Lawn Solutions TA2106HOF1 Operator's Manual

Form No. 3370-862

Operator’s Manual

21-Inch Walk-Behind Aerator

Model: TA2106HOF1

Serial No. LS02001 and Up

Lawn Solutions Commercial Products, Inc.

G013071

502-968-3188

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Introduction

Thisaerator,whichiscontrolledbyawalkingoperator,

isintendedtobeusedbytrainedoperatorsinresidential

andcommercialapplications.Itisprimarilydesigned

foraeratingsmalltomid-sizedareasofwell-maintained

lawnsonresidentialgrounds,parks,sportselds,andon

commercialgrounds.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactLawnSolutionsdirectlyat

http://lawnsolutionscp.comforproductandaccessory

information,helpndingadealer,ortoregisteryour

product.

Wheneveryouneedservice,genuineLawnSolutions

parts,oradditionalinformation,contactanAuthorized

ServiceDealerorLawnSolutionsCustomerService

andhavethemodelandserialnumbersofyourproduct

ready.

Figure1illustratesthelocationofthemodeland

serialnumbersontheproduct.Writethenumbersin

thespaceprovided.

g013131

1

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

SlopeIndicator.....................................................5

SafetyandInstructionalDecals.............................6

Setup...........................................................................7

UnfoldingtheHandle...........................................7

FillingtheCrankcasewithOil...............................7

ProductOverview........................................................7

Controls...............................................................7

Specications.......................................................8

©2011—LawnSolutionsCP

5406ShepherdsvilleRd.

Louisville,KY40228

2

Contactusathttp://lawnsolutionscp.com.

PrintedintheUSA.

AllRightsReserved

Operation.....................................................................8

CheckingtheEngineOilLevel..............................8

FillingtheFuelTankwithGasoline.......................9

StartingtheEngine.............................................10

StoppingtheEngine...........................................10

DrivingtheMachine...........................................10

Aerating.............................................................11

AddingWeight...................................................11

AdjustingtheCoringDepth................................12

SecuringtheMachineforTransport....................12

OperatingTips...................................................12

Maintenance...............................................................13

RecommendedMaintenanceSchedule(s)................13

PremaintenanceProcedures....................................13

AccessingtheTines............................................13

TippingtheMachine...........................................13

Lubrication.............................................................14

GreasingtheCenterTines..................................14

LubricatingtheDriveChains..............................14

EngineMaintenance...............................................15

ServicingtheAirCleaner....................................15

ChangingtheEngineOil....................................16

ServicingtheSparkPlug.....................................16

DriveSystemMaintenance.....................................17

CheckingtheTirePressure.................................17

CheckingtheTensionofAeratorDrive

Chains............................................................17

BeltMaintenance....................................................18

TineMaintenance...................................................18

Checking/ReplacingTines..................................18

Storage.......................................................................19

Troubleshooting.........................................................20

Safety

Improperuseormaintenancebytheoperator

orownercanresultininjury.Toreducethe

potentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety

alertsymbol,whichmeans

Caution

,

W ar ning

,or

Danger

—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheANSI

B71.4—2004andB71.8—2004standard.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludingsafetyglasses

andhearingprotection.Longhair,looseclothing,or

jewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toys,andwire

whichcanbecontactedbytheaerator.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwiththe

enginerunning.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

3

–Neverrefuelordraintheaeratorindoors.

•Checkthatthecontrols,safetyswitches,andshields

areattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralbeforestartingengine.

•Neveroperatewithouttheshields,covers,orother

guardssecurelyinplace.Besureallinterlocksare

functioningproperly.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Raisethetines,stopthemachine,andstoptheengine

beforeleavingtheoperator’spositionforanyreason.

•Stoptheequipmentandinspectthetinesafter

strikinganobjectorifanabnormalvibrationoccurs.

Makenecessaryrepairsbeforeresumingoperation.

•Keephandsandfeetawayfromthetinearea.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Bealert,slowdown,andusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Slowdownandusecautionwhencrossingroads

andsidewalks.

•Donotoperatetheaeratorundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Useextremecarewhenloadingorunloadingthe

aeratorintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Alwaysbeawareofobstaclesthatmaybeinthe

areaofoperation.Planyouraerationpathtoavoid

contactwithanyobstaclebyyouorthemachine.

SlopeOperation

•Donotoperateonslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromtheoperatingarea.Tallgrasscanhide

obstacles.

MaintenanceandStorage

•Waitforallmovementtostopbeforeadjusting,

cleaning,orrepairing.Raisethetines,stopthe

machine,stoptheengine,anddisconnectthespark

plugwire.

•Cleangrassanddebrisfromthetines,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstore

nearame.

•Shutoffthefuelwhilestoringortransportingon

trailers.Donotstorefuelnearamesordrain

indoors.

•Parktheaeratoronlevel,hardground.Neverallow

untrainedpersonneltoserviceit.

•Usejackstandsorsafetylatchestosupportthe

machinewhenworkingunderit..

•Removethesparkplugwirebeforemakingany

repairs.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•UseonlyLawnSolutions-approvedattachments.

Thewarrantymaybevoidedifthemachineisused

withunapprovedattachments.

4

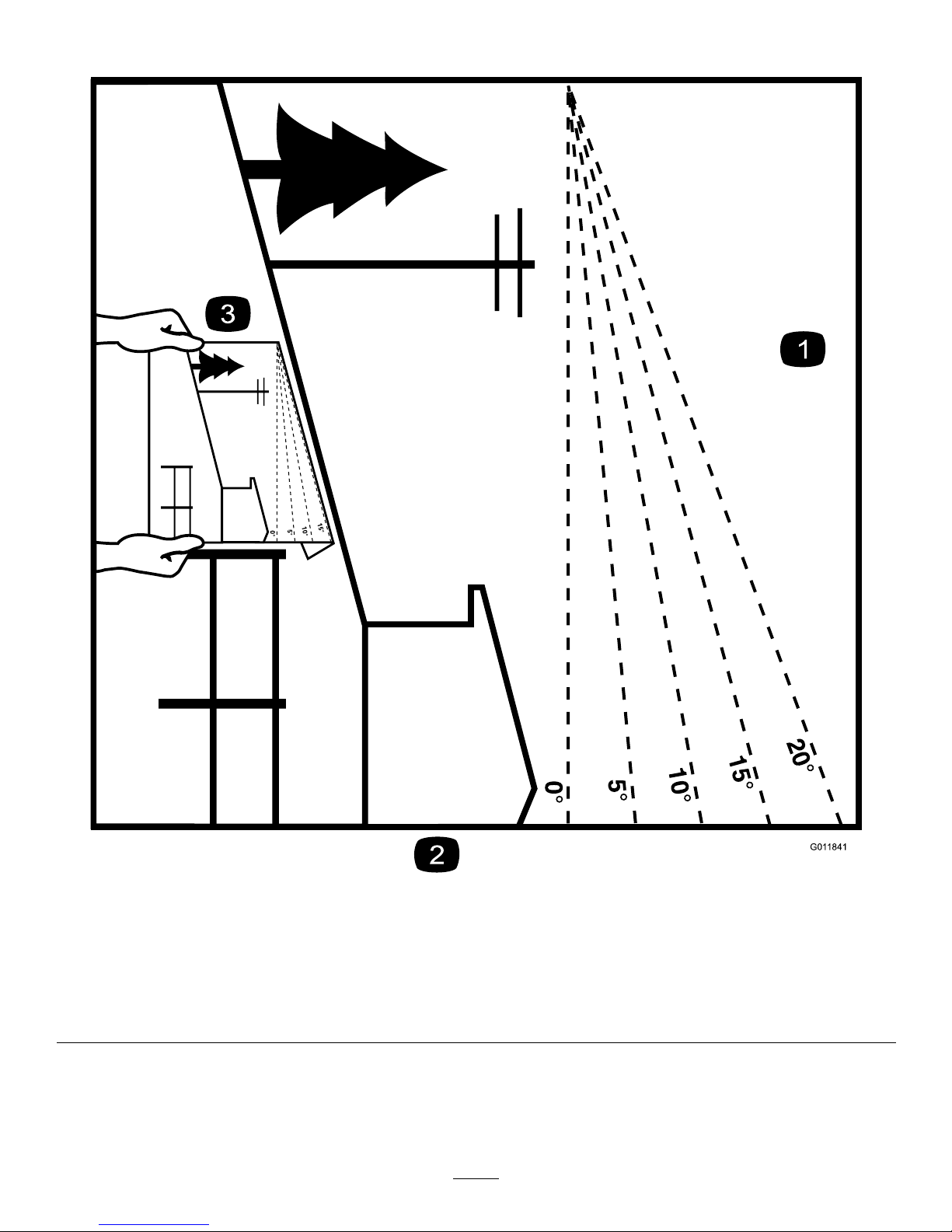

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

5

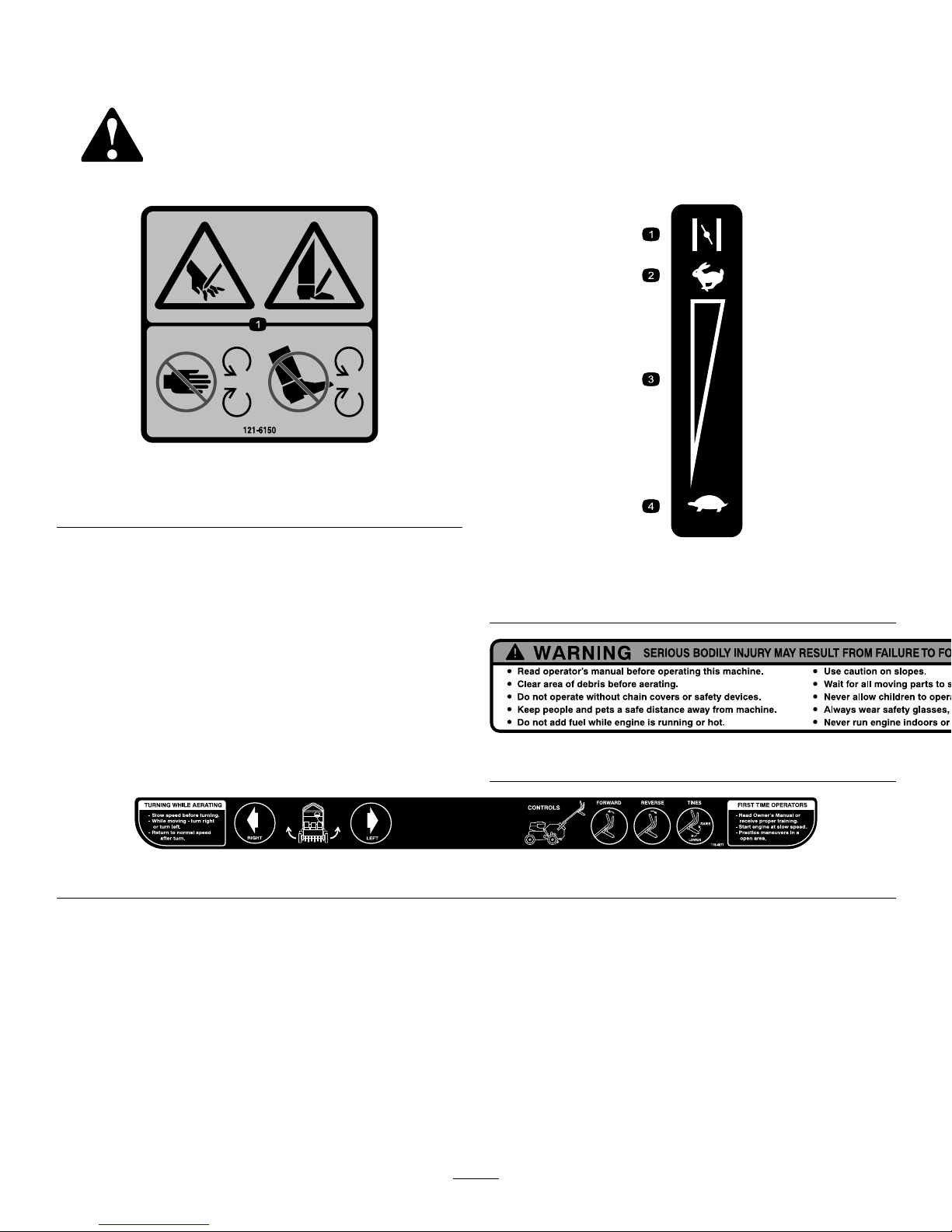

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

121-6150

1.Cuttinghazardofhandandfoot–stayawayfrommoving

parts.

121-6151

121–6151

1.Choke3.Continuousvariable

2.Fast

4.Slow

119-4672

119-4671

6

Setup

UnfoldingtheHandle

1.Raisethehandletotheoperatingposition.

g013073

1

Figure4

2.Slidetheovallockingringsdowneachsideofthe

upperhandleoverthelowerhandle,lockingthe

handlesectionstogether.

FillingtheCrankcasewithOil

Theenginecrankcaseisshippedwithoutoil.You

mustllitwithapproximately22ounces(0.65l)ofoil

beforestartingtheengine.RefertoCheckingtheEngine

OilLevelinCheckingtheEngineOilLevel(page8),for

oilspecicationsandinstructions.

