Page 1

Solution

airIDEAL

®

3P

TM

Traceability

AeroBioCollector

User's Manual

96307 - G – en - 2010/07 — P/N 4501 - 1716

Manufactured par:

Distributed by:

LCB 71260 La Salle France

bioMérieux S.A. 69280 Marcy l'Étoile / France

RCS Lyon 673 620 399

Tel. 33 (0)4 78 87 20 00 - Fax 33 (0)4 78 87 20 90

http://www.biomerieux.com

Page 2

Page 3

Revisions

The list of revisions below summarizes replacements or additional pages in your

User’s Manual

Version

Date of

printing

Modifications Pages modified

A 2001/01 Bilingual

(FR / EN)

B 2001/04 Multilingual

(FR / EN / ES / IT / DE / PT)

C 2005/11 Update of the manual

(FR / EN / ES)

D 2006/03 Update of the manual

(FR / EN / ES / IT / DE / PT)

E 2008/03 Environmental conditions

(FR / EN / ES / IT / DE / PT)

F 2010/10 Addition of a remote user interface device (RUID)

to ensure sampling traceability.

G 2011/01 Regulatory modifications:

FCC (USA) and IC (Canada).

All

All

All

All

2-12

All

Pages 2-7, 2-8, 2-11, 2-13

Pages 3-2 and 5-1

airIDEAL

®

3P™ Traceability AeroBioCollector User's Manual Revisions-1

Page 4

Page 5

Warning

IMPORTANT! Use of the instrument and manual implies acceptance of the clauses

The content of this manual is based on the Software release 0.9

This manual is periodically updated. The updates shall be included in the new

releases of the Software.

Information supplied in this manual may be subject to modifications before the

products described become available.

This manual may contain information or references relating to certain

bioMérieux S.A. products, software or services which are not available in the

country of release; this shall not mean that bioMérieux S.A. intends to market

such products, software or services in such country

To request copies of publications or for any technical request, contact

bioMérieux S.A. or your local distributor.

below and the clauses set out in the regulatory booklet. Users are invited

to refer to these clauses.

DANGER! To ensure user safety, the instrument must be used in accordance with

this manual.

Trademarks

bioMérieux, the blue logo, 3P, airIDEAL and Count-Tact are used, pending

and/or registered trademarks belonging to bioMérieux S.A. or one of its

subsidiaries.

Any other name or trademark is the property of its respective owner.

© 2010 bioMérieux S.A.

Photos: bioMérieux / Printed in France / bioMérieux S.A. RCS Lyon 673 620 399

Page 6

Page 7

Table of contents

1 How to use this manual 1-1

Finding topics and procedures ................................................................................................................ 1-1

Glossary.................................................................................................................................................. 1-2

Typographic conventions ........................................................................................................................ 1-3

The airIDEAL 3P Traceability keypad................................................................................................... 1-3

2 Functional description 2-1

Presentation............................................................................................................................................ 2-1

Principle of use.................................................................................................................................. 2-1

Operating principle ............................................................................................................................ 2-2

Performance...................................................................................................................................... 2-2

Collection efficiency validated according to the ISO 14698 standard ..........................................2-3

Physical efficiency testing approach............................................................................................2-3

Biological efficiency testing approach ..........................................................................................2-3

Use in glove boxes ......................................................................................................................2-4

Applications....................................................................................................................................... 2-4

Description.............................................................................................................................................. 2-5

Consumables ....................................................................................................................................2-6

Culture media for general use .....................................................................................................2-6

Irradiated media........................................................................................................................... 2-6

Identification of the instrument .......................................................................................................... 2-7

Front face of the airIDEAL 3P Traceability...................................................................................... 2-7

Rear face of the airIDEAL 3P Traceability ...................................................................................... 2-8

Keypad .............................................................................................................................................. 2-8

Configuration for 65, 70 or 90 mm Petri dishes ................................................................................. 2-9

Tripod assembly .............................................................................................................................. 2-10

General specifications........................................................................................................................... 2-11

Environmental conditions ................................................................................................................ 2-11

Physical features ............................................................................................................................. 2-11

Dimensions................................................................................................................................ 2-11

Mass .......................................................................................................................................... 2-11

Materials .................................................................................................................................... 2-11

Characteristics of materials .......................................................................................................2-11

Technical characteristics ................................................................................................................. 2-12

Electrical characteristics.................................................................................................................. 2-13

Functional specifications ................................................................................................................. 2-13

airIDEAL

®

3P™ Traceability AeroBioCollector User's Manual I-1

Page 8

Table of contents

Using airIDEAL 3P Traceability 3-1

3

Unpacking airIDEAL 3P Traceability.....................................................................................................3-1

Recommendations for installation and use .............................................................................................3-2

Cleaning and decontamination procedure...............................................................................................3-2

Sterilization of grids ...........................................................................................................................3-3

Decontamination of the external part.................................................................................................3-3

Decontamination of the air circuit ...................................................................................................... 3-3

Decontamination in a glove box ........................................................................................................3-3

Sampling positions..................................................................................................................................3-4

Screwing on the sampling grid ................................................................................................................3-5

Electrical power supply ...........................................................................................................................3-6

Operation on the battery.................................................................................................................... 3-6

Low battery signals ...................................................................................................................... 3-6

Charging ......................................................................................................................................3-7

Operation using mains power............................................................................................................3-8

Automatic standby.............................................................................................................................3-8

Automatic switch off ..........................................................................................................................3-8

Operation in slave mode .........................................................................................................................3-9

Operation in manual mode......................................................................................................................3-9

Programming.....................................................................................................................................3-9

Programming characteristics .......................................................................................................3-9

Sampling controls ........................................................................................................................ 3-9

airIDEAL 3P Traceability menus......................................................................................................3-10

Turning on airIDEAL 3P Traceability ...............................................................................................3-11

Standby ...........................................................................................................................................3-12

Turning off airIDEAL 3P Traceability.............................................................................................3-12

Selection of one of the 4 pre-programmed sample volumes (Menu 1) ............................................ 3-12

Programming a sample volume not in memory (Menu 2)................................................................ 3-14

Modification of the 4 pre-programmed sample volumes (Menu 3)................................................... 3-15

Programming delayed start-up (Menu 4) ......................................................................................... 3-18

Programming sequenced sampling (Menu 5)..................................................................................3-20

Battery autonomy test (Menu 6) ......................................................................................................3-22

Starting sampling ...............................................................................................................................3-23

Stopping the motor ..........................................................................................................................3-25

Setting airIDEAL 3P Traceability parameters (summary diagram)...................................................3-26

Navigation using <+> and<-> keys........................................................................................................3-28

I-2 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 9

Table of contents

4 Procedure 4-1

Principle ..................................................................................................................................................4-1

Procedure ............................................................................................................................................... 4-1

How to obtain a good quality sample ...................................................................................................... 4-2

Precautions of use.............................................................................................................................4-2

Sampling in manual mode.................................................................................................................4-3

Incubation and reading......................................................................................................................4-3

Sampling plan ......................................................................................................................................... 4-4

Recording and evaluating results............................................................................................................4-5

5 Maintenance 5-1

Preventive maintenance .........................................................................................................................5-1

Routine servicing ....................................................................................................................................5-2

Cleaning ............................................................................................................................................ 5-2

Decontamination of the external part.................................................................................................5-2

Decontamination of the air circuit ...................................................................................................... 5-2

Decontamination in a glove box ........................................................................................................ 5-2

Sterilization of the sampling grid .......................................................................................................5-2

Airflow control.................................................................................................................................... 5-2

6 Troubleshooting 6-1

7 Appendix 7-1

Using the reading table ........................................................................................................................... 7-1

Information on FELLER’s law .................................................................................................................7-2

Reading tables ........................................................................................................................................ 7-3

Notes

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual I-3

Page 10

Note: Screen captures and figures are given as examples only.

2 Functional description

Figure 2-1: Principle of the impaction biocollector .......................................................................2-2

Figure 2-2: airIDEAL 3P Traceability in its carrying case...........................................................2-5

Figure 2-3: Identification of the instrument...................................................................................2-7

Figure 2-4: Front face .................................................................................................................. 2-7

Figure 2-5: Rear face................................................................................................................... 2-8

Figure 2-6: Keypad ...................................................................................................................... 2-8

Figure 2-7: Sampling head and grid – 65, 70 or 90 mm Petri dishes ........................................... 2-9

Figure 2-8: Tripod assembly ...................................................................................................... 2-10

List of figures

3 Using airIDEAL 3P Traceability

Figure 3-1: Sampling positions ....................................................................................................3-4

Figure 3-2: Screwing on the sampling grid................................................................................... 3-5

I-4 airIDEAL

®

3P™ Traceability AeroBioCollector User's Manual

Page 11

1 How to use this manual

IMPORTANT! Please read the "General safety and regulatory information" booklet

provided with the instrument.

Finding topics and procedures

This manual is divided into 7 chapters.

Table of contents

List of figures

The table of contents of the manual is located on pages I-1 to I-3.

It lists each chapter and the procedures within each chapter.

The list of figures for the manual is located on page I-4.

Warnings

Different types of warnings are used throughout the manual:

- for safety reasons (DANGER!),

- to ensure that the instruments are maintained in good working condition

(CAUTION!),

- for regulatory reasons (WARNING!) or,

- for optimum performance of operations, procedures, etc. (IMPORTANT!).

Page headers and

page footers

Notes

Apart from the first page of every chapter, each page of the manual includes a

page header and a footer.

