Page 1

LAUREATE SERIES

COUNTER/TIMER OWNERS MANUAL

LAUREL Electronics Inc.

3183-G Airway Ave, Costa Mesa, CA USA 92626

Tel: (714) 434-6131 Fax: (714) 434-3766 Website: www.laurels.com

Page 2

ORDERING GUIDE

L ........... Laureate series counter/timer with

screw terminal connectors.

Display Color

5 ................................................ Green LED

6 ....................................................Red LED

7 ...............................Extended capabilities,

custom curves, Green LED

8 ...............................Extended capabilities,

custom curves, Red LED

Power

0 ..................... 85 to 264Vac, 90 to 370Vdc

1 ........................... 9 to 32 Vdc, 8 to 28 Vac

Setpoint Output

0 ..........................................................None

1 ........................................Dual 10 A relays

2 .................Opto isolated solid state relays

Analog Output

Channel A: Dc to 1MHz, Channel B: Dc to

250kHz, 20mV to 250V, NPN, PNP, contact

closure, logic level inputs, selectable debounce

and frequency response

FR ................................. Scalable to 999,999

Analog Input

Basic: rate, square root, flow

Extended: basic plus rate and total, square

root, batching, linearize curves

Voltage to Frequency converter, single chan-

nel, displays to +/-999,999

VF1 ...............................................4 to 20mA

VF2 ................................................0 to 1 mA

VF3 ..................................................0 to 10V

Quadrature

Basic: position,length, angle

Extended: basic function or rate

0 ..........................................................None

1 ............................ 0 to 20 mA, 0 to 10 Vdc

2 .......Batch relay(for FR batch mode only)

Digital Interface

0 ..........................................................None

1 ...................................................... RS-232

2 ...................................................... RS-485

3 ...........................................................BCD

Input Type

Select one of the following input option boards:

Dual Channel Pulse or AC

Basic: Frequency, rate, period, total, time

interval

Extended: Basic plus rate and total, ratio,

phase angle. stopwatch, arithmetic functions, batching, linearize curves

Count input x1, 2, or 4, anti-jitter circuitry, z

channel zeroing, inputs are differential line

receivers or logic levels.

QD ........................................ Position,length

Remote Display

6-digit display plus minus sign. Accepts RS232 or RS-485 from computer, PLC, or other

Laurel meters and displays transmitted value.

Displayed value may be retransmitted as 0 to

10V or 4 to 20mA via the analog output and

setpoints may be added to provide alarms

from displayed value or alarm data via the

serial interface. Requires RS485 or rs232

interface.

No letters after model # ............ +/-99999

Page 3

TABLE OF CONTENTS

1. INTRODUCTION........................................................................................................PAGE 2

2. RECEIVING AND UNPACKING..............................................................................PAGE 3

3. SAFETY CONSIDERATIONS ..................................................................................PAGE 3

4. CONNECTOR WIRING INFORMATION ...............................................................PAGE 4

5. MECHANICAL ASSEMBLY.....................................................................................PAGE 6

6. PANEL MOUNTING ..................................................................................................PAGE 7

7. CONNECTORS ..........................................................................................................PAGE 7

8. OPERATING THE METER ......................................................................................PAGE 8

9. SETTING MENU LOCKOUTS .................................................................................PAGE 9

10. SETUP MENU..........................................................................................................PAGE 10

11. DUAL CHANNEL SIGNAL CONDITIONER .........................................................PAGE 23

11.1 SETTING JUMPERS FOR INPUT SIGNAL LEVELS............................PAGE 23

11.2 COMMON JUMPER SETTINGS ...............................................................PAGE 23

11.3 MODES OF OPERATION ..........................................................................PAGE 24

11.4 RATE .............................................................................................................PAGE 24

11.5 PERIOD .........................................................................................................PAGE 26

11.6 TOTAL...........................................................................................................PAGE 26

11.7 TIME INTERVAL ..........................................................................................PAGE 28

11.8 STOPWATCH ..............................................................................................PAGE 28

11.9 PHASE ANGLE............................................................................................PAGE 28

12. V-TO-F SIGNAL CONDITIONER..........................................................................PAGE 29

12.1 SETTING JUMPERS FOR INPUT SIGNAL LEVELS............................PAGE 29

12.2 RATE .............................................................................................................PAGE 29

12.3 BATCH ...........................................................................................................PAGE 29

12.4 RATE AND TOTAL......................................................................................PAGE 30

12.5 1/RATE ..........................................................................................................PAGE 30

13. QUADRATURE SIGNAL CONDITIONER ...........................................................PAGE 31

13.1 SETTING JUMPERS FOR INPUT SIGNAL LEVELS............................PAGE 31

13.2 QUADRATURE DECODING ......................................................................PAGE 32

13.3 ZERO INDEX SETUP .................................................................................PAGE 33

13.4 MECHANICAL ZERO..................................................................................PAGE 35

13.5 SETUP SUMMARY .....................................................................................PAGE 36

13.6 MANUFACTURERS OF OPTICAL ENCODERS ...................................PAGE 37

13.7 QUADRATURE RATE ................................................................................PAGE 39

14. DUAL ALARM OUTPUTS ......................................................................................PAGE 40

15. RS-232 AND RS-485 INTERFACE.......................................................................PAGE 42

16. ANALOG OUTPUT ..................................................................................................PAGE 44

17. PARALLEL BCD OUTPUT.....................................................................................PAGE 45

18. 5, 10, AND 24VDC EXCITATION OUTPUTS .....................................................PAGE 46

19. DIGITAL INPUTS .....................................................................................................PAGE 47

20. CALIBRATION .........................................................................................................PAGE 48

21. SPECIFICATIONS ...................................................................................................PAGE 48

22. GLOSSARY OF TERMS ........................................................................................PAGE 51

Page 4

1. INTRODUCTION

The series of panel instruments is a versatile, cost effective solution to a wide variety of

monitoring and control applications. These instruments are easily set to produce an

accurate display of frequency, rate, total, period, time interval, phase, position , flow, etc.

Front panel pushbutton or RS-232/RS-485 setup allows the user to customize the unit for

a specific application. Digital scaling of zero and span provides direct readout in

engineering units. A high stability crystal and digital calibration of all ranges eliminates

drift associated with potentiometers found in non-microcomputer-based meters. The

meter measures the period of the input signal to calculate frequency or rate. This fast

read rate provides an accurate display of peak signal input and quick response in control

applications. Selectable gate time (10ms to 99s) and adaptive filter ensure stable

displayed readings and outputs while responding rapidly to changes of the input signal.

Selective security lockout of the front panel setup protects against accidental changes to

the meter configuration and simplifies use by the operator. The series uses a lightweight,

high-efficiency switching power supply that operates from either AC or DC voltages and

complies with safety regulations. The meter can be powered worldwide without changes

to the supply. An optional low voltage supply operates on 9 to 37 Vdc from batteries or

8 to 28 Vac from sources such as 400 Hz aircraft power. Both supplies have isolated 5,

10, and 24Vdc excitation outputs to power transducers. The NEMA 4 (IP65) 1/8 DIN case

is made of high impact, 94V-0 UL-rated plastic. Mounting is from the front of the panel and

requires less than 110 mm behind the panel. All wiring is by removable plugs conforming

to IEC950 safety standards. All output options are isolated from meter and power ground

by 250 Vac minimum.

The dual setpoints have two form C ( 10 A @ 250 Vac ) relays or open collector outputs

for alarm and control capabilities. Either setpoint may be latching or nonlatching and may

be separately configured to be energized above or below the setpoint or in a fail-safe

mode. Outputs may also be selected to operate from the filtered signal to reduce relay

chatter or from the unfiltered signal for fast response. Snubber circuits and programmable relay switching time delay extend relay contact life.

Isolation of the 4 to 20 mA and 0 to +10 V analog outputs eliminates ground loop problems.

The output may be scaled by front panel pushbuttons or RS-232/RS-485. For square root

and custom curves, the output is linearized. Depending on the application, the analog

output may be selected to operate from the filtered or unfiltered signal input. The 4 to 20

mA output will drive up to an 800 Ohm load with 16 V compliance

The meter offers RS-232 or RS-485 bidirectional communications or parallel, 3-state

BCD output to interface with computers, PLC’s or other digital devices. IBM PC

compatible software is available for programming of the unit by the RS-232 and RS-485

interfaces.

-2-

Page 5

2. RECEIVING AND UNPACKING

Your meter was carefully tested and inspected prior to shipment. Should the meter be damaged

in shipment, notify the freight carrier immediately. In the event the meter is not configured as

ordered or the unit is inoperable, return the unit to the place of purchase for repair or

replacement. Please include a detailed description of the problem.

3. SAFETY CONSIDERATIONS

Warning : The use of this equipment in a manner other than specified may impair the

protection of the device and subject the user to a hazard.

Visually inspect the unit for signs of damage. If the unit is damaged, do not attempt to

operate.

This unit must be powered with AC ( mains ) from 85 to 264 Vac (90 to 370 Vdc) with the high

voltage power supply option or 8 to 28 Vac (9 to 37 Vdc) with the low voltage power supply

option. Verify that the proper power option is installed for the power to be used.

This meter has no AC ( mains ) switch; it will be in operation as soon as power is connected.

Caution: The 85 to 264 Vac (90 to 370 Vdc) mains connector (J1 Pins 1-3) is color coded

Light Blue to differentiate it from other input and output connectors. The 8 to 28 Vac (9 to

37 Vdc) mains connector is not color coded because these voltages are not considered

hazardous.

Do not make signal wiring changes or connections when power is applied to the instrument.

Make signal connections before power is applied and, if reconnection is required, disconnect

the AC ( mains ) power before such wiring is attempted.

To prevent electrical or fire hazard, do not expose the instrument to excessive moisture.

Do not operate the instrument in the presence of flammable gases or fumes; such an

environment constitutes a definite safety hazard. This meter is designed to be mounted in a

metal panel.

Verify the panel cutout dimensions and mount according to instructions.

-3-

Page 6

4. CONNECTOR WIRING INFORMATION

4.1 CONNECTOR LOCATION

The connectors are the screw terminals that plug into the mating jack mounted on the printed

circuit board. P3 is either a 6 conductor phone plug for RS-232 and RS-485 or a 30 pin, mass

termination, edge connector for parallel BCD.

J1

1

J2 J3

1

6

A

1

6

B

6

6

1

4.2 J1 - POWER AND DIGITAL CONTROLS

J1

AC HI (+DC HI)

AC LO (DC RET)

EARTH GROUND

CONTROL INPUT B (+5V)*

CONTROL INPUT A*

DIGITAL GROUND*

1

2

3

4

5

6

*Note: Non-isolated external control inputs

4.3 J5 - SIGNAL INPUT

VOLTAGE-TO-FREQUENCY CONVERTER

-EXCITATION

+EXCITATION

- SIGNAL INPUT

+SIGNAL INPUT

J5

1

2

3

4

Signal Source

out

in

-

in

+

-

out

+

1 2

J4

1

3

30

J5

1

6

A and B are menu selectable.

QUADRATURE INPUT (DIFFERENTIAL)

A INPUT

A INPUT

B INPUT

B INPUT

Z INPUT ( + EXCITATION)

Z INPUT (- EXCITATATION)

1

2

3

4

5

6

J5

DUAL CHANNEL PULSE INPUT

J5

-EXCITATION

+EXCITATION

SIGNAL INPUT B

GROUND

SIGNAL INPUT A

GROUND

1

2

3

4

5

6

-4-

Note: Z input or excitation is jumper

selectable

QUADRATURE INPUT (SINGLE-ENDED)

J5

+A INPUT

+EXCITATION

+B INPUT

-EXCITATION

+Z INPUT

GROUND

1

2

3

4

5

6

Page 7

4.4 J 2 - DUAL SETPOINT CONTROLLER

RELAY OUTPUTS

ALARM 1 - N/O CONTACT

ALARM 1 - N/C CONTACT

ALARM 1 - COMMON

ALARM 2 - N/O CONTACT

ALARM 2 - N/C CONTACT

ALARM 2 - COMMON

SOLID STATE RELAY OUTPUTS

Switching DC 125Vdc @240 ma max.

ALARM 1 - SOURCE 1

ALARM 1 - SOURCE 2

ALARM 1 - DRAIN

ALARM 2 - SOURCE 1

ALARM 2 - SOURCE 2

ALARM 2 - DRAIN

This configuration is directly compatible with the optotransistor output board.

