LCT 79cc, 136cc, 291cc, 254cc, 179cc Service Manual

...

LCT Engines

Service Manual

PGM45015 12/04/17 rev G

ENGINEERING A NEW

GENERATION OF POWER

Table of Contents

Engine Model Number & Serial Numbering System 2-3

General Specifications 4-5

General Troubleshooting 6-7

Advanced Troubleshooting (for authorized LCT technicians) 8-10

Spark Plug Service 10

Engine Oil Level Check 11

Engine Oil Change 11

Engine Oil Recommendations 11

Maintenance Schedule 12

Torque Specifications 13-14

Summer Engine Dimensions 15-20

79cc 15

136cc 16

179cc / 208cc 17

291cc 18

414cc 19

420cc 20

Winter Engine Dimensions 21-25

136cc 21

179cc / 208cc (Gen II) 22

254cc 23

291cc / 306cc 24

369cc / 414cc 25

Current Patents: D596649; D634,337; D611,411; D593,190; D635,585, D549,241; RE43920; RE45,913; D572,659; D595,227; 9328696; 7975806; D580610; D590,110S; D627,368; D585,348;

D600,252; D604,686; 201030127679.3; 200830020200.9; 200830299875.1; 201530458407.4; 201520911505.3; 201630277717; 201620636943.8; 201620636960.1; 201620636872.1; 201620636858.1;

201620528656.5; 201620583290.1; 201620616109.2; 200720046150.1; 200820217113.7; 200820214886.X; 200820217112.2; 200820214887.4; 200920040686.1; 200920038850.5; 200920044163.4;

201020258898.X; 200730184074.6; 200730184075; 200830021742.8; 200830023405.2; 200830028283.6; 200830299876.6; 200830299874.7; 200830299873.2; 200930031746.9; 200930036278.4;

200930035200; 201030127696.7; 201030127678.9; 201030127608.3; 200910210967.1; 201130459836.5; 201130500118.8; 201130459770.X; 201220024217.2; 201220042903.2; 201220186503.9;

201220218354.X; 201230237494.7; 201230271026.1; 201420342024.0; 201420633124.9; 201430417951.X; 201520233712.8; 201530103964.4; 201530225241.1; 201530225068.5; 201530225179.6;

201520911627.2; 201621429154.3; 201621429150.5; 201621429142.0; 201630636079.7; 201630636165.8; 201630636136.1; 201621326210.0; 201621429144.X; 201630636166.2

Engine Model Number & Serial Numbering System

The rst two lines of an engine’s number is the model number. It is alphanumeric and engraved on the side of the block to the right of

the recoil. The third line is alphanumeric and is also the serial number.

