Page 1

Installation Instructions for

980AMBRASP

Ambra

Suspension

GENERAL PRODUCT INFORMATION:

This product can mount to either a 4" square electrical box with

round plaster ring or an octagon electrical box.

This product is suitable for indoor dry locations only.

This product can be dimmed with a standard incandescent dimmer.

CAUTION - RISK OF FIRE

This product requires installation by a qualified

electrician. Before installing be sure to read all

instructions and TURN THE POWER TO THE

ELECTRICAL BOX OFF.

HS399AM_2J150

1.0

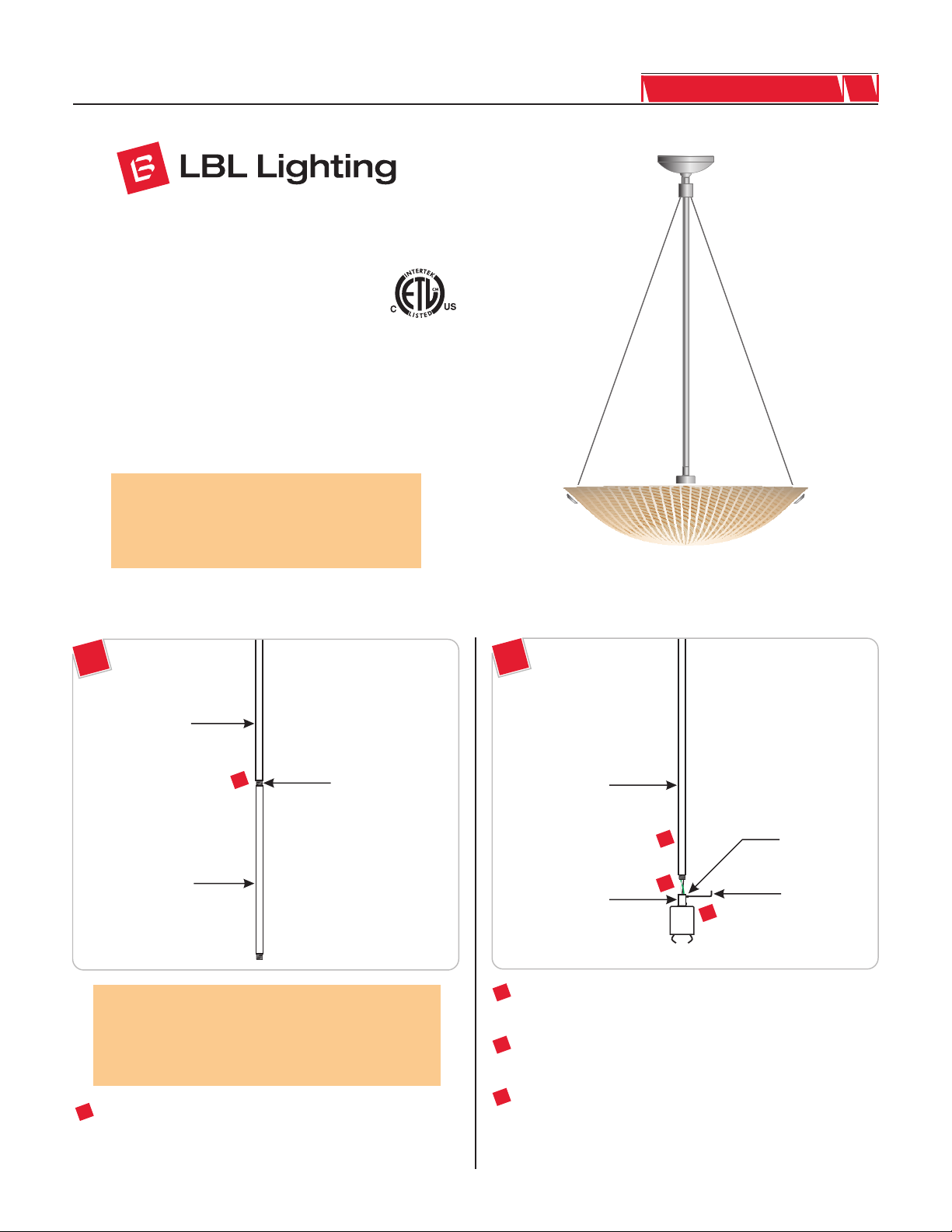

Adjust the Fixture Height

1A

EXTENSION STEM

1

EXTENSION STEM

NOTE: Use a 24" stem for the minimum 32" overall

height. To extend the fixture height to 44", or 56", or 68",

use the additional 12", or 24", or combination of 12" and

24" provided extension stems respectively. The extension

stems are not field cuttable.

THREADED NIPPLE

1B

FIXTURE STEM

3

2

SOCKET BUSHING

2

Feed the fixture wires through the exposed threaded nipple of

the fixture stem. Slide the fixture stem down the cord.

