Handbook for the

Wyvern

®

2000R Timer

Part Number 918-000-746 March 2018 Issue Number 7 (Version 8.34)

Contents

Introduction .............................................................................................................. 1

Operational Features ................................................................................................. 1

Timer Operation ......................................................................................................... 2

Mechanical Installation ........................................................................................... 3

Electrical Installation ............................................................................................... 4

Good Wiring Practice ................................................................................................ 5

Voltage Free Contacts ............................................................................................... 6

Wiring Connections … ............................................................................................... 8

Programming the Wyvern 2000R ...........................................................................10

Selecting Programming Mode ...................................................................................11

Program Example .....................................................................................................13

Programming Time ...................................................................................................14

Session Time ............................................................................................................15

Coin Time .................................................................................................................16

Start Delay Time or Pre-time ....................................................................................17

Secondary Output ON/OFF Time .............................................................................18

Lockout & Buzzer Time .............................................................................................19

Programming Money Values.....................................................................................20

Programming Coin Values ........................................................................................21

Coin Learn Mode ......................................................................................................22

Auxiliary Programming Functions .............................................................................24

Special Options .........................................................................................................27

Interrogation Menu .................................................................................................28

Smart Card Operation ............................................................................................30

User Card .................................................................................................................31

Profit Share ...............................................................................................................33

Specification .............................................................................................................35

Service Information ................................................................................................36

Summary of Program Codes .................................................................................37

Contact Address:

Leisure Controls International Ltd

Clump Farm Industrial Estate, Higher Shaftesbury Road,

BLANDFORD FORUM, Dorset. DT11 7DT. United Kingdom

Tel: +44 (0) 1258 489075/455393 (General) or +44 (0) 1258 483574 (Technical support)

Fax: +44 (0) 1258 488526/456410

E-mail: General enquires: info@lcigb.com, Technical support: support@lcigb.com

Web Site: www.lcigb.com

The following options are available for use

with the Wyvern 2000R timers:

7kVA switching

Key over-ride or panic button or start

button

Smart card (Wyvern 2000RS)

PC interface (Wyvern 2000RPC)

Network interface (Wyvern 2000RCN)

Remote display

©2000 - 2018. Wyvern is a registered trade mark of Leisure Controls International Ltd

The following input voltages are available:

230V 50Hz 7A

115V 60Hz 7A

24V 50/60Hz 7A

Wyvern Timer 2000R Operating Instructions

(7)

Introduction

Operational Features

1

Coin Entry

Over-ride

Switch

Hidden

Programming

Switches (10)

Coin Return

Steel Case

Coin Sticker

Display (1)

Smart Card

Smart Card

Entry Slot (5)

Cover Lock

(1) The 4 digit 7 segment display is used to program the Wyvern 2000R as well as showing

time of day and time remaining.

(2) The coin sticker is applied after programming (see page 23)

(3) The coin entry accepts all sizes of coin and token up to 31mm in diameter

(4) Coins that are not accepted by the Wyvern 2000R are returned into the coin return

(5) When the smart card option is fitted smart cards are inserted into the smart card entry

slot

(6) Confirmation of acceptance of smart card data is achieved by pressing the smart card

pushbutton

(7) The optional key over-ride switch turns the timer outputs on permanently. Turn key to

the right to turn on

(8) Access to the cash tray is via the cover lock situated underneath the Wyvern 2000R

(9) Strong epoxy covered steel case with hidden large capacity coin box

(10) Hidden programming switches (page 13)

Figure 1 – Main Features

2 Wyvern Timer 2000R Operating Instructions

The Wyvern 2000R Timer offers an extensive range of features to suit virtually all coin/card

timer applications. Advanced electronic control provides programmable options allowing up to

six different coins to be recognised, peak and off-peak timing cycles, smart card operation,

together with profit sharing facilities. Both switched outputs are voltage free; this means the

Wyvern 2000R can be used to switch a load operating from any voltage, not just mains

operated equipment. A full description of voltage free and load switching appears on pages 6

and 7.

Figure 1 shows the main operational features and this manual provides all information for

correct installation and programming.

Timer Operation

The Wyvern 2000R may be programmed to operate in one of four modes as described below.

The explanations all use UK coinage as examples but the principles apply for all currencies.

1. Fixed time

For fixed time operation the session cost or session time options are not programmed, so

the Wyvern 2000R operates using the times allocated to the coins (options 31 to 42, page

16). The timer turns ON as soon as the first coin is inserted and the time incremented with each

additional coin.

2. Session time

With session time sufficient coins must be inserted to meet a specified amount of time before

the timer turns ON. To activate session time options 08 to 09 are programmed (page 15), but

not session cost (options 04 to 05, page 20). The timer will only activate when coins equalling

the session time have been inserted. For example if the Wyvern 2000R were programmed with

a session time of 19 minutes the timer would only start when coins equal to 19 minutes are

inserted. The timer will flash the character ‘A’, and display the total time as each coin is added.

Upon insertion of the final coin, the display will show 19:00 and the timer will turn ON and start

counting down

3. Session cost

With session cost sufficient coins must be inserted to meet a specified price before the timer

turns ON. To activate session cost options 04 to 05 are programmed (page 20), but not session

time (options 08 to 09, page 15). The timer will only activate when coins equalling the session

cost have been inserted. For example if the Wyvern 2000R were programmed with a session

cost of £3.80, the timer would only start when coins to the value of £3.80 are inserted. The timer

will flash the character ‘A’, and display the total amount of money added. When the displayed

value reaches 380, meeting the £3.80 session cost, the timer will turn ON, and start counting

down.

4. Combined session cost and session time

With combined session cost and session time sufficient coins must be inserted to meet a

specified price before the timer turns ON for a specified time, even if this time is different from

the time allocated to the coins making up the session cost. To activate combined session cost

and time, options 04 to 05 (page 20) and options 08 to 09 (page 15), are programmed. The

addition of further coins is influenced by program code 30 (page 26). Once the initial cost is met,

if program code 30 is not set, further coins will add the time allocated for that coin (codes 31 to

42, page 16). If program code 30 is set to proportional session (3004) further coins to meet the

session cost must be inserted. For example If the Wyvern 2000R were programmed with a

session time of 5 minutes and a session cost of £3.80, the timer would turn ON after £3.80 has

been inserted and would run for 5 minutes. With program code 30 set to proportional session

coins totalling £3.80 must be inserted for an additional 5 minutes. However if program code 30

Wyvern Timer 2000R Operating Instructions

3

is not set further coins inserted ignore the combination and the timer is incremented by the time

allocated to that coin.

Note: Lockout time must not be set to a value less than the session time for modes 2, 3 or 4

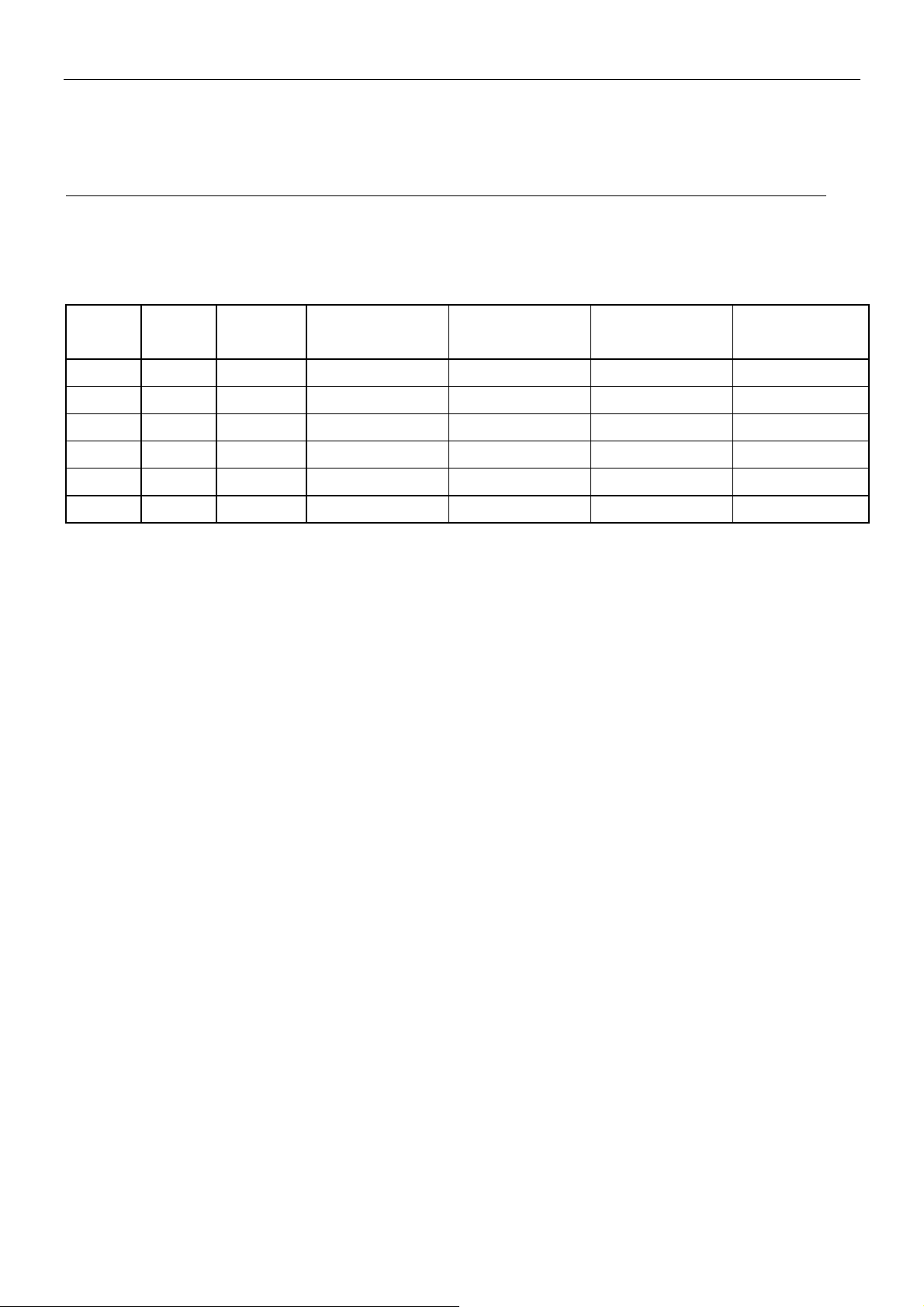

Using the previous examples the table below shows the status of the display and state of the

timer outputs as coins are inserted from coin 1 through to coin 6. The table assumes that coin 2

is inserted after coin 1 and so on.

Coin

Value Time Fixed

Session

Session

Combination

No.

Time

Time = 19 min

Cost = £3.80

£3.80 = 5 min

1 10p 30 sec 00:30 ON A0:30 OFF * A010 OFF * A010 OFF *

2 20p 1 min 01:30 ON A1:30 OFF * A030 OFF * A030 OFF *

3 50p 2 ½min 04:00 ON A4:00 OFF * A080 OFF * A080 OFF *

4 £1-00 5 min 09:00 ON A9:00 OFF * A180 OFF * A180 OFF *

5 £2-00 10 min 19:00 ON 19:00 ON 19:00 ON 05:00 ON

6 £3.80 ɫ 19 min 38:00 ON 38:00 ON 38:00 ON 10:00 ON ˭

Notes

ɫ Coin 6 would be a token programmed for a value of £3.80 and a time of 19 minutes

* A will flash on the display and indicates that further coins need to be inserted to turn the

timer ON

˭ Program code 30 set to proportional session

Values and times are for peak sessions only.

Mechanical Installation

The Wyvern 2000R Timer should be mounted on a smooth vertical wall away from corners, so

its front door can be opened fully to allow easy access to the coin box and internal components.

