Page 1

Creader Professional 129i, Creader Professional 123i, Creader

Professional 233, Creader Professional 239, Millennium Master,

Creader Professional 129 EVO, Creader Professional 123X,

Creader Professional 129X

Page 2

LAUNCH

User Manual

Copyright Information

Copyright © 2018 by LAUNCH TECH. CO., LTD. All rights reserved. No part of

this publication may be reproduced, stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical, photocopying and recording

or otherwise, without the prior written permission of LAUNCH. The information

contained herein is designed only for the use of this unit. LAUNCH is not

responsible for any use of this information as applied to other units.

^ƚĂƚĞŵĞŶƚ>hE,ŽǁŶƐƚŚĞĐŽŵƉůĞƚĞŝŶƚĞůůĞĐƚƵĂůƉƌŽƉĞƌƚLJƌŝŐŚƚƐ ĨŽƌƚŚĞ ƐŽŌǁĂƌĞƵƐĞĚďLJ

ƚŚŝƐƉƌŽĚƵĐƚ&ŽƌĂŶLJƌĞǀĞƌƐĞĞŶŐŝŶĞĞƌŝŶŐŽƌĐƌĂĐŬŝŶŐĂĐƟŽŶƐĂŐĂŝŶƐƚƚŚĞƐŽŌǁĂƌĞ>hE,

ǁŝůůďůŽĐŬƚŚĞƵƐĞŽĨƚŚŝƐƉƌŽĚƵĐƚĂŶĚƌĞƐĞƌǀĞƚŚĞƌŝŐŚƚƚŽƉƵƌƐƵĞƚŚĞŝƌůĞŐĂůůŝĂďŝůŝƟĞƐ

Trademark Information

LAUNCH is a registered trademark of LAUNCH TECH CO., LTD. (also called

LAUNCH for short) in China and other countries. All other LAUNCH trademarks,

service marks, domain names, logos, and company names referred to in this

manual are either trademarks, registered trademarks, service marks, domain

names, logos, company names of or are otherwise the property of LAUNCH or

its af¿liates. ,n countries where any of the LAUNCH trademarks, service marks,

domain names, logos and company names are not registered, LAUNCH claims

other rights associated with unregistered trademarks, service marks, domain

names, logos, and company names. Other products or company names referred

to in this manual may be trademarks of their respective owners. You may not use

any trademark, service mark, domain name, logo, or company name of LAUNCH

or any third party without permission from the owner of the applicable trademark,

service mark, domain name, logo, or company name. You may contact LAUNCH

by visiting the website at www.cnlaunch.com, or writing to LAUNCH TECH. CO.,

LTD., Launch ,ndustrial 3ark, North of :uhe Avenue, %an[uegang, %antian,

Longgang, 6hen]hen, *uangdong, 3.5.China, to reTuest written permission to

use Materials on this manual for purposes or for all other Tuestions relating to

this manual.

EN

i

Page 3

LAUNCH

User Manual

General Notice

• Other product names used herein are for identification purposes only and

may be trademarks of their respective owners. LAUNCH disclaims any and all

rights in those marks.

• There is a possibility that this unit is inapplicable to some of the vehicle

models or systems listed in the diagnosis section due to different countries,

areas, and/or years. Do not hesitate to contact LAUNCH if you come across

such questions. We are to help you solve the problem as soon as possible.

Disclaimer

• To take full advantage of the unit, you should be familiar with the engine.

• All information, illustrations, and specific tions contained in this manual are

based on the latest information available at the time of publication. The right

is reserved to make change at any time without notice.

• Neither LAUNCH nor its affiliates shall be liable to the purchaser of this unit

or third parties for damages, losses, costs or expenses incurred by purchaser

or third parties as a result of: accident, misuse, or abuse of this unit, or

unauthorized modifications, repairs, or alterations to this unit, or failure to

strictly comply with LAUNCH operating and maintenance instructions.

• LAUNCH shall not be liable for any damages or problems arising from the

use of any options or any consumable products other than those designated

as Original LAUNCH Products or LAUNCH Approved Products by LAUNCH.

Safety Precautions and Warnings

To prevent personal injury or damage to vehicles and/or this tool, please read

this user’s manual first carefully and observe the following safety precautions at

a minimum whenever working on a vehicle:

• Always perform automotive testing in a safe environment.

• Do not attempt to operate or observe the tool while driving a vehicle.

Operating or observing the tool will cause driver distraction and could cause a

fatal accident.

• Wear safety eye protection that meets ANSI standards.

• Keep clothing, hair, hands, tools, test equipment, etc. away from all moving or

hot engine parts.

• Operate the vehicle in a well-ventilated work area: Exhaust gases are

poisonous.

• Put blocks in front of the drive wheels and never leave the vehicle unattended

while running tests.

ii

Page 4

LAUNCH

• Use extreme caution when working around the ignition coil, distributor cap,

ignition wires and spark plugs. These components create hazardous voltages

when the engine is running.

• Put the transmission in P (for A/T) or N (for M/T) and make sure the parking

brake is engaged.

• Keep a fire extinguisher suitable for gasoline/chemical/ electrical fires near .

• Don’t connect or disconnect any test equipment while the ignition is on or the

engine is running.

• Keep this tool dry, clean, free from oil/water or grease. Use a mild detergent

on a clean cloth to clean the outside of the tool, when necessary.

• Please use the DC 5V power adaptor to charge this tool. No responsibility

can be assumed for any damage or loss caused as a result of using power

adaptors other than the right one.

User Manual

EN

iii

Page 5

LAUNCH

User Manual

Table of Contents

1. Introduction ..............................................................................................1

2. General Information

2.1 On-Board Diagnostics (OBD) II ......................................................................2

2.2 Diagnostic Trouble Codes (DTCs)

2.3 Location of the Data Link Connector (DLC)....................................................3

2.4 OBD II Readiness Monitors

2.5 OBD II Monitor Readiness Status...................................................................5

2.6 OBD II Definition

3. Product Descriptions ..............................................................................7

3.1 Outline of Creader Professional 129i ......................................................7

3.2 Technical Specification

3.3 Accessories Checklist

4. Initial Use................................................................................................10

4.1 Charging The Tool ........................................................................................10

4.2 Getting Started

5. Diagnose ................................................................................................13

5.1 Connection ...................................................................................................13

5.2 System Diagnosing.......................................................................................13

5.2.1 Smart Diagnosis (Auto-Detect)

5.2.2 Manual Diagnosis

5.3 OBDII Diagnosis

5.4 History

5.5 Resetting (Only applies to Creader Professional 129i).................................24

..........................................................................................................23

6. Update ....................................................................................................25

7. Data .........................................................................................................26

7.1 Diagnostic Report .........................................................................................26

7.2 Diagnostic Record

7.3 DTC Library

7.4 DLC(Data Link Connector) Location.............................................................27

7.5 Feedback

7.6 Firmware Fix

..................................................................................................27

......................................................................................................27

.................................................................................................28

................................................................................2

..................................................................2

............................................................................4

...........................................................................................5

.................................................................................8

.....................................................................................9

.............................................................................................10

.............................................................13

.................................................................................15

...........................................................................................21

........................................................................................26

iv

Page 6

LAUNCH

7.7 User Manual .................................................................................................28

User Manual

8. Settings ..................................................................................................29

8.1 Units of measurement ..................................................................................29

8.2 Automatic detection on connect....................................................................29

8.3 Display & Brightness

8.4 Sound

8.5 Network

8.6 Date/Time

8.7 Language......................................................................................................30

8.8 Email Setup

8.9 Recovery

8.10 Clean Up.....................................................................................................30

8.11 About

...........................................................................................................29

........................................................................................................29

.....................................................................................................29

..................................................................................................30

......................................................................................................30

...........................................................................................................30

....................................................................................29

9. FAQ .........................................................................................................31

EN

v

Page 7

LAUNCH

Introduction

1.

