Leader Electronics Corp. LT 443D, LT 443D-HD, LT 443D-HDB, LT 443D-SD, LT 443D-SDB Instruction Manual

...Page 1

LT 443D

MULTIFORMAT

VIDEO GENERATOR

INSTRUCTION MANUAL

Page 2

Page composition of a TABLE OF CONTENTS

■ MAINFRAME

LT 443D ............................................................................................................................ 2-1

■ UNIT INSTALLATION / REPLACEMENT ......................................................................... I-1

■ GENLOCK UNIT

LT 443D-GLA ............................................................................................................... GLA-1

■ HD-SDI UNIT / HD-SDI & BLACK UNIT

LT 443D-HD / LT 443D-HDB................................................................................. HD/HDB-1

■ ANALOG BLACK UNIT

LT 443D-BL .....................................................................................................................BL-1

■ SD-SDI UNIT / SD-SDI & BLACK UNIT

LT 443D-SD / LT 443D-SDB ..................................................................................SD/SDB-1

■ LOGO MARK DISPLAY FUNCTION

LT 443D-HD / HDB / SD / SDB ..................................................................... LOGO MARK-1

■ DIGITAL AUDIO UNIT

LT 443D-DA ................................................................................................................... DA-1

■ ANALOG AUDIO UNIT

LT 443D-AA ................................................................................................................... AA-1

■ ANALOG COMPOSITE UNIT

LT 443D-CS ................................................................................................................... CS-1

■ LIST OF BLACK SIGNAL FORMAT ............................................................................. BF-1

■ MENU TREE .................................................................................................................. MT-1

Page 3

TABLE OF CONTENTS

GENERAL SAFETY SUMMARY ...................................................................................................... I

1. INTRODUCTION .................................................................................................................. 1-1

1.1 Scope of Warranty........................................................................................................ 1-1

1.2 Operating Precautions ................................................................................................. 1-1

1.2.1 Line Voltage and Fuse ..................................................................................... 1-1

1.2.2 Maximun Allowable Input Voltage .................................................................... 1-2

1.2.3 Shorting the Output Connectors, Reverse Voltage.......................................... 1-2

1.2.4 Installation........................................................................................................ 1-2

1.2.5 Mechanical Shock............................................................................................ 1-2

1.2.6 Calibration........................................................................................................ 1-2

1.2.7 Routine Maintenance ....................................................................................... 1-2

2. SPECIFICATIONS ................................................................................................................ 2-1

2.1 Description ................................................................................................................... 2-1

2.2 Features ....................................................................................................................... 2-1

2.3 Specifications ............................................................................................................... 2-2

2.3.1 Compartment ................................................................................................... 2-2

2.3.2 LCD Panel ....................................................................................................... 2-2

2.3.3 Internal Clock ................................................................................................... 2-2

2.3.4 Memory Card Slot ............................................................................................ 2-2

2.3.5 External Interface............................................................................................. 2-2

2.3.6 General Specifications ..................................................................................... 2-2

2.4 Options ......................................................................................................................... 2-3

2.4.1 LT 443D-70 (NATURAL PICTURE Memory: Option 70) .................................. 2-3

2.4.1.1 Description ................................................................................................ 2-3

2.4.1.2 Specifications ............................................................................................ 2-3

2.5 Plug-In Units .................................................................................................................. 2-4

2.5.1 Plug-In Units for LT 443D ................................................................................... 2-4

2.5.2 LT 443D-GLA ..................................................................................................... 2-5

2.5.2.1 Description ................................................................................................ 2-5

2.5.2.2 Specifications ............................................................................................ 2-5

2.5.3 LT 443D-HD/HDB ............................................................................................... 2-6

2.5.3.1 Description ................................................................................................ 2-6

2.5.3.2 Specifications ............................................................................................ 2-6

2.5.4 LT 443D-BL ...................................................................................................... 2-6

2.5.4.1 Description ................................................................................................ 2-6

2.5.4.2 Specifications ............................................................................................ 2-7

Page 4

2.5.5 LT 443D-SD/SDB ............................................................................................... 2-7

2.5.5.1 Description ................................................................................................ 2-7

2.5.5.2 Specifications ............................................................................................ 2-7

2.5.6 LT 443D-DA ..................................................................................................... 2-7

2.5.6.1 Description ................................................................................................ 2-7

2.5.6.2 Specifications ............................................................................................ 2-8

2.5.7 LT 443D-AA ..................................................................................................... 2-8

2.5.7.1 Description ................................................................................................ 2-8

2.5.7.2 Specifications ............................................................................................ 2-8

2.5.8 LT 443D-CS ..................................................................................................... 2-8

2.5.8.1 Description ................................................................................................ 2-8

2.5.8.2 Specifications ............................................................................................ 2-9

3. PANEL DESCRIPTION ......................................................................................................... 3-1

3.1 Front Panel ................................................................................................................... 3-1

3.2 Rear Panel ................................................................................................................... 3-2

4. USING THE MAINFRAME .................................................................................................... 4-1

4.1 Turning Power On ........................................................................................................ 4-1

4.2 Selecting Unit ............................................................................................................... 4-1

4.3 Selecting Format .......................................................................................................... 4-2

4.4 Selecting Pattern .......................................................................................................... 4-2

4.5 UTILITY Menu Structure .............................................................................................. 4-2

4.5.1 UTILITY Menu Screen ..................................................................................... 4-2

4.5.2 LCD BACK LIGHT ........................................................................................... 4-2

4.5.3 KEY LOCK SET ............................................................................................... 4-2

4.5.3.1 Key Lock Mode Set With Menu ................................................................ 4-2

4.5.3.2 Setting KEY LOCK ON ............................................................................. 4-3

4.5.3.3 Setting KEY LOCK OFF............................................................................ 4-3

4.5.4 Using Front Panel KEY LOCK Switch ............................................................. 4-3

4.5.5 PRESET/RECALL ........................................................................................... 4-4

4.5.5.1 Selecting the Preset Storage Media ......................................................... 4-4

4.5.5.2 Creating Presets ....................................................................................... 4-4

4.5.5.3 Recalling Presets (ALL Mode) .................................................................. 4-5

4.5.5.4 Recalling Presets (UNIT Mode) ................................................................ 4-6

4.5.5.5 POWER ON RECALL ............................................................................... 4-8

4.5.6 ETHERNET SET ............................................................................................. 4-9

4.5.6.1 Remote Control via ETHER Port .............................................................. 4-9

4.5.6.2 Exiting Remote Control Mode ................................................................. 4-10

4.5.6.3 Remote Control Command ..................................................................... 4-11

4.5.7 VERSION DISPLAY ....................................................................................... 4-17

Page 5

4.6 Main Menu Structure .................................................................................................. 4-18

4.6.1 Two Modes Selectable With MENU Key........................................................ 4-18

4.6.2 STATUS Display Mode .................................................................................. 4-18

4.6.3 SETTING Menu Mode ................................................................................... 4-19

5. NOTES ON RACK MOUNTING ............................................................................................ 5-1

6. ABOUT RUBBER FEET........................................................................................................ 6-1

7. DATA BACKUP ..................................................................................................................... 7-1

8. DEFAULT SETTINGS ........................................................................................................... 8-1

8.1 Default Settings for All Data [MENU] + [FORMAT] ....................................................... 8-1

8.2 Default Settings for Selected Data [MENU] + [ENTER] ............................................... 8-1

9. MAINTENANCE .................................................................................................................... 9-1

9.1 Preventing Power Cord Disconnection ........................................................................ 9-1

9.1.1 Connecting the Power Cord............................................................................. 9-1

9.1.2 Disconnecting the Power Cord ........................................................................ 9-2

Page 6

GENERAL SAFETY SUMMARY

■ To Avoid Personal Injury

It is recommended that only qualified personnel with technical knowledge use this

instrument only after reading and fully understanding all functions of the instrument

described this instruction manual.

This instrument is not designed and manufactured for consumers.

If you do not have enough knowledge on electricity, to avoid personal injury and

prevent damage to this product, please be sure to use this product only under the supervision of an engineer who has sufficient knowledge about electronics.

■ Precautions on Contents

Should you find the contents in this manual and any of its technical terms confusing,

please feel free to contact your local LEADER agent.

■ Symbols and Terms

Following terms and symbols indicate necessary warnings and cautions used in this

manual and on the product are there for safe operation.

<Symbol>

<Te r m>

WARNING

<Te r m>

CAUTION

The sections where this symbol is marked in this manual or

instrument, if not correctly performed or practiced, could result in

personal injury or cause serious danger to the instrument. Misuse

could also produce unintentional movement to create an

operational impediment on the instrument or other products that

might be connected to it.

Be sure to refer to the safety precautions in this manual to safely

use the part of the instrument where the symbol is marked.

Warning statements identify warning conditions that if

or not correctly performed or adhered to, could result in serious

personal injury or even loss of life.

Caution statements identify caution conditions that if disregarded

or not correctly performed or adhered to, could result in personal

injury or damage to the instrument.

disregarded

— I —

Page 7

GENERAL SAFETY SUMMARY

Review the following safety precautions to avoid operator's injury and loss of life

and prevent damage and deterioration to this instrument. To avoid potential hazards, use

this product as specified.

WARNING

■ Warnings on the Cases and Panels of the Instrument

Operator should not remove any cases or panel for any reasons. If you touch

inside the instrument it could result personal shock or fire hazard. Refrain

from spilling any liquid on or inserting anything flammables or piece of metal

into the ventilation of the instrument. Such actions could cause fire, shock,

malfunction and be an accident hazard while the power is on.

■ Warnings on Power Line

●

Make sure to connect only to the rated power line voltage. Excess

voltage may cause fire.

Confirm the voltage of the commercial power line before connecting the AC power

cord. The power frequency of the power line should be 50/60 Hz.

●

Warning on the Power Cord

Use only the optional power cord that is attached to this instrument. The use of the

power cord other than that attached could cause fire hazard.

If the attached cord is damaged stop using it and contact your local LEADER

agent. Should you use a damaged cord, it could cause a shock or create a fire

hazard. When you pull out the cord be sure to hold it by plug and pull from the

socket not by holding the cord wire.

●

Cover/Inlet stopper

Use the Cover/Inlet stopper that comes with the package only after establishing

a means to immediately shut down the power supply when a malfunction

occurs on the LT 443D.

— II —

Page 8

GENERAL SAFETY SUMMARY

WARNING

■ Warning on Installation Environments

●

About the Operating Temperature Range

Operate the instrument between the temperature range of 0 to 40 °C. Operating the

instrument at higher temperatures could cause a fire hazard.

Rapid changes of temperatures from cold to warm can create internal moisture or

condensation and could damage the instrument. If there is a possibility of moisture

condensation allow the instrument to sit for 30 minutes without the power on.

●

About the Operating Humidity Range

Operating humidity range is

≤ 90 % RH.

Do not operate the instrument with wet hands. This could cause a shock and fire

hazard.

●

About the Operation in the Presence of Gasses

Operating the instrument in and near the presence or storage locations of flammable, explosive gasses or fumes could create an explosion and fire hazard. Do not

operate the instrument anywhere near such environments.

●

Avoid Insertions

Do not insert metals or flammable objects or drop liquid on or into the instrument.

To do so could cause fire, shock, malfunction and create a dangerous accident hazard.

■ Abnormal symptom

Incase of smoke, fire, or abnormal smell while operating this instrument,

immediately disconnect the power cord from the mains. Otherwise, you run

the risk of fire or electrical shock. If the trouble cannot be solved, contact

your local

LEADER agent.

■ Warning about Ground

The instrument has a ground terminal to avoid electric shock hazard and to protect the

instrument from damage. Ensure that the product is properly grounded for safe operation.

— III —

Page 9

GENERAL SAFETY SUMMARY

CAUTION

■ Caution on Input/Output Terminals

Input Terminals are rated with a maximum input. Do not supply an input over the

specified rating in the standard section of the instruction manual. Also, do not supply

external power to Output terminal, this could cause the instrument to malfunction.

■ Caution when Not Using the Instrument for a Long Time

Make sure to disconnect the power cord from the socket when you do not use the

instrument for a long time.

Please conform to the above warnings and cautions for safe operation. There are cautions in

each area of this instruction manual, so please conform to each caution. If you have any

questions about this manual, please feel free to contact your local LEADER agent.

— IV —

Page 10

1. INTRODUCTION

Thank you for purchasing LEADER’s measuring instruments.

Please read this instruction manual carefully to ensure correct and safe operation.

If you have any difficulties or questions on how to use the instrument after you have read this

manual, please feel free to contact your local LEADER agent.

1.1 Scope of Warranty

This LEADER instrument has been manufactured under the strictest quality control

guidelines. LEADER shall not be obligated to furnish free service during the warranty

period under the following conditions.

1. Repair of malfunction or damages resulting from fire, natural calamity, or improper

voltage applied by the user.

2. Repair of an instrument that has been improperly repaired, adjusted, or modified by

personnel other than a factory-trained LEADER representative.

3. Repair of malfunctions or damages resulting from improper use.

4. Repair of malfunctions caused by devices other than this instrument.

5. Repair of malfunctions or damages without the presentation of a proof of purchase or

receipt bill for the instrument.

1.2 Operating Precautions

WARNING

1.2.1 Line Voltage and Fuse

Confirm that the power line voltage is correct before connecting the power cord.

The voltage range and fuse rating are indicated on the rear panel.

The instrument must be connected to the rated line voltage and line frequency of 50 Hz

to 60 Hz.

1-1

Page 11

CAUTION

1.2.2 Maximum Allowable Input Voltage

The maximum allowable input voltage to the input connector is shown below.

Do not apply excessive voltage to prevent damage to the instrument.

Input Connector

GENLOCK IN

1.2.3 Shorting the Output Connectors, Reverse Voltage

• Shorting the output connectors

Do not short any output connectors to prevent damage the instrument.

• Applying external voltage

Do not apply external voltage to the output connectors, it can cause trouble.

