Page 1

Version: V1.01.000

Revised date: 2013-04-16

NOTES:

Carefully read the user manual before using, and keep it well for future

reference.

Carefully check the device parts list before using. For any doubt, contact

Launch distributor immediately.

Due to the product upgrade, tiny difference between the user manual and

the device will not be further noticed. Take the device as standard.

Page 2

LAUNCH BST-460 Battery System Tester User Manual

i

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference

that may cause undesired operation.

Page 3

LAUNCH BST-460 Battery System Tester User Manual

ii

Copyright Information

Copyright © 2013 by LAUNCH TECH. CO., LTD. All rights reserved. No part of

this publication may be reproduced, stored in a retrieval system, or transmitted

in any form or by any means, electronic, mechanical, photocopying, recording

or otherwise, without the prior written permission of LAUNCH. The information

contained herein is designed only for the use of this unit. LAUNCH is not

responsible for any use of this information as applied to other units.

Neither LAUNCH nor its affiliates shall be liable to the purchaser of this unit or

third parties for damages, losses, costs, or expenses incurred by purchaser or

third parties as a result of: accident, misuse, or abuse of this unit, or

unauthorized modifications, repairs, or alterations to this unit, or failure to

strictly comply with LAUNCH operating and maintenance instructions.

LAUNCH shall not be liable for any damages or problems arising from the use

of any options or any consumable products other than those designated as

Original LAUNCH Products or LAUNCH Approved Products by LAUNCH.

Trademark Information

LAUNCH is a registered trademark of LAUNCH TECH CO., LTD. (also called

LAUNCH for short) in China and other countries. All other LAUNCH

trademarks, service marks, domain names, logos, and company names

referred to in this manual are either trademarks, registered trademarks, service

marks, domain names, logos, company names of or are otherwise the property

of LAUNCH or its affiliates. In countries where any of the LAUNCH trademarks,

service marks, domain names, logos and company names are not registered,

LAUNCH claims other rights associated with unregistered trademarks, service

marks, domain names, logos, and company names. Other products or

company names referred to in this manual may be trademarks of their

respective owners. You may not use any trademark, service mark, domain

name, logo, or company name of LAUNCH or any third party without

permission from the owner of the applicable trademark, service mark, domain

name, logo, or company name. You may contact LAUNCH by visiting the

website at www.cnlaunch.com, or writing to LAUNCH TECH. CO., LTD.,

Launch Industrial Park, North of Wuhe Avenue, Banxuegang, Bantian,

Longgang, Shenzhen, Guangdong, P.R.China, to request written permission to

use Materials on this manual for purposes or for all other questions relating to

this manual.

Page 4

LAUNCH BST-460 Battery System Tester User Manual

iii

Table of Contents

Chapter 1 Product Summary .................................................................... 1

1.1 Product Profile .............................................................................. 1

1.2 Product Function ........................................................................... 1

1.3 Technical Parameters ................................................................... 2

1.4 Working Environment Requirement .............................................. 3

Chapter 2 Tester Structure ....................................................................... 4

Chapter 3 Operation .................................................................................. 5

3.1 Pre-Test ........................................................................................ 5

3.1.1 Connect Tester .................................................................. 5

3.1.2 Key Description ................................................................. 5

3.2 Tester Startup ................................................................................ 6

3.3 Battery Test ................................................................................... 7

3.3.1 IN-VEHICLE or OUT-OF-VEHICLE ................................... 7

3.3.2 Select Battery Charge State .............................................. 8

3.3.3 Select Battery Type............................................................ 9

3.3.4 Battery System Standard and Rating ............................... 10

3.3.5 Battery Test Result........................................................... 12

3.4 Cranking Test .............................................................................. 14

3.5 Charging System and Rectifier Diode Test.................................. 15

3.6 24V System Test ......................................................................... 18

