Laurel Metal 300 User Manual

Vend

Price

50¢

75¢

$1.00

$1.25

$1.50

$1.75

$2.00

$2.25

$2.50

$2.75

$3.00

#8 Stop Screw

Location

50¢ Hole

75¢ Hole

Not Used

$1.25 Hole

$1.50 Hole

$1.75 Hole

Not Used

$2.25 Hole

$2.50 Hole

$2.75 Hole

Not Used

#1

Coin-Diverter

Closed

Closed

Closed

Open

Open

Open

Open

Open

Open

Open

Open

#2

Coin-Diverter

Open

Open

Open

Closed

Closed

Closed

Closed

Open

Open

Open

Open

Diverter

Lockout

Up

Up

Up

Down

Down

Down

Down

Rotate 180°

Rotate 180°

Rotate 180°

Rotate 180°

Coin Mechanism Instructions

1. To change vend price, remove the Coin

Mechanism’s three mounting screws and pull it forward slightly to disengage its rear flange from the

locating slot at the rear of the Cabinet. Now, move

the Coin Mech to the left to disengage the Actuating

Pin from the slot in the Actuating Arm on the side of

the Magazine.

2. To set the vend price at even dollar amounts ($1.00,

$2.00 or $3.00), the #8 Stop Screw is not required only the Diverter Lockout is used on the Coin

Diverters. Put the Diverter Lockout “Up” to close

Diverter #1 for a $1.00 vend setting. Put the Diverter

Lockout “Down” to close Diverter #2 for a $2.00

vend setting. Remove the Diverter Lockout and

rotate it 180° so it leaves both Diverters “Open” for

a $3.00 setting.

3. To set the vend price at 50¢, 75¢, $1.25, etc. use the

#8 Stop-Screw in the appropriately marked stop

hole. Then, either Diverter #1 or #2 will be “closed”

with the Diverter Lockout. For example: to set at

$1.75, put the #8 stop screw in the $1.75 hole and

“close” Diverter #2 by moving the Diverter Lockout

“Down”. Example #2: To set at 50¢, put the #8 Stop

Screw in the 50¢ hole and “close” Diverter #1 by

moving the Diverter Lockout “Up”.

For vending above $2.00, remove the Nylock nut and

rotate the Diverter Lockout 180° and secure it to the

Coin Platform with the Nylock nut so it leaves both

Diverters in the “Open” position.

If you need to drop the shelves without going through

the effort of inserting quarters, simply push the Latch

Wire (under each shelf) with your fingernail or any flat

tool, such as a screwdriver.

Customer Service

Should you need repair, parts may be sent to:

Laurel Metal Products

3500 W. Touhy Ave.

Lincolnwood, IL 60712

Please include phone number and return address.

Limited Warranty

Laurel Metal Products warrants that the goods

described in this warranty are free from defects in

workmanship and materials for the period of six (6)

months.

For breach of the express warranty and any implied

warranty on this product, you are limited to the following damages:

If within six (6) months from the date of purchase,

this product fails due to a defect in materials or

workmanship, Laurel Metal will repair or replace it

free of charge. In no event shall Laurel Metal be

liable for incidental or consequential damages.

Laurel Metals’ liability for any claims arising out of

this warranty shall not exceed the purchase price of

the product.

NOTE: some states do not allow the exclusion or

limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to

you.

This warranty does not cover damage resulting from

accident or from misuse or alteration of the product.

The term of this warranty begins on the date the product is purchased by you, and continues for a period of

six (6) months from that date.

To obtain performance of any obligation under this

warranty, you must return the complete product

prepaid, together with a description of the problem,

approximate date of purchase, your name, address

and telephone number, to the address listed above.

This warranty gives you specific legal rights, and you

may also have other rights that vary from state to state.

This warranty covers any mechanical vender manufactured by Laurel Metal Products.

3500 W. Touhy Ave.

Lincolnwood, IL 60712

Toll Free (888) 528-7358

(847) 674-0064

Fax # (847) 674-0094

www.laurelmetal.com

11/05

MODEL 300

Drop Shelf Vender

Operation & Service

Manual

The vender can be mounted on any vertical surface

without removing any part of the unit. Any standard fastener not larger than 3/8" diameter such as wood screws,

expansion bolts, machine bolts or carriage bolts can be

used depending on the type of wall. The wall section

selected for installation should be sturdy.

The top two fasteners should be loosely installed in the

wall with the heads of the fasteners projecting out

approximately 1/4" from the wall. Raise the top shelf of

the magazine into its vend position to expose one of the

two top mounting holes in the back of the cabinet. The

keyhole shape of the mounting holes will permit you to

hang the cabinet on the two fasteners. While in this

unsecured position, mark the bottom mounting holes on

the wall and remove the cabinet. Install the bottom two

fasteners and secure the cabinet to the wall using washers under the heads of all fasteners.

Loading

The shelves can be easily and quickly reset into the

vend position (horizontal) by running the index finger of

your right hand up the right side of the shelves. This

“fanning” will take only seconds to reset all 24 shelves.

The top shelf has an automatic empty device that will

cause the coin mechanism to reject all coins when the

vender is empty. Therefore, it is extremely important to

load from the top shelf down if the vender will not be

fully loaded during restocking.

Coin Mechanism Features

The vender will be factory set to vend at $1.00

(or $2.00 for the bottle vender) unless otherwise

requested.

The Coin Mechanism incorporates a new “Speed Lock”

device to deter people from rapidly vending the

machine, allowing enough time for all the quarters to

drop into the Coin Box. If it is vended too fast, the

Speed Lock will activate and stop the Pull Rod.

