Laversab 6600 User Manual

MODEL 6600 Rev. B4

USER'S MANUAL

LAVERSAB INC.,

505 GILLINGHAM LANE .

SUGAR LAND TX 77478

(281) 325-8300

FAX: (281) 325-8399

Email: aservice@laversab.com

Document Number : 9051 REV B4

Date: June 07, 2011.

WARRANTY

Laversab Inc., warrants its products to conform to or exceed the specifications as

set forth in its catalogs in use at the time of sale and reserves the right, at its own

discretion, without notice and without making similar changes in articles previously

manufactured, to make changes in materials, designs, finish, or specifications. Laversab

Inc. warrants products of its own factory against defects of material or workmanship for a

period of three years from date of sale.

Liability of Laversab Inc. under this warranty shall be limited to replacing, free of

charge (FOB Houston, Texas), any such parts proving defective within the period of this

warranty, but Laversab Inc. will not be responsible for transportation charges,

consequential or incidental damages. No liability is assumed by Laversab for damages

that are caused by misuse or abuse of the product.

The warranty of Laversab Inc. is not made for products manufactured by others

which are illustrated and described in Laversab catalogs or incorporated in Laversab

products in essentially the same form as supplied by the original manufacturer.

Warranties of the original manufacturers supplant the warranty of Laversab Inc., but, in

applicable instances, the latter agrees to use its best efforts to have original suppliers make

good their warranties.

i

COPYRIGHT NOTICE

Copyright (c) 2007 onward by Laversab Inc. All rights reserved. The content of this

manual may not be reproduced in any form by any means, in part or in whole, without

the prior written permission of Laversab Inc.

DISCLAIMER

No representations or warranties are made with respect to the contents of this user's

manual. Further, Laversab Inc. reserves the right to revise this manual and to make

changes from time to time in the content hereof without obligation to notify any person of

such revision.

ii

REVISION HISTORY

Document No. Release Date Description

9051 Rev A

9051 Rev B

12/20/2007

04/20/2008

6600 User’s Manual

6600 Rev B User’s Manual

9051 Rev B1

9051 Rev B2

9051 Rev B3

9051 Rev B4

12/09/2009

04/27/2010

02/23/2011

06/07/2011

6600 Rev B1 User’s Manual

6600 Rev B2 User’s Manual

6600 Rev B3 User’s Manual

6600 Rev B4 User’s Manual

iii

THE 6600 USES LINE VOLTAGES FOR ITS OPERATION WHICH ARE POTENTIALLY

DANGEROUS. IMPROPER OPERATION OF THIS EQUIPMENT MAY RESULT IN

PERSONAL INJURY OR LOSS OF LIFE. HENCE THE EQUIPMENT DESCRIBED IN

THIS MANUAL SHOULD BE OPERATED ONLY BY PERSONNEL TRAINED IN

PROCEDURES THAT WILL ASSURE SAFETY TO THEMSELVES, TO OTHERS AND

TO THE EQUIPMENT.

BEFORE PERFORMING ANY MAINTENANCE, TURN THE POWER OFF AND

DISCONNECT THE POWER CORD FROM THE POWER SOURCE.

ALWAYS USE A 3-PIN GROUNDED OUTLET AS YOUR AC POWER SOURCE

WARNING

iv

TABLE OF CONTENTS

Warranty ............................................................................................................................. i

Copyright notice, disclaimer .............................................................................................. ii

Revision History ................................................................................................................... iii

Warning ............................................................................................................................. iv

Section 1: Introduction .................................................................................................. 1

Section 2: Controls and Connections ........................................................................ 2

2.1 Main Unit Top Panel .............................................................................................. 2

2.2 Remote Unit Top Panel ........................................................................................... 10

Section 3: Understanding the 6600 .............................................................................. 13

3.1 Start Up ..................................................................................................................... 13

3.2 Main Operating Screen .......................................................................................... 15

3.2.1 Displayed Parameters ................................................................................... 18

3.2.2 Target Value Entry ........................................................................................ 25

3.2.3 Units Selection ............................................................................................... 30

3.2.4 Mode Selection ............................................................................................... 34

3.3 Leak Screen ............................................................................................................. 38

3.4 Self Test Screen ........................................................................................................ 40

3.5 Function Select Screen ............................................................................................ 41

3.5.1 Function 1: View Limits ............................................................................... 42

3.5.2 Function 2: Set Limits .................................................................................. 42

3.5.3 Function 3: Set Knots Rate ........................................................................... 44

3.5.4 Function 4: View and Execute Profiles ....................................................... 45

3.5.5 Function 5: Setup Profiles ............................................................................. 46

3.5.6 Function 6: Height Correction .................................................................... 46

3.5.7 Function 7: Set Ground ................................................................................ 46

3.5.8 Function 8: Go To Ground .......................................................................... 47

Section 4: Profiles ........................................................................................................... 48

4.1 What is a Profile ...................................................................................................... 48

4.2 Creating a Profile .................................................................................................... 50

4.3 Setting Up Hyperterminal ................................................................................... 51

4.4 Downloading a Profile ........................................................................................... 52

4.5 Executing a Profile .................................................................................................. 53

Section 5: Typical Use ................................................................................................... 55

Section 6: Calibration .................................................................................................... 58

6.1 Equipment ............................................................................................................... 58

6.2 General Notes ............................................................................................................ 58

6.3 Ps1 and Ps2 Calibration .......................................................................................... 59

6.4 Pt Calibration ........................................................................................................... 60

v

TABLE OF CONTENTS (contd.)

Section 7: Maintenance ................................................................................................. 64

Section 8: Communication Interface ............................................................................ 65

8.1 RS232 Serial Interface .............................................................................................. 65

8.2 Communication Syntax ........................................................................................... 65

Appendix A: Error Codes .................................................................................................. 69

Appendix B: Specifications ................................................................................................ 70

Appendix C: Connector Pin-Outs ..................................................................................... 71

Appendix D: Repair and Return Policies ........................................................................ 72

vi

1

SECTION 1

INTRODUCTION

Note: Pt = Pitot , Ps1 = Primary Static, Ps2 = Secondary Static

The model 6600 is a high accuracy automated pressure controller, specifically designed for

controlling air data parameters such as altitude, airspeed, Mach and climb. It provides three

independent outputs – Ps1, Ps2 and Pt, which allows the unit to be used on aircraft which use

“smart” probes capable of reading Angle of Attack based on Static differential pressures. This

instrument can also be used to control pressures in units of inHg and mbar. The 6600 is

equipped with internal pressure and vacuum pumps. The Remote unit is used to interface

with the Main unit. The small size of the Remote unit allows it to be used in the cockpit of an

aircraft.

The 6600 has three high accuracy transducers that measure pressure in the range of 0 to 38

inHg absolute on the Ps1 (primary static) output, 0 to 38 inHg absolute on the Ps2 (secondary

static) output and 0 to 60 inHg absolute on the Pt (pitot) output. These transducers are

designed to accurately measure the pressure of dry air over an ambient temperature range of 10oC to 50oC. The 6600 can be used by connecting only two outputs (Pt and Ps1) or all three

outputs (Pt, Ps1, Ps2) to an aircraft. The 6600 is RVSM compliant.

