Page 1

JT-11

Automatic Antenna Tuner

For Ten-Tec Jupiter

Manual Version 1.0

LDG Electronics

1445 Parran Road, PO Box 48

St. Leonard MD 20685-2903 USA

Phone: 410-586-2177 Fax: 410-

586-8475

www.ldgelectronics.com

ldg@ldgelectronics.com

Copyright © LDG Electronics 2005. All rights reserved.

Page 2

JT-11

Automatic Antenna Tuner

For the Ten-Tec Jupiter

Introduction 3

Specifications 3

JT-11 Auto Tuner Overview 4

Installation 6

Operation 10

Theory Of Operation 11

Some Basic Ideas About Impedance 11

Transmitters, Transmission Lines, Antennas and Impedance 11

The LDG JT-11 12

A Word About Tuning Etiquette 14

Care and Maintenance 14

Technical Support 14

Warranty and Service 14

Firmware Upgrades 15

Feedback 15

2

Page 3

Introduction

y

y

g

f

Congratulations on selecting the JT-11 tuner for your Ten-Tec Jupiter transceiver. This tuner,

when installed, will be fully integrated with your transceiver, and will be controlled by the radio's

user interface. Your JT-11 will quickly and automatically match an amazing variety of antennas.

LDG pioneered the automatic, wide-range switched-L tuner in 1995. From its laboratories near

the nation’s capitol, LDG continues to define the state of the art in this field with innovative

automatic tuners and related products for every amateur need.

Specifications

•

Fully integrated with the Jupiter transceiver

• 200 memories for instantaneous frequency or band changing

• Automatic reset of last tuned setting on power-up

• Tuning time: 0.1 to 4 seconds full tune, < 0.1 second memory tune

• Frequency coverage: 1.8 to 30.0 MHz.

• Tunes 6 to 1000 ohm loads, 32 to 4000 ohms with optional external 4:1 Balun

(LDG RBA-4:1)

• For Dipoles, Verticals, Vs, Beams or and Coax Fed Antenna

• Optional external Balun allows tuning of random length, long wire or ladder line

fed antennas

• Powered directly by the Jupiter radio

Never install antennas or transmission lines over or near

power lines. You can be seriousl

of the antenna, support or transmission line touches a power

line. Alwa

the nearest power line should be at least twice the len

the longest antenna, transmission line or support dimension.

