Page 1

09/19-W13-Wei

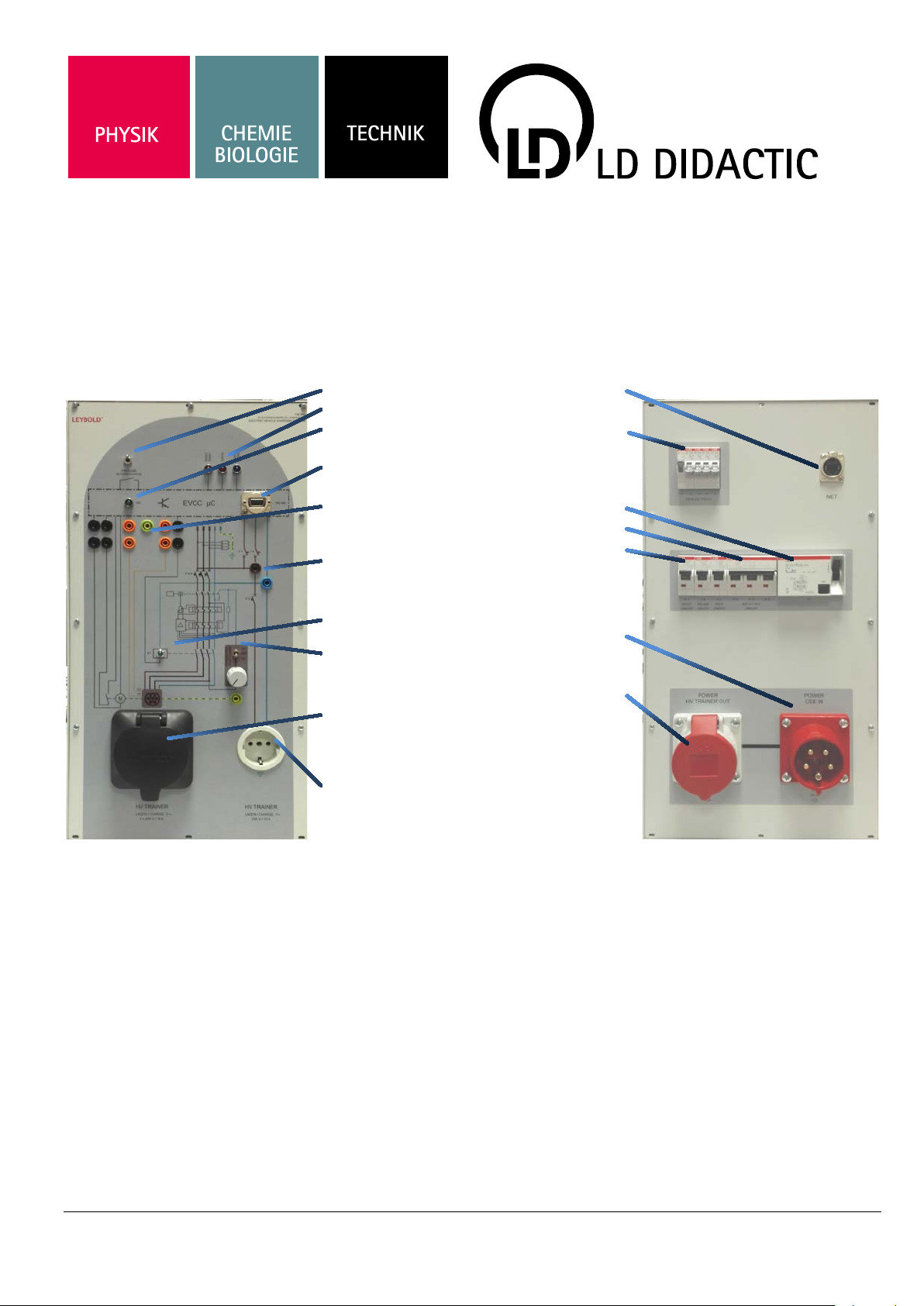

Charging socket

Instructions for use 739 948

Electric vehicle charging station

1 Activate “Charging”

2 Operating mode dis-

play

3 Ready indicator

4 System interface

MODBUS RTU

5 Measuring sockets

5a CP signal (left)

5b PP/CC signal (right)

6 Measuring sockets

L1 and N

7 Main contactor indi-

cator

8 Trip RCCB with

DC/AC switching and

knob

9

with hinged lid and interlock

10 Schuko socket

230 V~

11 RJ45 connector

(Option!)

