Page 1

1

Rear case screws - please note

The rear panel is held in place with finger-screws, which

only need to be gently tightened.

Do not use tools to tighten or loosen the screws, as

this could cause damage to the internal threads.

!

Caution: Risk of electrical shock if this instrument is not properly installed.

Caution: Read the whole manual before you install this display.

LAUREL Electronics, Inc.

3183-G Airway Ave, Costa Mesa, CA 92626, USA

Tel +1 714-434-6131 Fax +1 714-434-3766

www.laurels.com sales@laurels.com

8.8.8.8.

OK

dg

8.8.8.8.8.8.

OK

dg

Large digit serial input indicator / controller

MAGNA 4 or 6-Digit RS232/RS485

Installation & Operating Manual

Page 2

2

.

Warranty

We warrant our products against defects in materials or workmanship for a period of one

year from the date of purchase.

In the event of a defect during the warranty period, the unit should be returned, freight (and

all duties and taxes) prepaid by the Buyer to the authorised distributor from where the unit

was purchased.

The Distributor, at its option, will repair or replace the defective unit. The unit

will be returned to the Buyer with freight charges prepaid by the distributor.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from:

1. Improper or inadequate maintenance by the buyer.

2. Unauthorised modification or misuse.

3. Operation outside the environmental specification of the product.

4. Mishandling or abuse.

The warranty set forth above is exclusive and no other warranty, whether written or oral is

expressed or implied. We specifically disclaim the implied warranties of merchantability

and fitness for a particular purpose.

EXCLUSIVE REMEDIES

The remedies provided herein are the buyer’s sole and exclusive remedies.

In no event shall we be liable for direct, indirect, incidental or consequential damages

(including loss of profits) whether based on contract, tort or any other legal theory.

Page 3

3

Warranty 2

Warnings 4

Introduction 5

General Description 6

Suspension Mounting 7

Wall Mounting 8

Panel Mounting 9

Connections 10-11

Installation hints for best performance 12-13

Declaration of Conformity 14

Language Selection 15

Display Brightness 16

Display Modes 17

Serial Data settings 18-19

Logic Input functions 20

Logic Input connections & Front Buttons 21

Factory defaults 22

Calibration Audit number 22

Scale Factor adjustment 23

Offset Adjustment 24

Menu Timeout adjustment 25

Reverse / Mirror display setting 26

Bootup Routine choices 27

Multi Memory MEM option 28

Error Codes and fault finding 29

Output Options - installing 30

WEEE 31

Equipment Specifications 32

Record of Revisions 33

ASCII Hex codes and displayed characters 34

Signal Levels 35

Special data commands 35

Separate manuals for options

Alarm option settings See Alarm manual *

Analog output option settings See Analog manual *

Serial output option settings See Serial manual *

Real Time Clock setting See Serial manual *

* Need a manual urgently? You can download manuals from our website.

Contents

Page 4

4

Warnings

Please carefully read this manual and all warnings. Install the display ONLY when you are sure

that you’ve covered all aspects.

Where the product is intended for “UL” installations, removal or addition of option

boards is not permitted.

Check that the model number and supply voltage suit your application before

you install the display.

Connect the display according to current IEE regulations, IEC61010 &

NFPA:70 National Electric Code in USA.

Power supplies to this equipment must have anti-surge (T) fuses rated at 1A for

230V supply, 2A for 110V supply, 5A for 48VAC supply or 10A for 11-30VDC.

Don’t touch any circuitry after you have connected the display, because there may

be lethal voltages on the circuit board.

Do not apply power to the display if its case is open.

Only adjust on-board switches or connections with the power turned off

Make sure all screw terminals are tight before you switch the meter on.

Only clean the display’s case and window with a soft damp cloth. Only lightly dampen

with water. Do not use any other solvents.

!

!

!

!

!

Rear case screws - please note

The rear panel is held in place with finger-screws, which

only need to be gently tightened.

Do not use tools to tighten or loosen the screws, as

this could cause damage to the internal threads.

Page 5

5

Introduction

Please contact us if you need help, if you have a complaint, or if you have suggestions to help

us improve our products or services.

If you contact us about a product you already have, please tell us the full model number and

serial number, so that we can give you accurate and fast help.

This product has a 1-year warranty. We will put right or replace any display which is faulty

because of bad workmanship or materials. This warranty does not cover damage caused by

misuse or accident.

If you return a unit for repair, please include a detailed description of the problem, and the

name of a contact who we can refer to for any questions. Please mark for the attention of the

QA Department.

IMPORTANT

If this equipment is important to your process, you may want to buy a spare to cover possible

failure or accidental damage in the future.

This is because during factory shutdown periods, you may have to to wait several weeks for

an equivalent replacement, or we may have no stock at the time you urgently need it.

You may also need to pay extra carriage charges if you want a fast, guaranteed courier service.

Warranty repairs or replacements are usually returned with a standard courier service.

We do not offer compensation for losses caused by failure of this instrument.

If you do not agree with these conditions, please return this item in unused condition, in its

original packaging and we will refund the purchase price, excluding any carriage paid.

We thought you’d prefer to know about possible delays and extra charges now, rather than

during a panic. A spare unit could help to avoid these issues.

We always try to improve our products and services, so these may change over time. You

should keep this manual safely, because future manuals, for new designs, may not describe

this product accurately.

We believe these instructions are accurate, and that we have competently designed and

manufactured the product, but please let us know if you find any errors.

Page 6

6

General Description

This series of displays accepts industrial sensors to allow various physical measurements to

be made, such a weight, temperature, pressure, humidity etc. Different models are available

for different sensor types.

The main function of this series is to give a clear numeric readout of the variable being

monitored. Most models include an excitation power output, to power the sensor directly.

Various digit heights are available, to suit the maximum viewing distance required in each

installation. For every 10 metres of viewing distance required, use 1” of digit height.

Various optional output modules are also available to give alarm relay outputs, analogue

output or digital communications, or any combination of these options.

Displays are programmed using front panel pushbuttons. The front panel buttons can be

disabled. In addition, you can connect 4 remote wired pushbuttons to the display, so that you

can make adjustments while the display is mounted in an inaccessible location.

Power supply options : 100-240 VAC, 48 VAC or 11-30VDC or 48V AC

These displays must be installed fully assembled, and must be installed according to local

electrical installation rules.

When properly installed, and provided they have been ordered with cable glands exiting the

lower surface of the case, they provide ingress protection to IP65 / NEMA4X from all directions.

Safety

Obey all safety warnings in this manual, and install the display according to local wiring and

installation regulations. Failure to follow these guidelines may cause damage to the display,

connected equipment, or may be harmful to personnel.

Any moving mechanical device controlled by this equipment must have suitable access guards

to prevent injury to personnel if the display should fail.

!

