Leading Edge 36201, 48201, 56001LC, 48203, 5600-3 Operators Manual

...

ASSEMBLY INSTRUCTIONS & PARTS MANUAL FOR

COMMERCIAL CEILING FANS

CEILING FANS SHOULD BE INSTALLED

MODEL: 36201, 48201, 56001LC

48203, 5600-3, 48201B

BY QUALIFIED INSTALLER.

SPECIFICATIONS

MODEL

NUMBER

36201

48201

48201B

56001LC

48203*

56003*

*This ceiling fan is operated by a pull chain switch which controls the three speeds: 0-off, 1-low, 2-medium, 3-high. (See figure 5 for illustration)

READ INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE OR SERVICE THE LEADING EDGE

CEILING FAN. FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR

PROPERTY DAMAGE.

RETAIN FOR FUTURE REFERENCE.

BLADE

SWEEP COLOR VOLTAGE

36”

48”

48”

56”

48”

56”

White

White

Black

White

White

White

120

120

120

120

120

120

MAX

HZ

50/60

50/60

50/60

50/60

50/60

50/60

MAX

RPM

395

315

315

265

315

265

MAX

AMPS WATTS

.65

.85

.85

1.0

.86

1.0

75

86

86

110

80

110

WT

(LBS)

20

22

22

24

23

26

General Safety Information

WARNING: DISCONNECT POWER BEFORE

INSTALLING OR SERVICING THIS EQUIPMENT.

1. All electrical wiring should be done by a qualified

electrician in accordance with applicable National

Electrical Code and local electrical codes.

2. Do not allow moving blades to come in contact with

any part of the body.

3. Mount fan so that fan blades are 7 feet or higher

from floor.

4. Make sure hanger hooks are mounted securely to

structural ceiling members.

5. Do not mount in an area which will allow the fan to

get wet.

WARNING: DO NOT USE IN AN EXPLOSIVE

ATMOSPHERE.

6. Make certain that the ground wire is connected to

the ground terminal and to a suitable electrical

ground.

NOTE: When mountedin cathedral ceilings, the blade tip

should be at least 12 inches from the angled roof line to

prevent air “blow back” causing possible fan sway.

CAUTION: Read and follow instructions carefully.

Failure to comply with instructions could result in

the risk of fire, shock and injury to persons.

WARNING: TO REDUCE THE RISK OF PERSONAL

INJURY DO NOT BEND THE BLADE BRACKETS

WHEN INSTALLING THE BRACKETS OR CLEANING

THE FAN. DO NOT INSERT FOREIGN OBJECTS IN

BETWEEN ROTATING FAN BLADES.

Description

Leading Edge Fans are designed as a dual purpose

product. By minimizing temperature stratification in

winter, they can reduce heating costs in high bay

buildings. The summertime application provides a gentle

downward movement of air for general air recirculation

and evaporative cooling. A permanent split capacitor

motor and permanently lubricated ball bearings add to

the efficiency and quietness of the fans.

Unpacking

1. Remove fan components from carton carefully.

2. Check for shipping damage.

3. Check for missing parts against parts list.

RECOMMENDED MOUNTING HEIGHTS

For heat reclamation, this fan should be mounted on the

standard 2’ downrod included. In low ceiling applications,

the 8” downrod must be used in order to keep the fan

blades a minimum of 7’ from the floor. On installations

through drop ceilings, note the diameter of the downrod

hole in the ceiling should be 2

CAUTION: Fan blades should not be mounted lower

than 7 feet above the floor.

1

/2”.

Assembly

This fan includes a “secondary support” safety cable feature that complies with existing C.S.A. (Canadian

Standards Association) requirements and all other

proposed safety regulations for overhead air movement

equipment. To insure proper installation of this important

safety feature, please read and follow these instructions

carefully.

1. Carefully unwrap the coiled safety cable and motor

lead wires.

2. At the motor yoke assembly (A), remove the cotter pin

and loosen the hexagon nut. Carefully remove spring

washer and the hexagon screw (E).

3. Slide the upper canopy cover (B) (bell shaped) up the

rod. Slide the lower canopy cover (C) up to rod.

4. Feed the three motor lead wires and the safety cable

through the center hole in the steel yoke above the

motor housing and then continue feeding wires and

cable through the downrod until the wires and cable

come out at the upper (shackle) end.