12 Fault switch

13 RCCB Type B

14 Triple fuse

(charging socket)

15 Fuses

single

16 Power supply con-

nection 3*400 V,

50/60 Hz

17 Connection auto-

motive high voltage

trainer,

739 947

Scope of delivery:

1 Electric vehicle charging station, 739 948

2 4 mm safety bridge connector orange

3 4 mm safety bridge connector black

1 CEE connection cable 400 V/16 A, 3 m

1 Instructions for use 739 948

LEYBOLD DIDACTIC GMBH . Leyboldstrass e 1 . D-50354 Hürth, Germany . Phone +49 2233 604-0 . Fax +49 2233 604-222 . e-mail: info@leybolddidactic.de

by Leybold Didactic GmbH Printed in the Federal Republic of Germany

Technical alterations reserved

0. Intended use

The “electric vehicle chargi ng station” dev ice is a teac hing aid for

vehicle high-voltage technology training.

The device allows t he tr ai nee to perform typical w or kshop measurements realistically.

Together with the automotive high voltage trainer, 739 947, the

device is used to creat e an electric v ehicle charging infrastructure

situation. A three-phase passive charging cable or a singlephase active charging cable can be connected.

Page 2

Instructions for use 739 948 Page 2/6

Failure to observe these operating instructions will void the

• Measurements on all 4 mm measuring sockets may only

Safety Information

Read these instructions for use completely before

warranty/guarantee. No liability will be assumed for any consequential damage!

No liability will be assumed for material damage or personal

injury resulting from improper handling or non-observance of

the safety information and the warranty/guarantee will expire

as a result!

• The device is only approved for use in dry indoor areas

that are installed in accordance with VDE 0100 Part 723!

• Operate and use only in accordance with DIN VDE 0105-112!

• The device must not be put into operat ion if it ex hibits vis-

ible signs of damage or behav es irr egular ly. If y ou are u nsure, then do not put the device into operation! Have the

device immediately inspected by our service repair shop!

• The device may be used for training purposes only! The

device is not a toy and is not suitable for children!

• The device may only be used under the expert supervision of skilled and responsible personnel!

• Unauthorised modifications and/or changes to the device

are not permitted. The device may neither be opened nor

repaired!

1. Operation

1.0 Switch-on conditions

1. Make sure that all fault switches 12 are in the lower

1.1 Power supply

1.2 Connecting the automotive high voltage trainer,

position

1. Plug the CEE socket of the supplied con nection cable

into the right CEE socket 16 at the rear

2. a.) Switch fuses F1 and F2 (15) on (top position)

b.) Switch fuses F4- F6 (14) on (top position)

b.) Switch residual-curre nt circuit breaker RCCB (13) on

(top position)

739 947

1. Plug the CEE plug of the connection cable of the automotive high voltage trainer, 739 947, into the lef t CEE

socket 17 into the back of the device

2. Plug the CEE plug of the connection cable of the auto-

motive high voltage trainer, 739 947, into the CEE

socket to the right of the Automotive high voltage

trainer, 739 947

3. Put the automotive high voltage trainer, 739 947 into

operation according to the instructions for use

commissioning and operating the device!

be made as described in the instr uc tio ns for u se. A p ply ing

external voltages or generating high and low impedance

short circuits is expressly prohibited!

• Only the components described in these instructions for

use may be used on all 4 mm connection sockets!

• The dev ice may only b e u sed i n con jun ction with the auto-

motive high voltage t ra iner, 739 947 or the test adapter for

e-charging station, 739 953. Do not connect it t o a real ve-

hicle!

• Exercise c aution w hen hand ling the device . It can be d amaged by impacts, blows or from being dropped even from

a low height!

• Attention: the device is very he avy and may on ly be carr ied

by two persons!

• Only conn ect it to the mains us ing the s upplie d conne cti on

cable!