3.7 Additional Functions .................................................................... 19

3.7.1 Select Language .............................................................. 19

3.7.2 Voltmeter ......................................................................... 19

3.7.3 Screen Light Adjustment .................................................. 20

Chapter 4 Daily Maintenance ................................................................. 21

4.1 Troubleshooting .......................................................................... 21

4.1.1 Screen Not Light ...................................................................... 21

Page 5

LAUNCH BST-460 Battery System Tester User Manual

1

Chapter 1 Product Summary

1.1 Product Profile

BST -460 Battery Tester adopts the state-of-the-art conductance testing

technology in the world to easily, quickly and accurately measure the actual

cold cranking amps capability of the vehicle starting battery, healthy state of

the battery itself, and common fault of the vehicle starting system and charging

system, which can help maintenance personnel to find the problem quickly and

accurately, thus to achieve quick vehicle repair.

1. Test all automotive cranking lead acid battery, including ordinary lead acid

battery, AGM flat plate battery, AGM spiral battery, and Gel battery, etc.

2. Directly detect bad cell battery.

3. Feature reverse polarity protection: reverse connection may not damage

the tester or affect the vehicle and battery.

4. Directly test the battery with loss of electricity, full charge is not required

before testing.

5. Testing standards cover the majority of world's battery standards, such as

CCA, BCI, CA, MCA, JIS, DIN, IEC, EN, SAE and GB.

6. Support multi-languages, customer can select different language package,

which includes: Chinese Simple, Chinese Traditional, English, Japanese,

Russian, Spanish, French, Italian, German, etc. Other languages can also

be customized according to user's need.

1.2 Product Function

BST -760 battery tester features the following functions: battery test, cranking

test, charging test and other additional functions.

Battery test mainly aims to analyze the battery healthy status to calculate the

actual cold cranking capability of the battery and the aging extent, which

provide reliable analysis evidence for the test and maintenance of the battery.

It may notify the user to replace battery in advance when the battery gets

aged.

Page 6

LAUNCH BST-460 Battery System Tester User Manual

2

Cranking test is used to test and analyze the starting motor. Testing the actual

required cranking current and cranking voltage of the starting motor is helpful

to determine whether the starting motor works properly or not. If the starting

motor runs improperly, find the possible reasons: lubricating system

malfunction may cause an increased starting loaded torque; or rotor friction of

the starting motor generates an increasing friction of the starting motor itself.

Charging test is to check and analyze the charging system, including

generator, rectifier, rectifier diode, etc., thus to find out whether the output

voltage of the generator is normal, the rectifier diode works properly and the

charging current is normal. In case one of the above mentioned parts is

abnormal, it will lead to over charge or incomplete charge of the battery, thus

cause quick damage to the battery and greatly shorten the life of other loaded

appliance.

Additional functions include: Set language, Set voltmeter and screen

brightness adjustment.