Caution: There is a risk of electrical

shock if this display is not properly installed

Caution: Risk of danger: Read the whole

manual before you install this display

Page 7

7

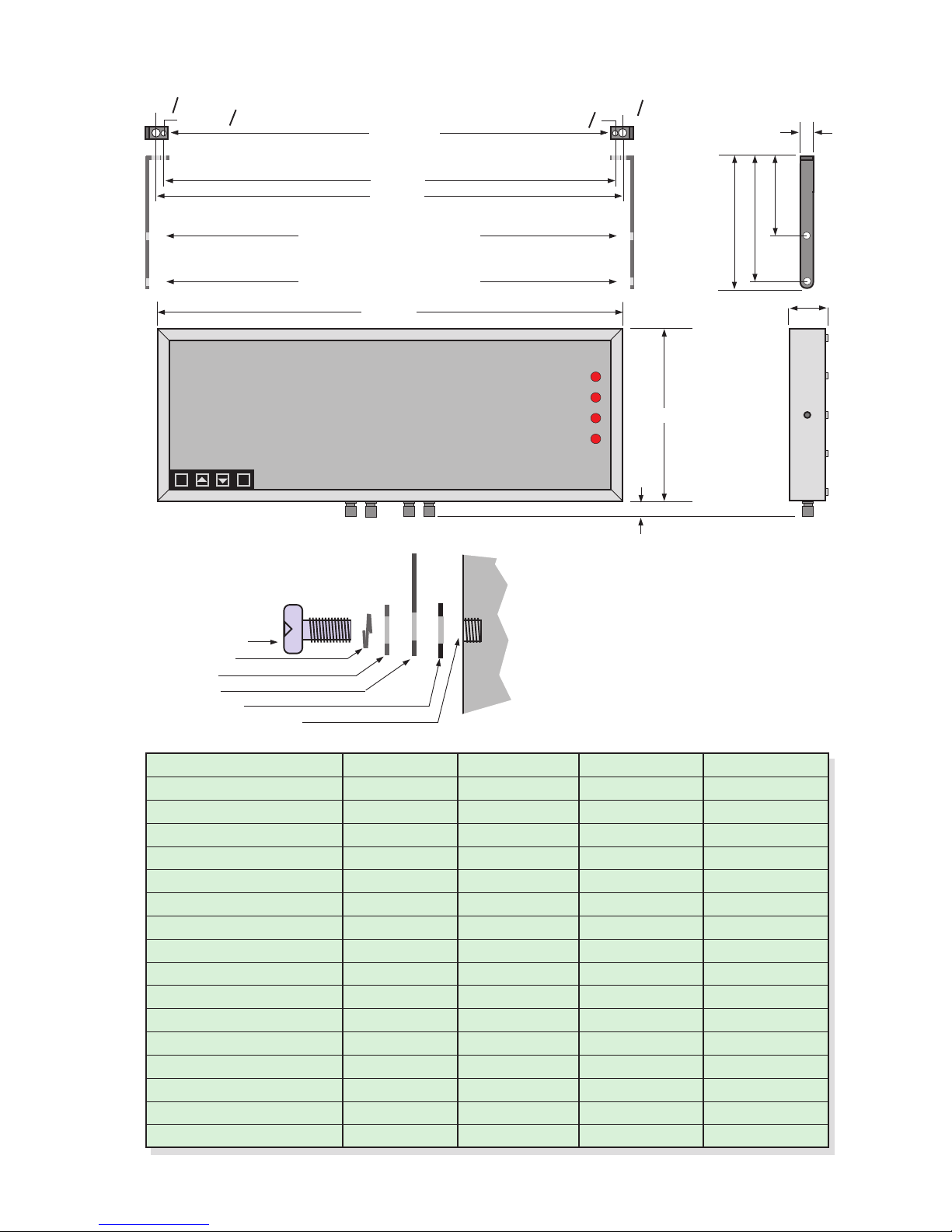

Suspension Mounting Dimensions

Display Format X mm H mm W mm Y mm

2” 4 digit clock 231 154.5 291 247

2” 4 digit numeric 219.5 154.5 279.5 249.5

2” 6 digit clock 340 154.5 400 370

2” 6 digit numeric 316 154.5 376 346

4” 4 digit clock 393 195.5 453 423

4” 4 digit numeric 374 195.5 434 404

4” 6 digit clock 593 195.5 653 623

4” 6 digit numeric 556 195.5 616 586

6” 4 digit 520 246 580 550

6” 6 digit 760 246 820 790

8” 4 digit 690 290 750 720

8” 6 digit 1012 290 1072 1042

12” 4 digit 990 408 1050 1020

12” 6 digit 1480 408 1540 1510

16” 4 digit 1308 515 1368 1338

16” 6 digit 1960 515 2020 1990

77 mm

H mm

X mm

Plan View

Short-drop mounting holes

Long-drop mounting holes

Y mm

15mmO

6.35mmO

15mmO

6.35mmO

25mm

157.5mm

207.5mm

220mm

8.8.8.8.8.8.

OK

dg

W mm

Cable Glands. Number of glands

depends on installed options.

H mm

25mm

You can order these displays with the cable

glands in the bottom surface (as shown) the

rear, or top.

Rear glands allow you to mount the display on

top of a cubicle, using the brackets shown.

M8X12 S.S. bolt

Spring washer

Flat washer

Bracket

Rubber washer

Display boss M8 female

*

Case

Detail showing bracket

hardware fitting sequence

* Do not use longer bolt threads than

12mm , or you will fracture the female boss

and the case will no longer be sealed.

Page 8

8

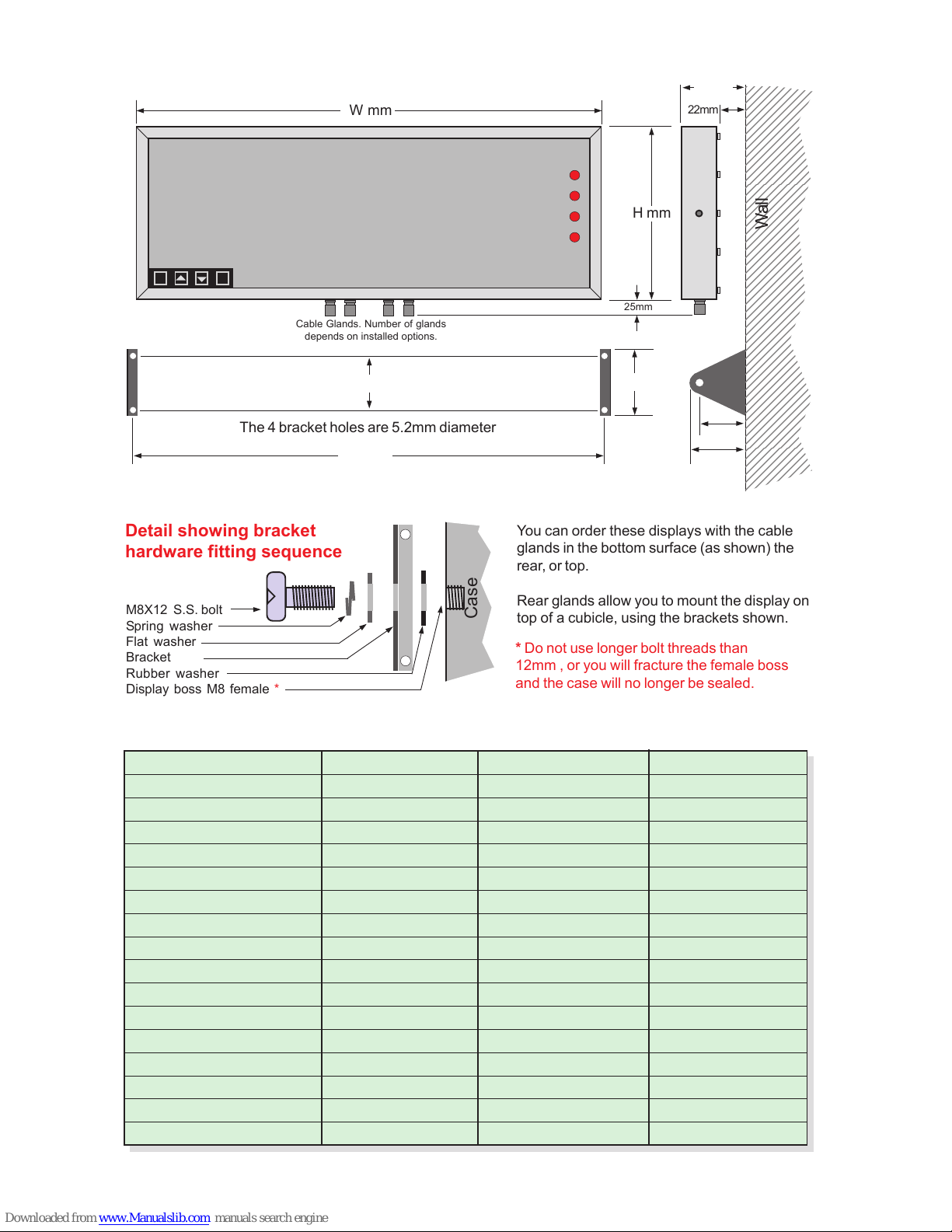

Wall Mounting Dimensions

Display Format X mm H mm W mm

2” 4 digit clock 278 154.5 291

2” 4 digit numeric 266.5 154.5 279.5

2” 6 digit clock 387 154.5 400

2” 6 digit numeric 363 154.5 376

4” 4 digit clock 440 195.5 453

4” 4 digit numeric 421 195.5 434

4” 6 digit clock 640 195.5 653

4” 6 digit numeric 603 195.5 616

6” 4 digit 567 246 580

6” 6 digit 807 246 820

8” 4 digit 737 290 750

8” 6 digit 1059 290 1072

12” 4 digit 1037 408 1050

12” 6 digit 1527 408 1540

16” 4 digit 1355 515 1368

16” 6 digit 2007 515 2020

8.8.8.8.8.8.

OK

dg

X mm

60 mm

80 mm

72.5 mm

60 mm

98 mm

60 mm

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

123456789012345

Wall

H mm

The 4 bracket holes are 5.2mm diameter

22mm

W mm

25mm

Cable Glands. Number of glands

depends on installed options.

You can order these displays with the cable

glands in the bottom surface (as shown) the

rear, or top.

Rear glands allow you to mount the display on

top of a cubicle, using the brackets shown.

M8X12 S.S. bolt

Spring washer

Flat washer

Bracket

Rubber washer

Display boss M8 female

*

Case

Detail showing bracket

hardware fitting sequence

* Do not use longer bolt threads than

12mm , or you will fracture the female boss

and the case will no longer be sealed.