1.3 Connecting the three-phase charging cab l e

4. Plug the charging cable mode 3, 3~, 739 951, into the

charging socket 9 on the charging station

5. Plug the charging cable mode 3, 3~, 739 951, into the

charging socket on the rig ht side o f the A utomotive high

voltage trainer, 739 947

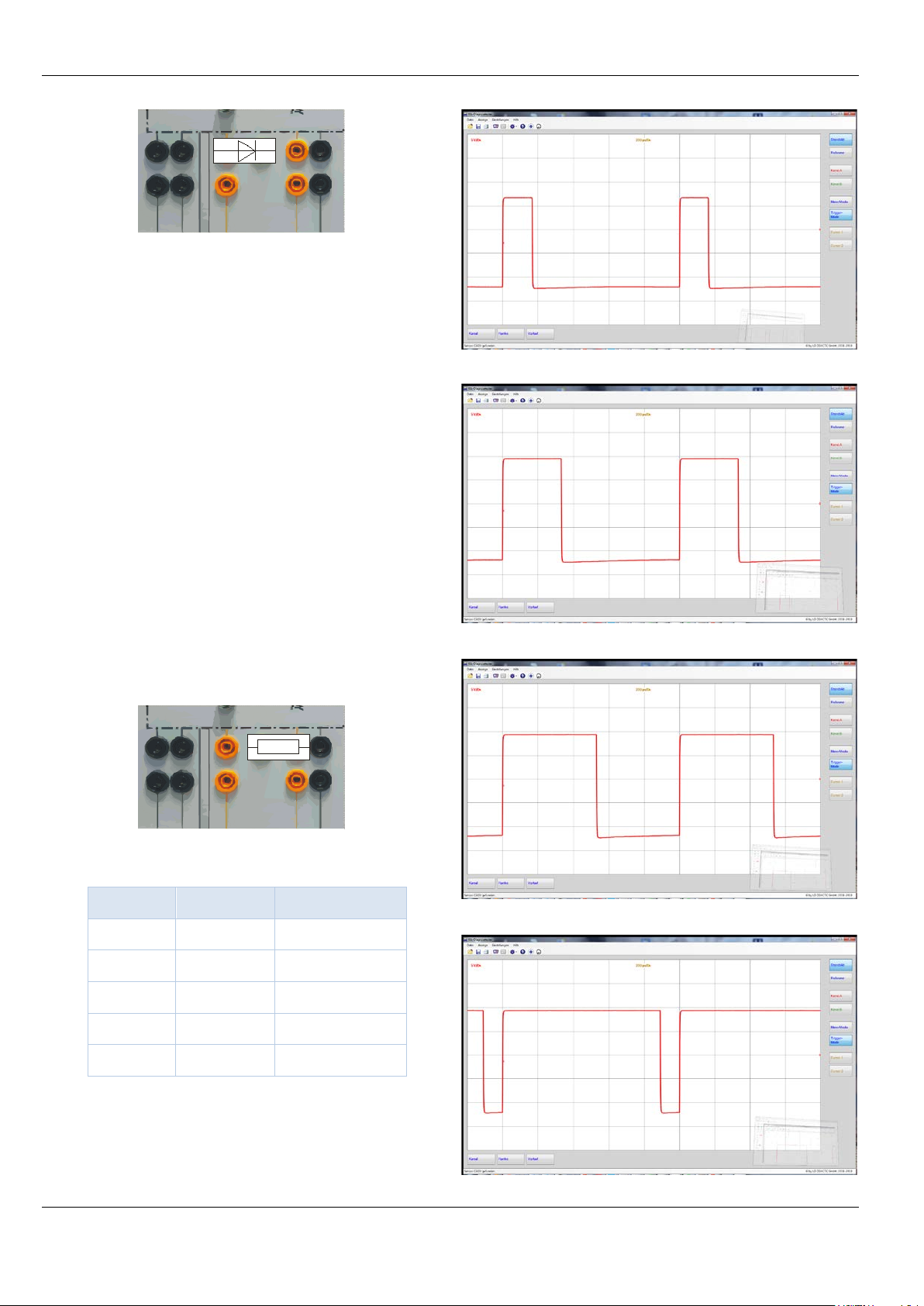

. 1 - Charging socket on the automotive high voltage

Fig

trainer, 739 947

LEYBOLD DIDACTIC GMBH . Leyboldstrass e 1 . D-50354 Hürth, Germany . Phone +49 2233 604-0 . Fax +49 2233 604-222 . e-mail: i nfo@l eybolddidactic.de

by Leybold Didactic GmbH Printed in the Federal Republic of Germany

Technical alterations reserved

Page 3

Instructions for use 739 948 Page 3/6

1.4 Charging

6. Activate the charging station by actuating ena bling

switch 1

7. Activate the “charging” switch on the automotive high

voltage trainer, 739 947

8. The main contactor switches the charging voltage on

and blue indicator light 2 lights up.

