4000 SERIES

PRODUCT SELECTION GUIDE

Surface mounted 4000 Series LCN closers feature a modern design engineered for each application, easy installation,

and superior performance. This guide is based on the desired mounting of the closer.

NOTE: For 4040 parallel mountings order “P” version to also receive PA shoe.

E X T E R I O R

D O O R

PUSH SIDE

M O U N T E D

PULL SIDE

M O U N T E D

D O U B L E

LEVER ARM

4020 4040

P4040 4110

4210*

I N T E R I O R

D O O R

PUSH SIDE

M O U N T E D

D O U B L E

LEVER ARM

4020 4040

P4040 4110

P4030 4210*

4030

* INDICATES HIGH SECURITY CLOSER. REFER TO THAT SECTION OF THE CATALOG.

“P” = PARALLEL ARM MOUNTING

S I N G L E

LEVER ARM

4110T

4040T

4210T*

PRODUCT COMPARISON

This chart shows a basic comparison of 4000 Series Closers.

Refer to the specific closer chapter for complete details.

LEVER ARM

4010 4040

4510*

D O U B L E

LEVER ARM

4010 4030

4040 4510*

D O U B L E

PULL SIDE

M O U N T E D

S I N G L E

LEVER ARM

4000T 4010T

4020T 4510T*

4040T 4030T

Available

Not available

Closer available with less than 5.0 lbs. opening force on 36" door.

**Maximum opening/hold-open point with standard template. See individual closer series

for degrees of opening per installation.

*** Advanced Variable Backcheck

1

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

©2010 Ingersoll-Rand Company

4000 SERIES

APPLICATIONS

For aluminum, hollow metal, or wood swinging doors and frames.

Can be used with hinge or pivot mounted door.

Adapter plates and other installation accessories available for

unusual conditions.

FEATURES COMMON TO 4000 SERIES

Each closer (except 4040, 4040T, 4030, 4030T) is designed for a

specific mounting; hinge side, top jamb, or parallel arm. 4040 closer

with regular or hold-open arm mounts hinge side or top jamb. P4030

& P4040 closers include 62PA SHOE required to parallel arm mount

either regular or hold-open arm.

Handed for right or left swinging doors, except 4000T, 4030, 4030T,

4040, and 4040T.

Closers to meet ADA reduced opening force requirements except

4000T.

Adjustable hydraulic backcheck cushions opening swing prior to 90°.

Separate regulation of general closing speed and latching speed.

Joints in regular arm and shoe adapt to uneven trim.

Reversible shoe to boost latching power on double lever arms.

Available in a wide range of standard or optional custom powder

coat finishes to blend with door and frame.

Plated finishes available to accent door and frame.

Not designed for exterior mounting or exposed to elements.

DESIGN ASSISTANCE

LCN has been providing reliable solutions to unique door control

problems for over 75 years. Design and specification assistance are only

a phone call away.

Contact LCN for assistance or technical information at 800-526-2400 or

FAX 800-248-1460 (Customer Service), Fax 815-879-1495 for

Application Engineering.

WARRANTY

10 year limited warranty. See General Section for complete warranty

details.

LCN’s powder coat finish surpasses 100 hours of salt spray which

is over four times the ANSI standard for corrosion resistance.

For installations where a higher level of corrosive resistance is

required, LCN offers an optional special rust inhibiting (SRI) pretreatment. Closers that combine the exclusive LCN powder coat

finish and the SRI pre-treatment exceed the ANSI standard for

corrosion resistance even further.

Plated finishes are available as an option to accent door and frame.

(SRI not available with plated finishes)

LISTINGS & APPROVALS

UL listed for self-closing doors without hold-open under "SWINGING

DOOR CLOSERS"(GVEV) file R1943.

Tested and certified under ANSI Standard A156.4 Grade One. Consult

factory for details.

Consult factory for other listings such as; cUL, California State Fire

Marshal, Bureau of Standards and Appeals.

POSITIVE PRESSURE

LCN closers have been certified for three hours by UL to be in

compliance with UBC 7-2 (1997) and UL 10C. Contact LCN for specific

details on door closer fire ratings.

FASTENERS

4010, 4010T, 4020, 4020T, 4040, 4040T, 4110, 4110T series closers are

shipped with: A standard SELF-REAMING and TAPPING SCREW (SRT)

pack contains Philips head SRT screws to install the closer 4000T series

closers are shipped with: A standard WOOD and MACHINE SCREW

(WMS) pack contains Philips head wood and machine screws to install

the closer. 4030, 4030T series closers are shipped with: A standard

WOOD and SELF-TAPPING MACHINE SCREW (WMS) pack that contains

Phillips head wood and self-tapping machine screws to install the

c l o s e r .Standard LCN thru bolts (TB) can be installed on 1 3/4” (44 mm)

thick doors with 1/4-20 machine screws. Optional thru bolt (TB) sizes

are available for 1 5/8” (41 mm) or 1 3/8” (35 mm) door thickness, but

this must be specified when ordering.

SPECIFICATIONS

Refer to ”SPECIFICATIONS” section for suggested architectural

specifications.

MATERIALS

High strength cast iron cylinder.

Forged steel main arms.

One piece forged steel piston.

Double heat treated pinion.

All weather fluid eliminates seasonal adjustments temperatures

ranging from 120° F (49° C) to -30°F.(-35° C).

High efficiency, full complement, low friction bearings.

Tamper resistant regulating screws.

Full rack and pinion hydraulic action.

Quiet, low friction track and roller combination for all single lever

arm closers.

FINISHES

Available in six standard or optional custom powder

coat finishes to blend with door and frame.

Notes:

1. For Thru Bolts, specify door thickness if other than 1 3/4” (44mm).

2 . Phillips head, metric machine screws are available, please specify.

3. LCN recommends the use of wood screws, available in optional

WMS screw packs, for wood door applications.

MAINTENANCE

Closers mounted according to LCN installation instructions require no

periodic maintenance or adjustments.

2

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

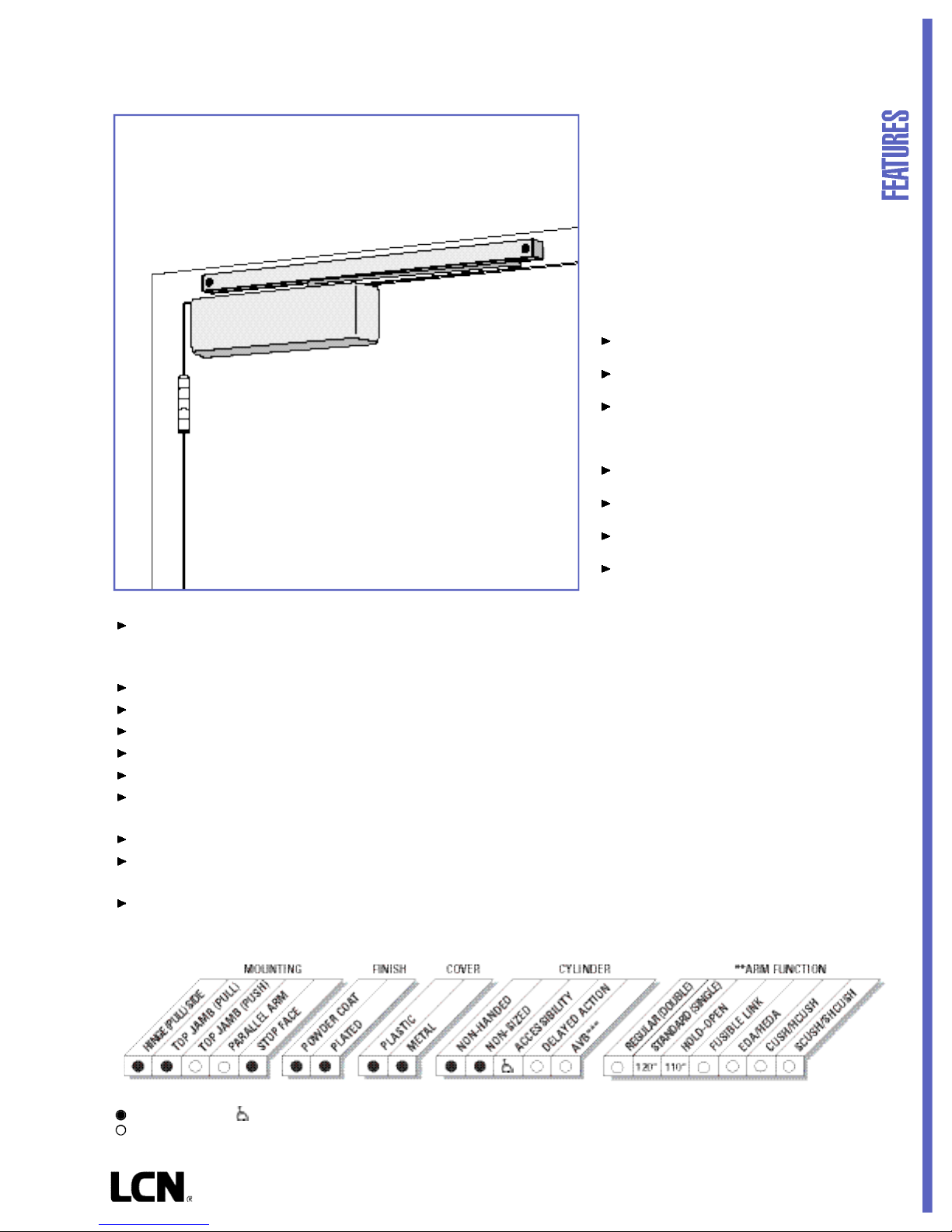

LCN 4010 SERIES

The 4010 SMOOTHEE®is LCN’s

HINGE (PULL) SIDE MOUNT

best performing heavy duty

closer designed specifically for

institutional and other rugged

high traffic applications.

Ten Million Cycles

Cast Iron

Forged Steel Main Arm

Double Heat Treated Steel

Pinion

All Weather Fluid

LCN

Fast™ Power Adjust

®

Fast & Accurate Installation

UL & cUL Listed

Standard 4010 series closer is shipped with regular arm, standard plastic

c o v e r, and self reaming and tapping screws. See 4010 Series pages

5 & 6 for options.

Size 6 (4010) cylinder for interior doors to 5’0” and exterior doors to 4’0”.

Non-sized cylinder (4011) adjustable for interior doors to 4’6” and exterior

doors to 3’6”.

Closer mounts hinge side, specify right or left swinging door.

4011 cylinder meets ADA requirements. See 4010 Series page 7.

Standard or optional custom powder coat finish.

Optional plated finish on metal cover, arm and fasteners.

Optional SRI primer for installations in corrosive conditions is available with

powder coat only.

The 4010 Series is UL and cUL listed with regular or fusible link arms for

self-closing doors.

Tested and certified under ANSI Standard A156.4, grade one.

The 4011 includes the

®

LCN

FAST™ Power Adjust,

a revolutionary visual indicator

for Spring Power Adjustment.

Available

Not available

Closer available with less than 5.0 lbs. opening force on 36" door.

**Maximum opening/hold-open point with standard template.

*** Advanced Variable Backcheck

3

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4010 SERIES

HINGE (PULL) SIDE

MOUNTING

MAXIMUM OPENING

Can be templated for 100°,

A = 5 15/16” (151 mm)

B = 11 15/16” (303 mm)

or 140°.

A = 4 3/16” (106 mm)

B = 10 3/16” (259 mm)

Hold-open points up to maximum

opening with hold-open arm.

Arm Clearance above door.

Regular arm requires C =

1 1/16” (27 mm).

Hold-open arm requires C =

1 3/8” (35 mm).

Fusible link arm requires C =

1 5/8” (41 mm).

Options

Size 6 or non-sized cylinder.

Delayed action cylinder.

Hold-open or fusible link arm.

Metal cover.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications.

Contact LCN for assistance.

Butt Hinges should not exceed 5” (127 mm) in width.

Auxiliary Stop is recommended at hold-open point or where a door

cannot swing 140°.

Reveal should not exceed 3/4” (19 mm). Fusible link arm should not

exceed 1/8” (3 mm).

3

Top Rail less than 3

Plate requires 2” (51 mm) minimum.

Clearance of 2 1/4” (57 mm) behind door required for 90° installation.

Delayed Action Add suffix “DEL” to selected cylinder.

Not available with 4016 cylinder.

Delays closing from maximum opening to approximately 70°.