*

1

2

3

4

5

6

1

2

3

4

5

6

+ DC

+ DC

- DC

+ DC

+ DC

- DC

SOLID STATE RELAY OUTPUTS

Switching AC 125Vac @120 ma max.

ALARM 1 - SOURCE 1

ALARM 1 - SOURCE 2

ALARM 1 - DRAIN

ALARM 2 - SOURCE 1

ALARM 2 - SOURCE 2

ALARM 2 - DRAIN

SOLID STATE RELAY OUTPUTS

*

Switching DC 125Vdc @120 ma max.

ALARM 1 - SOURCE 1

ALARM 1 - SOURCE 2

ALARM 1 - DRAIN

ALARM 2 - SOURCE 1

ALARM 2 - SOURCE 2

ALARM 2 - DRAIN

4.5 J3 DIGITAL INTERFACE

1

2

3

4

5

6

1

2

3

4

5

6

AC

AC

AC

AC

+ DC

- DC

+ DC

- DC

RS - 232 INTERFACE - J3A

N/C

ISO GROUND

RX

TX

RTS

N/C

RS - 485 INTERFACE - J3A & J3B

ISO GROUND

BRX

ARX

ATX

BTX

ISO GROUND

ISO GROUND

ATX/ARX

BTX/BRX

ISO GROUND

6

5

4

3

2

1

FULL DUPLEX

6

5

4

3

2

1

HALF DUPLEX

6

5

4

3

2

1

COMPUTER

GROUND

TRANSMIT

RECEIVE

RTS

COMPUTER

GROUND

TRANSMIT +

TRANSMIT RECEIVE RECEIVE +

GROUND

COMPUTER

GROUND

TX/RX TX/RX +

GROUND

BCD OUTPUT

1

10

40

100

400

1K

4K

10K

40K

100K

400K

+ POL

BCD HOLD

ISOLATED GND

1

4

3

5

7

9

11

13

15

17

19

21

23

25

27

29

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

4.6 J4 - ANALOG OUTPUT

0 TO 20 MA OUTPUT

0 TO 10 VDC OUTPUT

ISOLATED GROUND

2

8

20

80

200

800

2K

8K

20K

80K

200K

800K

DATA READY

BCD ENABLE

ISO 5 / 15VDC

1

2

3

-5-

Page 8

5. MECHANICAL ASSEMBLY

5.1 REMOVING THE REAR PANEL

To remove the rear panel, first remove any connectors that are installed. Press down on both

rear panel retaining tab releases (see Fig. 5.1) and pull the top of the rear panel away from the

case. The bottom of the rear panel will now lift out.

Retaining Tab

and Release

Retaining Tab Retaining Tab

Figure 5.1

5.2 REMOVING THE METER FROM THE CASE

After removing the rear panel, the meter can be taken out of the case by carefully grasping the

power supply board and signal conditioner board at the connectors and sliding the unit out the

back of the case. See Figure 5.2.

Retaining Tab

and Release

Figure 5.2

5.3 REASSEMBLING THE METER

Reverse the preceding procedures to reinstall the meter in the case. After the meter

is in the case, insert the bottom tabs on the rear panel into the case first. Care must

be taken to ensure the printed circuit boards are properly aligned by the board

retaining pins on the inside of the rear panel.

-6-

Page 9

6. PANEL MOUNTING

Ensure the O-ring is in place. Turn the two mounting screws counterclockwise until the space

between the mounting pawl and the bezel is greater than the panel thickness. Insert the meter

in the panel cutout. Turn the mounting screws clockwise until the meter is securely mounted

in the panel. Do not overtighten the mounting screws.

48mm

(1.89in)

4mm

(0.157in)

102mm

(4.02in)

96mm

(3.78in)

FRONT VIEW

TOP VIEW

J1 J2 J3 J4 J5

10mm

(0.394in)

J1 J2 J3 J4 J5

REAR VIEW

SIDE VIEW

Mounting Pawl

PANEL CUTOUT

45 +0.6/-0.0mm

(1.772 +.024/-0.0in)

92 +0.8/-0.0mm

(3.622 +.032/-0.0in)

7. CONNECTORS

The meter uses UL/VDE rated screw terminal connections that plug into the mating PC jack.

-7-

Page 10

8. OPERATING THE METER

ALARM 1 STATUS

INDICATOR

MENU KEY

PEAK DISPLAY KEY

( DIGIT SELECT )

Figure 8.1

DISPLAYED ITEM /

RESET KEY

( VALUE SELECT )

ALARM 2 STATUS

INDICATOR

DISPLAYED ITEM

INDICATOR

ALARM KEY

(REVERSE MENU)

OPERATING MODE

The meter is in normal operation and the input signal value is displayed.

MENU MODE

The meter display and outputs do not respond to the input signal and alarm relays are

deenergized.

MENU KEY

The menu key changes the meter from the operating mode to the menu mode and steps

through the various meter parameters that may be selected. These menu items may be “locked

out” from front panel selection by software and hardware.

PEAK DISPLAY KEY (DIGIT SELECT)

In the Operating Mode, pressing the Peak Display Key causes the peak value of the input

signal to be displayed. Pressing the key again returns the display to the present value. In the

Menu Mode, the Digit Select Key (Peak Display Key) is used to select input type and decimal

point or to select one of the five display digits for programming. In the main menu, pressing the

Digit Select Key causes the value or code that is stored for that menu item to be displayed and

the left hand digit flashes. Each time the key is pressed, the next digit to the right will flash. The

value of the flashing digit may be changed using the Value Select Key. In the Alarm Mode,

pressing the Digit Select Key causes the most significant digit of the displayed setpoint value

to flash. Digits are then selected the same as in the Menu Mode.

RESET KEY (VALUE SELECT)

In the Operating Mode, holding the Reset Key depressed and pressing any other key causes

a reset to occur. The Menu Key resets all meter functions, the Alarm Key resets any alarm

conditions and the Peak Display Key resets the peak value to present value. If the Displayed

Item Key (Reset Key) is pushed and released without depressing another button (and if the

-8-

Page 11

meter is configured to display more than 1 item), display item #2 is displayed and the displayed

item indicator lights. Repeating this selects display item #3 and displayed item indicator

flashes. In the Menu Mode or Alarm Mode, the Value Select Key ( Reset Key) sets the value

of the flashing digit. Each time the key is pressed, the value increases by one. Holding the key

down causes the digit to automatically step through the numbers.

ALARM KEY (REVERSE MENU)

In the Operating Mode, pressing the Alarm Key displays the setpoint of Alarm 1 and then Alarm

2. These values may be changed using the Digit Select Key and the Value Select Key. In the

Menu Mode, pressing the Alarm Key steps the display backward through the menu.

9. SETTING MENU LOCKOUTS

For security and ease of operation, any or all program menu items may be disabled. Each

function to be disabled is set to "1" in the menu items, " Loc 1"," Loc 2", "Loc 3" or "Loc 4". These

lockout menu items may in turn be "locked-out" by installing an internal hardware shorting

jumper. With the jumper installed, the operator has access only to enabled menu items.

9.1 SETTING HARDWARE LOCKOUT JUMPER

a

Power Supply Board

Figure 9.1

Lockout Jumper

To access the jumper, remove the rear panel per Section 5.1.

Remove jumper "a" located on the lower portion of the power

supply board next to the input connectors (see figure at left) to

allow access to the software lockout menu. Replace the jumper

to remove access to lockout menu items.

Jumper Removed - Loc 1,2, 3 and 4 are displayed as menu items

and allow other menu items to be locked out or enabled.

Jumper Installed - Loc 1,2, 3 and 4 are not displayed on program

menu

-9-

Page 12

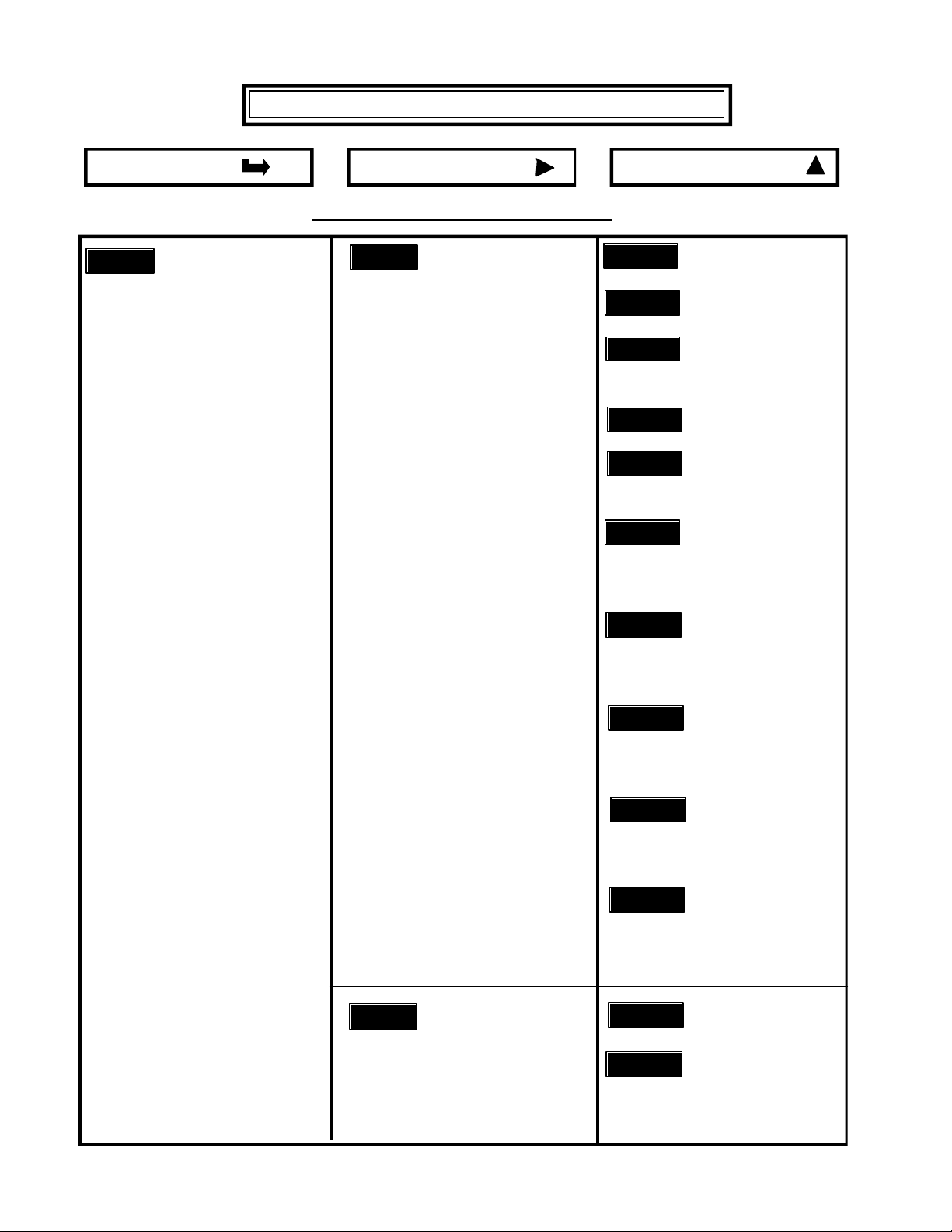

10. SETUP MENU

MENU KEY

InPut

Input signal type

DIGIT SELECT KEY

DUAL CHANNEL SIGNAL CONDITIONER

rAtE

Frequency or rate

VALUE SELECT KEY

A b calculates rates for

inputs A (I1) & B (I2)

A OnLy calculates rate for

Note:

(I1), (I2), and (I3) are display

items 1, 2, and 3. The value

that is displayed may be selected via front panel

pushbutton.

input A (I1)

bAtCH calculates rate (I3),

total (I1), grand total for batching (I2), input A

A Atot calculates rate (I1)

and total for input A (I2)

A btot calculates rate for

Basic counter:

A b, A Only

Extended counter:

All items shown

input A (I1) and total for input

B (I2)

A + b calculates rate for

input A (I2), rate for input B

(I3), and sum of both inputs

(I1)

A - b calculates rate for

input A (I2), rate for input B

(I3), and difference of both

inputs (I1)

A . b calculates rate for

input A (I2), rate for input B

(I3), and product of both inputs (I1)

A / b calculates rate for

input A (I2), rate for input B

(I3), and ratio of both inputs

(I1)

A/b-1 calculates rate for

input A (I2), rate for input B

(I3), and draw of both inputs

(I1)

PEriod

Period

Basic counter:

A b, A Only

Extended counter:

All items shown

-10-

A b calculates period

for inputs A (I1) & B (I2)

A OnLy calculates period

for input A (I1)

Page 13

MENU KEY

DUAL CHANNEL SIGNAL CONDITIONER (CONT'D)

DIGIT SELECT KEY

VALUE SELECT KEY

InPut

Input signal type (cont"d)

PEriod

Period (cont'd)

Note:

(I1), (I2), and (I3) are display

items 1, 2, and 3. The value

that is displayed may be selected via front panel

pushbutton.

