Page 1

Modbus Protocol

COMMUNICATIONS MANUAL

For Series 2 Laureate Digital Panel Meters,

Counters, Timers & DIN-Rail Transmitters

Now with Ethernet

LAUREL Electronics Inc.

3183-G Airway Ave, Costa Mesa, CA, 92626, USA

Tel: (714) 434-6131 Fax: (714) 434-3766 Website: www.laurels.com

- 1 -

Page 2

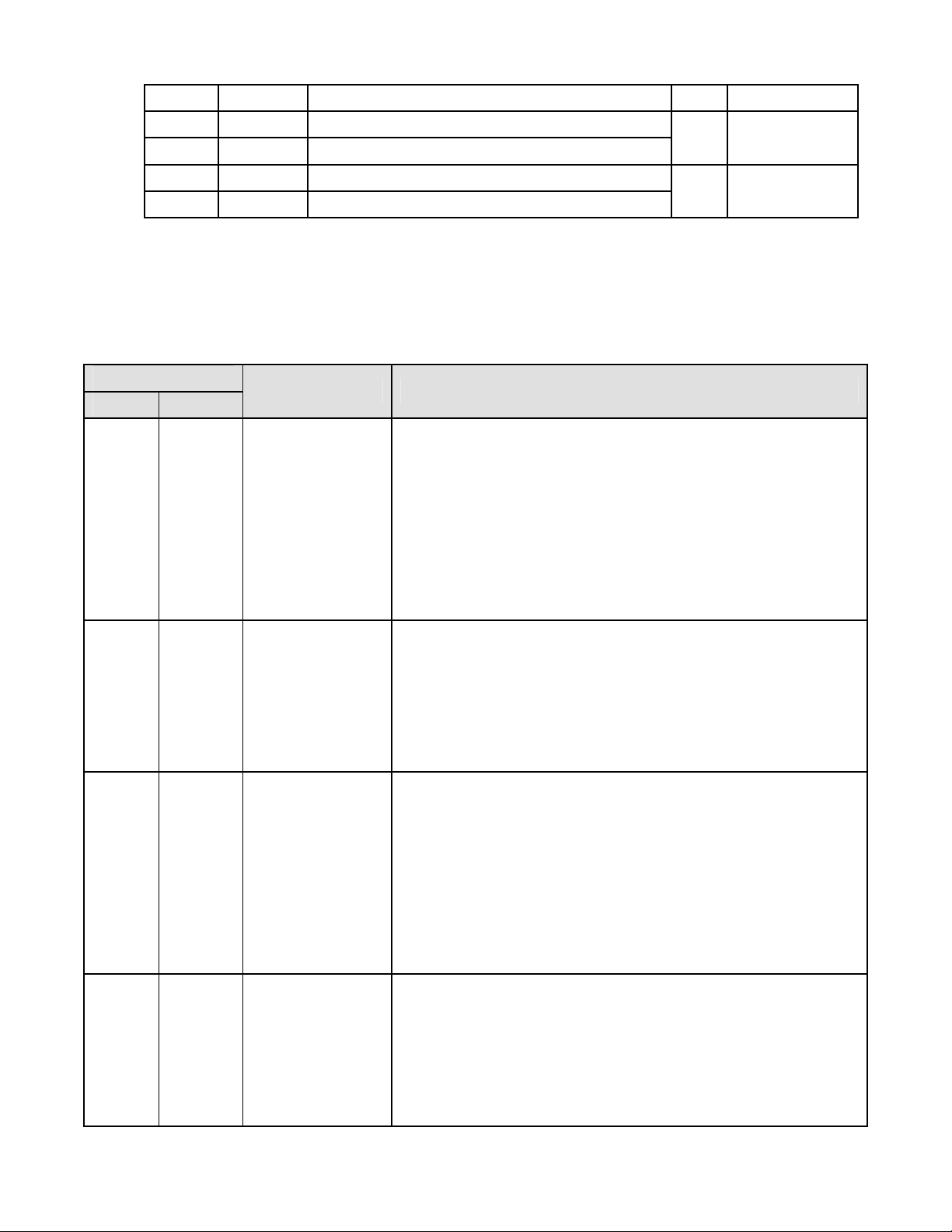

1. TABLE OF CONTENTS

1. TABLE OF CONTENTS ....................................................................................................... 2

2. INTRODUCTION, MODBUS PROTOCOL............................................................................ 3

3. MODBUS CONNECTION EXAMPLES................................................................................. 4

4. JUMPER SETTINGS & FIELD WIRING .............................................................................. 5

5. PROGRAMMING YOUR MODBUS DEVICE........................................................................ 9

6. MODBUS PROTOCOL IMPLEMENTATION ........................................................................ 10

1. General .................................................................................................................. 10

2. Framing.................................................................................................................. 10

3. Electrical Interface ................................................................................................. 11

4. Parameters Selectable via Instrument Setup (IS) Software ................................... 11

5. Parameters Selectable via Front Panel Meter Setup ............................................... 11

6. Supported Function Codes .................................................................................... 11

7. Register Numbers vs. Meter Addresses................................................................. 11

8. Supported Exception Response Codes .................................................................. 14

9. Message Formatting .............................................................................................. 14

10. Message Examples for Device Address= 01, No Parity .......................................... 15

11. Data Types Internal Registers ................................................................................ 16

12. DPM & Analog Input Transmitter Internal Register Addresses ............................. 17

13. Counter / Timer Internal Register Addresses ......................................................... 23

7. WARRANTY ...................................................................................................................... 32

- 2 -

Page 3

2. INTRODUCTION, MODBUS PROTOCOL

The Modbus Protocol is an industry-standard communications protocol that is selectable with all

our serial communications signal options: Ethernet, USB, RS485 and RS232. It is implemented by

the microcomputer on the main board and is compliant with Modbus RTU or ASCII transmission

modes (software selectable), as specified in Modbus over Serial Line Specification V1.0 (2002).

Digital panel meters, counters and timers require a plug-in option board for Modbus communications. This board can be any of the following:

• RS232 board

• RS485 board with dual RJ11 jacks.

• RS485 Modbus board with dual RJ45 jacks

• USB board

• USB-to-RS485 converter board

• Ethernet board

• Ethernet-to-RS485 converter board

Our RS485 and Modbus RS485 boards are both Modbus compliant, but the RS485 board uses

RJ11 jacks while the Modbus board uses RJ45 jacks as recommended in the Modbus Specification. With either board, the two jacks are wired in parallel to allow daisy chaining of meters with

no need for a hub.

Our USB-to-RS485 and Ethernet-to-RS485 converter boards allow the host meter to function as a

normal meter, be connected to a host computer or Ethernet local area network (LAN), and also act

as the device server for an RS485 network with up to 31 other meters equipped with an RS485

board. These meters can then be daisy-chained using readily available, straight-through 6-wire

data cables (not 4-wire telephone cables or crossover cables). Use repeaters to increase the

number of addressable meters.

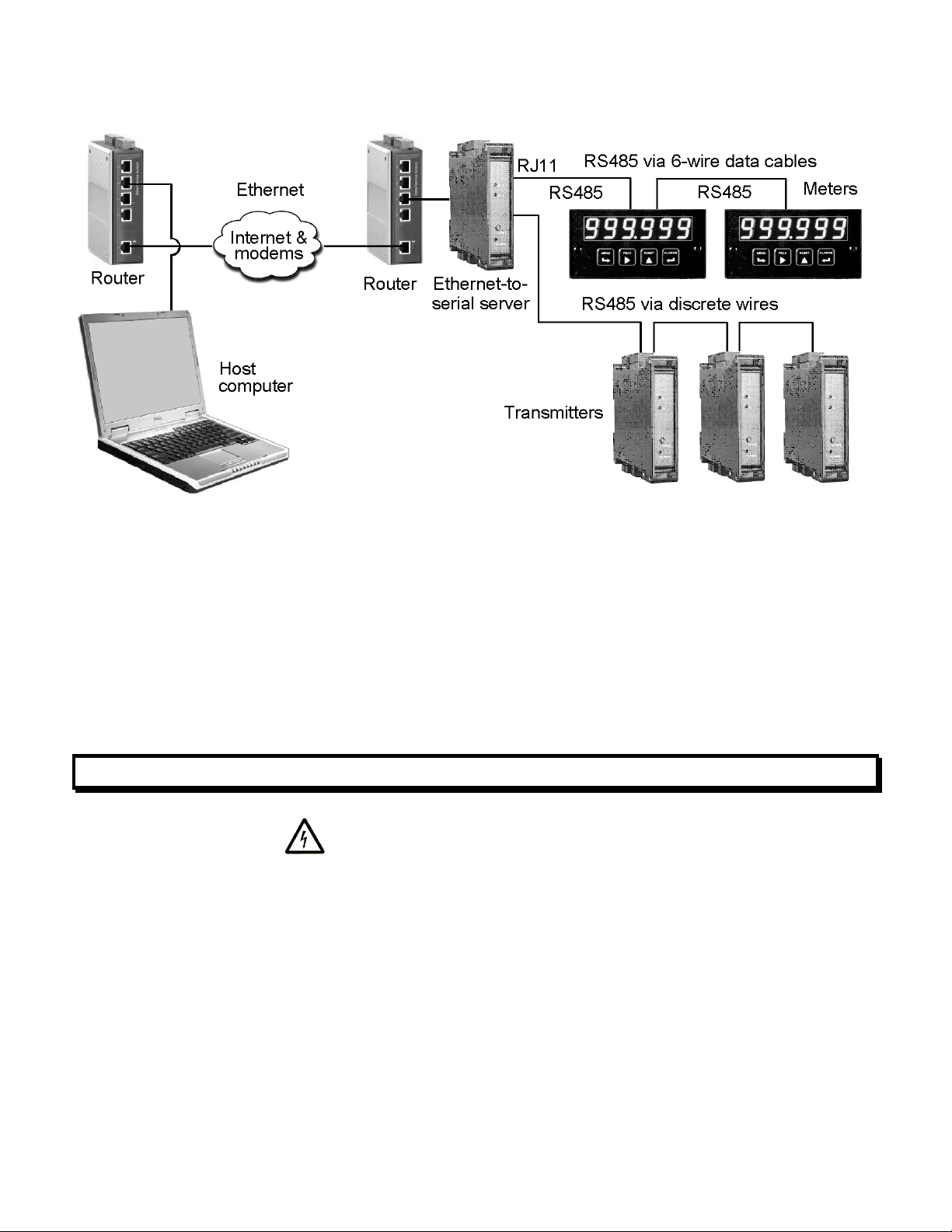

Our DIN-rail transmitters come with a user-selectable Ethernet or RS232/RS485 I/O port in addition to a scalable 4-20 mA output, which is standard.

Our DIN-rail Ethernet-to-RS485 device server provides an RJ45 jack for connection to the

Ethernet, an RJ11 jack to support an RS485 network of meters, plus screw terminals to support

an RS485 network of DIN-rail transmitters via a set of 3 or 5 parallel wires (half- or full-duplex).

The Modbus TCP protocol is seamlessly converted by our Ethernet Nodes to Modbus RTU or

Modbus ASCII for communication with meters and transmitters on an RS485 bus. Please see our

Ethernet Manual for more information.

The Custom ASCII Protocol is a software-selectable alternative to the Modbus Protocol. It also

allows device addressing of up to 31 devices. It is less complex than the Modbus protocol, but is

limited to use with our devices. Please see our Custom ASCII Protocol Communications Manual.

