The right temperature worldwide

Operating instructions

Microcool

MC 250, MC 600, MC 1200, MC 1200 W

Circulation chiller

LAUDA DR. R. WOBSER GMBH & CO. KG

Postfach 1251

97922 Lauda-Königshofen

Germany

Phone: +49 (0)9343 / 503-0

Fax: +49 (0)9343 / 503-222

E-Mail: info@lauda.de

Internet: www.lauda.de

Translation of the original operating instructions

YAWE0033 V02REV60 10/022/2014 © LAUDA 2013

Microcool 2

Table of contents

Table of contents

1 Safety.................................................................................................................................................... 6

1.1 General safety instructions.......................................................................................................... 6

1.2 Intended use................................................................................................................................ 7

1.3

Foreseeable misuse.................................................................................................................... 7

1.4 Modifications to the device.......................................................................................................... 7

1.5 Heat transfer liquid...................................................................................................................... 7

1.6 Materials...................................................................................................................................... 8

1.7 Hoses.......................................................................................................................................... 8

1.8 Application area........................................................................................................................... 8

1.9 Personnel qualification................................................................................................................ 8

1.10 Personal protective equipment.................................................................................................... 9

1.11 Structure of safety instructions.................................................................................................... 9

2 Unpacking.......................................................................................................................................... 11

3 Design and function.......................................................................................................................... 12

3.1 Device types.............................................................................................................................. 12

3.2 Design of the circulation chiller.................................................................................................. 13

3.3 Controls..................................................................................................................................... 17

3.3.1 Mains power switch.................................................................................................... 17

3.3.2 Display buttons........................................................................................................... 18

3.4 Function elements..................................................................................................................... 19

3.4.1 LEDs for function display........................................................................................... 19

3.4.2 Hydraulic circuit.......................................................................................................... 19

3.4.3 Manometer................................................................................................................. 20

3.4.4 Level indicator............................................................................................................ 20

3.4.5 Refrigeration unit........................................................................................................ 20

3.4.6 Interfaces................................................................................................................... 21

3.5 Rating plate............................................................................................................................... 22

3.6 Serial number............................................................................................................................ 22

4 Before commissioning...................................................................................................................... 23

4.1 EMC classification..................................................................................................................... 23

4.2 Device Placement..................................................................................................................... 24

4.3 External consumer.................................................................................................................... 25

4.3.1 Hoses......................................................................................................................... 25

4.3.2 Connecting external consumer.................................................................................. 27

4.4 Cooling water............................................................................................................................ 27

4.4.1 Cooling water requirements....................................................................................... 27

Microcool 3

Table of contents

4.4.2 Connecting cooling water........................................................................................... 29

4.5 RS232 interface......................................................................................................................... 30

4.5.1 Cable and interface test RS232................................................................................. 30

4.6 Alarm output 12N...................................................................................................................... 30

Commissioning.................................................................................................................................. 32

5

5.1 LAUDA heat transfer liquids...................................................................................................... 32

5.2 Filling device with heat transfer liquid........................................................................................ 33

5.3 Establishing power supply......................................................................................................... 34

5.4 Switching on the device............................................................................................................. 35

5.5 Refilling heat transfer liquid....................................................................................................... 35

5.6 Setting pump pressure.............................................................................................................. 36

6 Operation............................................................................................................................................ 38

6.1 Switching on the device............................................................................................................. 35

6.2 Default display and menu items................................................................................................ 38

6.3 Screen displays......................................................................................................................... 40

6.4 Specifying the setpoint temperature.......................................................................................... 40

6.5 Restricting temperature limit values.......................................................................................... 41

6.6 Configuring timer....................................................................................................................... 42

6.7 RS232 interface......................................................................................................................... 44

6.7.1 Configuring RS232 interface...................................................................................... 44

6.7.2 Protocol...................................................................................................................... 45

6.7.3 Write commands........................................................................................................ 46

6.7.4 Read commands........................................................................................................ 46

6.7.5 Error messages.......................................................................................................... 47

6.8 Configuring alarm output........................................................................................................... 47

6.9 Inputting offset of the temperature sensor................................................................................. 48

6.10 Restoring the factory settings.................................................................................................... 49

7 Maintenance....................................................................................................................................... 50

7.1 General safety instructions........................................................................................................ 50

7.2 Maintenance intervals............................................................................................................... 50

7.3 Cleaning the device................................................................................................................... 51

7.4 Cleaning air-cooled condenser.................................................................................................. 51

7.5 Cleaning the water filter............................................................................................................. 52

7.6 Decalcification of the cooling water circuit................................................................................. 52

7.7 Checking the heat transfer liquid............................................................................................... 53

8 Faults.................................................................................................................................................. 54

8.1 Alarms, errors and warnings..................................................................................................... 54

8.2 Alarms overview........................................................................................................................ 55

Microcool 4

Table of contents

8.3 Warnings overview.................................................................................................................... 55

9 Decommissioning.............................................................................................................................. 57

9.1 Draining the device.................................................................................................................... 57

9.2 Draining condenser (only water-cooled devices)...................................................................... 57

Disposal.............................................................................................................................................. 59

10

10.1 Disposing of refrigerant............................................................................................................. 59

10.2 Device disposal......................................................................................................................... 59

10.3 Disposing of packaging............................................................................................................. 59

11 Technical data.................................................................................................................................... 60

11.1 General data.............................................................................................................................. 60

11.2 Refrigeration unit....................................................................................................................... 61

11.3 Hydraulic circuit......................................................................................................................... 62

11.4 Voltage-dependent data............................................................................................................ 62

12 General............................................................................................................................................... 63

12.1 Copyright................................................................................................................................... 63

12.2 Technical changes.................................................................................................................... 63

12.3 LAUDA contact.......................................................................................................................... 63

12.4 EC conformity............................................................................................................................ 63

13 Index................................................................................................................................................... 65

Microcool 5

Safety

1

1.1

Safety

General safety instructions

The equipment must only be operated for the intended use

under the conditions stated in this operating manual. Any other

type of operation is considered to be not-intended use and can

impair the protection provided by the device.

The operating manual is part of the device. The information in

this operating manual must therefore be available in close

vicinity to the device. Also store this copy of the operating

manual carefully.

If you lose this operating manual, contact the LAUDA

Constant Temperature Equipment service. The contact

details can be found in Ä Chapter 12.3 ‘LAUDA contact’

on page 63.

Use of the device results in hazards from high or low temperatures,

fire and from the use of electrical energy. The hazards of the

device must be eliminated as much as possible by the design in

accordance with the appropriate standards. Residual hazards are

reduced using any of the following measures:

If relevant, there are safety devices for the device. These

devices are essential for the safety of the device. Their functionality must be ensured with appropriate maintenance activities.

The safety devices of the device are described in this "Safety"

chapter.

If relevant, there are warning symbols on the device. These

symbols must always be observed.

The warning symbols on the device are described in this

chapter “Safety”.

There are safety instructions in this operating manual. These

instructions must always be observed.

There are additional specific requirements for the personnel

and for the personal protective equipment.

These requirements are described in this "Safety" chapter.

An overview of the authorised personnel and the protec-

Ä

tive equipment can be found in

sonnel qualification’ on page 8 and

‘Personal protective equipment’ on page 9.

Further information about the general structure of safety

instructions can be found in

of safety instructions’ on page 9.

Chapter 1.9 ‘Per-

Ä

Chapter 1.10

Ä

Chapter 1.11 ‘Structure

Microcool 6

Safety

1.2

Intended use

Intended use

Non-intended use

1.3

Foreseeable misuse

The present device is exclusively permitted to be used for tempering and delivering non-combustible heat transfer liquids in a

closed circuit.

The following applications are considered to be not-intended:

medical applications

in potentially explosive areas

for tempering foodstuffs

with a glass reactor without overpressure protection

Misuse of the device must always be prevented.

Among other things, the following uses are considered to be foreseeable misuse:

Operation of the device without heat transfer liquid

Incorrect connection of hoses

Placement of the device on a tabletop surface, only permitted

for MC 600

Setting an incorrect pump pressure

and MC 1200 (W)

1.4

Modifications to the device

1.5

Heat transfer liquid

Any technical modifications to the machine are prohibited. Service

works may be carried out only by the LAUDA Constant Temperature Devices service or one of the service partners authorized

by LAUDA.

The device is exclusively designed for nonflammable heat

transfer liquids in Class I according to DIN 12876-1.

Heat transfer liquids are used for the temperature control. Only

LAUDA heat transfer liquids are approved for the device.