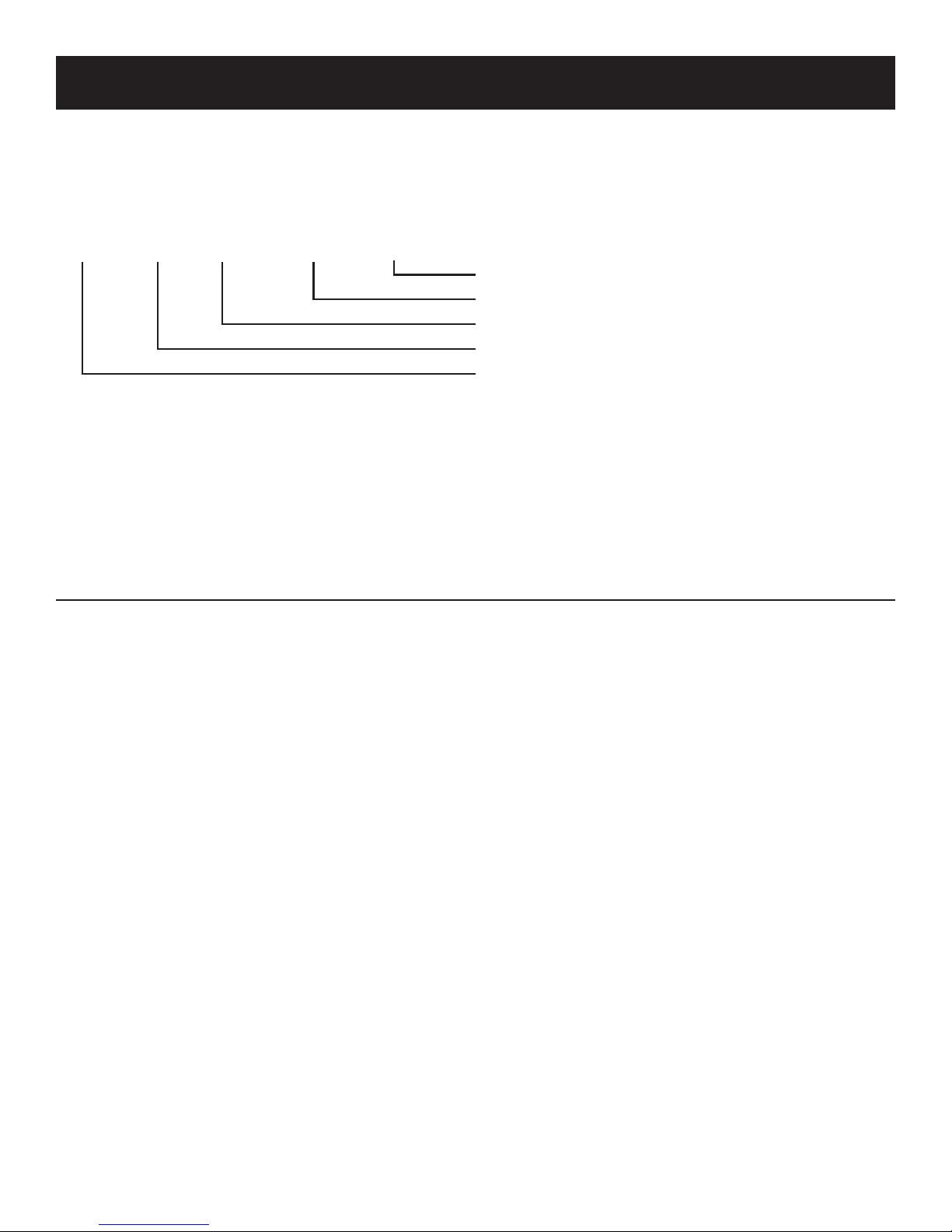

Engine Serial Number Sequence

16 95H 03 00001 A:

Example:

Engine Serial Number 1695H0300001A represents:

16: 2016

95H: 306cc Horizontal Engine Series

03: March

00001: 1st Engine Produced During Month of March

A: Horizontal Assembly Line

Assembly Line Designation (A, B, C, D)

Sequential Engine Number

Produced Month

Engine Series Designation

Produced Year

LCT Engine Model Numbering System Definition (see chart on page 3):

1. Preproduction - This column is coded and reserved for prototype engines only.

2. Plant - This column is coded and used for LCT internal use only.

3. Design Family - This column is used for emissions regulations and coded for LCT internal use only.

4. Crankshaft - This column indicated whether the PTO shaft (crankshaft) is congured in the engine horizontally or vertically.

5. Shaft - This column is used for the description of the PTO shaft. This will aid in determining what will be the engine’s primary use.

6. Shaft Detail - This column references a chart that designates which LCT engineering drawing corresponds to the PTO shaft.

This is for LCT internal use only.

7. Horsepower - This column is coded to designate the engine’s power output (horsepower) with its corresponding size

(cubic centimeters).

8. Paint Code - This column is coded to which color scheme the engine is equipped with.

9. Starter Type - This column is coded to which type of starting system the engine is equipped with.

10. Options - This column is coded to designate which equipment options the engine is equipped with.

11. Emissions Label - This column is coded for the emissions standards the engine meets.

12. Pack Code - This column is reserved for LCT Packaging Department only.

NOTE:

The LCT Engine Model and Serial Number Systems is subject to be changed or edited at any time.

Copyright © 2018 Liquid Combustion Technology, LLC LCT Engine Service Manual: 79, 136, 179, 208, 254, 291, 306, 369, 414 & 420cc 2

Engine Model Number & Serial Numbering System

Plant Design Family

P LM Moderate H Horizontal T Threaded 150

S LO ***Hybrid V Vertical K Straight-Keyed 175

D LX Extended P Tapered 200

LD Diesel S Splined (No Attach.) 250

W1 GEN I Snow G1 2:1 Reduction (GEAR) 350

W2 GEN II Snow G2 6:1 Reduction (GEAR) 400

W3 Single Stage

Snow 1

W4 *Snow King G4 2:1 Reduction (CLUTCH) 650

W5 **Snow King 750

W6 Private Label

Snow

W7 Ariens Single

Stage

W8 GEN III Snow 1000

ID Inverter Design

Engine

NOTES:

* W4 DESIGNATOR IS USED FOR FULL ENGINE DRESSED SNOW KING PLATFORMS

** W5 DESIGNATOR IS USED FOR LIMITED ENGINE DRESSED SNOW KING

PLATFORMS

*** LO DESIGNATOR IS USED FOR SUMMER SPEC ENGINES WITH WINTER SELF

TAPPING MOUNT CYLINDERS

Crankshaft

Shaft HP Paint Code Starter Type Options Emissions Label Pack Code

[1.5hp (63cc)]

[ 1.75hp (79cc) ]

[ 2.0hp (87cc) ]

[ 2.5hp (98cc) ]

[ 3.5hp (106cc) ]

G3 2:1 Reduction (CHAIN) 500

Both Model & ID Numbers to be

on PMI & Specification Sheet

[ 4.0hp (136cc) ]

