteresis, the status will

be FAIL: SIGNAL TOO HIGH.

5. Under Range Set Point: This is an absolute value (in μA) that indicates an abnormal low

sensor signal value limit. If measured sensor's signal is lower than Under Range Set Point

minus Hysteresis, the status will be FAIL: SIGNAL TOO LOW.

6. Air Delta: A value (in μA) above Air Calibration. It is used for ensuring Air status even if

the sensor is a bit wet or doesn’t sit correctly on the bottom flange. If measured sensor's

signal is less than Air Calibration + Air Delta – Hysteresis, then the status is AIR.

7. Sensor Current Pos Reading: This is a read only value (in μA), shown in red, of the

measured current through the positive wire of the sensor, representing current

consumption of the sensor. It is updated each time the Advanced screen is entered.

8. Sensor Current Neg Reading: This is a read only value (in μA), shown in red, of the

calculated current through the negative wire of the sensor, representing return current

consumption of the sensor. The value equals the difference between measured current

through the positive wire and Sensor Signal (shown on Main View Screen). It is updated

each time the Advanced screen is entered.

SLC-220 User Guide Rev 2.0 June 2018

45

Pressing the View Outputs button displays the status of the relays and 4-20mA output that are

associated to the specific sensor (for example, Outputs board #1 is associated to Sensor #1):

SLC-220 User Guide Rev 2.0 June 2018

46

4.5 SLC-220 Settings Screen

This screen enables viewing of general and common parameters.

The parameters are:

1. Sensors Enabled: Shows the enabled sensors. The disabled sensors are not shown. In

the above example, only sensor 1 and sensor 3 are enabled. Only these sensors will be

activated and monitored, and will have influence on all the available outputs.

Note: For disabled sensors, all relays will be de-energized, and all 4-20mA outputs will be

set to 4.33 mA.

2. Safety Barriers Installed: Used for reference only. No actual functionality.

3. Lights: There are two operating modes for the lights: Common or Individual. Refer to

chapter 2.2.6 above.

4. Outputs boards installed: This should represent the actual number of installed Outputs

boards. This can be none, 1, 2, 3 or 4 boards.

The last option is one board with a common function:

Relay #1 will be activated when sensor #1 has Oil status,

Relay #2 will be activated when sensor #2 has Oil status,

Relay #3 will be activated when sensor #3 has Oil status,

Relay #4 will be activated when sensor #4 has Oil status,

Relay #5 will be activated when any of the four sensors has Fail status.

In addition, the Analog output (4-20mA) will be associated to sensor #1.

SLC-220 User Guide Rev 2.0 June 2018

47

5. Relay Fail-safe operation: There are three options for the operation logic of the relays in

the Outputs boards:

• No fail-safe: The relays are de-energized unless an appropriate event (for example Oil

alarm) occurred.

• One fail-safe: Only the Fail relay (Relay #5) is fail-safe.

• All fail-safe: All relays are energized unless an appropriate event occurred and released

them.

6. 4-20mA Output: Enable / Disable the 4-20mA outputs for all Outputs boards. If Disable is

selected, all 4-20mA outputs will be set to 4.33 mA.

7. Internal Buzzer: Not implemented. Affecting a small buzzer located on the SLC-220 Main

board. It can be disabled or set to beep in various alarm/fail conditions.

8. External Buzzer/Horn: Not implemented. Affecting an external audio alarm device

connected to TB6 on the SLC-220 Main board. It can be disabled or set to beep in various

alarm conditions.

9. Display: LCD with touch screen is optional. When not installed or not used, it should be

disabled.

10. MODBUS Address: Individual address for each SLC-220 unit when connected to a

SCADA through RS-485. The address can be between 1 to 255.

11. MODBUS Baud Rate: Baud Rate setting, between 1200 and 115200.

SLC-220 User Guide Rev 2.0 June 2018

48

12. Technician Password: Initial password is 1234.

13. Power Supply Voltage: Indication of voltage supply to the Main board, for viewing only.

Save PC Time and Date: If checked, the time & date from the PC will be sent to the SLC-220

when pressing the Save to SLC button.

Save to SLC button: Writes the updated parameters to the SLC-220 unit, and updates the View

Parameters column of the left.

Load from SLC button: Reads the existing parameters from the SLC-220 unit for viewing and

changing if necessary.

Save to PC button: Writes the updated parameters to the PC as a xml file.

Load from PC button: Reads parameters from a xml file in the PC for viewing and changing if

necessary, and for saving a file to the SLC-220 if necessary.

Exit (Back) button: Return to the Main Sensors View screen.

Notes:

1. In each screen where parameter where changed, press Save to SLC button or Save to

PC button (as appropriate) BEFORE changing to a different screen or exiting the

program.

2. It is recommended to have the parameters saved also to the PC for future reference.

3. When a parameter is changed, it is colored red until it is saved to the SLC or to the PC.

4. After the parameters are saved on the SLC-220 controller, the on-board Buzzer will

confirm it with a single beep, or reject the data by sounding multiple beeps.