5. Reconnect the downrod to the steel yoke and replace

the hexagon screw. Secure the spring washer, hexagon nut, and the cotter pin making sure cotter pin is

spread to secure in place.

NOTICE: The safety cable should be taped to one side

of the yoke with electrical tape to prevent the cable from

resting on top of motor during running operation.

(See Figure 2)

6. Slide the lower canopy (C) to allow a 1/4” minimum

height above the motor.

CAUTION: Do not allow the permanently installed

lower canopy to touch the revolving motor as damage will occur. Make sure all wires are securely

placed to avoid rubbing against the motor.

7.Attach the three blades, curved side down to the motor

with the insulation pad mounted between the blade

and the motor (See Figure 5). Make sure blade holder is flat against motor platform when tightening blade

nuts for secure fit.

CAUTION: Blades must be fastened to the motor as

shown in Figure 1. DO NOT reverse blades when

installing.

NOTE: Blades are weight balanced per set. DO NOT mix

on multiple fan installations.

NOTE:Do not bend fan blade brackets.

WARNING: DISCONNECT CIRCUIT POWER BEFORE

MAKING ANY ELECTRICAL CONNECTIONS.

CAUTION: To reduce the risk of personal injury,

install the primary mounting directly from building

structure and use only the hardware provided with

the fan.

8. Before attaching the appropriate “J” hook to the

building structure member note the following:

IMPORTANT. WHEN MOUNTING THIS FAN, THE

SUPPORT BEAM MUST BE SUITABLE FOR A 50

(See Figure 1)

OUND LOAD LIMIT.

P

CAUTION: If Pilot hole is used with the wood thread

hook, the pilot hole should be drilled no larger than

the minor diameter of the screw threads on the hook.

Do not put lubricant on the “J” hook. At least 1

the screw threads should be inserted into the

structural wood joist. When the threaded bolt hook

is used, be careful to secure tightly with supplied

lockwashers and nuts. Attach the hook as instructed

and hang the fan.

