Page 1

LTM “CTR” SERIES

TRANSMITTERS

PULSE, AC or PROCESS TOTALIZER INPUT,

SERIAL DATA OUTPUT

OWNERS MANUAL

LAUREL Electronics Inc.

3183-G Airway Ave, Costa Mesa, CA, 92626, USA

Tel: (714) 434-6131 Fax: (714) 434-3766 Website: www.laurels.com

Page 2

1. ORDERING GUIDE, LTM “CTR” SERIES TRANSMITTERS

Configure a model number in this format: LTM600VF1, CBL04

LTA Transmitter with serial I/O, Modbus or

Custom ASCII protocol. Includes 4-20 mA,

0-20 mA or 0-10V isolated analog output,

isolated 5V, 10V or 15V transducer excitation output, and dual solid state relays.

Default jumpered for full duplex RS485 and

RS232, and 10V excitation.

Main Board

6............................... Standard pulse or AC input

8............................... Extended pulse of AC input

Please see notes for “Extended”

Power

0............................................. 95-240 Vac ±10%

1....................................12-30 Vac or 10-48 Vdc

Relay Output

0................................................................. None

2....................................... Dual solid state relays

Input Type

FR .................. .. Dual Channel Pulse or AC Input

Standard main board

Frequency (2 channels), rate (2 channels), total

(2 channels), period, stopwatch, time interval.

Extended main board

Above plus rate and total simultaneously, linearized inputs using up to 180 points, arithmetic

functions applied to channels A & B (A+B, A-B,

A*B, A/B, A/B-1), phase angle, duty cycle, up/

down counting, batch control.

VF1 ............................... 4-20 mA Process Input

VF2 ................................. 0-1 mA Process Input

VF3 ................................. .. 0-10V Process Input

VF1 .............................................. Custom Input

Standard main board

Rate or total from analog process signals.

Selectable square root extraction for use with

differential pressure flow meters.

Extended main board

Above plus rate and total simultaneously (analog

totalizer), custom curve linearization using up to

180 points, batch control, and time based on

rate.

QD.................................................. .. Quadrature

Standard main board

Position or length from encoders. Accepts differential or single-ended inputs: 1x, 2x or 4x, plus

zero index.

Extended main board

Above plus bidirectional rate (rate and position

or length are not simultaneous).

ACCESSORIES

CBL04 ...... RS232 cable, 3-pin connector on

transmitter end, DB9 connector on

computer end.

CBL02 ...... USB to DB9 adapter cable.

-

- 2 -

Page 3

2. TABLE OF CONTENTS

1. ORDERING GUIDE, “CTR” SERIES TRANSMITTERS ........................................................ 2

2. TABLE OF CONTENTS ....................................................................................................... 3

3. INTRODUCTION, “CTR” SERIES TRANSMITTERS ............................................................ 4

4. RECEIVING & UNPACKING YOUR TRANSMITTER ........................................................... 5

5. SAFETY CONSIDERATIONS .............................................................................................. 5

6. TRANSMITTER FIELD WIRING ......................................................................................... 6

7. PROGRAMMING YOUR TRANSMITTER............................................................................ 8

8. OPENING YOUR TRANSMITTER CASE ............................................................................. 16

9. DUAL CHANNEL PULSE OR AC INPUT SIGNAL CONDITIONER BOARD........................... 17

10. V-TO-F CONVERTER SIGNAL CONDITIONER BOARD ...................................................... 21

11. QUADRATURE SIGNAL CONDITIONER BOARD ................................................................ 22

12. MAIN BOARD JUMPER SETTINGS ................................................................................... 24

13. DUAL RELAY OPERATION ............................................................................................... 25

14. INPUT SIGNAL FILTERING................................................................................................ 26

15. TRANSMITTER CALIBRATION .......................................................................................... 26

16. CUSTOM CURVE LINEARIZATION .................................................................................... 27

17. MODBUS PROTOCOL TRANSMITTER COMMUNICATIONS .............................................. 28

18. CUSTOM ASCII PROTOCOL TRANSMITTER COMMUNICATIONS .................................... 33

19. “CTR” SERIES TRANSMITTER SPECIFICATIONS ............................................................. 38

18. WARRANTY ...................................................................................................................... 40

-

- 3 -

Page 4

3. INTRODUCTION, “CTR” SERIES TRANSMITTERS

This manual covers “CTR” Series DIN rail transmitters with an isolated serial data output and a

pulse, AC or process signal input (converted to a frequency by the unit’s voltage-to-frequency

converter). The transmitters duplicate the signal conditioning and signal processing features of

their 1/8 DIN panel-mounted counter / timer counterparts for exceptional accuracy at high read

rate. A wide range of counter / timer functions are accommodated by three signal conditioners:

• Dual-channel pulse input signal conditioner (for frequency, rate, total, arithmetic combinations of two channels, stopwatch, timer, phase angle, duty cycle).

• Voltage-to-frequency signal conditioner (for rate or total from 4-20 mA, 0-1 mA or 0-10V

process signals).

• Quadrature signal conditioner (for position or rate from quadrature encoder signals).

Serial communications are standard.

The transmitter serial port

is default jumpered for RS232 or

full-duplex RS485 (same jumper settings). Half-duplex RS485 is also selectable either via internal

or external jumpers. Three serial protocols are software selectable: Modbus RTU, Modbus ASCII

and Custom ASCII. Modbus allows devices by different manufacturers to be addressed on the

same data line. The simpler Custom ASCII protocol is recommended when there are no devices by

other manufacturers on the data line.

An isolated 4-20 mA, 0-20 mA or 0-10V output is standard.

This output is generated by an

ultralinear 16-bit digital to analog converter. It is scaled in software and tracks an internal linearized

digital reading.

An isolated transducer excitation output is standard. Three output levels are jumper selectable:

5V at 100 mA, 10V at 120 mA, or 24V at 50 mA.

Dual solid state relays are standard. 130 mA at 140 Vac or 180 Vdc.

Isolation to 250V rms is provided for power, signal input, analog output, relay outputs, and com-

munications. Isolation adds safety and avoids possible ground loops. The transducer excitation

output is isolated to 50V from signal ground.

Internal jumpers are used to select the signal range, communication type, and excitation level.

The transmitter configuration is specified by the model number on the transmitter label. A user

can reconfigure the transmitter by opening the case and moving jumpers.

Transmitter scaling is via serial connection to a PC using MS Windows based Instrument Setup

Software, which can be downloaded at no charge. The required transmitter-to-PC interface cable

is available for purchase.

-

- 4 -

Page 5

4. RECEIVING & UNPACKING YOUR TRANSMITTER

Your transmitter was carefully tested and inspected prior to shipment. Should the transmitter be

damaged in shipment, notify the freight carrier immediately. In the event the transmitter is not

configured as ordered or is inoperable, return it to the place of purchase for repair or replacement.

Please include a detailed description of the problem.

5. SAFETY CONSIDERATIONS

Warning: Use of this transmitter in a manner other than specified may impair the protection

of the device and subject the user to a hazard. Visually inspect the unit for signs of damage. If

the unit is damaged, do not attempt to operate.

Caution:

• This unit may be powered with AC (mains) from 95-240 Vac ±10% with the worldwide voltage

power supply option, or 12-30 Vac or 10-48 Vdc with the low voltage power supply option.

Verify that the proper power option is installed for the power to be used. This transmitter has

no AC (mains) switch. It will be in operation as soon as power is applied.

• The 95-240 Vac ±10% mains connector (P1 Pins 1-3) is colored Green to differentiate it from

other input and output connectors. The 12-30 Vac or 10-48 Vdc mains connector is colored

Black.

• To avoid dangers of electrocution and/or short circuit, do not attempt to open the case while

the unit is under power. However, signal wiring changes external to the case can be made

safely while the unit is under power.

• To prevent electrical or fire hazard, do not expose the transmitter to excessive moisture.

• Do not operate the transmitter in the presence of flammable gases or fumes. Such an

environment constitutes an explosion hazard.

•

Secure the transmitter to a 35 mm DIN rail.

Symbols used:

Caution (refer to accompanying documents)

Caution, risk of electric shock.

Earth (ground) terminal.

Both direct and alternating current.

Equipment protected throughout by double

insulation or reinforced insulation.

Operating environment:

Transmitter Class II (double insulated) equipment designed for use in Pollution degree 2.