Each page header includes the chapter title and the title of a procedure or its

corresponding description.

The footers contain the title of the manual, the name of the product and the

page number.

This manual contains a certain number of notes that are used to emphasize a

procedure or certain information.

airIDEAL

®

3P™ Traceability AeroBioCollector User's Manual 1-1

Page 12

How to use this manual

Glossary

Glossary

ABS Acrylonitrile butadiene styrene.

AeroBioCollector or

Air sampler

CFU

Delayed start-up

Li-ion

MPN

PVDF Polyvinylidene fluoride.

Ra coefficient

RUID "Remote User Interface Device"

Sampling grid

airIDEAL 3P Traceability, instrument used to collect and count viable bacterial

and fungal particles in a known and precise volume of air.

Number of Colony Forming Units read on the agar plate.

The number of CFU corresponds to the number of clusters that have grown on

the agar.

Time between pressing the

Lithium ion

Most Probable Number of micro-organisms collected. Statistical correction of

the CFU value (FELLER’s law).

Roughness factor of a surface. It is the arithmetic mean of all profile deviations,

positive or negative, compared to the mean line.

Remote control containing the user interface.

Perforated and calibrated plastic device. The number of orifices, their diameter

and arrangement, guarantee a CFU count (positive clusters) and a flow of air

corresponding to the motor setting.

START button and the motor starting up.

Solution

airIDEAL 3P Traceability

Time-delay

1-2 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

airIDEAL 3P Traceability (AeroBioCollector) + RUID (remote control) +

airIDEAL 3P Traceability software.

Two seconds required by the software to record a parameter.

Page 13

How to use this manual

Typographic conventions

Typographic conventions

These conventions are used in the different chapters of the manual.

• Press

PROGRAM 1

A bullet point is used to denote an action to be performed.

This typography is used to represent messages which appear on the display.

The airIDEAL 3P Traceability keypad

There are 5 keys on the instrument keypad. (See page 2-8 of the manual).

In this manual, the keys are referred to by their individual names, enclosed in

angle brackets "< >".

1

2

3

airIDEAL

®

3P™ Traceability AeroBioCollector User's Manual 1-3

4

5

Page 14

Page 15

2 Functional description

Presentation

“Pharmaceutical manufacturing evolves from an art to a science”.

This sentence alone from the FDA Guideline “Pharmaceutical cGMP for the 21st

century – A Risk-Based Approach” summarizes the current revolution in the

Pharmaceutical industry.

Conscious of these changes and remaining attentive to its customers,

bioMérieux decided to improve its airIDEAL 3P Traceability AeroBioCollector in

Principle of use

order to best respond to these new needs.

The instrument was thus developed and validated in order to provide a tool to

the pharmaceutical industry that would guarantee a scientifically proven method

of air sampling.

This instrument evidently remains perfectly suited to the enumeration of airborne

micro-organisms in less demanding work environments such as agribusiness.

In addition and in order to continue its universal application,

airIDEAL 3P Traceability is still available in two versions:

− one for the use of culture media in 90 mm diameter Petri dishes,

− the other designed for use with 65 or 70 mm plates.

The aspiration flow-rate of airIDEAL 3P Traceability is calibrated at 100 l/min

with an impact velocity of less than 20 m/s.

According to good sterilization practices, sampling grids can be sterilized in an

autoclave, see "Sterilization of grids" on page 3-3.

1

2

3

4

airIDEAL 3P Traceability can operate in 2 modes:

• Slave mode: using airIDEAL 3P Traceability with the RUID.

• Manual mode: autonomous operation using the keypad.

The present manual describes how to use the instrument in

manual mode; for use of the instrument in slave mode, please refer

to the RUID User Manual.

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 2-1

5

Page 16

Functional description

A

A

A

Presentation

Operating prin ciple

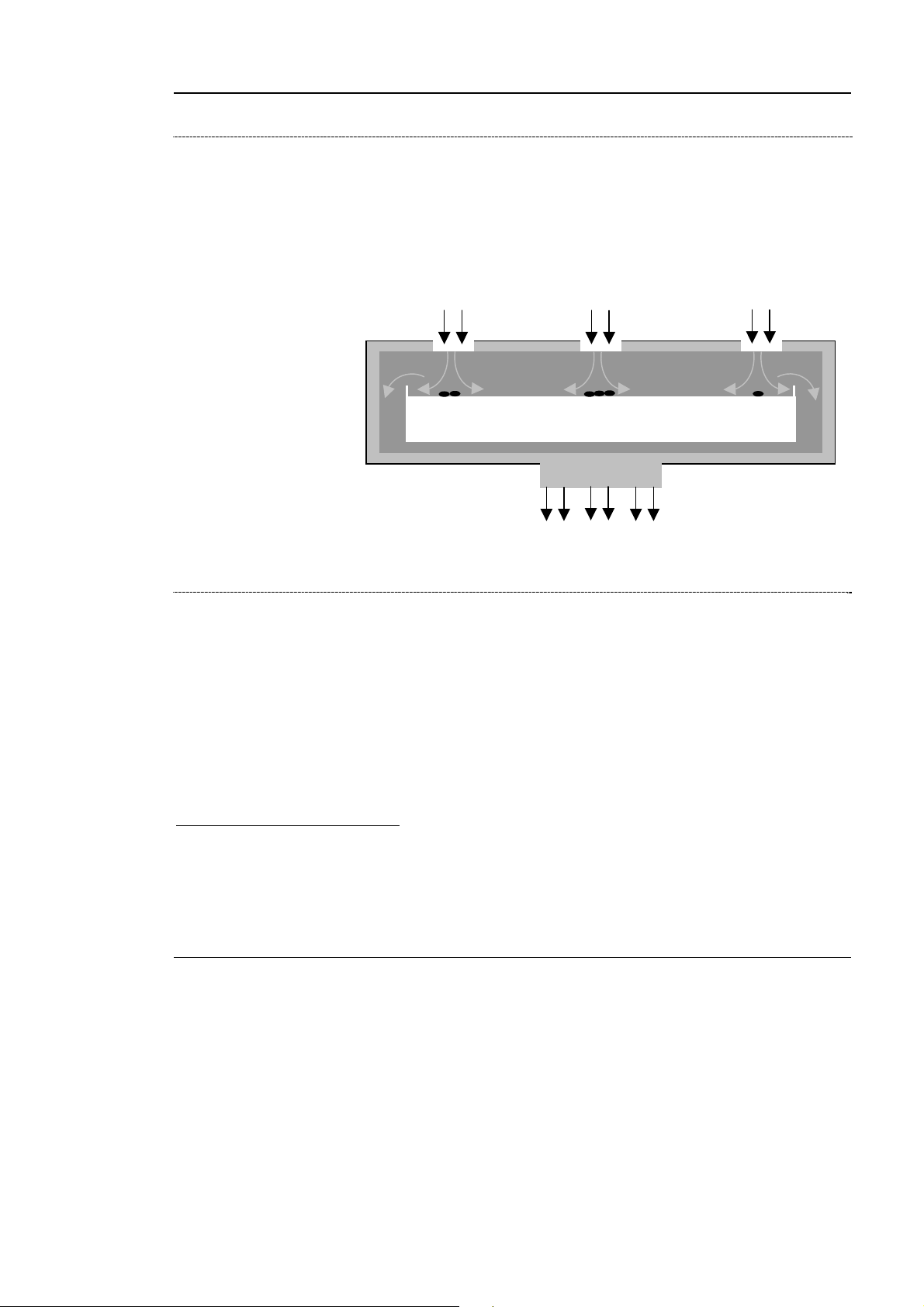

airIDEAL 3P Traceability is an impaction AeroBioCollector used to detect the

presence of viable micro-organisms in the environment to be tested, by precise

sampling of a given volume of air.

Air is taken up with a turbine through a grid surface. The acceleration of airflow

results in the impaction of airborne micro-organisms on the agar. Passage of the

air through the grid filters out particles, thereby facilitating the enumeration of

CFU (colony forming units) after incubation of the medium.

A reading and statistical correction table is used to convert the number of CFU

to the most probable number of micro-organisms collected per m

ir inlet

Micro-organisms

Impaction

Nutrient medium

90 or 65 mm diameter

Petri dishes

ir outlet

3

of air.

Calibrated orifice

ir jets

Figure 2-1: Principle of the impaction biocollector

Performance

The performance characteristics of an AeroBioCollector depend on its capacity

to collect micro-organisms in the air without compromising their viability during

impaction on the agar. This property can be obtained only with a perfect

compromise between the high aspiration velocity leading to effective collection,

and a sufficiently low impaction velocity to guarantee the revivification of

collected micro-organisms.

airIDEAL 3P Traceability was developed in close cooperation with aeraulics

experts in order to optimize this ratio.

Since the industry has increasing needs for scientifically proven methods,

bioMérieux commissioned two recognized independent organizations

*

to

validate the physical and biological efficiency of the instrument.

*

CETIAT: Centre Technique des Industries Aérauliques et Thermiques/Technical Center of Aeraulic and Thermal

Industries

Domaine Scientifique de la Doua, 69603 Villeurbanne, France

HPA : Health Protection Agency - Porton Down - Wiltshire SP4 0JG Salisbury - UK

2-2 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 17

Functional description

Presentation

Collection efficiency validated according to the ISO 14698 standard

airIDEAL 3P Traceability was third party validated by the Health Protection

Agency (UK) to meet the requirements of ISO 14698-1 for the control of clean

rooms. Both the physical and biological efficiencies of the equipment have been

validated according to this standard.