- 3 -

Page 4

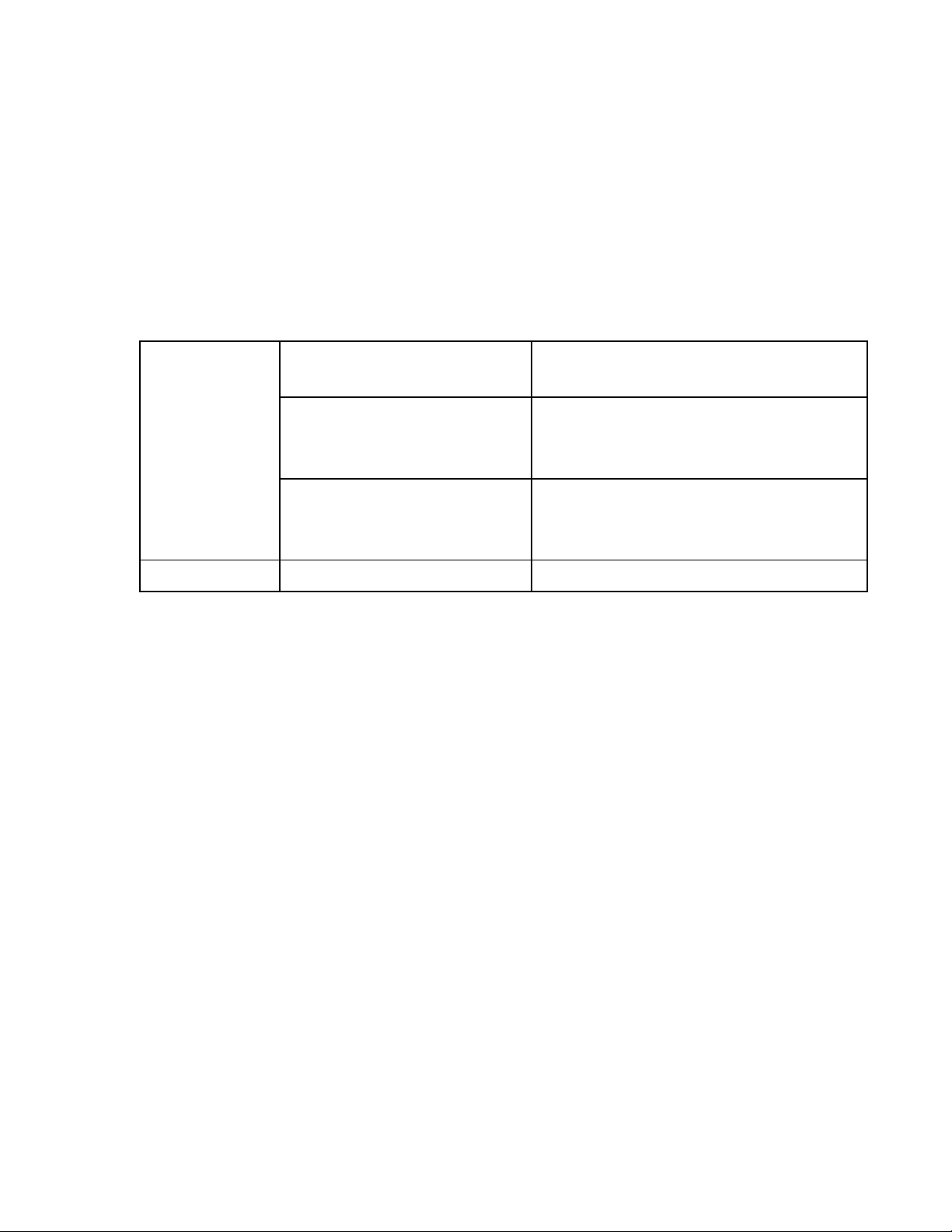

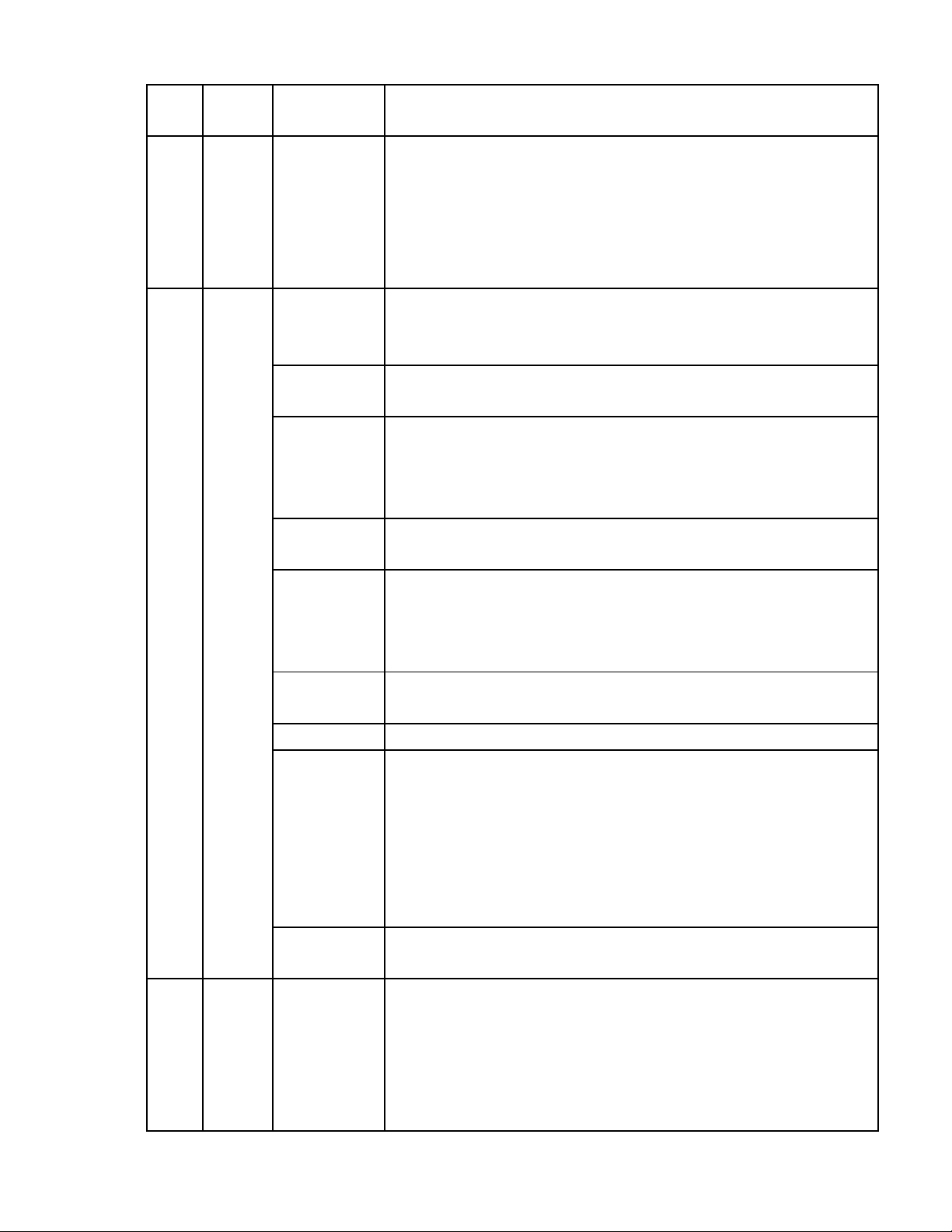

3. MODBUS CONNECTION EXAMPLESS

- 4 -

Page 5

4. JUMPER SETTINGS & FIELD WIRING

1. SAFETY WARNINGS

Digital panel meters, counters, timers and transmitters may be powered with AC (mains) from

85-264 Vac or 95-300 Vdc with standard high voltage power, or 12-34V ac or 10-48 Vdc with the

low voltage power supply option. To avoid the possibility of electrical shock or damaging short

circuits, always unplug the device before opening the case. Please refer to the respective device

manuals for full safety information and instruction on how to open the case. Signal wiring changes

external to the case can be made safely while the units are under power.

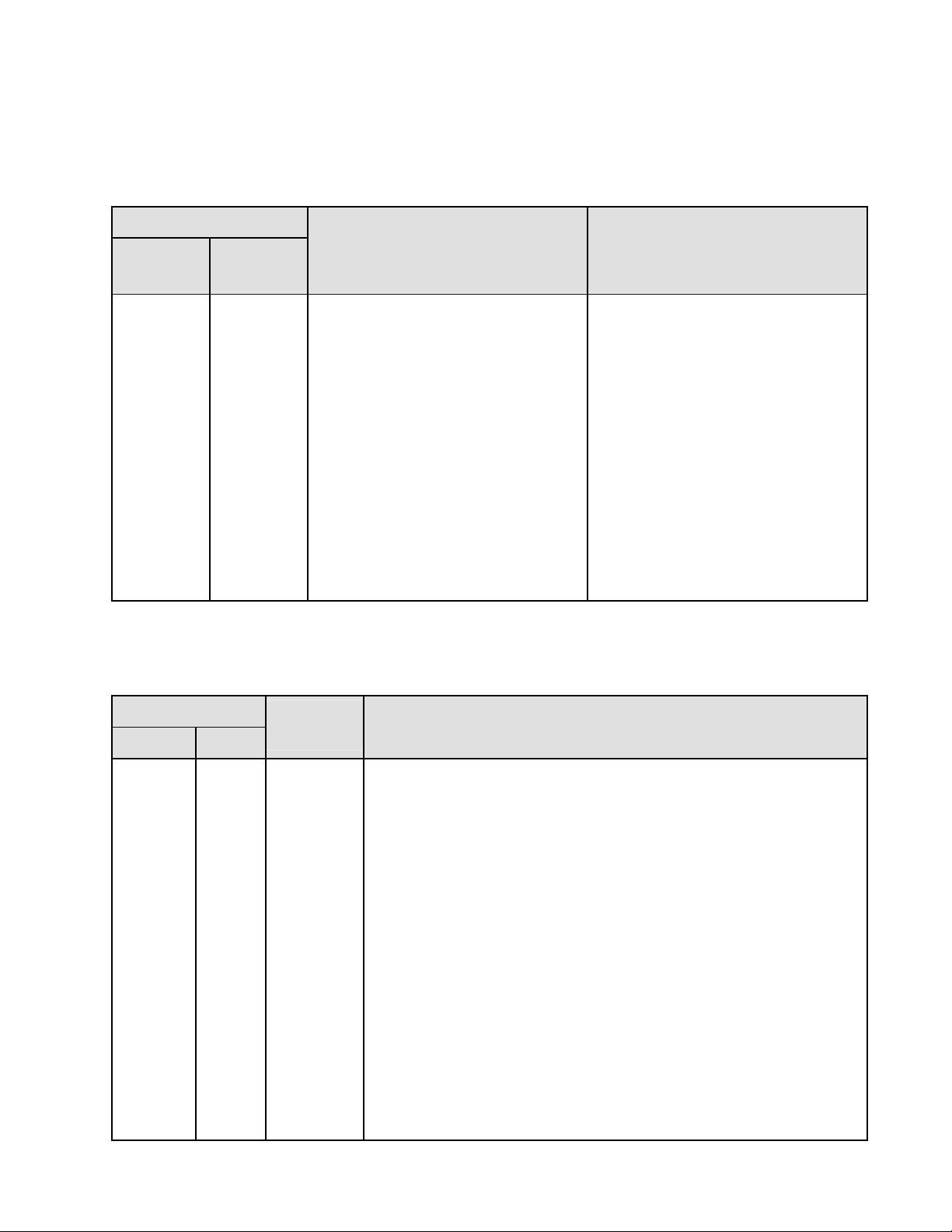

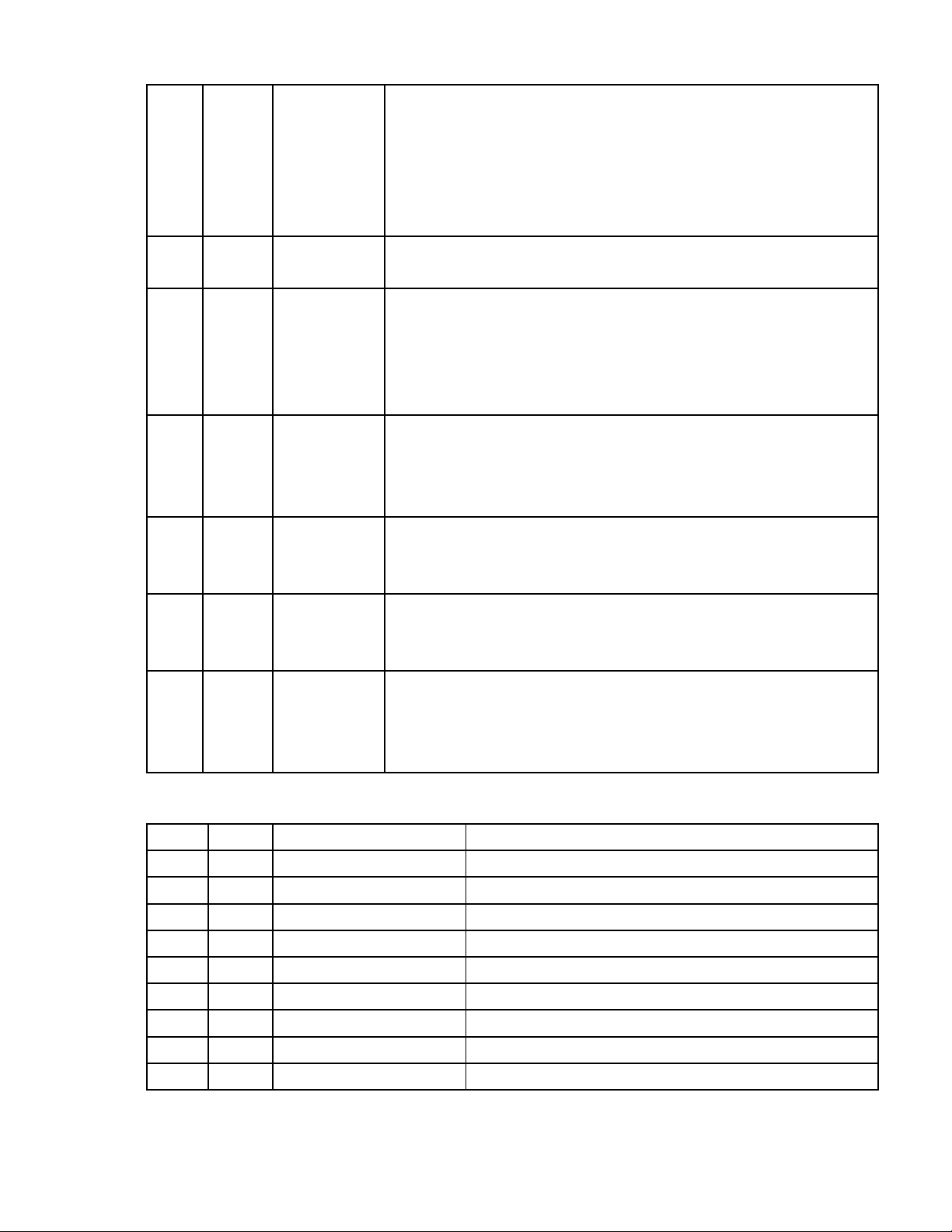

2. JUMPERS ON SERIAL METER BOARDS

- 5 -

Page 6

USB Board &

Basic Ethernet Board

No jumpers needed.