[ 5.0hp (179cc) ]

[6.5hp (208cc) ]

[7.5hp (254cc) ]

850

[ 8.5hp (291cc) ]

950

[ 9.5hp (306cc) ]

[ 10.0hp (369cc) ]

1250

[ 12.5hp (414cc) ]

1300

[13.0hp (420cc) ]

CI219A

[ 4hp (219cc) ]

CI306

[ 6hp (306cc) ]

CI306A

[ 7hp (306cc) ]

CI418

[ 8hp (418cc) ]

CI418A

[ 9hp (418cc) ]

CI219

[ 3.5hp (219cc)]

CI219A

[4.0hp (219cc)]

CI435A

[ 9hp (435cc) ]

▼ ▼

Model No. PLMHK14650124PBGPSTUVE2M ID Number 920811000

P Manufacturing Facility 9 Horizontal

LM Moderate Design Family 208 cc Displacement

H Horizontal Crankshaft 1 Summer

K Keyed PTO design 1000 Sequential Number

14 #14 Crankshaft Drawing

650 6.5hp (208cc) engine

1 Black Recoil (Glossy)

2G Blue Recoil (PMS287C)

2 Black Tank (Glossy)

4 Black Blower Housing (Glossy)

P Pull Start

B Manual Choke

G High Oil Fill Tube

P Pleated Paper Air Filter

S Atmosphere Vented Plastic Fuel

T Two Low Oil Fill Plugs

U C&U Bearings

V Viton Oil Seals

E2 49 State Compliant

M Multi-Pack

Cap w/ Tether Cord

1 - JPC Black Recoil

(Standard JPC Black)

2 - Black Tank

(Pantone Black G (Glossy))

3 - Titan Yellow Blower Housing Z - Recoil/

4 - Black Blower Housing (Pantone

Black G (Glossy))

5 - Yellow Recoil

(Pantone 1235C)

6 - Yellow Tank

(Pantone 1235C)

7 - Black Tank

(Pantone Black M (Matte))

8 - Black Blower Housing (Pantone

Black M (Matte))

9 - Yellow Blower Housing

(Pantone 1235C)

1A - Titan Green Blower Housing

(Pantone Green 364C)

1B - Titan Green Recoil

(Pantone Green 364C)

1D - XH Black Recoil

(Pantone Black M (Matte))

1C - Carmine Red Blower Housing

(RAL 3002)

1E - Blue Recoil

(PMS 294C)

1F - Blue Fuel Tank

(PMS 294C)

1G - Blue Blower Housing

(PMS 294C)

1H - Titan Orange Blower Housing Q - No Low Oil Sensor

1I - Titan Orange Recoil R - Low Temperature Muffler

IJ - Sliver Recoil

(Titan Spec Silver)

1K - Sliver Blower Housing

(Titan Spec Silver)

1L - [TBD] U - Upgrade Bearing

1M - [TBD] V - Viton Oil Seals

1N - XH Black Recoil (Pantone

Black G (Glossy)

1O - Yellow Fuel Tank

(PMS B1046)

1P - JPC Black Recoil (Lightweight

Recoil Design)

1Q - [TBD] 1 - Integrated On/Off Speed Controls

1R - [TBD] 2 - Remote Choke

1S - [TBD] 3 -2.7L Fuel Tank

1T - [TBD] 4 - 3.6L - Fuel Tank

1U - [TBD] 5 - 60W AC Alternator

1V - [TBD] 6 - ROV Fuel Tank Equipped

1W - [TBD] 7 - Reduced Sound Muffler Package

1X - [TBD] 8 - [TBD]

1Y - [TBD] 9 - Front Oil Drain Tube

1Z - [TBD] 10 - [TBD]

2A - [TBD] 11 - [TBD]

2B - [TBD]

2C - [TBD]

2D - Yellow Recoil (Yellow C)

2E - Yellow Blower Housing

(Yellow C)

2F - Yellow Fuel Tank (Yellow C)

2G - Blue Recoil (PMS 287C)

2H - Blue Blower Housing

(PMS 287C)

2I - Blue Fuel Tank (PMS287C)

2J - [TBD]

2K - [TBD]

2L - [TBD]

EXAMPLE

2M - [TBD]

2N - [TBD]

2O - [TBD]

2P - [TBD]

E - 12VDC/

120VAC Electric

P- Recoil B - Manual Choke E2 - 49 State M - Multi-Pack

Electric Provision

Y - 220VAC Electric D - Generator Air Filter E5 - California Exh Only

X - 12V DC with Starter Box E - Generator Muffler E7 - European Compliant

V - [TBD] F - No Tank E8 - Australian Compliant

U - [TBD] G - High Oil Fill Tube E9 - South East Asia

T - [TBD] H - Commercial Fuel Tank (Large

S -[TBD] I - AC Charging Coil Equipped EB - NON CERTIFIED

A - Fixed Speed E1 - 50 State S - Single Pack

C - Catalytic Muffler E4 - California Preempt

Fuel Tank)