The timer is 275mm high by 204mm wide and has a depth of 90mm, so allow at least 210mm

clearance from any corner wall. Take care to mount the case level in both the vertical and

horizontal axes, failure to do so may prevent the coin mechanism from operating correctly.

Choose an area where an ambient temperature of 40°C is not exceeded, away from any

source of moisture, dust or direct heat.

Note. If during the installation it is necessary to remove the ribbon cable connecting the two

circuit boards, you must re-program the real time clock once the boards are re-connected.

Power consumption of the timer is approximately 10W (at 230V AC). Loads of up to 1kVA (3A

resistive) can be switched directly by the timer. This is typically five 100W incandescent or two

100W fluorescent lamps. Adding the 7kVA option increases the capacity up to a maximum of

7kVA (30A resistive), which is typically one 7kW shower or 12 fluorescent lamps.

When used as a voltage free switch, the timer can be used with external switching contactors to

control high current loads. See pages 6 and 7 in the Electrical Installation section for a

description of voltage free switching.

4 Wyvern Timer 2000R Operating Instructions

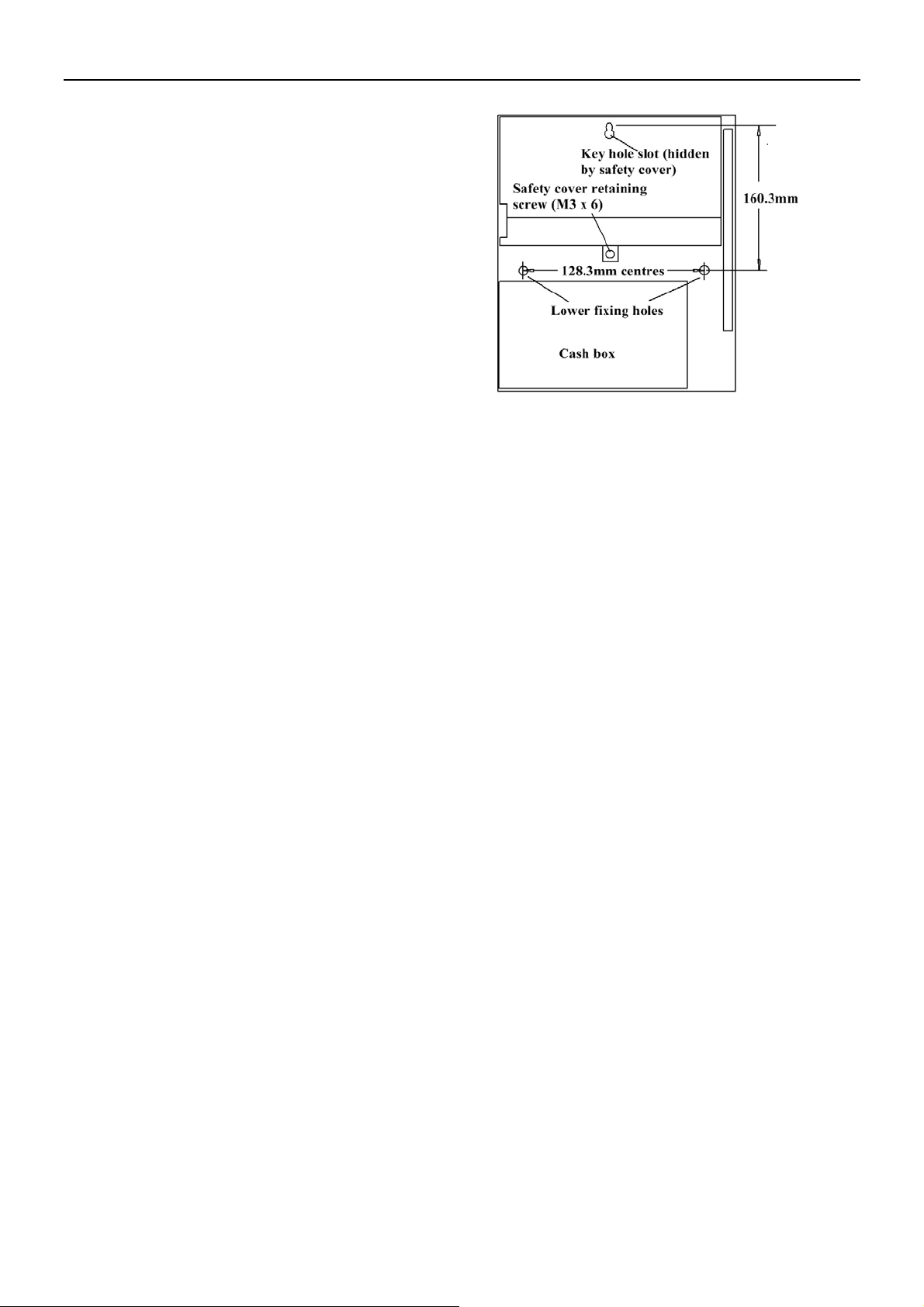

1. Lay the timer on its back and open the

case using the key supplied. Remove the

cash box and using a small flat bladed

screwdriver remove the 3mm screw (M3 x 6)

holding the safety cover in place,

as shown in Figure 2. Once the screw has

been removed the cover may be lifted and

unhooked from the main case to fully expose

the back of the case and the main circuit

board.

Figure 2 – Removing Circuit Board Cover

2. The timer has three fixing holes arranged in a triangular formation, pre-drilled in its back

cover. Position the case on the wall and mark the position of the uppermost single fixing

hole (the one in-line with the cable knockouts). Remove the timer and plug the wall and fit

with No. 8 or 10 screws of not less than 22mm. Hang the timer case on this screw and

tighten, use a spirit level to check the case is level both vertically and horizontally. Mark the

bottom two screw positions, remove case and plug the wall.

3. Remove the required cable knockouts, and fix to the wall.

If the case is not level the coin mechanism may not work.

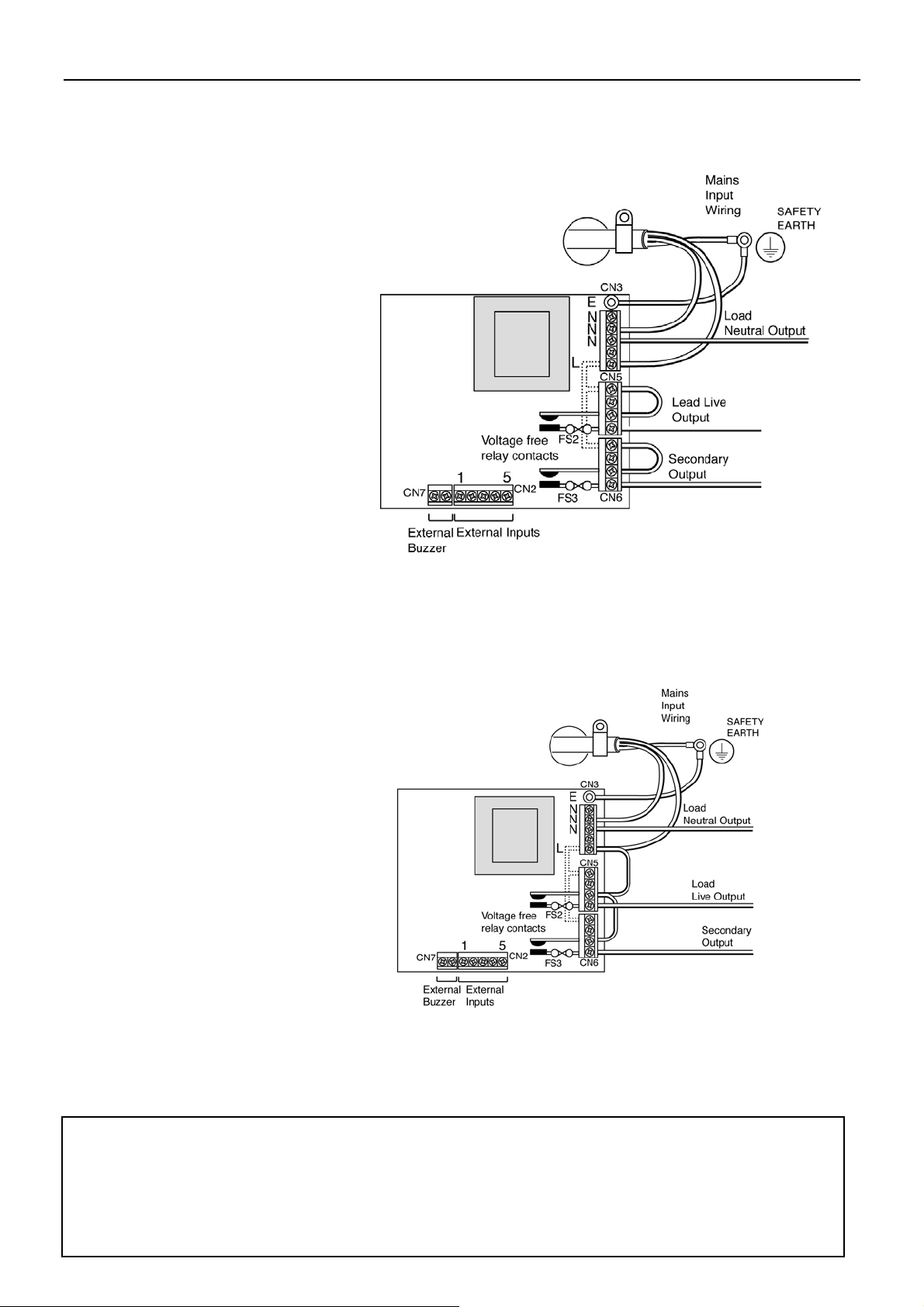

Electrical Installation

The timer will require a fused double pole switch for the mains input. Wire the unit as shown

in Figure 7 using appropriately rated and approved cable conforming to the relevant regional

standards. Minimum wire sizes for European usage are given on page 8.

With the configuration of Figure 7 the total load current (the combination of main output and

secondary output) is 3.15A, limited by the size of the main circuit board’s track width. If required

to switch a total load current greater than 3.15A, the circuit board track limitations can be

overcome by externally wiring the relays to switch 3.15A each, giving a total switching

capacity of 6.3A. See Figure 8 for the circuit arrangement.

Note: each relay is fuse protected and cannot switch more than 3.15A. If replacing a blown fuse

ensure the replacement is a type T HBC with 250V breaking capacity.

It is essential that the safety earth is connected to a known good earth at the same bonding

point as the main earth for the load being switched by the Wyvern 2000R. Poor earthing or bad

routing of connecting cables could create electrical noise leading to erratic operation of the

Wyvern 2000R. See following page for good wiring practice.

Wyvern Timer 2000R Operating Instructions

5

Good Wiring Practice to Reduce Susceptibility to Electrical Noise

The Wyvern 2000R has been designed to reduce the amount of electrical noise seen by the

control circuits, however bad grounding or inappropriate wiring techniques can create noise

problems that overwhelm the control system. A symptom of electrical noise is randomness, both

in the occurrence of the problem and in what the Wyvern 2000R does in its failure.

The built in noise protection of the Wyvern 2000R is dependent on a good ground connection

which usually short-circuits any electrical noise to earth. Without a good, correctly installed

ground connection the noise protection is essentially defeated.

