Page 1

`

LazyMan Gourmet Grills

USE AND CARE GUIDE

LM210-20 LM210-30

Page 2

WARNING

READ THIS MANUAL CAREFULLY and completely before using your grill to reduce the risk of:

1. Fire

2. Burn hazard, personal injury, or property damage

3. Burned food or unpleasant cooking experiences

4. Unapproved installation or servicing

THIS PRODUCT IS DESIGNED FOR OUTDOOR USE ONLY. Improper installation, adjustment, alteration, service,

or maintenance can cause property damage, injury, or death.

Read this manual thoroughly before installation, use, or servicing of this product

DANGER

IF YOU SMELL GAS:

1. Shut off all gas supply lines to the grill.

2. Extinguish any open flames.

3. If the gas odor continues, keep everyone away from the grill and immediately call your gas company

or fire department.

WARNING

1. DO NOT store or use gasoline or any other flammable liquids in the vicinity of this or any other

appliance.

2. Propane (LP) gas cylinders, not connected to the grill, should NOT be stored in the vicinity of this, or

any other appliance. Propane cylinders must be stored outdoors.

WARNING

1. The burning of gas cooking fuels generates by-products which are on the list of substances, known by

some states, to cause cancer or reproductive harm.

2. To minimize exposure to such substances, always operate this appliance according to the use and care

instructions found in this manual.

3. NOTE TO INSTALLERS: assure that grill owner receives this manual after installation.

i

Page 3

WARNING

1. Never use dented, rusty, or damaged propane cylinders. Never store additional or empty propane

cylinders next to, or in the vicinity of this or any other appliance. Never store propane cylinders

indoors or on their sides.

2. Children should NEVER be left alone or unattended in the area where the appliance is located.

Place your grill unit well away from areas where children play. Do not store items that may be of

interest to children, in or around the grill or island enclosure.

3. Never attempt to move the appliance when hot. When in use, portions of the grill are hot enough

to cause severe burns.

4. Always maintain the required clearances to combustibles as detailed in this manual. This grill is

designed for outdoor use ONLY. Never use inside a garage, building, shed, breezeway, or other

enclosed area. Do not use this appliance under any overhead combustible construction.

5. Gas grills are not designed or certified to be used or installed on any recreational vehicle, portable

trailers, boats, or any other moving installation.

6. Always have an ABC fire extinguisher accessible. Never attempt to extinguish a grease fire with

water or other liquids.

7. If this appliance is removed and stored INDOORS, leave propane cylinders OUTDOORS in a well

ventilated area, away from heat or where children may have access to them.

8. Do not repair or replace any part of this grill unless specifically recommended in this manual.

9. If this appliance is installed by a professional installer or technician, be sure that he/she shows you

where the gas supply shut-off valve is located. All gas lines must have a shut-off valve that is readily

and easily accessible. If you smell gas, check for leaks IMMEDIATELY. Refer to section entitled ‘Leak

Test Procedure’. Check leak with soap and water only. Never use an open flame to check for gas

leaks.

10. When using a propane cylinder, inspect the gas supply hose prior to each use of the grill. If there is

excessive abrasion or wear, or the hose is cut, it must be replaced before using the grill.

11. THIS MANUAL MUST REMAIN WITH THE PRODUCT OWNER FOR FUTURE REFERENCE.

To obtain replacement parts or service, contact:

LazyMan Inc. 560 Independence Street, Belvidere, NJ 07823

Customer Service (908) 475-5315 (800) 475-1950

ii

Page 4

TABLE OF CONTENTS

Important Safety Precautions…………………………………………………………………….…1

Built-in Grill Application Requirements and Cutouts…………………………………….2

Island Installations………………………………………………………………………………………..4

Gas Connections…………………………………………………………………………………………..6

Natural Gas (NG)…………………………………………………………………….……………..…..6

Liquid Propane (LP)…………………………………………………………………………..….…… 6

Final Checks………………………………………………………………………………………………..8

Operation of Your Grill…………………………………………………………………………………10

Introduction……………………………………………………………………………………………..10

Checklists…………………………………………………………………………………………..…….10

Manual Lighting………………………………………………………………………………………..11

Lighting Your Grill……………………………………………………………………………………..12

Cleaning Your Grill………….………………………………………….…………………………..……13

Troubleshooting……………………………………………………………………….………………….15

Replacing the Electronic Igniter……………………………………………………………….…..19

Exploded View Parts Lists…………………………………………………………………….……...20

LazyMan Warranty Information…………………………………………………………………...22

iii

Page 5

IMPORTANT SAFETY PRECAUTIONS

1. The LazyMan LM210 Series grills arrive nearly fully assembled and require only minor assembly steps.

Assure that ALL packaging materials have been removed before attempting to light the appliance. This

includes removing all shipping tie wraps, zip ties and cardboard. Remove the cooking grates and look

for ALL internal packaging materials INSIDE the grill. Last, peel off all protective vinyl coating from ALL

exterior and interior surfaces on the appliance.

2. Avoid wearing loose fitting clothing or long sleeves while cooking. They could ignite.

3. Never leave the appliance unattended while cooking.

4. Never touch the grill racks or surrounding metal surfaces with your bare hands while cooking. These

surfaces will be HOT.

5. The use of an insulated glove or mitt is recommended while cooking.

6. The stainless steel cover MUST BE removed before attempting to light the grill, as an explosion could

occur. Do not lean over the appliance when lighting.

7. Do not heat unopened food containers on the appliance, as, pressure will build up and the container

can explode.

8. Do not use aluminum foil on the grill racks. This will prevent proper ventilation and allow excessive

heat to build inside the grill. Such heat can damage components of the grill.

9. Never remove the drip pan while cooking. Always assure that it is pushed all the way in. Hot overflow

can leak downward and produce a fire or explosion. The drip pan should be cleaned on a regular basis

when the appliance is cold.

10. If burner does not light within 5 seconds, turn gas off and wait 5 minutes before attempting to re-light.

If any burner goes out during operation, turn burner off and check for adequate fuel. Wait 5 minutes

before attempting to re-light.

11. When using portable LP gas cylinders, always turn off the main valve on the cylinder after each use.

12. Use caution when operating the appliance in windy conditions. Wind can enter from the back or sides

and interrupt air flow. This can cause an overheating condition and damage the appliance and its

components.

13. This grill has been made with the finest materials available and, as a result, this grill is HEAVY. Always

use caution when moving or installing this product. Failure to follow this instruction can result in back

or other personal injuries.

