TM

Probot

Micro Fraction Collector

User’s Manual

P/N 161403

D960R3

www.lcpackings.com

Notice: The Probot Micro Fraction Collector is covered by a limited warranty. A

copy of this warranty is included with this manual. The customer is required to

perform routine maintenance as described in the User’s Manual on a periodic

basis to keep the warranty in effect.

All information in this manual is subject to change without notice and does not

represent a commitment on the part of LC Packings, BV.

The material included in this manual is provided to assist users in the operation,

maintenance and repair of the Probot Micro Fraction Collector. It is assumed that

the individual using this manual has sufficient training in the use of analytical

instrumentation and is aware of the potential hazards including (but not limited

to) electrical hazards, chemical solvent hazards and the exposure to pressurized

solvents.

© November 2004, LC Packings, BV - A Dionex Company. All rights reserved.

No part of this manual may be reproduced or transmitted in any form or by any

means without the written permission of LC Packings, BV.

The following are Trademarks or Registered Trademarks of LC Packings - A

Dionex Company: Probot, Carrier, UltiMate, UltiChrom, FAMOS, Thermos,

Switchos II, Acurate, UZ-View, UV-Booster, FluoBoost, Pepmap, µ-Dumper, µFluidics, Fusica, Nano Series, Pico Series, µ-Guard, µ-Precolumn, NanoPrecolumn.

Dionex™ is a Trademark of Dionex Corporation.

CHROMELEON is a Trademark of the Dionex Corporation.

PEEK™ polymer is a Trademark of Victrex plc.

Teflon® is a Registered Trademark of E.I. duPont de Nemours and Company.

Analyst® is a Registered Trademark of Applied Biosystems/MDS Sciex.

HyStar is a Trademark of Bruker-Daltonics Group.

MassLynx is a Trademark of Waters® Corporation.

Xcalibur® is a Registered Trademark of ThermoFinnigan.

TM

Belkin

and VideoBusII are Trademarks of the Belkin Corporation.

Windows® and Microsoft® are Registered Trademarks of Microsoft Corporation.

Other product names or company names mentioned herein may be the

trademarks of their respective owners.

Printed in the Netherlands.

ii D960R3 User’s Manual Probot

Table of Contents

Warranty vii

Liability viii

Instructions for Returning Instruments ix

Warnings xi

Safety Precautions xi

CHAPTER 1

Introduction 1-1

1.1 Features of the Probot Micro Fraction Collector 1-1

1.2 General Design of the Probot Micro Fraction Collector 1-2

1.3 Front View of Probot 1-4

1.4 The Manual Control Unit 1-4

1.5 Rear View of Probot 1-5

1.6 Control of the Probot Micro Fraction Collector 1-5

1.7 About this Manual 1-6

CHAPTER 2

Installation and Getting Started 2-1

2.1 Installation 2-1

2.1.1 Location of Probot in the Laboratory 2-2

2.2 Unpacking 2-3

2.3 Removing Shipping Components 2-3

2.3.1 Removing the Top Cover 2-4

2.3.2 Drive Table Safety Brackets 2-5

2.4 Installing the Probot with the UltiMate Capillary HPLC System 2-6

2.4.1 Electrical Connections 2-6

2.4.1 A RS-232 Connector 2-6

2.4.1 B START Connector 2-6

2.4.1 C REMOTE Connector 2-7

2.4.1 D TTL IN Connector 2-7

2.4.1 E INTERLOCK Connector 2-7

2.4.1 F RELAY Connector 2-7

2.4.1 G ANALOG IN Connector 2-8

2.4.1 H VIDEO Connector 2-8

2.4.1 I POWER Connector 2-8

2.4.2 Fluidic Connections for Fraction Collection 2-9

2.4.2 A Connecting the µ-Tee for Matrix Addition 2-9

2.4.2 B Connecting the Dosage Module 2-10

2.5 Software Installation 2-11

2.5.1 System requirements 2-11

2.5.2 Installation of Carrier 2-11

2.6 Introduction to the Carrier Software 2-12

2.6.1 Key Features 2-12

2.6.2 Design of µCarrier 2-13

2.6.3 The Editors and Wizards 2-13

User’s Manual Probot

D960R3 iii

Table of Contents

2.6.4 Necessary Steps to create and run the Application 2-13

2.6.5 The Main Toolbar 2-14

2.7 µCarrier – First Steps 2-15

2.7.1 Launching µCarrier 2-15

2.7.2 Using the Predefined Applications, Trays and Sample Carriers 2-17

2.7.2 A Loading a Predefined Application 2-17

2.7.3 Alignment of the Sample Carriers 2-19

2.7.4 Checking and Modifying Application Parameters 2-21

2.7.4 A Checking and Modifying Groups 2-21

2.7.4 B Checking/Modifying the Tasks List 2-22

2.7.4 C Checking/Modifying the Task Parameters 2-23

2.7.5 Running a predefined Application 2-24

2.8 µCarrier – Basics Steps 2-25

2.8.1 Create a New Sample Carrier using the Sample Carrier Wizard 2-26

2.8.2 Create a New Tray using the Tray Setup Wizard 2-30

2.8.3 Modify an Existing Tray Setup using the Tray Editor 2-32

2.8.4 Create a New Application using the Wizard 2-34

2.8.5 Control the Table Position Manually 2-44

2.8.5 A Using the Manual Drive Panel 2-44

2.8.5 B Using the Manual Control Unit 2-44

2.8.6 Measure the Column (X) and Row (Y) Distance 2-45

2.8.7 Default Calibration and Acceleration Settings 2-47

CHAPTER 3

Maintenance and Troubleshooting 3-1

3.1 Overview 3-1

3.2 Maintenance 3-2

3.3 Replacing Major Components 3-3

3.3.1 Installing the Pipetting Option 3-3

3.3.2 Installing the Video Camera 3-4

3.3.3 Replacing the Syringe 3-4

3.3.4 Replacing the Dosage Unit 3-5

3.3.5 Replacing the Fractionation Needle of the µ-Tee 3-6

3.3.6 Replacing the Standard Needle 3-8

3.3.7 Replacing the Light Bulb of the Pen Light 3-8

3.3.8 Replacing the Main Fuse 3-9

3.4 Troubleshooting 3-10

3.5 Spare Parts Lists 3-11

3.5.1 Major Items 3-11

3.5.2 Accessories 3-11

3.5.3 Spare Parts 3-12

3.5.4 Adapter Tables 3-13

CHAPTER 4

Specifications 4-1

4.1 Physical 4-1

4.2 Electrical 4-1

4.3 Electrical Connections 4-2

4.4 Rotary Valve 4-2

4.5 Safety Devices 4-2

iv D960R3 User’s Manual Probot

Table of Contents

APPENDIX A

Dosage Module Purge Routine 1

A.1 Overview 1

A.1.1 The Step-By-Step Purge Routine 1

APPENDIX B

Peak Collection in Conjunction with CHROMELEON®

Software 1

B.1 Overview 1

B.2 Contact Closure Signals for Peak Detection with CHROMELEON 2

B.3 Setting up µ-Carrier for Peak Collection 3

B.4 Electrical Connections 6

B.5 Listing of the CHROMELEON Program used for this Example 6

B.6 Additional Hints/Troubleshooting 8

APPENDIX C

Table Alignment Instructions 1

C.1 Overview 1

C.2 Table Alignment 2

C.2.1 Leveling 2

C.2.2 Test Needle and Carrier Setup 2

C.2.3 Checking and Aligning of the X-axis and Y-axis 3

C.2.4 Alignment of the X-axis 4

C.2.5 Alignment of the Y-axis 4

APPENDIX D

The Vacuum Waste Removal Option 1

D.1 Overview 1

D.2 General Design 2

D.3 Setting up the Probot 3

D.3.1 Electrical Connections 3

D.3.2 Connecting the Vacuum Pump 3

D.3.3 Installing the Fused Silica Capillary 4

D.4 Setting up µCarrier and CHROMELEON 5

D.4.1 Enabling the Vacuum Waste Removal Option 5

D.4.2 Adjusting the Fused Silica Capillary and the Needle Height 5

D.4.3 Using the Waste Removal Option - Example 6

D.5 Listing of the CHROMELEON Example Program 8

D.6 Additional Hints/Troubleshooting 9

APPENDIX E

Installing and Using the Belkin

E.1 Installation of the Belkin VideoBusII Image Capture Device 1

E.2 Software Installation and µCarrier Setup 2

E.2.1 Connecting the Camera and Displaying the Video Signal 2

E.2.2 Saving a the current Image or Recording a Sequence 4

E.2.3 Optimizing the Video Settings in Carrier 2.0 4

E.2.4 Troubleshooting 5

E.3 Uninstall Instructions 6

USB Video Adapter 1

User’s Manual Probot D960R3 v

Table of Contents

[This page intentionally left blank]

vi D960R3 User’s Manual Probot

Warranty

LC Packings (Netherlands) BV, warrants that the products manufactured and sold

by it to be free from defects in material and workmanship for normal use and

service from the date of delivery to original purchaser for a period of one (1) year

from the date of shipment. This limited warranty does not cover, and no

warranty is provided, for parts that by their nature are required to be replaced

periodically as a function of use of the normal operation of the system. These

items include, without limitation: HPLC columns, fuses, tubing, detector sources,

pump piston seals, injector rotors, check valves, filters, any software, etc. In

addition, damage due to corrosion, misuse, negligence, accident, alteration of the

system or repair by an unauthorized individual is not covered by the warranty. It

is understood that the performance characteristics of the instrument require that

the mobile phase is degassed with He or vacuum degassed as described in the

User’s Manual.