The 6600 allows the user to control altitude in feet, meters, inHg or mbar; Rate of change in

feet/minute, meters/minute, inHg/min or mbar/min; airspeed in knots, mach, mph and

kmph. The Ps2 port can be controlled in absolute units of feet, meters, inHg or mbar as well

as differential (Ps2-Ps1) units of differential inHg (Dfin), differential mbar (Dfmb), knots or

kmph. The 6600 also allows the user to control EPR on the Pt output.

The model 6600 features programmable limits on altitude, airspeed, mach number, climb rate,

and static differential (Ps2-Ps1). These limits are checked during data entry and thereby

prohibit entry of erroneous target values. These limits are also checked continuously during

operation, and if any of these is exceeded, the unit automatically takes abortive action.

The user has the ability to program into the 6600 a profile of set-points to be controlled in a

sequence. Once such a profile has been setup, the user can command the unit to move from

one set-point to the next simply by pushing the 'GO' button. Up to 50 points can be stored in

one profile. The 6600 can store up to 12 such profiles in non-volatile memory at any one time.

Calibration of the unit is required only once a year. This process is the only scheduled

maintenance function required on the 6600.

The model 6600 comes with an RS232 interface. This interface is mainly used to download

profiles from a computer.

2

SECTION 2

CONTROLS AND CONNECTIONS

Note: Pt = Pitot , Ps1 = Primary Static and Ps2 = Secondary Static

2.1 MAIN UNIT TOP PANEL

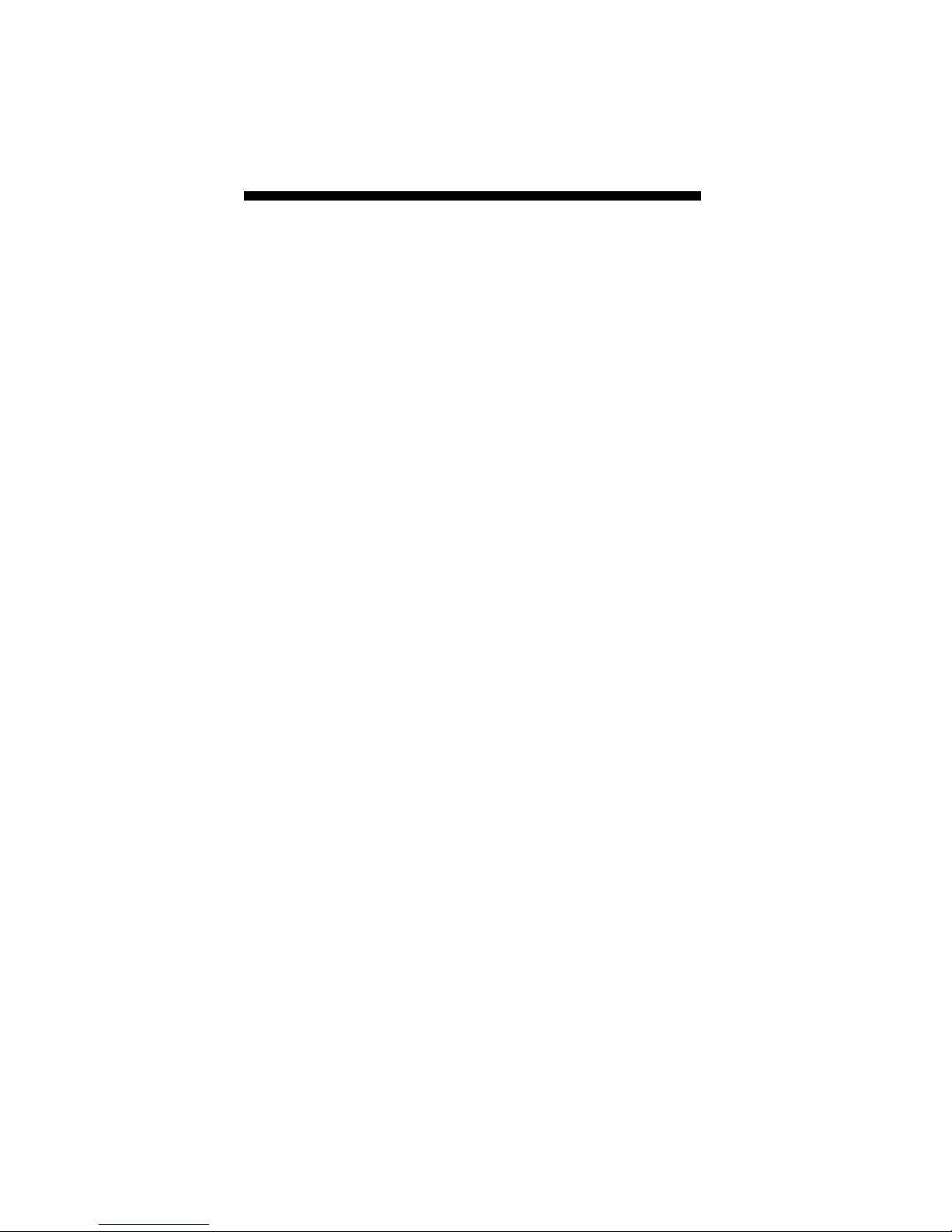

The model 6600 top panel provides easy access to all the connections. Please refer to Figure

2.1.

[1] AC INPUT connector :

This is a 3-pin male circular connector. A power cord is provided with the 6600. The circular

connector end of the power cord needs to connected here. The power requirement of the 6600

is 90-260 VAC, 47-440 Hz with a maximum power consumption of 200 VA.

Caution: Connecting incorrect power to the 6600 will cause considerable damage

The power cord is normally left connected to the 6600 at the AC INPUT connector and is

wrapped around two cord posts. The cord retainers on top of these posts swivel in either

direction and latch at 180 degree positions, allowing easy wrapping and unwrapping of the

power cord. A cord clamp allows the cord to be held in place after it is wrapped.

[2] Fuse :

A 5x20 mm fuse is located inside the fuse holder. The fuse is a time-delay fuse with a rating of

3.0 amps, 250 Volts.

[3] AC On/Off switch :

This toggle switch connects (or disconnects) AC power between the AC INPUT connector and

the 6600. Even when this switch is ON, the 6600 becomes operational only after the On/Off

switch located on the right side of the Remote Unit is turned ON. (Push in to turn ON)

[4] Remote Unit connection:

The 6600 is provided with a 50 foot remote cable to connect to the Remote unit. The male end

of the remote cable is connected here on the top panel. The female end of the remote cable is

connected to the Remote unit. This cable should be connected prior to applying power to the

