Page 1

LAUREL

ELECTRONICS, INC.

Key Features of Meter Linearizing

•

Applicable to Laureate™ process, strain gauge, load cell meters, frequency /

rate meters, and totalizers

•

Easy programming using custom nonlinear curve fits

•

Improves accuracy of low-cost transducers

•

Extends transducer operating range on high and low ends

•

Solves application problems involving non-linear relationships

•

Included with Extended versions of Laureate digital panel meters, counters

and timers

•

Easy setup by entering data points into a computer spreadsheet, or typing in

desired readings for actual signal inputs.

•

Exceptional accuracy from 0.1% to 0.01% of full scale with few data points,

made possible by curvilinear spline fits.

Description

Custom curve linearization is a feature available with the

Extended option version of all Laureate digital panel meters,

counters and timers, excluding only the temperature meter,

which already has built-in linearization curves.

Benefits: Custom curve linearization can provide exceptional

accuracy from low cost transducers of these are repeatable. It

can extend the working range of transducers on their high and

low ends. It can also solve special application problems where

there is a non-linear relationship between the input and the

desired readout.

Implementation: Linearizing is implemented in the form of

20 nonlinear spline-fit segments, which provide much better

accuracy than a larger number of straight line segments. The

typical error will be from 0.1% to 0.01% of full scale, depending

on the number of data points used for setup, the error in the data

points, and the severity of non-linearities or discontinuities.

Easy Setup: Setup of a Laureate Linearizing Process Meter

requires an external PC, which is connected to the meter via

RS232 or USB cable, and utilizes linearizing software furnished

by Laurel Electronics. To download, go to our Software Download web page. A serial communications board is required, but

Laureate™ Meters with

Custom Curve Linearization

can be removed from the meter following setup. Three meter

programming methods are offered:

•

Spreadsheet Method: Data points consisting of the input

signal in Volts or Amps and the desired reading are entered

into an Excel spreadsheet or into a text file using a space,

comma or tab as the delimiter. There can be up to 180 data

points. Laurel's software then calculates 20 spline-fit segments and downloads their coefficients into the meter.

•

Actual Input Method: The meter is hooked up to the actual

signal source, and the user enters the desired readings for

different signal levels. There can be up to 180 input / reading

combinations. Laurel's software then calculates 20 spline-fit

segments and downloads their coefficients into the meter.

This method automatically compensates for any errors in the

transducer.

•

Polynomial Method: The mathematical formula relating the

input to the output is entered into the computer, which then

uses this data to calculate the spline-fit segments. This

method is ideal if the mathematical relationship is knows, for

example to calculate the contents of a tank based on the

known geometry of the tank.

Application Examples

•

Thermistors and other sensors whose output is a non-linear

changing resistance.

•

Altimeters, since the relationship between pressure and

altitude is non-linear.

•

Rate of ascent based on successive altimeter readings.

•

Volume of irregularly-shaped tanks, such as horizontal

cylinders, based on measured liquid level or liquid pressure at

the base of the tank.

•

Fine-calibration of linear transducers, since even nominally

linear transducers will have nonlinear components.

•

Extending the working range of transducers, since many

transducers become nonlinear at their low and high ends.

Compensating for inaccuracy of low-cost transducers.

LAUREL

ELECTRONICS INC., 3183-G Airway Ave., Costa Mesa, CA 92626, USA • Tel 714-434-6131 • www.laurels.com 1

Measuring tank volume

The Extended Laureate process meter can display the volume of

irregularly shaped tanks based on the static pressure at the base

of the tank. An example is a cylindrical tank lying on its side. The

tank can be tilted to facilitate drainage, as illustrated.