Delay time adjustable up to approximately 1 minute.

/4” (95 mm) requires PLATE, 4010-18.

4

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

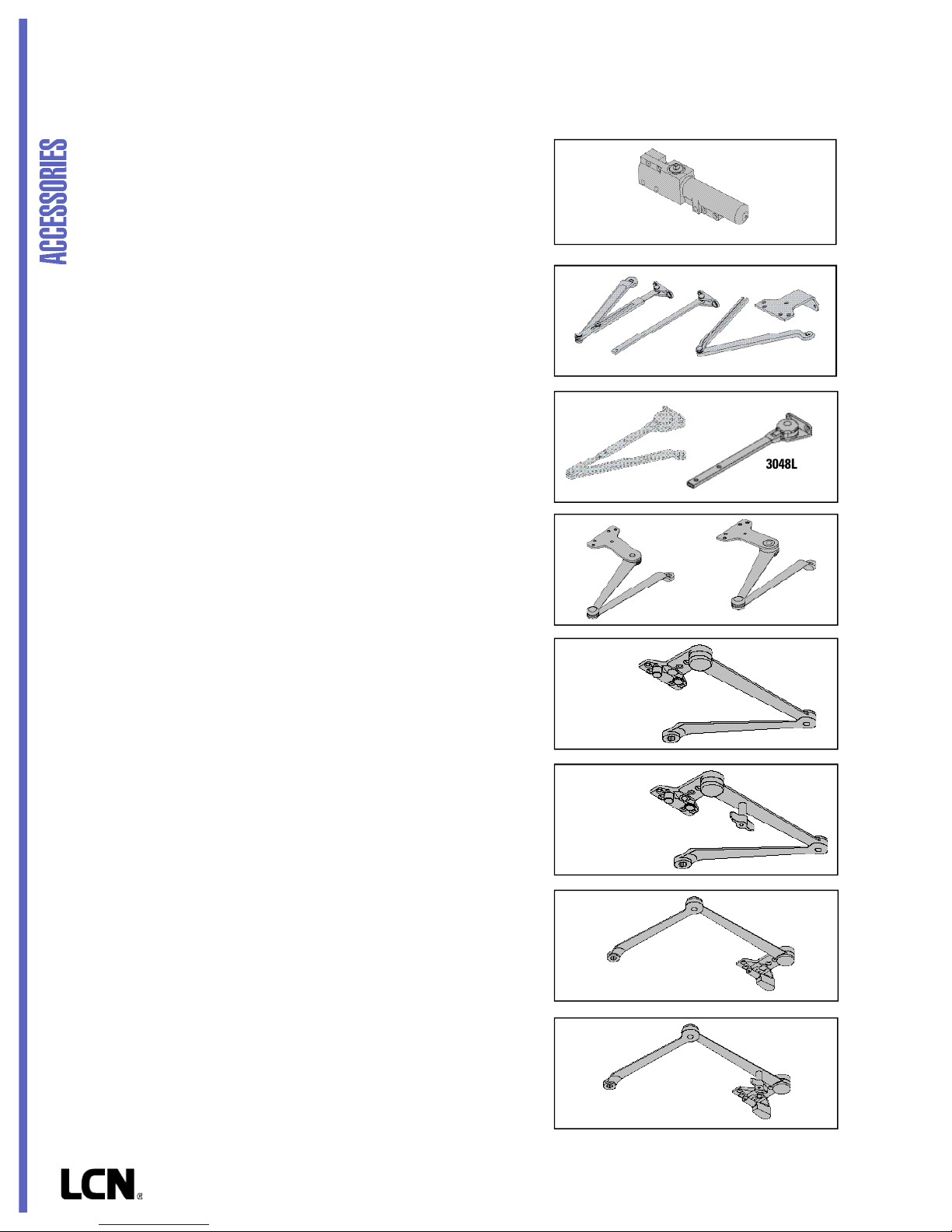

CYLINDERS

CYLINDER, 4010-3071

Standard, handed cast iron cylinder assembly.

For various applications see “Table of Sizes” on 4010 Series

page 7.

LCN 4010 SERIES

3071

COVERS

COVER, 4010-72

Standard, non-handed plastic cover.

METAL COVER, 4010-72MC

Optional, handed cover. Required for plated finishes and

custom powder coat finishes.

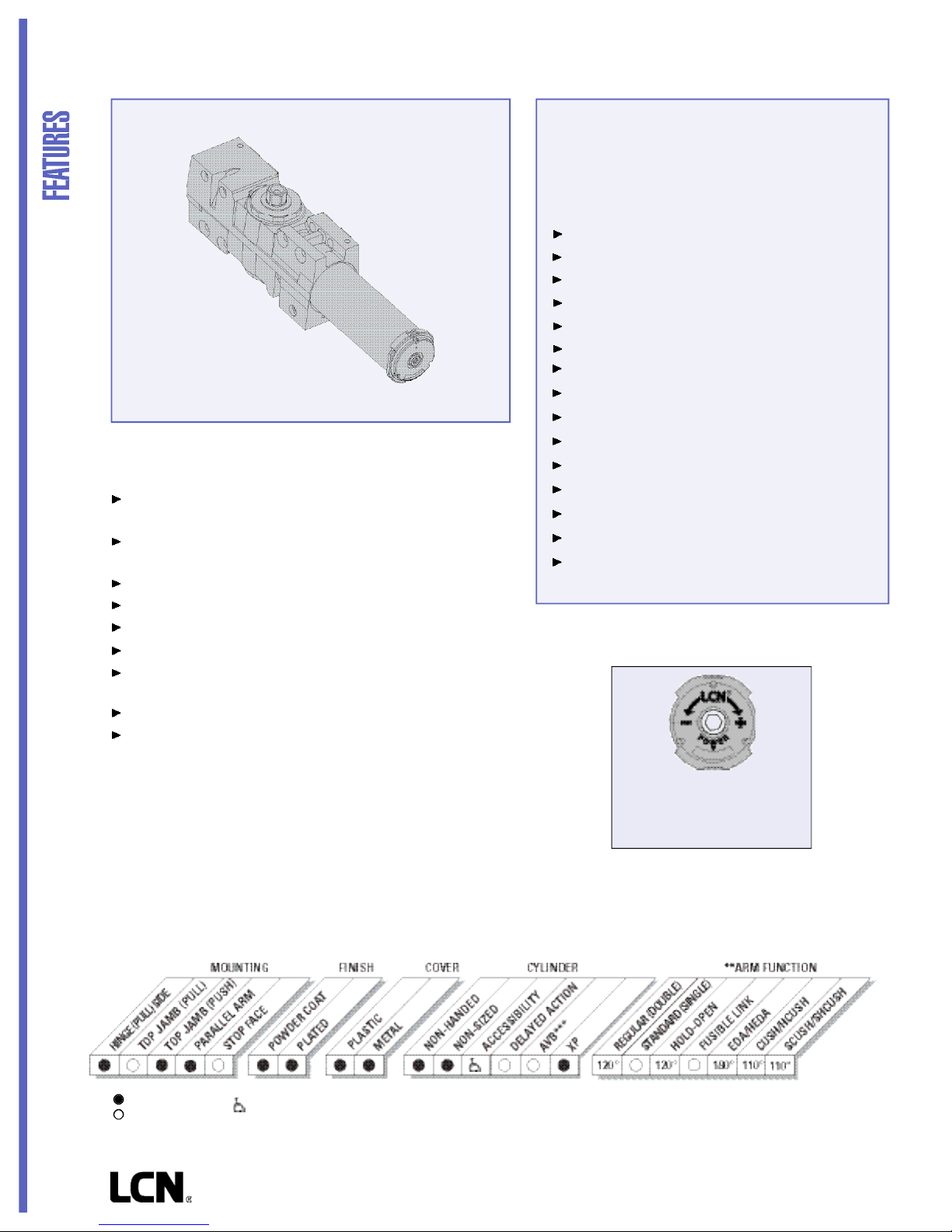

ARMS

REGULAR ARM, 4010-3077

Non-handed arm.

HOLD-OPEN ARM, 4010-3049

Optional, handed arm provides hold-open function,

72

72MC

3077

3049

adjustable at elbow.

FUSIBLE LINK ARM, 4010-3049FL

Optional, handed arm releases hold-open function when

exposed to temperatures above 165° F.

1/8” (3 mm) maximum reveal. NOTE: Check local codes

before specifing FL arms. NOT A LIFE SAFETY PRODUCT!

5

3049FL

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4010 SERIES

INSTALLATION ACCESSORIES

PLATE, 4010-18

Required where top rail is less than 3 3/4” (95 mm).

Plate requires minimum 2” (51 mm) top rail.

18

6

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4010 SERIES

TABLE OF SIZES

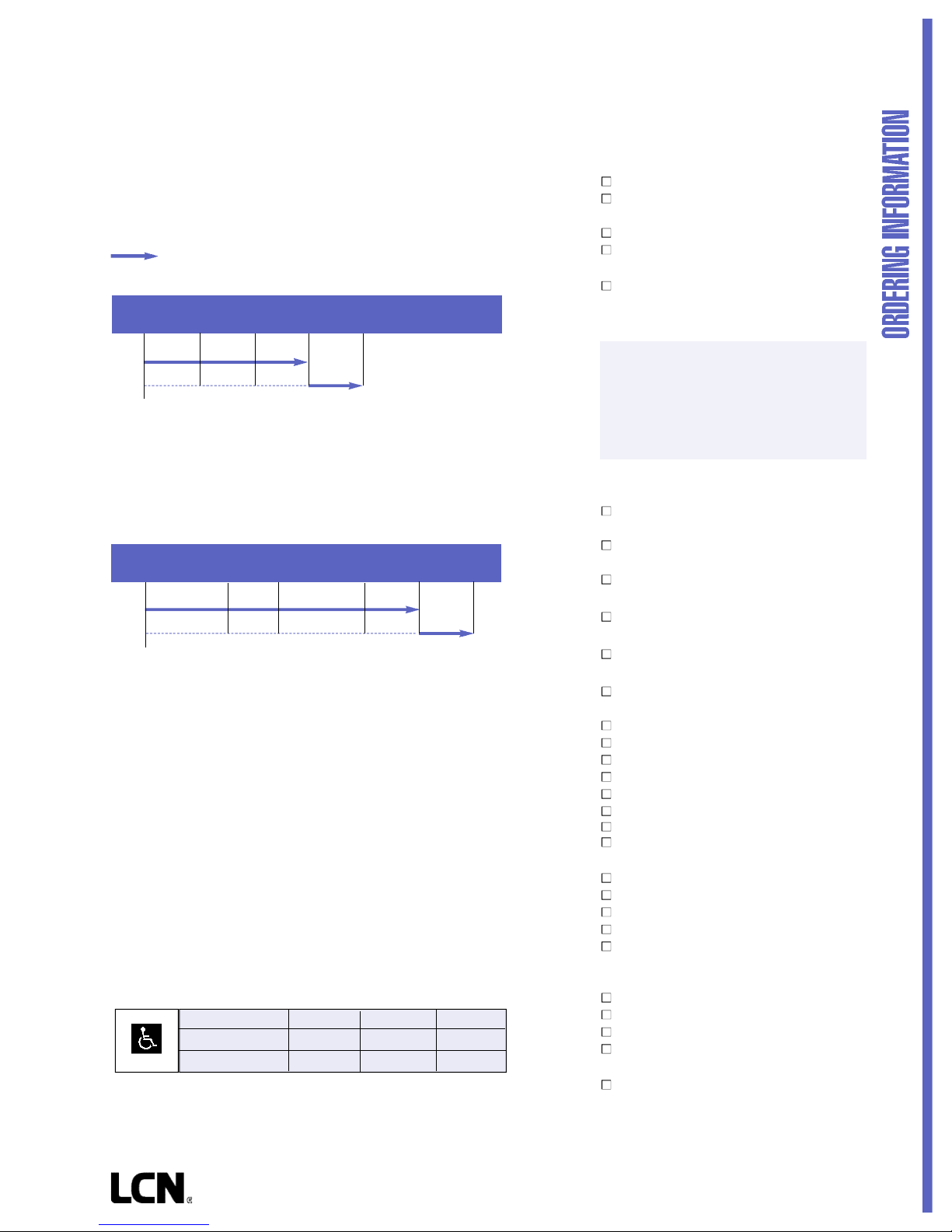

The spring power of non-sized 4011 cylinder is adjustable from size 1 through

size 5 and is shipped set to size 3.

