Lazer Safe LZS-003-HS Operation Manual

DATASHEET

LZS003

INDRAMAT

OTHER SYMBOLS:

RGB ELEKTRONIKA AGACIAK CIACIEK

SPÓŁKA JAWNA

Jana Dlugosza 2-6 Street

51-162 Wrocław

Poland

biuro@rgbelektronika.pl

+48 71 325 15 05

www.rgbautomatyka.pl

www.rgbelektronika.pl

www.rgbelektronika.pl

www.rgbautomatyka.pl

YOUR

PARTNER IN

MAINTENANCE

Repair this product with RGB ELEKTRONIKA

LINEAR

ENCODERS

ENCODERS

SERVO AMPLIFIERS

CNC

MACHINES

OUR SERVICES

PLC

SYSTEMS

CNC

CONTROLS

ORDER A DIAGNOSIS

INDUSTRIAL

COMPUTERS

POWER

SUPPLIERS

∠

MOTORS

SERVO

DRIVERS

At our premises in Wrocław, we have a fully equipped servicing facility. Here we perform all the repair

works and test each later sold unit. Our trained employees, equipped with a wide variety of tools and

having several testing stands at their disposal, are a guarantee of the highest quality service.

Buy this product at RGB AUTOMATYKA

OPERATOR

PANELS

BUY

∠

LZS-003-HS Operation Manual

Dual Laser Version

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

DDooccuummeenntt SSttaattuuss

Document Reference Code: LS-CS-M0005-EN

Version: 1.11

Released: 03/12/2007

DDooccuummeenntt RReevviissiioonn HHiissttoorryy

Date Version Summary of Change

10/01/2007 1.08 New error code display sequence information added.

4/07/2007 1.09

24/07/2007 1.10 Language settings added to parameter settings

03/12/2007 1.11 Updated error code section and listing

CCooppyyrriigghhtt IInnffoorrmmaattiioonn

"Lazer Safe", "LZS", "LZS-003", LZS-003-SS4", "LZS-003-SS6", "LZS-003-HS", "PCSS" and "Press Control Safety System" are

trademarks of Lazer Safe Pty Ltd.

The content of this manual is supplied for informational use only, is subject to change without notice and should not be construed

as a commitment by Lazer Safe Pty Ltd. Lazer Safe Pty Ltd assumes no responsibility or liability for any errors, inaccuracies or

omissions that may appear within this publication.

Copyright in this documentation is owned by Lazer Safe Pty Ltd. No part of this document may be reproduced or copied in any

form or by any means (graphic, electronic, or mechanical including photocopying, recording, taping, or information storage and

retrieval systems) without the written permission of Lazer Safe Pty Ltd.

Lazer Safe's copyright in this document is protected by Australian copyright laws (including the Copyright Act 1948

(Commonwealth)) and by international copyright treaties.

© 2005-7 Lazer Safe Pty Ltd. All rights reserved.

New software version eliminates use of magnetic card. Mute point set-up and

material sensing test improved functionality.

Version 1.11 Released: 03/12/2007

Page ii

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

TTaabbllee ooff CCoonntteennttss

Document Status.....................................................................................................ii

Document Revision History.....................................................................................ii

Copyright Information.............................................................................................ii

Table of Contents ...................................................................................................iii

1 About This Manual .........................................................................................1

1.1 Document Organisation.......................................................................................................... 1

1.2 Document Objectives.............................................................................................................. 1

1.3 Technical Competence Requirements..................................................................................... 1

1.4 Related Documentation .......................................................................................................... 1

1.5 Guide to Notes, Notice and Cautions...................................................................................... 1

1.6 Obtaining Technical Assistance .............................................................................................. 2

2 Critical Safety Information ............................................................................3

2.1 Proper Use of the LZS-003-HS................................................................................................ 3

2.2 Special Warnings .................................................................................................................... 3

3 General Overview...........................................................................................4

3.1 Key Benefits............................................................................................................................ 4

3.2 System Operation ................................................................................................................... 4

3.2.1 LZS-003-HS High Speed Dual Laser Model .......................................................................................4

3.2.2 Setup ...........................................................................................................................................5

3.2.3 Mute Point ....................................................................................................................................5

3.2.4 Normal Mode.................................................................................................................................6

3.2.5 Tray / Box Mode............................................................................................................................6

3.2.6 Field Muted Mode..........................................................................................................................7

3.2.7 Stop at Mute Point.........................................................................................................................7

3.3 Tool Change ............................................................................................................................ 7

3.4 Closed Loop Design................................................................................................................. 8

4 Transmitter & Receiver Adjustment...............................................................9

4.1 Adjusting the laser to punch distance .................................................................................... 9

4.2 Adjusting the receiver for tray/box bending........................................................................ 10

5 Operating the LZS-003-HS...........................................................................12

5.1 Operator Controls ................................................................................................................. 12

5.1.1 Operator Panel............................................................................................................................ 12

5.1.2 LZS-003-HS Controller.................................................................................................................. 13

5.2 System Start-up.................................................................................................................... 13

5.3 Start-up Test......................................................................................................................... 14

5.4 Setting the Mute Point.......................................................................................................... 16

5.5 Selecting Tray / Box Mode....................................................................................................19

5.6 Returning From Tray / Box Mode to Normal Mode............................................................... 20

5.7 Selecting Field Muted Mode.................................................................................................. 21

5.8 Returning From Field Muted Mode to Normal Mode............................................................. 22

5.9 Selecting Stop at Mute Point Mode....................................................................................... 23

5.10 Disengage Stop at Mute Point Mode..................................................................................... 25

6 Operator Instruction and Demonstration ....................................................26

6.1 Equipment Identification...................................................................................................... 26

6.2 Starting the System .............................................................................................................. 26

6.3 Mute Point Setting................................................................................................................ 26

6.4 Operation in Normal Mode.................................................................................................... 27

6.5 Tray / Box mode ................................................................................................................... 27

6.6 Field Muted Mode.................................................................................................................. 27

6.7 Stop at Mute Point ................................................................................................................ 27

6.8 Setting Laser Position........................................................................................................... 28

6.9 Back Gauge Interference...................................................................................................... 28

6.10 Running the System..............................................................................................................28

6.11 Customer Sign Off – Training Completed ............................................................................. 28

7 Parameter Programming with the 1003-03 Operator Panel........................29

7.1 Using the Keypad in Parameter Programming Mode............................................................ 29

Version 1.11 Released: 03/12/2007

Page iii

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

7.2 Entering Parameter Programming Mode.............................................................................. 30

7.3 Selecting the Parameter to be Programmed ........................................................................31

7.4 New Password.......................................................................................................................33

7.5 Field Muted Button Functionality.......................................................................................... 35

7.6 Mute Stop Button Functionality............................................................................................ 37

7.7 Crawl Distance...................................................................................................................... 38

7.8 Language............................................................................................................................... 39

7.9 Exit........................................................................................................................................ 39

8 Error and Condition Codes ...........................................................................40

8.1 LZS-003-HS Controller Display Codes................................................................................... 40

8.2 Condition Codes.................................................................................................................... 40

8.2.1 Controller Condition Code Display..................................................................................................40

2

88..22..2

8.3 Understanding Error Codes................................................................................................... 42

8.4 Initial Start-Up Test.............................................................................................................. 43

8.4.1 Initial Start-Up Test Faults............................................................................................................ 43

8.5 Mute Point Set-up................................................................................................................. 44

8.5.1 Mute Point Set-up Faults.............................................................................................................. 44

8.6 Condition Codes.................................................................................................................... 45

8.7 Error Codes for LZS-003-HS..................................................................................................46

8.7.1 Primary Display Error Codes ......................................................................................................... 46

8.7.2 Secondary Display Error Codes ..................................................................................................... 49

11000033--0033 OOppeerraattoorr PPaanneell CCoonnddiittiioonns

s...............................................................................................

41

9 Glossary of Terms ........................................................................................54

9.1 Abbreviations........................................................................................................................ 54

10 Specifications...............................................................................................55

10.1 Circuits .................................................................................................................................. 55

10.2 Circuit Load Conditions and Contact Impedances (interfacing to 24 V systems) ................ 56

Version 1.11 Released: 03/12/2007

Page iv

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

11

11..11

AAbboouutt TThhiiss MMaannuuaall

This chapter contains information about this manual, containing the following elements:

• Document Organisation

• Document Objectives

• Technical Competence Requirements

• Prerequisites

• Related Documentation

• Guide to Notes, Notice and Cautions

• Obtaining Technical Assistance.