-

- 5 -

Page 6

See manuals

for different

signal types

Control input 2

Control input 1

GND

Analog out - 1

Analog out + 2

AL2 1

AL2 2

AL1 3

AL1 4

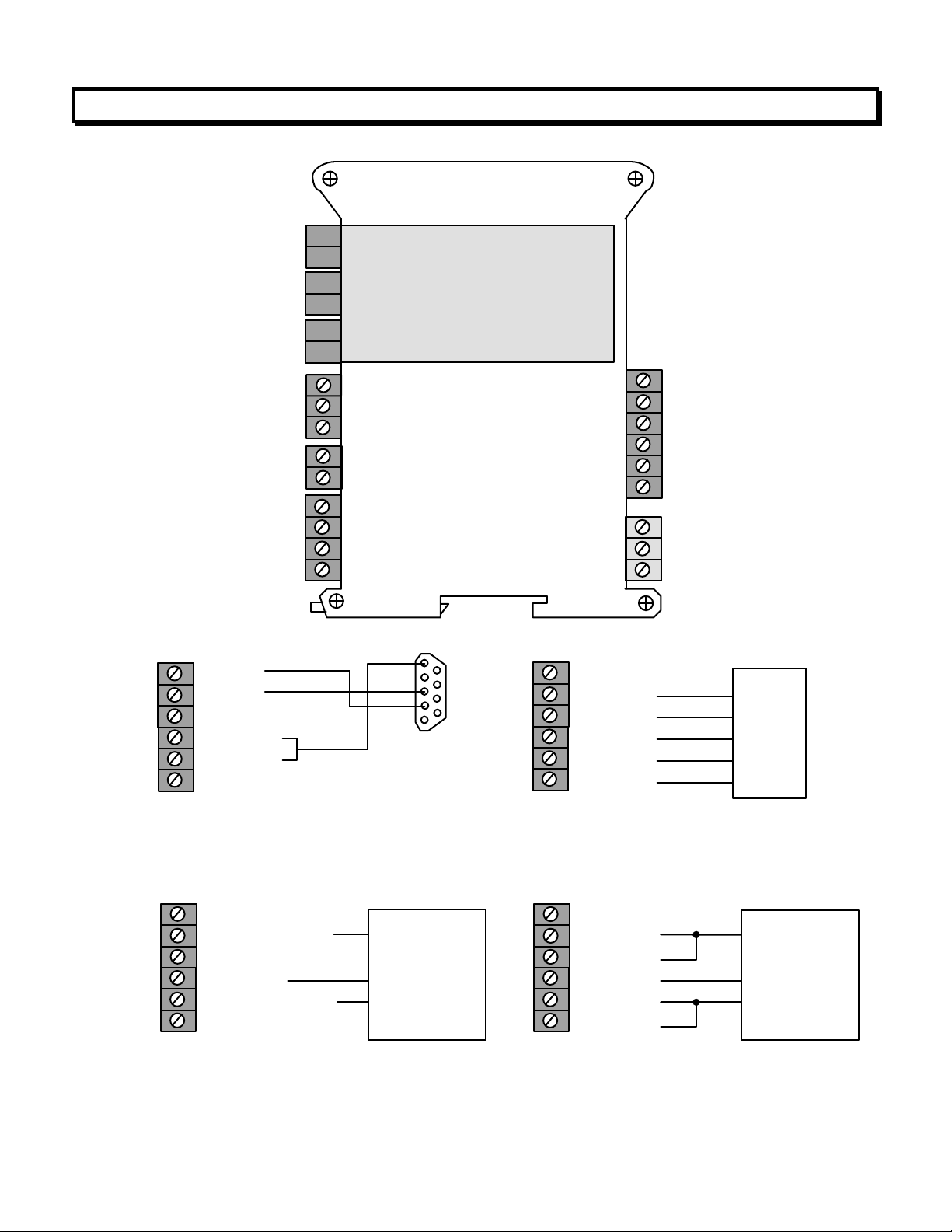

6. TRANSMITTER FIELD WIRING

1

2

3

4

5

6

1

2

3

P6 Signal

input &

excitation

output

P5 Control

inputs 1 & 2

P4 Analog

output

P3 Solid

state relays

Signal

conditioner

board

P2 Serial

data I/O

P1 Power

input

RS485

6 N/C

5 ARX

4 ATX

3 GND

2 BRX

1 BTX

RS232

TX

RX

NC

GND

GND

N/C

3 Power GND

2 AC neutral or -DC

1 AC high or +DC

6 TX

5 RX

4 NC

3 GND

2 BRX

1 N/C

Transmitter

RS232 wiring

6 N/C

5 ARX / ATX

4 N/C

3 GND

2 BRX / BTX

1 N/C

Transmitter

RS485 wiring, half duplex

with internal jumpers.

5

9

4

8

3

7

2

6

1

DB9 connector

to PC

(rear view)

ATX / ARX

GND

BTX / BRX

Master

-

- 6 -

6 N/C

5 ARX

4 ATX

3 GND

2 BRX

1 BTX

ATX

ARX

GND

BTX

BRX

Transmitter Master

RS485 wiring, full duplex-

6 N/C

5 ARX

ATX / ARX

4 ATX

3 GND

2 BRX

GND

BTX / BRX

1 BTX

Transmitter

Master

RS485 wiring, half duplex

with external jumpers.

Page 7

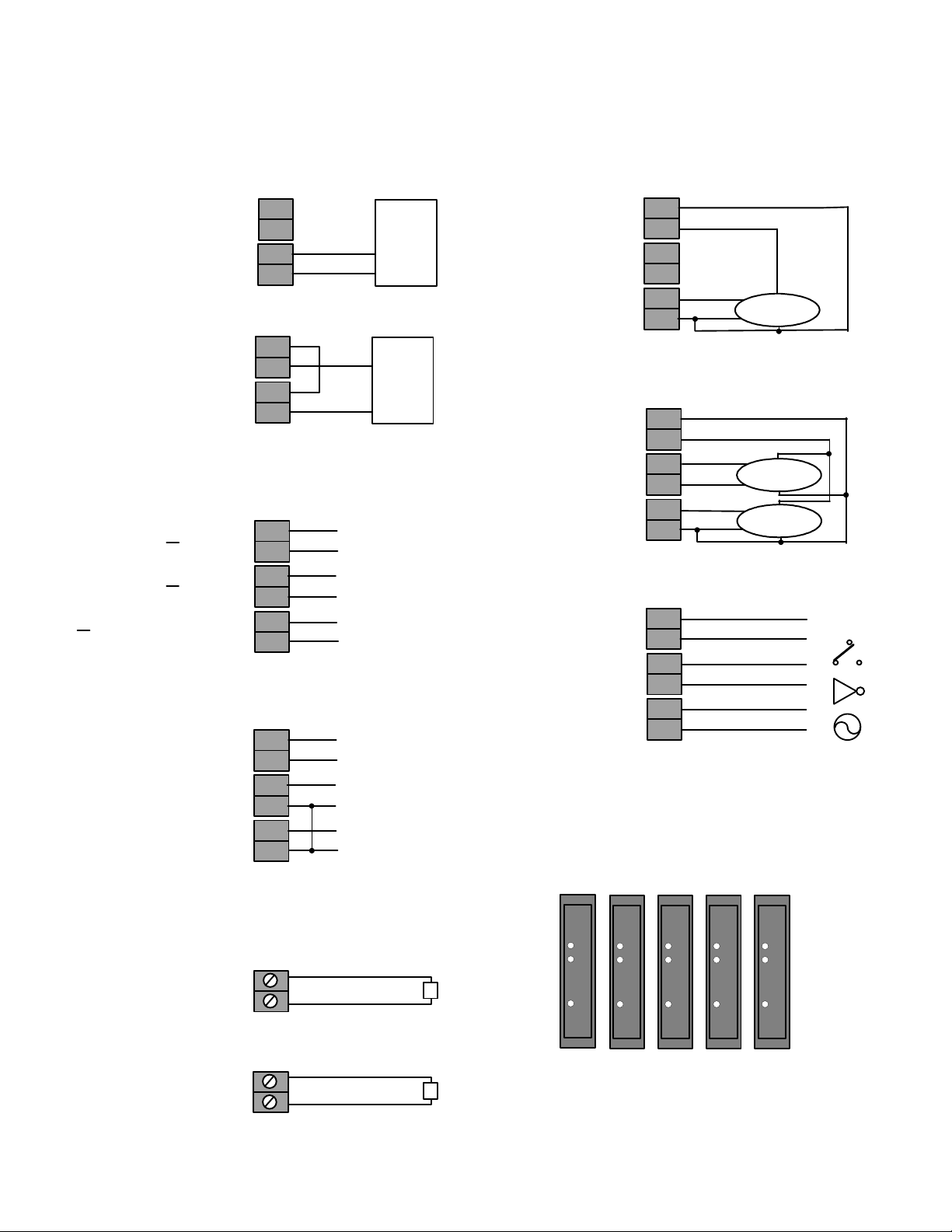

P6 - SIGNAL INPUT DETAIL

digital logic, magnetic pickups, or AC inputs to 250V .

PROCESS / TOTALIZER SIGNAL INPUT

DC & Externally Powered Process

Excitation return 1

+ Excitation 2

- Signal input 3

+ Signal input 4

2-Wire Process Transmitter

Excitation return 1

+ Excitation 2

- Signal input 3

+ Signal input 4

QUADRATURE SIGNAL INPUTS

Differential or Complementary Inputs

A Input 1

A Input 2

B Input 3

B Input 4

Z Input (+Excitation) 5

Z Input (Exc. return) 6

Single Ended Inputs

A Input 1

+Excitation 2

B Input 3

Excitation return 4

Z Input 5

Signal Ground 6

-DC

+DC

+

-

A Channel In

B Channel In

Zero Index In or

Excitation Output

A Channel In

+ Power Output

B Channel In

- Power Output

Zero Index In

Sensor common

DUAL CHANNEL PULSE SIGNAL INPUT..

Single Powered Sensor Input

Excitation return 1

+ Excitation 2

+B Signal Input 3

Signal Ground 4

+A Signal Input 5

Signal Ground 6

Power to sensor

+

Sensor 1

-

Two Powered Sensor Inputs

Excitation return 1

+ Excitation 2

+B Signal Input 3

Signal Ground 4

+A Signal Input 5

Signal Ground 6

Power to sensor

+

Sensor 2

-

+

Sensor 1

-

Active and Passive Inputs

Excitation return 1

+ Excitation 2

+B Signal Input 3

Signal Ground 4

+A Signal Input 5

Signal Ground 6

Inputs can be proximity switches, contact closures,

Warning: Dual-channel signal grounds 4 & 6 are

connected internally.

MOUNTING FOR COOLING

P4 - ANALOG OUTPUT DETAIL

Driving a Load with 4-20 mA

Analog return 1

4-20 mA output 2

500 Ohms max

Driving a Load with 0-10V

Analog GND 1

0-10V output 2

5 kOhms min

-

- 7 -

AL 1

AL 2

RESET

POWER

AL 1

AL 2

RESET

POWER

AL 1

AL 2

RESET

POWER

AL 1

AL 2

RESET

POWER

AL 1

AL 2

RESET

POWER

Mount transmitters with ventilation holes at

top and bottom. Leave minimum of 6 mm (1/4")

between transmitters, or force air with a fan.