WIRE

RUBBER

ROLLER

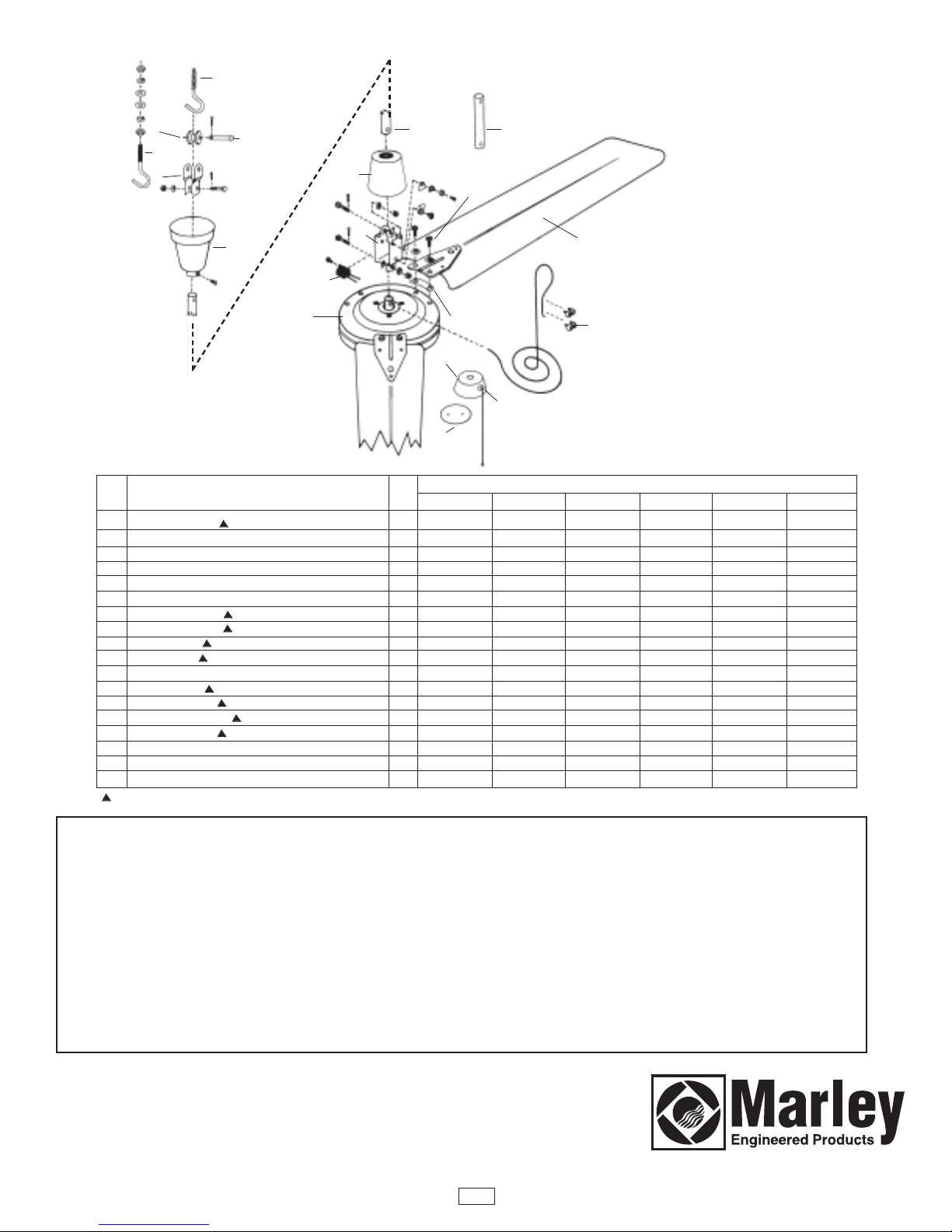

Figure 1 - Assembly

COTTER PIN

MOTOR YOKE

ASSEMBLY

STEEL YOKE

CAPACITOR

CAUTION: Never adjust the

lower shaft bolt assembly which

is precision secured during the

manufacture of this fan.

WOOD JOIST

HOOK

(D) UPPER SHACKLE ASSEMBLY

CAUTION: Leave 1/4” clearance

between upper canopy

and ceiling.

(B) UPPER CANOPY COVER

(F) SET SCREW

DOWNROD

(C) LOWER CANOPY COVER

CAUTION: Leave 1/4” clearance

between lower canopy

and motor housing.

(E) MOUNTING HEX BOLT SET

METAL BEAM

STYLES

HEX BOLT

OCKWASHER

L

PLASTIC PAD

MOTOR HOUSING

CAUTION: Make sure that blades are attached as

shown.

9. This fan is equipped with the required “secondary

support” cable. This cable must be affixed to the

beam structures and securely clamped in such a manner to support the weight of the fan in the event the

mounting hook or other parts fail. After wrapping cable

around a structural member that will support 300

lbs., secure cable with supplied cable clamps as

illustrated in Figure 3. (Note: Any additional materials

needed for specific installations may be purchased

from your local distributor.)

NOTICE: Leave approximately 3” but no more than 5” of

slack on this safety cable to allow for possible fan

movement. Do not exceed more than 5” total slack.

IMPORTANT CAUTION: The safety cable must not be

placed between the rubber roller and hook but as

illustrated in Figure 3.

2

BLADE

1

/2” of

10. When hanging fan on factory supplied “J” hook,

make sure cable at top of rod is positioned

behind “J” hook as illustrated in Figure 3.

ELECTRICAL WIRE

RUBBER

ROLLER

SAFETY CABLE

Figure 2

Figure 3

HOOK

SAFETY CABLE

IMPORTANT NOTICE: It is important to note proper

installation position of the cable clamps as illustrated in

Figure 4. To obtain maximum holding power, install

U-bolt section of clip on dead or short end of cable and

saddle on long end of cable. Improper installation

reduces the efficiency of the connection by as much as

40 percent.

HITE

W

MOTOR

Figure 5

BLACK

GRD.

WHITE/BLACK

OPTIONAL

OLID STATE

S

REGULATOR

B

13. If a remote speed control is to be used refer to the

installation included with that control for proper in-

installation and wiring.

14. Restore power.

15. After completing installation, test run fan in normal

operating manner. Inspect for any possible shake or

wobble which may be caused by binding as a result

of “tight cable“. If this should happen, shut off power

supply and re-check instructions to correct problem.

NOTE: When any solid state motor speed control is

used, a humming noise will be present in the fan on low

speed. This hum in no way affects the operation of the

fan and is acceptable in most industrial installations. (Not

applicable to Models 4820-3 and 5600-3).

CAUTION: Do not flip switch from forward to reverse

or vice versa without waiting for motor to stop.

Damage to motor or driven equipment can result.

