Littfinski DatenTechnik (LDT)

Assem

bly Instruction

Pos.

Qty.

Component

Remarks

Ref.

Done

Reverse-Loop Module

from the Digital-Professional-Series !

KSM-SG-B Part-No.: 700501

Suitable for the digital operation of all digital

The polar reversal at the reverse-loop will be performed

without short-circuit via two sensor rails.

With reason to an external power supply possibility is a

simple control of the reverse-loop with track occupancy

module (e.g. RM-GB-8(-N) and RS-8) possible. The sensor

rails will be controlled as well.

This product is not a toy! Not suitable for children under 14 years of age!

The kit contains small parts, which should be kept away from children under 3!

Improper use will imply danger of injuring due to sharp edges and tips! Please

store this instruction carefully.

CE Part-No.:

24 80 35

Introduction:

You have purchased a kit for your model railway supplied within

the assortment of Littfinski DatenTechnik (LDT).

This kits are a high quality product which is easy to assemble.

We are wishing you having a good time for assembling and

application of this product.

General:

Tools required for the assembly

Please assure that the following tools are available:

• a small side cutter

• a mini soldering iron with a small tip

• solder tin (if possible 0,5mm diameter)

Safety Instructions

• All electrical and electronic components included in this kit

shall be used on low voltage only by using a tested and

approved voltage transducer (transformer). All components

are sensitive to heat. During soldering the heat shall be

applied for a very short period only.

• The soldering iron develops a heat up to 400°C. Please keep

continual attention to this tool. Keep sufficient distance to

combustible material. Use a heat resistant pad for this work.

• This kit consist of small parts which can possibly be

swallowed from children. Children (especially under 3 years)

shall not participate on the assembly without supervision.

>> kit <<

formats

Set-Up:

For the board-assembly please follow exact the sequence of the

below assembly list. Cross each line off as done after

completing the insertion and the soldering of the respective

part.

For the diodes and zener diodes please keep special attention

to the correct polarity (marked line for the cathode).

With reason to different makes of electrolytic capacitors you

will find different markings of the polarity. Some are marked with

"+" and some are marked with "-". Each capacitor has to be

assembled to the board that the marking on the capacitor is in

correspondence with the marking on the pc-board.

Integrated circuits (IC`s) are either marked with a half round

notch on one end or a printed point for the correct mounting

position. Push the IC`s into the correct socket or directly into the

pc-board (IC3) assuring that the notch or the printed point is

corresponding to the half-rounded marking on the pc-board.

Please attend to the sensitivity of the IC`s to electrostatic

discharge which will cause immediate damage of the IC.

Before touching those components please discharge yourself

by contacting an earthed metal (for example an earthed

radiator) or work with an electrostatic safety pad.

Please attend to the mark "+" of the rectifiers. Some

manufacturers mark the "+" connections additionally with a

longer connection wire. If the rectifier shows as marking a

flattened side this side has to correspond with the marking on

the pc-board.

The clamps KL1 to KL4 have to be connected to a block with 8

connections.