Basic counter:

A b, A Only

Extended counter:

All items shown

totAL

Total

Note:

To count down, use negative

scale factor.

Basic counter:

A b, A Only

Extended counter:

All items shown

A + b calculates period

for input A (I2), period for

input B (I3), and sum of both

inputs (I1)

A - b calculates period

for input A (I2), period for

input B (I3), and difference of

both inputs (I1)

A . b calculates period

for input A (I2), period for

input B (I3), and product of

both inputs (I1)

A / b calculates period

for input A (I2), period for

input B (I3), and ratio of both

inputs (I1)

A b calculates totals

for inputs A (I1) & B (I2)

A OnLy calculates totals

for input A (I1)

A-BUpDn calculates difference (I1) between A total

and B total

bursT calculates total #

of bursts (I1) and burst frequency (I2), input A

b Arat calculates total for

input b (I1) and rate for input

A(I2)

A bUPd calculates total

for input A (I1) with input B

up/down control

A binH calculates total for

input A (I1) with input B as

count inhibit control

A + b calculates total for

input A (I2), total for input B

(I3), and sum of both inputs

(I1)

-11-

Page 14

MENU KEY

DIGIT SELECT KEY

DUAL CHANNEL SIGNAL CONDITIONER

VALUE SELECT KEY

InPut

Input signal type (cont'd)

totAL

Total (cont'd)

Note:

Use A-B for up/down counting where input A is the up

counts and input B is the

down counts.

Basic counter:

A b, A Only

Extended counter:

All items shown

ti Int

Time interval

A - b calculates total for

input A (I2), total for input B

(I3), and difference of both

inputs (I1)

A . b calculates total for

input A (I2), total for input B

(I3), and product of both inputs (I1)

A / b calculates total for

input A (I2), total for input B

(I3), and ratio of both inputs

(I1)

A to b calculates time

from input A (leading or trailing edge of signal) to input B

(leading or trailing edge of

signal) . Display in mS or

clock format (I1).

InPut

Input signal type

StoP t

Stopwatch

Extended counter only

PHASE

Phase angle

Extended counter only

QUADRATURE INPUT

quAdr

Input from quadrature

encoder

Basic counter: total

Extended counter: total or

rate

A to A calculates time

from input A leading edge to

leading edge or trailing edge

to trailing edge.

A to b calculates time

from input A (leading or trailing edge of signal) to input B

(leading or trailing edge) .

A to b calculates phase

angle of input A to input B

totAL calculates total or

position (I1)

rAtE calculates rateand

direction(I1) or total (I1)

-12-

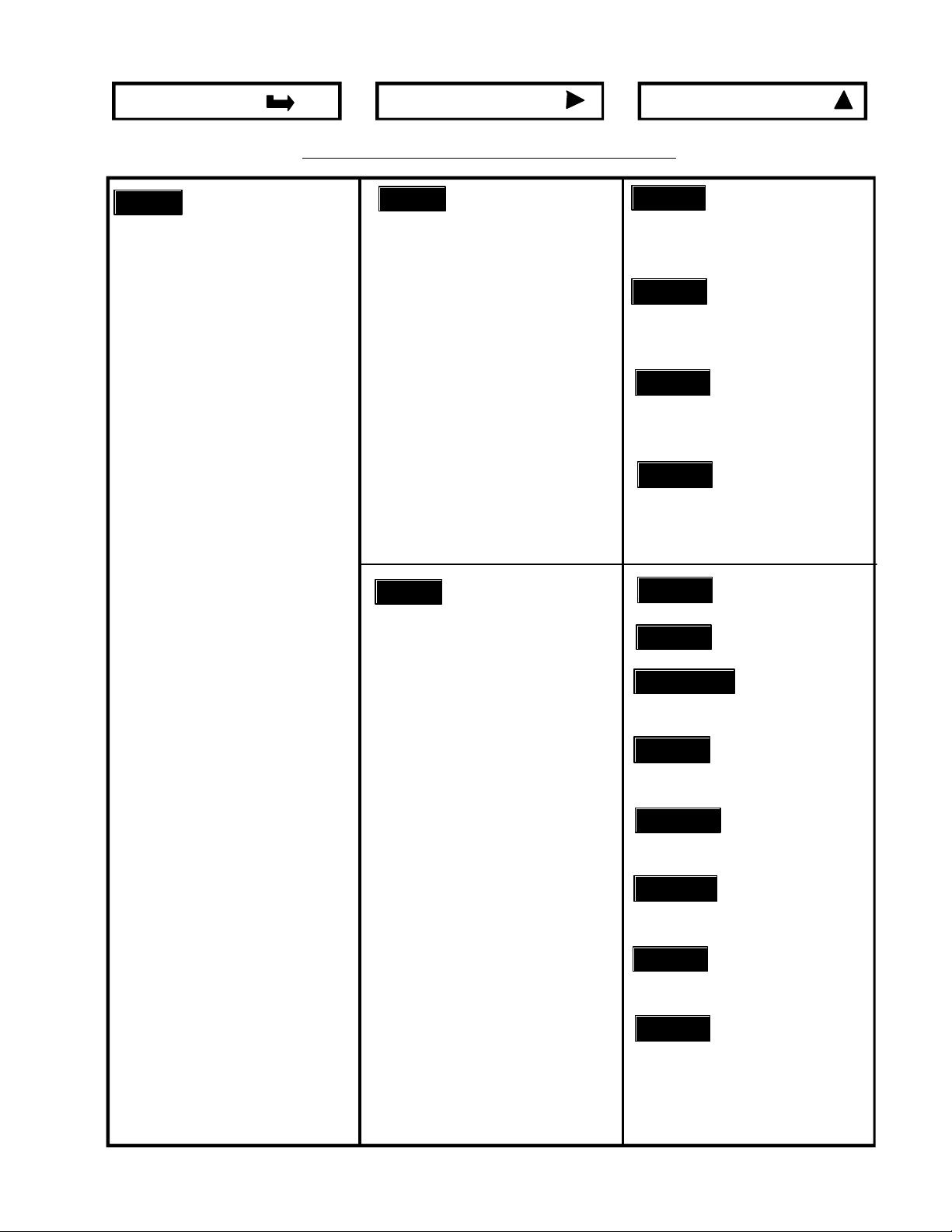

Page 15

MENU KEY

DIGIT SELECT KEY

VOLTAGE-TO-FREQUENCY CONVERTER

VALUE SELECT KEY

InPut

Input signal type

Note:

(I1), (I2), and (I3) are display

items 1, 2, and 3. The value

that is displayed may be selected via front panel

pushbutton.

SEtuP

Meter Setup

UF4 20

4 to 20ma signal input

UF 0 1

0 to 1ma signal input

UF0 10

0 to 10V signal input

Basic counter:

A Only

Extended counter:

All items shown

00000

Display total at power on

00000

Display of leading zeros

A OnLy calculates rate for

input A (I1)

bAtCH calculates rate

(I3), total (I1), grand total for

batching (I2), input A

A Atot calculates rate (I1)

and total for input A (I2)

Atot A calculates rate for

input A (I2) and total for input

A (I1)

1 / A calculates the

inverse of rate for input A (I1)

0 Reset total

1 Display stored total

0 Blank leading zeros

1 Display leading zeros

00000

Method of scaling (Scale1)

00000

Method of scaling (Scale2)

00000

Rear connector inputs A & B

Low input = true

0 Scale1 using scale and

offset

1 Scale1 using coordinates

of 2 points

0 Scale2 using scale and

offset

1 Scale2 using coordinates

of 2 points

0 A: Meter reset

B: Function reset

1 A: Meter reset B: Hold

2 A: Meter reset

B: Peak display

3 A: Meter reset

B: External gate

4 A: Funct. reset B: Hold

5 A: Function reset

B: Peak display

6 A:Funct reset B:Ext gate

7 A: Hold B: Peak display

-13-

Page 16

MENU KEY

DIGIT SELECT KEY

VALUE SELECT KEY

SEtuP

Meter Setup (cont'd)

ConFIG

Meter configuration

00000

Connector inputs (cont'd)

Low input = true

0000

Display type

8 A: Hold B: Ext. gate

9 A: Peak display

B: External gate

A A: Meter reset

B: Display blank

b A: Function reset

B: Display blank

C A:Hold B: Display blank

d A:Display blank

B: External gate

E A:Peak B: Display blank

F A:Display item 2

B: Display item 3

0 Normal, exponential

overload

1 Normal, 99999

overload

2 1 right dummy zero

3 2 right dummy zeros

4 Clock (hr, min, or sec)

5 Clock time (hh:mm:ss)

6 Remote display (K

command)

7 Remote display

(single value)

Slave Remote Display

8 1st value in string

9 2nd value in string

A 3rd value in string

b 4th value in string

0000

Meter type

(Selectable only if extended

meter)

0000

Square root of input rate

0000

Negative samples for

sample-time totals.

-14-

0 Basic

1 Extended

2 Custom curve #1

3 Custom curve #2 (V-F)

0 Rate input

1 Square root of rate

0 Neg samples excluded

1 Neg. samples included

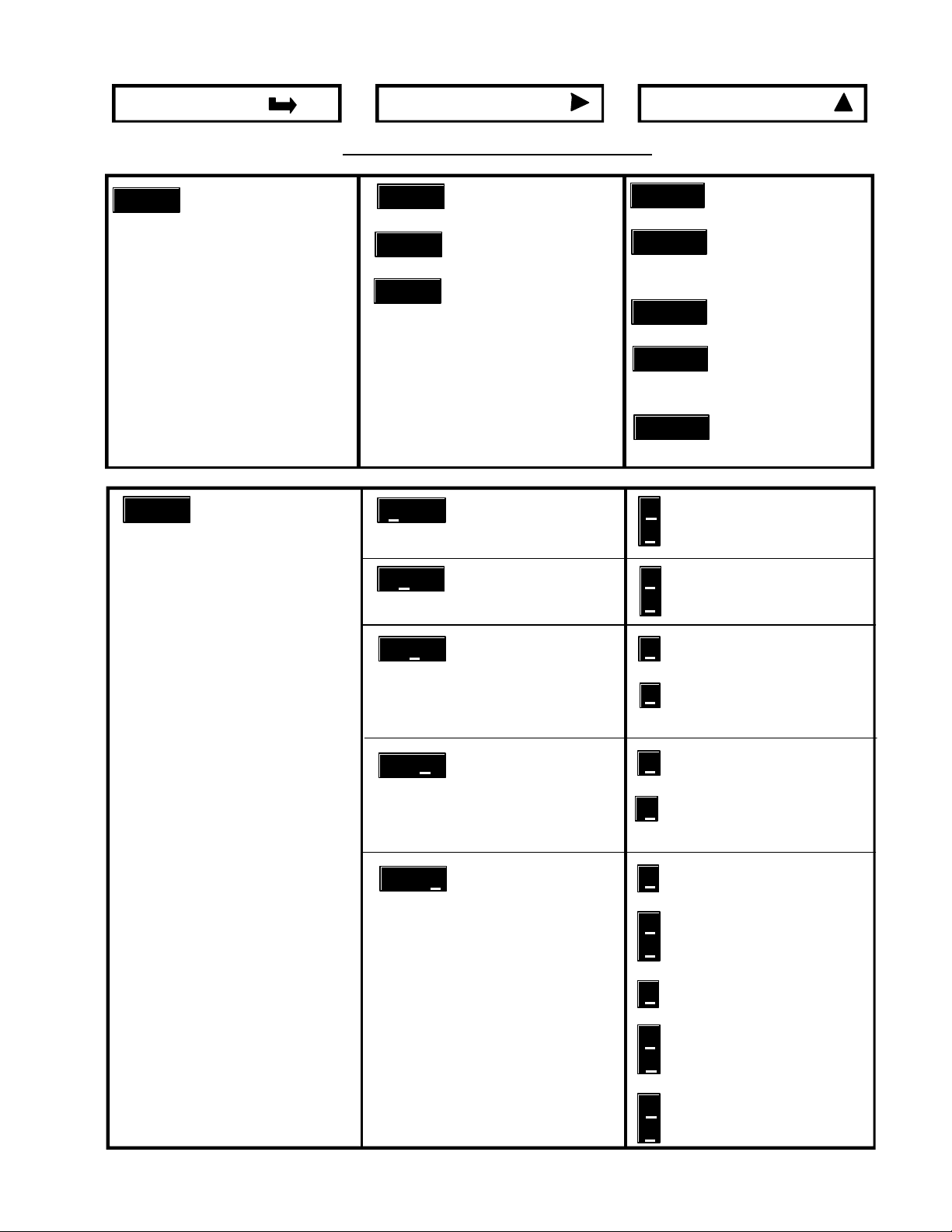

Page 17

MENU KEY

DIGIT SELECT KEY

VALUE SELECT KEY

dSPYno

Item to be displayed at power

on.

