Page 1

LAUREL

ELECTRONICS, INC.

Laureate™ Pulse or Analog Input Batch Controller

Automatic batch control for repetitive liquid fill operations

Features

•

Available for turbine flow meter pulse signals from 0 Hz to 1 MHz or analog

flow meter signals (4-20 mA, 0-1 mA or 0-10V)

•

Selectable display of batch total, grand total, number of batches, or flow rate

•

6-digit LED display scalable to ±999,999

•

Counts up from 0 to preset or down from preset to 0

•

Universal AC power, 85-264 Vac

•

Isolated 5, 10 or 24 Vdc excitation supply to power sensors

•

NEMA 4X, 1/8 DIN case

•

Choice of relay outputs: 2 or 4, contact or solid state

•

Optional serial I/O: Ethernet, USB, RS232, RS485, Ethernet-to-RS485 converter

•

Optional isolated analog output: 4-20 mA, 0-20 mA, 0-10V, -10 to +10V

•

Optional low voltage power: 10-48 Vdc or 12-32 Vac

Description

The Laureate batch controller is a low cost, powerful and highly

accurate batching controller for repetitive fill operations. It can

use the Laureate FR dual channel pulse input signal conditioner

for use with turbine flow meters, or the Laureate V-to-F analog

signal conditioner for use with 4-20 mA, 0-1 mA or 0-10V conditioned flow meter signals. Relay control can be provided by two

or four 8A contact relays, or by two or four 120 mA AC/DC solid

state relays. Fill operations are repeated continually with a

programmable delay from 10 ms to 199.99 sec, or based on an

external control input.

Three items are tracked by the batch control software. These

can each be scaled to engineering units of total or flow rate and

displayed by the controller's six-digit LED display: Item #1 is the

current batch total, which can be set up to count up from zero to

a preset limit, or down from a preset limit to zero. Item #2 can be

assigned to grand total or number of batches. Item #3 is the flow

rate.

Two or four relays can be used. Relay #1 is assigned to batch

total to control the filling operation. Relays #2, #3 and #4 can

each be assigned by the user to Items #1, #2 or #3. For example,

Relay #2 can be assigned to Item #1 (batch total) with a lower

setpoint to serve as a pre-warn and slow down the fill rate near

the batch setpoint, and Relay #3 can be assigned to the total

number of batches to terminate the batching when a present

number of bottles have been filled.

An optional serial communications board allows the batch

controller to transmit Items #1, #2 and #3, as well as peak for

item #3 (rate). If required, all four items can be displayed

simultaneously by augmenting the batch controller with up to

three Laureate remote displays. Each of these can have its own

analog output and relays for alarm or control.

Batch Control with Turbine Flowmeters

The pulse-input batch controller utilizes the FR dual channel

signal conditioner, which accepts pulses from turbine flow meters

and most industrial transducers with a pulse output such as

proximity switches with PNP or NPN output, TTL or CMOS logic,

or magnetic pickup pulses down to 12 mV. The same signal is

applied in parallel to the A and B input channels, which are used

independently. Either channel can accept pulse rates from 0.005

Hz to 250 kHz, which exceeds the working range of turbine flow

meters.

•

Channel A is used for totalizing. The measured total is scaled

mathematically for control and display of volume in engineering units, such as liters.

•

Channel B is used for rate. The pulse frequency is determined by timing an integral number of periods over a

specified gate time (plus 30 ms and 0-2 periods), and then

taking the inverse of period. The inverse period approach

allows greater much accuracy and faster update times than

conventional rate meters which count signal pulses over a

specified time interval. Update times can be up to 25/sec.

Rate in engineering units, such as liters per second, is

obtained by multiplying the input by a scale factor.

Batch Control with Conditioned Flow Signals

The analog input batch controller utilizes the Laureate VF

voltage-to-frequency converter signal conditioner board, which

converts 4-20 mA, 0-1 mA or 0-1V conditioned flow meter signals

to a frequency from 10 kHz to 110 kHz. This allows the counter

controller to totalize flow, to count up to a preset value, or to

count down to zero from a preset value for batch control. One of

the relays is dedicated to On/Off batch control, while the other

relay is available to slow down rate near the setpoint or to

provide another alarm or control function based on rate or total.