Page 8

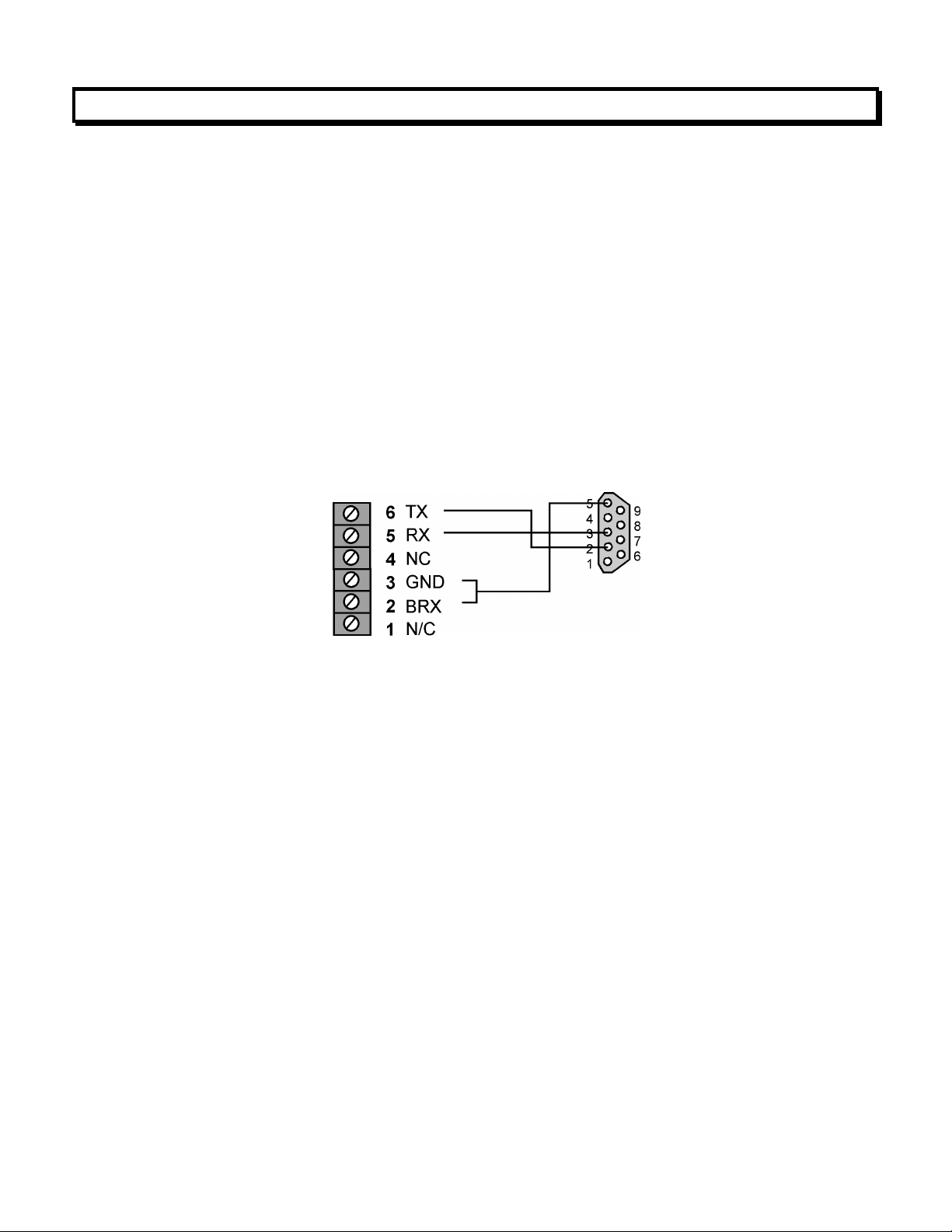

7. PROGRAMMING YOUR TRANSMITTER

OVERVIEW

Our transmitters are easily programmed using a PC with an RS232 port and Instrument Setup

(IS) software, which provides a graphical user interface. The software allows uploading, editing,

downloading and saving of setup data, execution of commands under computer control, listing,

plotting and graphing of data, and computer prompted calibration.

USING IS SOFTWARE

Use a 3-wire RS232 cable (P/N CBL04) to connect your transmitter to the COM port of your PC.

Download the file

Install Instrument Setup Software

Start => Programs => IS2 => Instrument Setup

created. Following a brief splash screen, the

ISx_x_x.exe

from our website and double-click on the file name. Click on

and follow the prompts. To launch IS software, press on

or on the desktop icon that you may have

Communications Setup

screen will appear.

RS232 cable with rear view of DB9 connector to PC

-

- 8 -

Page 9

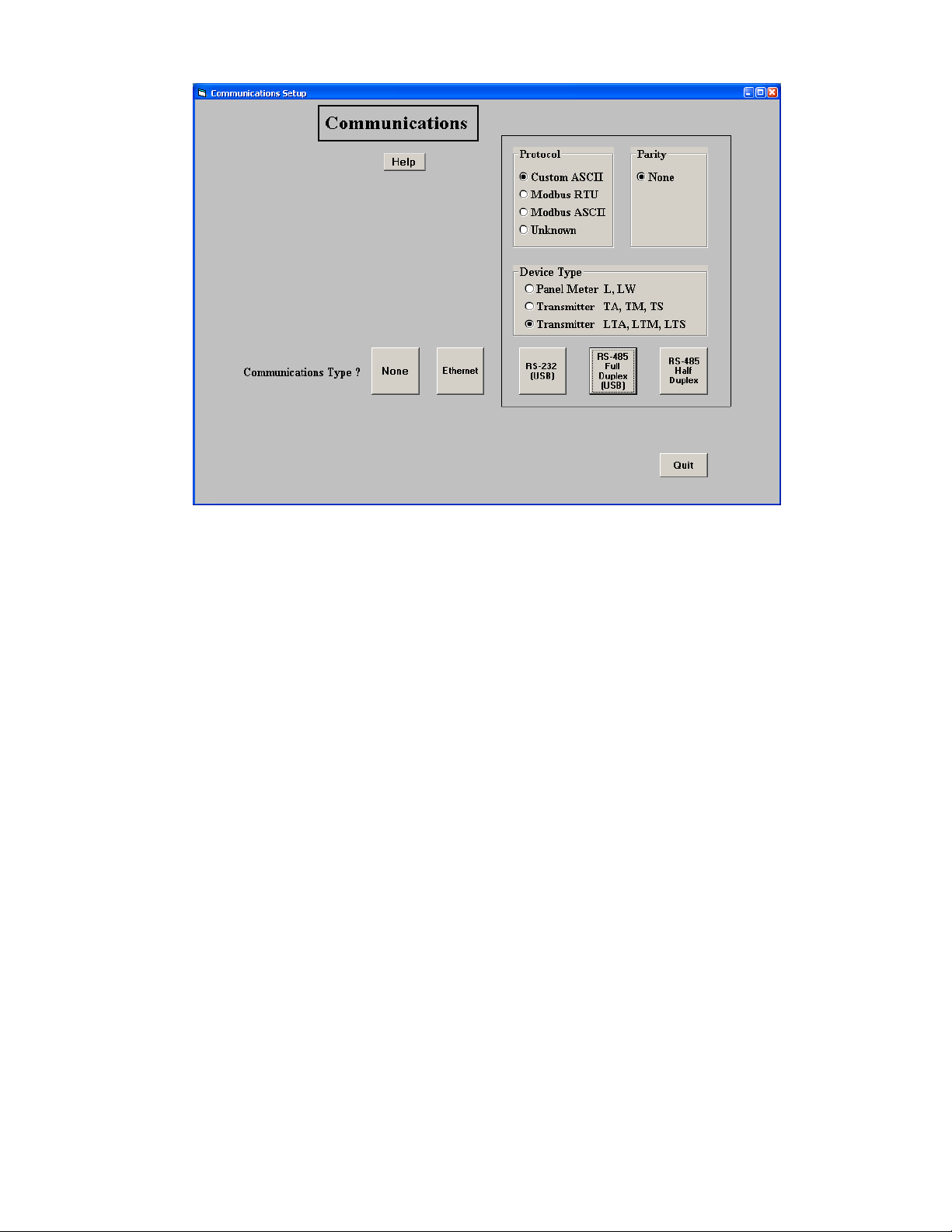

In the Communications Setup screen, select the

factory default setting. Select

RS-232 (USB)

button. This will take you to the

Transmitter LTA, LTM, LTS

Establish Communications

Custom ASCII

as the Device Type. Then click on the

as the protocol, as this is the

screen.

-

- 9 -

Page 10

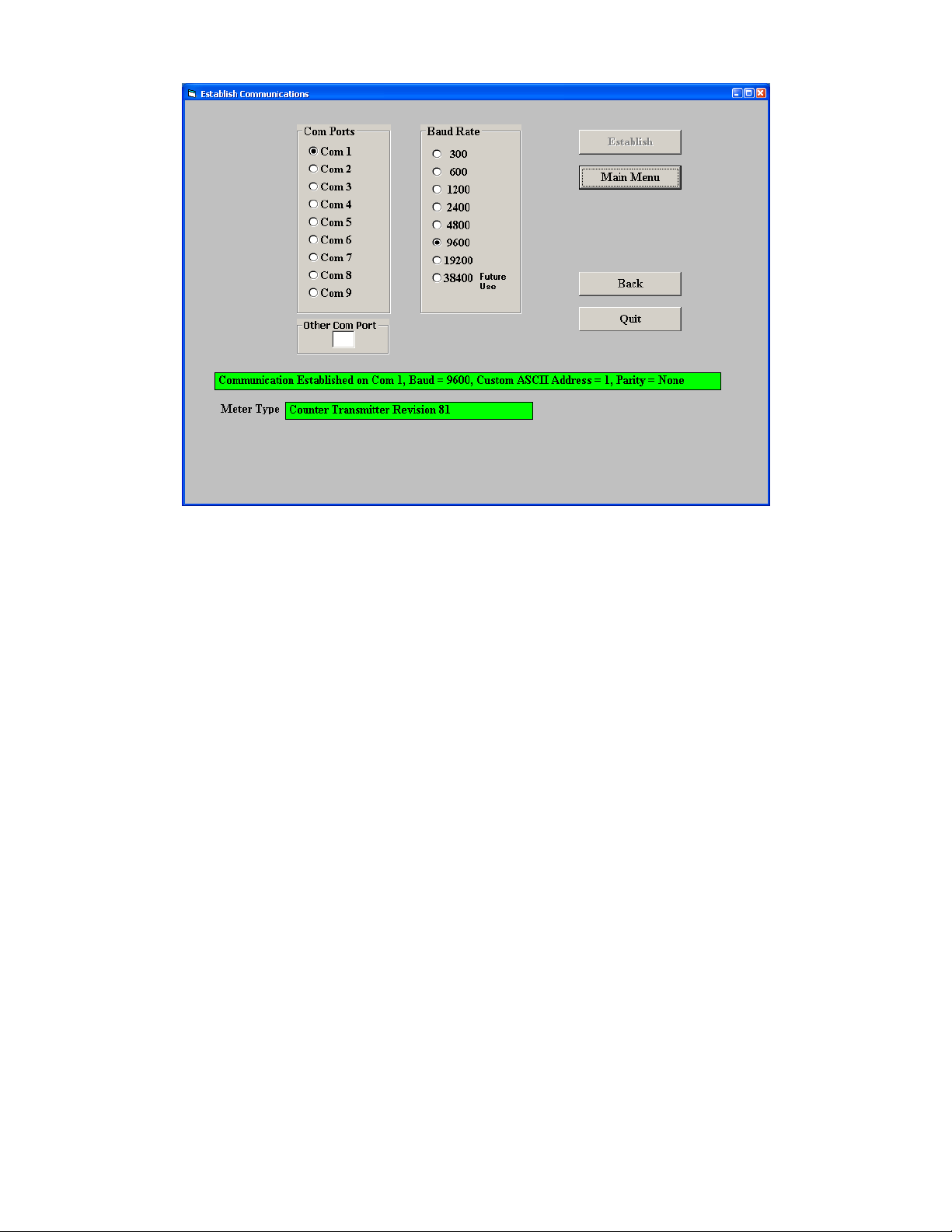

In the

You will be able to change your protocol and baud rate later under the

tab. Click on

on the

From the

from your counter transmitter. Click on

easily edit the setup file using pull-down menus and other selection tools. You can download

(or put) your edited file into the transmitter by clicking on

your setup file to disk by clicking on

disk by click on

The best way to learn IS software is to experiment with it.

For detailed help on any data entry field under any tab, select that field and press on the F1

key.

Establish Communications

Establish

Main Menu

Main Menu

File

, and the two fields at the bottom of the screen should turn green. Click

button.

, click on

=>

Open

Counter

.

screen, select your Com Port and

=>

File

Get Setup

View

=>

=>

Save Setup

to retrieve (or get) the existing setup data

Setup

to bring up screens which allow you to

Counter

and retrieve a previously saved file from

=>

9600

as the Baud Rate.