RS232 Board

e - Normal operation.

f - Slave display to RS232 from another meter.

g - Pull-up resistor on RTS line.

Note: Board is shipped with jumpers e and g installed

RS485-Modbus Board, Full Duplex Operation

b & e - Bias jumpers should be installed on 1 board.

a & d - Installed on last meter in long cable run.

RS485-Modbus Board, Half Duplex Operation

b & e - bias jumpers installed on 1 board.

c & f - installed for half duplex operation.

a - installed on last meter in line with long cable runs.

Note: Board is shipped with no jumpers installed.

RS485 Board, Full Duplex Operation

b & d - Installed on last meter in long cable run.

RS485 Board, Half Duplex Operation

a & c - Installed for half duplex operation.

d - Installed on last meter in line with long cable runs.

Note: Board is shipped with no jumpers installed.

Ethernet-to-RS485 Converter Board

& USB-to-RS485 Converter Board

Full Duplex Operation

Modbus

cd

e

f

a

b

RJ45

RJ45

No jumpers for short cable runs.

Add b & d for long cable runs.

Half Duplex Operation

a & c for short cable runs.

d - Installed on last meter in line with long cable runs.

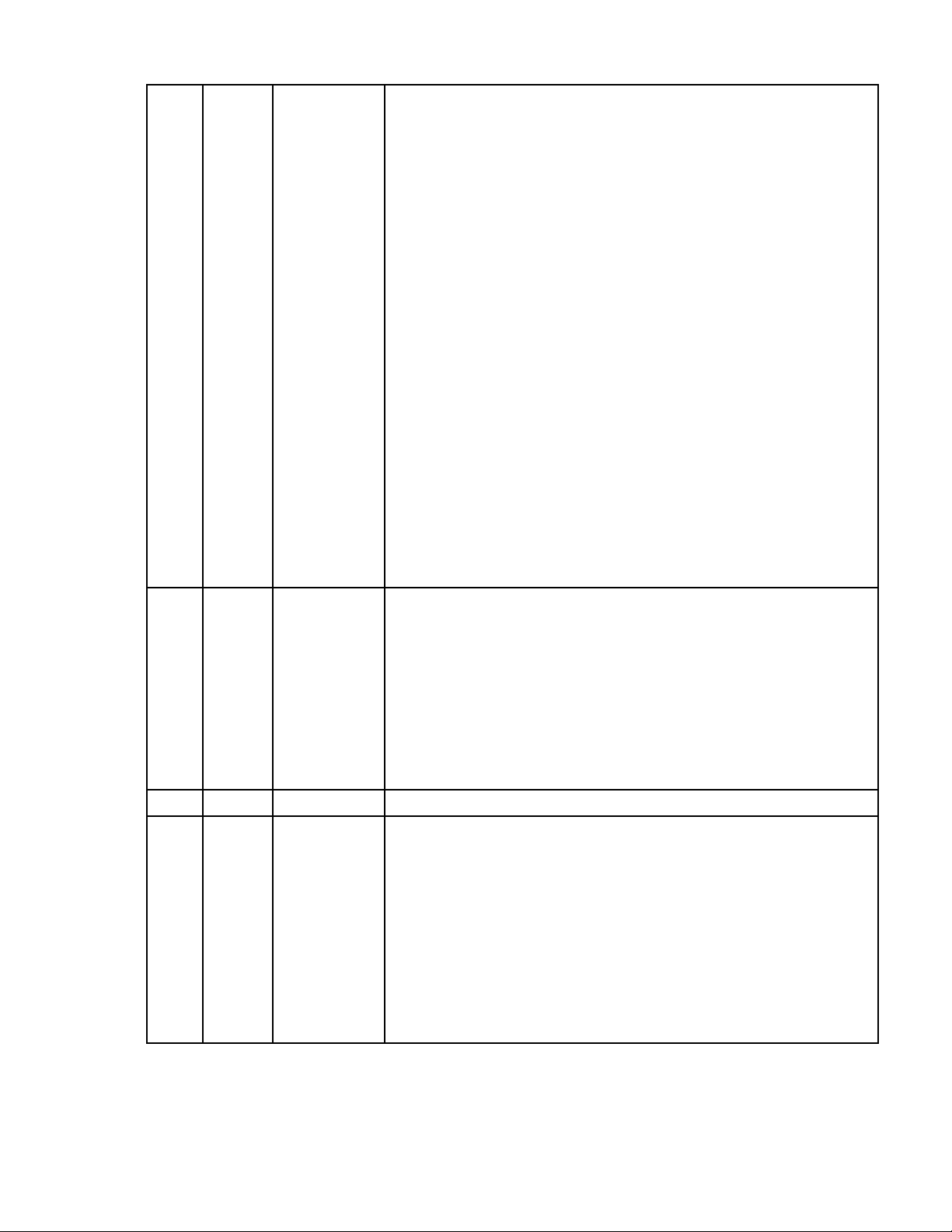

3. CONNECTOR WIRING, SERIAL BOARD TO COMPUTER

- 6 -

Page 7

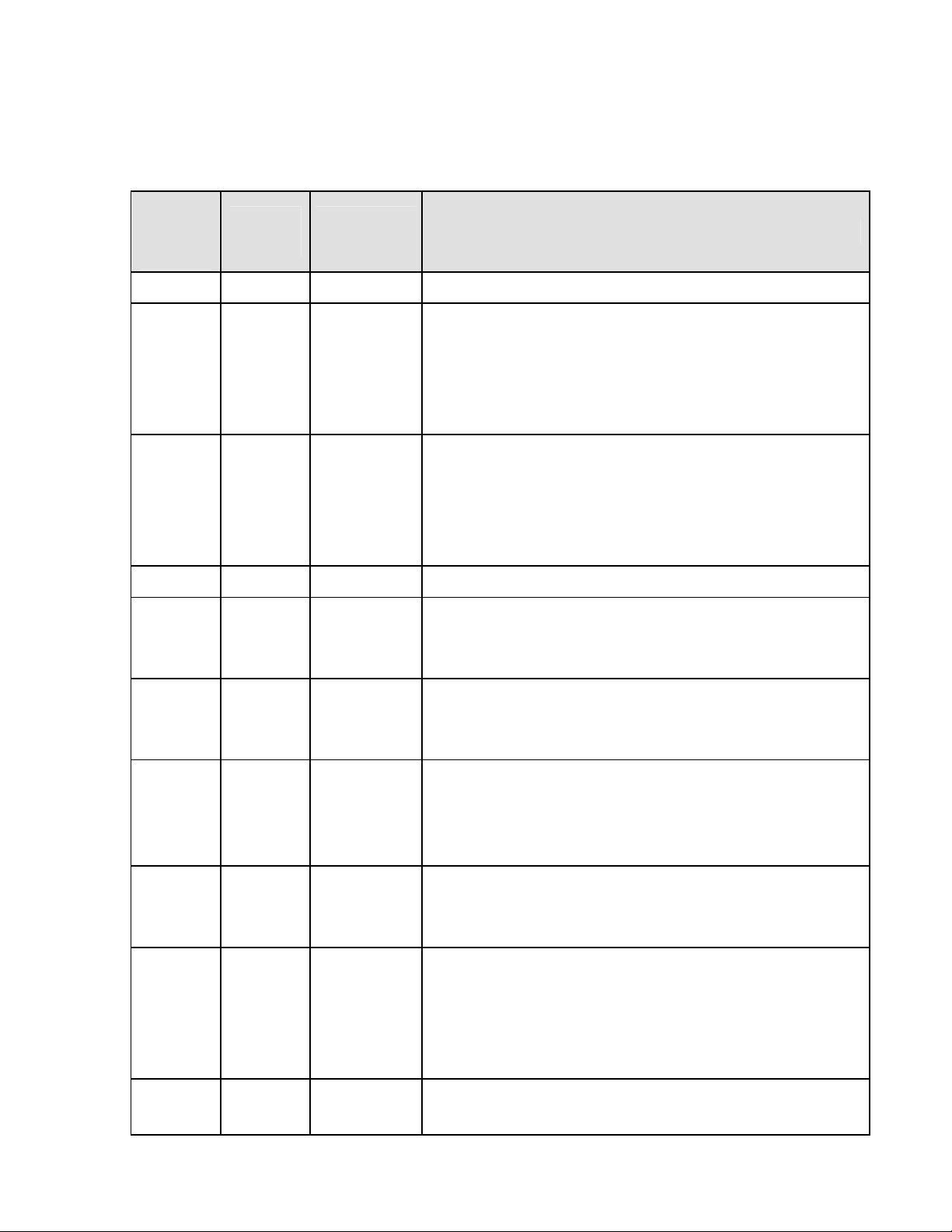

RS232 INTERFACE Computer

N/C

ISO GND

RX

TX

RTS

N/C

RS485 INTERFACE - FULL DUPLEX

ISO GND

BRX

ARX

ATX

BTX

ISO GND

6

5

4

3

2

1

GND

TX

RX

RTS

RS485 INTERFACE - HALF DUPLEX

6

5

4

3

2

1

GND

BTX

ATX

ARX

BRX

GND

ISO GND

ATX / ARX

BTX / BRX

ISO GND

6

5

4

3

2

1

GND

ATX / ARX

BTX / BRX

GND

RS485-MODBUS - FULL DUPLEX RS485-MODBUS - HALF DUPLEX

(A') RXD0 (B') RXD1 +

(B) TXD1 *

(A) TXD0 -

ISO GND

1

2

3

4

5

6

7

8

TXD0

TXD1

RXD1

RXD0

GND

(B) TX / RXD1

(A) TX / RXD0

ISO GND

1

2

3

4

5

6

7

8

(B) TX/RXD1

(A) TX/RXD0

GND

4. TRANSMITTER CONNECTOR WIRING

1

AL2 1

AL2 2

AL1 3

AL1 4

2

3

4

5

P6 Signal

input &

excitation

output

Signal

conditioner

board

6

P2 Serial

P4 Analog

data I/O

output

P3 Solid

state relays

P1 Power

input

See below

for different

signal types

Analog out - 1

Analog out + 2

- 7 -

RS485 RS232

6 N/C TX

5 ARX RX

4 ATX NC

3 GND GND

2 BRX GND

1 BTX N/C

3 Power GND

2 AC neutral or -DC

1 AC high or +DC

5

9

4

8

3

7

2

6

1

RS232 cable with

rear view of DB9

connector to PC

Page 8

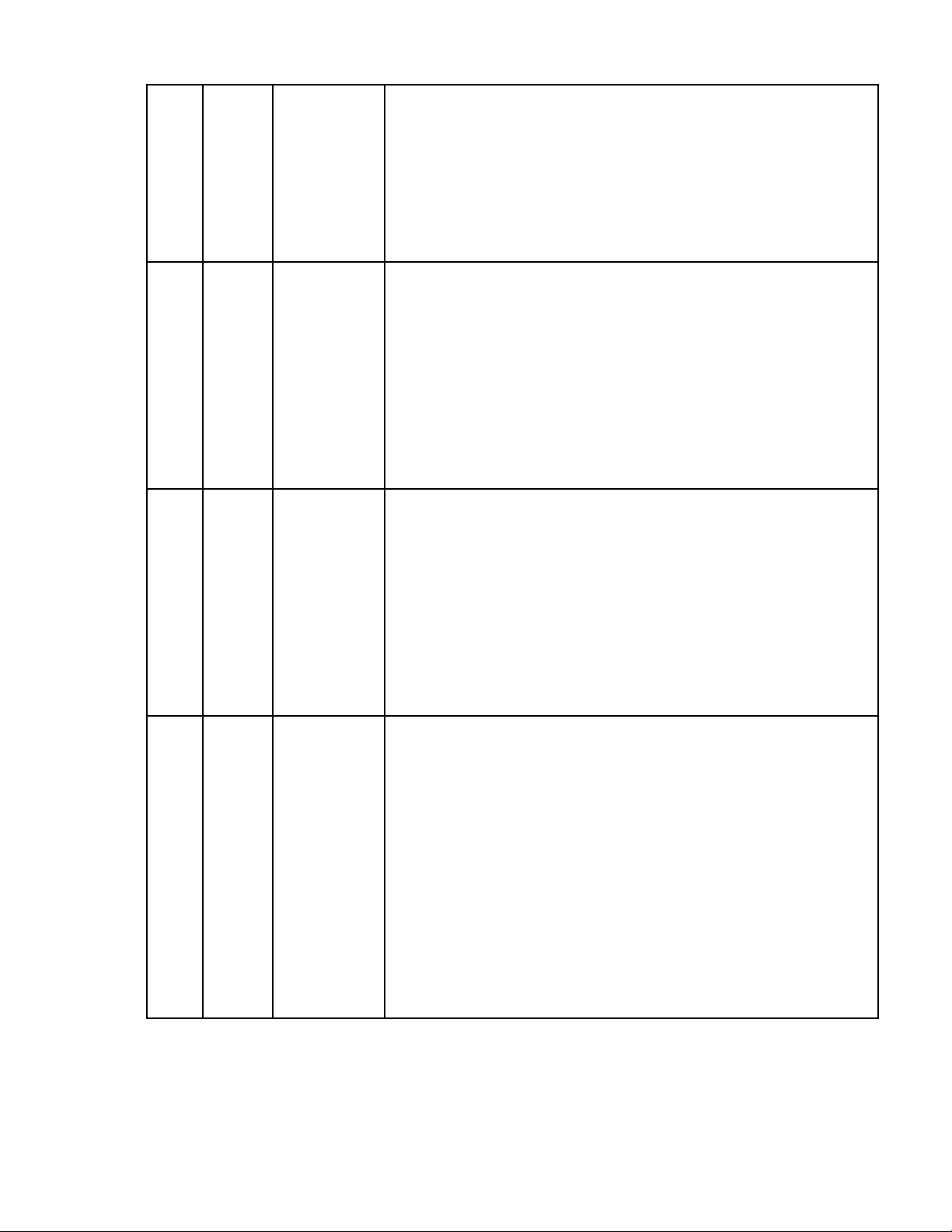

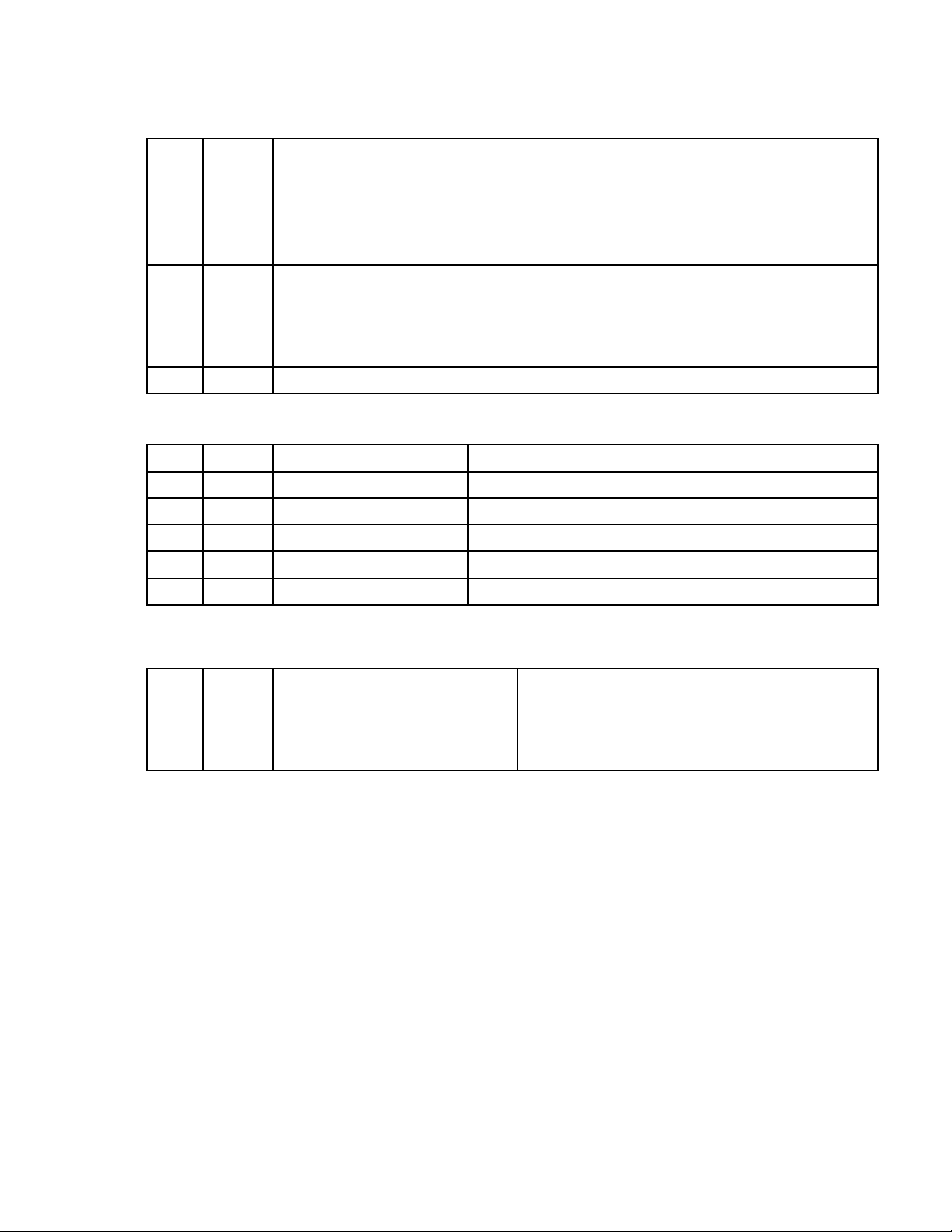

* The termination resistor jumper

a

d

a

E4

b

c

b

E6

settings should only be selected

if the transmitter is the last device

on an RS485 line longer than 200

feet (60 m).

E1

E2

a

E3

c ab

b

cd

and ATX to ARX (same effect as

internal jumpers).

Serial Signal Duplex Jumpers Termination Resistor*

E6 a = Transmit

Full None

** Or jumper external BTX to BRX

RS485

E6 c = Receive

Half E6 b + d** E6 c

RS232 Full None None

Serial Signal Duplex Jumpers Termination Resistor*

E6 a = Transmit

Full None

RS485

E6 c = Receive

Half E6 b + d** E6 c

RS232 Full None None

* The termination resistor jumper settings should only be selected if the transmitter is the last

device on an RS485 line longer than 200 feet (60 m).

** Attempting to draw more than the rated current will shut down the output.

To reset communications to 9600 baud, command mode, Custom ASCII protocol, and Address 1,

place a jumper at E1 and power up the transmitter.

Analog Output Jumpers

Current E2 a + d

Voltage E2 b + c

Excitation Output* Jumpers

5V, 100 mA E3 a + c; E4 a

10V, 120 mA E3 a + c; E4 b

24V, 50 mA E3 b, E4 none

- 8 -

Page 9

5. PROGRAMMING YOUR MODBUS DEVICE

OVERVIEW

Modbus digital panel meters, counters, timers and transmitters are easily programmed via their

serial port using Windows-based Instrument Setup (IS) software, which provides a graphical

user interface and is available at no charge. This software allows uploading, editing, downloading and saving of setup data, execution of commands under computer control, listing,

plotting and graphing of data, and computer prompted calibration. Digital panel meters,

counters and timers can also be programmed via their 4-key front panel as explained in their

respective manuals; however, online programming is easier. For Ethernet, please see our

separate Ethernet Manual.

GETTING STARTED WITH INSTRUMENT SETUP SOFTWARE

To install IS software, download the file

file name to extract three files, double-click

software, press

matching settings between the instrument and PC, and click on

tions have been established, click on

The best way to learn IS software is to experiment with it. From the Main Menu, click on

to retrieve (or get) the existing setup data from your device. Click on

Setup

bring up screens which allow you to edit the setup file using pull-down menus and other

selection tools. You can save your file to disk by clicking on

download (or put) your edited file into the device by clicking on

items will only be displayed if the appropriate hardware has been detected, such as the dual

relay option for meters. Pressing the F1 key at any time will bring up detailed help information.

An analog output is defined in two steps. The input to the device is first scaled to a digital