IMPORTANT SAFETY WARNING

injured or killed if any part

s follow this antenna safety rule: the distance to

th o

3

Page 4

JT-11 Auto Tuner Overview

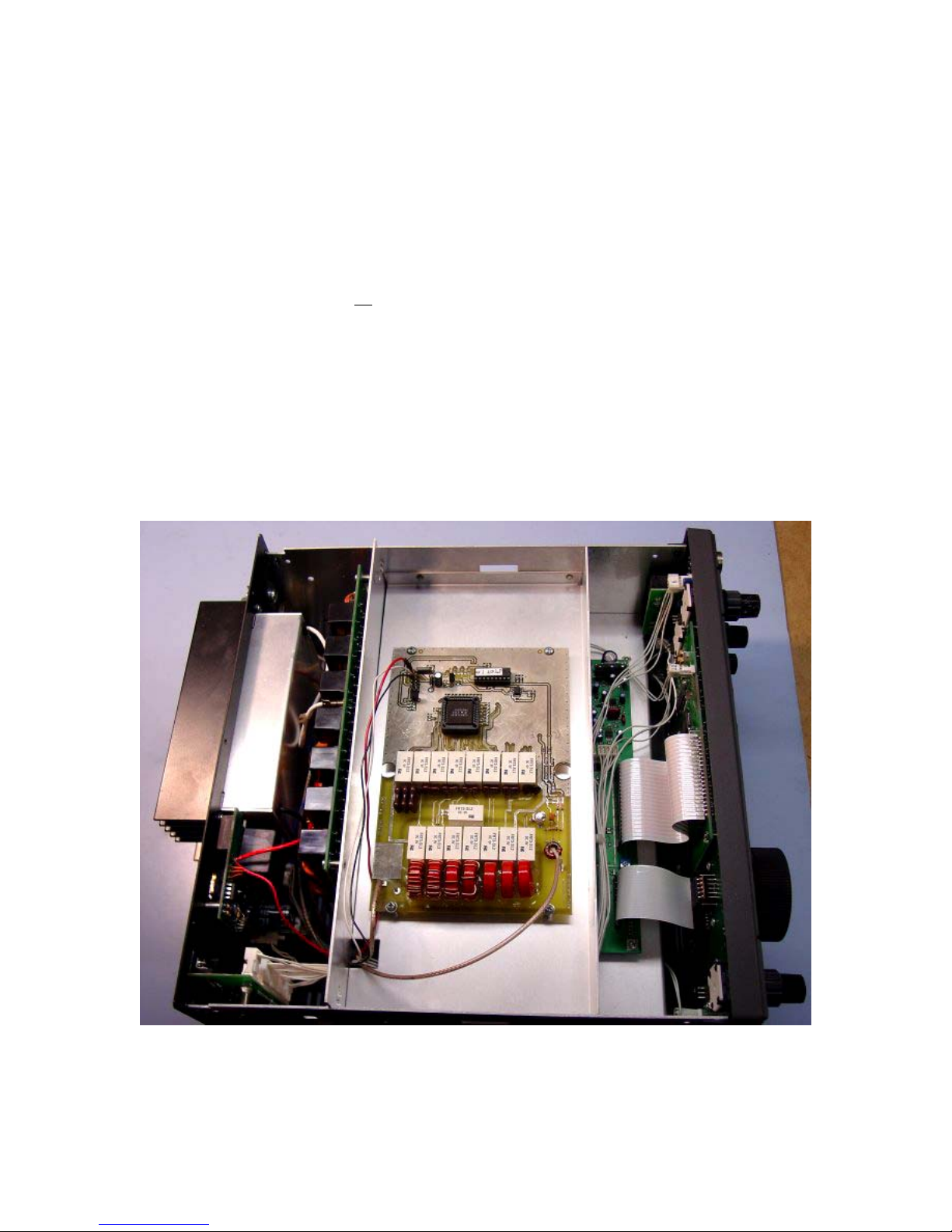

Your JT-11 comes fully assembled, aligned and mounted in its own shield enclosure. You will

install the tuner inside your Jupiter transceiver, resulting in a fully integrated internal tuner. After

installation, your JT-11 tuner will be controlled by the Jupiter's user interface.

Installation is straightforward; you will mount the tuner inside your Jupiter transceiver, remove

one coax cable and solder four connections.

Installation requires that you un

solder two existing coaxial connections and make three new

solder connections. These are simple steps, well within the abilities of anyone with basic

electronic assembly skills. Simply follow the step-by-step directions, referring to the

accompanying illustrations. Work patiently, read through each step completely before proceeding

and check your work often.

Your workplace should be uncluttered, well lighted and well ventilated, and protected from static

discharge. A grounded static mat is ideal, but you should at least be able to touch a ground point

(light switch, water pipe, etc) from time to time to avoid static buildup.

Installing the JT-11 according to these instructions does not void your Ten-Tec warranty.

4

Page 5

A word about power levels

Your JT-11 is custom designed specifically for the Jupiter transceiver and its power levels. When

used with the Jupiter, the RF power will automatically be lowered to approximately 20 watts

during the tuning cycle.

LDG does not recommend using the JT-11 in any other application. If you choose to do so, never

exceed 125 watts peak power input to the tuner. A minimum of 0.1 watts is required to activate

the tuner.

Required Tools:

You will need a few basic electronic assembly tools to install your JT-11:

Small soldering iron, 25-40 watts (a temperature-controlled iron is preferred)

Rosin-core or other solder intended for electronic assembly (NEVER use acid core solder for

electronic assembly)

“Solder Wick” solder removal material, or “solder sucker” solder removal tool

Medium Phillips screwdriver, small hex or star driver

Small pliers

Small wire cutters

A few words about soldering and unsoldering:

In one step, you will be instructed to “tack solder” a wire. This refers to soldering a wire end to a

pad on the PC board where there is no available hole. Simply hold the wire against the pad, heat

with your soldering iron, and apply a small amount of solder. Hold the wire in place until the

solder cools. It will help to tin the wire first, flowing solder onto the wire before soldering it into

place.