This warranty covers products sold under the LC Packings trademark. If a

different warranty than the above is indicated in the sales literature, the warranty

indicated in the sales literature will prevail. If the system includes equipment

supplied by LC Packings but manufactured by a third party, LC Packings makes

no warranty of any kind, express or implied, including, without limitation, any

warranty of merchantability or fitness for a particular purpose. LC Packings will

make available to you, to the extent permitted, the warranties of the

manufacturer of the relevant equipment following your timely written request.

If any product covered by this warranty becomes defective during the warranty

period, it will be repaired or replaced by LC Packings at no charge to the

customer (the repair/replace decision is solely at the option of LC Packings). All

warranty requests must be received by LC Packings during the warranty period.

LC Packings will pay for surface transportation to the applicable LC Packings

Office (North America – Sunnyvale CA, Europe and Asia - Amsterdam, the

Netherlands), if the instrument proves defective within thirty (30) days from the

date of shipment (this does not include air freight, drayage, labor, crating

charges, customs clearance charges, etc.). The user should carefully follow the

directions indicated on the Return Goods Instruction Sheet in the User’s Manual.

After thirty days, all transportation costs will be at the expense of the customer.

User’s Manual Probot

D960R3 vii

Warranty

Liability

Under no circumstances shall LC Packings be liable for damage to persons or

property. This warranty is the only warranty given by LC Packings with respect

to products and software provided with the products and is given in lieu of all

other warranties, express or implied, including, without limitation, any warranty

of merchantability or fitness for a particular purpose.

Your exclusive remedies and LC Packings’s sole liability for any non-conformity

or defect in the products and such software will be those expressed herein.

Under no circumstances will LC Packings’s liability arising from the performance

or failure to perform of any product or software, in contract, in tort (including

negligence), or otherwise, exceed the purchase price of the product and

software. In no event will LC Packings be liable, in contract, in tort (including

negligence), or otherwise for special, incidental, consequential or analogous

damages, including, without limitation, damages resulting from loss of use, loss

of profits, loss of business or loss of goodwill, even if LC Packings has been

advised of the possibility of such damages.

This warranty comprises the entire warranty between LC Packings and the

customer. It overrides any warranty related language that may appear in the

customer purchase order or other documentation provided by the customer.

This warranty shall be governed by, and construed and enforced in accordance

with, the laws of the Netherlands. It is non-transferable and shall run to the

benefit of the original purchaser only. Any change, alteration or amendment to

this warranty is not valid unless it has been approved in writing by an officer of

LC Packings.

North America Europe and Asia

LC Packings / Dionex LC Packings (Netherlands) BV

A Dionex Company

500 Mercury Drive Abberdaan 114

Sunnyvale, CA 94088-3603 1046 AA Amsterdam

USA The Netherlands

Technical Call Center Phone: + 31 20 683 9768

USA/CA: (800) 346-6390 Fax: + 31 20 685 3452

viii D960R3 User’s Manual Probot

Instructions for Returning Instruments

Before you return any item for repair, please contact the nearest LC Packings

office or its local distributor for instructions and obtain a return authorization

number and the ‘Health and Safety Form’ (if applicable).

Pack the equipment carefully, preferably in its original shipping container and

ship it to the LC Packings Service Department, using the appropriate address.

North America Europe and Asia

LC Packings / Dionex LC Packings (Netherlands) BV

A Dionex Company

500 Mercury Drive Abberdaan 114

Sunnyvale, CA 94088-3603 1046 AA Amsterdam

USA The Netherlands

Technical Call Center Phone: + 31 20 683 9768

USA/CA: (800) 346-6390 Fax: + 31 20 685 3452

IMPORTANT:

1) Make certain that the return authorization number together with the HEALTH

AND SAFETY form (if applicable) is attached outside of the package so that

we can properly track and account for your system.

2) Please include the following

a) Company letterhead with the following information.

Your Name

Complete Mailing Address

Telephone Number, fax number and e-mail address

Return Authorization Number

A detailed description of the problem.

The name of the LC Packings personnel to whom you have

spoken to regarding the problem

Return Shipping Information (if appropriate)

b) Relevant chromatograms

c) A purchase order (if the system is not in warranty)

Note: The completed and signed HEALTH AND SAFETY form must be returned

to LC Packings service department (fax or mail) prior to the return of any

component, or attached outside the shipping package. In addition, the provided

RMA number must be clearly marked on the outside of the shipping package.

Failure to complete and return this form will result in the return of the unopened

package. The parts will not be inspected nor will credit be issued.

User’s Manual Probot

D960R3 ix

Instructions for Returning Instruments

[This page intentionally left blank]

x D960R3 User’s Manual Probot

Warnings

The Danger sign, Warning sign and the Caution sign shown below are included in

various locations in this manual. These signs provide the following information:

DANGER

Danger: The information in a danger statement relates to a procedure, practice

condition or action that if not done correctly or adhered to could lead to personal

injury or loss of life.

WARNING

Warning: The information in a warning statement relates to a procedure, practice

condition or action that if not done correctly or adhered to could lead to severe

injury and/or damage or destruction to parts or all of the equipment.

CAUTION

Caution: The information in a caution statement relates to a condition that could

lead to damage to equipment and/or lead to invalid analytical results.

Note: The information in a note statement relates to important information that

should be read and understood before continuing.

Safety Precautions

Note: The following precautions should be followed to minimize the possibility of

personal injury and/or damage to property.

Note: Make certain that you are familiar with the contents of this manual before

working on the system.

The Probot Micro Fraction Collector is typically incorporated into an LC/MS

system. The user should follow all safety precautions, warnings, etc provided by

the manufacturer of the system(s), in addition note the items presented below:

1) Install the system in a well-ventilated laboratory. If the mobile phase includes

volatile or flammable solvents, make certain that they are not allowed to

enter the workspace.

2) If the mobile phase includes volatile or flammable solvents, avoid open

flames and sparks.

User’s Manual Probot

D960R3 xi

Warnings and Safety Precautions

3) If a leak occurs, turn off power to the instrument and remedy the situation

immediately.

4) All components of the system should be plugged into a common power line

that is directly connected to a true ground.

5) Always replace blown fuses with fuses of the same size and rating indicated

on the fuse holder and panel. Refer to Section 3.3.8 of this manual for more

information on how to replace fuses.

6) Repair or replace faulty power cords and all communication cables.

7) Many organic solvents and buffers are toxic. Make certain that you know the

toxicological properties of all mobile phases that you are using.

8) The toxicological properties of many samples may not be well known. If you

have any doubt about a sample, treat it as if it contained a potentially

harmful substance.

9) Wear protective eye goggles when handling mobile phases or operating the

instrument. An eye wash facility and a sink should be close to the unit. If

any mobile phase is splashed on the eyes or skin, wash the affected area

and seek medical attention.

10) Dispose of all waste mobile phase in an environmentally safe manner that is

consistent with all local regulations. Do not allow flammable and/or toxic

solvents to accumulate. Follow a regulated, approved waste disposal

program. Never dispose flammable and/or toxic solvents through the

municipal sewage system

11) Wear protective eye goggles when handling fused silica tubing (i.e.

installation, cutting etc.)

12) If a buffer is used as a part of the mobile phase, flush the system with

several volumes of a methanol/water (50/50) solution before it is shut down.

This will prevent salt buildup inside the unit.

13) Do not use the instrument in ways other than those indicated in the

instructions given in this manual.

xii D960R3 User’s Manual Probot

DECLARATION OF CONFORMITY

We

declare that our product

LC Packings Nederland BV

A Dionex Company

Abberdaan 114

1046 AA Amsterdam

The Netherlands

Probot Micro Fraction Collector

is in confirmation with the following documents:

# EEC directives 89/392, incl. 91/368 and 93/44 (machine safety) and EEC

directives 73/23 and 93/68 (low voltage safety), applied with the following

standard:

EN61010-1 Safety requirements for laboratory equipment

(Class I, Installation cat. II, Pollution degree II)

WARNING

# EEC directives 89/336 and 92/31 (EMC requirements), applied with the following

EN 50081-1 Generic emission standard

EN 50082-1 Generic immunity standard

EN 61000-3-2 Harmonic current emissions

LC Packings will not accept any liability for damages direct or indirect

caused by connecting this instrument to devices which do not meet relevant

safety standards.

standards:

Use shielded cables and connectors for all remote connections.