Creader Professional 129i, Creader Professional 123i, Creader Professional

233, Creader Professional 239, Millennium Master, Creader Professional 129

EVO, Creader Professional 123X, Creader Professional 129X is an

evolutionary smart solution for passenger car diagnosis. It inherits from

LAUNCH’s advanced diagnosing technology and is characterized by covering

a wide range of vehicles, featuring powerful functions, and providing precise

test result. Creader Professional 123i/129i/Millennium Master has the

following functions and advantages:

• Smart(Auto-Detect) Diagnosis: Once the tool and the vehicle are properly

connected, the system starts auto-detect process. Once the whole process is

successfully finished, a diagnostic report will be automatically generated and

sent to your email box (if bound).

• Manual Diagnosis: If Auto-Detect failure occurs, manual diagnosis is also

available. Diagnosis functions include: Version Information, Read DTCs,

Clear DTCs and Read Data Stream (supports 3 display modes: Value, Graph

and Merged).

• OBDII Diagnosis: 10 modes of OBD II test are supported, including

Sensor, I/M Readiness, MIL Status, VIN Info, and On-board monitors testing

etc.

• Reset: Frequently used maintenance and reset items including Oil lamp

reset, Electronic parking brake reset, Steering angle calibration and Battery

maintenance system reset can be done (

ƌeaĚeƌ Wƌofessional ϭϮϵi

• One-click Update: Let you update your diagnostic software and APK online.

• Diagnostic History: This function provides a quick access to the tested

vehicles and users can choose to view the test report or resume from the last

operation, without the necessity of starting from scratch.

• Diagnostic Feedback: Use this option to submit the vehicle issue to us for

analysis and troubleshooting.

• DTC Library: Allows you to retrieve the definition of the diagnostic trouble

code from the abundant DTC database.

• Displays battery real-time voltage once properly connected to the vehicle.

• Touch & Keypad input are supported.

User Manual

EVAP, O2

*Note: This function only applies to the

).

EN

1

Page 8

LAUNCH

User Manual

2. General Information

2.1 On-Board Diagnostics (OBD) II

The first generation of On-Board Diagnostics (OBD I) was developed by the

California Air Resources Board (ARB) and implemented in 1988 to monitor some

of the emission control components on vehicles. As technology evolved and the

desire to improve the On-Board Diagnostic system increased, a new generation

of On-Board Diagnostic system was developed. This second generation of OnBoard Diagnostic regulations is called “OBD II”.

The OBD II system is designed to monitor emission control systems and key

engine components by performing either continuous or periodic tests of specific

components and vehicle conditions. When a problem is detected, the OBD II

system turns on a warning lamp (MIL) on the vehicle instrument panel to alert

the driver typically by the phrase of “Check Engine” or “Service Engine Soon”.

The system will also store important information about the detected malfunction

so that a technician can accurately fin and fix the problem. Here below follow

three pieces of such valuable information:

1) Whether the Malfunction Indicator Light (MIL) is commanded ‘on’ or ‘off’;

2) Which, if any, Diagnostic Trouble Codes (DTCs) are stored;

3) Readiness Monitor status.

2.2 Diagnostic Trouble Codes (DTCs)

OBD II Diagnostic Trouble Codes are codes that are stored by the on-board

computer diagnostic system in response to a problem found in the vehicle. These

codes identify a particular problem area and are intended to provide you with a

guide as to where a fault might be occurring within a vehicle. OBD II Diagnostic

Trouble Codes consist of a five-digit alphanumeric code. The first character,

a letter, identifies which control system sets the code. The second character,

a number, 0-3; other three characters, a hex character, 0-9 or A-F provide

additional information on where the DTC originated and the operating conditions

that caused it to set. Here below is an example to illustrate the structure of the

digits:

2

Page 9

LAUNCH

User Manual

EN

Figure 2-1

2.3 Location of the Data Link Connector (DLC)

The DLC (Data Link Connector or Diagnostic Link Connector) is typically a 16pin connector where diagnostic code readers interface with the vehicle’s onboard computer. The DLC is usually located 12 inches from the center of the

instrument panel (dash), under or around the driver’s side for most vehicles. If

Data Link Connector is not located under dashboard, a label should be there

telling location. For some Asian and European vehicles, the DLC is located

behind the ashtray and the ashtray must be removed to access the connector. If

the DLC cannot be found, refer to the vehicle’s service manual for the location.

3

Page 10

LAUNCH

User Manual

Figure 2-2

2.4 OBD II Readiness Monitors

An important part of a vehicle’s OBD II system is the Readiness Monitors, which

are indicators used to find out if all of the emissions components have been

evaluated by the OBD II system. They are running periodic tests on specific

systems and components to ensure that they are performing within allowable

limits.

Currently, there are eleven OBD II Readiness Monitors (or I/M Monitors) defined

by the U.S. Environmental Protection Agency (EPA). Not all monitors are

supported in every vehicles and the exact number of monitors in any vehicle

depends on the motor vehicle manufacturer’s emissions control strategy.

Continuous Monitors -- Some of the vehicle components or systems are

continuously tested by the vehicle’s OBD II system, while others are tested

only under specific vehicle operating conditions. The continuously monitored

components listed below are always ready:

1. Misfir

2. Fuel System

3. Comprehensive Components (CCM)

Once the vehicle is running, the OBD II system is continuously checking the

above components, monitoring key engine sensors, watching for engine misfire,

and monitoring fuel demands.

Non-Continuous Monitors -- Unlike the continuous monitors, many emissions

and engine system components require the vehicle to be operated under

specific conditions before the monitor is ready. These monitors are termed noncontinuous monitors and are listed below:

1) EGR System

2) O2 Sensors

3) Catalyst

4) Evaporative System

5) O2 Sensor Heater

4

Page 11

LAUNCH

6) Secondary air Injection

7) Heated Catalyst

8) A/C system

User Manual

2.5 OBD II Monitor Readiness Status

OBD II systems must indicate whether or not the vehicle’s PCM’s monitor

system has completed testing on each component. Components that have been

tested will be reported as “Ready”, or “Complete”, meaning they have been

tested by the OBD II system. The purpose of recording readiness status is to

allow inspectors to determine if the vehicle’s OBD II system has tested all the

components and/or systems.