Maintenance

LACK

BLACK

GRD.

Figure 4

WARNING: DISCONNECT CIRCUIT POWER BEFORE

MAKING ANY ELECTRICAL CONNECTIONS.

11. Run the wires from the downrod assembly to the

electrical supply using appropriate wiring in accordance with the local code. Connect with listed wire

connectors available from your local distributor.

Connect black to black, white to white, and green

grounding lead to the grounded conductor of the

supply circuit. No loose strands or loose connections

should be present. After splices are made, the wires

should be spread apart so that the green and white

are on one side of the outlet box and the black is on

the other side. Turn splices upward and carefully

push all wiring into outlet box.

12. Slide the upper canopy (B) up the rod to within 1/4”

of the ceiling or beam and securely tighten the set

screw (F).

WARNING: THIS FAN HAS AN INTERNAL SELFRESETTING THERMAL OVERLOAD PROTECTOR.

ALWAYS DISCONNECT FROM POWER SUPPLY

BEFORE SERVICING.

LUBRICATION

All bearings are permanently lubricated and do not

require further lubrication.

CLEANING

This fan may be wiped off with a damp cloth. Do not

allow the motor to get wet. Do not use solvents or harsh

detergent.

CAUTION: Before servicing or cleaning unit, switch

power off at service panel and lock service

disconnecting means to prevent power from being

switched on accidentally. When the service

disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag, to

the service panel.

3

1

3

1

2

7

Figure 5 - Replacement Parts List

Replacement Parts

REF.

NO.

1

“J” Hook Kit

2

Upper Shackle

3

Rubber Roller

4

Clevis Pin

5

24” Downrod

6

8” Down Rod Pipe

7

Upper Canopy

8

Lower Canopy

9

Steel Yoke

10

Capacitor

11

Blades (set of three)

12

Blade pads

13

Blade Screws

14

Motor Assembly

15

Cable Clamps

16

3-Speed Switch w/Cord

17

Switch Box

18

Switch Box Bottom Plate

Included in motor assembly.

DESCRIPTION QTY

4

8

9

10

14

5

12

17

18

6

13

11

15

16

PART NO.

36201 48201

1

9F2900-01

1

9F2900-03A

1

9F2900-04A

1

9F2900-05A

1

9D24BW

1

9D08

1

9F2900-07A

1

9F2900-08A

1

9F2900-10A

1

2100140A

1

9B3620-1

3

9F2900-19A

6

9F2900-20A

1

9M3620-1

2

9G063947

1

1

1

-

-

-

9F2900-01

9F2900-03A

9F2900-04A

9F2900-05A

9D24BW

9D08

9F2900-07A

9F2900-08A

9F2900-10A

2100140A

9B4820-1

9F2900-19A

9F2900-20A

9M4820-1

9G063947

-

-

-

48201B 56001LC 48203 56003

9F2900-01

9F2900-03A

9F2900-04A

9F2900-05A

9D24BBLK

9D08BBLK

9F2900-07A

9F2900-08A

9F2900-10A

2100140A

9B4820-1B

9F2900-19A

9F2900-20A

9M4820-1B

9G063947

-

-

-

9F2900-01

9F2900-03A

9F2900-04A

9F2900-05A

9D24BW

9D08

9F2900-07A

9F2900-08A

9F2900-10A

2100141A

9B5600-1LC

9F2900-19A

9F2900-20A

9M5600-1LC

9G063947

-

-

-

9F2900-01

9F2900-03A

9F2900-04A

9F2900-05A

9D24BW

9D08

9F2900-07A

9F2900-08A

9F2900-10A

2100144A

9B4820-3

9F2900-19A

9F2900-20A

9M4820-3

9G063947

9F2900-26

2200003A

2200005A

9F2900-01

9F2900-03A

9F2900-04A

9F2900-05A

9D24BW

9F2900-07A

9F2900-08A

9F2900-10A

2100145A

9B5600-3

9F2900-19A

9F2900-20A

9M5600-3

9G063947

9F2900-26

2200003A

2200005A

9D08

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

the motor which is warranted against defects in workmanship and materials for three years from date of installation. This warranty does not apply to damage from accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products to Marley Engineered Products Service Center.Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is

agreed that such repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED

FROM THIS AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the

factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization, include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Part No. 5200-2398-002 10/05

LIMITED WARRANTY

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

ECR 36666

4

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Loading...

Loading...