Operating instructions

PROLINE

Low-temperature Thermostats

with SmartCool System

RP 845, RP 855, RP 870, RP 890, RP 1290

RP 1840, RP 1845, RP 3530

Valid from series: 07-0001 (see item 9.4)

YACE0072 / 08/07

replaced 04-0001

from softwareversion of Control system (Master) 1.46

from softwareversion of Protection system (Master) 1.33

from softwareversion of Operating system (Command) 1.69

from softwareversion of Cooling system 1.44

from softwareversion of Analogue interface 1.33

from softwareversion of RS232/485-Module 1.38

from softwareversion of contact I/0 module 1.38

from softwareversion of solenoid valve 1.37

LAUDA DR. R. WOBSER

GMBH & CO. KG

P.O.Box 1251

97912 Lauda-Koenigshofen

Germany

Phone: (+49) 9343/ 503-0

Fax: (+49) 9343/ 503-222

E-Mail info@lauda.de

Internet http://www.lauda.de

Proline Low-temperature Thermostats

Safety notes

Before operating the equipment, please read carefully all the instructions and safety

notes in Section 1.

If you have any questio

Follow the instructions on setting up, operation etc. This is the only way to avoid

incorrect operation of the equipment and to ensure full warranty protection.

ns, please phon

e us!

The Operating Instructions include additional safety notes, which are identified by a triangle

with an exclamation mark. Carefully read the instructions and follow them accurately !

Disregarding the instructions may have serious consequences, such as damage to the

equipment, damage to property or injury to personnel!

• Transport the equipment with care!

The unit may NEVER be overturned nor put upside down!

• Equipment and its internal parts can be damaged:

− by dropping,

− by shock.

• Technically qualified personnel must only operate the equipment!

• Never operate the equipment without the heat carrier liquid!

• Do not start up the equipment if:

− it is damaged or leaking,

− cable (not only supply cable) is damaged.

• Switch off the equipment and pull out the mains plug:

− for servicing or repair,

− moving the equipment

• Drain the bath before moving the equipment!

• Do not carry out any technical changes on the device!

• Have the equipment serviced or repaired by properly qualified personnel only!

We reserve the right to make technical alterations!

YACE0072 / 21.08.07 Safety notes 3

Proline Low-temperature Thermostats

Contents

1 SAFETY INFORMATION............................................................................................................................................8

1.1 GENERAL SAFETY INFORMATION............................................................................................................................... 8

1.2 OTHER SAFETY INFORMATION...................................................................................................................................8

2 BRIEF OPERATING INSTRUCTIONS..................................................................................................................... 9

2.1 MENU STRUCTURE: MASTER...................................................................................................................................10

2.2 MENU STRUCTURE: COMMAND ............................................................................................................................... 11

3 CONTROLS AND FUNCTIONAL ELEMENTS.....................................................................................................12

4 UNIT DESCRIPTION.................................................................................................................................................15

4.1 ENVIRONMENTAL CONDITIONS................................................................................................................................ 15

4.2 TYPES OF UNIT ........................................................................................................................................................15

4.3 VARIOFLEX PUMP ...................................................................................................................................................15

4.4 MATERIALS.............................................................................................................................................................16

4.5 TEMPERATURE DISPLAY, CONTROL AND SAFETY CIRCUIT ....................................................................................... 16

4.6 PROGRAMMER AND RAMP FUNCTION ...................................................................................................................... 17

4.7 INTERFACES ............................................................................................................................................................17

4.8 INTERFACE MODULES (ACCESSORIES) .....................................................................................................................17

4.9 COOLING UNIT.........................................................................................................................................................18

4.10 AVOIDANCE OF DEWING..........................................................................................................................................18

4.11 HEATER RATING AND POWER CONSUMPTION FROM THE MAINS............................................................................... 18

5 UNPACKING............................................................................................................................................................... 19

6 PREPARATION...........................................................................................................................................................20

6.1 ASSEMBLY AND SITING ........................................................................................................................................... 20

6.2 FILLING AND DRAINING...........................................................................................................................................21

6.3 HEAT CARRIER LIQUIDS AND HOSE CONNECTIONS...................................................................................................22

6.4 CONNECTING EXTERNAL LOADS..............................................................................................................................24

7 STARTING UP.............................................................................................................................................................25

7.1 MAINS CONNECTION ............................................................................................................................................... 25

7.2 SWITCHING ON ........................................................................................................................................................25

7.3 SWITCHING OFF / STANDBY .....................................................................................................................................27

7.4 KEY FUNCTIONS ...................................................................................................................................................... 27

7.4.1 General key functions and pilot lamps ...........................................................................................................27

7.4.2 Changing window information (Command Console).....................................................................................31

7.4.3 Locking the keyboard .....................................................................................................................................32

7.5 "MASTER" MENU STRUCTURE .................................................................................................................................34

7.6 "COMMAND" MENU STRUCTURE.............................................................................................................................. 35

7.6.1 Basic settings and branching to submenus (Master)......................................................................................36

7.6.2 Submenu

7.6.3 Submenu

7.6.4 Submenu

7.6.5 Submenu

7.6.6 Submenu

7.6.7 Submenu

chains (adjustment)........................................................................................................................................................43

7.6.8 Submenu

7.6.9 Submenu

7.6.9 Submenu

7.6.10 Submenu

7.6.11 Submenu

LMDkt

(Master): Branching to further submenus...........................................................................37

LMnet

(Master): Configuration of modules ...................................................................................38

LMDkt Æ O@pALMDkt Æ O0c-LMDkt Æ O0c-LMDkt Æ B@K--

LMDkt Æ RgmY

LMnet Æ RDC-LMnet Æ RDC-LMnet Æ B/<PLMnet Æ B/<P- Æ RgmY

(Master): Configuration of device parameters...................................................39

(Master): Setting internal control parameters................................................... 40

(Master): Setting external control parameters...................................................41

(Master): Calibrating internal and external Pt100 temperature probe measuring

\ (Master): Displaying internal values of the thermostat.......................................44

(Master): Safety system settings.........................................................................46

(Master): Safety system settings.........................................................................47

(Master): Refrigerating system settings.............................................................48

\ (Master): Displaying refrigerating system settings...........................49

4 Contents YACE0072 / 21.08.07

Proline Low-temperature Thermostats

7.6.12 Submenu

7.7 IMPORTANT SETTINGS..............................................................................................................................................52

7.7.1 Temperature setpoint setting...........................................................................................................................52

7.7.2 Displaying the actual external temperature....................................................................................................54

7.7.3 Setting pump power or standby.......................................................................................................................55

7.7.4 Activating external control .............................................................................................................................56

7.7.5 Current consumption from the mains..............................................................................................................57

7.7.6 Setting the date and time (Command).............................................................................................................59

7.7.7 Display resolution setting (Command)...........................................................................................................59

7.8 SPECIAL SETTINGS ...................................................................................................................................................60

7.8.1 Setpoint resolution..........................................................................................................................................60

7.8.2 Defining the type of start mode.......................................................................................................................60

7.8.3 Defining temperature limits............................................................................................................................62

7.8.4 Setpoint offset operating mode........................................................................................................................63

7.8.5 Restoring works settings.................................................................................................................................65

7.8.6 Setting the volume of the acoustic signals.......................................................................................................67

7.8.7 Entering the offset of the internal temperature probe .....................................................................................68

7.8.8 Restoring the works setting of the internal temperature-probe offset.............................................................69

7.8.9 Entering the offset of the external temperature probe....................................................................................70

7.8.10 Restoring the works setting of the external temperature-probe offset ............................................................71

7.9 GRAPHICAL DISPLAY OF TEMPERATURE MEASUREMENTS (COMMAND)...................................................................72

7.10 PROGRAMMER (PGM ONLY COMMAND) .................................................................................................................74

7.10.1 Program example............................................................................................................................................74

7.10.2 Selecting and starting the program (Start, Hold, Stop) ..................................................................................76

7.10.3 Interrupting, continuing or terminating the program (Hold, Continue, Stop)................................................77

7.10.4 Creating or modifying a program (Edit).........................................................................................................78

7.10.5 Defining the number of program loops (Loops) .............................................................................................82

7.10.6 Viewing the program sequence as a graph (Graph).......................................................................................82

7.10.7 Obtaining information on a program (Info)....................................................................................................83

7.11 RAMP FUNCTION......................................................................................................................................................84

7.12 TIMER FUNCTION (COMMAND)................................................................................................................................85

7.13 CONTROL PARAMETERS...........................................................................................................................................86

7.13.1 Internal control variable (integral measurement probe)................................................................................87

7.13.2 External control variable (External measurement probe)..............................................................................88

7.14 ALARMS, WARNINGS AND ERRORS ......................................................................................................................... 91

7.14.1 Overtemperature protection and checking......................................................................................................91

7.14.2 Low-level alarm and low-level checking.........................................................................................................93

7.14.3 High-level settings..........................................................................................................................................94

7.14.4 High-level warning or alarm..........................................................................................................................95

7.14.5 Pump-motor supervision: Overload or blockage............................................................................................96

7.14.6 Pump-motor supervision: Dry running...........................................................................................................96

7.14.7 Fault list „Alarms and Warnings“..................................................................................................................97