6600. This cable should not be disconnected while power is applied to the 6600.

3

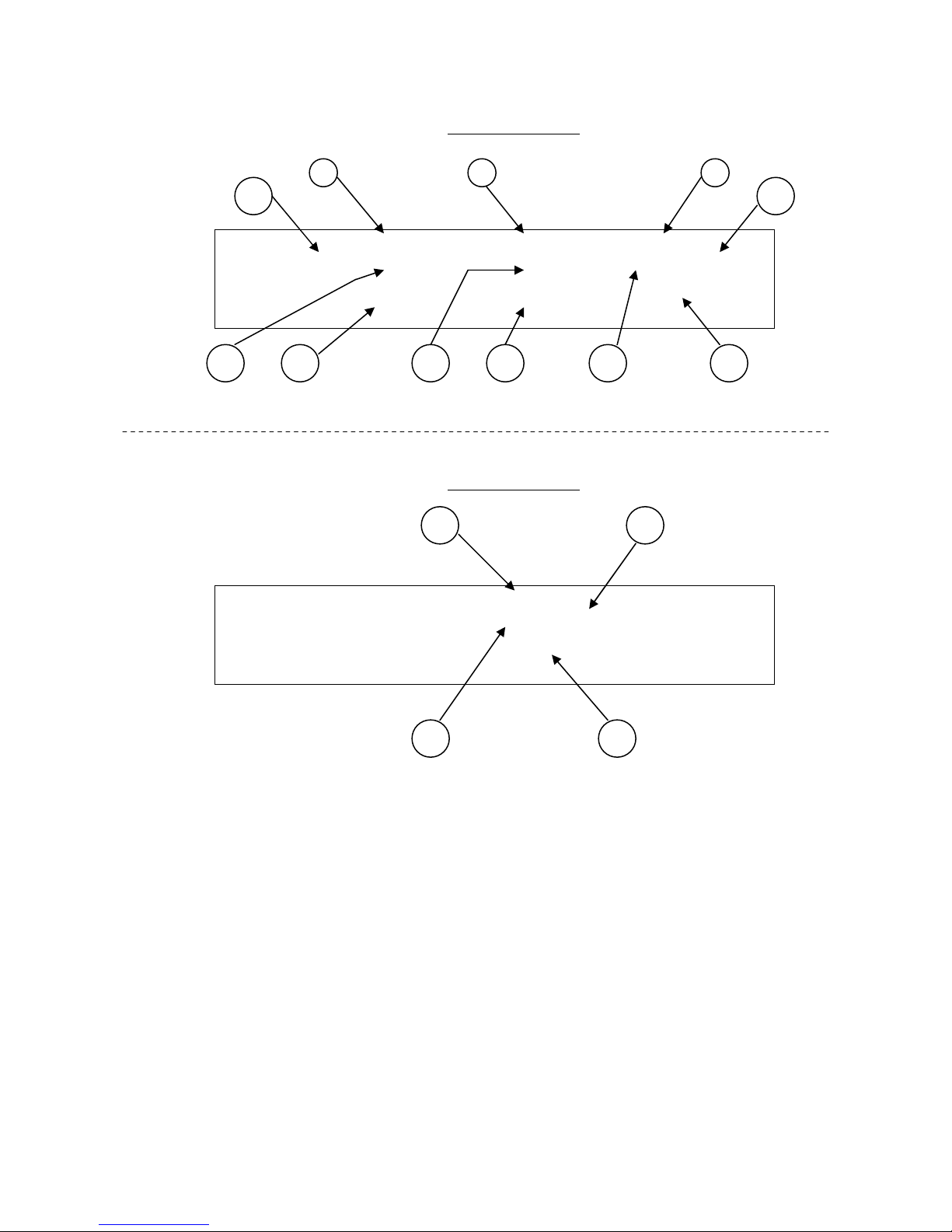

Figure 2.1 (A)

4

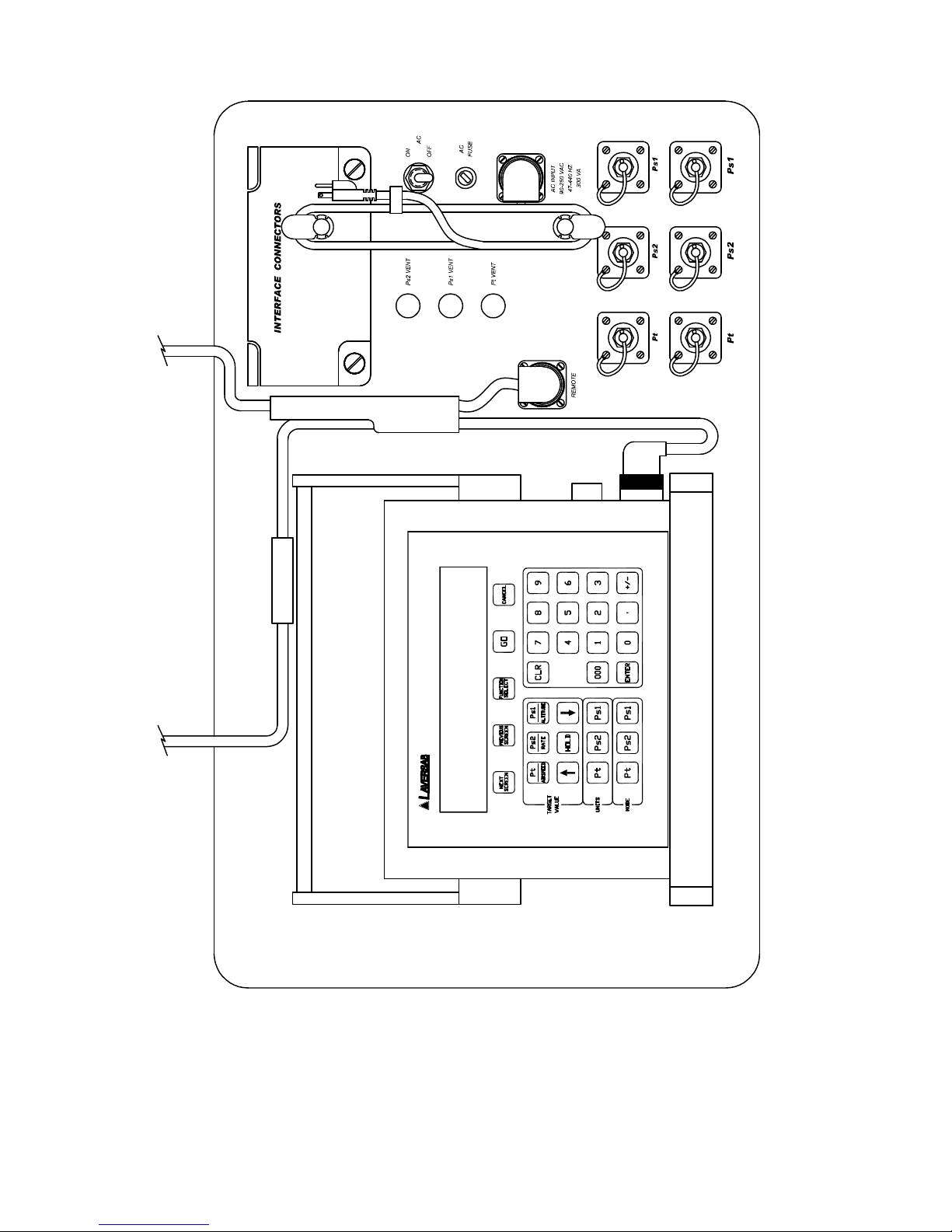

Figure 2.1 (b)

5

The remote cable is normally left connected to the 6600 at the “Remote” connector on the top

panel and is wrapped around four cord posts on the lid of the 6600 case. The cord retainers

on top of these posts swivel in either direction and latch at 180 degree positions, allowing easy

wrapping and unwrapping of the remote cable. A cord clamp allows the cable to be held in

place after it is wrapped. It is easier to wrap the remote cable around the posts after

disconnecting the cable from the Remote unit.