Physical efficiency testing approach

The physical efficiency of an air sampler for collecting airborne bacteria is

evaluated by comparison with a membrane filter sampler. Uniform particles of

different diameters containing bacterial spores of Bacillus subtilis var niger were

generated in a controlled room. The physical efficiency of the instrument was

determined by comparison with the membrane filtration standard operating sideby-side.

1

2

Biological efficiency testing approach

Air sampler inefficiency can either be due to a failure of the sampler to capture

particles containing micro-organisms (physical loss), or to inactivation of viable

micro-organisms during collection, so that formation of visible colonies on agar

will not occur (biological loss).

To address this point, airIDEAL 3P Traceability was evaluated for recovery of a

mixture of Bacillus subtilis (standard indicator for physical loss) and

Staphylococcus epidermidis (standard indicator for biological loss).

The ratio of S. epidermidis / B. subtilis for the test samplers was divided by the

ratio obtained with the reference standard membrane filter sampler to give a

comparative biological efficiency.

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 2-3

3

4

5

Page 18

Functional description

Presentation

Use in glove boxes

In order to be used to test glove boxes, the design and materials of

airIDEAL 3P Traceability had to be entirely reviewed in order to optimize

system air tightness.

In addition and in order to guarantee the optimal operation of the instrument in

this application, the system underwent a complete validation in a glove box

(SKAN AG, model ARIS glove box).

Applications

airIDEAL 3P Traceability enables precise and reproducible air sampling.

The volumes taken can be set in 10 l steps up to a maximum volume of 2000 l.

This sampling range enables the instrument to be used in all types of

environments, from sterile zones to more contaminated surroundings and in all

applications, e.g. qualification of sterile rooms or daily monitoring.

2-4 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 19

Functional description

Description

Description

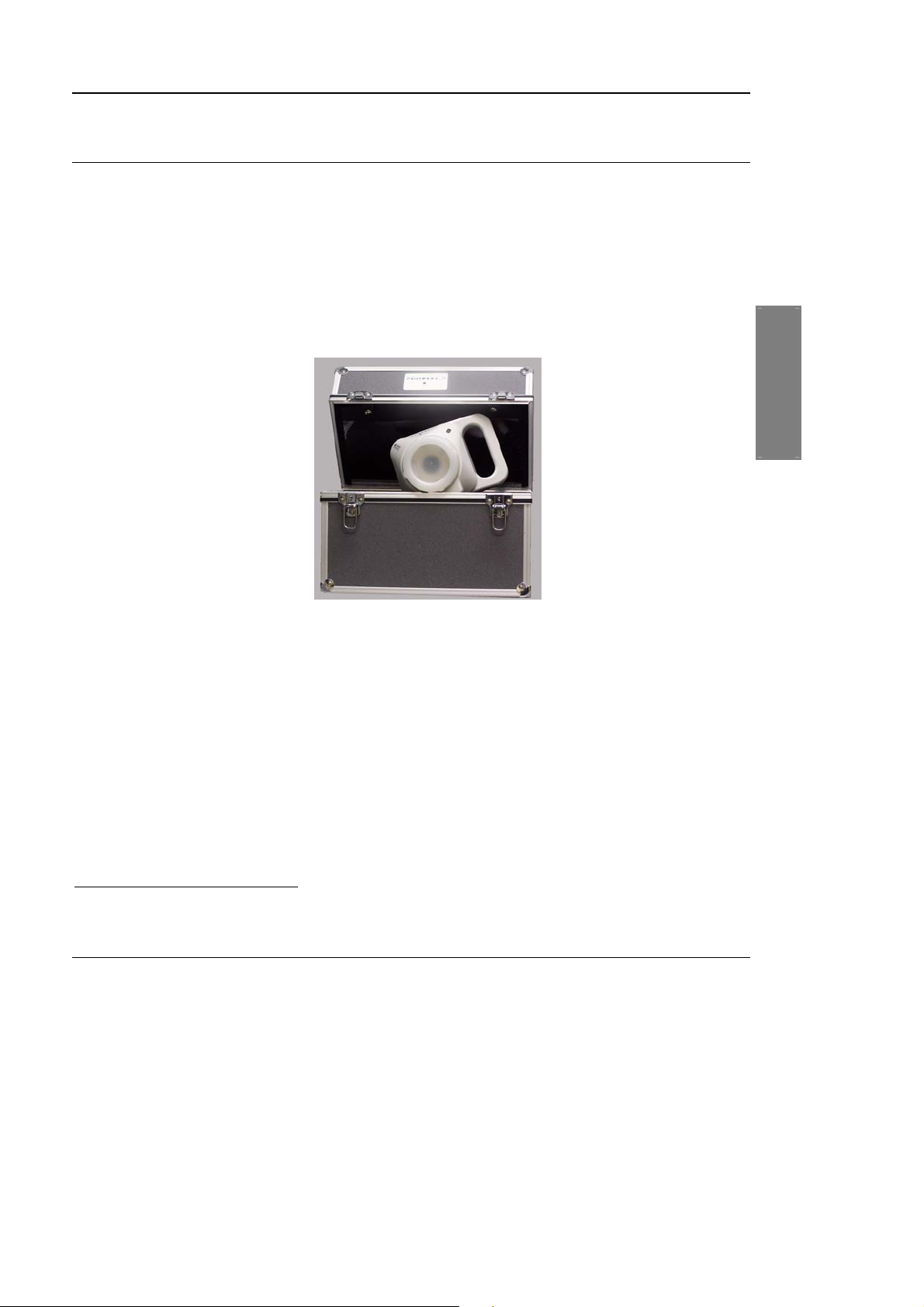

airIDEAL 3P Traceability is supplied in a carrying case. Inside the case is a

rigid lid which can be used as a small work surface [dimensions 22.7 x 13.9 cm

(8.9 in. x 5.4 in.)].

The instrument is available in two versions:

− for 90 mm agar plates (product no. 96302)

− for 65/70 mm agar plates Count-Tact

®

(product no. 96303)

∗ For each product no., please refer to the packing list provided with the

instrument.

1

2

3

Figure 2-2: airIDEAL 3P Traceability in its carrying case

∗ Accessories:

− 65/70 mm Count-Tact diameter additional sampling grid (product No. 96304).

− 90 mm diameter additional sampling grid (product No. 96309).

− Aluminum telescopic tripod with ball joint (product No. 96308).

− Sterile box for transport and incubation of 65/70 mm Count-Tact plates – Kit of 10

(product No. 96301).

− Sterile box for transport and incubation of 90 mm plates – Kit of 10

(product No. 96311

*

).

4

5

*

Availability: consult bioMérieux

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 2-5

Page 20

Functional description

Description

Consumables

airIDEAL 3P Traceability is adapted to all types of Petri dishes available on the

market: 65, 70 and 90 mm.

Moreover, the use of a large range of ready-to-use culture media – irradiated or

classic – developed and manufactured by bioMérieux, the reference in this field,

enables you to obtain the best possible performance from the instrument.

The media comply with specific industrial and hospital environmental controls.

Culture media for general use

− TSA 20 x 90 mm plates (product No. 43011) / GTS 100 x 90 mm plates

(product no. 43018 and product no. 43019)

− PCA agar 20 x 90 mm plates (product no. 43558)

− Sabouraud Dextrose agar 20 x 90 mm plates (product no. 43555)

− Sabouraud Dextrose Chloramphenicol agar 20 x 90 mm plates (product no.

43596)

− Count-Tact

− Count-Tact TSA agar 20 x 65 mm plates (product no. 43582)

− Count-Tact Sabouraud Dextrose Chloramphenicol agar 20 x 65 mm plates

(product no. 43580)

®

agar 20 x 65 mm plates (product no. 43501)

Irradiated media

− Irradiated GTS 3P agar 20 x 90 mm plates (product no. 43711)

− Irradiated GTS 3P agar 100 x 90 mm plates (product no. 43169)

− Irradiated GTS 3P agar with neutralizers 20 plates (product no. 43811)

− Irradiated GTS 3P agar with neutralizers 100 plates (product no. 43819)

− Irradiated Count-Tact 3P agar 20 x 65 mm plates (product no. 43691)

− Irradiated Count-Tact 3P agar 100 x 65 mm plates (product no. 43699)

− irradiated Sabouraud Dextrose agar 20 x 90 mm plates (product no. 43554)

− Irradiated Sabouraud Dextrose 3P agar with neutralizers 20 plates (product

no. 43814)

− Irradiated Sabouraud Dextrose Chloramphenicol agar 20 x 90 mm plates

(product no. 43595)

− Irradiated Count-Tact Sabouraud Dextrose 3P agar with neutralizers 20

plates (product no. 43812)

− Irradiated Count-Tact Sabouraud Dextrose Chloramphenicol agar with

neutralizers 20 x 65 mm plates (product no. 43581)