Page 9

9

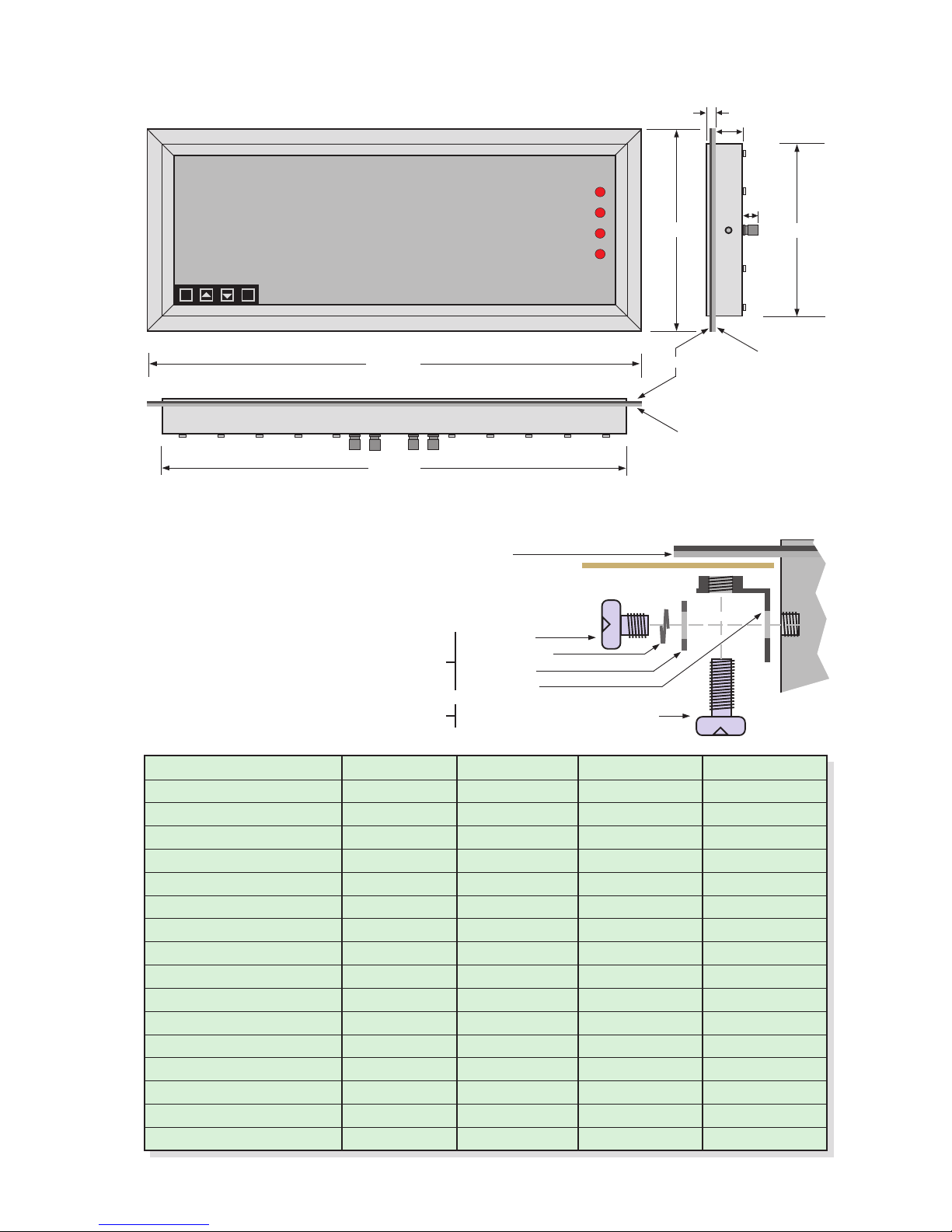

Panel Mounting Dimensions

8.8.8.8.8.8.

OK

dg

A mm

W mm

B mm

Neoprene

gasket

Neoprene

gasket

Bezel

H mm

Display Format H mm A mm B mm Wmm

2” 4 digit clock 172.5 154.5 291 309

2” 4 digit numeric 172.5 154.5 279.5 297.5

2” 6 digit clock 172.5 154.5 400 418

2” 6 digit numeric 172.5 154.5 376 394

4” 4 digit clock 213.5 195.5 453 471

4” 4 digit numeric 213.5 195.5 434 452

4” 6 digit clock 213.5 195.5 653 671

4” 6 digit numeric 213.5 195.5 616 634

6” 4 digit 264 246 580 598

6” 6 digit 264 246 820 838

8” 4 digit 308 290 750 768

8” 6 digit 308 290 1072 1090

12” 4 digit 426 408 1050 1068

12” 6 digit 426 408 1540 1558

16” 4 digit 533 515 1368 1386

16” 6 digit 533 515 2020 2038

M8 x 15 bolt

Spring washer

Flat washer

Wall Bracket

M8 x 20 bolt, gasket compresser

Case

Detail showing bracket hardware fitting sequence

Fit first

Fit last

Panel cutout dimensions

A+3mm(h) x B+3mm(w)

25mm

Panel

Bezel

Neoprene gasket

Cable glands

8mm

67mm

Page 10

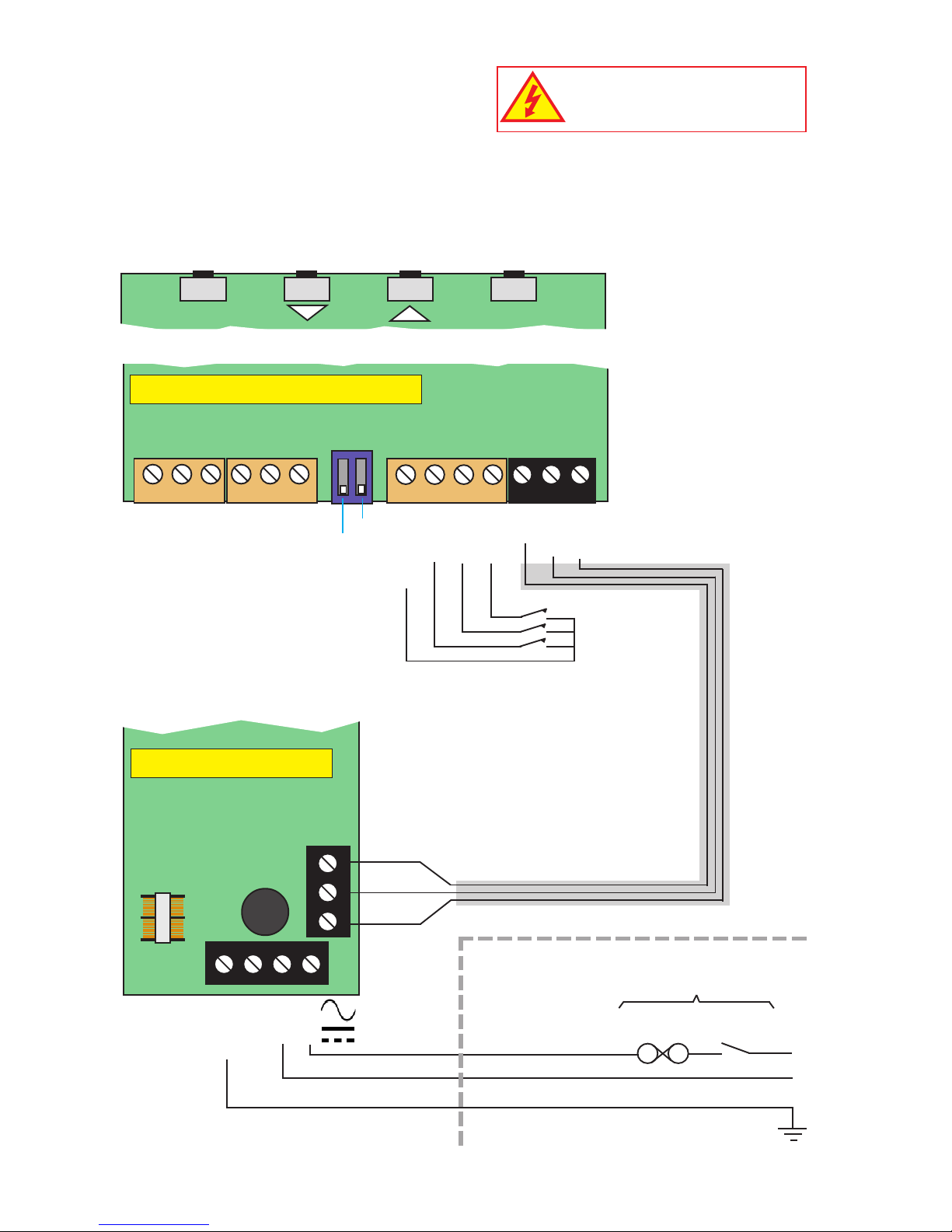

10

Demand

Common

Data A+/Rxd

Data B- /Txd

nil

nil

Connections

Alarm Lock

Calib’n Lock

Common

CC.1

CC.2

CC.3

Logic Inputs Power

Signal Input & Excitation

N L

- +

Remote

contacts

(5V DC 1mA)