Communication

Put Setup

. You can save

setup

-

- 10 -

Page 11

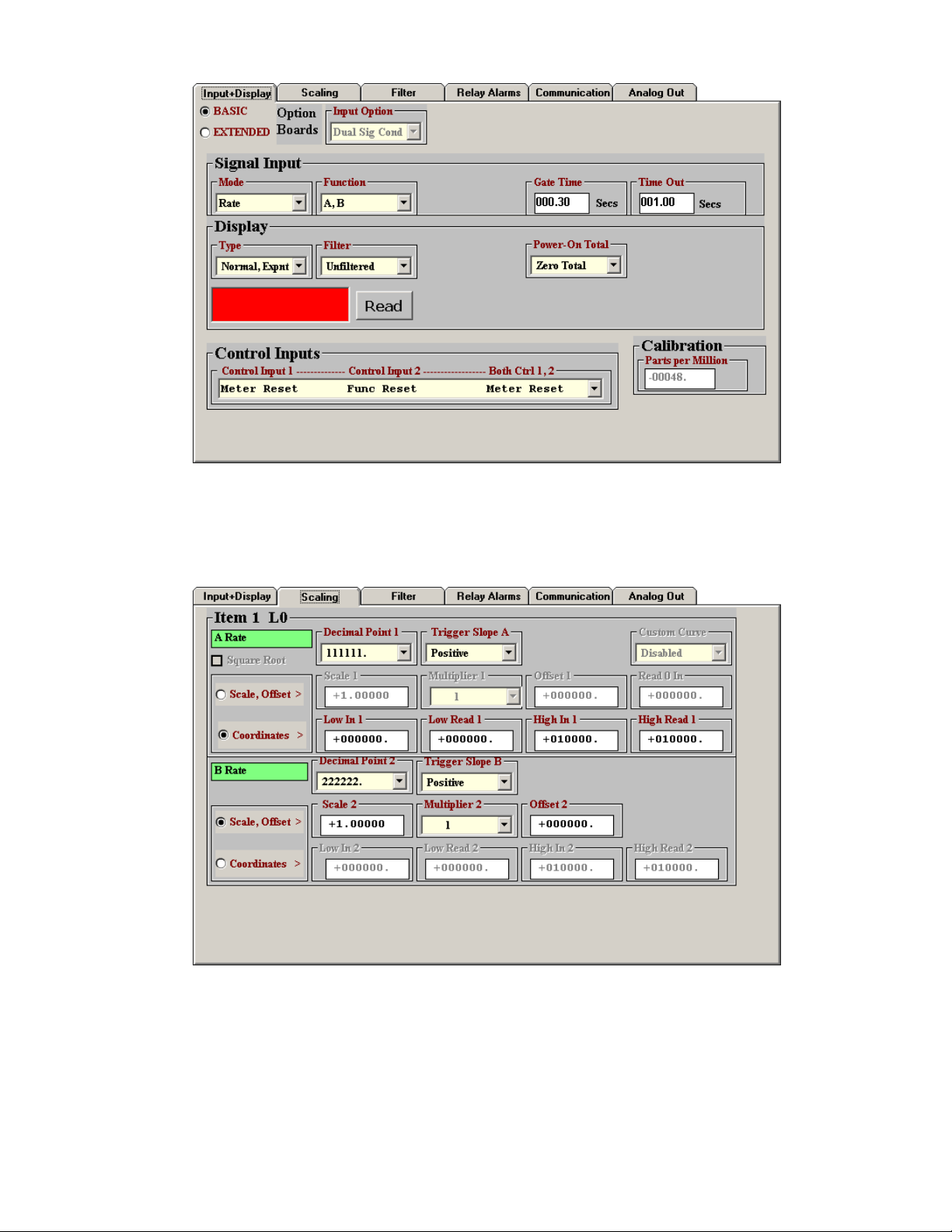

Click on

transmitter, then on

screen to set up

Counter

=>

Signal Input, Display

Get Setup

View

=>

to retrieve the current setup information from your counter

Setup

, which will take you to the

, and

Control Inputs

.

Input+Display

tab. Use this

Click on the

methods: 1) direct entry of Scale and Offset, and 2) the Coordinates of 2 Points method, where

(Low In, Low Read) and (High In, High Read) data points are entered numerically.

Reminder: for detailed help on any data entry field under any tab, select that field and press on

the F1 key.

Scaling

tab to scale your transmitter. You will be given the choice of two scaling

-

- 11 -

Page 12

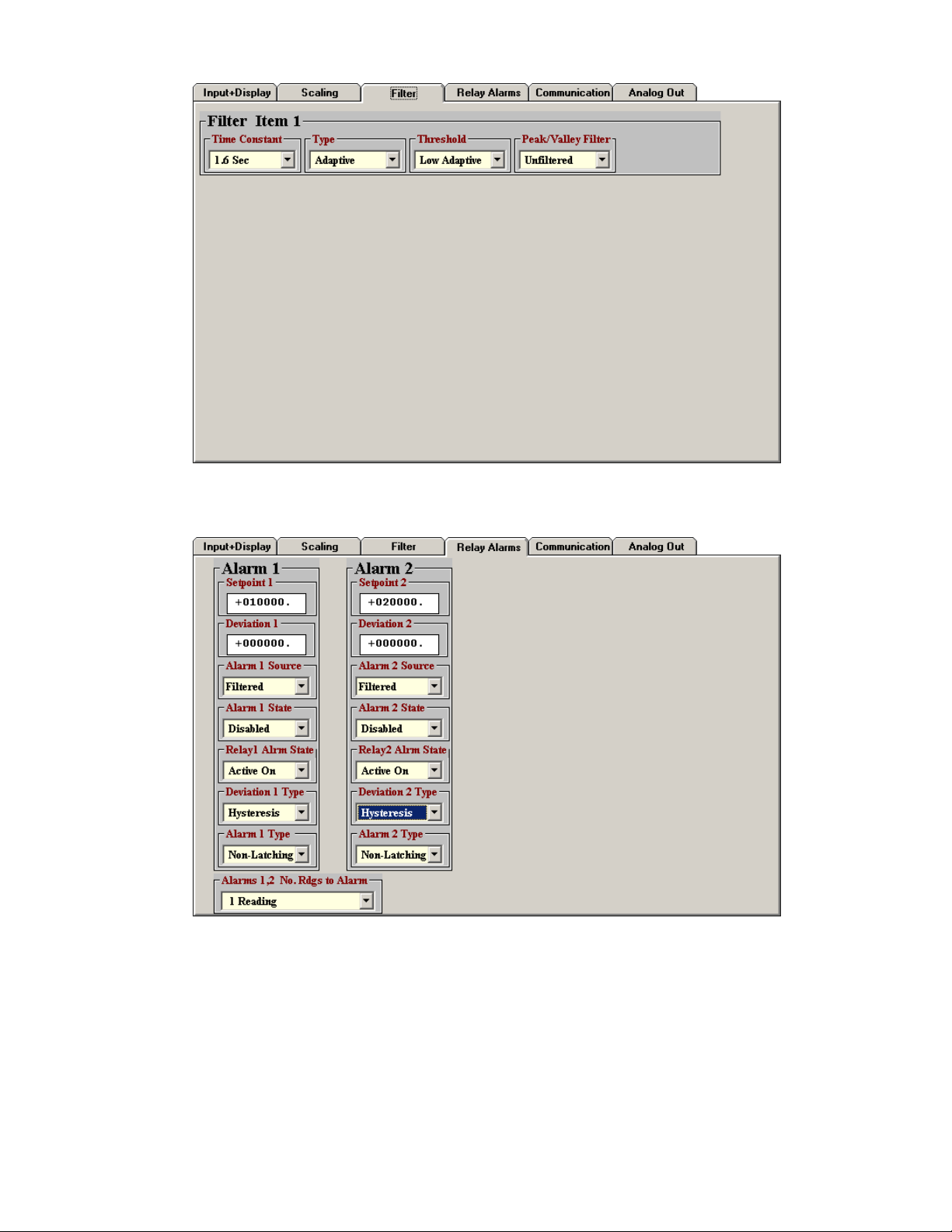

Click on the

Filter

tab to set to set up filtering for your readings.

Click on the

Relay Alarms

tab to set up your transmitter’s two solid state relays, which are

standard.

Reminder: for detailed help on any data entry field under any tab, select that field and press on

the F1 key.

-

- 12 -

Page 13

Click on the

establish default communications with your transmitter. You can reselect

Address

values to establish initial communications with your PC.

,

Communication

Serial Protocol

tab to view the communication parameters that you used to

, and

Full/Half Duplex

, even though you may have selected different

Baud Rate, Device

Click on the

select

0-20 mA Current, 0-10V Voltage

Range reading

Reminder: for detailed help on any data entry field under any tab, select that field and press on

the F1 key.

Analog Out

. These will create the two endpoints of your analog output range.

tab to scale your analog output, which is standard. Under

, or

4-20 mA

-

- 13 -

. Type in your

Lo Range Reading

Range

and

,

Hi

Page 14

ADDITIONAL FEATURES

• The Commands pull-down menu allows you to execute certain functions by using your

computer mouse. This menu will be grayed out unless a

• The Readings pull-down menu provides three formats to display input data on your PC

monitor. Use the

press

Print

for a hardcopy on your PC printer.

Pause

and

Continue

buttons to control the timing of data collection, then

Get Setup

has been executed.

- List presents the latest internal readings in a 20-row by 10-column table. Press

time to freeze the display. Press

- Plot generates a plot of internal readings vs. time in seconds. It effectively turns the

transmitter-PC combination into a printing digital oscilloscope.

- Graph generates a histogram, where the horizontal axis is the internal reading, and the

vertical axis is the number of occurrences of readings. The display continually resizes itself

as the number of readings increases.

Print

for a hardcopy.

Pause

at any

Plot

-

- 14 -

Page 15

Graph

• The Jumpers pull-down menu shows jumper positions for the selected signal conditioner

boards and the main board, duplicating information in this manual.

-

- 15 -

Page 16

8. OPENING YOUR TRANSMITTER CASE

WHEN TO CHANGE JUMPERS

Most users will never have the need to open the transmitter case. The transmitters are

shipped fully jumpered and ready for scaling. The signal conditioner type, range and temperature sensor are specified by the model number on the transmitter label.

To select a different signal conditioner range, you may open the transmitter case and change

jumper settings. Your selected range should encompass your maximum expected signal levels.

All ranges of each signal conditioner board are factory calibrated, with calibration factors stored

in EPROM on the board.

The selection serial signal (RS232 or RS485) and excitation (5V, 10V or 15V) is achieved by

jumpers on the main board. The factory default setting for the serial signal level is RS232. The

default excitation setting for pulse input transmitters is 10V.