J - DC Charging Coil Equipped E12 - [TBD]

K - Evaporative Emission Equipped E13 - [TBD]

L - Coaxial Idle Down Equipped E14 - [TBD]

M - Remote Throttle Control E15 - [TBD]

N - High Ouput Air Filter - Non CA

O - Snow Equipped

P - Pleated Paper Air Filter

S - Atm. Vented Plastic Fuel Cap w/

Tether Cord

T - Two Low Oil Fill Plugs

X - Single Stator Charging System

Y - Dual Stator Charging System

Z - CE Compliance Package

EA - Canadian Compliant

Copyright © 2018 Liquid Combustion Technology, LLC LCT Engine Service Manual: 79, 136, 179, 208, 254, 291, 306, 369, 414 & 420cc 3

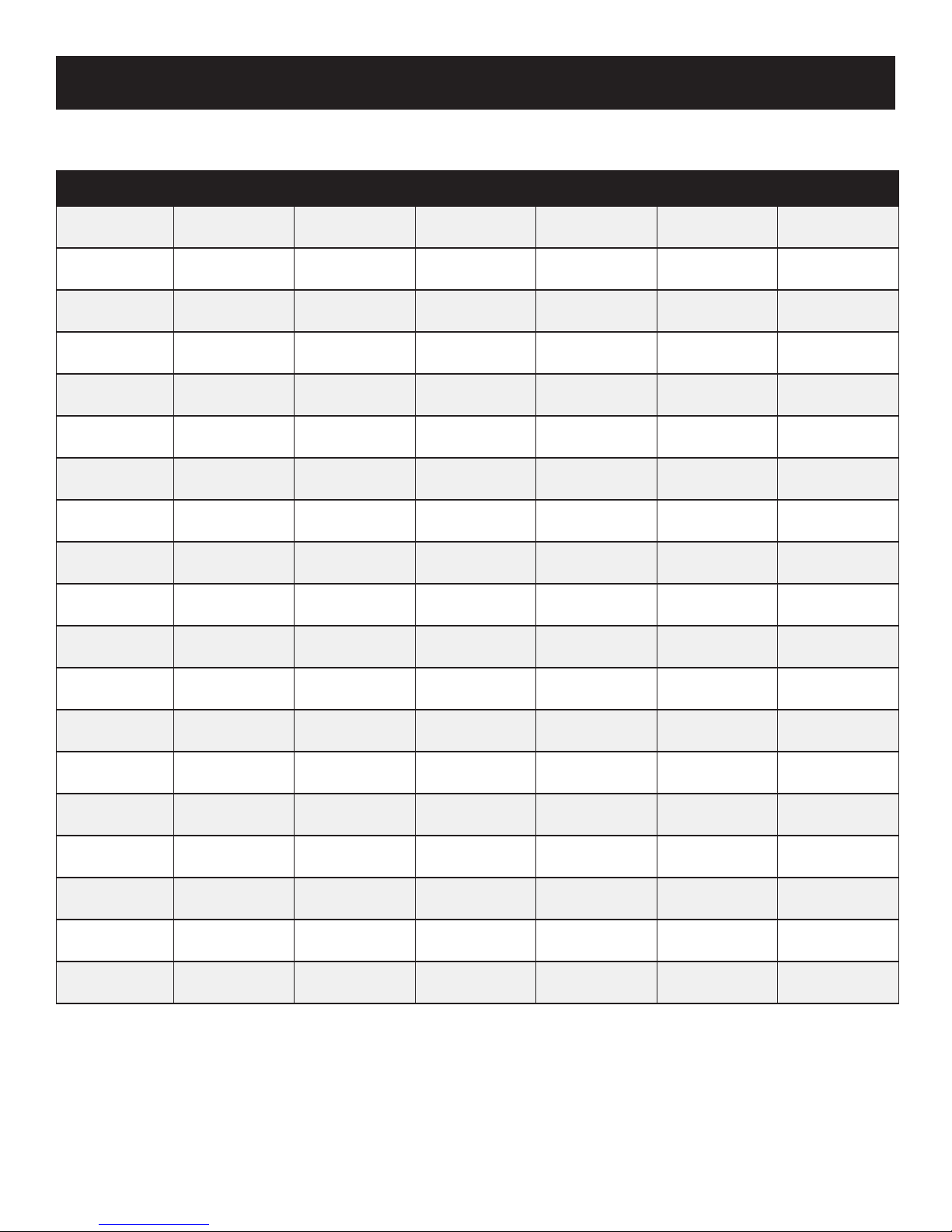

General Specifications

Item 79cc 136cc 179cc 208cc 223cc 254cc

Maximum Speed 3850±50rpm 3850±50rpm 3850±50rpm 3850±50rpm 3850±50rpm 3600±50rpm

Idle Speed 2050+/-50rpm 2050+/-50rpm 2050+/-50rpm 2050+/-50rpm 2050+/-50rpm 2050+/-50rpm

