LCI Solera Destination Installation And Owner's Manual

®

Solera

Destination Awning

Installation and Owner’s Manual

(For Aftermarket Application)

Solera®

Destination

Awning

Installation and

Owner’s Manual

(For Aftermarket Applications)

Table of Contents

Introduction ..............................................2

Quick Facts ..............................................2

Preparation ...............................................2

Resources Required .....................................2

Installation ................................................3

Installing the Awning Rail (If Necessary) ................3

Assembling the Awning ..................................4

Mounting the Bottom Mounting Brackets ................4

Mounting the Awning ....................................5

Securing the Fabric ......................................6

Installing the Stop Bolt ...................................7

Operation .................................................7

Extending the Awning ...................................7

Retracting the Awning ...................................7

Fabric Replacement ......................................8

Fabric Removal ..........................................8

Installing Replacement Fabric ...........................9

Classic Awnings Fabric Replacement Turn Chart .......9

lci1.com 574-537-8900 Rev: 03.09.18

Maintenance - Solera

Fabric Care ............................................ 10

Solera

Awnbrella™ Parts List .................................. 12

Resources Required ................................... 13

Installation .............................................. 13

Ground Support Introduction ......................... 18

Resources Required ����������������������������������� 18

Installation .............................................. 18

Removal of Ground Support .......................... 20

1

®

Destination Awning Troubleshooting ........ 11

Spacing Awnbrella Arms ���������������������������� 13

Drilling the Roller Tube ................................ 14

Mounting Hanger Blocks .............................. 15

Inserting Awnbrella Arms .............................. 15

Velcro® Stabilizers ..................................... 16

Proper Awning Extention for Awnbrella Arms ......... 17

Special Notes: ......................................... 17

CCD-0001255

®

Awnings ....................... 10

®

Solera

Destination Awning

Installation and Owner’s Manual

(For Aftermarket Application)

Introduction

Destination campers (or seasonal campers) who set up

camp for extended stays will love the Solera® Destination

Awning because it provides an additional 20 percent more

shaded outdoor area. Not only does the Solera Destination

Awning provide a 9'8" projection canopy, it also comes

with a Solera® Awning Ground Support and the Solera®

Awnbrella® to keep the fabric arched and taut to minimize

wind ap and enable rain runoff.

Quick Facts

• Operates like any manual spring roll up awning - basically

it’s a jlarger version of the Solera Classic Awning

• Wide selection of vinyl fabric and acrylic fabrics

• Comes standard with the Solera Awnbrella awning bows

which hold fabric tight and arched so water doesn’t pool

and debris can easily runoff

• Comes with a Solera Ground Support for added

stabilization

• Custom hardware color options available

Additional information about this product can be obtained

from www.lci1.com/support or by downloading the free

MyLCI app. The app is available on iTunes® for iPhone®

and iPad® and also on Google Play™ for Android™ users.

iTune s®, iPhone® and iPad® are registered trademarks of

Apple Inc. Google Play™ and Android™ are trademarks of

Google Inc.

FAILURE TO FOLLOW THE INSTRUCTIONS PROVIDED

IN THIS MANUAL MAY RESULT IN DEATH, SERIOUS

INJURY, COACH DAMAGE, OR VOIDING OF THE

COMPONENT WARRANTY�

NOTE: Solera Destination Awning drive and idler heads

are preloaded with tension and secured with cotter pins

from the factory. If the cotter pins have been removed

or otherwise lost, and tension needs to be added to the

heads, use the turn chart (Fig.1) to add the correct number

of turns to the awning heads.

Classic Awnings Pre-Install Turn Chart

Size Turns

6' to 10'

11' to 14'

15' to 18'

19' and up

Fig.1

4

5

6

8

Preparation

MOVING PARTS CAN PINCH, CRUSH OR CUT� KEEP

CLEAR AND USE CAUTION�

Do NOT remove the following items until instructed:

1� Tape securing the fabric.