DDooccuummeenntt OOrrggaanniissaattiioonn

This manual is organised into the following chapters:

1. About This Document (this chapter)

2. Critical Safety Information

3. General Overview

4. Transmitter & Receiver Adjustment

5. Operating the LZS-003-HS

6. Operator Instruction and Demonstration

11..22

11..33

11..44

11..55

7. Parameter Programming with the Operator Panel

8. Error and Condition Codes

9. Glossary of Terms

10. Specifications

DDooccuummeenntt OObbjjeeccttiivveess

This manual provides information on the operation of Lazer Safe's LZS-003-HS press brake

operator guarding system.

TTeecchhnniiccaall CCoommppeetteennccee RReeqquuiirreemmeennttss

All operators of the LZS-003-HS equipment should be trained to use it and the press brake

upon which it is installed in a manner that complies with established safety practices.

RReellaatteedd DDooccuummeennttaattiioonn

This manual should be used in conjunction with;

• The Operation Manual for your press brake

• The Lazer Safe Transmitter and Receiver Alignment Manual

GGuuiiddee ttoo NNootteess,, NNoottiiccee aanndd CCaauuttiioonnss

Note:

This symbol indicates helpful information that helps you make better use of your

Lazer Safe product.

Caution

This symbol alerts you to situations that could result in equipment damage

Warning

This symbol indicates danger. You are in a situation that could cause bodily injury.

Before you work on any equipment, be aware of the hazards involved with electrical

circuitry and be familiar with standard practices for preventing accidents. To see

translations of the warnings that appear in this publication, refer to the translated

Version 1.11 Released: 03/12/2007

Page 1

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

safety warnings that accompanied this device.

11..66

OObbttaaiinniinngg TTeecchhnniiccaall AAssssiissttaannccee

For technical support with the LZS-003-HS, email customerservice@lazersafe.com.au detailing

your specific requirements.

Version 1.11 Released: 03/12/2007

Page 2

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

22

22..11

CCrriittiiccaall SSaaffeettyy IInnffoorrmmaattiioonn

PPrrooppeerr UUssee ooff tthhee LLZZSS--000033--HHSS

The LZS-003-HS is designed to protect hands and fingers in the area close to the edge of the

punch. When installed correctly and safety instructions are observed fully, the LZS-003-HS

permits safe manipulation close to the punch, as well as offering effective protection while tools

close at high speed.

Please note these general safety notices:

• The LZS-003-HS is designed exclusively for installation and operation on hydraulic press

brakes, or press brakes that comply with the statutory machine safety and accident

prevention rules and regulations valid for the place where the press brake is operated, in

particular after the LZS-003-HS has been installed.

• The LZS-003-HS must be installed either in the press brake factory, or by specialist

technicians trained by Lazer Safe (or its authorised representatives).

• The operator must be fully conversant with the operation of the press brake and the risks

associated with it, as well as the operation of the LZS-003-HS guarding system.

• The alignment of the protective equipment for punches of different lengths should be

performed by a die setter (or someone with equivalent specialist expertise) trained in all

relevant aspects of operating the press brake and the LZS-003-HS guarding system.

• Suitable protective equipment must be worn by the operator at all times.

22..22

SSppeecciiaall WWaarrnniinnggss

To ensure the highest possible degree of safety in operating a press brake fitted with the LZS-

003-HS, it is important to note the following special warnings.

Warning: AVOID FAST, ERRATIC MOVEMENTS AS TOOLS CLOSE

When the tools close at high speed (above mute point) towards a static (fixed)

obstruction, there will be less than maximum protection at the point where the laser

detects the obstruction. For example, if a small obstruction, such as a finger, is

rapidly and erratically pushed between punch and obstruction immediately before the

laser senses the static obstruction, the finger might be touched.

Warning: NO PROTECTION BETWEEN MUTE POINT AND WORKPIECE

In Normal mode, the LZS-003-HS protects until the laser is within 2mm of the

material surface. Even though this gap is too small for a finger to be inserted, always

exercise care.

Warning: NO PROTECTION IN FIELD MUTED MODE

In Field Muted mode, the optical sensing is deactivated. Although the LZS-003-HS

ensures that the machine does not exceed crawl speed in this mode, particular

caution must still be exercised.

The LZS-003-HS Operator Panel requires a password to enable the Field Muted

mode button. The password should only be available to suitably trained personnel.

Field Muted mode should only be used by suitably trained personnel and only

in exceptional circumstances (changing tools, maintenance, etc.)

Version 1.11 Released: 03/12/2007

Page 3

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

33

33..11

GGeenneerraall OOvveerrvviieeww

The Lazer Safe LZS-003-HS is a guarding system for hydraulic press brakes that provides a

highly effective solution for both operator safety and machine productivity.

The system comprises the following components:

• LZS-003-HS Controller

• Operator Panel

• Optical Encoder

• Laser Transmitter / Receiver pair

• Brackets for mounting the Transmitter and Receiver

The LZS-003-HS can be installed either at the time of manufacture or as a retrofit to a press

brake already in service.

KKeeyy BBeenneeffiittss

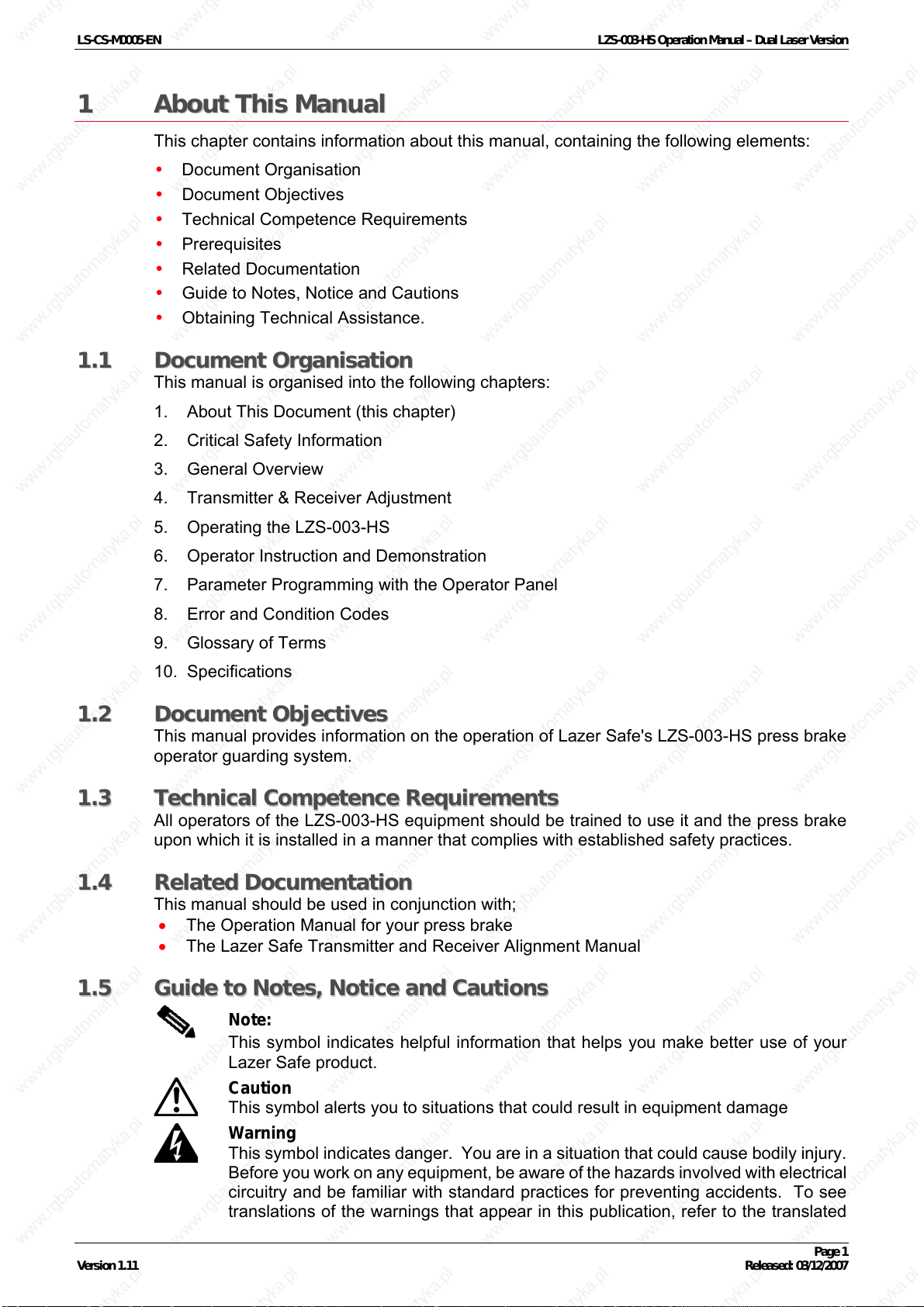

• Delivers comprehensive operator protection at

close proximity to work piece.

