Layher Uni Light Tower

Instructions for Assembly and Use

Mobile working platforms

according to DIN EN 1004:2005-03

Working platform 0.75 x 1.8 m

max. working height:

indoors 9.3 m

outdoors 9.3 m

Rolling Towers

Load bearing capacity 2.0 kN/m

on max. one working level

(scaffold group 3 as per DIN EN 1004:2005-03)

2

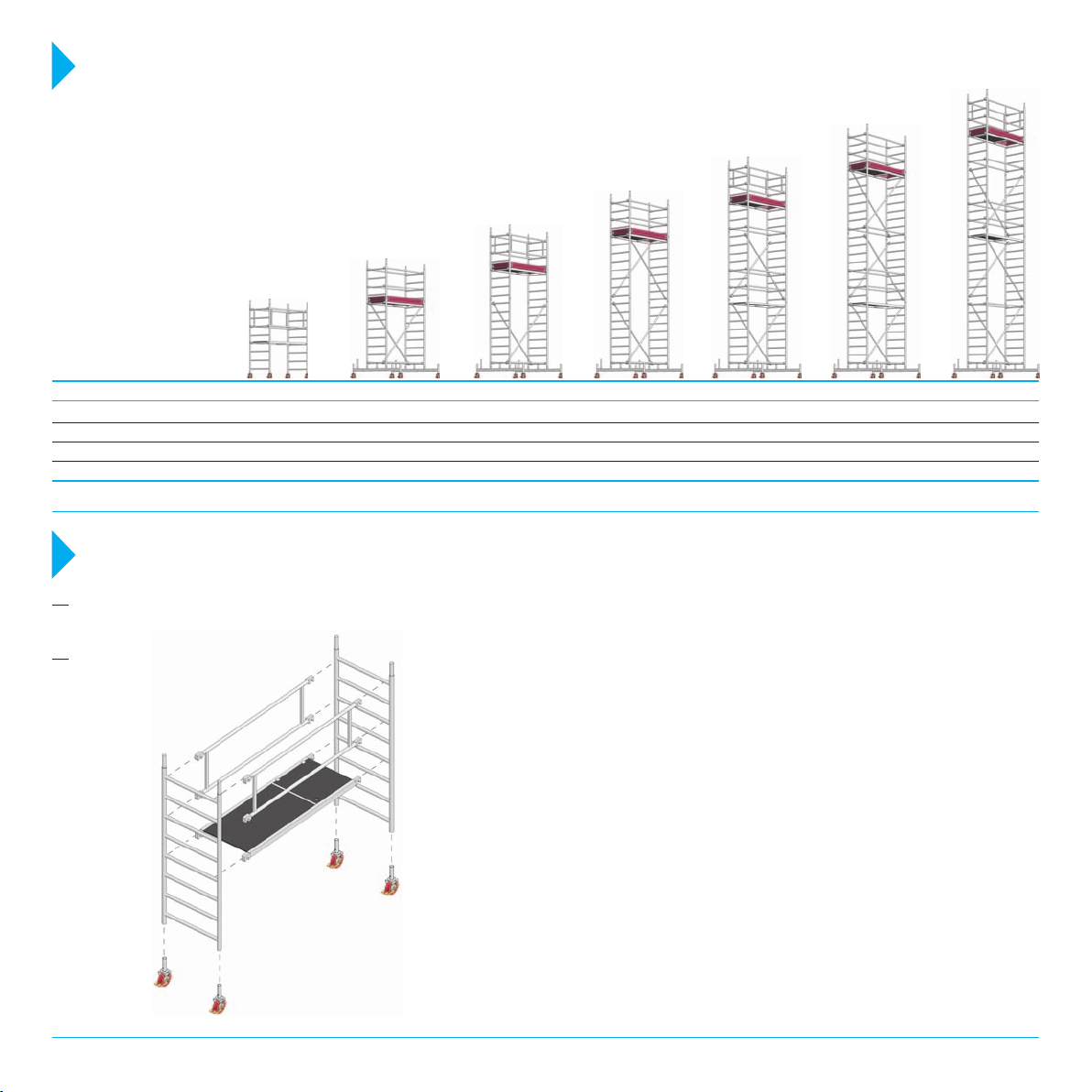

Tower Types Layhe r Uni L i ght T o w er

For outdoor use observe height limits!