PULSES

Number of pulses per zero

(Quadrature only)

GAtE t

Gate time

(If not Batch)

dSPY t

Relay output time

( Batch only )

ti Out

Time out to display "0" if no

input (If not Batch)

bAtCH

Batch (batch mode only)

1

Enter display item #

00000 00000 00000

00000 00000

Enter number of pulses

199.99

Select value from .01 to

199.99 seconds

199.99

Select value from .01 to

199.99 seconds

199.99

Select value from .01 to

199.99 seconds

00000

Batch total and grand totals

stop at preset values or

count all input pulses

1 Display item 1

2 Display item 2

3 Display item 3

Select 0 through 9 for

flashing digit.

Select 0 through 9 for

flashing digit.

Select 0 through 9 for

flashing digit.

Select 0 through 9 for

flashing digit.

0 Batch preset, grand preset

1 Batch all, grand preset

2 Batch preset, grand all

3 Batch all, grand all

FiLtEr

Filtering

00000

Reset and count direction

00000

Reset at end of gatetime or

with external signal

0000

Grand total or batch #

0000

Batch start

00000

Filter type

00000

Display value

0 Reset to 0 and count up

1 Set to offset1 & cnt down

0 Use gatetime to reset

1 Use External Function

reset

0 Item #2 = grand total

1 Item #2 =total # of batches

0 Display "rEAdy" after reset

1 Start batch after reset

0 Adaptive filter

1 Conventional filter

0 Unfiltered display value

1 Filtered display value

-15-

Page 18

DIGIT SELECT KEY

VALUE SELECT KEYMENU KEY

FiLtEr

Filtering (continued)

SLOPE

Trigger slope of input signal

(if not V-to-F)

dEc.Pt1

Decimal point selection

00000

Peak value

00000

Adaptive filter threshold

00000

Filter time constant

00

Channel A input

00

Channel B input

1.11111 11.1111 111.111

1111.11 11111.1 111111.

0 Unfiltered peak value

1 Filtered peak value

0 Low adaptive threshold

1 High adaptive threshold

0 No filter

1 0.1 sec

2 0.2 sec

3 0.4 sec

4 0.8 sec

5 1.6 sec

6 3.2 sec

7 6.4 sec

0 Positive slope

1 Negative slope

0 Positive slope

1 Negative slope

Use value select key to select decimal point

dEc.Pt2

Decimal point selection

SCALE1

Scale factor and multiplier

(Scale and Offset selected)

OFFSt1

Offset or Zero Value

Lo in1

Low signal input value (Coor-

dinates of 2 points selected)

Lo rd1

Low Displayed Reading at

Low Signal Input

Hi in1

High signal input value

2.22222 22.2222 222.222

2222.22 22222.2 222222.

0.00000 0.00000 0.0 0000

0.00000 0.00000 0.00000

Scale factor

0.00001 to 100000 Multiplier

0000.00 0000.00 0000.00

0000.00 0000.00 0000.00

0.00000 0.00000 0.0 0000

0.00000 0.00000 0.00000

0000.00 0000.00 0000.00

0000.00 0000.00 0000.0 0

0.00000 0.00000 0.0 0000

0.00000 0.00000 0.00000

Use value select key to select decimal point

Select 0 through 9 for

flashing digit. Decimal point

fixed. Select scale factor

multiplier

Select 0 through 9 for

flashing digit. Decimal point

fixed by DecPt1.

Select 0 through 9 for

flashing digit. Decimal point

fixed by input range on V-F

Select 0 through 9 for

flashing digit. Decimal point

fixed by DecPt1.

Select 0 through 9 for

flashing digit. Decimal point

fixed by input range on V-F

-16-

Page 19

MENU KEY

DIGIT SELECT KEY

VALUE SELECT KEY

Hi rd1

High displayed reading at

high Signal Input

(Scale and Offset selected)

SCALE2

Scale factor and multiplier

OFFSt2

Offset or Zero Value

( Coordinates of 2 points

selected)

Lo in2

Low signal input value

0000.00 0000.00 0000.00

0000.00 0000.00 0000.0 0

0.00000 0.00000 0.0 0000

0.00000 0.00000 0.00000

Scale factor

0.00001 to 100000

Multiplier

0000.00 0000.00 0000.00

0000.00 0000.00 0000.00

0.00000 0.00000 0.0 0000

0.00000 0.00000 0.00000

Select 0 through 9 for

flashing digit. Decimal point

fixed by DecPt1.

Select 0 through 9 for

flashing digit. Decimal point

fixed. Select scale factor

multiplier

Select 0 through 9 for

flashing digit. Decimal point

fixed by DecPt1.

Select 0 through 9 for

flashing digit.

Lo rd2

Low Displayed Reading at

Low Signal Input

Hi in2

High signal input value

Hi rd2

High displayed reading at

high Signal Input

rd0 In

(V-to-F, square root and custom curve only)

Corrects for zero errors

rESoLn Resolution of

arithmetic functions

0000.00 0000.00 0000.00

0000.00 0000.00 0000.0 0

0.00000 0.00000 0.0 0000

0.00000 0.00000 0.00000

0000.00 0000.00 0000.00

0000.00 0000.00 0000.0 0

04.0000

Value set to actual voltage or

current input at zero

0.00001 to 100000

Multiplier

Select 0 through 9 for

flashing digit. Decimal point

fixed by DecPt1.

Select 0 through 9 for

flashing digit.

Select 0 through 9 for

flashing digit.

Select 0 through 9 for

flashing digit.

Select multiplier

-17-

Page 20

DIGIT SELECT KEY

VALUE SELECT KEYMENU KEY

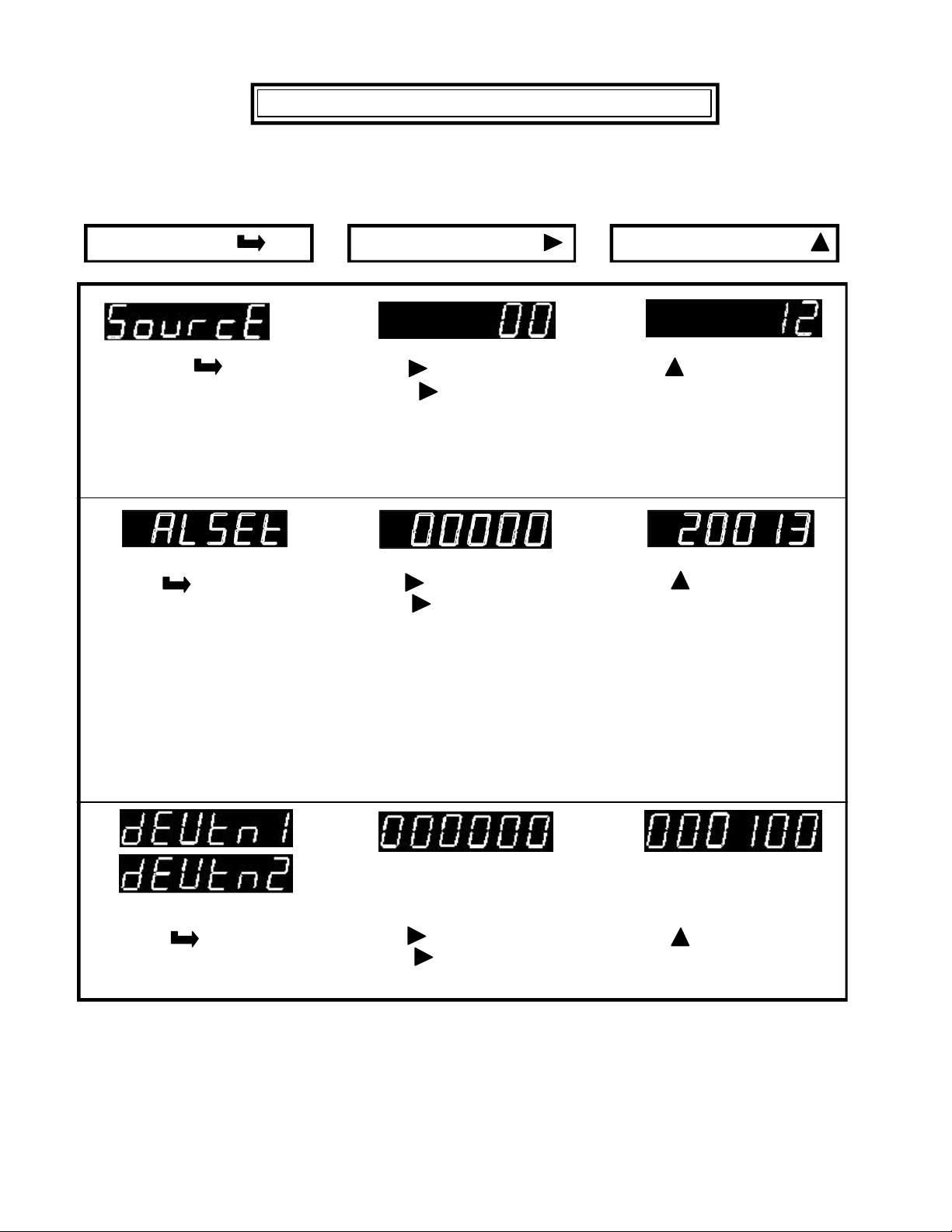

SourcE

Source of alarm operation

(only enabled if relay output

installed)

ALSEt

Alarm Operation Setup

(only enabled if relay output

installed)

00

Compare Alarm 1 to:

00

Compare Alarm 2 to:

00000

Relay output status when

alarm active (On or off)

00000

Relay output status when

alarm active (Latching or

nonlatching)

0 Filtered item

1 Item 1

2 Item 2

3 Item 3

0 Filtered item

1 Item 1

2 Item 2

3 Item 3

0 relay 1 on, relay2 on

1 relay 1 off, relay2 on

2 relay 1 on, relay2 off

3 relay 1 off, relay2 off

0 AL1 nonlatching

AL2 nonlatching

1 AL1 latching

AL2 nonlatching

2 AL1 nonlatching

AL2 latching

3 AL1 latching

AL2 latching

00000

00000

Alarm status

If deviation > 0, then:

active high = energizes outside deviation band

active low = energizes inside

deviation band

0 AL1 active high

AL2 active high

1 AL1 active low

AL2 active high

2 AL1 disabled

AL2 active high

3 AL1 active high

AL2 active low

4 AL1 active low

AL2 active low

5 AL1 disabled

AL2 active low

6 AL1 active high

AL2 disabled

7 AL1 active low

AL2 disabled

8 AL1 disabled

AL2 disabled

-18-

Page 21

MENU KEY

DIGIT SELECT KEY

VALUE SELECT KEY

ALSEt

Alarm Operation Setup

(cont'd)

dEUtn1

Amount of deviation or

hysteresis - Alarm 1

(only enabled if relay or open

collector output installed)

00000

Select to operate as band

deviation alarms or as hysteresis around the setpoint

(if deviation set to > 0)

00000

Number of consecutive readings in the alarm zone to

cause an alarm

000000 000000 000000

000000 000000 000000

When deviation value is >

0, alarms operate above

and below setpoint by the

value entered.