After changing jumper settings, you will need to enter the new information into Instrument

Setup software. While this software can sense the instrument type (transmitter, panel meter or

counter) and signal conditioner type, it cannot sense jumper settings which modify the

electrical circuit. You should also update the information on the transmitter label.

HOW TO OPEN & CLOSE THE CASE

The two clamshell halves of the case are held together with 4 bolts and 4 nuts. When removing

these, take care to ensure that they are not lost. Separate the case halves. When closing the

case, make sure the ventilation grills are properly aligned.

-

- 16 -

Page 17

9. DUAL CHANNEL PULSE OR AC INPUT SIGNAL CONDITIONER BOARD

This signal conditioner board is used for the frequency, rate, period, timing, phase angle, or

duty cycle functions. The board needs to be configured via jumpers for the input signal type

and level. It is recognized by Instrument Setup software, which will bring up the applicable

menu items for the Input Option “Dual Sig Cond.” The board does not require calibration, since

the quartz crystal oscillator used for frequency and timing applications is located on the

transmitter main board.

Jumper Settings for Expected Signal Levels

The jumper settings for Channel A (A2 & A3) and Channel B (B2 & B3) need to be set for the

expected signal voltage. This voltage must be outside of the high and low thresholds per the

following table, or the transmitter will not operate properly. The larger the difference between

the high and low thresholds, the more immune the transmitter is to input signal noise.

Input must be Input must be Input must be A3

below above

-12 mV

-150 mV

-1.15V

+12 mV

+150 mV

+1.15V

A3

B3

a

a

a

A2

B2

a

b

-

below above

+30 mV

+350 mV

+1.25V

+60 mV

+600 mV

+2.1V

A3

B3

b

b

b

A2

B2

a

b

-

below above

-60 mV

-600 mV

-2.1V

-30 mV

-350 mV

-1.25V

B3

-

-

-

A2

B2

a

b

-

Jumper Settings for Frequency Response, Bias Resistor, Debounce Time

Pull-up or pull-down resistors are used with open collector devices and dry contact closures

to provide input signal bias. They should not be connected for other inputs. Debounce

circuitry keeps the transmitter from counting extra pulses due to contact bounce.

-

- 17 -

Page 18

Function Block Jumper Setting

Frequency Response A0 & B0 -

b

a

Bias Resistor A1 & B1 a

b

Contact Debounce A4 & B4 b

a, c

c

Common Jumper Settings

1 MHz max

30 kHz max

250 Hz max

10 kOhm pull-up to 5V

10 kOhm pull-down to -5V

None

3 msec

50 msec

Input Type Vmax A0 & B0 A1 & B1 A2 & B2 A3 & B3 A4 & B4

Logic levels 250V - - - a b

NPN open collector NA b a - a b

PNP open collector NA b b - b b

Contact closures NA a or b a - a a, c

Line frequency 250V b - - - a, c

Turbine flow meter 250V b - a - b

RATE & FREQUENCY MODES

Frequency in Hz is determined by timing an integral number of pulses over a user-specified

Gate Time from 0 to 199.99 sec and taking the inverse of average period. The typical internal

display update rate is Gate Time + 1 period + 30 ms. Selecting a longer Gate Time produces a

more stable reading as more cycles are averaged, but slows down the update rate. At very low

frequencies, the update rate is controlled by the period. A Time Out from 0 to 199.99 sec is also

selectable. This is the time the transmitter waits for a signal to start or end a conversion. If the

signal is not received before the Time Out ends, the transmitter reads zero. The longer the Time

Out, the lower the minimum frequency that can be processed.

Rate in engineering units can be obtained by applying a scale factor to frequency, or by using

the Coordinates of 2 Points method, where two inputs in Hz and the corresponding desired two

internal readings are entered directly.

• Rate A, B determines rate independently for Channel A (Item #1) and Channel B (Item #2).

Either item can be selected for the analog output.

• Rate A Only determines rate only for Channel A. Channel B is not used.

• Rate A, A Total (Extended counter) determines Rate for Channel A (Item #1) and Total for

Channel A (Item #2) since last reset. Total can count down from an offset by entering a

negative scale factor. Only used for non-linear inputs.

-

- 18 -

Page 19

•

Rates A+B, A-B, AxB, A-B, A/B, A/B-1 (Extended counter) can output arithmetic combinations of Rates A and B (Item #1), Rate A (Item #2), or Rate B (Item #3). With rates A and

B scaled to produce a ratio close to 1 and an offset of -1, the special combination A/B-1,

called “Draw,” can output percentage changes, such as elongation of material as it passes

between rollers.

PERIOD MODES

The inverse of frequency. Normally expressed in seconds.

TOTAL MODES

•

Total A, B determines Total independently for Channel A (Item #1) and Channel B (Item #2).

Either item can be selected for the analog output.

• Total A Only determines Total only for Channel A (Item #1). Channel B is not used.

• Total Burst (Extended counter) determines the total number of signal bursts applied to

Channel A (Item #1) and signal frequency within a burst (Item #2). Gate time must be

greater than the period of the lowest signal frequency and less than the minimum time

between bursts. Time Out must be greater than the maximum time between bursts.

• Total B, A Rate (Extended counter) determines Total for Channel B (Item #1) and Rate for

Channel A (Item #2).

• Total A, B UpDnCtl (Extended counter) determines Total A (Item #1), where the up or down

count direction is determined by an input on Channel B. If the menu item SLOPE is set to 0

for Channel B, an input level on B below the jumper set Low Threshold B causes the count to

go up, and an input level above the jumper set High Threshold causes the count to go down.

If SLOPE for Channel B is set to 1, the opposite occurs. The maximum frequency on A that

can be counted is 250 kHz, or a minimum of 4 µs between pulses.

• Total A, B InhibitCtl (Extended counter) determines Total A (Item #1), where counting may

be inhibited by a control input on Channel B. If the menu item SLOPE is set to 0 for Channel

B, a low input level on B allows counting, and a high input level inhibits counting. If the

SLOPE for Channel B is set to 1, the opposite occurs. The maximum frequency on A that can

be counted is 1 MHz.

• Totals A+B, A-B, AxB, A/B, A/B-1 (Extended counter) determine arithmetic combinations of

Totals A and B (Item #1).

be selected for analog ouput.

Total A (Item #2) and Total B (Item #3) are also tracked and can

TIMING MODES

•

Time Interval A to B determines the time between periodic inputs on Channels A and B.

Timing starts when a pulse is applied to Channel A (positive edge if slope A is 0, negative

edge if slope A is 1), and ends when a pulse is applied to Channel B (positive edge if slope B

is 0, negative edge if slope B is 1). Pulse width may be measured by tying inputs A and B

-

- 19 -

Page 20

together and selecting a positive or negative edge to start (Slope A) and the opposite polarity

edge to stop (Slope B). If multiple start and stop pulses occur during the Gate Time, the

displayed value is the average of pulse widths. The value is updated at the end of each Gate

Time. With a scale factor of 1, one count is one microsecond.

•

Stopwatch A to A times individual events applied to Channel A (Item #1) and the accumulated “Grand Total Time” of all events since last reset (Item #2). Timing is based on the

same positive (or negative) edge of start and stop pulses. Time of individual events is reset

to 0 when a new start pulse occurs. Time of accumulated events is reset via a reset line.

With a scale factor of 1, one count is one microsecond.

•

Stopwatch A to B measures time between a start pulse on Channel A and a stop pulse on

Channel B. Timing is the same as for A to A, except that positive or negative edges may be

selected separately for Channels A and B. This allows the pulse width measurement of single

pulses by tying Channels A and B together. One slope is selected to start timing, and the

opposite slope to stop timing.

PHASE ANGLE MODES (Extended counter).

•

Phase A to B (0-360) measures the phase difference between signals of the same period

applied to Channels A and B over a span from 0° to 360°. Select this span if no negative

readings are expected, as negative readings would cause high readings.

•

Phase A to B (+/-180) measures the phase difference between signals of the same period

applied to Channels A and B over a span from -180° to +180°. Select this span if negative

readings are expected, which will then not cause high readings.

DUTY CYCLE (Extended counter)

•

Duty Cycle (A to B)/A measures On or Off period of periodic square waves as a percentage

of total period over a Gate Time which is selectable from 10 ms to 199.99 s. The same signal

is applied to Channels A and B. Time is measured between positive and negative edges of

the signal, with averaging over multiple integral periods over the selected Gate Time. Scaling

can be via Scale and Offset, or the Coordinates of 2 Points method.

-

- 20 -

Page 21

10. V-TO F CONVERTER SIGNAL CONDITIONER BOARD

This process receiver signal conditioner board converts 0-1 mA, 4-20 mA or 0-10 V analog

process signals to a frequency signal, which is then processed mathematically by the counter

main board to produce an internal reading of rate, total (time x rate), or 1/rate (time based on

rate). Square root extraction is selectable in software. With this capability, the transmitter can

output a 4-20 mA process signal which tracks flow rate or totalized flow from a differential

pressure flow transducer. The board needs to be configured via jumpers for the input signal

type. It is recognized by Instrument Setup software, which will bring up the applicable menu

items for the V-F Converter input option.

JUMPER SETTINGS

Input Range Jumper Position A1

0-10V

0-1 mA

4-20 mA

None

a

b

OPERATING MODES

• A Only (Rate A, Basic counter) accepts 0-1 mA, 4-20 mA or 0-10 V analog process signals

to calculate an internal rate reading, which is then converted to the analog output. Scaling

can be done by entering Scale and Offset, or using the Coordinates of 2 Points method.

Measurements are averaged over a Gate Time, which is programmable from 10 ms to

199.99 sec. Selecting a long Gate Time provides a slower display update rate, but superior

noise filtering. Moving average filtering is selectable for noise reduction. Square root

extraction is selectable for use with differential pressure flow transducers. Custom curve

linearization is available with the Extended counter.

•

A, A Total (Rate A, Total A, Basic Counter) allows rate to be determined as Item #1 and total

as Item #2. Rate can be scaled using Scale and Offset, or the Coordinates of 2 Points

method. Total can only be scaled using Scale and Offset. Total is calculated as the product of

rate and time in seconds. If square root extraction or custom curve linearization (available

with Extended counter) are selected, totalizing is of the linearized rate readings.

• 1/(A Rate) (Extended Counter) determines the inverse of rate. For example, this can be the

time it takes an item to traverse an oven at a measured rate. Like Rate, 1/Rate can be scaled

using Scale and Offset, or the Coordinates of 2 Points method. Square Root extraction can

be selected for rate. 1/Rate is not available with custom curves.

-

- 21 -

Page 22

11. QUADRATURE SIGNAL CONDITIONER BOARD

This signal conditioner can be used for quadrature position (Basic or Extended main board) or

for quadrature position and rate (Extended main board). Two quadrature signals, which are 90º

out of phase, are applied to the Channel A and B inputs. Their phase relationship determines

whether the count is clockwise (+) or counterclockwise (-). A zero index signal may be applied

to a Z Channel as a position reference.