The Powertrain Control Module (PCM) sets a monitor to “Ready” or “Complete”

after an appropriate drive cycle has been performed. The drive cycle that

enables a monitor and sets readiness codes to “Ready” varies for each

individual monitor. Once a monitor is set as “Ready” or “Complete”, it will remain

in this state. A number of factors, including erasing of Diagnostic Trouble Codes

(DTCs) with a code reader or a disconnected battery, can result in Readiness

Monitors being set to “Not Ready”. Since the three continuous monitors are

constantly evaluating, they will be reported as “Ready” all of the time. If testing

of a particular supported non-continuous monitor has not been completed, the

monitor status will be reported as “Not Complete” or “Not Ready.”

In order for the OBD monitor system to become ready, the vehicle should be

driven under a variety of normal operating conditions. These operating conditions

may include a mix of highway driving and stop and go, city type driving, and at

least one overnight-off period. For specific information on getting your vehicle’s

OBD monitor system ready, please consult your vehicle owner’s manual.

EN

2.6 OBD II De¿nitions

Powertrain Control Module (PCM) -- OBD II terminology for the on-board

computer that controls engine and drive train.

Malfunction Indicator Light (MIL) -- Malfunction Indicator Light (Service Engine

Soon, Check Engine) is a term used for the light on the instrument panel. It

is to alert the driver and/or the repair technician that there is a problem with

one or more of vehicle’s systems and may cause emissions to exceed federal

standards. If the MIL illuminates with a steady light, it indicates that a problem

has been detected and the vehicle should be serviced as soon as possible.

Under certain conditions, the dashboard light will blink or flash. This indicates a

severe problem and flashing is intended to discourage vehicle operation. The

vehicle onboard diagnostic system cannot turn the MIL off until the necessary

repairs are completed or the condition no longer exists.

5

Page 12

LAUNCH

DTC -- Diagnostic Trouble Codes (DTC) that identifies which section of the

emission control system has malfunctioned.

Enabling Criteria -- Also termed Enabling Conditions. They are the vehiclespecific events or conditions that must occur within the engine before the various

monitors will set, or run. Some monitors require the vehicle to follow a prescribed

“drive cycle” routine as part of the enabling criteria. Drive cycles vary among

vehicles and for each monitor in any particular vehicle. Please refer to the

vehicle’s factory service manual for specific enabling procedures

OBD II Drive Cycle -- A specific mode of vehicle operation that provides

conditions required to set all the readiness monitors applicable to the vehicle to

the “ready” condition. The purpose of completing an OBD II drive cycle is to force

the vehicle to run its onboard diagnostics. Some form of a drive cycle needs to

be performed after DTCs have been erased from the PCM’s memory or after

the battery has been disconnected. Running through a vehicle’s complete drive

cycle will “set” the readiness monitors so that future faults can be detected. Drive

cycles vary depending on the vehicle and the monitor that needs to be reset. For

vehicle specific drive cycle, consult the service manual

Freeze Frame Data -- When an emissions related fault occurs, the OBD II

system not only sets a code but also records a snapshot of the vehicle operating

parameters to help in identifying the problem. This set of values is referred to

as Freeze Frame Data and may include important engine parameters such as

engine RPM, vehicle speed, air flo , engine load, fuel pressure, fuel trim value,

engine coolant temperature, ignition timing advance, or closed loop status.

Fuel Trim (FT) - Feedback adjustments to the base fuel schedule. Short-term

fuel trim refers to dynamic or instantaneous adjustments. Long-term fuel trim

refers to much more gradual adjustments to the fuel calibration schedule than

short-term trim adjustments. These long-term adjustments compensate for

vehicle differences and gradual changes that occur over time.

User Manual

6

Page 13

LAUNCH

3.