0 AL1: Dev AL2: Dev

1 AL1: Hys AL2: Dev

2 AL1: Dev AL2: Hys

3 AL1: Hys AL2: Hys

4 No Hys or Dev in menu

0 After 1 reading

1 After 2 readings

2 After 4 readings

3 After 8 readings

4 After 16 readings

5 After 32 readings

6 After 64 readings

7 After 128 readings

Select 0 through 9 for

flashing digit.

dEUtn2

Amount of deviation or

hysteresis - Alarm 2

(only enabled if relay or open

collector output installed)

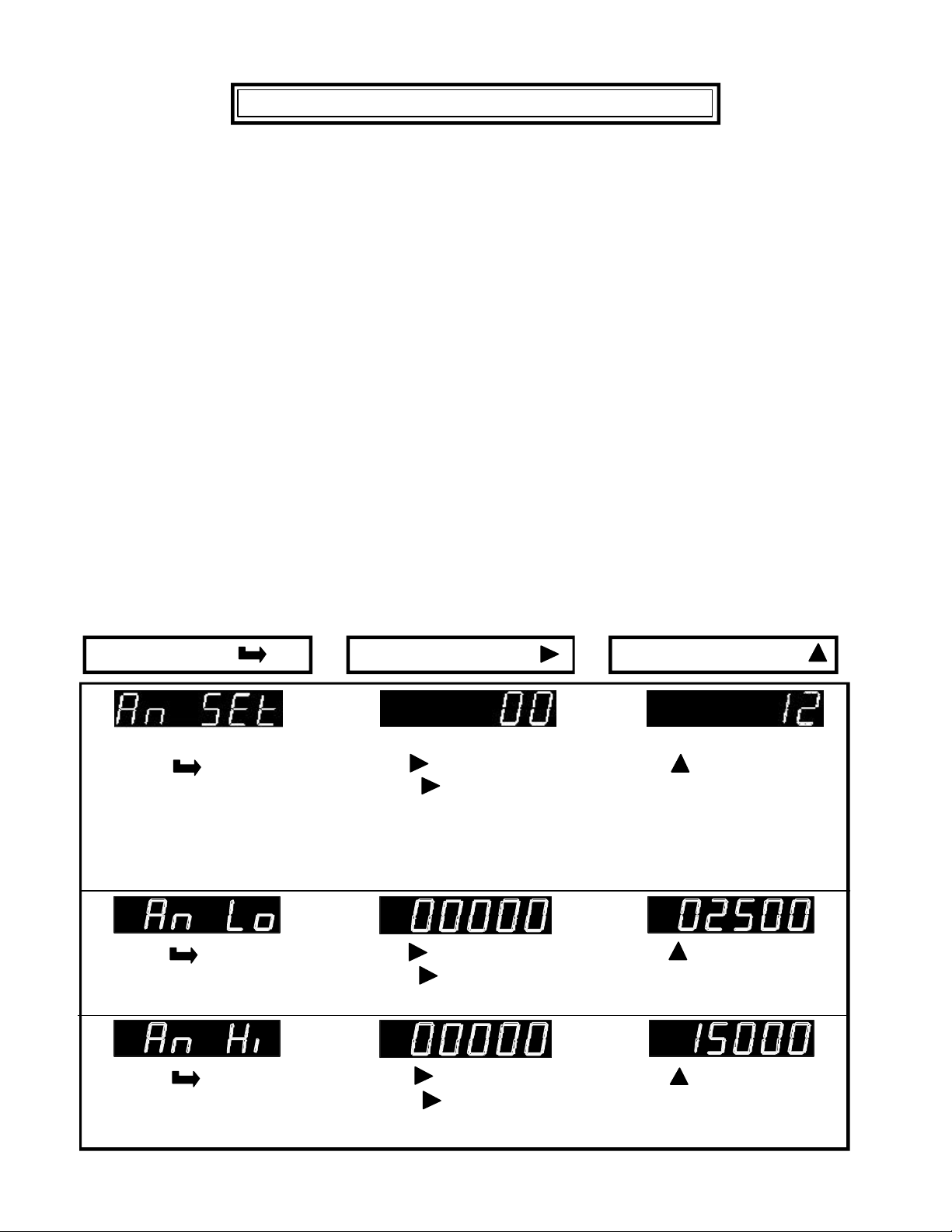

An Set

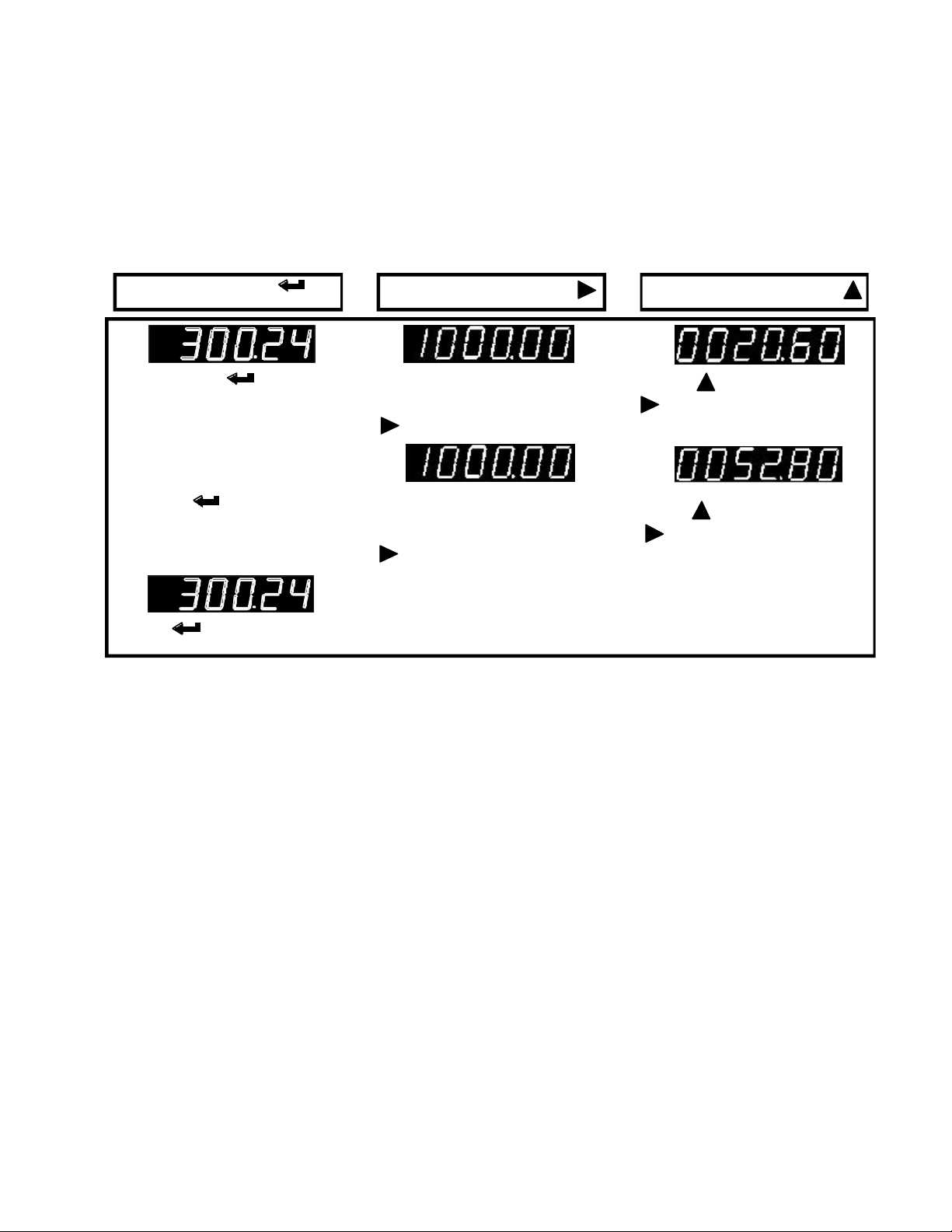

Setup of analog output

(only enabled if analog output

installed)

An Lo

Display value for 0 voltage or

current output

000000 000000 000000

000000 000000 000000

When deviation value is >

0, alarms operate above

and below setpoint by the

value entered.

00

Calibrated output is current

or voltage

00

Analog output source

0000.00 0000.00 0000.00

0000.00 0000.00 0000.0 0

Select 0 through 9 for

flashing digit.

0 Current output

1 Voltage output

0 Filtered item

1 Item #1

2 Item #2

3 Item #3

Select 0 through 9 for

flashing digit. Decimal point

location fixed by dEC.Pt

selection.