Earth

1 2 3 4 5 6 7 8 9 10 11 12 13

Processor and signal input board

Power Supply board

Internal power link, installed by the factory

Fuse

Earth

- or N

+ or L

N L

- +

Earth

Fuse Switch

Customer-supplied disconnection

and overload protection devices

Circuit breaker

Power

E

Inside the enclosure Outside the enclosure

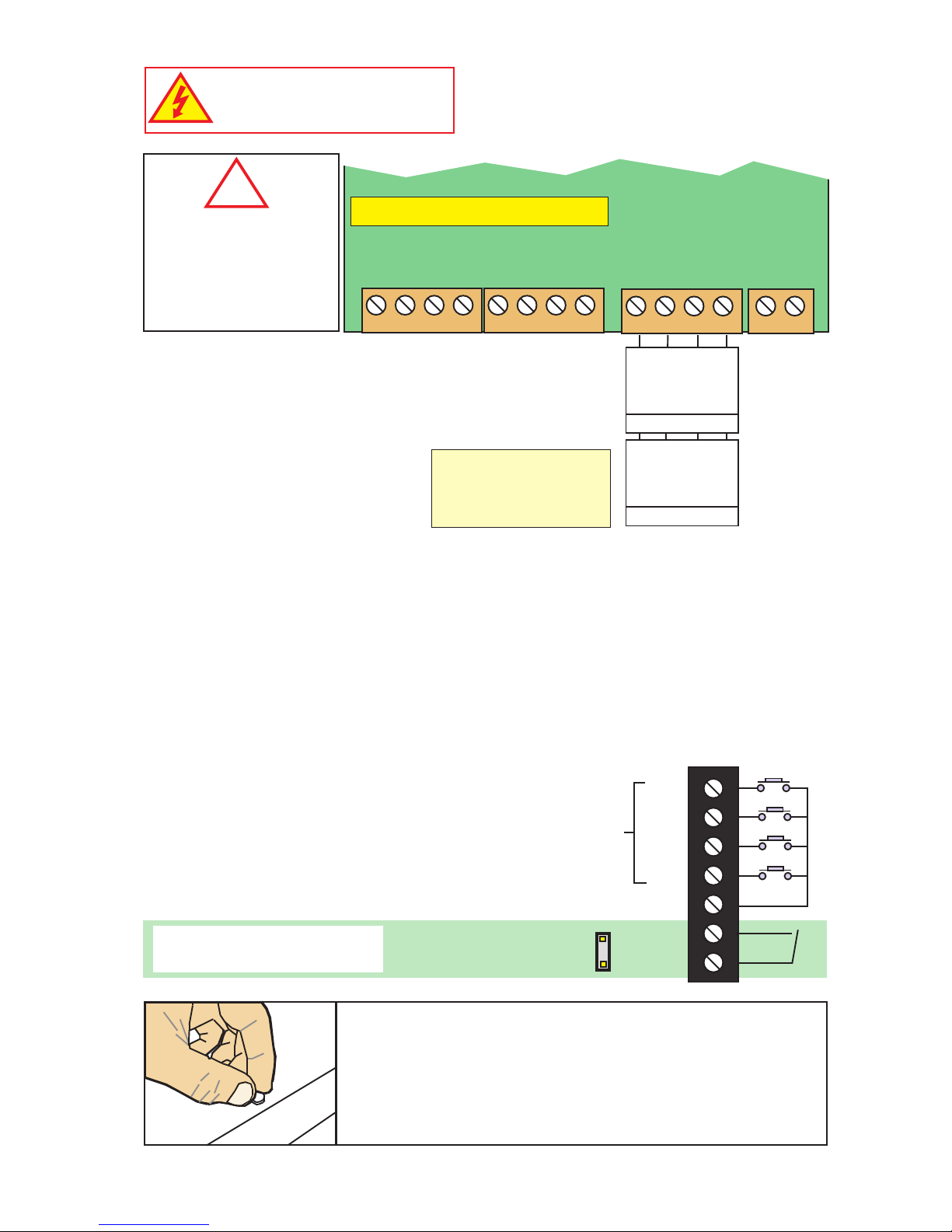

Warning:

Disconnect all power before

removing the rear of the display

There is a wide range of possible locations for the input board, output board and power

supply board/s. Their locations depend on the height of digits, number of digits, brightness of

digits and any installed options. Because the permutation of possible locations is large, we

will not describe the location of boards within the display, but simply identify the connectors

and their functions on each board, below ...

OK Digit

Page 11

11

Connections

Serial Data

output option

0, 2 or 4 Alarm Relay

output options

- +

AL4 AL3 AL2 AL1

B

A

Comm

Enable

TxD

RxD

Comm

Enable

Rated 2A 250VAC Resistive

Enable is used in mode C1

to activate or de-activate the

RS232 or RS485 serial output.

Connect to Comm to continually

transmit data.

27 26 25 24 23 22 21 20 19 18 17 16 15 14

RS485

RS232

Output option board (if fitted)

Analog

output

option

Button function

Remote buttons

Display’s front panel

buttons enabled/disabled

by jumper or connection

Remote programming button connector

On one of the display boards, you will find a 7 way connector, to which you can wire remote

programming buttons, to allow adjustment of the display’s settings when the display is

inaccessible.

You can also enable or disable the display’s front panel buttons, either by a remote contact

closure, or by an on-board push-on jumper switch, which is located near to the remote

button connector. When the contact is closed, or the push-on switch fitted, the front buttons

are enabled.

Connectors and options

Connectors may be

present even if output

options are not installed.

Refer to rating label to see

installed options.

!

Warning:

Disconnect all power before

removing the rear of the display

Rear case screws - please note

The rear panel is held in place with finger-screws, which

only need to be gently tightened.

Do not use tools to tighten or loosen the screws, as

this could cause damage to the internal threads.

Close contact or fit jumper to

enable front panel buttons

OK

Output

Set2

Set1

Common

Common

Enable

Page 12

12

Installation Hints for Best Performance

This section offers several suggestions which will help you get the best performance from

your system.

RS232 and RS485 use comparitively small signals which can easily be corrupted by the

potentially high level of electrical noise which can be created by electrical machinery such as

motors, welding systems, discharge lighting, AC power inverters and solenoids. These steps

will ensure you get the best possible performance from your system.

RS232 has limited capability over long cable distances, due its low driving power (which

causes the signal to reduce in level as cable length increases) and single ended signal (which

is prone to interference by local electrical noise) , as shown below.

Maximum recommended cable distances if using LOW

capacitance screened cable such as CAT5 cable:

Baud Rate RS232 RS485 or RS422

1200 50 m (164 ft) 1200 m (3900 ft)

9600 20 m (66 ft) 150 m (500 ft)

19200 10 m (33 ft) 75 m (250 ft)

38400 5 m (16.4 ft) 30 m (100 ft)

115200 2 m (6.6 ft) 10 m (33 ft)

1. Use good quality screened signal cable, with twisted pairs. Screened twisted pair

CAT5 cable is ideal. The screen should be earthed at the display end only.

2. If you are using multi-pair twisted cable, each pair should be dedicated to a single

display as shown opposite, for maximum noise immunity.This will ensure that any

electrical noise induced in the cable is properly cancelled. Mixing destinations

carelessly amongst the twisted pairs can easily corrupt data.

3. The cable should be routed away from noisy wiring and devices such as power

feeds from inverters, discharge-lighting cables, welder cabling etc, and should

preferrably be routed in a dedicated low voltage signalling/instrumentation conduit

or cable tray.

4. If you want to simulate data, a useful free terminal, with good flexibility is

RealTerm, available from http://sourceforge.net/projects/realterm/

Connect screen

to earth ONLY

at this end.

Do not

connect

screen at

this end.

Length of screened cable

Clean Earth

Signal Input

Logic Input

Power Input

Display connections

Sender connections

RS232 or

RS485

transmitter

Page 13

13

Display 1

Display 2

Display 3

Data 1

Data 2

Data 3

When using multi-core screened cable to connect several displays to several data sources, please be sure to use one twisted

pair for each display and sensor.

Do NOT use a wire from one pair for signal positive and a wire from another pair for signal negative, as this will prevent the

twisted cables form cancelling any induced electrical noise, and can couple noise from one source to another.

Displays

Data Sources

Page 14

14

Declaration of CE Conformity

Conditions

The meters are permitted a worst case error of 1% of A/D range during electro-magnetic

disturbance, and must recover automatically when disturbance ceases without the need for

human intervention, such as resetting, power-down etc.

The meters covered by this certificate must be installed in adherence to the following

conditions :-

Signal cabling shall be routed separately to power carrying cabling (includes relay output

wiring)

All signal cabling shall be screened. The screen shall only be terminated to the power earth

terminal at the meter end of the cable.

Declared as true and correct, for and on behalf of London Electronics Ltd.

J.R.Lees Director

This is to confirm that the Product covered by this declaration has been designed and

manufactured to meet the limits of the following EMC Standard :

EN61326-1:1997

and has been designed to meet the applicable sections of the following safety standards

EN61010-1:2001

Declaration Reference : INTUITIVE Mk2

Issue Date : 30 April 2007

Products Covered : INTUITIVE Mk2 series

Title : DOC-INTUITIVE2

Page 15

15

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Language Selection for user interface

You can select English or French menu prompts.