Amsterdam, January 11, 2001

User’s Manual Probot

D960R3 xiii

Robert van Ling, QA manager

CE Declaration

[This page intentionally left blank]

xiv D960R3 User’s Manual Probot

CHAPTER 1

1.1 Features of the Probot Micro Fraction Collector

Introduction

The LC Packings Probot Micro Fraction Collector is a robotic fraction collector

that can be used to collect samples from a capillary HPLC or CZE system and

deposit onto targets such as a MALDI mass spectrometer target, a PVDF

membrane (e.g. for protein sequencing), a nitrocellulose membrane or a micro

titer plate.

The heart of the unit is a robotic table that can be positioned in the X, Y and Z

directions by means of 3 stepper motors under the control of a personal

computer and the Carrier software package. The table can be driven in either

a linear or circular motion and the distance from point to point, the time spent at

a point and the speed of movement are readily programmed. A reference position

is defined by the system, and the user can select a starting position as well as a

park position (where the plate should be moved to during rest periods). Various

adapter tables are available for carrying the different targets.

When the Probot Micro Fraction Collector is employed with the µCarrier

software, the system provides the following features:

High precision X-Y-Z movement of the table – any position within the working

area can be programmed with a resolution down to ± 2 µm.

Smooth operation – results in no vibration of the needle, which is essential for

nanoliter spotting and smooth UV-detection.

Short capillary connection between outlet and needle – extremely low dwell

volume.

Fully automated adding of matrixes or make-up solutions – simplifies spotting

Capillary/Nano LC fractions onto MALDI targets. The matrix can either be

added before the needle (µ-Tee) or co-axially at the needle tip (standard Tee).

Dual-Collection mode - a fraction can be split between two sample carriers

simultaneously, i.e., a MALDI/MS target and a well plate, or a PVDF

membrane. The split ratio is programmable and all sample vessels, including

1536 well plates can be used.

User’s Manual Probot

D960R3 1-1

Introduction

µ

1.2 General Design of the Probot Micro Fraction Collector

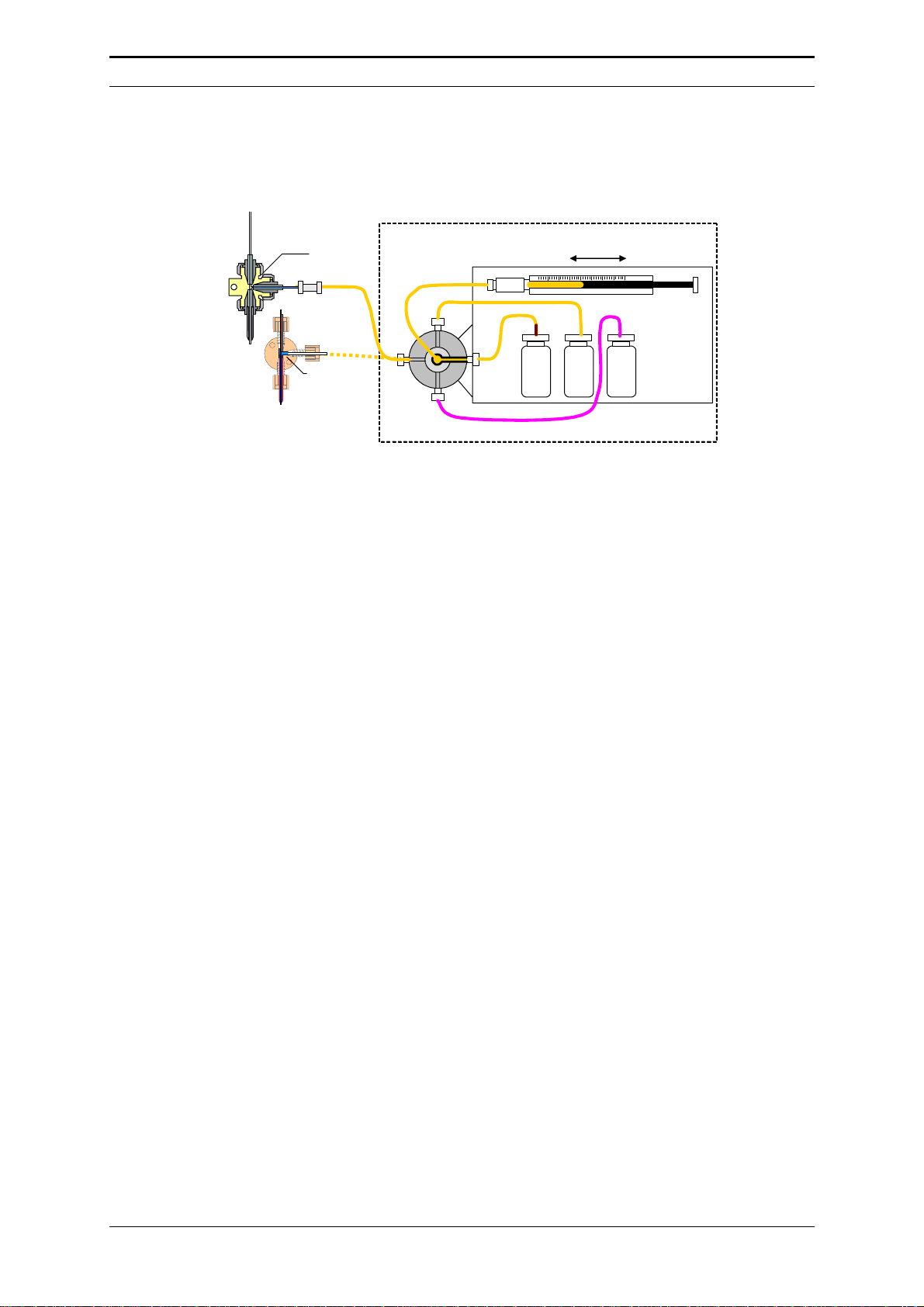

The general configuration of the system (with sample deposition on a MALDI

target and the Dosage Module option) is presented in FIGURE 1-1.

UltiMate UV Detector

Flow Cell

Probot

Target

Table

From LC/CZE

Z

Y

Rotary

Valve

System

X

-Tee

Union

Needle

Capillary

Waste

Dosage

Module

Syringe

Vials

Fill

Wash

FIGURE 1-1 General Configuration of the Probot Micro Fraction Collector

The Probot Micro Fraction Collector is supplied with a µ-Tee connection

(FIGURE 1-1). The lower end of the needle Tee holds a hollow needle in which a

fused silica capillary is mounted, the horizontal inlet is used to add reagent (e.g.

a matrix solution) to the sample using the Dosage Module and the upper

connection is connected to the LC/CZE system (e.g. the capillary flow cell outlet

of the UltiMate UV detector).

1-2 D960R3 User’s Manual Probot

Introduction

The following options are available for the Probot:

Manual Control Unit – allows for moving the sample table manually.

Dosage Module – The dosage module consists of a 4 way rotary valve with a

syringe drive and a 100 L syringe. It can be used in different modes:

- Continuous Flow Mode – a matrix solution/reagent is added on a

continuous basis (nL/min to µL/min).

- Dosage Mode –a user-defined volume is added to each sample.

- Wash Mode – the needle can be entirely flushed to avoid crystallization of

the matrix solution.

µ-Tee for Matrix Addition – allows for adding the matrix solution before the

needle directly in the Nano flow path (default configuration).

Standard Needle Tee – allows for adding the matrix solution through the

hollow needle co-axially at the needle tip (supplied with the instrument).

Camera Option – A camera kit (P/N 160590) is available which allows for easy

monitoring of the needle and target(s) in conjunction with µCarrier 2.x or a

standalone monitor.

Pipetting Option – The pipetting option (P/N 161072) allows for pipetting from

a source plate (e.g. a well plate) to a destination plate (e.g. MALDI target). It

consists of a Teflon tube (45 cm, I.D. 250 m) with fittings and a fused silica

capillary (15 cm, O.D. 280 m, I.D. 100 m).

Waste Removal Option – allows the user to remove undesired portions of the

separation (‘waste’) without the need to spot them onto the target. A vacuum

can be applied to draw the solvent into a waste container.