reading in engineering units, and this reading is then scaled to the analog output. The digital

reading is also used for setpoint control and can be transmitted as serial data.

ADDITIONAL FEATURES

• The Commands pull-down menu allows you to execute certain functions by using your

computer mouse. The

been executed.

Start

=>

Programs

Commands

pull-down menu will be grayed out unless a

instrument.exe

on setup.exe

=>

IS2

=>

Main Menu

from our website, double-click on the

, and follow the prompts. To launch IS

IS2

. Establish communications by selecting

Establish

.

. Once communica-

Get

View

= >

Setup

to

File

= >

Save Setup

Put Setup

. You can

. Programmable

Get Setup

has

• The Readings pull-down menu provides three formats to display input data on your PC

monitor. In all formats, use the

collection, then press

readings in a 20-row by 10-column table. Plot generates a plot of digital readings vs. time in

seconds, like an oscilloscope. Graph generates a histogram, where the horizontal axis is the

reading and the vertical axis is the number of readings.

- 9 -

Print

for a hardcopy on your PC printer. List presents the latest digital

Pause

and

Continue

buttons to control the timing of data

Page 10

6. MODBUS PROTOCOL IMPLEMENTATION

1. GENERAL

The Modbus capability conforms to the Modbus over Serial Line Specification & Implementation guide, V1.0. Both the Modbus RTU and Modbus ASCII protocols are implemented:

Modbus RTU

Baud Rate........... .............................................. 300, 600, 1200, 2400, 4800, 9600 or 19200

Data Format ....... ........................1 start bit, 8 data bits, 1 parity bit, 1 stop bit (11 bits total)

Parity.................. ............................. None, Odd, Even (if None, then 2 Stop bits for 11 total)

Address.............. ...............................................0 for broadcast, 1-247 for individual meters

Modbus ASCII

Baud Rate........... .............................................. 300, 600, 1200, 2400, 4800, 9600 or 19200

Data Format ....... ...................... 1 Start bit, 7 Data bits, 1 Parity bit, 1 Stop bit (10 bits total)

Parity.................. ............................. None, Odd, Even (if None, then 2 Stop bits for 10 total)

Address.............. ...............................................0 for broadcast, 1-247 for individual meters

2. FRAMING

Modbus RTU

Message frames are separated by a silent interval of at least 3.5 character times. If a silent

interval of more than 1.5 character times occurs between two characters of the message frame,

the message frame is considered incomplete and is discarded. Frame Check = 16 bit CRC of the

complete message excluding CRC characters.

Modbus ASCII

The message begins immediately following a colon (:) and ends just before a Carriage Return/

Line Feed (CRLF). All message characters are hexadecimal 0-9, A-F (ASCII coded). The system

allowable time interval between characters may be set to 1, 3, 5 or 10 seconds. Frame Check =

1 byte (2 hexadecimal characters) LRC of the message excluding the initial colon (:) and trailing

LRC and CRLF characters.

3. ELECTRICAL INTERFACE

Four-wire (plus common) full-duplex or two-wire (plus common) half-duplex RS485 signal

levels are jumper selectable for digital panel meters, counters and timers. A polarization

resistor and termination resistor are also jumper selectable. In case of a long line (greater then

500 ft) to the first device, a termination resistor should be selected for the first device. In case

of a long line length (greater then 500 ft) between the first and last devices, a termination

resistor should be selected for the first and last devices. Never add termination resistors to

more than two devices on the same line. A two-wire, half-duplex RS485 signal level is jumper

selectable for transmitters.

- 10 -

Page 11

4. PARAMETERS SELECTABLE VIA INSTRUMENT SETUP (IS) SOFTWARE

Serial Protocol .................................................. Custom ASCII, Modbus RTU, Modbus ASCII

Modbus ASCII Gap Timeout.......................................................... 1 sec, 3 sec, 5 sec, 10 sec

Baud Rate..............................................................300, 600, 1200, 2400, 4800, 9600, 19200

Parity ...............................No parity, 2 stop bits; odd parity,1 stop bit; even parity, 1 stop bit

Device Address .........................................................................................................0 to 247

5. PARAMETERS SELECTABLE VIA FRONT PANEL METER SETUP

The two menu items related specifically to Modbus setup are SEr_4 and Addr.

SEr_4

Serial Comm 4

000

Modbus ASCII Gap Timeout

000

Serial Protocol

000

Parity

Addr 000 Meter Address Set to desired address 1-247

The baud rate is set in SEr_1 per the Meter manual. The selection of Modbus RTU or

Modbus ASCII in SEr_4 above overrides any LF or Command Mode selections that have

been made, since they are determined by the Modbus protocol.

6. SUPPORTED FUNCTION CODES

FC03: Read Holding Registers. Reads internal registers containing setup parameters

(Scale, Offset, Setpoints, etc.)