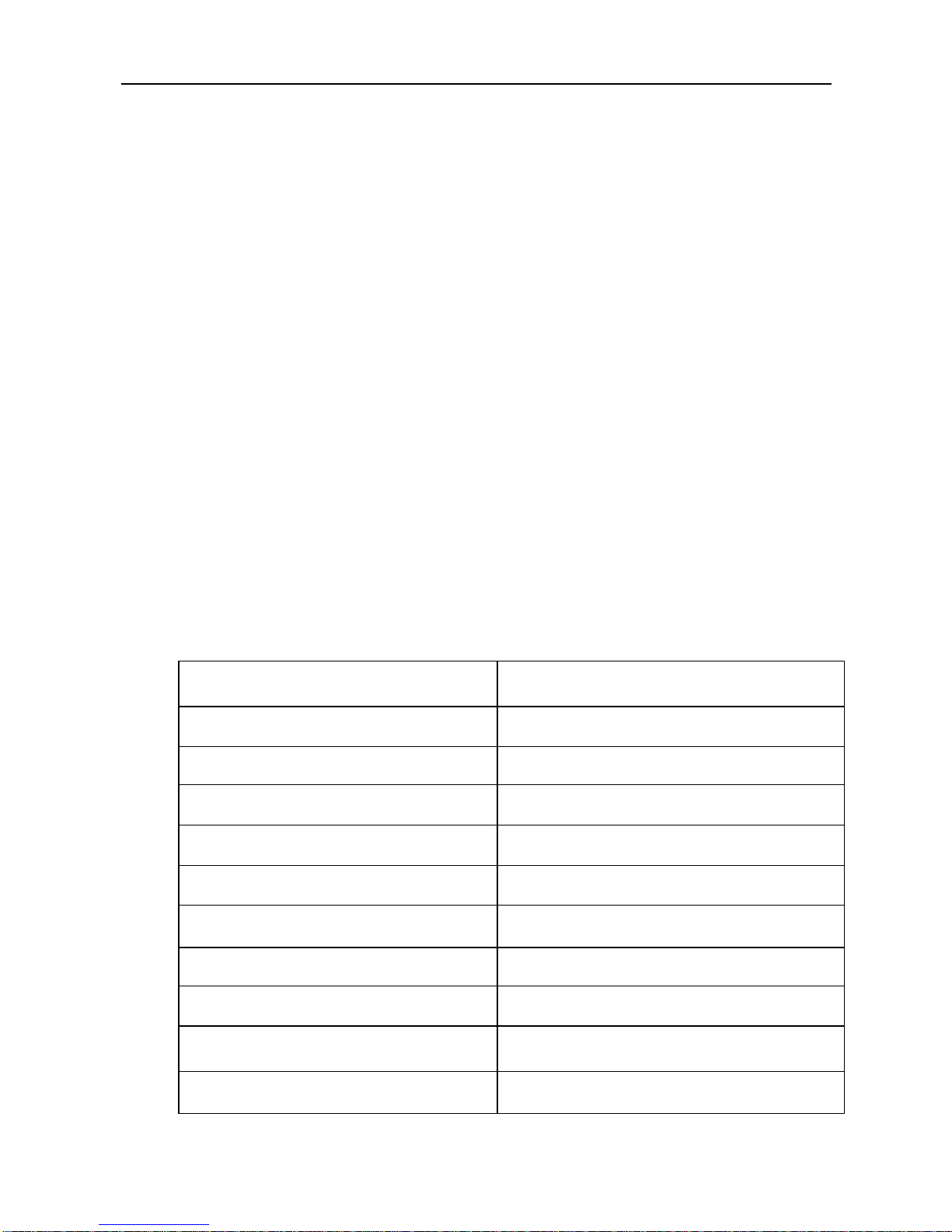

1.3 Technical Parameters

1. Cold Cranking Amps Measurement Range:

Measurement Standard

Measurement Range

CCA

100-2000

BCI

100-2000

CA

100-2000

MCA

100-2000

JIS

26A17--245H52

DIN

100-1400

IEC

100-1400

EN

100-2000

SAE

100-2000

GB

100-1400

Page 7

LAUNCH BST-460 Battery System Tester User Manual

3

2. Voltage Measurement Range: 8-30VDC

1.4 Working Environment Requirement

Working Environment Temp.: -20°C-55°C /-4°F-131°F

It is applicable for automotive manufacturers, automotive maintenance and

repair workshops, automotive battery factories, automotive battery distributors,

and educational organizations, etc.

Page 8

LAUNCH BST-460 Battery System Tester User Manual

4

Chapter 2 Tester Structure

BST -460 mainly consists of battery tester main unit and testing cables.

BST -460 Battery Tester main unit cover is made of ABS acid-resistant plastic.

Removable testing cables

Page 9

LAUNCH BST-460 Battery System Tester User Manual

5

Chapter 3 Operation

3.1 Pre-Test

3.1.1 Connect Tester

Before test, clean battery poles with metal wire brush and

alkaline detergent to avoid the tolerance caused by oil and dust

to the test result.