1

Page 6

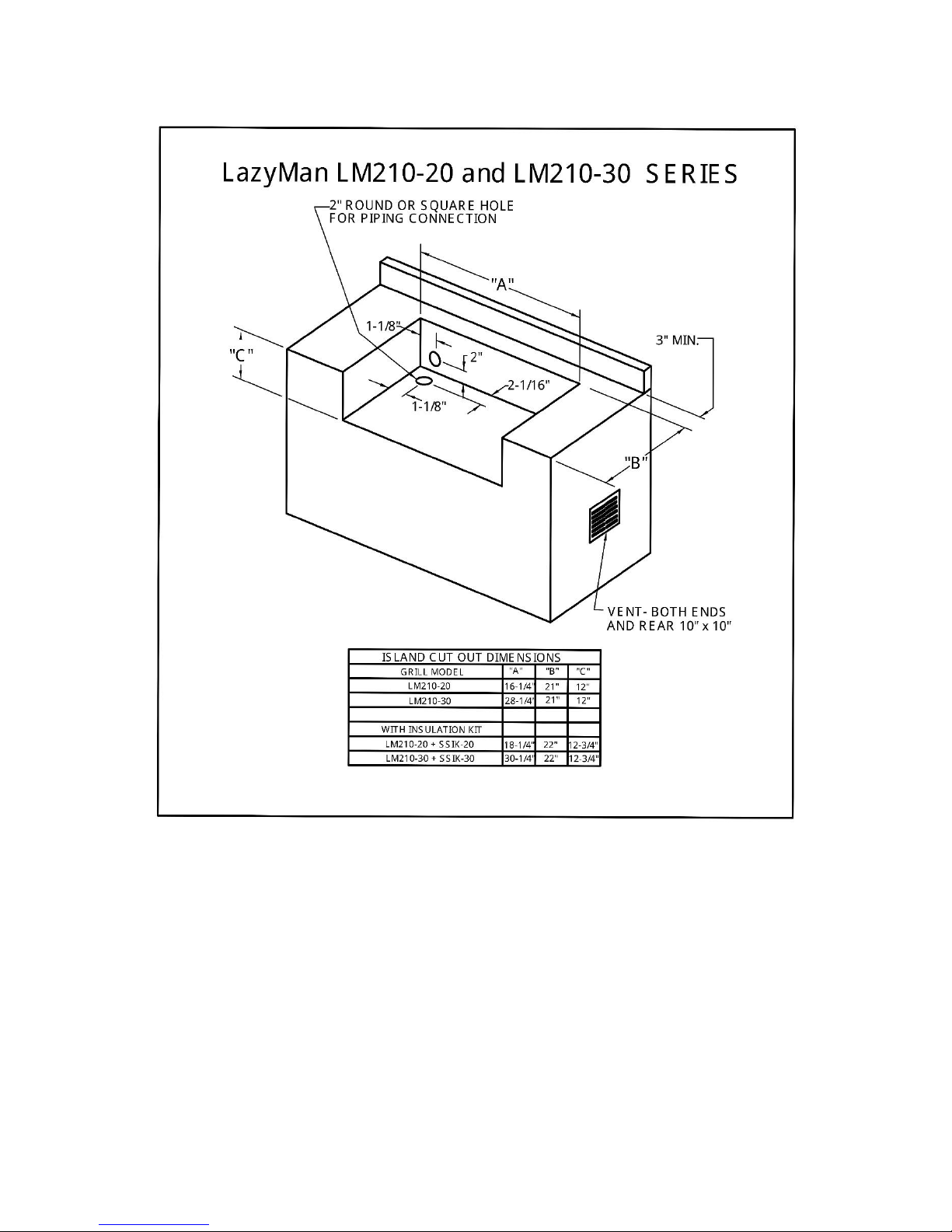

BUILT-IN APPLICATION REQUIREMENTS AND CUTOUTS

All LazyMan grills are manufactured to very tight tolerances. To ensure the best possible fit, however, it is best

to purchase and have the grill available for the contractor BEFORE constructing a new island. As a guideline,

prepare your island cutout per the dimensions found in the chart above. The LazyMan LM210 Series built-in

grill is intended to be mounted and installed in a built-in enclosure (island) made from NON-COMBUSTIBLE

materials such as masonry, brick, or steel. For installations in wood or other combustible materials, LazyMan

offers a stainless steel insulation kit. These kits add extended cutout requirements as shown in chart and will

insulate most of the heat generated by the grill from the combustible construction. These kits are available

from your local dealer and are identified as follows:

STAINLESS STEEL INSULATION KITS:

SSIK-20- Insulation Kit for LM210-20

SSIK-30- Insulation Kit for LM210-30

2

Page 7

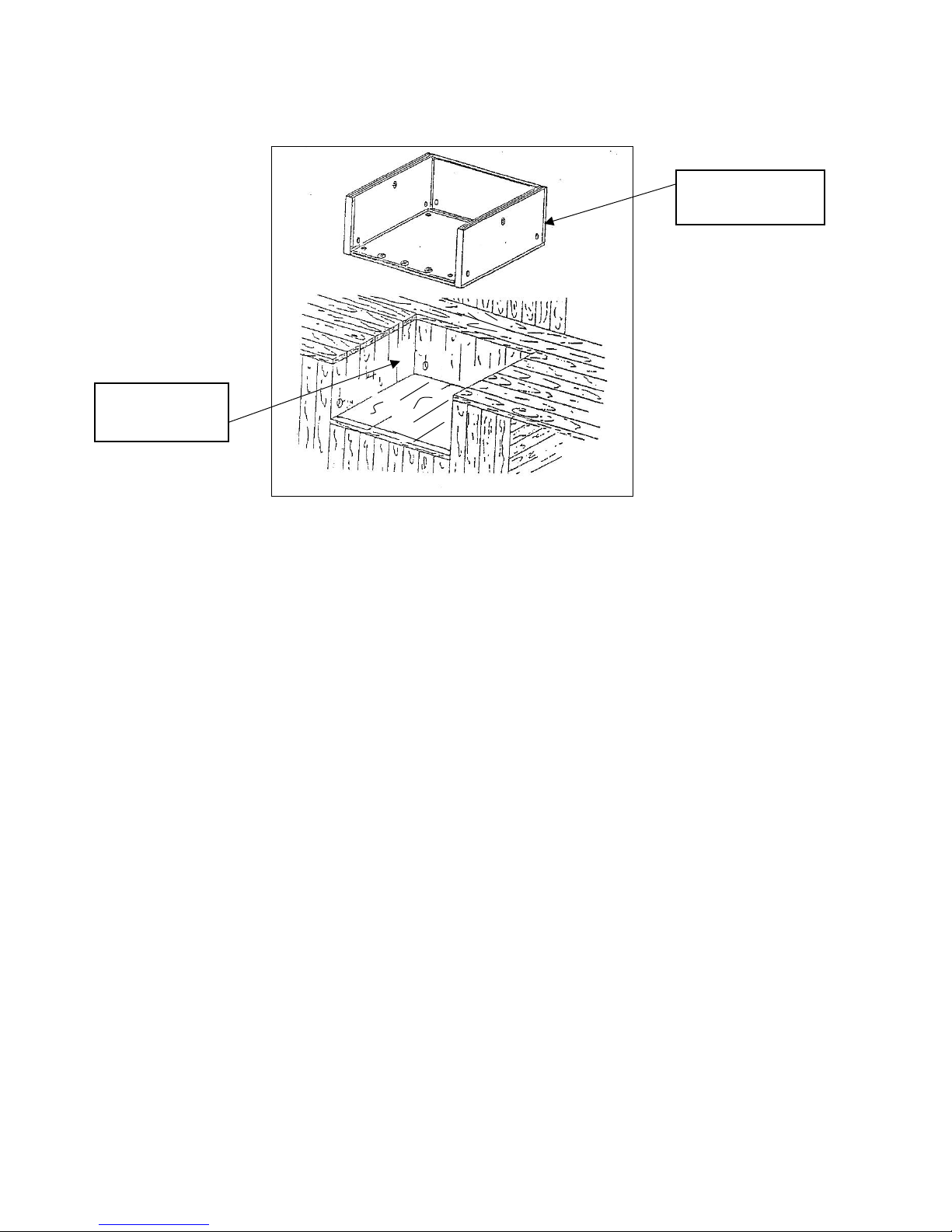

BUILT-IN APPLICATION REQUIREMENTS AND CUTOUTS

STAINLESS STEEL

INSULATION KIT

COMBUSTIBLE

ISLAND

The LM210 Series grill is designed to be placed in an island cutout that has a bottom in the cutout. The grill

rests inside and on the bottom of the cutout. Additionally, access holes will need to be cut in the bottom or

back to allow for pipe routing.