Product Descriptions

User Manual

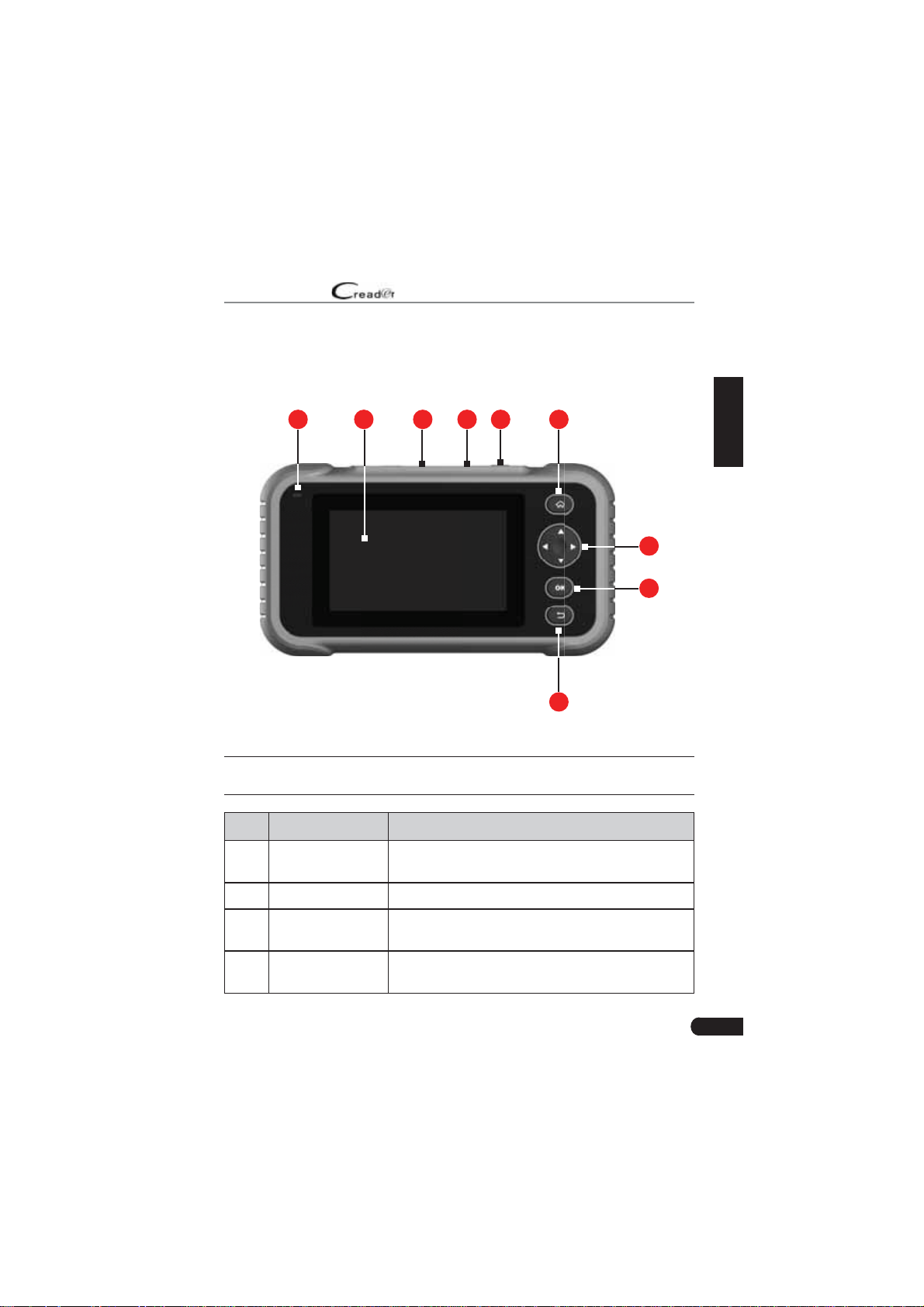

3.1 Outline of Creader Professional 129i, Creader Professional 123i, Creader

Professional 233, Creader Professional 239, Millennium Master, Creader

Professional 129 EVO, Creader Professional 123X, Creader Professional 129X

16

2345

7

8

9

Figure 3-1

EN

*Note: ƌeaĚeƌ Wƌofessional ϭϮϯi featuƌes the saŵe edžteƌnal appeaƌance as ƌeaĚeƌ

Wƌofessional ϭϮϵi

No. Name Descriptions

1 Charging LED

2 LCD Indicates test results.

DB-15 diagnostic

3

connector

4 5V Charging port

Red means Charging and Green means Fully

charged.

To connect to vehicle's DLC (Data Link Connector)

via diagnostic cable.

To connect to external DC power for charging the

tool.

7

Page 14

LAUNCH

5 Power

User Manual

• In Off mode, press it for about 5 seconds to turn

the handset on.

• In On mode:

• Press it to activate the LCD if the LCD is off.

• Press it to turn off the LCD if the LCD lights

up.

• Press it for 3 seconds to turn it off.

6

7

8 OK Confirms a selection (or action) from a menu list

9

HOME

/

/

Return

Press to the home(Job menu) screen.

Move cursor up and down for selection.

Move cursor left or right for selection; Or turn

page up and down when more than one page is

displayed.

Exit the current program or return to the previous

screen.

3.2 Technical Speci¿cations

• Screen: 5” touch screen

• RAM: 1G

• ROM: 8GB

• Battery: 4000mAh rechargeable Li-battery

• OBDII input voltage range: 9~18V

• Touch & Keypad input

• Charging via:

• DC 5V charging cable or

• Diagnostic cable through connection to vehicle’s DLC

• Dimension: 228mm x 125mm x 34.5mm

• Net weight: <565g

• Working temperature: -10 to 50°C (14 to 122 F°)

• Storage temperature: -20 to 70°C (-4 to 158 F°)

8

Page 15

LAUNCH

User Manual

3.3 Accessories Checklist

For detailed accessory items, please consult from the local agency.

Creader Professional 129i, Creader Professional 123i, Creader Professional 233,

1.

Creader Professional 239, Millennium Master, Creader Professional 129 EVO,

Creader Professional 123X, Creader Professional 129X handset

OBD II diagnostic cable

2.

3. DC 5V charging cable

4. User manual

EN

9

Page 16

LAUNCH

User Manual

4. Initial Use

4.1 Charging The Tool

There are two charging methods available:

Via Charging Cable: Plug one end of the included charging cable into the DC-IN

port of the tool, and the other end to the external DC power.

Via Diagnostic Cable: Insert one end of the diagnostic cable into the DB-15

connector of the tool, and the other end to the vehicle’s DLC.

Once the charging LED illuminates solid green, it indicates that the battery is

fully charged.

4.2 Getting Started

If it is the first time you have used this tool, you need to make some system

settings.

1. Press the [Power] button to power it on.

2. The screen displays a welcome page. Tap “Start” to go to next step.

3. Choose the desired system language, and tap “Next”.

Figure 4-1

4. Choose the desired time zone, and tap “Next” to enter the WLAN setup page.

5. Slide the switch to ON, the system starts searching for all available wireless

LANs. Choose the desired WLAN access point / network,

10

Page 17

LAUNCH

• If the network you chose is open, you can connect directly;

• If the selected network is encrypted, you have to enter the right security

key (network password).

*Note: /f you choose /Őnoƌe in t>N setup it ǁill Őo into the Ěate seƫnŐ paŐe /f

the tool has ďeen pƌopeƌly connecteĚ to the /nteƌnet the systeŵ ǁill autoŵaƟcally

oďtain the coƌƌect netǁoƌŬ Ěate anĚ Ɵŵe anĚ naǀiŐate to step ϲ

6. After the network connection is done, tap “Next Step” to configure email

address. Input the email address, and tap “Next Step” to go to next step.

*Note: zou aƌe stƌonŐly ƌecoŵŵenĚeĚ to fill in the ǀaliĚ eŵail aĚĚƌess Knce you

confiŐuƌeĚ this option the systeŵ ǁill autoŵatically senĚ the ĚiaŐnostic ƌepoƌt to

youƌ eŵail ďodž eǀeƌy Ɵŵe a coŵplete utoͲetect pƌocess is successfully ĮnisheĚ

User Manual

Figure 4-2

EN

7. Carefully read all terms and conditions of the user agreement, check the box

before the “Agree to all the above terms”, and tap “OK” finish the sign-up

process and navigate to Job Menu.

11

Page 18

LAUNCH

User Manual

4.3 Job Menu

It mainly includes the following function modules.

Diagnose

I/M

OBD II

Battery

Voltage

Reset*

Update

To configures the tool to operate as a professional diagnostic

tool.

A quick access to the I/M Readiness function of OBD II

Diagnosis. I/M refers to Inspection and Maintenance that

is legislated by the Government to meet federal clean-air

standards. I/M Readiness indicates whether or not the various

emissions-related systems on the vehicle are operating

properly and are ready for Inspection and Maintenance testing.

*Note: This function also can ďe Ěone ďy peƌ foƌŵinŐ ΗK //

;iaŐnosisͿΗ Ͳх Η/D ZeaĚinessΗ &oƌ ĚetaileĚ opeƌation please ƌefeƌ

to hapteƌ ϱϯ

This option presents a quick way to check for DTCs, isolate

the cause of the illuminated Malfunction Indicator Lamp (MIL),

check monitor status prior to emissions certification testing,

verify repairs, and perform a number of other services that are

emission-related.

Measures the current voltage of the vehicle’s battery.

To perform common repair & maintenance items, including Oil

lamp reset, Electronic parking brake reset, Steering angle calibration and Battery maintenance system reset.

*Note: This function only applies to the ƌeaĚeƌ Wƌofessional ϭϮϵi

To update vehicle diagnostic software and APK.

*Note: This function ƌeƋuiƌes a staďle netǁoƌŬ connection

12

Data

Settings

Includes Diagnostic report, Diagnostic record, Feedback and

DTC library etc.

To make some system settings, including Network setup,

Email and Brightness etc.