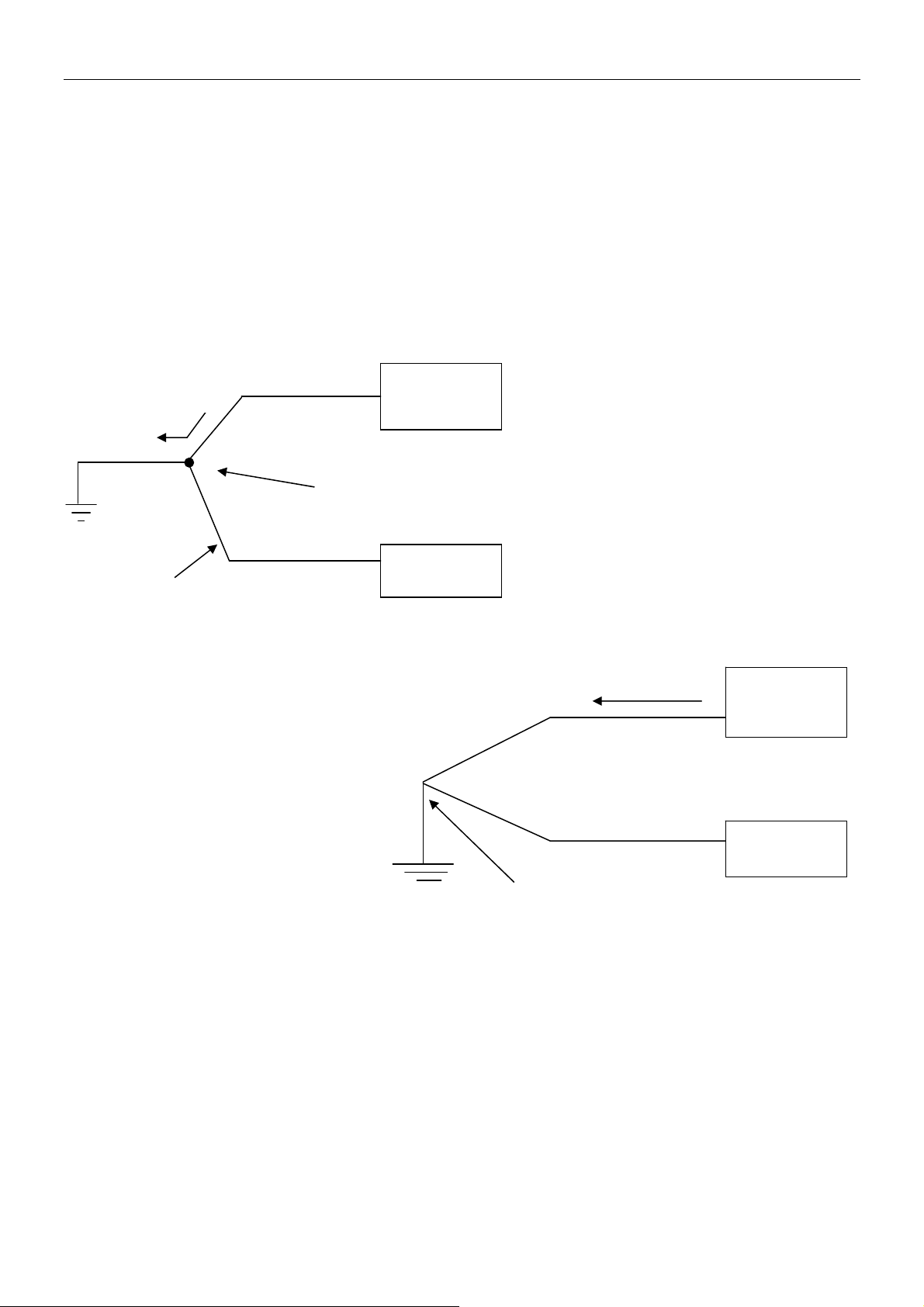

Ground current

Induced by noise

Extra ground connection

causes ground loop and

acts as an aerial for noise

Load that

may generate

noise

Ground

point

Noise voltage caused by ground

current flowing through wire

impedance. Wyvern 2000R

experiences noise on its ground

connection.

Bad Grounding Technique

Wyvern

2000R

At installation the best

approach is to establish a

central grounding point for the

load and the Wyvern 2000R.

The illustration opposite shows

bad grounding technique. By

connecting the grounds

together and then routed

through a single wire to the

grounding point, any noise

generated by the load is

superimposed on the ground

of the Wyvern 2000R.

Ground current

Induced by noise.

Load that

may generate

noise

Proper grounding technique

dictates using separate

ground wires from the timer

and the load to a central

grounding point as shown

opposite

Ground

point

Very little noise voltage is

present because of low

impedance to ground at the

connection point

The separate wire for the Wyvern 2000R

protects it from sharing the noisy ground

wire from the load.

Wyvern

2000R

Good Grounding Technique

The separation of power cables is another practice that helps increase noise immunity in

the installed system. If any of the input or output wires connecting the Wyvern 2000R to the

load are bundled closely together with the power wiring of the load then noise currents can

be transformer coupled to the Wyvern 2000R. Always keep wiring from the timer away from

motors, solenoids, inductors and similar devices; if necessary use shielded cable with only

one end of the shield connected to ground.

Following good wiring practices as detailed above will enhance the noise protection already

built into the Wyvern 2000R.

6 Wyvern Timer 2000R Operating Instructions

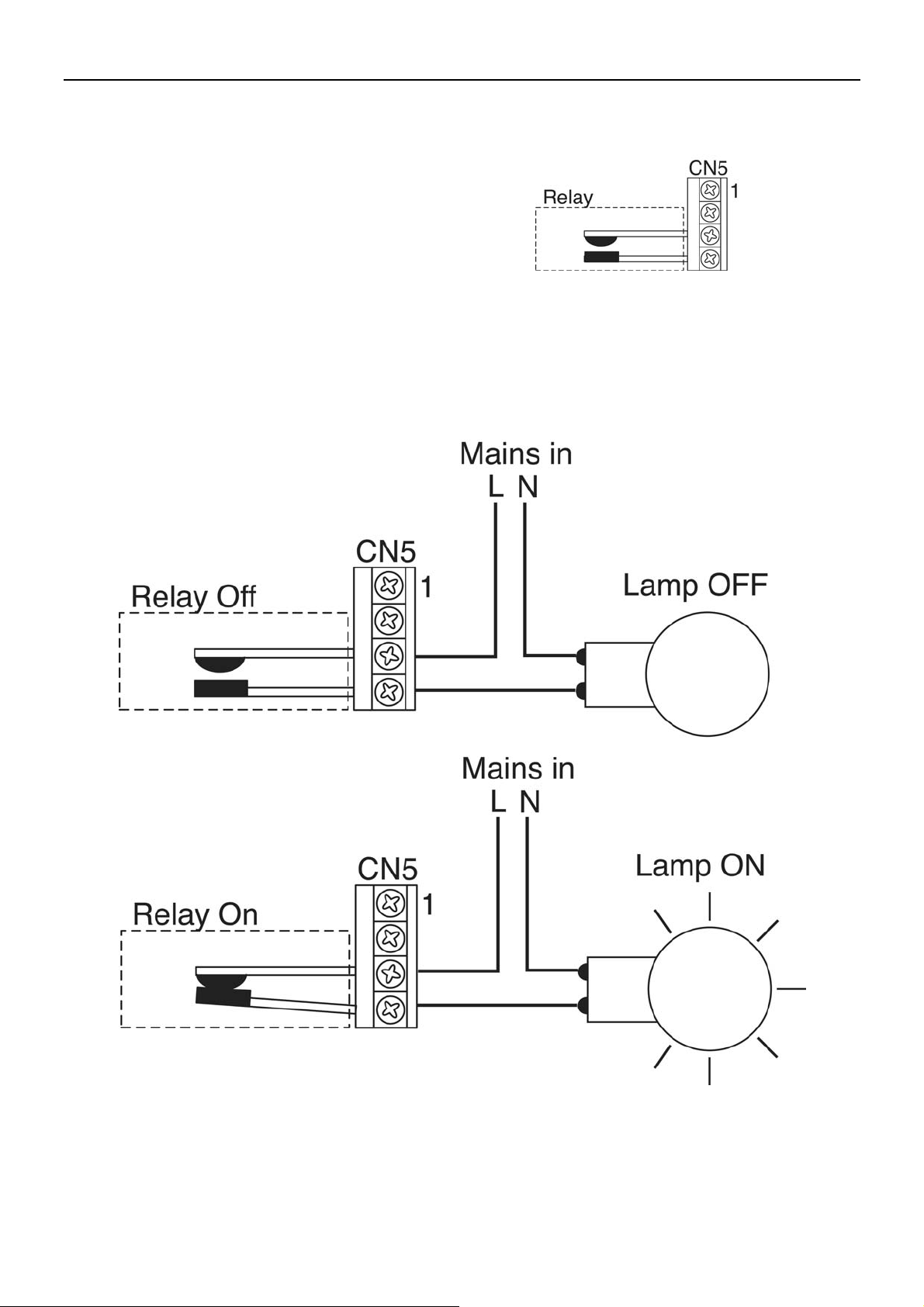

Voltage Free Contacts

The timer controls the operation of

external equipment by a relay, which

turns power ON and OFF. As

supplied, the timer’s relay contacts are

said to be ‘voltage free’, which means

they have no connections made to

them, as shown in Figure 3.

To be able to use the relay contact to switch equipment ON and OFF, it needs to be wired as

shown in Figure 4. This shows a light bulb being powered from the mains, but any source of

power could be used, so long as it is wired via the timer’s main output relay contact.

Figure 3 - Voltage Free Relay Contacts

Figure 4 - Relay Contacts Wired to Control a Lamp

Wyvern Timer 2000R Operating Instructions

7

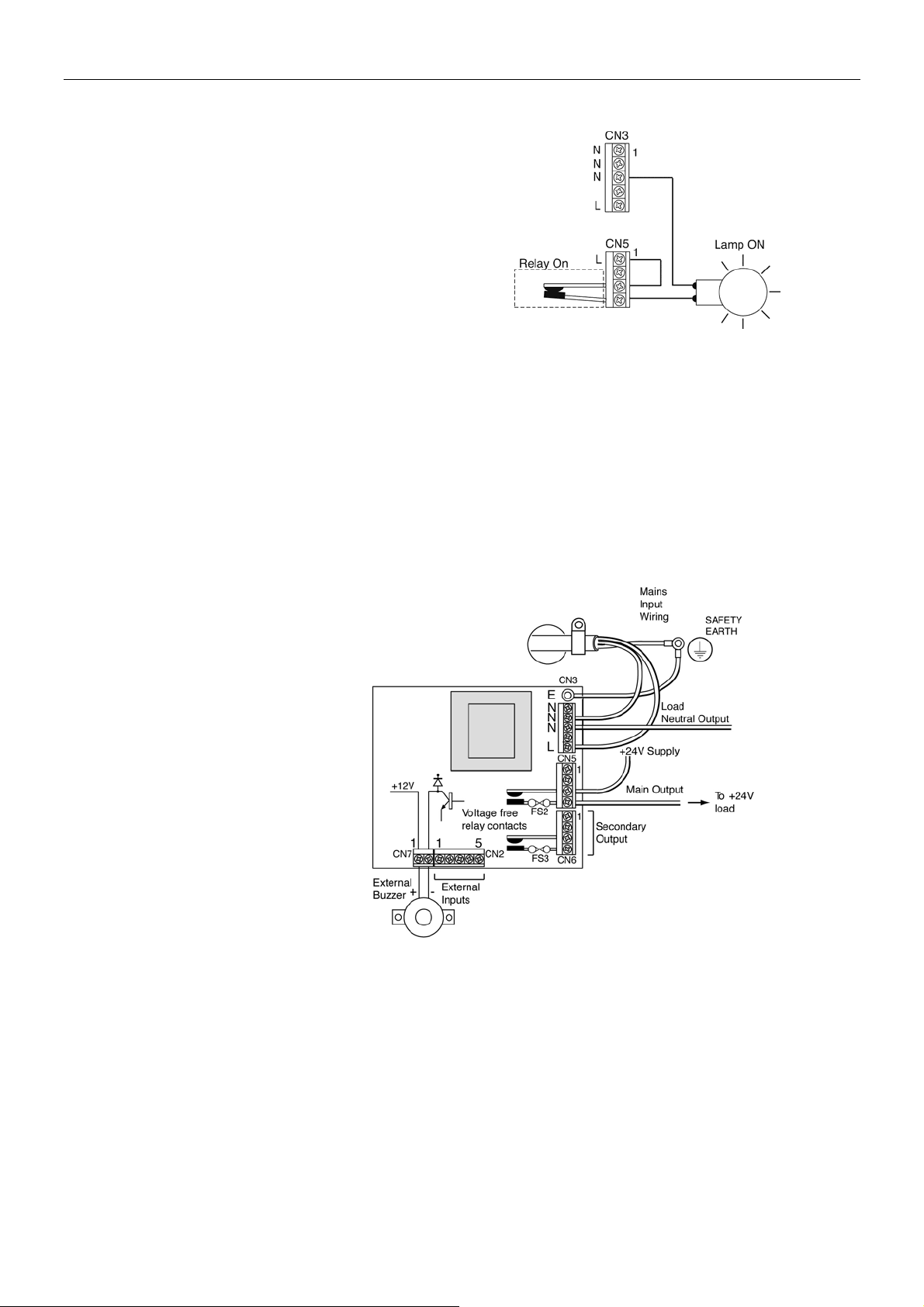

On the timer's main circuit board connectors

CN5 & CN6 already have a source of mains

power connected to pin1. This is supplied

via a circuit board track from the mains live

input on CN3. Therefore, the mains ‘L’ (live)

wire can be taken from pin 1 of CN5. The ‘N’