COMBUSTIBLE MATERIALS: the grill should be mounted so that there are no combustible materials within 12”

of the sides, front, or back of the grill.

See section entitled ‘Important Safety Precautions’, items #1. After unpacking, lift the appliance into place.

The cut-out dimensions provided should result in the grill side edges clearing the sides of the island cutout by

1/8” per side. Leave the grill partially out and away from the rear wall at this point. This will allow access for

gas hook-ups.

The island/ enclosure should have ventilation holes to prevent gas build-up in the event of a leak. See “Built-In

Application Requirements and Cutouts Diagram” for recommended cutouts. The MINIMUM vent size is 10” x

10” or an equivalent rectangular size creating 100 square inches in three places on the island enclosure.

The deck ledges need to flat and level to prevent uneven burner flames and soot build-up inside the grill. Refer

to ANSI Z21.58 Standard for Outdoor Cooking Gas Appliances. It is recommended that a 120Volt, 60 Hertz, 15

Amp GFI certified outdoor outlet be installed on a vertical wall of the island being constructed. This outlet will

be used for general purpose and is not required for his appliance. The REAR vertical wall of the island, if

present, is ideal for placing this outlet. All electrical connections must be installed by a qualified electrician.

3

Page 8

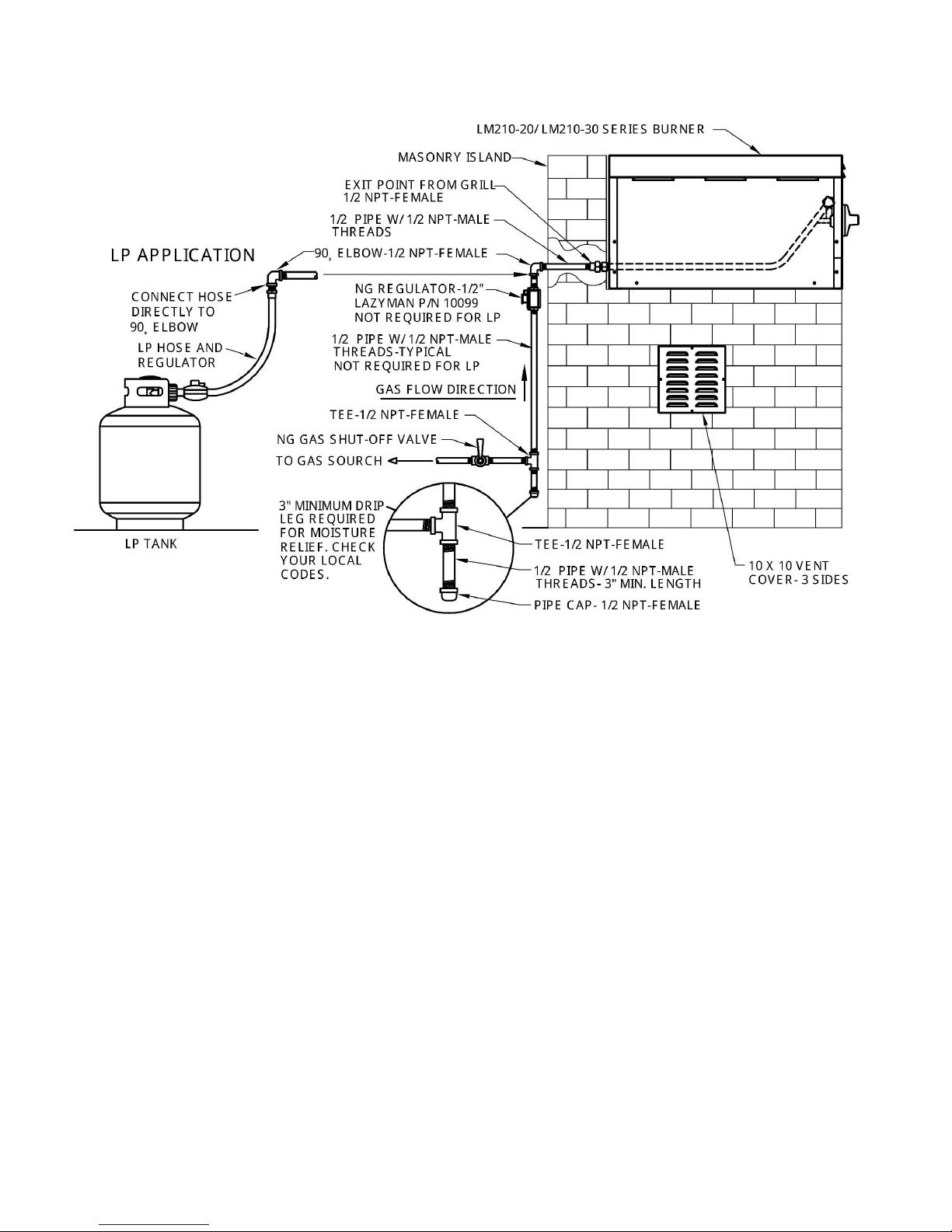

LM210-20 and LM210-30 ISLAND INSTALLATION

NOTE: Use this INSTALLATION section in conjunction with the following ‘GAS CONNECTIONS’ section to assure that all

gas considerations have been made before installing your appliance.

INSTALLATION- USING NG GAS: After the island has been constructed and built per the previous cutout

recommendations and guidelines, it’s now time to install the LazyMan 210 Series Burner into the island. The above

diagram shows a typical Natural Gas installation where the gas piping is routed through the back of the island and

externally to the gas source. This routing can also be accomplished internally (inside the island) if the island is

constructed with a hollow design and there is space between the back wall of the cutout and the back wall of the island.

This burner is shipped with a ½ NPT (female) fitting at the end of the gas manifold for both NG connections and LP hose

connections. It is also shipped with an NG regulator (for natural gas grills) and an LP regulator with hose for burners set

up for liquid propane.

It is highly recommended that a qualified plumber or gas technician make this installation and perform the gas hookup procedure.

1. Measure the distance from the back of the cutout to the back of the island. You will need a ½” pipe with ½”

NPT male threads at both ends that match this distance plus 2”. This pipe is called a ‘nipple’. Nipples come

pre-threaded at both ends and are available in a variety of different lengths.

2. Use pipe joint compound or Teflon tape (to seal the threads) FOR ALL PIPE CONNECTIONS and install this

first pipe into the fitting at the back of the appliance.

3. Using two or more people, carefully lift the burner into the island cutout and slide it toward the back of the

cutout. Allow the newly installed pipe to slide through the pre-cut hole or opening and through the back

wall of the island. Slide the burner all the way in so that the front of the burner is flush with the front of the

island.

4

Page 9

4. Make your first connection using a ½” NPT female elbow. Point this elbow downward if the main gas supply

is near the ground. If the main gas supply is in a location other than the ground, point the elbow in that

direction.

5. Install a short nipple into the open end of the elbow and install the supplied NG regulator at the end of this

nipple. Make sure the regulator is installed so the arrow (marked on the regulator) is pointing to the

appliance, i.e., in the direction the gas will be flowing. NOTE: if this appliance is being installed in line and

after an adjacent grill, and that grill has a gas regulator, then DO NOT INSTALL the NG regulator to this

appliance. Only ONE regulator is required for all appliances connected to the same gas line.

6. Measure the distance from the open end of the regulator to the ground and subtract 8” from this

measurement to allow for the next 3 connections. This will be the length of your next nipple.

7. Install this nipple to the regulator and at the other end, install a ½” NPT female ‘Tee’ connection. The third

(downward) leg of the ‘Tee’ is used to install a 3” minimum length ‘Drip Leg’ with cap. This leg is required in

many states and is used for periodic moisture relief. Check your local codes. This complete pipe routing

should now be resting 1-2 inches above the ground.