2� Cotter pins in the spring assemblies.

REMOVING THESE ITEMS PREMATURELY MAY CAUSE

SERIOUS INJURY OR PROPERTY DAMAGE�

Resources Required

• 1 to 3 People

• Cordless or Electric Drill or Screw Gun

• Appropriate Drive Bits, including ⁄" and ½"

• Screwdriver

• Ratchet

• ⁄" Socket

• ½" Socket

• ½" Wrench

• ⁄" Drill Bit

• Non-Permanent Method of Marking

• Silicone Sealant or Butyl Tape

• Silicone Lubricant

lci1.com 574-537-8900 Rev: 03.09.18

2

CCD-0001255

®

Solera

Destination Awning

Installation and Owner’s Manual

(For Aftermarket Application)

Installation

NOTE: All fasteners supporting the awning assembly MUST have a backer within the structure of the wall of the unit.

Refer to unit manufacturer for proper location.

Installing the Awning Rail (If Necessary)

NOTE: Awning rail not included.

1� Position the awning rail along the line where roof and wall meet.

NOTE: The awning rail MUST be level and parallel with the oor line of the unit (Fig.2).

2� After determining the awning rail’s proper location, mark its position with a non-permanent method of marking.

3� Seal the back of the awning rail.

4� Align the awning rail on the wall and secure with #10 x ¾" screws, using all fastener holes.