FC04: Read Input Registers. Reads measurement values and alarm status

0 1 Sec 2 5 Sec

1 3 Sec 3 10 Sec

0 Customl ASCII (Non-Modbus)

1 Modbus RTU

2 Modbus ASCII

0 No Parity, 2 or more stop bits

1 Odd Parity, 1 or more stop bits

2 Even Parity, 1 or more stop bits

FC05: Write Single Coil. Action command to device

FC08: Diagnostics. Checks communications between Master and Slave.

FC10: Write Multiple Registers (FC10 = 16 dec). Writes internal registers containing

setup parameters (Scale, Offset, Setpoints, etc.)

7. REGISTER NUMBERS VS. METER ADDRESSES

Some Master devices (e.g., Modicon) require that the desired Register Number and not the

Register Address be entered. The Register Number is 1 higher than the Register Address.

For entry to these devices, add 1 to the Register Address shown in the tables below. The

Register Address shown will then be output from these devices.

- 11 -

Page 12

FC04: Read Input Registers

Reads measurement values and alarm status. Returns values in M31 or 2C32 format without

decimal point (see Sec 11, p 16). The displayed system decimal point can be read with FC03 at

addr 0057. Use only high word Starting Register Addresses and an even number of Registers.

Register Address

Base 1

Std addr.

00 01

00 02

00 03

00 04

00 05

00 06

00 07

00 08

00 09

00 0A

00 0B

00 0C

Base 0

PLC addr.

00 02

00 03

00 04

00 05

00 06

00 07

00 08

00 09

00 0A

00 0B

00 0C

00 0D

Meter or Analog Input

Transmitter Response

(M31 format)

Hi word of Alarm status

Lo word of Alarm status

Hi word of Measurement value *

Lo word of Measurement value *

Hi word of Peak value

Lo word of Peak value

Hi word of Valley value **

Lo word of Valley value **

N/A

N/A

N/A

N/A

* Net value for Scale Meter. ** Gross value for Scale Meter.

FC05: Write Single Coil: Action command to device

Counter, Timer, or Pulse Input

Transmitter Response

(2C32 format)

Hi word of Alarm status

Lo word of Alarm status

Hi word of Item 1 value

Lo word of Item 1 value

Hi word of Peak value

Lo word of Peak value

Hi word of Valley value

Lo word of Valley value

Hi word of Item 2 value

Lo word of Item 2 value

Hi word of Item 3 value

Lo word of Item 3 value

Output Address

Base 1 Base 0

00 01

00 02

00 03

00 04

00 05

00 06

00 07

00 08

00 09

00 0A

00 0B

00 0D

00 0E

00 0F

00 10

00 02

00 03

00 04

00 05

00 06

00 07

00 08

00 09

00 0A

00 0B

00 0C

00 0E

00 0F

00 10

00 11

Output

Value

FF 00

FF 00

FF 00

FF 00

FF 00

FF 00

FF 00

FF 00

FF 00

FF 00

FF 00

FF 00

FF 00

FF 00

FF 00

Action Command

Device Reset (No Response)

Function Reset (Peak, Valley, latched alarms)

Latched Alarm Reset (only)

Peak Reset

Valley Reset

Remote Display Reset (Counters in Remote Display Mode)

Display Item 1 (Meters, Counters, Timers)

Display Item 2 (Counters, Timers)

Display Item 3 (Counters, Timers)

Display Peak (Meters, Counters, Timers)

Display Valley (Meters except Weight, Counters, Timers)

Meter Hold (output value = 00 00 resets Meter Hold)

Blank Display (output value = 00 00 resets Display Blank)

Activate External Input A (output value = 00 00 deactivates)

Activate External Input B (output value = 00 00 deactivates)

- 12 -

Page 13

FC08: Diagnostics

Checks communications between the Master and Slave, and returns the count in the Modbus

Slave counters (which are reset when the meter is reset).

Hex Sub

Function

Data

Sent

Response

Data

Description

Code

00 00 Any Same Returns Query Data (N x 2 bytes). Echo Request.

00 01

Restarts Communications. If in the Listen-Only mode,

no response occurs. Takes Slave out of the ListenOnly mode and one of the following:

FF 00

00 00

FF 00

00 00

— Clears communications event counters.

— Does not clear communications event counters.

00 04 00 00 None Forces Listen-Only. All addressed and broadcast

Messages are monitored and counters are incremented, but no action is taken or response sent. Only

Sub-Function 00 01 causes removal of this ListenOnly state.

00 0A 00 00 00 00 Clears all Modbus slave counters.

00 0B 00 00 Total

Message

Count

Returns total number of messages detected on the

bus, including those not addressed to this Slave.

Excludes bad LRC/CRC, parity error or length < 3.

00 0C 00 00 Checksum

Error Count

Returns total number of messages with bad LRC/

CRC, parity or length < 3 errors detected on the bus

including those not addressed to the Slave.

00 0D 00 00 Exception

Error Count

Returns total number of Exception responses

returned by the Addressed Slave or that would have

been returned if not a broadcast message or if the

Slave was not in a Listen-Only mode.

00 0E 00 00 Slave

Message

Count

00 0F 00 00 No

Response

Count

Returns total number of messages, either broadcast

or addressed to the Slave. Excludes bad LRC/CRC,

parity or length < 3 errors.

Returns total number of messages, either broadcast

or addressed to the Slave, for which Slave has

returned No Response, neither a normal response nor

an exception response. Excludes bad LRC/CRC, parity

or length < 3 errors.

00 11 00 00 Slave Busy Returns total number of Exception Code 6 (Slave

Busy) responses.

- 13 -

Page 14

8. SUPPORTED EXCEPTION RESPONSE CODES

Code

Name Error Description

01 Illegal Function Illegal Function Code for this Slave. Only hex Function

Codes 03, 04, 05, 08, 10 (dec 16) are allowed.

02 Illegal Data Address Illegal Register Address for this Slave and/or Register

Length.

03 Illegal Data Value Illegal data value or data length for the Modbus protocol.

04 Slave Device Failure Slave device failure (eg. Device set for external gate).

9. MESSAGE FORMATTING

MA = Meter Address DD = Data (Hex) CL = CRC Lo Byte

FC = Function Code WW = Data (On/Off) CH = CRC Hi Byte

RA = Register Address SF = Sub-Function CR = Carriage Return

NR = Number of Registers EC = Error Code LF = Line Feed

NB = Number of bytes LRC = ASCII Checksum

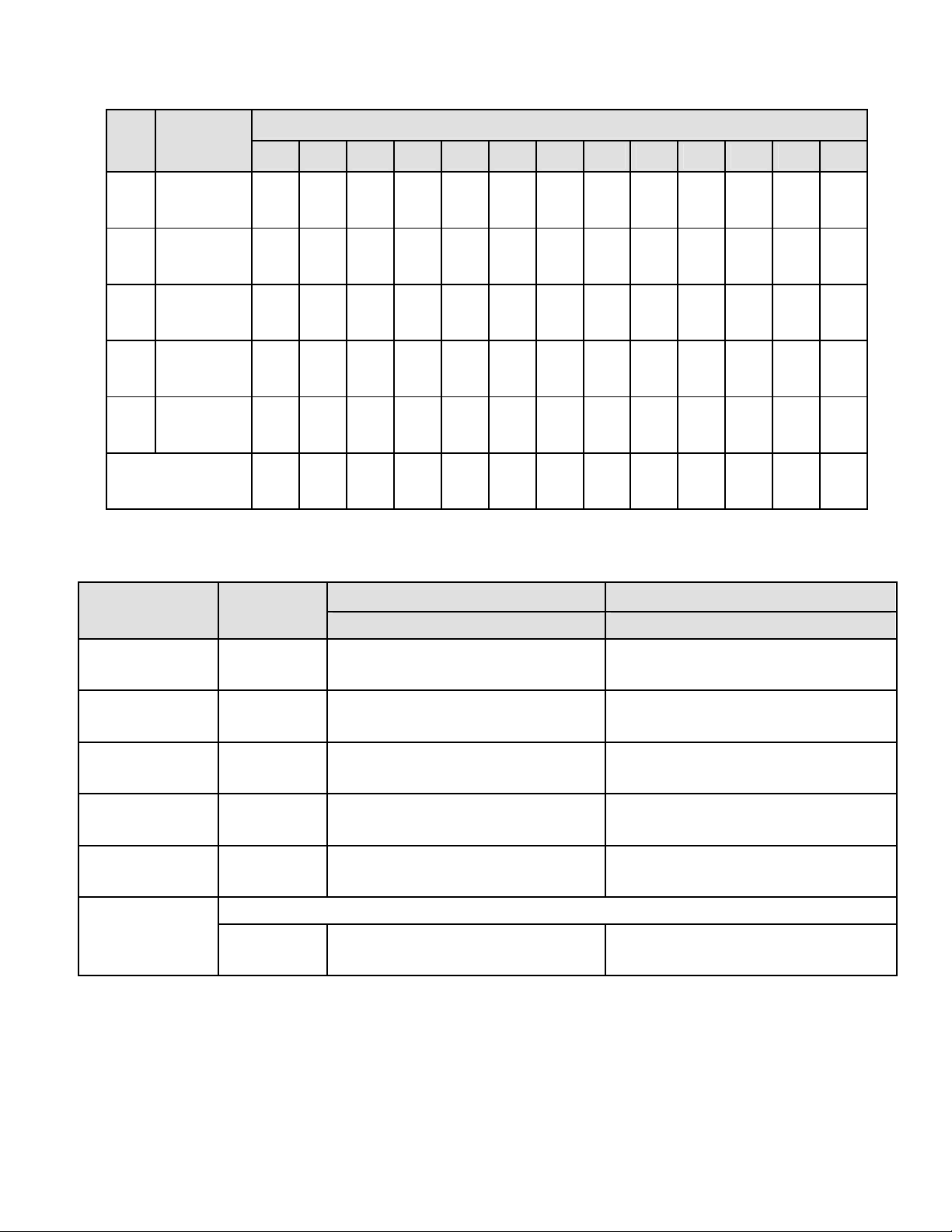

Modbus RTU Format

FC Action

03

Request

03

Response

04

Request

04

Response

05

Request

05

Response

08

Request

08

Response

10

Request

10

Response

Exception

Response

Modbus ASCII Format

> 3.5

Char

NoTx

NoTx

NoTx

NoTx

NoTx

NoTx

NoTx

NoTx

NoTx

NoTx

1 2 3 4 5 6 7 8 9 10 11

MA

MA

MA

MA

MA

MA

MA

MA

MA

MA

FC

FC

FC

FC

FC

FC

FC

FC

FC

FC

NoTx MA FC

RA

NB

RA

NB

RA

RA

RA

RA

SF

SF

RA

DD*

RA

DD*

RA

RA

SF

SF

RA

RA

EC CL CH

Byte Number

NR

NR

DD*

NR

DD*

WW

WW

WW

DD

NR

NR

CL

NR

CL

WW

WW

WW

DD

NR

NR

CL

CH

CL

CH

CL

CL

CL

CL

NB

CL

+80

DD* = (DD DD) times NR (Number of Registers)

CH

CH

CH

CH

CH

CH

DD*

DD* CL CH

CH

Except for the colon, CR and LF, each column is 2 hex character bytes.

DD* = (DD DD) times NR (Number of Registers)

- 14 -

Page 15

Read Setpoint 1

FC Action

Column Number

1 2 3 4 5 6 7 8 9 10 11 12 13

03

Request

03

Response : :

04

Request

04

Response : :

05

Request

05

Response : :

08

Request

08

Response : :

10

Request

10

Response : :

Exception

Response

MA

MA

MA

MA

MA

MA

MA

MA

MA

MA

FC

FC

FC

FC

FC

FC

FC

FC

FC

FC

: MA FC

+80

RA

NB

RA

NB

RA

RA

RA

RA

SF

SF

RA

DD*

RA

DD*

RA

RA

SF

SF

RA

RA

NR

DD*

NR

DD*

WW

WW

WW

DD*

NR

NR

NR

LRC

NR

LRC

WW

WW

WW

DD*

NR

NR

LRC

CR

LRC

CR

LRC

LRC

LRC

LRC

NB

LRC

EC LRC CR LF

10. MESSAGE EXAMPLES FOR DEVICE ADDRESS = 01, NO PARITY

CR

LF

CR

LF

CR

CR

CR

CR

DD*

CR

LF

LF

LF

LF

LF

LF

DD*

LRC CR LF

LF

Example Action

Modbus RTU Modbus ASCII

Ser_4 = 010 Addr = 001 Ser_4 = 020 Addr = 001

Restart Communications*

Meter Reset Request

Digital Reading

= +25.18

Write Setpoint

1 = +37.00

= +37.00

Request

Response

Response

Request

Response

Request

Response

Request

Response

010800010000B1CB

010800010000B1CB

01050001FF00DDFA

None

01040003000281CB

010404000009D67C4A

0110000100020400000E743624

0110000100021008

01030001000295CB

01030400000E74FE74

:010800010000F6crlf

:010800010000F6crlf

:01050001FF00FAcrlf

None

:010400030002F6crlf

:010404000009D618crlf

:0110000100020400000E7466crlf

:011000010002ECcrlf

:010300010002F9crlf

:01030400000E7476crlf

First send decimal point, address 0057 as 00 03. Send -12.34 to

Remote Display

**

Request

Response

01100069000204FFFFFB2EF6E5

01100069000291D4

:01100069000204FFFFFB2E59crlf

:01100069000284crlf

* Suggested as first message after power-up. If device is in Listen-Only mode, no response is

returned.