2. Application

2.1 CP communication signal

Communication with vehicle via the CP contact begins. The

charging current upper limit is transmitted to the vehicle by a

PWM signal. The protective earth conductor connection is

checked at the same time. A warning symbol or faulty installation

lights up when the protective earth conductor is missing.

The communication signal b etween the v ehicle and chargin g station can be measured at the C P (5) soc ket aga inst the PE s ocket

while charging.

Fig. 2 - Measuring sockets for the CP contact

The positive amplitu de of th e C P signal depend s o n the c hargi ng

status:

Status A «Active» U

Status B «Ready» U

= +12 V

max

≈ +9.3 V

max

Status C «Charging» U

≈ +6.7 V, PWM active:

max

. 3 - Status C, Charging

Fig

The coding resistance for the maximum permissible charging

current can be measured betw een the PP /CC and PE mea suring

sockets. For charging cable mode 3, 3~, 739 951 that is 680 Ω,

which corresponds to 20 A.

Safety note

While charging is active, the plug is locked. Do not attempt

to forcibly pull out the plug since the locking mechanism

could otherwise be damaged!

In the delivery state, the charging request with Status D is rejected with an error message. This behaviour can be reprogrammed via the MOD BUS interface by setting th e 4010 addr ess

(16 bit) from «0» (default) to «1».

Status D «Charging» U

≈ +3.4 V, PWM active:

max

Fig. 4 - Status D, charging with ventilation

The positions of the 4 mm measuring sockets of the CP and

PP/CC signals are selected so that a plug-in element can be inserted as a replacement directly against PE.

Insert an STE diode 578 5 1 as shown in order t o gro und the v oltage of the CP signal and thus induce the «Status E» fault state.

This is indicated by an indicator light.

LEYBOLD DIDACTIC GMBH . Leyboldstrass e 1 . D-50354 Hürth, Germany . Phone +49 2233 604-0 . Fax +49 2233 604-222 . e-mail: i nfo@l eybolddidactic.de

by Leybold Didactic GmbH Printed in the Federal Republic of Germany

Technical alterations reserved

Page 4

Instructions for use 739 947 Page 4/6

Fig. 5 - Fault simulation of the CP contact

2.2 Checking the residual current circuit breaker (“RCCB”)

RC can be tripped while charging. To do this, first activate fault

#F5 and set the potentiometer t o the left stop. Subsequently use

Fig. 7 - 13 A

switch 8 to select whether you would like to induce an AC fault

current (top position)

or a DC fault current ( botto m p osition). Sin ce resi dual c urrent circuit breaker 13 must be a Type B model, residual DC currents

are detected as well.

Begin with an AC fault current (switch up). Slowly turn knob 8

clockwise to the right u ntil th e RCCB tr ips audibly. Keep the k nob

in this position! Now switch to the “DC fault current” position

(switch down) and switch the residual current circuit breaker on

again. Keep turning the knob until the DC fault current trips the

residual current circuit breaker as well.

2.3 PP resistance

. 8 - 20 A, duty cycle 33 % (33*0.6 A = 19.8 A≈20 A)

Insert an STE resis tor as s hown in order t o simulate differe nt cur-

Fig

rent carrying capacities of the charging cable as per IEC 61851.

Refer to the following table for the values.

Fig. 6 - Simulation of the current carrying capacity of the charging cable

Value [Ω]

Current [A] Item number

. 9 - 32 A, duty cycle 53 % (53*0.6 A = 31.8 A≈32 A)

Fig

100 63 577 32

220 32 577 36

680 20 577 42

1500 13 577 46

>2200 0 -

Table 1 - Coding resistances of the PP contact

. 10 - 63 A, duty cycle 89 % ([89-64]*2.5 A = 62.5 A≈63 A)

Fig

LEYBOLD DIDACTIC GMBH . Leyboldstrass e 1 . D-50354 Hürth, Germany . Phone +49 2233 604-0 . Fax +49 2233 604-222 . e-mail: i nfo@l eybolddidactic.de

by Leybold Didactic GmbH Printed in the Federal Republic of Germany

Technical alterations reserved

Page 5

Instructions for use 739 948 Page 5/6

Fault during residual current circuit brea ker

CP

PP

PE

The communication signals between the vehicle and charging

station can also be measured on the automotive high voltage

trainer, 739 947 at the intended 4 mm measuring socket for CP

against the PE socket while charging.