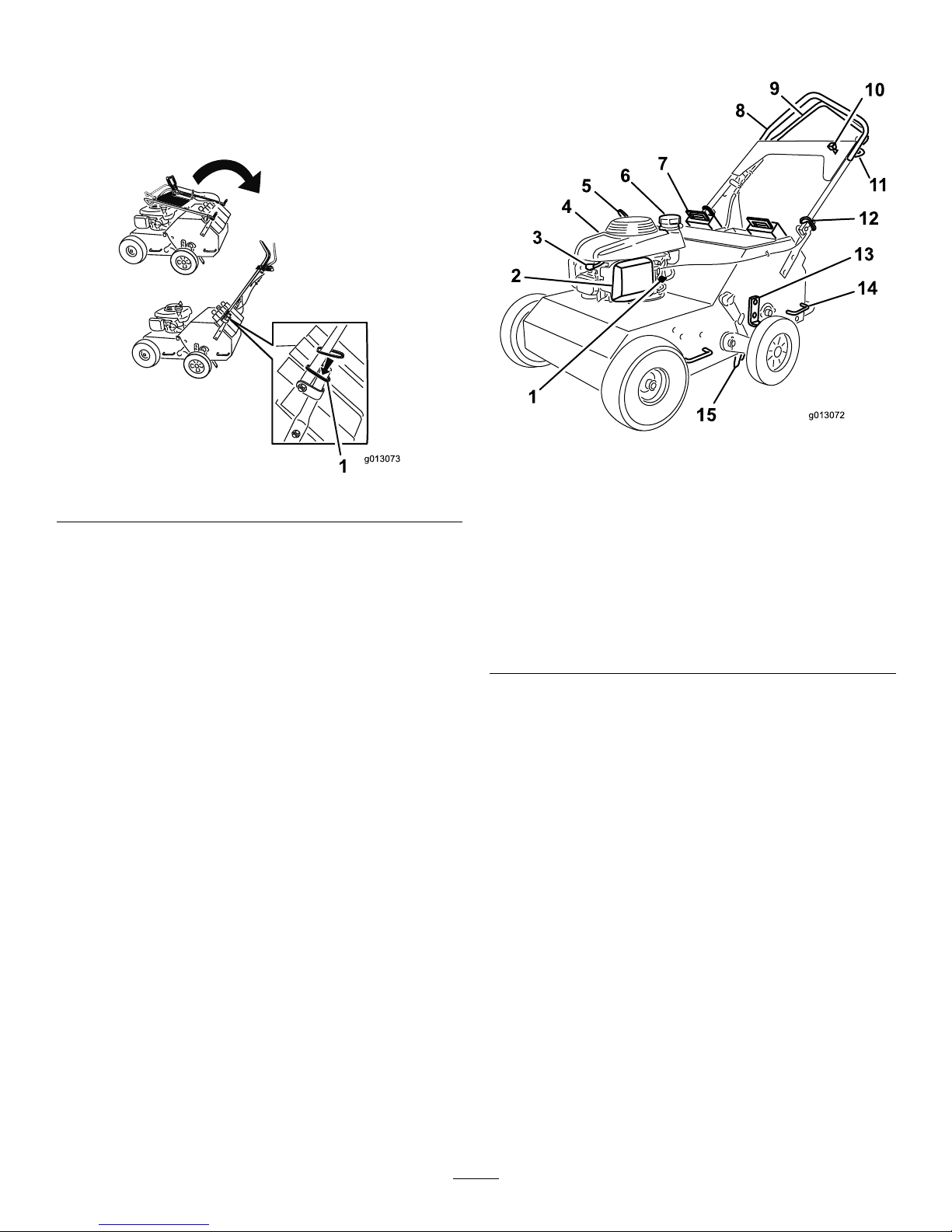

ProductOverview

g013072

1

2

3

5

6

7

8

9

10

11

12

13

14

15

4

Figure5

1.Fuelshut-offvalve

9.Tractioncontrollever

2.Aircleaner10.Throttlelever

3.Sparkplugwire

11.Tinecontrollever

4.EngineOn/Offswitch

(ontherightsideofthe

engine)

12.Ovalhandlelockingring

5.Recoilstarter

13.Coringdepth,wheelstop

6.Fueltank

14.Tie-down/liftloops

7.Rearweights15.Tines

8.Handle

Controls

RecoilStarter

Pulltherecoilstarterhandletostartengine(Figure5).

FuelShut-offValve

Closethefuelshut-offvalvewhentransportingor

storingthemachine(

Figure5).

EngineOn/OffSwitch

ToggletheengineonoffswitchtoOntoenablethe

engineelectricalsystemsothatitcanbestarted.Switch

ittoOfftostoptheengine.

ThrottleLever

Beforestartingacoldengine,movethethrottlelever

forwardtotheChokeposition.Aftertheenginestarts,

pullthethrottleleverbacktotheFastposition.

7

Note:Awarmenginerequireslittleornochoking.

TractionControlLever

Thetractioncontrollevercontrolstheforward,

reverse,andneutralactionsofthemachine.Referto

DrivingtheMachine(page10)formoreinformation.