** 1234 decimal = 000004D2 hex. -1234 = FF FF FB 2E in 4-byte 2’s complement hex. Decimal point

is ignored.

RTU: Bolded last 4 characters indicate the CRC (added automatically by the device).

ASCII: Bolded last 2 characters indicate the LRC ((added automatically by the device).

- 15 -

Page 16

Because the Counter/Timer can provide up to 3 display items during normal operation, it can

Note:

be used to provide additional features when used as a Remote Display. It is possible to send

Remote Data to Item 3 using addresses 006B,C or 006D,E. If the Counter/Timer is set up with

the "Source" menu item set to Item 3, it will make alarm comparisons to its Setpoints using the

Remote Data. Likewise, the Analog Output will respond to the Remote Data if "AnSEt" selects

Item 3 for the Analog Output source and the Display mode (Config Dig 3 = 7).

Address 0069,A sends Remote Data to the display only (any Display mode).

Address 006B,C sends Remote Data to Item 3 only for Alarms and/or Analog Out.

Address 006D,E sends Remote Data to both the display and Item 3.

11. DATA TYPES INTERNAL REGISTERS

S = Sign Bit, 0 = Positive, 1 = Negative.

DDD = Decimal Point XXXXXX. = 1 (Magnitude x 10^0)

XXXXX.X = 2 (Magnitude x 10^-1)

XXXX.XX = 3 (Magnitude x 10^-2)

XXX.XXX = 4 (Magnitude x 10^-3)

Meters and the

analog input transmitter

only have 5 digits and 5

decimal points.

XX.XXXX = 5 (Magnitude x 10^-4)

X.XXXXX = 6 (Magnitude x 10^-5)

C = Bits of 2's Complement Binary Value

M = Bits of Positive Binary Magnitude

B = Bits of Configuration Data

For Modbus RTU, each data character consists of 8 bits (or 1 byte).

For Modbus ASCII, each data character consists of 4 bits (or 1 hexadecimal nibble).

Data characters are sent most significant first, lease significant last.

2C32 Two's Complement (4 bytes)

Hi Word (Register) Lo Word (Register) .

CCCC CCCC CCCC CCCC CCCC CCCC CCCC CCCC

M32 Binary Magnitude (4 bytes)

Hi Word (Register) Lo Word (Register) .

MMMM MMMM MMMM MMMM MMMM MMMM MMMM MMMM

M31 Sign + Binary Magnitude (4 bytes)

Hi Word (Register) Lo Word (Register) .

SMMM MMMM MMMM MMMM MMMM MMMM MMMM MMMM

M48 Binary Magnitude (6 bytes

Hi Word (Register) Mid Word (Register) Lo Word (Register) .

XXXX XXXX MMMM MMMM MMMM MMMM MMMM MMMM MMMM MMMM MMMM MMMM

Ignore XXXX XXXX - Use LS 5-byte result

- 16 -

Page 17

B16 Bit Significance M16 Binary Magnitude M15 Sign + Binary Magnitude

Hi Byte Lo Byte . Hi Byte Lo Byte . Hi Byte Lo Byte .

0000 0000 BBBB BBBB XXXX XXXX XXXX XXXX SXXX XXXX XXXX XXXX

7654 3210

12. METER & ANALOG INPUT TRANSMITTER INTERNAL REGISTER ADDRESSES

Data Types - as shown: FC03 READ and FC10 (dec16) WRITE

Use high word starting Register Addresses and an even number of Registers.

Register Address

Register Name

Dec* Hex*

1 0001 Setpoint 1 (Hi word)

2 0002 Setpoint 1 (Lo word)

3 0003 Setpoint 2 (Hi word)

4 0004 Setpoint 2 (Lo word)

5 0005 Setpoint 3 (Hi word) (not for Scale Meter)

6 0006 Setpoint 3 (Lo word) (not for Scale Meter)

7 0007 Setpoint 4 (Hi word) (not for Scale Meter)

8 0008 Setpoint 4 (Lo word) (not for Scale Meter)

9 0009 Scale (Hi word)

10 000A Scale (Low word)

11 000B Offset (Hi word)

12 000C Offset (Low word)

17 0011 Lo In (Hi word)

18 0012 Lo In (Low word)

19 0013 Lo Rd (Hi word)

20 0014 Lo Rd (Low word)

Data

Type

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

Scaling &

Dec Point

Dec pt same

as displayed

Dec pt same

as displayed

Dec pt same

as displayed

Dec pt same

as displayed

** See

footnote

Dec pt same

as displayed

Uses dec pt

of input range

Dec pt same

as displayed

21 0015 Hi In (Hi word)

Uses dec pt

2C32

22 0016 Hi In (Low word)

23 0017 Hi Rd (Hi word)

of input range

Dec pt same

2C32

24 0018 Hi Rd (Low word)

25 0019 Rd0 (Hi word) (tare for Scale Meter)

as displayed

Dec pt same

2C32

26 001A Rd0 (Lo word) (tare for Scale Meter)

33 0021 Deviation 1 (Hi word) (SP1DIFF for Sc M)

as displayed

Dec pt same

2C32

34 0022 Deviation 1 (Lo word) (SP1DIFF for Sc M)

35 0023 Deviation 2 (Hi word) (SP2DIFF for Sc M)

as displayed

Dec pt same

2C32

36 0024 Deviation 2 (Lo word) (SP2DIFF for Sc M)

37 0025 Deviation 3 (Hi word) (not for Scale Meter)

as displayed

Dec pt same

2C32

38 0026 Deviation 3 (Lo word) (not for Scale Meter)

as displayed

39 0027 Deviation 4 (Hi word) (not for Scale Meter) 2C32 Dec pt same

- 17 -

Page 18

40 0028 Deviation 4 (Lo word) (not for Scale Meter)

as displayed

41 0029 Analog Lo (Hi word)

2C32

42 002A Analog Lo (Lo word)

43 002B Analog Hi (Hi word)

2C32

44 002C Analog Hi (Lo word)

* Values are for Base 1 Standard addressing. Add 1 for Base 0 PLC addressing.

** Scale = .0001 x dec value of (Hi word + Lo word)

Data Type B16

For the following, use any starting Register Address and any number of Registers.

Register Address

Register Name Bit Significance

Dec Hex

65

0041 Alarm Config 1 Bit 0 0 = AL1 Hi Active 1 = Lo Active

Bit 1 0 = AL1 Enabled, 1 = Disabled

Bit 2 0 = AL2 Hi Active 1 = Lo Active

Bit 3 0 = AL2 Enabled 1 = Disabled

Bit 4 0 = AL1 Non-Latched 1 = Latched

Bit 5 0 = AL2 Non-Latched 1 = Latched

Bit 6 0 = Relay1 Active On 1 = Off

Bit 7 0 = Relay2 Active On 1 = Off

Dec pt same

as displayed

Dec pt same

as displayed

66 0042 Alarm Config 2 Bits 2:0 # Readings before Alarms 1 & 2.

000 = 1, 001 = 2, 010 = 4, 011 = 8, 100 = 16,

101 = 32, 110 = 64, 111 = 128

Bit 3 AL1 0 = Deviation 1 = Hysteresis

Bit 4 AL2 0 = Deviation 1 = Hysteresis

Bit 5 0 = Deviation in Menu 1 = Omitted

67 0043 Alarm Config 3

(not applicable

to Scale Meter)

Bit 0 0 = AL3 Hi Active 1 = Lo Active

Bit 1 0 = AL3 Enabled 1 = Disabled

Bit 2 0 = AL4 Hi Active 1 = Lo Active

Bit 3 0 = AL4 Enabled 1 = Disabled

Bit 4 0 = AL3 Non-Latched 1 = Latched

Bit 5 0 = AL4 Non-Latched 1 = Latched

Bit 6 0 = Relay3 Active On 1 = Off

Bit 7 0 = Relay4 Active On 1 = Off

68 0044 Alarm Config 4

(not applicable

to Scale Meter)

Bits 2:0 = # Readings before Alarm 3 & 4

000 = 1, 001 = 2, 010 = 4, 011 = 8, 100 = 16,

101 = 32 110 = 64 111 = 128

Bit 3 AL3 0 = Deviation 1 = Hysteresis

Bit 4 AL4 0 = Deviation 1 = Hysteresis

Bit 5 0 = Deviation in Menu 1 = Omitted

- 18 -

Page 19

69 0045 Input Type Lo Byte Hex value

40-4D Thermocouple JF, C, KF, KC, NF, NC, EF, EC,

TF, TC, SF, SC, RF, RC

50-5C RTD pre-2009: 4-wire DIN°F, 4-wire DIN°C,

50-57 RTD post-2009: DIN°F, DIN°C, ANSI°F,

60-64 DC 0.2V, 2V, 20V, 200V, 660V

70-73 DC 2 mA, 20 mA, 200 mA, 5A

A0-A2 Ratio 0.2V, 2V, 20V

80-84 RMS 0.2V, 2V, 20V, 200V, 660V

90-93 RMS 2 mA, 20 mA, 200 mA, 5A

C0-C4 Strain 20, 50, 100, 250, 500 mV

D0-D4 Load Cell 20, 50, 100, 250, 500 mV

E0-E4 Ohms 20, 200, 2000, 20K, 200K

4-wire ANSI°F, 4-wire°C, 3-wire DIN°F, 3-wire

DIN°C, 3-wire ANSI°F, 3-wire ANSI°C, 2-wire

DIN°F, 2-wire DIN°C, 2-wire ANSI°F, 2-wire

ANSI°C, Short

ANSI°C, Ni°F, Ni°C, Cu°F, Cu°C,

70 0046 Setup

(applicable to

DPM)

M = Meter

F = Function

D = Display

Bits 3:0 Ctrl In 1 Ctrl In 2 Both Reset

Hex 0 M Reset M Hold M Reset

Hex 1 F Reset Pk, Vy M Reset

Hex 2 M Hold Pk, Vy F Reset

Hex 3 M Hold Tare M Reset

Hex 4 Pk, Vy Tare FReset

Hex 5 Tare M Reset M Reset

Hex 6 DP2 DP3 DP5 Neither = DP1

Hex 7 DP3 DP4 DP6 Neither = DP2

Hex 8 F Reset D Blank M Reset

Hex 9 M Hold D Blank M Reset

Hex A Pk, Vy D Blank F Reset

Hex B Tare D Blank M Reset

Hex C Valley Peak F Reset

Hex D Tare T Reset M Reset

Bits 5:4

Hex 00 Scale using Scale, Offset

Hex 01 Scale using Coordinates of 2 Points

Hex 10 Scale using Reading Coordinates

Bit 6 Spare

Bit 7 0 = 60 Hz, 1 = 50 Hz

- 19 -

Page 20

70 0046 Setup

(applicable to

Scale Meter)

M = Meter

F = Function

D = Display

T = Tare

Bits 3:0 Ctrl In 1 Ctrl In 2 Both Reset

Hex 0 M Reset M Hold M Reset

Hex 1 F Reset Peak D M Reset

Hex 2 M Hold Peak D F Reset

Hex 3 M Hold Tare Tare

Hex 4 Peak Tare F Reset

Hex 5 M Reset Tare M Reset

Hex 6 F Reset Tare M Reset

Hex 7 T Reset Tare M Reset

Hex 8 D Blank Tare M Reset

Hex 9 M Reset D Blank M Reset

Hex A F Reset D Blank M Reset

Hex B D Item Tare Tare

Hex C D Item D Blank F Reset

Hex D M Reset D Item M Reset

Hex E F Reset D Item M Reset

Hex F M Hold D Item M Reset

Bit 4 0 = Scale, Offset 1 = Coord of 2 Points

Bit 5 0 = Peak key is Peak 1 = Peak key is Tare

Bit 6 0 = 60 Hz 1 = 50 Hz

Bit 7 0 = No dummy zero 1 = Dummy zero

71 0047 Filter Bits 3:0 Filtering

Hex 0 = Auto Filter, 1 = Batch 16, 2-9 = Moving

Avg, 2 = .08S, 3 = .15S, 4 = .3S, 5 = .6S, 6 = 1.2S,

7 = 2.4S, 8 = 4.8S, 9 = 9.6S, A = Unfiltered

Bit 4 0 = Low Adaptive 1 = High Adaptive

Bit 5 0 = Display Batch of 16 1 = Display Filtered

Bit 6 0 = Peak of Unfiltered 1 = Peak of Filtered

Bit 7 0 = Alarm source Unfiltered, 1 = Filtered

72 0048 Options Do Not Use.