• Allows tools to close at high speed, increasing

productivity.

• Complex shapes can be achieved with the "Tray /

Box" and "Field Muted" modes of operation.

• Encoder feedback provides closed-loop monitoring

of speed and stopping distance of the press beam.

• A flat band of continuous laser light detects

obstructions as small as 4mm while remaining

vibration tolerant.

• The mute point is automatically determined, easily

set and continuously monitored.

• The rear section of laser is easily muted to ignore the back gauge in "up-close" situations.

• Failure detection is performed by real-time monitoring of the process under control.

The LZS provides protection at close

proximity to work-piece.

33..22

SSyysstteemm OOppeerraattiioonn

The transmitter and receiver are mounted on the upper beam of the press brake, allowing the

operator to remain close to the work-piece as the tools close at high speed. Hands and fingers

are protected by a continuous band of laser light that senses the zone below the punch. If an

obstruction is detected the beam movement is stopped. The punch cannot make contact with

the obstruction.

The LZS-003-HS system continuously monitors the critical speeds and stopping distance of the

moving member of the machine. If the crawl speed is exceeded and / or the stopping distance

is exceeded, the LZS-003-HS controller will issue a stop command to the machine. There is no

need for a separate stopping distance monitor.

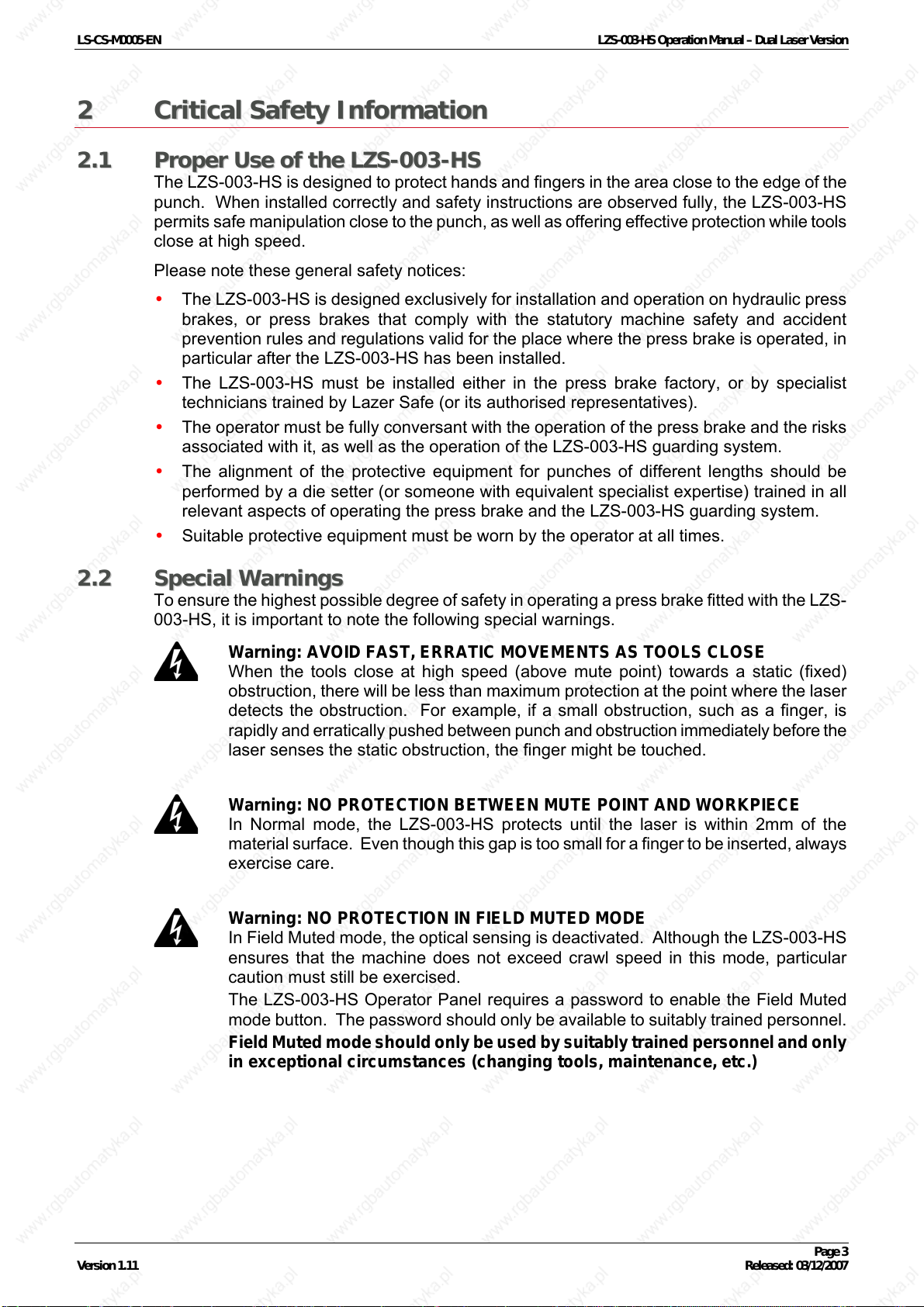

3.2.1 LZS-003-HS High Speed Dual Laser Model

For press brakes with a high closing speed (150 mm / sec or faster) the LZS-003-HS is

recommended (

4mm and 14mm below the punch. The lower laser (laser B) triggers the deceleration of the

press to bending speed while the higher laser (laser A) continues to provide protection.