JUMPER SETTINGS

Input Type E2 E4 E6 E5

Single-ended (signal & return)

Differential

Differential (with excitation and no zero index)

Input Termination (for differential inputs only) E1 E2 E3

a, c

b

b

a, c

b

b

a, c

b

-

c

c

b, d

For long cable runs

For short cable runs

-

- 22 -

a

none a none a none

Page 23

Phase for Up Count E7

A positive, negative B transition (A leads B)

A positive, positive B transition (B leads A)

none

a

Count-by Options E9

X1 = positive edge of A input

X2 = positive & negative edges of A input

X4 = positive & negative edges of A & B inputs

none

a

b

Zero Index Polarity E8

Positive

Negative

c

none

Zero Index ANDing E10 E8

Zero Index (no ANDing)

Zero Index AND /A

Zero Index AND /B

Zero Index AND A

Zero Index AND B

Zero Index AND /A AND /B

Zero Index AND /A AND B

Zero Index AND A AND /B

Zero Index AND A AND B

c

a

a

a

a

b

b

b

b

-

a

b

a, b

a

b

a, b

OPERATING MODES

• Quadrature Total (Basic or Extended counter) determines position in engineering units by

subtracting counterclockwise transitions from clockwise transitions, as determined by the

signal phase relationship, applying a programmable scale factor to the total, and adding a

programmable offset to the scaled total. The output update rate is set by a Gate Time, which

should be set to its minimum of 10 ms. When the scaled total reaches a programmable

Preset, it is reset to Offset.

A zero index function can zero the counts when a pulse is applied to a zero index (or Z)

channel. Zero indexing uses the programmable Pulses per Rev, which is the number of

pulses between zero index marks times the edges per pulse (1, 2 or 4). Since a wide zero

index pulse could cause a discrepancy in the region between transitions, the zero index

pulse can be shaped by an AND combination with the A or B channels, as set by jumpers.

• Quadrature Rate (Extended counter) determines rate engineering units by subtracting coun-

terclockwise rate from clockwise rate. Both rates can be scaled using Scale and Offset, or

the Coordinates of 2 Points method.

programmable from 10 ms to 199.99 sec. Since one of the two channels may not be

measuring any pulses over the gate time, a Time Out from 10 ms to 199.99 sec is also

programmable. The transmitter update rate will never be less than every Time Out.

Rate is measured over a gate time, which is

-

- 23 -

Page 24

12. MAIN BOARD JUMPER SETTINGS

a

d

c

a

E4

b

b

E6

E1

E2

E3

a

c ab

b

cd

Serial Signal Duplex Jumpers Termination Resistor*

E6 a = Transmit

Full None

RS485

E6 c = Receive

Half E6 b + d** E6 c

RS232 Full None None

* The termination resistor jumper settings should only be selected if the transmitter is the last

device on an RS485 line longer than 200 feet (60 m).

** Or jumper external BTX to BRX and ATX to ARX (same effect as internal jumpers).

To reset communications to 9600 baud, command mode, Custom ASCII protocol, and Address 1,

place a jumper at E1 and power up the transmitter.

Analog Output Jumpers

Current E2 a + d

Voltage E2 b + c

Excitation Output* Jumpers

5V, 100 mA E3 a + c; E4 a

10V, 120 mA E3 a + c; E4 b

24V, 50 mA E3 b, E4 none

* Attempting to draw more than the rated current will shut down the output.

-

- 24 -

Page 25

13. DUAL RELAY OPERATION

The optional dual solid state relays can operate in a basic alarm mode, in a hysteresis band mode,

or in a deviation band modes, as explained below. Setpoint operation is referenced to the digital

reading in engineering units that is internal to the transmitter. For example, rate alarm or control

would be referenced to a setpoint in RPM.

1000

g

n

i

d

a

e

R

l

a

t

i

g

i

D

Setpoint

ON

OFF OFF

Time

1000

g

n

i

d

a

e

R

l

a

t

i

g

i

D

Setpoint

OFF

ONON

Time

Active High Basic Alarm Active Low Basic Alarm

A basic alarm changes state automatically when the reading rises above a specified limit, and

changes back automatically when the reading falls below that limit. A red LED indicates the

relay is in an alarm condition, which can be active high or active low, as programmed.

Heater

ON

OFF

1050

950

g

n

i

d

a

e

R

Fail

Pass

Fail

Setpoint = 1000

Deviation limit = 50

Deviation band = 100

1050

950

g

n

i

d

a

e

R

OFF

ON

Setpoint = 1000

Hysteresis limit = 50

Hysteresis band = 100

OFF

ON

Time

Time

Hysteresis band Deviation band

A hysteresis band controls relay action symmetrically around a setpoint. The relay closes (or

opens) when the reading goes above the setpoint plus one hysteresis limit, and opens (or

closes) when the reading falls below the setpoint less one hysteresis limit. A narrow hysteresis

-

- 25 -

Page 26

band is often used to minimize relay chatter. A wide hysteresis band can be used for on-off

control applications. The hysteresis band equals two hysteresis limits.

A deviation band controls relay action symmetrically around a setpoint. The relay actuates

when the reading falls within the deviation band, and de-actuates when the reading falls

outside. A limit (such as 50 counts) is set up around both sides of the setpoint to create the

deviation band, which equals two limits. Passbands around a setpoint are often used for

component testing.

14. INPUT SIGNAL FILTERING

A moving average filter is selectable in software to process the internal digital readings, which

are taken at 60/sec with 60 Hz power and 50/sec with 50 Hz power. Eight moving average

settings are selectable with the following equivalent RC time constants: 0.08 sec, 0.15 sec, 0.3

sec, 0.6 sec, 1.2 sec, 2.4 sec, 4.8 sec, 9.6 sec. The longer time constants provide superior

noise filtering at the expense of fast response time.

Adaptive moving average filtering allows the transmitter to respond rapidly to actual changes

in signal while filtering out normal noise. An adaptive filter threshold causes the moving

average filter to be reset to the latest reading when the accumulated difference between

individual readings and the filtered reading exceeds that threshold. The accumulated difference

is also reset to zero when the latest reading has a different polarity than the filtered reading. The

adaptive filter threshold can be selected as low or high. Low is normally selected. High should

be selected if the signal has large transients.

15. TRANSMITTER CALIBRATION

All ranges of transmitters have been digitally calibrated at the factory prior to shipment using

computers and calibration equipment certified to NIST standards. If recalibration is required, the

transmitter may be returned to the factory or to an authorized distributor.

The counter main board contains an EEPROM, which stores calibration constants for the quartz

crystal oscillator and the analog output. The V-to-F converter signal conditioner board stores its

own stores its own voltage-to-frequency calibration constants EEPROM. The dual channel pulse

input signal conditioner and quadrature signal conditioner boards do not require calibration. As a

result, transmitter boards can be interchanged without requiring recalibration.

-

- 26 -

Page 27

Calibration of the quartz crystal is easily accomplished using Instrument Setup software. Select

Calibration from the Main Menu. Apply a frequency reference signal, and enter the known

frequency in Hz. Calibration of the V-to-F signal conditioner requires use of voltage reference

signals and the calibration program vfcal3.exe, which is available for download.

16. CUSTOM CURVE LINEARIZATION

Curve.exe is a DOS-based, executable PC program used to set up an Extended transmitter so

that the analog output and internal digital readings have a user-defined, non-linear relationship

with the input signal. The calculated linearizing parameters are downloaded into non-volatile

memory of the transmitter. The curve-fitting algorithm uses quadratic segments of varying

length and curvature, and includes diagnostics to estimate curve fitting errors. The program is

self-prompting, avoiding the need for detailed printed instructions. This manual section is only

intended as an introduction.

GETTING STARTED

Download curve.exe from the distribution CD into the same directory that will contain your

data files, such as c:\curves. Connect your transmitter to the PC and double-click on curve.exe,

which is an executable file. Follow the steps on the computer screens, which will prompt you

and provide extensive help information. Pressing R (Enter) returns to the main menu. You will

be given the choice of four data entry modes, all of which are explained in detail.

1) Text file entry mode,

2) 2-coordinate keyboard entry mode,

3) 2-coordinate file entry mode, and

4) Equation entry mode.

-

- 27 -

Page 28

17. MODBUS PROTOCOL TRANSMITTER COMMUNICATIONS

1.0 GENERAL

The Modbus capability conforms to the Modbus over Serial Line Specification & Implementation guide, V1.0. Both the Modbus RTU and Modbus ASCII protocols are implemented:

Modbus RTU

Baud Rate........... 300, 600, 1200, 2400, 4800, 9600 or 19200

Data Format ....... 1 start bit, 8 data bits, 1 parity bit, 1 stop bit (11 bits total)

Parity.................. None, Odd, Even (if None, then 2 Stop bits for 11 total)

Address.............. 0 for broadcast, 1-247 for individual meters

Modbus ASCII

Baud Rate........... 300, 600, 1200, 2400, 4800, 9600 or 19200

Data Format ....... 1 Start bit, 7 Data bits, 1 Parity bit, 1 Stop bit (10 bits total)

Parity.................. None, Odd, Even (if None, then 2 Stop bits for 10 total)

Address.............. 0 for broadcast, 1-247 for individual meters

2.0 FRAMING

Modbus RTU

Message frames are separated by a silent interval of at least 3.5 character times. If a silent

interval of more than 1.5 character times occurs between two characters of the message frame,

the message frame is considered incomplete and is discarded. Frame Check = 16 bit CRC of the

complete message excluding CRC characters.

Modbus ASCII

The message begins immediately following a colon (:) and ends just before a Carriage Return/

Line Feed (CRLF). All message characters are hexadecimal 0-9, A-F (ASCII coded). The system

allowable time interval between characters may be set to 1, 3, 5 or 10 seconds. Frame Check =

1 byte (2 hexadecimal characters) LRC of the message excluding the initial colon (:) and trailing

LRC and CRLF characters.

3.0 ELECTRICAL INTERFACE

RS232, two-wire half-duplex RS485, or four-wire full-duplex RS485 signal levels are selectable

via jumpers on the transmitter main board and a the connector. Please see Section 13. The

RS485 selection provides a jumper selection for insertion of a line termination resistor. In case

of a long line (greater then 500 ft) to the first device, a termination resistor should be selected

for the first device. In case of a long line between the first and last devices, a termination

resistor should be selected for the first and last devices. Never add termination resistors to

more than two devices on the same line.