If the remote cable needs to be disconnected and removed from the 6600 completely for

storage elsewhere then opening the Interface Connectors cover allows the cable to be

dislodged from the cable guide.

[5] Primary Static ports (Ps1) :

The Primary Static output is provided on two ports that are internally connected. Both ports

have #4 AN fittings. At least one of these ports must be connected through a hose to the Static

port (Ps1 and P1 on smart-probe) on the aircraft. The hose must be connected after

performing the Self Test on the 6600. The hose, once connected, must not be disconnected

while the aircraft Static system is not at “Ground” level. An unused port must remain closed.

Caution: Do not connect this output to the aircraft before performing the Self Test.

Caution: Do not disconnect this output from the aircraft unless the aircraft’s Pitot Static

system is at “Ground” level and the tester is OFF.

[6] Secondary Static ports (Ps2) :

The Secondary Static output is provided on two ports that are internally connected. Both

ports have #4 AN fittings. These ports are typically used when the aircraft has “smartprobes” requiring a differential static input. These ports may also be used either as a

secondary static output or a secondary airspeed output. When using the tester with aircraft

with “smart-probes”, at least one of these ports must be connected through a hose to the P2

port of the smart-probe on the aircraft. The hose must be connected after performing the Self

Test on the 6600. The hose, once connected, must not be disconnected while the aircraft Static

system is not at “Ground” level. An unused port must remain closed.

WARNING: If the Ps2 output is not being used then it must be capped-off (closed).

Caution: Do not connect this output to the aircraft before performing the Self Test.

Caution: Do not disconnect this output from the aircraft unless the aircraft’s Pitot Static

system is at “Ground” level and the tester is OFF.

6

[7] Pitot ports (Pt) :

The Pt output is provided on two ports that are internally connected. Both ports have #4 AN

fittings. At least one of these ports must be connected through a hose to the Pitot port on the

aircraft. The hose must be connected after performing the Self Test on the 6600. The hose,

once connected, must not be disconnected while the aircraft Pitot system is not at “Ground”

level. An unused port must remain closed.

Caution: Do not connect this output to the aircraft before performing the Self Test.

Caution: Do not disconnect this output from the aircraft unless the aircraft’s Pitot Static

system is at “Ground” level and the tester is OFF.

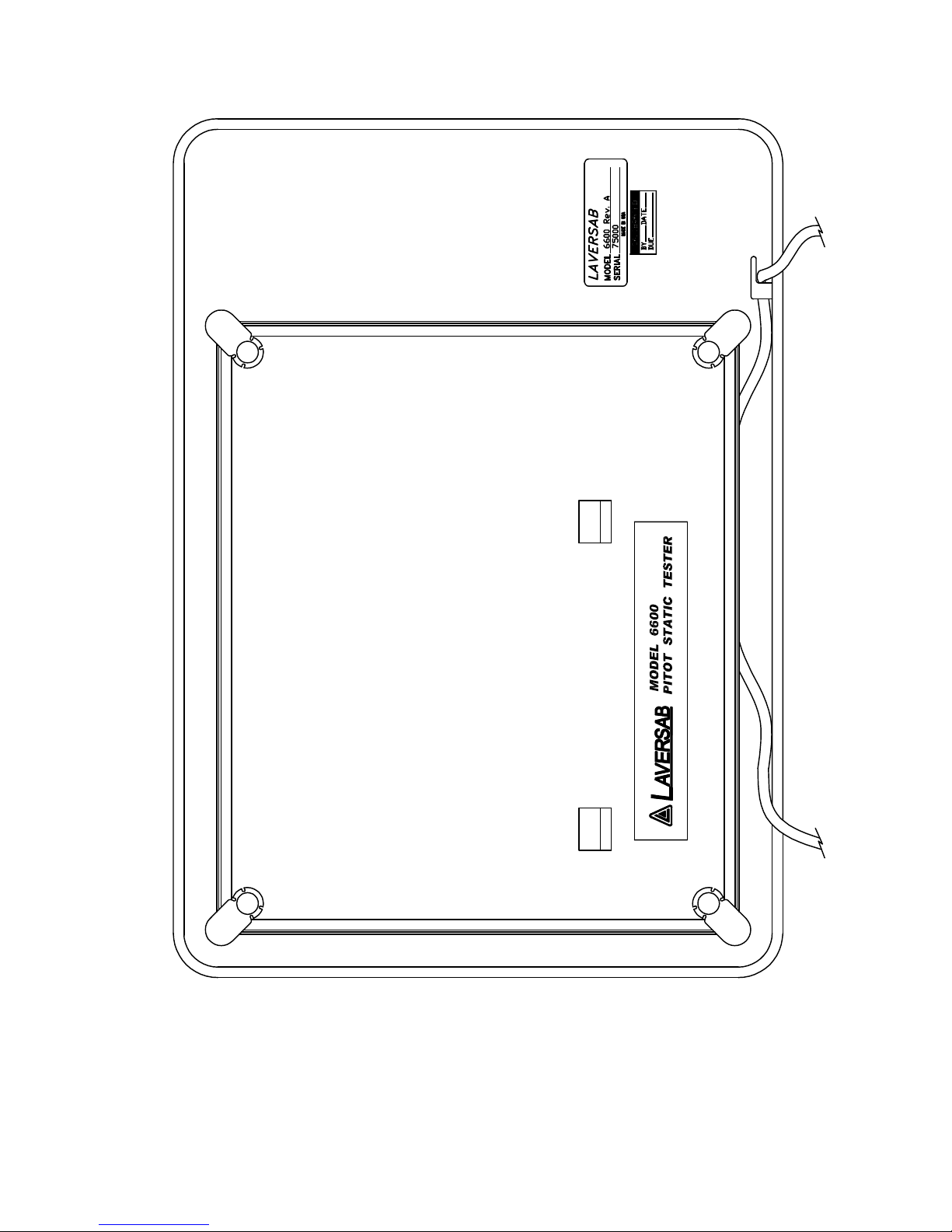

[8] RS232 interface connector:

This connector is accessed by opening the “Interface Connectors” access panel. The

connector is a standard DB-9 female connector used for a serial RS232 interface. It can be

connected directly to the “COM” port of a standard PC to allow communication. This port is

normally used for downloading “profiles” from a computer. Other remote communication

with the 6600 is also possible through this interface. Figure 2.2 shows the RS232 connector

with the panel removed. For more details on downloading profiles, please refer to Section 4.

For more details on communication with the 6600, please refer to Section 8.

[9] IEEE-488 interface connector:

This feature is currently not available on the 6600.

[10] Encoder interface connector:

This feature is currently not available on the 6600.

[11] Primary Static Vent (Ps1 Vent) :

In the event that the 6600 is in-operable due to a malfunction or due to loss of power, it is

possible to vent the Static system manually. This is done using the metering valve labeled

“Ps1 Vent”. This valve is a positive shut-off valve. Opening this valve slowly will vent the

Static output of the 6600 to ambient pressure. While venting, care must be taken to ensure

that the maximum climb rate of the aircraft connected to the tester is not exceeded.