8. Install the next nipple into the center opening of the ‘Tee’ and run this connection to the gas source.

IMPORTANT NOTE: If the gas source does not have a gas shut-off valve, then a new ½” quarter turn valve

MUST be installed between the last gas pipe and the existing gas source. This gas valve should be installed

by a qualified plumber or gas technician. See the next step.

9. If the gas source is a stubbed gas pipe coming from the side of the house or exit point, then THE GAS MUST

BE TURNED OFF AT THE METER. A new quarter turn gas valve must be installed, either at the gas source or

inline from the gas source in a convenient location.

10. Use the ‘Leak Test Procedure’ found in the ‘FINAL CHECKS’ section of this manual to check all gas

connections prior to operation of this appliance.

INSTALLATION- USING LP GAS (LIQUID PROPANE-BOTTLE)- when using bottled LP, then use the LP regulator and hose

equipped with the LP appliance. The installation should begin the same as the NG installation where a ½ NPT pipe

(threaded at both ends) is routed from the gas exit point at the rear of the appliance through the rear of the island. A ½

NPT female elbow is then added to the end of the ½ pipe. At this point, the hard piping is complete. Connect the fitting

at the end of the LP hose to the newly installed elbow. Use the above diagram for this hard piping requirement and

connection of the LP hose. As previously mentioned, if the island is constructed in a ‘hollow’ manner, and there is a

hollow space between the back of the cutout and the back of the island, then the first hard piping can be routed directly

DOWNWARD into the island interior. Additional fittings will be required. This piping can terminate with either a ½ NPT

female elbow or a ½ NPT straight coupler. The LP hose can then be connected directly to the last fitting. Always assure

that the LP hose is completely visible and accessible inside the island.

1. Use 2 or more people and lift the grill onto the top island surface.

2. Follow steps #1 through #4 of the NG piping installation. This portion of the installation completes the hard

piping requirements and routes the piping through the back of the island.

3. Use pipe joint compound or Teflon tape on the fitting at the end of the LP hose and install directly to the ½

NPT female elbow at the rear of the island.

4. Use the ‘Leak Test Procedure’ found in the ‘FINAL CHECKS’ section of this manual to check all gas

connections.

INSTALLATION- USING LP (LIQUID PROPANE) BULK TANK- If you have ordered a burner configured for LP (Liquid

Propane), then you have received an LP regulator and hose with your burner. If you plan to attach the appliance directly

to a bulk propane tank, then you cannot use the supplied hose. You must obtain a regulator from LazyMan Inc. Please

order P/N 10099. This is a regulator which converts from NG to LP. Please use the instructions that come with the

regulator for this conversion. Follow the same connection pattern shown above for NG connections.

5

Page 10

GAS CONNECTIONS

PRESSURE (WATER COLUMN INCHES)

FUEL

MAXIMUM

MINIMUM

LP

14

11

NG 7 4

MAXIMUM GAS PIPING LENGTH

PIPING LENGTH (FEET, ¾”

PIPE)

TOTAL BTUS (ALL

APPLIANCES ON LINE)

10

360,000

20

245,000

30

198,000

40

169,000

50

150,000

60

135,000

70

123,000

80

115,000

This appliance has been factory pre-set to

use either Propane Gas (LP) or Natural Gas

(NG). It is critical that the gas you use

matches the gas that the grill has been set

up for. You can verify this by checking the

label mounted on the right rear side of the

appliance.

Ensure that the gas supplied meets

minimum pressure requirements, as shown

below, under full load:

Both the regulator and the manifold orifices

have been set for the type of gas specified

on the label. If it is desired to convert to a

different type of gas, a gas conversion kit

must be obtained from LazyMan Inc. or

from one of its dealers, and must be

installed by a qualified technician.

chart entitled “Gas Supply Line Runs” to

determine allowable run line distances. Failure

to meet these minimum run requirements will

reduce the performance of the appliance and

any other grills/appliances connected to this

line. In general, always keep the supply line run

as SHORT as possible.

The longer the gas run line, the lower the

gas pressure and the smaller number of

BTU’s the line can handle.

NATURAL GAS:

LazyMan Inc. recommends that only a

qualified professional performs the

required gas hook-ups on this product.

To ensure satisfactory performance, the gas

supply line must be sized to accommodate

the TOTAL BTU requirements of all the gas

fired equipment that will be connected to

this line. Minimum pipe size should be 1/2”

I.D., however, 3/4" I.D. is recommended for

the long runs and best performance. For

this, a 3/4" FIP x 1/2” MIP reducer fitting

will be required (not supplied).

Calculate the total BTU output of all appliances

that will be attached to this line and use the

A gas shut-off valve must be installed between

the gas appliances and the gas line in an easily

accessible location. This valve should be

installed by a qualified plumber.

All pipe joints must be sealed with threading

tape or pipe joint compound. The first 2 threads

should be free and clear of any compound to

avoid the compound from entering into the

pipe. Never use threading compound on flare

fittings.

LIQUID PROPANE GAS:

Grills set up for LP gas come equipped with an

LP hose/regulator assembly for connection to a

standard 20 lb (5 gal) LP gas cylinder. All

6

Page 11

GAS CONNECTIONS

fittings necessary to attach the hose

assembly to the grill are included.

BULK TANK LP:

Some residences and/or commercial

establishments use bulk propane cylinders

and are permanently plumbed with LP

connections. When this is the case, then a

4/11 regulator must be obtained and set for

the proper gas type (LP). 4/11 regulators

are convertible from NG to LP. To convert,

follow the instructions provided by the

regulator’s manufacturer.

WARNING

Do not change the regulator/ hose

assembly or use any other assembly other

than the one supplied with your LazyMan

grill.

Do not attempt to use a 5LP-A equipped

regulator/hose assembly with a standard

510 POL cylinder/valve assembly.

A dented or rusty LP cylinder may be

hazardous and should not be used. If in

doubt, have it checked by your LP supplier.

Always shut off the LP gas when finished

using the grill, both at the grill valves and

the LP cylinder valve.

Cylinders must always be stored outdoors in

a well ventilated area and out be of reach of

children. If your grill is stored indoors, the

LP cylinder must be removed and stored

outdoors.

LP CONNECTIONS:

Make sure the LP cylinder valve is fully

closed before connecting to the grill. It is

possible for the valve to be partially open

without releasing gas, but, as soon as the

regulator is connected, gas can leak from

the connection. Insert the regulator inlet

into the cylinder valve and turn the black

coupler clockwise until the coupler is hand

tight. Do not over-tighten this connection.

Do not store a spare LP gas cylinder under

or near this appliance

LP CYLINDER REQUIREMENTS:

The LP cylinder must be constructed and

marked in accordance with the U.S.

Department of Transportation (DOT) specifications for LP cylinders and be designed

for use with a Type 1 system only.

When exchanging your cylinder for a refill,

exchange only with a Type 1, 20 lb cylinder

with an overfill protection device.

Never use a cylinder with a damaged valve.

To disconnect the coupler, first make sure

the cylinder valve is turned completely off.

Turn the coupler counter-clockwise. The

inlet will then disengage.

Always leak test the connection after

refilling or exchanging LP gas cylinders. See

‘Leak Test Procedure’.

GAS LINE PURGING:

After refilling or replacing an LP gas

cylinder, it is always best to purge the

system of air before attempting to light the

grill.

Make sure all controls are in the “OFF”

position.

7

Page 12

GAS CONNECTIONS

Make sure the LP cylinder valve is turned

‘OFF’.

Turn one or more of the grill burner valves

to ‘ON’. This releases pressure in the

system.

