lb Lautsprecher DE Plan 200, DE Plan 200 T, DE Plan 400 T, DE Plan 500 S, DE Plan 600 Installation Instructions Manual

...

Installation Instructions

Invisible Speaker Series

Patented at plate sound transducers for invisible mounting in ceilings and walls. On account of the combination of

cone speakers in the low-frequency range, specially developed exciters in the high- frequency range and complex

crossovers the various models of the DE Plan Series achieve excellent outstanding sound characteristics and

excellent low frequency reproduction.

READ AND FOLLOW THESE INSTRUCTIONS BEFORE INSTALLING THIS PRODUCT.

Content

Important Informations and Accessories .................................................................. Page 2

1. Installation in Drywalls and -ceilings ..................................................................... Page 3

2. Installation with Back Boxes in Drywalls and -ceilings ...................................... Page 5

3. Installation in Solid Walls ......................................................................................... Page 6

4. Installation in Concrete Ceilings ............................................................................. Page 7

2

Accessories

The following components are included in your delivery:

• Assembly frame for positioning the mounting feet

• Mounting feet

• Special quick- x screws for attaching the mounting feet

(Do not use standard drywall screws)

• Springs and screws for attaching the speaker:

– 55 mm springs and 70 mm screws for wall/ceiling

thicknesses of 10 – 25 mm (including back box)

– 65 mm springs and 80 mm screws for wall/ceiling

thicknesses of 25 – 35 mm (including back box)

• Dispersion adhesive

• Glas ber lining for covering the speaker (34 g / m2)

• Acoustic eece (in combination with DE Plan back boxes)

Important Informations

We recommend that all lining, plastering and painting work is

carried out by professionals. The speaker will only deliver the

desired visual and acoustic results if it is installed correctly.

Drying times between the individual steps must be observed.

The models in the DE Plan series are designed to be installed

in walls/ceilings that are 10 – 35 mm thick (= max. two drywall

sheets + 10 mm thick back box). Solutions for other installation

scenarios are available on request.

Damage resulting from incorrect handling is not covered by

the warranty.

Refer to individual product datasheets for

more detailed technical information. These

are available at: www.lb-lautsprecher.de/en/

Invisible-loudspeakers

You will also nd a link to our YouTube video

showing how to install a DE Plan speaker

at: www.lb-lautsprecher.de/en/Invisibleloudspeakers

Springs 65 mm

+ Screws 80 mm

Mounting feet

Quick-fi x screws

Glas fi ber lining

Assembly Frames

Dispersion

adhesive

MR Plan 200

Dim.: 300 × 310 mm

MR Plan 400

Dim.: 420 × 370 mm

MR Plan 500

Dim.: 560 × 210 mm

MR Plan 600

Dim.: 626 × 370 mm

Springs 55 mm

+ Screws 70 mm

Acoustic Fleece

1.1 Mark out the opening for the speaker and

also mark the positions of the mounting feet to

make sure the screws are drilled in the correct

position later. Use the assembly frame as a

template.

1.2 Cut out the opening with a utility cutter

or saw (only cut out the rectangular outline).

Make sure the edges are smooth.

1.3 Use a sharp utility cutter to taper the

edges of the aperture to an angle of 45

degrees.

1.4 Smooth the edges with sandpaper (100 –

150 grain). Remove any bits of drywall paper

that are protruding.

1.5 Insert the assembly frame with the

mounting feet attached.

1. Installation in Drywalls and -ceilings

Turn the feet to the inside if you are installing

the speaker in a wall/ceiling where there is

limited space.

1.6 Drill the quick- x screws supplied through

the front of the drywall and into the mounting

feet. Do not use standard drywall screws!

1.7 Remove the assembly frame. Only the

mounting feet and springs remain in the wall/

ceiling. Use the long springs (65 mm) for wall/

ceiling thicknesses of 25 mm or more.