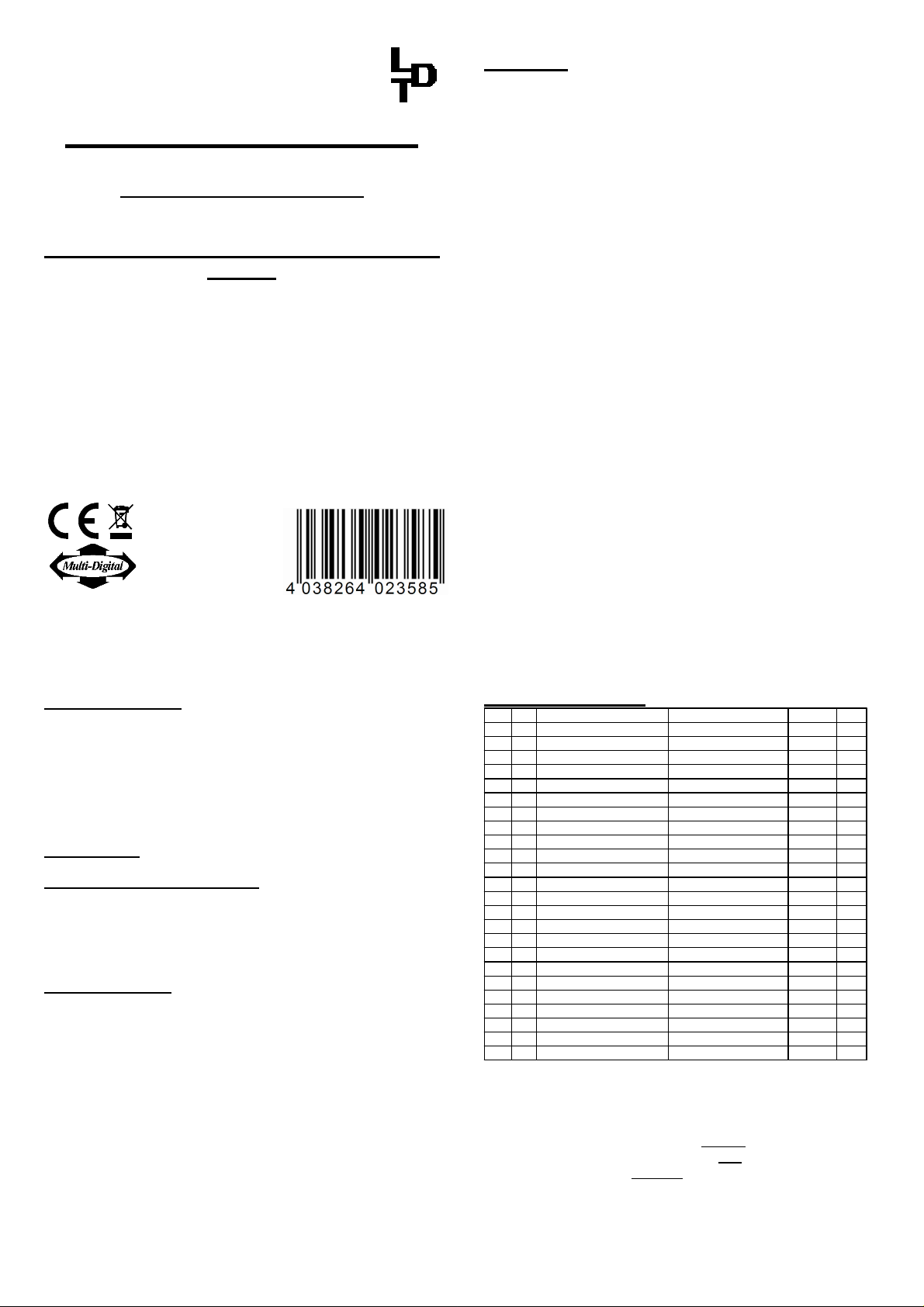

Assembly List:

1 1 Printed circuit board

2 1 Z-Diode BZX ... 5V1 attend to the polarity! D1

3 5 Diodes 1N4003 attend to the polarity! D2, D6

4 1 Z-Diode BZX ... 30 attend to the polarity! D7

5 1 Resistor 820Ohm gray-red-black-black R1

6 2 Resistors 1,5kOhm brown-green-black-brown R2, R3

7 1 Resistor 220kOhm red-red-black-orange R4

8 1 Resistor 1MOhm brown-black-black-yellow R5

9 2 Capacitors 100nF 100nF = 104 C3, C4

10 2 IC-Sockets 18poles IC1, IC2

11 1 IC-Socket 8poles IC4

12 1 IC: 814 attend to the polarity! IC3

13 1 Resonator CR1

14 1 Electrolytic-cap. 100µF/25V attend to the polarity! C2

15 1 Electrolytic-cap. 470µF/35V attend to the polarity! C1

16 1 Rectifier attend to the polarity! GL1

17 1 Multi Fuse R050 MF1

18 3 Relay REL1..3

19 4 Clamps 2poles build blocks before assy. KL1, KL4

20 1 Clamp 2poles KL5

21 1 IC: Z86E0..PSG attend to the polarity! IC1

22 1 IC: ULN2803A attend to the polarity! IC2

23 1 IC: 93C46 attend to the polarity! IC4

Subject to technical changes and errors. 05/2013 by LDT

Final control

Made in Europe by

Littfinski DatenTechnik (LDT)

Kleiner Ring 9

D-25492 Heist/Germany

Phone: 0049 4122 / 977 381

Fax: 0049 4122 / 977 382

Internet: http://www.ldt-infocenter.com

Soldering instruction

Provided you have no special experience in soldering electronic

components please read first this soldering instruction before starting

the job. Soldering has to be trained!