SLC-220 User Guide Rev 2.0 June 2018

49

Pressing the Advanced button enables an Administrator user to view and change additional

special parameters:

Pressing the View Parameters button returns the display to the basic SLC-220 parameters.

1. Administrator Password: Initial password is 5678.

2. Project Index: All SLC-220 units considered as a single group in a site will have the same

project index. The index can be between 1 and 65536. This is important when working

under a common controller, such as SLR-220.

3. Hysteresis: A value in µA that is added / subtracted to/from the calculation of each cross-

point between two adjacent statuses. This can be 1, 3 5 or 10 µA. A lower number is good

for operation in calm water, a higher number is better for turbulent water.

4. Test Mode: For firmware version 4.1 or later. For normal and default SLC-220 operation,

the setting is No. After selecting Yes, the scanning of the enabled sensors is slowed down

significantly, to enable current measurement of sensors wires with a mA meter. A beep

from the Main board is heard every 10 seconds, when the next sensor is powered. Status

updates are slowed down, therefore it is the responsibility of the user to exit the Test Mode

at the end of the test.

SLC-220 User Guide Rev 2.0 June 2018

50

5. Low Battery Threshold for Warning: For battery operated units. A warning will be sent if

battery voltage decreases below this value.

6. Low Battery Threshold: Save Power: For battery operated units. The SLC-220 will enter

a power save mode and will not monitor the sensors. The idea is not to drain the battery

too much. Power save mode will continue until battery voltage rises above this value.

7. Sensor + Supply Upper Legal Limit: Maximum allowed current consumption through the

positive sensor wire.

8. Sensor + Supply Lower Legal Limit: Minimum allowed current consumption through the

positive sensor wire.

9. Sensor - Supply Upper Legal Limit: Maximum allowed current consumption through the

negative sensor wire.

10. Sensor - Supply Lower Legal Limit: Minimum allowed current consumption through the

negative sensor wire.

SLC-220 User Guide Rev 2.0 June 2018

51

5 Using the optional front panel LCD

The 4.3" graphic color display with integrated touch panel enables the viewing of sensors status

and parameters, and enables setting of the parameters in a similar way as with the SLC-Manager

PC program.

The SLC-220 button is the entry to screens that show parameters which influence general

features that influence all the sensors.

Sensor #1 through Sensor #4 buttons are used to view and set Individual sensors.

System Overview Screen

The System Overview Screen shows the sensors status and names & a corresponding Bargraph for each active sensor.

Bar-graph interpretation:

Sensor status

Bar-graph fill percentage

Bar-graph color

Water

20%

Green

Signal too low

20%

Yellow

Signal too high

20%

Yellow

Air

Full (100%)

Yellow

Oil and High Oil

1%(min. oil) ÷ 100% (max. oil)

Red

The small blue button named "i" is not relevant for any settings. Pressing it shows company logo,

power supply voltage, Main board serial number and its' Software version.

The empty area on the left side of "i" is reserved for optional error messages.

Both SLC-220 and Sensors settings have two levels of parameters: Normal and Advanced. As

implied by the name, the "Normal" parameters are those which may be required to change during

SLC-220 User Guide Rev 2.0 June 2018

52

normal use, whereas the "Advanced" parameters should only be modified by an Administrator who

knows the system in depth.

The explanation of each parameter is found in chapter 4 above (sections 4.4 & 4.5).

Pressing Sensor #x to edit its' parameters. To edit sensor Name, press the Edit button for this

parameter. A keypad appears with UPPERCASE letters:

By pressing the "abc" button (on the left side of the "Space" button, bottom row) the keypad

changes to a lowercase keypad:

SLC-220 User Guide Rev 2.0 June 2018

53

The button "abc" has changed to "1&2" as well as the letters changed to lowercase.

Pressing the "1&2" button will change the keypad to the Numbers & Symbols keypad:

The button "1&2" has changed to "ABC" as well as the letters changed to Numbers & Symbols.

Pressing the "ABC" button will change the keypad back to the UPPERCASE keypad. The keypad

changes in a cyclic manner.

When a numeric parameter is edited, a numeric keypad appears:

SLC-220 User Guide Rev 2.0 June 2018

54

Notes:

• The system performs a 2-3 seconds self-test when turned on and after saving changes to

parameters.

• After changing parameters, the user should save the changes or discard them by pressing

"Back" and agree to discard the changes.

• When the PC is connected to the SLC-220, the user is not supposed to work with the LCD

and change parameters, to avoid contradictions; Therefore, the LCD is automatically

disabled when the unit is connected to PC.

• The display mode "Back Light Auto Off" shuts the display back light after 10 minutes of no

touch-panel activity. To activate the display again just touch anywhere on the display. It

resumes at the System Overview Screen and discards all unsaved changes. This mode is

recommended to enable longer life time for the display module.

• After the parameters are saved on the SLC-220 controller, the on-board Buzzer will

confirm it with a single beep, or reject the data by sounding multiple beeps.