1.2.4 Installation

Do not use the instrument in the following environments.

• High temperature environments

Do not place the instrument under direct sunlight or near a heater (e.g., stove).

Do not move the instrument from cold to warm environment abruptly, it may cause

condensation.

Operating temperature range: 0 to 40 ˚C

• High humidity environments

Do not place the instrument in the high humidity environment (e.g., bathroom, near a

humidor).

Operating humidity range: ≤ 90 % RH

• Dusty environments

Maximum Allowable Input Voltage

± 4.5V (DC + peak AC)

1.2.5 Mechanical Shock

Please be careful not to expose the instrument to other forms of severe mechanical shock

as this product contains shock sensitive precise parts.

1.2.6 Calibration

When calibration or service is required, contact your local LEADER agent.

1.2.7 Routine Maintenance

When cleaning the instrument, do not use such solvents as thinner or benzol which will

remove paint or damage the plastic surface. Use a soft cloth dampened with neutral

detergent.

Do not drop water or detergent, or insert metal object into the instrument while cleaning.

Otherwise, you run the risk of electrical shock or fire.

1-2

Page 12

2. SPECIFICATIONS

2.1 Description

The LT 443D Signal Generator can be flexibly used for the multiformat digital broadcast

systems. Various plug-in units enable the output of SDI signals (i.e., HDTV, SDTV), sync

signals, and analog signals. By using these signals and genlock functions, users can

customize this signal generator as desired.

2.2 Features

• Plug-in units provide various functions

Since up to four plug-in units can be installed in the mainframe (consisting of a power

supply, main signal generator, and controller), users can customize this signal generator

as desired.

• Applicable to multiformat HDTV

For the SDI signals, HDTV 14 format unit and 525 line/625 line SDTV unit are provided.

The NTSC/PAL analog video signal unit is also available.

Since each unit can output the signal simultaneously, a multiformat system can be

constructed to satisfy user’s requirements.

• Various sync outputs

Two units can simultaneously output HD signals with 74.25 MHz clock and 74.25/1.001

MHz clock.

• Easy-to-use sync signals

For today’s modern age of digital TV systems, BB signal (for NTSC, PAL) and HDTV trilevel sync signals can be generated from the Analog BB Unit.

• Ethernet provided

Since the ethernet capability is provided as standard. This feature can remotely control

various functions and monitor he genlock status.

• User-friendly operability

LEADER’s traditional design and operability concepts are also reflected in this

instrument. User-friendly operation includes significantly reduced power-on initialization

time is advantageous to a high-performance instrument.

2-1

Page 13

2.3 Specifications

2.3.1 Compartment

Number of compartments 4

ID Function Automatically identifies the unit installed.

*2 Refer to Section 2.5 and specifications of each unit.

2.3.2 LCD Panel

Number of Characters 20 characters x 2 lines can be displayed (w/backlight).

2.3.3 Internal Clock

Internal Reference Frequency 27 MHz

2.3.4 Memory Card Slot

Function Storing/reading preset data

Applicable Card Compact flash memory card (CFA TYPE-1) *4

*3 The NATURAL picture function is only usable when the LT 443D-70 Option is installed

in the mainframe.

*4 No compact flash memory card is supplied as standard accessory.

Memory cards produced by following manufacturers should be procured (as of August

2002):SanDisk

*5 A microdrive can’t be used.

Reading logo mark data

Reading NATURAL PICTURE data *3

2.3.5 External Interface

Ethernet 10/100 Base T (Automatic selection)

Function Transferring operation status (e.g., genlock status)

USB (Universal Serial Bus) Applicable to USB 1.1

Function This function will be supported. (Hardware is installed as

2.3.6 General Specifications

Environmental Conditions

Operating Temperature Range 0 to 40 ˚C

Operating Humidity Range ≤ 90% RH (without condensation)

Spec-Guaranteed Temperature Range 10 to 35 ˚C

Spec-Guaranteed Humidity Range ≤ 85% RH (without condensation)

Operating Environment Indoor use

Operating Altitude Up to 2000 m

Overvoltage Category w

Pollution Degree 2

Power Requirements 90 to 250 VAC, 50/60 Hz

Power Consumption Approx. 150 W max. (Approx. 75 W max. *5)

Dimensions and Weight 426 (W) x 44 (H) x 560 (D) mm,

Remote control (e.g., pattern switching)

standard.)

Approx. 7 kg *5

2-2

Page 14

Accessories Power cord .............................................. 1

Cover/Inlet Stopper .................................. 1

Rack Support (Right and left) .................. 1

Screw (for rack support) .......................... 4

About Rubber Feet .................................. 5

Instruction Manual ................................... 1

LOGO MARK SOFTWARE CD-R ........... 1

*5 When four plug-in units (i.e., LT 443D-HD, LT 443D-SD, LT 443D-BL, LT 443D-GL)

are installed.

2.4 Options

2.4.1 LT 443D-70 (NATURAL Picture Memory: Option 70)

2.4.1.1 Description

This option adds the NATURAL picture pattern output capability to the LT 443D

mainframe.

A compact flash memory card is used as an additional memory to store the NATURAL

picture pattern.

2.4.1.2 Specifications

(1) NATURAL PICTURE Memory

Additional memory ≥16 M byte (Compact flash memory card)

(2) Number of Storable Screens

In case of 32 M byte memory is used: *6

1920 (H) x 1080 (V) format Up to 3 screens

720 (H) x 574 (V) format Up to 19 screens

*6 The number of storable screens to the memory is described above.

When the power is turned on or the screen size is changed, data contained in

this memory is transferred to the RAM in the plug-in unit.

Refer to the unit specifications for the number of storable screens to the RAM.

Any combination of the screen sizes can be stored.

The same size of NATURAL picture data can only be stored; difference size of

screens cannot be stored.

(3) Number of Video Data Quantitative Bits

, C

Y, C

b

r

(4) File Format

Before Conversion Bit map format (.bmp)

After Conversion Dedicated format for LT 443D (.img) *7

*7 Converted by using Windows (R) application software supplied.

10 bits

8 bits for each R, G, B component

10 bits for each Y, C

, Cr component

b

2-3

Page 15

(5) Conversion of Color Matrix

Colorimetry parameter used to convert data from R, G, B (eight bits data) to Y, C

(10 bits data) by using the Windows (R) application software.

C

r

1080/720 System Rec. ITU-R BT. 709-3 Part II

1035 System SMPTE 240M

SD 525/SD 625 System SMPTE 125M

NTSC System SMPTE 170M

PAL System Rec. ITU-R BT. 470-6

(6) Transferring NATURAL Picture Pattern

Memory Picture data should be stored in a compact flash memory

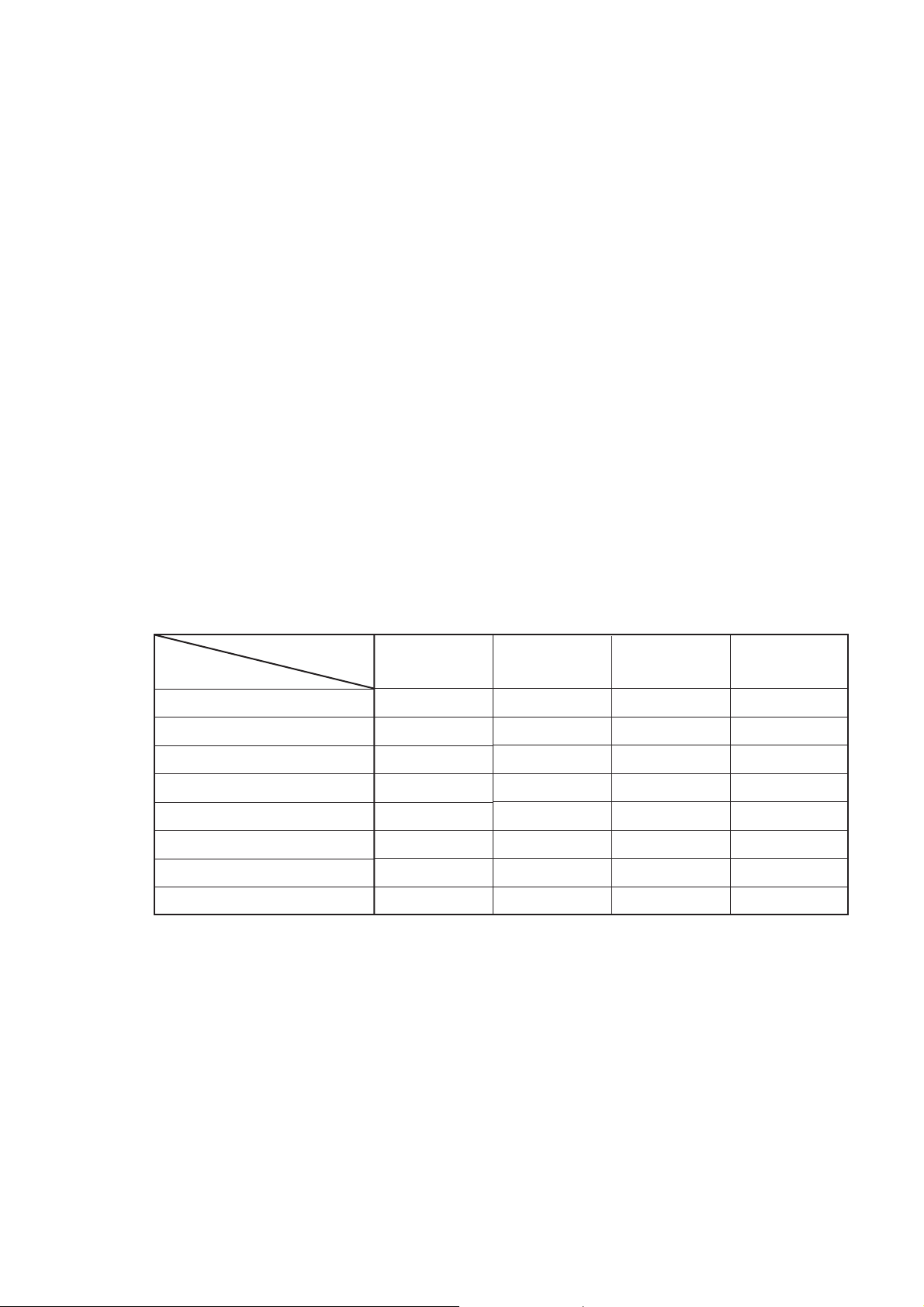

2.5 Plug-In Units

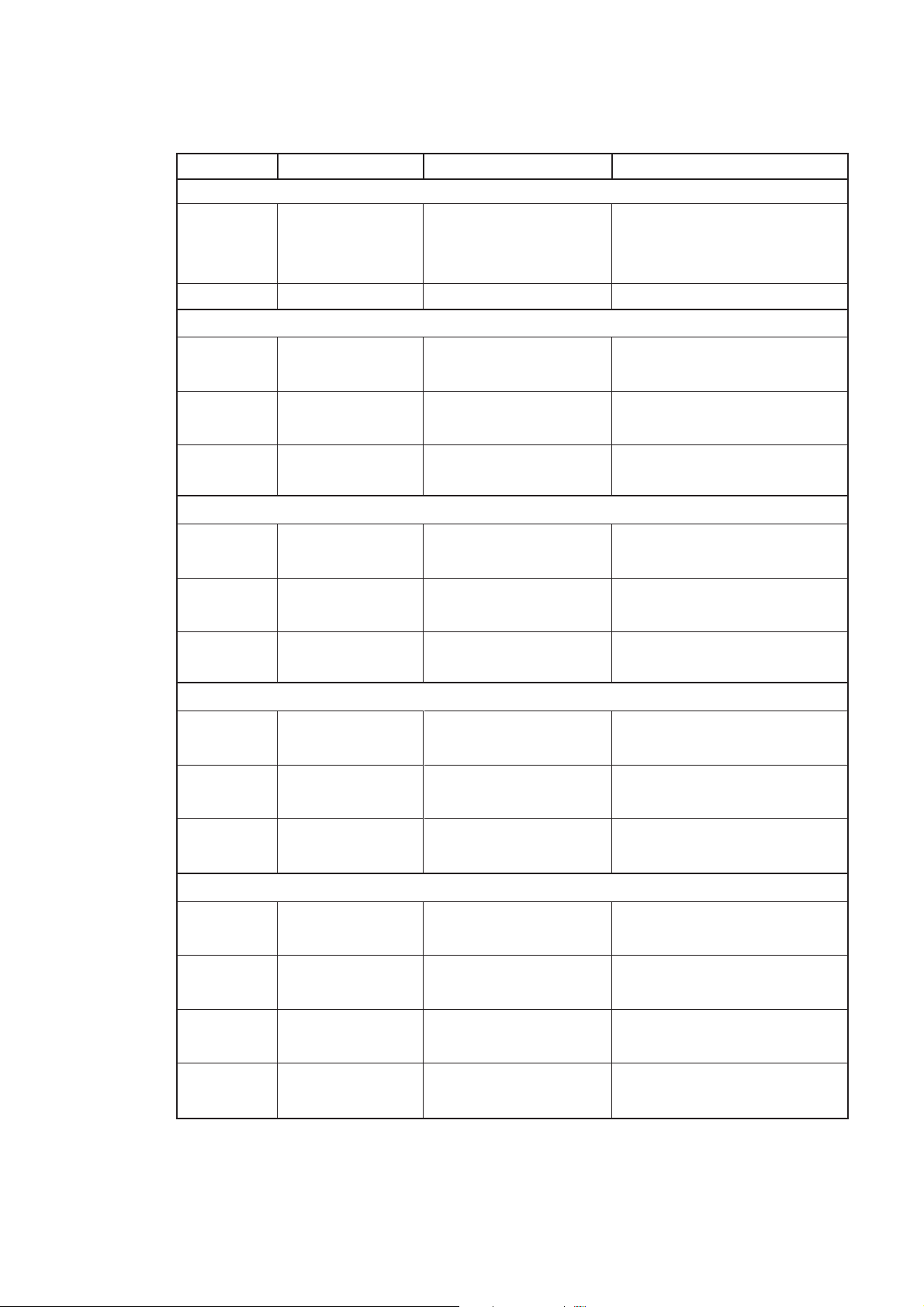

2.5.1 Plug-In Units for LT 443D

card.