7.15 RS 232 INTERFACE................................................................................................................................................100

7.15.1 Connecting cables and interface test RS 232................................................................................................100

7.15.2 Protocol RS 232............................................................................................................................................100

7.15.3 Connecting cable RS 485..............................................................................................................................101

7.15.4 Protocol RS 485............................................................................................................................................101

7.15.5 Write commands (Data commands to the thermostat)..................................................................................102

7.15.6 Read commands (Data requested from the thermostat) ................................................................................103

7.15.7 Error messages.............................................................................................................................................105

7.15.8 Driver software for LABVIEW®...................................................................................................................105

LMnet Æ B/<P- Æ RDp--

(Master): Displaying refrigerating system settings......................51

8 INTERFACES - MODULES.....................................................................................................................................106

8.1 INSTALLING OF MODULES .....................................................................................................................................106

8.2 MENU STRUCTURE FOR ALL MODULES (ONLY COMMAND) ....................................................................................107

8.3 SERIAL INTERFACES RS232 / 485 ..........................................................................................................................108

8.3.1 Menu structure for RS232 / 485 Interface Module (Master).........................................................................108

8.4 ANALOGUE MODULE..............................................................................................................................................109

YACE0072 / 21.08.07 Contents 5

Proline Low-temperature Thermostats

8.4.1 Menu structure Analogue module (Master)..................................................................................................110

8.5 CONTACT MODULE................................................................................................................................................111

8.5.1 Contact module LRZ 915 with three inputs and three outputs.....................................................................111

8.5.2 Namur-Contact module LRZ 914 with only one input and one output.........................................................112

8.5.3 Menu structure contact module (Master)..................................................................................................... 113

9 MAINTENANCE.......................................................................................................................................................114

9.1 CLEANING.............................................................................................................................................................114

9.2 DEVICE STATUS.....................................................................................................................................................114

9.2.1 Interrogating the device type........................................................................................................................114

9.2.2 Software version...........................................................................................................................................114

9.2.3 Serial numbers..............................................................................................................................................114

9.2.4 Device data................................................................................................................................................... 115

9.2.5 Fault memory (Command)............................................................................................................................115

9.3 SERVICING REPAIR AND DISPOSAL INFORMATIONS ................................................................................................116

9.3.1 Servicing.......................................................................................................................................................116

9.3.2 Repair informations...................................................................................................................................... 117

9.3.3 Disposal informations ..................................................................................................................................117

9.4 HELP DESK AND ORDERING REPLACEMENT PARTS.................................................................................................118

10 ACCESSORIES......................................................................................................................................................119

11 TECHNICAL DATA .............................................................................................................................................121

12 INDEX.....................................................................................................................................................................125

6 Contents YACE0072 / 21.08.07

Proline Low-temperature Thermostats

Explanation of signs:

Danger: This sign is used where there may be injury to

personnel if a recommendation is not followed

accurately or is disregarded.

Note: Here special attention is drawn to some aspect. May

Reference Refers to other information in different sections.

include reference to danger.

Ì

YACE0072 / 21.08.07 Explanation of signs 7

1 Safety information

1.1 General safety information

A laboratory thermostat heats and circulates liquids according to specified parameters. This involves

hazards due to high temperatures, fire and general hazards due to the application of electrical energy.

The user is largely protected by the application of relevant standards.

Further hazard sources may arise due to the type of tempering medium, e.g. by exceeding or

undercutting certain temperature thresholds or by the breakage of the container and reaction with the

heat carrier liquid.

It is not possible to consider all eventualities. They remain largely subject to the judgment and

responsibility of the operator.

The equipment may only be used as prescribed and as described in these operating instructions. This

includes operation by instructed specialist personnel.

The equipment fulfills the following classes of the EMC standard EN 61326-1:1997 VDE 0843-20:

Class A: Operation only on networks without connected domestic areas.

Class B: Equipment for operation on networks with connected domestic areas.

Class B*: Equipment fulfills Class B when a house connection > 100 A is involved. With unfavorable

network conditions disturbing voltage variations may otherwise occur.

The equipment is not

IEC 601-1.

rated for use under medical conditions according to DIN EN 60601-1 or

Proline Low-temperature Thermostats

1.2 Other safety information

• Only connect equipment to PE grounded mains sockets.

• At higher operating temperatures, parts of the bath cover can reach surface temperatures exceeding

70°C. Be careful when touching it Æ Risk of burning!

• Use suitable hoses Ì Section 6.3.

• Secure hose again

• Check hoses from time to time for any possible material fatigue.

• Thermal medium hoses and other hot parts must not come into contact with the mains cable.

• With the use of thermostats as circulating thermostats hot liquid can be emitted when the hose

breaks, presenting a hazard to persons and material.

• If no external load is connected, the pump outflow must be closed (use screw plugs) and the bypass

valve must be set to "internal" Ì 4.3.

•

Take into account the thermal expansion

• Depending on the heat carrier liquid used and the type of operation, toxic vapors can arise. Ensure

suitable extraction.

• When changing the heat carrier liquid from water to a thermal transfer medium for temperatures

above 100°C, carefully remove all water residues, including from the hoses and loads. When doing

this, also open the blanking caps of the pump outputs and inputs and blow compressed air

through all the pump outputs and inputs. Æ Risk of burning due to delay in boiling!

st slippage with the aid of hose clips. Avoid kinks in the hoses.

of the heat carrier oils with increasing bath temperature.

• Withdraw the mains plug before cleaning, maintenance or moving the thermostat.

• Specialist personnel must only carry out repairs in the control section.

• Figures of temperature constancy and display accuracy apply under normal conditions according to

DIN 12876. Electromagnetic high frequency fields may in special cases lead to unfavorable values.

Safety is not impaired.

• The following action may start the thermostat unintentionally from the standby mode: Previously

activated timer mode Ì 7.12, "Start" command via interfaces Ì8.

8 Safety information YACE0072 / 21.08.07

Proline Low-temperature Thermostats

2 Brief operating instructions

These brief instructions shall give you the possibility to operate the unit quickly. For safe

operation of the unit, it is necessary to read carefully all the instructions and safety

notes!

1. Assemble unit and add items as appropriate (Ì 6.1).

The unit may NEVER be overturned nor put upside down!

Take care of the hose tubing con

2. Fill the unit with corresponding heat carrier liquid (Ì 6.3). The units are designed for

operation with non-flammable and flammable liquids to DIN EN 61010-2-010. Æ Take care

of the level of the heat carrier liquid! (Ì 6.2).

nections (Ì 6.3 and 6.4).

Compare the information on the ra

3.

4. Connect the unit only to a socket with a protective earth (PE) connection.

5. Check whether the main fuse-switch at the back

is in the "On =

6. Switch the unit on with the switch

7. With

(Ì 7.14.1).

8. Now you see the current bath temperature

in the displa

If instead, a warning or error message is displayed, then refer to Section 7.14.

–" position.

set the overtemperature cut-off point to a value clearly above room temperature

y, for example:

ting label with the supply details.

at the front.