2-6 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 21

Functional description

Description

Identification of the instrumen t

Figure 2-3: Identification of the instrument

Front face of the airIDEAL 3P Traceability

1

2

3

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 2-7

Figure 2-4: Front face

4

5

Page 22

Functional description

A

Description

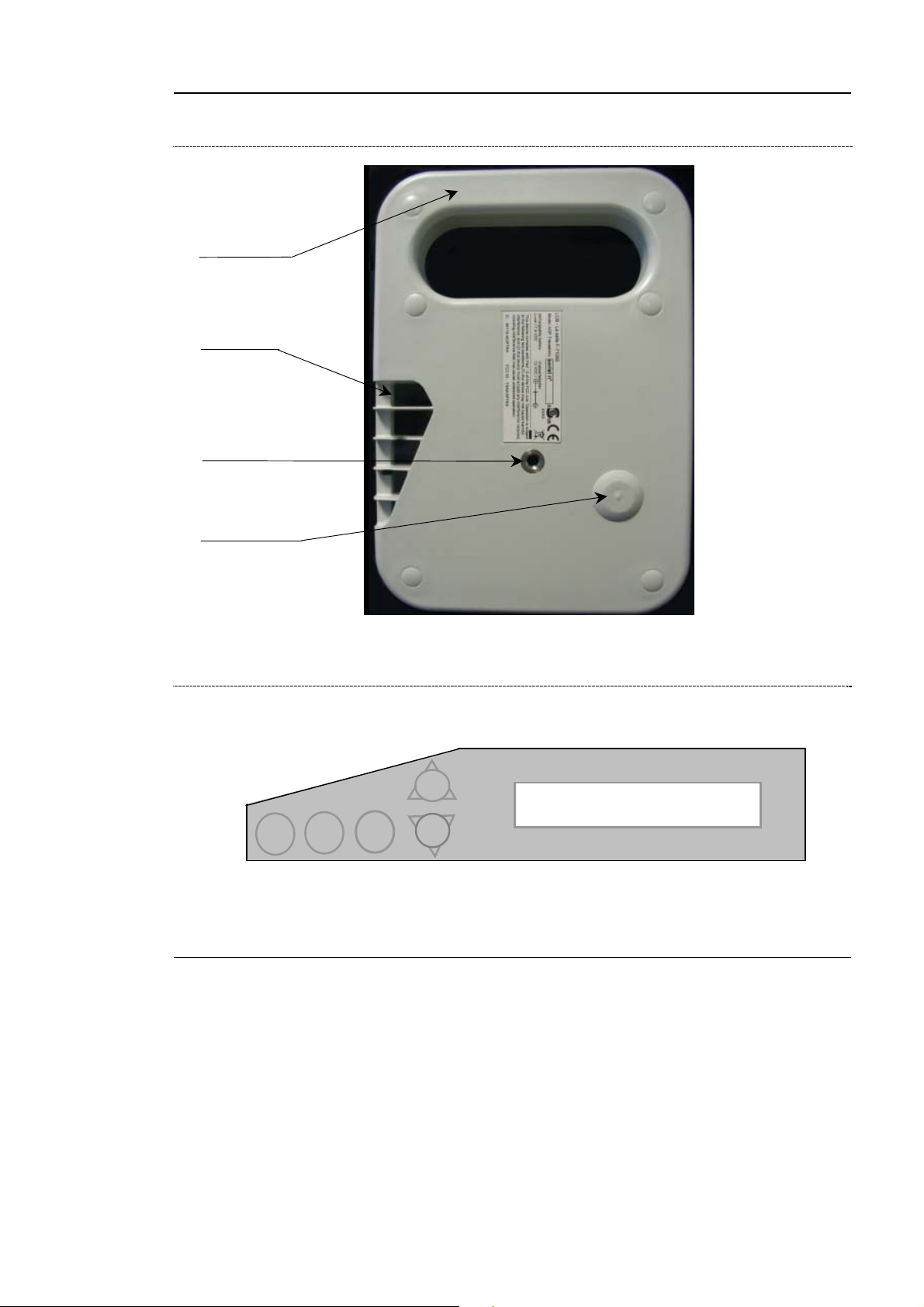

Rear face of the airIDEAL 3P Traceability

Handle

ir outlet

Threading

for tripod

Jack socket

Figure 2-5: Rear face

Keypad

+

ON

2-8 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

OFF

START

STOP

MENU

-

Figure 2-6: Keypad

Page 23

Functional description

A

Description

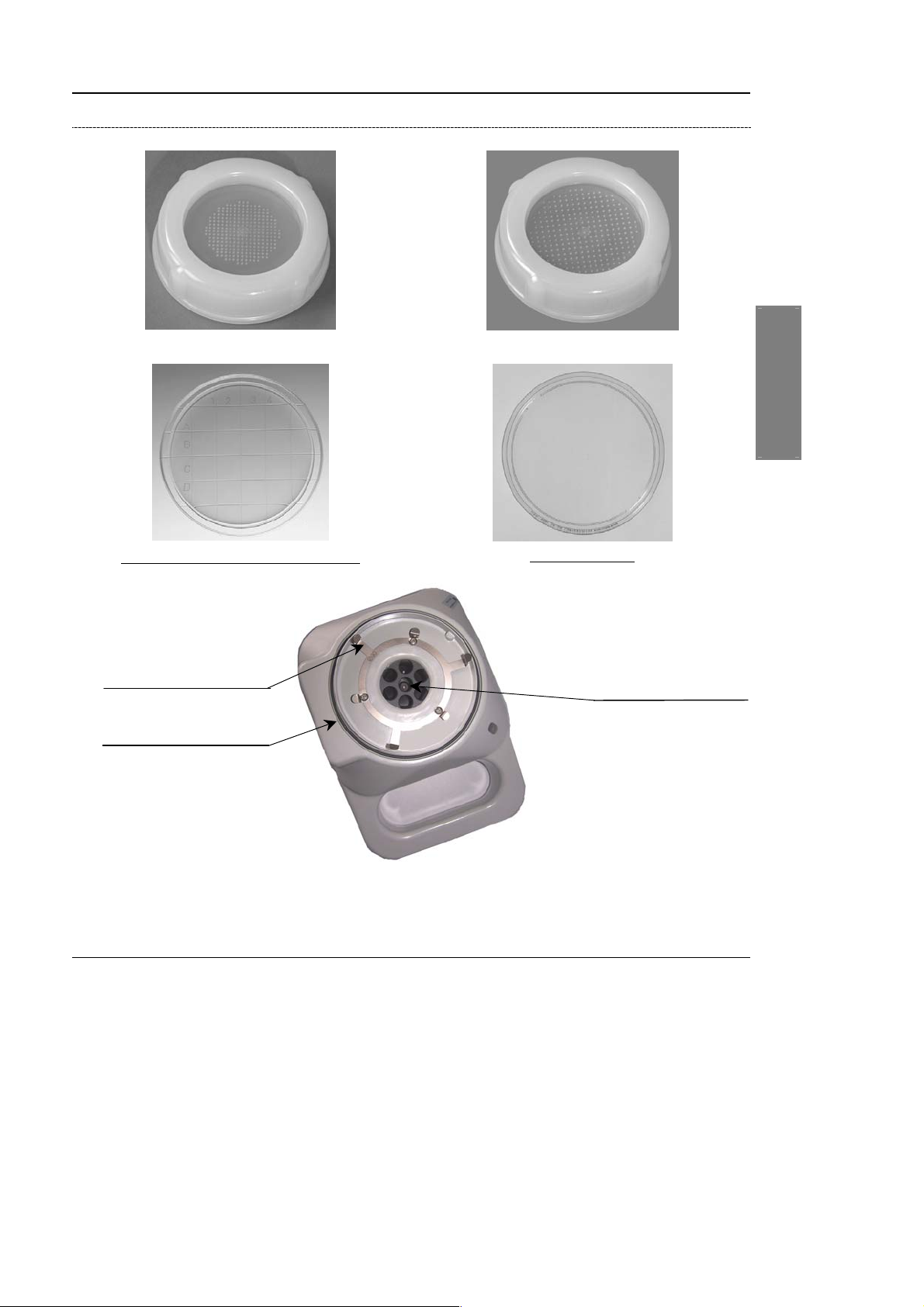

Configuration for 65, 70 or 90 mm Petri dishes

Sampling grid for 65 or 70 mm Petri dishes

®

65 or 70 mm (Count-Tact

) Petri dish

Stainless steel strip

for attachment

Seal

1

Sampling grid for 90 mm Petri dishes

2

90 mm Petri dish

spiration orifice

3

4

Figure 2-7: Sampling head and grid – 65, 70 or 90 mm Petri dishes

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 2-9

5

Page 24

Functional description

Description

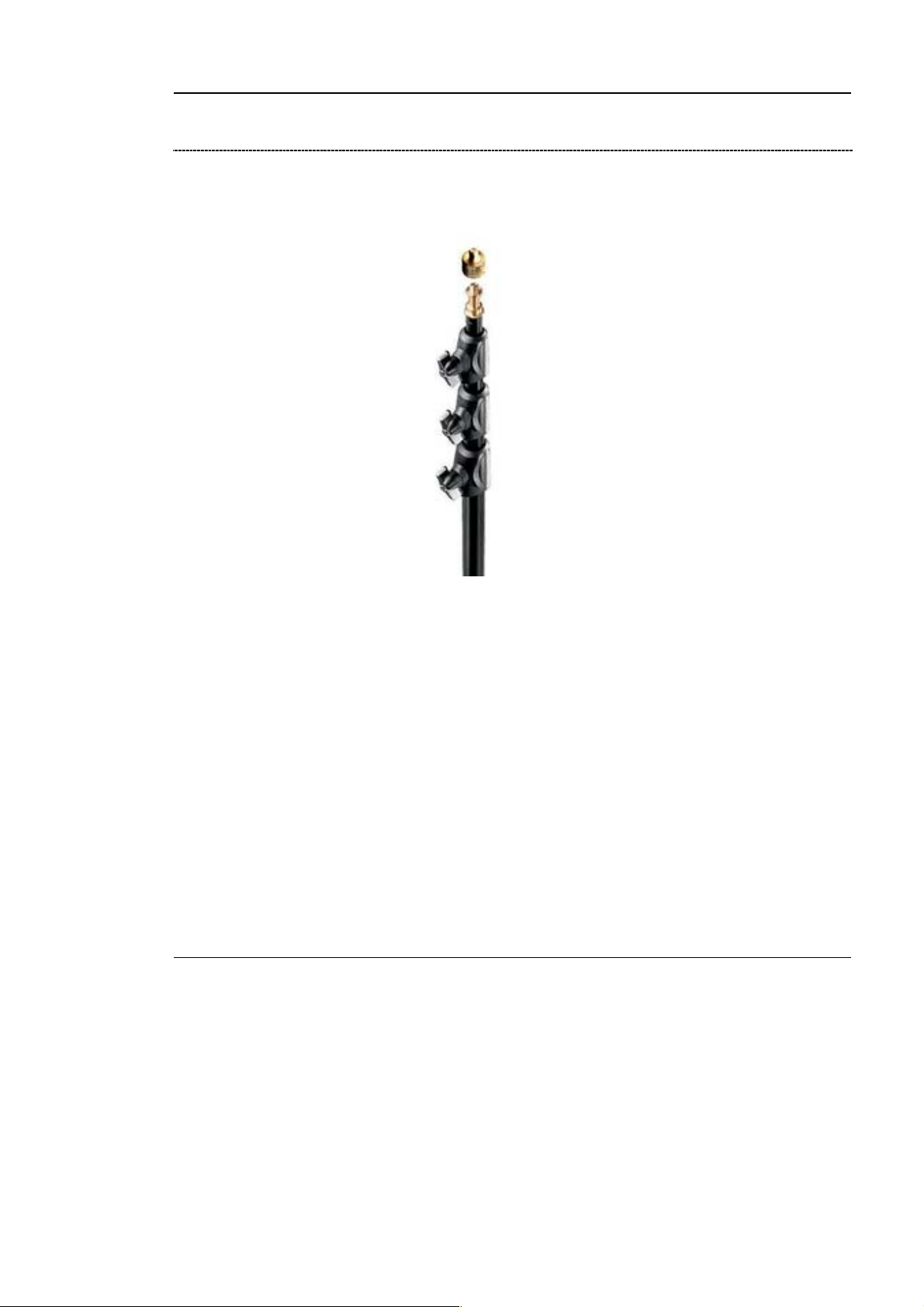

Tripod assembly

Figure 2-8: Tripod assembly

2-10 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 25

Functional description

General specifications

General specifications

Environmental conditions

Physical features

Dimensions

Instrument alone Instrument in its case

Height 128 mm

Width 146 mm

Depth 208 mm

Mass

Instrument alone Instrument in its case Shipping carton

≈ 1.2 kg ≈ 5.5 kg ≈ 7.1 kg

Materials

Characteristics of materials

Normal storage condition................................................................-20° to + 50°C

Inside use in an air class zone, sterile room or glove box.

Normal conditions of use ...........................................0 to 40 °C (32 °F to 104 °F)

Relative humidity ....................................................................................0 to 95%

Maximum installation altitude................................................................ < 2 000 m

Standards applicable .........................................................See product certificate

The instrument must be transported in its specific case.

(5.03 in.) 301 mm (11.8 in.)

(5.75 in.) 250 mm (9.84 in.)

(8.18 in.) 400 mm (15.75 in.)

∗ ABS/Polycarbonate shell

∗ Polycarbonate keypad

∗ PVDF sampling grid

∗ Stainless steel mounting strips and screws

∗ Elastomer jack protection caps

1

2

3

4

− Shock resistance: shell and keypad.

− Chemical resistance: to most standard disinfectants (hydrogen peroxide,

concentrated peracetic acid, bleach, 70% ethanol, quaternary ammoniums,

etc).

− Thermal resistance: sampling grid that can be autoclaved using Good

Note: With increasing numbers of autoclaving cycles, the grids become increasingly yellow-gray,

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 2-11

Sterilization Practices, see section "Sterilization of grids" on page 3-3.

but this has no effect on grid performance.

− Surface finish: Ra coefficient of grid = 0.14 micron.

− Fire resistance: ABS/POLYCARBONATE V0 shell (highest grade of fire

resistance).

5

Page 26

Functional description

General specifications

Technical characteristics

Keypad Key control.

Display Liquid crystal display (2 x 16 characters).

Sampling grid 1/8-turn screw-on sampling grid.

Possibility of sampling on 90 mm 65/70 mm diameter Petri dishes (specific

sampling grids and fixing strips).

User interface airIDEAL 3P Traceability can operate in 2 modes:

• Slave mode: using airIDEAL 3P Traceability with the RUID.

• Manual mode: autonomous operation using the keypad.

5 buttons for access to all airIDEAL 3P Traceability functions.

An LCD screen is used to program the instrument and follow its operation.

Messages are in English.

Additional information on instrument operation is given as audible signals.

A flashing indicator light indicates, from a distance, the status of the instrument:

− Green flashing indicator light: sampling in progress. The indicator light

changes to constant green when sampling is performed successfully. In