In installing your JT-11, you will unsolder two coaxial cable connections on your Jupiter; you

must remove the excess solder from these connections. You have two options: Solder Wick or a

“Solder Sucker” solder removal tool. Solder Wick is a metal braid impregnated with rosin. Place

the end of the Solder Wick against the connection to be unsoldered and heat the wick with your

soldering iron; the wick will conduct the heat to the solder connection. As the solder melts, the

wick will absorb it; cut off and discard the used end of the wick and continue until all excess

solder is removed.

A “Solder Sucker” is a spring-loaded vacuum syringe with a heat-resistant tip. Cock the spring

plunger, and press the tip against the connection along with your soldering iron. When the solder

melts, trigger the Solder Sucker; the spring-loaded syringe will pop up, drawing the molten solder

into the tip. Do this with care, as the jolt of the spring could dislodge your soldering iron. Practice

a few times with a cold iron to get the feel of it.

5

Page 6

Installation

Before installing your JT-11 tuner, you should upgrade the radio's firmware to the latest version.

Consult the radio's manual and the Ten-Tec web site for instructions on how to do this. When the

firmware upgrade is complete, proceed with installing the tuner.

With your Jupiter powered down and disconnected from the DC power supply, remove the top

and bottom covers from the radio. Using a medium cross-point screwdriver, remove four screws

from the sides of the radio (two on each side). Using a cross-point or star tool, remove the small

screws from the back of the covers. Set these and all other screws aside for later reassembly; they

will all be reused. As you remove the top cover, take care not to damage the speaker. Disconnect

the speaker connector from the header and store the top and bottom out of harm's way.

Turn the radio bottom-up on your workbench with the front panel facing you. The DSP/LOGIC

board will be facing up. You will install the JT-11 tuner over this board, connecting it to the radio

via the four cables attached to the tuner (one black/white pair (Control), one red wire (+12 vdc),

and two coaxial cables (RF IN and RF OUT).

Step 1: Locate the connection header on the left side of the DSP/LOGIC board (viewed from the

front). Locate the two empty pins on this header; they are nearest the front of the radio. Route the

black/white wire pair through the notch in the back edge of the tuner shield, then under the tuner

to the connector header on the DSP/LOGIC board. Attach the connector to this header as shown;

be sure to observe the correct orientation of the connector (same as others already there).

Step 2: Route the red wire and both coax cables connected to the JT-11 through the notch in the

JT-11, then through the large grommet in the back left corner of the DSP/LOGIC board

compartment.

Step 3: Carefully slide the JT-11 into position above the DSP/LOGIC board, routing all the wires

through the notch in the back of the tuner shield; be careful not to pinch or foul any of the wires

connected to the tuner. The JT-11 assembly goes in with the components up (looking down into

the bottom of the radio), and with the large side-lip toward the front of the Jupiter.

6

Page 7

The tuner shield is a fairly tight fit, so you may have to gently flex the sides of the Jupiter chassis

to slide the tuner in. Align the four mounting holes in the tuner shield with the four holes in the

Jupiter chassis. Secure with the four small cross-point screws provided. Hand tighten only; do not

overtighten.

Step 4: Route the red wire from the JT-11 to the vertical board on the inside-back of the radio,

just to the left of the RF deck. Locate the top-center solder pad that already has one red wire

soldered to it. Carefully tack solder the red wire from the JT-11 to this same solder pad. When

you're done, there should be two red wires soldered to this pad.

Step 5: Locate the FILTER board. It is the vertically mounted board behind the DSP/LOGIC

board, between it and the RF deck. You will loosen, but not remove this board.

Step 6: Using a medium Phillips screwdriver, remove the four screws holding the FILTER board

to the vertical chassis wall. This will allow you to move the board enough to complete the next

few steps.

7

Page 8

Step 7: Unsolder and remove the coaxial cable connecting the FILTER board to the SO-239

connector on the back panel of the radio. Carefully melt the solder, then remove it using either

solder wick or a solder sucker. Repeat until all excess solder is removed and the cable can be

removed from the board and from the SO-239 connector. With the board unscrewed from the

chassis, you can move it around enough to reach the solder side with your soldering iron and

solder wick or solder sucker. Take great care not to damage the small toroid inductor through

which the cable is connected to the FILTER board. Keep the white insulating sleeve for reuse in

the next few steps.

Unsolder the cable from the SO-239 connector in the same way. Again, keep the insulating sleeve

from the shield but discard the cable; it will not be reused.