Close the burner valve(s) back to the ‘OFF’

position.

Turn the LP cylinder valve to the ‘ON’

position.

Light the burners as usual, one at a time, by

opening the valves slowly.

DANGER!

To prevent fire or explosion, DO NOT smoke

or allow any potential source of ignition

(sparks, electrical arcing, etc.) in the area

while performing a leak test. Leak tests

should be conducted outdoors only. NEVER

conduct a leak test using fire or flame.

FINAL CHECKS

LEAK TEST PROCEDURE:

Create a soapy solution of one part dish

soap and three parts water.

Confirm that all control knobs are in the

‘OFF’ position.

Turn on the fuel supply. For Natural Gas,

turn the valve handle 1/4 turn so the handle

is in-line with the pipe and gas flow.

For LP, turn the cylinder valve knob one

complete turn (minimum) in the counterclockwise direction.

Apply the soap solution generously with a

paint brush or squirt bottle on every

connection and fitting.

If bubbles appear to ‘grow’ on any of the

connections, then gas is escaping. Turn off

gas supply immediately.

FIXING A GAS LEAK: Make sure the main

gas supply has been turned ‘OFF’.

Turn all grill control knobs to ‘HIGH’ to

purge the system of any gas build-up, then

return them to ‘OFF’.

Wash off the soapy solution and then dry

off.

Tighten the loose joint or replace any fitting

that may be suspect.

For LP applications, do NOT attempt to

repair any leaks found at the main cylinder

valve. The LP cylinder needs to be replaced.

Repeat the leak test procedure to confirm

that no leaks are present.

8

Page 13

GAS CONNECTIONS

BURNER FLAME-AIR SHUTTER

ADJUSTMENT

Air flow that enters the burner is controlled

by the ‘Air Shutter’. Each burner is installed,

adjusted and tested in the factory prior to

shipment. However, fluctuations in gas

pressure, gas conversions, and gas quality

can affect performance of the burner and

adjustments to the flame height may be

necessary.

Flames should be blue in color and stable,

with a slight yellow tip. The bright blue core

should be about 3/8” tall with a total flame

height of 1-1/2”.

Begin by completely removing the drip pan

and setting it aside. The valve and burner air

shutter can be seen by looking upward at

them from the front. You will see a small

Phillips head screw which secures the air

shutter. Loosen this screw. NOTE: the air

shutter opening has been factory pre-set to

the half-way position.

Ignite the burner and observe the flame. By

opening or closing the air shutter opening,

the burner flame will change in color.

The flames should burn quietly and not

appear to ‘lift’ up from the burner. If your

flames do not match this description, use the

following procedure.

To Adjust:

DANGER

BE EXTREMELY CAREFUL AROUND HOT

BURNERS AND ADJACENT GRILL PARTS.

Air shutters are located near the brass valves

at the front of each burner. Each burner

needs to be adjusted separately.

If the flame is too YELLOW, this indicates a

lack of air and excess carbon is being

produced. OPEN up the air shutter by sliding

it TO THE REAR. Use a flat screw driver or

other long steel tool to accomplish this. DO

NOT USE YOUR BARE HANDS OR FINGERS TO

MAKE THIS ADJUSTMENT. See also ‘Yellow

Burner Flames’ in the ‘Trouble Shooting’

section. If the flame is noisy (sounds like a

torch) and tends to lift up, then the air

shutter is delivering TOO MUCH air. Slide

the air shutter FORWARD slightly to CLOSE

the opening and reduce the air flow. Your

goal is to create the most efficient, quiet,

soft blue flame.

After adjusting each burner, tighten up the

Phillips head screw which secures the air

shutter.

Replace the drip pan. NEVER operate the

appliance without the drip pan installed, as

this can cause a potentially dangerous

condition.

9

Page 14

OPERATION OF YOUR GRILL

INTRODUCTION

Outdoor burner appliances create more

heat than interior kitchen cooking ranges,

as the high-performance burner(s) creates a

much hotter flame. The burner(s) contained

in this appliance requires a constant, steady

supply of fresh air to mix with the fuel.

Using the burner in windy conditions may

disrupt the proper air flow. Wind can be

particularly disruptive (and damaging) if you

are cooking on HIGH. Excessive winds can

trap the hot air and gasses inside the

appliance and cause an overheating

condition. An early warning sign of this

condition can be seen by the lack of

apparent heat reaching the pot or pan. If

this is the case, turn down the heat.

Any damage caused by this overheating

condition is NOT COVERED by warranty.

PRE-COOKING CHECKLIST BEFORE YOUR

FIRST USE:

1. Make sure ALL packing materials have

been removed from the interior and the

exterior of the appliance. This includes the

removal of all protective vinyl coating found

on the appliance.

2. Make sure the fuel lines have been

connected per instructions in the

installation section of this manual.

AT EACH NEW SEASON:

At the start of each new grilling season, the

grill should be inspected. Remove the

weather cover and the top finger grate pan

from the unit. Remove the burner(s) by

sliding it toward the rear and off of the

valve orifice. Check the burner for any

apparent obstructions. Also check the

orifices at the tip of each valve. Look

especially for cotton-like or mud-like

formations. Spiders, wasps, and other

insects nest in these areas and can disrupt

air and gas flow, and can cause damage to

the grill or personal injury.

A wire brush can be used on the outside of

the burner(s) to remove any scale or foreign

matter. The inside of the burners can be

cleaned and flushed out with a garden hose.

Make sure burners are completely dry

before re-inserting into the grill.

Obstructions found in the orifice at the tip

of the valves can be cleared using a paper

clip or a small wire. Never use a wooden

toothpick as it can break off and clog the

hole.

As a final check, inspect all hoses and gas

lines for any evidence of damage.

By following these procedures, you can

keep your outdoor burner operating like

new for years to come. If you have any

questions, you can always call the factory at

(800) 475-1950

CHECKLIST BEFORE EACH USE:

Always make sure that:

1. You DO NOT smell gas BEFORE you light

the appliance. If you smell gas, shut

everything OFF and call a qualified

plumber to check for leaks. See also

section in this manual entitled ‘FINAL

CHECKS’ in the ‘GAS CONNECTIONS’

portion of this manual.

10

Page 15

OPERATION OF YOUR GRILL

2. The cooking area is free from

combustibles that could ignite.

3. All control knobs turn freely.

4. All burners are seated properly.

5. Connections to any Propane cylinder, if

being used, have been leak tested.

6. If you are using a Propane (LP) cylinder,

be sure the valve has been turned ON

before attempting to light the grill.

7. If you are using Natural Gas (NG), be sure

that the main gas valve has been turned

ON before attempting to light the grill.

WARNING

3. DO NOT release fuel into a closed grill

before lighting. This will increase the risk

of explosion, property damage, personal

injury, or death.

4. When lighting, keep your face and body

as far from the appliance as possible. If a

burner does not light within 5 seconds, turn

the control OFF, and wait 5 minutes for the

gas to dissipate, before attempting to

reignite.

5. NEVER LEAVE THE APPLIANCE

UNATTENDED WHILE COOKING.

MANUAL LIGHTING OF YOUR GRILL:

Please become familiar with the following

section (next page) called “Lighting Your

Grill” before attempting to manually light

this appliance.

8. Wind is not blowing too strongly around

the sides or rear of the appliance.

WARNING

1. Never attempt to light the appliance if

you smell gas.

2. Never light the appliance before

removing the Stainless Steel Weather

Cover.