Figure 3-1). This model features a transmitter with two parallel lasers that are

Version 1.11 Released: 03/12/2007

Page 4

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

Laser to punch

distance

Laser A 4mm

Laser B 14mm

Mute point

Figure 3-1: LZS-003-HS Dual Laser

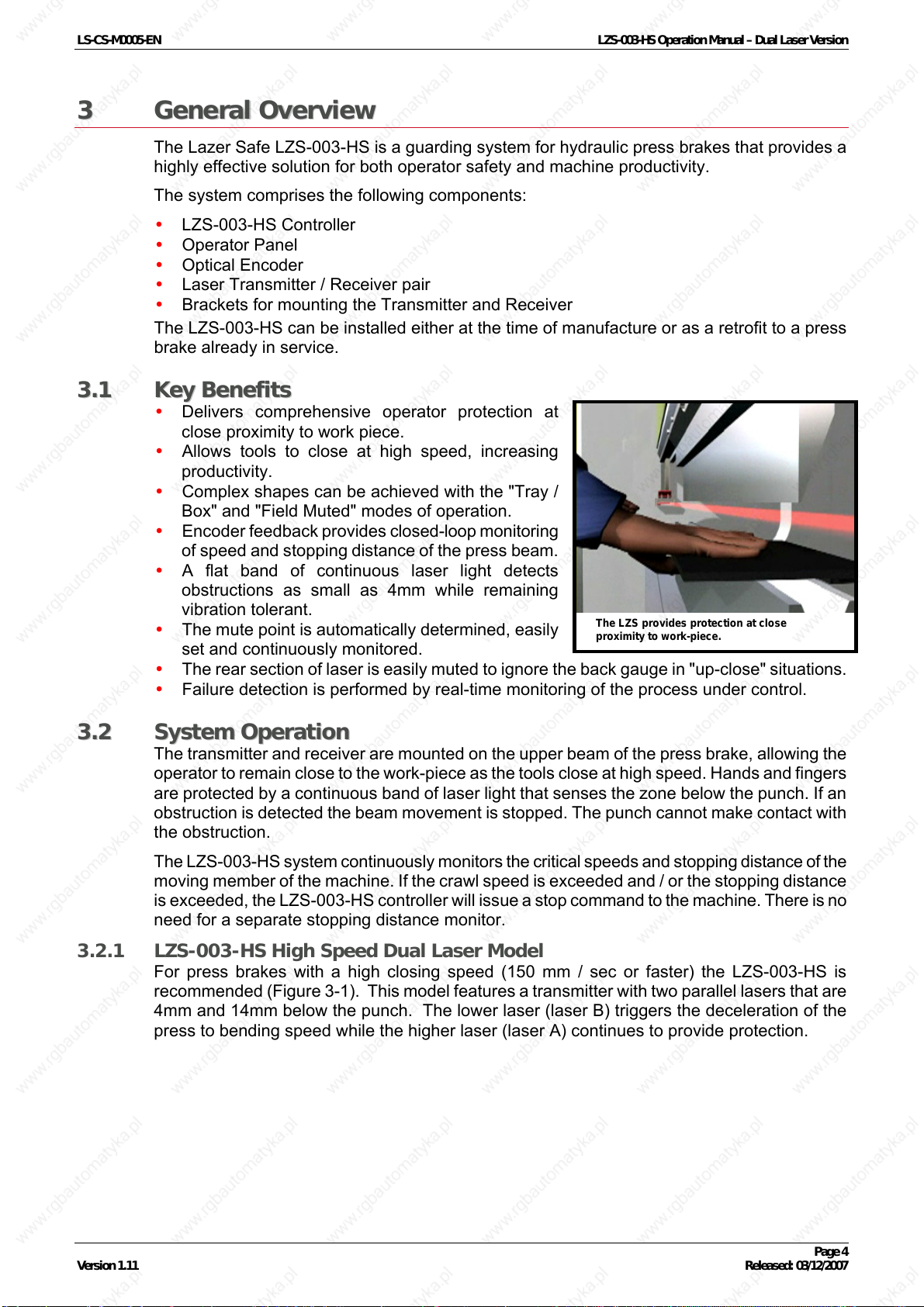

3.2.2 Setup

During setup the laser is set at a distance of 14mm below the tip of the punch. When using the

LZS-003-HS dual laser only the lower laser (Laser B) is switched on during set-up.

Laser B to

punch distance

Mute point

14mm

2mm

Figure 3-2: Laser to punch distance / Mute point distance

3.2.3 Mute Point

The Mute point must first be established so that the LZS-003-HS will not treat the material

being formed as an obstruction. The Mute point is automatically set at 2.0mm above the

surface of the material as the tools close for the first stroke. This mute point set-up can be

initiated whenever the material thickness is substantially changed.

Version 1.11 Released: 03/12/2007

Page 5

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

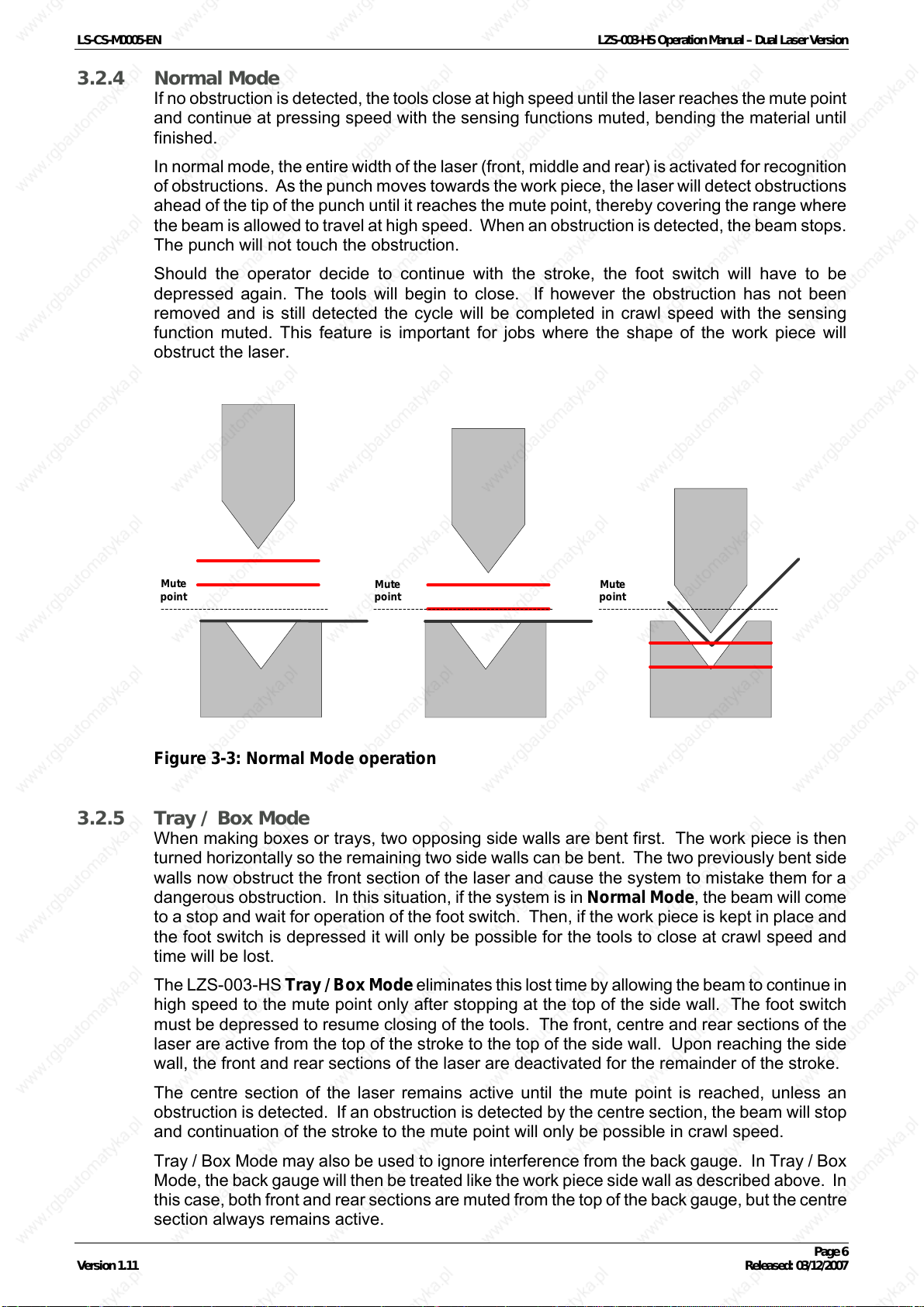

3.2.4 Normal Mode

If no obstruction is detected, the tools close at high speed until the laser reaches the mute point

and continue at pressing speed with the sensing functions muted, bending the material until

finished.

In normal mode, the entire width of the laser (front, middle and rear) is activated for recognition

of obstructions. As the punch moves towards the work piece, the laser will detect obstructions

ahead of the tip of the punch until it reaches the mute point, thereby covering the range where

the beam is allowed to travel at high speed. When an obstruction is detected, the beam stops.

The punch will not touch the obstruction.

Should the operator decide to continue with the stroke, the foot switch will have to be

depressed again. The tools will begin to close. If however the obstruction has not been

removed and is still detected the cycle will be completed in crawl speed with the sensing

function muted. This feature is important for jobs where the shape of the work piece will

obstruct the laser.