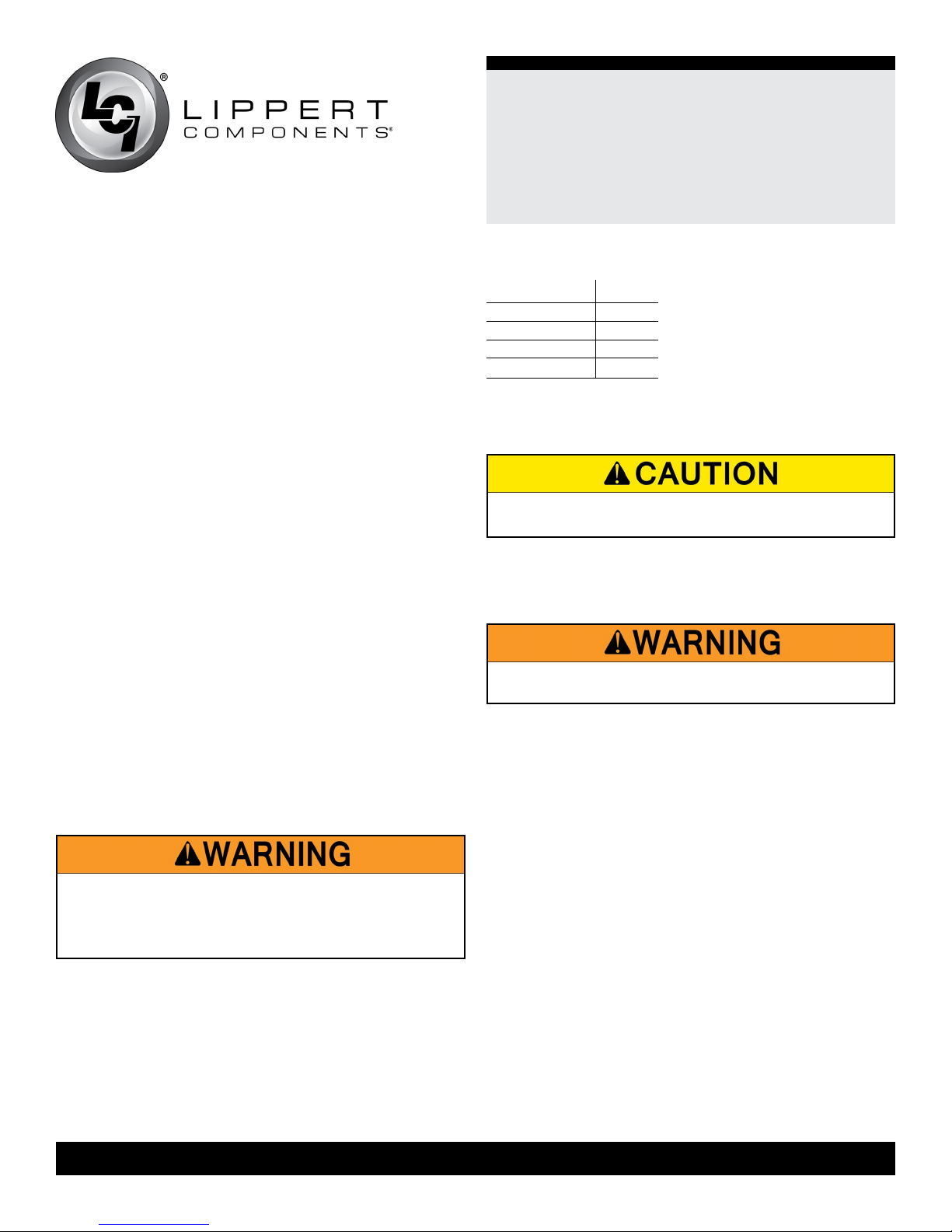

Assembling the Awning

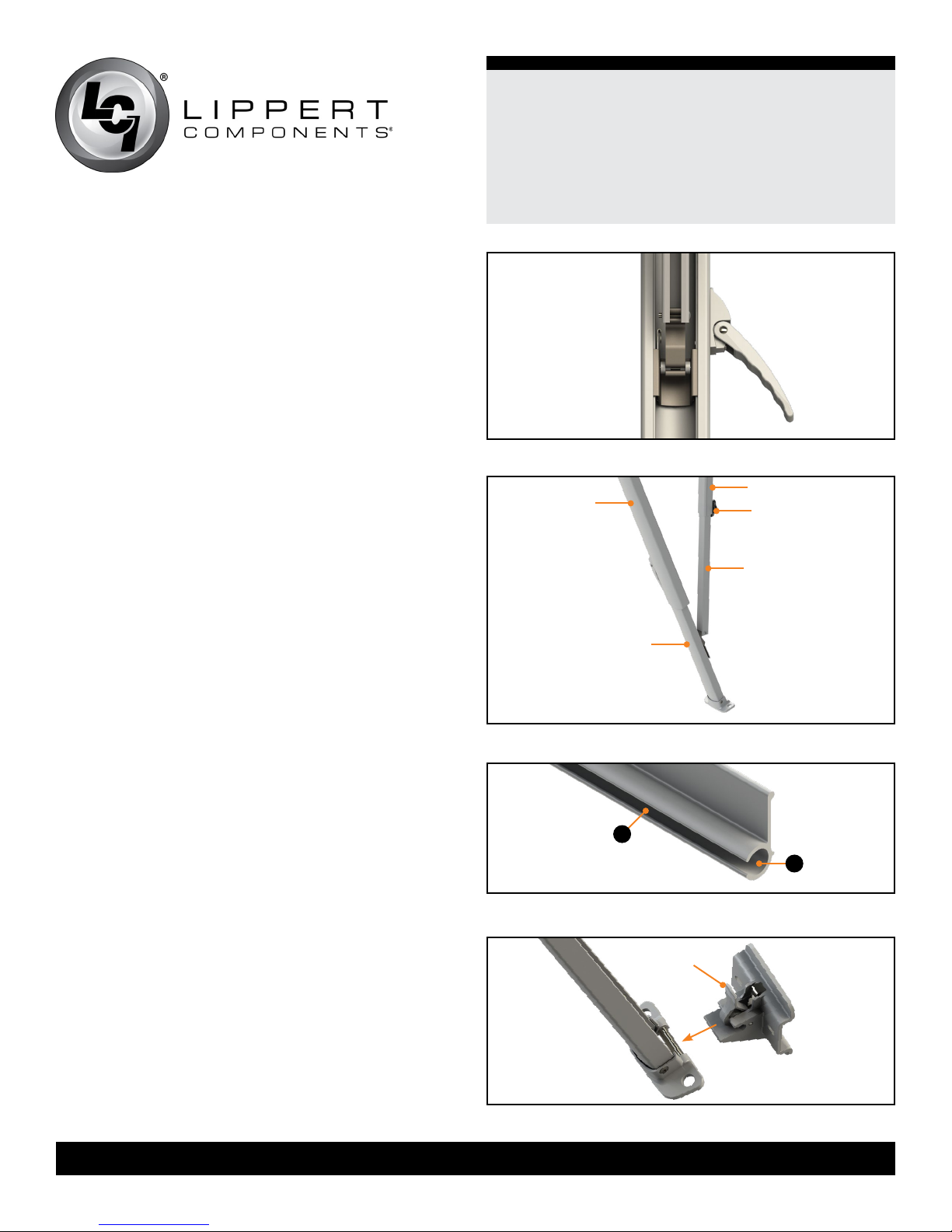

NOTE: The head assemblies (Fig.3A) and support arm assemblies (Fig.3B) are numbered to ensure proper assembly.

Match the proper support arm assembly to the correct head assembly.

A

B

Dotted line

= vertical

centerline

Fig.2

Letter Description

A Awning Rail

B Support Arm Assembly

C Roll Tube Assembly

D Lower Mounting Bracket

E Upper Mounting Bracket

Awning Width = Head Bolt to Head Bolt

C

90°

Front Facing View

Floor Line

Side View

E

B

Dotted line

= Vertical

centerline

D

D

lci1.com 574-537-8900 Rev: 03.09.18

3

CCD-0001255

®

Solera

Destination Awning

Installation and Owner’s Manual

(For Aftermarket Application)