Compression Ratio 8.5:1 8.5:1 8.5:1 8.5:1 8.5:1 8.5:1

Displacement 79cc 136cc 179cc 208cc 223cc 254cc

Compression Release yes yes yes yes yes yes

Cast Iron Sleeve yes yes yes yes yes yes

Bore x Stroke

PTO Rotation

Fuel

(DO NOT USE E85)

Low Oil Shutoff if equipped if equipped if equipped if equipped yes if equipped

Fuel Shutoff Valve yes yes yes yes yes yes

Oil Fill Capacity 13oz 16oz 16oz 16oz 16oz 20oz

Spark Plug Gap

Ignition Air Gap

(At Flywheel)

Valve Adjustment

(gap) Intake

Valve Adjustment

(gap) Exhaust

Dry Weight

(Summer Engines)

Dry Weight

(Winter - Gen II / PW2)

Dry Weight (Winter

- PW3)

2.02" x 1.49" (51.4mm

x 38mm)

CCW (measured from

PTO side)

regular unleaded

gasoline

0.7-0.8mm (.027-.030

in.)

0.4 +/- 0.2mm 0.4 +/- 0.2mm 0.4 +/- 0.2mm 0.4 +/- 0.2mm 0.4 +/- 0.2mm 0.4 +/- 0.2mm

.11 +/- .02mm (.003-

.005in)

.13 +/- .02mm (.004-

.006 in.)

22.72 lbs. (10.3kg) 31 lbs. (14.1kg) 35 lbs. (16.6kg) 35 lbs. (16.6kg) 35 lbs. (16.8kg) NA

NA 38 lbs. (17.3kg) 42 lbs. (19.1kg) 42 lbs. (19.1kg) 42 lbs. (19.3kg) 45.23 lbs. (20.5kg)

NA 30 lbs. (13.6kg) 36 lbs. (16.4kg) 36 lbs. (16.4kg) NA NA

2.44" x 1.77" (62mm x

45mm)

CCW (measured from

PTO side)

regular unleaded

gasoline

0.7-0.8mm (.027-.030

in.)

.15 +/- .02mm (.005-

.007in)

.20 +/- .02mm (.007-

.009 in.)

2.55" x 2.13" (65mm x

54mm)

CCW (measured from

PTO side)

regular unleaded

gasoline

0.7-0.8mm (.027-.030

in.)

.15 +/- .02mm (.005-

.007in)

.20 +/- .02mm (.007-

.009 in.)

2.76" x 2.13" (70mm x

54mm)

CCW (measured from

PTO side)

regular unleaded

gasoline

0.7-0.8mm (.027-.030

in.)

.15 +/- .02mm (.005-

.007in)

.20 +/- .02mm (.007-

.009 in.)

70x58

CCW (measured from

PTO side)

regular unleaded

gasoline

0.7-0.8mm (.027-.030

in.)

.15 +/- .02mm (.005-

.007 in.)

.20 +/- .02mm (.007-

.009 in.)

2.99" x 2.2" (76mm x

56mm)

CCW (measured from

PTO side)

regular unleaded

gasoline

0.7-0.8mm (.027-.030

in.)

.15 +/- .02mm (.005-

.007in)

.20 +/- .02mm (.007-

.009 in.)

Copyright © 2018 Liquid Combustion Technology, LLC LCT Engine Service Manual: 79, 136, 179, 208, 254, 291, 306, 369, 414 & 420cc 4