(Procure a compact flash memory card on your side. At

least 16 M bytes required)

,

b

Up to four units can be installed.

Table 2-1 lists installable combination of the unit and UNIT compartment. *8

Compartment

Model

LT 443D-GLA

LT 443D-GL

LT 443D-HD/HDB

LT 443D-BL

LT 443D-SD/SDB

LT 443D-DA

LT 443D-AA

LT 443D-CS

UNIT 1

Yes *8

Yes *8

Yes

Yes

Yes

Yes

Yes

Yes

UNIT 2

No

No

Yes

Yes

Yes

Yes

Yes

Yes

UNIT 3

No

No

Yes

Yes

Yes

Yes

Yes

Yes

UNIT 4

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Table 2-1 Installable unit and compartment

*8 The LT 443D-GLA and the LT 443D-GL can only be installed in the UNIT 1

compartment.

*Note: The firmware version 3.0 and later is used for the LT 443D-GLA.

The firmware version can be confirmed on the VERSION DISPLAY in

MAINFRAME menu.

2-4

Page 16

2.5.2 LT 443D-GLA

2.5.2.1 Description

This unit provides genlock capability to lock the LT 443D mainframe with the external

reference signal, and three independent black signal generators.

The NTSC/PAL black burst signals, principal 20 types of HDTV analog tri-level sync

signal formats, and 525p/625p analog sync signals can be used as an external

reference signal.

The following black burst signal formats can be selected.

For NTSC/PAL system, black burst signal with field reference pulse is provided. For

NTSC system, black burst with 10-field sequence identification conforming to the

SMPTE 318M standards is provided.

The instrument continues operation since the flywheel mode is provided even if the

external reference signal is accidentally removed in genlock mode. By logging the

genlock status, the time can be obtained when the external reference signal is

removed. The log information can be stored on the CF CARD.

The genlock timing can be adjusted for the entire color frame range when the NTSC/

PAL black burst signal is applied; entire frame range when the HDTV analog tri-level

sync signal is applied.

Three black burst signal output systems with selectable formats are available as

follows:

For NTSC/PAL system, standard black burst signal and black burst signal with field

reference pulse are provided. For NTSC system, black burst with 10-field sequence

identification conforming to the SMPTE 318M standards, 525p/625p analog sync

signal, and HDTV analog tri-level sync signal are provided.

The format and output signal timing of each output can be respectively set.

The black signal timing can be adjusted for the entire color frame range when the

NTSC/PAL black burst signal is applied; entire frame range when the HDTV analog trilevel sync signal is applied.

2.5.2.2 Specifications

(1) Genlock Function

Reference Input Signal Level

• HDTV Positive polarity: 300 mV

• 525p/625p -300 mV

• NTSC -286 mV

• PAL -300 mV

Input Connector BNC (75 Ω, loop through)

Negative polarity: -300 mV

2-5

Page 17

(2) Analog Sync Signal Output

Sync Level (into 75 Ω)

• HDTV Positive polarity: 300 mV ±6 mV

• 525p -300 mV ±6 mV

• 625p -300 mV ±6 mV

• NTSC 40 IRE ±1 IRE

• PAL -300 mV ±6 mV

Output Connector BNC (BLACK 1/BLACK 2/BLACK 3)

Number of Outputs 1 each

2.5.3 LT 443D-HD/HDB

2.5.3.1 Description

The LT 443D-HD (HD-SDI Unit) and LT 443D-HDB (HD-SDI & BLACK Unit) add the

capability to output 14 types of HD-SDI signal formats to the LT 443D mainframe.

Various functions (e.g., ID character display, simple motion pictures, embedded audio,

NATURAL picture pattern *1) are provided.

The LT 443D-HDB (HD-SDI & BLACK Unit) can output HD-SDI black signal

independently of the HD-SDI test signals.

*1: The option should be installed.

Negative polarity: -300 mV ±6 mV

2.5.3.2 Specifications

(1) Applicable Format

1035i/60, 1035i/59.94,

1080i/60, 1080i/59.94, 1080i/50,

1080p/30, 1080p/29.97, 1080p/25,

1080p/24, 1080p/23.98,

1080PsF/24, 1080PsF/23.98,

720p/60, 720p/59.94,

The verification has not completed though the following formats were built in since

the firmware version 3.3 of the LT 443D.

720p/24, 720p/23.98, 720p/29.97,

720p/50, 720p/30, 720p/25

(2) HD-SDI Video Output 1 system, 2 outputs (75 Ω, BNC)

HD-SDI Black Output 1 system, 2 outputs (75 Ω, BNC)

(The HD-SDI black signal is only output when the LT 443D-HDB is installed.)

2.5.4 LT 443D-BL

2.5.4.1 Description

This unit outputs the 20 format HDTV analog tri-level sync signal, 525p/625p analog

sync signals, and NTSC/PAL black burst signals.

Three independent output systems (six outputs, two outputs per system) are provided

to output multiformat black sync signal.

The format and output signal timing can be respectively set each output.

2-6

Page 18

2.5.4.2 Specifications

(1) Sync Level (into 75 Ω)

• HDTV Positive polarity: 300 mV ±6 mV

• 525p -300 mV ±6 mV

• 625p -300 mV ±6 mV

• NTSC 40 IRE ±1 IRE

• PAL -300 mV ±6 mV

(2) Output Connector BNC (BLACK 1, 2/BLACK 3, 4/BLACK 5, 6)

(3) Number of Outputs 2 each

2.5.5 LT 443D-SD/SDB

2.5.5.1 Description

The LT 443D-SD (SD-SDI Unit) and LT 443D-SDB (SD-SDI & BLACK Unit) add the

capability to output 525/625 line format SD-SDI signal (4:2:2 component signal) to the

LT 443D mainframe.

Various functions (e.g., ID character display, simple motion pictures, embedded audio,

NATURAL picture pattern *1) are provided.

The LT 443D-SDB (SD-SDI & BLACK Unit) can output SD-SDI black signal

independently of the SD-SDI test signals.

*1:The option should be installed.

Negative polarity: -300 mV ±6 mV

2.5.5.2 Specifications

(1) Applicable Format 525i/59.94-270 MHz, 625i/50-270 MHz

(2) SD-SDI Video Output 1 system, 2 outputs (75 Ω, BNC)

SD-SDI Black Output 1 system, 2 outputs (75 Ω, BNC)

(The SD-SDI black signal is only output when the LT 443D-SDB is installed.)

2.5.6 LT 443D-DA

2.5.6.1 Description

Installing the LT 443D-DA Digital Audio Unit in the LT 443D mainframe can output

AES/EBU digital audio signals (four systems), silence signals (one system), and 48

kHz word clock signals.

The AES/EBU signal characteristics (e.g., output level, frequency) can be

independently set for each output system.

The sampling frequency is synchronized with the video signal of plug-in unit installed

in the mainframe.

2-7

Page 19

2.5.6.2 Specifications

AES/EBU Digital Audio Output

• Number of Outputs 4 (2-channel output)

• Output Impedance 75 Ω unbalanced

• Output Amplitude 1 Vp-p (into 75 Ω)

• Output Connector BNC

Silence Signal (DARS grade 2) Output

• Number of Outputs 1 (2-channel output)

• Output Impedance 75 Ω unbalanced

• Output Amplitude 1 Vp-p (into 75 Ω)

• Output Connector BNC

48 kHz Word Clock

• Number of Outputs 1

• Output Impedance 75 Ω unbalanced (“1 Vp-p” output)

• Output Amplitude 1 Vp-p (into 75 Ω), 5 V CMOS, selectable

• Output Connector BNC

2.5.7 LT 443D-AA

2.5.7.1 Description

Installing the LT 443D-AA Analog Audio Unit in the LT 443D mainframe can output

analog audio signal (two systems). Output characteristics (e.g., output level,

frequency) can be independently set for each output system. The sound sampling

frequency is synchronized with the video signal of plug-in unit installed in the

mainframe.

2.5.7.2 Specifications

• Number of Outputs 2

• Output Impedance 600 Ω, balanced

• Output Amplitude 0.775 Vrms (into 600 Ω at 0 dBm)

• Output Connector XLR-3P x 2

2.5.8 LT 443D-CS

2.5.8.1 Description

The LT 443D-CS Analog Composite Unit adds the NTSC/PAL analog composite

signal output capability to the LT 443D mainframe. Various functions (e.g., ID

character, simple motion pictures, NATURAL picture pattern *1) are provided.

*1: The NATURAL picture function is only usable when the Option LT 443D-70 is

installed in the mainframe.

2-8

Page 20

2.5.8.2 Specifications

Test Signal Output

• Number of Outputs 2

• Signal Level 1 Vp-p (into 75 Ω)

Black Signal Output

• Number of Outputs 2 systems (one each)

• Signal Level 1 Vp-p (into 75 Ω)

Horizontal Drive Pulse Output

• Number of Outputs 1

• Signal Level 2 Vp-p (into 75 Ω)

Vertical Drive Pulse Output

• Number of Outputs 1

• Signal Level 2 Vp-p (into 75 Ω)