Designed for system use. Available plug-in boards include

Ethernet and other serial communication boards, dual or quad

relay boards, and an isolated analog output board. Laureates

may be powered from 85-264 Vac or optionally from 12-32 Vac

or 10-48 Vdc. The display is available with red or green LEDs.

The 1/8 DIN case meets NEMA 4X (IP65) specifications from the

front when panel mounted. Any setup functions and front panel

keys can be locked out for simplified usage and security. A builtin isolated 5, 10, or 24 Vdc excitation supply can power transducers and eliminate the need for an external power supply. All

power and signal connections are via UL / VDE / CSA rated

screw clamp plugs.

LAUREL

ELECTRONICS INC., 3183-G Airway Ave., Costa Mesa, CA 92626, USA • Tel 714-434-6131 • www.laurels.com 1

Page 2

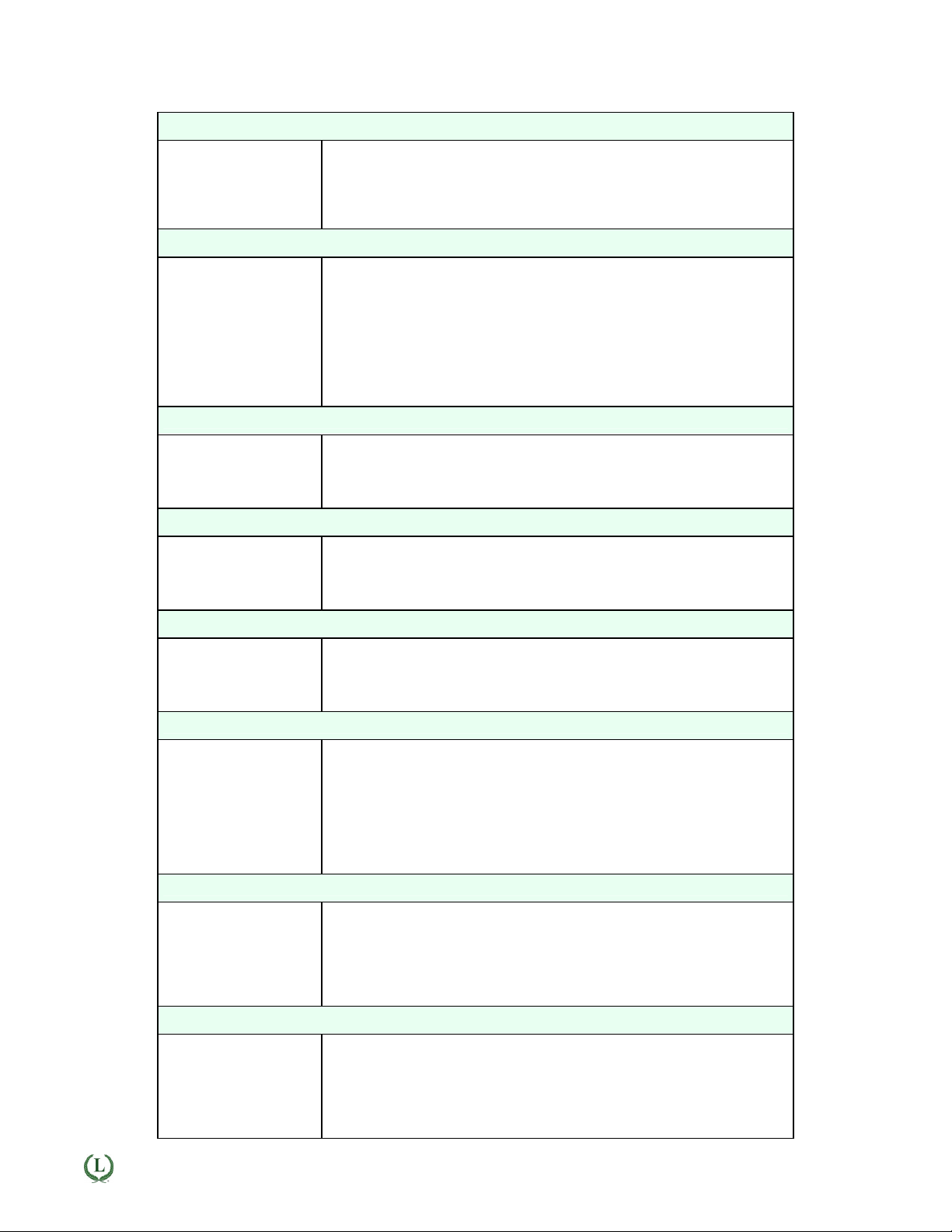

Specifications

Display

Readout

Display Range

Zero Adjust

Span Adjust

Indicators

Pulse Inputs (FR signal conditioner)

Signal Types

Ch A Frequency, Max

Ch B Frequency, Max

Signal Ground

Minimum Signal

Maximum Signal

Maximum Frequency

Conversion Technique

Delay between batches

Analog Input (V-to-F signal conditioner)

Signal Types

Conversion Technique

Update Rate

Gate Time

Power

Voltage, standard

Voltage, optional

Frequency

Power Isolation

6 LED digits, 7-segment, 14.2 mm (.56"), red or green

-999999 to +999999, XXXXEX scientific notation beyond 999999

-999999 to +999999

0 to 999999

Four LED lamps

AC, pulses from NPN, PNP transistors, contact closures, magnetic pickups.

1 MHz

250 kHz

Common ground for channels A & B