User’s Manual Probot D960R3 1-3

Introduction

1.3 Front View of Probot

Light Pencil

Light Switch

Rotary Valve LEDs

FIGURE 1-2 Front View Probot - Doors and Needle Cover Removed

Power Switch

µ-Tee

with

Needle

Camera

(optional)

Target

Table

Adapter

X-Y-Z Drive

Dosage

Module

(optional)

1.4 The Manual Control Unit

X Axis Control Buttons

Y Axis Control Buttons

Z Axis Control Buttons

Mode Buttons

Mode LEDs

FIGURE 1-3 Manual Control Unit

1-4 D960R3 User’s Manual Probot

1.5 Rear View of Probot

Introduction

VIDEO out

POWER

Connector

RELAY

Connector

INTERLOCK

Connector

RS-232

Connector

FIGURE 1-4 Rear View Probot

1.6 Control of the Probot Micro Fraction Collector

The Carrier Application Designer software, which is a Windows® based program

is used to control all functions of the Probot Micro Fraction Collector and to

support time based fraction collection. It can be used for peak collection in

conjunction with any software package that allows for peak detection (e.g. the

LC Packings CHROMELEON

contact closure signals). Fractionating can then be controlled by the TTL inputs

“Peak Start’, ‘Peak Top’ and ‘Peak End’ of the Probot Micro Fraction Collector.

Software) and that can provide control signals (e.g.

START

Connector

ANALOG IN

Connector

TTL IN

Connector

REMOTE

Connector

User’s Manual Probot D960R3 1-5

Introduction

1.7 About this Manual

This manual describes the LC Packings Probot Micro Fraction Collector and

includes the following information:

CHAPTER 2: Installation and Getting Started describes how to install the

Probot and the

performed to setup the system, defines how to define a table and targets, set up

a task list with the

CHAPTER 3: Maintenance and Troubleshooting describes a variety of

maintenance procedures to optimize the performance of the Probot Micro

Fraction Collector. In addition, it discusses how the operator can determine the

cause of a difficulty in the operation of the instrument and includes a list of

spare/replacement parts.

CHAPTER 4: Specifications presents the specifications of the Probot.

In addition, a number of appendices discussing different topics in more details

are included:

Carrier Software. It includes the various steps that should be

Carrier software and prepare the system for operation.

APPENDIX A: Dosage Module Purge Routine provides a step-by-step procedure

of how to purge the syringe and tubing of the dosage module properly.

APPENDIX B: Peak Collection in Conjunction with CHROMELEON® Software

discusses the setup of the CHROMELEON and the µCarrier software packages

and the Probot for peak collection.

APPENDIX C: Table Alignment Instructions

are recommended whenever the instrument has been relocated or shipped.

APPENDIX D: The Vacuum Waste Removal Option describes the features and

usage of this option in conjunction with the CHROMELEON software.

APPENDIX E: Installing and Using the Belkin USB Video Adapter describes the

installation and usage of the Belkin VideoBusII Image Capture Device.

If you are using the Probot Micro Fraction Collector in conjunction with the

LC Packings UltiMate System and/or CHROMELEON software, please refer to the

documentation provided with these products for supplemental information.

The Probot Micro Fraction Collector is used with equipment supplied by other

manufacturers (e.g. a mass spectrometer). The manuals provided with these

systems should be consulted for additional information (e.g. interfacing).

discusses alignment procedures that

The manual provides basic information about how to install, setup and use the

µCarrier software package. In addition, it provides information about defining

tables and targets and how to control the Probot Micro Fraction Collector. For

more detailed information how to use the

software manual provided on the

Note: This manual covers the Probot with S/N 1120 or higher and with the

standard Needle-Tee or the Micro-Tee installed (factory installed since January

2004). If you are using instruments with a serial number lower than 1120, please

refer to the documentation provided with the instrument.

1-6 D960R3 User’s Manual Probot

Carrier installation CD ROM.

Carrier software package refer to the

CHAPTER 2

2.1 Installation

Installation and Getting Started

The instructions provided below are provided for installation of the LC Packings

Probot Micro Fraction Collector as part of the LC Packings Capillary HPLC

System or for installing the instrument as a stand-alone component in an HPLC

system. When the Probot Micro Fraction Collector is used in conjunction with the

UltiMate system and the FAMOS Microautosampler, please refer to the User’s

Manuals supplied with these units for additional information.

Chapter 2 provides the following installation information:

Removing Shipping Components (Section 2.3 )

Installing the Probot with the UltiMate Capillary HPLC System (Section 2.4)

Electrical Connections (Section 2.4.1).

Fluidic Connections (Section 2.4.2).

Software Installation (Section 2.5).

Introduction to the Carrier (Section 2.6).

User’s Manual Probot

D960R3 2-1

Installation and Getting Started

2.1.1 Location of Probot in the Laboratory

The Probot Micro Fraction Collector should be installed in a facility with the

following environmental conditions:

The temperature range should be maintained between 10 and 40

o

C. The

system should be installed in an area in which the temperature is fairly

constant (do not place the system near a window, an air conditioning duct or a

heating duct). The humidity should be maintained between 20 and 80 %

relative humidity.

If flammable or toxic solvents are to be used, a suitable ventilation system

should be provided.

The use of open flames in the laboratory should be prohibited.

Corrosive vapors or dust should not be present as these materials can

adversely affect the long-term performance of the system.

The Probot Micro Fraction Collector requires approximately 480 mm (18.9”) of

linear bench space. The lab bench should be capable of supporting the entire

system (for the LC Packings

UltiMate, FAMOS and Switchos II, we recommend

that the lab bench be capable of supporting at least 100kg (225 lb.). The power

consumption of the Probot is 100 VA (the power consumption of the

UltiMate

Capillary HPLC System is 250 VA and of the FAMOS Microautosampler it is

250 VA).

DANGER

Danger: The Probot Micro Fraction Collector must be connected to a power

source that is connected to a true ground. In addition, all other components of

the system (e.g. the HPLC pump, the detector) should be connected to the same

ground.

CAUTION

Caution: Do not install the Probot Micro Fraction Collector in areas subject to

shock, dust, or in direct sunlight.

Note: It is recommended that you check the alignment whenever the instrument

has been moved (e.g. after shipping or relocation of the instrument). See

APPENDIX C for more details.

2-2 D960R3 User’s Manual Probot

Installation and Getting Started

2.2 Unpacking

When the Probot Micro Fraction Collector is received, carefully unpack the unit

and verify receipt of all components according to the packing list (some

components include sub-packing lists). It is recommended that all packing

materials be saved in the event that it is necessary to return any item to the

factory.

CAUTION

Caution: When lifting the instrument from the shipping container, make sure that

the unit is kept upright. Lift the unit by placing your hands under the instrument.

CAUTION

Caution: The instrument weighs 23 kg. When the unit is being unpacked and

placed on the laboratory bench, take care to ensure that suitable support is

provided at all times.

If there is external damage to the shipping box, the damage should be reported

to the shipping agent and LC Packings upon receipt of the goods. If internal

damage is observed or if any items are missing, this should be reported to the

shipping agent and to LC Packings as soon as it is observed.

CAUTION

Caution: If there is any apparent damage to the instrument, the user should

investigate the nature of the damage before plugging the unit into the mains to

ensure that powering up of the instrument will not create a hazardous condition

or damage internal components. If the damage appears significant, call

LC Packings or its local representative before connecting the unit to the mains.

2.3 Removing Shipping Components

To ensure that the Probot Micro Fraction Collector is not damaged during

shipment, several components are secured before the unit is packed. It is

necessary for the user to remove the brackets securing these items before the

unit is used. The top cover must be removed to access these brackets.

CAUTION

Caution: Do not operate the Probot Micro Fraction Collector with the safety

brackets installed.

CAUTION

Caution: Do not discard the safety brackets. Whenever the instrument needs to

be shipped, the safety brackets must be re-installed to avoid any damage before

the instrument is moved or shipped.

User’s Manual Probot D960R3 2-3

Installation and Getting Started

2.3.1 Removing the Top Cover

To remove the top cover of the Probot:

Remove the needle cover that covers the needle tee.

a)

Remove the left door and right door by simply lifting them few centimeters

b)

(item 1; FIGURE 2-1).

Rear Cover

Top Cover

Needle Cover

1

2

3

4

FIGURE 2-1 Removing the Covers – Left Side View

c) Remove the screw on the left side (item 2; FIGURE 2-1) and the screw on

the right side that hold the rear cover. Remove the rear cover.

d)

Remove the two black screws on the lower left side (item 3, 4; FIGURE 2-1)

and the two screws on the lower right side that hold the top cover.

1

2

FIGURE 2-2 Removing the Rear Cover

e) Remove the two screws (item 1, 2; FIGURE 2-2).

Carefully lift the top cover.

f)

CAUTION

Caution: When replacing the covers, take care not to bend or damage any tubing

or cable.