2-9

Page 21

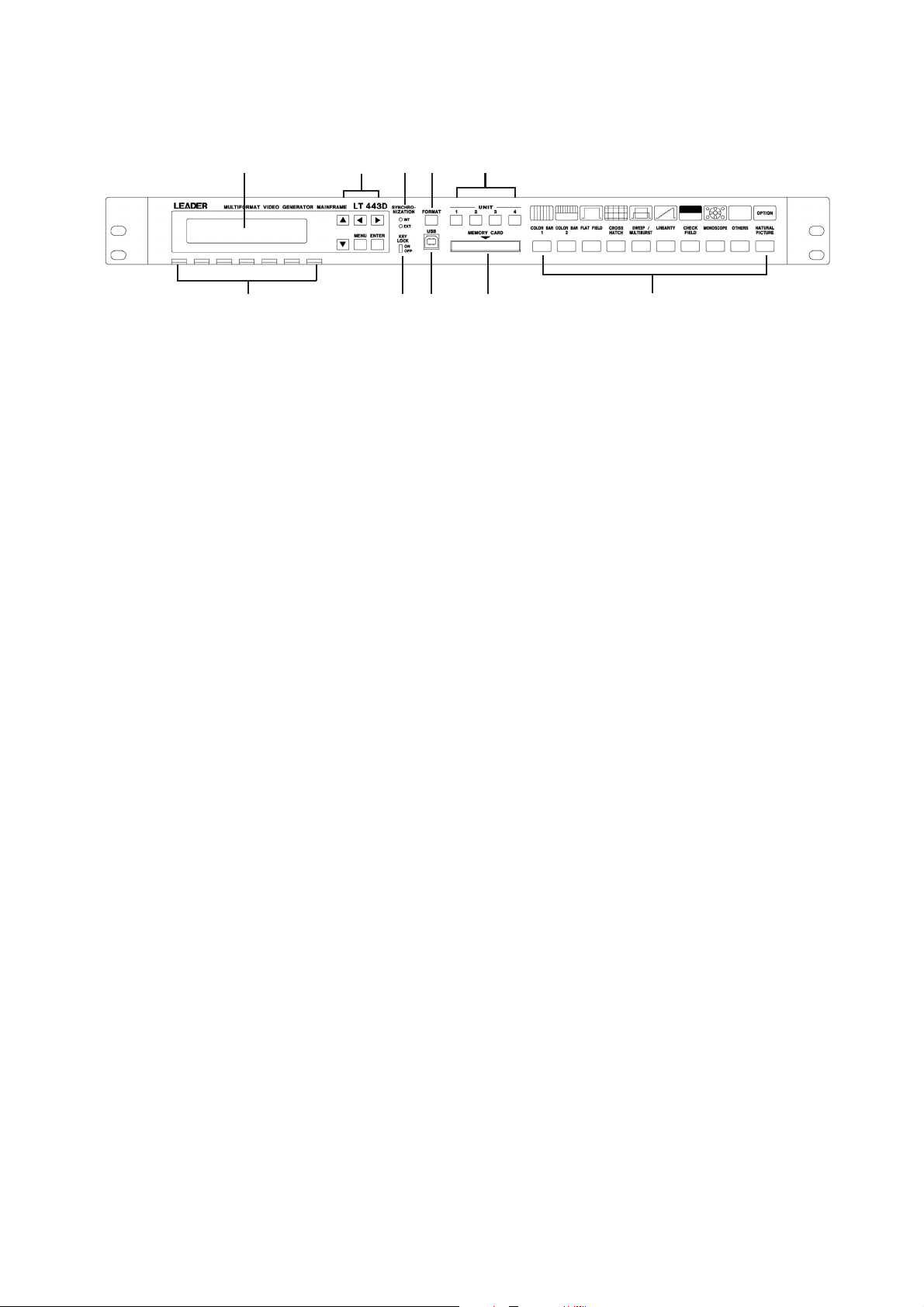

3. PANEL DESCRIPTION

q

er t

w

uio!0

y

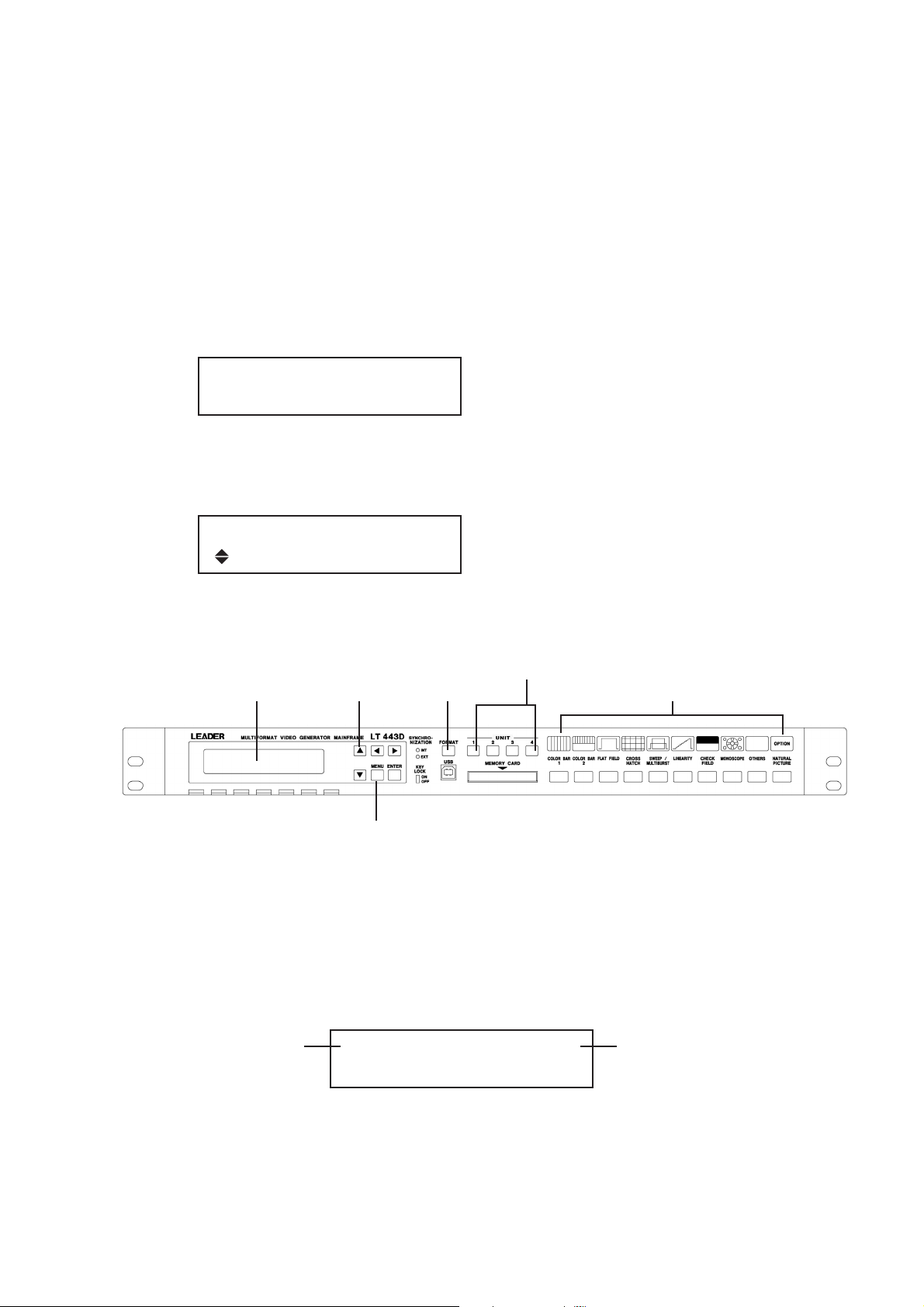

Figure 3-1

3.1 Front Panel

Figure 3-1 shows the LT 443D front panel.

q LCD panel

Displays the information in 20 characters x 2 lines.

Generally displays the status (e.g., output format of the selected unit).

In the setting mode, the setting item of the selected unit is displayed.

w Menu keys

Sets the menu in the setting mode.

(These keys are also used in status display mode.)

e SYNCHRONIZATION indicators

The [EXT] lights when the instrument is synchronized to the external sync signal (e.g., black

burst, tri-level sync).

The [INT] lights when the internal sync is used.

r FORMAT key

Selects the signal format of the selected unit.

t UNIT keys

Select the unit when changing or confirming the setting item.

y Pattern keys

Select the pattern output from the selected unit.

These keys are common to all units.

When the unit without a pattern output capability (e.g., genlock unit) is selected, all pattern

LEDs go off. And pattern key could not use.

3-1

Page 22

u MEMORY CARD slot

To insert memory card to store the optional NATURAL PICTURE pattern.

Procure a compact flash memory card recommended by Leader Electronics Corp. Refer to

Section 2.3.4, “Memory Card Slot” for detail.

*Note: When formatting a CF card, use the FAT system; the LT 443D cannot recognize the

CF card formatted in FAT32 system.

To format the CF card of 32 MB or larger capacity on Windows XP, select FAT from

the default (FAT32 file system selected) for formatting.

Notes on using CF memory card:

• A “Vcc = 5 V” type memory card cannot be used.

• Insert the memory card until it in place. If the card cannot be inserted properly, check the

card for up side down. Do not insert the card forcibly. It may cause trouble.

• Do not remove the card while writing or recalling data.

• Do not turn power off while writing or recalling data.

i USB connector

Used for maintenance in the factory. This connector will be installed.

o KEY LOCK switch

Turns on and off the key lock mode.

!0 Ventilation hole

To prevent instrument damage due to overheating, do not block airflow through the ventilation

vents (i.e., air-intake vents on the rear panel and exhaust holes on the front panel).

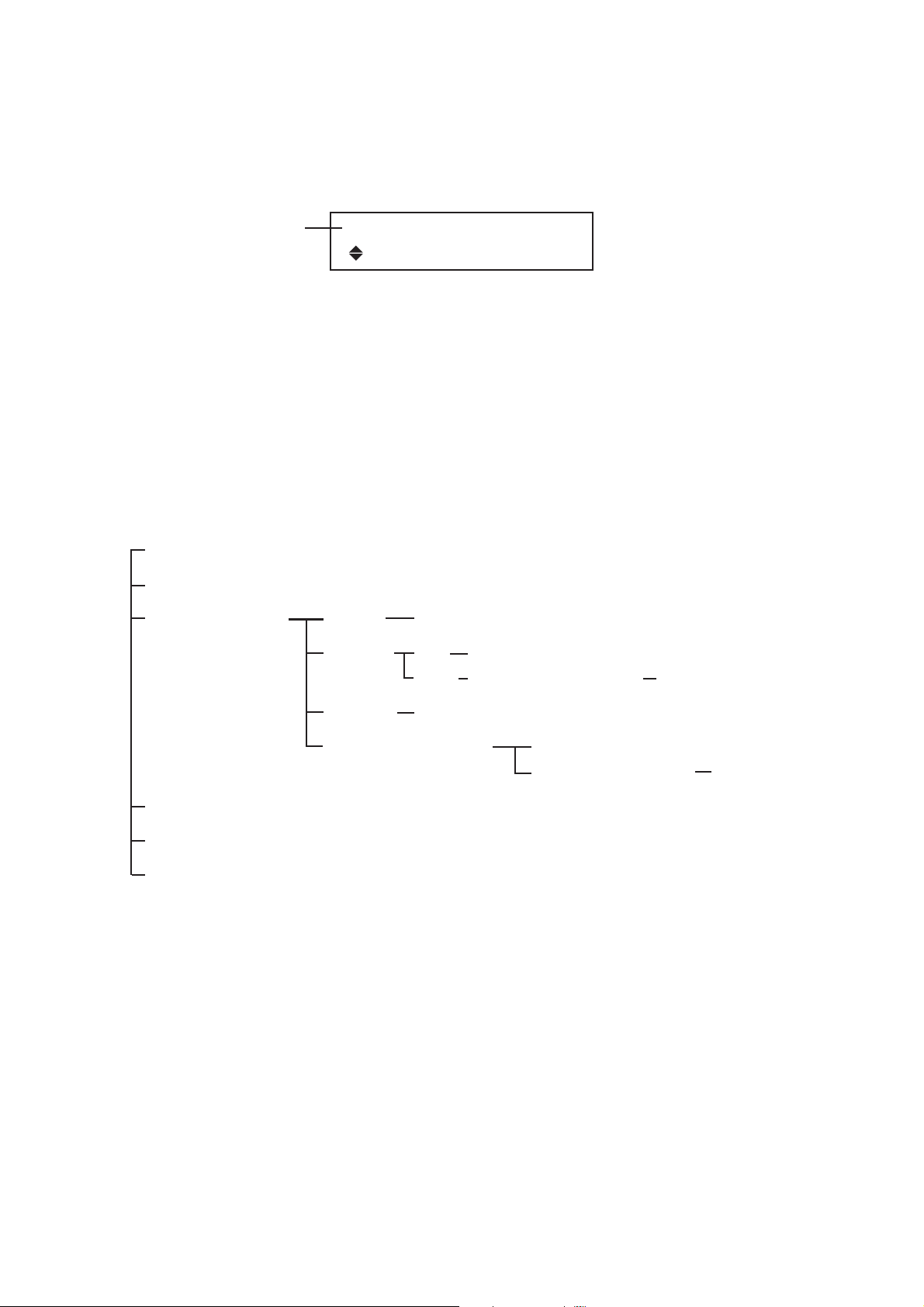

3.2 Rear Panel

!1 !2 !3 !4 !5 !6 !7 !8

UNIT1 UNIT2 UNIT3 UNIT4

Figure 3-2

Figure 3-2 shows the LT 443D rear panel.

!1 UNIT 1 compartment

!2 UNIT 2 compartment

!3 UNIT 3 compartment

!4 UNIT 4 compartment

3-2

Page 23

!5 Cooling fan

Do not block air flow and ventilation holes.

!6 Grounding terminal

Connected to the chassis of this instrument.

!7 AC inlet

AC power inlet. Usable AC voltage range is 90 to 250 V, universal.

!8 ETHER connector

Used for 10 BASE-T/100 BASE-TX ethernet.

3-3

Page 24

4. USING THE MAINFRAME

4.1 Turning Power On

*Note: There is no power switch on the LT 443D; connecting the power cord immediately

supplies the power.

(1) Supplying the power initializes this instrument.

The following message is displayed until initialization is completed.

During initialization, incorrect signal is output and key operation is disabled.

LEADER LT443D

(Example: When the power is supplied.)

INITIALIZING •••

(2) After initialization is completed, the setting status (e.g., video format being output) is

displayed as shown below.

[STATUS] FORMAT TYPE

(Example of status display)

1080/59.94

Refer to Sections 4.2, 4.3, and 4.4 for front panel operations.

UNIT switch

LCD panel Up/Down key

qwr

FORMAT key

t

Pattern selection key

y

4.2 Selecting Unit

Pressing one of UNIT keys displays the UNIT number and its information on the LCD

panel.

This section describes the operating procedure in case of the HD-SDI unit is installed in

the UNIT 2 compartment.

Hierarchy level 1

If [STATUS] is displayed, pressing the [MENU] key can display the [SETTING].

w

MENU key

1. HD SETTING #2

▼ FORMAT SELECT

4-1

In case of the LT 443D-HD

unit is installed in the UNIT 2

compartment.

Page 25

4.3 Selecting Format

Press the FORMAT switch to select the signal format.

Pressing the [Up] or [Down] key in the LCD panel group can also select the signal format.

Hierarchy level 2

4.4 Selecting Pattern

Press the Pattern key to select the pattern.

Pressing the key lights the key LED and outputs the pattern.

4.5 UTILITY Menu Structure

The UTILITY menu can be commonly used for each unit.

To enable this menu, turn four UNIT LEDs off, then press the [MENU] key.

4.5.1 UTILITY Menu Screen

LCD BACK LIGHT (HIGH, MID, LOW, OFF)

KEY LOCK SET (ON/OFF)

PRESET/RECALL MEDIA MEDIA INT/EXT (INT_MEM, EXT_CARD)

RECALL ALL RECALL No. 1 to No. 9

2. FORMAT SELECT

*1080i/59.94

UNIT RECALL No. 1 to No. 9 SLOT1 to 4 → SLOT1 to 4

PRESET PRESET No. 1 to No. 9

POWER ON RECALL

ETHERNET SET (IP: ***. *** . ***. ***)

DATE & TIME SET (20XX/XX/XX XX:XX:XX)

VERSION DISPLAY

4.5.2 LCD BACK LIGHT

The backlight brightness can be selected: HIGH, MIDDLE, LOW, or OFF.

4.5.3 KEY LOCK SET

The key lock function prevents a trouble from accidental key operation.

There are two key lock modes as follows:

All front panel keys are locked by using the [KEY LOCK SET] in setting mode.

The [FORMAT] key is only locked by pressing the KEY LOCK switch in the SYSTEM block

r on the front panel.

4.5.3.1 Key Lock Mode Set With Menu

P-ON RECALL ON/OFF

RECALL NUMBER INT_MEM 1 to 3

When the [KEY LOCK SET] is ON, keys related to the SYSTEM (including [FORMAT]

and [INT/EXT] keys) are disabled.

4-2

Page 26

4.5.3.2 Setting KEY LOCK ON

(1) Select the [KEY LOCK SET] by pressing the [Up] or [Down] key, then press the

[ENTER] key.

Hierarchy level 1

(2) The key lock mode is enabled. [KEY LOCK ON] is displayed for about one second,

then status mode is enabled.

When the key is pressed in key lock mode, the following message is displayed for

about one second.

4.5.3.3 Setting KEY LOCK OFF

(1) To cancel key lock mode, hold down the MENU key for at least two seconds.

[KEY LOCK OFF] is displayed for about one second.

1. UTILITY MENU

KEY LOCK SET

KEY LOCK ON

KEY LOCK !!

PUSH MENU KEY 2 sec

KEY LOCK OFF

*The [FORMAT] in the SYSTEM block are disabled during the KEY LOCK switch

o is set ON even when the key lock mode is canceled with the menu.

4.5.4 Using Front Panel KEY LOCK Switch

Setting the [KEY LOCK] slide switch on locks the [FORMAT] key operation.