1. Never use additional fluxes for soldering electronic circuits which

contain acids (e.g. zinc chloride or ammonium chloride). Those can

destroy components and printed circuits when not washed off

completely.

2. As soldering material only lead free soldering tin with a rosin core

for fluxing should be used.

3. Use a small soldering iron with max 30 Watt heating power. The

solder tip shall be free from scale to assure an excellent heat

transfer to the area to be soldered.

4. The soldering shall be performed on a speedy way because a long

heat transfer can destroy the components. To much or to long

heating can take off the copper pads and copper tracks from the

board.

5. For a good soldering a well tinned solder-tip has to be brought in

contact to the copper-pad and the component wire at the same

time. Simultaneous a little solder-tin shall be applied for heating up.

As soon as the solder-tin starts melting the tin wire has to be taken

away. Just wait until the tin has well wetted the pad and the wire

and take the soldering iron away from the soldering area.

6. Make sure not to move the just soldered component for about 5

seconds after removing the soldering iron. This should create a

silver shining faultless soldering joint.

7. For a faultless soldering joint and well done soldering is a clean

non-oxidized soldering-tip absolutely required. It is not possible to

perform a sufficient soldering joint with a dirty soldering tip.

Therefore please clean the soldering tip from excessive solder-tin

and dirt by using a wet sponge or a silicone cleaning pad after each

soldering process.

8. After completion of the soldering all connection wires have to be

cutted off directly above the soldering joint by using a side cutter.

9. By soldering semiconductors (transistors, diodes), LED`s and IC`s

is it very important never to exceed the soldering time of 5 seconds

to prevent the destruction of the component. It is absolutely

required to attend to the correct polarity of the component before

starting the soldering process.

10. After the board assembly carefully control the pc-board about

correct insertion of the components and the correct polarity. Please

check if no connections or copper tracks are accidentally short

circuited by soldering tin. This can not only result to malfunction of

the module but also result to a destruction of expensive

components.

11. Please take into account that improper soldering joints, wrong

connections, faulty operation or wrong board assembly is not a

matter within our sphere of influence.

General installation information

The contact-wires of resistors and diodes to be assembled in a lying

position shall be bended in accordance to the raster distance into a right

angular position and assembled into the specified bores (in accordance

to the board assembly plan or the assembly markings). To prevent that

the components will not fall out by turn-over the pc-board please bend

the connection wires about 45° apart and solder them carefully to the

copper pads on the rear side of the board. Finally the excessive wires

shall be cutted off with a small side cutter.

The resistors in the supplied kits are metal-foil resistors. Those have a

tolerance of 1% and are marked with a brown “tolerance-ring”. The

tolerance ring can be identified by the larger margin distance

respectively the larger distance to the other four marking rings.

Normally there are five color rings on the metal-foil resistors. To read

the color code you have to locate the resistor that way that the brown

tolerance ring will be on the right side. The color rings will be red now

from left to right!

Please take care to assemble diodes with the correct polarity (position

of the cathode marking). Take care about a very short soldering time!

The same will apply to the transistors and the integrated circuits (IC`s).

The flat side of the transistors has to correspond with the marking on

the pc-board.

The transistor legs should never be assembled in a crossed position.

Further those components should have a distance of about 5mm to the

board. Attend to the short soldering time to prevent the damage of the

component by excessive heat.

Capacitors shall be assembled into the respective marked bores, the

wires to be bent a little apart and careful soldered to the copper pad. By

the assembly of electrolytic capacitors (electrolytic cap) it has to be

attended to the correct polarity (+,-)! Wrong-way soldered electrolytic

capacitors can explode during the application! Therefore is it very

important to check the correct polarity two- or even better three-times.

In addition it has to be attended to the correct capacitor values, e.g. n10

= 100pF (not 10nF!).

A careful and clean assembly will drastically reduce the possibility that

anything will not be in correct function. Check every step and every

soldering joint two times before carrying on! Attend closely to the

assembly list! Perform the described step not different and do not skip

any step! Mark each step as done at the foreseen column after

assembly and careful check.

Take your time. Private work is no piece-work because the time for

careful assembly work is much less than an extensive fault diagnosis.

Final assembly

Sockets and integrated circuits (IC´s) of the kits will be supplied on a

piece of foam to assure safe transport.

This foam shall never be used below or between components as this

foam is electrical conductive.