2-4 D960R3 User’s Manual Probot

Installation and Getting Started

2.3.2 Drive Table Safety Brackets

Two safety brackets (two pieces of metal) are used to secure the drive table as

shown in FIGURE 2-3.

To remove the drive table safety brackets:

Remove the top cover as described in Section 2.3.1.

a)

Remove the piece of styrofoam supporting the table unit.

b)

Unscrew the four screws that hold the brackets in place (item 1-4;

c)

FIGURE 2-3).

Remove the brackets.

d)

Replace the covers.

e)

1

2

4

FIGURE 2-3 Removing the Safety Brackets - Location of the Screws

CAUTION

Caution: Do not keep these screws in the original holes inside Probot. The

movement of the Probot table may be seriously impaired by these screws!

Note: Keep all screws and the two safety brackets in the accessory box in case

it is necessary to move the Probot in future.

3

Note: It is recommended that you check the alignment whenever the instrument

has been moved (e.g. after shipping or relocation of the instrument). See

APPENDIX C for more details.

User’s Manual Probot D960R3 2-5

Installation and Getting Started

2.4 Installing the Probot with the UltiMate Capillary HPLC System

The following section describes how to install the Probot Micro Fraction Collector

as a component in the LC Packings UltiMate Capillary HPLC system.

2.4.1 Electrical Connections

The Probot Micro Fraction Collector is controlled by the Carrier software

package using a serial communication port of the personal computer (PC). In

addition, the Probot can be controlled by external events (e.g. START, TTL IN).

A manual control unit can be connected which allows for manual movement of

all three axes.

All electrical connections are made on the rear panel of the instrument

(FIGURE 1-4).

CAUTION

Caution: Avoid touching the electrical contacts on the terminal strips.

Electrostatic discharges could damage internal components. The manufacturer

will not accept any liability for damages directly or indirectly caused by

connecting the Probot Micro Fraction Collector to instruments which do not meet

relevant safety standards.

2.4.1 A RS-232 Connector

Connect the RS-232 cable to the RS-232 connector on the Probot and to the

COM port of the personal computer.

TABLE 2-1 The Probot RS-232 Communication Cable

Probot (9-pin male) PC (9-pin female) Description

2 3 TxD

3 2 RxD

5 5 Ground

7 7 Reset

2.4.1 B START Connector

If the external start feature is used, connect the Start Cable to the START

connector on the Probot and to the device that will provide the start signal for

the Probot (e.g. a TTL output of the UltiMate Micropump or a relay output of the

FAMOS).

TABLE 2-2 The START Cable

Input Pin No. Color Code Description

Start 7 lilac Start input

Ground 9 black Ground connection

CAUTION

Caution: If the controlling device does not use a switch or relay contacts, make

certain that the polarity is correct (e.g. connect the ground pin of the Probot to

the ground pin of the controlling device). The output signal of the controlling

device must be TTL level compatible.

2-6 D960R3 User’s Manual Probot

Installation and Getting Started

2.4.1 C REMOTE Connector

Connect the manual control unit to the REMOTE connector.

2.4.1 D TTL IN Connector

The TTL IN connector is used for fraction collection. The TTL input provides four

control signals as presented in TABLE 2-3.

TABLE 2-3 The TTL Cable

Input Pin No. Color Code Description

TTL1

TTL2

TTL3

TTL4

Ground

1

3

5

7

9,11,13,15

Red Peak Start

Orange Peak End

Yellow

Green

Blue

Peak Top

n/a - reserved option

Ground Connection

Refer to APPENDIX B for more details and an example describing how to control

the Probot by the TTL inputs using the peak detection functionality of the

CHROMELEON software.

CAUTION

Caution: If the controlling device does not use a switch or relay contacts, make

certain that the polarity is correct (e.g. connect the ground pin of the Probot to

the ground pin of the controlling device). The output signal of the controlling

device must be TTL level compatible.

Note: If you are using a TTL output (e.g. of the UltiMate Micropump), the control

logic will be inverted (e.g. an inactive output of the Micropump will be recognized

as an active input by the Probot).

2.4.1 E INTERLOCK Connector

The INTERLOCK connector is used if the Probot is to be installed in conjunction

with a system that is operated at high voltage (e.g. a CZE system). If connected,

the entire system can be shut down to avoid any hazardous situation. Connect

the Interlock Cable to the shut down input of your system (TABLE 2-4).

TABLE 2-4 The INTERLOCK Cable

Output Pin No. Color Code Description

Relay

Ground

- 2,3 - (internal jumper)

1 Brown

4 Yellow

6,7,8 green, blue,

lilac, black

Interlock contact closure

Ground connection

2.4.1 F RELAY Connector

The Probot provides 4 programmable relay outputs. Connect the input(s) of the

device(s) to be controlled to the RELAY output(s) using the Relay Cable to meet

the needs of your application (TABLE 2-5).

User’s Manual Probot D960R3 2-7

Installation and Getting Started

TABLE 2-5 The RELAY Cable

Output Pin No. Color Code Description

1 brown Relay 1, normally open

Relay 4

Relay 3

Relay 2

Relay 1

2 red Relay 1, common

3 orange Relay 1, normally closed

4 pink Relay 2, normally open

5 yellow Relay 2, common

6 green Relay 2, normally closed

8 blue Relay 3, normally open

9 light blue Relay 3, common

10 lilac Relay 3, normally closed

11 gray Relay 4, normally open

12 white Relay 4, common

13 Black Relay 4, normally closed

2.4.1 G ANALOG IN Connector

This input is reserved for future use.

2.4.1 H VIDEO Connector

If the camera option is installed in your Probot, connect the BNC type connector

of the VIDEO output to the monitor (e.g. P/N 160567) using the connecting

cable provided with the camera.

2.4.1 I POWER Connector

Since the Probot Micro Fraction Collector is fitted with a universal power supply

for input voltages from 90 to 260 V (47 - 62 Hz), manual setting of the supply

voltage is not required. The power cord should be inserted in the black socket on

the left side of the rear panel (FIGURE 1-4).

CAUTION

Caution: Make certain that the system is properly grounded to a true earth

ground. Connecting the instrument to an ungrounded power line can cause

injuries and serious damage to the system.

2-8 D960R3 User’s Manual Probot

Installation and Getting Started

2.4.2 Fluidic Connections for Fraction Collection

2.4.2 A Connecting the µ-Tee for Matrix Addition

The Probot Micro Fraction Collector should be installed as near as possible to the

UltiMate Capillary HPLC system. Since the µ-Tee is located in the center of the

cover of the unit, the Probot can be placed on either side of the LC system.

The µ-Tee as originally installed in the Probot is equipped with 30 µm I.D.

(280 µm O.D.) fused silica fractionation needle which allows for a maximum flow

rate of up to 30 µL/min (matrix solution and LC flow). To reconfigure the

instrument for a maximum flow rate up to 300 µL/min, refer to Section 3.3.5.

CAUTION

Caution: Exceeding the maximum flow rate limits specified in Section 3.3.5 may

cause the rotary valve to leak or may damage the rotary valve.

To connect the Probot µ-Tee to the flow cell outlet of the UltiMate UV Detector:

Depending on your application (e.g. capillary or Nano LC) use either a 30 m

a)

I.D. (280 µm O.D.) fused silica capillary (P/N 161473, for Nano LC) or a 100

m I.D. (280 µm O.D.) capillary (P/N 160479, for capillary LC) to extend the

outlet capillary of the flow cell (not included in the accessory kit).

Install the fused silica capillary into the upper port of the µ-Tee (FIGURE 2-4)

b)

inside the Probot using one long orange PEEK sleeve (P/N 162146), which is

provided with the Probot. Turn the fitting until it is finger tight. You should

not be able to move the capillary in the sleeve (e.g. it should be grabbed by

the sleeve).

Fused Silica Capillary

PEEK Sleeve (long)

Ferrule

Inlet for Matrix

Solution

µ-Tee

PEEK Sleeve (short)

Stainless Steel

Needle

X

Fused Silica

Needle

X = 2 - 3 mm

I.D. of the

Fractionation Needle

30 µm 30 µL/min

100 µm 300 µL/min

Maximum Flow Rate

(Matrix + LC flow)

FIGURE 2-4 The µ-Tee

c) Use a Microtight union (P/N 161497, not included in the accessory kit) and

two orange PEEK sleeves (P/N 161498) to connect the capillary to the outlet

of the flow cell (280

m O.D.).

User’s Manual Probot D960R3 2-9

Installation and Getting Started

d) Depending on your application, either connect the matrix tubing (Section

2.4.2 B) or use the blind plug provided with the accessories to plug the third

needle tee port.

2.4.2 B Connecting the Dosage Module

The Dosage Module (optional) consists of a 4 way rotary valve and a syringe

drive (FIGURE 2-5). It is used to add a reagent in continuous or in dosage mode.