The Secondary Static (Ps2) and Pitot (Pt) ports are referenced to the Primary Static (Ps1) port.

The “Ps2 Vent” and “Pt Vent” valves are used to cross-bleed to the Primary Static (Ps1) ports.

Therefore the manual vent valves must be opened in sequence. First open the “Ps2 Vent”

valve, then the “Pt Vent” valve and last, the “Ps1 Vent” valve.

7

Caution: Before opening the “Ps1 Vent” valve, both the “Ps2 Vent” and “Pt Vent”

valves must be completely open.

Caution: Do not over-tighten the valve as this may damage the seat of the valve.

[12] Secondary Static Vent (Ps2 Vent) :

In the event that the 6600 is in-operable due to a malfunction or due to loss of power, it is

possible to vent the Ps2 system manually. This is done using the metering valve labeled “Ps2

Vent”. This valve is a positive shut-off valve. Opening this valve slowly will cross-bleed the

Ps2 output to the Ps1 output of the 6600. While venting, care must be taken to ensure that the

maximum climb rate of the aircraft connected to the tester is not exceeded. Also, the “Pt

Vent” may need to be used to maintain the airspeed within limits of the indicator on the

aircraft.

The Secondary Static (Ps2) and Pitot (Pt) ports are referenced to the Primary Static (Ps1) port.

The “Ps2 Vent” and “Pt Vent” valves are used to cross-bleed to the Primary Static (Ps1) ports.

Therefore the manual vent valves must be opened in sequence. First open the “Ps2 Vent”

valve, then the “Pt Vent” valve and last, the “Ps1 Vent” valve.

Caution: Before opening the “Ps1 Vent” valve, both the “Ps2 Vent” and “Pt Vent”

valves must be completely open.

Caution: Do not over-tighten the valve as this may damage the seat of the valve.

[13] Pitot Vent (Pt Vent) :

In the event that the 6600 is in-operable due to a malfunction or due to loss of power, it is

possible to vent the Pitot system manually. This is done using the metering valve labeled “Pt

Vent”. This valve is a positive shut-off valve. Opening this valve slowly will cross-bleed the

Pt output to the Ps1 output of the 6600. While venting, care must be taken to maintain the

airspeed within limits of the indicator on the aircraft.

The Secondary Static (Ps2) and Pitot (Pt) ports are referenced to the Primary Static (Ps1) port.

The “Ps2 Vent” and “Pt Vent” valves are used to cross-bleed to the Primary Static (Ps1) ports.

Therefore the manual vent valves must be opened in sequence. First open the “Ps2 Vent”

valve, then the “Pt Vent” valve and last, the “Ps1 Vent” valve.

Caution: Before opening the “Ps1 Vent” valve, both the “Ps2 Vent” and “Pt Vent”

valves must be completely open.

Caution: Do not over-tighten the valve as this may damage the seat of the valve.