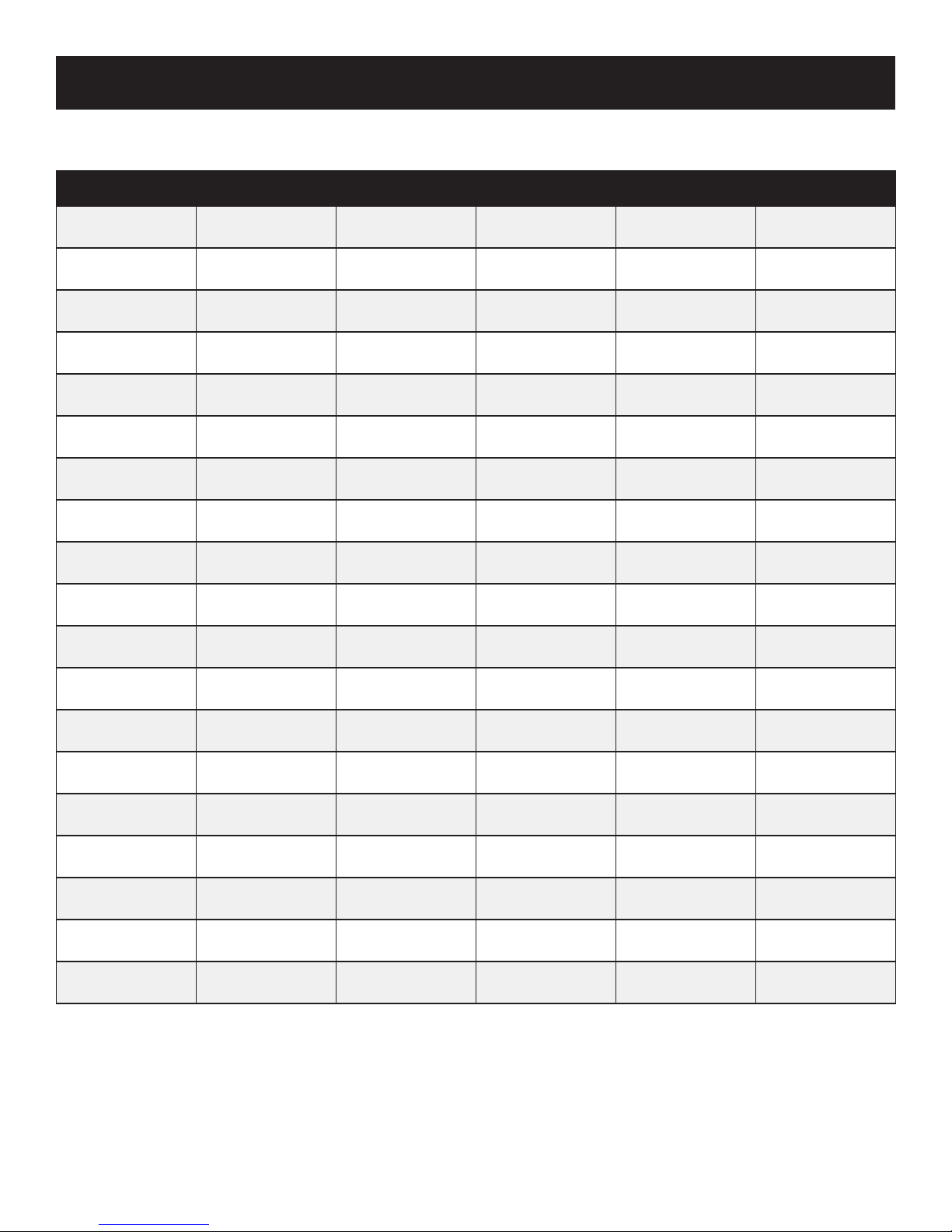

General Specifications

Item 291cc 306cc 369cc 414cc 420cc

Maximum Speed 3850±50rpm 3850±50rpm 3850±50rpm 3850±50rpm 3850±50rpm

Idle Speed 2050+/-50rpm 2050+/-50rpm 2050+/-50rpm 2050+/-50rpm 2050+/-50rpm

Compression Ratio 9:1 9:1 8.1:1 8.1:1 8.1:1

Displacement 291cc 306cc 369cc 414cc 420cc

Compression Release yes yes yes yes yes

Cast Iron Sleeve yes yes yes yes yes

Bore x Stroke

PTO Rotation

Fuel (DO NOT USE E85) regular unleaded gasoline regular unleaded gasoline regular unleaded gasoline regular unleaded gasoline regular unleaded gasoline

Low Oil Shutoff if equipped if equipped if equipped if equipped if equipped

Fuel Shutoff Valve yes yes yes yes yes

Oil Fill Capacity 32oz 32oz 38oz 38oz 38oz

Spark Plug Gap 0.7-0.8mm (.027-.030 in.) 0.7-0.8mm (.027-.030 in.) 0.7-0.8mm (.027-.030 in.) 0.7-0.8mm (.027-.030 in.) 0.7-0.8mm (.027-.030 in.)

Ignition Air Gap

(At Flywheel)

Valve Adjustment

(gap) Intake

Valve Adjustment

(gap) Exhaust

Dry Weight

(Summer Engines)

Dry Weight

(Winter - Gen II / PW2)

3.15" x 2.28" (80mm x

58mm)

CCW (measured from PTO

side)

0.4 +/- 0.2mm 0.4 +/- 0.2mm 0.4 +/- 0.2mm 0.4 +/- 0.2mm 0.4 +/- 0.2mm

.15 +/- .02mm (.005-

.007in)

.20 +/- .02mm (.007-.009

in.)

57.32 lbs. (26kg) 57.32 lbs. (26kg) 69.45 lbs. (31.5kg) 69.45 lbs. (31.5kg) 69.45 lbs. (31.5kg)

61 lbs. (27.7kg) 61 lbs. (27.7kg) 72 lbs. (32.7kg) 72 lbs. (32.7kg) 72 lbs. (32.7kg)

3.22" x 2.28" (82mm x

58mm)

CCW (measured from PTO

side)

.15 +/- .02mm (.005-

.007in)

.20 +/- .02mm (.007-.009

in.)