If the [FORMAT] key is pressed when the [KEY LOCK] slide switch is set on, the LCD

displays the following messages:

KEY LOCK ON

TURN OFF KEY_LOCK_SW

When setting the KEY LOCK slide switch, use an insulated wedge-shaped screwdriver, for

example.

4-3

Page 27

4.5.5 PRESET / RECALL

You can store up to three presets of the panel key settings to in the internal memory

(INT_MEM) and up to nine presets to a Compact Flash card (EXT_CARD) *1, *2.

There are two methods to recall presets: One method in which the settings of all slots are

recalled at once (ALL mode) and another method in which the settings are recalled on

each slot individually (UNIT mode). *3

*1 The compact flash card is not included in the package. The memory card can be

shared with Option 70 (color still picture memory).

*2 The INT_MEM preset function is supported on firmware version 1.8 or later.

*3 The recall function per slot is supported on firmware version 2.1 or later.

*4 The POWER ON RECALL mode has been applied for firmware version 3.0 and later.

4.5.5.1 Selecting the Preset Storage Media

Set the medium for storing presets. You can select INT_MEM (internal memory) or

EXT_CARD (Compact Flash card).

Data stored in the INT_MEM (internal memory) can only be recalled in the POWER ON

RECALL mode.

Hierarchy level 1

Hierarchy level 2

Hierarchy level 3

4.5.5.2 Creating Presets

You can create three presets in INT_MEM and nine presets in EXT_MEM.

Hierarchy level 3

1. UTILITY MENU

PRESET/RECALL

2. PRESET/RECALL

▼ MEDIA

▼ MEDIA

RECALL

PRESET

▲POWER ON RECALL

3. MEDIA INT/EXT

■INT_MEM □ EXT_CARD

3. PRESET (INT_MEM)

▼PRESET No. 1 NO DATA

▼PRESET No. 1 NO DATA

PRESET No. 2

▲PRESET No. 3

The current information about the preset data is

displayed at the right edge of the second line.

NO DATA: No preset data is stored.

No display: Preset data is stored.

4-4

Page 28

Hierarchy level 3

3. PRESET (EXT_CARD)

▼PRESET No. 1 NO DATA

▼PRESET No. 1 NO DATA

PRESET No. 2

▲PRESET No. 8

PRESET No. 9

Hierarchy level 4

Hierarchy level 4

Hierarchy level 4

The following messages may appear in addition to the messages above.

Hierarchy level 3

Hierarchy level 4

4. PRESET No. 1

□OK ■ CANCEL

4. PRESET No.1

WORKING...

4. PRESET No.1

COMPLETE !

3. PRESET (EXT_CARD)

NO CARD !

4. WARNING !! OVER WR?

□OK ■ CANCEL

Writing

Writing complete

When the Compact Flash

card is not inserted

When a preset is already

stored

(overwrite confirmation)

4.5.5.3 Recalling Presets (ALL Mode)

In ALL mode, the settings of the units installed in the four slots can be recalled at once.

However, if the configuration of the units installed in slots 1 to 4 differs from that when the

preset was created, the settings cannot be recalled. If this happens, you may be able to

recall using UNIT mode.

Hierarchy level 3

The current information about the preset data is

displayed at the right edge of the second line.

NO DATA: No preset data is stored.

No display: Preset data is stored.

3. RECALL (INT_MEM)

▼RECALL No. 1 NO DATA

▼RECALL No. 1 NO DATA

RECALL No. 2

▲RECALL No. 3

4-5

Page 29

Hierarchy level 3

3. RECALL (EXT_CARD)

▼RECALL No. 1

▼RECALL No. 1

RECALL No. 2

▲RECALL No. 8

RECALL No. 9

Hierarchy level 4

Hierarchy level 5

Hierarchy level 5

Hierarchy level 5

The following messages may appear in addition to the messages above.

Hierarchy level 5

4. RECALL (EXT_No. 1)

■ALL □ UNIT

5. RECALL (EXT_No. 1)

□OK ■ CANCEL

5. RECALL (EXT_No. 1)

WORKING...

5. RECALL (EXT_No. 1)

COMPLETE !

5. RECALL (EXT_No. 1)

NO RECALL DATA !

Select the ALL.

Loading

Loading complete

When there is no data

Hierarchy level 5

Hierarchy level 5

4.5.5.4 Recalling Presets (UNIT Mode)

In UNIT mode, the settings of a particular slot can be recalled from the preset data of all

the settings of the units installed in the four slots.

Hierarchy level 4

5. RECALL (EXT_No. 1)

MISMATCH UNIT !

5. RECALL (EXT_No. 1)

NO CARD !

4. RECALL (EXT_No. 1)

□ALL ■ UNIT

When the data was

created using a different

unit configuration

When the Compact Flash

card is not inserted

Select UNIT.

4-6

Page 30

Hierarchy level 5

q Preset data information (unit configuration when the preset was created)

w The LT 443D slot number for which the settings are to be recalled

e Unit type matching

OK: The unit type for q and w match or are compatible, and the settings can be

recalled.

NG: The unit type for q and w do not match or are not compatible, and the settings

cannot be recalled.

Select the unit within the preset data corresponding to q using the [ ▲ ] or [ ▼] key.

5. RECALL (EXT_No. 1)

▼SLOT1・GLA →SLOT1 OK

▼SLOT1・GLA→ SLOT1 OK

SLOT2・HD → SLOT1 NG

SLOT3・BL → SLOT3 OK

▲SLOT4・SD → SLOT4 OK

q w e

Hierarchy level 5

Use the [] or [] key to move the cursor to the w position and select the LT 443D unit

whose settings are to be recalled. The settings can be recalled using a combination in

which OK is displayed in e.

Hierarchy level 6

Hierarchy level 6

Hierarchy level 6

The following messages may appear in addition to the messages above.

Hierarchy level 5

5. RECALL (EXT_No. 1)

SLOT1・GLA →▼SLOT1 OK

6. EXT_No. 1・GLA (1 →1)

□OK ■ CANCEL

6. EXT_No. 1・GLA (1 →1)

WORKING...

6. EXT_No. 1・GLA (1 →1)

COMPLETE !

5. RECALL (EXT_No. 1)

NO RECALL DATA !

Loading

Loading complete

When there is no data

Hierarchy level 6

Hierarchy level 5

6. EXT_No. 1・GLA (1 →2)

MISMATCH UNIT !

5. RECALL (EXT_ −−)

NO CARD !

4-7

When the unit type does

not match (a combination

consisting of NG displays)

When the Compact Flash

card is not inserted

Page 31

4.5.5.5 POWER ON RECALL

The following functions can be selected in the POWER ON RECALL mode.

To initialize each unit based on the last memory setting information (i.e., information

immediately before turning power off) when power is turned on.

To initialize each unit by recalling the setting information from preset data stored in the

internal memory (INT_MEM).

Hierarchy level 3

Hierarchy level 4

Select POWER ON RECALL ON/OFF by pressing the or key, then press the ENTER

key.

When OFF is selected, each unit is initialized based on the last memory setting

information.

When ON is selected, each unit is initialized by recalling the setting information of the

RECALL NUMBER listed below from preset data stored in the INT_MEM (internal

memory).

When there is no setting information at the specified number, each unit is initialized

based on the last memory setting information.

3. POWER ON RECALL

▼ P-ON RECALL ON/OFF

▼ P-ON RECALL ON/OFF

▲RECALL NUMBER

4. P-ON RECALL ON/OFF

□OK ■ OFF

Hierarchy level 4

Select the number by pressing the ▲ (Up) or ▼(Down) key. The item indicated as NO

DATA cannot newly be specified by attaching “ * ” (asterisk).

4. RECALL NUMBER

▼* INT_MEM 1

▼*INT_MEM 1

INT_MEM 2 NO DATA

▲INT_MEM 3 NO DATA

4-8

Page 32

4.5.6 ETHERNET SET

The ethernet capability can remotely control and monitor genlock status.

Hierarchy level 2

The current setting value is displayed.

The underline cursor can be moved by pressing the [Left] or [Right] key.

The cursored number can be changed by pressing the [Up] or [Down] key.

Pressing the [ENTER] key enters data.

*”ETHER” is set to IP address when power is turned on.

4.5.6.1 Remote Control via ETHER Port

This section describes the remote control procedure using the “TELNET” software.

2. ETHERNET SET

IP: 192. 168. 20. 63

IP: 192. 168. 20. 63

■ OK □ CANCEL

Select “Run” from the Start menu.

To run application software, enter “TELNET” in the

“Open” column, then click “OK.”

Click “Remote System” in the “Connect” menu.

4-9

Page 33

Enter LT 443D IP address in the “Host Name,”

select “telnet” for “Port,” select “vt100” for

“Term Type,” then click “Connect.”

When “login:” is displayed, enter “LT443D” in uppercase letters,

then press the “Enter” key. A password can now be entered.

Enter “LT443D” in uppercase letters, then press the “Enter” key.

The command prompt “LT443D>” is displayed. A command can

now be entered.

LT443D>MO?

MO:LT443D-70,GLA,--,BL,SD

LT443D>

The command can be entered on this screen; data can be

sent to the LT 443D.

Command “MO?” (to query the plug-in unit inserted) is

entered, for example, “MO: LT443D-70, GLA, - -, BL, SD” is

replied.

When the prompt “LT443D>” is displayed, a new command

can be entered.

4.5.6.2 Exiting Remote Control Mode

To exit “TELNET,” click “Exit” in the “Connect” menu.

4-10

Page 34

4.5.6.3 Remote Control Command

Operating precautions for remote controlling via the ETHER port

Do not enter multistatement command.

Enter a space (0X20) between command and data.

Enter a comma (0X2C) between data.

In remote control mode, LED on the main frame is undefined, either on or off. Use the

query command to confirm the settings in this case.

(1) MAINFRAME

Query of Model Number MO?

MO: LT443D-70, GLA, HD, BL, SD With Option 70

MO: LT443D, - -, HD, BL, - - Without Option 70

The unit type is sequentially displayed from the UNIT compartment 1.

”- -” indicates “without option.”

Confirming firmware version VR? VR: LT443D-70 V1.0

(2) HD Unit (Installed in UNIT 2)

• Getting format FM2? FM2: 11

0 = 1035i/60 7 = 1080p/25 14 = 720p/50

1 = 1035i/59.94 8 = 1080p/24 15 = 720p/30

2 = 1080i/60 9 = 1080p/23.98 16 = 720p/29.97

3 = 1080i/59.94 10 = 1080PsF/24 17 = 720p/25

4 = 1080i/50 11 = 1080PsF/23.98 18 = 720p/24

5 = 1080p/30 12 = 720p/60 19 = 720p/23.98

6 = 1080p/29.97 13 = 720p/59.94

• Selecting pattern PA2 X

0 = COLOR BAR 75 % 11 = RAMP

1 = COLOR BAR 100 % 12 = SHALLOW RAMP

2 = MULTIFORMAT COLOR BAR 1 13 = 10 STEP

3 = (unused) 14 = CHECK FIELD

4 = (unused) 15 = MONOSCOPE (NORMAL)

5 = FLAT FIELD 100 % 16 = MONOSCOPE (INVERT)

6 = FLAT FIELD 50 % 17 = BOWTIE 100 %

7 = FLAT FIELD 0 % 18 = PULSE & BAR

8 = CROSS & DOT 19 = RED RASTER

9 = LINE SWEEP 100 % 20 = (unused)

10 = MULTIBURST 100 % 21 = (unused)

4-11

Page 35

• Getting pattern PA2? PA2: 0

0 = COLOR BAR 75 % 11 = RAMP

1 = COLOR BAR 100 % 12 = SHALLOW RAMP

2 = MULTIFORMAT COLOR BAR 1 13 = 10 STEP

3 = MULTIFORMAT COLOR BAR 2 14 = CHECK FIELD

4 = MULTIFORMAT COLOR BAR 3 15 = MONOSCOPE (NORMAL)

5 = FLAT FIELD 100 % 16 = MONOSCOPE (INVERT)

6 = FLAT FIELD 50 % 17 = BOWTIE 100 %

7 = FLAT FIELD 0 % 18 = PULSE & BAR

8 = CROSS & DOT 19 = RED RASTER

9 = LINE SWEEP 100 % 20 = NATURAL PICTURE 1 (w/Option 70)

10 = MULTIBURST 100 % 21 = NATURAL PICTURE 2 (w/Option 70)

• Setting ID ON/OFF ID2 X

0 = ID OFF 1 = ID ON

• Getting ID ON/OFF ID2? ID2: 0

0 = ID OFF 1 = ID ON

4-12

Page 36

(3) SD Unit (Installed in UNIT 4)

• Getting format FM4? FM4: 0

0 = 525i/59.94

1 = 625i/50

• Selecting pattern PA4 X

[ 525i/59.94 ] [ 625i/50 ]

0 = COLOR BAR 100 % 0 = COLOR BAR 100 %

1 = COLOR BAR 75 % 1 = EBU COLOR

2 = SMPTE 2 = BBC COLOR

3 = RAMP & COLOR BAR 3 = RAMP & COLOR BAR

4 = FLAT FIELD 100 % *4 to 28: Same as the “525i/59.94.”

5 = FLAT FIELD 50 %

6 = FLAT FIELD 0 %

7 = FIELD ID

8 = CROSSHATCH

9 = LINE SWEEP 100 %

10 = LINE SWEEP 60 %

11 = MULTIBURST 100 %

12 = MULTIBURST 60 %

13 = OVER SIZE RAMP

14 = DIGITAL LIMIT RAMP

15 = SHALLOW RAMP

16 = 10 STEP

17 = CHECK FIELD

18 = MONOSCOPE (NORMAL)

19 = MONOSCOPE (INVERT)

20 = BOWTIE 100 %

21 = PULSE & BAR

22 = RED RASTER

23 = MULTIPULSE

24 = (unused)

25 = (unused)

26 = (unused)

27 = (unused)

28 = (unused)

4-13

Page 37

• Getting pattern PA4? PA4: 0

[ 525i/59.94 ] [ 625i/50 ]

0 = COLOR BAR 100 % 0 = COLOR BAR 100 %

1 = COLOR BAR 75 % 1 = EBU COLOR

2 = SMPTE 2 = BBC COLOR

3 = RAMP & COLOR BAR 3 = RAMP & COLOR BAR

4 = FLAT FIELD 100 % *4 to 28: Same as the “525i/59.94.”