LAUDA heat transfer liquids are heat transfer liquids that have

been tested and approved by the company LAUDA DR. R.

WOBSER GMBH & CO. KG.

Microcool 7

Safety

In each case, the heat transfer liquids cover a specific tem-

perature range. This temperature range must match the temperature range of your application.

The use of heat transfer liquids can cause hazards from high or

low temperatures and fire if certain temperature thresholds are

exceeded or undercut or if the container breaks and there is a

reaction with the heat transfer liquid .

The heat transfer liquid safety data sheet specifies all possible

hazards and appropriate safety measures for handling the

liquid. The safety data sheet must therefore be consulted for

the intended use of the device.

1.6

Materials

1.7

Hoses

1.8

Application area

All parts coming into contact with the heat transfer liquid are made

of high quality materials suitable for the operating temperature.

Stainless steel and temperature-resistant plastics are used.

Only LAUDA hoses are permitted to be used for the external

hydraulics circuit. LAUDA hoses are hoses that are approved by

LAUDA DR. R. WOBSER GMBH & CO. KG. When selecting suitable hoses for the application, the permissible temperature range

and the maximum permissible pressure must be particularly

observed.

The device is exclusively permitted to be used in the following

areas.

Commercial area

Indoor use, no outdoor installation

Ambient temperatures from 5 to 40 °C

1.9

Personnel qualification

Operating personnel

Operating personnel are employees that have been instructed by

technical staff in the intended use of the device according to the

operating manual.

Microcool 8

Safety

1.10

1.11

Danger

Personal protective equipment

Protective clothing

Protective clothing is required for certain activities. This protective

clothing must comply with the legal requirements for personal protective equipment. Protective clothing should have long sleeves.

Safety footwear is additionally required.

Protective gloves

CE protective gloves are required for certain activities. These protective gloves must comply with the legal requirements for personal

protective equipment of the European Union.

Protective goggles

Protective goggles are required for certain activities. These protective goggles must comply with the legal requirements for personal

protective equipment of the European Union.

Structure of safety instructions

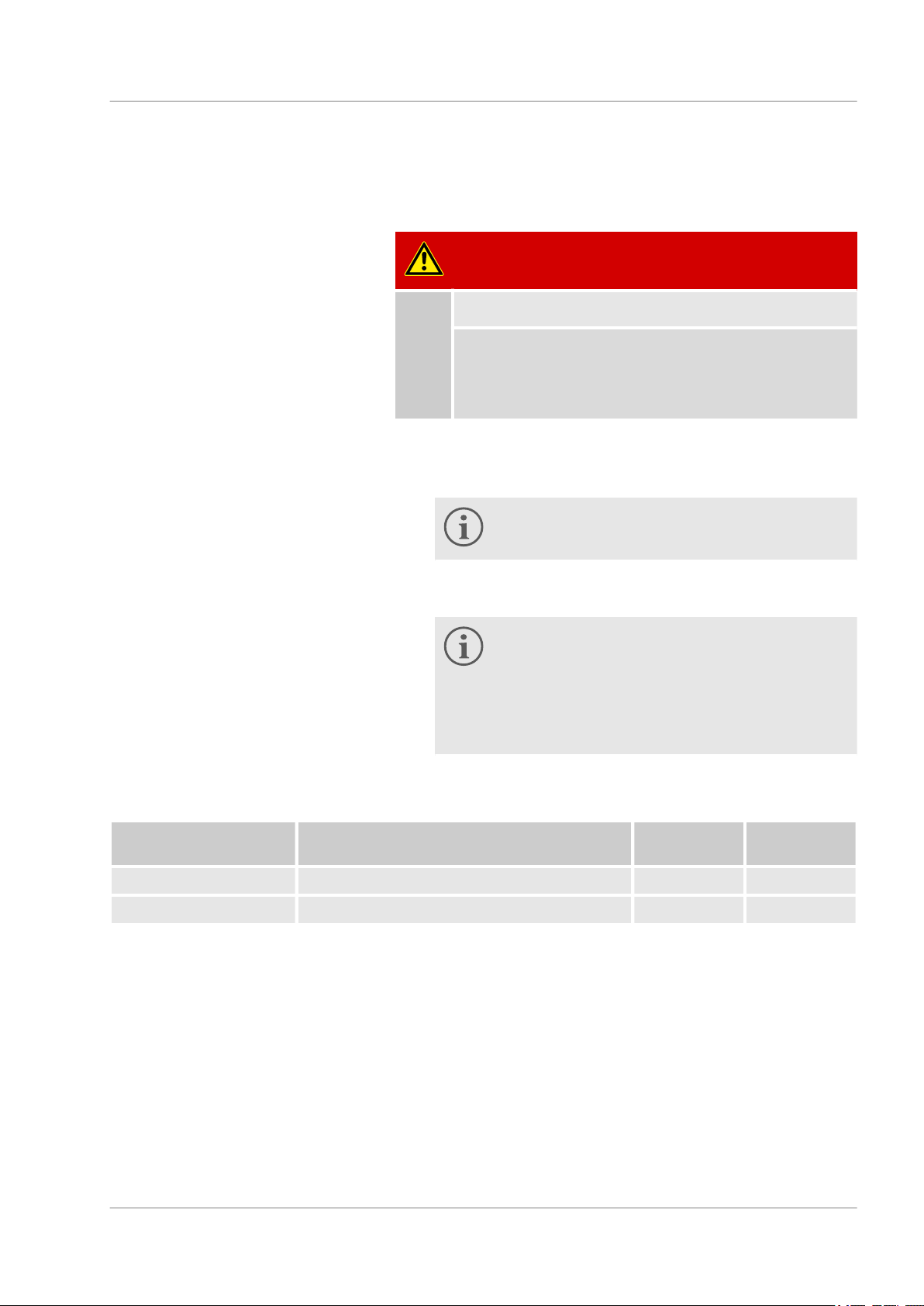

A safety instruction of the type "Danger" indicates an immedi-

This results in death or severe, irreversible injuries if the

ately hazardous situation.

safety instruction is disregarded.

Warning

DANGER!

Type and source

Consequences in the case of non-compliance

Measure 1

Measure…

A safety instruction of the type "Warning" indicates a poten-

tially hazardous situation.

This can result in death or severe, irreversible injuries if the

safety instruction is disregarded.

WARNING!

Type and source

Consequences in the case of non-compliance

Measure 1

Measure…

Microcool 9

Safety

Caution

Notice

A safety instruction of the type "Caution" indicates a poten-

tially hazardous situation.

This can result in minor, reversible injuries if the safety

instruction is disregarded.

CAUTION!

Type and source

Consequences in the case of non-compliance

Measure 1

Measure…

A"notice" warns about possible property or environmental damage.

NOTICE!

Type and source

Consequences in the case of non-compliance

Measure 1

Measure…

Microcool 10

Unpacking

2

Unpacking

DANGER!

Transport damage

Electric shock

Inspect the device for transport damage before

commissioning.

Never put the device into operation if you have dis-

covered any transport damage.

Personnel:

1. Unpack the device.

Keep the original packaging of the device for later

transport.

2. Inspect the device and the accessories immediately after

delivery for completeness and transport damage.

Operating personnel

If there is unexpected damage to the device or

accessories, inform the carrier immediately so that

a damage report is produced and a check of the

transport damage can be made. Also inform

LAUDA Constant Temperature Equipment Service

immediately. Contact details can be found in

Ä

Chapter 12.3 ‘LAUDA contact’ on page 63.