(neutral) wire can be connected to pins 1, 2

or 3 of CN3 where a direct connection to the

mains neutral input can be made. These

connections are shown in Figure 5.

Figure 5 - CN3 and CN5 Final Wiring

Use of Voltage Free Contacts in the Wyvern 2000R Timer

Using voltage free contacts, the Wyvern 2000R Timer can be used to control

equipment operating from a range of voltages, not just mains powered devices. For

example, the timer could control +24V DC supplies just as easily as AC mains supplies.

Supplying the timer with voltage free contacts does involve a slight overhead in installation

wiring, but gains a greater versatility in the ways it may be used.

The relay contacts are

voltage free - they have

not been pre-wired to

supply a particular

voltage when the

contacts are closed.

This means you can use

the contacts to turn-ON a

supply of your choice.

For example, Figure 6

shows how a 24V DC

supply can be controlled

via the main output. This

can switch up to 3.15A,

which is adequate for

most external contactors.

Figure 6 – Voltage Free Contacts & External Buzzer Wiring

8 Wyvern Timer 2000R Operating Instructions

Wiring Connections

Cable and fuse size:

With 24V, VF (volt-free)

and 1kVA loads use cable

of cross-sectional area not

less than 1.0sq. mm

(1mm2) and externally fuse

at 5A.

With 7kVA rated models

use cable of not less than

6.0sq. mm (6mm2) and

externally fuse as

appropriate up to a

maximum of 30A.

The use of 20mm conduit is

recommended (use male

thread adaptor with lockring, for example Ega type

EMA 1ZM). Alternatively fit

a 20mm nylon compression

cable gland to provide

strain relief.

The high current

connections shown in

Figure 8 are required only if

the total current of both

outputs exceeds 3.15A.

Refer to page 3 of the

electrical installation section

for further details.

Figure 7 – Mains Wiring

Figure 8 - High Current Connections

WARNING

THE TIMER CASE MUST BE SECURELY CONNECTED TO A KNOWN EARTH

Refer to page 5

Wyvern Timer 2000R Operating Instructions

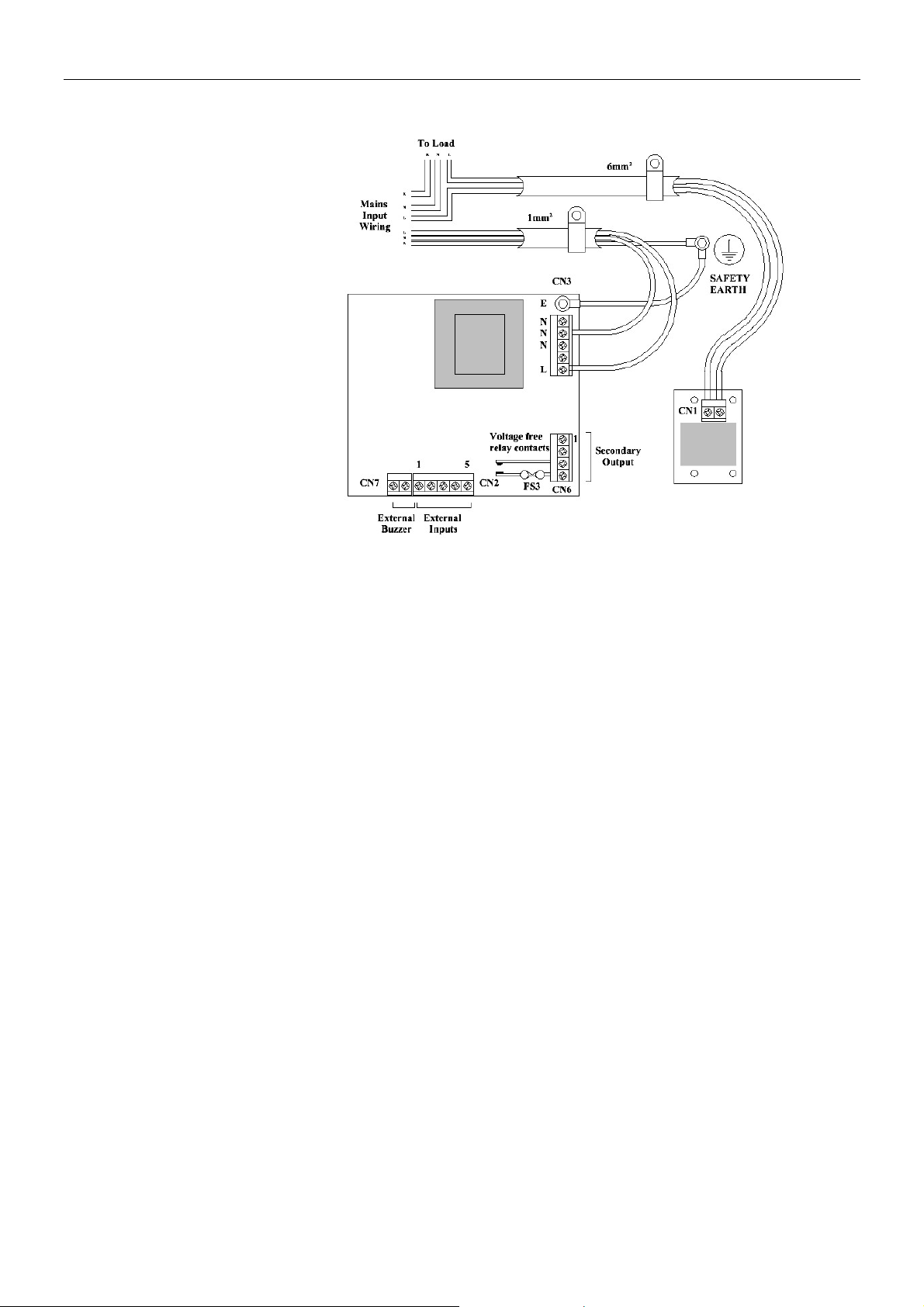

Optional 7kVA Output

Timers fitted with the

optional 7kVA output

have the main output

relay mounted off-board.

This is wired as shown in

Figure 9.

The 7kVA circuit can be

used to switch currents

of up to 30A (resistive

load), and will require a

suitable fuse to be fitted

on the mains input side

to protect whatever load

is connected.

9

Figure 9 – 7kVA Option Wiring

External Buzzer Connections

You can wire an external buzzer, or relay, to the timer using connector CN7. Use a 12V

piezo-electric buzzer or a relay with 12V dc coil with the positive (+) side wired to the left-handside (pin 1) of connector CN7. The buzzer or relay is driven from an open collector transistor

mounted on the main circuit board and is wired as shown in Figure 6. In both cases maximum

current consumption must not exceed 100mA.

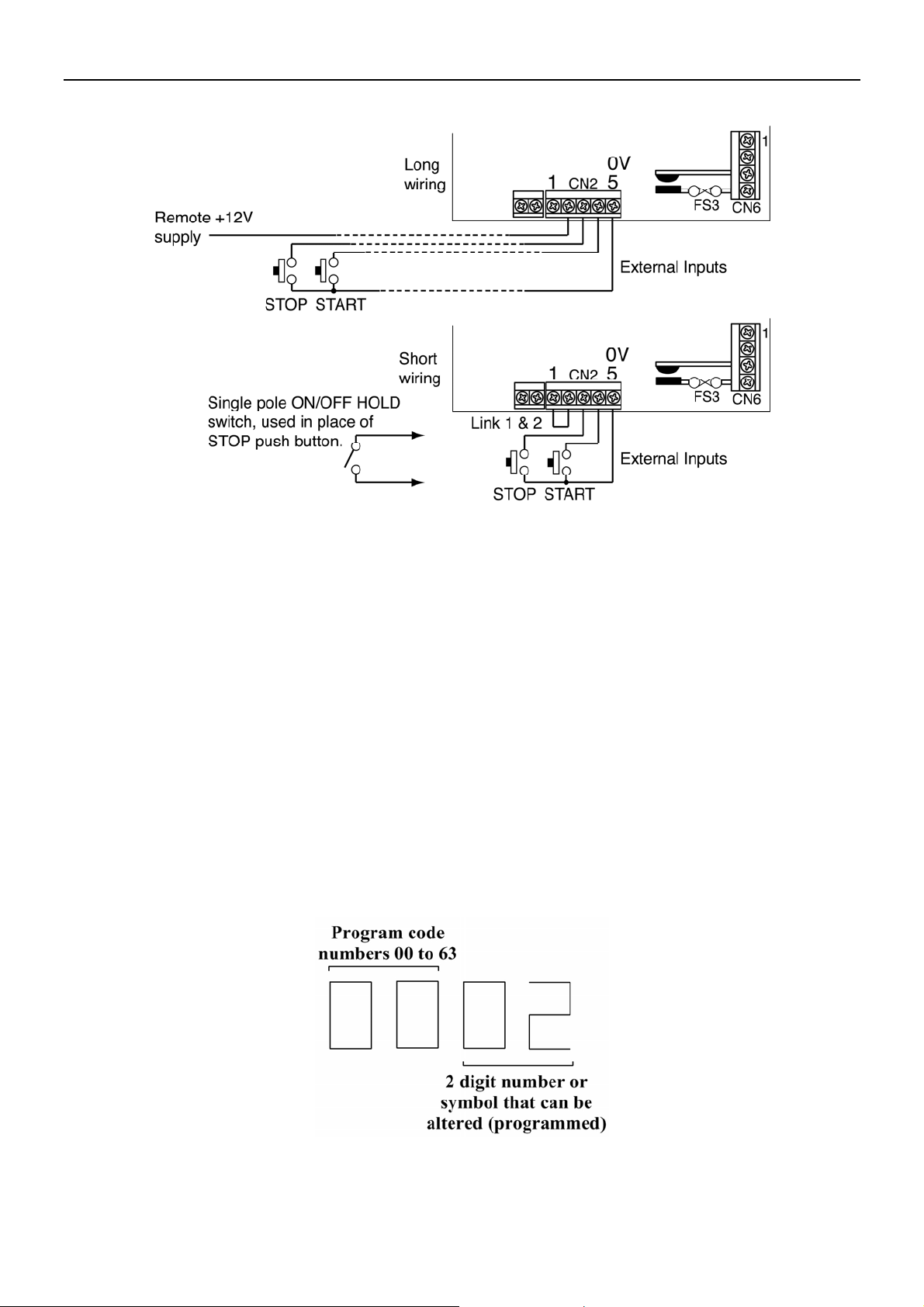

External Input Connections

Where the timer is to be controlled remotely, using externally connected push-button

switches; the connections available on CN2 can be used. These inputs are optically isolated

and require a low current +12V DC supply to operate correctly. Where the external buttons are

only mounted a few metres away from the timer, they can be supplied directly from the timer

itself. But if mounted tens of metres away, they will require an externally generated +12V DC

supply to operate reliably. The two possible circuit arrangements are shown in Figure 10,

which also illustrates the wiring of the HOLD switch, used when it is required to turn the timing

function on and off remotely.