5 = FLAT FIELD 50 %

6 = FLAT FIELD 0 %

7 = FIELD ID

8 = CROSSHATCH

9 = LINE SWEEP 100 %

10 = LINE SWEEP 60 %

11 = MULTIBURST 100 %

12 = MULTIBURST 60 %

13 = OVER SIZE RAMP

14 = DIGITAL LIMIT RAMP

15 = SHALLOW RAMP

16 = 10 STEP

17 = CHECK FIELD

18 = MONOSCOPE (NORMAL)

19 = MONOSCOPE (INVERT)

20 = BOWTIE 100 %

21 = PULSE & BAR

22 = RED RASTER

23 = MULTIPULSE

24 = NATURAL PICTURE 1 (w/Option 70)

25 = NATURAL PICTURE 2 (w/Option 70)

26 = NATURAL PICTURE 3 (w/Option 70)

27 = NATURAL PICTURE 4 (w/Option 70)

28 = NATURAL PICTURE 5 (w/Option 70)

• Setting ID ON/OFF ID4 X

0 = ID OFF 1 = ID ON

• Getting ID ON/OFF ID4? ID4: 0

0 = ID OFF 1 = ID ON

4-14

Page 38

(4) BL Unit (Installed in UNIT 3)

• Getting BLACK 1, 2 format FM31? FM31: 1

Getting BLACK 3, 4 format FM32? FM32: 0

Getting BLACK 5, 6 format FM33? FM33: 3

0 = 1035i/60 17 = 720p/25

1 = 1035i/59.94 18 = 720p/24

2 = 1080i/60 19 = 720p/23.98

3 = 1080i/59.94 20 = NTSC BB

4 = 1080i/50 21 = NTSC BB+Ref

5 = 1080p/30 22 = NTSC BB+ID

6 = 1080p/29.97 23 = NTSC BB+Ref+ID

7 = 1080p/25 24 = NTSC BB+Setup

8 = 1080p/24 25 = NTSC BB+S+Ref

9 = 1080p/23.98 26 = NTSC BB+S+ID

10 = 1080PsF/24 27 = NTSC BB+S+R+ID

11 = 1080PsF/23.98 28 = 525i/59.94

12 = 720p/60 29 = 525p/59.94

13 = 720p/59.94 30 = PAL BB

14 = 720p/50 31 = PAL BB+Ref

15 = 720p/30 32 = 625i/50

16 = 720p/29.97 33 = 625p/50

(5) GLA Unit (Installed in UNIT 1)

• Getting GENLOCK operation status GE1? GE1: 0

0 = INTERNAL or FLYWHEEL 1 = EXTERNAL

• Getting BLACK 1 format FM11? FM11: 1

Getting BLACK 2 format FM12? FM12: 0

Getting BLACK 3 format FM13? FM13: 3

Parameters are same as the “Getting BLACK 1, 2 format” of BL.

4-15

Page 39

(6) List of Query Command

Command Parameter Function

• MAINFRAME

MO?

VR?

• HD (Installed in UNIT 2, for example)

FM2?

PA2?

ID2?

• SD (Installed in UNIT 4, for example)

FM4?

PA4?

None

None

UNIT No. (1-4)

UNIT No. (1-4)

UNIT No. (1-4)

UNIT No. (1-4)

UNIT No. (1-4)

Queries unit inserted

Queries version

Confirming format

Getting pattern

Getting ID ON/OFF

Confirming format

Getting pattern

Reply Example

MO: LT443D-70, GL, HD,

BL, SD

MO: LT443D, - -, HD, BL, - -

VR: LT443D-70 V1.0

FM2: 0

FM2: 13

PA2: 0

PA2: 21

ID2: 0

ID2: 1

FM4: 0

FM4: 1

PA4: 0

PA4: 28

ID4?

• BL (Installed in UNIT 3, for example)

FM31?

FM32?

FM33?

• GLA (Installed in UNIT 1, dedicated)

GE1?

FM11?

FM12?

FM13?

UNIT No. (1-4)

UNIT No. (1-4)

Output No. (1)

UNIT No. (1-4)

Output No. (2)

UNIT No. (1-4)

Output No. (3)

UNIT No. (1)

UNIT No. (1)

Output No. (1)

UNIT No. (1)

Output No. (2)

UNIT No. (1)

Output No. (3)

Getting ID ON/OFF

Confirming BLACK

1, 2 format

Confirming BLACK

3, 4 format

Confirming BLACK

5, 6 format

Getting GENLOCK

operation status

Confirming BLACK 1

format

Confirming BLACK 2

format

Confirming BLACK 3

format

ID4: 0

ID4: 1

FM31: 0

FM31: 33

FM32: 0

FM32: 33

FM33: 0

FM33: 33

GE1: 0

GE1: 1

FM11: 0

FM11: 33

FM12: 0

FM12: 33

FM13: 0

FM13: 33

4-16

Page 40

(7) List of Setting Command

Command Parameter Function

• HD (Installed in UNIT 2, for example)

PA2 X

ID2 X

• SD (Installed in UNIT 4, for example)

PA4 X

ID4 X

*There is no setting item for the MAINFRAME, BL unit, and GLA unit.

4.5.7 VERSION DISPLAY

The software version used for this instrument can be confirmed.

UNIT No. (1-4)

Pattern No.

UNIT No. (1-4)

Setting ID

UNIT No. (1-4)

Pattern No

UNIT No. (1-4)

Setting ID

Selecting pattern

Setting ID ON/OFF

Selecting pattern

Setting ID ON/OFF

Reply Example

PA2: 0

PA2: 19

ID2: 0

ID2: 1

PA4: 0

PA4: 23

ID4: 0

ID4: 1

2. VERSION DISPLAY

LT 443D Ver 3.3

4-17

Page 41

4.6 Main Menu Structure

STATUS display mode display

SETTING menu mode display

MENU key

Executing status display

Executing setting menu

MENU or FORMAT key

MENU or EXIT key

ENTER key

MENU key

4.6.1 Two Modes Selectable With MENU Key

When one of four UNIT LEDs lights, pressing the [MENU] key on the LT 443D front panel

can select the STATUS display mode or SETTING menu mode.

4.6.2 STATUS Display Mode

This mode displays the current setting conditions of the LT 443D mainframe.

The principal setting conditions of the selected unit (e.g., UNIT 2) is displayed as follows.

The status display mode is only used for checking the status; cannot be used for settings.

Display example

[STATUS] FORMAT TYPE

1080i/59.94

(1) Status Display Structure

The hierarchical structure for each unit is shown below:

q GENLOCK STATUS

GENLOCK STATUS: INT/EXT xxx *xxx The sign displays the locked format.

GENLOCK MODE: INTERNAL/AUTO (GO INTERNAL)/MANUAL (GO INT)/

AUTO (FLYWHEEL)/MANUAL (FLYWHEEL)

FORMAT TYPE BLK 1

FORMAT TYPE BLK 2

FORMAT TYPE BLK 3

4-18

Page 42

w ANALOG BLACK STATUS

t DA STATUS

FORMAT TYPE BLK 1, 2

FORMAT TYPE BLK 2, 4

FORMAT TYPE BLK 3, 6

e HD-SDI STATUS

FORMAT TYPE

V-PHASE (HD)

H-PHASE (HD)

V-PHASE (HDB)

H-PHASE (HDB)

EMB. AUDIO (HD)

EMB. AUDIO (HDB)

Y, Cb, Cr

ID CHARACTER

PATTERN SCROLL

PATTERN CHANGE

*Items with “(HDB)” is only applicable

to HDB.

CH1/CH2 ON/OFF

CH3/CH4 ON/OFF

CH5/CH6 ON/OFF

CH7/CH8 ON/OFF

y AA STATUS

CH1 ON/OFF, CH2 ON/OFF

u CS STATUS

FORMAT TYPE

CS F-PHASE

CS V-PHASE

CS H-PHASE

Y, C ON/OFF

APL MODE

ID CHARACTER

PATTERN SCROLL

PATTERN CHANGE

r SD-SDI STATUS

FORMAT TYPE

V-PHASE (SD)

H-PHASE (SD)

V-PHASE (SDB)

H-PHASE (SDB)

EMB. AUDIO (SD)

EMB. AUDIO (SDB)

Y, Cb, Cr

ID CHARACTER

PATTERN SCROLL

PATTERN CHANGE

*Items with “(SDB)” is only applicable

to SDB.

BLACK1 F-PHASE

BLACK1 V-PHASE

BLACK1 H-PHASE

BLACK2 F-PHASE

BLACK2 V-PHASE

BLACK2 H-PHASE

V. DRIVE V-PHASE

H. DRIVE H-PHASE

4.6.3 SETTING Menu Mode

This mode is described in the instruction manual of each unit.

4-19

Page 43

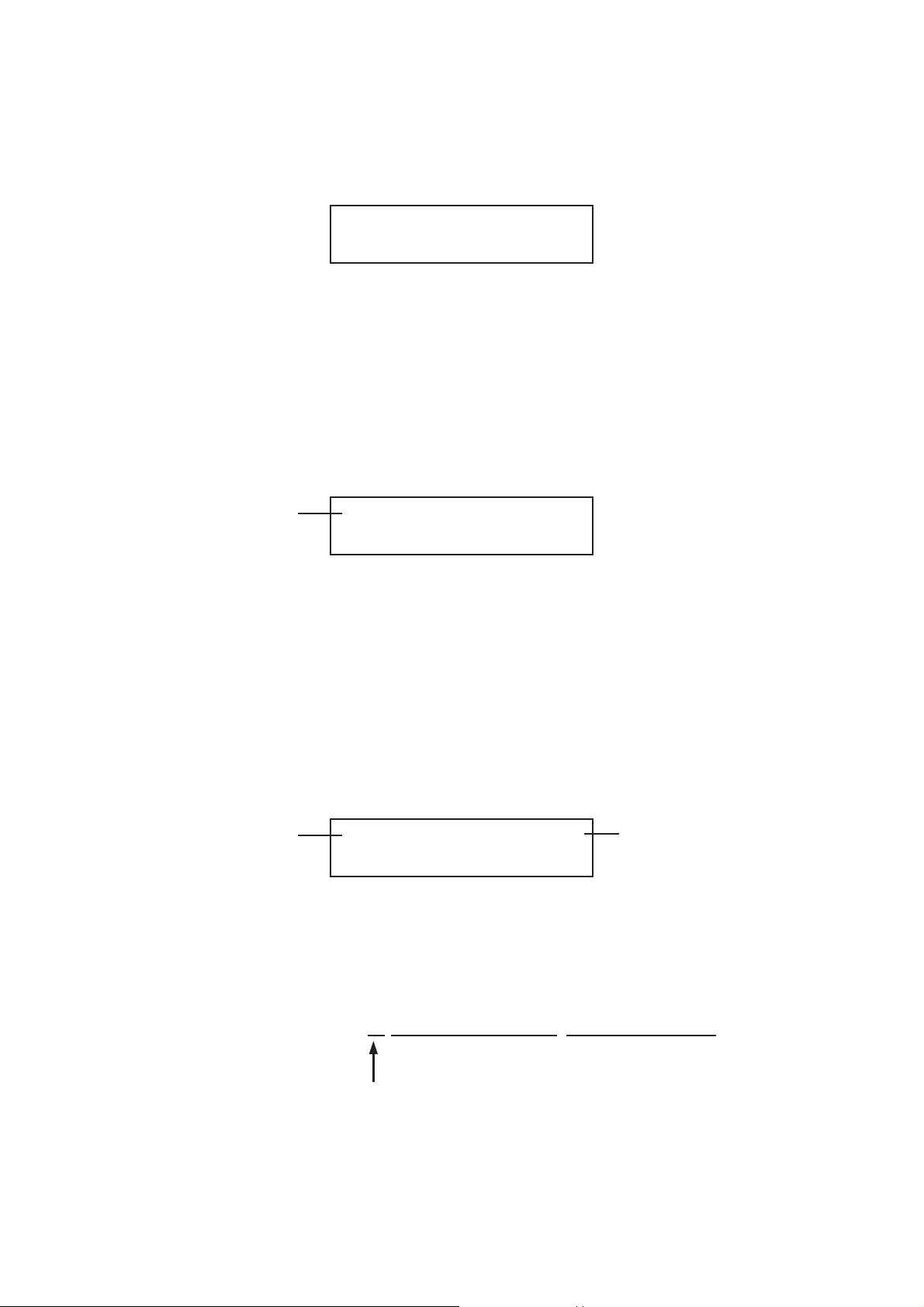

5. NOTES ON RACK MOUNTING

A size of this instrument conforms to 1U standards. Use the Rack Support supplied as standard

accessory. Also procure L-angles, shelves, and slide rails. Secure them to prevent damaging the

instrument.

Contact your local leader agent for more information.

Rack support

M3x10

(3mm in dia.)

screws

M4x10

(4mm in dia.)

screws

Slide rail

(inner member)

Slide rail

(outer member)

Fixed to the rack

Figure 5-1 Mounting slide rail

*Slide rail (outer member) mount method depends on types of racks. Read the rack instruction

manual for mounting.