Accessories included as standard

Device type Designation Quantity

MC 600, MC 1200 (W) ¾" olive with ¾" union nut 2 EOA 004

All equipment Operating manual 1 --

Catalogue

number

Microcool 11

Design and function

3

3.1

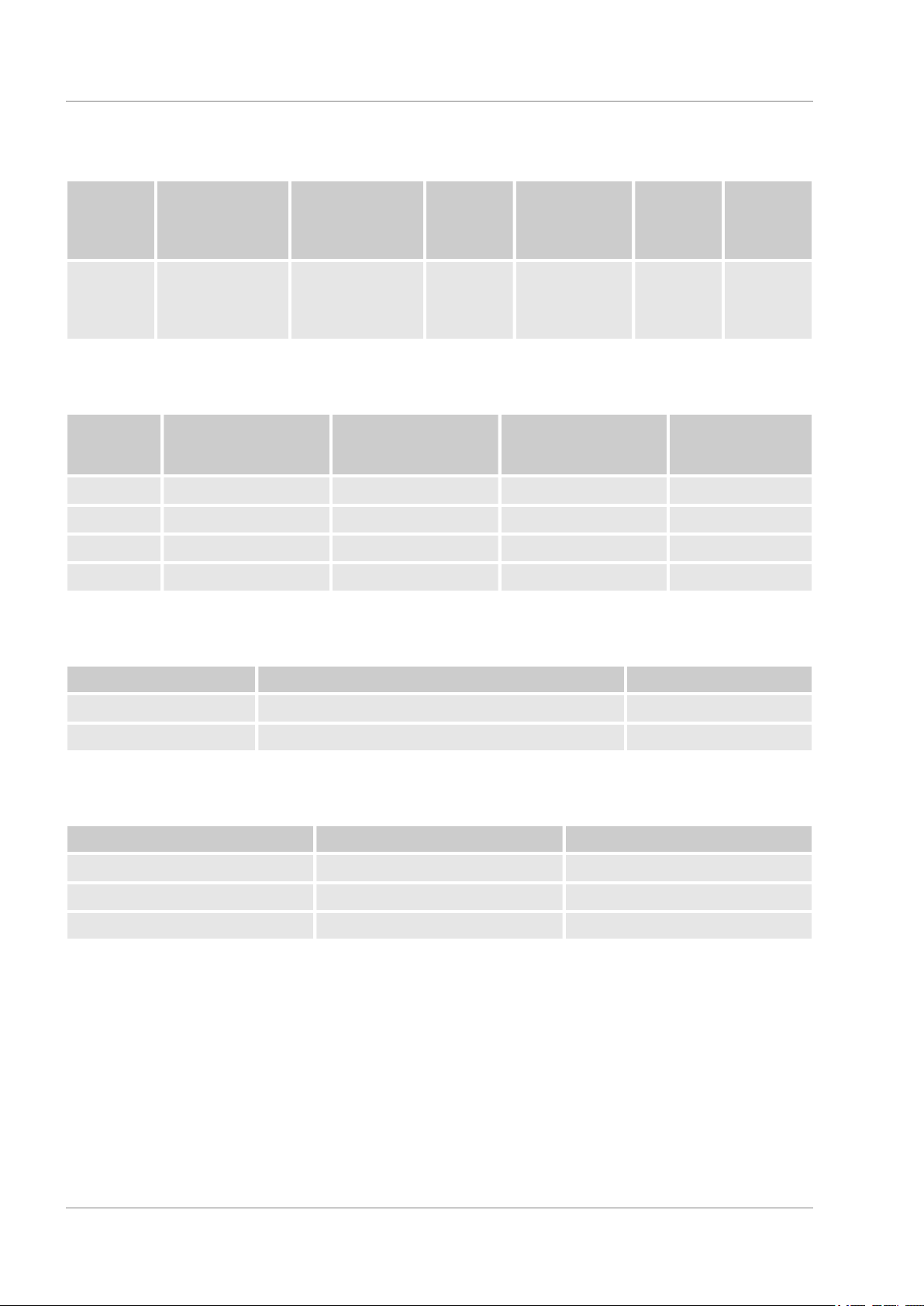

Available device types

Design and function

Device types

The type designation of the equipment is composed of the following elements.

Element Description

MC Microcool

<number>, e.g. 600 Specification of the cooling capacity in

watts

W Device with water cooling

This specification in the device type is

optional. It identifies water-cooled equipment.

Device type Description

MC 250 Air-cooled tabletop device with a cooling

capacity of 250 watts

MC 600 Air-cooled floor-standing device with a

cooling capacity of 600 watts. The pump

pressure can be adjusted using a bypass

adjustment wheel.

MC 1200 Air-cooled floor-standing device with a

cooling capacity of 1200 watts. The pump

pressure can be adjusted using a bypass

adjustment wheel.

MC 1200 W Water-cooled floor-standing device with a

cooling capacity of 1200 watts. The pump

pressure can be adjusted using a bypass

adjustment wheel.

Microcool 12

Design and function

Rear side MC 250

Fig. 2: Overview of the rear side

1 Pump connection, outlet

2 Overflow connection

3 Pump connection, return

4 Rating plate

5 Drain plug

6 RS232 interface

7 Alarm output

8 Mains cable

9 Ventilation openings

Microcool 14

Design and function

3.2

Design of the circulation chiller

Front side MC 250

Fig. 1: Overview of the front side

1 Filler nozzle with cover

2 Level indicator

3 Control panel

4 Front panel with ventilation openings

5 Four support feet

Microcool 13

Front side MC 600, MC 1200 (W)

Design and function

Fig. 3: Overview of the front side

1 Filler nozzle with cover

2 Control panel

3 Level indicator

4 Manometer

5 Front panel with ventilation openings

6 Four castors with locking brakes

Microcool 15

Design and function

Rear side MC 600, MC 1200 (W)

Fig. 4: Overview of the rear side

1 Pump connection, outlet

2 Bypass adjustment wheel

3 Pump connection, return

4 Overflow connection

5 Rating plate

6 Drain plug

7 RS232 interface

8 Alarm output

9 Mains cable

10 Ventilation openings

Microcool 16

Control panel

Design and function

Fig. 5: Control panel

1 Display

2 LEDs

3 Display buttons

4 Mains power switch

3.3

3.3.1

Controls

Mains power switch

The mains power switch can be put in the following positions:

In position [I], the device is switched on.

In position [O], the device is switched off.

Microcool 17

Design and function

3.3.2

Display buttons

Fig. 6: Display buttons

1 UP arrow button

2 ENTER button

3 DOWN arrow button

Functions in the display of the device can be controlled using the

display buttons.

A selection in the display can be confirmed with the ENTER

button.

The UP and DOWN arrow buttons can be used to navigate in

the display.

Microcool 18

Design and function

3.4

Function elements

3.4.1

LEDs for function display

Fig. 7: LEDs

1 Yellow LED

2 Blue refrigeration LED

3 Red error LED

Each device has three LEDs with the following functions:

3.4.2

Hydraulic circuit

Hydraulic circuit

The yellow glycol LED lights if Kryo 30 is necessary as heat

transfer liquid.

The blue refrigeration LED indicates whether the refrigeration

unit is active.

The red error LED lights in the event of device faults.

The hydraulic circuit designates the circuit through which the heat

transfer liquid flows.

The circuit basically consists of the following components:

internal storage bath with heat transfer liquid

pump for conveying the heat transfer liquid into the external

consumer via the pump connections

Starting with MC 600, devices are equipped with an adjustable

bypass to be able to adapt the pump pressure to the requirements of the external consumer.

Microcool 19

Design and function

Pump

3.4.3

Manometer

The devices are equipped with a magnetically coupled pressure

pump.

Further information about the technical data of the pump

and the pump characteristic curve can be found

Ä

Table on page 62.

The device types with bypass have a manometer for reading the

set pump pressure. The pump pressure is regulated using the

bypass adjustment wheel on the rear side.

Fig. 8: Manometer

3.4.4

Level indicator

The fill level of the heat transfer liquid in the circuit can be read

using the level indicator.

The top arrow indicates the maximum liquid level of the

machine.

The bottom arrow indicates the minimum liquid level of the

machine.

Fig. 9: Level indicator

1 Maximum level

2 Minimum level

3.4.5

Refrigeration unit

The refrigeration unit includes the following components:

Microcool 20

Design and function

Compressor

A hermetically sealed compressor is used in the refrigeration

unit. The compressor is equipped with overload protection

which trips on the compressor temperature and compressor

current consumption.

Condenser

Depending on the device type, an air-cooled or water-cooled

condenser is used in the refrigeration unit. In air-cooled condensers, the condensation heat is discharged to the environment. The fresh air is sucked in through the front of the device

using a fan, heated and discharged on the rear of the device.

In water-cooled condensers, the condensation heat is discharged via cooling water.

Evaporator

In the internal bath, heat is discharged using a pipe coil evaporator.

Technical information for the refrigeration unit can be

found in

Ä

on page 61.

3.4.6

RS232 interface

Alarm output

Interfaces

Note the following:

The equipment connected to the low voltage inputs and out-

puts must have safe separation from dangerous voltages

according to DIN EN 61140 such as by double or reinforced

insulation according to DIN EN 60730-1 or DIN 60950-1.

Specific functions of the device such as the setpoint temperature

can be controlled with the RS232 interface using a PC. Thus,

custom programs for controlling the device can be developed.