Tower Models

3201– 3207

Tower Model 3201 3202 3203 3204 3205 3206 3207

Working height (m) 3.15 4.3 5.3 6.3 7.3 8.3 9.3

Scaffold height (m) 2.44 3.55 4.55 5.55 6.55 7.55 8.55

Platform height (m) 1.15 2.3 3.3 4.3 5.3 6.3 7.3

Weight (kg) 54.3 118.7 127.1 148.9 190.6 208.3 222.7

Assembly

A1 Pay attention to the General Assembly and Usage Instructions on page 6. The examples shown of the tower models 3201– 3207 are designed for use indoors

and outdoors. Pay attention to the parts list and ballasting table on page 5.

A2 Tower Model 3201

Drawing 1

9

2

Insert the castors 9 into the ladder frames 1 and

secure against falling out by fastening the bolts M

1

12x60 and self-securing nuts through the holes pro-

5

5

2

9

1

9

vided. Connect and brace both ladder frames 1 with

two double guardrails 5. Clip the access deck 2 onto

the 4th rung from the bottom. The snap-on claws of

all parts are to be locked onto the ladder frames 1

from above.

A three-part side guard must be attached when this

is required by the regulations applying for the job to

be performed.

In order to remove the different parts, depress the

locking clips of the snap-on claws. The red claws

9

of the deck enable a single person to assemble or

dismantle them easily; open them at one end and

rest the base of the clips on the rung. Now open

the opposite clips and remove the deck.

Assembly Layhe r Uni L i ght T o w er

2

A3 Basic assembly

Tower Models

3202 –3207

1

13

13

9

6

6

4

4

7

9

8

9

1

Insert the castors 9 into the mobile beam 8 and

secure against falling out by fastening the bolts

Once mounted push all diagonal braces 6 and

guardrails 4 outwards as far as possible.

M 12 x60 and self-securing nuts through the holes

provided. Insert the ladder frames 1 onto the mobile

13

beam 8 and secure with spring clips 13. Clip the two

diagonal braces 6 onto the ladder frames 1. Mount

8

9

two guardrails 4 and one horizontal brace 7 onto the

first rung of the ladder frame 1 from the bottom.

For models 3205 and 3206 only, one access deck 2

will be locked onto the first rung of the ladder frame

For the following assembly steps see:

for Tower Model 3202 chapter 5.1.

for Tower Model 3203 chapter 5.2.

for Tower Model 3204 up to 3207 chapter 4.

1 from the top. For model 3207 only, two guardrails 4

will be locked onto the first rung of the ladder frame

1 from the top.Pay attention to the ballasting tables.

A4 Assembling the intermediate platform

Tower Models 3204, 3205,

3206 and 3207

6

1

13

13

A5 Assembling of the top

working platform

A5. 1 Tower Models 3202,

3204 and 3206

13

10

4

1a

11

2

13

A5. 2 Tower Models 3203,

3205 and 3207

l

1

10

13

l

5

4

l

13

l

6

1

ladder frames 1 and fixing two diagonal braces 6.

Secure the ladder frames 1 with spring clips 13.

Erect the intermediate platform by inserting two

For the following assembly steps see:

for Tower Model 3204 and 3206 chapter 5.1.

for Tower Model 3205 and 3207 chapter 5.2.

For tower model 3205, 3206 and 3207 only 4 guard-

4

4

4

rails 4 will be locked onto the 2nd and 4th rung of

the ladder frames 1 from the bottom.

13

Once mounted push all diagonal braces 6 and

guardrails 4 outwards as far as possible.

During assembly and dismantling, system decks or

scaffold planks according to DIN 4420-3

(minimum measurement: 28 x 4.5 x 220 cm long)

must be built in as auxiliary decks at maximum

height intervals of 2.0 m. These auxiliary decks,

providing a safe footing for assembly and

dismantling, are removed after the erection. Each

platform must be completely boarded.