On the socket busing, loosen (Do Not Remove) the top M3

3

set screw with the provided 1.5MM Allen wrench.

4

M3 SET SCREW

1.5MM ALLEN

WRENCH

1

Optional - To combine the fixture extension stems, simply

tighten one extension stem threaded nipple completely to the

back of the other extension stem.

Screw the fixture stem completely to the socket bushing and

4

tighten the top M3 set screw with the 1.5MM Allen wrench.

1

Page 2

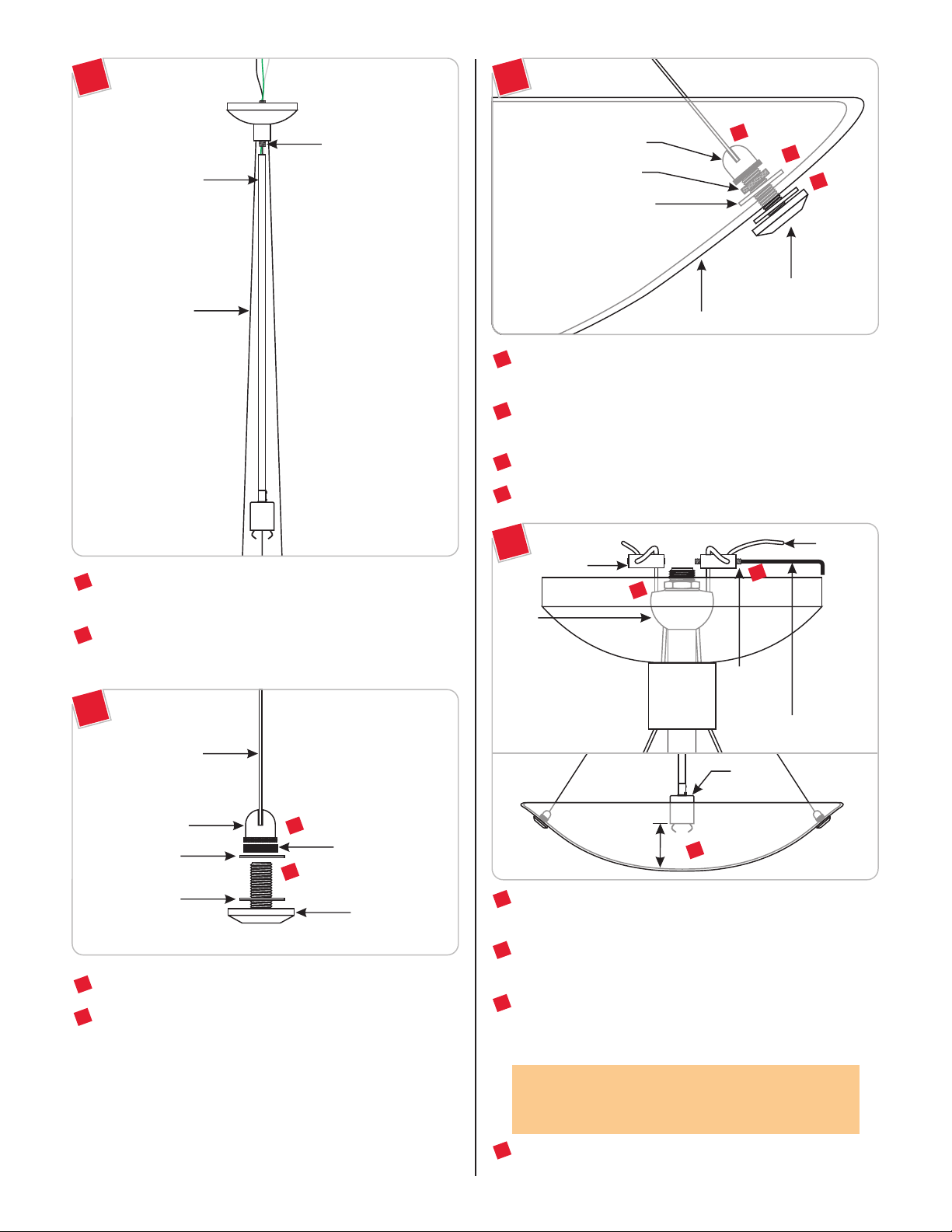

1C

1E

CANOPY

THREADED NIPPLE

FIXTURE STEM

AIRCRAFT CABLE

5

Feed the fixture wires coming out of the fixture stem through

the canopy threaded nipple.

6

Tighten the fixture stem completely to the canopy threaded

nipple. Make sure that the aircraft cables do not get tangled up.

1D

CABLE BUSHING

KNURLED NUT

PLASTIC WASHER

GLASS SHADE

From outside of the glass shade, insert the cap screw through

9

11

10

CAP SCREW

one glass shade hole.