Further information about the connection and configura-

Ä

tion can be found in

RS232 interface’ on page 44.

Changeover contact which switches in the event of a device fault.

For example, faults can be registered on a system.

Using the display, it can be set in which fault situations

a signal is output via the interface.

Chapter 6.7.1 ‘Configuring

Microcool 21

Design and function

3.5

Rating plate

The rating plate information is explained in detail in the following

table. Certain information is dependent on installed device options.

This information is noted with an appropriate suffix.

Specification Description

Type Device type

Catalogue No. Catalogue number of the device

Serial No. Serial number of the device

Refrigerant I Refrigerant that is used in the compressor

of the device

Filling charge I Fill quantity of the refrigerant

PS high pressure I maximum permitted operating pressure

on the refrigerant high pressure side

(compressor, condenser)

PS low pressure I maximum permitted operating pressure

on the refrigerant low pressure side

(expansion, evaporation)

Fig. 10: Rating plate

3.6

Serial number

Voltage Device must only be connected to this

voltage and frequency

Power consumption Power consumption of the device during

operation

Protection class IP protection class of the device

Fuse Fuse used in the device

Class according to

DIN 12876-1

The serial number of a LAUDA device has the following structure:

LAUDA catalogue number

Year of manufacture

The year is indicated with two digits.

Sequential number of the device in the year of manufacture.

The sequential number is a four-digit number.

This information is displayed in the format <catalogue number><year of manufacture>-<sequential number>.

An example for Microcool devices: LWM118-13-0130.

German standard for electrical laboratory

equipment

Microcool 22

Before commissioning

4

4.1

Before commissioning

EMC classification

Approval of the equipment according to EMC classification

Countries EMC Class

Europe Class A

This classification has been made according

to the EMC standard DIN EN 61326-1 (corresponds to VDE 0843-20-1).

USA Class A

This classification has been made according

to the FCC (Federal Communications Commission) regulations, Section 15.

Canada Class A

This classification has been made according

to the ICES-003 (Interference Causing

Equipment Standards) and NMB-003 regulations.

Instructions for machines, Europe

Instructions for Class A digital

device, USA

Instructions for Class A digital

device, Canada

EMC classification of the equipment:

Class A: Operation only on mains power supplies without con-

nected residential areas.

Class B: Operation on mains power supplies with connected

residential areas.

In the case of unfavourable mains conditions, disruptive voltage

fluctuations can occur.

"This equipment has been tested and found to comply with the

limits for Class A digital device, pursuant to Part 15 of the FCC

(Federal Communication Commission) Rules. These limits are

designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area

is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense."

“This Class A digital apparatus complies with Canadian ICES-003”

(ICES = Interference Causing Equipment Standards).

« Cet appareil numérique de la classe A est conforme à la norme

NMB-003 du Canada ».

Microcool 23

Before commissioning

4.2

Device Placement

Very specific placement conditions are applicable for the equipment. These placement conditions are specified in the technical

data of the device for the most part.

Further information about the technical data can be

found in

Additional placement conditions are described below.

Toxic vapours can be produced depending on the heat transfer

liquid used and type of operation. Ensure sufficient extraction

of the vapours.

Observe the requirements of the device for electromagnetic

compatibility (EMC).

Do not cover the ventilation openings.

Further information about EMC requirements can be

found in

Ä

Chapter 11.1 ‘General data’ on page 60.

Ä

Chapter 4.1 ‘EMC classification’ on page 23.

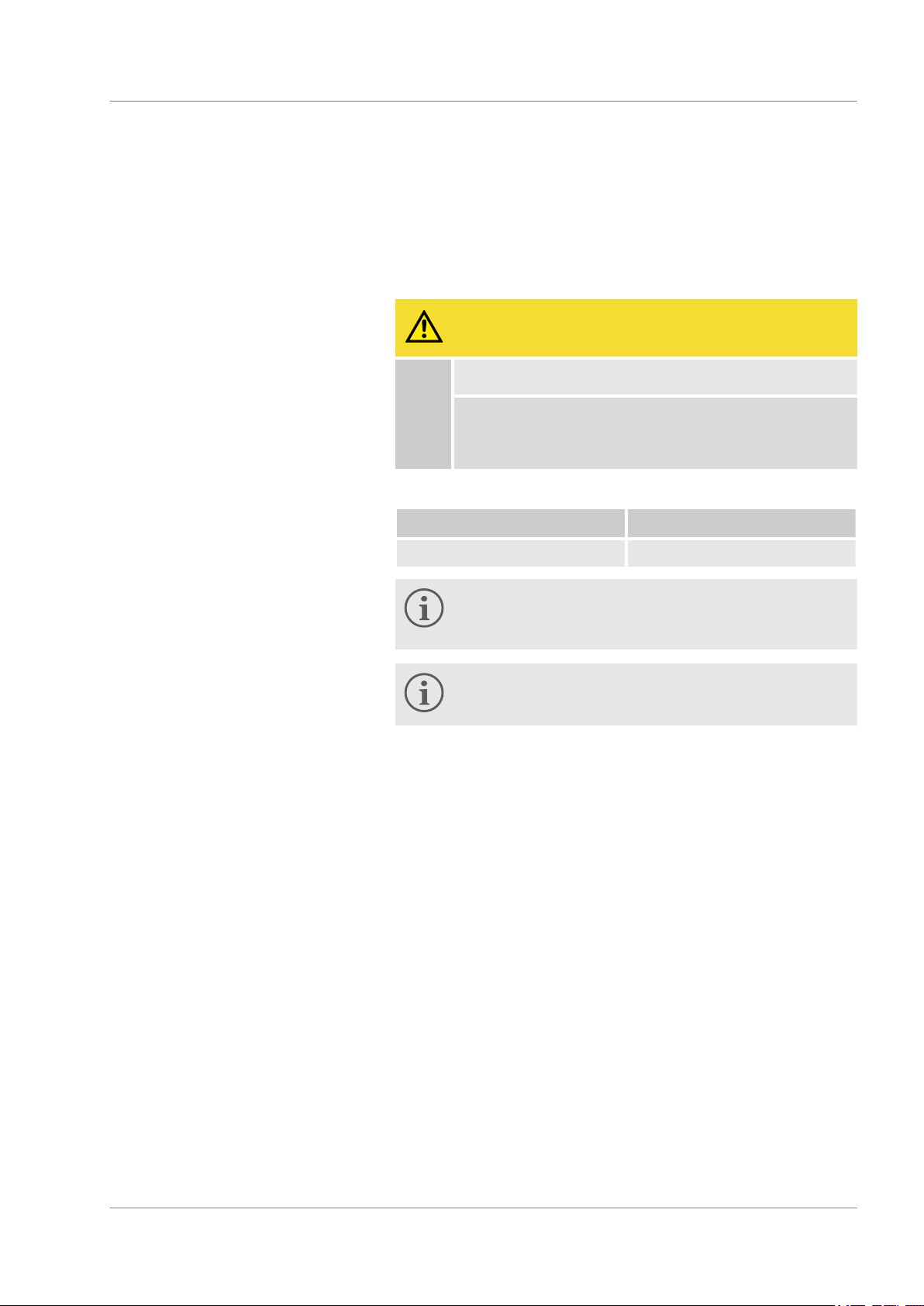

WARNING!

Rolling away, falling over of the device

Impact, crushing

Do not tilt the device.

Place the device on a level, non-slip surface with

sufficient load bearing capacity.

Engage the castor brake when setting up the

device.

Do not place any heavy parts on the device.

1. Place the device at a suitable location in the room.

Place tabletop devices on a suitable table. Support the

device for this by reaching under the device.

Place floor-standing devices on a suitable base.

Floor-standing devices can be moved. Release

the locking brakes of the castors for this by

pressing the [Off] lever downwards.

Several devices can be positioned next to each

other.

2. Lock the castors of the device for floor-standing devices.

Press the [On] lever downwards to lock.

Microcool 24

Before commissioning

4.3

External consumer

4.3.1

Hoses

CAUTION!

Discharge of heat transfer liquid during operation

caused by use of unsuitable hoses

Frostbite

Use hoses with temperature resistance that is

appropriate for the operating temperature range of

the device.

CAUTION!

Contact with cold hoses

Frostbite

Use insulated hoses for temperatures below 0 °C.

The hoses specified below can be used for all heat

transfer liquids that are approved for the devices.