3.34" x 2.55" (85mm x

65mm)

CCW (measured from PTO

side)

.15 +/- .02mm (.005-

.007in)

.20 +/- .02mm (.007-.009

in.)

3.54" x 2.56" (90mm x

65mm)

CCW (measured from PTO

side)

.15 +/- .02mm (.005-

.007in)

.20 +/- .02mm (.007-.009

in.)

3.54" x 2.59" (90mm x

66mm)

CCW (measured from PTO

side)

.15 +/- .02mm (.005-

.007in)

.20 +/- .02mm (.007-.009

in.)

Dry Weight (Winter - PW3) NA NA NA NA NA

Copyright © 2018 Liquid Combustion Technology, LLC LCT Engine Service Manual: 79, 136, 179, 208, 254, 291, 306, 369, 414 & 420cc 5

General Troubleshooting

ST ART

Engine will not start:

1. Check oil level- Do you have the correct amount of oil? (Ref: Engine Oil Service, pg. 10)

Remedy: Oil should be visible and to the top 2 threads of the LOWEST oil ll spout.

2. Is on/off switch on?

Remedy: Turn to the on position per engine specication.

3. Snow Only:

a) Is the Run/Stop switch in the Run Position?

Remedy: Push switch to the Run Position.

b) Is the snow safety key inserted into slot?

Remedy: Push key into slot to fully engage.

4. Do you have fuel in the fuel tank?

Remedy: Add fuel.

5. Is the fuel petcock turned to the on position?

Remedy: Turn to the on position.

OFF

ON

6. Was the engine choked?

Remedy: When starting the engine the choke lever should be pushed left to the on

position, and after starting, pushed right to the off position. If engine is equipped with

RUN

twist type choke, the knob should be turned clockwise to the start position, and after

starting, turned counter-clockwise to the run position. If engine still does not start

move to half choke and pull twice.

START

SnowTwist Choke

7. Is the spark plug boot securely fastened to the spark plug?

Remedy: Slide over spark plug and t securely.

8. Has the fuel being used been purchased within the last 30-days and was it stored in a plastic container?

Remedy: Replace old fuel with new fuel.

9. Is the engine ooded?

Remedy: Remove spark plug and replace with any of the spark plugs listed under Spark Plug Service, pg. 9.

• NOTICE

Using an incorrect spark plug may cause engine damage.

Summer

Copyright © 2018 Liquid Combustion Technology, LLC LCT Engine Service Manual: 79, 136, 179, 208, 254, 291, 306, 369, 414 & 420cc 6

General Troubleshooting

ST ART

Engine stops running:

1. Has the fuel being used been purchased within the last 30-days and was it stored in a plastic container?

Remedy: Replace old fuel with new fuel.

2. Is the air lter dirty?

Remedy: Replace air lter element if dirty. Clean prelter of any dirt or dust per engine specication.

3. Was the engine choked?

Remedy: When starting the engine the choke lever should be pushed left to the on

position, and after starting, pushed right to the off position. If engine is equipped with

twist type choke, the knob should be turned clockwise to the start position, and after

starting, turned counter-clockwise to the run position. If engine still does not start

move to half choke and pull twice.

Twist Choke

4. Is the spark plug corroded?

Remedy: Remove spark plug and replace with any of the plugs listed under Spark Plug Service, pg.9.

RUN

START

Snow

Summer

• NOTICE

Using an incorrect spark plug may cause engine damage.

5. Has the engine run out of fuel?

Remedy: Refuel engine.

6. Is the fuel petcock turned to the on position?

Remedy: Turn to the on position.

7. Is the throttle set too low (variable speed models only)?

Remedy: Increase the throttle per engine specication.

OFF

ON

Copyright © 2018 Liquid Combustion Technology, LLC LCT Engine Service Manual: 79, 136, 179, 208, 254, 291, 306, 369, 414 & 420cc 7