8

Figure 2.2

9

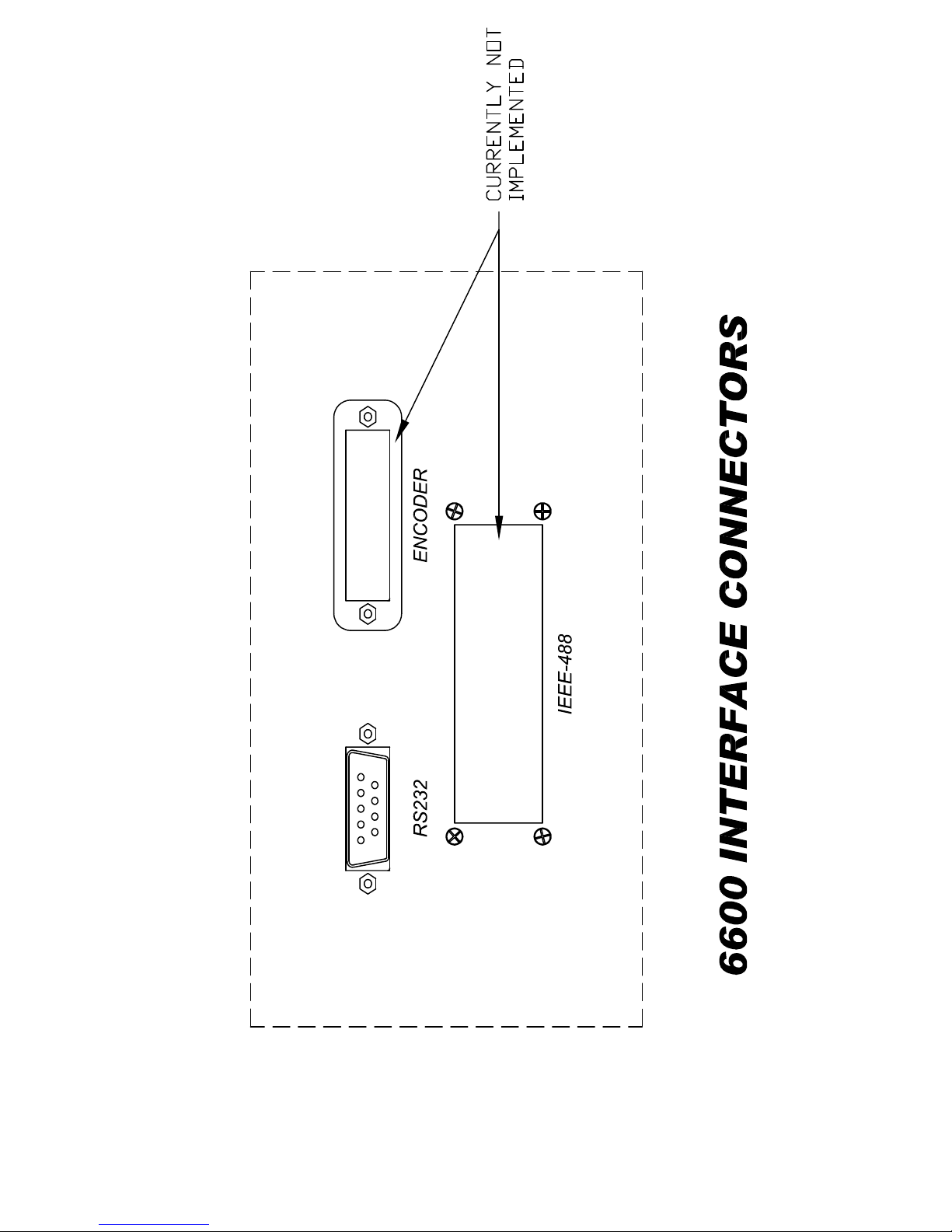

Figure 2.3

10

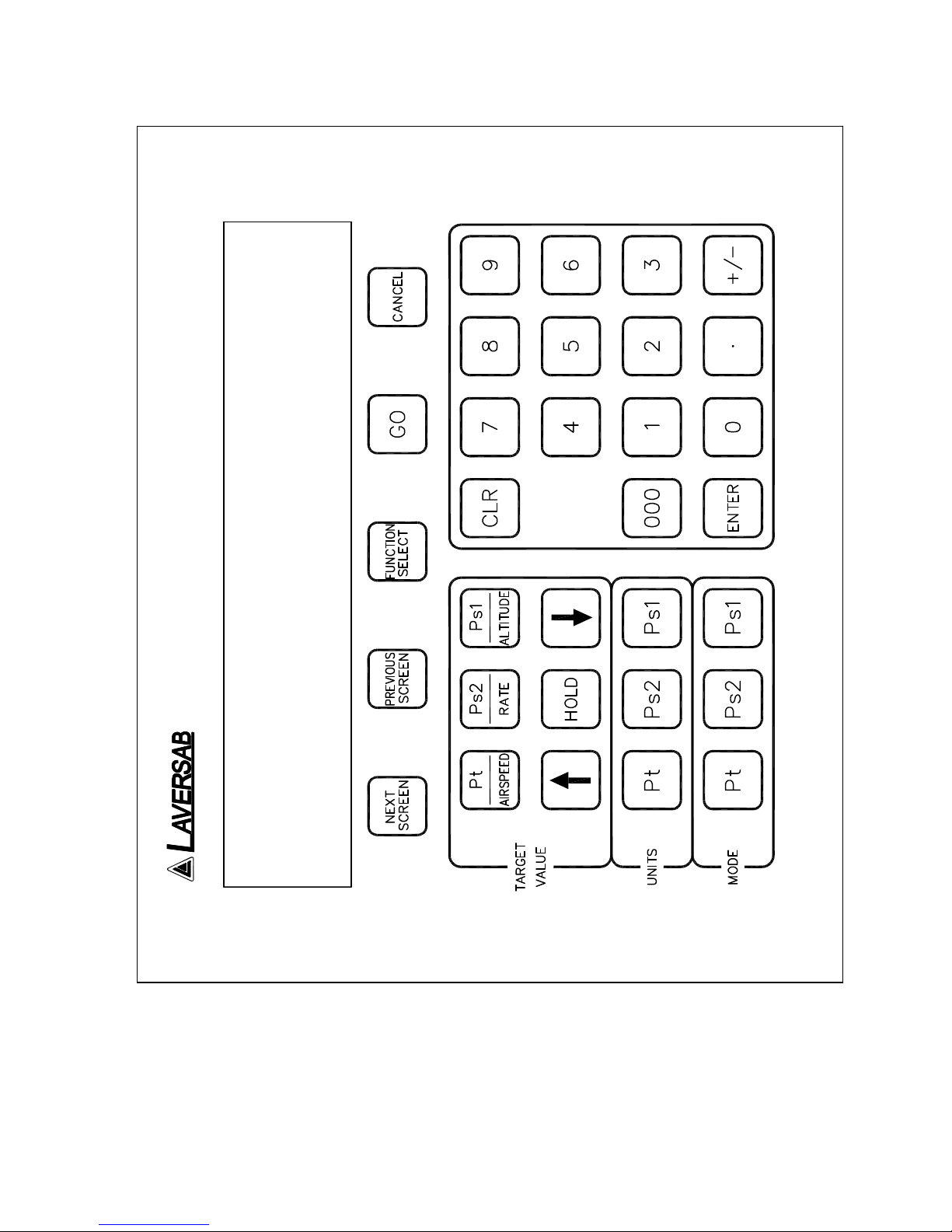

2.2 REMOTE UNIT TOP PANEL

Please refer to Figure 2.3 which shows the front panel of the Remote unit. The LCD display

has 4 lines of 40 characters each. There are five function keys just below the display. NEXT

SCREEN and PREVIOUS SCREEN are used to move between the different operating screens

of the 6600. At present there are only three upper level operating screens : Main, Calibrate

and Self test.

The PREVIOUS SCREEN key is also used to toggle the Main Screen between the 2-output

format and the 3-output format. Please refer to Section 3.2 for more details.

The FUNCTION SELECT key is used to go into a screen which allows the user to choose any

one of eight functions. The functions are:

1. View Limits

2. Set Limits

3. Set Knots rate

4. Execute profile

5. Setup profile

6. Height Correction

7. Set “Ground”

8. Go to “Ground”

These functions are described in detail in Section 3.

The GO key is used to execute all changes made through the Remote unit. After the changes

have been 'ENTER' ed, they will flash on the screen until executed by the GO key. This allows

for simultaneous execution of several changes in target values, modes, units etc.

The CANCEL key has multiple purposes. It is used to abort all changes that are flashing on

the screen. It is also used to exit out of target value entry, unit selection and mode selection.

It is used to exit out of other screens like Leak test and Function select. The CANCEL key is

also used to acknowledge error messages or exit an executing profile.

NUMERIC KEYS :

These keys are used for numeric entry of target values and other numeric data. The '+/-' key

operates just like on a calculator and is used to enter negative values. This key must be used

after entering the positive value, to make it negative.

The CLR key is used to clear the data entry field.

The ENTER key is used to accept numeric entries and also select units and modes.

11

The ‘000’ key is used to when numbers are needed to entered in thousands. For example, to

enter the number 5000, press ‘5’ and then press ‘000’.

TARGET VALUE KEYS :

There are typically 4 parameters that the 6600 controls - Airspeed (or Pt pressure), Altitude

(or Ps1 pressure), Climb (or Pt, Ps1, Ps2 rate) and Secondary Altitude (or Ps2 pressure). Each

parameter can be changed using a specific target-value key.

The Pt /AIRSPEED key is used to select Pt or Airspeed target value.

The Ps2/RATE key is used to select Ps2 target value if the Main screen being displayed is in

the 3-output format (section 3.2). If the Main screen being displayed is in the 2-output format

then this key is used to select the target value for Rate of change of Ps1, in Ps1 units per

minute (i.e. feet/min, meters/min, inHg/min or mbar/min).

The rate of change of Ps1 is also used as the rate of change of Ps2, and in units of inHg and

mbar, is also used as the rate of change of Pt. For more details please see “Effects of Rate

target value” in section 3.2.2.

The Ps1/ALTITUDE key is used to select Ps1 or Altitude target value.

After selecting the target value key, the new value can be entered using the numeric keypad.

The UP ARROW and DOWN ARROW keys are used to “Jog” a target value. For more

information, please refer to Section 3.2.2. The arrow keys are also used to move between

various choices during Unit selection and Mode selection.

The HOLD key is used to hold the current pressure on all three outputs. Pressing the HOLD

key again will allow pressure to continue to ramp towards the desired target.

UNITS SELECT KEYS :

Units can be selected independently for the Pt, Ps1 and Ps2 outputs.

The Pt UNITS key will bring up the choices in Pt units onto the 4th line of the display. To exit

from this selection mode, press CANCEL. To move between the choices use the arrow keys.

There are nine Pt units in all. The cursor location is indicated by the blinking unit mnemonic.

Once the cursor is on the desired units, press 'ENTER' to select that unit.

The Ps1 UNITS key brings up the choices for Ps1 units onto the 4th line of the display. Use

CANCEL to exit this unit selection mode. Use the arrow keys to move between the choices.

Use the ENTER key to select a choice. There are four Ps1 units to choose from.

12

The Ps2 UNITS key brings up the choices for Ps2 units onto the 4th line of the display. Use

CANCEL to exit this unit selection mode. Use the arrow keys to move between the choices.