4 mm measuring sockets at the front of the device:

Fig. 11 - Measuring sockets on the automotive high voltage trainer, 739

Note

Even while charging, the PE socket of the charging socket is not

connected to the PE sockets of the automotive high voltage

trainer!

A “Status A” must follow after each change in resistance, otherwise the new value is not loaded!

947

3. Fault switch

Fault Description

#F1

#F2

Return information Interlock Interruption

Control Interlock Interruptio n

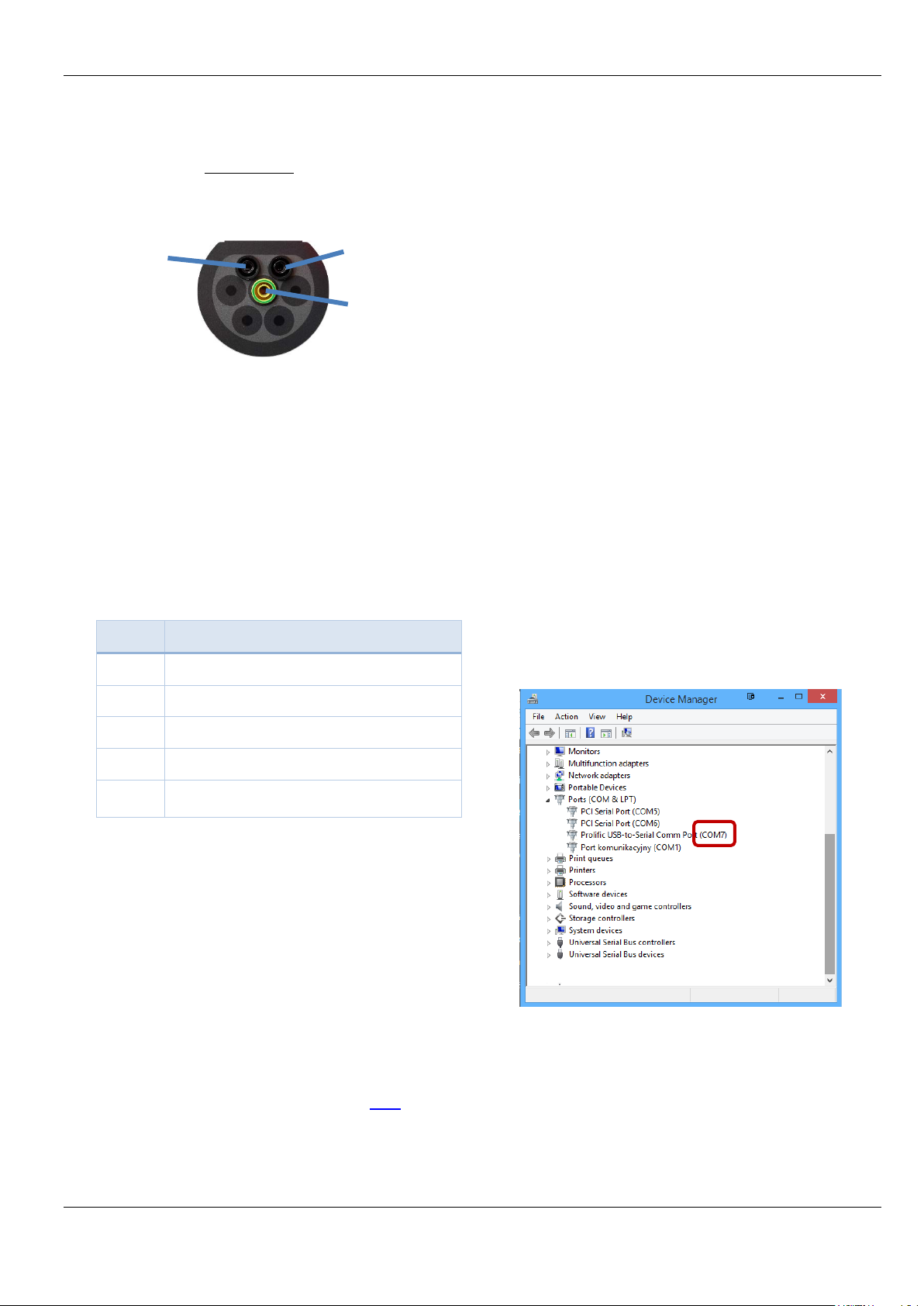

4.2 Establishing a connection

You need an RS485 interface (e.g. LEYBOLD

735 315USB), optiona lly a 9-pin serial standard connec tion cable as well communication software (everything not

included in the scope of deli very). You use the cable to

connect interface 4 on the charging station to the RS485

interface of the com puter. The 9-pin Sub-D socket is assigned as follows (without fixed 120 Ωterminating resistor!):