Mute

point

Figure 3-3: Normal Mode operation

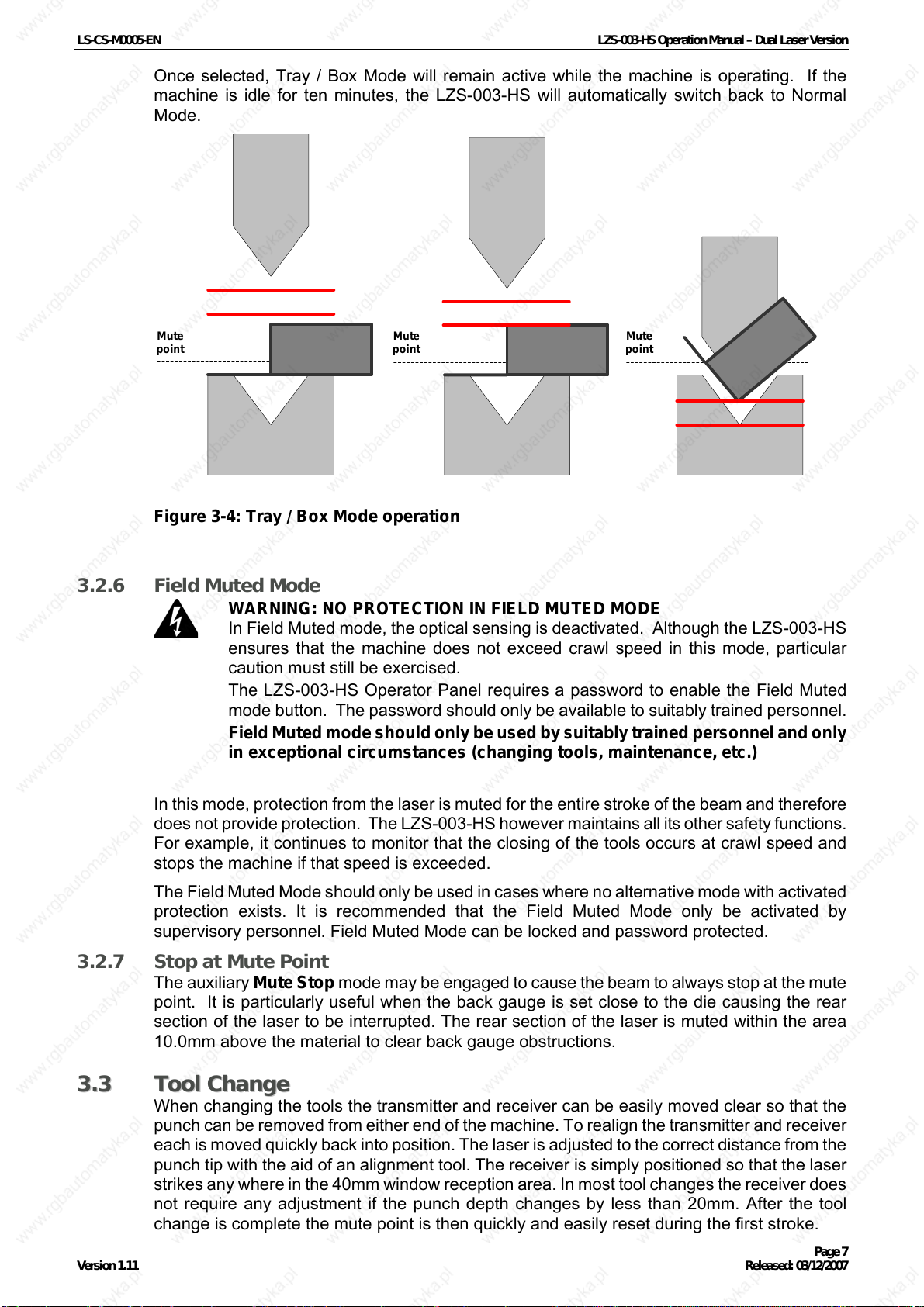

3.2.5 Tray / Box Mode

When making boxes or trays, two opposing side walls are bent first. The work piece is then

turned horizontally so the remaining two side walls can be bent. The two previously bent side

walls now obstruct the front section of the laser and cause the system to mistake them for a

dangerous obstruction. In this situation, if the system is in Normal Mode, the beam will come

to a stop and wait for operation of the foot switch. Then, if the work piece is kept in place and

the foot switch is depressed it will only be possible for the tools to close at crawl speed and

time will be lost.

The LZS-003-HS Tray / Box Mode eliminates this lost time by allowing the beam to continue in

high speed to the mute point only after stopping at the top of the side wall. The foot switch

must be depressed to resume closing of the tools. The front, centre and rear sections of the

laser are active from the top of the stroke to the top of the side wall. Upon reaching the side

wall, the front and rear sections of the laser are deactivated for the remainder of the stroke.

Mute

point

Mute

point

The centre section of the laser remains active until the mute point is reached, unless an

obstruction is detected. If an obstruction is detected by the centre section, the beam will stop

and continuation of the stroke to the mute point will only be possible in crawl speed.

Tray / Box Mode may also be used to ignore interference from the back gauge. In Tray / Box

Mode, the back gauge will then be treated like the work piece side wall as described above. In

this case, both front and rear sections are muted from the top of the back gauge, but the centre

section always remains active.

Version 1.11 Released: 03/12/2007

Page 6

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

Once selected, Tray / Box Mode will remain active while the machine is operating. If the

machine is idle for ten minutes, the LZS-003-HS will automatically switch back to Normal

Mode.

Mute

point

Figure 3-4: Tray / Box Mode operation

3.2.6 Field Muted Mode

WARNING: NO PROTECTION IN FIELD MUTED MODE

In Field Muted mode, the optical sensing is deactivated. Although the LZS-003-HS

ensures that the machine does not exceed crawl speed in this mode, particular

caution must still be exercised.

The LZS-003-HS Operator Panel requires a password to enable the Field Muted

mode button. The password should only be available to suitably trained personnel.

Field Muted mode should only be used by suitably trained personnel and only

in exceptional circumstances (changing tools, maintenance, etc.)

Mute

point

Mute

point

In this mode, protection from the laser is muted for the entire stroke of the beam and therefore

does not provide protection. The LZS-003-HS however maintains all its other safety functions.

For example, it continues to monitor that the closing of the tools occurs at crawl speed and

stops the machine if that speed is exceeded.

The Field Muted Mode should only be used in cases where no alternative mode with activated

protection exists. It is recommended that the Field Muted Mode only be activated by

supervisory personnel. Field Muted Mode can be locked and password protected.

3.2.7 Stop at Mute Point

The auxiliary Mute Stop mode may be engaged to cause the beam to always stop at the mute

point. It is particularly useful when the back gauge is set close to the die causing the rear

section of the laser to be interrupted. The rear section of the laser is muted within the area

10.0mm above the material to clear back gauge obstructions.

33..33

TTooooll CChhaannggee

When changing the tools the transmitter and receiver can be easily moved clear so that the

punch can be removed from either end of the machine. To realign the transmitter and receiver

each is moved quickly back into position. The laser is adjusted to the correct distance from the

punch tip with the aid of an alignment tool. The receiver is simply positioned so that the laser

strikes any where in the 40mm window reception area. In most tool changes the receiver does

not require any adjustment if the punch depth changes by less than 20mm. After the tool

change is complete the mute point is then quickly and easily reset during the first stroke.

Version 1.11 Released: 03/12/2007

Page 7

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

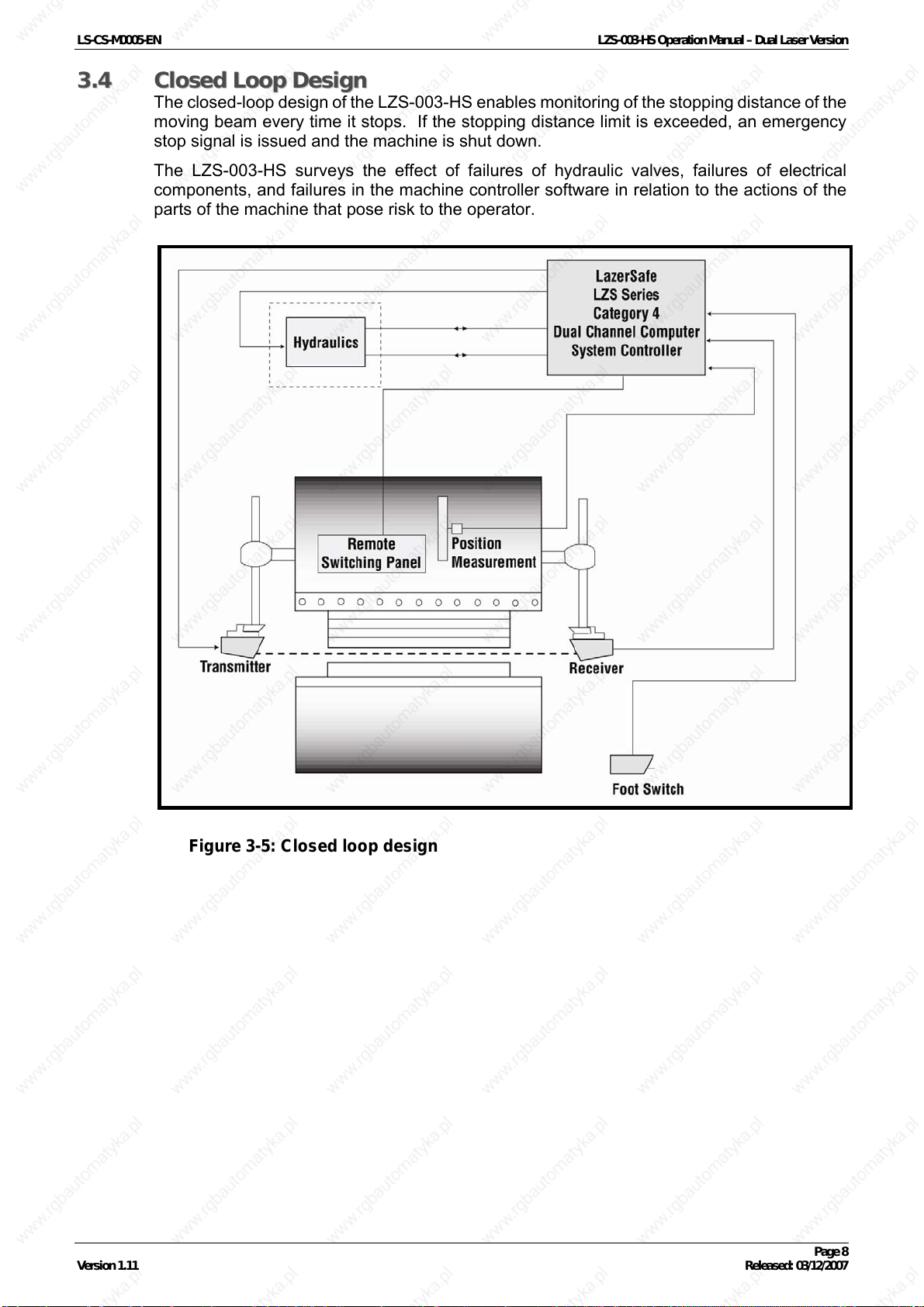

33..44

CClloosseedd LLoooopp DDeessiiggnn

The closed-loop design of the LZS-003-HS enables monitoring of the stopping distance of the

moving beam every time it stops. If the stopping distance limit is exceeded, an emergency

stop signal is issued and the machine is shut down.