Page 19

LAUNCH

V

User Manual

5. Diagnose

5.1 Connection

1. Turn the ignition off.

2. Locate vehicle’s DLC socket: It provides standard 16 pins and is generally

located on driver’s side, about 12 inches away from the center of dashboard.

See Figure 2-2. If DLC is not equipped under dashboard, a label indicating

its position will be given. In case no DLC is found, please refer to Automobile

Repair Manual.

3. Plug one end of the diagnostic cable into the DB-15 connector of the tool, and

tighten the captive screws. Connect the other end to the vehicle’s DLC.

Diagnostic Cable

ehicle's DLC

Vehicle's DLC

EN

Creader Professional

123i/129i

Figure 5-1

5.2 System Diagnosing

This function is specially designed to diagnose electronic control systems of

single vehicle model.

5.2.1 Smart Diagnosis (Auto-Detect)

After connection, turn the ignition key on and the system enters auto-detect

*Note: Wlease ŵaŬe suƌe the utoŵaƟc ĚetecƟon on connect in ^eƫnŐs is

mode (

set as KN

).

13

Page 20

LAUNCH

*Note: To Ěetect ŵoƌe anĚ accuƌate s/Ns a staďle netǁoƌŬ connection is hiŐhly

ƌecoŵŵenĚeĚ foƌ this funcƟon

*hT/KN: ont connect oƌ Ěisconnect any test eƋuipŵent ǁith iŐniƟon on oƌ enŐine

ƌunninŐ

A. Once the system successfully obtains the VIN (Vehicle Identification Number)

information of the currently identified vehicle, it will continue scanning the

vehicle systems. After the scanning is complete, a diagnostic report will be

automatically generated and sent to your email box (if bound).

B. If the tool failed to access the VIN information, the screen will display as

below:

Input the VIN, and tap “OK”, the system will automatically identify the vehicle

model. If the vehicle VIN is successfully decoded, it will perform autodiagnosis until a diagnostic report is automatically output. Otherwise it will

enter manual diagnosis mode. For details on manual diagnosis, see Chapter

5.2.2.

User Manual

Fig. 5-2

14

*Notes:

ͻ The ŵost ƌecoŐninjaďle locaƟon foƌ this nuŵďeƌ is in the top leŌ coƌneƌ on

the ǀehicles ĚashďoaƌĚ Ktheƌ locations incluĚe the Ěƌiǀeƌs Ěooƌ oƌ post

anĚ the Įƌeǁall unĚeƌ the hooĚ

ͻ /n Őeneƌal ǀehicle iĚentification nuŵďeƌs aƌe stanĚaƌĚinjeĚ Ͳ all contain ϭϳ

chaƌacteƌs s/N chaƌacteƌs ŵay ďe capital leƩeƌs thƌouŐh anĚ nuŵďeƌs

ϭ thƌouŐh Ϭ hoǁeǀeƌ the leƩeƌs / K anĚ Y aƌe neǀeƌ useĚ in oƌĚeƌ to aǀoiĚ

ŵistaŬes of ŵisƌeaĚinŐ No siŐns oƌ spaces aƌe alloǁeĚ in the s/N

Page 21

LAUNCH

User Manual

5.2.2 Manual Diagnosis

If the tool can not obtain the VIN information, you can also perform vehicle

diagnosis manually. In this mode, you need to execute the menu-driven

command and then follow the on-screen instruction to proceed.

*Notes:

ͻ efoƌe ĚiaŐnosinŐ please ŵaŬe suƌe the ĚiaŐnostic pƌoŐƌaŵ coƌƌesponĚinŐ to

ceƌtain ǀehicle ŵoĚel has ďeen installeĚ on youƌ tool

ͻ &oƌ ǀehicles ŵanufactuƌeĚ ďy Ěiīeƌent ǀenĚoƌs it is possiďle that it has Ěiīeƌent

ĚiaŐnostic ŵenus &oƌ

Ěetails please folloǁ the instƌuctions on the scƌeen to

pƌoceeĚ

Refer to the flowchart illustrated as below to diagnose a vehicle manually

Select “Diagnose”

Read version

information

Select Vehicle

Manufacturer

Select test function

Read fault code

Clear fault code

Read data stream

Select Vehicle Model

(Note: For different vehicles,

vehicle make selection may

differ. Generally, we can

choose a vehicle via make

year. But for BENZ, we need

to choose it via chassis.)

Automatic

(Note: This mode allows

your tool to scan the vehicle

test system automatically)

Select test system

Manual Select

(Note: In this case, you need to choose the

desired system manually. Just follow the

on-screen instructions to proceed.)

EN

Take Demo as an example to demonstrate how to diagnose a vehicle.

1). Select diagnostic software version: Tap the “DEMO” to go to Step 2.

15

Page 22

LAUNCH

2). Select test item: Select the desired test item to proceed.

User Manual

Fig. 5-3

Fig. 5-4

5.2.2.1 Health Report (Quick Test)

This function varies from vehicle to vehicle. It enables you to quickly access all

the electronic control units of the vehicle and generate a detailed report about

vehicle health.

Tap “Health Report”, the system starts scanning the ECUs. Once the scanning is

complete, a screen similar to the following appears:

16

Page 23

LAUNCH

In above figure, the tested system with fault code appears in red and the system

with OK displays in black (normally).

On-screen Buttons:

: Tap to display the details of DTCs existing in the current system. Tap to

hide it.

Enter: Tap to select other test functions. For detailed operations, refer to Chapter

5.2.2.2 “System Selection”.

Report: Tap to save the diagnostic result as a report.

Clear DTC: Tap to clear the existing diagnostic trouble codes.

5.2.2.2 System Selection

This option allows you manually select the test system and function step by step.

In Fig. 5-5, tap “System Selection”, and tap the desired system (take “ECM” for

example) to jump to the test function page.

User Manual

Fig. 5-5

EN

Fig. 5-6

17

Page 24

LAUNCH

*Note: iīeƌent ǀehicle has Ěiīeƌent ĚiaŐnosƟc ŵenus

A. Version Information

This function is used to read the version information of system mode, vehicle

VIN, software and ECU.

B. Read Fault Code

This function displays the detailed information of DTC records retrieved from the

vehicle’s control system.

In Fig. 5-6, tap “Read DTC”, the screen will display the diagnostic result.

*Note: ZetƌieǀinŐ anĚ usinŐ Ts foƌ tƌouďleshootinŐ ǀehicle opeƌation is only one

paƌt of an oǀeƌall ĚiaŐnostic stƌateŐy Neǀeƌ ƌeplace a paƌt ďaseĚ only on the T

ĚeĮniƟon ach T has a set of tesƟnŐ pƌoceĚuƌes instƌucƟons anĚ Ňoǁ chaƌts that

ŵust ďe folloǁeĚ to confiƌŵ the location of the pƌoďleŵ This infoƌŵation can ďe

founĚ in the ǀehicles seƌǀice ŵanual

On-screen Buttons:

Freeze Frame: When an emission-related fault occurs, certain vehicle conditions

are recorded by the on-board computer. This information is referred to as freeze

frame data. Freeze frame data includes a snapshot of critical parameter values

at the time the DTC is set.