slave mode the green indicator light continues to flash until sampling is

stopped using the RUID.

− Slow flashing green indicator light: the battery is charging. The indicator light

changes to constant green as soon as the battery has been fully charged.

− Constant green indicator light: the instrument is powered on and ready to start

sampling in manual or slave mode.

− Flashing green/red indicator light: the battery is low.

− Flashing or constant red indicator light: a problem has occurred.

− Indicator light off: the instrument is powered off.

Language used for the software: English

Ergonomics Ergonomic handle (right hand/left hand).

Possibility of stable sampling with the unit in four positions (see page 3-4).

Possibility of suspending airIDEAL 3P Traceability with a hook, especially in a

glove box.

Optionally, the instrument can be mounted on a telescopic tripod equipped with

a ball joint enabling the sampling axis to be orientated through an angle of 0° to

90° (from horizontal to vertical), and its height to be adjusted (between 0.7 and

2.50 meters).

2-12 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 27

Functional description

General specifications

Electrical characteristics

Voltage ...................................................................................... 7.4 VDC nominal

Power supply .......................................................................................... 1 A max.

airIDEAL 3P Traceability is designed to run on a battery (6 NiMH batteries

CAUTION! The AC-DC power supply adapter must have the following characteristics:

connected in series, each with a nominal voltage of 3.7 V).

The instrument can also be powered and/or recharged using one of the

adapters indicated or an equivalent one.

- Voltage: 12 VDC

- Power: 2 A max.

- Plug mod. Jack 12.0 x 2.1 mm

-

AC input voltage corresponding to the characteristics of the power

supply in the country where the instrument is installed.

1

2

Note: It is recommended to use the adapter provided with the instrument. You will find the

Functional specifications

Flow-rate 100 ± 6.4 liters per minute regardless of the grid used.

Autonomy More than or equal to 4 hours, enabling at least 24 consecutive 1000 liter

Charge time It takes 3 hours to fully charge the battery.

Soud level < 50 dB

Security Male plug outlet serves as the power supply sectioning device.

details of its characteristics below.

POWER SUPPLY complying with - UL/CSA standards

INPUT 100 – 240 VAC 0.7 A – 0.4A 47 – 63 Hz

UL STD plug or STD European plug

OUTPUT 12 VDC 2 A max.

d = 2.1 mm JACK plug

Flow-rate measured and adjusted according to the bioMérieux quality control

protocol reference 96302-protocol.

samples to be collected.

Specification valid for a new battery not having undergone a thermal shock or a

prolonged period of inactivity.

3

4

5

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 2-13

Page 28

Page 29

3 Using airIDEAL 3P Traceability

Unpacking airIDEAL 3P Traceability

The instrument is supplied in a carrying case and box.

∗ When opening the box:

• Make sure you have all the items described in the packing list.

• Keep the shipping carton in case you need to ship the instrument back to

bioMérieux.

CAUTION! Any damage directly or indirectly resulting from the transport of the

instrument without adequate containers will not be covered by the

warranty or maintenance contract.

1

2

DANGER! Do not use the instrument in an explosive atmosphere as sparks could

cause an explosion.

Recommendations for installation and use

• Install the instrument on a flat, perfectly horizontal surface, on its tripod or by

IMPORTANT! When the instrument is used for th e first time, it is imperative to perform 1

its hook.

• Avoid locations directly exposed to sunlight, excessive heat, damp or dust.

• The instrument must not be used near strong sources of electromagnetic

interference.

• Do not use the instrument with its original protective cover cap, but with a

grid.

battery charge-discharge cycle.

•

Charge the battery for 3 hours.

•

Discharge the battery by performing successive sampling

(see page 3-22 "Battery autonomy test (Menu 6)").

•

Recharge for 3 hours.

•

Make sure the grid holes are not blocked.