73 0049 Serial Config 1 Bits 3:0 Time between Continuous Serial Outputs

Hex 0=.017S, 1=.28S, 2=.57S, 3=1.1S, 4=2.3S,

5=4.5S, 6=9.1S, 7=18.1S, 8=36.3S, 9=1M13S,

A=2M25S, B=4M50S, C=9M40S, D=19M20S,

E=38M41S, F=77M21S

Bits 6:4 Baud Rate

000 = 300, 001 = 600, 010 = 1200, 011 = 2400,

100 = 4800, 101 = 9600, 110 = 19200

Bit 7 0 = Send Unfiltered value, 1 = Send Filtered Val

- 20 -

Page 21

74 004A Serial Config 2 Bits 4:0 Meter Serial Address (0-31) [Non-Modbus]

Hex 0 = Broadcast (01 = 1 to 0A = 10),

0F = 15, 10 = 16, 1F = 31

Bit 5 0 = Continuous Mode, 1 = Command Mode

Bit 6 0 = No Alarm data with readings, 1 = Alarm data

Bit 7 0 = No LF following CR, 1 = LF following CR

75 004B Serial Config 3 Bits 2:0 for DPM. Data sent in serial output

0 = Reading, 1 = Peak, 2 = Valley,

3 = Rdg + Peak, 4 = Rdg + Valley,

5 = Rdg + Peak + Valley

Bits 2:0 for Scale Meter

0 = Net + Gross

1 = Net only

2 = Gross only

3 = Peak only

4 = Net + Gross + Peak

Bit 3 0 = Termination chars at end of all items

1 = " " at end of each item

Bit 4 0 = Non-latching RTS, 1 = Latching RTS

Bit 5 0 = Normal continuous serial transmission

1 = Special Start & Stop characters

Bit 6 0 = Full Duplex 1 = Half Duplex

76 004C Serial Config 4 Bits 1:0 00 = No Parity 01 = Odd Parity

10 = Even Parity

Bits 3:2 00 = Custom ASCII 01 = Modbus RTU

10 = Modbus ASCII

Bits 5:4 Modbus ASCII Gap Timeout

00 = 1S, 01 = 3S, 10 = 5S, 11 = 10S

77 004D Config

(applicable to

DPM)

Bit 0 0 = Linear Curve 1 = Custom Curve

Bit 1 0 = 2-wire RTD Read 1= 2-wire RTD Short

Bits 2 0 = No Auto-tare 1 = Auto-tare

Bits 4:3 Peak button display response

00 = Peak 01 = Valley

10 = Peak then Vall. 11 = Tare

Bits 7:5 000 = Not Rate 001 = Rate x 0.1,

010 = Rate x 1 011 = Rate x 10,

100 = Rate x 100 101 = Rate x 1000

110 = Rate x 10000

77 004D Config

(applicable to

Scale Meter)

Bit 1 0 = Peak of net value 1 = peak of gross value

Bit 2 0 = Dribble enabled 1 = Dribble disabled

Bit 3 0 = Scale & offset setup method

1 = Reading coordinates of 2 points method

- 21 -

Page 22

78 004E Lockout 1

(applicable to

DPM)

0 = Enabled, 1 = Locked out

Bit 0 Offset, Lo, Hi Rd Bit 1 Scale, Lo In, Hi In

Bit 2 Filter Bit 3 Setup, Config, DP

Bit 4 Input Type

78 004E Lockout 1

(applicable to

Scale Meter)

0 = Enabled, 1 = Locked out

Bit 0 Count Bit 1 Setup, Config, DP

Bit 2 Input Type Bit 3 Change Display Item#

Bit 4 Tare Bit 5 Offset, Lo Rd, Hi Rd

Bit 6 Scale, Lo, Hi In Bit 7 Filter

79 004F Lockout 2 Bit 0 Serial Comm Config

Bit 1 Analog Out Scaling

Bit 2 Alarm Setpoint Programming

Bit 3 Alarm Config

Bit 4 Front Panel Meter Reset

Bit 5 Front Panel Function Reset

Bit 6 View Setpoints Bit 7 View Peak

81 0051 Setup 1

(not for Scale

Meter)

Bits 1:0 00 = 4-1/2 Digits, 0.1 degree

01 = Slave Remote Display

10 = 4-1/2 Dig/10, 0.01 degree

11 = 3-1/2 Digits,1 degree

81 0051 Count (applies

to Scale Meter)

Bits 3:0 0 = No auto-zero band 1= 1-count zero band

2 = 2-count zero band 3 = 3-count zero band

Etc. 9 = 9-count zero band

Bits 6:4 0 = Count by 1 1 = Count by 2

2 = Count by 5 3 = Count by 10

4 = Count by 20 5 = Count by 50

6 = Count by 100

82 0052 Analog Output

Setup (applies

to DPM)

Bit 0 0 = Source Unfiltered 1 = Filtered

Bit 1 0 = Current Output 1 = Voltage Output

Bits 2:1 00 = Current (0-20 mA) 10 = Curr. (4-20 mA)

01 = Voltage (0-10V) 11 = Voltage (±10V)

82 0052 Analog Output

Setup (applies

to Scale Meter)

Bit 0 0 = Net Value 1 = Gross Value

Bit 1 0 = Filtered 1 = Unfiltered

Bits 3:2 00 = Current (0-20 mA) 10 = Curr. (4-20 mA)

01 = Voltage (0-10V) 11 = Voltage (±10V)

87 0057 System Decimal

Point

Bits 2:0 001 = ddddd. 010 = dddd.d

011 = ddd.dd 100 = dd.ddd

101 = d.dddd 110 = .ddddd

93 005D Start Character Bits 7:0 ASCII Hex Character

94 005E Stop Character Bits 7:0 ASCII Hex Character

95 005F Modbus Addr. Bits 7:0 Hex value of Decimal Address from 1-255

- 22 -

Page 23

READ ONLY (FC03) – Data Type B16

100 0064 Analog Output

DAC Type

Bits 7:0 0 = none,

1 = 1 output, unipolar (12-bit, pre 2009)

2 = 1 output, unipolar (16-bit, pre 2009)

3 = 1 output, uni or bipolar (16-bit, post 2009)

4 = 2 outputs, unipolar (16-bit, post 2009, not

for Scale Meter)

101 0065 Device Type Bits 7:0 01 = DPM meter 02 = Scale meter

03 = Counter/timer met. 05 = DPM transmitter

06 = Scale transmitter

07 = Counter/timer transmitter

102 0066 Revision Bits 7:0 Hex value of Decimal Revision number

103 0067 Overload Value Bits 7:0 Hex overload value

104 0068 Signal Condi-

tioner Type

Bits 7:0 01 = DC, TC/RTD (pre 2009)

02 = RMS (pre 2009)

03 = Load Cell

22 = RMS (post 2009)

31 = TC (post 2009)

41 = RTD or Ohms (post 2009)

WRITE ONLY (FC10 dec16) – Data Type 2C32

105 0069 Display Data (Hi Word) Hi word of Remote Data to be displayed.

106 006A Display Data (Lo Word) Lo word of Remote Data to be displayed.

13. COUNTER / TIMER REGISTER ADDRESSES FC03 & FC10 (dec16)

Data Types - as shown

Use high word starting Register Addresses and an even number of Registers.

Register Address

Dec* Hex*

1

2

3

4

5

6

7

8

9

0001

0002

0003

0004

0005

0006

0007

0008

0009

Register Name

Setpoint 1 (Hi word)

Setpoint 1 (Lo word)

Setpoint 2 (Hi word)

Setpoint 2 (Lo word)

Setpoint 3 (Hi word)

Setpoint 3 (Lo word)

Setpoint 4 (Hi word)

Setpoint 4 (Lo word)

Scale 1Y (Hi word)

Data

Type

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

M32

Scaling & Decimal Point

Dec point same as displayed.

Dec point same as displayed.

Dec point same as displayed.

Dec point same as displayed.

Scale = .00001 x dec value

- 23 -

Page 24

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

000A

000B

000C

000D

000E

000F

0010

0011

0012

0013

0014

0015

0016

0017

0018

0019

001A

001B

001C

001D

001E

001F

0020

0021

0022

0023

0024

0025

0026

0027

0028

0029

002A

002B

002C

002D

002E

002F

0030

Scale 1Y (Lo word)

Offset 1 (Hi word)

Offset 1 (Lo word)

Scale 2Y (Hi word)

Scale 2Y (Lo word)

Offset 2 (Hi word)

Offset 2 (Lo word)

Lo In 1 (Hi word)

Lo In 1 (Lo word)

Lo Rd 1 (Hi word)

Lo Rd 1 (Lo word)

Hi In 1 (Hi word)

Hi In 1 (Lo word)

Hi Rd 1 (Hi word)

Hi Rd 1 (Lo word)

Lo In 2 (Hi word)

Lo In 2 (Lo word)

Lo Rd 2 (Hi word)

Lo Rd 2 (Lo word)

Hi In 2 (Hi word)

Hi In 2 (Lo word)

Hi Rd 2 (Hi word)

Hi Rd 2 (Lo word)

Deviation 1 (Hi word)

Deviation 1 (Lo word)

Deviation 2 (Hi word)

Deviation 2 (Lo word)

Deviation 3 (Hi word)

Deviation 3 (Lo word)

Deviation 4 (Hi word)

Deviation 4 Lo word)

Analog Lo 1 (Hi word)

Analog Lo 1 (Lo word)

Analog Hi 1 (Hi word)

Analog Hi 1 (Lo word)

Analog Lo 2 (Hi word)

Analog Lo 2 (Lo word)

Analog Hi 2 (Hi word)

Analog Hi 2 (Lo word)

M32

2C32

2C32

M32

M32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

M32

M32

M32

M32

M32

M32

M32

M32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

2C32

of (Hi word + Lo word)**

Dec point same as displayed.

Scale = .00001 x dec value

of (Hi word + Lo word)**

Dec point same as displayed.

Lo In = .00001 x dec value

of (Hi word + Lo word)**

Dec point same as displayed.

Hi In = .00001 x dec value

of (Hi word + Lo word)**

Dec point same as displayed.

Lo In = .00001 x dec value

of (Hi word + Lo word)**

Dec point same as displayed.

Hi In = .00001 x dec value

of (Hi word + Lo word)**

Dec point same as displayed.

Dec point same as displayed.

Dec point same as displayed.

Dec point same as displayed.

Dec point same as displayed.

Dec point same as displayed.

Dec point same as displayed.

Dec point same as displayed.

Dec point same as displayed.

* Values are for Base 1 Standard addressing. Add 1 for Base 0 PLC addressing.

** Max Value = 21,474.1

- 24 -

Page 25

For the following, use any starting Register Addresses and any number of Registers.

Register Addr

Register Name

Dec Hex

Data

Scaling & Decimal Point

Type

49

50

51

52

53

54

55

56

57

58

50

0031

0032

0033

0034

0035

0036

0037

0038

0039

003A

003B

Data Type B16

Register Addr

Dec Hex

65 0041 Alarm

GateTime

TimeOut

Pulses

Total B (Hi word)

Total B (Mid word)

Total B (Lo word)

Total A (Hi word)

Total A (Mid word)

Total A (Lo word)

Cutoff

Calibration

Register

Name

Bit 0 0 = AL1 Hi Active 1 = Lo Active

Config 1

Bit 1 0 = AL1 Enabled, 1 = Disabled

Bit 2 0 = AL2 Hi Active 1 = Lo Active

Bit 3 0 = AL2 Enabled 1 = Disabled

Bit 4 0 = AL1 Non-Latched 1 = Latched

Bit 5 0 = AL2 Non-Latched 1 = Latched

Bit 6 0 = Relay1 Active On 1 = Off

Bit 7 0 = Relay2 Active On 1 = Off

M16

M16

M16

M48

M48

M48

M48

M48

M48

M16

M15

1-19999 (4E1F) Dec Pt =XXX.XX

1-19999 (4E1F) Dec Pt =XX.XXX

1-59999 (4E1F) Dec Pt =XXXXX.

0-65535

SXXX XXXX XXXX XXXX

Sign + Magnitude (PPM)

Bit Significance

66 0042 Alarm

Config 2

Bits 2:0 # Readings before Alarms 1 & 2.

000 = 1, 001 = 2, 010 = 4, 011 = 8, 100 = 16,

101 = 32, 110 = 64, 111 = 128

Bits 4:3 Setpoint Compare Source

Bit 3 AL1 0 = Deviation 1 = Hysteresis

Bit 4 AL2 0 = Deviation 1 = Hysteresis

Bit 5 0 = Deviation in Menu 1 = Omitted

67 0043 Alarm

Config 3

Bit 0 0 = AL3 Hi Active 1 = Lo Active

Bit 1 0 = AL3 Enabled 1 = Disabled

Bit 2 0 = AL4 Hi Active 1 = Lo Active

Bit 3 0 = AL4 Enabled 1 = Disabled

Bit 4 0 = AL3 Non-Latched 1 = Latched

Bit 5 0 = AL4 Non-Latched 1 = Latched

- 25 -

Page 26

Bit 6 0 = Relay3 Active On 1 = Off

Bit 7 0 = Relay4 Active On 1 = Off

68 0044 Alarm

Config 4

69 0045

Rate 00-0F 00 = A&B, 01 = AOnly, 02 = Batch,

Input

Type

Period 10-1E 10 = A&B, 11 = AOnly

Total 20-2E 20 = Total A&B, 21 = AOnly

Time

Interval

Stopwatch 50-53 50 = A to A,

Bits 2:0 = # Readings before Alarms 3 & 4.