Vials

Syringe with

Luer Lock

Adapter

Port 3

PURGE

Port 2

FILL

Rotary

Valve

Center

Port

Port 4

(AUX)

Port 1

PUMP

FIGURE 2-5 The Dosage Module with Rotary Valve

To connect the rotary valve and the syringe:

Connect the tubing from the needle tee to port 1 (PUMP).

a)

Connect port 2 (FILL) to one of the 3 vials. Use the tubing supplied with the

b)

accessories kit. Fill the vial with the matrix solution that fit the needs of your

application.

c)

Connect port 3 (PURGE) to one of the 3 vials. Use the tubing supplied with

the accessories kit.

d)

To use the extra wash option, connect port 4 (AUX) to one of the 3 vials.

Use the tubing supplied with the accessories kit. Fill the vial with a wash

reagent that is suitable for your application (e.g. water/acetonitrile [50/50] or

methanol).

e)

Fill the syringe with the matrix solution, remove any air bubbles and install

the syringe in the holder. Tighten the holding screw hand tight. Refer to

A.1.1 for more information how to purge the syringe.

Connect the syringe to the port in the center of the rotary valve. Use the

f)

adapter that is supplied.

2-10 D960R3 User’s Manual Probot

Installation and Getting Started

2.5 Software Installation

The following section describes the installation of the Carrier Software, Version

2.0. Please refer to the ‘Readme’ file provided on the

additional information and updated instructions.

2.5.1 System requirements

To run the Carrier software, your personal computer must fulfill the following

minimal specifications:

PC with Intel Pentium II, Celeron, AMD ATHLON, DURON microprocessor or

compatible, min. 277 MHz.

64 MB main memory.

One CD ROM drive, a hard disk with at least 20 MB free storage capacity.

SVGA-graphics adapter (at least: 800x600 pixels, 32kByte colors).

Color monitor with appropriate resolution and color specifications.

Microsoft

Windows 2000.

Windows XP (SP1 recommended), NT (Version 4.0 SR3, 5, 6),

Carrier CD ROM for

Mouse (a mouse-wheel is recommended).

One free serial COM-port for the RS232-connection to the Probot Micro

Fraction Collector.

One free USB port for the connection of the video adapter (as part of the

optional camera).

2.5.2 Installation of Carrier

To install the Carrier software:

Put the Carrier CD ROM into the CD ROM drive. If you have the Autostart

a)

function of Windows activated, the setup program will start automatically. If

Autostart is not activated, use the Windows Explorer or the

from the Windows Start menu to run SETUP.EXE on the CD ROM. All

necessary files are decompressed and copied to your computer.

b)

Select which options you want to install. If your Probot includes the camera

option with the Belkin

TM

VideoBusII, you can choose to unpack the required

drivers to a specified location on your hard disk.

c)

Respond to each dialog box of the installation program as it is presented. If

you always choose the

the default folder (e.g.

Next button, the µCarrier software will be installed in

C:\Program Files\LCP\uCarrier).

Run command

If you have chosen to copy the Belkin drivers to your PC, the installation

d)

software will tell you at some point to connect the Belkin video adapter.

Windows will automatically start the ‘New hardware found’ wizard. Enter the

location where the wizard finds the drivers installed in step b). Refer to

APPENDIX E for more details about the installation and usage of the video

adapter.

e)

After installation is completed, restart your computer.

User’s Manual Probot D960R3 2-11

Installation and Getting Started

2.6 Introduction to the Carrier Software

The following sections provide a basic introduction in the Carrier Liquid

Handling Application Designer Software (V2.0) and information of how to setup

and use the software. For more detailed information, refer to the user’s manual

of µCarrier provided with the CD ROM.

2.6.1 Key Features

To improve the ease of use, the following features have been introduced in

Carrier 2.0 and can be found throughout the program.

One window design – All relevant information is displayed in one window.

Various wizards – Easy design of sample carriers, trays and applications.

Easy file access – via the new browser pane.

‘What You See Is What You Get’ operation (WYSIWYG) – in both, the editors

and the wizards.

Basic fractionation task – Only the most important settings need to be

programmed, what can be set by default is set by default.

Advanced fractionation task – Advanced settings can be programmed to

achieve for optimized applications.

Easy file access

with preview

option.

New button opens the wizard, corresponding to the active editor

Only the most

relevant settings

are displayed.

WYSIWYG

Changes made in the settings, are

immediately visible in the Preview window

FIGURE 2-6 Sample Carrier Window

Note: Carrier 2.0 is backward compatible, e.g. you can load your old

applications in Carrier 2.0. Saving them again in Carrier 2.0 will automatically

update your programs.

2-12 D960R3 User’s Manual Probot

Installation and Getting Started

2.6.2 Design of µCarrier

The Carrier Liquid Handling Application Designer Software (V2.0) is built around

the following three basic components:

The sample carrier – represents the target (e.g. a MALDI target or a microtiter

plate), which is used. It describes the number of spots on this target and their

position relative to each other.

The tray – represents a number of sample carriers and there positions on the

table. It is required to define the position of every spot on the tray. By aligning

the sample carriers, every spot on the MALDI targets is defined with respect to

the exact X, Y and Z coordinate relative to the needle of the Probot.

The application – represents all ‘rules’ (tasks) required for spotting. A

collection of spots is grouped and these groups are used within the different

tasks. Every spot is defined by its X, Y and Z coordinates, so each spot can be

found individually. This allows you to use your MALDI targets in any way you

want (e.g. you can collect two runs on one MALDI target or one run on two

MALDI targets). The application file holds the parameters for the sample

carriers, the tray and the tasks.

For each component a special wizard assisted ‘Editor’ is available.

2.6.3 The Editors and Wizards

For the ease of use µCarrier provides various wizards and editors for the design

of the sample carrier, the tray and the application:

Sample Carrier Alignment Wizard – Section 2.7.3

Sample Carrier Wizard – Section 2.8.1

Sample Carrier Editor – Section- 2.8.1

Tray Setup Wizard – Section 2.8.2

Tray Editor – Section 2.8.3

Fractionation Application Wizard - Section 2.8.4

Application Editor – Section 2.8.4

Depending on the editor which is currently active or the task that is to be done

next, the corresponding wizard starts automatically if the

2.6.4 Necessary Steps to create and run the Application

A series of basic steps is required to create and to prepare and to run your

application. For the ease of use, µCarrier V2.0 provides predefined sample

carriers and tray definitions for the most commonly used MALDI mass

spectrometer. In addition, predefined standard applications are available to get

easily started.

New button is selected.

Section 2.7.2 shows how to define applications using these definitions. Sections

2.8.1 - 2.8.4 show how to use the wizards to create new sample carriers, tray

and application.

User’s Manual Probot D960R3 2-13

Installation and Getting Started

2.6.5 The Main Toolbar

The main toolbar (FIGURE 2-7), which is presented in the upper left of the main

window of µCarrier (FIGURE 2-10) presents several buttons:

FIGURE 2-7 The Main Toolbar

Removes the tray and all tasks in the task list and starts the

wizard corresponding to the editor which is currently active.

This button shows or hide the browser pane on the left and

enables or disables easy file access.

Opens an existing sample carrier, tray table or application file.

The sample carrier files have the extension ‘.rck’, the tray files

have the extension ‘.try’ and the application files have the

extension ‘.app.’

/

/

Saves a (new) sample carrier, a tray table or an application.

Activates the

Sample Carrier Editor to create new or modify

existing sample carriers.

Activates the

Tray Editor to create new or modify existing trays.

Tray layout and spot grouping is available in this editor.

Activates the

Application Editor to create new or modify

existing applications. Grouping of sample carrier spots is also

available.

Activates

Manual Device Control to control the Probot table and

dosage module manually.

Opens the manual control panel of the robot drive.

Runs the application

Pauses the application (only active during run)

Aborts the application (only active during run)

2-14 D960R3 User’s Manual Probot

Installation and Getting Started

2.7 µCarrier – First Steps

2.7.1 Launching µCarrier

When µCarrier is opened for the first time, the following window appears

(FIGURE 2-8):

FIGURE 2-8 The Run a Real Device? Window

a) Choose the Yes button if you want to control Probot (all available COM ports

will then be scanned until µCarrier will detect the instrument), choose the

button if you want to launch the software in offline mode.

No

Note: Depending on the position of the table, one or more of the security

switches may be activated. If a switch is activated, a corresponding message is

presented and the Probot will perform reference runs.

b) In the next window that appears you will be asked whether or not a dosage

module is present in your Probot. Choose the

present or choose the

No button if not (FIGURE 2-9).

Yes button if there is one

FIGURE 2-9 The Dosage Module Installed? Window

c) After initializing of the Probot (when running in ‘real device’ mode only) the

Carrier software is ready and the Main Screen will be presented

(FIGURE 2-10).