Use the ENTER key to select a choice. There are eight Ps2 units to choose from.

For more information on Units Selection please refer to Section 3.2.3.

MODE SELECT KEYS :

These keys are used to select between one of three operating modes (Measure, Leak, Control).

Modes can be selected independently for the Ps1, Ps2 and Pt outputs. Pressing the Pt Mode,

Ps1 Mode or Ps2 Mode keys brings up the selection of modes for the corresponding output

onto the 4th line of the display. The desired selection can be chosen by moving the cursor

using the arrow keys and then pressing ENTER. The GO key will execute the entered

selection.

For more information on Mode Selection please refer to Section 3.2.4.

13

SECTION 3

UNDERSTANDING THE 6600

Note: Pt = Pitot , Ps1 = Primary Static and Ps2 = Secondary Static

The 6600 is typically used to calibrate and check air data instruments like altimeters, climb

indicators, and airspeed/ Mach indicators on an aircraft. It is also used to leak-check the

Pitot/ Static system of an aircraft. This section will explain how to use the 6600 to perform

these functions.

3.1 START UP

Step 1: Check the ON/OFF switch on the Remote unit and make sure it is OFF.

Step 2: Remove the protective caps from one each of the Pt, Ps1 and Ps2 outputs on the

main unit. DO NOT connect any hoses to the aircraft yet. Make certain that the

outputs are open to ambient. Close the Pt, Ps1 and Ps2 Vent valves.

Step 3: Connect the power cable from the “AC INPUT” connector on the main unit to a

suitable AC supply.

Step 4: On the Main unit, turn the AC On/Off switch ON. On the Remote unit, turn

the ON/OFF switch ON.

The 6600 will turn ON and the Remote unit will turn ON. The display will briefly show the

sign-on screen and then go into the Main screen. The Main screen should appear as follows:

Units: knots Feet/min Feet

Actual: M 101.2 3500 1005 M

Target: 20.0 3000 0

The Actual values shown on line 2 will be different from the ones shown. The 4th line should

be blank.

Before actually using the 6600 to perform certain tasks, it is important to understand how to

use the Remote unit to make the 6600 do what you want. This section explains everything

about the information that you see on the Remote unit and what it means, and

14

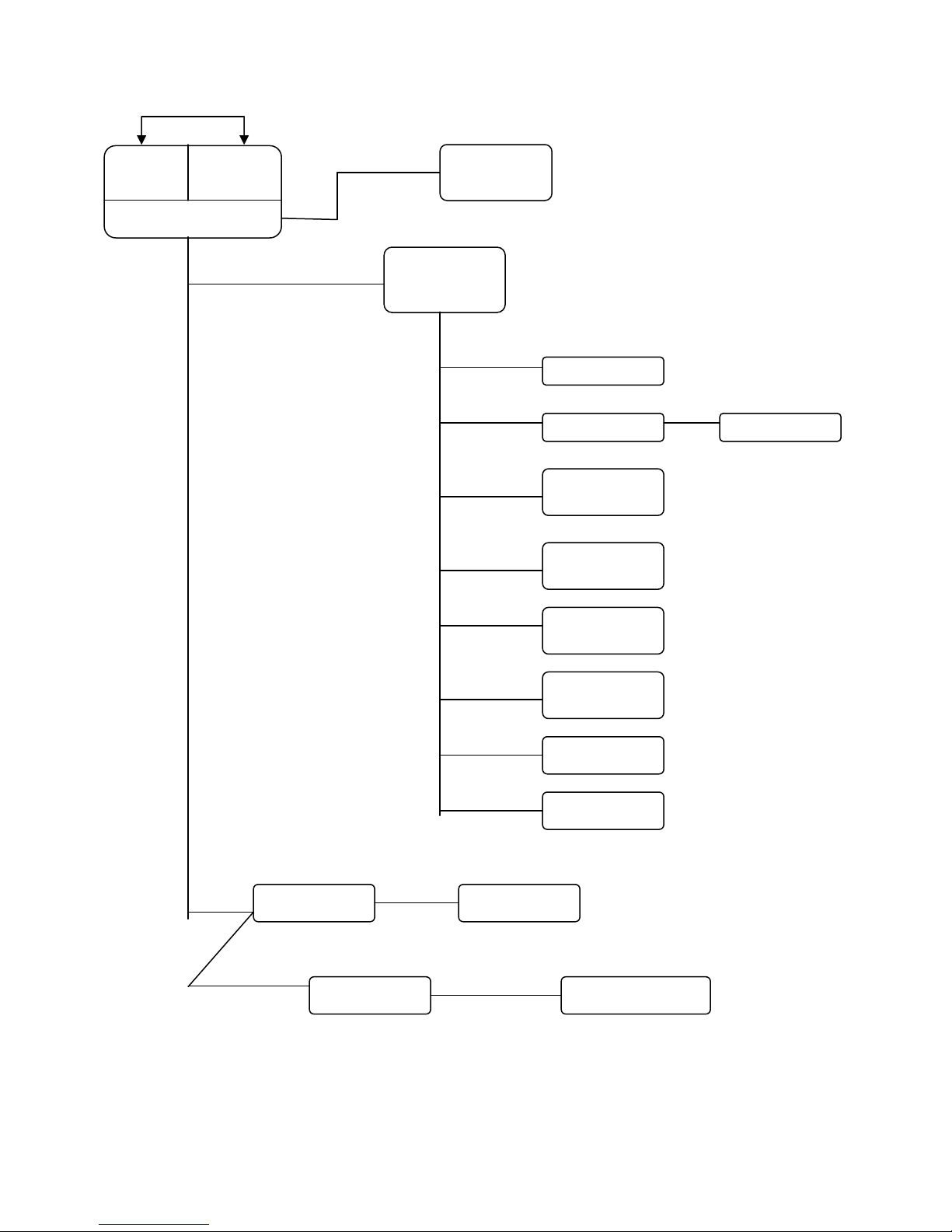

Prev Screen

2-output 3-output Leak mode Leak

format format Screen

Main Screen

Function

Select Function Select

Screens (2)

1

View Limits

2

Password Change Limits

3 Change

knots rate

4 Execute profile

(Return to Main)

5

Setup Profile

6

Height Correction

7

Set Ground

8

Go to Ground

Next

Screen Password Calibration

Next

Screen

Self Test Self Test Progress

Figure 3.1

15

how to change all the parameters that are shown on the display. As we proceed through

the explanations, it will become clearer as to how the 6600 actually operates.

Interaction with the 6600 is done through several different screens that are displayed on the

Remote unit. All the screens are shown in Figure 3.1. Of the screens shown in Figure 3.1, the

Self Test screen is used only at startup, all the Function Select screens are used only a few

times during normal operation and also when first setting up the 6600. The Calibrate screen is

used only once a year by the calibration facility. During normal operation, the two screens

that are used the most are the Main Operating screen (Main Screen), in either 2-output format

or 3-output format, and the Leak Screen. All the different screens, except the calibration

screen, are explained in this section. The Calibration screen is explained in section 6.

3.2 MAIN OPERATING SCREEN

Most of the operation of the 6600 is done in the Main Screen. All the pertinent parameters are

displayed on this screen. The screen is also used to change Target values, Units, and Modes.