000 = 1, 001 = 2, 010 = 4, 011 = 8, 100 = 16,

101 = 32 110 = 64 111 = 128

Bit 3 AL3 0 = Deviation 1 = Hysteresis

Bit 4 AL4 0 = Deviation 1 = Hysteresis

Bit 5 0 = Deviation in Menu 1 = Omitted

03 = A_Atot, 05 = A_Btot, 0B = A+B,

0C = A-B, 0D = A*B, 0E = A/B, 0F = A/B-1

1B = A+B, 1C = A-B, 1D = A*B, 1E = A/B

24 = A-B_ud, 26 = Burst=26, 27 = B_Arat,

29 = A_Bud, 2A = A_Binh, 2B = A+B, 2C = A-B,

2D = A*B, 2E = A/B

41-42 41 = Time Interval A to B

42 = 1 / (A to B)

51 = A to B

52 = 1 / (A to A)

53 = 1 / (A to B)

Phase

Duty Cycle 71 A to B

V-to-F

Signal

Conditioner

Quadrature C0-C1 C0 = Total

70 0046 Setup

M = Meter

F = Function

D = Display

61-62 61 = 0-360

62 = -180 to +180

XY X = 8, 4-20 mA input

X = 9, 0-1 mA input

X = A, 0-10V input

Y = 1, A only

Y = 2, Batch

Y = 3, A to A total

Y = F, 1/A

C1 = Rate

Bits 3:0 Ctrl In 1 Ctrl In 2 Both Reset

Hex 0 Meter Reset Function Reset MReset

Hex 1 Meter Reset Meter Hold MReset

Hex 2 Meter Reset Peak or Valley MReset

Hex 3 Meter Reset External Gate MReset

Hex 4 Function Reset Meter Hold MReset

- 26 -

Page 27

Hex 5 Valley Peak FRest

Hex 6 Function Reset External Gate MReset

Hex 7 Meter Hold Peak or Valley FReset

Hex 8 Reset Total A Reset Total B FReset

Hex 9 Force Alarm1 Force Alarm2 No Action

Hex A Meter Reset Display Blank MReset

Hex B Function Reset Display Blank MReset

Hex C Meter Hold Display Blank MReset

Hex D Peak or Valley Display Blank FReset

Hex E Display Blank External Gate MReset

Hex F Item2 Item3 Item 1 = Neither/Both

Hex F Tare Enable Tare (Remote Display Only)

Bit 4 0 = Scale2 using Scale, Offset

1 = Scale2 using Coordinates of 2 Points

Bit 5 0 = Scale1 using Scale, Offset

1 = Scale1 using Coordinates of 2 Points

Bit 6 0 = Blank leading zeros

1 = Display leading zeros

Bit 7 0 = Zero Total upon Power-On

1 = Restore Total upon Power-On

71 0047 Filter Bits 2:0 1 = .1S, 2 = .2S, 3 = .4S, 4=.8S, 5=1.6S,

6 = 3.2S, 7=6.4S

Bit 3 0 = Low Adaptive, 1 = High Adaptive

Bit 4 0 = Display Unfiltered, 1=Display Filtered

Bit 5 0 = Peak, Valley of Unfiltered

1 = Peak,Valley of Filtered

Bit 6 0 = Adaptive Filter

1 = Conventional Filter

72 0048 Options Do Not Use.

73 0049 Serial

Config 1

Bits 3:0 Time between Continuous Serial Outputs

Hex 0=.017S, 1=.28S, 2=.57S, 3=1.1S, 4=2.3S,

5=4.5S, 6=9.1S, 7=18.1S, 8=36.3S, 9=1M13S,

A=2M25S, B=4M50S, C=9M40S, D=19M20S,

E=38M41S, F=77M21S

Bits 6:4 Baud Rate

000 = 300, 001 = 600, 010 = 1200, 011 = 2400,

100 = 4800, 101 = 9600, 110 = 19200

Bit 7 0 = Send Unfiltered value, 1 = Send Filtered Val

- 27 -

Page 28

74 004A Serial

Config 2

Bits 4:0 Meter Serial Address (0-31) [Non-Modbus]

Hex 0 = Broadcast (01 = 1 to 0A = 10),

0F = 15, 10 = 16, 1F = 31

Bit 5 0 = Continuous Mode, 1 = Command Mode

Bit 6 0 = No Alarm data w/ readings, 1 = Alarm data

Bit 7 0 = No LF following CR, 1 = LF following CR

75 004B Serial

Config 3

76 004C Serial

Config 4

Bits 2:0 Data sent in serial output

0 = All active Items, 1 = Item1, 2 = Item2,

3 = Item3, 4 = Peak, 5 = All active Items+

Peak, 6 = Valley, 7 = All active Items + Peak +

Valley

Bit 3 0 = Termination chars at end of all items

1 = Termination chars at end of each item

Bit 4 0 = Non-latching RTS

1 = Latching RTS

Bit 5 0 = * is Recognition Character

1 = Custom Recognition Character

Bit 6 0 = No Serial Start / Stop Characters

1 = Start / Stop Characters

Bit 7 0 = Full Duplex, 1 = Half Duplex

Bits 1:0 00 = No Parity

01 = Odd Parity

11 = Even Parity

Bits 3:2 00 = Custom ASCII

01 = Modbus RTU,

10 = Modbus ASCII

Bits 5:4 Modbus ASCII Gap Timeout

00 = 1S, 01 = 3S, 10 = 5S, 11 = 10S

77 004D Config Bit 0 0 = VF Batch, Atot zero cutoff

1 = Allow negative values

Bit 1 0 = Calculate Rate value

1 = Calculate Square Root of Rate

Bits 3:2 00 = Basic Counter, 01 = Extended Counter

10 = Custom Curve #1

11=Custom Curve #2 (if V-to-F)

Bits 7:4 0 = Exponential Overload

1 = 999999 Overload

2 = One Right Hand Dummy Zero

3 = Two Right Hand Dummy Zeros

4 = Clock Time in Seconds

5 = Clock Time in HH.MM.SS Format

6 = Remote Display, HKL Command

- 28 -

Page 29

7 = Remote Display, Value

8 = 1st Value in String

9 = 2nd Value in String

A = 3rd Value in String

B = 4th Value in String

C = Remote Display using Start, Stop, Skip,

Show Characters

78 004E Lockout 1 0 = Enabled, 1 = Locked out

Bit 0 Filter

Bit 1 Gate Time, Timeout, Batch, Preset, Pulses, Cutoff

Bit 2 Setup, Config, Display Number

Bit 3 Input Type

Bit 4 Setpoint Programming

Bit 5 Alarm Config, Deviation / Hysteresis

Bit 6 Scale, Offset, Resolution, 2 Coordinates

Bit 7 Slope, Decimal Points

79 004F Lockout 2 0 = Enabled, 1 = Locked out

Bit 0 Change Item# displayed

Bit 1 Calibration

Bit 2 Serial Comm Config

Bit 3 Analog Out Scaling & Setup

Bit 4 Front Panel Meter Reset

Bit 5 Front Panel Function Reset

Bit 6 View Setpoints

Bit 7 View Peak

80 50 Batch

Operation

Bit 0 0 = Display “rEADy” after Reset

1 = Start

Bit 1 0 = Item2 is Grand Total

1 = Item2 is Total Number of Batches

Bit 2 0 = Gate Time resets

1 = Control Input 2 resets

Bit 3 0 = Reset to Zero, Count Up

1 = Reset to SETPT1, Count Down

Bits 5:4 Residual Input

0,2 = Input Discard, Grand Total Discard

1 = Input Accept, Grand Total Discard

3 = Input Accept, Grand Total Accept

- 29 -

Page 30

81 0051 Alarm

Source

Bits 1:0 Setpoint 2

Bits 3:2 Setpoint 1

Bits 5:4 Setpoint 4

Bits 7:6 Setpoint 3

For each Setpoint: 00 = Filtered Item,

01 = Item1, 10 = Item2, 11 = Item3

82 0052 Analog Out

Setup

83 0053 Scale

Multiplier

Bits1:0 0 = Filtered Item, 1 = Item1, 2 = Item2, 3 = Item3

Bit 2 0 = Current Output, 1 = Voltage Output

Bits 3:0 Scale1 Multiplier

Bits 7:4 Scale2 Multiplier

0 = .00001, 1 = .0001, 2 = .001, 3 = .01,

4 = .1, 5 = 1, 6 = 10, 7 = 100, 8 = 1000,

9 = 10000, A = 100000

84 0054 Trigger

Slope

Bit 0 0 = Positive Slope, B Input

1 = Negative Slope, B Input

Bit 1 0 = Positive Slope, A Input

1 = Negative Slope, A Input

85 0055 Display Item Bits 1:0 1 = Item1, 2 = Item2, 3 =Item3

Bits 3:2 Display Response to Peak Button:

00 = Peak, 01 = Valley, 10 = Peak then Valley

86 0056 Resolution Bits 3:0 0 = .00001, 1= .0001, 2 = .001, 3 = .01,

4 = .1, 5 = 1, 6 = 10, 7 = 100, 8 = 1000,

9 = 10000, A = 100000

87 0057 System

Decimal

Point

Bits 3:0 DecPt1

Bits 7:4 DecPt2

1 = dddddd., 2 = ddddd.d, 3 = dddd.dd,

4 = ddd.ddd, 5 = dd.dddd, 6 = d.ddddd

Special Characters

88 0058 Recognition Bits 7:0 ASCII Hex Character

89 0059 Remote Start Bits 7:0 ASCII Hex Character

90 005A Remote Stop Bits 7:0 ASCII Hex Character

91 005B Remote Skip Bits 7:0 ASCII Hex Character

92 005C Remote Show Bits 7:0 ASCII Hex Character

93 005D Serial Transm. Start Bits 7:0 ASCII Hex Character

94 005E Serial Transm. Stop Bits 7:0 ASCII Hex Character

95 005F Modbus Address Bits 7:0 Hex Value of Decimal Address 1-255

96 60 Reserved

97 61 Reserved Do not use

- 30 -

Page 31

READ ONLY (FC03) – Data Type B16

100 0064 Analog Output

DAC Type

0 = none,

1 = 1 output, unipolar (12-bit, pre 2009)

2 = 1 output, unipolar (16-bit, pre 2009)

3 = 1 output, uni or bipolar (16-bit, post 2009)

4 = 2 outputs, unipolar (16-bit, post 2009)

101 0065 Device Type

Bits 7:0 01 = DPM meter

03 = Counter/Timer meter

05 = DPM transmitter

07 = Counter/Timer transmitter

102 0066 Revision Bits 7:0 Hex value of Decimal Revision number

WRITE ONLY FC10 (dec16) – Data Type 2C32

105 0069 Display Data Hi Word Displayed

106 006A Display Data Lo Word Displayed

107 006B Data to Item3 Hi Word Applied to Item3

108 006C Data to Item3 Lo Word Applied to Item3

109 006D Data to Both Hi Word Displayed and Applied to Item3

110 006E Data to Both Lo Word Displayed and Applied to Item3

WRITE ONLY FC10 (dec16) – Data Type B16

111 006F Force Alarms, Remote

Display Mode

Bit 0 = Alarm 1

Bit 1 = Alarm 2

Bit 2 = Alarm 3

Bit 3 = Alarm 4

Please see the description at the end of Section 10 for comparing the Remote Data to

the Relay Setpoints or using it as the source for setting the Analog Output.

- 31 -

Page 32

7. WARRANTY

Laurel Electronics Inc. warrants its products against defects in materials or workmanship for a

period of one year from the date of purchase. In the event of a defect during the warranty period,

the unit should be returned, freight prepaid (and all duties and taxes) by the Buyer, to the

authorized Laurel distributor where the unit was purchased. The distributor, at its option, will

repair or replace the defective unit. The unit will be returned to the buyer with freight charges

prepaid by the distributor.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from 1) Improper or inadequate

maintenance by Buyer, 2) Unauthorized modification or misuse, 3) Operation outside the

environmental specifications of the product, 4) Mishandling or abuse. The warranty is exclusive

and no other warranty, whether written or oral, is expressed or implied. Laurel specifically

disclaims the implied warranties of merchantability and fitness for a particular purpose.

EXCLUSIVE REMEDIES

The remedies provided herein are Buyer’s sole and exclusive remedies. In no event shall

Laurel be liable for direct, indirect, incidental or consequential damages (including loss of

profits) whether based on contract, tort, or any other legal theory.

Copyright 2004-2012 Rev 07/11/2012

- 32 -

Loading...

Loading...