-19-

Page 22

MENU KEY

DIGIT SELECT KEY

VALUE SELECT KEY

An Hi

Display value for 10 volts or

20 ma output

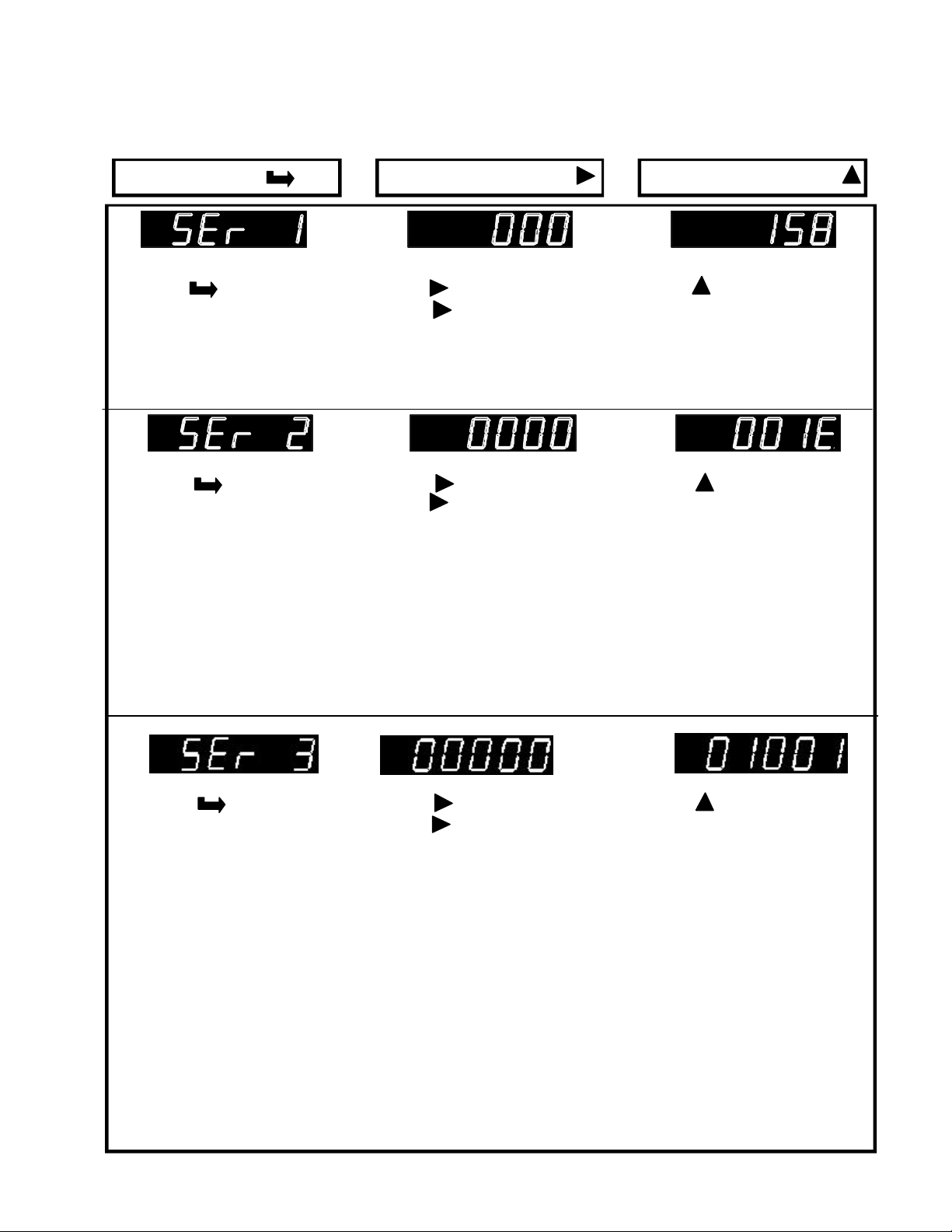

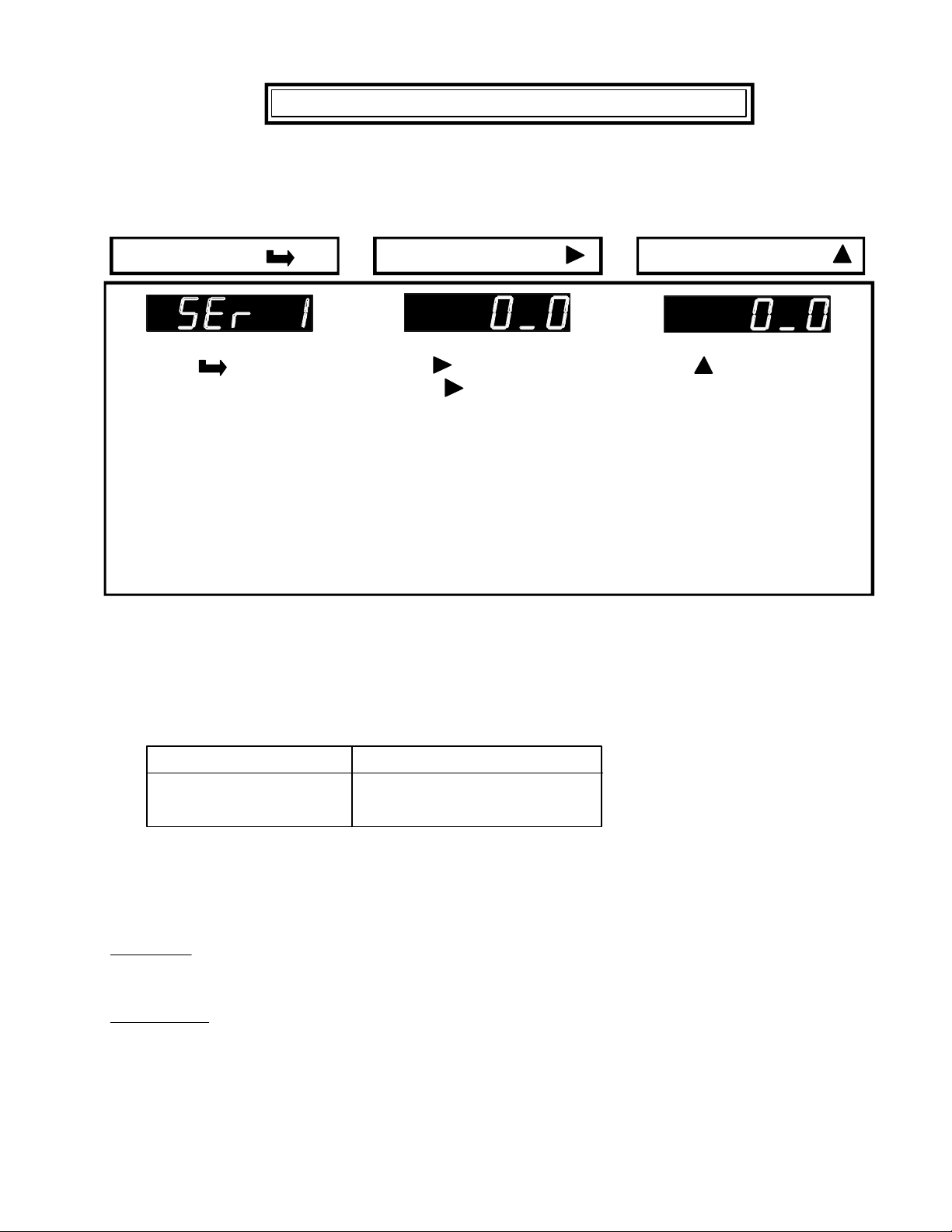

Ser 1

Serial interface setup

(only enabled if communications board installed)

0000.00 0000.00 0000.00

0000.00 0000.00 0000.0 0

000

Output filtering

000

Baud rate

000

Digital output rate

rr = reading rate (rate dependent on gate time and input

frequency)

Select 0 through 9 for

flashing digit. Decimal point

location fixed by dEC.Pt

selection.

0 Send unfiltered signal

1 Send filtered signal

0 300 baud

1 600 baud

2 1200 baud

3 2400 baud

4 4800 baud

5 9600 baud

6 19200 baud

0 Output at reading rate

1 Output at rr/2

2 Output at rr/4

3 Output at rr/8

4 Output at rr/16

5 Output at rr/32

6 Output at rr/64

7 Output at rr/128

8 Output at rr/256

Ser 2

Serial interface setup

(only enabled if communications board installed)

0000

Line Feed

0000

Alarm data transmitted with

meter readings

0000

Control of digital output

0000

Meter address for RS-232/

RS-485 communication

-20-

0 None after carriage rtn

1 LF after carriage return

0 No alarm data

1 Alarm data with reading

0 Continuous output

1 Output on RS-232 /

RS-485 command only

Addresses 1 thru 15 are

denoted by 1 thru 9 and A

thru F. Addresses 16 thru 31

use the same character followed by a decimal point

Page 23

MENU KEY

DIGIT SELECT KEY

VALUE SELECT KEY

Ser 3

Serial interface setup

(only enabled if communications board installed)

00000

RS485 full or half duplex

00000

Meter recognition character

00000

RS232 RTS type

00000

Carriage return (and LF, if

selected)

00000

Data sent via communications (if BCD, only 1 item

allowed

0 Full duplex

1 Half duplex

0 " * " character

1 Custom character

0 Nonlatching RTS

1 Latching RTS

0 Only at end of all items

1 At end of each item

(If alarm, only at end)

0 All active items sent

1 Item #1 only

2 Item #2 only (if active)

3 Item #3 only (if active)

4 Peak value

5 All active items + peak

CALib

Calibration

Loc 1

Lockout of Menu Items

(Lockout jumper must be removed to access Loc 1, 2, 3,

4. See Figure 9.1)

000000

Calibration of crystal in parts

per million

0000

Input type selection

0000

Meter setup and configuration

0000

Pulses, gate time, time out,

and batch setup

0000

Filter set up

Select 0 through 9 for

flashing digit.

0 Enabled

1 Disabled

0 Enabled

1 Disabled

0 Enabled

1 Disabled

0 Enabled

1 Disabled

-21-

Page 24

MENU KEY

DIGIT SELECT KEY

VALUE SELECT KEY

Loc 2

Lockout of Menu Items

(Lockout jumper must be removed to access Loc 1, 2, 3,

4. See Figure 9.1)

Loc 3

Lockout of Menu Items

(Lockout jumper must be removed to access Loc 1, 2, 3,

4. See Figure 9.1)

0000

Slope and decimal points

0000

Scale and offset, coordinates

of 2 points, resolution

0000

Alarm setup and deviation

0000

Allow alarm setpoint changes

0000

Analog out setup & scaling

0000

Serial communications setup

0 Enabled

1 Disabled

0 Enabled

1 Disabled

0 Enabled

1 Disabled

0 Enabled

(if view setpoints enabled)

1 Disabled

0 Enabled

1 Disabled

0 Enabled

1 Disabled

Loc 4

Lockout of Menu Items

(Lockout jumper must be removed to access Loc 1, 2, 3,

4. See Figure 9.1)

0000

Calibration

0000

Change displayed item

0000

View peak display

0000

View setpoints

0000

Front panel auxiliary resets

(Peak and latched alarm)

0000

Front panel counter reset

0 Enabled

1 Disabled

0 Enabled

1 Disabled

0 Enabled

1 Disabled

0 Enabled

1 Disabled

0 Enabled

1 Disabled

0 Enabled

1 Disabled

-22-

Page 25

11. DUAL CHANNEL SIGNAL CONDITIONER

11.1 SETTING JUMPERS FOR INPUT SIGNAL LEVELS

a

b

c

B4

B3

a

b

a

Channel B

a

c

b

A4

B2

A3

b

a

b

a

A2

Channel A

Minimum High and Low Input Signal Levels

The jumper settings for Channel A (A2 & A3) and Channel B (B2 & B3) are selected depending on the

input amplitude. The input signal voltage must exceed the high and low threshold per the following table

or the meter will not operate properly. The larger the difference between the high and low thresholds,

the more immune the meter is to input signal noise.

A2 Low High

B2 Threshold Threshold

a -12mV +12mV

b -150mV +150mV

- -1.15V +1.15V

A3 A2 Low High

B3 B2 Threshold Threshold

a a +30mV +60mV

a b +350mV +600mv

a - +1.25V +2.1V

b

A3 A2 Low High

B3 B2 Threshold Threshold

b a -60mV -30mV

b b -600mv -350mV

b - -2.1V -1.25V

B1

B0

A1

A0

a

b

a

b

a

b

a

b

Jumper Definition and Debounce Circuit

Pullup or pulldown resistors are used with open collector devices and dry contact closures to provide

input signal bias and should not be connected for other inputs. The debounce circuit keeps the meter

from counting extra pulses due to contact bounce.

A0 & B0 - 1MHz Input max

b 30KHz Input max

a 250Hz max

A1 & B1 a 2Kohm input pullup +5V

A1 & B1 b 2Kohm input pulldown -5V

11.2 COMMON JUMPER SETTINGS

Input type

Logic Levels

Open Collector

Npn Transistor

Pnp Transistor

Contact closures

Line Frequency

Turbine Flow

Vmax

250

NA

NA

NA

250

250

A0 & B0 A1 & B1 A2 & B2 A3 & B3 A4 & B4

-

b

b

a or b

b

b

Channel A and B Jumpers

-

a

b

a

-

-

A4 & B4 Time Constant

(Debounce)

b None

a, c 3 mSec

c 50 mSec

-

-

-

-

-

a

a

a

b

a

-

-

b

b

b

a, c

a, c

b

Note: All Channel A and Channel B settings may be different based on input signal type.

-23-

Page 26

11.3 MODES OF OPERATION

Input

Arm Signal

Gate

Internal Clk

The measurement starts with an input signal transition in one direction and ends, after the

expiration of the selected gate time, with the next input signal transition in the same direction

such that the conversion time or period is measured over an integral number of input cycles.

The internal Start signal ARMS the gate circuit so that the next input signal transition actually

OPENS the gate. When the gate is detected to be open, the gate time begins. At the end of

the gate time, the gate circuit is DISARMED, and the next input signal transition CLOSES the

gate. When both inputs A & B are active with separate gates, such as measuring Rate on both

channels, the gate time begins when both gates are detected to be open. The program

calculations begin when both gates are detected to be closed.

11.4 RATE

A ONLY, RATE A B Either one or two channels of rate may be displayed. If one channel

is displayed the input is on channel A and decimal point1, scale1 and offset1 apply to

the input. If two channels are displayed decimal point1, scale1 and offset1 apply to

channel A and decimal point2, scale2 and offset2 apply channel B. Either channel may

be displayed by pressing and releasing the reset key . Gate time setting selects the

update rate of meter. The longer the gate time, the more cycles of the input signal

averaged. If the period of the input signal is longer than the gate time, only 1 period of

the input is calculated and determines the conversion time. Time out is the length of time

the meter waits for a signal to start a conversion or end a conversion. If pulses are not

received before the time out ends, the meter reads zero. The longer the time out, the

lower the minimum frequency the meter can display

Frequency displayed in Hz with scale factor of 1 and multiplier of 1. Increasing the

multiplier increases resolution (.1 to .00001Hz). Decreasing the multiplier allows display

in kHz or MHz.

Rate displayed in engineering units by scale factor and multiplier. Using coordinates

of 2 points to scale meter, low input and high input are entered in Hz.

BATCH displays total of channel A as item 1, grand total or number of batches as item

2 and rate as item 3. Batch requires a Batch Relay board that plugs into the Analog

Output Slot. It contains Relay #3 for use as the Batch Controller. This leaves Relay #1

and Relay #2 for use as either Pre-warn, End-of-process or Rate alarms. When Reset

in the BATCH mode, the counter resets and then displays "rEAdy". It waits until the

Reset button is pushed and then immediately energizes Relay #3 and starts displaying

the Batch Total. When the preset value is reached, Relay #3 de-energizes for a period

of time equal to the GATETIME setting. At the end of GATETIME, the Batch Total resets,

-24-

Page 27

Relay #3 energizes and the cycle repeats.

As an option, the cycle can be reset from an external signal FUNCTION RESET. The

GATETIME is not used and Relay #1 remains de-energized until the FUNCTION RESET

external input is grounded for a minimum of 3.33 mS. Sometime during that period, the

Batch Total is reset and Relay #1 is energized.

The Batch Total is displayed as Item #1 and may be configured to count up from 0 to

the preset value, or to count down from the preset value to 0. The preset value is placed

in OFFST1 and the Batch Total is the total input pulses with SCALE1 and DECPT1

applied. In the BATCH mode, SCALE1 is always set to a positive value whether counting

up or counting down.

The Grand Total is kept as Item #2. SCALE1 and DECPT1 also apply to the Grand Total

except the absolute value is used so that the Grand Total always increases from an initial

value of zero when the counter is initially Reset. It is calculated as the sum of the

previous Batch Totals + the current Batch Total. The Grand Total can overflow to the

exponential format.