SLC-220 User Guide Rev 2.0 June 2018

55

6 Using the optional GSM MODEM

The optional GSM & WCDMA cellular MODEM (Sierra Wireless AirLink GL8200) enables a

remote over-the-air cellular wireless connectivity of the SLC-220 to cell phones or other cellular

modems. A cellular modem communicating with the SLC-220 can be a part of SLR-220 receiver

or a part of any end-user computerized system.

The SLC-220 will send reports only to pre-defined users. The reports are text (SMS) messages

generated according to the status of the sensors and according to the messaging setup.

The format of status messages is:

nn,sensor name,Status,Signal

nn - Serial number of the message. The number rolls to 01 after reaching 99. Message

numbers help to identify the order of sent messages in cases of multiple messages during

a short period of time, or in case that the cellular infra-structure is heavily loaded.

sensor name - Sensor name (up to 13 characters), as programmed previously by the user.

The name appears in the messages inside double quote characters, for example

“Tank 15”.

Status – Can be either Air or Water or Oil or HiOil or Fail.

Signal - a 4 digit value with the uA units (micro Amperes) at the end. This is the last known

reading of the sensor before the message was sent.

Example:

24,”TANK 7 DRAIN”,Water,1563uA

Repeated messages of the current status will be sent as often as required and set, and this

serves as an indication that the system is alive.

The user can set many operational parameters by sending text messages in one of the formats

listed in paragraphs 6.1, 6.2 and 6.3 below. Each message is responded by the SLC-220 in a

similar format as an acknowledge. The user should wait for this acknowledge before sending the

next message to the SLC-220.

There are three main types of text messages to the SLC-220:

• Configuration - set & get an acknowledge.

• Calibration - set & get an acknowledge.

• Inquiry - inquire & get a reply containing the requested data / parameters.

Currently the SLC-Manager PC program is sufficient to set and review all parameters of SLC-220,

except the specific parameters related to the GSM option.

The LCD on the front panel of the SLC-220 (if installed), is another way for setting and review all

parameters of SLC-220, and in addition can be used to set GSM users.

Configuration setup can be done through the LCD and through SMS messaging to / from the

SLC-220.

SLC-220 User Guide Rev 2.0 June 2018

56

Notes:

• The text of all messages is NOT case sensitive, i.e. “b” is the same as “B”. The only

exception is Sensor Name, which must be in capital letters.

• There are no space characters in all messages, only coma (,) separation is allowed. The

only exception is the text of Sensor Name which may include space character/s.

• Message sender (the GSM modem of the SLC-220) is identified by the phone number of

the SIM card installed (user responsibility).

• The messages don’t include a date/time stamp. The user will have a date/time stamp when

the SMS message is received by the cell phone or receiving computer with GSM modem.

The serial number of the message helps to identify the order of the incoming messages to

the user.

• When sending Configuration, Calibration or Inquiry text messages to SLC-220, the replies

from SLC-220 will be sent to the phone number which sent the initial message. Therefore,

the phone number of the sender must be recognizable and shouldn’t be hidden.

• Text messages sent to human user #1 are followed by a voice dial, which the user should

reject. This is to indicate that a message was sent, even if it wasn’t received yet.

Notes for battery operated SLC-220 with GMS option:

The GSM modem will turn off after 10 minutes of inactivity of incoming / outgoing messages in

order to conserve battery power. After one hour, the modem will be turned on to check for

incoming messages.

The user can send text messages to the SLC-220 for quick response (subject to cellular network

load) in the following timing windows:

1. Within 10 minutes after system power-on - A session window of 10 minutes is initiated by

the first SMS sent to the SLC-220, and the SLC-220 will respond immediately.

2. Within 10 minutes after SLC-220 sends any text message – A session window of 10

minutes is initiated, and the user can communicate with the SLC-220 immediately.

Therefore the 10 minutes window will be extended as required, until the session is not

active for 10 minutes.

The user can send up to 20 messages to the SLC-220 at any time even when the GSM modem is

turned off. The SLC-220 will respond within one hour and initiate a session window of 10

minutes. It is the responsibility of the user to send correct messages and wait for confirmation

from the SLC-220 before continuing with additional settings which may create a conflict.

Note: The above is not implemented yet in firmware versions 4.1 and up.

Installing a SIM card in the GSM Modem:

The modem is attached to the instrument frame with a detachable two-part “Scotch” tape.

Locate the slot for inserting the SIM card (mini SIM size) and verify that the card is locked in place.

The SIM card should not be protected by a PIN code.

The GSM modem supports 2nd generation and 3rd generation networks.

SLC-220 User Guide Rev 2.0 June 2018

57

6.1 Configuration Messages

6.1.1 User Configuration

It is possible to define up to 8 cellular users. Users 1 to 6 are cell phones that receive humanreadable messages, and users 7 & 8 are GSM modems connected to computers and receive the

data in a “computer friendly” format.

Message format:

CFGUSM,user number,phone number,status list,enable

user number: 1 to 6 are human users (cell phones), 7 & 8 are GSM modems & computers.

phone number: The cell phone number that will receive the messages from the SLC-220.