5-1

Page 44

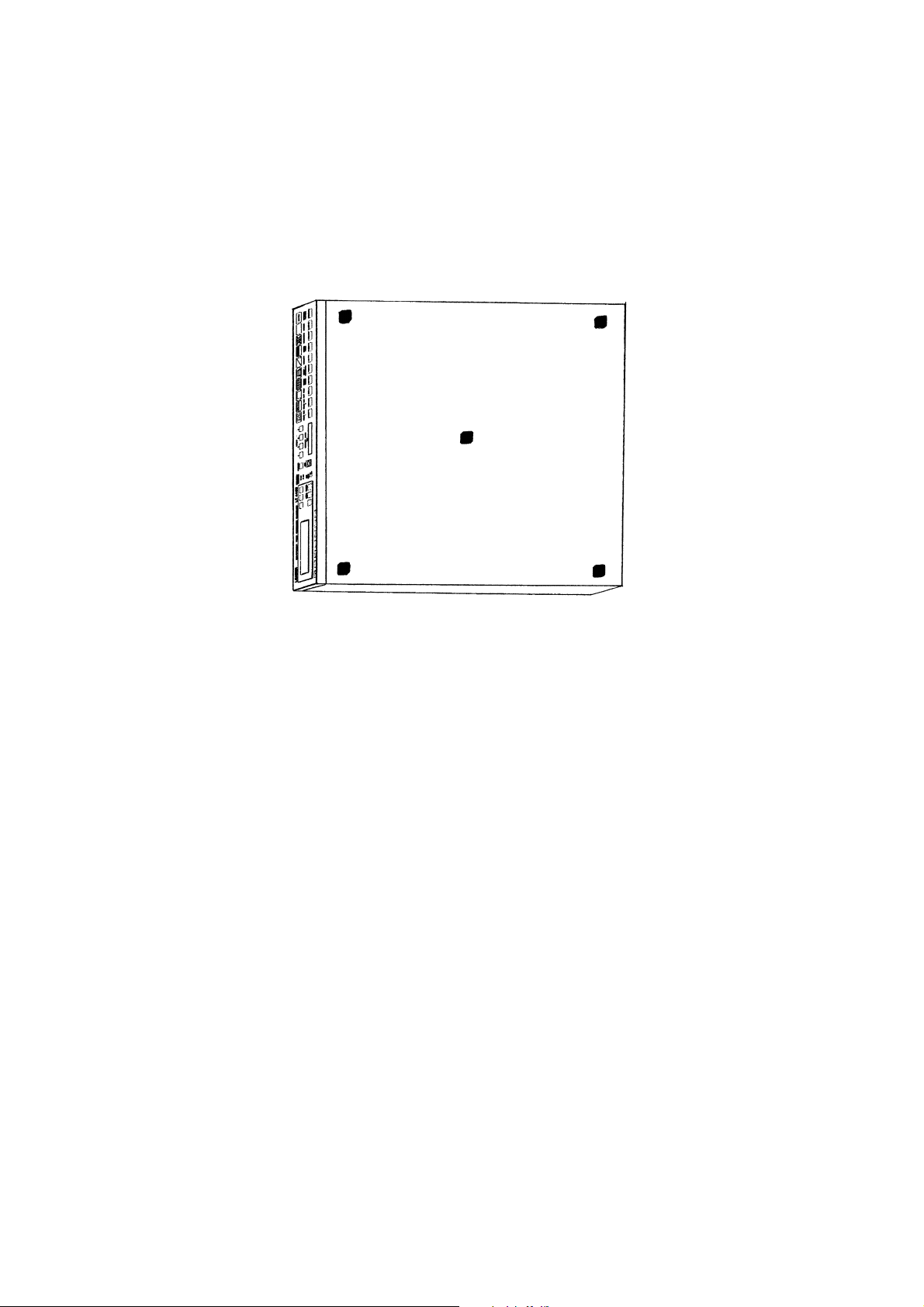

6. ABOUT RUBBER FEET

There are no rubber feet on the bottom of this instrument for rack-mounting purposes.

When using the instrument outside the rack or stack instruments on top of each other, attach five

rubber feet (supplied as standard accessory) as shown in Figure below to prevent the instrument

from scratching or falling.

Peel the seals before attaching the rubber feet.

LT 443D bottom

6-1

Page 45

7. DATA BACKUP

This instrument retains the menu setting contents and panel settings even when the power is

turned off.

• Backup battery

Manganese-Lithium primary battery

• Backup period

Data is backed up for about five years.

* Backup period depends on storage environment, operating conditions, etc.

7-1

Page 46

8. DEFAULT SETTINGS

8.1 Default Settings for All Data [MENU] + [FORMAT]

This section described the setting procedure to default all setting data (except DATE &

TIME).

*Caution: When the default setting is made, such data as backup and preset return to the

default value.

Procedure

1 Disconnect the power cord from the main unit for [POWER: OFF] state.

2 Hold down the [MENU] and [FORMAT] keys on the front panel simultaneously, then

insert the power cord to the main unit for [POWER: ON] state; do not release the keys,

here.

3 When [INITIALIZING...] is displayed on the front panel, release the [MENU] and

[FORMAT] keys.

4 When default setting is completed, [ALL DEFAULT SET COMPLETE!] is displayed on

the front panel LCD. A display check and ENTER key is pushed.

5 The default setting is now completed.

8.2 Default Settings for Selected Data [MENU] + [ENTER]

This section described the setting procedure to default basic data except the followings:

Preset data [INT_MEM PRESET No. 1 to 3]

[IP address] data

[DATE & TIME] data

*This function can be applied from the firmware version 1.8.

Procedure

1 Disconnect the power cord from the main unit for [POWER: OFF] state.

2 Hold down the [MENU] and [ENTER] keys on the front panel simultaneously, then

insert the power cord to the main unit for [POWER: ON] state; do not release the keys,

here.

3 When [INITIALIZING...] is displayed on the front panel, release the [MENU] and

[ENTER] keys.

4 When default setting is completed, [DEFAULT SET COMPLETE!] is displayed on the

front panel LCD. A display check and ENTER key is pushed.

5 The default setting is now completed.

8-1

Page 47

9. MAINTENANCE

9

The LT 443D is designed to operate stably under normal handling. If you have questions

regarding calibration and service, contact your local Leader agent.

9.1 Preventing Power Cord Disconnection

To prevent power cord disconnection from the AC inlet, the Cover/Inlet stopper is supplied

with the instrument. Refer to the procedure below.

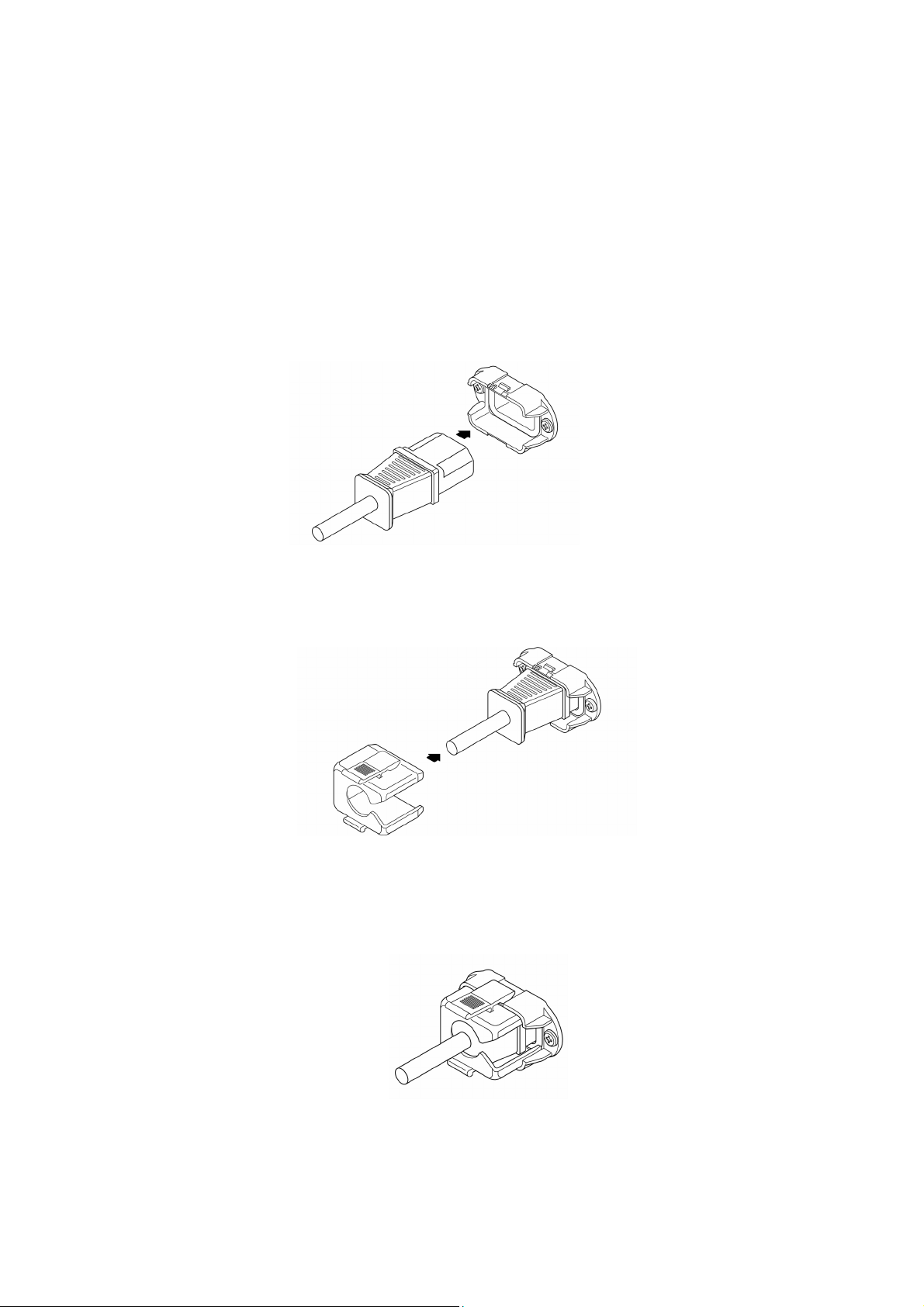

9.1.1 Connecting the Power Cord

① Insert the power cord connector into the AC inlet.

Base

Connector

② Place the Cover/Inlet stopper on top of the connector as shown below.

Cover/Inlet stopper

③ Press the cover until it clicks into place.

④ Confirm that the Cover/Inlet stopper is locked to the base.

-1

Page 48

9.1.2 Disconnecting the Power Cord

9

① Press the levers on the Cover/Inlet stopper with your fingers to release the lock.

② Remove the Cover/Inlet stopper from the base.

Cover/Inlet stopper (side view)

Cover/Inlet stopper

③ Disconnect the power cord connector from the AC inlet.

Base

Connector

-2

Page 49

UNIT INSTALLATION / REPLACEMENT

INSTRUCTION MANUAL

NOTE:

This instruction manual describes the procedures necessary for installing/replacing

various LT 443D units. Perform the work after checking the information and precautions

of the relative items in this manual.

LEADER ELECTRONICS CORP.

Page 50

TABLE OF CONTENTS

1. Introduction ............................................................................................................................ I-1

2. Scope of Warranty ................................................................................................................. I-1

3. Equipment and Tools Necessary for Performing the Work .................................................... I-1

4. Work Procedure ..................................................................................................................... I-2

4.1 Firmware Upgrade ........................................................................................................ I-2

4.2 Slot Selection ................................................................................................................ I-4

4.3 Unit Installation .............................................................................................................. I-5

4.4 System Initialization ...................................................................................................... I-7

4.5 About the Operation Check ........................................................................................... I-7

5. Operation Check .................................................................................................................... I-8

5.1 Operation Check of the LT 443D-GLA Genlock Unit ..................................................... I-8

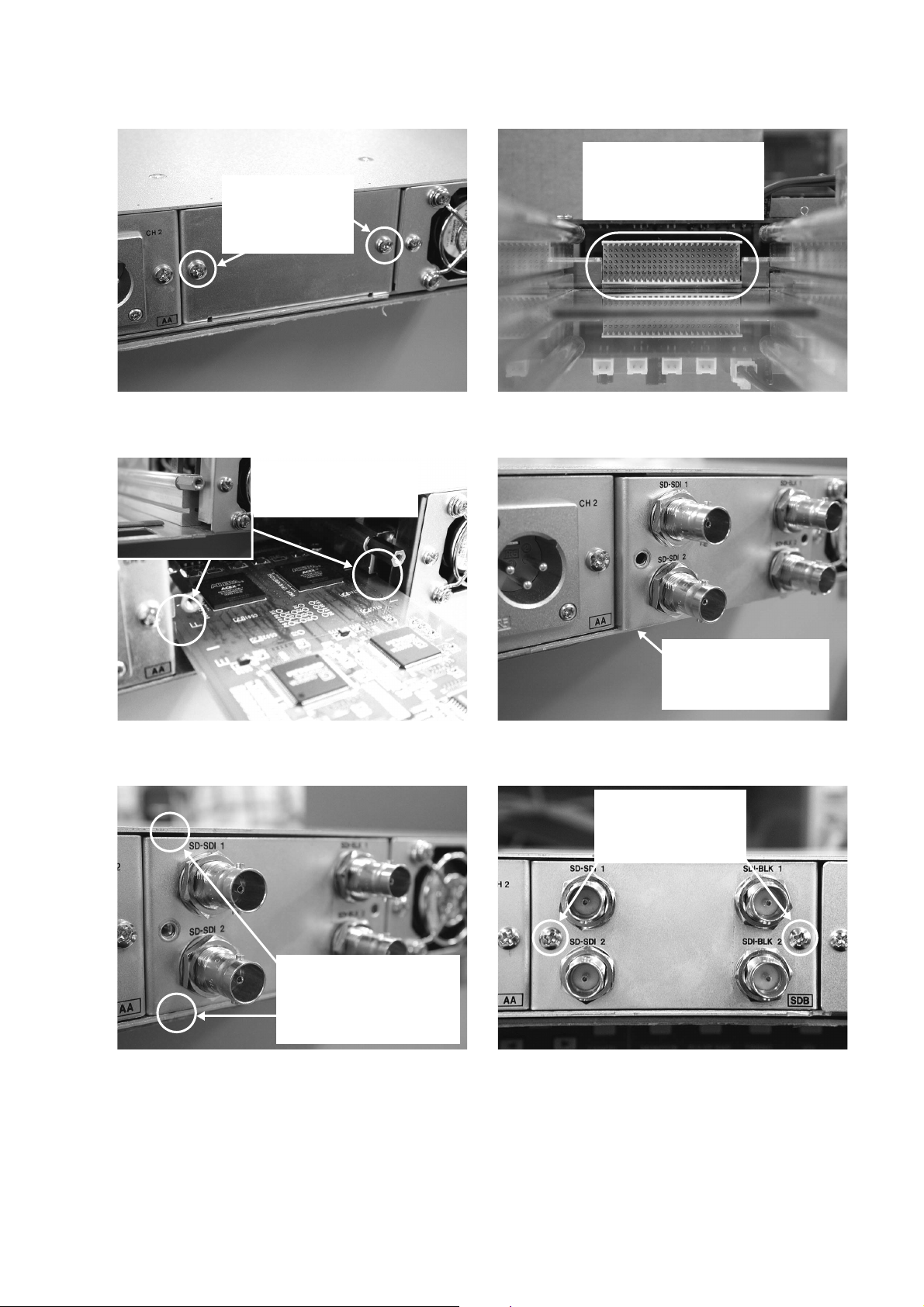

5.2 Operation Check of the LT 443D-HD -HDB HD-SDI Unit ............................................ I-10

5.3 Operation Check of the LT 443D-BL Analog Black Unit .............................................. I-11

5.4 Operation Check of the LT 443D-SD -SDB SD-SDI Unit ............................................ I-12

5.5 Operation Check of the LT 443D-DA Digital Audio Unit .............................................. I-13

5.6 Operation Check of the LT 443D-AA Analog Audio Unit.............................................. I-14

5.7 Operation Check of the LT 443D-CS Analog Composite Unit ..................................... I-15

Page 51

1. Introduction

This instruction manual describes the procedures necessary for installing/replacing various LT

443D units.