1.8 Connect the speaker system.

MAKE SURE THE POLARITY IS CORRECT.

DE Plan speakers can be installed without

back boxes in closed ceilings and walls.

DE Plan 600 SUB subwoofers must be

installed with a back box to ensure they

can be correctly balanced. Back boxes

from the EG Plan series are usually used

in acoustic ceilings or to reduce sound

transmission into adjacent rooms (see

page 5).

3

Use springs with 55 mm and screws with 70 mm for wall thickness from 10 to 25 mm.

1.9 Install the speaker: Insert the drill bit into

the head of the assembly screw in the speaker.

Drill the speaker into the wall/ceiling. Use the

long screws supplied with your product for

wall/ceiling thicknesses of 25 mm or more.

1.11 Use the assembly screws to adjust the

speaker so that the plastic membrane protrudes

by approximately 0.5 mm in front of the wall/

ceiling on all sides.

1.10 Test the speaker and wiring, for example,

by playing music. (The speaker will not

produce the correct sound until the surface is

nished.)

1.13 Plaster and sand down (grain 120 – 240)

the seam between the wall/ceiling and the

membrane twice, and plaster over the screw

holes twice.

1.14 Only sand the edge of the membrane

and only apply light pressure when doing this.

Make sure no plaster is left on the membrane.

1.15 Use a foam roller to evenly apply

the dispersion adhesive delivered with

your product over the membrane and the

surrounding area.

1.16 Place the glass ber lining over the

adhesive area while it is still moist. Make sure

the lining is centered.

1.17 Use the roller to apply another light coat

of adhesive over the lining. Make sure the

surface is smooth. Allow the adhesive to dry

completely (overnight).

1.18 Apply one very light coat of ller over

the entire area. Apply two to three very light

coats of ller to the seam where the lining

meets the wall/ceiling and sand down until

you have a ush surface.

1.19 IMPORTANT! Before you start painting,

make sure that the ller has dried completely

(overnight). If it is not completely dry, the paint

may not adhere correctly to the surface!

1.20 Paint the area. The high frequency level

will decrease slightly if three coats or more are

applied (approx. 0.5 - 1 dB per coat).

1.12 The membrane should not be too deep

otherwise you will not be able to plaster over

the seam.