Bath-temperature

/1%21

°C

YACE0072 / 21.08.07 Brief operating instructions 9

y

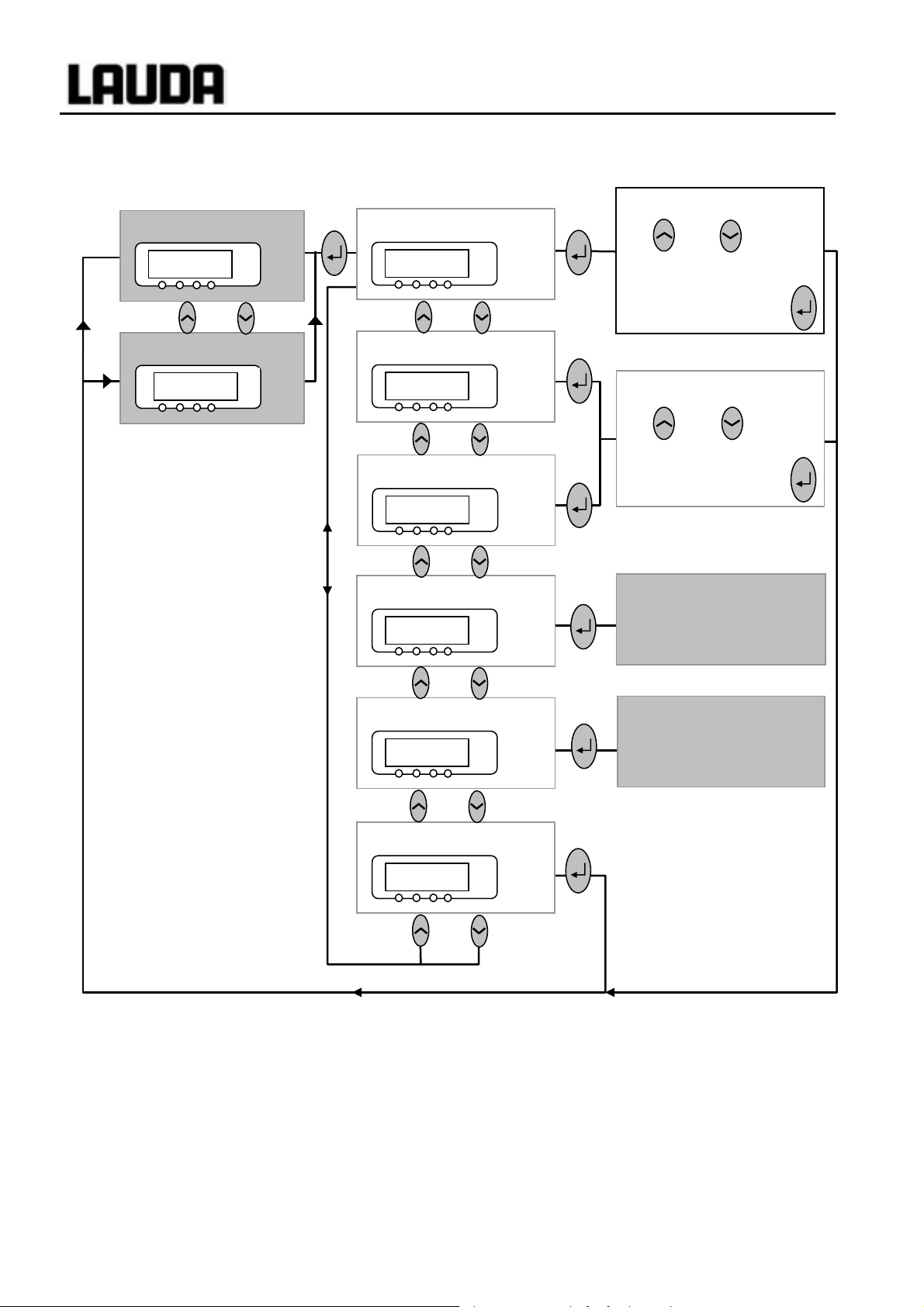

2.1 Menu structure: Master

Bath temperature

1%21

°C

Setpoint

RDr

Proline Low-temperature Thermostats

Display flashes. Set setpoint

with or . Display

°C

is accepted afer 4 sec. or

proceed immediately

with the key:

External temperature

1%/1

EXT

°C

Pump power.1-8/Standby.0

Os 7

Control Intern / Extern

Bml 0

Further settings

LMDkt

Configure modules

LMnet

°C

°C

°C

°C

⇒ Section 7.7.1

Display flashes. Set value

with or . Display

is accepted afer 4 sec. or

proceed immediately

with the ke

⇒ Section 7.7.3

⇒ Section 7.7.4

Control parameters,

setpoint resolution,

setpoint-source input,

calibration, etc.

⇒ Section 7.6.2

Protection system,

Command, cooling system,

analog and RS232 digital

module, etc.

:

To reset the unit to the factory default state which enables basic operation with internal control, there is

the default function in the menu

LMDls Æ O@p@ Æ cDE Ì 7.6.4.

Dlc

End

°C

⇒ Section 7.6.3

10 Brief operating instructions YACE0072 / 21.08.07

Proline Low-temperature Thermostats

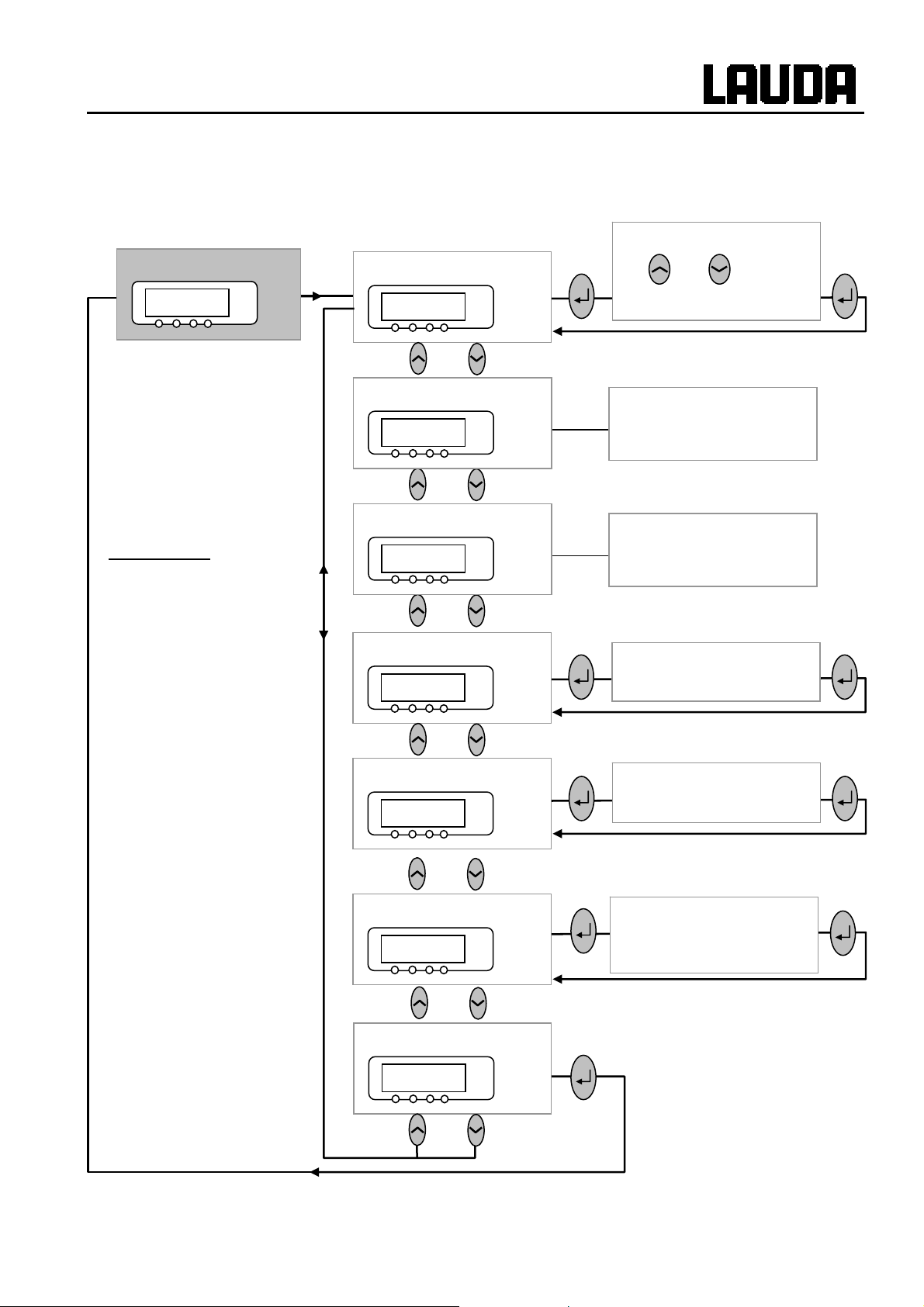

2.2 Menu structure: Command

Menu

Pump

Settings

Clock

Graph

Programmer

Interfaces 1

Control

Limits

1

Ì Capter 8

2

no menu in

Command

Pump Level

Calibration

Works settings

Resolution

Device status

Display data

Basic settings

Overlevel handling

Set time

Set data

Timer 1

Timer 2

Format of date

Settings

Program 1

Program 2

Program 3

Program 4

Program 5

Ramp function

Serial Command

2

serial Master /

Profibus

Analog interfaces

Switching contact

Refill valve

Shut off unit

Smart Cool

off

on

automatic

internal

external Pt100

Analog interface

RS232/485

Control variable

Control parameters

Setpoint offset

T il (min)

T ih (max)

intern Pt100

extern Pt100

All Modules

Master

Command

Cool

Other connected

modules

Device type

Software Version

Serial numbers

Device data

Error store

Basic window

Standard window

Super window

Display

Sounds Master

Sounds Command

Language

Master-Mode

Autostart

Current Consumpt.

Mode

Displayed value

Legend

Sample Time

Time axis

Time base

Temp. scale

Temp. limits

Status

Edit

Loops

Graph

Info

Status

Temp. Change

Time

Time unit

Mode

Baud rate

RS485 address

Control parameters

Control para. sets

Tv manual/auto

Correction limitation

Offset source

Setpoint offset

Calibration

Default

all default

All default

Only control par. int.

Only control par. ext.