Approved hoses, adapters and

hose clamps

Hoses, not insulated

Type Olive Application area

EPDM hose 10 mm

EPDM hose

Rubber hose with

fabric reinforcement

Rubber hose with

fabric reinforcement

½"

(13 mm)

½"

(13 mm)

¾"

(19 mm)

Further information about the pump connections of the

individual devices can be found in

‘Hydraulic circuit’ on page 62.

Devices with max-

imum pump pressure

of < 1 bar

Devices with max-

imum pump pressure

of < 1 bar

no restrictions

no restrictions

Ä

Chapter 11.3

Internal

Ø in mm

9 11 -35 ... 90 RKJ 111

12 14 -35 ... 90 RKJ 112

13 (½")

19 (¾")

External

diameter

in mm

19 -40 ... 100 RKJ 031

27 -40 ... 100 RKJ 032

Temperature

range in

°C

Cata-

logue

number

Microcool 25

Before commissioning

Hoses, insulated at the factory

Type

Pump connec-

tions

Application area

Internal Ø

in mm

External diam-

eter in mm

Tem-

perature

range in

°C

Catalogue

number

EPDM

hose, insu-

lated

Insulated hoses for subsequent insulation, length 1 m

Insulation

catalogue

number

RKJ 058 105 19 54 RKJ 112

RKJ 024 125 16 36 RKJ 112

RKJ 009 105 23 43 RKJ 031

RKJ 013 125 29 50 RKJ 032

Adapters, suitable for MC 600 and MC 1200 (W)

Designation Description Catalogue number

Olive 13 mm,

M16 x 1

Max. temperature in

°C

Olive ¾" union nut, ½ " olive LWZ 016

Devices with

maximum pump

pressure of

< 1 bar

Internal Ø in mm

12 23 -35 ... 90 LZS 021

External diameter in

mm

Suitable for hose

Olive ¾" union nut, 10 mm olive LWZ 040

Hose clamps

Stainless steel 10 ... 16 EZS 012

Stainless steel 12 ... 22 EZS 013

Stainless steel 20 ... 32 EZS 015

Material Ø from ... to in mm Catalogue number

Microcool 26

Before commissioning

4.3.2

Connecting external consumer

Note the following:

Temperature control hoses: Always use the largest possible

Secure the temperature control hoses with hose clamps.

If the external consumer is at a higher level than the device,

In the event of hose rupture, cold liquid can escape and

CAUTION!

Discharge of heat transfer liquid during operation

caused by open consumer

Electric shock, frostbite

Only use closed consumers.

CAUTION!

Bursting of the external hydraulic circuit due to

overpressure

Impact, cutting, frostbite

Lay hoses so that they do not kink.

diameters and shortest possible hose lengths in the external

liquid circuit.

If the temperature control hose diameter is too small, a temperature drop between device and external consumer occurs

due to flow rate too low. In this case, increase or lower the temperature accordingly.

emptying of the external volume can occur if the pump is

stopped and there is ingress of air in the external liquid circuit

even for closed circuits. In this case, you risk device overflow.

become a danger for persons and material.

4.4

Cooling water

4.4.1

Cooling water requirements

This section is relevant for the following:

For water-cooled devices

Microcool 27

Before commissioning

General requirements

There are specific requirements for the cooling water concerning

its purity. In accordance with the cooling water requirements, a

suitable process for treatment and maintenance of the water must

be used. The condenser and the complete cooling water circuit can

be clogged, damaged and leak due to unsuitable cooling water.

Extensive consequential damage to the complete refrigerant circuit

can occur. The cooling water quality is dependent on the local conditions.

Free chlorine, e.g. from disinfectants and water containing

chloride results in pitting corrosion in the cooling water circuit.

Distilled, deionised or demineralised water is not suitable due

to its corrosive properties and results in corrosion in the cooling

water circuit.

Seawater is not suitable due to its corrosive properties and

results in corrosion in the cooling water circuit.

Water containing iron and iron particles in the water result in

rust formation in the cooling water circuit.

Hard water is not suitable for cooling due to the high lime con-

tent and results in calcification in the cooling water circuit.

Cooling water with suspended matter is not suitable.

Untreated, not purified water, e.g. river or cooling tower water

is not suitable due to its microbiological content (bacteria)

which can settle in the cooling water circuit.

Suitable cooling water quality

Data Value Unit

pH value 7.5 – 9.0

Sulphates [SO4 2-]

Hydrogen carbonate [HCO

-

] / Sul-

3

< 70 mg/l

> 1.0

phates [SO4 2-]

Water hardness (alkaline earth ions

0.71 - 1.52 mmol/l

content)

Hydrogen carbonate [HCO

-

]

3

70 – 300 mg/l

Conductivity 10 - 500 μs/cm

Chlorides (Cl-)

Sulphite (SO3 2-)

< 50 mg/l

< 1 mg/l

Free chlorine gas (Cl2) < 1 mg/l

Nitrates (NO

-

)

3

< 100 mg/l

Ammonia (NH3) < 2 mg/l

Iron (Fe), dissolved < 0.2 mg/l

Manganese (Mn), dissolved < 0.1 mg/l

Aluminium (Al), dissolved < 0.2 mg/l

Free, aggressive carbonic acid (CO2) < 5 mg/l

Microcool 28

Before commissioning

Data Value Unit

Hydrogen sulphide (H2S) < 0.05 mg/l

Algae growth not permitted

Suspended matter not permitted

4.4.2

Connecting cooling water

This section is relevant for the following:

For water-cooled devices

Specification Value

Maximum cooling water

6 bar

pressure

Differential pressure

1 ... 6 bar

cooling water rp

approx. 15 °C recommended

Cooling water temperature

10 ... 30 °C permissible (with performance limitations)

Note the following:

Fix the cooling water hoses in place with hose clamps.

Fix the supply hose of the water cooling in place in the sink

area to prevent uncontrolled sliding, also in the event of pressure surges.

Fix the supply hose of the water cooling in place in the sink

area so that spraying out of hot cooling water is not possible.

Prevent kinking or squeezing of the hoses.

We recommend using a leak detector with water shut-off to

prevent damage due to cooling water system leaks.

Ensure that the cooling water meets the required criteria.

In the case of leaks in the condenser, there is the danger that

refrigerator oil and refrigerant from the refrigerant circuit of the

device can get into the cooling water. Comply with all applicable legal provisions and the requirements of the water supply

companies at the operating site.

Microcool 29

Before commissioning

4.5

RS232 interface

4.5.1

Cable and interface test RS232

Computer Thermostat

Signal 9-pin Sub-D female con-

nector

with hardware handshake

RxD 2 2 3 3 2 2 TxD

TxD 3 3 2 2 3 3 RxD

DTR 4 20 4 DSR

Signal

Ground

DSR 6 6 6 DTR

RTS 7 4 7 CTS

CTS 8 5 8 RTS

5 5 7 7 5 5 Signal

without

hardware

handshake

25-pin Sub-D female

connector

with hardware handshake

Note the following:

without

hardware

handshake

9-pin Sub-D female connector

with hardware handshake

without

hardware

handshake

Signal

Ground

4.6

Alarm output 12N

Available functions

With hardware handshake: Use a straight-through and not a

null modem cable for connecting a thermostat to the PC. The

RS232 interface can be connected directly to the PC using a

straight-through cable.

Without hardware handshake: Set the corresponding operating

mode on the PC. Use shielded connection cables. Connect

shield to connector case. The cables must be galvanically isolated from the rest of the electronics. Do not connect unassigned pins.

The RS232 interface can be easily checked on a connected

PC with the Microsoft Windows operating system. Using the

HyperTerminal program for Windows®

Starting with Windows Vista, HyperTerminal is no longer

an integral part of Windows. However, it is possible to

purchase and download the program. Alternatively,

there are also free Open Source terminal programs

such as putty with a similar range of functions.

Function Description

95/98/NT/XP.

Alarm output --

Alarm and standby for on-site return flow protection

Microcool 30

Before commissioning

View of flange connector (front) or solder side coupling socket

Max. 30 V DC; 1 A

Fig. 11: Flange connector (front) in idle state

1 Normally open contact

2 Centre

3 Normally closed contact

Idle state

The device is in idle state when it is switched off and in the

case of failure.

Pins 1 and 2 are open.

Pins 3 and 2 are closed.

GO state

The device is in GO state immediately after switching on and

during normal operation without faults.

Pins 1 and 2 are closed.

Pins 3 and 2 are open.

Note the following:

The equipment connected to the low voltage inputs and out-

puts must have safe separation from dangerous voltages

according to DIN EN 61140 such as by double or reinforced

insulation according to DIN EN 60730-1 or DIN 60950-1.