4

2 × coated (standard), 3 × coated, 4 × coated

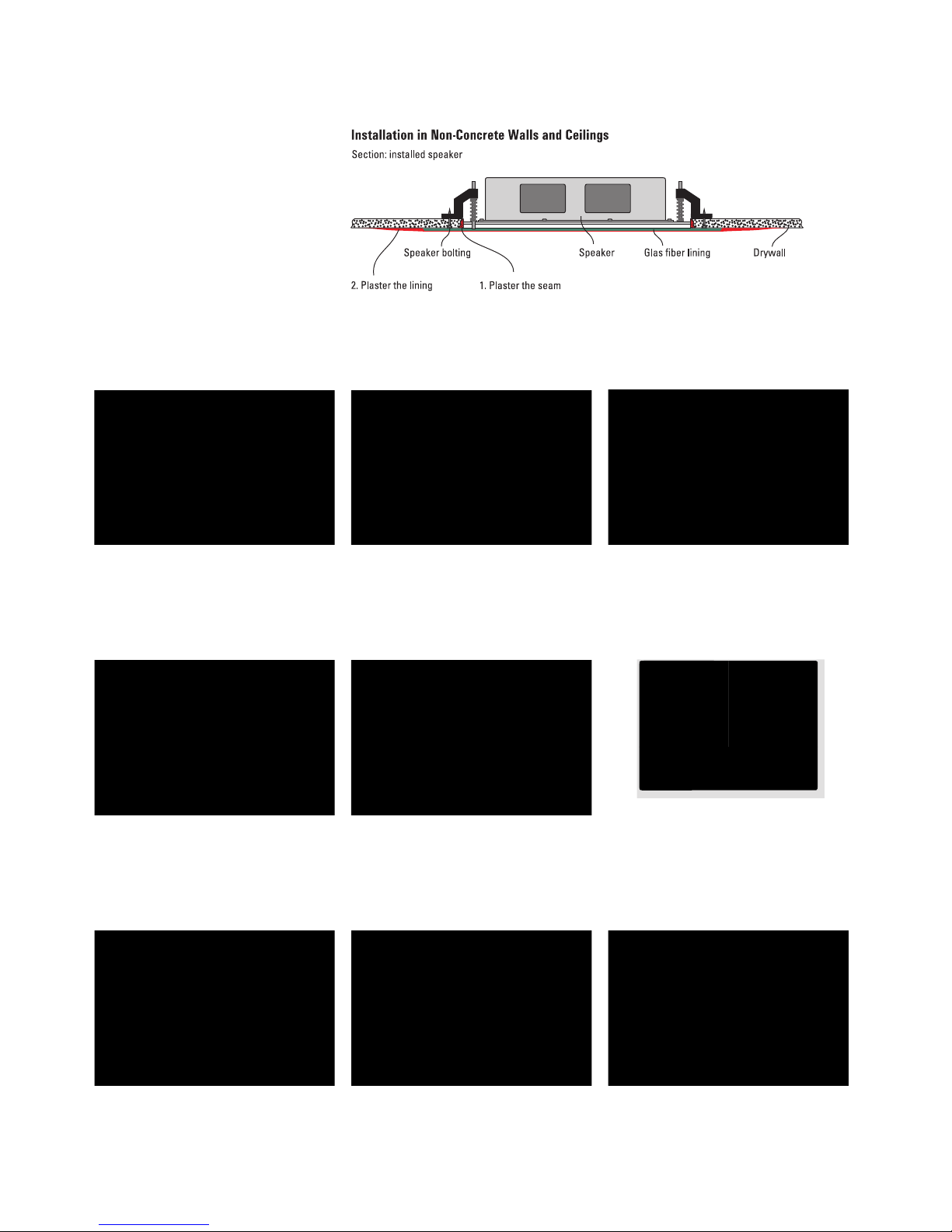

2. Installation with Back Box in Non-Concrete Walls and Ceilings

Use EG Plan series back boxes in walls

or ceilings that are not closed (e.g. for

acoustic ceilings, ventilated ceilings,

open recessed lighting), or if you need

additional sound proo ng for adjacent

rooms. The mounting feet are already

attached in these back boxes. You will

have to make the holes for cables in the

back box yourself.

Frequency range of DE Plan speakers with its infl uence of paint coating

The sound quality of DE Plan speakers

depends on the material placed over the

membrane. The membrane is designed

to be covered by the glass ber lining (34

g / m²), a thin layer of ller, which is then

sanded, and 1 – 3 coats of paint (emulsion).

If any other material is applied over the

membrane (e.g. thicker lining, thicker coats

of ller or acoustic plaster), this will cause

a drop in sound pressure levels in the midhigh range. You can compensate for this

using a system controller or an equalizer,

for example. Please contact us if you have

any questions.

5

EG Plan 200

400 × 350 × 100 mm

EG Plan 400

500 × 480 × 120 mm

EG Plan 500 S

620 × 240 × 100 mm

EG Plan 600

700 × 480 × 120 mm

DE Plan 400

EG Plan 600

Place the back boxes behind the drywall

sheet. Glue and screw them in position.

Fit the acoustic eece into. Pin the

springs on the mounting feet. Use the

long springs supplied for wall/ceiling

thicknesses of 25 mm or more. Drill the

speaker into the wall/ceiling and make

sure it is level (installation step 1.8

onwards).

Use springs with 55 mm and screws with 70 mm for wall thickness from 10 up to 25 mm.

Use springs with 65 mm and screws with 80 mm for wall thickness from 25 up to 35 mm.