Only miscellaneous

Display

Edit

Default

Brightness

Contrast

Alarm

Warning

English

Deutsch

Français

Español

on

off

on

none

Warning

Warn. + Heater off

Alarm

Start / Stop

Hold / continue

Modify

Erase

Show chart

Xp

Tn

Tv (auto)

Td (auto)

Kpe

Tne

Tve (auto)

Tde (auto)

Xpf

Prop_E(a)

Automatic

Manual

off

external Pt100

RS 232

YACE0072 / 21.08.07 Brief operating instructions 11

)

Suctio

etu

bath)

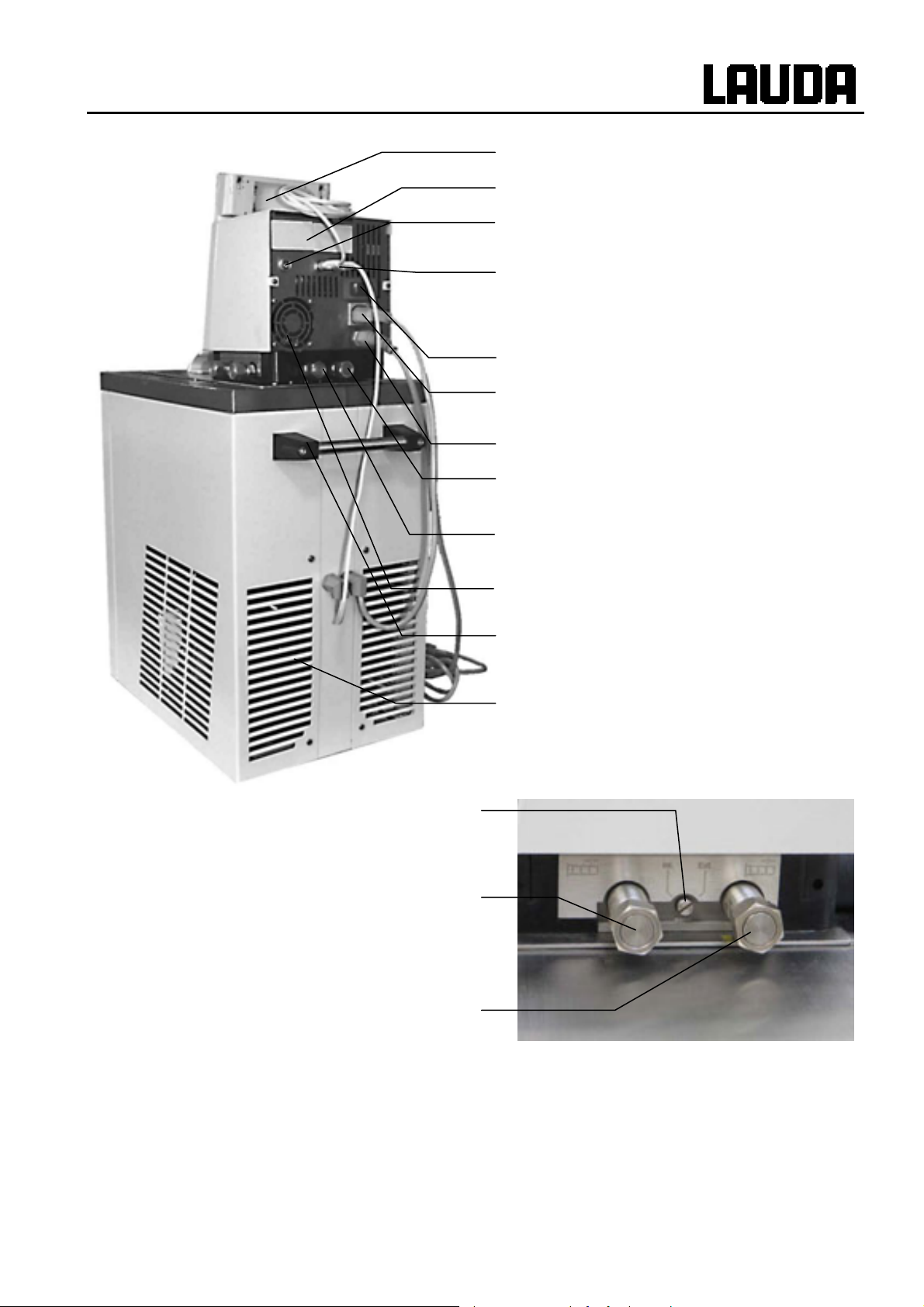

3 Controls and functional elements

Proline Low-temperature Thermostats

Mobile Command Console (see page 14

Master control panel (see page 14)

Mains switch

Pump connection at side:

n nozzle (r

Bypass valve (see illustration on next page)

Side pump connection:

Pump outflow, pressure output

Bath cover

Recessed grip

rn to

Front cover (open)

Bath drain nozzle

Bath drain tap

Grille (on both sides)

Front cover (closed)

Transport rollers (concealed)

Feet (concealed)

Condenser

12 Controls and functional elements YACE0072 / 21.08.07

Proline Low-temperature Thermostats

00

y

Mobile Command Console (see next page)

Covers for the two module slots

Connection socket 10S

for the external Pt1

Connection socket 70S (LAUDA internal bus

(LiBus)) for bus suitable for unit and to which

the refrigerating lower section, the integrated

electricall

Main fuse-switch

Connection socket 51H for refrigerating lower

section

Mains connecting lead

Rear pump connection:

Suction nozzle (return to bath)

heated cover plate and Command

temperature probe

Bypass valve

(in "external" position)

Side pump connection:

Pump outflow, pressure output

(closed off with screw plug)

Rear pump connection:

Pump outflow, pressure output

Air intake for electronic head

Transport handle

Rear grid

Side pump connection:

Suction nozzle (return to bath)

(closed off with screw plug)

YACE0072 / 21.08.07 Controls and functional elements 13

p

Control element: Master

EXT

Proline Low-temperature Thermostats

Error signal (red LED blinking)

Bath controlled by external

temperature source (geen LED

The temperature of an external

source is displayed

(EXT is lit green)

Cooler active (blue LED is lit)

Heater active (yellow LED is lit)

Mains On

(green LED is lit)

Control element: Command

Select and Enter keys

Overtemperature set point to

check or set T

Graphical display,

here in the standard window displaying the values:

• Actual temperature T

• Setpoint temperature T

• Actual temperature T

of internal bath temperature probe

int

set

of the external temperature probe

ext

• Bath level

• Pum

level

Enter key

Cursor key

max

Decimal point or "-" symbol

Escape key to quit a

window without any

Standby key,

brings the thermostat into

the idle mode. Heater,

Yellow Stand-By LED

5 soft-key duo-keys – their

RS 232-socket

associated functions are

shown in the display.

(hidden on the back Command )

14 Controls and functional elements YACE0072 / 21.08.07

Proline Low-temperature Thermostats

4 Unit description

4.1 Environmental conditions

The operation of the thermostats is only allowed under the following conditions as specified in

DIN EN 61010-2-010:2003 and DIN EN 61010-1:2001:

− Indoor use.

− Altitude up to 2000 m above sea level.

− Foundation must be dense, even, non-slippery and non-flammable.

− Keep clear distance Ì 6.1 Assembly and siting.

Ambient temperatures

−

Use only within this range for an undistur

− Mains supply voltage fluctuations Ì 11 Technical data.

− Relative

− Transient over voltage according to Insta

− Pollution degree: 2.

humidity Ì 11 Technical data.

range Ì 11 Technical data.

bed operation.

llation Categories (Over voltage Categories) II.

4.2 Types of unit

The type designation of the Proline Low-Temperature Thermostats comprises the prefix R (to

designate the refrigeration machine), a P for Proline, the bath volume in liters and the lowest bath

temperature (guide figure without arithmetic sign).

Units in Command version are marked with a “C” at the end of the model description.

Examples: RP 855 is a low-temperature thermostat with 8-liter bath and -55 °C min. temperature.

RP 1845 is a low-temperature thermostat with 18-liter bath and -45 °C min. temperature.

4.3 VarioFlex pump

All units are fitted with a VarioFlex pump with an 8-stage variable drive. The pump power can

therefore be optimally matched to the relevant task: High pump pressure when, for example, long

hoses pass to external loads or circulation is to be provided for a large bath. Low pressure when the

heat input into the bath must be low.

As a delivery/ suction pump, the VarioFlex pump enables the very effective supply of pressuresensitive glass reactors, which have a minimum permissible pressure rating.

Furthermore, open vessels can be operated when a constant level controller (accessory L CZ 0 660) is

used.

At the right-hand side and at the back of the unit outflow and inflow nozzles are fitted for external

loads. This means that up to two external loads can be directly connected without a distributor.

Connections, which are not required, must be closed off with the supplied caps and union nuts.

A bypass valve can subdivide the total volume flow variably between the bath (internally) and the

connected load (externally). Consequently, no "pump short circuit" is needed. If no load is connected

to the pump connector, the bypass valve must be set to the “internal” position for the best bath

circulation.

In the heating range, the VarioFlex pump operates up to viscosity values of 150 mm²/s. In the closedloop control mode 50 mm²/s should not be exceeded. The temperature control is the best with

30 mm²/s and lower viscosity.

With small bath coolers (e.g. RP 845) power level 1 to 3 is practicable.

YACE0072 / 21.08.07 Unit description 15

Proline Low-temperature Thermostats

For operation as a circulating thermostat with an external load, a higher power level is practicable to

maintain the temperature difference low, among other things also with higher temperatures in

conjunction with oils as heat carrier liquid.

The pump connections on the unit are fitted with M16 x 1 thread.

The pump outflows of the VarioFlex pump can be closed off without any impairment to the pump.

Here, the "internal" setting of the bypass controller is recommended.

Pump characteristics

(Ì Section 11).

4.4 Materials

All parts being exposed to the heat carrier liquid are made of high quality material appropriate to the

operating temperature. Non-rusting stainless steel and high quality temperature-resistant, primarily

solvent-resistant plastics are used.

4.5 Temperature display, control and safety circuit

In the Master Version, the units are equipped with a 5-character green LED display, which is used for the

display of the measurements and settings, as well as the operating status. The entry of setpoints and

other settings occurs under menu guidance via four keys.