1a

4

4

4

Insert an access deck 2 on the top rung of the ladder

10

frames 1. Start mounting the top working platform

by inserting both ladder frames 1a and secure them

13

with spring clips 13. Lateral protection will consist of

four guardrails 4.

Once mounted push all diagonal braces 6 and

guardrails 4 outwards as far as possible.

Mount two toe boards 1.8 m 11 between the ladder

11

1

5

2

l

l

11

l

4

frames 1a and secure them by adding two end toe

boards 0.75 10.

Insert ladder frames 1 and secure them with spring

10

clips 13. Onto the 5th rung of the ladder frame from

the top attach the access deck 2. Then build in the

lateral protection with two double guardrails 5. After

that mount two toe boards 1.8 m 11 between the

ladder frames 1 and secure them by adding two end

13

l

toe boards 0.75 m 10.

For tower model 3205/3207 only, two additional

guardrails 4 are clipped onto the first rung of the

ladder frame 1 from the bottom. After assembly

push all double guardrails 5 and guardrails 4 outwards as far as possible.

3

Assembly Layhe r Uni L i ght T o w er

During assembly and while working, the castors 9

A6 Operating the castors

Tighten bolt

M 12 x 60

STOP

Õ

8

must be kept locked by pressing down the brake

lever labelled STOP.

330

9

When the brake is locked, the lever labelled STOP

is in the down position. For movement, the castors

are unlocked by pushing the other lever down.

Wall support under load

1

side view

1a

Top view

15

15

14

15

14

15

2

8

For work performed on a load-bearing wall,

ballasting can be reduced in accordance with

the ballasting table (see page 5). In this case,

15

wall supports must be installed on both sides of

14

the tower. Use a Uni-distance-tube 14 and fix it

to the ladder frame 1, 1a with the couplers 15.

15

8

The mobile beams are to be mounted so that the

extension arms project from the side opposite to the

wall. The wall supports must be attached at the

height of the top working platform or at most 1 m

below that.

Dismantling

During assembly and dismantling, system decks or scaffold planks according to DIN 4420-3 (minimum measurement: 28 x 4.5 x 220 cm long) must be built in as

auxiliary decks at maximum height intervals of 2.0 m. These auxiliary decks, providing a safe footing for assembly and dismantling, are removed after the erection.

Each platform must be completely boarded.

To remove the different parts open the snap-on

claws by depressing the locking clips. The red claws

of the decks enable a single person to assemble or

Components

1a Ladder frame 75/4 1297.004

Riefelung

1

Ladder frame 75/8 1297.008

ung

2 Access deck 1242.180

1.8 m

3 Deck 1241.180

1.8 m

dismantle them easily; open them at one end and

rest the base of the clips on the rung. Now open the

opposite clips and remove the deck.

Dismantling is carried out in the reverse order of

assembly.

5 Double

guardrail

1206.180

1.8 m

6

Diagonale 1208.180

2.5 m

7 Horizontal

1209.180

brace

1.95 m

8 Mobile beam 1214.180

1.8 m

9 Castor 150, 1308.150

Plastic wheel,

4 kN

with single action

brake device

Bolt 1203.060

M 12 x 60 with nut

Remove the diagonal braces 6 and bracing

elements only after having taken down the

ladder frames 1 situated above.

11 Toe board 1239.180

with claw

1.8 m

12 Ballast (10 kg) 1249.000

13 Spring clip 1250.000

14 Uni- 1275.110

distance tube

1.1 m

15 Special double coupler,

rigid

19 mm WS 1269.019

22 mm WS 1269.022

4 Guardrail 1205.180

1.8 m

10 End toe board 1238.075

0.75 m

16 Base ledger 1211.180

1.8 m

4

Parts List Layhe r Uni L i ght T o w er

Tower Model Ref. 3201 3202

Ladder frame 75/4 1297.004 – 2 – 2 – 2 –

Ladder frame 75/8 1297.008 2 2 4 4 6 6 8

Access deck 1.8 m 1242.180 1 1 1 1 2 2 2

Double guradrail 1.8 m 1206.180 2 – 2 – 2 – 2

Guardrail 1.8 m 1205.180 – 6 2 6 8 12 10

Diagonal brace 2.5 m 1208.180 – 2 2 4 4 6 6

Mobile beam 1214.180 – 2 2 2 2 2 2

Horizontal brace 1.95 m 1209.180 – – – 1 1 1 1

Toe board 1.8 m, with claw 1239.180 – 2 2 2 2 2 2

End toe board 0.75 m 1238.075 – 2 2 2 2 2 2

Spring clip 1250.000 – 8 8 12 12 16 16

Castor 150, 4 kN 1308.150 4 4 4 4 4 4 4

Special bolt with nut 1203.060 4 4 4 4 4 4 4

Ballast 1249.000 For the number of ballast weights see the Ballasting table.