Sized 4010 series cylinder available in size 6.

Delayed action not available with 4016 cylinder.

Indicates recommended range of door width for closer size.

EXTERIOR (and VESTIBULE) DOOR WIDTH

24"

610mm

*4011

4016

Minimum

Door

Width

INTERIOR DOOR WIDTH

24"

610mm

*4011

4016

Minimum

Door

Width

30"

762mm

size 3 size 4 size 5 size 6

size 2 size 3 size 4 size 5 size 6

Select closer based on width of door.

36"

914mm

34"

864mm

* Adjustable Size 1 thru 5.

38"

965mm

42"

1067mm

1219mm

1219mm

48"

48"

54"

1372mm

60"

1524mm

REDUCED OPENING FORCE 4010 CLOSERS

CAUTION ! Any manual door closer, including those certified by BHMA to

conform to ANSI Standard A156.4, that is selected, installed and adjusted

based on ADA or other reduced opening force requirements may not provide

sufficient power to reliably close and latch a door.

Refer to POWER OPERATORS section for information on systems that meet

reduced opening force requirements without effecting closing power.

DOOR WIDTH 36" 42" 48"

8.5* lbs. 4011 4011 4011

5.0* lbs. 4011 4011 4011

HOW-TO-ORDER

4010 SERIES CLOSERS

1. SELECT CYLINDER SIZE

4011 (adjustable from size 1 to 5)

4016 (DEL not available)

2. SPECIFY HAND

RH

LH

3. SELECT FINISH

Standard Powder Coat __________

Aluminum, Dark Bronze , Statuary,

Light Bronze, Black, Brass.

Closer will be shipped with:

- STANDARD COVER,

- REGULAR ARM,

- SELF-REAMING and TAPPING SCREWS,

unless options listed below are selected.

CLOSER OPTIONS

CYLINDER

Delayed Action (DEL)

COVER

Metal (MC)

ARM

Hold-Open (H)

Fusible Link, 165°F (FL)

FINISH

Custom Powder Coat (RAL) ___________

(handed metal cover required)

Plated Finish, US ___________

(handed metal cover required)

SRI primer

SCREW PACK

TB* & SRT Screw (TBSRT)

Wood & Machine Screw (WMS)

TB*, Wood & Machine Screw (TBWMS)

TORX Machine Screw (TORX)

TB* & TORX Machine Screw (TBTRX)

* Specify door thickness if other than 1 3/4”.

INSTALLATION ACCESSORIES

Plate, 4010-18

SPECIAL TEMPLATE

ST- _________

* Maximum opening force

7

Notes

8

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

HINGE (PULL) SIDE MOUNT

LCN 4010T SERIES

The 4010T SMOOTHEE®is LCN’s

best performing heavy duty

track closer designed

specifically for interior doors in

institutional and other rugged

high traffic applications.

Cast Iron

Forged Steel Arm

Double Heat Treated Steel

Pinion

All Weather Fluid

Fast & Accurate Installation

UL & cUL Listed

Standard 4010T series closer is shipped with standard arm, standard track,

track roller, standard plastic cover, and self reaming and tapping screws.

See 4010T Series pages 11 & 12 for options.

Sized cylinders for interior doors to 4’0”.

Closer mounts hinge side, specify right or left swinging door.

Closers to meet ADA requirements. See 4010T Series page 13.

Standard or optional custom powder coat finish.

Optional plated finish on metal cover, arm and fasteners.

Optional SRI primer for installations in corrosive conditions is available with powder

coat only.

4010T-DE available for double egress frames. See 4010T Series page 11.

The 4010T Series is UL and cUL listed with a standard track for self-closing doors.

Tested and certified under ANSI Standard A156.4, grade one.

Available

Not available

Closer available with less than 5.0 lbs. opening force on 36" door.

** Maximum opening with standard template.

*** Advanced Variable Backcheck

9

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4010T SERIES

HINGE (PULL) SIDE

MOUNTING

MAXIMUM OPENING

Templating allows 180° with

standard arm, limited to

120° when optional bumper is

installed.

Consult factory if door will be held

open at 180°

Hold-open points at , 90°, 95°, 100°,

105°, 110° or 120°, depending on the

clip location in track.

Please note that many track style door

closers are capable of allowing 180°

of door swing. Be aware that the

majority of track style closers are at

their weakest closing force in the

180 – 130° range. Consult factory for

applications where exterior or

large/heavy door must swing 180°.

Butt Hinges should not exceed 5” (127 mm) in width.

Options

Standard track with bumper,

hold-open track, hold-open

track with bumper.

Double egress arm.

Metal cover.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications.

Contact LCN for assistance.

Auxiliary Stop is recommended at hold-open point or where a door

cannot swing 180°.

Optional track bumper assembly assists backcheck in cushioning the

opening swing of the door. It is not intended to replace an auxiliary stop.

Reveal should not exceed 1/8” (3 mm) for standard arm.

Should not exceed 3 5/16” (84 mm) for double egress arm.

Top Rail less than 3 3/4” (95 mm) requires PLATE, 4010T-18.

Plate requires 2” (51 mm) minimum.

Head Frame requires 1 1/2” (38 mm) minimum.

Clearance of 2 1/4” (57 mm) behind door required for 90° or 180°

installation.

10

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4010T SERIES

CYLINDERS

CYLINDER, 4010T-3071

Standard, handed cast iron cylinder assembly.

For various applications see “Table of Sizes” on 4010T Series

page 13.

COVERS

COVER, 4010T-72

Standard, non-handed plastic cover.

METAL COVER, 4010T-72MC

Optional, handed cover. Required for plated finishes and

custom powder coat finishes

ARMS

STANDARD ARM, 4010T-3077T

Handed arm.

Arm does not include track roller.

DOUBLE EGRESS ARM, 4010T-3077DE

Optional, handed arm for double egress doors and frames.

Arm does not include track roller.

Maximum reveal is 3 5/16” (84mm).

3071

72

72MC

3077T

TRACKS

STANDARD TRACK, 4010T-3038

Standard, non hold-open, non-handed track.

Will accept hold-open clip and/or bumper assembly.

STANDARD TRACK with BUMPER, 4010T-3038B

Optional non hold-open, non-handed track with bumper

assembly installed.

Will accept hold-open clip.

HOLD-OPEN TRACK, 4010T-3038H

Optional, non-handed track with hold-open clip installed.

Will accept bumper assembly.

HOLD-OPEN TRACK with BUMPER, 4010T-3038HB

Optional, non-handed track with hold-open clip and bumper

assembly installed.

3077DE

3038

3038B

3038H

3038HB

11

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4010T SERIES

INSTALLATION ACCESSORIES

PLATE, 4010T-18

Required where top rail is less than 3 3/4” (95 mm).

Plate requires minimum 2” (51 mm) top rail.

TRACK BUMPER, 4010T-169

Mounts in track to assist backcheck, does not replace auxiliary stop.

Limits maximum opening.

Consists of bumper, bumper post, and mounting screw.

18

169

HOLD-OPEN CLIP, 4010T-3054

Mounts in track to provide hold-open function.

Hold-open point controlled by clip location.

Consists of clip and mounting screws.

TRACK ROLLER, 4010T-3034

Quiet, low friction roller assembly.

Shoulder dimension "X" = 1/16" (2mm).

3054

3034

12

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4010T SERIES

TABLE OF SIZES

Sized 4010T series cylinders available in size 1,3 or 4.

Closing power of all 4010T Series closers may be increased 15%.

Indicates recommended range of door width for closer size.

INTERIOR DOOR WIDTH

26"

660mm

4013T

4014T

Minimum

Width

Note: Using this closer on double-egress doors and frames requires the closer

**

to be ordered with a “DE” suffix (i.e., 4014T DE). Standard “DE” option will

accommodate pull side reveals up to 3 5/16”. For deeper reveals, consult

factory.

size 1 size 3 size 4

Door

Select closer based on width of door.

34"

868mm

38"

965mm

48"

1219mm

REDUCED OPENING FORCE 4010T CLOSERS

CAUTION ! Any manual door closer, including those certified by BHMA to

conform to ANSI Standard A156.4, that is selected, installed and adjusted

based on ADA or other reduced opening force requirements may not provide

sufficient power to reliably close and latch a door.

Refer to POWER OPERATORS section for information on systems that meet

reduced opening force requirements without effecting closing power.

DOOR WIDTH 36" 42" 48"

8.5* lbs. N/A N/A N/A

5.0* lbs. 4011T 4011T 4011T

* Maximum opening force

HOW-TO-ORDER

4010T SERIES CLOSERS

1. SPECIFY CYLINDER SIZE

4011T (ADA)

4013T

4014T

2. SPECIFY HAND

RH

LH

3. SPECIFY FINISH

Standard Powder Coat __________

Aluminum, Dark Bronze , Statuary,

Light Bronze, Black, Brass.

Closer will be shipped with:

- STANDARD COVER,

- STANDARD ARM,

- TRACK ROLLER,

- STANDARD TRACK,

- SELF-REAMING and TAPPING SCREWS,

unless options listed below are selected.

CLOSER OPTIONS

COVER

Metal (MC)

ARM

Double Egress (DE)

TRACK

Regular with Bumper (BUMPER)

Hold-Open (HO)

Hold-Open with Bumper (HBUMPER)

FINISH

Custom Powder Coat (RAL) ___________

(handed metal cover required)

Plated Finish, US ______________

(handed metal cover required)

SRI primer

SCREW PACK

TB* & SRT Screw (TBSRT)

Wood & Machine Screw (WMS)

TB*, Wood & Machine Screw (TBWMS)

TORX Machine Screw (TORX)

TB* & TORX Machine Screw (TBTRX)

* Specify door thickness if other than 1 3/4”.

INSTALLATION ACCESSORY

Plate, 4010T-18

SPECIAL TEMPLATE

ST- _________

**

13

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

Notes

14

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4020 SERIES

The 4020 SMOOTHEE®is LCN’s

TOP JAMB (PUSH SIDE) MOUNT

Standard 4020 series closer is shipped with regular arm, standard plastic cover,

and self reaming and tapping screws. See 4020 Series page 17 for options.

Size 6 cylinder for interior doors to 5’0” and exterior doors to 4’0”.

Non-sized cylinder (4021) adjustable for interior doors to 4’6” and exterior doors

to 3’6”.

Closer mounts top jamb (push side), specify right or left swinging door.

4021 cylinder meets ADA requirements. See 4020 Series page 18.

Standard or optional custom powder coat finish.

Optional plated finish on metal cover, arm and fasteners.

Optional SRI primer for installations in corrosive conditions is available with

powder coat only.

The 4020 Series is UL and cUL listed with regular or fusible link arms for

self-closing doors.

Tested and certified under ANSI Standard A156.4, grade one.

best performing heavy duty

closer designed specifically

for institutional and other

rugged high traffic

applications.

Ten Million Cycles

Cast Iron

Forged Steel Main Arm

Double Heat Treated Steel

Pinion

All Weather Fluid

®

Fast™Power Adjust

LCN

Fast & Accurate Installation

UL & cUL Listed

The 4021 includes the

® FAST™ Power Adjust,

LCN

a revolutionary visual indicator

for Spring Power Adjustment.

Available

Not available

Closer available with less than 5.0 lbs. opening force on 36" door.

**Maximum opening/hold-open point with standard template.

*** Advanced Variable Backcheck

15

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4020 SERIES

TOP JAMB (PUSH SIDE)

MOUNTING

MAXIMUM OPENING

Can be templated for

100°,

A = 6” (152 mm)

B = 12 3/8” (314 mm)

140°,

A = 4” (102 mm)

B = 10 3/8” (264 mm)

or 180°.

A = 2” (51 mm)

B = 8 3/8” (213 mm)

Hold-open points up to maximum

opening or 140° , whichever is less,

for hold-open or fusible link arm.

For hold-open beyond 140°, use 4110

Series closer.

Options

Size 6 or non-sized cylinder.

Delayed action cylinder.

Hold-open, or fusible link arm.

Metal cover.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications.

Contact LCN for assistance.

Butt Hinges should not exceed 5” (127 mm) in width.

Auxiliary Stop is recommended at hold-open point or where the door

cannot swing 180°.

Reveal of 2 9/16” (65 mm) allows 180° opening with regular arm .

4 13/16” (122 mm) allows up to 140° opening with regular arm.