For Group31 or side-installed battery, install and fix the terminal

wiring connector. Otherwise, inaccurate test result will be

caused due to wrong installation or dirty or bad wiring

connectors.

While testing, ensure none of the in-vehicle electrical appliance

is on, doors are closed and the ignition key is in OFF status.

Connect the red test clamp with battery anode and the black one

with cathode.

Shake the clamps back and forth to make sure they are well

connected.

The tester requires the two clamps are well connected with the

battery poles. Otherwise, the tester cannot power on. In this case,

clean the poles and re-connect it properly.

Tester has reverse connection protection function. When clamps are

reversely connected, tester screen will not light, but it damages

neither the tester nor the automotive load.

NOTE: For parallel connected batteries, break off the cathode

connection first, then do single test to each battery. Suppose

cathode connection is not cut off, there will be error in test result.

3.1.2 Key Description

● Up / Down keys

Select upwards or downwards via white UP and DOWN keys.

Page 10

LAUNCH BST-460 Battery System Tester User Manual

6

● Return key

Return to previous menu via blue RETURN key.

● OK key

Confirm the selection via green OK key

● MENU key

Enter additional function program via MENU key.

3.2 Tester Startup

The tester automatically starts up after the clamps are correctly

connected, and displays the Launch startup interface (Default

voltmeter is ON) refer to figure 1.

Figure 1, Startup Interface with Voltmeter on

By default, the voltmeter value at the middle bottom of the startup

interface can be used as DC voltmeter. The measurement range of

DC Voltmeter is 8-30DCV, out of which will damage the tester.

Voltmeter function can be set as "OPEN/CLOSE" in “ Set voltmeter”

under Additional Functions.

If Voltmeter is OPEN and no activities are made on the tester after

startup, the screen will remain as the startup interface all the time. In

this case, it can be used as a DC Voltmeter. When OK key is pressed,

tester enters the battery test program. Press MENU key, it enters

additional function program.

When Voltmeter is OFF, the startup interface will display as figure 2.

After 2 seconds, it automatically enters the battery test program.

Press MENU key within this 2 seconds, it enters additional function

program.

Key Photo

Page 11

LAUNCH BST-460 Battery System Tester User Manual

7

Figure 2, Startup Interface with Voltmeter off

3.3 Battery Test

After entering battery test program, the tester will display the tester

model and version approx. 2 seconds, see figure 3.

Figure 3, Interface with tester model and version

The tester will display the following contents in a sequence, select

the desired items accordingly.

3.3.1 IN-VEHICLE or OUT-OF-VEHICLE

Press UP/DOWN key to select the battery location, in-vehicle or out-

-of-vehicle, then press OK key to confirm.

1) IN-VEHICLE means the battery is connected with vehicle engine or

vehicle electrical appliance.

When the tester detects surface charge, a prompt message

"SURFACE CHARGE DETECTED, TURN LIGHTS ON" will appear on

the screen.

Page 12

LAUNCH BST-460 Battery System Tester User Manual

8

Follow the instructions to turn lights on to eliminate battery surface

charge, the tester will then display the following messages in a

sequence:

Now the tester detects the surface charge has been eliminated, turn

lights off as prompted, then press OK key. The tester will recover

automatic test.

2) OUT-OF-VEHICLE means battery is not connected with any of the

vehicle load, namely, battery connection is cut off.

3.3.2 Select Battery Charge State

After selecting the battery location, the tester will prompt to select the

battery charge status, i.e. Before Charging or After Charging.

Press UP/DOWN key to select, then press OK key to confirm. In this

Page 13

LAUNCH BST-460 Battery System Tester User Manual

9

way, it ensures a more accurate test result.

NOTE: In case of In-Vehicle, select Before Charging for Cold Vehicle

and After Charging for Hot Vehicle.