-

- 28 -

Page 29

4.0 COMMUNICATIONS SETUP

Parameters selectable via Instrument Setup software, distributed on CD ROM:

Serial Protocol ...............................Custom ASCII, Modbus RTU, Modbus ASCII

Modbus ASCII Gap Timeout...........1 sec, 3 sec, 5 sec, 10 sec

Baud Rate.......................................300, 600, 1200, 2400, 4800, 9600, 19200

Parity .............................................No parity, odd parity, even parity

Device Address .............................0 to 247

5.0 SUPPORTED FUNCTION CODES, TM TRANSMITTERS W/ ANALOG INPUT

FC03: Read Holding Registers

Reads internal registers containing setup parameters (Scale, Offset, Setpoints, etc.)

FC10: Write Multiple Registers (FC10 = 16 dec)

Writes internal registers containing setup parameters (Scale, Offset, Setpoints, etc.)

FC04: Read Input Registers

Reads measurement values and alarm status. Returns values in 2's Complement Binary Hex

format without a decimal point. The displayed system decimal point can be read with FC03 at

address 0057. Use only odd Register Addresses and an even number of Registers.

Register

Address TM Transmitter Response

------- ----------------------------------------------00 01 Returns Hi word of Alarm status

00 02 Returns Lo word of Alarm status

00 03 Returns Hi word of Measurement value

00 04 Returns Lo word of Measurement value

00 05 Returns Hi word of Peak value

00 06 Returns Lo word of Peak value

00 07 Returns Hi word of Valley value

00 08 Returns Lo word of Valley value

FC05: Write Single Coil

Action command to meter

Output Output

Address Value Action Command

------- -------- ---------------------------------------00 01 FF 00 Transmitter Reset (No Response)

00 02 FF 00 Function Reset (Peak, Valley)

00 03 FF 00 Latched Alarm Reset

00 04 FF 00 Peak Reset

00 05 FF 00 Valley Reset

00 0C FF 00 Tare Command (Weight Transmitter) (00 00 resets Tare)

-

- 29 -

Page 30

FC08: Diagnostics

Returns total number of Exception Code 6 (Slave Busy)

Checks communications between the Master and Slave, and returns the count in the Modbus

Slave counters (which are reset when the meter is reset).

Hex Sub

Function

Data

Send

Response

Description

Data

Code

00 00 Any Same

Returns Query Data (N x 2 bytes). Echo Request.

as sent

00 01

Restarts Communications. If in the Listen-Only mode, no

response occurs. Takes Slave out of the Listen-Only mode

and one of the following:

FF 00

00 00

FF 00

00 00

Clears communications event counters.

Does not clear communications event counters.

00 04 00 00 None Forces Listen-Only. All addressed and broadcast

Messages are monitored and counters are incremented,

but no action is taken or response sent. Only SubFunction 00 01 causes removal of this Listen-Only state.

00 0A 00 00 00 00 Clears all Modbus slave counters.

00 0B 00 00 Total

Message

Count

Returns total number of messages detected on the bus,

including those not addressed to this Slave. Excludes bad

LRC/CRC, parity error or length < 3.

00 0C 00 00 Checksum

Error

Count

00 0D 00 00 Exception

Error

Count

00 0E 00 00 Slave

Message

Count

00 0F 00 00 No

Response

Count

00 11 00 00 Slave

Busy

Returns total number of messages with bad LRC/ CRC,

parity or length < 3 errors detected on the bus including

those not addressed to the Slave.

Returns total number of Exception responses returned by

the Addressed Slave or that would have been returned if

not a broadcast message or if the Slave was not in a

Listen-Only mode.

Returns total number of messages, either broadcast or

addressed to the Slave. Excludes bad LRC/CRC, parity or

length < 3 errors.

Returns total number of messages, either broadcast or

addressed to the Slave, for which Slave has returned No

Response, neither a normal response nor an exception

response. Excludes bad LRC/CRC, parity or length < 3

errors.

responses.

- 30 -

-

Page 31

6.0 SUPPORTED EXCEPTION RESPONSE CODES

Code Name Error Description

---- -------------------- -----------------------------------------------------01 Illegal Function Illegal Function Code for this Slave. Only hex Function

Codes 03, 04, 05, 08, 10 (dec 16) are allowed.

02 Illegal Data Address Illegal Register Address for this Slave.

03 Illegal Data Value Illegal data value or data length for the Modbus protocol.

04 Slave Device Failure Slave device failure (eg. Transmitter set for external gate).

7.0 MESSAGE FORMATTING

MA = Meter Address DD = Data (Hex) CL = CRC Lo Byte

FC = Function Code WW = Data (On/Off) CH = CRC Hi Byte

RA = Register Address SF = Sub-Function CR = Carriage Return

NR = Number of Registers EC = Error Code LF = Line Feed

NB = Number of bytes LRC = ASCII Checksum

Modbus RTU Format

FC Action

03

Request

03

Response

04

Request

04

Response

05

Request

05

Response

08

Request

08

Response

10

Request

10

Response

Exception

Response

> 3.5

Char

NoTx

NoTx

NoTx

NoTx

NoTx

NoTx

NoTx

NoTx

NoTx

NoTx

1 2 3 4 5 6 7 8 9 10 11

MA

MA

MA

MA

MA

MA

MA

MA

MA

MA

FC

FC

FC

FC

FC

FC

FC

FC

FC

FC

NoTx MA FC

RA

RA

NB

DD*

RA

RA

NB

DD*

RA

RA

RA

RA

SF

SF

RA

RA

SF

SF

RA

RA

EC CL CH

Byte Number

NR

DD*

NR

DD*

WW

WW

WW

DD

NR

NR

NR

CL

NR

CL

WW

WW

WW

DD

NR

NR

CL

CH

CL

CH

CL

CL

CL

CL

NB

CL

+80

DD* = (DD DD) times NR (Number of Registers)

CH

CH

CH

CH

CH

CH

DD*

DD* CL CH

CH

-

- 31 -

Page 32

Modbus ASCII Format

FC Action

1 2 3 4 5 6 7 8 9 10 11 12 13

03

Request

03

Response : :

04

Request

04

Response : :

05

Request

05

Response : :

08

Request

08

Response : :

10

Request

10

Response : :

Exception

: MA FC

Response

DD* = (DD DD) times NR (Number of Registers)

8.0 MESSAGE EXAMPLES

MA

MA

MA

MA

MA

MA

MA

MA

MA

MA

FC

FC

FC

FC

FC

FC

FC

FC

FC

FC

+80

Byte Number

RA

NB

RA

NB

RA

RA

SF

SF

RA

RA

RA

DD*

RA

DD*

RA

RA

RA

RA

SF

SF

NR

DD*

NR

DD*

WW

WW

WW

DD

NR

NR

NR

LRC

NR

LRC

WW

WW

WW

DD

NR

NR

LRC

CR

LRC

CR

LRC

LRC

LRC

LRC

NB

LRC

CR

LF

CR

LF

CR

CR

CR

CR

DD*

CR

LF

LF

LF

LF

LF

LF

DD*

LRC CR LF

LF

EC LRC CR LF

All examples are for Transmitter Address = 01 and No Parity.

Ser_4 ->

Action

Addr ->

Restart Communications

Request

Response*

Meter Reset Request

Response

Digital Reading

** ***

Write Setpoint

1 = +37.00***

Read Setpoint

1 = +37.00***

Request

Response

Request

Response

Request

Response

Modbus RTU

010

001

010800010000B1CB

010800010000B1CB

01050001FF00DDFA

None

01040003000281CB

010404000009D67C4A

0110000100020400000E743624

01030400000E74FE74

01030001000295CB

01030400000E74FE74

:0110000100020400000E7466crlf

Modbus ASCII

020

001

:010800010000F6crlf

:010800010000F6crlf

:01050001FF00FAcrlf

None

:010400030002F6crlf

:010404000009D618crlf

:011000010002ECcrlf

:010300010002F9crlf

:01030400000E7476crlf

* Suggested as first message after power-up. If transmitter is in Listen-Only mode, no response

is returned. ** Example while reading +25.18 *** Decimal point is ignored.

9.0 INTERNAL REGISTERS: Please refer to the full Modbus Protocol Communications Manual,

which is downloadable from our website.

-

- 32 -

Page 33

18. CUSTOM ASCII PROTOCOL TRANSMITTER COMMUNICATIONS

1.0 SERIAL COMMUNICATION FORMAT

The Custom ASCII serial communication format for both RS232 and RS485 is the following:

Mode ................ Full Duplex (Separate transmit and receive lines) and Half Duplex (RS485 only)

Baud Rate ......... 300, 600, 1200, 2400, 4800, 9600, 19200 selectable with Instrument Setup

software.

Parity ................ None

Word length...... 8 data bits

Stop bit ............ 1

2.0 MEASUREMENT DATA FORMAT

The basic measurement data format consists of 8 ASCII characters for analog input “DPM”

transmitters, such as +999.99<CR>, where <CR> is the carriage return character. The first

character is always a plus or minus sign. A decimal point is always furnished, even when it

follows the last digit.

Adding a Line Feed Character to the Basic Format

Printers and other devices that receive the data may require a line feed character <LF> following

the <CR>. The line feed character <LF> may be selected using Instrument Setup software.

Adding a Coded Data Character to the Basic Format

A coded character from A to H may be added to the data string according to the table below to

indicate the alarm and overload status of the device. If used, this character precedes the <CR>,

so that it is the last printable character in the string. With the optional <LF> and coded

character selected, the data string will consist of 10 characters for analog input “DPM”

transmitters, such as +999.99A<CR><LF>.

Alarm Status No Overload Overload

Neither Alarm set

Alarm 1 set only

Alarm 2 set only

Both Alarms set

A

B

C

D

E

F

G

H

For example, a coded character “G” indicates that Alarm 2 only is set and that the transmitter is

in the overload condition. This information is useful when data is supplied to a computer for

listing and analysis, or when data is supplied to a Remote Display in a Master-Slave configuration.

-

- 33 -

Page 34

Values are transmitted in a continuous string with no intervening spaces. If the 5th digit in is

set to 1 using Instrument Setup software, the termination characters of <CR> and optional

<LF> appear after each value. If the 5th digit is et to 0, the termination characters appear only

once at the end of the string. In either case, if included, the coded character appears at the end

of the last value only.

3.0 NETWORK CONFIGURATIONS

Using the Custom ASCII protocol, TM Series transmitters can operate in a point-to-point mode

using RS232 or RS485, or in a multi-point mode using RS485.

The point-to-point mode is a direct connection between a computer (or other digital device)

and the transmitter. An device address can be selected; however, it is suggested that address 1

be selected as a standard for the point-to-point mode.

The multi-point mode is a connection from a host computer to a multiplicity of transmitters

bused together with their inputs and outputs connected in parallel. For long cable runs, the last

device should have a termination resistor installed. It is necessary to set up each device on the

bus with a different address from 1 to 31. To command a particular device, its address is used

in conjunction with the command, and only that device responds. The outputs of all of the

devices on the bus are set to a high impedance state, except the device being addressed. The

device addresses range from 1 to 31, with 0 being a special address to which a meter responds

only internally (e.g. Reset), but does not transmit any response on the output lines. All devices

may be commanded simultaneously with a 0 address, and there will not be any output

response contention. Addressing of transmitters can be set with Instrument Setup software.