Only use shielded connection cables; connect the shield to the

connector case. Cover unused plug connections with protective

caps.

Microcool 31

Commissioning

5

5.1

Approved heat transfer liquids

Commissioning

LAUDA heat transfer liquids

LAUDA

designa-

tion

Chemical

designation

perature

range in °C

Tem-

Note the following:

The heat transfer liquids each cover a recommended tem-

perature range and must be suitable for the temperature range

of your application.

At the lower limit of the temperature range, the heat transfer

liquid becomes more viscous and influences temperature constancy, pump power and cooling capacity. The formation of

vapours and odours increases in the upper range. Therefore,

only use all of the temperature range if required. Particularly

with Aqua 90 (water), ice forms which can result in destruction

of the device.

Never use contaminated or degenerated heat transfer liquids.

You can request the safety data sheets of the heat transfer

liquid at any time if required.

Viscosity

(kin) in mm²/s

(at 20 °C)

Viscosity

(kin) in mm²/s

for

temperature

Container size

Catalogue number

5 l 10 l 20 l

Mono eth-

Kryo 30

Aqua 90

Heat transfer liquid water

ylene

glycol /

water

decalcified

water

-30 ... 90 4 50 at -25 °C LZB 109 LZB 209 LZB 309

5 ... 90 1 --- LZB 120 LZB 220 LZB 320

Note the following for Kryo 30:

The water content reduces during long operating with higher

temperatures and the mixture becomes flammable (flame point

128 °C). Check the mixture ratio using a hydrometer.

The alkaline earth ions content (hardness) of the water must be

between 0.71 mmol/l

8.0 °dH). Harder water results in lime deposits in the device.

The pH value of the water must be between 6.0 and 8.5.

Distilled, deionised, demineralised (DM) water or seawater

must not be used due to the corrosive properties. Ultra-pure

water and distillates are suitable as medium after addition of

0.1 g soda (Na2CO3, sodium carbonate) per litre of water.

Any chlorine content in the water must be strictly avoided. Do

not add any chlorine to the water. Chlorine is contained, for

example, in cleaning agents and disinfectants.

and 1.42 mmol/l (equivalent to 4.0 and

Microcool 32

Commissioning

The water must be free of impurities. Water containing iron is

unsuitable due to rust formation and untreated river water is

unsuitable due to algae formation.

The addition of ammonia is not permitted.

5.2

Filling device with heat transfer liquid

Personnel:

Protective equipment:

Operating personnel

Protective goggles

Protective clothing

Protective gloves

DANGER!

Use of incorrect heat transfer liquid

Fire

Select a heat transfer liquid with a temperature

range 20 K above the temperature range of the

application.

WARNING!

Overflow of heat transfer liquid

Electric shock

Ensure that the device is not overfilled. Note the

level indicator and the thermal volume expansion of

the heat transfer liquid.

WARNING!

Spraying of heat transfer liquid

Electric shock

Avoid spraying heat transfer liquid. Use a funnel for

filling.

1. Close the drain plug. For this, turn the plug clockwise as far

as the stop.

2. Attach a suitable hose to the overflow connection of the

device.

The permitted hose diameter for the overflow must

be complied with. Further information about the

suitable hose diameter can be found in the technical data Ä Chapter 11.3 ‘Hydraulic circuit’

on page 62.

Microcool 33

Commissioning

3. Insert this hose into a suitable canister to collect overflowing

heat transfer liquid.

Running dry of the consumer can also occur in a

closed temperature control circuit with consumer

at a higher level in the case of stopped pump and

ingress of air into the temperature control circuit

(for example, a not completely closed or defective

bleed valve). Match the size of the overflow container to this if possible.

4. Carefully pull up the cover of the filler nozzle; do not turn.

5. Fill the heat transfer liquid into the filler nozzle carefully. Mon-

itor the level indicator. Fill the device up to the maximum fill

level.

If necessary, use a funnel for the filling.

The level indicator must not be above the maximum fill level.

5.3

Establishing power supply

6. Press the cover carefully into the filler nozzle.

Personnel:

NOTICE!

Use of unauthorised mains voltage or mains frequency

Device damage

Compare the rating plate with available mains

voltage and mains frequency.

Also note the following:

The mains plug of the device provides a mains power discon-

nection component. The mains plug must be easily recognisable and easily accessible.

Only connect the device to an earthed (PE) power socket.

Operating personnel

Microcool 34

Commissioning

5.4

Switching on the device

WARNING!

Overheating of the pump

Device damage

Never operate device without heat transfer liquid.

Personnel:

1. Switch on the device using the mains power switch.

A signal tone sounds. The actual temperature is shown

on the display. The pump is started. The refrigeration unit

is started after approx. 2 minutes. The blue LED lights if

the refrigeration unit is active.

2. Depending on the size of the consumer, heat transfer liquid

must be refilled if necessary. Monitor the level indicator for

this.

Further information about refilling heat transfer

liquid can be found in

heat transfer liquid’ on page 35.

Operating personnel

Ä

Chapter 5.5 ‘Refilling

5.5

Refilling heat transfer liquid

Personnel:

Protective equipment:

DANGER!

Use of incorrect heat transfer liquid

Fire

Select a heat transfer liquid with a temperature

range 20 K above the temperature range of the

application.

Operating personnel

Protective goggles

Protective clothing

Protective gloves

Microcool 35

Commissioning

WARNING!

Overflow of heat transfer liquid

Electric shock

Ensure that the device is not overfilled. Note the

level indicator and the thermal volume expansion of

the heat transfer liquid.

1. Check whether the drain plug is closed.

The drain plug is closed if it is turned clockwise as

far as the stop.

2. Carefully pull up the cover of the filler nozzle; do not turn.

3. Fill the heat transfer liquid into the filler nozzle carefully. Mon-

itor the level indicator.

If necessary, use a funnel for the filling.

5.6

Setting pump pressure

The level indicator must not be above the maximum fill level.

The level indicator must be above the minimum

level. Otherwise a warning is output and the

device is switched off with an alarm after approx.

5 minutes.

4. Press the cover carefully into the filler nozzle.

For devices with bypass (starting from MC 600), the pump

pressure can be set using a control valve on the rear side of the

device. Individual setting of the pump pressure is possible with this

when using pressure-sensitive external consumers.

Microcool 36

Commissioning

Personnel:

CAUTION!

Bursting of the external consumer

Scalding, impact, cutting

A bypass regulator is provided to set the pump

pressure (starting from MC 600).

For consumers with a maximum permissible oper-

ating pressure below the maximum pressure of the

pump, use a safety valve for protection. This safety

valve must be installed in the outlet of the device.

1. To reduce the pump pressure, turn the bypass adjustment

wheel anticlockwise until the maximum permitted pressure

for the external consumer is reached.

Monitor the display on the manometer for this.

2. To increase the pump pressure, turn the bypass adjustment

wheel clockwise until the required pressure for the external

consumer is reached.

Operating personnel

Microcool 37

Operation

6

6.1

Operation

Switching on the device

WARNING!

Overheating of the pump

Device damage

Never operate device without heat transfer liquid.

Personnel:

1. Switch on the device using the mains power switch.

A signal tone sounds. The actual temperature is shown

on the display. The pump is started. The refrigeration unit

is started after approx. 2 minutes. The blue LED lights if

the refrigeration unit is active.

2. Depending on the size of the consumer, heat transfer liquid

must be refilled if necessary. Monitor the level indicator for

this.

Further information about refilling heat transfer

liquid can be found in

heat transfer liquid’ on page 35.

Operating personnel

Ä

Chapter 5.5 ‘Refilling

6.2

Default display and menu items

1. Press the ENTER button to reach the menu items from the

default display of the actual temperature.

If no button has been pressed for longer than 4

seconds, you exit from the menu item or input

window.

2. Scroll from menu item to menu item using the arrow buttons.

3. Press the ENTER button at the selected menu item.

The display flashes.

4. The value or the setting can be changed using the arrow but-

tons.

5. The changed value or setting is applied immediately by

pressing the ENTER button.

If no button has been pressed for longer than 4

seconds, changed values or settings are applied

automatically and you exit from the menu item or

input window.

Microcool 38

Operation

Fig. 12: Menu

Microcool 39

Operation

6.3

Screen displays

Default display

Fig. 13: Default display

Menu

Editing display

6.4

Specifying the setpoint temperature

The default display is the indication shown in the screen if no other

operations such as configuring settings are being performed. The

actual temperature of the machine is shown in the default display.