The extra features of the Command Version include a removable console with a backlit graphical

display. The entry of the setpoint and other settings occurs under menu guidance via situationdependent cursor keys and soft keys.

A Pt100 temperature probe acquires the outflow temperature in the bath. A high-resolution A/D converter

processes the measurement. Further measurement conditioning occurs using a special control algorithm

for controlling the heater actuator, which has a low reactive effect on the mains, and the SmartCool

refrigeration equipment together with further transducers.

An external Pt100 can be connected via a socket (10S) for the acquisition of an external temperature.

This value can be displayed and, if required, used as the controlled variable with external control

(Master) switched on. In this way, the system controls the external measurement and not the outflow

temperature Ì 7.7.4.

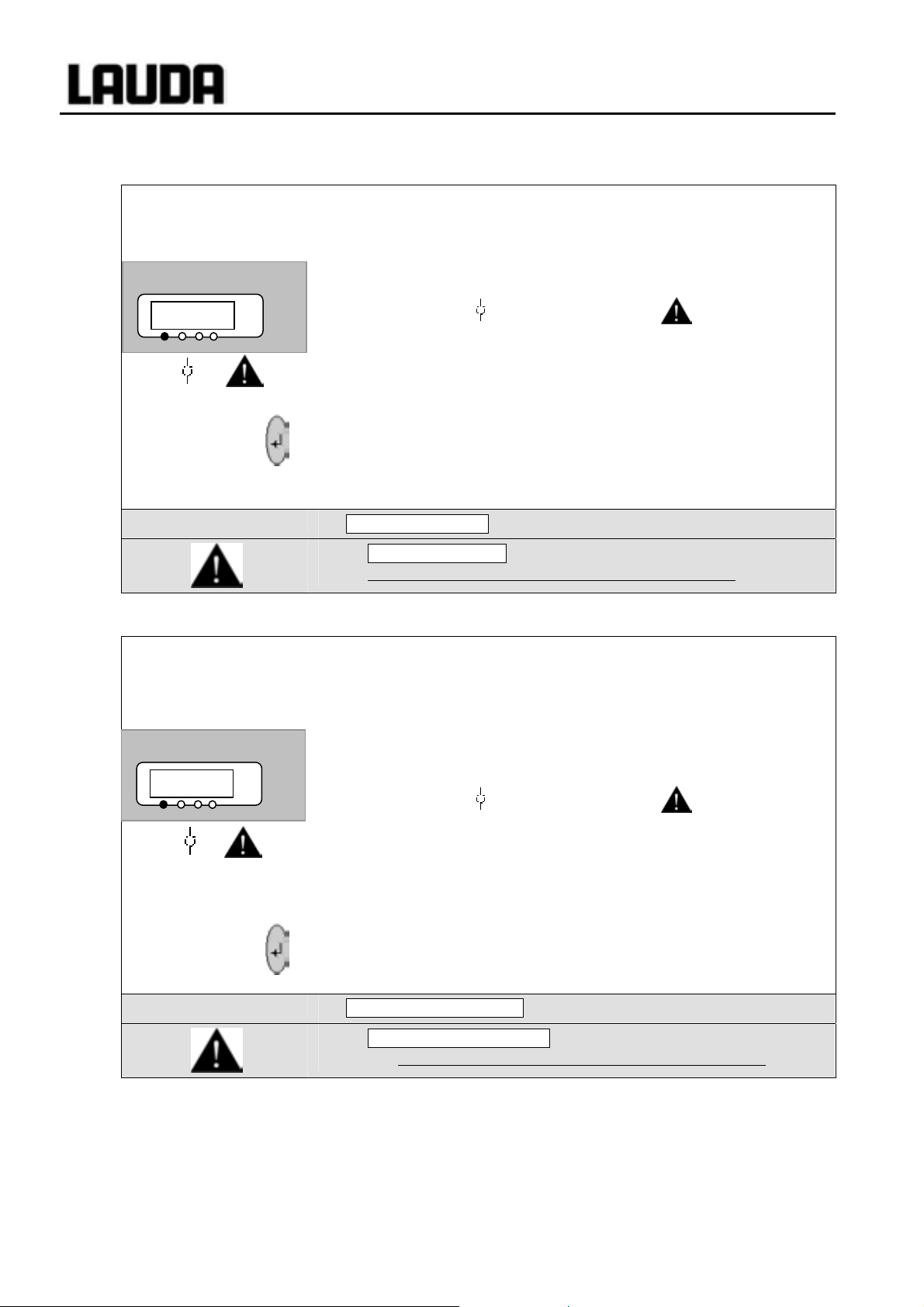

The saf

parameters. A dual-channel system is used in which two microcontrollers monitor one another. Along

with the bath temperature measurement and control probes, there are also two safety temperature

probes (Pt100) for the safety circuit for the overtemperature cut-off and for monitoring the bath

temperature probe.

The overtemperature cut-off point is displayed on pressing the key

Changing the overtemperature cut-off point: Ì 7.2 (Switching on) on page 25.

The bath level is acquired

with the Command Version. At the Master version, it is showed in the submenu

level is undercut, the pump, heater and the SmartCool System refrigerating machine are switched off.

The reaction of the thermostat in case of overfill can be set to simply display a warning, to display a

warning and switch off the heater or to switch off the unit completely with pump, heater and SmartCool

System refrigerating machine.

When the level is too low, with overtemperature, or with other alarms the SelfCheck Assistant switches

the heater off on all poles. The pump and the refrigerating machine are also switched off.

This switch-off under fault conditions is retained, i.e. after the fault is rectified, the fault must be reset

ety system conforms to DIN EN 6

by the SelfCheck Assistant in 8 stages. A permanent display is provided only

1010-2-010. The SelfCheck Assistant monitors about 50 unit

on the Master.

RgmY[ . If the minimum

16 Unit description YACE0072 / 21.08.07

Proline Low-temperature Thermostats

(released) on the Master operating panel with the key.

Other unit functions are described in the appropriate sections and in Section 7. (Starting up).

4.6 Programmer and ramp function

Master Version:

No programmer provided.

Command Version:

The units are equipped with a programmer function, which enables five temperature/time programs to

be saved. Each program consists of a number of temperature/time segments. These also include details

of how often the program is to be executed. Up to 150 segments can be distributed amongst the five

programs.

With the ramp function, a rate of change can be directly entered in °C/ unit time. (Ì 7.10).

4.7 Interfaces

Master Version:

In the basic version, the Master unit is equipped with the following sockets at the back of the control

head:

• For the connection of an external Pt100 temperature sensor (10S).

• Two sockets (70S) for the connection of components via the LAUDA equipment bus (cooling

section, Command Console, external solenoid valve, etc.).

Command Version:

The Command unit is equipped as standard with the following sockets:

• For the connection of an external Pt100 temperature probe (10S).

• Two sockets (70S) for the connection of components via the LAUDA equipment bus (cooling

section, Command Console, external solenoid valve, etc.)

• An RS232 / RS485 interface (65S) at the back of the Command Console.

4.8 Interface modules (accessories)

The Master and Command can be supplemented with further interface modules, which are simply

inserted into two module slots (see Section 3) at the back of the control head.

The following modules are curre

ntly available :

1. RS232 / 485 Interface Module (Order No. LRZ 913) with 9-pole SUB-D socket. Electrically

isolated through optocouplers. Command set largely compatible with the Ecoline, Integral XT and

Integral T Series. The RS2323 interface can be directly connected to the PC with a cable wire d

1:1 straight through (Order No. EKS 037).

Further details can be found in section 8.3.

2. Analog Mo

inputs and outputs can be set independently as 4...20 mA, 0...20 mA or 0...10 V interface.

YACE0072 / 21.08.07 Unit description 17

dule (Order No. LRZ 912)

with two inputs and two outputs on 6-pole DIN socket. The

Proline Low-temperature Thermostats

Further details can be found in section 8.4.

3. Contact Module (Order No. LRZ 915) on 15-pole SUB-D socket. With three relay contact outputs

(changeover, max. 30V/ 0.2A) and three binary inputs for control via external voltage-free

contacts. Plug 15-pole, Order No. EQM 030 and plug case Order No. EQG 017.

Further details can be found in section 8.5.

ontact Mo

4. C

LRZ 915, but only one output and one input on each of two DIN sockets. Coupling socket 3-pole,

LAUDA Order No. EQD 047 and coupling plug 3-pole, LAUDA Order No. EQS 048.

Further details can be found in section 8.5.

5. Profibus

Further details can be found in the operating instructions of the Profibus Modules YAAE0020.

dule (Order No. LRZ 914) with connector to NAMUR NE28. Functionality as

Modules (Order No. LRZ 917

4.9 Cooling unit

The refrigerating machine mainly consists of one or two fully hermetically sealed compressors. The

heat from the condensation process and the motor is dissipated via a lamellar condenser. Here, fresh

air is drawn in at the front of the unit, heated towards the back and output at the side. To ensure proper

air circulation the ventilation slots must not be restricted. See Section 6.1.

The co

use of the compressor and only then cools when refrigerating capacity is demanded by the controller.

To achieve this, a number of sensors in the cooling circuit monitor the operating conditions.