8” (203 mm) allows up to 140° opening with LONG ARM where standard

rod and shoe is replaced with optional LONG ROD and S H O E ( 4 0 2 0 - 7 9 L R ) .

Head Frame less than 3 7/16” (87 mm) requires PLATE, 4020-18

Use PLATE, 4020-18G for flush ceiling condition.

Either plate requires 1 3/4” (44 mm) minimum.

Top Rail requires minimum 1 1/2” (38 mm).

Closer on 4020-18 plate requires 2” (51 mm) minimum.

Closer on 4020-18G plate requires 2 3/4” (70 mm) minimum.

Delayed Action Add suffix “DEL” to selected cylinder.

Not available with 4026 cylinder.

Delays closing from maximum opening to approximately 75°.

Delay time adjustable up to approximately 1 minute.

16

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4020 SERIES

CYLINDERS

CYLINDER, 4020-3071

Standard, handed cast iron cylinder assembly.

For various applications see “Table of Sizes” on 4020 Series

page 18.

COVERS

COVER, 4020-72

Standard, handed plastic cover.

METAL COVER, 4020-72MC

Optional, handed cover. Required for plated finishes and

custom powder coat finishes.

ARMS

REGULAR ARM, 4020-3077

Non-handed arm.

LONG ARM, 4020-3077L

Optional non-handed arm includes 4020-79LR for deep reveals.

(see page 16 for allowable reveals)

HOLD-OPEN ARM, 4020-3049

Optional, handed arm provides hold-open function, adjustable

at elbow. 5 3/4” (146 mm) maximum reveal, 140° hold open.

FUSIBLE LINK ARM, 4020-3049FL

Optional, handed arm releases hold-open function, adjustable

at shoe, when exposed to temperatures above 165° F.

3 7/8” (98 mm) maximum reveal. NOTE: Check local codes

before specifing FL arms. NOT A LIFE SAFETY PRODUCT!

3071

72

72MC

3077

79LR

3049

INSTALLATION ACCESSORIES

PLATE, 4020-18

Required where head frame is less than 3 7/16” (87 mm).

Plate requires minimum 1 3/4” (44 mm) minimum head

frame and 2” (51 mm) top rail.

3 7/8” (98 mm) maximum reveal.

PLATE, 4020-18G

For flush ceiling condition.

Plate requires minimum 1 3/4” (44 mm) minimum head

frame and 2 3/4” (70 mm) top rail.

17

3049FL

18

18G

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4020 SERIES

TABLE OF SIZES

The spring power of non-sized 4021 cylinder is adjustable from size 1 through

size 5 and is shipped set to size 3.

Sized 4020 series cylinder available in size 6.

Delayed action not available with 4026 cylinder.

Indicates recommended range of door width for closer size.

EXTERIOR (and VESTIBULE) DOOR WIDTH

24"

610mm

*4021

4026

Minimum

Door

Width

INTERIOR DOOR WIDTH

24"

610mm

*4021

4026

Minimum

Door

Width

30"

762mm

size 3 size 4 size 5 size 6

size 2 size 3 size 4 size 5 size 6

Select closer based on width of door.

36"

914mm

34"

864mm

* Adjustable Size 1 thru 5

38"

965mm

42"

1067mm

1219mm

1219mm

48"

48"

54"

1372mm

60"

1524mm

REDUCED OPENING FORCE 4020 CLOSERS

CAUTION ! Any manual door closer, including those certified by BHMA to

conform to ANSI Standard A156.4, that is selected, installed and adjusted

based on ADA or other reduced opening force requirements may not provide

sufficient power to reliably close and latch a door.

Refer to POWER OPERATORS section for information on systems that meet

reduced opening force requirements without effecting closing power.

DOOR WIDTH 36" 42" 48"

8.5* lbs. 4021 4021 4021

5.0* lbs. 4021 4021 4021

HOW-TO-ORDER

4020 SERIES CLOSERS

1. SELECT CYLINDER SIZE

4021 (adjustable from size 1 to 5)

4026 (DEL not available)

2. SPECIFY HAND

RH

LH

3. SELECT FINISH

Standard Powder Coat __________

Aluminum, Dark Bronze , Statuary,

Light Bronze, Black, Brass.

Closer will be shipped with:

- STANDARD COVER,

- REGULAR ARM,

- SELF-REAMING and TAPPING SCREWS,

unless options listed below are selected.

CLOSER OPTIONS

CYLINDER

Delayed Action ( DEL)

COVER

Metal (MC)

ARM

Hold-Open (H)

Fusible Link, 165°F (FL)

FINISH

Custom Powder Coat (RAL) __________

(handed metal cover required)

Plated Finish, US _____________

(handed metal cover required)

SRI primer

SCREW PACK

TB* & SRT Screw (TBSRT)

Wood & Machine Screw (WMS)

TB*, Wood & Machine Screw (TBWMS)

TORX Machine Screw (TORX)

TB* & TORX Machine Screw (TBTRX)

* Specify door thickness if other than 1 3/4”.

INSTALLATION ACCESSORIES

Plate, 4020-18

Plate, 4020-18G

SPECIAL TEMPLATE

ST- _________

* Maximum opening force

18

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4020T SERIES

TOP JAMB (PULL SIDE) MOUNT

The 4020T SMOOTHEE

® is LCN’s

best performing heavy duty

track closer designed

specifically for interior doors in

institutional and other high

traffic applications.

Cast Iron

Forged Steel Arm

Double Heat Treated Steel

Pinion

All Weather Fluid

Fast & Accurate Installation

UL & cUL Listed

Standard 4020T series closer is shipped with standard arm, standard track,

track roller, standard plastic cover, and self reaming and tapping screws.

See 4020T Series pages 21 & 22 foroptions.

Sized cylinders for interior doors to 4’0”.

Closer mounts top jamb (pull side), specify right or left swinging door.

Closers to meet ADA requirements. See 4020T Series page 23.

Standard or optional custom powder coat finish.

Optional plated finish on metal cover, arm and fasteners.

Optional SRI primer for installations in corrosive conditions is available

with powder coat only.

The 4020T Series is UL and cUL listed with a standard track for self-

closing doors.

Tested and certified under ANSI Standard A156.4, grade one.

Available

Not available

Closer available with less than 5.0 lbs. opening force on 36" door.

**Maximum opening/hold-open point with standard template.

*** Advanced Variable Backcheck

19

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4020T SERIES

TOP JAMB (PULL SIDE)

MOUNTING

MAXIMUM OPENING

Templating allows 180° with

standard track arm, limited to

100° with optional bumper installed.

Consult factory if door will be held

open at 180°

Hold-open points at 80°, 85°, 90°,

95°, or 100° with hold-open tracks.

Please note that many track style door

closers are capable of allowing 180°

of door swing. Be aware that the

majority of track style closers are at

their weakest closing force in the

180 – 130° range. Consult factory for

applications where exterior or

large/heavy door must swing 180°.

Butt Hinges should not exceed 5” (127 mm) in width.

Auxiliary Stop is recommended at hold-open point or where a door

cannot swing 180°.

Optional track bumper assembly assists backcheck in cushioning the

opening swing of the door. It is not intended to replace an auxiliary stop.

Options

Standard track with bumper,

hold-open track, hold-open

track with bumper.

Metal cover.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications.

Contact LCN for assistance.

Reveal should not exceed 1/8” (3 mm).

Head Frame less than 3 7/8” (98 mm), requires PLATE, 4020T-18.

Plate requires 1 3/4” (44 mm) minimum.

Clearance of 1 1/2” (38 mm) behind door required for 90° or 180°

installation.

20

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4020T SERIES

CYLINDERS

CYLINDER, 4020T-3071

Standard, handed cast iron cylinder assembly.

For various applications see “Table of Sizes” on 4020T Series

page 23.

COVERS

COVER, 4020T-72

Standard, handed plastic cover.

METAL COVER, 4020T-72MC

Optional, handed cover. Required for plated finishes and

custom powder coat finishes.

ARMS

STANDARD ARM, 4020T-3077T

Handed arm.

Roller not included with arm.

3071

72

72MC

TRACKS

STANDARD TRACK, 4020T-3038

Standard, non hold-open, non-handed track.

Will accept hold-open clip and/or bumper assembly.

STANDARD TRACK with BUMPER, 4020T-3038B

Optional non hold-open, non-handed track with bumper

assembly installed.

Will accept hold-open clip.

HOLD-OPEN TRACK, 4020T-3038H

Optional, non-handed track with hold-open clip installed.

Will accept bumper assembly.

HOLD-OPEN TRACK with BUMPER, 4020T-3038HB

Optional, non-handed track with hold-open clip and bumper

assembly installed.

3077T

3038

3038B

3038H

3038HB

21

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4020T SERIES

INSTALLATION ACCESSORIES

PLATE, 4020T-18

Required where head frame is less than 3 7/8” (98 mm).

Plate requires minimum 1 3/4” (44 mm) frame face.

TRACK BUMPER, 4020T-169

Mounts in track to assist backcheck, not replace auxiliary stop.

Limits maximum opening.

Consists of bumper, bumper post, and mounting screw.

18

169

HOLD-OPEN CLIP, 4020T-3054

Mounts in track to provide hold-open function.

Hold-open point controlled by clip location.

Consists of clip and mounting screws.

TRACK ROLLER, 4020T-3034

Quiet, low friction roller assembly.

Shoulder dimension "X"= 1/16" (2mm).

3054

3034

22

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4020T SERIES

TABLE OF SIZES

4020T Series cylinders available in size 1, 3 or 4.

Closing power of all 4020T Series closers may be increased 15%.

Specify next higher size closer where strong drafts exist

Indicates recommended range of door width for closer size.

INTERIOR DOOR WIDTH

26"

660mm

size 1 size 3 size 4

4023T

4024T

Minimum

door

width

Select closer based on width of door.

34"

868mm

38"

965mm

48"

1219mm

HOW-TO-ORDER

4020T SERIES CLOSERS

1. SELECT CYLINDER SIZE

4021T (ADA)

4023T

4024T

2. SPECIFY HAND

RH

LH

3. SPECIFY FINISH

Standard Powder Coat __________

Aluminum, Dark Bronze , Statuary,

Light Bronze, Black, Brass.

Closer will be shipped with:

- STANDARD COVER,

- STANDARD ARM,

- TRACK ROLLER,

- STANDARD TRACK,

- SELF-REAMING and TAPPING SCREWS

unless options listed below are selected.

REDUCED OPENING FORCE 4020T CLOSERS

CAUTION ! Any manual door closer, including those certified by BHMA to

conform to ANSI Standard A156.4, that is selected, installed and adjusted

based on ADA or other reduced opening force requirements may not provide

sufficient power to reliably close and latch a door.

Refer to POWER OPERATORS section for information on systems that meet

reduced opening force requirements without effecting closing power.

DOOR WIDTH 36" 42" 48"

8.5* lbs. N/A N/A N/A

5.0* lbs. 4021T 4021T 4021T

* Maximum opening force

CLOSER OPTIONS

COVER

Metal (MC)

FINISH

Custom Powder Coat (RAL) __________

(handed metal cover required)

Plated Finish, US _____________

(handed metal cover required)

SRI primer

TRACK

Standard with Bumper (BUMPER)

Hold-Open (HO)

Hold-Open with Bumper (HBUMPER)

SCREW PACK

TB* & SRT Screw (TBSRT)

Wood & Machine Screw (WMS)

TB*, Wood & Machine Screw (TBWMS)

TORX Machine Screw (TORX)

TB* & TORX Machine Screw (TBTRX)

* Specify door thickness if other than 1 3/4”.