Lockout Switch must be OFF

Press together, briefly

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Display shows

UI EngUI Eng

UI EngUI Eng

UI Eng (Default)

for User Interface English

or

UI FrAUI FrA

UI FrAUI FrA

UI FrA

for User Interface French

1

2

3

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Done!

Press to toggle

Press to accept

OFF

Circuit board ON

Page 16

16

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Display Brightness

You can adjust the display brightness at any time, provided the display is locked.

Lockout Switch must be ON

Press 3 seconds

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press for 3 seconds

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press to accept

1

Done!

!

!

Did you know, we make this display in two brightness versions?

Standard brightness for use inside, and Daylight Viewing for use outside

in direct sunlight. The Daylight Viewing version has suffix -DLV in its part

number.

OFF

Circuit board ON

For 4 digits, display shows

briLbriL

briLbriL

briL

For 6 digits, display shows

brightbright

brightbright

bright

Each press of the UP button selects

a new brightness level.There are 7

brightness levels to choose from.

(Default = Full brightness)

2

3

Page 17

17

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Display Modes

You can choose from three operating modes.

Lockout Switch must be OFF

Press 3 seconds

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press to select

For 4 digits, display shows

ASCASC

ASCASC

ASC ,

quan quan

quan quan

quan or

q.totq.tot

q.totq.tot

q.tot

For 6 digits, displayay shows

ASCIIASCII

ASCIIASCII

ASCII ,

quantquant

quantquant

quant

or

qua.totqua.tot

qua.totqua.tot

qua.tot

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press to accept

Done!

OFF

Circuit board ON

ASCIIASCII

ASCIIASCII

ASCII (4 digits) or

ASCII ASCII

ASCII ASCII

ASCII (6 digits) is used for

any application where non-numeric characters

need to be displayed. You can not have alarms,

analog output, tare, peak, valley or any mathematical functions with this mode.

quanquan

quanquan

quan (4 digits) or

quantquant

quantquant

quant (6 digits) is used for

any numeric display work which needs alarms,

analogue output, tare, peak, valley or mathematical functions.

q.totq.tot

q.totq.tot

q.tot (4 digits) or

qua.totqua.tot

qua.totqua.tot

qua.tot (6 digits) is used

in applications where you want to sum values,

for example to add together ingredient weights

to get a combined weight.

1

2

3

Page 18

18

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Serial Data Settings

Choose the serial data settings to suit the transmitting device.

Lockout Switch must be OFF

Press 3 seconds

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Display shows each of the parameters

and you can edit or move on to the next

one with the OK button. You can edit the

settings with the DIGIT, UP and DOWN

buttons. OK to accept. The default

parameters are:

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press to accept

1

2

3

Done!

OFF

Circuit board ON

Ad.01 Ad.01

Ad.01 Ad.01

Ad.01 or

Addr.01 Addr.01

Addr.01 Addr.01

Addr.01

S.C.02 S.C.02

S.C.02 S.C.02

S.C.02 or

S.Chr.02 S.Chr.02

S.Chr.02 S.Chr.02

S.Chr.02

E.C.03 E.C.03

E.C.03 E.C.03

E.C.03 or

E.Chr.03 E.Chr.03

E.Chr.03 E.Chr.03

E.Chr.03

baud 9600baud 9600

baud 9600baud 9600

baud 9600

8n1 8n1

8n1 8n1

8n1 or

dF. 8n1 dF. 8n1

dF. 8n1 dF. 8n1

dF. 8n1

t.r.05 t.r.05

t.r.05 t.r.05

t.r.05 or

t.reP.05 t.reP.05

t.reP.05 t.reP.05

t.reP.05

t.c.00 t.c.00

t.c.00 t.c.00

t.c.00 or

t.chr.00 t.chr.00

t.chr.00 t.chr.00

t.chr.00

to. 03 to. 03

to. 03 to. 03

to. 03 or

to. 03 to. 03

to. 03 to. 03

to. 03

S.P.00 S.P.00

S.P.00 S.P.00

S.P.00 or

S.Pos.00 S.Pos.00

S.Pos.00 S.Pos.00

S.Pos.00

d.L.06 d.L.06

d.L.06 d.L.06

d.L.06 or

d.LEn.06 d.LEn.06

d.LEn.06 d.LEn.06

d.LEn.06

d.dd.d

d.dd.d

d.d

.d.d. .d.d.

.d.d. .d.d.

.d.d. or

d.d.d.d.d.d.d.d.d.d.d.d.

d.d.d.d.d.d.d.d.d.d.d.d.

d.d.d.d.d.d.

The display’s address, from 00 to FF. Choose

00 if you do not need addressing.

The Start Character. 02 = STX. Select 00 if you

do not have a defined start character.

The End Character. 03 is ETX, 0d is Carriage

return.

Choose a baud rate to suit the sender.

Data format 8 data bits, no parity, 1 stop.

Time to reply forllowing a request, in mS.

Time in mS between each character.

Timeout Secs. if data lost. Display shows ------

Start position for data editing (see opposite).

Data length for editing (see oppopsite).

Decimal point position for alarms.

Page 19

19

Serial Data Setting Examples

Sending data to an addressed display

Let us assume the display has address 45 and you want to send the value 123.4 to it at

19200 baud. Your data will be sent as <STX>45123.4<CR>.

For 4 digits, set:

Ad.45Ad.45

Ad.45Ad.45

Ad.45,

S.C.02 S.C.02

S.C.02 S.C.02

S.C.02,

E.C.0d E.C.0d

E.C.0d E.C.0d

E.C.0d,

baud 19200 baud 19200

baud 19200 baud 19200

baud 19200,

8n1 8n1

8n1 8n1

8n1,

t.r.05t.r.05

t.r.05t.r.05

t.r.05,

t.c.00t.c.00

t.c.00t.c.00

t.c.00,

to. 03 to. 03

to. 03 to. 03

to. 03,

S.P.00 S.P.00

S.P.00 S.P.00

S.P.00,

d.L.06 d.L.06

d.L.06 d.L.06

d.L.06,

ddd.dddd.d

ddd.dddd.d

ddd.d

For 6 digits, set:

AA

AA

A

ddr.45ddr.45

ddr.45ddr.45

ddr.45,

S.Chr.02 S.Chr.02

S.Chr.02 S.Chr.02

S.Chr.02,

E.Chr.0d E.Chr.0d

E.Chr.0d E.Chr.0d

E.Chr.0d,

baud 19200 baud 19200

baud 19200 baud 19200

baud 19200,

dF. 8n1 dF. 8n1

dF. 8n1 dF. 8n1

dF. 8n1,

t.reP.05t.reP.05

t.reP.05t.reP.05

t.reP.05,

t.chr.00 t.chr.00

t.chr.00 t.chr.00

t.chr.00,

to. 03 to. 03

to. 03 to. 03

to. 03,

S.Pos.00 S.Pos.00

S.Pos.00 S.Pos.00

S.Pos.00,

d.LEn.06 d.LEn.06

d.LEn.06 d.LEn.06

d.LEn.06,

ddddd.dddddd.d

ddddd.dddddd.d

ddddd.d

Extracting data from a complex string (data editing)

Let us assume the data is sent as a complex string at 1200 baud such as ...

<Start Char><Address Characters><Data: ligo6ho987hmw1234.56kg abcd><End Char.>

and you want to display only the numeric weight value...

For 4 digits, set:

AdAd

AdAd

Ad

.78.78

.78.78

.78,

S.C.02 S.C.02

S.C.02 S.C.02

S.C.02,

E.C.03 E.C.03

E.C.03 E.C.03

E.C.03,

baud 1200 baud 1200

baud 1200 baud 1200

baud 1200,

8n1 8n1

8n1 8n1

8n1,

t.r.05 t.r.05

t.r.05 t.r.05

t.r.05,

t.c.00t.c.00

t.c.00t.c.00

t.c.00,

to. 03 to. 03

to. 03 to. 03

to. 03,

S.P.15 S.P.15

S.P.15 S.P.15

S.P.15,

d.L.06 d.L.06

d.L.06 d.L.06

d.L.06,

dd.dddd.dd

dd.dddd.dd

dd.dd

For 6 digits, set:

Addr.78Addr.78

Addr.78Addr.78

Addr.78,

S.Chr.02 S.Chr.02

S.Chr.02 S.Chr.02

S.Chr.02,

E.Chr.03 E.Chr.03

E.Chr.03 E.Chr.03

E.Chr.03,

baud 1200 baud 1200

baud 1200 baud 1200

baud 1200,

dF. 8n1 dF. 8n1

dF. 8n1 dF. 8n1

dF. 8n1,

t.reP.05t.reP.05

t.reP.05t.reP.05

t.reP.05,

t.chr.00 t.chr.00

t.chr.00 t.chr.00

t.chr.00,

to. 03 to. 03

to. 03 to. 03

to. 03,

S.Pos.15 S.Pos.15

S.Pos.15 S.Pos.15

S.Pos.15,

d.LEn.06 d.LEn.06

d.LEn.06 d.LEn.06

d.LEn.06,

dddd.dddddd.dd

dddd.dddddd.dd

dddd.dd

d.Len.xx

s.Pos.xx -1 to -19

s.Pos.xx 0 to 99

Value to

display

Start Character Address Characters ligo6ho987hmw1234.56kg abcd end

character

STX 78 ETX

9122-0670 P4

Solder Switch closed

9122-0670 P4

Bias +5V on Sig B

Bias 0V on Sig A

120 Ohm termination resistor

Solder Switch closed

IC4

IC3

IC4

IC3

RS232 Version (IC3 missing)

RS485 Version (IC4 missing)

C

B

A

C

B

A

Page 20

20

Logic Input Functions

The three contact closure inputs on the rear of the meter have default functions which are:

Contact closure 1 = Tare

Contact closure 2 = Peak/Valley display

Contact closure 3 = Reset

You can re-assign these to include :HOLD, Nett/Gross value display, Memory page

address 1,2 or 4 (only if Multi-memory MEM option is installed)

1

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Use UP or DOWN buttons to select from

these available functions...

taretare

taretare

tare = Tare display to 0

PVPV

PVPV

PV = Peak/Valley toggle

rstrst

rstrst

rst = Reset

HoLdHoLd

HoLdHoLd

HoLd = Freeze display

nt.grnt.gr

nt.grnt.gr

nt.gr = Net / Gross display (4 digits)

net.gronet.gro

net.gronet.gro

net.gro = Net / Gross display (6 digits)

PA.1PA.1

PA.1PA.1

PA.1 = Page Address 1*

PA.2PA.2

PA.2PA.2

PA.2 = Page Address 2*

PA.4PA.4

PA.4PA.4

PA.4 = Page Address 4*

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Done!

* Only available if the Multi-memory MEM option is installed

Defaults are:-

CC.1CC.1

CC.1CC.1

CC.1 =

taretare

taretare

tare

CC.2CC.2

CC.2CC.2

CC.2 =

PVPV

PVPV

PV

CC.3CC.3

CC.3CC.3

CC.3 =

rstrst

rstrst

rst

Press to accept

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Lockout Switch must be OFF

Press 3 seconds

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press repeatedly until you see

CC.1 CC.1

CC.1 CC.1

CC.1 , followed by the existing function for

Contact Closure 1.

After you have set

CC.1CC.1

CC.1CC.1

CC.1, you will get the

prompt

CC.2 CC.2

CC.2 CC.2

CC.2 to allow you to set Contact

Closure 2 function and when you have set

CC.2 you will get the prompt

CC.3CC.3

CC.3CC.3

CC.3 to allow

you to set Contact Closure 3 function

OFF

Circuit board ON

2

3

4

Page 21

21

Logic Input Connections and Front Buttons

The previous page explained how to select the functions of the 3 logic inputs. You can

connect remote contact closures or open NPN collectors to activate these logic inputs.

The logic input provides a 5V DC signal. When you connect this to common, a current of

1mA will flow. Because this is a small signal, we recommend you use switches with gold

plated contacts, or self cleaning contacts, for best long term reliability.

The logic inputs are not galvanically isolated from the input signal.

The logic inputs are only activated when the lockout switch is ON

Logic Inputs Power

Signal I/P & Excitation

1 2 3 4 5 6 7 8 9 10

11 12 13

Normally open (disables front

panel Tare, Peak/Valley and

Reset buttons)

Normally closed (this enables

front panel Tare, Peak Valley and

Reset buttons also) Or simply link

NPN (could be opto-isolators if

you need the logic control lines to

be galvanically isolated from the

input signal.)

taretare

taretare

tare = Tares display to 0. Often used in weighing systems to zero a display

prior to making a measurement. Net weight is shown once tared.

When a display has been tared the small LED above the Set1 button

will be illuminated.

PVPV

PVPV

PV = Peak/Valley toggle. Allows you to view the maximum and minimum

values which have been displayed since last reset. 0% LED illuminates when showing valley, 100% LED illuminates when showing

peak.

rstrst

rstrst

rst = Reset. This clears any tare, peak, valley, alarm latch

HoLdHoLd

HoLdHoLd

HoLd = Freezes the displayed value for as long as the Hold input is closed.

nt.grnt.gr

nt.grnt.gr

nt.gr = Toggles between Nett and Gross values on the display (6 digits)

net.gronet.gro

net.gronet.gro

net.gro = Toggles between Nett and Gross values on the display (6 digits)

PA.1 .. 4PA.1 .. 4

PA.1 .. 4PA.1 .. 4

PA.1 .. 4 = Page Addresses, if MEM option is installed.

ON

OFF

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Showing Nett value (steady)

Showing Gross value (flashing)

Showing Valley

Showing Peak

Page 22

22

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Factory Defaults

You can return the display to its factory default conditions whenever you wish. If you do so,

you will permanently loose all your settings and will need to start from the beginning again.

The calibration Audit Counter will NOT be reset, there is no way provided to reset this value,

as it is intended as a secure record to indicate whether changes have been made to the

display since it was last calibrated..

Lockout Switch must be OFF

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press to accept

1

2

3

Done!

Press together for 3 seconds

OFF

Circuit board ON

Calibration Audit Number

Your display includes a non-resettable counter which increments each time you make a

change to the display’s calibration. This is useful if you want to check whether a display has

been altered since it was last calibrated.

The calibration audit number ranges from

CL.01 CL.01

CL.01 CL.01

CL.01 to

CL.FF CL.FF

CL.FF CL.FF

CL.FF (4 digits) or

CAL.01 CAL.01

CAL.01 CAL.01

CAL.01 to

CAL.FF CAL.FF

CAL.FF CAL.FF

CAL.FF

(6 digits), allowing up to 255 alterations to be recorded. Whenever you want to check the

calibration audit number, press and hold the 2 outer buttons (Set1 + Alarms) for more than

3 seconds.

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Done!

1

Press together for 3 seconds

For “Defaults No”, the display shows

def.ndef.n

def.ndef.n

def.n (4 digits) or

defS.ndefS.n

defS.ndefS.n

defS.n (6 digits).

For “Default Yes” and to return to default

conditions, press the DOWN button to

change the display to

def.ydef.y

def.ydef.y

def.y (4 digits)

or

defS.y defS.y

defS.y defS.y

defS.y (6 digits).

Page 23

23

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Scale Factor Adjustment

After you have calibrated your meter, you can use the SCALE feature to make fine adjust-

ments to calibration, without affecting the calibration itself. You must have mode =

QuantQuant

QuantQuant

Quant

Examples

1.Changing weight units of measure from kg to pounds

You could also use the SCALE to convert your readout from kg to pounds, without affecting

the calibration. Simply set SCALE = 2.205 and your meter which was calibrated in kg will

now read in pounds.

2. Correcting for gravitational variance

Your weighing system was calibrated where gravitational acceleration = 9.812m/s2 (London) You then move the system to Bankok where gravitational acceleration is reduced to

9.782m/s

2

You can correct for this difference by setting Scale = 9.812 / 9.782 = 1.003, so that a given

mass in Bangkok will show the same weight as it did in London. Set Offset = 0.0000

See

http://en.wikipedia.org/wiki/Earth%27s_gravity

Lockout Switch must be OFF

Press 3 seconds

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

1

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Use DIGIT button to select each digit in

turn, UP or DOWN buttons to increase or

decrease each digit’s value. Press OK

when done.

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Done!

You may want to adjust an offset value also, see separate OFFSET page for this feature.

Press to accept

OFF

Circuit board ON

For 4 digits, press repeatedly until you

see

SCALSCAL

SCALSCAL

SCAL , followed by the existing scale

factor. (Default =

001.0001.0

001.0001.0

001.0)

For 6 digits, press repeatedly until you

see

SCALESCALE

SCALESCALE

SCALE , followed by the existing scale

factor. (Default =

001.000001.000

001.000001.000

001.000)

2

3

4

Page 24

24

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Offset Adjustment

After you have calibrated your meter, you can use the

OFFSET OFFSET

OFFSET OFFSET

OFFSET feature to make fine addi-

tions or subtractions to the reading, without affecting the calibration itself. You must have

mode =

quanquan

quanquan

quan (4 digits) or

quantquant

quantquant

quant (6 digits).

For example if your weighing structure is altered after calibration and you want to subtract

the effect of 37kg of extra metalwork which was welded to the hopper, you can easily do this

by entering a value of -37 in the offset value.

Lockout Switch must be OFF

Press 3 seconds

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

1

2

3

4

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Use DIGIT button to select each digit in

turn, UP or DOWN buttons to increase or

decrease each digit’s value. If you want

to set a negative value, use DIGIT to

select the left hand digit, and press the

down button to go below 0 to activate the

- sign. Press OK when done.