The compressors are equipped with overtemperature cutouts, which respond to the compressor

temperature and the compressor current consumption. In addition, the refrigeration system is backed

up by a pressure control device against over pressure. The cooling unit is normally switched in

automatically, but can be switched manually via the operating menu. (Ì Section 7.6 with Command

und 7.6.3 with Master).

When the fault circuit trips, the cooli

olers of the Proline Series

).

are equipped with the SmartCool technology which makes optimum

ng unit is also switched off.

Cooling curves

(Ì Section 11).

4.10 Avoidance of dewing

In order to avoid dewing on the edge of the bath when using the low temperature thermostats RP 855,

RP 870, RP 890 and RP 1290, these instruments are equipped with a device for heating the edge of

the bath, using the waste heat of the cooling unit.

As a standard feature, the minimum temperature thermostats RP 890 and RP 1290 are equipped with

an additional electric heating of the bath bridge. This can be ordered as an option for RP 855 and

RP 870.

With the bath covers of the minimum temperature thermostats, RP 890 and RP 1290, it is possible, by

means of a nipple, to let nitrogen or dry air into the bath with a low volume flow.

4.11 Heater rating and power consumption from the mains

The Proline Low-Temperature Thermostats have an extraordinarily high heater rating of 3.5 kW

maximum. If your mains fuse is rated below 16A, the current consumption can be reduced in steps

from 16 A to 10 A Ì 7.7.5. The maximum heater rating of 3.5 kW i

accordingly.

s then, of course, also reduced

18 Unit description YACE0072 / 21.08.07

Proline Low-temperature Thermostats

5 Unpacking

After unpacking, firstly check the device and accessories for any damage in transit. If, contrary to

expectations, there is visible damage to the unit, the shippers or the postal service must be

immediately informed, so that an investigation can be made. Please also inform the LAUDA Service

Centre (Contact Ì 9.4.).

Standard Accessori

Article number Quantity A rticle

YACE0072 1 Operating instructions (this document) for all cooling thermostats

HDQ 108 1 Bath cover at RP 845, RP 855 and RP 870

HDQ 109 1 Bath cover at RP 1840, RP 1845 and RP 3530

LCZ 9671 1 Bath cover for bath bridge heating at RP 890 and RP 1290

es:

HKO 026

(UD 413)

HKM 032 4 Union nuts for olives (M16x1) for all cooling thermostats

HKN 065 4 Screw plugs (for M16x1) for all cooling thermostats

EKS 073 1

EZB 260 1

2 Hose olive Ø 13mm for all cooling thermostats

T-piece adaptor cable for the internal

LAUDA device bus (LiBus)

Warning label "Hot"

with Command cooling thermostats

only

for all cooling thermostats

YACE0072/ 21.08.07 Unpacking 19

6 Preparation

6.1 Assembly and siting

Proline Low-temperature Thermostats

− Site the unit on a flat surface

− The unit must not be put into operation if its

temperature during storage or transport has dropped

below the dew point.

Wait for about one hour.

− The unit may NEVER be overturned nor put upside

down!

− Do not cover the ventilation openings at the back of

the control head and on all sides of the lower section

of the unit.

− Leave at least 40 cm of free space on all sides.

− For operation as bath thermostat, set the bypass valve

to internal (without external loads) (Ì Section 3).

Plug the (high resistance

−

corresponding socket 51H on the back of the control

head, the Bus-cable into the plug 70S and secure

both.

− Only RP 890 and RP 1290: In case of disturbing

dewing, connect the heating of the bath bridge. Plug

the supplied T-piece adaptor cable for the LAUDA

device bus into the 70S socket and secure it. Connect

it with the connection cable of the bath bridge heating.

− Plug the bus connector of the Command console also

into the 70S socket or into the T-piece and secure it.

) connector into the

Operation with external loads

(Circulating thermostat) continue at ÌSection 6.4.

− Check whether the pump connectors at the side and back are fitted with sealing

− With bath temperatures o

− Do not carry out technical changes on the device!

− The unit can be safely operated up to an ambient temperature of 40°C.

− An increased ambient temperature reduces the cooling capacity.

caps (Ì Section 3) or that hoses are fitted for external loads.

should be applied on the bath at an easily visible point.

In particular, it is not allowed to bore into the edges of the bath!

− Further T-adaptors are available as accessories

EKS 073.

− Avoid condensation of air humidity: Connect nitrogen

or dry air with a low volume flow for superposition to

the nipples of the bath covers of the minimum

temperature thermostats RP 890 and RP 1290.

ver 70°C the supplied self-adhesive label

20 Preparation YACE0072 / 21.08.07

Proline Low-temperature Thermostats

6.2 Filling and draining

Filling

− The units are designed for use with non-flammable and flammable liquids to

DIN EN 61010-2-010. Flammable liquids must not be used higher than 25°C below the

fire point (Ì Section 6.3).

When using heat carrie

−

− With enclosed external loads, the overall expansion takes place in the bath.

− Ensure that with the connection of an external load, the liquid level does not drop

impermissibly due to filling the load Æ top up with liquid if necessary.

− Set the upper and lower temperature limits (Ì 7.8.3) in accordance with the limits of the

rri

heat ca

er li

quid in u

r oils note that they expand on heating (approx. 8%/ 100°C).

e.

s

− Close the drain cock.

− Carefully remove all residues of the previous

heat carrier liquid (blow dry and remove screw

plugs!).

− Maximum filling level is up to 10 mm below

the top edge of the bath. Overfilling leads to

the display of the warning

(Ì Section 7.14.4).

− Best operation is with a level 20-80 mm below

the top edge of the bath.

− The cooling pipe of the evaporator should be

covered. Depending on the operation up to

three pipe windings might be uncovered.

− Low-level cut-off occurs at about 95 mm

below the top edge of the bath.

VW@pl0/2

Draining

Drain cock

− Follow the regulations for the disposal of used heat carrier liquid.

Do not drain heat carrier liquid when hot or at bath temperatures below 0°C!

− Switch off the thermostat withdraw the mains plug.

− Let out the heat carrier liquid through the drain cock; fit

a hose when doing this.

− On thermostats, the drain cock is located behind the

front panel.

YACE0072 / 21.08.07 Preparation 21

Proline Low-temperature Thermostats

6.3 Heat carrier liquids and hose connections

Heat carrier liquids

LAUDA

designation

Aqua 90 +5...+90 Decalcified water 1 -- -- LZB 120 LZB 220 LZB 320

Kryo 85 -85...+30 Silicone oil 1.8 17 at -80°C > 56 LZB 113 LZB 213 LZB 313

Kryo 60 -60...+80 Silicone oil 3 25 at –60 °C > 110 LZB 102 LZB 202 LZB 302

Kryo 51 -50...+120 Silicone oil 5 34 at -50°C > 160 LZB 121 LZB 221 LZB 321

Kryo 40 -40...+60

Kryo 30 -30...+90

Kryo 20 -20...+180 Silicone oil 11 28 at -20°C > 230 LZB 116 LZB 216 LZB 316

Therm 160 +60...+160

Temper-

ature

range

from °C

to °C

Chemical

designation

Hydrous

alcalisalt solution

Monoethylene

glycol/ water

Polyalkylene

glycol

Viscosity

(kin)

mm²/s

at 20°C

2.36 24 at –40 °C -- LZB 119 LZB 219 LZB 319

4 50 at –25 °C -- LZB 109 LZB 209 LZB 309

141 28 at 60 °C > 273 LZB 106 LZB 206 LZB 306

Viscosity

(kin) at

temperature

mm²/s 5 L 10 L 20 L

Fire

point

Packing drum

Order number

Therm 180 0...+180 Silicone oil 23 36 at 0 °C > 288 LZB 114 LZB 214 LZB 314

Therm 200 +60...+200 Silicone oil 44 28 at +60°C > 362 LZB 117 LZB 217 LZB 317

Therm 240 +50...+240 Silicone oil 130 45 at +50°C > 378 LZB 122 LZB 222 LZB 322

{ At higher temperatures Æ Evaporation losses Æ Use bath covers.

Only use distilled water or fully demineralized high purity water after adding 0.1 g of soda

(Na

sodium carbonate) / liter of water, Æ Risk of corrosion!

2CO3

Water content falls with longer operation at high temperatures Æ Mixture becomes flammable

(flash point 128 °C). Æ Check the mixture ratio with a hydrometer.

− At devices with nickel-plated evaporator (RP 845, RP 855, RP 890, RP 1290 and RP 1845)

you must not use acid, aqueous heat carrier liquids resp. detergents (ph-value < 7).

− With the selection of the heat carrier liquid, it should be noted that impairment of the

properties is to be expected at the lower limit of the temperature range due to increasing

viscosity. Therefore, only make maximum use of temperature ranges when essential.

− Application ranges of heat carrier liquids and hoses are general figures, which may be

restricted by the operating temperature range of the units.

With silicone rubber, silicone oils lead to substantial swelling Æ Never use silicone oil with

silicone hoses.

Safety data sheets can be ordered if required.