When controlled from a remote location, pressing the start push-button will start the timer

regardless of any pretime/start delay that may have been set. Pressing the stop push-button

will immediately stop the timer. The secondary output may or may not turn off when the external

stop push-button is pressed depending on the setting of special option program code 01 (see

page 18). If a single ON/OFF HOLD switch is used in place of the start push-button and

program code 28 ‘set remote hold’ is selected (see page 24), the timer can be turned ON or

OFF from a remote location. With the switch ON the timer behaves normally, but stops timing

when the switch is turned OFF, only to restart when the switch is turned ON again.

All external inputs will only be recognised if program code 23 is set ON (see page 24).

10 Wyvern Timer 2000R Operating Instructions

Figure 10 - External Inputs For Local and Remote Wiring

Programming The Wyvern 2000R

To control the operation of the timer, for example to let it know when to charge at peak rate,

or how much time to allow for each coin inserted, it needs to be programmed. This consists

of entering two digit numbers or options into various empty memory locations, identified by

program code numbers (00 to 63). You step forwards or backwards through the program

code number to where you wish to make a change, alter the settings, and then return the timer

to normal operation. If you don’t wish to use all the timer’s facilities those code numbers can be

ignored and left blank.

For example, if you wished to set the timer to wait 2 minutes before switching ON whatever

was being controlled (start delay time), you would select the general programming mode,

choose program code 00 and alter the two digit contents to 02. This will program the pretime as 2 minutes. The display is as shown in Figure 11. For a complete programming

example see page 13.

Figure 11 – Programming Start Delay Time

Wyvern Timer 2000R Operating Instructions

11

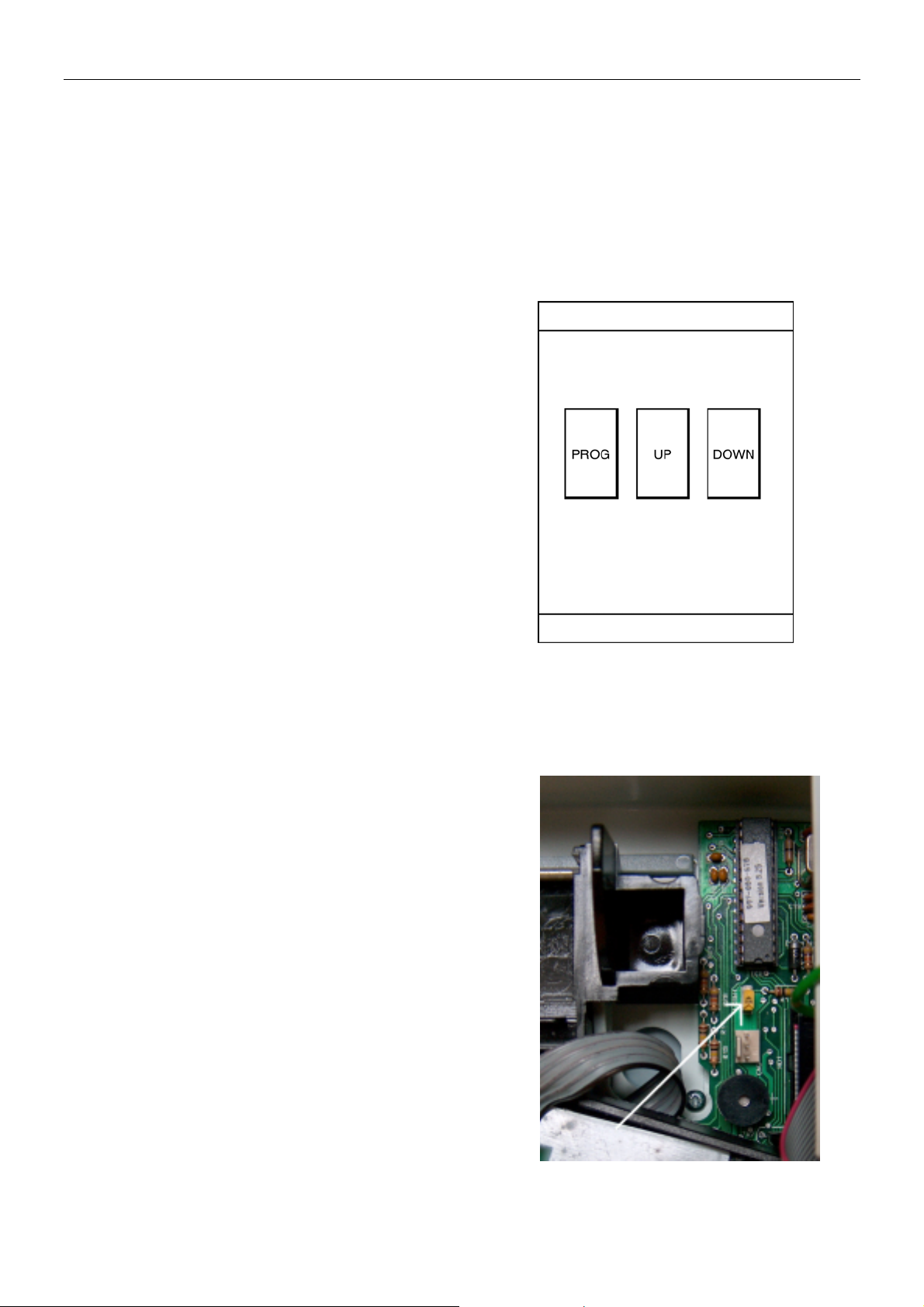

Selecting programming modes

Before changing the two digit values held in each program code number setting, it is necessary

to place the timer into programming mode. Place the programming template (shown in Figure

12), over the timer front panel logo (covering the name Wyvern 2000). The template shows the

positions of three hidden programming buttons. Note: these buttons cannot be used until the

programming switch is turned ON.

Together with the front panel four digit

display, these three buttons allow program

code numbers to be selected to customise

the timer.

Three menus are possible:

1. Setup programming. Selected using the

DOWN button.

2. Special options. Selected using the PROG

button. See page 27

3. Interrogation mode, total coin count or

hours used. Selected using the UP button.

Note: If the wrong button is pressed, return

the programming switch to its normal

position, wait for ‘Stor’ to be displayed then

Figure 12 – Programming Template

return to the programming mode once more.

The programming switch is mounted on a

circuit board held inside the front opening part

of the timer case. Open the timer case door to

its full extent and look to the right hand side of

the coin mechanism (attached to the back of

the door), where a circuit board as shown in

Figure 13 will be visible. The programming

switch is marked LKSW1, this needs to be slid

gently upwards to put the timer into its

programming mode.

LKSW1 must be left in the programming mode

position until all programming has been

completed, when it can be slid down into its

normal operating position. Returning LKSW1

to its normal down position will automatically

store all the programming information

previously entered.

Figure 13– Position of LKSW1

12 Wyvern Timer 2000R Operating Instructions

To alter program settings follow the procedure described below:

Note: The UP and DOWN keys do not zoom (automatically increment when held down) and

once at ‘9’ the display remains at ‘9’ until altered.

1. Apply power to the timer and the Wyvern 2000R should power up, finally displaying the time

(in 24-hour format) on its 4-digit display. Using the key supplied open the front cover and set

the programming switch to the ON position. Keep the switch in this position until all

programming is complete, and then return it to the normal OFF position (at step 9).

2. Close the front cover and lock in place.

3. With the programming template in position, a choice of programming mode can be made

using the UP, DOWN or PROG buttons. Note: pressing the DOWN button will give you access

to all the general programming options, while selection of the UP button gives access to the

interrogation options. Pressing the PROG button gives access to special options menu and is

described on page 27.

Pressing DOWN will flash the message ‘Prog’ on the display and will select program code

00, which is the first general programming memory location. General program locations 00

to 63 on the coin reject timer can be programmed in this mode.

Pressing UP will flash the message ‘Tot’ on the display and will select program code 00,

which is the first total money memory location. Interrogation locations 00 to 05 can be

selected in this mode (see page 28).

4. To start programming, choose the program mode by pressing the DOWN key.

At this point the first two digits of the display are indicating the program code (00) and the

second two digits are indicating the value stored at this location.

5. To change the contents of program locations, choose the program code you wish to alter

by pressing the UP or DOWN keys. This will increment or decrement the first two digits of

the display until you reach the required number.

6. At the chosen program code setting, press the PROG key, and the third digit (first digit of the

stored value) will start to flash. Using the UP and DOWN keys select the required number and

press the PROG button to accept it.

7. The last display digit will start to flash, indicating it is now ready for programming to the

required number in a similar way to the first. Press PROG button to complete the selection.

8. To program further options repeat from step 5 onwards.

9. Once programming is complete, open the timer case (with power still applied) and return

the programming switch to its normal ‘run’ mode (slide the switch DOWN). The display will

briefly indicate the word ‘Stor’ (for store the settings) and will once more return to its clock

display mode, ready for timing operations.

Wyvern Timer 2000R Operating Instructions

Program Example

To get an idea of how to program the timer, work through the following example:

Problem: You wish to sound the buzzer for 25 seconds.

Solution: Look for the program code that controls the buzzer duration. This is in the timing

section and is controlled by code 20. You need to store the value 25 (25 seconds duration)

at program code setting 20. Code setting 20 is a general programming option.

Note: If more than one option is being programmed it is only necessary to return the

programming switch to normal when the last option has been programmed.

Move the program switch LKSW1 upwards to the

ON position

Press the DOWN key and the front panel display will

show

Wait a few seconds and the display will change to

0000

Press the UP key to increase the value of the first

two digits to 20

13

Then press the PROG key. The third digit will start

flashing

Using the UP key, step the value of the flashing digit

up to 2

Then press the PROG key to enter the value 2, the

final digit will start flashing, ready for data entry

Using the UP key, step the value of the flashing digit

up to 5

Press the PROG key to enter the data value 25 into

program code setting 20

To store this value, return the program switch

LKSW1 downwards to the OFF position

The display will flash STOR and will then return to

its normal display

14 Wyvern Timer 2000R Operating Instructions

Programming Time

This section describes how all timing options are programmed within the Wyvern Timer 2000R.

Selecting Hours or Minutes (program code 22)

Certain timing operations have the option of being timed in hours and minutes or minutes

and seconds. Program code 22 allows the selection of hours and minutes or minutes and

seconds. This option applies to all timing functions except the start delay/pre-time and fan

time options which are only available in minutes and seconds.

Use the UP and DOWN buttons to change between ON and OFF options.

In the following sections the Value Used column can be used to note your own settings.