4.0 COMMAND MODE OVERVIEW

Using the Custom ASCII protocol, TM Series transmitters operate in the Command Mode only.

In this mode, the device does not send data automatically, but responds to commands received

from a host computer. These commands can be:

• To transmit the latest or peak measurement

• To reset the meter completely or just the peak value and/or latched alarms

• To display a value sent from the computer

• To transmit present setup parameters

• To receive new setup parameters,

• To monitor or alter data in selected memory locations of the meter.

5.0 COMMAND MODE FORMAT

CHAR 1 - Command Identifier

All commands begin with “*” followed by the meter address, then a command letter

followed by a sub-command number or letter. Additional characters may be appended. All commands terminate with <CR> (<LF> ignored).

-

- 34 -

Page 35

Char # Character Description

1

2

3

4

*

0-V

A-Z

0-U

Command Identifier. Recognition Character.

Device Address. 0 addresses all devices, 1-V specific devices.

Command Function

Sub-command. Number of Bytes of RAM or Words (2 Bytes) of

non-volatile memory data being transferred.

CHAR 2 - Address Codes

A Serial Communications Address Code from 1 to V follows the “*” to indicate the device

address number from 1 to 31.

Device #

1

2

3

4

5

6

7

8

9

10

11

Address

Code

1

2

3

4

5

6

7

8

9

A

B

Device #

12

13

14

15

16

17

18

19

20

21

22

Address

Code

C

D

E

F

G

H

I

J

K

L

M

Device #

23

24

25

26

27

28

29

30

31

Address

Code

N

O

P

Q

R

S

T

U

V

CHARS 3 & 4 - Commands and Subcommands

The examples below use a default address of 1 following the “*“. Substitute the desired

address from the above table of Serial Comm Address Codes. All command sequences shown

must terminate with <CR>, followed by an optional <LF>.

Request DPM Values

Get reading** *1B1

Peak reading *1B2

Valley reading *1B3

** The meter transmits the value or values selected with Instrument Setup software.

Reset Functions, DPM Transmitter

Cold reset *1C0 Reads NVMEM into RAM locations after RAM is zeroed.

Latched alarms reset *1C2

-

- 35 -

Page 36

Peak value reset *1C3

Remote display reset *1C4

Valley reset *1C9

Tare function *1CA

Tare reset *1CB

6.0 READING AND WRITING TO RAM AND NONVOLATILE MEMORY

CHAR 1, 2

The Recognition character and Meter Address Code are the same as shown in previous table.

CHAR 3

Command character:

G Read bytes from RAM Memory

F Write bytes to RAM Memory (DPM and Scale meter only)

R Read bytes from Upper RAM Memory

Q Write bytes to Upper RAM Memory

X Read words from Non-Volatile Memory

W Write words to Non-Volatile Memory

CHAR 4

Command character. Sub-command. Number of Bytes of RAM or Words (2 Bytes) of nonvolatile memory data being transferred.

Code # Number Code # Number Code # Number

1

2

3

4

5

6

7

8

9

A

1

2

3

4

5

6

7

8

9

10

B

C

D

E

F

G

H

I

J

K

11

12

13

14

15

16

17

18

19

20

L

M

N

O

P

Q

R

S

T

U

21

22

23

24

25

26

27

28

29

30

CHAR 5, 6

See tables for the RAM MEMORY ADDRESSES and NONVOLATILE MEMORY ADDRESSES with

their respective data definitions.

-

- 36 -

Page 37

General, Reading and Writing Ram Memory Data

RAM memory data is read and written as a continuous string of bytes consisting of 2 hex

characters (0-9,A-F) per byte. Included in the command are the total number of bytes to be

transferred and the most significant address in RAM of the continuous string of bytes. The

format is:

Read lower RAM data *1Gnaa

Write lower RAM data *1Fnaa<data>

Read upper RAM data *1Rnaa

Write upper RAM data *1Qnaa<data>

where: n is the number of bytes to be read or written.

aa is the most significant address in RAM of the bytes to be read

or written.

<data> is n bytes of 2 hex characters per byte in order from the most

to the least significant byte.

The number of bytes n consists of a single code character representing values from 1 to 30 as

shown above under CHARACTER 4. The most significant address aa consists of 2 hex characters as shown below under RAM MEMORY ADDRESSES AND DATA DEFINITIONS.

General, Reading and Writing Nonvolatile Memory Data

Nonvolatile data is read and written as a continuous string of words consisting of 2 bytes or 4

hex characters (0-9,A-F) per word. Included in the command is the total number of words to

be transferred and the most significant address in nonvolatile memory of the continuous string

of words. The format is:

Read nonvolatile memory data *1Xnaa (followed by Meter reset)

Write non-volatile memory data *1Wnaa <data> (followed by Meter reset)

where: n is the number of words to be read or written.

aa is the most significant address in nonvolatile memory of the words to be

read or written.

<data> is n words of 2 bytes or 4 hex characters per word in order from the most to

the least significant address.

The coded number of words n consists of a single character representing values from 1 to 30

as shown under CHARACTER 4. The most significant address aa consists of 2 hex characters

as shown under NONVOLATILE MEMORY ADDRESSES.

-

- 37 -

Page 38

19. “CTR” TRANSMITTER SPECIFICATIONS

Mechanical

Case Dimensions ......................................................................................... 120 x 101 x 22.5 mm

Case Mounting................................................................................ 35 mm DIN rail per EN 50022

Electrical Connections..............................................................Detachable screw plug connectors

Environmental

Operating Temperature ............................................................................................... 0°C to 55°C

Storage Temperature ...............................................................................................-40°C to 85°C

Relative Humidity........................................................... 95% from 0°C to 40°C, non-condensing

Power & Electrical

Power to Transmitter ................. 95-240 Vac ±10% or 90-300 Vdc (DC range is not UL certified)

.................................................................... 12-30 Vac or 10-48 Vdc (low voltage power option)

Power Isolation.................. 250 Vrms between power, analog output, signal input, and serial I/O

Transmitter Setup

Selection of Signal Ranges & Temperature Sensors............Jumpers on signal conditioner board

Selection of Serial Format (RS232 or RS485) & Excitation Level ............ Jumpers on main board

Programming................ Via RS-232 from PC using Instrument Setup software and CBL04 cable

Analog Output

Output Levels................0-20 mA, 4-20 mA or 0-10V. Voltage or current selectable at connector.

Compliance at 20 mA..................................................................................10V (0-500 ohm load)

Compliance at 10V......................................................................... 2 mA (5 kohm minimum load)

Output Resolution.......................................................................................16 bits (65,536 steps)

Output Accuracy ............................±0.05% of full span for DC inputs, ±0.1% for AC RMS inputs

Output Update Rate .............................................. 60/sec at 60 Hz power, 50/sec at 50 Hz power

Output Filtering .........................................................................................Digitally programmable

Serial I/O (standard)

Serial Formats.......................RS232 or half-duplex RS485 (jumper selectable, default is RS232)

Protocol ...................................................................................................................Custom ASCII

Comm. Connector........................................ Detachable 3-position plug for TX, RX, Comm. GND

Transducer Excitation Output (standard)

Output Isolation ....................................................................................... 50 Vdc to meter ground

Selectable levels ................. 5 Vdc ± 5%, 100 mA; 10 Vdc ± 5%, 120 mA; 24 Vdc ± 5%, 50 mA

Dual Relay Output (standard)

Relay type ...................................................Two solid state relays, SPST, normally open, Form A

Load rating ................................................................................... 130 mA at 140 Vac or 180 Vdc

-

- 38 -

Page 39

DUAL CHANNEL SIGNAL CONDITIONER

Crystal Accuracy at 25ºC....................................................................................................±2 ppm

Crystal Tempco...................................................................................................±1 ppm/degree C

Long-Term Drift of Crystal .........................................................................................±5 ppm/year

Signal Types .................... AC, NPN, PNP transistor outputs, contact closures, magnetic pickups

Max Pulse Rate ........................................................ 1 MHz on Channel A, 250 kHz on Channel B

Channel Isolation ..................................................Channel A & channel B share common ground

Low Pass Filter ................................................................................ 250 Hz or 30kHz (selectable)

Hysteresis..................................................................................... 15 mV to 2.2 Vp-p (selectable)

Trigger level ....................................................................................±15 mV to ±1.7 V (selectable)

Debounce Circuitry ...................................................................................0, 3, 50 ms (selectable)

V-TO-F PROCESS RECEIVER & TOTALIZER SIGNAL CONDITIONER

Signal Levels.......................................................................0-1 mA, 4-20 mA, 0-10 V (selectable)

Accuracy at 25ºC............................................................................................................. ±0.025%

Span Tempco........................................................................................... ±0.003% of reading /°C

Zero Tempco.......................................................................................... ±0.003% of full scale /°C

QUADRATURE SIGNAL CONDITIONER

Signal Type .......................................................................Differential or single-ended quadrature

Transitions Monitored................................................................................................. x1, x2 or x4

Max Pulse Rate ........................................................ 250 kHz at x1, 125 kHz at x2, 62.5 kHz at x4

Maximum Differential Signal Amplitude...................................................................................14V

Conversion Technique for Rate.........................................................................................1/period

Conversion Time for Rate ................................................ Gate time + 30 ms + 0-2 signal periods

Time Before Zero Output for Rate...................................................... 0 to 199.99 sec (selectable)

Zero Wait Time for Rate..................................................................... 0 to 199.99 sec (selectable)

Output & Display Update Rate ................................................................Same as conversion rate

Time Base Accuracy for Rate........................................................................Calibrated to ±2 ppm

-

- 39 -

Page 40

20. WARRANTY

Laurel Electronics Inc. warrants its products against defects in materials or workmanship for a

period of one year from the date of purchase.

In the event of a defect during the warranty period, the unit should be returned, freight prepaid

(and all duties and taxes) by the Buyer, to the authorized Laurel distributor where the unit was

purchased. The distributor, at its option, will repair or replace the defective unit. The unit will be

returned to the buyer with freight charges prepaid by the distributor.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from:

1. Improper or inadequate maintenance by Buyer.

2. Unauthorized modification or misuse.

3. Operation outside the environmental specifications of the product.

4. Mishandling or abuse.

The warranty set forth above is exclusive and no other warranty, whether written or oral, is

expressed or implied. Laurel specifically disclaims the implied warranties of merchantability

and fitness for a particular purpose.

EXCLUSIVE REMEDIES

The remedies provided herein are Buyer’s sole and exclusive remedies. In no event shall Laurel

be liable for direct, indirect, incidental or consequential damages (including loss of profits)

whether based on contract, tort, or any other legal theory.

Copyright 2006-2012, Laurel Electronics, Inc. Rev 6 February 2012

-

- 40 -

Loading...

Loading...