The Main Screen can be toggled between the 2-ouput format and 3-output format using the

PREV SCREEN key.

Main Screen: 2-output format

In the 2-output format, information pertaining only to Pt and Ps1 is displayed. Although all

three outputs of the 6600 are always active, if only the Pt and Ps1 outputs are connected to the

aircraft then the Main Screen should be in the 2-output format. The 2-output format appears

as shown below.

Main Screen: 2-output format

Units: knots Feet/min Feet

Actual: M 5.2 0 1005 M

Target: 20.0 3000 0

Pt Ps1 Rate of change Ps1

As shown above in the sample 2-ouput format, information is divided into three vertical

sections. The left section shows information for the Pt output, the right section shows

information for the Ps1 output and the middle section shows information for the rate of

change of the Ps1 output. There is no information for the Ps2 output.

16

The best indication that the screen is in the 2-output format is that the middle vertical section

of the display will have Rate units that indicate “per minute”. In the sample display shown

above, the Rate units are “Feet/min”.

Main Screen: 3-output format

If all three outputs (Pt, Ps1 and Ps2) are connected to the aircraft then the Main Screen should

be in the 3-output format. The 3-output format appears as shown below.

Main Screen: 3-output format

Units: knots Feet Feet

Actual: M 5.2 1006 M 1005 M

Target: 20.0 0 0

Pt Ps2 Ps1

As shown above in the sample 3-ouput format, information is divided into three vertical

sections. The left section shows information for the Pt output, the right section shows

information for the Ps1 output and the middle section shows information for the Ps2 output.

Notice that in 3-output format there is no information for the rate of change of the Ps1 output.

To see (or change) information on the rate of change of Ps1, the screen needs to be changed to

the 2-output format. This is done by pressing the PREV SCREEN key. The PREV SCREEN

key toggles the Main Screen between the 2-output format and the 3-output format.

As an example, if all three outputs are connected to the aircraft, the preferred format would be

the 3-output format. Now, to view or change the Ps1 rate, your would toggle to the 2-output

format using the PREV SCREEN key, view or change the Ps1 rate in the 2-output format, then

toggle back to the 3-output format using the PREV SCREEN key again.

The best indication that the screen is in the 3-output format is that the middle vertical section

of the display will NOT have Rate units indicating “per minute”; i.e. the units displayed in the

middle section will not indicate “/min”. Another indication is that in the middle vertical

section the Mode for Ps2 will be displayed to the right of the Actual value. In the sample

display above, the Ps2 Mode is indicated as “M”.

The following sub-sections explain the various uses of the Main Screen.

17

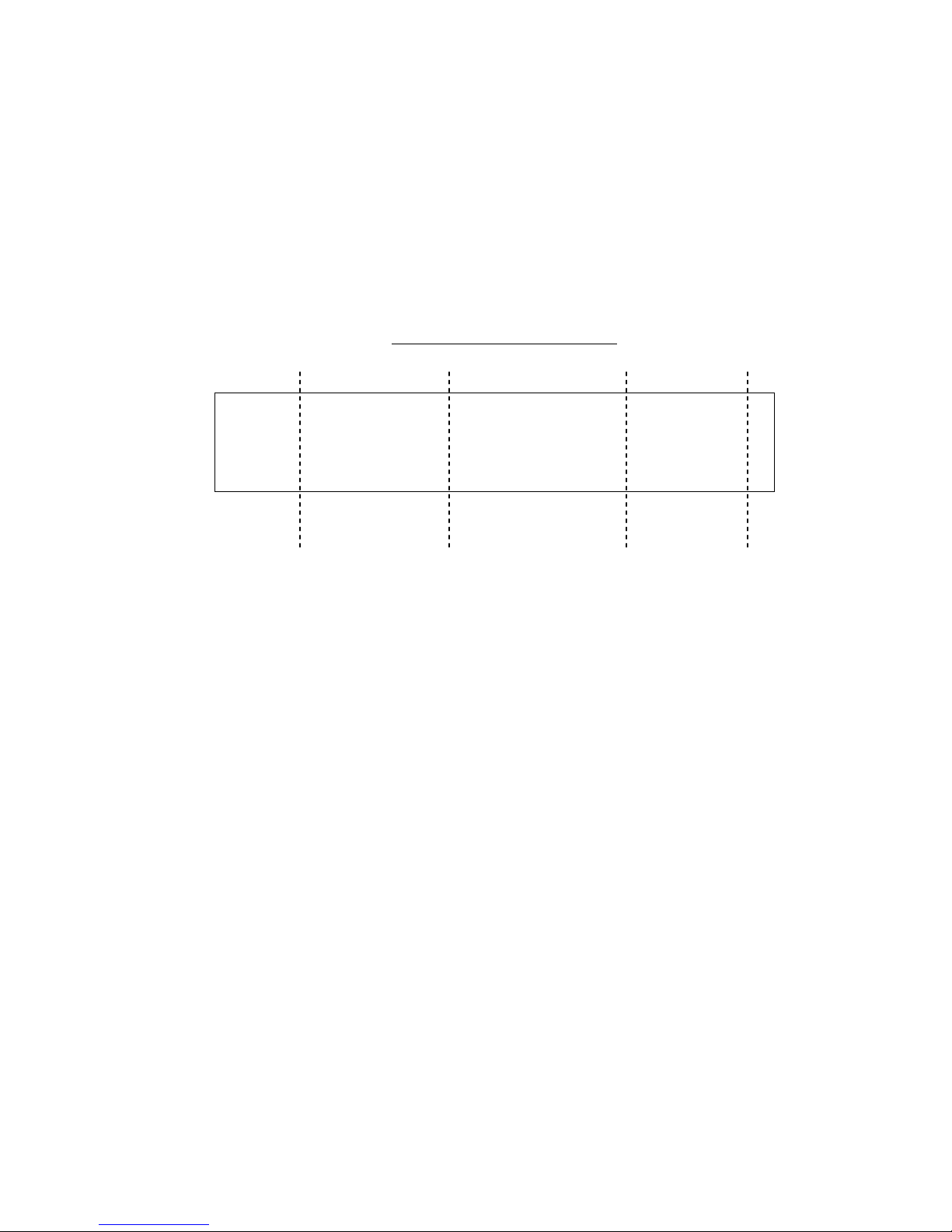

2-output format

1 4 2

13 14

Units: knots Feet/min Feet

Actual: M 5.2 0 1005 M

Target: 20.0 3000 0

5 9 8 12 6 10

3-output format

3 15

Units: knots Feet Feet

Actual: M 5.2 1006 M 1005 M

Target: 20.0 0 0

7 11

1. Pt units

2. Ps1 units

3. Ps2 units (3-output format only)

4. Ps1 Rate units (2-output format only)

5. Pt Actual value

6. Ps1 Actual value

7. Ps2 Actual value (3-output format only)

8. Ps1 Rate Actual value (2-output format only)

9. Pt Target value

10. Ps1 Target value

11. Ps2 Target value (3-output format only)

12. Rate Target value (2-output format only)

13. Pt mode

14. Ps1 mode

15. Ps2 mode (3-output format only)

Figure 3.2

Loading...

Loading...