Program

Code

Description Maximum

Value

Value Used

Select hours or minutes

22

Setting the Time of Day

A real time 24-hour clock is fitted to the coin reject version of the timer. Time is set using

program code 62. Once program code 62 is selected, pressing the PROG button will start to

flash the very first digit of the 4-digit display. In the normal manner, the UP and DOWN

buttons can be used to set the first 2 digits to the required hours and the last 2 digits to the

required minutes. The clock is set following the last press of the PROG button for minute

entry.

If you do not require the 24-hour clock display, set the time to 00:00. This will not change the

count-down operation of the display, but once zero time has been reached the display will

permanently display 00:00, with a flashing colon (:).

Program

Code

Hours & minutes=ON

or

Minutes & seconds=OFF

Hours or Minutes Programming Codes

Description Maximum

Value

-

Value Used

62 Setting the real time clock -

Setting the Real Time Clock

Wyvern Timer 2000R Operating Instructions

Setting Session Times and Peak/Off Peak Times

The Wyvern 2000R Timer can be programmed with peak and off peak session times (codes 08

to 15).

Peak Time allows a premium session rate to be charged when demand is high, giving you

the opportunity of maximising profits during busy periods.

Off Peak Time can be set to coincide with less busy periods where cheaper rates can be

offered to attract more business.

Session times can be programmed as a time period in hours and minutes or minutes and

seconds, depending on the setting of Program Code 22. The time at which peak rate starts

or off peak rate starts can also be programmed, each time requiring a further two program

codes – one for hours and the other for minutes.

Note: Program codes are generally programmed as a pair, the first giving a value in hours or

minutes and the second, a value in minutes or seconds.

Program codes summarising all of these timing options is presented in the table below:

Program

Codes

Description Maximum

Value

Value Used

15

08

09

10

11

12 Peak time ON in hours MAX 23

13 Peak time ON in minutes MAX 59

14 Off peak time ON in hours MAX 23

15 Off peak time ON in minutes MAX 59

Note: If you program the peak and off peak times to overlap, the peak time takes

precedence.

See also session cost (page 20), selecting additional features (page 26) and combination

of cost and time (page 2).

Peak session time in hours or

minutes

Peak session time in minutes or

seconds

Off peak session time in hours

or minutes

Off peak session time in

minutes or seconds

Time Programming Codes

-

MAX 59

-

MAX 59

16 Wyvern Timer 2000R Operating Instructions

Coin Time

This allows a period of time to be allocated to a particular coin value. For each coin type,

time can be programmed as a period in hours and minutes or minutes and seconds,

depending on the setting of Program Code 22.

Remember, these options must match the coin order of the coin value and coin learn modes.

Program

Codes

Description Maximum

Value Used

Value

31 Coin 1 time in minutes/hours -

32 Coin 1 time in seconds/minutes -

33 Coin 2 time in minutes/hours -

34 Coin 2 time in seconds/minutes -

35 Coin 3 time in minutes/hours -

36 Coin 3 time in seconds/minutes -

37 Coin 4 time in minutes/hours -

38 Coin 4 time in seconds/minutes -

39 Coin 5 time in minutes/hours -

40 Coin 5 time in seconds/minutes -

41 Coin 6 time in minutes/hours -

42 Coin 6 time in seconds/minutes -

Coin Time Programming Codes

Wyvern Timer 2000R Operating Instructions

17

Start Delay Time or Pre-time

This is the time between inserting money or a card into the timer and the timer turning ON.

As soon as you start inserting coins or card and press the blue button, the display shows the

time purchased for a period determined by option 21. Once option 21 times-out the display

will show the programmed pre-time, along with a flashing ‘P’.*

Inserting further coins or pressing the smart card blue button will again cause the display to

show the total time purchased for a time determined by option 21.

*Note: If option 21 is set to zero pre-time is not displayed.

A further option (program code 27) allows the secondary output to be switched ON or OFF

during this pre-time period.

Program

Codes

Description Maximum

Value Used

Value

00 Start delay time in minutes 59

01 Start delay time in seconds 59

21 Time purchased display time 59

Secondary output on = ON

27

-

Secondary output off = OFF

Start Delay Time Programming Codes

18 Wyvern Timer 2000R Operating Instructions

Secondary Output ON/OFF Time

Equipment controlled by the Wyvern Timer 2000R may require a secondary output to continue

running following the end of the timed operation (for example a fan operated cool-down period).

The secondary output program codes only allow you to set this time in minutes and seconds.

During the run-on period the display may flash ‘Cool’, depending on how program code 25 has

been set. Additionally by selecting program code 3002 coin lockout may be activated during

cool down.

Further options include the use of program code 27 to allow the secondary output to be

switched ON or OFF during the start delay or pre-time, and program code 28, which allows

the keyswitch to control the secondary output operation.

Program

Codes

Description Maximum

Value Used

Value

02

03

25

Secondary output time in

minutes

Secondary output time in

seconds

Display of ‘cool’ = ON

-

-

-

Display blank = OFF

27

Secondary output on = ON

-

Secondary output off = OFF

When keyswitch is active,

secondary output is on=ON

28

-

When keyswitch is active,

secondary output is off=OFF

Secondary Output Time Programming Codes

Additionally to the options described above special option program code 01 (see page 27)

determines whether the secondary output remains on or turns off when the external stop, or

optionally fitted emergency stop switch, is pressed. With special option program code 01 set to

OFF (default factory setting) both the main and secondary outputs turn off and all remaining

time is cancelled. If special option program code 01 is set to ON only the main output turns off

and the secondary output remains running for the time determined by program codes 02 and

03. The external input must be enabled with program code 26 (see page 24).

Special

Code

Description Maximum

Value Used

Value

01

Secondary output = ON

-

Secondary output = OFF

Emergency Stop Special Option Code

Wyvern Timer 2000R Operating Instructions

19

Lockout Time

A safety feature built into the Wyvern 2000R Timer is the ability to prevent the timer

from exceeding a maximum time despite a customer inserting more coins or a card. This

lockout time is particularly useful in setting a limit to the exposure of UV radiation in tanning bed

applications.

Lockout will activate once a defined maximum time has been exceeded. During this time,

the display will flash an ‘L’ character to indicate lockout is active and additional coins are

rejected. If program codes 16 and 17 are set to zero lockout is not operative.

Important: Do not set lockout time to a value less than the session time (options 08 and 09).

Lockout can be initiated after the insertion of the first valid coin by using program code 3008,

during cool down with program code 3002 (page 26), or at the end of pre-time with special

option code 00.

Program

Codes

Description Maximum

Value Used

Value

16

17

Special

Code

00

Lockout time in hours or

minutes (see program code 22)

Lockout time in minutes or

seconds (see program code 22)

Description Maximum

Normal operation = OFF

-

59

Value Used

Value

-

Lockout at pre-time end = ON

Lockout Time Programming Codes

Buzzer Time

To warn that a timed operation is coming close to ending, a buzzer may be sounded.

Buzzer ON time is the time the buzzer is sounded before the timer switches OFF.

Buzzer duration is the time for which the buzzer is sounded.

To select the buzzer duration time in minutes select program code 3001 (see page 26)

Program

Codes

Description Maximum

Value Used

Value

18

19

Buzzer ON time in hours or

minutes (see program code 22)

Buzzer ON time in minutes or

seconds (see program code 22)

MAX 59

MAX 59

20 Buzzer duration time in seconds MAX 59

Buzzer Time Programming Codes

20 Wyvern Timer 2000R Operating Instructions

Programming Money Values

This section tells you how to program the cost of sessions, and the value given to each coin

type. The options described are selected using the general programming mode. The

amount of money collected can also be examined, using the interrogation mode, described

at the end of this section.

Note: In a similar manner to time, program codes are generally programmed as a pair, the

first giving a value in a particular country’s base currency (such as pounds or dollars) and the

second, a value in one hundredths of the base currency (such as pence or cents).

Session Costs

Peak and off-peak session costs can be programmed using program codes 04

to 07. This allows you to charge at two rates within any 24-hour period.

Program

Codes

Description Maximum

Value Used

Value

04

05

06

07

Peak session cost in base

currency

Peak session cost in hundredths

of base currency

Off peak session cost in base

currency

Off peak session cost in

hundredths of base currency

-

-

-

-

Session Value Programming Codes

Note: If you program the peak and off peak session costs to overlap, the overlap period will

default to the peak session cost.

See also session time (page 15), selecting additional features (page 26) and combination

of cost and time (page 2).

Wyvern Timer 2000R Operating Instructions

21

Programming Coin Values

Programming coin values gives you the means of relating a cost, in real money terms, to a

particular coin type. Each coin type has two program codes that can be used to give it a

value in the base currency and in one hundredths of the base currency.

A single session can have any time you like, programmed by the Coin Time Programming

Codes, the cost of this session can be related to a particular coin type and therefore a

particular cost. This allows you to program the timer for use with coins of any currency.

Remember, this option must match the coin order of the coin time program and coin learn

mode.

Program

Codes

Description Maximum

Value Used

Value

43 Coin 1 value in base currency -

44

Coin 1 value in hundredths of

base currency

-

45 Coin 2 value in base currency -

46

Coin 2 value in hundredths of

base currency

-

47 Coin 3 value in base currency -

48

Coin 3 value in hundredths of

base currency

-

49 Coin 4 value in base currency -

50

Coin 4 value in hundredths of

base currency

-

51 Coin 5 value in base currency -

52

Coin 5 value in hundredths of

base currency

-

53 Coin 6 value in base currency -

54

Coin 6 value in hundredths of

base currency

-

Coin Value Programming Codes

Example

For example, if coin 3 were to be a UK 50p coin, program code 47 is set to ‘00’ and program

code 48 is set to ‘50’. This would buy the amount of time allocated to coin 3 by program codes

35 and 36. Also learn coin 3, set using program code 57, would need to be learnt using twelve

different 50p coins.

Note how the coin values are programmed in pairs (47=00, 48=50) for each coin type. This

allows odd value coins, such as €1.50 to be programmed. To set coin 5 as a €1.50 set program

code 51=01 and 52=50.

22 Wyvern Timer 2000R Operating Instructions

Coin Learn Mode

One of the features of the Wyvern Timer 2000R is its ability to learn particular coin

types. This enables the timer to be used with coins from a variety of currencies and also

allows tokens to be given money values.

If you know or suspect that the timer has been previously programmed, use programming

option 61 (see page 23) to identify what coins have previously been learnt. Unwanted coins

may be overwritten by reprogramming with the correct coin or special options 03 and 04 (see

page 27) may be used to clear all existing coin data.

To program a particular coin you will need at least twelve sample coins for the timer to ‘learn’

that coin’s particular characteristic. Consequently, a mix of old and new coins should be

used and the slot entry point and speed varied as each coin is inserted*. When the first

program code is selected press the PROG button once and 12 will be displayed. Insert the

coins one after the other and the display will count down. Continue adding coins until the

display shows the program code and ‘cx’ (where x represents the coin number, 1 to 6).

The learn process is normally completed with 12 coins but occasionally a coin may be ignored if

the learn process detects abnormal coin characteristics. To move to a new code press either

the UP or DOWN button followed by PROG.

*Use coins of varying condition, or else the timer may be over sensitive and reject valid

coins. NOTE. In the Eurozone the different characteristics of national coins requires a different

learn mode. Special option 06 needs to be turned ON (see page 27).

Remember, the coin number must match the coin order of the coin time program and coin value

program.

Use program code 61 to check that coins have been learnt as required (see page 23).

Program

Codes

Description Maximum

Coin Value

Value

55 Learn coin 1 -

56 Learn coin 2 -

57 Learn coin 3 -

58 Learn coin 4 -

59 Learn coin 5 -

60 Learn coin 6 -

Learn Coin Programming Codes

Wyvern Timer 2000R Operating Instructions

23

Attaching the Coin Label

Once you have decided what coins or tokens are to be used, these may be indicated to the

user by sticking the appropriate symbol underneath the translucent window of the front panel

coin label. This label, shown in Figure 14, fits into the front panel recess just below the coin

entry slot. Stick the coin symbols on the timer’s front panel such that they show through the

translucent window and are held in place by the front panel sticker.