3

4

5

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-1

Page 30

Using airIDEAL 3P Traceability

Recommendations for installation and use

WARNING! The user’s manual or instruction manual for an intentional or unintentional

WARNING! Industry Canada requirements:

radiator shall caution the user that changes or modifications not expressly

approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

In cases where the manual is provided only in a form other than paper,

such as on a computer disk or over the Intern et, the information required

by this section may be included in the manual in that alternative form,

provided the user can reasonably be expected to have the capability to

access information in that form.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates uses

and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction, may cause harmful interfer ence to radio

communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception which can be determined by

turning the equipment off and on, the user is en couraged to try to correct

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

RSS-Gen - General Requirements and Information for the Certification of

Radio Apparatus, Clause 7.1.2 statement:

Under Industry Canada regulations, this radio transmitter may only

operate using an antenna of a type and maximum (or lesser) gain

approved for the transmitter by Industry Canada. To reduce potential radio

interference to other users, the antenna type and its gain should be so

chosen that the equivalent isotropically radiated power (e.i.r.p.) is not

more than that necessary for successful communication.

RSS-Gen - General Requirements and Information for the Certification of

Radio Apparatus, Clause 7.1.3 statement:

This device complies with Industry Canada licence-exempt RSS

standard(s). Operation is subject to the following two conditions: (1) this

device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired operation of

the device.

This device complies with FCC and Industry Canada RF radiation

exposure limits set forth for general population (uncontrolled exposure).

This device must not be collocated or operating in conjunction with any

other antenna or transmitter.

3-2 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 31

Using airIDEAL 3P Traceability

Cleaning and decontamination procedure

Cleaning and decontamination procedure

Sterilization of grids

airIDEAL 3P Traceability is delivered with a set of 5 grids. They can be

sterilized by autoclaving at 134°C for 18 min.

Decontamination of the external part

bioMérieux has validated that the grid specifications and performance are not

altered after autoclaving up to:

- 40 times at 134°C for 18 minutes

- 200 times at 121°C for 20 minutes

After autoclaving 14 times or more, the grid may begin to turn yellow and may

become difficult to screw onto the instrument.

1

Decontamination of the air circuit

All the external parts of the instrument can be decontaminated with most of the

usual disinfectants at the usual effective concentration (hydrogen peroxide,

concentrated peracetic acid, bleach solution, 70% ethanol, quaternary

ammonium).

∗ Decontamination protocol:

• Spray twice with 70% isopropyl alcohol with the motor off: one spray at the

air inlet, the other at the outlet.

Decontamination in a glove box

• Allow to react for 15 minutes before using the instrument.

Decontamination of the instrument according to this protocol with ClearKlens

IPA (Johnson Diversey) has been validated.

A summary of this validation is available on request.

airIDEAL 3P Traceability was specially developed for use in production or

control glove boxes. The suitability of this instrument for use in glove boxes was

evaluated by the SKAN ag "Center of Competence for Isolator Technology".

∗ Two parameters were tested:

− The capacity of the instrument to withstand standard decontamination cycles

in glove boxes.

− The capacity of a standard decontamination cycle to disinfect the different

types of materials that compose the instrument.

A summary of this validation is available on request.

2

3

4

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-3

5

Page 32

Using airIDEAL 3P Traceability

Sampling positions

Sampling positions

c d

e f

Figure 3-1: Sampling positions

IMPORTANT! airIDEAL 3P Traceability is delivered with a hook for suspending it in a

glove box during decontamination phases. Even though sampling can be

done while suspended, it is preferable to position the instrument along the

axis of one-way flow at the air outlets. This con figuration is the worst ca se

scenario since the air sampled has swept the entire volume of the gl ove

box before emerging.

Do not obstruct the air outlet during use to respect operating parameters.

3-4 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 33

Using airIDEAL 3P Traceability

Screwing on the sampling grid

Screwing on the sampling grid

CAUTION! Do not insert any foreign objects into the aspiration orifice located under

the grid (see pages 2-9).

∗ To screw on the sampling grid easily,

• Position the grid on the threading of the shell and turn it clockwise by 1/8 of

a turn without forcing or pressing it.

1

Figure 3-2: Screwing on the sampling grid

2

3

4

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-5

5

Page 34

Using airIDEAL 3P Traceability

Electrical power supply

Electrical power supply

airIDEAL 3P Traceability operates self-sufficiently through a Lithium-ion battery

pack.

It can also run off the mains using the charger/adapter.

Operation on the battery

The microprocessor manages and displays the available autonomy at all times,

on the basis of a theoretical autonomy of 4 hours for sampling cycles of 1000

liters.

As soon as the flashing symbol appears , there are 20 minutes of

autonomous running remaining.

Immediately put the battery on charge; if a sampling cycle is in progress it will be

completed just the same.

A sampling cycle cannot start if its duration exceeds the remaining autonomy

displayed.

Low battery signals

∗ When the autonomy has expired, the following low battery signals are output:

Visual signal on the welcome message display:

STORED VOL: ZZZL

BATTERYLIFE XHXX

Flashing symbol

Visual signal on the sample in progress display:

Audible signal when the instrument is turned on: 2 lon g bee ps emitted eac h tim e

the instrument is powered on.

IMPORTANT! In slave mode, if the battery is low at the beginning of an analysis, the

operator is warned by a message displayed on the RUID (please r efer to

the remote control user manual).

3-6 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

STORED VOL ZZZL

SAMPLE VOL: XL

Flashing symbol

Page 35

Using airIDEAL 3P Traceability

Electrical power supply

Charging

∗ To charge the battery,

• Use the charger supplied or one with the same specifications.

• During the charging phase, the instrument can be either switched on or

IMPORTANT! During sampling with airIDEAL 3P Traceability running off the mains, do

switched off.

• Connect the charger to the instrument jack connector after removing the

protection cap.

• Connect the charger to the power outlet.

The display indicates:

Charge

Battery

The normal time required to completely charge a discharged battery pack is 3

hours.

During the charging phase, it is possible to perform sampling with airIDEAL 3P

Traceability running off the mains. The charging process will be suspended

during sampling and will restart automatically when sampling is finished.

not disconnect the instrument from the mains as there is a risk of it

switching off and the sampling cycle in progress would be definitively

lost.

1

2

3

∗ At the end of the operation,

IMPORTANT! If airIDEAL 3P Traceability is not used for more than 10 days, the battery

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-7

• Disconnect the charger from the power outlet.

• Disconnect the charger from the the instrument jack connector.

• Install the protection cap.

• Check that the battery life displayed is again 4 hours.

must be totally recharged (3 hours).

4

5

Page 36

Using airIDEAL 3P Traceability

Electrical power supply

Operation using mains pow er

Connection to the mains is carried out in the same way as for charging the

battery.

The display indicates:

Charge

Battery

• Press the <START> or <MENU> button to return to the welcome

message.

Then

• Press the <START> button to start (the volume sampled will be the last

recorded).

or,

• Select the sample volume by means of MENU 1 or MENU 2, and then start

by pressing the

∗ To turn off,

• Disconnect the charger from the Jack socket on the instrument.

IMPORTANT! During sampling with airIDEAL 3P Traceability running off the mains, do

not disconnect the instrument from the mains as there is a risk of it

switching off and the sampling cycle in progress would be definitively

lost.

<START> button.

Automatic standby

To preserve the battery life, the instrument automatically goes into standby

mode after 5 minutes of inactivity.

Pressing any key will reactivate the instrument.

The RUID can activate the instrument so that it is ready for sampling.

Automatic switch off

In manual or slave mode, the instrument switches off after 1 hour of inactivity.

While it is switched off, airIDEAL 3P Traceability cannot communicate with a

RUID.

3-8 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 37

Using airIDEAL 3P Traceability

Operation in slave mode

Operation in slave mode

In slave mode, the airIDEAL 3P Traceability is used with a RUID.

Please refer to the RUID User Manual.

Operation in manual mode

In manual mode the airIDEAL 3P Traceability operates autonomously.

Programming

airIDEAL 3P Traceability enables sampling to be programmed and monitored.

This section describes how to program the instrument.

Programming characteristics

− Sample volumes adjustable from 5 to 10 liters in 1-liter steps.

− Sample volumes adjustable from 10 to 2000 liters in 10-liter steps.

− Automatic selection of last sample volume used.

− Storage of 4 sample volumes in the memory.

− Delayed start-up (maximum 60 minutes).

• 0 to 60 seconds in 1-second steps

• 1 minute to 60 minutes in 1-minute steps

− Sequenced sampling.

1

2

3

Sampling controls

− Volume counter.

− Volume of air sampled remains on display after sampling is interrupted.

− Sampling status is indicated by an indicator light.

− Possibility of interrupting and resuming a sample in progress (only in manual

mode).

− End of sample buzzer (6 short beeps).

− Count-down of time.

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-9

4

5

Page 38

Using airIDEAL 3P Traceability

Operation in manual mode

airIDEAL 3P Traceability menus

ON_

OFF

Turning on

WELCOME

MESSAGE

Last sample taken.

Remaining autonomy.

MENU 1:

Selection of one of 4 sample volumes among the 4 volumes preprogrammed in menu 3.

MENU 2: Programming 1 sample volume not in memory.

MENU 3: Modification of the 4 pre-programmed sample volumes.

MENU 4: Programming delayed start-up

MENU 5: Programming sequenced sampling.

MENU 6: Battery autonomy test.

ON_

OFF

Turning off

3-10 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 39

Using airIDEAL 3P Traceability

L

X

Operation in manual mode

Turning on airIDEAL 3P Traceability

ON_

OFF

∗ To turn on the instrument,

• Press <ON/OFF>.

The display indicates:

STORED VOL: ZZZ

BATTERYLIFE XHX

Note: The symbol is displayed if a delayed start-up is programmed.

− ZZZL corresponds to the last sample volume recorded.

XHXX corresponds to remaining autonomy.

−

1

2

∗ If the symbol appears:

• Recharge the instrument.