3.1 Make the opening in the

brickwork.

3.2 Install the EGB series plastic back

box using mortar or a similar material. Make sure the box is free from

mechanical stress and fix in place

using adhesive or plugs (otherwise

the position of the speaker may

shift visibly over time).

3. Installation in Solid Walls

3.3 Apply the plaster mesh (to prevent

cracks forming at the seam) and

plaster to the edge of the opening.

3.4 Fit the acoustic eece into the back

box. Pin the springs on the mounting

feet.

3.5 Connect, install, test and adjust the

speaker (see steps 1.8 – 1.11).

3.6 Plaster the edge and sand until

smooth (see steps 1.12 – 1.13).

3.7 Place the glass fiber lining over

the plastic membrane

(see steps 1.14 – 1.16).

3.8 Plaster and sand down the lining

and seams

(see steps 1.17 – 1.18).

3.9 Paint over the area

(steps 1.19 – 1.20).

When installing speakers in solid walls,

please use our EGB series plastic back

boxes. The mounting feet are already

attached in these back boxes. You will

have to make the holes for cables in the

back box yourself. The speakers can

then be installed in the same way as

for non-concrete walls/ceilings. Please

note that the speaker is not designed

to be used with rough render, textured

render or similar plastering. Applying

these kinds of material over the speaker

membrane will have a major impact on

sound (see page 5).

6

EGB Plan 200

400 × 350 × 100 mm

EGB Plan 400

500 × 480 × 120 mm

EGB Plan 500 S

620 × 240 × 100 mm

EGB Plan 600

700 × 480 × 120 mm

4.1 Insert and affix the EGB series

plastic back box in the formwork

ready for the concrete ceiling to

be cast (make sure the correct

reinforcement is used above and

below the back boxes).

4.2 Once the ceiling is cast, remove

the rigid foam insert from the back

box.

4. Installation in Concrete Ceilings

4.3 Fit the acoustic eece into. Pin the

springs on the mounting feet.

4.4 Connect, install, test and adjust the

speaker (see steps 1.8 – 1.11).

4.5 Plaster the edge and sand until

smooth (see steps 1.12 – 1.13).

4.6 Place the glass fiber lining over the

plastic membrane

(see steps 1.14 – 1.16).

4.7 Plaster and sand down the lining

and seams (see steps 1.17 – 1.18).

4.8 Paint over the area

(steps 1.19 – 1.20).

If you are installing speakers in a

concrete ceiling, EGB series plastic

back boxes must rst be cast into the

concrete ceiling (precast concrete

ceilings and concrete ceilings cast in

place). The mounting feet are already

attached in these back boxes. You will

have to make the holes for cables in

the back boxes yourself. The speakers

can then be installed in the same way

as for non-concrete walls/ceilings.

7

EGB Plan 200

400 × 350 × 100 mm

EGB Plan 400

500 × 480 × 120 mm

EGB Plan 500 S

620 × 240 × 100 mm

EGB Plan 600

700 × 480 × 120 mm

Technical Data

Changes and errors excepted.

lb Lautsprecher und Beschallungstechnik GmbH · Steinerstr. 15 K · 81369 München · Tel +49 89 1893109 -0 · Fax -29 · info@lb-lautsprecher.de · www.lb-lautsprecher.de

05122017CD

DE Plan 200 2-way

at transducer

70 Hz –

20 kHz

RMS/Prog.

40/80 watts,

8 Ohm

81 dB (1W@1m)

max. 99 dB

180° 300 × 240 mm

incl. mounting

feet

300 × 310 mm

304 × 244 mm

wall / ceiling

thickness

10 – 35 mm

(incl. back

box)

72 mm 2.8 kg EG / EGB

Plan 200

Dim.:

400 × 350

× 100 mm

DE Plan 200 T

100 V version

7.5/15/30

watts

max. 95 dB 3.2 kg

DE Plan 200 ST Stereo-

2-way at

transducer

90 Hz –

20 kHz

RMS/Prog.