3.3.3 Select Battery Type

After the battery charge status is chosen, the tester will enter battery

type selection interface: Regular Flooded, AGM Flat Plate, AGM

Spiral or Gel battery. Press UP/DOWN key to select, and press OK

key to confirm.

Page 14

LAUNCH BST-460 Battery System Tester User Manual

10

When it's IN-VEHICLE test, battery installation type shall also be

selected, e.g. TOP POST, SIDE POST or REMOTE (This selection

does not apply to OUT-OF-VEHICLE), then press OK key to confirm.

REMOTE is applicable to some in-vehicle battery which is too tightly

installed to use the test clamps to connect the battery poles.

NOTE: For REMOTE test, tolerance may exist. For any doubt, remove

the battery and select "OUT-OF-VEHICLE" to re-test.

3.3.4 Battery System Standard and Rating

BST-460 battery tester will test each battery according to the

selected system and rating.

Use UP/DOWN key to select according to the actual system standard

and rating marked on the battery. See the arrow position as indicated

Page 15

LAUNCH BST-460 Battery System Tester User Manual

11

in the below picture.

CCA: Cold Cranking Amps, specified by SAE&BCI, most frequently

used value for starting battery at 0°F (-18°C).

BCI: Battery Council International standard

CA: Cranking Amps standard, effective starting current value at

0°C

MCA: Marine Cranking Amps standard, effective starting current value

at 0°C.

JIS: Japan Industrial Standard, displayed on the battery as combination of

the numbers and letters, e.g. 55D23, 80D26.

DIN: German Auto Industry Committee Standard

IEC: Internal Electro technical Commission Standard

EN: European Automobile Industry Association Standard

SAE: Society of Automotive Engineers Standard

GB: China National Standard

Rating range is as follows:

Measurement Standard

Measurement Range

CCA

100-2000

Page 16

LAUNCH BST-460 Battery System Tester User Manual

12

BCI

100-2000

CA

100-2000

MCA

100-2000

JIS

26A17--245H52

DIN

100-1400

IEC

100-1400

EN

100-2000

SAE

100-2000

GB

100-1400

Input correct test standard and rating, press OK key, the tester starts

to test and a screen similar to the following figure will appear:

It takes around 3 seconds to display the battery test result.

3.3.5 Battery Test Result

Battery test result is mainly classified into 5 types:

1) Good Battery

Page 17

LAUNCH BST-460 Battery System Tester User Manual

13

The battery is in good health, please be free to use!

NOTE:

SOH means State of Health

SOC means State of Charge

2) Good, Recharge

The battery is good but with low power. Please recharge it before

using.

3) Replace

The battery is near to or already reached the end of its service life,

replace it immediately, otherwise, potential hazard will be followed.

4) Bad Cell, Replace

Page 18

LAUNCH BST-460 Battery System Tester User Manual

14

The battery has internal damage, broken cell or short circuit, please

replace it.

5) Charge, Retest

Unstable battery shall be recharged and retested to avoid error. If

same test result appears after recharge and retest, the battery is

regarded as damaged, please replace it.

Attention: If "Replace" resulted from IN-VEHICLE mode, it might be

the reason that vehicle cable is not well connected with the battery.

Ensure to cut off the cable and retest the battery under

OUT-OF-VEHICLE before making a decision to replace battery.

NOTE: To exit after testing, press RETURN key to directly return to

the startup interface.

After testing: if it's "IN-VEHICLE" mode, press OK key to enter

Cranking Test.

3.4 Cranking Test

Tester prompts as following:

Page 19

LAUNCH BST-460 Battery System Tester User Manual

15

NOTE: While the system prompts you to start engine, pressing

RETURN key can not exit the current interface.

Follow the on-screen instructions to start the engine, the tester will

automatically complete the cranking test and display the result.

Generally, cranking voltage lower than 9.6V is regarded as abnormal

and it is OK if it is higher than 9.6V.