Figure 14 - Front Panel Sticker and Coin Symbols

Replacement stickers and coin symbols can be obtained from Leisure Controls International Ltd.

Display Coin Numbers

Program code 61 allows you to determine the coin number already assigned to a particular coin.

Note: a coin number is set by using learn coin program codes 55 to 60. Select program code 61

using UP/DOWN buttons. The display shows ‘61c7’. Press PROG button and the display shows

‘_ _c’. Insert a coin and its coin number will be displayed, for example

‘_ _c2’ or ‘_ _c3’. If a coin is not recognised the display shows ‘_ _ c0’.

Program

Codes

Description Maximum

Value Used

Value

61

Display coin number 1 to 6

-

0=coin not recognised

Display Coin Numbers Programming Code

24 Wyvern Timer 2000R Operating Instructions

Auxiliary Programming Functions

When used for a particular purpose the Wyvern Timer 2000R can be fitted with hardware

options that improve its capabilities, for example remote start or over-ride timer input.

External Input

The coin reject Wyvern 2000R Timer has optically coupled remote ‘stop’ and ‘start’ inputs

that can be enabled or disabled by program code 23. Where no external inputs are used

program code 23 can be left OFF.

The external inputs can be used to provide an emergency stop, a timer remote start or to hold

the timer OFF until it is enabled again, depending upon the setting of program code 26. These

options can only be used if program code 23 is set to ON. When a push-button is used to

remotely start the timer it will automatically over-ride any start delay/pretime. Pressing the

button will immediately start the timer. If the start delay/pretime is set to zero, the timer will only

start when you press the remote start push-button. When the external stop input is activated the

main output turns off and all time cancelled. The status of the secondary output is determined

by special option program code 01 (see page 18).

The remote HOLD option allows the timing operation to be suspended by turning the switch

OFF and then later resumed by turning the switch back ON again.

Use the program UP and DOWN buttons to change between options.

Program

Code

Description Maximum

Value Used

Value

23

Enable/disable external input

Enable=ON

-

Disable=OFF

26

Set remote start = ON

-

Set remote hold = OFF

External Input Programming Code

Pulsed Output

Option 29 allows an application (for example some sunbeds) to receive a pulsed output from the

timer rather than a continuous supply of power (normal operation). When enabled, this

option pulses the main output relay for 250 milliseconds for every coin inserted, or for every

push of the blue button. Set option 29 to ON to enable this facility.

The pulse output allows the timer to act as a remote display. If this option is used the Wyvern

2000R and the equipment being controlled must be programmed for the same time duration.

Program

Code

29

Description Maximum

Value

Pulsed output

Pulse output=ON

-

Value Used

Normal operation=OFF

Pulsed Output Programming Code

Wyvern Timer 2000R Operating Instructions

Key Switch (2000RMP)/EM Button (2000REM)

An optional key switch or EM button can be factory fitted to the front panel of the timer, to the

left of the display. The key switch can be used to over-ride the timer function, for example during

snooker competitions or during servicing of equipment. When activated ‘PL’ is displayed. The

EM button can be programmed to take the form of an emergency stop button (panic mode) for

immediate power turn off and ‘E5P’ is shown on the display when pressed. Alternatively, using

special option code 07, the EM button may be configured to initiate a timed manual override

function (DPL mode, see page 40), typically for washing machine applications. Program code

24 selects key switch or EM button function as shown below. A further option (program code 28)

allows the key switch to control the operation of the fan output.

Program

Code

Description Maximum

Value

Value Used

25

Key switch input function

24

When keyswitch is active, fan

28

Special

Code

07

Network Control Option (2000RCN only)

Network control of the Wyvern 2000R allows the connection of multiple timers controlled from a

single PC or the Sigma console. Used with commercial tanning software or the Sigma console

all timers connected to the network may be controlled from a reception area. Real time

information allows the status of each bed to be centrally monitored. Each timer is assigned its

own unique id number and this is allocated with program code 64. The network interface module

must be fitted and program code 3040 selected for network control. The remote display module

(which allows the timer display to be seen in other locations) and failsafe monitor also work in

conjunction with the network option.

Program

Code

When keyswitch is active, fan

EM button in panic mode = OFF

EM button in DPL mode = ON

Play=ON

EM=OFF

output is on=ON

output is off=OFF

Description Maximum

Key Switch/EM Button Programming Codes

Description Maximum

-

-

Value

-

Value

Value Used

Value Used

64 Set timer id from 01 to 99 99

Network Control Selection Code

26 Wyvern Timer 2000R Operating Instructions

PC Programming (2000RPC only)

Using the PC interface allows direct programming and interrogation of the timer without using

the front panel hidden buttons. A PC interface module must be fitted to the timer to allow

connection to a PC’s RS232 serial port. The PC interface also allows use of customised

software to control the timer in specific applications. Instructions for the use of the Wyvern 2000

PC Interface are provided in the form of a PDF file on the CD containing the software.

Program

Code

Description Maximum

Value Used

Value

63

Select option 63, display shows

63co. Press PROG button, co

-

on the display starts to flash.

PC Interface Selection Code

Selecting Additional Features

Provision is made for additional features to be selected which affect other program codes.

These features would normally only be selected at installation. To select the feature it is

necessary to go to program code 30 and select the code shown in the table (for example if the

buzzer duration time is required to be in minutes instead of seconds enter code 01)

These codes are additive so to select buzzer in minutes and lockout in cool set program code to

03 or for proportional session cost and no card data set program code to 14 and so on.

NOTE. The sum of the individual digits must not exceed 9 so for example program code 04 and

program code 08 cannot be selected to give program code 12 as this represents program code

02 and program code 10.

Program

Codes

Description Maximum

Value Used

Value

3000 No additional features selected -

3001

3002

3004

3008

3010

Buzzer duration time in minutes

(code 20, Page 19)

Lockout coins/cards during

‘Cool’ (code 25, Page 18)

Proportional session

cost/session time (Page 2)

Activate lockout after first valid

coin (Page 19)

Card data not stored in

interrogation menu (Page 25)

-

-

-

-

-

3020 Door lock control -

3040 Enable network devices -

3080 Remote start & dual cycle -

Additional Features Programming Codes

Wyvern Timer 2000R Operating Instructions

27

Special Options

The special options menu, selected by pressing the PROG programming button, further

enhances the Wyvern 2000R with additional features. See also pages 18, 19 and 25.

Learn Mode for Euro Currency

In the European Monetary Area (Eurozone) each participating country mints its own version of

the currency. Consequently the consistency of the coins varies very slightly which can cause the

Wyvern 2000R to reject valid coins. To overcome this problem certain parameters in the learn

mode are modified for Euro coins. To select the Eurocoin learn mode set special option code 06

ON.

Special

Codes

Description Maximum

Value Used

Value

06

Eurozone Learn Mode = ON

-

All other Learn Modes = OFF

Eurozone Special Option Codes

Inhibit Coin & Clear Coin Data

If the smart card option is fitted (see page 30) and the coin facility is not required all coins can

be rejected. This is achieved by selecting special option code 03. If the timer has been

programmed with coins that are no longer required all coin data may be cleared from memory

by selecting special option 04.

To clear coin data it is necessary to first set special code 03 to ON then set special code 04 to

ON. When PROG button is pressed to exit the special code the display will show cL for half a

second then revert to OFF. NOTE. Re-entering the special options menu will always reset code

03 to OFF; if other codes are re-programmed then inhibit coin will also have to be reprogrammed

Special

Codes

Description Maximum

Value Used

Value

03 Inhibit Coin = ON -

04 Clear Coin Data = ON -

Inhibit and Clear Coin Special Option Codes

External Start Special Pulse Mode

This option allows a 300mS low going pulse on the external input to select coin 6 data.

Special

Codes

Description Maximum

Value Used

Value

05 External Pulse Mode = ON -

External Start Pulse Special Option Code

NOTE. Program Codes 23 and 29 must be OFF for this option to be activated

28 Wyvern Timer 2000R Operating Instructions

Interrogation Menu

The interrogation menu is selected by pressing the UP programming button and allows you to

view the total on time and total money collected by the timer. In normal use both coin and card

data are accumulated together. If only coin data is required then card data may be ignored by

using program code 30 (page 26).

Time Used Interrogation

The following codes become available when the timer is set to the interrogation menu using

the UP button. Note: Although codes 03 to 05 have been used in the program menu the

following selection codes relate to the interrogation menu.

Total Time Accumulated Values

When you select one of these selection codes, the data values displayed ‘xx’ will indicate the

accumulated time ON recorded by the timer.

Selection

Codes

Description Maximum

Value Used

Value

03

Total time xx in hundreds of

minutes

-

04 Total time xx in minutes -

05 Total time xx in seconds -

Stored Total Time Programming Codes

To reset the total time and total money values to zero, the internal programming switch must be

set to the programming mode before pressing the UP button. All the code data values must then

be set to zero (selection codes 00 to 05 inclusive). The timer will only allow data values of ‘00’

to be entered (reset), if any other value is attempted the timer reverts to the original data setting.

Return the programming switch to normal for the reset to take effect. If any one data value is not

set to zero the original data values are retained for selection codes 00 to 05 inclusive.

Example

Suppose the following figures were obtained:

Selection code 03 gives a value of 05 (100 X 05=500 minutes)

Selection code 04 gives a value of 33 (1 X 33=33 minutes)

Selection code 05 gives a value of 25 (1 X 25=25 seconds)

So the total time recorded by the timer (500+33+25seconds) will be 533 minutes and

25 seconds.

Wyvern Timer 2000R Operating Instructions

Money Interrogation Options

The following codes become available when the timer is set to the interrogation mode using

the UP button. Note: Although codes 00 to 02 have been used in the program menu the

following selection codes relate to the interrogation menu.

Money Collected Values

When you select one of these codes, the data values displayed ‘xx’ will indicate the

accumulated money values recorded by the timer.

Selection

Codes

Description Maximum

Value

Value Used

29

00

01

02

To reset the total time and total money values to zero, the internal programming switch must be

set to the programming mode before pressing the UP button. All the code data values must then

be set to zero (selection codes 00 to 05 inclusive). The timer will only allow data values of ‘00’

to be entered (reset), if any other value is attempted the timer reverts to the original data setting.

Return the programming switch to normal for the reset to take effect. If any one data value is not

set to zero the original data values are retained for selection codes 00 to 05 inclusive.

Example

Suppose the following figures were obtained from a timer set to operate with dollars and

cents:

selection code 00 gave a value of 02 (100 X 02=200 dollars)

selection code 01 gave a value of 59 (1 X 59=59 dollars)

selection code 02 gave a value of 50 (0.01 X 50=0.5 dollars or 50 cents)

So the total takings reported would be (200+59+0.5) $259.50.

Total money xx in hundreds of

base currency

Total money xx in units of base

currency

Total money xx in hundredths

of base currency

Stored Total Value Programming Codes

-

-

-

30 Wyvern Timer 2000R Operating Instructions

Smart Card Operation

Smart card operation creates a range of versatile options for the Wyvern Timer 2000R.

Card Types

The Wyvern Timer 2000R can use up to five different types of smart card divided into the

following two groups:

Control Cards

In Use Cards

Control Cards

There are three types of Control Card:

Reset Timer Card (standard mode, coins and cards accepted on any timer)

Set Timer to Site Card (only cards from that site will be accepted)

Set Timer to Profit Card (puts the timer into profit mode)

Reset Timer Card

This returns a timer to normal operation after being programmed to ‘Set Timer to Site Card’

or ‘Set Timer to Profit Card’ mode.