Advanced Troubleshooting – For Authorized LCT Technicians

ENGINE

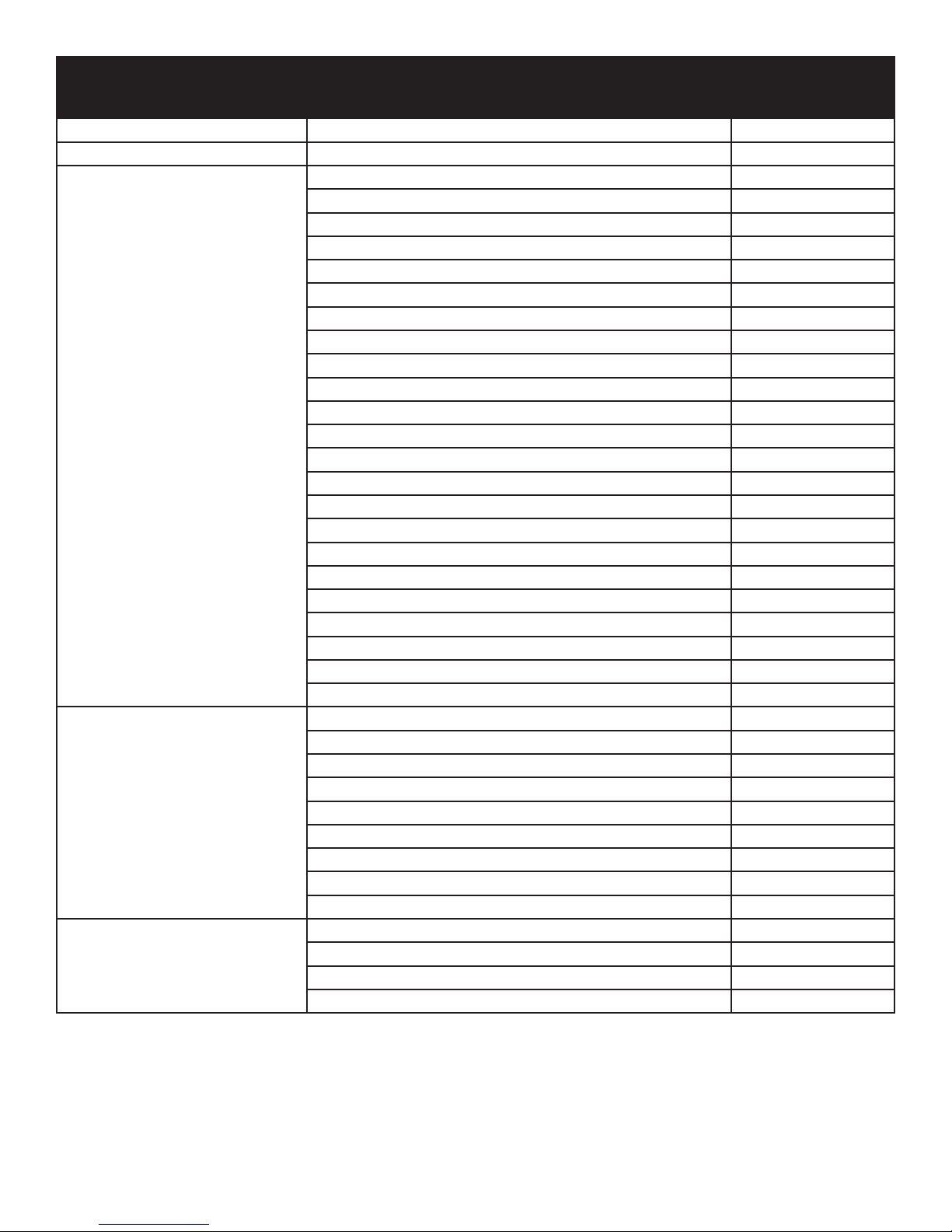

Complaint Symptom and possible causes Remedy

Engine will not start, or is

hard to start

Compression too low

1. Valves out of adjustment Adjust

2. Worn valve guides or poor seating of valves Repair or Replace

3. Mistiming valves Adjust

4. Excessively worn piston rings Replace

5. Worn-down cylinder bore Replace

6. Poor seating of spark plug Retighten

7. Failed head gasket Replace

Plug not sparking

1. Fouled spark plug Replace

2. Wet spark plug Dry off

3. Defective ignition coil Replace

4. Spark plug wire damaged Replace

5. Kill switch in “OFF” position Switch to “On”

6. Ignition coil air gap is too wide Reset

7. Ignition coil failure Replace

No fuel reaching the intake manifold

1. Clogged fuel filter or fuel line Replace

2. Dirty/gummed up carburetor Clean

3. Fuel petcock is turned off Turn on

4. Fuel tank is empty Fill

Engine idles poorly 1. Out of adjustment tappet clearance Adjust

2. Poor seating of valves Replace or Repair

3. Defective valve guides Replace

4. Worn down camshaft Replace

5. Too wide spark plug gap Adjust or replace

6. Defective ignition coil Replace

7. Ignition coil air gap too wide Adjust

8. Dirty/gummed up carburetor Clean

9. Stale fuel Replace

Engine stalls easily 1. Dirty/gummed up carburetor Clean

2. Fouled spark plug Replace

3. Clogged fuel line Replace

4. Valves out of adjustment Adjust

Copyright © 2018 Liquid Combustion Technology, LLC LCT Engine Service Manual: 79, 136, 179, 208, 254, 291, 306, 369, 414 & 420cc 8

Loading...

Loading...