The LZS-003-HS surveys the effect of failures of hydraulic valves, failures of electrical

components, and failures in the machine controller software in relation to the actions of the

parts of the machine that pose risk to the operator.

Figure 3-5: Closed loop design

Version 1.11 Released: 03/12/2007

Page 8

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

44

44..11

TTrraannssmmiitttteerr && RReecceeiivveerr AAddjjuussttmmeenntt

Note:

Refer to the Transmitter and Receiver Alignment Manual for more detailed

information.

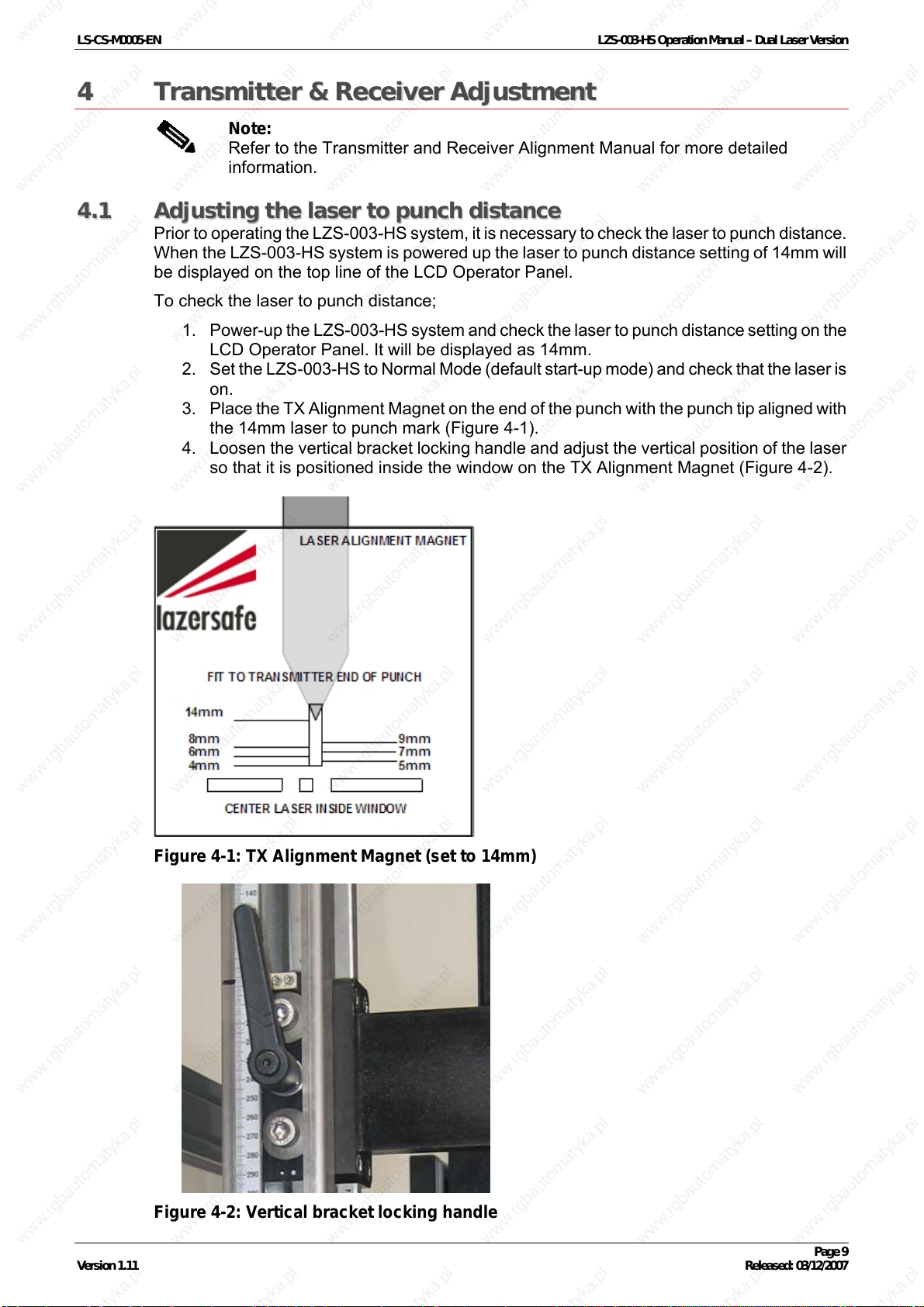

AAddjjuussttiinngg tthhee llaasseerr ttoo ppuunncchh ddiissttaannccee

Prior to operating the LZS-003-HS system, it is necessary to check the laser to punch distance.

When the LZS-003-HS system is powered up the laser to punch distance setting of 14mm will

be displayed on the top line of the LCD Operator Panel.

To check the laser to punch distance;

1. Power-up the LZS-003-HS system and check the laser to punch distance setting on the

LCD Operator Panel. It will be displayed as 14mm.

2. Set the LZS-003-HS to Normal Mode (default start-up mode) and check that the laser is

on.

3. Place the TX Alignment Magnet on the end of the punch with the punch tip aligned with

the 14mm laser to punch mark (

4. Loosen the vertical bracket locking handle and adjust the vertical position of the laser

so that it is positioned inside the window on the TX Alignment Magnet (

Figure 4-1).

Figure 4-2).

Figure 4-1: TX Alignment Magnet (set to 14mm)

Figure 4-2: Vertical bracket locking handle

Version 1.11 Released: 03/12/2007

Page 9

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

44..22

AAddjjuussttiinngg tthhee rreecceeiivveerr ffoorr ttrraayy//bbooxx bbeennddiinngg