3203 3204 3205 3206 3207

Ballasting

In order to ballast the tower use Layher ballast weights 12 , Part No. 1249.000 (10 kg each). Couplers with hand wheels permit simple, quick and secure fixing of

the respective ballast required at the correct places. Only these ballast weights are to be used, liquid or granular ballast materials must not be used.

The ballast weights must be distributed evenly to all ballasting fixing points. The remainder, not divisible by 4, is distributed to the fixing points A.

Tower Model 3201 3202 3203 3204 3205 3206 3207

Indoor use

Erection in off-centre position – 2 6 10 14 12 16

Erection in off-centre position

with wall support

Outdoor use Erection in centre position

Erection in off-centre position – 4 8 12 20 20 26

Erection in off-centre position

with wall support

Erection in centre position 1 1 4 8 12 12 16

–

1 1 4 10 14 20 26

–

1 4 8 10 12 14

1 4 8 10 12 14

How to position

ballast weights

1 = Fixing points for

ballast weights

A = Fixing points for

remainder of ballast weights

not divisible by 4

5

Centre position

(Top view)

A

A

Access deck 2

The figures shown indicate the number of ballast weights of 10 kg each. 1 = No ballasting required.

Off-centre position

Mobile beam 8

A

A

(Top view)

Mobile beam 8

AA

Access deck 2

General Instructions on Assembly and Usage

Layhe r Uni L i ght T o w er

The rolling tower may be used for the scaffolding group

and as additionally specified in the German operating

safety regulations (BetrSichV).

The user of mobile working platforms must

comply with the following instructions:

1. The user must check the suitability of the selected

rolling tower for the work to be performed (Section 4

of BetrSichV).

2. The max. platform height is, in accordance with

DIN EN 1004:2005-03

– inside buildings 12.0 m

– outside buildings 8.0 m

The material and ballasting requirements on page 5 must

be complied with; risk of accidents in the event

of non-compliance. For greater heights, additional

measures are necessary, obtainable from the manufacturer. Stability of the rolling tower must be assured.

3. The assembly, modification or dismantling of the rolling tower in accordance with the present instructions

for assembly and use may only be performed under the

supervision of a qualified person and by

professionally suitable personnel after special

instruction. Only the scaffolding types shown in these

instructions for assembly and use may be used.

The unit must, after assembly and before being put

into service, be inspected by persons qualified to do so

(Section 10 of BetrSichV). The inspection must be documented (Section 11 of BetrSichV). During assembly,

modification or dismantling, the rolling tower must be

provided with a prohibition sign indicating “No access

allowed” and be adequately safeguarded by means

of barriers preventing access to the danger zone (BetrSichV Annex 2, para. 5.2.5).

4. Before starting assembly, examine all components in

order to make sure they are in perfect condition. Only

undamaged original components for Layher Mobile

tower systems may be used. Tower parts such as snapon claws and spigot must be cleaned of dirt after use.

Tower parts must be protected against slipping and

impacts during truck transportation. It must be ensured

that the tower parts are stored where they are free from

weather effects. Tower parts must be handled in such a

way that they are not damaged. For the fixing of ballast

weights and wall supports see the tables on page 5 of

these Assembly and Use Instructions.

5. During assembly and dismantling, system decks

or scaffold planks according to DIN 4420-3 (minimum measurement: 28 x 4.5 x 220 cm long) must

be built in as auxiliary decks at maximum height

intervals of 2.0 m. Observe the equirements

mum support distances of scaffold boards

for maxi-

according

to their thickness. These auxiliary decks, providing

a safe footing for assembly and dismantling, are

removed after the erection. Each platform must be

completely boarded.