Note: After the initial launch of µCarrier, the last saved application is

automatically loaded when µCarrier is opened. In the case the last saved

application could not be loaded, µCarrier will present the Main Screen

(FIGURE 2-10) again.

User’s Manual Probot D960R3 2-15

Installation and Getting Started

FIGURE 2-10 The Main Window of Carrier with Table

If desired, Carrier can be configured so that it does not show some the previous

dialogs on each start. Select the

Options menu in the main window to open the

Options Window (FIGURE 2-10) and adjust the ‘Startup’ settings (e.g. select

‘Always start the software in the real device control mode’ to start up in real

device control node).

FIGURE 2-11 The Settings Window –Startup Section on the Main Tab

2-16 D960R3 User’s Manual Probot

Installation and Getting Started

2.7.2 Using the Predefined Applications, Trays and Sample Carriers

In addition to the predefined sample carriers and trays, µCarrier V2.0 provides

ready-to-use applications for the most common used MALDI MS instruments.

These applications are based on a ‘Basic fractionation task’, which is a time

controlled collection by default. It requires only three steps to run such an

application.

Loading a Predefined Application – Section 2.7.2 A

Alignment of the Sample Carriers– Section 2.7.3

Checking and Modifying Application Parameters – Section 2.7.4

As an example, the following sections will present in detail how to use and

modify the predefined application for a time controlled fractionation application

onto 6 Applied Biosystems® OptiTof

not meet the specific needs of your application, it is likely that it can be used

with minor modification.

2.7.2 A Loading a Predefined Application

24x24 targets. While this example may

a) Activate the Application Editor by selecting the ApplicationEditor button.

Select the Show Browser button to replace the list of available ‘Tasks’ by the

b)

browser pane (FIGURE 2-12).

Available

Tasks

Browser

Pane

FIGURE 2-12 Left - List of available Tasks, Right – The Browser Pane

c) Select the desired application, and then double click to load this application.

All parameters of this task are then loaded in the

the

Tray Editor (FIGURE 2-13).

User’s Manual Probot D960R3 2-17

Application Editor and in

Installation and Getting Started

Task List

Parameters

of the

selected

Task

Group

Definitions

FIGURE 2-13 Application Editor - Application loaded

All tasks of this application are loaded in the Task List and the parameters of a

selected task (row) are displayed in the right part of the

Application Editor.

Selecting a different task (row) in the table will automatically load the

corresponding parameters. The tray with the six sample carriers and all groups

are presented in the

Group Mode section, which is the lower part of the window.

2-18 D960R3 User’s Manual Probot

Installation and Getting Started

2.7.3 Alignment of the Sample Carriers

The following procedure needs to be performed to define the exact position of

the sample carriers on the table relative to the needle tip (including the ‘spotting

height’). During this procedure the table is moved manually to certain reference

positions and their coordinates (X, Y, Z) will be stored in the

Once this procedure has been performed successfully, this setup can be used as

long as the hardware has not been modified (e.g. the needle has been replaced or

bent).

Note: The proper alignment is essential to achieve optimal spotting performance.

Once the hardware has been modified (e.g. the needle has been replaced or bent

or a different table is used) or the Probot has been moved, it is necessary to

repeat this procedure.

If the tray definition includes the exact positions of all sample carriers relative to

each other (e.g. multiple sampler carriers of the same type in predefined

positions), the µCarrier software needs only one spot as reference position to

align all carriers in one step. If the tray definition does not provide the exact

(relative) X and Y positions, the alignment has to be performed for each sample

carrier individually.

Carrier Software.

To align the sample carriers:

Open the Sample Carrier Alignment Wizard by selecting Sample carrier

a)

alignment

from the Tools menu. The introduction window (FIGURE 2-14)

presents the origin of reference sample carrier as red diagonal cross.

Red ‘X’ represents the

origin of the reference

sample carrier.

Current coordinates.

Z = Spotting Height

FIGURE 2-14 Introduction Screen of the Sample Carrier Alignment Wizard

b) To select one or more carriers, draw a frame around the origins (the red ‘+’)

of all sample carriers while keeping the left mouse button pressed. After the

selection the origin of the reference carrier is presented by a red ‘X’

(FIGURE 2-14).

User’s Manual Probot D960R3 2-19

Installation and Getting Started

c) Follow the steps of the wizards by choosing the Next button. The origin of

the reference sample carrier will start to blink for a better identification.

d)

Choose the ‘Manual Drive Panel’ of µCarrier (Section 2.8.5 A) or the ‘Manual

Control Unit’ of the Probot (Section 2.8.5 B) to move the table. Select one

option, and then choose

Enter the ‘step width’ (e.g. 0.1 mm) and choose Next.

e)

Now move the table by either the ‘Manual Drive Panel’ or the ‘Manual

f)

Control Unit’ (as selected in step d) to that the needle tip is centered above

the reference position of the reference target.

Next.

FIGURE 2-15 Aligning the Reference Position using the Camera

g) Finally, adjust the table height (Z axis) so that the needle tip just touches the

surface of the target. This adjustment is the ‘spotting height’ which will be

used during spotting for all carrier positions (selected in step b).

Note: The optimal distance of the needle tip to the carrier surface depends on

your application parameters (e.g. the LC flow rate, the matrix flow rate, etc.).

h) Once all axes are moved to their proper positions confirm by Next, and then

wait for the message box telling you the sample carriers have been aligned

(FIGURE 2-18). This can take a few seconds. When finished, the table will

move to home position

FIGURE 2-16 The Alignment Procedure of one (or more) Carriers is finished

i) Repeat steps a) – h) for any unaligned sample carrier on the table.

Exit the wizard and save the application.

j)

2-20 D960R3 User’s Manual Probot

Installation and Getting Started

2.7.4 Checking and Modifying Application Parameters

The next step is to check and/or modify the application parameters. After the

application parameters have been checked/modified, the alignment of the sample

carriers should be checked (Section 2.7.3).

2.7.4 A Checking and Modifying Groups

All predefined applications have a tray setup with the maximum number of

sample carriers on the tray, one group per sample carrier and a meander spotting

pattern.

1

FIGURE 2-17 6 Sample Carriers, 1 Group on each Sample Carrier

Check if this groups setup fulfills the requirements of the application you need to

perform. If not, the group setup can be modified as follow:

Select a group in the group list (e.g. click on ‘LC_Collect_1 in the table).

a)

To remove all spots from this group, use the Clear Group button.

b)

To assign non-grouped spots to a certain group, mark the spots with the

c)

mouse cursor.

To change the spotting pattern, select the appropriate spotting pattern from

d)

the drop down menu.

e)

Add a new group with the Create a new Group button.

User’s Manual Probot D960R3 2-21

Installation and Getting Started

f) To remove the group, make sure that it is not used as ‘Collect group’ or

‘Standby position’ in a task, e.g. ‘Users’ must be ‘0’ (item 1, FIGURE 2-17).

Unselect if appropriate, and then use the

Note: There is no need to change group settings of groups you do not intend to

use them. As an example, if you want to spot on the first target only, you do not

need to modify the groups 2 - 6. Just make sure that your task list is correct and

that these groups are not used.

2.7.4 B Checking/Modifying the Tasks List

If you changed the number of groups or if you want to perform fewer runs than

the total number of this predefined application, you may have to modify the task

list (FIGURE 2-18), e.g. to add, delete or modify tasks.

Delete Group button.

Tasks

FIGURE 2-18 Available Tasks, Task List and Task Description

Task List

Task Description

To delete a task in the task list, select the task and press the Del key on the

keyboard or click the right mouse key, and then select ‘Delete’.

To add a task to the task list:

selecting the

To add a new task, double click on the required task from the ‘Tasks’ section

b)

Show Browser button ((FIGURE 2-18)).

Present ‘Tasks’ section (e.g. if the browser pane is currently visible) by

a)

presented in the left side of the window. The new task will be added to the

bottom of the task list (FIGURE 2-18).

Note: Selecting a task in the ‘Tasks’ section with one mouse click (rather than

double-click) will display the task description in the right side of the Application

Editor window (FIGURE 2-18).

c) Drag and drop the task to the desired position in the task list.

Check or modify the task parameters (Section 2.7.4 C).

d)

2-22 D960R3 User’s Manual Probot

Installation and Getting Started

2.7.4 C Checking/Modifying the Task Parameters

To check or modify the task parameters, select the task that needs to be

checked in the task list. The task parameter box (e.g. Basic Fractionation) will be

presented in the

Application Editor window (FIGURE 2-19).

Task List Task

Parameters

FIGURE 2-19 Task List and Parameters

FIGURE 2-20 Basic Fractionation Task

The most common task, which is to be performed with the Probot, is a time

controlled fractionation task. The ‘Basic Fractionation’ task is provided to

simplify the setting up of such a task, and it needs very few parameters to run it.