As an alternative, Item #2 can be configured to be the Number of Batches instead of the

Grand Total. If it is, SCALE1 does not apply to it and the Decimal Point is always 1.

Item #3 is the Rate calculated with a fixed 20 mS (or 1 cycle min) gatetime. SCALE2,

OFFSET2 and DECPT2 apply to the Rate.

Relay #1 is activated by SETPT#1 and Relay #2 is activated by SETPT#2, and each may

be configured for either

Item#1 - Batch Total (Pre-warn),

Item #2 - Grand Total or # Batches, or

Item #3 - Rate.

It is possible to configure both for the same Item. An example would be two Pre-warns.

RATE A , TOTAL A displays total of channel A as item 2, and rate as item 1. Total is

a sample time total determined the rate multiplied by the time between conversions. This

input is used if square root or custom curve is selected. Decimal point2, scale2 and

offset2 apply to total and is calculated from the displayed valued of rate and decimal

point1, scale1 and offset1 apply to rate. Total may count down from an offset value

by entering a negative scale factor. Use Rate A, Total B to display the rate and total of

a single linear input by tying channel A and B inputs together.

RATE A AND TOTAL B displays total of channel B as item 2, and rate of channel A as

item 1. Decimal point2, scale2 and offset2 apply to total and decimal point1, scale1 and

offset1 apply to rate. Total may count down from an offset value by entering a negative

scale factor. Rate and total of a single input may be displayed by tying channel A and

B inputs together

RATE A+B is the same as Rate A, Rate B except that Rate A is displayed as item 2, Rate

B is displayed as item 3 and the sum of A and B is displayed as item 1. Decimal point

1 applies to both A and B and decimal point 2 applies to the sum of A and B. The

resolution of the sum is determined by setting the multiplier (Resolution) from .00001 to

100000.

RATE A-B is the same as Rate A+B except that B is subtracted from A

-25-

Page 28

RATE AxB is the same as Rate A+B except that A is multiplied by B.

RATE A/B (Ratio) is the same as Rate A+B except that A is divided by B. Rate A and

B may be scaled such that the ratio of A/B is 1. When the value of B increases the ratio

is a number less than 1 and when it decreases the number is greater than 1.

RATE A/B-1 (Draw) is the same as Rate A/B (Ratio) except that 1 is subtracted from the

ratio to give a zero value when the ratio of the 2 inputs is 1. This is used in applications

where two rollers, etc. should be rotating at the same speed and displays the amount

of tension between the two rollers.

11.5 PERIOD

A ONLY, PERIOD A B Period of either channel A input or both A and B may be displayed.

If one channel is displayed the input is on channel A and decimal point1, scale1 and

offset1 apply to the input. If two channels are displayed decimal point1, scale1 and

offset1 apply to channel A and decimal point2, scale2 and offset2 apply channel B.

Either channel may be displayed by pressing and releasing the reset key . The displayed

period of the input signal is not affected by the gate time but the longer the gate time the

more periods of the input signal that are averaged. The shorter the gate time, the faster

the meter outputs and alarms are updated.

PERIOD A+B is the same as Period A, Period B except that Period A is displayed as item

2, Period B is displayed as item 3 and the sum of A and B is displayed as item 1. Decimal

point 1 applies to both A and B and decimal point 2 applies to the sum of A and B. The

resolution of the sum is determined by setting the multiplier (Resolution) from .00001 to

100000.

PERIOD A-B is the same as Period A+B except that B is subtracted from A

PERIOD Ax/B is the same as Period A+B except that A is multiplied by B.

PERIOD A/B (Ratio) is the same as Period A+B except that A is divided by B. Period

A and B may be scaled such that the ratio of A/B is 1. When the value of B increases

the ratio is a number less than 1 and when it decreases the number is greater than 1.

11.6 TOTAL

A ONLY, TOTAL A B Total of the number of pulses of either channel A or both A and

B may be displayed. If one channel is displayed the input is on channel A and decimal

point1, scale1 and offset1 apply to the input. If two channels are displayed decimal

point1, scale1 and offset1 apply to channel A and decimal point2, scale2 and offset2

apply channel B. Either channel may be displayed by pressing and releasing the reset

key or both channels may be reset using the external input "Function Reset". By setting

an offset in the meter and a negative scale factor, the meter counts down from a preset

value to zero.

-26-

Page 29

TOTAL A-B UPDN is the same as Total A, Total B except that Total A is displayed as

item 2, Total B is displayed as item 3 and the difference of A minus B is displayed as

item 1. Decimal point 1 applies to both A and B and decimal point 2 applies to the sum

of A and B. The resolution of the sum is determined by setting the multiplier (Resolution)

from .00001 to 100000.

BURST measures the frequency of a burst of pulses from channel A as item 2, and total

number of bursts as item 1. Decimal point2, scale2 and offset2 apply to total and

decimal point1, scale1 and offset1 apply to rate. Gate time must be set greater than

the minimum frequency of the burst frequency and less than the minimum time between

bursts. Time out is set to the maximum value.

TOTAL A AND RATE B displays total of channel A as item 1, and rate of channel B as

item 1. Decimal point2, scale2 and offset2 apply to total and decimal point1, scale1 and

offset1 apply to rate. Total may count down from an offset value by entering a negative

scale factor. Rate and total of a single input may be displayed by tying channel A and

B inputs together.

TOTAL A AND B UP/DOWN CONTROL displays total of channel A as item 1. Decimal

point1, scale1 and offset1 apply to total. Up/down counting is controlled by the input

level of channel B. The maximum input frequency on A that can be counted is 250 kHz,

or a minimum of 4 uS between pulses. If the menu item SLOPE is set to 0 for Channel

B (Digit 6) then a low level on the B input causes Channel A to count Up and a high level

on the B input causes Channel A to count Down. If the SLOPE of Channel B is set to

1, the opposite occurs.

TOTAL A AND B INHIBIT displays total of channel A as item 1. Decimal point1, scale1

and offset1 apply to total. The input signal to be counted is applied to Channel A and

the Inhibit control signal to Channel B. The maximum input frequency that can be

counted is 2 MHz or a minimum of 0.5 uS between pulses. If the menu item SLOPE is

set to 0 for channel B (Digit 6) then a low level on the B input allows counting of the

Channel A input signal and a high level on the B input inhibits counting. If the SLOPE

of Channel B is set to 1, the opposite occurs.

TOTAL A+B is the same as Total A, Total B except that Total A is displayed as item 2,

Total B is displayed as item 3 and the sum of A and B is displayed as item 1. Decimal

point 1 applies to both A and B and decimal point 2 applies to the sum of A and B. The

resolution of the sum is determined by setting the multiplier (Resolution) from .00001 to

100000.

TOTAL A-B is the same as Total A+B except that B is subtracted from A

TOTAL AxB is the same as Total A+B except that A is multiplied by B.

TOTAL A/B (Ratio) is the same as Total A+B except that A is divided by B. Total A and

B may be scaled such that the ratio of A/B is 1. When the value of B increases the ratio

-27-

Page 30

is a number less than 1 and when it decreases the number is greater than 1.

11.7 TIME INTERVAL

TIME INTERVAL A TO B measures time between an input on channel A and an input

on channel B. Time measurement starts when a pulse is applied to channel A (positive

edge if slope A is 0, negative edge if slope A is 1) and the measurement ends when a

pulse is received on channel B (positive edge if slope B is 0, negative edge if slope B

is 1). A single pulse may be measured by tying input A and B together and selecting a

positive or negative edge to start (Slope A) and the opposite polarity edge to stop (Slope

B). If a number of start and stop pulses occur during the gate time, the value displayed

is the average of the pulse widths. The value is updated at the end of each gate.

11.8 STOPWATCH

STOPWATCH A TO A measures time between an start pulse on channel A and a

second pulse on A to stop timing. Timing may be set to start and stop on either the

positive or negative edges of the pulses (Slope A). The time (item #1) may be displayed

in seconds, minutes or hours (with decimal point) using scale and multiplier with the

clock time display (hr, min, or sec)selected. Clock time (fixed format) displays

HH:MM:SS. Time is reset to 0 when a new start pulse occurs. Item #2 displays the

accumulated total time of Item #1.

STOPWATCH A TO B measures time between an start pulse on channel A and a stop

pulse on B. to stop timing. Timing is the same as A to A except in addition to separate

start and stop pulses, by tying input A and B together, a single contact closure may start

and stop timing by selecting the opposite Slope for A and B.

11.9 PHASE ANGLE

PHASE ANGLE A TO B measures the phase relationship between a signal on input A

and input B. The displayed value is 0 to 360 degrees. Resolution is determined by Scale

1.

-28-

Page 31

12. V - TO - F SIGNAL CONDITIONER

12.1 SETTING JUMPERS FOR INPUT SIGNAL LEVELS

A1

a

Input Jumper Position

Range A1

0 to 10V None

0 to 1mA a

4 to 20mA b

b

12.2 RATE

Rate A is the voltage or current input converted to a frequency output of 0 to 100kHz.

The period of the frequency is measured and converted to a rate by 1/period and

applying Scale1 and Offset1. Scaling may also be set by using coordinates of 2 points

where low and high input signals and the corresponding low and high displayed values

are entered.

12.3 BATCH

Batch displays total of voltage or current input as item 1, grand total or number of

batches as item 2 and rate as item 3. Relay #1 is used as the Batch Controller. This

leaves Relay #2 for use as either Pre-warn, End-of-process or Rate alarm. When reset

in the batch mode, the counter resets and then displays "rEAdy". It waits until the reset

button is pushed and then immediately energizes Relay #1 and starts displaying the

batch total. When the preset value is reached, Relay #1 de-energizes for a period of time

equal to the Time out setting. At the end of time out, the Batch Total resets, Relay #1

energizes and the cycle repeats.

As an option, the cycle can be reset from an external signal Function Reset. The Time

Out is not used and Relay #1 remains de-energized until the Function Reset external

input is grounded for a minimum of 3.33 mS. Sometime during that period, the Batch

Total is reset and Relay #1 is energized.

The Batch Total is displayed as Item #1 and may be configured to count up from 0 to

-29-

Page 32

the preset value, or to count down from the preset value to 0. The preset value is placed

in Setpoint 1 and the Batch Total is the total with Scale1 and decimal point1 applied. In

the Batch mode, Scale1 is set to a positive value to count up and a negative value to

count down. Offset1 is set to zero when counting up and to the preset value when

counting down.

The Grand Total is kept as Item #2. Scale1 and decimal point1also apply to the Grand

Total except the absolute value is used so that the Grand Total always increases from

an initial value of zero when the counter is initially Reset. It is calculated as the sum of

the previous Batch Totals + the current Batch Total. The Grand Total can overflow to

the exponential format.

As an alternative, Item #2 can be configured to be the Number of Batches instead of the

Grand Total. If it is, Scale2 does not apply to it and the Decimal Point is always 1.

Item #3 is the Rate calculated with a selectable gatetime. Scale2, Offset2 and decimal

point 2 apply to the Rate.

Relay #2 is activated by Setpoint#2, and may be configured for either

Item#1 - Batch Total (Pre-warn),

Item #2 - Grand Total or # Batches, or

Item #3 - Rate.

12.4 RATE AND TOTAL

Rate A, Total A rate is calculated the same as Rate A above and displayed as Item1

and total is calculated based on the rate versus time between conversions. Scale2 and

Offset2 are calculated from the displayed rate and apply to total. The rate may be

displayed as units per second, per min, or per hour but the total is always incremented

by the displayed value of the rate every second when the scale factor is set to 1. If the

rate is per minute, the rate must be multiplied by 1/60 , so that the total will equal the

displayed rate at the end of 1 min. To totalize units per hour , the rate must be multiplied

by 1/3600. The scale and multiplier for Scale 2 is set to 1.66667 and .01 for units per

minute and 2.77778 and .0001 for units per hour. Total is displayed as Item 2.

Total A, Rate A same as above except total is displayed as Item1 and rate as Item2

12.5 1/RATE

1/Rate A is the voltage or current input converted to a frequency output of 0 to 100kHz.

The period of the frequency is measured and converted to time by applying Scale1 and

Offset1. Scaling may also be set by using coordinates of 2 points where low and high

input signals and the corresponding low and high displayed values are entered. An

example is converting speed to time and displaying the time an item takes to travel

through an oven.