Place the second plastic washer onto the cap screw and finger

10

tighten the knurled nut to secure the cap screw in place.

11

Screw the cable bushing completely to the cap screw.

12

Repeat steps 7 through 11 for the remaining glass shade holes.

1F

HUB

STRAIN

RELIEF

13

15

M3 SET

SCREW

1.5MM ALLEN WRENCH

9

AIRCRAFT

CABLE

AIRCRAFT CABLE

CABLE BUSHING

PLASTIC WASHER

PLASTIC WASHER

Remove the cap screw from the cable bushing.

7

Remove the knurled nut and one of the plastic washers from

8

7

KNURLED NUT

8

CAP SCREW

the cap screw.

SOCKET

CAP

3.5"

13

For each strain relief, loosen (Do Not Remove) the M3 set

14

screws with the provided 1.5MM Allen wrench.

14

Mark the aircraft cables so that there is at least 3.5" space

between bottom of the socket cap and the inside glass shade.

Adjust the marked aircraft cables in the strain relief and make

15

sure that the strain relief sits against the hub; tighten the two

M3 set screws with the 1.5MM Allen wrench.

CAUTION: These set screws must be very tight to

secure the glass in place. Failure to do so may cause the

glass shade to fall.

16

For a nice and neat look, trim off excess aircraft cables coming

out of the strain reliefs.

2

Page 3

Install the Fixture

2A

1

CROSSBAR

1

Mount the crossbar to the electrical box with the provided

#8-32 SCREW

two #8-32 screws.

1

2B

2

3

4

2C

6

5

Place all wire and wire nut connections inside the electrical

5

box.

6

Align the canopy holes with the crossbar holes. Secure the

canopy in place by tightening the two M5 button head screws

with the provided 2.5MM Allen wrench.

Tighten the three aircraft cable bushings to the glass shade cap

7

screws (refer to step 11 and figure 1E on page 2).

6

M5 BUTTON

HEAD SCREW

2.5MM ALLEN

WRENCH

Install the Lamp

3A

NOTE: To ease the installation, it is recommended to

remove the glass shade by unscrewing the cable bushings

(refer to drawing 1E).

2

Connect the fixture bare wire and the crossbar green wire to

the ground in accordance with local electrical codes.

3

Connect the fixture black wire to the hot power line wire with

a wire nut.

4

Connect the fixture white wire to the neutral power line wire

with a wire nut.

SOCKET

CAUTION: To reduce the risk of a burn or electric shock

during relamping, disconnect the power to the fixture.

NOTE: Use only your fingers and a soft cloth to replace

the lamp.

Use MAX 120 Volt, 150 Watt Type E11

Base Mini Candelabra Lamp.

1

Carefully swing the socket assembly out of the glass shade.

1

2

LAMP

2

Screw the lamp completely into the socket.

3

Page 4

IMPORTANT SAFETY INSTRUCTIONS

3B

SPRING CLIP

3

Push the lamp shield completely onto the socket spring clips.

3C

3

LAMP

SHIELD

To reduce the risk of fire, electrical shock, exposure to

excessive UV radiation, or injury to person:

– Use this fixture indoors only.

– Do not look directly at the lighted lamp.

– Do not remain in light if skin feels warm.

– Risk of fire: Use only the type of lamp and maximum wattage

indicated in this instruction manual.

– Never cover the halogen lamp with anything other than a LBL

Lighting lamp shield and never place flammable material close to

your fixture.

– Never turn the fixture on and off by connecting and

disconnecting the halogen lamp.

– Do not touch the fixture shades or lamp shield while the fixture

is on. These surfaces may be HOT.

Halogen Lamp General Information

– A new halogen lamp may smoke slightly when it is used for the

first time. This is perfectly normal; the protective coating is simply

being vaporized.

4

4

Carefully swing the socket assembly back into the glass shade.

Two Tips For Prolonging Halogen

Lamp Life

– First avoid touching the lamp with bare hands during installation.

Any contaminant, even the oil from your hands can deteriorate

the lamp. Rubbing alcohol can be used to remove any

contaminant.

– Second, do not run the lamps at full power when you do not

need to. However, if dimming the fixture for an extended period

of time, occasionally bring the light up to full brightness for a few

minutes to complete the halogen cycle.

SAVE THESE INSTRUCTIONS!

7400 Linder Ave, Skokie, IL 60077

800.323.3226 - 847.626.6300

www.lbllighting.com

© 2008 LBL Lighting. All rights reserved. The "LBL Lighting" graphic is a

registered trademark of LBL Lighting. LBL Lighting reserves the right to

change specifications for product improvements without notification.

4

A Generation Brands Company

Loading...

Loading...