MANUAL LIGHTING

Manual lighting is used when the AAA

battery used to power your ignition is

discharged and there is no replacement

battery immediately available. Use either a

long wooden match or a long-tipped lighter

and insert between the large hole in the

finger grate pan and the edge of the burner

directly below. Turn the control knob to

‘HIGH’ to light the burner. Remove the

match or lighter.

11

Page 16

LM210-20 AND LM210-30 SERIES BURNER CONTROLS

CONTROL

KNOB

IGNITION

SWITCH

15-7/8”

12”

LEFT

BURNER

CONTROL

IGNITION

SWITCH

RIGHT

BURNER

CONTROL

KNOB

28”

LM210-20

LM210-30

LIGHTING YOUR GRILL

For Propane (LP) grills, turn the propane cylinder

valve at least one full turn in the counterclockwise

direction.

LIGHTING PROCEDURE

Remove the weather cover from your grill.

Assure that the main gas source is turned

on, as shown above. Rotate the control

knob in a COUNTERCLOCKWISE direction

until the knob pointer is facing UP (HIGH

position).

AT THE SAME TIME, depress the

IGNITION switch on the front panel to ignite

the burner. The electronic igniter will

continue to spark as long as you depress

the switch. Once the burner is lit, you can

remove your finger from the switch.

Repeat the process for the second burner (if

you are lighting the LM210-30 model).

If, at any time, the burner does NOT light

after 5 seconds, then turn the burner control

knob to OFF and wait 5 minutes to allow

unburned gas to dissipate. After 5 minutes,

it will be safe to start the procedure again.

Make sure control knobs are in the ‘OFF’ position.

For Natural Gas (NG) grills, turn the main gas

control to ON. The valve is ON when the valve

lever is in line and parallel to the gas piping and

gas flow.

12

Page 17

CLEANING YOUR GRILL

Drip Pan

CLEANING YOUR GRILL

The LazyMan LM210 Series grill products

have been built with the finest grade of 304

stainless steel available. All exterior surfaces

feature a #4 brushed finish. With proper

maintenance, this finish will last for many

years. Here are a few pointers to keep your

appliance looking and functioning like new:

After each use, wipe down the complete

exterior of your grill using a soft cloth and a

commercially available stainless steel

cleaner. It is important to remove the

grease splatters and food debris at this

time, rather than allowing it to become

‘cooked on’. It will be much harder to

remove the next time.

Always wipe in the direction of the grain

finish. The front surfaces, the drip pan front,

and the weather cover have the grain

running in a horizontal direction.

GRAIN DIRECTION

DO NOT use metallic abrasives (like steel

wool) to clean your grill’s front surfaces.

DO NOT use solvents on the grill label.

CLEANING THE DRIP PAN

Similar to cleaning the main grill

components, the longer you wait to clean

the Drip Pan, the harder it will be to

remove the grease and food debris. The

drip pan can be removed completely from

the grill for easier cleaning.

Start by draining any free flowing grease by

tilting the pan over a waste container (an

empty coffee can is perfect). Scoop up the

food debris with a dust pan or similar

device. Wipe the remaining grease with

paper towels, and then finish by using a

mild solution of dish soap and a kitchen

sponge backed by a Scotch-Bright® pad. A

commercially available stainless steel

cleaner can also be used.

When trying to remove a heavier grease

and dirt build-up, a mild mixture of dish

soap and warm water can be used for

cleaning. To remove the most stubborn

stains, a non- metallic, medium grit abrasive

like Scotch-Brite® can be used, but ALWAYS

remember to work in the direction of the

grain.

WARNING

It is critical to keep the drip pan free from

food build-up, as this debris can still cause

flare-ups and create a fire hazard. Always

remember to replace the drip pan into the

grill after cleaning. DO NOT USE THIS

APPLIANCE WITHOUT THE DRIP PAN IN

PLACE.

It is also good practice to check the contents

of the drip pan after a heavy rain.

13

Page 18

CLEANING YOUR GRILL

Pan Support

Finger Grate Pan

Burner

If the appliance is not covered, the drip pan can

collect water and prevent it from doing its job.

CLEANING THE FINGER GRATE PAN

It is best to clean the Finger Grate Pan after

each use, but after the appliance has cooled. It

is important to remove the grease splatters and

food debris at this time rather than allowing it

to be ‘baked-on’ at the next cook-out.

CLEANING THE BURNER(S)

Once the Finger Grate Pan has been removed

from the appliance (see above), you will have

access to the burner(s). Make sure the

appliance is cool and that all control knobs and

main gas supply lines are turned OFF.

Clean the pan as you would clean your interior

cook-top by using a warm, damp sponge with a

small amount of dish soap. For the more

stubborn stains, use a sponge backed with

Scotch-Brite® and carefully apply pressure to

the stain. Remember to always rub in the

horizontal direction.

Periodically you should do a more thorough

cleaning by completely REMOVING the Finger

Grate Pan from the appliance. Then separate

the Pan Support from the Finger Grate Pan and

clean these supports as well.

Carefully tilt the burner UP at the rear (off of its

supports) and slide it TOWARD the rear and off

of the brass valve orifice at the front. Then lift

the burner straight up. Working over a trash

can, turn the burner over to allow the loose

debris to fall. Use a brass or steel brush to

remove as much debris as possible. For any

stubborn stains or debris spots, use a metal

scraper (putty knife or equivalent) to remove.

Inspect all burner ports (holes) to assure that

they are not clogged. Clear any clogged ports

with a paper clip. DO NOT use a wooden tooth

pick as it can break off inside the port.

Finish the cleaning process by tilting the burner

upright, with the venturi opening facing down,

and over the trash can. Shake the burner and

allow all remaining INSIDE debris to fall out

from the venturi opening. Be careful not to

disrupt or change the air flow setting created by

the air shutter.

They can be placed in a pan of dish soap water

(similar to cleaning a kitchen pot or pan) and

then scrubbing them with a non-metallic

medium grit abrasive (like a sponge backed with

Scotch-Brite® or equivalent). Using metallic

abrasives (like steel wool) is NOT recommended

since portions of the steel fibers can remain on

the supports.

The INSIDE of the burner can be cleaned by

flushing it out with a garden hose. Be sure the

burner is completely dry before re-installing.

WARNING

Proper placement of ALL burners, after cleaning,

is CRITICAL. They must be centered over the

brass orifices and resting on their rear supports.

14

Page 19

TROUBLESHOOTING

Please check the more common and more

obvious functions before further attempting

to troubleshoot your LazyMan LM210 Series

appliance, and before you call for service.

Sometimes great aggravations can result

from simple oversights.

For Natural Gas (NG)- is the main

shut-off valve turned on? The valve

will be ON when the valve lever is

parallel to the gas line.

In most cases, the following trouble-

For Liquid Propane Gas (LP)- is the valve

knob turned at least one complete turn in

the COUNTERCLOCKWISE direction?

shooting tips can be performed by the grill

owner and can be performed relatively

safely. Please read and follow the steps

carefully to assure that there have not been

oversights in troubleshooting your LazyMan

product. If you have exhausted the

troubleshooting steps, OR if you are simply

not comfortable working on your grill, you

can contact the LazyMan Customer Service

team and they will be glad to assist you.

on the label at the right rear of the

appliance.

Is the ignition operating properly,

i.e., do you hear clicking when the

ignition button is pushed ? If not,

replace the AAA battery found

inside the ignition button assembly.

See also the following section

entitled ‘GRILL DOESN’T LIGHT’ for

instructions on replacing the

battery.

Does the Liquid Propane (LP) gas

cylinder have fuel? Is the hose

connection tight? These cylinders

have a built-in safety valve that

prevents the fuel from being

supplied (or may reduce the gas

flow) if the tank has recently been

tilted or jarred. This will make the

cylinder appear to be empty. If so,

wait 5 minutes for the valve to reset

and try again. This time, open the

valve very SLOWLY to help allow the

valve to reset.