INSTALLATION ACCESSORY

Plate, 4020T-18

SPECIAL TEMPLATE

ST- _________

23

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

Notes

24

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

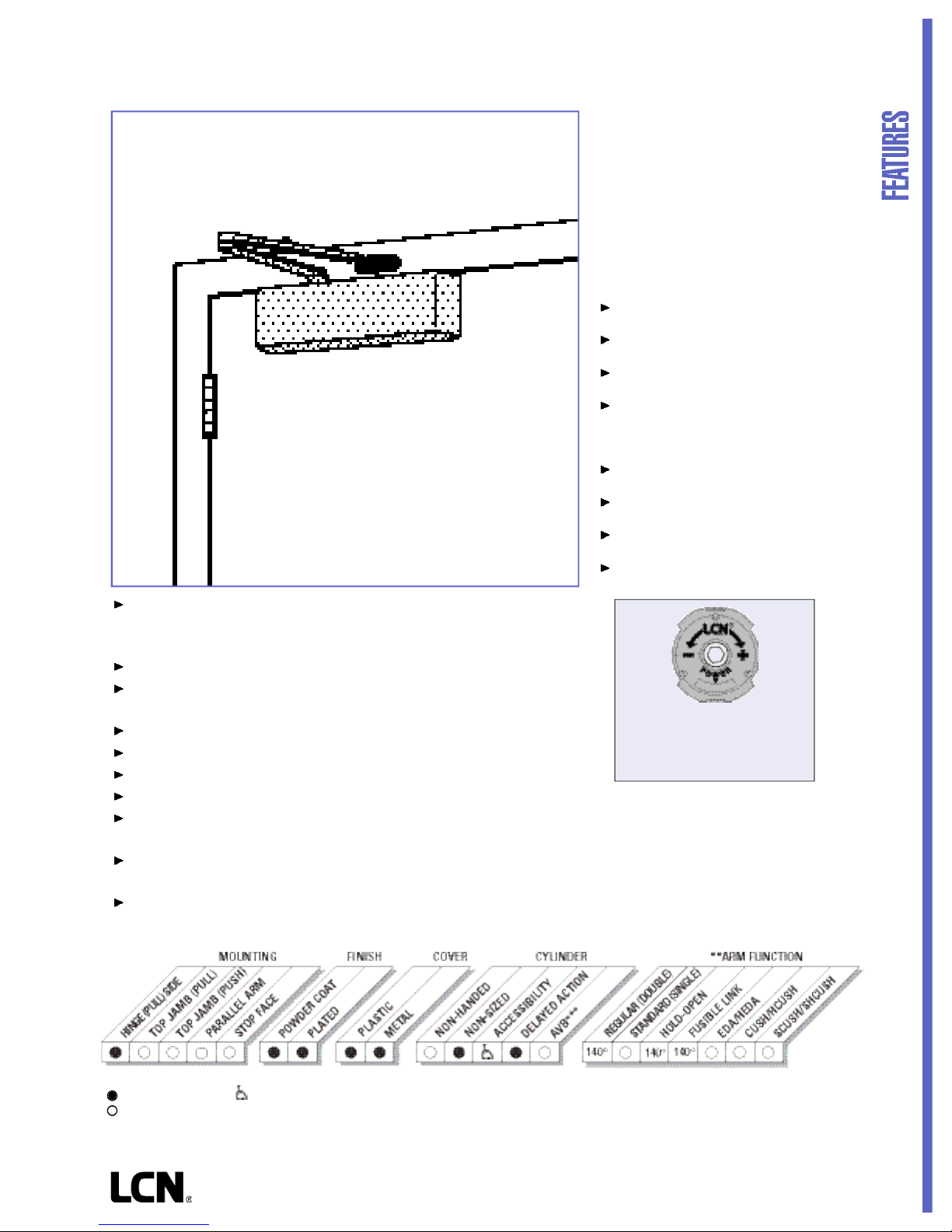

CLOSER MOUNTS

*HINGE (PULL) SIDE

TOP JAMB (PUSH SIDE)

PARALLEL (PUSH SIDE)

LCN 4030 SERIES

The 4031 is a cast iron, universal

closer designed specifically for

doors in moderate traffic

conditions. This versatile closer

compliments the rest of the heavy

duty 4000 Series and offers the

choice of three mountings and

multiple arm options.

Cast Iron

Forged Steel Main Arm

Heat Treated Steel Pinion

*HINGE (pull) side mount shown

Standard 4030 series closer is shipped with forged regular arm, metal

cover and wood/self-tapping machine screw pack. See 4030 Series

pages 30 & 31 for options.

Non-sized (1-4) 4031 cylinder for exterior doors to 36” (914 mm) and interior doors

to 48” (1219 mm).

Closer mounts hinge side, top jamb, and parallel arm, on either right or left

swinging doors.

Closer meets ADA requirements. See 4030 Series page 32.

Standard or optional custom powder coat finish.

Optional plated finish on metal cover, arm and fasteners.

Optional SRI primer for installations in corrosive conditions is available

with powder coat only.

The 4030 Series is UL and cUL listed for Self-closing doors without hold-open.

Tested and certified under ANSI Standard A156.4, grade one.

All Weather Fluid

UL & cUL Listed

Available

Not available

Closer available with less than 5.0 lbs. opening force on 36" door.

**Maximum opening/hold-open point with standard template. See individual closer series

for degrees of opening per installation.

*** Advanced Variable Backcheck

25

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4030 SERIES

HINGE (PULL) SIDE

MOUNTING

MAXIMUM OPENING

Can be templated for

180°.

Hold-open points up to maximum

opening with hold-open arm.

Options

Hold-open arm.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications.

Contact LCN for assistance.

Butt Hinges should not exceed 5” (127 mm) in width.

Auxiliary Stop is recommended at hold-open point or where a door

cannot swing 180°.

Reveal should not exceed 3/16” (5 mm) for regular arm or 3/16” (5 mm)

for hold-open arm.

Top Rail requires 2 7/8” (73 mm) minimum.

Clearance of 1 3/4” (44 mm), behind door required for installation.

26

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4030 SERIES

TOP JAMB (PUSH SIDE)

MOUNTING

MAXIMUM OPENING

Can be templated for

180°.

Hold-open points up to maximum

opening with hold-open arm.

Butt Hinges should not exceed 5” (127 mm) in width.

Auxiliary Stop is recommended at hold-open point or where the door

cannot swing 180°.

Reveal up to 3 1/2” (89 mm) allows 180° opening. Reveal up to

7 1/2” (191 mm) with long arm allows for 140° opening.

Top Rail requires 1 1/2" (38 mm) minimum from stop.

Head Frame less than 2 1/4” (57 mm) requires PLATE, 4030-18TJ.

Plate requires 1 1/2” (38 mm) minimum.

Options

Hold-open arm.

Long arm.

Long Hold-open arm.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications.

Contact LCN for assistance.

27

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

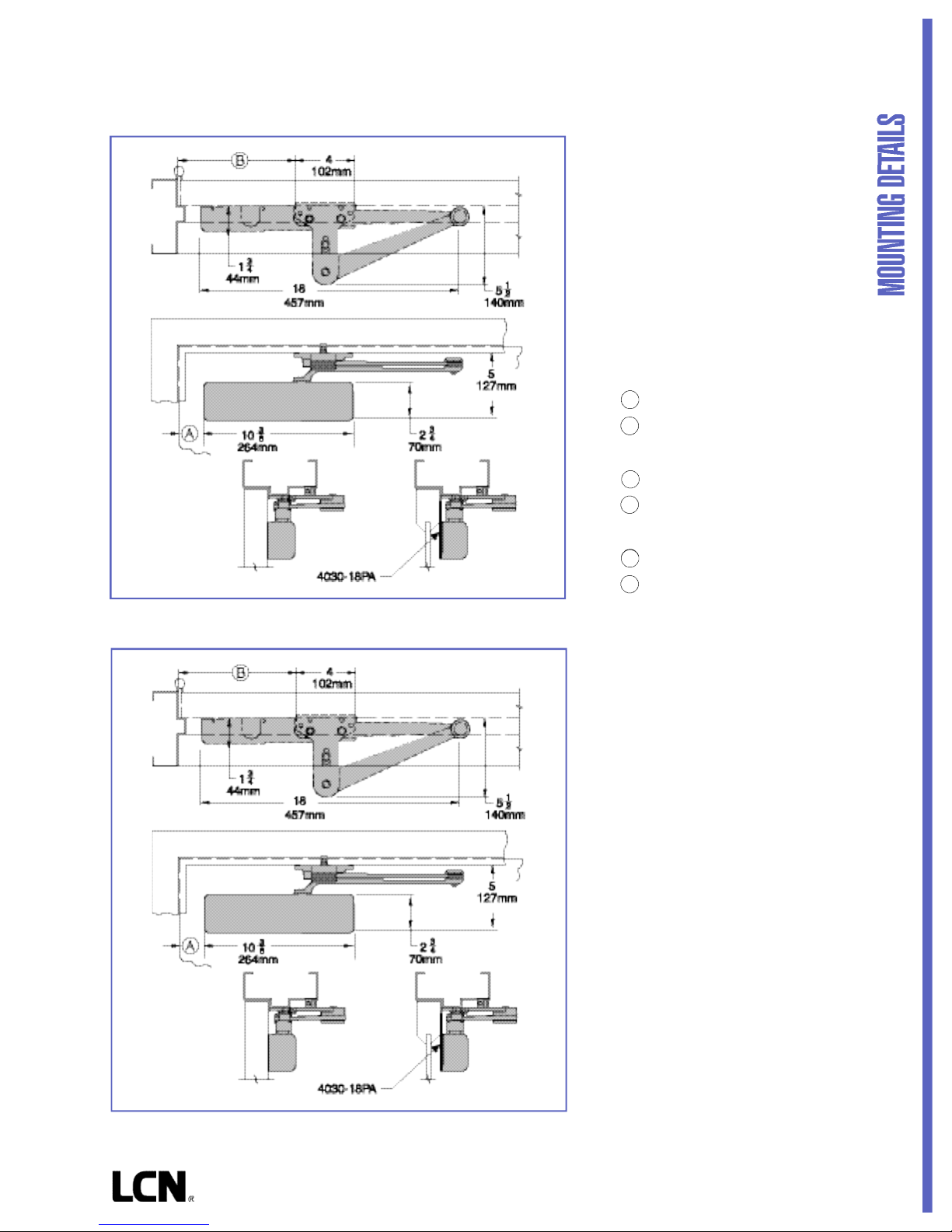

LCN 4030 SERIES

PARALLEL ARM (PUSH SIDE) MOUNTING

REGULAR or HOLD-OPEN arm mounting requires PA

SHOE, 4030-62PA for REGULAR or HOLD-OPEN

arms. Add prefix "P" to closer description (eg.

P4031). P4031 closer includes 4030-201 FIFTH HOLE

SPACER to support PA SHOE.

MAXIMUM OPENING

REGULAR or HOLD-OPEN arms can be templated for

180°.

EDA template allows 110° maximum opening.

Hold-open points up to maximum opening with

hold-open arm.

Butt Hinges should not exceed 5” (127 mm) in

w i d t h .

Auxiliary Stop is recommended at hold-open point

or where a door cannot swing maximum opening.

C l e a r a n c e for 4030-62PA shoe is

4” (102 mm) from door face. E D A arm is

5 1/2” (140 mm) from door face.

Top Rail less than 5“ (127 mm) measured from the

stop requires PLATE, 4030-18PA. Plate requires

1 3/4” (44 mm) minimum.

Stop Width minimum 1” (25 mm).

Head Frame flush or single rabetted requires PA

SHOE ADAPTER, 4030-419.

BLADE STOP clearance, requires 1/2” (13 mm)

BLADE STOP SPACER, 4030-61.

Auxiliary Shoe 4030-62A allows installation of

regular arm with overhead holder/stop. Special

templating required.

EDA ARM requires SHOE SUPPORT, 4030-30 for

fifth screw anchorage where reveal is less than

3 1/16” (78 mm).

4030 PARALLEL ARM MOUNT

4030 EDA MOUNT

Options

Hold-open, EDA, HEDA,

CUSH or HCUSH arm.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications.

Contact LCN for assistance.

28

4030 closers ordered with EDA arms include 4030-201

FIFTH HOLE SPACER to support the shoe.

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4030 SERIES

4030 CUSH MOUNT

4030 SPRING CUSH MOUNT

CUSH-N-STOP or SPRING

CUSH MOUNTING

4031 closers ordered with CUSH or

SPRING CUSH arms include 4030-201

FIFTH HOLE SPACER to support the

shoe.

MAXIMUM OPENING

CUSH and SPRING CUSH arms can

be templated for m a x i m u m

opening/hold-open point at

85°,

A = 3 5/8” (92 mm)

B = 9 3/4” (248 mm)

90°,

A = 3 ” (76 mm)

B = 9 1/8” (232 mm)

or 100°*.

A = 1 7/8” (48 mm)

B = 8 ” (203 mm)

*100° mounting will not work with

swing clear hinges.

29

Spring Cush hold-open points are

approximately 5° less than templated

stop point.

Clearance for CUSH or SPRING

CUSH shoe is 5 1/2” (140 mm)

from door face.