The machine menu with possible settings can be invoked using the

ENTER button.

The display flashes when a menu item in the screen has been

selected. The setting can now be made. The value entered is

applied when the setting is confirmed.

Further information about the menu structure and the

Ä

menu navigation can be found in

display and menu items’ on page 38.

Chapter 6.2 ‘Default

Relationship between temperature

setpoint and temperature limit

values

You specify a setpoint for the temperature control. This value

specifies to which temperature the heat transfer liquid will be

cooled. The upper and lower temperature limit values of the device

have been set to the default values

perature limits define the temperature range of your application, i.e.

in which range any temperature control can take place. A warning

is output by the device if the temperature is outside the limits. This

range is necessary so that no unnecessary warnings are output

during transient conditions of the temperature regulation. The

default values can be limited subsequently depending on the heat

transfer liquid.

For operation of the device with Aqua 90, the temperature setpoint

must not be set smaller than 5 °C. Also use the lower temperature

Ä

limit value Lo

set this to 3 °C so that a warning is output for lower temperatures.

The yellow LED on the device lights if any temperature setpoint or

actual temperature is less than 5 °C. It warns about incorrect use

of the heat transfer liquid and consequential damage to the device.

‘Lower temperature limit value’ on page 42 and

If the device is operated with liquid temperatures below

5 °C, Kryo 30 (glycol / water) must be used in the device

as heat transfer liquid.

45.0 °C and 5.0 °C. The tem-

Microcool 40

Operation

Personnel:

1. Select the menu item for specifying the temperature setpoint.

2. Specify the setpoint.

Fig. 14: Setpoint input

3. Confirm with the ENTER button.

6.5

Restricting temperature limit values

The range of the temperature limit values must be restricted for

safety reasons. These two values depend on the heat transfer

liquid used. The default settings of

device cannot be changed.

Practical temperature limit values are:

Aqua 90 - Set the range to the values 42 °C and 3 ℃.

Kryo 30 (water /

glycol)

Operating personnel

If the entered setpoint is outside the specified temperature limit values, the value cannot be

adopted. Editing mode is active. An audible signal

is also output. You can input the setpoint again.

45.0 °C and

- Set the range to the values 42 °C and

-12 ℃.

5.0 °C stored in the

Upper temperature limit value

Fig. 15: Upper limit value

By adjusting the temperature limit values, the configurable setpoint range is automatically limited to as 2 °C

below the upper temperature limit and 2 °C above the

lower temperature limit.

Personnel:

1. Select the menu item for the upper temperature limit value.

2. Confirm with the ENTER button.

3. Specify the upper limit value.

The maximum value of the upper limit is 45 °C.

4. Confirm with the ENTER button.

Operating personnel

Microcool 41

Operation

Lower temperature limit value

Personnel:

1. Select the menu item for the lower temperature limit value.

2. Confirm with the ENTER button.

3. Specify the lower limit value.

Operating personnel

Fig. 16: Lower limit

6.6

Configuring timer

Special features of the timer

Functions for automatic switching

off - Auto-Shut-Down

The minimum value of the lower limit is 5 °C when

using Aqua 90 and -15 °C when using Kryo 30.

4. Confirm with the ENTER button.

The integrated timer can be used for switching the device on and

off automatically. The timer can be viewed and configured during

normal operation of the device.

The timer is configured using a number of hours and minutes in

the format hh.mm. The first two digits represent the number of

hours and the last two are the minutes. The timer can be set to

a maximum of 99 hours and 59 minutes.

The timer is only active while the machine is switched on. If the

machine is switched off using the mains power switch during

the running time of the timer, the timer is reset.

If Auto-Shut-Down of the timer is active, the current actual tem-

perature on the display is shown with a flashing decimal point.

If Auto-Shut-Down is invoked using the corresponding menu

item, the remaining time, for example 05.30 , is shown flashing.

If Auto-Shut-Down is deactivated, 00.00 is shown flashing.

Once the time for Auto-Shut-Down has elapsed, the device is

not switched off completely but switched to standby. Standby

means all components of the device are switched off and only

the display of the device is still supplied with power.

Functions for automatic switching

on - Auto-Start

If Auto-Start of the timer is configured, the device switches to

standby and Auto-Start is active immediately. If any Auto-ShutDown is active, the Auto-Start is not active until after completion of the Auto-Shut-Down.

If Auto-Start is active, the remaining time until the automatic

start is shown on the display. An audible signal is also output

during the complete last minute before starting the device.

Microcool 42

Configuring Auto-Shut-Down

Fig. 17: Auto-Shut-Down

Fig. 18: Standby

Operation

1. Select the menu item for specifying the Auto-Shut-Down.

2. Confirm with the ENTER button.

3. Specify the time until the device should be switched to

standby.

Wait for approx. 4 seconds if you would not like to

apply the specified value. The screen automatically returns to the default display.

4. Confirm with the ENTER button.

The value must be confirmed within 4 seconds

after the last input. Otherwise the screen returns

to the default display.

The device will be switched to standby after the time

entered. This is shown on the display as follows.

5. Auto-Start can now be configured before the expiry of Auto-

Shut-Down to switch the device on again afterwards after a

specified time. Otherwise you can start the device manually

by pressing the ENTER button.

Configuring Auto-Start

Fig. 19: Auto-Start

CAUTION!

Automatic device start using the auto-start timer

Frostbite, risk of injury, device damage

Before using the auto-start timer, ensure that all

preparations for the intended use have been made.

1. Select the menu item for specifying the Auto-Start.

2. Confirm with the ENTER button.

3. Specify the time until the device should be switched on

again.

If no Auto-Shut-Down is configured for the device,

the device is switched directly into standby with

the confirmation.

Wait for approx. 4 seconds if you would not like to

apply the specified value. The screen automatically returns to the default display.

Microcool 43

Operation

Displaying and editing remaining

time

4. Confirm with the ENTER button.

The value must be confirmed within 4 seconds

after the last input. Otherwise the screen returns

to the default display.

1. Select the menu item for the Auto-Shut-Down or Auto-Start.

2. Confirm with the ENTER button.

The remaining time is displayed.

3. You have the following options:

Wait approx. 4 seconds if you only want to display the

remaining time. The default display is shown again.

To edit the remaining time, set the time accordingly. Con-

firm with the ENTER button.

Reset

Restart manually

6.7

RS232 interface

6.7.1

Configuring RS232 interface

1. Select the menu item for the Auto-Shut-Down or Auto-Start.

2. Input 00.00.

3. Confirm with the ENTER button.

The value must be confirmed within 4 seconds

after the last input. Otherwise the screen returns

to the default display.

If the device has been switched to standby using Auto-Shut-Down

and no Auto-Start is configured, the device can be switched on

again manually.

1. Press the ENTER button to switch the device on again.

This function is only available if no Auto-Start is

active.

The baud rate for the RS232 interface can be configured using the

display.

Microcool 44

Operation

Fig. 20: RS232 interface

6.7.2

Protocol

RS232 protocol

Personnel:

Operating personnel

1. Select the menu item for configuration of the RS232 inter-

face.

2. Select the appropriate baud rate.

The following baud rates can be selected:

2.4

4.8

9.6

19.2

The hundreds and thousands digits are not visible

on the display.

3. Confirm with the ENTER button.

Your input is applied automatically after approx. 4

seconds.

Note the following:

The interface operates with 1 stop bit, no parity bit and 8 data

bits.

Selectable transmission speed: 2400, 4800, 9600 (factory set-

ting) or 19200 baud.

The RS232 interface can be operated with or without hardware

handshake (RTS/CTS).

The command from the computer must be terminated with CR,

CRLF or LFCR.

CR = Carriage Return (hex: 0D); LF = Line Feed (hex: 0A)

The response from the thermostat is always terminated with

CRLF.

Example for setpoint transfer of 30.5 °C to the thermostat.

Computer Thermostat

"OUT_SP_00_30.5"CRLF

"OK"CRLF

Microcool 45

Operation

6.7.3

Write commands

The write commands are data specifications to the thermostat.

Command Meaning

OUT_SP_00_XXX.XX Setpoint transfer with max. 3 digits before the dec-

imal point and max. 2 digits afterwards

OUT_SP_04_XXX [Hi] Upper limit of flow temperature

OUT_SP_05_XXX [Lo] Lower limit of flow temperature

START Switches on device (from standby)

STOP Switches device to standby (pump, refrigeration unit

off).

Note the following:

For "_", " " (space character) is also permitted.