Step 8: Solder the RF IN cable from the JT-11 to the FILTER board. The RF IN coaxial cable is

the one connected to the front of the JT-11 (that is, the side nearest the front of the radio) through

a small toroid inductor. Connect the other end of this coaxial cable to the FILTER board, exactly

where you removed the cable in Step 7. The center conductor goes through the toroid. Again, take

care not to damage the toroid on the FILTER board. You can nudge the toroid around a little bit

to reveal the solder hole if needed, but the toroid wire is very delicate so be careful. Place the

insulating sleeve from Step 7 over the coax shield before soldering it to the FILTER board.

Step 9: Route the other coax cable (RF OUT) from the JT-11 to the SO-239 connector on the

back of the radio. The RF OUT cable is attached to the back of the JT-11 board to a solder pad

labeled "Antenna". Solder the cable to the connector; the coax center conductor goes to the center

pin of the connector. Again, use the insulating sleeve from Step 7 to insulate the shield before

soldering it to the ground lug on the connector.

8

Page 9

Step 10: Reattach the FILTER board to the chassis using the screws you removed in Step 6. Do

not overtighten.

Step 11: Carefully check your work. Look especially for solder splashes or bridges. Make sure all

wires are routed neatly, and that none will be pinched or fouled when you replace the case covers.

Step 12: Replace the bottom case cover. Reattach the speaker connector, being careful to observe

connector orientation. Replace the top case cover.

Congratulations! You have completed installation of your JT-11 automatic tuner. Proceed to

Operation.

Upgrading other Internal Tuners

If your radio already has an internal autotuner in it, you may be able to upgrade or replace it. If it

is an LDG tuner V3.5, you can simply purchase a new processor to get the upgraded features (see

our web site for purchasing information). If you have an LDG tuner with a version number lower

than V3.5 (or any other brand tuner), the tuner will need to be replaced.

To replace the tuner follow the installation instructions in reverse to remove the old tuner, then

follow the instructions for normal installation.

9

Page 10

Operation

Enabling the tuner:

In the Jupiter setup menu, check the AUTOTUNER setting. If it is presently set to OFF, change it

to ON. You only have to do this once, the first time you use the tuner.

Normal operation:

Operation of your JT-11 tuner is controlled by the Jupiter's Tune button. To tune, simply set the

radio to the desired operating frequency and press the Tune button on the radio's control panel. A

tuning cycle will begin; stored tuning parameters will be used if available. The radio will transmit

a carrier of about 20 watts, and the tuner will cycle. You may hear the relays switching in and

out; they make a fairly loud buzzing noise. The tuning cycle will automatically end in a few

seconds. The radio will unkey, with power set back to the normal level. The letter "T" will appear

on the display, indicating that the tuner is active.

Bypass mode:

To transmit without using the tuner, simply press the Tune button again. This sets the tuner to

Bypass mode; RF goes directly to the antenna with no matching. The "T" indicator goes out,

indicating that the tuner is not active. Repeatedly pressing the Tune button toggles between

active and bypass tuner modes.

Forcing a full tune:

As you use your JT-11 it will automatically memorize tuning parameters for up to 200 of your

favorite frequencies and bands. When you transmit on or near that frequency again, your JT-11

will restore these parameters almost instantly, much faster than a full tuning cycle. Your JT-11

literally "learns" as you use it.

You can, if you wish, force the tuner to run a full tuning cycle even when there are tuner

parameters stored for that operating frequency. Press the Tune button to start a tune cycle, then

press it again to abort the cycle. Press Tune a third time to clear the "T" indicator, then once more

to start a full tune cycle. Yes, this procedure is a bit clunky, but then again, you won't need to do

it very often; your JT-11 is very good at finding a match.

Each time you power up your Jupiter, the JT-11 will automatically reset the last-used tuning

parameters, so you don't have to retune each time. Memory operation is fully automatic, and

requires no input from you.

SWR readings:

Due to the way that the Jupiter reads the SWR, you may get a lower SWR reading when tuning

than after the tuner stops. This is because the radio lowers the RF power during a tuning cycle.

For example, you may tune and see a 1.5 SWR, but then keying the radio at full power after the

tuning cycle will read a 1.9 SWR. This is due to non-linearities in the Jupiter’s SWR reading

circuits. Typically the lower the RF power, the lower the SWR will read. This may happen even

on a dummy load.