Nine ranges from (-12 to +12 mV) to (+1.25 to +2.1V)

250 Vac

1 MHz, 30 kHz, 250 Hz (selectable)

Inverse period

Selectable 10 ms to 199.99 s

0-1 mA, 4-20 mA, 0-10V

Inverse period applied to 10 kHz- 110 kHz

50 ms (max)

Selectable 10 ms to 199.99 s

85-264 Vac or 90-300 Vdc (DC operation not UL approved)

12-32 Vac or 10-48 Vdc

DC or 47-63 Hz

250V rms working, 2.3 kV rms per 1 min test

Excitation Output (standard)

5 Vdc

10 Vdc

24 Vdc

Output Isolation

Analog Output (optional)

Output Levels

Current compliance

Voltage compliance

Scaling

Resolution

Isolation

Relay Outputs (minimum of 2 relays required)

Relay Types

Current Ratings

Output common

Isolation

Serial Data I/O (optional)

Board Selections

Protocols

Data Rates

Digital Addresses

Isolation

5 Vdc ± 5%, 100 mA

10 Vdc ± 5%, 120 mA

24 Vdc ± 5%, 50 mA

50 Vdc to meter ground

4-20 mA, 0-20 mA, 0-10V, -10 to +10V (single-output option)

4-20 mA, 0-20 mA, 0-10V (dual-output option)

2 mA at 10V ( > 5 kΩ load)

12V at 20 mA ( < 600 Ω load)

Zero and full scale adjustable from -99999 to +99999

16 bits (0.0015% of full scale)

250V rms working, 2.3 kV rms per 1 min test

(dual analog outputs share the same ground)

2 Form C contact relays or 4 Form A contact relays (NO)

2 or 4 Form A, AC/DC solid state relays (NO)

8A at 250 Vac or 24 Vdc for contact relays

120 mA at 140 Vac or 180 Vdc for solid state relays

Isolated commons for dual relays or each pair of quad relays

250V rms working, 2.3 kV rms per 1 min test

Ethernet, Ethernet-to-RS485 server, USB, USB-to-RS485 server, RS485

(dual RJ11), RS485 Modbus (dual RJ45), RS232.

