LBL Lighting Straight Monorail User Manual

Installation Instructions for

980MRLRAIL

Straight Monorail

Monorail

GP I :ENERAL RODUCT NFORMATION

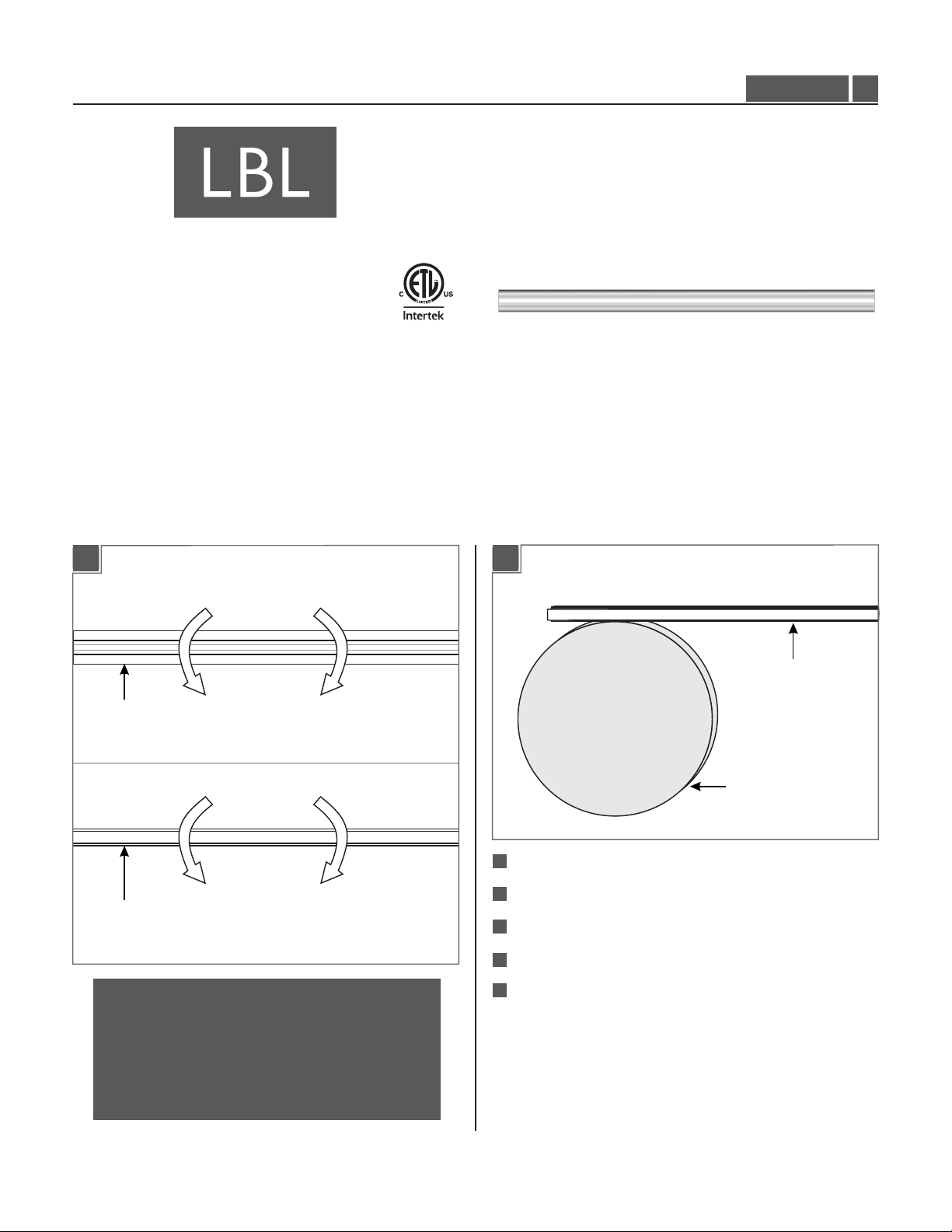

Standard Monorail bends horizontally to a radius as small as 6" and

vertically to a radius as small as 24".

Bending the Monorail

RAIL-ST-_

1.1

PlywoodTemplate to Form a Curve

or Circle (Horizontal Bend Only)

1A

1A

FRONTVIEW OF

THE MONORAIL

TOPVIEW OF

THE MONORAIL

NOTE:There are three techniques for bending the

Monorail horizontally, PlywoodTemplate,Wiremold Pipe

Bender, and Freestyle.When bending the Monorail

vertically, only use theWiremold Pipe Bender technique.

Monorail bends horizontally easier than vertically.When

bending the Monorail vertically, do small bends at a time

and avoid bending the Monorail back which may cause the

rails to separate from the insulator.

VERTICAL BENDING

HORIZONTAL BENDING

1B

2A

CIRCULAR

PLYWOOD

1

Determine the radius of the curve or circle.

2

On a piece of plywood draw the curved pattern.

3

Cut out the curved pattern from the plywood.

4

Make sure the cutout plywood is secured in place.

5

Hold one edge of the Monorail against the plywood.