∗ If the last sample did not terminate correctly (sampling stopped before the end,

protection cap in place of the grid, motor blocked),

AND

3

∗ If the instrument is then switched off or put on standby,

The following message will appear when the instrument is switched on again or

is reactivated:

LAST SAMPLING

In this case, press <MENU> once to display the welcome message.

NOT COMPLETED

4

DANGER! Do not insert any foreign objects into the motor compartment when the

instrument is running.

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-11

5

Page 40

Using airIDEAL 3P Traceability

Operation in manual mode

Standby

ON_

OFF

∗ To put the instrument on standby,

• Briefly press <ON/OFF> , the indicator light must not go off.

or

• Wait for 5 minutes.

∗ To reactivate the instrument,

• Press any key.

Turning off airIDEAL 3P Traceability

ON_

OFF

∗ To turn off the instrument,

• Press <ON/OFF> until the indicator light goes off.

Selection of one of the 4 pre-programmed sample volumes (Menu 1)

∗ Factory programming memorizes the following 4 volumes in

airIDEAL 3P Traceability: 100, 500, 1000, 2000 liters.

3-12 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

MENU

∗ To select menu 1,

• Press <MENU>.

The display indicates:

MENU 1 : CHOSEN

PRESET VOLUME

• Press the < + > button to select 1 of the 4 volumes memorized.

Page 41

Using airIDEAL 3P Traceability

Operation in manual mode

Example:

+

+

∗ To select stored volume No. 2 from menu 1,

• Press < + > twice.

• Wait 2 seconds.

Note: If you did not wait for the end of the first timeout, in other words if you pressed another

button before the 2 seconds, the new value selected (

value (

Preset volume 1

XX Liters

PRESET VOLUME 2

YYY LITERS

ZZZ) remains in memory.

YYY) is not recorded. The initial

1

2

The value YYY selected is recorded.

The display indicates:

RECORDED

3

4

∗ There are 3 possibilities:

• Start sampling immediately by pressing the <START> button.

• Wait: the selected sampling can be started at a later time.

• Press the <ON/OFF> button to turn off the instrument. The volume selected

will be displayed the next time it is turned on.

5

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-13

Page 42

Using airIDEAL 3P Traceability

Operation in manual mode

Programming a sample volume not in memory (Menu 2)

MENU

∗ To select menu 2,

• Press <MENU> twice.

The display indicates:

MENU 2: CHOSEN

VOLUME XXL

∗ To program a new volume,

• Press < + > or <- > until the desired volume is displayed.

IMPORTANT! It is imperative to press the

program a new volume.

After a 2-second delay, the volume displayed is recorded.

The display indicates:

RECORDED

∗ There are 3 possibilities:

• Start sampling immediately by pressing <START>.

• Wait: the selected sampling can be started at a later time.

• Press the <ON/OFF> button to turn off the instrument. The volume selected

will be displayed the next time it is turned on.

< + > or < - > buttons immediately to

3-14 airIDEAL

®

3P™ Traceability AeroBioCollector User's Manual

Page 43

Using airIDEAL 3P Traceability

Operation in manual mode

Modification of the 4 pre-programmed sample volumes (Menu 3)

MENU

∗ To select menu 3,

• Press <MENU> 3 times.

The display indicates:

MENU 3:

STORE IN MEMORY

1

• Wait 2 seconds.

The display indicates:

PROGRAM 1

Volume: XL

2

3

∗ To program a new volume for program 1,

• Press < + > or <- > until the desired volume is displayed.

IMPORTANT! It is imperative to press the

program a new volume.

Note: If the <MENU>, < + > or < - >, buttons are not pressed, each of the 4 pre-

After a 2 second delay, the volume displayed is recorded.

The display indicates:

programmed volumes is displayed every 2 seconds.

PROGRAM 2

Volume

: XL

< + > or < - > buttons immediately to

4

5

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-15

Page 44

Using airIDEAL 3P Traceability

Operation in manual mode

∗ To program a new volume of program 2,

• Press < + > or < - > until the desired volume is displayed.

IMPORTANT! It is imperative to press the

program a new volume.

After a 2-second delay, the volume displayed is recorded.

The display indicates:

PROGRAM 3

Volume

: XL

∗ To program a new volume for program 3,

• Press < + > or < - > until the desired volume is displayed.

IMPORTANT! It is imperative to press the

program a new volume.

After a 2-second delay, the volume displayed is recorded.

The display indicates:

PROGRAM 4

Volume: XL

< + > or < - > buttons immediately to

< + > or < - > buttons immediately to

3-16 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 45

Using airIDEAL 3P Traceability

L

X

Operation in manual mode

∗ To program a new volume for program 4,

• Press < + > or < - > until the desired volume is displayed.

IMPORTANT! It is imperative to press the

Note: If the < + > or < - > buttons are not pressed, the pre-programmed volumes are

program a new volume.

After a 2-second delay, the volume displayed is recorded.

The display indicates:

The screen the returns to the welcome message.

STORED VOL: ZZZ

BATTERYLIFE XHX

sequentially displayed without modification.

END

< + > or < - > buttons immediately to

1

2

3

∗ Possibility of going directly to "MENU 4", once selected volumes are modified:

When "END" is displayed on the screen,

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-17

• Immediately press <MENU>.

Menu 4 is displayed.

4

5

Page 46

Using airIDEAL 3P Traceability

Operation in manual mode

Programming delayed start-up (Menu 4)

∗ Delayed start-up can be programmed for up to 60 minutes:

− 0 to 60 seconds in 1-second steps

− 1 minute to 60 minutes in 1-minute steps.

MENU

∗ To select menu 4,

• Press <MENU> 4 times.

The display indicates:

MENU 4: TIMED

Ømin Øsec

∗ To program a delay value,

• Press < + > or < - > until the desired delay value is displayed.

IMPORTANT! It is imperative to immediately press

volume.

After 2-seconds, the delay value is recorded.

The display indicates:

3-18 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

RECORDED

< + > or < - > to program a new

Page 47

Using airIDEAL 3P Traceability

L

X

Operation in manual mode

The screen returns to the welcome message.

STORED VOL ZZZ

BATTERYLIFE XHX

1

The delay is recorded: the symbol

∗ There are 3 possibilities:

appears in the welcome message.

2

• Start sampling immediately by pressing <START>.

• Wait: the selected sampling can be started at a later time.

• Press the <ON/OFF> button to turn of the instrument. The volume selected

will be displayed the next time it is turned on.

3

4

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-19

5

Page 48

Using airIDEAL 3P Traceability

Operation in manual mode

Programming sequenced sampling (Menu 5)

Menu 5 is used to sample a selected volume several times.

∗ This sequencing is defined with 3 parameters:

− The unit volume (of each sequence).

This volume is defined with menus 1 or 2 (see pages 3-12 and 3-14).

− The number of sequences.

This number is included between 2 and 5.

− The time interval between each sequence.

It is included between 10 minutes and 4 hours, in 10-minute steps.

∗ Total sampling time must be less than 5 hours or else an error message

appears.

MENU

∗ To select menu 5,

• Press <MENU> 5 times.

The following message appears and the 1

MENU 5 : SEQ NB X

VOL ZZZL INTXHXX

The unit volume is shown on the lower left and cannot be modified in this menu.

st

line flashes:

∗ To modify the number of sequences,

• Press < + > or < - > until the desired number is displayed.

• Press <MENU> once the number of sequences is selected.

The "INTXHXX" (INTERVAL ) field flashes.

• Press < + > or < - > to define the time interval between each sequence.

IMPORTANT! Check that the remaining battery autonomy is sufficient to carry out

complete sampling (base: 10 min/1000 liters).

3-20 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 49

Using airIDEAL 3P Traceability

Operation in manual mode

∗ Once sequenced sampling has been correctly programmed,

• Press the <START> button to start sampling.

IMPORTANT! A sequenced sampling is run from the specific menu, without returning to

The total duration of sequences and intervals must not exceed 5 hours or else

an error message appears:

Then,

The screen automatically returns to Menu 5.

To return to the welcome message, press <MENU> twice.

the main menu.

If the last sampling was sequenced, the menu 5 screen is d isplayed when

the instrument is turned on.

ERROR

TIME > 5H

1

2

3

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-21

4

5

Page 50

Using airIDEAL 3P Traceability

Operation in manual mode

Battery autonomy test (Menu 6)

This menu is used to verify that the battery is still compliant with specifications of

new material (autonomy ≥ 4 hours).

The autonomy test can be performed using a volume chosen by the operator.

1000 liters is the reference volume for verifying that specifications have been

respected (4 hours of autonomy for 1000-liter samples).

If the volume generally used is, for example, 100 liters, then it is wiser to

perform the test on 100 liter volumes.

∗ To check battery autonomy:

− Note the autonomy displayed when the instrument is turned on.

− Using Menu 1, select a 1000 liter sample volume.

− Go to Menu 6.

• Press the <START> button to run the battery discharge cycle.

MENU

∗ To select menu 6,

• Press <MENU> 7 times.

The display indicates:

MENU 6:AUT . TEST

BATTERYLIFE : XHXX

∗ The battery discharge cycle can be stopped as follows:

• Press <STOP>.

∗ To resume at a later time,

• Press <START>.

CAUTION! After stoppage of more than 5 minutes, the instrument goes into standby

mode and the sampling program is interrupted.

When the instrument is reactivated, the following message is displayed:.

• Press <MENU> to return to the welcome message.