Response from the thermostat “OK” or “ERR_X” in the case of

an error.

Permitted data formats

-XXX.XX -XXX.X -XXX. -XXX XXX.XX XXX.X XXX. XXX

-XX.XX -XX.X -XX. -XX XX.XX XX.X XX. XX

-X.XX -X.X -X. -X X.XX X.X X. X

-.XX -.X .XX .X

6.7.4

Read commands

The following read commands are data requests to the thermostat.

Command Meaning

IN_PV_00 Query of the bath temperature (outlet temperature)

IN_SP_00 Query of the temperature setpoint

IN_SP_04 Query of the outlet temperature limit Hi

IN_SP_05 Query of the outlet temperature limit Lo

TYPE Query of the device type (response = "MC").

VERSION Query of the software version number

Microcool 46

Operation

Command Meaning

STATUS Query of the device status, 0 = OK, -1 = fault

STAT Query for the fault diagnosis, response: XXXXXXX;

X = 0 no fault, X = 1 fault

Character 1 = error

Character 2 = not assigned

Character 3 = not assigned

Character 4 = not assigned

Character 5 = low level

Character 6 = not assigned

Character 7 = not assigned

Note the following:

For "_", " " (space character) is also permitted.

Unless otherwise specified for the command, the reply is

always in fixed decimal format "XXX.XX" or "-XXX.XX" for negative values or "ERR_X".

6.7.5

6.8

Error messages

Configuring alarm output

The error messages of the modules are described in the following.

Error Description

ERR_2 Incorrect input (e.g. buffer over-

flow)

ERR_3 Incorrect command

ERR_5 Syntax error in the value

ERR_6 Impermissible value

ERR_32 The upper temperature limit is

less than or equal to the lower

temperature limit.

In the case of an alarm or error, an electrical signal is output via

the alarm output of the device as default. However, you can also

configure that a signal will also be output in the case of a warning.

Microcool 47

Operation

Fig. 21: Alarm output

Fig. 22: Option error and alarm

Fig. 23: Option with additional warning

Personnel:

1. Select the menu item for configuring the alarm output.

2. Select the following option for the output of an electrical

signal for alarms and errors.

3. Select the following option for the additional output of an

electrical signal for warnings.

Wait for approx. 4 seconds if you would not like to

apply the specified value. The screen automatically returns to the default display.

4. Confirm with the ENTER button.

The value must be confirmed within 4 seconds

after the last input. Otherwise the screen returns

to the default display.

Operating personnel

6.9

Inputting offset of the temperature sensor

If any temperature difference is discovered when checking the

device with a reference thermometer, the offset (additive part of the

characteristic curve) of the internal measurement chain can be

adjusted using the CAL menu item.

A calibrated reference thermometer (e.g. from the LAUDA DigiCal

series) with the required degree of accuracy is required. Otherwise

the factory calibration should not be changed.

The reference thermometer must be installed in the flow of the

device in accordance with the specifications in the calibration certificate.

Personnel:

1. Select the menu item CAL.

2. Enter the temperature value read from the reference ther-

mometer at the device.

Fig. 24: Calibrating temperature

sensor

The calibration overwrites the factory calibration.

Operating personnel

Microcool 48

Operation

3. Keep the ENTER button pressed for approx. 3 seconds after-

wards.

The display shows donE . The new value has been

applied.

6.10

Fig. 25: Factory settings

Restoring the factory settings

Execute this menu item if you would like to restore the factory settings stored in the device.

The range of the temperature limit values is reset to

5 °C.

The timers are reset to 00.00 .

The signal output at the alarm output is reset to alarms and

faults .

The baud rate is reset to 9600 baud .

Personnel:

1. Select the menu item (dEF) for restoring the factory settings.

2. Confirm with the ENTER button.

3. Keep the ENTER button pressed for approx. 3 seconds after-

wards.

The display shows donE . The factory settings have been

restored.

Operating personnel

45 °C and

Microcool 49

Maintenance

7

7.1

Maintenance

General safety instructions

DANGER!

Contact with live or moving parts

Electric shock, impact, cutting, crushing

The device must be disconnected from the mains

power supply before any maintenance work.

CAUTION!

Contact with hot / cold device parts, accessories

and heat transfer liquid.

Burns, scalding, frostbite

Ensure device parts, accessories and heat transfer

liquid are at room temperature before touching

them.

NOTICE!

Contact with rotating part

7.2

Maintenance intervals

Severed parts of the body

Repairs must only be performed by specialist per-

sonnel.

Also note the following:

Before all maintenance work, you should ensure that decon-

tamination of the device has been performed if it came into

contact with hazardous materials.

The maintenance intervals described in the following table must be

complied with. The following maintenance work is mandatory

before every longer unsupervised operation.

Microcool 50

Maintenance

Interval Maintenance work

daily Inspection of the drain plug by visual inspection from the outside

monthly Inspection of the external hoses for material fatigue

Cleaning of the condenser

(only air-cooled devices)

Cleaning of the water filter

(only for water-cooled devices)

quarterly Decalcification of the cooling water circuit (a shorter interval must be selected depending

on water hardness and operating time)

(only for water-cooled devices)

half-yearly Inspection of the heat transfer liquid

7.3

Cleaning the device

7.4

Cleaning air-cooled condenser

Personnel:

WARNING!

Ingress of cleaning agents in the device

Electric shock

Use a moist cloth for cleaning.

Also note the following:

Only clean the control panel with water and detergent. Do not

use acetone or solvents. The consequence would be permanent damage of the plastic surfaces.

Operating personnel

Personnel:

1. Switch off the device.

2. Remove the front cover by holding underneath with both

hands and pulling the grating to the front. Remove the front

cover slowly and carefully to prevent damage.

3. Brush off or vacuum the condenser.

4. Replace the front cover carefully.

Microcool 51

Operating personnel

Maintenance

7.5

Cleaning the water filter

Fig. 26: Removing water filter

7.6

Decalcification of the cooling water circuit

Personnel:

1. Switch off the device using the mains power switch.

2. Undo the union nut at the supply of the water cooling.

3. Remove the cooling water hose with the hose nozzle from

the threaded connection.

4. Remove the water filter from the threaded connection care-

fully.

5. Clean the water filter and then put it back into the threaded

connection.

6. Press the cooling water hose with the hose nozzle back onto

the threaded connection of the supply. Carefully tighten the

water hose using the union nut at the threaded connection.

Personnel:

Operating personnel

If necessary, use tweezers to remove / insert the

water filter.

Operating personnel

Fig. 27: Decalcification

1. Switch off the device and prepare the decalcification process

accordingly.

The descaling agent should be fed to the water

cooling using a pump or a funnel through the

supply hose. The descaling agent return flow

should be via flow hose of the water cooling into a

container with sufficient capacity (at least 10

litres).

LAUDA descaling agent (catalogue number LZB

126, 5 kg packaging) is required for decalcification. Read the safety instructions and the instructions for use on the packaging for handling the

chemical.

2. Clean the water filter of the device. The water filter is in the

supply of the water cooling.

Further information for cleaning the water filter can

be found in

filter’ on page 52.

3. Fill the supply hose of the water cooling with LAUDA desca-

ling agent (pump or funnel). Continuously refill or pump the

descaling agent. Continue this process until the foaming

reaction goes down. This is usually the case after approx. 20

to 30 minutes.

Ä

Chapter 7.5 ‘Cleaning the water

Microcool 52

Maintenance

4. Drain the condenser afterwards.

Further information about draining the condenser

can be found in .

5. Reconnect the device to the water supply and rinse it thor-

oughly.

Allow at least 10 litres of water to flow through the

device.

7.7

Checking the heat transfer liquid

Soiled or degenerated heat transfer liquid must be replaced. Further use of the heat transfer liquid is only permitted with appropriate test results.

The heat transfer liquid must be checked according to DIN 51529.

Microcool 53

Faults

8

8.1

Procedure in the event of alarms

Procedure in the event of warnings

Procedure in the event of errors

Faults

Alarms, errors and warnings

Any alarms, error signals and warnings triggered on the device are

shown on the display as 7-segment text.

Alarms can be cancelled using the ENTER button after rectification

of the cause of the fault.

A list of alarms can be found in

on page 55.

Warnings can be cancelled using the ENTER button after rectification of the cause of the fault.

A list of warnings can be found in

view’ on page 55.

A two-tone signal is output if any error occurs. The red LED on the

device also lights.

In the case of an error, switch off the device at the mains power

switch. If the error occurs again after restarting the device, note the