Perform the work after checking the information and precautions of the relative items in this

manual.

2. Scope of Warranty

Install/Replace units or upgrade the firmware at the user’s own responsibility. If the product

malfunctions due to the user’s inadequate handling or a failure in the upgrading of the firmware,

repairs will be provided for a fee even if it is within the warranty period.

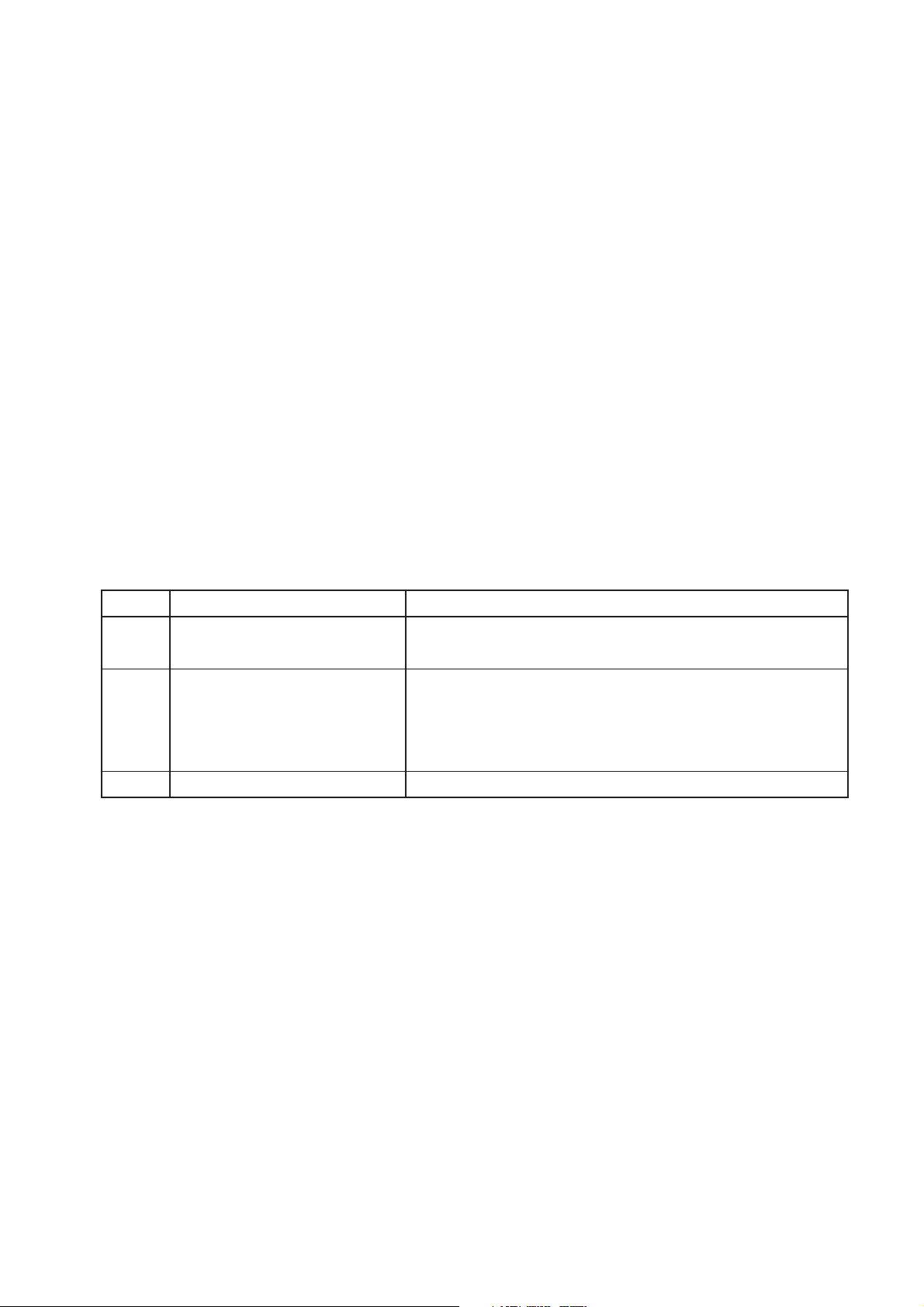

3. Equipment and Tools Necessary for Performing the Work

The table below shows the equipment and tools necessary for installing/replacing units and

upgrading the firmware. Additional measurement instruments are necessary if you are going to

check the operation of each unit. For details, see the operation check procedure of the

respective unit in chapter 5, “Operation Check.”

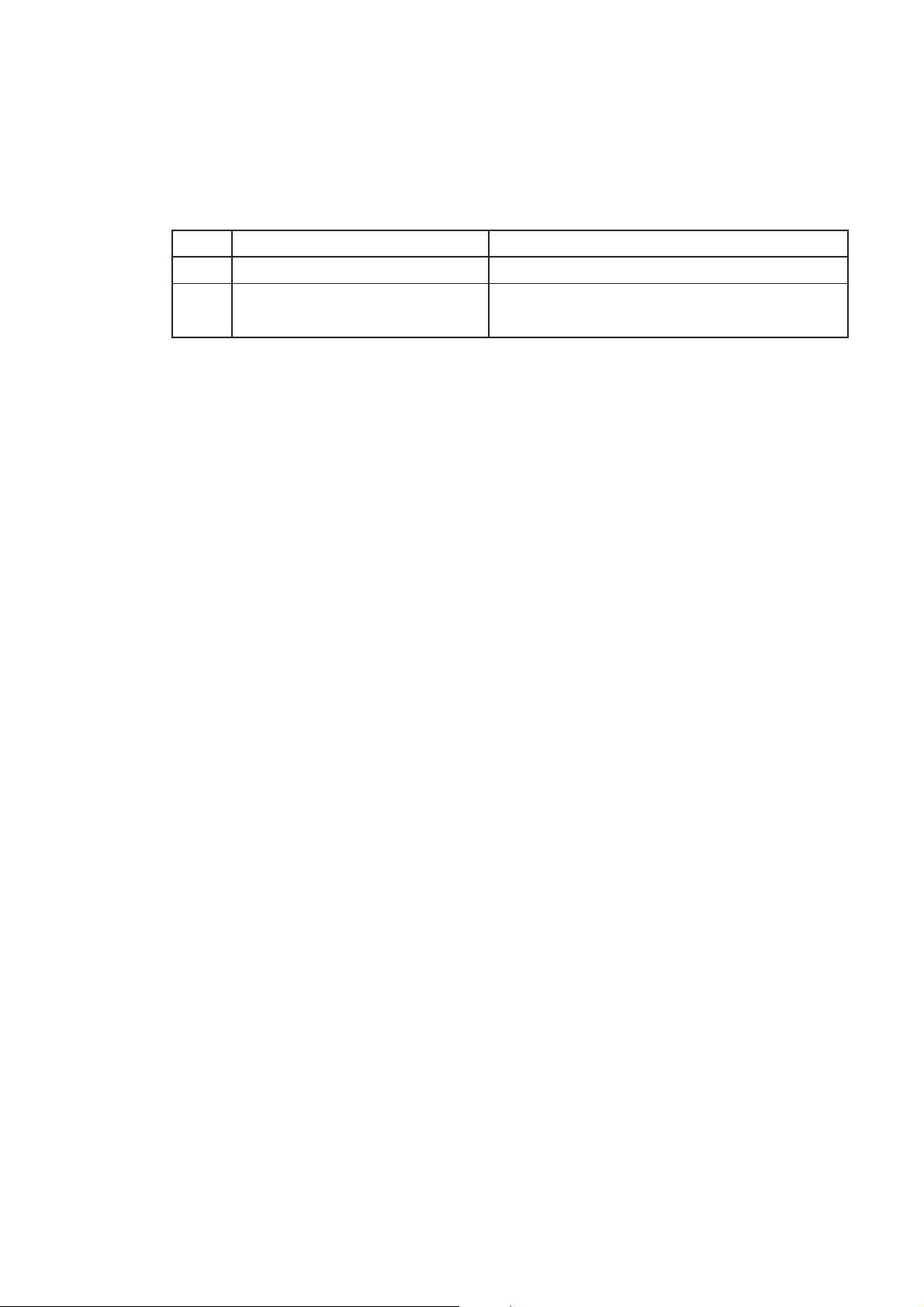

List of Equipment and Tools Necessary for Performing the Work

No.

1

2

3

Name

Screwdrivers for TORX

screws

Compact Flash card

(CF card)

Wrist strap

Note

For M3 x 6 mm binding screws with Hexalobular

socket head cap

CF card tested for compatibility by LEADER (made by

SanDisk Corporation)

For preset backup: 1 card

For firmware updating: 1 card

As a measure for countering electrostatic discharge

I-1

Page 52

4. Work Procedure

The work flow is shown below.

4.1 Firmware upgrade

4.2 Slot selection

4.3 Unit installation

4.4 System initialization

4.5 Unit operation check

4.1 Firmware Upgrade

If you are installing/replacing units, you may need to upgrade the main frame firmware. In

addition, the main frame settings are initialized during the installation or replacement of

units. Therefore, you should back up the main frame settings as necessary.

*For information on obtaining the newest version of the firmware, contact your local

Leader agent.

1) Checking the Firmware Version

a) Turn off the front panel [UNIT] key LED on the main frame.

b) From “1. UTILITY MENU” that is shown on the front panel LCD, select “VERSION

DISPLAY.”

c) Check the firmware version that is shown. If the current main frame firmware version

is older (the version number is smaller) than the newest firmware version, you must

upgrade the firmware.

Note: Firmware upgrading

• Even if you are installing the same type of unit that is installed, if the firmware

version is older (the version number is smaller) than the newest version, upgrade

the firmware.

• Please note that if the unit is a special order model, functions specific to the model may

no longer work if you upgrade the firmware using the firmware of the standard model.

• If the firmware version is less than 1.6, it may be necessary to upgrade data other

than the firmware. Please consult your local Leader agent in this case.

2) Backing Up Various Settings

When you install/replace a unit or upgrade the firmware, settings must be initialized.

When initialization is performed, various unit settings (excluding the LT 443D time

setting) and internal presets are reset to their factory default. If you need to retain the

settings, backup the following items.

• Internal presets (No.1 to 3: 3 items)

• Last memory (main frame settings that exist immediately before the power is turned

OFF: 1 item)

• Ethernet (IP Address, Subnet Mask, and Gateway: 3 items)

I-2

Page 53

Note: Backing up the settings

• Internal presets and last memory can be backed up on a Compact Flash card (CF

card). Ethernet settings are not included in the preset. Please retain the settings

such as by taking a memo.

• For the procedure of storing presets to the CF card, see the item of “MAINFRAME”

in this manual.

• For backing up the data, use a CF card that is separate from the card used to

upgrade the firmware.

3) Upgrading the Firmware

a) Remove all cables that are connected to the LT 443D units.

b) Turn on the power to the main frame.

c) Insert the CF card for upgrading the firmware into the MEMORY CARD slot on the

front panel of the LT 443D main frame.

d) When the front panel LCD shows a screen illustrated in Figure 4-1-1, press the

[ENTER] key. The firmware upgrading starts.

CF OPERATION

▼CF (Ver X.X) → 443D

Figure 4-1-1

e) While the firmware is being upgraded, the LCD shows a screen illustrated in Figure

4-1-2, and the INT and EXT SYNCHRONIZATION LEDs illuminate alternately.

PROG. SYSTEM FLASH

Write: -------------- ------

Figure 4-1-2

f) When the firmware upgrading is finished, the main frame automatically restarts.

Then, the screen shown in Figure 4-1-1 appears again. Remove the CF card.

g) Check that the firmware has been upgraded by carrying out the procedure described

in 1), “Checking the Firmware Version.”

Note: Firmware upgrading

• When upgrading the firmware, remove all cables except the power cord. Be

especially certain that nothing is connected to the genlock connector. Upgrading the

firmware while the genlock function is in operation may hinder proper firmware