3-22 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

LAST SAMPLING

NOT COMPLETED

Page 51

Using airIDEAL 3P Traceability

Starting sampling

Starting sampling

CAUTION! Before starting, check that airIDEAL 3P Traceability is fitted with a

sampling grid and not its protective cover otherwise it could undergo

irreversible damage which is not covered by the bioMérieux warranty.

∗ If the protective cover remains on the instrument, the following alarm message

is displayed after several seconds and sampling stops automatically:

PROTECTION COVER

The indicator light flashes red.

REMOVE

• Remove the protection cover.

• Install the grid.

• Press <MENU> to return to the welcome message.

∗ To start sampling,

ON_

OFF

START

STOP

• Turn on the instrument,

• Press <ON/OFF>.

The indicator light is constant green and the following message appears:

STORED VOL: ZZZL

BATTERYLIFE XHXX

• Press <START/STOP>.

1

2

3

4

∗ During sampling, the display indicates:

STORED VOL: ZZZL

The indicator light changes to flashing green.

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-23

SAMPLE VOL: XL

5

Page 52

Using airIDEAL 3P Traceability

Starting sampling

The SAMPLE VOL display flashes during the sampling phase and the volume

counter is displayed.

− The last sample volume recorded is automatically displayed (shown as

A buzzer indicates the end of sampling (6 short buzzes) and the display returns

to the original message with automatic correction of the remaining battery life.

The indicator light changes to constant green. The instrument is free to perform

a new sampling cycle.

If a delayed start-up has been programmed, the display indicates:

∗

TIMED flashes during the count-down phase.

Note: The motor stops 2 liters before the total volume has been sampled.

ZZZL).

STORED_VOL:_ZZZL

BATTERYLIFE: XHXX

STORED VOL: ZZZL

TIMED : X Min YS

∗ Last sampling not terminated:

If the instrument was turned off during sampling, the following message appears

the next time the instrument is turned on:

The indicator light changes to flashing red.

CAUTION! In this case, the user will take all necessary precautions to deal with this

interrupted sampling.

• Press <MENU> to return to the welcome message.

3-24 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

LAST SAMPLING

NOT COMPLETED

Page 53

Using airIDEAL 3P Traceability

Starting sampling

Stopping the motor

START

STOP

• Press <START/STOP>.

Note: It is always possible to stop a sampling operation under way by pressing

<START/STOP>.

If the motor is stopped during the program, i.e. during the delayed start-up

count-down phase or during the sampling phase, the value displayed freezes

and the display continues to flash.

STORED VOL: ZZZL

SAMPLE VOL: XL

∗ To resume sampling,

• Press <START/STOP>.

If the motor is restarted after being stopped during a program, the program will

resume from the point where it was stopped.

1

2

3

Note: If stoppage during sampling is more than 5 minutes, the instrument will go into standby

mode and the sampling program will not be able to resume.

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-25

4

5

Page 54

Using airIDEAL 3P Traceability

Setting airIDEAL 3P Traceability parameters (summary diagram)

Setting airIDEAL 3P Traceability parameters (summary diagram)

MENU

1 ×

Menu 1 : Selection of one of

the 4 sampling volumes

among the 4 pre-programmed

volumes.

Press < + > or < - > until the

desired volume in memory is

displayed.

("Preset volume")

ON

OFF

LAST SAMPLING

NOT COMPLETED

STORED VOL: ZZZL

BATTERYLIFE : XHXX

MENU

2 ×

Menu 2 : Selection of a sampling

volume not in memory.

Press < + > or < - > until the

desired volume is displayed.

("CHOSEN VOLUME")

Menu 3 : Modification of the 4 pre-

programmed sampling volumes.

"PROGRAM 1, 2, 3 and 4

Press < + > or < - > until the

chosen volume is displayed.

3 ×

MENU

MENU

4 ×

MENU

STORED VOL: ZZZL

BATTERYLIFE : XHXX

3-26 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 55

Using airIDEAL 3P Traceability

q

g

q

Setting airIDEAL 3P Traceability parameters (summary diagram)

ON

OFF

LAST SAMPLING

NOT COMPLETED

MENU

Select delay before

startin

MENU

4 ×

Menu 4 : Programming

delayed start-up

Press < + > or < - > until the

delay value is displayed.

STORED VOL: ZZZL

BATTERYLIFE : XHXX

MENU

5 ×

Menu 5 : Programming

sequenced samplings.

Press< + > or < - > until the

desired number is displayed.

MENU

1 ×

Press < + > or < - > until the

desired time is displayed.

Select number of

se

Select time between

se

MENU

MENU

7 ×

Menu 6 : Battery autonomy test

uences

uences

STORED VOL: ZZZL

BATTERYLIFE : XHXX

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-27

Page 56

Navigation using <+> and<-> keys

ON

OFF

STORED VOL: ZZZL

BATTERYLIFE : XHXX

+

NEXT CALIBRATION

MM/DD/YYYY

-

Using airIDEAL 3P Traceability

Navigation using <+> and<-> keys

+

FSE (Field Service Engineer)

XXXXXX

-

+

RUID Serial

XXXXXXXXX

-

XX

-

-

+

FRMB Serial

+

LAST CALIBRATION

MM/DD/YYYY

XXXX

-

-

+

FREE MEMORY

XXXX WORDS

-

+

Soft Version

X.X

-

+

-

+

Serial number

+

MAC ADRESS

XXXXYXXXXYXX

3-28 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 57

Using airIDEAL 3P Traceability

Navigation using <+> and<-> keys

Welcome message

Date of next calibration (Month/Day/Year)

ID of operator who performed calibration

Serial number of RUID used for calibration

Flow Rate Measurement Bench serial number

Date of last calibration

airIDEAL 3P Traceability firmware version

airIDEAL 3P Traceability available memory size

MAC address (Media Access Control)

airIDEAL 3P Traceability serial number

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 3-29

Page 58

Page 59

4 Procedure

Principle

Implementation and following of a procedure to measure aerobiocontamination

corresponds to a process based on prevention, which involves:

• Evaluating the current level and standard of hygiene and controls.

• Selecting the critical areas to be controlled.

• Establishing a reference level and an alert level for each of the critical points.

• Developing a sampling plan.

• In manual mode, preparing a document for recording air sampling results.

• In slave mode, recording of air sampling results using the RUID

• Preparing a plan for corrective action in case of deviation.

The result of sampling should provide information on the level of risk, global

hygiene conditions and environment.

1

2

3

Procedure

The procedure must be adapted to the actual conditions in which air sampling

will take place (contaminated areas, clean areas, sterile areas, etc.)

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 4-1

When strictly followed, the procedure guarantees good quality sampling and

should include:

− Operators’ qualifications.

− Names of qualified operators.

− Hygiene of operators (clothes, hands, etc.).

− Protocol for disinfection of the AeroBioCollector.

− Detailed steps of the procedure.

4

5

Page 60

Procedure

How to obtain a good quality sample

How to obtain a good quality sample

Precautions of use

• Check the condition of the instrument and sampling grid.

• When unscrewing and screwing on the sampling grid avoid touching the

perforated zone.

The choice of medium depends on the area to be controlled and the type of

micro-organism to be isolated.

The agar in 90 mm Petri dishes, must be at least 2.5 mm thick at the center and

have a flat surface. It should not present dehydration or humidity droplets.

• During sampling, avoid any unnecessary movement, do not pass in front of

the instrument or cough etc.

• Begin by collecting from low contaminated areas.

• Collect several samples in each zone in order to obtain results that can be

used for statistical studies.

• Clean the instrument after use and sterilize sampling grids.

• Recharge the battery if necessary.

• Place the instrument in its carrying case and store it in a suitable place.

4-2 airIDEAL® 3P™ Traceability AeroBioCollector User's Manual

Page 61

Procedure

How to obtain a good quality sample

Sampling in manual mode

Note: For slave mode, please refer to the RUID User Manual.

• Turn on the instrument.

• Check the remaining battery life.

• Place the instrument on a flat surface (work bench, table...) in a vertical or

• Select the sample volume according to the critical area to be controlled.

• Remove the protective cover or the sampling grid.

• Mark the date, time and sample location on the Petri dish.

• Place the Petri dish with its cover between the attachment clips and make

• Remove the Petri dish cover and place it on a clean surface.

• Screw on the sampling grid corresponding to the type of plate used.

• Perform sampling.

• The instrument indicates the end of sampling (6 beeps and a constant green

• Unscrew the sampling grid.

• Carefully remove the Petri dish without touching the agar.

• Put the cover back on the Petri dish used.

• Put the protective cover back on.

Incubation and reading

The Petri dishes must be placed in the incubator as rapidly as possible.

After incubation, read as follows:

− Count the number of CFU (Colony Forming Units) which have grown and

− If results are not acceptable, proceed with colony identification to orientate

horizontal position, or set it up on its tripod.

sure it is correctly positioned.

indicator light).

refer to the reading table for the final result (see page 6-1).

corrective action.

1

2

3

4

5

airIDEAL® 3P™ Traceability AeroBioCollector User's Manual 4-3

Page 62

Procedure

Sampling plan

Sampling plan

The sampling plan must be drawn up very carefully and followed strictly. The

aim is to guarantee that the values obtained are comparable. Any discrepancy

between values should reveal a variation in aerobiocontamination.

A sampling plan must include:

− the critical points to be controlled

− the following must be mentioned for each point controlled:

• the time and frequency,

• the micro-organism(s) to be isolated,

• the media used,

• the revivification conditions,

• the sample volume,