Test result of the tester includes actual cranking voltage, cranking

amps, and actual cranking time.

When cranking test is abnormal, battery test result will be displayed.

See below picture:

It is convenient for maintenance personnel to quickly know the whole

state of the starting system according to the data.

After testing finished, do not shut down the engine, press OK key to

enter Charging Test.

3.5 Charging System and Rectifier Diode Test

When enter the charging test, the tester will display "Charging Test?"

Page 20

LAUNCH BST-460 Battery System Tester User Manual

16

NOTE: To exit when this prompt message appears on the screen,

misfire the engine and press RETURN key after about 50 seconds.

Press OK key to start the charging test.

NOTE: Do not shut down the engine during the test. All electrical

appliance and device are in OFF state. Turning on/off any electrical

appliance in the vehicle during the test will affect the accuracy of the

test result.

The tester will do the following tests in sequence:

For ripple test, the tester will present the real time waveform and

ripple volt and charging volt values are displayed at the bottom line.

It takes approx. 6 seconds for the ripple test.

After the ripple test, the tester will automatically start the loaded

voltage test. See below picture:

Loaded Volt Test takes approx. 3 seconds, and then the "INCREASE

REV" prompt will appear on the screen. See below picture:

Page 21

LAUNCH BST-460 Battery System Tester User Manual

17

Operate accordingly to increase the engine rotating speed to above

3000 revolutions, and keep it for 5 seconds.

The tester starts the charging volt test after an increased revolution is

detected. See below picture:

After the test finished, the tester displays the valid charging volts,

ripple test result and charging test result. See below picture:

NOTE: If no increased rev is detected, it shall be the fault of generator

regulator or connection with battery failed. The tester will try 3 times

to further detect, if still failed, it will skip the increase rev detect and

the test result displays "No Output". See below picture:

Check the connection between generator and battery, then retest.

Charging Test Result:

1) Charging Volt: Normal

Charging system shows the generator’ s output is normal, no

Page 22

LAUNCH BST-460 Battery System Tester User Manual

18

problems are detected.

2) Charging Volt: Low

Charging volt of the charging system is low.

Check whether slip or running off occurs on the generator drive belt.

Check the connection between generator and battery is normal or not.

If both of the drive belt and the connection are in good condition,

follow the manufacturer's suggestion to eliminate generator fault.

3) Charging Volt: High

Generator output volt is high.

Since most of the vehicle generators are using built-in regulator, the

generator assembly has to be replaced. (For some old style cars using

external regulator, directly replace the regulator.)

The normal high volt of the voltage regulator is maximum 14.7±0.5V.If

charging volt is too high, it will overcharge the battery. Therefore, the

battery life will be shortened and troubles will be caused.

4) No Volt Output:

No generator volt output is detected. Check whether the generator

connecting cable, the drive belt of generator and engine are normal or

not.

5) Diode Test:

Through the test of charging current ripple, the tester will find out

whether the diode works properly or not. When ripple volt is too high,

it indicates at least one diode is damaged. Check and replace the

diode.

Till now, all tests have been done.

3.6 24V System Test

Ordinary 24V battery group combines two 12V batteries in series

connection. Therefore, when testing 24V battery, the tester will

prompt "24V Battery", divide the batteries and test one by one. It's not

necessary to break off the connecting cable (Comparatively, the

parallel connected battery group must cut off the cathode connection),

test method is same as testing single 12V battery.

Page 23

LAUNCH BST-460 Battery System Tester User Manual

19

For 24V charging and cranking tests, connect the red clamp to the

anode of 24V battery group and the black one to the cathode of 24V

battery group (NOTE: it's not the anode and cathode of the single

battery but battery group), select IN-VEHICLE and the screen

displays "24V Battery". Ignore the prompt and after 3 seconds, the

tester will skip battery test program and enter the cranking test

directly. Follow the method of 12V system test to complete the 24V

charging and cranking tests. The test process is same as 12V system.