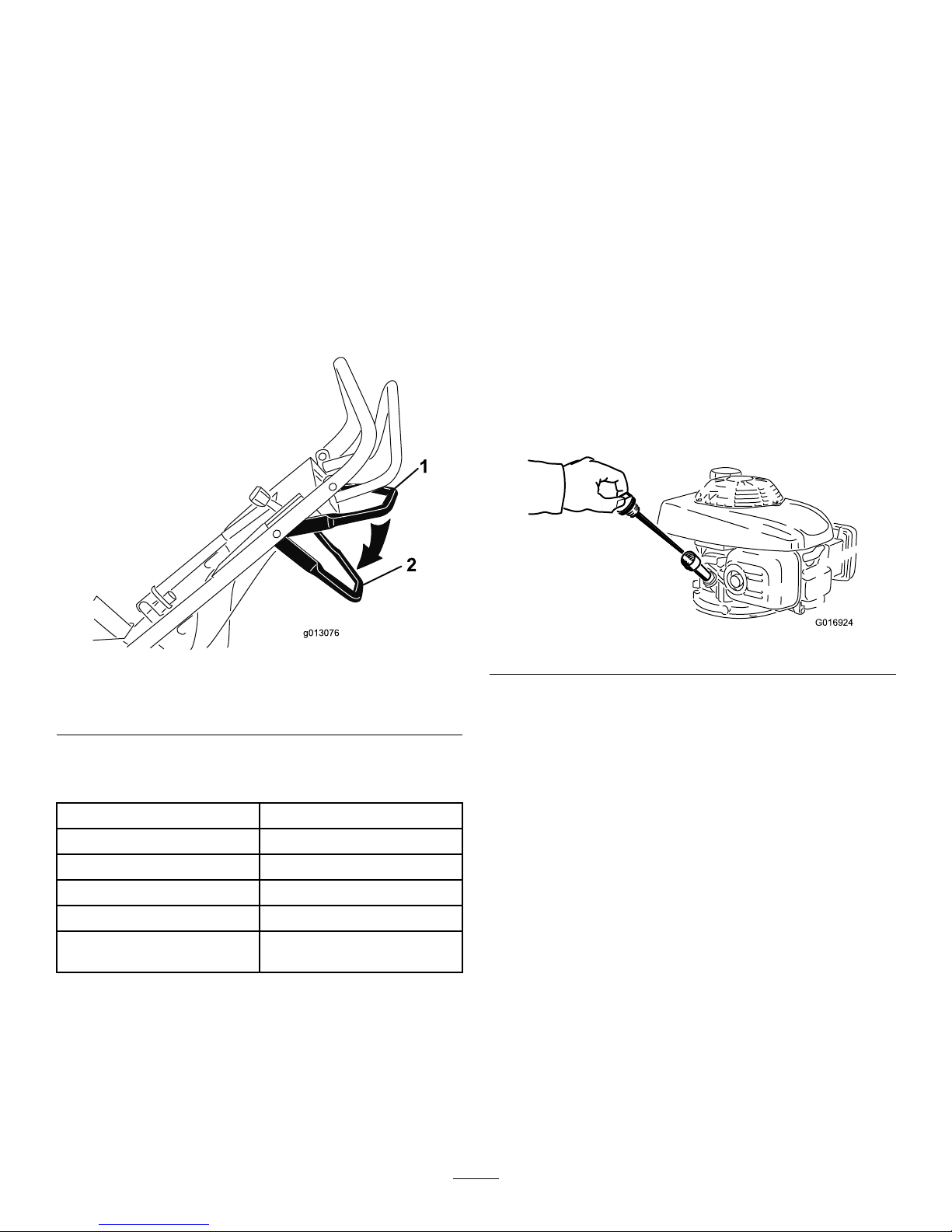

TineControlLever

Thetinecontrolleverliftstherearwheels,causingthe

rearofthemachinetobesupportedontheaerating

tines.Pushthetinecontrolleverdowntoliftthewheels

anddropthetines.Pullituptolowerthewheelsand

raisethetinesoutoftheground.

g013076

1

2

Figure6

1.Tinecontrollever—raised

position

2.Tinecontrol

lever—loweredposition

Specications

Length(operating)61inches(155cm)

Length(withhandlestored)48.5inches(123cm)

Width

31inches(79cm)

Height(operating)45.25inches(1 15cm)

Height(withhandlestored)32.5inches(82.5cm)

Weight(asshippedwith2

weights)

337lb(152.8kg)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theenginecrankcasecanhold20ounces(0.55liters)

ofoil.Useonlyhigh-qualitySAE10W-30weight

detergentoilthathastheAmericanPetroleumInstitute

(API)serviceclassicationSH,SJ,Slorhigher.

Note:Whenthecrankcaseisempty ,pourabout3/4

ofthecrankcasecapacityofoilinthecrankcase,then

followtheprocedureinthissection.

1.Movethemachinetoalevelsurface.

2.Cleanaroundthedipstick(

Figure7).

G016924

Figure7

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

4.Wipethedipstickcleanwithacleancloth.

5.Insertthedipstickintothellerneck,butdo

notrotatethecapclockwisetosecureit,then

removeit.

6.Readtheoillevelonthedipstick.

7.Iftheoillevelreadingisbelowthelowerlimitmark

onthedipstick,removethedipstickandslowly

pouronlyenoughoilintothellerholetoraisethe

oilleveltotheupperlimitmarkonthedipstick.

Important:Donotoverllthecrankcasewith

oilandruntheengine;enginedamagewill

result.Draintheexcessoiluntiltheoillevel

reachestheupperlimitmarkonthedipstick.

8.Insertthedipstickintothellerneckandrotatethe

capclockwiseuntilitistight.

8

Loading...

Loading...