MONORAIL

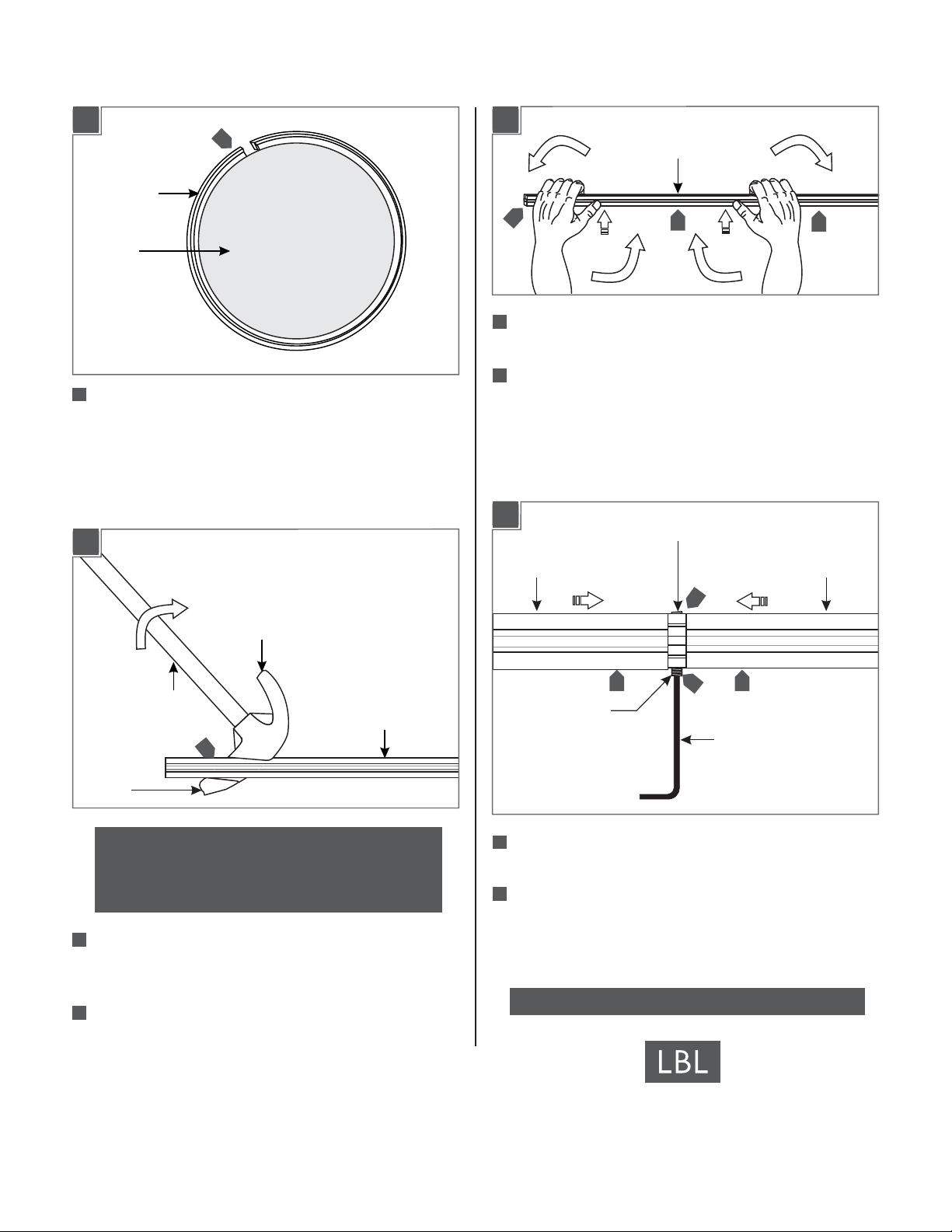

1

Freestyle Bending (Horizontal Bend

Only)

2B

6

MONORAIL

CIRCULAR

PLYWOOD

6

Start bending the rest of the Monorail against the circular

plywood until the desired curve or circle is achieved.

Wiremold Pipe Bender (Horizontal

or Vertical Bend)

1A3A

1B1A4A

2

PUSH

1

Choose the center of bending section on the Monorail.The

bending point should be centered between the hands.

2

To ensure a smooth curve, begin with hands as far as apart as

possible, moving the hands closer together as bending

progresses. Bend the Monorail until the desired shape is

achieved.

CENTER OF

BENDING SECTION

1

PUSH

2

Connecting the Monorail Sections

1A5A

MONORAIL

CONDUCTIVE OR ISOLATING

JOIN CONNECTORS

MONORAIL

PEDAL

ARM

MONORAIL

1

HOOK

NOTE: TheWiremold Pipe Bender can be used to create

smooth horizontal curve of 90° or less.Avoid stepping on

the pedal of the Pipe Bender which will flatten and damage

the Monorail.

1

Feed the Monorail through the Pipe Bender hook. Start

bending the Monorail by gently pulling back on the arm of the

Pipe Bender.

2

Start with small angle (MAX 10°) to avoid errors in shaping

the Monorail.After each bend unhook and check the Monorail

against the pattern.

2

1

M3 SET SCREW

1

Push two Monorail sections completely onto the conductive

or isolating join connectors.

2

Tighten the M3 set screws with the 1.5 MM Allen wrench

provided. Make sure that the set screw connection for

conductive connector is tight to avoid heat build up and

corrosion. For the isolating connector, tighten the #6-32 set

screw firmly to avoid stripping the thread.

2 1

1.5 MM ALLEN

WRENCH

SAVETHESE INSTRUCTIONS!

7400 Linder Ave, Skokie, IL 60077

800.323.3226 - 847.626.6300

www.lbllighting.com

© 2014 LBL Lighting.All rights reserved. The "LBL Lighting" graphic is a

registered trademark of LBL Lighting. LBL Lighting reserves the right to

change specifications for product improvements without notification.

2

A Generation Brands CompanyA Generation Brands Company

Loading...

Loading...