Is the correct type of fuel being

supplied? The type of fuel your grill

was built for (NG or LP) can be found

CONTACT:

LazyMan Inc.

CUSTOMER SERVICE: (908) 475-5315

(800) 475-1950

Customer Service Dept.

560 Independence Street, Belvidere, NJ

07823

15

Page 20

GRILL DOESN’T LIGHT

WIRE AND

ELECTRODE

IGNITION

SWITCH ASSY

TROUBLESHOOTING

Igniter IS Sparking:

Igniter IS NOT Sparking:

1. Remove the AAA battery found inside the

ignition switch assembly by turning the

outer button assembly counterclockwise to

remove cap. Replace the battery with a new

battery, replace the cap, and try the ignition

again.

2. If you still do hot hear the spark (rapid

‘clicking sound), then remove the Finger

Grate Pan and check the wire that leads

from the back of the ignition switch to the

‘ignition electrode’. Remove the lead from

the electrode and hold it 1/4” away from

any portion of the chassis. Depress the

ignition button and look for the spark. If the

wire creates a spark to the chassis, then the

fault is in the electrode itself. Make sure the

electrode and its connector is clean and

free from any dirt, grease, or debris.

Reconnect the wire to the electrode.

Replace all components before attempting

to light the grill.

3. If all attempts fail to activate the spark in

your ignition system, then refer to portion

of this manual entitled ‘REPLACING THE

ELECTRONIC IGNITER’ at the end of this

‘Trouble Shooting’ Section.

1. Confirm that the gas is turned ON. Push

in on the ignition switch, located near the

center of the front of the grill, and confirm

that you hear a ‘clicking’ sound coming

from the electronic igniter. If you hear the

‘clicking’ sound, proceed by

SIMULTANEOUSLY pushing in on the burner

control knob. If when pressing both the

ignition switch and the control knob you

cannot get the starter burner to light, than

you have a gas blockage. Follow the steps in

the ‘Cleaning the Burners’ section of the

‘Cleaning Your Grill’ section. The blockage

will probably be in or around the burner or

around the valve orifice.

LOW OR INSUFFICIENT HEAT

If you suspect that your appliance is NOT

providing the amount of heat that you

expect, there may be several things to look

at.

1. First, assure that you provide adequate

time for the food being prepared to heat

up. This process should be similar to and

exceed that amount of time you might

expect from your kitchen range.

2. Do not line ANY portion for the appliance

with aluminum foil. This will disrupt air flow

and cause the unit to burn unevenly.

3. Ensure that the appliance is level. This

will also disrupt air flow and cause uneven

cooking.

4. Make sure that the gas type being used

(NG or LP) is the gas type that the grill was

set for at the factory. The label with this

16

Page 21

TROUBLESHOOTING

information can be found on the right rear

of the appliance. If the gas type has been

converted (either at installation or at the

place of purchase) then check for the

following:

The Natural Gas (NG) unit has been

equipped with a gas regulator installed at

the rear. If this appliance has been

converted to Liquid Propane (LP), then

ensure that the original NG regulator has

been removed from the rear of the grill

before the LP hose connection was added.

Never use more than one gas regulator to

control gas flow. This will substantially

REDUCE cooking efficiency.

5. If a low heat condition still persists, check

that the gas line (for NG applications) is of

adequate size for the length of run for all of

the equipment being used. The minimum

size is 1/2"(I.D.), but the larger 3/4"(I.D.)

size is recommended for optimum

performance. See section entitled

‘NATURAL GAS’ under the ‘GAS

CONNECTIONS’ portion of this manual.

6. If the gas used is Liquid Propane (LP),

check that the gas hose is not being

‘crimped’ and is connected to the tank

properly. The hose and regulator assembly

MUST be the hose that has been supplied

with your LazyMan appliance.

7. Low or insufficient heat can also be

caused by burner obstructions. Follow the

burner removal instructions found in the

section entitled ‘CLEANING THE BURNERS’.

With the burners out of the grill, look inside

each burner for obstructions that may

interrupt gas flow. Follow the remainder of

that section.

8. Windy conditions can greatly interrupt air

flow and cause insufficient heat conditions.

If heavy winds are prevailing and are

coming from any direction, it is better to

turn DOWN the heat on the burner.

Cooking may take a little longer, but the

smaller flames will not be as disrupted from

the wind as the larger flames.

YELLOW BURNER FLAMES

1. A yellow flame from the burners

indicates a lack of air entering the burner.

This can also contribute to low or

insufficient heat. Note that as the appliance

interior becomes dusty or greasy, a yellow

tip may appear at the tip of a blue flame.

This is normal. The full yellow flame can be

adjusted by opening up the air shutter

found on the front intake (venturi) of the

burner. Please follow the burner removal

instructions found in the section of this

manual entitled ‘CLEANING THE BURNERS’.

With the burner in your hand, face the

venturi and air shutter toward you. The air

shutter has been factory tested and set so

the air shutter is opened HALF way.

2. Loosen the screw found on the side of

the air shutter. The shutter can now be slid

forward or backward to reach the desired

opening. Slide the shutter BACK to fully

open the air opening, as shown in the above

diagram, and use this as starting point.

Retighten the screw.

17

Page 22

TROUBLESHOOTING

3. Reinsert the burner and test. If the

flames are BLUE but are noisy (like a torch)

and appear to ‘lift’ off the burner, then

repeat the process by sliding the shutter

FORWARD slightly, to modify the

adjustment, until the flames are blue,

stable, and quiet.

IF YOU SMELL OF GAS

1. If you smell gas while the appliance is lit,

IMMEDIATELY TURN OFF ALL BURNERS AND

SHUT OFF THE MAIN FUEL SUPPLY

2. Perform a leak test per the instructions

under the ‘GAS CONNECTIONS’ section of

this manual entitled ‘LEAK TEST

PROCEEDURE’. If no leaks are found, check

for blockages in the burner inlets (venturis).

Refer to the section of this manual entitled

‘CLEANING THE BURNERS’. If you are

uncomfortable with performing these tests

yourself, then call your local gas company.

OFF the burner(s) and try relighting again

using the electronic igniters.

2. If your attempt to relight the burner(s)

fails using the electronic igniter, try

replacing the AAA battery in the ignition

button assembly. Saturated batteries take a

long time to dry out and sometimes never

recover. See section titled ‘Igniter is Not

Sparking’ for battery replacement.

VALVE DOES NOT TURN FREELY

Never attempt to lubricate valves. They are

sealed and lubricated at the time of

manufacture. They do not require further

maintenance. If your valves are hard to

turn, then they need to be replaced. Refer

to the parts lists at the end of this manual

or contact your dealer where the grill was

purchased.

APPLIANCE DOES NOT LIGHT AFTER A

LONG PERIOD OF TIME

Insects are attracted to the smell of gas.

Check the burner(s) and valve orifices to be

sure they are clear of any spider webs or

nests. The burner(s) should be cleaned at

least once a year for optimum performance.

APPLIANCE DOES NOT LIGHT AFTER RAIN

STORM OR WET CONDITIONS

The electronic ignition has most likely

become wet or saturated.

1. Manually light your grill using a long

wooden match or stick lighter. Follow the

instructions in this manual entitled ‘Manual

Lighting of Your Grill’. After the burner(s)

has been running for a few minutes, shut

18

Page 23

REPLACING THE ELECTRONIC IGNITER

Pan Support

Finger Grate Pan

Cast Iron Burner

Igniter Location

WARNING

Always make sure that the appliance is

COLD before attempting to replace the

electronic igniter. Handling hot parts can

result in severe burns to the hands and

fingers.