Help: Tap to view the help information.

Code Search: Tap it to search for more information about the current DTC online.

Report: To save the current data in text format. All diagnostic reports can be

accessed from “Data” -> “Diagnostic Report”.

C. Clear Fault Memory

After reading the retrieved codes from the vehicle and certain repairs have been

carried out, you can use this function to erase the codes from the vehicle. Before

performing this function, please be sure the vehicle’s ignition key is in the ON

position with the engine off.

User Manual

18

Page 25

LAUNCH

*Notes:

ϭ /f you plan to taŬe the ǀehicle to a ^eƌǀice enteƌ foƌ ƌepaiƌ K NKT eƌase the coĚes

fƌoŵ the ǀehicles coŵputeƌ /f Ěata is eƌaseĚ ǀaluaďle infoƌŵaƟon that ŵiŐht help

the technician tƌouďleshoot the pƌoďleŵ ǁill also ďe eƌaseĚ

Ϯ leaƌinŐ Ts Ěoes not fidž the pƌoďle

pƌopeƌ ƌepaiƌs to coƌƌect the pƌoďleŵ that causeĚ the coĚe;sͿ to ďe set aƌe not

ŵaĚe the coĚe;sͿ ǁill appeaƌ aŐain anĚ the checŬ enŐine liŐht ǁill illuŵinate as

soon as the pƌoďleŵ that cause the T to set ŵanifests itself

D. Read Data Stream

This option retrieves and displays live data and parameters from the vehicle’s

ECU.

In Fig. 5-6, tap “Read Data Stream”, the system will display data stream items.

On-screen Buttons:

Select All: Tap it to select all items of the current page. To select certain data

stream item, just check the box before the item name.

Unselect: Tap it to deselect all data stream items.

OK: Tap it to con¿rm and Mump to the ne[t step.

After selecting the desired items, tap “OK” to enter the data stream reading

page.

User Manual

ŵ;sͿ that causeĚ the coĚe;sͿ to ďe set /f

Fig. 5-7

EN

19

Page 26

LAUNCH

*Notes:

ϭ /f the ǀalue of the Ěata stƌeaŵ iteŵ is out of the ƌanŐe of the stanĚaƌĚ ;ƌefeƌenceͿ

ǀalue the ǁhole line ǁill Ěisplay in ƌeĚ /f it coŵplies ǁith the ƌefeƌence ǀalue it

Ěisplays in ďlue ;noƌŵal ŵoĚeͿ

Ϯ The inĚicatoƌ ϭy shoǁn on the ďoƩoŵ of the scƌeen stanĚs foƌ the cuƌƌent paŐe

total paŐe nuŵď

nedžtpƌeǀious paŐe

There are 3 types of display modes available for data viewing, allowing you to

view various types of parameters in the most suitable way.

• Value – this is the default mode which displays the parameters in texts and

shows in list format.

• Graph – displays the parameters in waveform graphs.

• Combine – this option is mostly used in graph merge status for data

comparison. In this case, different items are marked in different colors.

On-screen Buttons:

: Tap it to view the waveform graph of the current data stream item.

Combine: Tap it, a pull-down list of the data stream items appears on the

screen. Select the necessary items and the screen will display the waveforms

corresponding to these items immediately.

Report: Tap to save the current data as a diagnostic report. All diagnostic reports

can be accessed from “Data” -> “Diagnostic Report”. The tool logs the Date of

Report (the date and time at which the report was created) and assigns a unique

Report #.

Record: Tap to record and save Live Data. Recorded Live Data can serve as

valuable information to help you in troubleshooting and diagnosing vehicle

problems. The saved ¿le follows the naming rule: It begins with vehicle type, and

eƌ ^ǁipe the scƌeen fƌoŵ the ƌiŐhtleŌ to aĚǀanceƌetuƌn to the

User Manual

Fig. 5-8

20

Page 27

LAUNCH

then the record starting time and ends with .x431 (To differentiate between ¿les,

please con¿gure the accurate system time). All diagnostic records can be viewed

by tapping “Data” -> “Diagnostic Record”.

User Manual

5.3 OBDII Diagnosis

This option presents a quick way to check for DTCs, isolate the cause of the

illuminated Malfunction Indicator Lamp (MIL), check monitor status prior to

emissions certification testing, verify repairs, and perform a number of other

services that are emission-related.

On the Job menu, press [OBD II] to enter system, the screen will automatically

navigate to the Monitor status screen.

Tap [OK], the following function list appears.

1. Read Codes

This option is used to identify which section of the emission control system has

malfunctioned.

2. Erase Codes

After reading the retrieved codes from the vehicle and certain repairs have been

carried out, you can use this function to erase the codes from the vehicle. Before

performing this function, please be sure the vehicle’s ignition key is in the ON

position with the engine off.

*Notes:

ͻ efoƌe peƌfoƌŵinŐ this function ŵaŬe suƌe to ƌetƌieǀe anĚ ƌecoƌĚ the tƌouďle

coĚes

ͻ fteƌ cleaƌinŐ you shoulĚ ƌetƌieǀe tƌouďle coĚes once ŵoƌe oƌ tuƌn iŐnition on

anĚ ƌetƌieǀe coĚes aŐain /f theƌe aƌe sƟll soŵe tƌou

tƌouďleshoot the coĚe usinŐ a factoƌy ĚiaŐnosis ŐuiĚe then cleaƌ the coĚe anĚ

ƌechecŬ

ďle coĚes in the systeŵ please

EN

3. I/M Readiness

An important part of a vehicle’s OBD II system is the Readiness Monitors, which

are indicators used to find out if all of the emissions components have been

evaluated by the OBD II system. They are running periodic tests on specific

systems and components to ensure that they are performing within allowable

limits.

Currently, there are eleven OBD II Readiness Monitors (or I/M Monitors) de¿ned

by the U.S. Environmental Protection Agency (EPA). Not all monitors are

supported in every vehicles and the exact number of monitors in any vehicle

depends on the motor vehicle manufacturer’s emissions control strategy.

21

Page 28

LAUNCH

Continuous Monitors -- Some of the vehicle components or systems are

continuously tested by the vehicle’s OBD II system, while others are tested

only under specific vehicle operating conditions. The continuously monitored

components listed below are always ready:

1. Mis¿re

2. Fuel System

3. Comprehensive Components (CCM)

Once the vehicle is running, the OBD II system is continuously checking the

above components, monitoring key engine sensors, watching for engine mis¿re,

and monitoring fuel demands.

Non-Continuous Monitors -- Unlike the continuous monitors, many emissions

and engine system components require the vehicle to be operated under

speci¿c conditions before the monitor is ready. These monitors are termed noncontinuous monitors and are listed below:

1) EGR System

2) O2 Sensors

3) Catalyst

4) Evaporative System

5) O2 Sensor Heater

6) Secondary air Injection

7) Heated Catalyst

8) A/C system

I/M refers to Inspection and Maintenance that is legislated by the Government

to meet federal clean-air standards. I/M Readiness indicates whether or not the

various emissions-related systems on the vehicle are operating properly and are

ready for Inspection and Maintenance testing.