However, it will be in ratchet so there is no chance of

losing the vend - all you have to do is let off slightly and

then continue pulling, allowing the product to drop.

Also, there is a new Coin Throwout that will return any

quarters inserted if the Pull Rod is forward of its rest

position. This will stop people who pull the handle out

to the lock position and then inset quarters, trying to

cheat the vender. This Coin Throwout also is used to

return all quarters inserted when the last shelf drops

and the vender is empty.

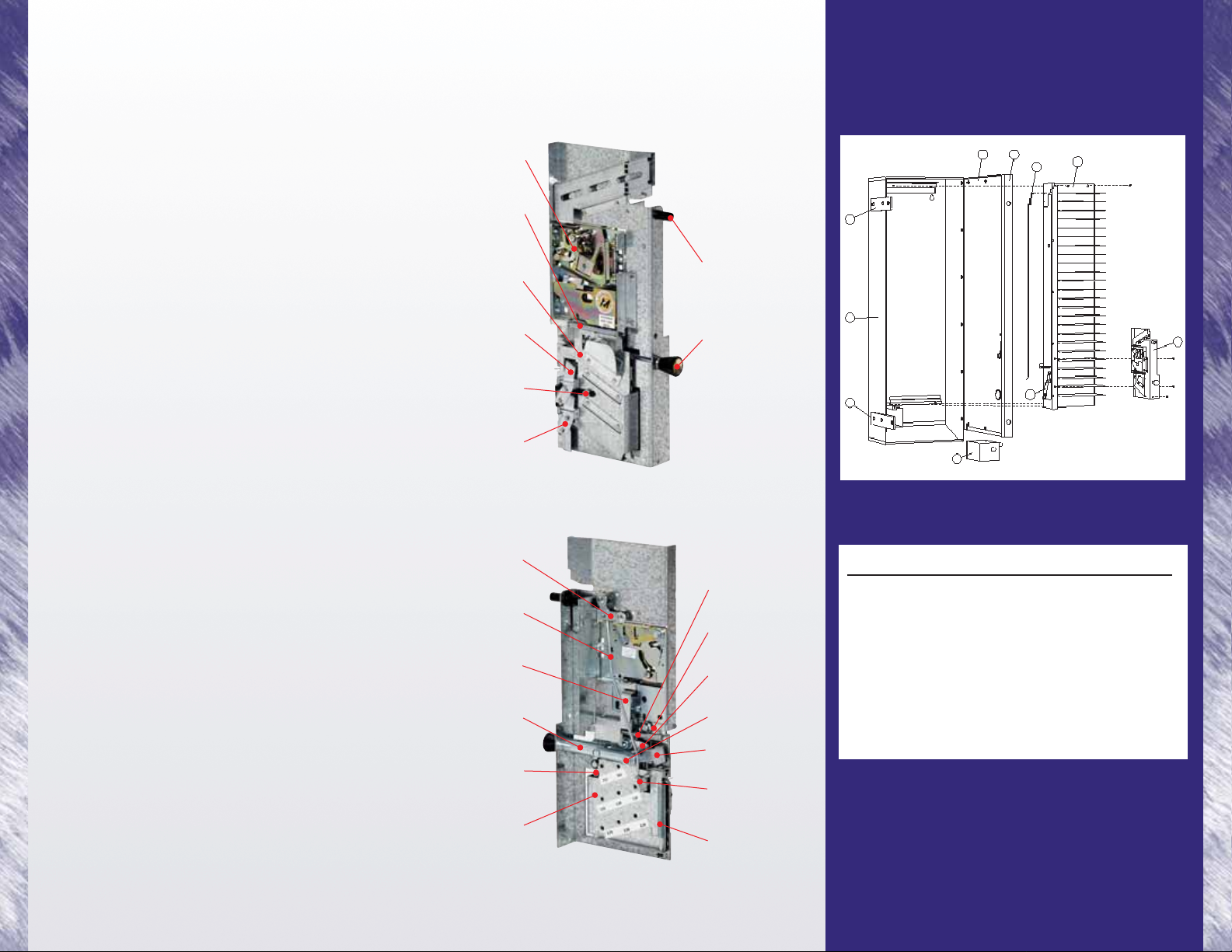

Model 300 Coin Mechanism

Part #300-D15

Coin Acceptor

2100-29

Spring-Coin

Platform

2100-111

Coin Return Rod

Coin Platform

300-A46

Coin-Diverter

300-A54

Diverter Lockout

300-57

Coin Diverter

300-A54

Front View of Coin Mechanism

Scavenger Lever

2100-A114

Link

300-29

Coin Throwout

300-44

Pull Rod

2100-A31

Ratchet Pawl

2100-23

Coin Gate

300-40

Rear View of Coin Mechanism

2100-119

Knob

2100-32

Spring-Ratchet

2100-124

Spring-Lock Lever

300-56

Speed Lock

300-39

Actuating Pin

2100-33

Lock Lever

300-32

Cam

300-24

Spring-Coin

Platform

2100-111

Model 300 Exploded ViewInstallation

8

7

9

4

9

6

1

Number Part # Description

1 2100-12 Actuating Arm

2 300-D1 Magazine Assembly

3 300-D15 Coin Mechanism

4 2100-A45 Cabinet

5 300-14 Empty Lock Rod

6 300-A69 Coin Box w/Lock

7 300-B70 Door w/Hinge

8 2100-63 Security Frame

9 2100-64 Side Bar

2

5

3

Loading...

Loading...