Head Frame flush or rabetted

requires CUSH FLUSH PANEL

ADAPTER, 4030-419.

CUSH or SPRING CUSH ARM

requires SHOE SUPPORT, 4030-30

for fifth screw anchorage where

reveal is less than 3 1/16” (78 m m ) .

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

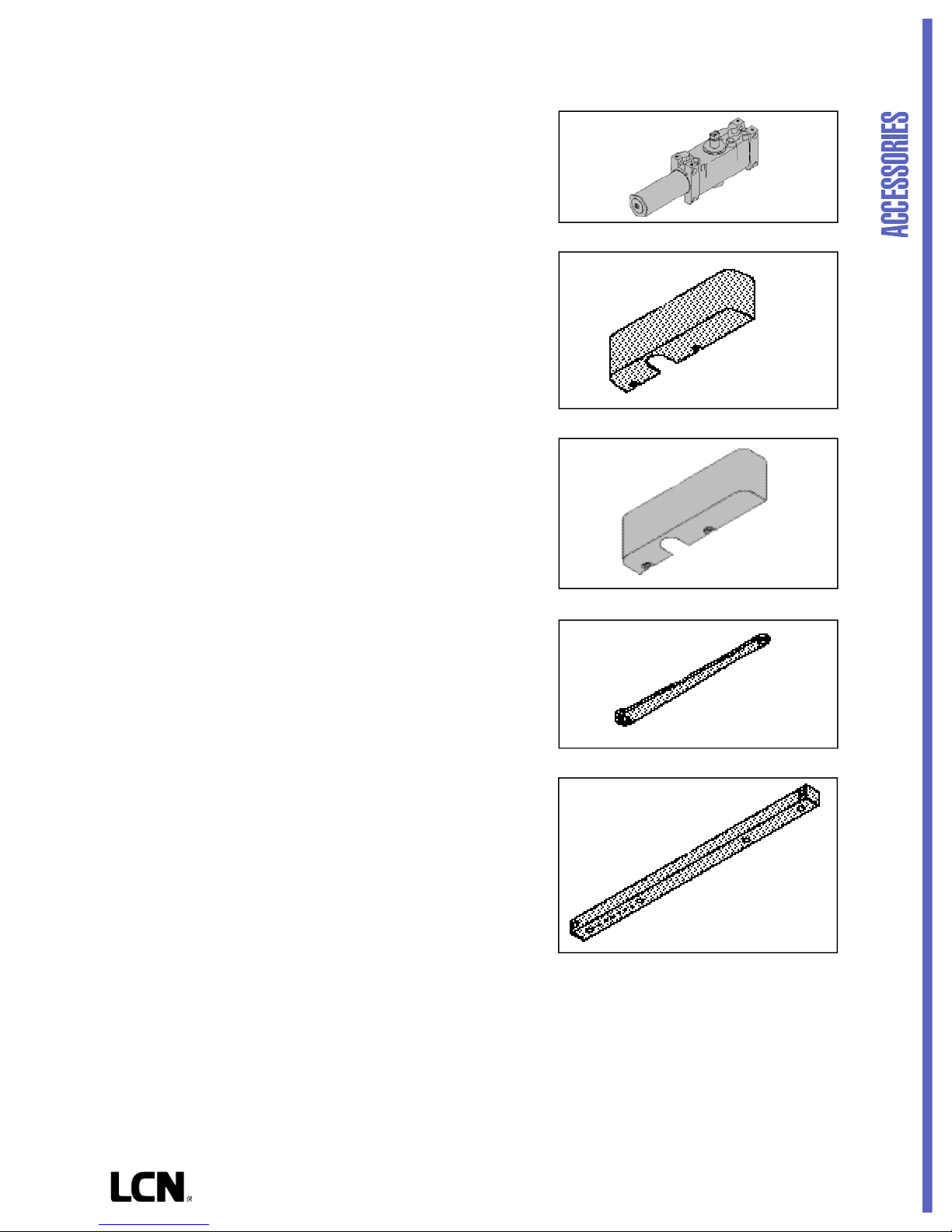

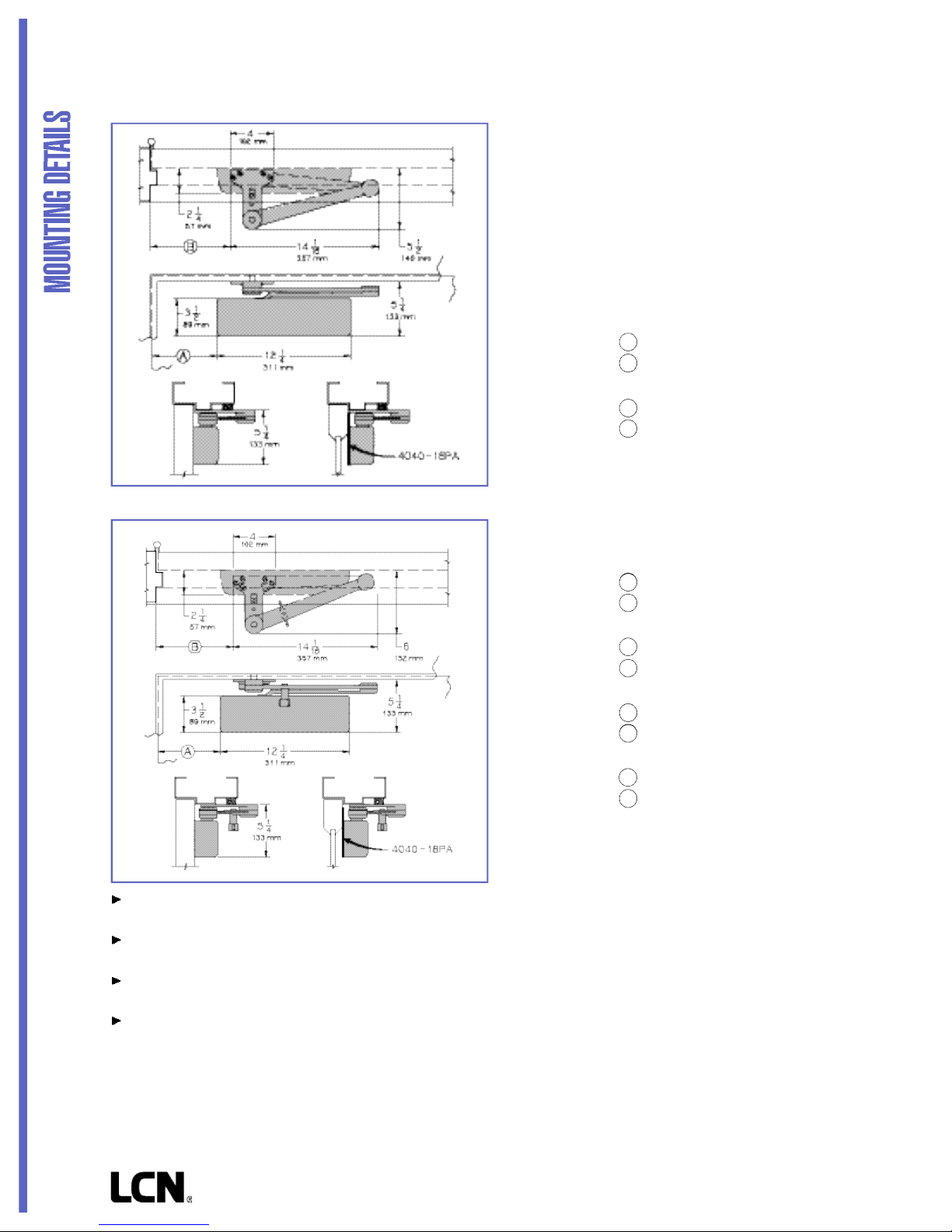

LCN 4030 SERIES

CYLINDERS

CYLINDER, 4031-3071

Standard, non-handed cast iron cylinder assembly.

ARMS

3071

REGULAR ARM, 4030-3077

Non-handed arm mounts hinge side or top jamb. P4031 closer

includes PA SHOE, 4030-62PA is required for parallel arm

mounting.

LIGHT DUTY ARM, 4030-3077LD

Optional non-handed stamped arm mounts hinge side, top

jamb or parallel arm (62PA required).

PA SHOE, 4030-62PA

Required for parallel arm mounting.

LONG ARM, 4030-3077L

Optional non-handed arm includes LONG ROD AND SHOE, 403079LR for top jamb mount with deep reveals.

HOLD-OPEN ARM, 4030-3049

Optional, non-handed arm mounts hinge side, top jamb or

parallel arm (62PA required).

Hold-open adjustable at shoe.

LONG HOLD-OPEN ARM, 4030-3049L

Optional non-handed arm includes LONG HEAD AND TUBE,

4030-3048L for top jamb mount with deep reveals.

EXTRA DUTY ARM, 4030-3077EDA

Optional, non-handed parallel arm features solid forged steel

main and forearm for potentially abusive installations.

3077

3049

3077CNS

79LR

3077EDA

62PA

3077LD

3048L

3049EDA

HOLD-OPEN EDA ARM, 4030-3049EDA

Optional handed arm, provides hold-open function adjustable

at shoe.

®

CUSH-N-STOP

ARM, 4030-3077CNS

Optional, non-handed parallel arm features solid forged steel

main arm and forearm with stop in soffit shoe.

HOLD-OPEN CUSH ARM, 4030-3049CNS

Optional non-handed arm, provides hold-open function with

templated stop/hold-open points. Handle controls hold-open

function.

SPRING CUSH ARM,4030-3077SCNS

Optional, non-handed parallel arm for abusive applications

features solid forged steel main arm and forearm with spring

loaded stop in the soffit shoe.

SPRING HCUSH ARM, 4030-3049SCNS

Optional, non-handed parallel arm for abusive applications

features solid forged steel main arm and forearm with spring

loaded stop in the soffit shoe. Handle controls hold-open

function.

30

3049CNS

3077SCNS

3049SCNS

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

C O V E R S

COVER, 4030-72MC

Non-handed metal cover.

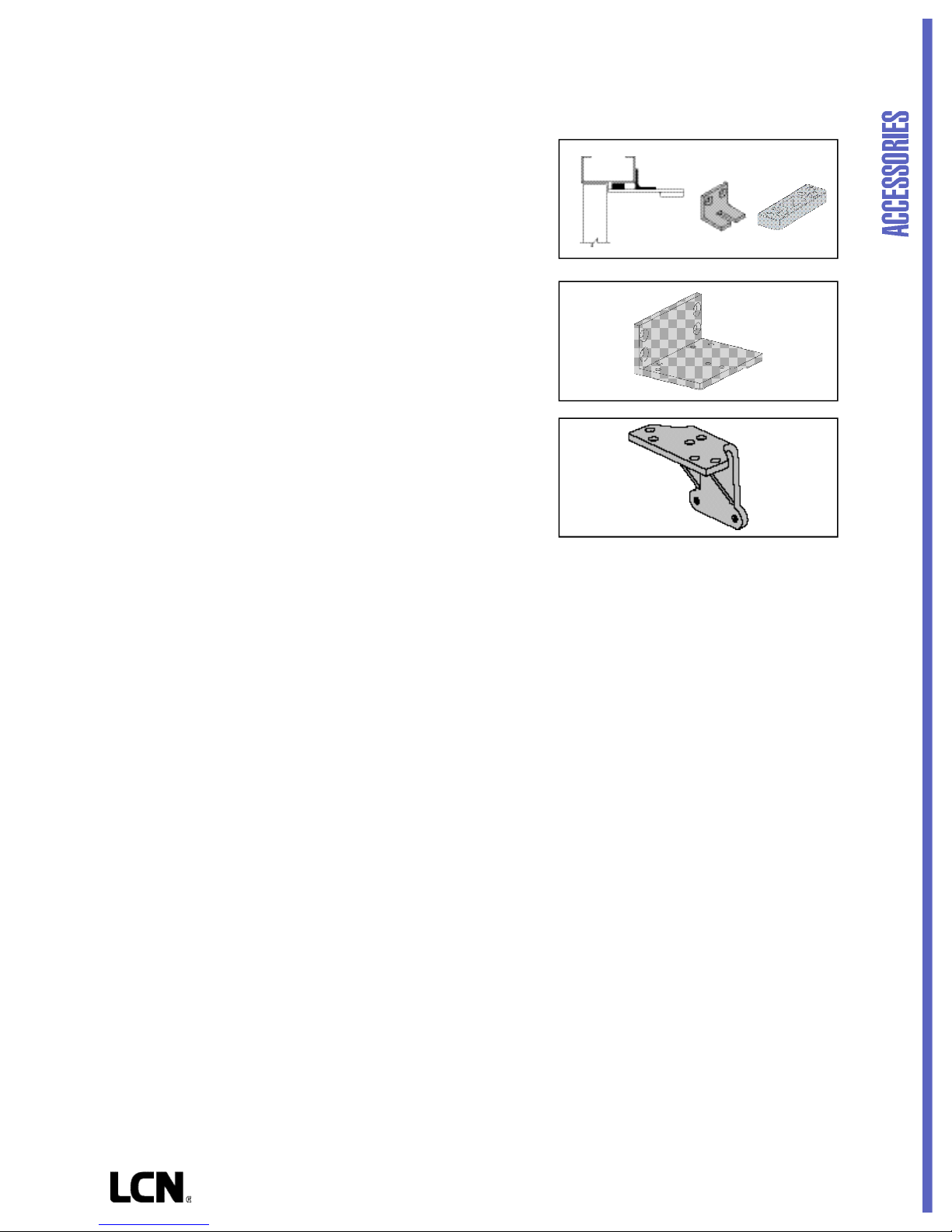

I N S TA L L A T I O N A C C E S S O R I E S

LCN 4030 SERIES

72MC

P L ATE, 4030-18TJ

Required for top jamb mounting where head frame is less than

2 1/4” (57 mm) or flush ceiling condition exists. Plate requires 1 1/2”

(38 mm) minimum.