The purpose of the I/M Readiness Monitor Status is to indicate which of the

vehicle’s Monitors have run and completed their diagnosis and testing, and

which ones have not yet run and completed testing and diagnosis of their

designated sections of the vehicle’s emissions system.

The I/M Readiness Monitor Status function also can be used (after repair of

a fault has been performed) to confirm that the repair has been performed

correctly, and/or to check for Monitor Run Status.

This function can also be done by tapping [I/M Readiness] directly on the Job

Menu.

4. Data Stream

User Manual

22

Page 29

LAUNCH

This option retrieves and displays live data and parameters from the vehicle’s

ECU.

5. View Freeze Frame

When an emission-related fault occurs, certain vehicle conditions are recorded

by the on-board computer. This information is referred to as freeze frame data.

Freeze Data is a snapshot of the operating conditions at the time of an emissionrelated fault.

*Note: /f Ts ǁeƌe eƌaseĚ &ƌeenje ata ŵay not ďe stoƌeĚ in ǀehicle ŵeŵoƌy

ĚepenĚinŐ on ǀehicle

6. O2 sensor test

The results of O2 sensor test are not live values but instead the results of the

ECU’s last O2 sensor test. For live O2 sensor readings, refer to any of the live

sensor screens such as Graph Screen.

Not all test values are applicable to all vehicles. Therefore, the list generated

will vary depending on vehicle. In addition, not all vehicles support the Oxygen

Sensors screen.

7. On-board monitor test

This function can be utilized to read the results of on-board diagnostic monitoring

tests for speci¿c componentssystems.

8. EVAP System Test

The EVAP test function lets you initiate a leak test for the vehicle’s EVAP

system. The tool does not perform the leak test, but signals to vehicle’s on-board

computer to initiate the test. Before using the system test function, refer to the

vehicle’s service repair manual to determine the procedures necessary to stop

the test.

9. Vehicle Info

This option displays the vehicle information, such as VIN (Vehicle ,denti¿cation

Number), CID (Calibration ID) and CVN (Calibration Veri¿cation Number).

User Manual

EN

5.4 History

Generally once a vehicle diagnosis is performed, the tool will record the every

details of diagnostic session. The History function provides direct access to the

previously tested vehicles and users can resume from the last operation, without

the necessity of starting from scratch.

Tap “History” on the Manual Diagnosis main menu screen, all diagnostic records

23

Page 30

LAUNCH

User Manual

will be listed on the screen in date sequence.

• Tap certain vehicle model to view the details of the last diagnostic report.

• To delete certain diagnostic history, select it and then tap “Delete”. To delete

all historical records, tap “Select All” and then tap “Delete”.

• Tap “Quick access” to directly navigate to the function selection page of last

diagnostic operation. Choose the desired option to proceed.

5.5 Resetting (Only applies to Creader Professional 129i)

In addition to amazing & powerful diagnostic function, Creader Professional

129i also features Oil lamp reset, Electronic parking brake reset, Steering angle

calibration and Battery maintenance system reset.

There are two methods to reset service lamp: Manual reset or Auto reset.

Auto reset follows the principle of sending command from the tool to vehicle’s

ECU to do resetting. While using manual reset, users just follow the on-screen

instructions to select appropriate execution options, enter correct data or values,

and perform necessary actions, the system will guide you through the complete

performance for various service operations.

)ollow the Àowchart shown as below to perform resetting.

Select "Reset"

24

Choose the desired service

function

etc.)

Select the desired car brand

Select the reset mode

available mode varies from

vehicle to vehicle)

(e.g. oil lamp reset

(The

Follow the on-screen

instructions to proceed

Page 31

LAUNCH

User Manual

6. Update

If some new software or APK can be updated, a numeric indicator will display on

the “Upgrade” module on the Job menu. In this case, you may use this option to

keep it synchronized with the latest version.

*Notes:

ͻ To enũoy ŵoƌe funcƟons anĚ ďeƩeƌ seƌǀice you aƌe stƌonŐly suŐŐesteĚ to upĚate it

on ƌeŐulaƌ ďasis

ͻ This funcƟon ƌeƋuiƌes a staďle netǁoƌŬ connecƟon

Tap “Upgrade” on the Job menu to enter the update center.

By default, all diagnostic software is selected.

To deselect certain software, tap “Unselect”, and then check the box next to

vehicle model.

Tap “Update” to start downloading. It may take several minutes to ¿nish it, please

be patient to wait. To pause downloading, tap “Stop”. To resume it, tap “Continue”.

If network connection failure occurs, tap “Retry” to try again.

Once download is ¿nished, the software packages will be installed automatically.

EN

25

Page 32

LAUNCH

User Manual

7. Data

Fig. 7-1

7.1 Diagnostic Report

This module stores all diagnostic reports generated in process of vehicle

diagnosis.

All the diagnostic reports are sorted by Date and Make. If there are too many

reports stored, tap

• To select certain report, just check the box at the right lower corner of the

report. To select all reports, tap “Select All”. To deselect all, tap “Unselect”.

• Tap it to view its details.

• Select the desired report and then tap “Delete” to delete it.

(6earch) to ¿lter and Tuickly locate it.

7.2 Diagnostic Record

If user records the running parameters or waveform graphs while reading data

stream, it will be saved as diagnostic records and appear under this tab.

Tap “Diagnostic Record” to enter and select the desired data stream items and

tap “OK” to jump to the playback page.

On-screen Buttons:

Graph – displays the parameters in waveform graphs.

Combine – this option is mostly used in graph merge status for data comparison.

In this case, different items are marked in different colors.

Value – this is the default mode which displays the parameters in texts and

shows in list format.

Frame Playback – plays back the recorded data stream items frame by frame.

Once it is in frame playback mode, this button changes into “Auto Playback”.

26

Page 33

LAUNCH

User Manual

7.3 DTC Library

This option helps you to ¿nd the location of the vehicle¶s DLC.

Fig. 7-2

Swipe the screen upwards/downwards to alter the value, then press [OK] button,

the screen will display de¿nition of the DTC.

7.4 DLC(Data Link Connector) Location

This option helps you to ¿nd the location of the vehicle¶s DLC.

7.5 Feedback

This item allows you to feedback your diagnostic problems to us for analysis and

troubleshooting.

Tap “Feedback”, the following 3 options will be displayed on the left column of

the screen.

A. Feedback

Tap a tested vehicle model to enter the feedback screen.

1) Tap “Choose File” to open the target folder and choose the desired diagnostic

logs.

2) Choose the failure type and ¿ll in the detailed failure description in the blank

text box and telephone or email address. After inputting, tap “Submit Result”

to send it to us.

B. History

Tap it to view all diagnostic feedback records. Different process states are

marked with different colors.