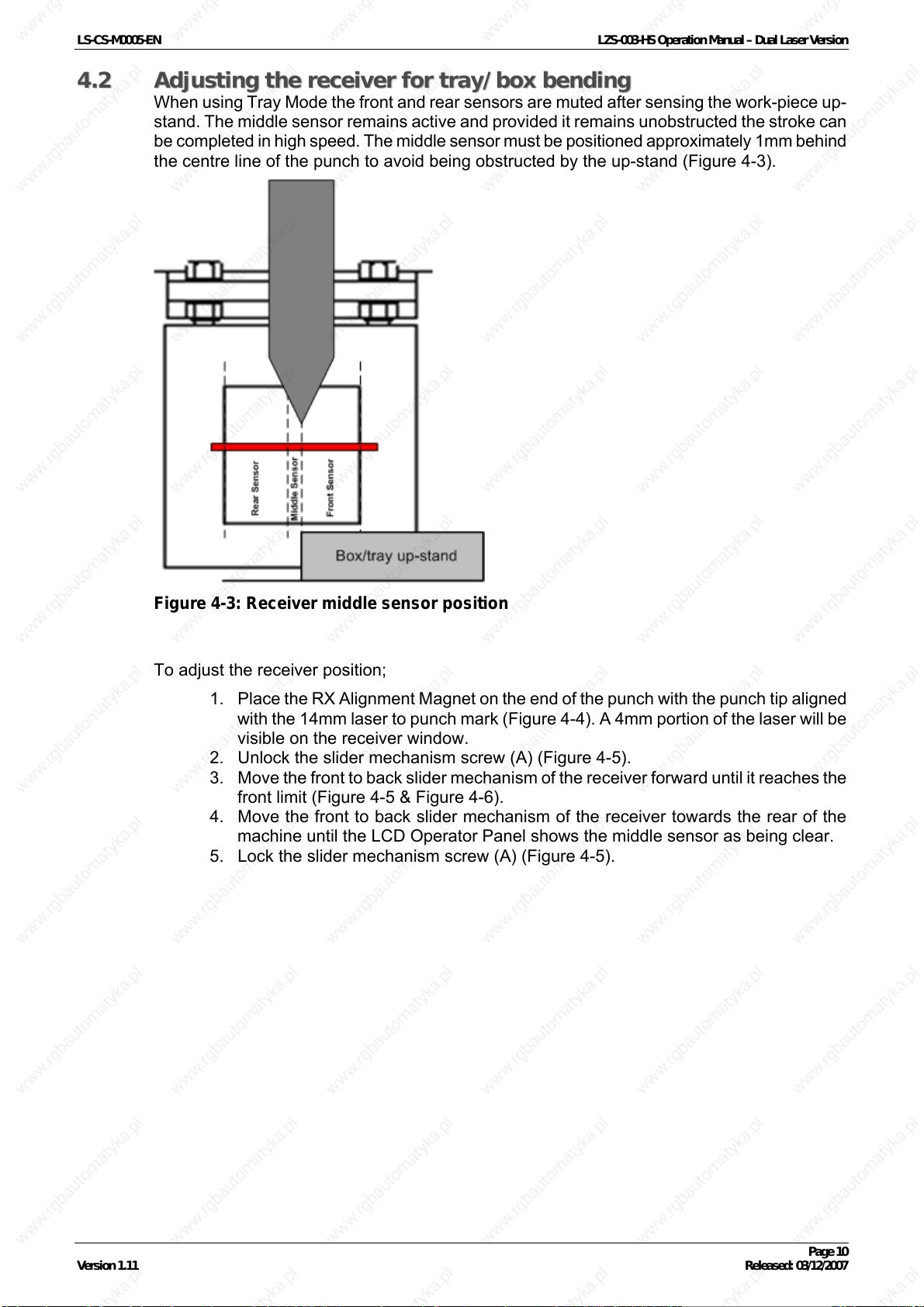

When using Tray Mode the front and rear sensors are muted after sensing the work-piece up-

stand. The middle sensor remains active and provided it remains unobstructed the stroke can

be completed in high speed. The middle sensor must be positioned approximately 1mm behind

the centre line of the punch to avoid being obstructed by the up-stand (

Figure 4-3).

Figure 4-3: Receiver middle sensor position

To adjust the receiver position;

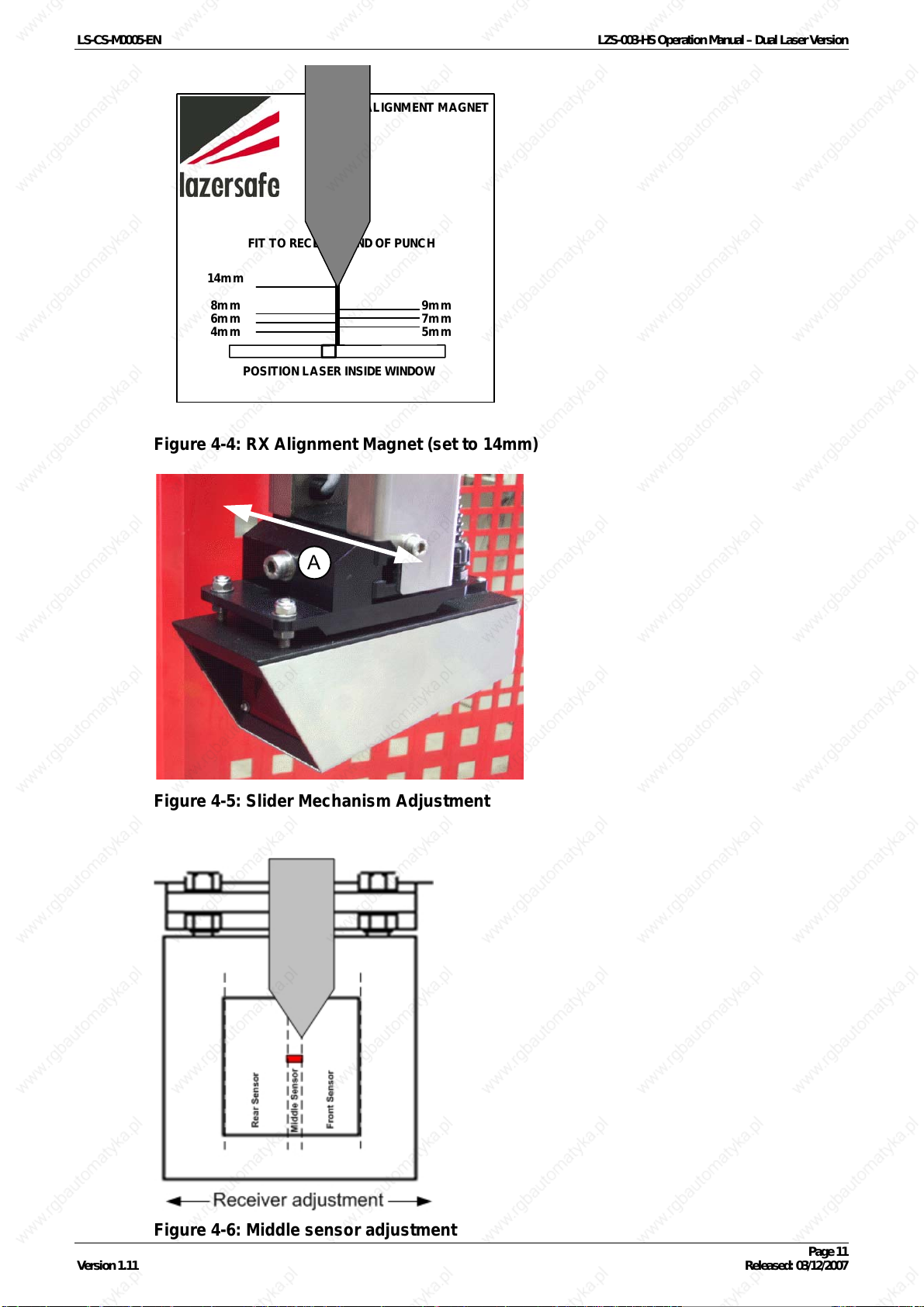

1. Place the RX Alignment Magnet on the end of the punch with the punch tip aligned

with the 14mm laser to punch mark (

visible on the receiver window.