In case the kit will be taken into operation the conductive foam can

produce a short circuitry and destroy the complete kit. Anyhow the

function of the module will not be as expected.

Warranty

As we have no influence to the proper and correct assembly we have to

limit our warranty to the complete supply and the faultless quality of the

components.

We guarantee the function of the components in accordance to the

identified values within a non-assembled condition of the parts and the

compliance of the technical data of the circuit by attending to the

respective soldering instruction and the specified start of operation of

the module including connection and operation.

Further demands are not accepted.

We are not taking over any warranty nor any liability for any harm or

sequential damage connected to this product.

We reserve our right for a repair, rework, supply of replacement or

refund of the purchase price.

The following criteria will result to a non-repair respectively to a lost of

right to claim under guarantee:

• if acid-containing soldering tin or fluxes with corrosive content and

others have been used

• if the kit has been improper soldered or assembled

• by alterations or repair-trials on the device

• by own circuit amendments

• by construction of non-intended improper displacement of

components, free wiring of components etc.

• application of other non-original kit-components

• by damaging of copper tracks or soldering copper pads on the

board

• by wrong assembly and the sub sequential damages

• overloading the module

• by damages caused by intervention of foreign persons

• by damages caused by disregarding the operation manual

respectively the connection plan

• by connecting a wrong voltage respectively a wrong current

• by wrong polarity connection of the module

• by wrong operation or damages caused by negligent usage or

abuse

• by defects caused by bridged or wrong fuses.

All such cases will result to a return of the kit to your expenses.

Subject to technical changes and errors. 05/2013 by LDT

Littfinski DatenTechnik (LDT)

Opera

tion Instruction

Reverse-Loop Module

from the Digital-Professional-Series !

KSM-SG-F LDT-Part-No.: 700502

>> finished module <<

Suitable for the digital operation of all digital

The polar reversal at the reverse-loop will be

performed without short-circuit via two sensor rails.

With reason to an external power supply possibility

is a simple control of the reverse-loop with track

occupancy module (e.g. RM-GB-8(-N) and RS-8)

possible. The sensor rails will be controlled as well.

This product is not a toy! Not suitable for children under 14 years of age! The kit

contains small parts, which should be kept away from children under 3! Improper

use will imply danger or injuring due to sharp edges and tips! Please store this

instruction carefully.

CE Part-No.:

24 80 36

Multi-Digital

formats

Introduction/Safety instruction:

You have purchased the reverse-loop module KSM-SG for

your model railway layout.

The KSM-SG module is a high quality product that is supplied

within the Digital-Professional-Series of Littfinski

DatenTechnik (LDT).

We are wishing you having a good time using this product.

• Please read the following instructions carefully. Warranty will

expire due to damages caused by disregarding the operating

instructions. LDT will also be not liable for any consequential

damages caused by improper use or installation.

The KSM-SG comes as finished module and as finished

module in a case with 24 month warranty.

Connecting the reverse-loop module to your

digital model railway layout:

• Attention: Before starting the installation switch off the

drive voltage by pushing the stop button or disconnect

the main supply.

The reverse-loop module receives the power supply via the

clamp KL5. The voltage of 16...18V~ of a model railway

transformer (ac output) is acceptable.

Operation mode:

The reversal polarity of the reverse-loop will be performed

without short circuit due to 2 sensor-tracks which are

located at the entrance and at the exit of the reverse-loop.

Both rails of the sensor tracks (A1/B1 and A2/B2) and the

reverse loop (AK/BK) will be completely isolated and

connected to the respective marked clamps at the reverseloop module KSM-SG.

The sample connection 1 at the rear side of this instruction

shows the complete wiring.

The optimal length of the sensor rails will be 5 to 20 cm. The

reverse-loop rail gets the supply via the clamps AK and BK.

The reverse-loop rail has to have at minimum the length of

the longest train of the layout.

The reverse-loop KSM-SG can switch up to 8 Ampere digital

current.

The input A and B of the reverse-loop module KSM-SG will

receive the digital current from the command station or from a

booster from the ring-conductor “driving”. It is important that the

reverse-loop will be complete inside one booster area and

not between two rail sections which get the supply from two

different boosters.

Because the KSM-SG itself requires no digital current and

receives the energy from a model railway transformer is a

simple wiring for the control of the reverse-loop in

combination with track occupancy sensors possible.

The sample connections 2 at the rear side of this instruction

shows the reverse-loop control via the feedback module RM GB-8(-N) with integrated track occupancy report.