Set Timer to Site Card

Card security is assured by the use of an embedded Wyvern code that prevents the use of

other smart cards, and a site code, which prevents the use of other Wyvern cards from

another site being used. Leisure Controls International Limited and its authorised distributors

control the site code by a user PIN number.

Set Timer to Profit Card

The Set Timer to Profit Card is used to put the timer into profit share mode and requires you

to enter your user PIN number before the change can be made. See the later section on

Profit Share.

Control Card Operation

To perform any of the above card operations, insert the Control Card into the reader and

press the front panel down button. Enter the user PIN number embedded on the card as if

you were entering a program code. Using the UP and DOWN buttons select each digit in

turn and press PROG to confirm each selection. Upon entry of the last digit, the display will

show ‘Acc’ until the card is removed. Entry of an incorrect PIN number will display ‘Err’.

Once the card is removed the timer will be set to the mode determined by the type of Control

Card used.

Wyvern Timer 2000R Operating Instructions

In Use Cards

There are two types of In Use Cards:

User Card (issued to the user of the timer)

Profit Card (a card that holds a pre-programmed number of session credits – see Profit

Share)

User Card

Each User Card has memory locations to contain:

Time

Value

Total value purchased

Total time purchased

NOTE Both total value purchased and total time purchased cannot be programmed on

the same card. Either one or the other must be chosen.

The User Card can be programmed in one of four ways:

1. Time and value stored on the card with the total value selected. Value on card deducted

from total value.

2. Time and value set to zero on the card (timer settings used) with total value selected.

Value stored in timer deducted from total value.

3. As value only stored on the card with total value selected. Value on card deducted from

total value.

4. As time only stored on card with total time selected. Time on card deducted from total

time.

Option 1 allows the card to control the time per session and the value allocated to that

session. This means it is possible to program the card to give a different rate to that of the

timer. For example, if the timer were set to give two minutes for £1-00, programming the card to

give three minutes for £1-00 would override the timer settings. To encourage card use, the

higher the cost of the card the greater the amount of discount that could be given.

Option 2 sets the value and time settings of the card to zero and uses the timer’s settings.

This will enable use of the card in a variety of timers all charging different rates. The timer

settings used depend upon the coin number programmed on the card. For example, suppose

coin 3 was programmed on the card and the timer had been set to identify coin 3 as a £2-00

coin that gave 2 minutes. The value used would be £2-00 and the time would be 2 minutes. If

no coin is specified a default of 6 is used.

Discount rates can be offered on the card using option 2 by setting a non-existing coin to any

value of (say) £3-00 within the timer. This non-existing coin will never be ‘seen’ by the timer, but

exists on a card and could give a discount rate for the card user. The coin number should not

be taught to learn a coin and the corresponding time needs to be set-up in the timer.

Option 3 allows programming the card as a fixed total value only with time being set to zero.

The timer will deduct the value from the total value each time the card is used. The card uses

the session time stored in the timer (program codes 08 and 09).

31

32 Wyvern Timer 2000R Operating Instructions

Option 4 allows programming the card as a fixed total time only with the value being set to zero.

The timer will deduct the time from the total time each time the card is used.

WARNING

For all the card programming modes described above the timer session time (options 08 and

09) will take precedence over session time values stored on the card. In practice, this means

that use of a card with a time value less than the session time offered by the timer will give only

the time programmed on the card. Multiple presses of the timer’s blue button will be required

(debiting value from the card) until sufficient time has been used to equal the timer’s session

time. To avoid these anomalies always ensure time programmed on the card equals or

exceeds any session time programmed in the timer.

User Card Operation

1. Insert the card as indicated. The timer’s display will change from displaying the time to

alternately flashing between the word ‘cArd’ and a display of total value available on the card.

After approximately two seconds, the display will start to flash the amount of time available on

the card. Removal of the card at this point will cancel the operation. If the card is empty, the

display alternates between ‘cArd’ and ‘00:00’ until removed.

2. Press the blue smart card pushbutton (Figure 1) to select time, further presses of the button

will transfer more time from the card to the timer. Selecting too much time may cause the

lockout time to be exceeded (options 16 and 17) and the display will indicate ‘Loc’. Once the

display indicates the required amount of time, remove the card. The display will show ‘Acc’ and

the timer will turn-on once any pre-time has been counted down.

Note 1: If an incorrect card is inserted the display shows ‘Err’.

Note 2: Insert a card at any time during a timing session to increase the session length.

Display of Total Value

The timer displays total value in complete units of base currency, there is no display of

hundredths of base currency. If you debit a card with less than one complete unit of base

currency (50p, for example) the display will show the total value to the nearest complete unit.

Example: Using a card with a total value of £33-00 which debits 50p for each insertion.

ACTION TIMER DISPLAY REAL AMOUNT

After first insertion 32 £32-50

After second insertion 32 £32-00

After third insertion 31 £31-50

After fourth insertion 31 £31-00

This continues until zero value remains on the card.

Inhibit Coins

If coin operation is not required with the smart card feature then set special option program

code 03 to ON (see page 27).

Wyvern Timer 2000R Operating Instructions

Profit Share

Profit share mode of operation can be used where a holding company leases out equipment

free of charge, but expects to share the profit generated by that leased equipment. The

system works using a ‘Set Timer to Profit Card’ Control Card to switch the timer to profit

share operation.

Once set to profit share, an In Use Profit Card sets-up the timer to offer a fixed number of

sessions at a certain cost per session. Once the timer has used-up all of the allocated

sessions it will require another Profit Card to be inserted to provide it with another fixed

number of sessions. For example, the company leasing the equipment may take the money

collected by the timer and will return a certain percentage of it to the holding company in

return for another Profit Card. Without another card, the timer will refuse to work and can

only be programmed to allow alteration of the real-time-clock.

This method of operation does not require the holding company to collect money directly

from installed timers and denies equipment operation until another In Use Profit Card is

purchased.

Profit Share Operation

To operate a profit share scheme the holding company will require two smart cards:

1. Set Timer to Profit Card (Control Card)

2. Profit Card (In Use Card - the one sent to the company leasing the equipment)

The Set Timer to Profit Card is used to put the timer into profit share mode and requires you

to enter a PIN code before the change can be made.

The Profit Card, as previously explained, is a card that holds a pre-programmed number of

session credits. A total time or money value is held on the card and the time or cost of each

session. This card is also protected with a PIN code.

Set Timer to Profit Cards and Profit Cards can be produced using a smart card programmer,

available from Leisure Controls International Ltd. Also available from Leisure Controls

International is a third type of card (Reset Timer Card) which can be used to return a timer to

normal operation.

33

34 Wyvern Timer 2000R Operating Instructions

Profit Share Setup

This is performed by following the Control Card Operation procedure explained previously.

Once set to profit share the timer is ready for the Profit Card. When the correct Profit Card

has been inserted the timer will then work normally using coins, tokens or User Cards, but

cannot be programmed to change any of the program codes other than setting the real time

clock. In profit mode the timer is completely controlled by the settings applied via the Set

Timer to Profit Card.

Note:

1. You do not need to select the timer’s programming mode to enable profit share setup.

2. The PIN code must agree with the code used while programming the setup smart card.

3. Once a timer is set to profit mode, pressing the PROG button will display the total profit

remaining within the timer.

Using the Profit Card

The following procedure applies the first time you use a Profit Card or when you need to

top-up the sessions within a timer:

1. Insert the Profit Card, the timer’s display will indicate the number of sessions remaining in

the timer. For example, if the timer had four sessions remaining the display will show:

‘P_:04’ Programmed with 04 remaining sessions

2. Press the front panel DOWN button. Now enter the PIN code, as if you were entering a

program code and data. Using the UP and DOWN buttons select each digit and press the

front panel PROG button to confirm each digit entered.

3. Press the front panel PROG button once more and the timer’s display will flash between

‘Acc’ and the number of sessions now loaded into the timer. For example, if the Profit Card

contained another ten sessions the display would flash between ‘Acc’ and ‘P_:14’ indicating

the timer now contains another ten (fourteen in total) sessions.

Wyvern Timer 2000R Operating Instructions

35

Technical Specifications

230V Models

Input 230V 50Hz 7A

Switching capacity 1kVA standard (3.15A resistive), 7kVA option (30A resistive)

Power consumption Less than 10W in standby, no output load active

115V Models

Input 115V 60Hz 7A

Switching capacity 1kVA standard (3.15A resistive), 3.5kVA option (30A resistive)

Power consumption Less than 10W in standby, no output load active

All Models

Fuses Type T HBC 250V breaking capacity, 20 x 5mm

FS1 500mA; FS2 & FS3 3.15A

Colour White epoxy polyester powder case, blue moulded fascia

Time intervals Programmable minutes & seconds or hours & minutes (99.99 Max)

Display 0.6 inch high green LED

Coin User programmable

Dimensions H: 275mm W: 204mm D: 90mm

Weight 3.7kgm

Case 18swg mild steel

Lock Radial 8 pin with two keys

Cash box capacity 400 coins of 23mm diameter x 2.5mm thick

Service Information

The Wyvern 2000R Timer has been designed to provide reliable long-term use for a variety of

timing applications. No regular servicing is required, apart from emptying of the

cash box.

Repairs

When reporting any fault with the timer it is useful to quote the serial number (located on

underside of the timer) and the firmware issue numbers first displayed when the timer is

turned ON.

When power is first applied the display indicates ‘I55’ (meaning issue) followed by ‘8.x’, followed

by ‘5. x’. These numbers have the following meanings:

8.x is the processor firmware revision number and follows the sequence 8.0, 8.1, 8.2 etc.

5.x is the coin detection firmware revision number and follows the sequence 5.1, 5.2 etc.

IN MOST CASES IT IS NOT NECESSARY TO REMOVE THE TIMER FROM THE WALL.

WARNING

Remove all sources of power from the timer before attempting any repairs.

36 Wyvern Timer 2000R Operating Instructions

Note. If during installation, if it is necessary to remove the ribbon cable connecting the two

circuit boards the real time clock must be re-program once the boards are re-connected.

If the 7kVA relay, mounted to the side of the main circuit board, fails, its loom should be

disconnected, and the two M3 nuts and washers removed carefully and a new relay fitted.

Module replacement

If a particular module or part is required to be replaced within the timer’s one year warranty

period, Leisure Controls International Limited Ltd offer a free of charge advanced module

replacement service. A replacement module will be despatched in return for the damaged part.

The faulty module must be returned within 14 days or a charge will be made. An authorised

returns number must first be obtained from the technical support department of Leisure Controls

International, or authorised distributor, before returning any parts.

Technical Support

Before contacting technical support please visit the support section of Leisure Controls

International’s web site at www.lcigb.com/support where many answers to questions may be

found.

Alternatively contact technical support directly by one of the following:-

E-mail: support@lcigb.com

Telephone: +44 (0) 1258 483574

Fax:: +44 (0) 1258 488526

IMPORTANT The Wyvern 2000R Timer is designed for indoor use only.

Enhancement Dates

This manual contains references to enhancements made in version 8 of the Wyvern 2000R. The

following lists the processor firmware revision number, the date of implementation and options

added.

8.19 September 2006 Special options 3 & 4 added

8.20 February 2007 Special option 5 added

8.24 June 2007 Special option 6 added

8.28 July 2008 Special option 1 added

8.34 March 2018 Special option 7 added

Approvals

Wyvern Timer 2000R Operating Instructions

Summary of Program Codes & Display Messages

General Programming Codes

Program

Code

Description Can be

changed

using code

22

See page

number

Value

Used

37

00

01

02 Fan time in minutes NO 18

03 Fan time in seconds NO 18

04

05

06

07