To replace the electronic igniter on models

LM210-20 and LM210-30, use the following

procedures:

REMOVAL

the bottom of the igniter. Remove the

complete Igniter/Holding Bracket

Assembly from the burner support bracing

(Cross Brace) by using a right-angle Philips

screw driver. A straight Philips screw driver

can also be used by ‘angling’ the screw

driver into the head of the screw.

1. Remove Finger Grate Pan and Pan

Support from the appliance by simply lifting

up on the assembly and setting it aside.

Igniter/Holding Bracket Assembly

REPLACEMENT

1. Place the new Igniter/ Holding Bracket

Assembly back into the original position.

Take special note that the igniter electrode

is positioned directly above one of the

burner ports. Secure using the original

Philips head screw.

2. Re-attach the lead wire to the bottom of

the igniter.

3. Test the igniter by depressing the Ignition

Switch and holding in. You should hear a

rapid ‘clicking’ sound.

4. Reinstall the Finger Grate Pan.

2. You will now see the igniter mounted on

a holding bracket to the rear side of the

burner. Use a pair of needle-nose pliers

and carefully disconnect the lead wire from

If you need further assistance, call the

LazyMan Customer Service team at:

(908) 475-5315 (800) 475-1950

They will be glad to help you!

19

Page 24

2202

2214CBN

2208-C

2209B

2201

2206

2207

2205-C

2208 WEATHER COVER

2214 CBN BURNER SUPPORT

2205-C CAST IRON BURNER

2207 GRATE SET OF 4

2206 GRATE SUPPORT PAN

2119 COPPER TUBE GAS SUPPLY

2209B FRONT LABEL

2203E ELECTRONIC IGNITION

2208-C SPARK PLUG

2204 MANIFOLD

2204V VAVE

2202 CHASSIS

2201 DRIP PAN

2204B KNOB

2204V

2203E

210-20 PARTS LIST

2204

2208

WITH ELECTRONIC IGNITION

L

A

Z

Y

-

M

A

N

I

N

C

.

2119

2204B

20

Page 25

3002

3004

3004V

2104B

2208-C

2205-C BURNER EA.

3005-C BURNER SET OF 2

3006 GRATE SUPPORT PANS

3007 GRATE SET OF 8

2207 GRATE SET OF 4

3003E ELECTRONIC IGNITION

3016-C FRONT LABEL

2119 COPPER TUBE GAS SUPPLY

3008 SPARK PLUG SET OF 2

2208-C SPARK PLUG EA.

3012

2207

3007

3006

2205-C

3005-C

3014

2119

3016-C

3003E

3012 WEATHER COVER

3014 CBN BURNER SUPPORT

3004 MANIFOLD

3004V VALVE

3002 CHASSIS

3001 DRIP PAN

2104B KNOBS

WITH ELECTRONIC IGNITION

210-30 PARTS LIST

3008

3001

21

Page 26

LIMITED LIFETIME WARRANTY

LIMITED LIFETIME WARRANTY: LazyMan Manufacturing, Inc. warrants fabricated stainless steel components (excluding

batteries, ignitor, collector box, burners, cooking grates, flash tubes, and flavor enhancers), to be free from defects in

materials and workmanship under normal residential use for the lifetime of the original owner starting with 2014 model

year grills. Previous models are covered by our ten (10) year warranty. This warranty covers the listed parts against

defects or failure under normal usage. LazyMan Manufacturing, Inc. will repair or replace, at its discretion, any part

which fails or is found to be defective during the warranty. They warranty excludes surface corrosion, scratches, and

discoloration which may occur during regular use. This warranty is limited to the replacement of the defective part(s),

with the owner paying all other costs including labor and freight. In limited situations, and only at the discretion of

LazyMan Manufacturing, Inc., repair labor or grill replacement may be included under warranty.

FIVE YEAR LIMITED WARRANTY: LazyMan Manufacturing, Inc. warrants the burners, cooking grates, flash tubes and

flavor enhancers (excluding ignitor and collector box), to be free from defects in materials and workmanship under

normal residential use for a period of five (5) years from the original date of purchase. LazyMan Manufacturing, Inc. will

repair or replace, at its discretion, any part which fails or is found to be defective during the warranty. They warranty

excludes surface corrosion, scratches and discoloration which may occur during regular use. This warranty is limited to

the replacement of the defective part(s), with the owner paying all other costs including labor and freight.

ONE-YEAR FULL WARRANTY: LazyMan Manufacturing, Inc. warrants the all of their component parts, to be free from

defects in materials and workmanship under normal residential use for a period of one year from the original date of

purchase. LazyMan Manufacturing, Inc. will repair or replace, at its discretion, any part which fails or is found to be

defective during the warranty period, at no cost to the original purchaser. Warranty service must be performed by a

LazyMan Manufacturing, Inc. authorized representative during normal business hours.

NINETY (90) DAY RESIDENTIAL PLUS WARRANTY: This warranty applies to applications where use of the product extends

beyond normal residential use such as bed and breakfasts, inns, and private clubs. The actual part will be repaired or

replaced, free of charge, with the owner paying for all other costs including labor and freight. This warranty excludes all

commercial locations such as restaurants and food service locations.

WARRANTY LIMITATIONS & EXCLUSIONS: This warranty shall apply only to the products purchased and located in the

continental United States and Canada. This warranty applies to the original purchaser with invoice or proof of purchase.

The warranty coverage begins on the original date of purchase and proof of date of purchase is required. In order to

activate the warranty, we require that you send in the warranty registration card. This warranty applies only to the

original owner and may not be transferred. This warranty does not apply to damages resulting from negligence,

alteration, misuse, abuse, accident, natural disaster, loss of electrical power to the product for any reason, improper

installation or improper operation, unauthorized adjustments or calibrations, dings, dents, scratches, or damages due to

harsh cleaning chemicals. This warranty excludes units purchased for use in all types of commercial and or community

use locations such as restaurants, hotels, catering operations food service establishments, condominium/apartment

complexes, rental properties, and to products with altered or removed serial numbers. LazyMan Manufacturing, Inc.

shall not be liable for incidental, consequential, special, or contingent damages resulting from its breach of this written

warranty or any implied warranty. WARRANTY SERVICE & REPLACEMENT PARTS: Call your authorized selling dealer or

call LazyMan Manufacturing, Inc. directly at (800) 475-1950. Be prepared to furnish the following information:

22

Page 27

Purchaser’s name, model and serial number of the grill, date of purchase, and the accurate description of the problem.

LazyMan Manufacturing Inc. will not pay for service calls for correcting an installation problem. Owner shall be

responsible for proper installation, providing normal care and maintenance, providing proof of purchase upon request,

and making the grill accessible for service. In the event of any warranty replacement, all removal, replacement,

installation, and shipping costs are the responsibility of the grill owner.

It specifically excludes liability for indirect or consequential damages. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This

warranty gives you specified legal rights and you may have other rights which may vary from state to state.

DISCLAIMER OF IMPLIED WARRANTIES AND LIMITATION OF REMEDIES

CUSTOMER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR OR

REPLACEMENT AS PROVIDED HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE, ARE EXCLUDED OR LIMITED TO ONE YEAR OR THE SHORTEST

PERIOD ALLOWED BY LAW. LAZYMAN MANUFACTURING INC. SHALL NOT BE LIABLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES. SOME STATES OR PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUETIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTY

OF MERCHANTIBILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS

WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH CAN VARY

FROM STATE TO STATE OR PROVINCE TO PROVINCE.

23

Loading...

Loading...