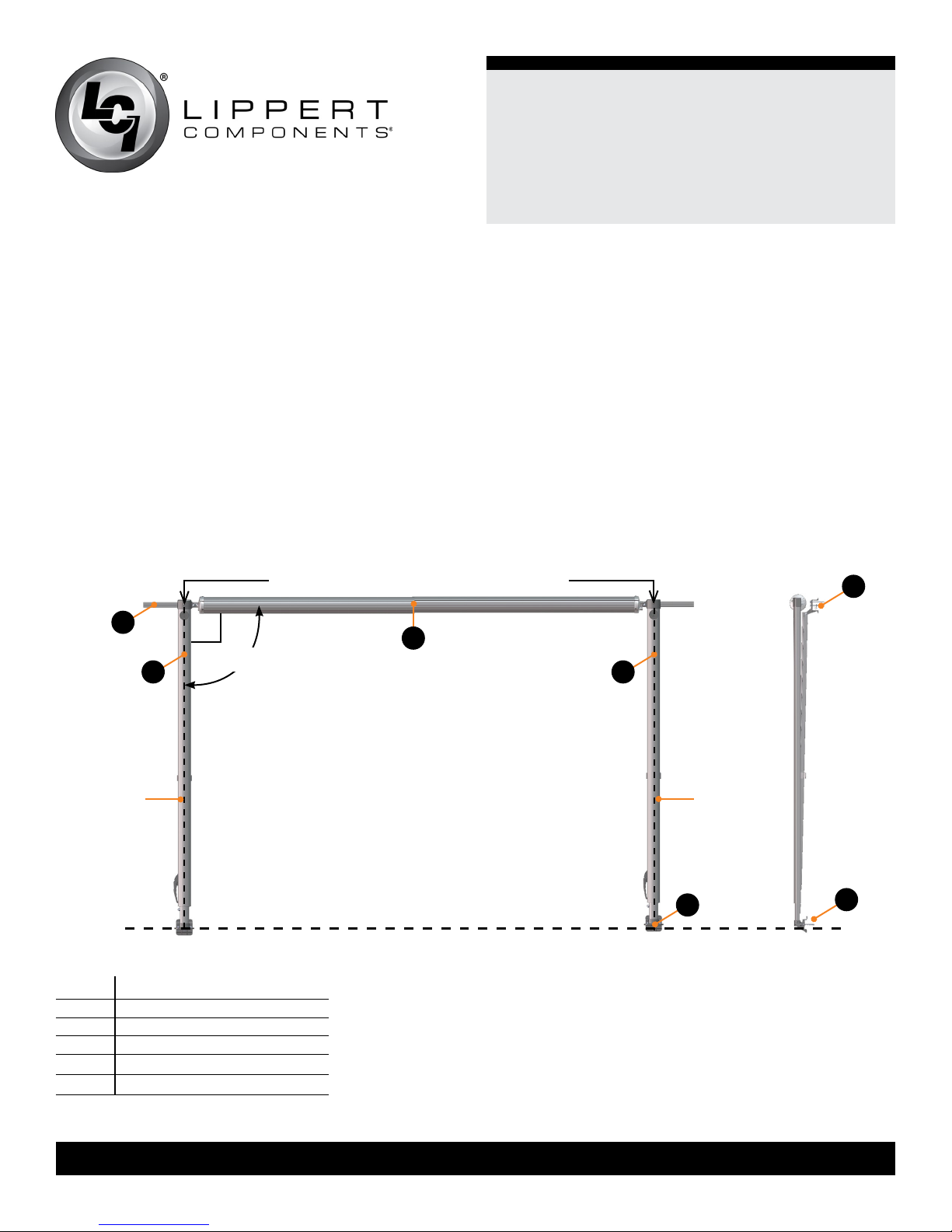

1� On a at surface, carefully lay out the support arm

assemblies and roll tube assembly. The cam lock MUST

be on the right side of the roll tube when facing the unit.

NOTE: Take care not to set the awning on any surface that

may damage the assembly or fabric.

2� Slide the left support arm assembly into the idler head

assembly of the roll tube. Align the holes and secure using

one (1) ¼-20 x ½" Phillips drive screw (Fig.4).

3� Repeat step 2 for the right support arm assembly.

4� Measure and conrm the width of the awning. The

distance is measured from head bolt to head bolt (Fig.2).

Mounting the Bottom Mounting Brackets

1� On the awning rail, mark the position of the support arm

assemblies using the head bolt to head bolt measurement.

Ensure that the support arm assemblies will not interfere with

any lights, vents or the operation of any windows or doors.

2� Using a non-permanent method of marking, mark a

perpendicular line from the mark on the awning rail down

to the oor line. This is the centerline of the support arm

assembly (Fig.2). Do this for both support arm assemblies.

3� Position the bottom bracket with the fastening points at the

oor line (Fig.5A) and center the bracket on the centerline mark

of the support arm assembly (Fig.5B). Mark the hole locations.

Using a ⁄" drill bit, pre-drill both holes. Apply a liberal amount

of sealant over the holes and attach the bracket using the ¼" x

2 ½" lag screws provided (Fig.5).

NOTE: All screws supporting the awning assembly MUST

have a backer within the structure of the wall of the unit. Refer

to unit manufacturer for proper location.

4� Repeat step 3 for the other side of the awning.

A

A

B

B

Fig.3 Fig.4 Fig.5

lci1.com 574-537-8900 Rev: 03.09.18

4

CCD-0001255

Mounting the Awning

1� Measure the distance from the awning rail channel to the

lower mounting bracket fastening point.

2� Compare the distance from the center of the roll tube

and the support arm assembly foot to the measurement in

Step 1 and adjust the support arm assembly to make both

distances equal.

