Lauda Integral XT 490 W, Integral XT 250 W, Integral XT 350 W, Integral XT 350 HW, Integral XT 550 Operating Instructions Manual

...

Operating instructions

Integral XT

Process thermostats

XT 150, XT 250 W, XT 280, XT 280 W, XT 350 W, XT 350 HW, XT 490 W,

XT 550, XT 550 W, XT 750, XT 750 S, XT 750 H, XT 750 HS,

XT 950 W, XT 950 WS, XT 1590 W, XT 1590 WS,

XT 1850 W, XT 1850 WS

High-temperature thermostats

XT 4 H, XT 4 HW, XT 8 H, XT 8 HW

Operating instructions

Process thermostats

XT 150, XT 250 W, XT 280, XT 280 W, XT 350 W, XT 350 HW, XT 490 W,

XT 550, XT 550 W, XT 750, XT 750 S, XT 750 H, XT 750 HS,

XT 950 W, XT 950 WS, XT 1590 W, XT 1590 WS,

XT 1850 W, XT 1850 WS

High-temperature thermostats

XT 4 H, XT 4 HW, XT 8 H, XT 8 HW

Read the instructions before starting work!

YAWE0028 Translation of the original operating instructions

release 11/2016 h

replaces release 06/2016 g6, 04/2016 g5, 01/2015 g4,

05/2013 g1, 02/2012 e3, 10/2011 d1, 08/2011 c4, 08/2011 c2,

05/2011 c1, 11/07/2009, 08/06/03/2008, 07/2007

Valid from:

software version of Command (Control Panel) 3.38

software version of Control system (Master) 2.44

software version of Security system (Master) 2.17

software version of Chilling system 3.34

software version of Pump 2.20

software version of Analogue IO module 3.13

software version of Serial IO module 3.14

software version of Digital IO module 3.14

software version of Ethernet module 1.21

software version of EtherCAT module 1.03

LAUDA DR. R. WOBSER GMBH & CO. KG

Pfarrstraße 41/43

97922 Lauda-Königshofen

Phone: +49 (0)9343 503-0

Fax: +49 (0)9343 503-222

E-mail info@lauda.de

Internet http://www.lauda.de

Germany

Integral XT

Prefixed safety notes

Before operating the equipment please read c aref ul l y all the instructions and safety

notes in Section 1.

If you have any questions please phone us!

Follow the instructions on setting up, operat ion et c. T his is the only way to avoid incor-

rect operation of the equipment and to ensure full warranty protection.

The Operating Instructions include additional safety notes which are ident i fi ed by a triangle

with an exclamation mark. Carefully read th e instructions and follow them accurately! Disregarding the instructions may have serious consequences, such as damage to the equipment,

damage to property or injury to personnel!

• Transport the equipment with care!

The unit may NEVER be overturned nor put upside down!

• Equipment and its internal parts can be damaged:

− by dropping,

− by shock.

• Equipment must only be operated by technically qualified personnel!

• Never operate the equipment without the heat transfer liquid!

• Do not start up the equipment if,

− it is damaged or leaking,

− cable (not only supply cable) is damaged.

• Switch off the equipment and pull out the mains plug:

− for servicing or repair,

− moving the equipment!

• Drain the device before moving the equipment!

• Do not carry out any technical changes on the devic e!

• Have the equipment serviced or repaired by prope rl y qualified personnel only!

We reserve the right to make technical alterations!

YAWE0028 / 24/06/2016 Prefixed safety notes 3

Integral XT

Contents

Prefixed safety notes .................................................................................................................................... 3

1 SAFETY INFORMATION .................................................................................................................. 7

1.1 GENERAL SAFETY INFORMATION ........................................................................................................... 7

1.2 OTHER SAFETY INFORMATION ............................................................................................................... 8

2 BRIEF OPERATING INSTRUCTIONS ........................................................................................... 10

2.1 MENU STRUCTURE: MASTER .............................................................................................................. 11

2.2 MENU STRUCTURE: COMMAND ........................................................................................................... 12

2.3 VIEW OF THE DEVICE AND CONNECTIONS ............................................................................................. 13

3 CONTROLS AND FUNCTIONAL ELEMENTS .............................................................................. 21

4 DEVICE DESCRIPTION .................................................................................................................. 22

4.1 ENVIRONMENTAL CONDITIONS ............................................................................................................ 22

4.2 TYPES OF DEVICES ............................................................................................................................ 22

4.3 HYDRAULIC CIRCUIT AND VARIO PUMP ................................................................................................. 23