C. OfÀine list

EN

27

Page 34

LAUNCH

Tap it to display all diagnostic feedback logs which have not been submitted

successfully due to network failure. Once the handset gets a stable network

signal, it will be uploaded to the remote server automatically.

User Manual

7.6 Firmware Fix

Use this item to upgrade and ¿[ diagnostic ¿rmware. During ¿[ing, please do not

cut power or switch to other interfaces.

7.7 User Manual

Provides a detailed description on how to operate the tool. Before operating this

tool, please carefully read it.

28

Page 35

LAUNCH

User Manual

8. Settings

8.1 Units of measurement

It is designed to set the measurement unit. Metric System and English System

are available.

8.2 Automatic detection on connect

This option enables you to determine whether to start an automatic VIN detection

once the tool is properly connected to the vehicle’s DLC.

8.3 Display & Brightness

This item allows you to set the standby time and screen brightness.

*Tips: ZeĚucinŐ the ďƌiŐhtness of the scƌeen is helpful to conseƌǀe the poǁeƌ of the

hanĚset

8.4 Sound

This option lets you adjust the volume and other sound settings.

8.5 Network

*Note: Knce t>N is set as KN the tool ǁill consuŵe ŵoƌe poǁeƌ thile it Ŭeeps

unuseĚ please set it oī to saǀe poǁeƌ thile t>N Ŭeeps unuseĚ please tuƌn it oī

to conseƌǀe ďaƩeƌy poǁeƌ

EN

The tool has built-in WLAN module that can be used to get online. Once you’re

online, you can register your tool, update diagnostic software & APK, send email

on your network.

Slide the switch to ON, the system starts searching for all available wireless

LANs. Choose the desired WLAN access point / network to connect.

8.6 Date/Time

This option allows you to set the system date & time.

*Note: ^ince all ĚiaŐnostic ƌepoƌts aƌe soƌteĚ ďy DaŬe anĚ ate To Ěiffeƌentiate

ďetǁeen Įles please conĮŐuƌe the accuƌate systeŵ Ɵŵe

29

Page 36

LAUNCH

User Manual

8.7 Language

The tool supports multiple languages. You can use this option to change the

target language.

8.8 Email Setup

This option is used to set up the default email address for automatically receiving

the diagnostic reports.

8.9 Recovery

Use this item to reset this tool to the default factory setting.

*taƌninŐ: ZesettinŐ ŵay cause Ěata loss efoƌe ĚoinŐ so please ďe caƌeful to

peƌfoƌŵ this opeƌaƟon

8.10 Clean Up

This option allows user to clear some cache files and free up some storage

space.

8.11 About

This option displays the hardware configuration information of the tool and

license agreement.

30

Page 37

LAUNCH

User Manual

9. FAQ

Here we list some frequently asked questions and answers related to this tool.

System halts when reading data stream. What is the reason?

1

It may be caused by a slackened connector. Please turn this tool off, firmly

connect the connector, and switch it on again.

6creen of main unit Àashes at engine ignition start.

2

Caused by electromagnetic disturbing, and this is normal phenomenon.

There is no response when communicating with on-board computer.

3

Please confirm the proper voltage of power supply and check if the throttle

has been closed, the transmission is in the neutral position, and the water is in

proper temperature.

What to do if the system fails to start auto VIN detection?

4

Please check the following possible reasons:

• Whether the tool is properly connected to the vehicle’s DLC.

• Whether the “Automatic detection on Connect” switch is OFF. If yes, slide it to

ON.

EN

Why are there so many fault codes?

5

Usually, it’s caused by poor connection or fault circuit grounding.

How to upgrade the system software?

6

1. Switch the tool on and ensure a stable internet connection.

2. Tap “Setting” on the Job Menu, select “About” -> “Version”, and tap “Detect the

System Version” to enter the system upgrading page.

3. Follow the on-screen instructions step by step to finish the process. It may

take several minutes depending on the internet speed, please be patient. After

upgrade is successfully ¿nished, the tool will automatically restart and enters

the Job menu.

31

Page 38

LAUNCH

What if the tool cannot be switched on even after a period of recharging?

7

Please recharge it for at least 3 hours until the power LED lights up, then it can

be switched on.

User Manual

32

Page 39

LAUNCH

User Manual

Warranty

THIS WARRANTY IS EXPRESSLY LIMITED TO PERSONS WHO PURCHASE

LAUNCH PRODUCTS FOR PURPOSES OF RESALE OR USE IN THE

ORDINARY COURSE OF THE BUYER’S BUSINESS.

LAUNCH electronic product is warranted against defects in materials and

workmanship for one year (12 months) from date of delivery to the user.

This warranty does not cover any part that has been abused, altered, used for a

purpose other than for which it was intended, or used in a manner inconsistent

with instructions regarding use. The exclusive remedy for any automotive meter

found to be defective is repair or replacement, and LAUNCH shall not be liable

for any consequential or incidental damages.

Final determination of defects shall be made by LAUNCH in accordance with

procedures established by LAUNCH. No agent, employee, or representative of

LAUNCH has any authority to bind LAUNCH to any af¿rmation, representation,

or warranty concerning LAUNCH automotive meters, except as stated herein.

Order Information

Replaceable and optional parts can be ordered directly from your LAUNCH

authorized tool supplier. Your order should include the following information:

1. Quantity

2. Part number

3. Item description

Customer Service

If you have any questions on the operation of the unit, please contact local

dealer, or contact LAUNCH TECH. CO., LTD.:

Website: www.x431.com

www.cnlaunch.com

Phone: +86 755 8455 7891

EN

Email: overseas.service@cnlaunch.com

Statement: >hN, ƌeseƌǀes the ƌiŐhts to ŵaŬe any chanŐe to this ŵanual ǁithout

notice te haǀe tƌieĚ ouƌ ďest to ŵaŬe the Ěescƌiptions anĚ illustƌations in the

ŵanual as accuƌate as possiďle anĚ Ěefects aƌe ineǀitaďle if you haǀe any Ƌ

please contact local Ěealeƌ oƌ >hN, T, K >T >hN, Ěoes not ďeaƌ any

ƌesponsiďility aƌisinŐ fƌoŵ ŵisunĚeƌstanĚinŐs

uesƟon

33

Page 40

Page 41

FCC Warning:

This device complies with part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Any Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the

equipment.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates uses and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

-Consult the dealer or an experienced radio/TV technician for help.

The device has been evaluated to meet general RF exposure requirement.

The SAR limit of USA (FCC) is 1.6 W/kg averaged over one gram of tissue.

Device types Professlonal Diagnostic Tool with model Creader Professional

123i, Creader Professional 129i, Millennium Master (FCC ID: XUJCRP12X)

has also been tested against this SAR limit. The highest reported SAR values

for body-worn is 0.94W/kg. This device was tested for typical body-worn

operations with the back of the handset kept 0mm from the body. The use of

accessories that do not satisfy these requirements may not comply with FCC

RF exposure requirements, and should be avoided.

Loading...

Loading...