P L ATE, 4030-18PA

Required for parallel arm mounting where top rail is less than 5”

(127 mm), measured from the stop.

Plate requires 1 3/4” (44 mm) minimum.

CUSH SHOE SUPPORT, 4030-30

Provide anchorage for fifth screw used with CUSH arms where

reveal is less than 3 1/16” (78 mm).

BLADE STOP SPACER, 4030-61

Lowers parallel arm shoe to clear 1/2” (13 mm) blade stop.

A U X I L I A RY SHOE, 4030-62A requires a top rail of 7” (178 mm).

Optional shoe replaces -62PA for parallel arm mounting of regular

arm with some overhead holder/stop. Consult factory.

PA FLUSH PANEL ADAPTER, 4030-419

Provides horizontal mounting surface for CUSH shoe on single

rabetted or flush frame.

18TJ 18PA

30

61

62A

419

31

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4030 SERIES

TABLE OF SIZES

to 4 and is shipped set to size 3.

Indicates recommended range of door width for closer size.

EXTERIOR (and VESTIBULE) DOOR WIDTH

26"

660mm

4031

Minimum

Door

Width

INTERIOR DOOR WIDTH

26"

660mm

4031

Minimum

Door

Width

30"

762mm

size 3 size 4

size 2 size 3 size 4

Non-sized 4031 cylinder is adjustable from sizes 1

36"

914mm

34"

864mm

38"

965mm

48"

1219mm

REDUCED OPENING FORCE 4030 CLOSERS

CAUTION ! Any manual door closer, including those certified by BHMA to

conform to ANSI Standard A156.4, that is selected, installed and adjusted

based on ADA or other reduced opening force requirements may not provide

sufficient power to reliably close and latch a door.

Refer to POWER OPERATORS section for information on systems that meet

reduced opening force requirements without affecting closing power.

DOOR WIDTH 36" 42" 48"

8.5* lbs. 4031 4031 4031

5.0* lbs. 4031 4031 4031

HOW-TO-ORDER

4030 SERIES CLOSERS

1. SELECT FINISH

Standard Powder Coat __________

Aluminum, Dark Bronze , Statuary,

Light Bronze, Black, Brass.

Closer will be shipped with:

- STANDARD CYLINDER,

- STANDARD METAL COVER,

- REGULAR ARM

- Wood and Self-tapping Machine screw pack

unless options listed below are indicated.

CLOSER OPTIONS

FINISH

Custom Powder Coat (RAL) ___________

Plated Finish, US ______________

SRI primer

ARM

Regular w/62PA (Rw/PA)

Regular w/62A (R/62A)

Long (LONG)

Hold-Open (H)

Hold-Open w/62PA (Hw/PA)

Long Hold-Open (HLONG)

Light Duty (LD)

Light Duty w/62A (LD/62A)

Light Duty w/62PA (LD/PA)

Light Duty Long (LDL)

EDA

HEDA (specify right or left hand)

Cush-N-Stop (CUSH)

HCush-N-Stop (HCUSH)

Spring Cush (SCUSH)

Spring HCush (SHCUSH)

OPTIONAL SCREW PACKS

TB*, Wood & Machine Screw (TBWMS)

* Specify door thickness if other than 1 3/4”.

INSTALLATION ACCESSORIES

Plate, 4030-18TJ

Plate, 4030-18PA

CUSH Shoe Support, 4030-30

Blade Stop Spacer, 4030-61

Auxiliary Shoe, 4030-62A

PA Flush Panel Adapter, 4030-419

SPECIAL TEMPLATE

ST- ________

* Maximum opening force

32

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4030T SERIES

The 4031T is a single lever (track)

CLOSER MOUNTS

*HINGE (PULL) SIDE

TOP JAMB (PULL SIDE)

STOP FACE (PUSH SIDE)

*HINGE (pull) side mount shown

arm, surface mounted closer

designed for interior use on

narrow head frames and top rails.

The choice of three mountings and

ease of installation offer a

versatile solution to door control in

moderate traffic applications. The

4030T compliments the heavy duty

4000 Series.

Cast Iron

Heat Treated Steel Pinion

All Weather Fluid

UL & cUL Listed

Standard 4031T series closer is shipped with a standard arm, metal

cover, a standard track and wood/self-tapping machine screw pack. See

4030T Series page 37 for options.

Non-sized 4031T cylinder for interior doors to 38” (965 mm).

Closer mounts pull side on door, pull side on frame and push side on

door, on either right or left swinging doors.

Closer meets ADA requirements. See 4030T Series page 38.

Standard or optional custom powder coat finish.

Optional plated finish on metal cover, arm and fasteners.

Optional SRI primer for installations in corrosive conditions is available

with powder coat only.

The 4030 Series is UL and cUL listed for Self-closing doors without hold-open.

Tested and certified under ANSI Standard A156.4, grade one.

Available

Not available

Closer available with less than 5.0 lbs. opening force on 36" door.

**Maximum opening/hold-open point with standard template. See individual closer series

for degrees of opening per installation.

*** Advanced Variable Backcheck

33

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4030T SERIES

HINGE (PULL) SIDE

MOUNTING

MAXIMUM OPENING

Can be templated for

180°.

Consult factory if door will be held

open at 180°

Hold-open points up to maximum

opening with hold-open option.

Please note that many track style door

closers are capable of allowing 180° of

door swing. Be aware that the majority

of track style closers are at their

weakest closing force in the

180 – 130° range. Consult factory for

applications where exterior or

large/heavy door must swing 180°.

Options

Hold-open track.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications.

Contact LCN for assistance.

Butt Hinges should not exceed 5” (127 mm) in width.

Auxiliary Stop is recommended at hold-open point or where a door

cannot swing 180°.

Reveal should not exceed 7/32” (6 mm).

Top Rail requires 2 7/8” (73 mm) minimum.

Clearance of 1 3/4” (44 mm) behind door required for installation.

34

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4030T SERIES

TOP JAMB (PULL SIDE)

MOUNTING

MAXIMUM OPENING

Can be templated for

180°.

Consult factory if door will be held

open at 180°

Hold-open points up to maximum

opening with hold-open option.

Please note that many track style door

closers are capable of allowing 180°

of door swing. Be aware that the

majority of track style closers are at

their weakest closing force in the

180 – 130° range. Consult factory for

applications where exterior or

large/heavy door must swing 180°.

Butt Hinges should not exceed 5” (127 mm) in width.

Auxiliary Stop is recommended at hold-open point or where the door

cannot swing 180°.

Reveal should not exceed 1/8” (3 mm).

Top Rail requires 1" (25 mm) minimum.

Head Frame requires 2 7/8” (73 mm) minimum.

Options

Hold-open track.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications.

Contact LCN for assistance.

35

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4030T SERIES

STOP FACE (PUSH SIDE)

MOUNTING

MAXIMUM OPENING

Can be templated for

110°.

Hold-open points up to maximum

opening with hold-open option.

Please note that many track style door

closers are capable of allowing 180°

of door swing. Be aware that the

majority of track style closers are at

their weakest closing force in the

180 – 130° range. Consult factory for

applications where exterior or

large/heavy door must swing 180°.

Options

Hold-open track.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications.

Contact LCN for assistance.

Butt Hinges should not exceed 5” (127 mm) in width.

Auxiliary Stop is recommended at hold-open point or where a door

cannot swing 110°.

Clearance projects 1 3/4” (44 mm).

Top Rail requires 4 1/8” (105mm) minimum measured from the stop.

Stop Width minimum 1 1/4” (32 mm).

36

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

CYLINDERS

CYLINDER, 4031T-3071

Standard, non-handed cast iron cylinder assembly.

COVERS

COVER, 4030T-72MC

Non-handed metal cover.

LCN 4030T SERIES

3071

ARMS

STANDARD ARM, 4030T-3077T

Non-handed single lever arm mounts hinge side, top jamb or

stop face. Track roller included with arm.

STANDARD TRACK, 4030T-3038

Standard, non hold-open, non-handed track mounts on either

side of the door. Will accept hold-open clip.

HOLD-OPEN TRACK, 4030T-3038H

Optional non-handed hold-open track mounts on either side of

the door. Comes with 4030T-3054 Hold-open clip.

HOLD-OPEN CLIP, 4030T-3054

Mounts in track to provide hold-open function. Hold-open point

controlled by clip location.

72MC

3077T

3038

3038H

3054

37

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4030T SERIES

TABLE OF SIZES

to 3 and is shipped set to size 3.

Indicates recommended range of door width for closer size.

INTERIOR DOOR WIDTH

26"

660mm

size 2 size 3

4031T

Minimum

Door

Width

Non-sized 4031T cylinder is adjustable from sizes 1

34"

864mm

38"

965mm

HOW-TO-ORDER

4030T SERIES CLOSERS

1. SELECT FINISH

Standard Powder Coat __________

Aluminum, Dark Bronze , Statuary,

Light Bronze, Black, Brass.

Closer will be shipped with:

- STANDARD CYLINDER

- STANDARD METAL COVER,

- STANDARD TRACK

- STANDARD ARM

- TRACK ROLLER

- Wood and Self-tapping Machine screw pack

unless options listed below are indicated.

CLOSER OPTIONS

TRACK

Hold-open (H)

FINISH

Custom Powder Coat (RAL) ___________

Plated Finish, US ___________

SRI primer

SCREW PACK

TB*, Wood & Machine Screws (TBWMS)

REDUCED OPENING FORCE 4030T CLOSERS

CAUTION ! Any manual door closer, including those certified by BHMA to

conform to ANSI Standard A156.4, that is selected, installed and adjusted

based on ADA or other reduced opening force requirements may not provide

sufficient power to reliably close and latch a door.

Refer to POWER OPERATORS section for information on systems that meet

reduced opening force requirements without affecting closing power.

DOOR WIDTH 36" 42" 48"

8.5* lbs. N/A N/A N/A

5.0* lbs. 4031T 4031T 4031T

* Maximum opening force

38

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

CLOSER MOUNTS

HINGE (PULL SIDE) (Shown)

TOP JAMB (PUSH SIDE)

PARALLEL ARM (PUSH SIDE)

LCN 4040 SERIES

The 4040 SUPER SMOOTHEE®is

LCN’s most flexible heavy duty

closer designed for institutional

and other rugged high traffic

applications.

Ten Million Cycles

Cast Iron

Forged Steel Arm

Double Heat Treated Steel

Pinion

All Weather Fluid

Non-Handed

Standard 4040 series closer shipped with regular arm, standard plastic

clip-on cover, and self reaming and tapping screws. See 4040 Series

pages 45-47 for options.

Non-sized cylinder is adjustable for interior doors to 5’0” and exterior

doors to 4’0”.

Closer mounts hinge side, top jamb, and parallel arm w/PA Shoe on

either right or left swinging doors.

Closers to meet ADA requirements. See 4040 Series page 48.

Standard or optional custom powder coat finish.

Optional plated finish on cover, arm, and fasteners.