3.7 Additional Functions

3.7.1 Select Language

This option lets you to select user interface language.

System contains multi-language package, including Chinese, English,

Russian, Japanese, Spanish, German, French, Italian, etc.

Once finished, it shows "OK" for 2 seconds, then return to the

previous interface.

3.7.2 Voltmeter

BST-460 Battery Tester can also be used as DC voltmeter.

The working range is 8VDC-30VDC.

CAUTION: BST-460 Tester may be damaged when connected to

voltage above 30V!

Page 24

LAUNCH BST-460 Battery System Tester User Manual

20

This function enables you to set the voltmeter On/Off at the bottom

line of the startup interface.

If successful, it shows "OK" for 2 seconds, then return to the previous

interface.

3.7.3 Screen Light Adjustment

This item enables you to adjust the screen backlight brightness for

power saving and for clear view of the displayed characters under the

sunlight.

Brightness range is adjustable from 1-4. Default brightness value is 2.

Press UP/DOWN key to set. Once finished, it shows "OK" for 2 seconds and

then returns to the previous interface.

Page 25

LAUNCH BST-460 Battery System Tester User Manual

21

Chapter 4 Daily Maintenance

4.1 Troubleshooting

4.1.1 Screen Not Light

Check whether the battery is well connected or reverse

connection between the positive pole and negative pole exists

or not.

Check whether the test cable is broken off or dropped down.

Page 26

LAUNCH BST-460 Battery System Tester User Manual

Warranty

THIS WARRANTY IS EXPRESSLY LIMITED TO PERSONS WHO

PURCHASE LAUNCH PRODUCTS FOR PURPOSES OF RESALE OR USE

IN THE ORDINARY COURSE OF THE BUYER’S BUSINESS.

LAUNCH electronic product is warranted against defects in materials and

workmanship for one year from date of delivery to the user.

This warranty does not cover any part that has been abused, altered, used for

a purpose other than for which it was intended, or used in a manner

inconsistent with instructions regarding use. The exclusive remedy for any

automotive meter found to be defective is repair or replacement, and LAUNCH

shall not be liable for any consequential or incidental damages.

Final determination of defects shall be made by LAUNCH in accordance with

procedures established by LAUNCH. No agent, employee, or representative of

LAUNCH has any authority to bind LAUNCH to any affirmation, representation,

or warranty concerning LAUNCH automotive meters, except as stated herein.

Disclaimer

The above warranty is in lieu of any other warranty, expressed or implied,

including any warranty of merchantability or fitness for a particular purpose.

Purchase Order

Replaceable and optional parts can be ordered directly from your LAUNCH

authorized tool supplier. Your order should include the following information:

Order quantity

Part number

Part name

Customer Service

Any question during the operation, please call +86-755-84528722.

If your unit requires repair service, return it to the manufacturer with a copy of

the sales receipt and a note describing the problem. If the unit is determined to

be in warranty, it will be repaired or replaced at no charge. If the unit is

Page 27

LAUNCH BST-460 Battery System Tester User Manual

determined to be out of warranty, it will be repaired for a nominal service

charge plus return freight. Send the unit pre-paid to:

Attn: Customer Service Department

LAUNCH TECH. CO., LTD.

Launch Industrial Park,

North of Wuhe Avenue,

Banxuegang, Bantian,

Longgang, Shenzhen, Guangdong

P.R.China, 518129

Launch website: http://www. cnlaunch.com

http://www.x431.com

Statement:

LAUNCH reserves the rights to make any change to product designs and

specifications without notice. The actual object may differ a little from the

descriptions in the manual in physical appearance, color and configuration. We

have tried our best to make the descriptions and illustrations in the manual as

accurate as possible, and defects are inevitable, if you have any question,

please contact local dealer or after-sale service center of LAUNCH, LAUNCH

does not bear any responsibility arising from misunderstandings.

Loading...

Loading...