Disabling the tuner if desired:

If you wish to disable the tuner altogether, set the AUTOTUNER setting to OFF in the Jupiter

setup menu. Thereafter, pressing the TUNE button will have no effect. To enable the tuner again,

change the AUTOTUNER setting back to ON.

10

Page 11

Theory Of Operation

Some Basic Ideas About Impedance

The theory underlying antennas and transmission lines is fairly complex, and in fact employs a

mathematical notation called “complex numbers” that have “real” and “imaginary” parts. It is

beyond the scope of this manual to present a tutorial on this subject

1

, but a little background will

help you understand what your JT-11 is doing, and how it does it.

In simple DC circuits, the wire resists the current flow, converting some of it into heat. The

relationship between voltage, current and resistance is described by the elegant and well-known

“Ohm’s Law”, named for Georg Simon Ohm of Germany, who first discovered it in 1826. In RF

circuits, an analogous but far more complicated relationship exists.

RF circuits also resist the flow of electricity. However, the presence of capacitive and inductive

elements causes the voltage in the circuit to lead or lag the current, respectively. In RF circuits

this resistance to the flow of electricity is called “impedance”, and can include all three elements:

resistive, capacitive, and inductive.

Capacitive

Reactance

Inductive

Reactance

The output circuit of your transmitter consists of inductors and capacitors, usually in a

series/parallel configuration called a “pi network”. The transmission line can be thought of as a

long string of capacitors and inductors in series/parallel, and the antenna is a kind of resonant

circuit. At any given RF frequency, each of these can exhibit resistance, and impedance in the

form of capacitive or inductive “reactance”.

Transmitters, Transmission Lines, Antennas and Impedance

The output circuit of your transmitter, the transmission line, and the antenna all have a

characteristic impedance. For reasons too complicated to go into here, the standard impedance is

about 50 ohms resistive, with zero capacitive and inductive components. When all three parts of

the system have the same impedance, the system is said to be “matched”, and maximum transfer

of power from the transmitter to the antenna occurs. While the transmitter output circuit and

transmission line are of fixed, carefully designed impedance, the antenna presents a 50 ohm, nonreactive load only at its natural resonant frequencies. At other frequencies, it will exhibit

capacitive or inductive reactance, causing it to have an impedance different from 50 ohms.

When the impedance of the antenna is different from that of the transmitter and transmission line,

a “mismatch” is said to exist. In this case, some of the RF energy from the transmitter is reflected

from the antenna back down the transmission line, and into the transmitter. If this reflected

energy is strong enough it can damage the transmitter’s output circuits.

The ratio of transmitted to reflected energy is called the “standing wave ratio”, or SWR. An SWR

of 1 (sometimes written 1:1) indicates a perfect match. As more energy is reflected, the SWR

1

For a very complete treatment of this subject, see any edition of the ARRL Handbook for Radio

Communications (previously the Handbook For Radio Amateurs)

11

Page 12

rises to 2, 3 or higher. As a general rule, modern solid state transmitters must operate with an

SWR of 2 or less. Tube exciters are somewhat more tolerant of high SWR. If your 50 ohm

antenna is resonant at your operating frequency, it will show an SWR close to 1. However, this is

usually not the case; operators often need to transmit at frequencies other than resonance,

resulting in a reactive antenna and a higher SWR.

SWR

=

+

FR

where F = Forward power (watts), R = Reflected power (watts)

FR

/1/1−

SWR is measured using a device called an “SWR bridge”, inserted in the transmission line

between the transmitter and antenna. This circuit measures forward and reverse power from

which SWR may be calculated (some meters calculate SWR for you). More advanced units can

measure forward and reverse power simultaneously, and show these values and SWR at the same

time.

An antenna tuner is a device used to cancel out the effects of antenna reactance. Tuners add

capacitance to cancel out inductive reactance in the antenna, and vice versa. Simple tuners use

variable capacitors and inductors; the operator adjusts them by hand while observing reflected

power on the SWR meter until a minimum SWR is reached. Your LDG JT-11 automates this

process.

No tuner will fix a bad antenna. If your antenna is far from resonance, the inefficiencies inherent

in such operation are inescapable; it’s simple physics. Much of your transmitted power may be

dissipated in the tuner as heat, never reaching the antenna at all. A tuner simply “fools” your

transmitter into behaving as though the antenna were resonant, avoiding any damage that might

otherwise be caused by high reflected power. Your antenna should always be as close to

resonance as practical.