FIGURE 2-20 shows the parameters box. The

Basic Fractionation box is divided

in three sections.

1 – How… - The column flow rate and the matrix flow rate is specified (as

multiples of the column flow rate) via this box. The

prior to fractionation

option compensates the dilution of the matrix solution in

Dispense 10 l of matrix

the case the needle rests in the wash vial between runs.

2 - When… - All timing related parameters are programmed via this box. The

Collection time is the maximum spotting time of the corresponding task.

Regardless of the number of available spots, the current task will be aborted if

User’s Manual Probot D960R3 2-23

Installation and Getting Started

the time elapsed after the task was started exceeds this limit. In the case all

spots have been processed, the run also stops. In both cases µCarrier will

prepare the next task. The

time includes the time the Probot needs to move, to lift the table and to spot

(t

spotting = tmovement + ton spot). It can be as low as 4 seconds (with optimized

needle movement only).

3 – Where… - The positions (groups) are defined via this box. The Collect

is where the Probot collects the LC eluent (with the matrix solution).

group

Standby position is where the needle rests before and after the spotting.

The

The

Z-coordinate for in-task movement defines the height at which the table

moves from spot to spot (‘0’ represents the lowest position of the table). A

typical value is approximately 2 mm below the spotting height (which was

defined during the sample carrier alignment step, Section 2.7.3).

CAUTION

Caution: The Z-coordinate for in-task movements must ALWAYS be lower than

the spotting height (Section 2.7.3). If it’s not lower, you may scratch your

MALDI target.

Note: For faster spotting (e.g. the spotting time needs to be decreased), the

Z-coordinate for in-task movements should be as close as possible to the spotting

height (Section 2.7.3).

Time per spot(s) is the actual spotting time. This

Check all tasks in the task list and save the application under any appropriate

name.

Carrier is now ready to fractionate. To run the application in this stage,

continue with step c) of the instructions provided in Section 2.7.5.

2.7.5 Running a predefined Application

To load and to run a predefined application, perform the following steps:

CAUTION

Double-click on the application you want to run in the browser window

a)

(FIGURE 2-13) or use the

The Application Editor and the Tray Editor is updated accordingly.

b)

Caution: To verify your application, we recommend that you remove the needle

and all parts from the table so that they cannot be damaged during the

verification process.

c) Start the application by selecting the Run the application button. You can

pause the application by choosing the

can stop the application by choosing the

Open file button in the main menu toolbar.

Pause the application button or you

Abort the application button.

2-24 D960R3 User’s Manual Probot

Installation and Getting Started

2.8 µCarrier – Basics Steps

The following sections discus the basis steps of the µCarrier software. We show

how to

Create a New Sample Carrier using the Sample Carrier Wizard – Section 2.8.1.

Create a New Tray using the Tray Setup Wizard – Section 2.8.2.

Modify an Existing Tray Setup using the Tray Editor – Section 2.8.3.

Create a New Application using the Wizard – Sect. 2.8.4.

Control the Table Position – Section 2.8.5.

Measure the Column (X) and Row (Y) Distance – Section2.8.6.

The various steps are explained in detail using the following typical application

example:

A table with six rectangular MALDI target plates with 24 x 24 spots is used

for the fractionation of a NanoLC run. The LC flow rate is 300 nL/min, the

distance between columns and rows is 1.45 mm and the spot diameter is 1

mm.

The fraction collection time is 20 sec.

A MALDI matrix solution is added at a flow rate of 1.2 µL/min (= 4 times the

LC flow rate) along with the fractionation of the mobile phase.

The start of the fractionation is synchronized with the injection of the UltiMate

Capillary HPLC system and the start signal is delayed by 5 minutes.

Between the runs the needle should remain in a wash vial to prevent

crystallization of the matrix solution. Dispensing 10

to fractionation will prevent any matrix dilution.

All available spots will be used.

The application discussed here corresponds to the application that was used to

shown in the ‘µCarrier – First Steps’ section. Please refer also to the user’s

manual of the

Carrier software for more detailed information.

L of matrix solution prior

User’s Manual Probot D960R3 2-25

Installation and Getting Started

2.8.1 Create a New Sample Carrier using the Sample Carrier Wizard

If the required sample carrier is not pre-defined, it has to be created. The Sample

Carrier Wizard

an existing one.

To define a new sample carrier using the wizard:

Open the Sample Carrier Editor by choosing the sample carrier editor icon.

a)

Then choose the

assists you in creating a new sample carrier as well as modifying

New button.

The Confirm message box will be presented. Choose Yes (FIGURE 2-21) if

b)

you are willing to lose any unsaved data. If you want to keep the existing

tray and tasks setup, quit with

Cancel and start the wizard from the File

menu (New/Sample Carrier).

FIGURE 2-21 Confirm Discarding the Tray and Tasks

c) The welcome screen of the Sample Carrier Wizard is presented

(FIGURE 2-22). Select the ‘Create a new sample carrier … ‘ option and

confirm with the

Next button.

FIGURE 2-22 Sample Carrier Wizard – Welcome Screen

d) In the first step (FIGURE 2-23) the spot geometry (e.g. diameter or size and

height) will be defined. Indicate the appropriate shape and dimensions of the

2-26 D960R3 User’s Manual Probot

Installation and Getting Started

spot (well, vial). Based on this information the spot volume is calculated. In

our example the shape is ‘circular’, the ‘Diameter’ is 1.000 mm and the

‘Height’ is 0.000 mm. Enter this data and confirm with the

Next button.

FIGURE 2-23 Sample Carrier Wizard - Single Spot Specifications

Note: The dimensions of the spot are used to calculate the volume of the spot

and are used for ‘overfill control’ within the application (if this option is enabled).

MALDI targets are usually planar surfaces (height = 0) making ‘overfill control’

virtually impossible to use with MALDI targets.

Note: The shape selected does not need to match exactly the shape of the

actual spot(s) of the MALDI target. Some manufacturers use triangular spot

shapes or round and rectangular shapes on the same MALDI target. Choose the

shape that fits best with your target. Circular shape is a safe choice to begin,

because the droplets created have also a circular shape.

e) In the next step the sample carrier geometry and the orientation of the spots

relative to each other are specified (FIGURE 2-24). Select the ‘rectangular

option’ and confirm with the

Next button.

User’s Manual Probot D960R3 2-27

Installation and Getting Started

FIGURE 2-24 Sample Carrier Wizard - Sample Carrier Geometry

f) Now enter the number of spots in X and Y direction (e.g. 24 by 24 in our

example) and the distance (e.g. 1.45 mm) between the rows and the

columns. The wizard automatically presents a preview of the target

(FIGURE 2-25).

FIGURE 2-25 Sample Carrier Wizard – Sample Carrier Dimensions

g) Choose Next to save the sample carrier. You are prompted to define a name

and a directory where you want µCarrier to save the sample carrier definition

(FIGURE 2-26).

2-28 D960R3 User’s Manual Probot

FIGURE 2-26 Sample Carrier Wizard - Completed

Installation and Getting Started

h) Either quit the wizard or continue to define or modify the next sample carrier.

Sample Carrier Editor (FIGURE 2-27) offers the same settings as the wizard,

The

but all at the same screen. It is an ideal tool for experienced users and if only

small changes of existing sample carriers are required.

FIGURE 2-27 Sample Carrier Editor

User’s Manual Probot D960R3 2-29

Installation and Getting Started

2.8.2 Create a New Tray using the Tray Setup Wizard

If the required tray is not predefined, it has to be created. The Tray Setup Wizard

assists you in creating a new tray setup as well as modifying an existing one.

Open the Tray Editor by clicking the TrayEditor icon, and then select the New

a)

button.

The Confirm message box will be presented. Choose Yes (FIGURE 2-28) if

b)

you are willing to lose any unsaved data. If you want to keep the existing

tray and tasks setup, quit with

Cancel and start the wizard form the File

menu (New/Tray).

FIGURE 2-28 Confirm Discarding the Tray and Tasks

c) The welcome screen of the Tray Setup Wizard is presented (FIGURE 2-29).

Select the ‘Make a new tray … ‘ option and confirm with the

Next button.

FIGURE 2-29 Tray Setup Wizard – Welcome Screen

d) In the first step, select the sample carrier(s) you want to use from the

available sample carriers (FIGURE 2-30). If you want to place only one carrier

choose the

Next button and continue with step f).

2-30 D960R3 User’s Manual Probot

Installation and Getting Started

FIGURE 2-30 Tray Setup Wizard – Selecting a Sample Carrier

e) If you want to place multiple carriers (of the same type) press the right

mouse button, and then select the

Add multiple carriers .. ‘ option

(FIGURE 2-31). Enter the appropriate coordinates of your tray setup, the