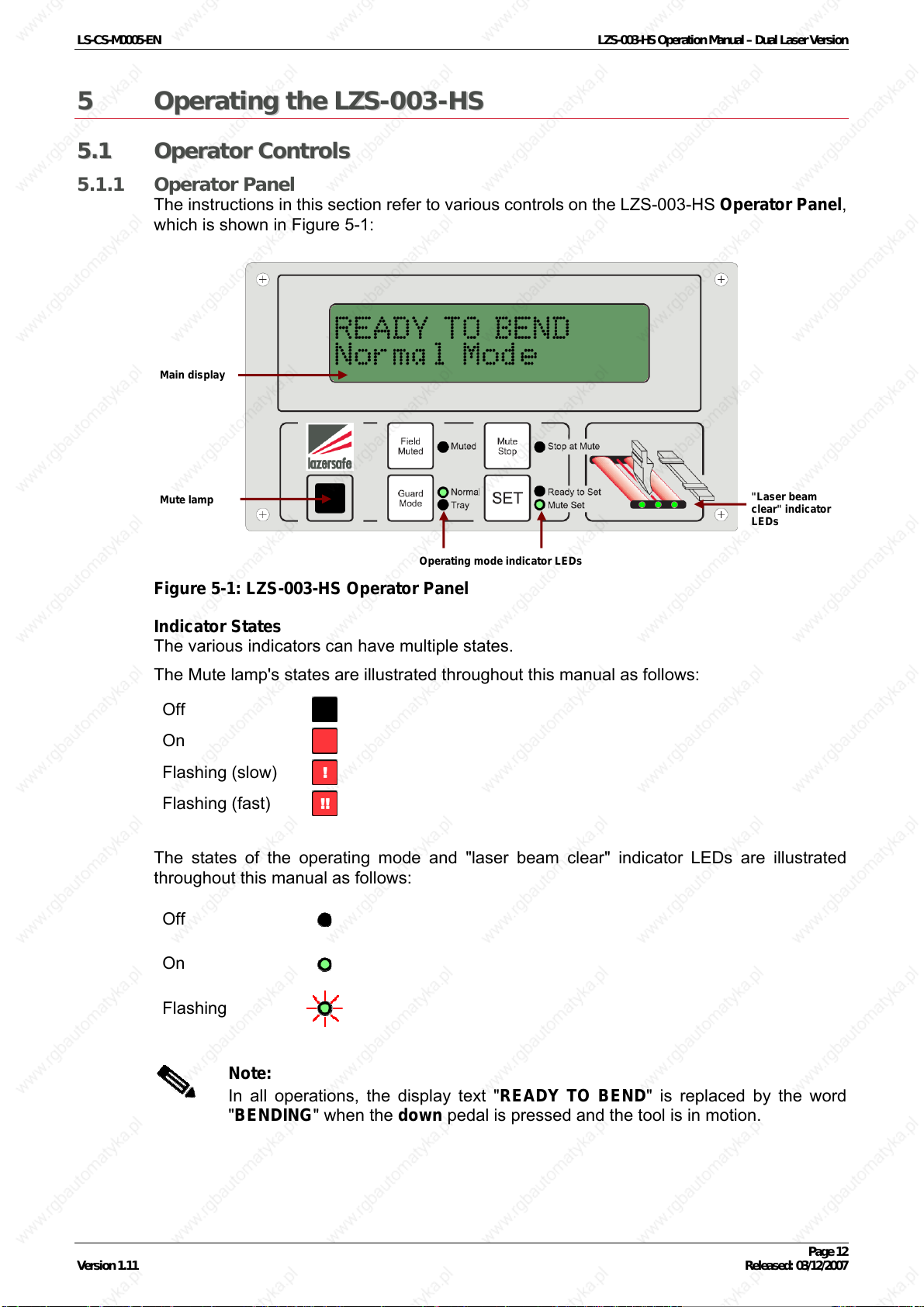

2. Unlock the slider mechanism screw (A) (

3. Move the front to back slider mechanism of the receiver forward until it reaches the

front limit (

4. Move the front to back slider mechanism of the receiver towards the rear of the

machine until the LCD Operator Panel shows the middle sensor as being clear.

5. Lock the slider mechanism screw (A) (

Figure 4-5 & Figure 4-6).

Figure 4-4). A 4mm portion of the laser will be

Figure 4-5).

Figure 4-5).

Version 1.11 Released: 03/12/2007

Page 10

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

LASER ALIGNMENT MAGNET

FIT TO RECEIVER END OF PU NCH

14mm

8mm

6mm

4mm

POSITION LASER INSIDE WINDOW

9mm

7mm

5mm

Figure 4-4: RX Alignment Magnet (set to 14mm)

A

Figure 4-5: Slider Mechanism Adjustment

Figure 4-6: Middle sensor adjustment

Version 1.11 Released: 03/12/2007

Page 11

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

55

55..11

OOppeerraattiinngg tthhee LLZZSS--000033--HHSS

OOppeerraattoorr CCoonnttrroollss

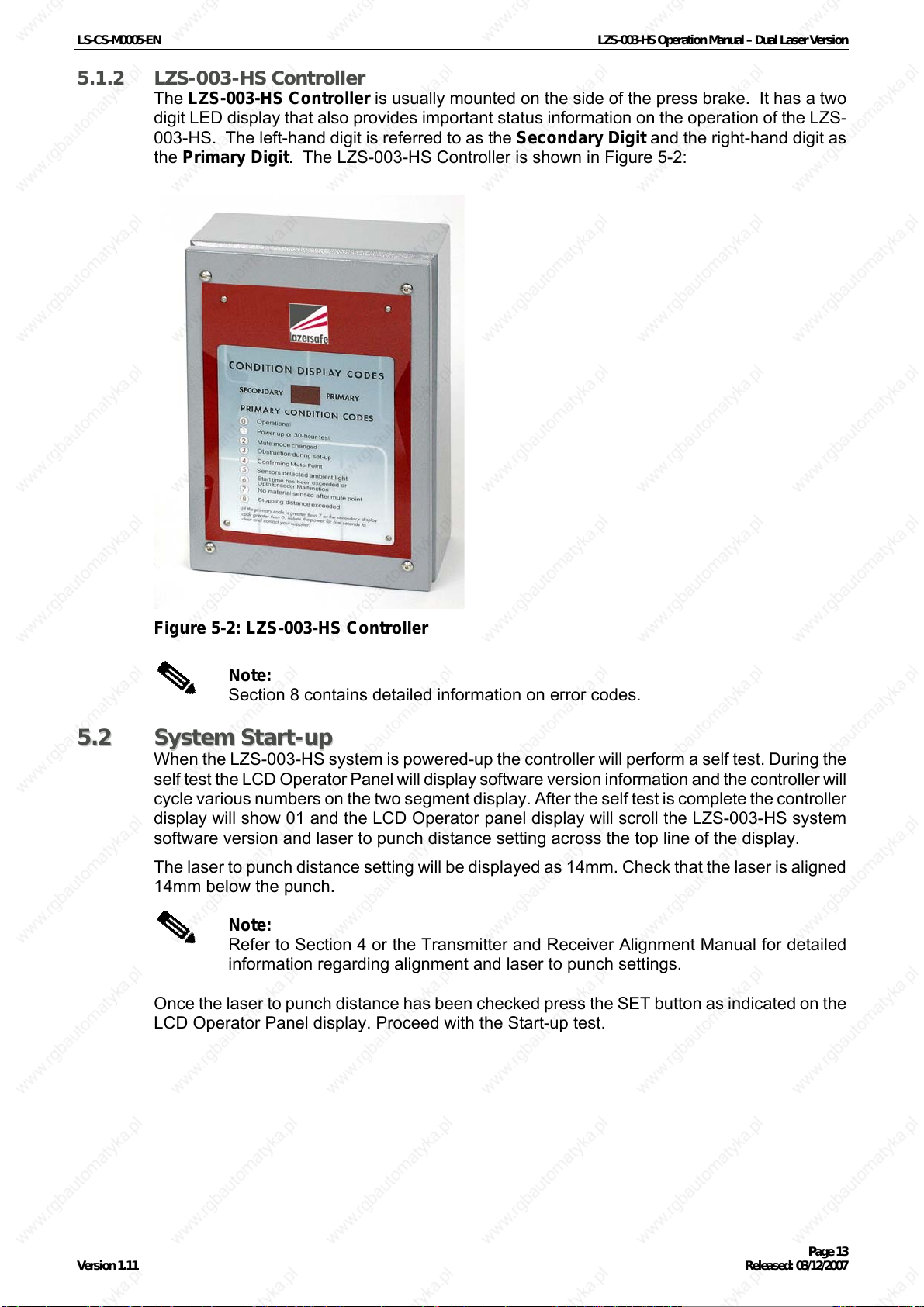

5.1.1 Operator Panel

The instructions in this section refer to various controls on the LZS-003-HS Operator Panel,

which is shown in

Main display

Mute lamp

Figure 5-1:

Operating mode indicator LEDs

"Laser beam

clear" indicator

LEDs

Figure 5-1: LZS-003-HS Operator Panel

Indicator States

The various indicators can have multiple states.

The Mute lamp's states are illustrated throughout this manual as follows:

Off

On

Flashing (slow)

Flashing (fast)

The states of the operating mode and "laser beam clear" indicator LEDs are illustrated

throughout this manual as follows:

Off

On

Flashing

Note:

In all operations, the display text "READY TO BEND" is replaced by the word

"BENDING" when the down pedal is pressed and the tool is in motion.

Version 1.11 Released: 03/12/2007

Page 12

LS-CS-M0005-EN LZS-003-HS Operation Manual – Dual Laser Version

5.1.2 LZS-003-HS Controller

The LZS-003-HS Controller is usually mounted on the side of the press brake. It has a two

digit LED display that also provides important status information on the operation of the LZS-

003-HS. The left-hand digit is referred to as the Secondary Digit and the right-hand digit as

the Primary Digit. The LZS-003-HS Controller is shown in

Figure 5-2:

55..22

Figure 5-2: LZS-003-HS Controller

Note:

Section

SSyysstteemm SSttaarrtt--uupp

When the LZS-003-HS system is powered-up the controller will perform a self test. During the

self test the LCD Operator Panel will display software version information and the controller will

cycle various numbers on the two segment display. After the self test is complete the controller

display will show 01 and the LCD Operator panel display will scroll the LZS-003-HS system

software version and laser to punch distance setting across the top line of the display.

The laser to punch distance setting will be displayed as 14mm. Check that the laser is aligned

14mm below the punch.

Note:

Refer to Section

information regarding alignment and laser to punch settings.

Once the laser to punch distance has been checked press the SET button as indicated on the

LCD Operator Panel display. Proceed with the Start-up test.

8 contains detailed information on error codes.

4 or the Transmitter and Receiver Alignment Manual for detailed

Version 1.11 Released: 03/12/2007

Page 13

Loading...

Loading...