A� Open the support arm assembly handle (Fig.6) and

slide the outer arm lower channel (channel#2) (Fig.7) up

or down to desired height. Close the handle and slide

the outer arm lower channel (channel#2) (Fig.7) until the

locking pin clicks into the nearest positioning hole.

3� Use a screwdriver to spread open either end of the

awning rail on the installation side (Fig.8A).

4� To protect the fabric from damage during installation, le

any sharp edges or burrs from the awning rail channel.

®

Solera

Destination Awning

Installation and Owner’s Manual

(For Aftermarket Application)

Fig.6

channel#3

channel#1

locking knob

channel#4

5� Use silicone lubricant and spray the inside of the awning

rail channel (Fig.8B).

6� Remove the packaging from the fabric. Unroll a small

portion of fabric, but not more than one rotation of fabric.

NOTE: The next step will require three people: One to feed

the polycord into the awning rail channel; two to walk the

support arm assemblies along the awning rail while the

fabric slides into position.

7� Slide the polycord into the awning rail channel and walk

the support arm assemblies and fabric down the awning

rail channel until the support arm assemblies are in line

with the centerline marks made previously.

8� Lift the support arm assembly up and secure the feet

into the previously installed bottom mounting brackets by

pressing the lever and opening the latch (Fig.9).

9� Center the upper mounting brackets on the support

arm assembly centerline marked previously and arrange

the upper mounting brackets to straddle the awning rail.

Tighten the black locking knob on the mount arm upper

channel (channel#3) (Fig.7).

channel#2

Fig.7

B

A

Fig.8

push to open

NOTE: If adjustments need made so the upper mounting

brackets straddle the awning rail, loosen the black locking

lci1.com 574-537-8900 Rev: 03.09.18

5

Fig.9

CCD-0001255

knob on the mount arm upper channel (channel#3) (Fig.7).

Slide the mount arm upper channel (channel#3) (Fig.7)

up or down as needed over the mount arm lower channel

(channel#4) (Fig.7).