The reverse-loop module KSM-SG inputs A and B receive

digital current from one of the 8 outputs of the RM-GB-8(-N).

On this process will be every current consumer within the

reverse-loop recognized and produces an occupancy report.

The sensor tracks will be controlled as well.

Further information related to the control of reverse-loops

can be found at the Internet on our Web-Site (www.ldtinfocenter.com) within the section “Downloads”. Please

download the file “Reversing loop monitoring” onto your PC.

At the section “Sample Connections” on our Web-Site are

additionally samples for the reversal polarity with the reverse-

loop module KSM-SG for further track layouts available.

Accessories:

For safe installation of the reverse-loop modules below your

model layout we offer an installation set under the order code

MON-SET and for the assembled kits a sturdy exact matching

case (order code: LDT-01).

Sample Connection 1: Automatic polarity of a standard reverse-loop with the reverse-loop module KSM-SG.

Littfinski DatenTechnik (LDT)

Reverse loop module

Kehrschleifenmodul

Digital-Profi werden!

Kehrschleifenmodul

KSM-SG

Kurzschlussfreie Umpolung über Sensorgleise.

Vom Modellbahntrafo

From transformer

Short free reversion through sensor tracks.

~ ~

16...18V

KSM-SG

KL5

Rev. 1.1

Multi-Digital

L

ittfinski DatenTechnik (

D-25492 Heist

www.ldt-infocenter.com

A1 B1

A2 B2

B1

AKA2

B2

AK BKINA B

Loop

Sensor 1 Sensor 2

A1

BK

LDT

)

KL1KL2KL3KL4

A

B

B1

Ç

Ç

Ç

BK

Ç

A2

B2

AK

Ç

A1

Ç

Ç

Ç

Von Digitalzentrale

oder Booster

Ringleitung "Fahren"

From command station

or booster

Ring conductor "driving"

Sample Connection 2: Reverse-loop polarity via the reverse-loop module KSM -SG plus track occupancy report at the reverse-

loop with the RM-GB-8-N. Sensor tracks will be monitored as well.

Littfinski DatenTechnik (LDT)

Reverse loop module

Kehrschleifenmodul

Digital-Profi werden!

Kehrschleifenmodul

KSM-SG

Kurzschlussfreie Umpolung über Sensorgleise.

Vom Modellbahntrafo

From transformer

Direkteinspeisung

ohne Rückmeldung.

Direct supply

without feedback.

Vom Modellbahntrafo

From transformer

braun

brown

gelb

yellow

braun

brown

braun

brown

rot

red

rot

red

Short free reversion through sensor tracks.

KL5

~ ~

16...18V

Ç Ç Ç

Überwachtes

"Normalgleis"

monitored

"standard track"

Intellibox

L

ittfinski DatenTechnik (

Multi-Digital

KSM-SG

Rev. 1.1

A1 B1

Sensor 1 Sensor 2

A1

12345678

IN1IN2

Digital-Profi werden!

Rückmeldemodul / Feedback module

RM-GB-8-N

8-fach Rückmeldemodul mit integrierten

Gleisbelegtmeldern für den s88-Rückmeldebus.

8-fold feedback module with occupancy

detectors for the s88-feedback bus.

s88-N

BU1 BU2

s88-N

OUT

OUT IN

Bestellbezeichnung/

Order code:

Kabel s88 xm

LDT

D-25492 Heist

www.ldt-infocenter.com

A2 B2

AK BKINA B

Loop

A

AKA2

BK

B2

B1

L

ittfinski DatenTechnik (

www.ldt-infocenter.com

ST2ST1

IN

weiss

white

)

KL1KL2KL3KL4

B

s88-N

LDT

D-25492 Heist

8-fach Rückmeldemodul

mit Gleisbesetztmeldern

8-fold feedback module

with occupancy detectors

RM-GB-8-N

Rev. 1.1

B1

BK

Ç

AK

Ç

)

Ç

A1

Ç

A2

Ç

Ç

Ç

B2

Made in Europe by

Littfinski DatenTechnik (LDT)

Kleiner Ring 9

D-25492 Heist/Germany

Phone: 0049 4122 / 977 381

Fax: 0049 4122 / 977 382

Internet: http://www.ldt-infocenter.com

Subject to technical changes and errors. 03/2015 by LDT

Loading...

Loading...