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Done!

You may want to adjust a SCALE FACTOR value also, without affecting calibration. See

the separate SCALE page for this feature.

Press to accept

OFF

Circuit board ON

Press repeatedly until you see

OF.StOF.St

OF.StOF.St

OF.St

(4 digits) or

OFFSEt OFFSEt

OFFSEt OFFSEt

OFFSEt (6 digits), followed

by the existing offset value.

(Default is

000.0 000.0

000.0 000.0

000.0 fo 4 digits or

000.000 000.000

000.000 000.000

000.000 for 6 digits)

Page 25

25

Menu Timeout Adjustment

The display has a default timeout of 60 seconds, to allow you sufficient time to refer to the

manual between key operations.

You can make this period shorter, if you wish, once you become more familiar with the

setup method.

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Lockout Switch must be OFF

Press together, briefly

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press repeatedly until you see

dYdY

dYdY

dY. XX

(4 digits) or

dLAYdLAY

dLAYdLAY

dLAY. XX (6 digits), where

XX is the delay in seconds. Choices are:

dy.1 0 dy.1 0

dy.1 0 dy.1 0

dy.1 0 or

dLAy.1 0dLAy.1 0

dLAy.1 0dLAy.1 0

dLAy.1 0

dy. 20 dy. 20

dy. 20 dy. 20

dy. 20 or

dLAy. 20dLAy. 20

dLAy. 20dLAy. 20

dLAy. 20

dy. 30 dy. 30

dy. 30 dy. 30

dy. 30 or

dLAy. 30dLAy. 30

dLAy. 30dLAy. 30

dLAy. 30

dy. 60dy. 60

dy. 60dy. 60

dy. 60 or

dLAy. 6 0dLAy. 6 0

dLAy. 6 0dLAy. 6 0

dLAy. 6 0 (default)

OFF

Circuit board ON

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press briefly to toggle

Press DOWN or UP button briefly and

repeatedly to choose from

dy.10dy.10

dy.10dy.10

dy.10 or

dy.20dy.20

dy.20dy.20

dy.20 or

dy.30 dy.30

dy.30 dy.30

dy.30 or

dy.60 dy.60

dy.60 dy.60

dy.60 (4 digits) or

dLAy.10dLAy.10

dLAy.10dLAy.10

dLAy.10 or

dLAy.20 dLAy.20

dLAy.20 dLAy.20

dLAy.20 or

dLAy.30 dLAy.30

dLAy.30 dLAy.30

dLAy.30 or

dDLy.60 dDLy.60

dDLy.60 dDLy.60

dDLy.60 (6 digits)

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Done!

Press to accept

1

2

3

4

1

2

3

4

Page 26

26

Reverse Display function (mirror image)

If you need to be able to see a reflection of the display in a mirror or other reflective

surface, for example in a simple heads-up system, or for drivers reversing into a bay, using

mirrors only, you can set the display to show as a mirror image.

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Lockout Switch must be OFF

Press together, briefly

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press briefly to toggle

1

2

3

4

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Done!

rEV.d 0rEV.d 0

rEV.d 0rEV.d 0

rEV.d 0

rEV.d 1rEV.d 1

rEV.d 1rEV.d 1

rEV.d 1

Example of normal display format Example of Mirror Reverse display format

displaying the number 876543 displaying the number 876543

Press to accept

OFF

Circuit board ON

Press OK button briefly and repeatedly

until you see:

rEV. 0rEV. 0

rEV. 0rEV. 0

rEV. 0 (Default) or

rEV.1rEV.1

rEV.1rEV.1

rEV.1 (4 digits)

rEV.d 0rEV.d 0

rEV.d 0rEV.d 0

rEV.d 0 (Default) or

rEV.d1rEV.d1

rEV.d1rEV.d1

rEV.d1 (6 digits)

Press DOWN or UP button briefly and

repeatedly to choose from

rEV.0rEV.0

rEV.0rEV.0

rEV.0 or

rEV.d 0rEV.d 0

rEV.d 0rEV.d 0

rEV.d 0 (normal display) or

rEV.1rEV.1

rEV.1rEV.1

rEV.1 or

rEV.d1 rEV.d1

rEV.d1 rEV.d1

rEV.d1 (mirror image display)

Page 27

27

Bootup Routine and Tare Save Choices

When you switch on your meter, it can be set to power up with 3 possible summary message combinations. The choices are:-

bt 0bt 0

bt 0bt 0

bt 0 (4 digits) or

boot 0 boot 0

boot 0 boot 0

boot 0 (6 digits) = Segment test, followed by a full summary of

software revision, calibration audit number, model number, installed options.

bt 1 bt 1

bt 1 bt 1

bt 1 (4 digits) or

boot 1 boot 1

boot 1 boot 1

boot 1 (6 digits) = Segment test followed by model number

(Default)

bt 2 bt 2

bt 2 bt 2

bt 2 (4 digits) or

boot 2 boot 2

boot 2 boot 2

boot 2 (6 digits) = No summary, meter displays the measurement

value immmediately when power is applied.

bt 3 bt 3

bt 3 bt 3

bt 3 (4 digits) or

boot 3 boot 3

boot 3 boot 3

boot 3 (6 digits) = All segments illuminate permanently, until a

button is pressed.

!

!

You can trigger the full summary message whenever you want, without

having to power the meter off, by pressing and holding the 2 outer

buttons (Set1 + Alarms) for more than 3 seconds.

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Lockout Switch must be OFF

Press together, briefly

OFF

Circuit board ON

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press OK button briefly and repeatedly

until you see

bt 0bt 0

bt 0bt 0

bt 0,

bt 1bt 1

bt 1bt 1

bt 1 ,

bt 2bt 2

bt 2bt 2

bt 2 or

bt 3bt 3

bt 3bt 3

bt 3

displayed (4 digits), or

boot 0boot 0

boot 0boot 0

boot 0,

boot 1boot 1

boot 1boot 1

boot 1,

boot 2boot 2

boot 2boot 2

boot 2 or

boot 3 boot 3

boot 3 boot 3

boot 3 (6 digits).

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press briefly to toggle

Press DOWN or UP button briefly and

repeatedly to choose from

bt 0 bt 0

bt 0 bt 0

bt 0 to

bt 3 bt 3

bt 3 bt 3

bt 3

(4 digits), or

boot 0 boot 0

boot 0 boot 0

boot 0 to

boot 3boot 3

boot 3boot 3

boot 3 (6 digits).

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Done!

Press to accept

Set1

Set2 Output

Alarms

Digit

OK

Max/Min

Reset

Press to accept

1

2

3

4

5

Page 28

28

Multi-Program Memory Option MEM

The three contact closure inputs on the rear of the meter may be used to call up between 1

to 7 additional meter setup memories (pages), if the MEM option has been installed. This

allows you to save up to 8 complete sets of independent calibrations, alarm settings, analogue output settings and serial comms settings.

First decide how many memory pages you want, as this will determine how many logic

inputs you will need to use for the addressing. Logic inputs not required for Page Addressing can be used for other functions such as Tare, Reset, Display Hold, Peak/Valley display.

If you have used all 3 logic inputs for Page Addressing, you can still use the meter’s front

panel buttons to perform Tare, Reset and peak/Valley view.

See “Contact Closure Input Functions” page for CC.1, CC.2, CC.3 and COP settings

Total number of pages Logic Inputs required for addressing

1 none, standard single page meter

2 1 Set CC.1 = PA.1

3 or 4 2 Set CC.1 = PA.1, Set CC.2 = PA.2

5 to 8 3 Set CC.1 = PA.1, Set CC.2 = PA.2, Set CC.3 = PA.4

1. Set lockout switches OFF, and set page address to 0 or unplug the logic connector.

2. Set the copy instruction to

COP.1COP.1

COP.1COP.1

COP.1 in page address 0 ( found after you set CC3) .

3. Press all 4 buttons together, display shows

defs. ndefs. n

defs. ndefs. n

defs. n

4. Press the Up arrow to change display to

defs. Ydefs. Y

defs. Ydefs. Y

defs. Y and press OK.

5. If you want all channels to share a common setting, eg calibration, do that setting now.

6. When you want to do separate settings for each channel, set COP.0

Programming and recalling individual pages

Plug the logic input connector back in, if you removed it earlier.

Select a page address using the switch combinations shown

below, wired to the Logic Input connector ...

Page address 0 All logic inputs open

Page address 1 CC.1 closed to Common

Page address 2 CC.2 closed to Common

Page address 3 CC.1 and CC.2 closed to Common

Page address 4 CC.4 closed to Common

Page address 5 CC.1 and CC.3 closed to Common

Page address 6 CC.2 and CC.3 closed to Common

Page address 7 All logic inputs closed to Common

Perform the settings you require, according to the pages in this manual. Do this for all page

addresses required. Then put the lockout switch in its ON position. Now, if you select a

page address, the meter will briefly confirm the chosen page address on screen, and will

then function according to the settings you programmed for that address.