22 Preparation YACE0072 / 21.08.07

Proline Low-temperature Thermostats

Hose connections

a) Elastomer hoses

Hose type

Internal width

Ø mm

EPDM hose

uninsulated

EPDM hose

uninsulated

EPDM hose

insulated

Silicone hose

uninsulated

Silicone hose

insulated

Viton 11 10...200

Viton

insulated

Viton

insulated

9 10...120

12 10...120

12

External Ø.

approx. 35mm

11 -30...100

11

External Ø.

approx. 35mm

8.5

External Ø.

approx. 30mm

11

External Ø.

approx. 32mm

Temperature

range °C

-60...120

-60...100

-60...150

-60...150

Field of

application

For all heat carrier

liquids except

Ultra 350 and

mineral oils

For all heat carrier

liquids except

Ultra 350 and

mineral oils

For all heat carrier

liquids except

Ultra 350 and

mineral oils

Water

Water/ glycol

mixture

Water

Water/ glycol

mixture

For all heat carrier

liquids

For all heat carrier

liquids

For all heat carrier

liquids

Order number

RKJ 111

RKJ 112

LZS 021

RKJ 059

LZS 007

RKJ 091

LZS 017

LZS 018

− EPDM hose is not

suitable for Ultra 350 and not suitable for mineral oils.

− With silicone rubber, silicone oils lead to substantial swelling Æ never use

silicone oil with silicone hoses.

− Secure hoses against slippage with hose clips.

b) Metal hoses in non-rusting stainless steel with union nut M 16x1, internal width 10 mm.

Type

Length

Temperature range °C Field of application Order number

(cm)

MC 50 50 10…400

MC 100 100 10…400 "

MC 150 150 10…400 "

MC 200 200 10…400 "

With single insulation,

for all heat carrier liquids

LZM 040

LZM 041

LZM 042

LZM 043

With foam insulation for

MK 50 50 -90…200

refrigeration range,

LZM 052

for all heat carrier liquids

MK 100 100 -90…200 "

MK 150 150 -90…200 "

MK 200 200 -90…200 "

LZM 053

LZM 054

LZM 055

YACE0072 / 21.08.07 Preparation 23

6.4 Connecting external loads

Proline Low-temperature Thermostats

− If cross-sectional area of tube is too low Æ temperature gradient between bath

and external load due to low flow rate.

− Always ensure the largest possible passages in the external circuit.

− When tightening the union nuts on the pump nipple AF 19, use a wrench AF 14

to counter the tightening torque (see figure).

− If external control is to be used, provide a Pt100 probe in the external load (Ì

Section 7.7.2 and 7.7.4).

Operation as circulating thermostat

− When used as circulation thermostat, care for

shortest hose connections with largest inner

diameter as possible. This gives the best flow.

− Push hose with 11-12 mm internal width onto

hose olive or connect metal hoses (Ì 6.3) to

pump conn

− Pump connectors at si

Inlet and outflow Ì see labeling housing.

− Pump connectors at back:

Inlet and outflow Ì see labeling housing.

− Set bypass valve to "external" (Ì 3).

ectors.

de:

− With loads at a higher position and with stationary pump and ingress of air into

the thermostatic circuit, the external volume can drain away, even with closed

circuits Æ Risk of thermostat overflowing!

− Secure hoses against slippage with hose clips.

− Unused pump connectors must be closed off.

24 Preparation YACE0072 / 21.08.07

Proline Low-temperature Thermostats

7 Starting up

7.1 Mains connection

Compare the rating on the nameplate (back of control head and behind the front panel) with the mains

voltage.

The device is according to EMC standard DIN EN 61326-1 Class B.

− Connect unit only to sockets with a protective earth conductor (PE).

− No liability is accepted for incorrect mains connections.

− Ensure that pump connectors without external loads are closed off.

− Ensure that the unit is filled according to Section 6.2.

7.2 Switching on

1 s

Self-test

77(((

Bath temperature

/1%21

Overtemp. cut-off

8/

°C

EXT

°C

°C

Check whether the main fuse switch at the back is in the "On =

position.

Switch on the mains switch:

− The green LED for "Mains ON" is lit,

− an acoustic signal is emitted for about 1 second,

− it is quite normal if the refrigerating machine makes a rattling sound

for a few seconds.

− The unit starts its self-test. All display segments and symbols

appear for about 1 second.

− The momentary bath temperature is displayed,

− the pump starts provided "Standby" or "Manual start" (Ì Section

7.8.2) has not been programmed,

− all values are accepted whic

Check or set overtemperature cut-off point:

− The switching point is shown in the LED display on pressing the key

h were active before switch-off.

–"

.

− Change overtemperature cut-off Ì Section 7.14.1 Overtemperature

protection and chec

− If necessary, top up heat carrier liquid, this has been pumped out by

YACE0072 / 21.08.07 Starting up 25

filling the external load.

king on page 91.

Proline Low-temperature Thermostats

Command

Level alarm

KDTDK

°C

− Display for

little liquid.

− Red LED

− Find cause of fault and, where necessary, top up missing heat

carrier liquid (Ì Section 6.3).

− Press the Enter key.

− Also, pres

− No release is possible

KDTDK (low level) appears when the bath has too

s the key if unit has been switched off in the fault state.

English

Deutsch

Français

Español

above the fault triangle flashes.

on Command Console!

Language

− If the Command Console is being

switched on for the first time, the

illustrated window appears automatically,

enabling you to select the dialog language

with the appropriate soft key.

Display

Sounds Master

Sounds Command

Language

English

Deutsch

Français

Español

Master-Mode

Autostart

Current Consumpt.

Help Menu End T

set

− The dialog language also can be changed

later via

Æ Settings Æ Basic settings Æ

Language .

− Mark the required language with or

.

− Confirm the selection with .

T

fix

26 Starting up YACE0072 / 21.08.07

Proline Low-temperature Thermostats

7.3 Switching off / standby

Switching off: Set mains switch to position 0. With operation at temperatures below 0° Celsius only

switch off the device via standby, because otherwise severe condensation and dew formation can

occur.

Standby operation: Use the key

the master display. The pump, heating and cooling unit are switched off, but the operating display and

the electrical bath bridge heating for RP 890 and RP 1290 remain active, so that dew formation and

condensation into the bath continue to be suppressed.

However, a started timer Ì 7.12 continues to run. Stop as required with Pause.

on the command console or by selecting the pump level Zero on

7.4 Key functions

Your Proline Thermostat is easy to operate. For the Command Version you will most probably rarely

need to use these operating instructions.

7.4.1 General key functions and pilot lamps

Master

Enter key:

− From the actual-value display at the main menu level,

− activates input, display flashes,

− saves input, display ceases to flash and menu point is left,

---

− press for approx. 3 seconds: Exit function and returns to bath

temperature display.

or

°C

− Paging with keys is possible within the relevant level,

or setting of numerical values

Speeds up entry by moving the counting position to the left:

a) Keys are pressed and held down or

b) one of the two keys is pressed and held down, followed

immediately by brief pressing of the other key.

Moves counting position to the right:

− Switching one place to the right occurs by briefly (1 second)

releasing the key, followed by another pressing of the key.

Useful additional information:

− 2 dots in the Master display indicate that a submenu follows.

− 3 dots in the display indicate that a submenu for a module

(interface...) or a component (thermostat, Command Console ....)

follows. Module/component-specific possible settings are only

displayed when the hardware is connected.

YACE0072 / 21.08.07 Starting up 27

Proline Low-temperature Thermostats

− The following always applies: After termination of the relevant

settings, they are accepted automatically after approx. 4 s

or

− the setting is accepted immediately with the Enter key.

− Fault signal: Flashing red Alarm LED and acoustic signal.

and

EXT

Command

End

− An acoustic signal can only sound when it has not been

intentionally deactivated! (Ì 7.8.6).

− The bath control occurs via the external temperature probe when

the green LED is lit.

− Heating is active when the yellow LED is lit.

− Cooling is active. When the setpoint temperature is lowered, it may

take up to one minute before the blue LED is lit.

− The temperature of the external probe is displayed.

− Enter key ("Confirm selection") and go

back one level.

− Soft key function to confirm a selection or

input and to return to the main display

window.

− Escape key to quit a window without

changes and to go back one level.

+

− Cursor keys for Up, Down, Left and Right.

− Standby activation (pump, heater and

refrigerating machine are deactivated

when the yellow LED is lit).

However, timer continues to run! Refer to

safety information in Ì 7.7.3.

Duo key:

− Top: Decimal-point key.

− Bottom: Key for arithmetical sign.

− Soft keys: 5 duo-keys, which each have

the function shown in display above them.

Soft-key entries are shown framed in the

operating instructions. Example: You

would like to change the setpoint

temperature then press the duo-key under

T

.

set

28 Starting up YACE0072 / 21.08.07

Proline Low-temperature Thermostats

Brightness Contrast

Display

Sounds Master

Sounds Command

Language

Master Mode

Autostart

Current Consumpt.

Brightness

Contrast

The brightness and contrast can be set on the

Command Console:

− The works setting can be changed via

Æ Settings Æ Basic settings Æ

Display Æ Brightness or Æ Contrast .

− The brightness of the LCD illumination can

be selected from eight steps or switched

off completely.

− The contrast can be set in eight steps.

Help Menu End T

Screen

T

°C

set

25.00

T

°C

int

Standby

25.01

Help Menu Screen T

set

55.3

Y(%)

0.0

set

T

fix

There are four different screen displays

available.