Forward Power (Watts)

20 30 40 50 60 70 80 90 100

2 1.92 1.70 1.58 1.50 1.45 1.41 1.38 1.35 1.33

4 2.62 2.15 1.92 1.79 1.70 1.63 1.58 1.53 1.50

6 3.42 2.62 2.26 2.06 1.92 1.83 1.75 1.70 1.65

8 4.44 3.14 2.62 2.33 2.15 2.02 1.92 1.85 1.79

10 5.83 3.73 3.00 2.62 2.38 2.22 2.09 2.00 1.92

12 7.87 4.44 3.42 2.92 2.62 2.41 2.26 2.15 2.06

14 11.24 5.31 3.90 3.25 2.87 2.62 2.44 2.30 2.20

16 17.94 6.42 4.44 3.60 3.14 2.83 2.62 2.46 2.33

Reflected Power (Watts)

18 37.97 7.87 5.08 4.00 3.42 3.06 2.80 2.62 2.47

20 - 9.90 5.83 4.44 3.73 3.30 3.00 2.78 2.62

22 - 12.92 6.74 4.94 4.07 3.55 3.21 2.96 2.77

24 - 17.94 7.87 5.51 4.44 3.83 3.42 3.14 2.92

26 - 27.96 9.32 6.17 4.85 4.12 3.65 3.32 3.08

28 - 57.98 11.24 6.95 5.31 4.44 3.90 3.52 3.25

30 - - 13.93 7.87 5.83 4.79 4.16 3.73 3.42

32 - - 17.94 9.00 6.42 5.18 4.44 3.95 3.60

34 - - 24.63 10.40 7.09 5.60 4.75 4.19 3.80

36 - - 37.97 12.20 7.87 6.07 5.08 4.44 4.00

38 - - 77.99 14.60 8.80 6.60 5.44 4.71 4.21

40 - - - 17.94 9.90 7.19 5.83 5.00 4.44

42 - - - 22.96 11.24 7.87 6.26 5.31 4.68

44 - - - 31.30 12.92 8.65 6.74 5.65 4.94

46 - - - 47.98 15.08 9.56 7.27 6.02 5.22

48 - - - 97.99 17.94 10.63 7.87 6.42 5.51

50 - - - - 21.95 11.92 8.55 6.85 5.83

SWR Lookup Table

Find SWR at intersection of

forward power column and

reflected power row

.

12

Page 13

The LDG JT-11

In 1995 LDG pioneered a new type of automatic antenna tuner. The LDG design uses banks of

fixed capacitors and inductors, switched in and out of the circuit by relays under microprocessor

control. A built-in SWR sensor provides feedback; the microprocessor searches the capacitor and

inductor banks, seeking the lowest possible SWR. The tuner is a “Switched L” network consisting

of series inductors and parallel capacitors. LDG chose the L network for its minimum number of

parts and its ability to tune unbalanced loads, such as coax-fed dipoles, verticals, Yagis; in fact,

virtually any coax-fed antenna. The inductors are switched in and out of the circuit by relays

controlled by the microprocessor. An additional relay switches between high and low impedance

ranges.

The capacitors are connected to ground with the inductor relays. Another relay switches the entire

capacitor bank to the input or output side of the inductor. This switching allows the JT-11 to

automatically handle loads that are greater than 50 ohms (high setting) and less than 50 (low

setting).

The SWR sensor is a variation of the Bruene circuit. This SWR measuring technique is used in

most dual-meter and direct-reading SWR meters. Slight modifications were made to the circuit to

provide voltages (instead of currents) for the analog-to-digital converters (ADCs) that provide

signals proportional to the forward and reverse power levels. The single-lead primary through the

center of the sensor transformer provides RF current sampling. Diodes rectify the sample and

provide a dc voltage proportional to RF power. Variable resistors calibrate the FORWARD and

REVERSE power levels. Once adjusted, the forward and reverse power sensors produce a

calibrated DC voltage proportional to the forward and reverse RF power levels. These two

voltages are read by the ADCs in the microprocessor. Once in a digital format, they are used to

calculate SWR in real time.