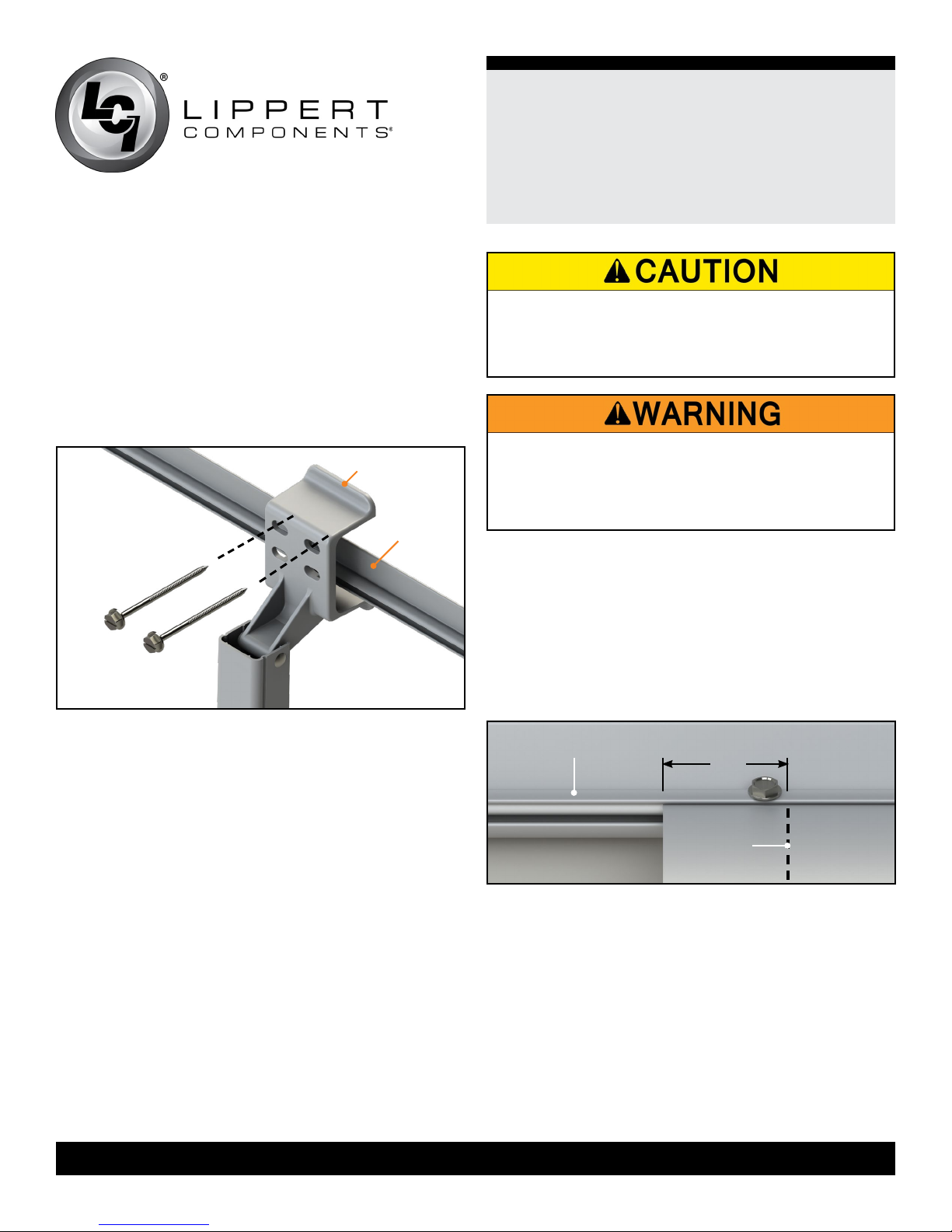

10� Once the upper bracket is placed, mark and pre-drill

two ⁄" holes through the awning rail or unit. Apply a

liberal amount of sealant over the holes and attach the

upper mounting bracket using the ¼” x 3" lag screws

provided (Fig.10).

upper mounting

bracket

awning rail

®

Solera

Destination Awning

Installation and Owner’s Manual

(For Aftermarket Application)

FAILURE TO MAINTAIN CONTROL OF THE ROLL

TUBE, FABRIC AND SUPPORT ARM ASSEMBLIES

MAY RESULT IN SERIOUS PERSONAL INJURY OR

PROPERTY DAMAGE�

USE CARE WHEN REMOVING THE COTTER PINS THE

COTTER PINS ARE HOLDING THE PRE-WOUND TENSION

OF THE SPRING� FAILURE TO SECURELY HOLD THE

ROLL TUBE MAY ALLOW THE ROLL TUBE TO RAPIDLY

ROLL UP AND CAUSE PERSONAL INJURY OR DAMAGE�

Securing the Fabric

Fig.10

NOTE: All screws supporting the awning assembly MUST

have a backer within the structure of the wall of the unit.

Refer to the unit manufacturer for proper location. It is

acceptable that the lag screws go through the at portion

of the awning rail.

11� Repeat steps 9-11 for the other support arm assembly.

12� Firmly grasp the roll tube and head and remove the

safety cotter pin from each end of the roll tube. Keeping a

rm grasp on the roll tube and head, place the cam lock in

the roll up position.

13� Allow the fabric to slowly roll up.

1� Roll the awning in and out several times to ensure that

the fabric is square on the roll tube.

2� Secure the fabric in the awning rail no more than 1"

inside the edge of the fabric on both ends using a #6 x

hex head screw. Install the screw down through the awning

rail into the fabric and the polycord (Fig.11).

awning rail

1"

fabric

stitching

Fig.11

½"

lci1.com 574-537-8900 Rev: 03.09.18

6

CCD-0001255

Loading...

Loading...