2 × 30 /2 × 60

watts,

2 × 8 Ohm

81 dB

(1W@1m)

max. 99 dB

180° 300 × 240 mm

incl. mounting

feet

300 × 310 mm

304 × 244 mm

wall / ceiling

thickness

10 – 35 mm

(incl. back

box)

72 mm 2.8 kg EG / EGB

Plan 200

Dim.:

400 × 350

× 100 mm

DE Plan 400 2-way at

transducer

48 Hz –

20 kHz

RMS/Prog.

80/160

watts,

8 Ohm

82 dB

(1W@1m)

max. 104 dB

180° 420 × 300 mm

incl. mounting

feet

420 × 370 mm

424 × 304 mm

wall / ceiling

thickness

10 – 35 mm

(incl. back box)

72 mm 3.9 kg EG / EGB

Plan 400

Dim.:

500 × 480

× 120 mm

DE Plan 400 T

100 V version

15/30/60

watts

max. 100 dB 4.3 kg

DE Plan 500 S 2-way at

transducer

110 Hz –

20 kHz

RMS/Prog.

80/160

watts,

8 Ohm

82 dB

(1W@1m)

max. 104 dB

180° 540 × 140 mm

incl. mounting

feet

560 × 210 mm

544 × 144 mm

wall / ceiling

thickness

10 – 35 mm

(incl. back

box)

72 mm 3.8 kg EG / EGB

Plan 500 S

Dim.:

620 × 240

× 100 mm

DE Plan 600 2-way at

transducer

42 Hz –

20 kHz

RMS/Prog.

160/320

watts,

8 Ohm

83 dB

(1W@1m)

max. 108 dB

180° 620 × 300 mm

incl. mounting

feet

626 × 370 mm

624 × 304 mm

wall / ceiling

thickness

10 – 35 mm

(incl. back

box)

72 mm 5.5 kg EG / EGB

Plan 600

Dim.:

700 × 480

× 120 mm

DE Plan 600

AlArray

4-channel

2-way at

transducer

40 Hz –

20 kHz

RMS/Prog.

4 × 40 / 4 × 80

watts,

4 × 8 Ohm

86 dB

(1W@1m)

max. 110 dB

horiz. 180°

vert.

ad just-

able via

controller

620 × 300 mm

incl. mounting

feet

626 × 370 mm

624 × 304 mm

wall / ceiling

thickness

10 – 35 mm

(incl. back

box)

72 mm 6.3 kg EG / EGB

Plan 600

Dim.:

700 × 480

× 120 mm

DE Plan 600 SUB

Only for use

with back box

EG / EGB Plan 600

Flat transducer

40 Hz –

180 Hz

RMS/Prog.

120/240

watts,

4 Ohm

82 dB

(1W@1m)

max. 105 dB

180° 620 × 300 mm

incl. mounting

feet

626 × 370 mm

624 × 304 mm

wall / ceiling

thickness

10 – 35 mm

(incl. back

box)

72 mm 6.5 kg EG / EGB

Plan 600

Dim.:

700 × 480

× 120 mm

*Installed with two coats of paint.

Models

Principle

Frequency Range*

Power Capacity

Sensitivity

Dispersion Angle

Dimensions

Cutout Size

Installation Depth

Weight

Back Box

DE Plan 600

vorneseitlich

DE Plan 600

vorneseitlich

DE Plan 400

vorne

DE Plan 200

vorneseitlich

DE Plan 200

vorneseitlich

10

142

620

72

540

12

96

212

542

Hartschaumeinsatz bei EGB-Serie

DE Plan 500 S

vorne

seitlich seitlich

seitlich

Montagerahmen MR 500 S

vorne

Einbaugehäuse EG Plan und EGB Plan 500 S

vorne

Loading...

Loading...