The relays operate from DC supplied by the power input jack. The total current drawn by the JT11 depends primarily on the number of energized relays, with the maximum current drain being

approximately 250 mA, but only during the few seconds a tuning cycle is running. At all other

times, the tuner is in a “deep sleep” mode drawing only a few milliamps. The last tuned setting is

automatically reset on the next power-up.

The microprocessor’s oscillator runs at 20 MHz. The main tuning routine takes about 75 cycles to

make a tuner adjustment and take a new SWR measurement, or 7 milliseconds per tuner

adjustment. If running at maximum speed, the microprocessor can try all inductor-capacitor

combinations in under 3 seconds. Unfortunately, the mechanical relays can’t react as quickly as

the microprocessor, and the tuning speed must be slowed down to compensate for relay settling

time.

The tuning routine includes an algorithm to minimize the number of tuner adjustments. The

routine first de-energizes the high/low impedance relay if necessary, then individually steps

through the inductors to find a coarse match. With the best inductor selected, the tuner then steps

through the individual capacitors to find the best coarse match. If no match is found, the routine

repeats the coarse tuning with the high/low impedance relay energized. The routine then fine

tunes the capacitors and inductors. The program checks LC combination to see if a 1.5 or lower

SWR can be obtained, and stops when it finds a good match.

13

Page 14

The microprocessor runs a fine tune routine just after the tuner finds a match at an SWR of 1.5 or

less. This routine tries to get the SWR as low as possible (not just 1.5); it takes about a half

second to run. There is also a quick tune mode. If the SWR is below 2.0 when you press the tune

button to start a tuning cycle, the tuner will first try a memory tune routine to see if it can achieve

a low SWR without a complete re-tune. This also takes about a half second to run. If it does not

find a good match, then it runs a full tuning routine.

A Word About Tuning Etiquette

Be sure to use a vacant frequency to tune. With today’s crowded ham bands, this is often difficult.

However, do your best to avoid interfering with other hams as you tune. Your JT-11’s very short

tuning cycle, often only a fraction of a second, minimizes the impact of your tuning

transmissions. Tune at reduced power whenever possible; one or two watts is plenty.

Care and Maintenance

Your JT-11 tuner is maintenance-free. As with any modern electronic device, your JT-11 can be

damaged by temperature extremes, water, impact or static discharge. LDG strongly recommends

that you use a good quality, properly installed lightning arrestor in the antenna lead.

Technical Support

We are happy to help you with your JT-11. Telephone technical support is available at 410-5862177 weekdays from 9 am to 5pm Eastern Time. Inquiries by Fax at 410-586-8475 are welcome,

and prompt e-mail support is available at ldg@ldgelectronics.com.

Warranty and Service

Your JT-11 is warranted against defects in parts or workmanship for two years from purchase.

The warranty does not cover damage due to abuse or exceeding specifications. This warranty

applies to the original purchaser only; it is not transferable. A copy of the receipt showing the

purchaser’s name and the date of purchase must accompany units returned for warranty service.

All returns must be shipped to us pre-paid; we will not accept units with postage due. A return

form is provided on our web site for your convenience.

If you need to return your JT-11 to us for service, package it carefully, keeping in mind that we

will re-use your packaging to return the unit to you. Download the return form from our web site

(ldg@ldgelectronics.com), fill it out and return it with your tuner. A self-addressed returnshipping label, while not required, will help insure speedy and accurate delivery of your repaired

unit. Include a full description of the problem, along with your name, address and a phone

number or e-mail address where we can reach you with any questions. Repairs average about 3 to

6 weeks.

We will be glad to service your JT-11 after the warranty period has ended. We will notify you of

repair charges by phone or e-mail, and bill you after repairs are completed.

14

Page 15

Firmware Upgrades

From time to time LDG may release upgraded firmware for the JT-11, refining operation and

adding features. Your JT-11 is not field programmable; you will have to remove the present chip

and replace it with the upgrade chip. Upgrades are expected to cost about $10-$20, and will be

announced on our web site when available.

Feedback

If you have an idea to improve our software or hardware, please send us a description. If we

incorporate your idea in the JT-11, we'll send you a free upgrade as a “thank you”.

We encourage everyone who uses the JT-11 to contact us (card, letter or e-mail preferred) telling

us how well it works for you. We are also always looking for photographs of our products in use;

we frequently place such pictures on our Web site (www.ldgelectronics.com).

15

Loading...

Loading...