Optional SRI primer for installations in corrosive conditions.

UL and cUL listed for self-closing doors without hold-open.

Tested and certified under ANSI Standard A156.4, grade one.

LCN

® Fast™ Power Adjust

Fast & Accurate Installation

UL & cUL Listed

For XP See Page 40

The 4040 Series includes the

® FAST™ Power Adjust,

LCN

a revolutionary visual indicator

for Spring Power Adjustment.

Available

Not available

Closer available with less than 5.0 lbs. opening force on 36" door.

**Maximum opening/hold-open point with standard template.

*** Advanced Variable Backcheck

39

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

4040XP

Non-sized cylinder is adjustable for interior doors to 5’0” and

exterior doors to 4’0”.

Closer mounts parallel arm (EDA arm) on either right or left

swinging doors.

Optional hinge side and top jamb mount with optional regular arm.

Closers to meet ADA requirements. See 4040XP Series page 49.

Standard or optional custom powder coat finish.

Optional plated finish on metal cover, arm and fasteners.

Optional SRI primer for installations in corrosive conditions is

available with powder coat only.

UL and cUL listed for self-closing doors without hold-open.

4040XP can be used with all 4041 accessories. See pages 45-

47 for options.

LCN 4040 SERIES

4040XP

The 4040XP is LCN’s most durable heavy duty closer

designed for the most demanding, high use and

abuse applications.

44% increased bearing load capacity

Strongest pinion ever- at 3/4” journal diameter

Widest bearing ever- at 5/8”

Stronger pinion teeth

New V-shield™ seal with longer life

XP = eXtra Protection in real world applications

Cast Iron

Forged Steel Arm

Double Heat Treated Steel Pinion

All Weather Fluid

Non-Handed

LCN

® Fast™ Power Adjust

Fast & Accurate Installation

UL & cUL Listed

Tested and certified under ANSI Standard A156.4,

grade one

The 4040 Series includes the

FAST™ Power Adjust,

LCN

®

a revolutionary visual indicator

for Spring Power Adjustment.

Available

Not available

Closer available with less than 5.0 lbs. opening force on 36" door.

**Maximum opening/hold-open point with standard template.

*** Advanced Variable Backcheck

40

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4040 SERIES

HINGE (PULL) SIDE

MOUNTING

MAXIMUM OPENING

Templating allows up to 120°.

Hold-open points 90° up to 120° with

hold-open arm.

Options

4040XP cylinder

4041 Delayed action cylinder.

Hold-open arm.

Metal cover.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications.

Contact LCN for assistance.

Butt Hinges should not exceed 5” (127 mm) in width.

Auxiliary Stop is recommended at hold-open point or where a door

cannot swing beyond 120°.

Reveal should not exceed 3/4” (19 mm) for regular arm or hold-open arm.

Top Rail less than 3 3/4” (95 mm) requires PLATE, 4040-18.

Plate requires 2” (51 mm) minimum.

Clearance of 2 3/8” (60 mm) behind door required for 90° installation.

Delayed Action (not available on 4040XP) Add suffix “DEL” to selected

cylinder (eg. 4041 DEL). Delays closing from 120° to 70°.

Delay time adjustable up to approximately 1 minute.

41

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4040 SERIES

TOP JAMB (PUSH SIDE)

MOUNTING

MAXIMUM OPENING

Templating allows up to 120°.

Hold-open points 85° up to 120° with

hold-open arm.

Butt Hinges should not exceed 5” (127 mm) in width.

Auxiliary Stop is recommended at hold-open point or where the

door cannot swing 120°.

Reveal of 2 9/16” (65 mm) allows 120° opening for REGULAR ARM or

standard HOLD-OPEN ARM. 4 13/16” (122 mm) allows up to 120°

opening with LONG ARM where standard rod and shoe is replaced

with optional LONG ROD AND SHOE 4040-79LR. Use H-LONG ARM

with LONG HEAD AND TUBE, 4040-78HL for hold-open. 8” (203 mm)

allows up to 120° opening with EXTRA LONG ARM where standard

rod and shoe is replaced with optional EXTRA LONG ROD AND SHOE,

4040-79ELR.

Top Rail requires 1 1/4" (32 mm) minimum.

2 1/4" (57 mm) minimum with closer on PLATE, 4040-18TJ.

3" (76 mm) minimum with closer on PLATE, 4040-18G.

Head Frame less than 3 1/2” (89 mm) requires PLATE, 4040-18TJ.

With flush ceiling, use PLATE, 4040-18G.

Either plate requires 1 3/4” (44 mm) minimum.

Delayed Action (not available on 4040XP) Add suffix “DEL” to

selected cylinder (eg. 4041 DEL). Delays closing from 120° to 80°.

Delay time adjustable up to approximately 1 minute.

Options

4040XP cylinder

4041Delayed action cylinder.

Long arm, extra long arm, holdopen arm, long hold-open arm.

Metal cover.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications.

Contact LCN for assistance.

42

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4040 SERIES

PARALLEL ARM (PUSH SIDE)

MOUNTING

Optional mounting requires PA SHOE,

4040-62PA for REGULAR or HOLDOPEN arms. Add prefix "P" to closer

description (eg. P4041). P4041 closer

includes 4040-201 FIFTH HOLE

SPACER to support PA SHOE.

MAXIMUM OPENING

180° opening/hold-open points with

all except CUSH arms.

110° opening/hold-open with CUSH

arms.

Options

4040XP cylinder

4041Delayed action cylinder.

Hold-open, EDA, HEDA,

CUSH, HCUSH, SPRING

CUSH, or SPRING HCUSH arm.

Metal cover.

Special Templates

Customized installation templates

or products may be available to

solve unusual applications. Contact

LCN for assistance.

Butt Hinges should not exceed 5” (127 mm) in width.

Auxiliary Stop is recommended at hold-open point, where the door cannot

swing 180°, or where CUSH-N-STOP arm is not used.

Clearance for 4040-62PA shoe is 4” (102 mm) from door face.

EDA shoe projects 5 1/2” (140 mm) from door face.

CUSH shoe projects 6” (152 mm) from door face.

Top Rail less than 5 3/8” (137 mm) measured from the stop requires PLATE,

4040-18PA. Plate requires 2” (51 mm) minimum from the stop.

Head Frame flush or rabetted requires PA SHOE ADAPTER, 4040-419.

Stop Width minimum 1” (25 mm).

Blade Stop clearance requires 1/2" (13mm) BLADE STOP SPACER, 4040-61.

Delayed Action (not available on 4040XP) Add suffix “DEL” to selected

cylinder (eg. P4041 DEL). Delays time adjustable up to approximately 1

minute.

43

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

4040 SERIES EDA MOUNT

LCN 4040 SERIES

Mounting details are the same as

4040 Series REGULAR or HOLDOPEN except as listed below.

4040 Series closers ordered with

EDA or CUSH arms include 4040201 FIFTH HOLE SPACER to

support the shoe.

MAXIMUM OPENING

EDA arm can be templated for

points at: 110°,

A = 6 3/8” (162 mm)

B = 7 3/4” (197 mm)

or 180°.

A = 2 7/8” (73 mm)

B = 4 1/4” (108 mm)

Hold-open points up to maximum

opening with HEDA arm.

4040 SERIES CUSH MOUNT

Clearance for 4040-62EDA is 5 1/2” (140 mm) from door

face. 6” (152 mm) for CUSH.

Head Frame flush or rabetted requires CUSH FLUSH

PANEL ADAPTER, 4040-419.

CUSH ARM requires SHOE SUPPORT, 4040-30 for fifth

screw anchorage for narrow frames.

Delayed Action (not available on 4040XP) Add suffix

“DEL” to selected cylinder (eg. 4041 DEL). Delays closing

from maximum opening to; 115˚ with 180˚ template.

95˚ with 110˚ template. 85˚ with 100˚ template.

75˚ with 90˚ template.

Delay time adjustable up to approximately 1 minute.

CUSH arms can be templated for

opening/hold-open point at:

85°,

A = 7 15/16” (202 mm)

B = 9 1/8” (232 mm)

90°,

A = 7 3/16” (183 mm)

B = 8 1/2” (216 mm)

100°,

A = 6 1/16” (154 mm)

B = 7 1/4” (184 mm)

or 110°.

A = 5 1/16” (129 mm)

B = 6 3/8” (162 mm)

Spring Cush dead stop points

are approximately 5˚ more than

templated stop point. Hold open

at templated stop points.

44

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4040 SERIES

C Y L I N D E R S

CYLINDER, 4041-3071

Standard, non-handed cast iron cylinder assembly.

CYLINDER, 4040XP-3071

Heavy duty, non-handed cast iron cylinder assembly.

C O V E R S

COVER, 4040-72

Standard, non-handed plastic clip-on cover.

M E TAL COVER, 4040-72MC

Optional, handed cover. Required for plated finishes and custom

powder coat finishes.

A R M S

REGULAR ARM, 4040-3077

Non-handed arm mounts pull side or top jamb with shallow reveal.

P4041 closer includes PA SHOE, 4040-62PA required for parallel arm

m o u n t i n g .

PA SHOE, 4040-62PA

Required for parallel arm mounting.

LONG ARM, 4040-3077L

Optional non-handed arm includes LONG ROD AND SHOE, 4040-79LR

for top jamb mount.

EXTRA LONG ARM, 4040-3077ELR

Optional non-handed arm includes EXTRA LONG ROD AND SHOE,

4040-79ELR for top jamb mount with deep reveal.

HOLD-OPEN ARM, 4040-3049

Optional, non-handed arm mounts pull side or top jamb with shallow

reveal, hold-open adjustable shoe. P4041 closer includes 4040-62PA

shoe required for parallel arm mounting.

LONG HOLD-OPEN ARM, 4040-3049L

Optional non-handed arm includes LONG HEAD AND TUBE, 40403048L for top jamb mount.

EXTRA DUTY ARM, 4040-3077EDA

Non-handed parallel arm features forged, solid steel main and

forearm for potentially abusive installations.

HOLD-OPEN EXTRA DUTY ARM, 4040-3049EDA

Optional handed arm provides hold-open function, adjustable at the

s h o e .

EDA ARM w/THICK HUB SHOE, 4040-3077EDAG

Optional for blade stop clearance, requires special templating.

HEDA ARM w/THICK HUB SHOE, 4040-3049EDAG

Optional for blade stop clearance, requires special templating.

3071

72

79LR

3077EDA

3049EDA

62G

3049L

79ELR

3071XP

72MC

62PA

3077

3049

45

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4040 SERIES

ARMS cont.

C U S H - N - S T O P ® ARM, 4040-3077CNS

Optional, non-handed parallel arm features solid forged steel

main arm and forearm with stop in soffit shoe.

HCUSH ARM, 4040-3049CNS

Provides hold-open function with templated stop/hold-open

points. Handle controls hold-open function.

SPRING CUSH ARM, 4040-3077SCNS

Optional, non-handed parallel arm for abusive applications

features solid forged steel main arm and forearm with spring

loaded stop in the soffit shoe.

SPRING HCUSH ARM, 4040-3049SCNS

Optional, non-handed parallel arm for abusive applications

features solid forged steel main arm and forearm with spring

loaded stop in the soffit shoe. Handle controls hold-open

f u n c t i o n .

INSTALLATION ACCESSORIES

PLATE, 4040-18

Required for hinge side mount where top rail is less than

3 3/4” (95 mm). Plate requires minimum 2” (51 mm) minimum top

rail.

3077CNS

3049CNS

3077SCNS

3049SCNS

PLATE, 4040-18G

Locates top jamb mounted closer flush with top of head frame

face in flush ceiling condition. Plate requires 1 3/4” (44 mm)

minimum head frame.

PLATE, 4040-18TJ

Centers top jamb mounted closer vertically on head frame

where face is less than 3 1/2” (89 mm). Plate requires 1 3/4”

(44 mm) minimum head frame.

PLATE, 4040-18PA

Required for parallel arm mounting where top rail is less than

5 1/2” (140 mm), measured from the stop. Plate requires

2” (51 mm) minimum top rail.

18G

18

18TJ

18PA

46

LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

LCN 4040 SERIES

INSTALLATION ACCESSORIES cont.

CUSH SHOE SUPPORT, 4040-30 provides anchorage for fifth

screw used with CUSH arms, where reveal is less than

3 1/16” (78 mm).

30

61

BLADE STOP SPACER, 4040-61 required to lower parallel arm