Page 2

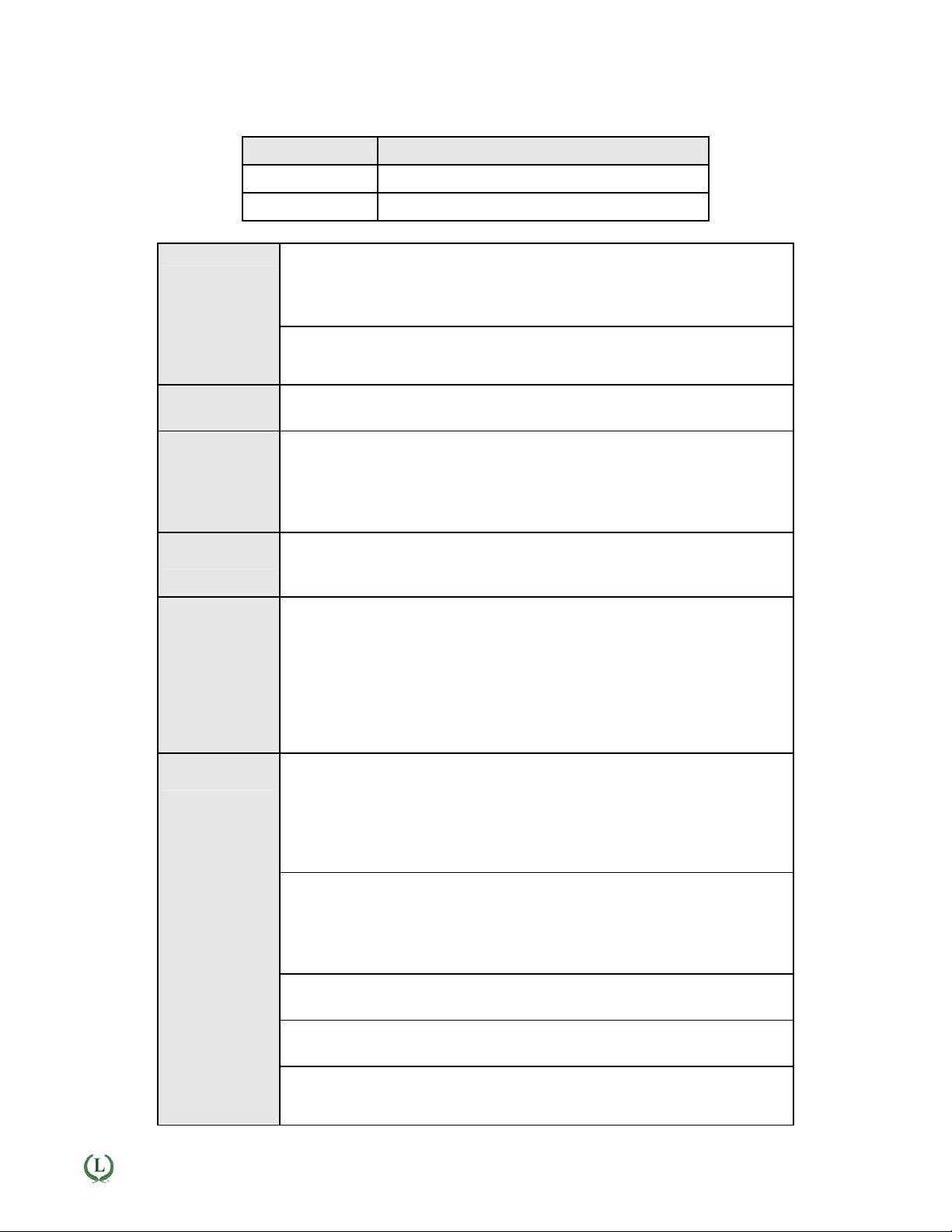

Ordering Guide

Create a model a model number in this format: L30000P, IPC

Main Board Compatible Signal Conditioner

L3 or L4 DC, P, SG, WM

L7 or L8 FR, VF

Main Board

Power

(isolated)

Relay Output

(isolated)

Analog Output

(isolated)

Digital Interface

(isolated)

L3 Extended DPM Main Board, Green LEDs.

L4 Extended DPM Main Board, Red LEDs.

L7 Extended Counter Main Board, Green LEDs.

L8 Extended Counter Main Board, Red LEDs.

Note: Extended capability is required for custom curve linearization or for display of

time rate of change, such as flow rate from changing tank level or acceleration from

changing speed. Not applicable to temperature meters.

0 Isolated 85-264 Vac

1 Isolated 12-32 Vac or 10-48 Vdc

0 None

1 Two 8A Contact Relays

2 Two 120 mA Solid State Relays

3 Four 8A Contact Relays

4 Four 120 mA Solid State Relays

0 None

1 Isolated 0-20 mA & 0-10 V

2 Dual isolated output, 4-20 mA, 0-20 mA, 0-10V

0 None

1 RS232

2 RS485 (dual RJ11 connectors)

4 RS485 Modbus (dual RJ45 connectors)

5 USB

6 USB-to-RS485 device server

7 Ethernet

8 Ethernet-to-RS485 device server

Signal Input

(isolated)

LAUREL

DC Volts

DCV1 ±200.00 mV

DCV2 ±2.0000 V

DCV3 ±20.000 V

DCV4 ±200.00 V

DCV5 ±300.0 V

DC Amps

DCA1 ±2.0000 mA

DCA2 ±20.000 mA

DCA3 ±200.00 mA

DCA4 ±5.000 A

Process Signals (e.g., 4-20 mA, 0-5 V)

P Field Scalable. Default scaling is 4-20 mA = 0-100.00

Strain Gage, Potentiometer (4-wire ratio)

SG Field scalable. Default scaling is 0-200 mV = 0-100.00

Note: The same DC signal conditioner board can be user-configured for DC Volts,

DC Amps, process, or strain. Precalibrated in EEPROM for all DC Volt and DC Amp

ranges listed.

ELECTRONICS INC., 3183-G Airway Ave., Costa Mesa, CA 92626, USA • Tel 714-434-6131 • www.laurels.com 2

Page 3

Load Cells (6-wire ratio)

WM Field scalable. Default scaling is 0-20 mV = 0-100.00

Resistance (4-wire ratio)

R1 0-20 ohms

R2 0-200 ohms

R3 0-2 kohms

R4 0-20 kohms

R5 0-200 kohms

Pulse Rate or Totalizing

FR Dual-Channel Frequency. Scalable to ±999,999 for frequency or rate.

Voltage-to-Frequency Converter

VF1 V-to-F Converter, 4-20 mA

VF2 V-to-F Converter, 0-1 mA

VF3 V-to-F Converter, 0-10 V

VF4 V-to-F Converter, Special Range.

Specify min input, min reading; max input, max reading. Component changes by the

factory may be required.

Add-on Options BL Blank Lens without Button Pads

CBL01 RJ11-to-DB9 Cable

CBL02 USB-to-DB9 Adapter

CBL05 USB Cable, A to B

IPC Splash-proof Cover

BOX1 NEMA-4 Enclosure

BOX2 NEMA-4 Enclosure plus IPC

Mechanical

LAUREL

ELECTRONICS INC., 3183-G Airway Ave., Costa Mesa, CA 92626, USA • Tel 714-434-6131 • www.laurels.com 3

Loading...

Loading...