The screen is switched over with the soft key

Screen :

1. Basic window with the three most

important items of information:

− T

− T

− Information: Heating / cooling. Here,

Soft keys:

− Help: Help function.

T

fix

− Menu: Set unit parameters.

− Screen: Changes between basic, normal,

− T

− T

, current bath temperature,

int

, setpoint of the bath or external

set

temperature,

heating is taking place at 55.3% and

0.0% cooling.

super and graphics recorder windows.

: Changes setpoint temperature.

set

: Calling and setting of saved

fix

setpoints.

T

set

°C

Level

4

25.00

T

°C

int

25.01

T

°C

ext

25.02

Help Menu Screen T

YACE0072 / 21.08.07 Starting up 29

Pump

3

set

T

fix

2. Standard window with five important

items of information:

− T

, current bath temperature,

int

− T

, setpoint,

set

− T

, current temperature on external probe

ext

(if connected),

− Level of heat carrier liquid in cm above the

minimum level,

− Pump level of the VarioFlex Pump.

Soft keys see as above.

Proline Low-temperature Thermostats

,

T

°C

set

25,00

T

max

130

T

°C

int

°C

25,01

T

°C

ext

25

02

Help Menu Screen T

Control Var.

T

int

55,3

Y(%)

0,0

Pump

3

set

3. Super window with seven items of

information:

− T

, current bath temperature.

int

− T

, setpoint.

set

− T

, current temperature on external probe

ext

(if connected).

− Overtemperature cut-off point T

− Pump level of the VarioFlex Pump.

− Control variable to T

− Information: Heating / cooling.

T

fix

Soft keys see as above.

4. Graphical measurement display

− All temperature values can be shown

graphically against time Ì 7.9.

int

or T

ext

.

max

.

30 Starting up YACE0072 / 21.08.07

Proline Low-temperature Thermostats

7.4.2 Changing window information (Command Console)

Command

T

set

°C

25.00

T

°C

int

25.01

T

°C

ext

25.02

Help Menu Screen T

Basic Window

Standard Window

Super Window

Edit

Default

Level

4

Pump

3

set

Display data

You can adapt the information displayed by

your Command Console to your

requirements. For example, if you have not

connected any temperature probe, you can

exchange it in the standard setting of the

normal window for the maximum temperature

T

(safety cut-off).

max

This is how it is done:

T

fix

− Open the unit parameter menu via the soft

key Menu .

− With and change from

Settings Æ

Display Data Æ

Standard Window Æ .

Edit

Help Menu End T

Center

Up left

Up right

Down left

Down right

T internal

T external

Setpoint

T max

Pump step

Set value

Level

Control variable

Date/time

Help Menu End T

set

set

T

fix

− or takes you to the illustrated

window.

− and marks T max as illustrated.

− Confirm selection with or End ,

− or quit the window with without any

changes being made.

T

fix

YACE0072 / 21.08.07 Starting up 31

7.4.3 Locking the keyboard

The keyboards of the Master and the Command Console can be lo cked independently of one another.

This is especially advantageous when the thermostat is positioned in anothe r room and the Command

Console is used as a remote control device. Then the Master keyboard can be locked to prevent

unintentional adjustment.

Proline Low-temperature Thermostats

Master

/////

R@ED

and hold

pressed

simultane-

ously for 3 s

°C

°C

and hold

pressed

simultane-

ously for 3 s

R@ED

Locking:

RDr appears for 3 seconds,

−

− then the segments of the first right-hand

− hold both keys pressed until this display is completely

−

R@ED flashes briefly and the display returns to the actual

temperature.

− The Master keyboard is now locked.

− The

Unlocking:

− For three seconds, then

− Then the segments of the left-hand

R@ED display signals the locked state when any Master key

is pressed.

R@ED appears.

/ are formed.

/ are formed,

visible.

Bath temperature

/1%21

°C

− The actual bath temperature appears again when all the

been formed.

/s have

32 Starting up YACE0072 / 21.08.07

Proline Low-temperature Thermostats

Command

Locking keyboard

Help Menu End T

Unlocking keyboard

set

Locking:

− Press and then and hold

pressed simultaneously for

three seconds.

− The locking window appears.

− Hold both keys pressed until the progress

bar is completely filled.

− Then the display skips back to the

previously set Screen mode.

T

fix

− The soft-key boxes are now blank,

indicating that the keyboard is locked.

− On pressing any Master key the display

appears:

Keyboard locked

Unlocking:

− Press and then and hold

pressed simultaneously for three

seconds.

− The unlocking window appears.

− Hold both keys pressed until the progress

bar is completely filled.

Then the display skips back to the previously

set Screen mode.

YACE0072 / 21.08.07 Starting up 33

Proline Low-temperature Thermostats

7.5 "Master" menu structure

1%21

Actual bath temperature

or actual value of

external temperature

Section 7.6.1

RDr Set setpoint

Section 7.7.1

Os Pump power

Section 7.7.3

Bml Control Int/Ext

Section 7.7.4

LMDkt Settings

Section 7.6.2

LMnet Conf. Modules

Section 7.6.3

RDB Protection system

Section 7.6.9

B/LM Command

Section 7.6.3

B//l Cooling system

Section 7.6.10

@l@ Analog module

Section 8.4

pR Conf. RS232/ 485

Section 8.3

c0a Conf. digit. mod.

Section 8.5

O@pA- Parameters

Section 7.6.4

O0c-- Control par.

Only internal or external

parameters are offered

depending on control

variable

Section 7.6.5 / 7.6.6

B@K-- Pt100 calibration

Section 7.6.7

RgmY[ Show values

Section 7.6.8

B@K 0 Offset int. Pt100

Section 7.8.7

cDE ! Works settgs. int. Pt

Section 7.8.8

B@K D Offset ext. Pt100

Section 0

cDE D Works settgs. ext. Pt

Section 7.8.10

Bsp Max. current consumpt.

Section 7.7.5

R Setpoint resolution

Section 7.8.1

Rr@pr Opern. w. mains fail.

Section 7.8.2

rhg Upper temp. limit

Section 7.8.3

rhK Lower temp. limit

Section 7.8.3

RDro- Setpoint relat. to act.

val. Section 7.8.4

cDE Works setting

Section 7.8.5

@scin Signal settings.

Section 7.8.6

rXOF- Detect type of unit.

Section 9.2.1

^O Int. proport.range (Xp)

Section 7.13.1

rl Internal reset time (Tn)

Section 7.13.1

rs Int. derivative time (Tv)

Section 7.13.1

rc Int. damping time (Td)=

Section 7.13.1

rsc Int. contr. par. auto/man.

Section 7.13.1

cDE Works settings

Section 7.13.1

DO Ext. prop. factor (Kpe)

Section 7.13.2

Dl External reset time (Tne)

Section 7.13.2

Dt Ext. derivative time (Tve)

Section 7.13.2

Dc Ext. damping time (Tde)

Section 7.13.2

Da Ext.propor.range (Prop_E)

Section 7.13.2

hO External P-controller (Xpf)

Section 7.13.2

D Ext. contr.par. auto/ man.

Section 7.13.2

Dr/K Ext.correct. var. (K)

Section 7.13.2

cDE Works settings

Section 7.13.2

TDp Software version

Section 9.2.2

Rlp^G Serial number Hi Word.

Section 9.2.3

Rlp^K Serial number Lo Word.

Section 9.2.3

KD Bath level [cm]

Section 9.2.4

RrDKK Control value of tempera.

controller. Section 9.2.4

hRDr Curr. controller setpoint.

Section 9.2.4

rD Or Extern temp. Pt100

Section 9.2.4

rD@l@ Ext. temp. analog. interf.

Section 9.2.4

rDRDp Ext.temp. RS232/485

Section 9.2.4

rGD@c Temp. of housing °C

Section 9.2.4

rGR Temp. of heatsink °C

Section 9.2.4

E@l T Fan voltage in V.

Section 9.2.4

0DEE Mains curr. consumpt. in A

Section 9.2.4

T^RDB Prot. syst. voltage in V.

Section 9.2.4

T13 Act. val. 24V voltage in V.

Section 9.2.4

OT O Power consumpt. pump W

Section 9.2.4

OT 0 Current consumpt. pump I.

Section 9.2.4

OT l Pump speed rpm.

Section 9.2.4

lE 4/ Mains frequency Hz

Section 9.2.4

lT Mains volt. % of rated volt.

Section 9.2.4

G^@ll Counter operating hours

Master complete

G^OT Counter operating hours

Pump

34 Starting up YACE0072 / 21.08.07

Proline Low-temperature Thermostats

7.6 "Command" menu structure

Menu

Pump

Settings

Clock

Graph

Programmer

Interfaces 1

Control

Limits

1

Ì Capter 8

2

no menu in

Command

Pump Level

Calibration

Works settings

Resolution

Device status

Display data

Basic settings

Overlevel handling

Set time

Set data

Timer 1

Timer 2

Format of date

Settings

Program 1

Program 2

Program 3

Program 4

Program 5

Ramp function

Serial Command

2

serial Master /

Profibus

Analog interfaces

Switching contact

Refill valve

Shut off unit

Smart Cool

off

on

automatic

internal

external Pt100

Analog interface

RS232/485

Control variable

Control parameters

Setpoint offset

T il (min)

T ih (max)