Pin 8 A

Pin 3 B

4.3 Programming

Install and start the software according to the manufacturer's specifications. An Int ernet search for «Modbus TCP

RTU Master Software» provides useful results for free software or for demo versions of programs offered commercially.

Regardless which software you are using, you will need

the following information for input:

Mode: RTU

COM port: look in the Windows Device Manager

to see the port number under which the

interface you use was set u p, her e, f or

example, number 7:

#F3

#F4

#F5

Table 2 - Meaning of the fault switches

Several faults may be activated at the same time!

PP signal Interruption

CP signal Interruption

test

4. Modbus communication

4.1 Description

You can access the device’s registers via Modbus/RTU via

system interface 4. Modbus/RTU also allows you to make

additional configurat ions on the dev ice, retr ieve status information and control access to the charging process. The

device works as a Modbus slave; the addres s is permanently set to 1. The baud r ate is 9600 for c omm unicat ion.

You can find a detail ed des cription of the regis ter assi gnment at the time this document was created here

.

Fig. 12 - Determining the COM port number

Baud: 9600

Data bits: 8

Stop bits: 1

Parity: none

Slave ID: 1

LEYBOLD DIDACTIC GMBH . Leyboldstrass e 1 . D-50354 Hürth, Germany . Phone +49 2233 604-0 . Fax +49 2233 604-222 . e-mail: i nfo@l eybolddidactic.de

by Leybold Didactic GmbH Printed in the Federal Republic of Germany

Technical alterations reserved

Page 6

Instructions for use 739 947 Page 6/6

5. Monitoring software

Follow the steps to establish a connection as described under

4.2. You can download at the time this document was cre-

the «EV CC Device Monitor» program from PHŒNIX

ated

CONTACT in order to display various information directly and

make changes. Caution: improper handling can put the de-

vice in a state that no longer permits a factory reset!

Start the program, agree to the licence then enter the interface

parameters and click the button «Connect». Available parameters will be shown automatically, changing parameters is simply

made by entering and confirming the new value.

Fig. 13 - Entering the interface parameters

If you want to read out «hardw are revisio n», for exam ple,

you will find a refer ence in the manufactur er information

that the hardware revision number is located in register

1030. The terms «address» and «register» are sometimes

used interchangeably.

In the program you also enter:

o

Address: 1030 (no offset or offset=0)

Value/data type: 16 bit (if necessary)

Function: 0x03 (read access)

Now start the requirement diagram with a «SEND» command or

similar

Fig. 14 - Reading out a register value

As a result, the charging controller returns the revision number

that is displayed in the software (in the example here, «5»

).

Use this procedure to s et register «4010» to «1», for example, in order to allow vehicles with charging status «D»

(ventilation required) without error messages (see point

2.1).

6 Maintenance

The device does not require special maintenance. Only the test

button of residual current circuit breaker 13 must be pressed

every month.

7 Technical data

• Power supply: 3x400 VAC, 50 Hz, 16 A

• Connection CEE socket 400 V/16 A, 6h

• Output voltage: 3x400 VAC, 50 Hz, 2 A

• Connection CEE plug 400 V/16 A, 6h

• Charging socket: Type 2, 16 A

• Weight: approx. 25 kg

• Protection class 1

8 Disposal

Do not dispose of electric and electronic products

with normal household waste. Dispose of the unusable product in accordance with the applicable

statutory requirements.

LEYBOLD DIDACTIC GMBH . Leyboldstrass e 1 . D-50354 Hürth, Germany . Phone +49 2233 604-0 . Fax +49 2233 604-222 . e-mail: i nfo@l eybolddidactic.de

by Leybold Didactic GmbH Printed in the Federal Republic of Germany

Technical alterations reserved

Loading...

Loading...