-30-

Page 33

13. QUADRATURE SIGNAL CONDITIONER

13.1 SETTING JUMPERS FOR INPUT SIGNAL LEVELS

1

E9

E8

a

a

b

b

E2

E7

a

a

c

b

E1

a

E3

a

c

a

b

E5

c

d

a

c

b

c

b

a

12

E10

b

E4

a

c

Input Type Jumper Position

E2 E4 E6 E5

Single-ended (signal & return) a, c a, c a, c c

Complementary (differential) b b b c

Complementary (with excitation b b - b, d

and no zero index)

Input Termination Jumper Position

(for differential inputs only) E1 E3 E5

For long input cable runs a a a

For short input cable runs None None None

E6

Note: Do not install E5-a if E5-b and d are installed

Input Phase Jumper Position

E7

Up count, negative transition of B,

A positive ( A leads B ) None

Up count, positive transition of B,

A positive ( B leads A ) a

Count by options Jumper Position

E9

X1 = positive edge of A input None

X2 = positive and negative edges of A input a

X4 = positive & negative edges of both A & B inputs b

See "ZERO INDEX SETUP" for jumper locations for zero index signal (Page 35).

-31-

Page 34

13.2 QUADRATURE DECODING

The quadrature decoder board generates up(+) and down(-) counts that are arithmetically

totalized on the main counter board and then displayed. The decoder board has input circuitry

that may be jumpered for either single-ended input signals or balanced line driver signals. It

will accept the normal A & B quadrature signals and, if present, a zero index signal. The A &

B signals are 90 deg out of phase and the phase relationship of A & B determine whether up

counts or down counts are produced. Up counts add to the total and down counts subtract from

the total.

Since incremental optical encoders may have a different A & B phase relationship to indicate

up and down, the board has a jumper E7 (BPOL) on the B signal to allow selection of the desired

phase. Without the jumper, Up output pulses are created when the B signal has a positive

transition while the A signal is at a positive level (A leads B). With the jumper installed, Up output

pulses are created when the B signal has a negative transition while

the A signal is at a positive level (B leads A).

A With the phase shown

E7 open - Counts up

B E7 jumpered - Counts down

With the opposite phase shown, the effect of E7 reverses.

The board has jumpers that allow counting by 1, 2 or 4 counts per cycle of the A or B signals.

The edges that are counted are:

X1 = positive transitions of the A signal.

X2 = positive and negative transitions of the A signal.

X4 = positive and negative transitions of both the A and the B signals.

Digital filtering is provided for the A & B signals to reduce the probability of noise providing false

counts.

Some optical encoders create a zero index signal once per revolution that indicates when the

encoding wheel is at its zero position. Each time this signal is created, the total count should

be a multiple of the number of counts per revolution of the coding wheel. If this feature is

enabled in the counter, the counter checks to see if the total counts is an exact multiple of the

counts per revolution. If so, it does nothing, and if not, it changes the total to the closest exact

multiple. The counts per revolution are entered into the counter via the menu item Pulses. From

0 to 59,999 pulses may be entered. If X2 or X4 counting is enabled on the board, then the value

entered into Pulses should be the counts (or pulses) per revolution of the encoder multiplied

by this factor of X2 or X4. Also, if Scale is a factor other than 1, include it as a multiplying factor

when determining the value of Pulses to enter.. Do NOT include the value of Offset1.

For example:

If the encoder produces 256 cycles per revolution and X2 counting is selected by a jumper

on the board, and from the front panel Menu of the counter, SCALE1 is set to 3 and OFFSET1

is set to 100, then from the front panel menu set PULSES = 256 * 2 * 3 = 1536.

-32-

Page 35

The zero index channel contains the same digital filtering that is provided for the A & B channels.

It contains a Polarity jumper that allows selection of either a positive or negative zero index

signal. It also contains two Control inputs, C1 and C2 that control the ANDing of the zero index

signal with the Channel A and Channel B signals. See “Zero Index Setup” below.

The Item indicator light (center right) may be used to determine the location of the Zero Index.

This indicator is lighted while the zero index signal is being received. The zero index signal must

be jumpered for the correct polarity. If, during encoder motion, the indicator is on more than

it is off, it is likely that the zero index signal is jumpered for the wrong polarity.. If so, add a Polarity

jumper to switch E8, position C. If it already has a jumper, remove it.

From the menu, a value may be entered for Offset1. As explained below under “Mechanical

Zero”, Offset1 allows a mechanical zero position different from the zero index position. The

displayed value is the sum of the following:

1. The total bidirectional counts from the optical encoder since the last counter reset or

function reset.

2. The correction factor from the last zero index correction calculation.

3. Offset 1

For example:

Suppose that the encoder contains 30 pulses per revolution and X1 counting is used. Further

suppose that when the mechanics are at 0 position, the zero index is at 10 and the OFFSET

1 = 10 and the counter is reset when the encoder is at the 5 position.

Reset

v

Position 0 5 10 20 30 40 50

Index ^ ^

Internal Total 0 5 15 25 35 45

Correction 0 -5 -5 -5 -5 -5

OFFSET 10 10 10 10 10 10

Display 10 10 20 30 40 50

Internal Total -5 0 5 15 25 35 45

Correction -5 -5 -5 -5 -5 -5 -5

OFFSET 10 10 10 10 10 10 10

Display 0 5 10 20 30 40 50

Once the index point has been passed, the display matches the position. Prior to that, the

display is in error.

When the counter is displaying Quadrature Total and the Total is reset using the Reset & Peak

buttons (Function Reset), the internal Total is set to zero, but the zero index correction is not

affected. This results in a display of the correction value plus Offset 1. To zero the internal Total

and the correction value, the counter must be reset using the Reset & Menu buttons (Meter

Reset). This results in a display of OFFSET 1.

-33-

Page 36

13.3 ZERO INDEX SETUP

The relationship between the zero index correction signal and the Channels A & B signals varies

with different encoder model numbers and different manufacturers. To accommodate this

variation, the Quadrature board has control jumpers and selectable outputs that provide

ANDing of the zero index signal with all possible combinations of the Channel A & B signals.

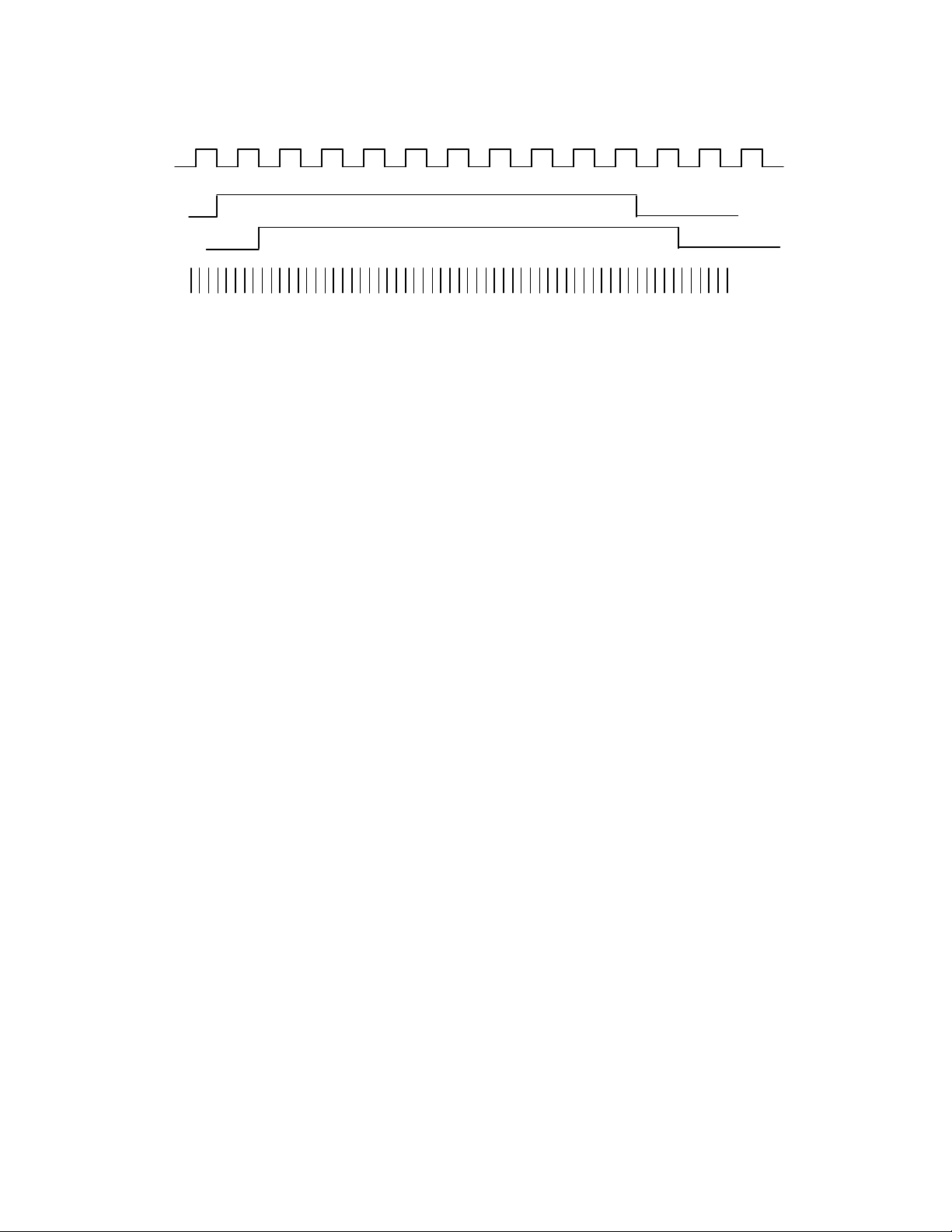

Consider a typical encoder model that produces the waveforms shown below. Assume X4

counting is selected. The count increases and decreases on each A & B transition and remains

steady between transitions. The counts shown below the waveforms represent the effect of

the zero index correction ZI if no ANDing is used. Note the difference in count in the regions

between transitions when counting up and then counting down. The zero index correction is

made on the leading edge transition of the zero index signal. When counting down, the leading

edge is the trailing edge of the signal shown below because time is increasing from right to left.

A Channel

B Channel

Zero Index

Up -3 -2 -1 0 1 2 3 4 5

ZI

Down -6 -5 -4 -3 -2 -1 0 3 4

ZI

| | | | | | | |

Up Region -3 -2 -1 0 1 2 3 4 5

Down Region -5 -4 -3 -2 -1 0 3 4 5

It follows that a wide zero index signal causes a discrepancy in the count in the regions between

transitions when counting up and counting down. To correct this situation, AND the zero index

signal with the A & B channel signals. Assume for this example the zero index is ANDed with

the inverse of A (/A) and the inverse of B (/B) to produce ZIY as shown below.

A Channel

B Channel

ZIY

Zero index AND ZIY = ZIR

Up -3 -2 -1 0 1 2 3 4

ZIR

Down -4 -3 -2 -1 0 1 2 3

ZIR

| | | | | | | |

Up Region -3 -2 -1 0 1 2 3 4

Down Region -3 -2 -1 0 1 2 3 4

By ANDing the zero index signal with the A & B channels, there is no regional discrepancy

-34-

Page 37

between counting up and counting down.

There are 2 control signals, C1 and C2, and 3 outputs, ZI, ZIX and ZIY that may be jumpered

to provide 8 selections of ANDed signals or the zero index signal without ANDing.

Zero Index Polarity Jumper Position

E7

Positive a

Negative None

Zero Index ANDing Jumper Position

E10 E8

Zero Index (no ANDing) c Zero Index AND /A a Zero Index AND /B a a

Zero Index AND A a b

Zero Index AND B a a, b

Zero Index AND /A AND /B b Zero Index AND /A AND B b a

Zero Index AND A AND /B b b

Zero Index AND A AND B b a, b

The manufacture's data sheet for the optical encoder will show the position and width of the zero

index signal with respect to the A channel and B channel signals. Selection of one of the above

combinations depends on that relationship and the polarity of the channel A & B signals when

the mechanical position is zero. Be sure to take into account the selected phase relationship

determined by the presence of or absence of jumper E7-a (BPOL). Jumper E7-a is selected

to cause the display to count in the proper direction. If jumper E7 is in place, the channel B signal

will have the opposite polarity from the channel B output of the encoder.

13.4 MECHANICAL ZERO

By using the Counter’s OFFSET1 value, it is possible to place the mechanical

zero (zero counter reading) at some point other than the location of the zero

index. The following technique describes how to accomplish this.

1. Set the E8 & E10 jumpers as described above to produce the desired Zero Index signal.

2. Set OFFSET1 = 0.

3. Reset the counter (counter reset).