Edition: 15.12.2011

Due to structural reasons intermediate platforms with

access decks must be built in at maximum intervals

of 4.00 m. For safety reasons, it is advisable for two

persons to erect the towers above a height of 4.0 m. To

assemble the upper tower sections, the individual parts

must be hoisted using transportation ropes.

Small quantities of tools and materials can be carried

up in person, otherwise also hoisted by transportation

ropes to the working level.

6. Secure the ladder frame joints with spring clips

against unintended lift-off.

7. During assembly push guardrails and diagonal

braces outwards as far as possible on the ladder

rungs.

8. At intermediate decks used for climbing only,

two guardrails are required. For small towers where

the height of the deck exceeds 1.0 m, equipment must

be provided that permits the attachement of side guards

in accordance with DIN EN 1004:2005-03

9. Access to the working platform is only permitted on

the inside (exception Tower Type 3201) using the

ladder rungs provided.

10. It is not permitted to work on two or more decks at

the same time. In the event of discrepancies consult the

manufacturer.

11. Persons working on mobile towers should not lean

or press against the guardrails, nor jump onto platforms.

12. It is not permitted to affix lifting or hoisting devices

to mobile towers.

13. Move the tower manually and only on firm, level

ground which is free from obstacles and sufficiently

load bearing. Move the tower only longitudinally or

diagonally. Avoid any impact. After extending the base

one-sided with wall supports in use, move parallel to

the wall only. Do not exceed normal walking speed

during movement.

14. No persons or loose objects must remain on the

tower when moving it.

15. After moving the tower, lock the castors by pressing

the brake lever.

16. Do not expose the tower to corrosive liquids or

gases.

17. Mobile working platforms must not be bridged

between each other, or a building without special

verification. The same applies to special erections, e.g.

suspende use etc.

18. At a wind force above 6 (Beaufort-Scale) and after

finishing the working shift, move the tower when

operating outdoors or in open buildings to a wind

protected area or secure ot by other approviate

measures against toppling over. (Wind speeds above

6 on the Beaufort scale can be recognised by noticeable

difficulty when walking.) If possible, rolling towers used

on the outside of buildings must be securely attached to

the building or to another structure. It is recommended

that rolling towers be anchored when they are left

unattended.

19. In order to achieve different working heights decks

may be fixed one rung higher or lower. Take care to

comply with the prescribed guardrails at heights of 1

m or more. Diagonal braces, too, must be placed a the

corresponding lower or higher level. Contact the manufacturer in order to find out whether an additional static

calculation will be necessary.

Avoid horizontal and vertical loads that can cause the

mobile work platform to topple over, such as:

- horizontal loads, for example when working on adjacent structures,

- additional wind loads (due to tunnel effect from

through-type buildings, unclad buildings and corners).

20. Keep the access hatches shut, except when

climbing the tower.

21. The mobile beam may double as a rung for climbing

up and down.

22. All couplers must be fastened with 50 Nm.

23. Set the rolling tower verhedly by placing suitable

materials underneath it. The inclination must not

exceed 1%.

24. A rolling tower is not intended for use as a stairway

tower providing access to other structures.

25. It is prohibited to jump on the decks.

26. A check must be made that all parts, auxiliary tools

and safety equipment (ropes etc.) for erecting the

rolling towers are available on the site.

27. If stipulated, mobile beams or tower supports or

outriggers and ballast must be installed.

28. It is prohibited to increase the height of the decking

by using ladders, boxes or other objects.

29. It is not permitted to construct bridges between the

rolling tower and a building.

30. Rolling towers are not designed to be lifted or

suspended.

All dimensions and weights are guideline values.

Subject to technical modification.

Our deliveries shall be made exclusively in accordance

with our currently valid General Terms of Sale.

Wilhelm Layher GmbH & Co. KG

Scaffolding Grandstands Ladders

Post Box 40

D-74361 Gueglingen-Eibensbach

Phone: +49-71 35-7 00

Fax: +49-71 35-7 03 72

E-mail: export@layher.com

www.layher.com

Loading...

Loading...