Modbus RTU, Modbus ASCII, Laurel ASCII protocol

300 to 19200 baud

247 (Modbus), 31 (Laurel ASCII),

250V rms working, 2.3 kV rms per 1 min test

LAUREL

ELECTRONICS INC., 3183-G Airway Ave., Costa Mesa, CA 92626, USA • Tel 714-434-6131 • www.laurels.com 2

Page 3

Environmental

Mechanical

Operating Temperature

Storage Temperature

Relative Humidity

Protection

Signal Connections

0°C to 60°C

-40°C to 85°C

95% at 40°C, non-condensing

NEMA-4X (IP-65) when panel mounted

LAUREL

ELECTRONICS INC., 3183-G Airway Ave., Costa Mesa, CA 92626, USA • Tel 714-434-6131 • www.laurels.com 3

Page 4

Application Examples

Drum Filling Application Utilizing Two Relay Outputs

Controlling Chemical Mixing of Materials

In this drum filling application, the Laureate pulseinput batch controller utilizes uses its two relays to

control a pump. The Prewarn relay slows down the

pump near the preset to avoid overshoot. The Batch

relay stops the pump at the preset.

Multiple Laureate batch controllers can be used

in combination to control the mixing of materials in

the proper ratio. Each feed line is equipped with its

own pump, flowmeter, and Laureate.

Controller setup and monitoring of the mixing

operation are facilitated by optional serial communications. RS-485 allows a single data line to

handle multiple controllers.

Up-Counting & Down-Counting Batch Control

Discrete Filling and Batch Counting

In up-counting batch control, the Laureate counts up

from zero to a preset maximum. A prewarn level is

available to slow down filling near the preset to

avoid overshoot. A time delay can be programmed

from the end of each batch to the start of the next

batch.

In down-counting batch control, the Laureate counts

down from the preset maximum to zero. A prewarn

level is available to slow down filling or emptying

near zero. Again, a time delay can be programmed

from the end of each batch to the start of the next

batch.

The Laureate batch controller is ideal for discrete

manufacturing as well as repetitive fill operations. In

this example, the Laureate counts bottles which it

then groups into sixpacks. Its Grand Total capability

can be used to track bottles or sixpacks.

LAUREL

ELECTRONICS INC., 3183-G Airway Ave., Costa Mesa, CA 92626, USA • Tel 714-434-6131 • www.laurels.com 4

Page 5

Ordering Guide

Create a model a model number in this format: L70100FR, IPC

Main Board L7 Extended Main Board, Green LEDs

L8 Extended Main Board, Red LEDs

Power 0 Isolated 85-264 Vac

1 Isolated 12-32 Vac or 10-48 Vdc

Relay Output

(isolated)

Analog Output

(isolated)

Digital Interface

(isolated)

Input Type

0 None

1 Two 8A Contact Relays

2 Two 120 mA Solid State Relays

3 Four 8A Contact Relays

4 Four 120 mA Solid State Relays

0 None

1 Single isolated 4-20 mA, 0-20 mA, 0-10V, -10 to +10V

2 Dual isolated 4-20 mA, 0-20 mA, 0-10V

0 None

1 RS232

2 RS485 (dual RJ11 connectors)

4 RS485 Modbus (dual RJ45 connectors)

5 USB

6 USB-to-RS485 converter

7 Ethernet

8 Ethernet-to-RS485 converter

Pulse Rate or Totalizing

FR Dual-Channel Pulse Input Signal Conditioner

Voltage-to-Frequency Converter

VF1 V-to-F Converter, 4-20 mA

VF2 V-to-F Converter, 0-1 mA

VF3 V-to-F Converter, 0-10 V

VF4 V-to-F Converter, Special Range

For special range, specify min input, min reading; max input, max reading.

Component changes by the factory may be required.

Add-on Options BL Blank lens without button pads

LAUREL

CBL01 RJ11-to-DB9 cable

CBL02 USB-to-DB9 adapter

CBL05 USB Cable, A to B

IPC Clear front panel cover sealed to NEMA 4X / IP65

BOX1 NEMA-4X wall-mount enclosure

BOX2 BOX1 plus IPC

ELECTRONICS INC., 3183-G Airway Ave., Costa Mesa, CA 92626, USA • Tel 714-434-6131 • www.laurels.com 5

Loading...

Loading...