7 8 9 10

Common

CC.1/BCD 1

CC.2/BCD 2

CC.3/BCD 4

6

BCD coded

switch

Suitable BCD coded switches are available from many electrical supply stores.

For example consider Kraus & Naimer part A540-600 E24 or Apem part number IRBC10N1248 or London

Electronics part number SW2P-8W-BCD, which also provides separate 2 pole 8 way signal selection

function.

Page 29

29

Error Codes and Fault Finding

1. Display shows minus signs.

This tells us that there is no response to input data, either because....

a) There is no data, and the display has timed out

b) There is an error in the data wiring.

c) One or more of the menu settings may be wrong.

You can test for a) and b) with a simple data monitor which you can make

with 2 diodes and a resistor, as shown below.

The Green LED should be on for most of the time, and you should see the

red LED flicker as data is sent.

If the red LED is lit most of the time, with the green flickering, your wiring may

be transposed.

If neither LED is lit, check your data source to make sure it is configured to

transmit continuously, and check your connections to make sure the cabling

and connector terminals used are correct.

If the Green LED is on, but no flickering of the red is seen, check that the

data source has been set to transmit permanently. If the data source is

another London Electronics Display, make sure it has been set to mode C1

and that the enable terminal on the serial output connector is connected to

data common.

2. You can use your PC to generate and monitor serial data, with a free

program called RealTerm which you can download from :-

http://sourceforge.net/projects/realterm/

This can be very useful in diagnosing communication problems.

------------

------------

------

1K

Terminal numbers on input

connector of display

RS232 RS422/485

3 4

2 3

Simple Data monitor.

2 x LEDs connected

back to back and a

resistor.

Green LED on

most of the time.

Red LED

flashes with

data.

Green Red

Page 30

30

RS232, RS422

RS485

plug-in option

Analogue

output

plug-in option

Alarm relays.

Depending on

the option, there

will be none, 2 or

4 relays fitted.

Main option board

Main board

How to Install Option Boards

Where the product is intended for “UL” installations

removal or addition of option boards is not permitted.

!

Warning: Disconnect

power before you expose

the internals of the display

If you want to open your display to install or modify option boards, follow these steps...

1) Switch off power to the display and unplug all connectors.

2) Undo all the thumb screws on the rear case, store them safely and remove the back

panel

3) Locate the main option board, which will be similar in appearance to the diagram below.

If a main option board is absent, which will be the case if the display was ordered without

any output options, then a main option board will need to be fitted.

The board assemblies will look like this...

The analogue output and RS232 or RS422 plug-in option boards are fixed to the main option

board with white plastic pillars. You must apply a firm force when fitting or removing these

options.

Always be careful to connect the pins to sockets accurately. When reassembling, make sure

option boards are firmly fixed to the upper option board.

Real Time

Clock option

Input board

Page 31

31

Waste Electrical Electronic Equipment (WEEE)

In Europe, this equipment must be disposed of in accordance with European

Parliamentary Directive 2002/96/EC

This directive encourages recycling and the reduction of waste materials in the

environment.

This means it must be sent to an approved recycling plant if you want to dispose of it.

It must not be thrown away with general rubbish.

If you are unable to dispose of this item locally, you may send it to us for recycling.

Conditions:

1. We will only accept items of our manufacture.

2. You must pay for the transport of the goods to us.

3. We will only accept items if they include a signed declaration by an authorised

person in your organisation, stating that :-

i. The item is safe to handle and has no contaminants which may be

harmful to health.

ii. You wish us to dispose of or destroy the item(s)

Page 32

32

Equipment Specifications

Case Material Heavy duty welded uPVC.

Connectors Internal detachable Screw Terminal connectors accessed via

compression glands

Environmental Storage Temperature range -20 to +70

°C, non condensing.

Operating temperature range 0 to 50°C. Internal heater option

available for use in conditions down to -25°C. Allow 30 minutes for

this product to reach thermal equilibrium.

Power 100-240 VAC, 45 to 60Hz, 11-30 VDC optional, 48V AC optional

Burden 40VA maximum,

Sealing IP65 all round, provided the display is mounted vertically and that

all cable glands and rear case-closure screws are properly

secured.

Input Signals RS232 on model INT2-S2

RS422 and RS485 on model INT2-S4

Baud rate selectable from 300 to 115200

Data format selectable 701,7e1,7n2,80,8E,8n,8n2

Address 00 to FF

Inter message delay time 00 to 99 mS

Inter character delay time 00 to 99 mS

Display update rate 10 readings per second

Display range -199999 to 999999

Plug-In Output Options

Analog Output See analogue output manual for details.

Available from our website.

Alarm Relay Output See alarm output manual for details.

Available from our website.

ASCII Data Output See serial output manual for details.

Available from our website.

Calendar/Clock option See serial output manual for details.

Available from our website.

Page 33

33

Record of Revisions

6 September 2010 Version F00.18 Software released. Manual format revised to improve

clarity and segregate easy from advanced menu functions. Optional

outputs now described in their own dedicated manuals. DIN Rail mounting option

added. Cabling guidance added.

7 January 2011 Version F00.20 software released.

3 February 2011 Version F00.21 released

28 February 2011 Warranty increased to 3 years and terms added.

30 August 2011 Corrected Remote Programmer connection details.

30 July 2014 Version F00.23 released

21 January 2016 Mounting dimensions amended for flush case bosses

Page 34

34

Hex Function

02 STX

03 ETX

04 EOT

0a Line Feed

0c Form Feed

0d Carriage Return

1b Escape

20 Space

21 !

25 %

26 &

28 (

29 )

2a *

2b +

20 space

2D

2E

30

31

32

33

34

35

36

--

--

..

..

.

00

00

0

11

11

1

22

22

2

33

33

3

44

44

4

55

55

5

66

66

6

37

38

39

41

42

43

44

45

46

47

48

49

4a

4b

4c

4d

4e

4f

50

51

52

53

54

55

56

57

58

59

5a

61

62

63

64

65

66

67

68

69

6a

6b

6c

6d

6e

6f

70

71

72

73

74

75

76

77

78

79

7a

77

77

7

88

88

8

99

99

9

AA

AA

A

BB

BB

B

CC

CC

C

DD

DD

D

EE

EE

E

FF

FF

F

GG

GG

G

HH

HH

H

II

II

I

JJ

JJ

J

KK

KK

K

LL

LL

L

MM

MM

M

NN

NN

N

OO

OO

O

PP

PP

P

QQ

QQ

Q

RR

RR

R

SS

SS

S

TT

TT

T

UU

UU

U

VV

VV

V

WW

WW

W

XX

XX

X

YY

YY

Y

ZZ

ZZ

Z

aa

aa

a

bb

bb

b

cc

cc

c

dd

dd

d

ee

ee

e

ff

ff

f

gg

gg

g

hh

hh

h

ii

ii

i

jj

jj

j

kk

kk

k

ll

ll

l

mm

mm

m

nn

nn

n

oo

oo

o

pp

pp

p

qq

qq

q

rr

rr

r

ss

ss

s

tt

tt

t

uu

uu

u

vv

vv

v

ww

ww

w

xx

xx

x

yy

yy

y

zz

zz

z

ASCII Hex Codes and Displayed Characters

Hex Function

2c ,

2d 2e .

2f /

3c <

3e >

5c \

5e ^

5f _

60 ‘

7b {

7c |

7d }

7e ~

7f DEL

Other ASCII Hex codes and their characters are:

Page 35

35

Typical UART output

RS485 data line levels 8n1

RS232 data line levels 8n1

Start 0 0 1 1 0 1 0 0

Stop

B(-)

A(+)

Start

0 0 1 1 0 1 0 0

Stop

A(+)

B(-)

+5V

0V

LSB MSB

LSB MSB

These examples show a single ASCII character 2C (0010 1100) which is a Comma, so

that you can see the voltages in RS485 and RS232 systems.

1 2 4 8 10 20 40 80

+4V

to

+25V

0V

-4V

to

-25V

Idle

Idle

Start

0 0 1 1 0 1 0 0

Stop

Idle

LSB MSB

Signal Levels

Special Data Commands

These messages are not handled by the normal data parsing:

If the escape character '~' is the first available character, the whole message is

treated as a command message.

Message format is <S.Chr><Addr>~[Command]<E.Chr>.

Display Brightness Control is '~Bx', where 'x' is 1 (dim) to 8 (bright). The brightness

setting is not saved to non-volatile memory.

Clear display is '~C'. Clears display and indicators (meter looks like it's turned off).

The display will return to its illuminated state on the next receipt of normal data.

Set/Clear Alarm Indicator is '~Aas', where 'a' is the Indicator ID (0 to 3), and 's' is

the state (0 or 1). When this command is received, normal alarm indication is

suspended until the meter is rebooted.

Loading...

Loading...