4.4 SUBSTANCES / MATERIALS .................................................................................................................. 23

4.5 TEMPERATURE DISPLAY, CONTROL AND SAFETY CIRCUIT ...................................................................... 23

4.6 PROGRAMMER AND RAMP FUNCTION ................................................................................................... 24

4.7 INTERFACES ...................................................................................................................................... 24

4.8 INTERFACE MODULES (ACCESSORIES) ................................................................................................. 25

4.9 REFRIGERATING UNIT ......................................................................................................................... 25

5 UNPACKING ................................................................................................................................... 26

5.1 AFTER UNPACKING ............................................................................................................................. 26

5.2 STANDARD ACCESSORIES: .................................................................................................................. 26

5.3 UNPACKING AND PACKING WITH ORIGINAL TRANSPORT PACKAGING MATERIAL ....................................... 27

5.3.1 Sector of application ........................................................................................................................ 27

5.3.2 Background ...................................................................................................................................... 27

5.3.3 Supposition ...................................................................................................................................... 27

5.3.4 Unpacking the device ....................................................................................................................... 27

5.3.5 Packing for shipping with original transp ort packaging material ...................................................... 27

5.3.5.1 Overview ................................................................................................................................... 27

5.3.5.2 Packing the device .................................................................................................................... 28

6 PREPARATIONS ............................................................................................................................ 33

6.1 ASSEMBLY AND SITING ....................................................................................................................... 33

6.2 HEAT TRANSFER LIQUIDS, COOLING WATER AND HOSES ....................................................................... 36

7 STARTING UP ................................................................................................................................ 39

7.1 MAINS CONNECTION ........................................................................................................................... 39

7.2 SWITCHING ON ................................................................................................................................... 39

7.3 SWITCHING OFF / STANDBY ................................................................................................................. 41

7.4 KEY FUNCTIONS ................................................................................................................................. 42

7.4.1 General key functions and pilot lam ps ............................................................................................. 42

7.4.2 Changing window information (Command remote control) ............................................................. 47

7.4.3 Locking the keyboard ....................................................................................................................... 48

7.5 LEVEL DISPLAY .................................................................................................................................. 50

7.6 FILLING, VENTING AND DEGASSING ...................................................................................................... 51

7.6.1 Filling ................................................................................................................................................ 51

7.6.2 Venting ............................................................................................................................................. 52

7.6.3 Degassing ........................................................................................................................................ 53

7.6.3.1 Automatic degassing program .................................................................................................. 53

4 Contents YAWE0028 / 24/06/2016

Integral XT

7.6.3.2 Permanently and automatic degassing ................................................................................... 54

7.6.4 Topping up ...................................................................................................................................... 54

7.7 DRAINING ......................................................................................................................................... 55

7.8 CHANGING THE HEAT TRANSFER LIQUID AND INTERNAL CLEANING ........................................................ 56

7.9 IMPORTANT SETTINGS ....................................................................................................................... 57

7.9.1 Temperature setpoint setting .......................................................................................................... 57

7.9.2 Displaying the actual external temperature .................................................................................... 59

7.9.3 Pump capacity or setting standby ................................................................................................... 60

7.9.4 Pressure control .............................................................................................................................. 62

7.9.5 Maximum pressure control .............................................................................................................. 62

7.9.6 Activating external control ............................................................................................................... 63

7.9.7 Current consumption from the mains .............................................................................................. 65

7.9.8 Setting the date and time (Command remote control) .................................................................... 66

7.9.9 Display resolution setting (Command remote control) .................................................................... 67

7.10 SPECIAL SETTINGS ............................................................................................................................ 68

7.10.1 Defining the type of start mode ....................................................................................................... 68

7.10.2 Defining temperature limits ............................................................................................................. 69

7.10.3 Setpoint offset operating mode ....................................................................................................... 70

7.10.4 Restoring works settings ................................................................................................................. 71

7.10.5 Setting the volume of the acoustic signals ...................................................................................... 72

7.10.6 Entering the offset of the internal temperature probe ..................................................................... 72

7.10.7 Restoring the works setting of the interna l temperature-probe offset ............................................. 73

7.10.8 Entering the offset of the external temperature probe .................................................................... 74

7.10.9 Restoring the works setting of the external temperature-probe offset ............................................ 74

7.10.10 SmartCool ....................................................................................................................................... 75

7.11 GRAPHICAL DISPLAY OF TEMPERATURE MEASUREMENTS (COMMAND REMOTE CONTROL) ..................... 76

7.12 PROGRAMMER .................................................................................................................................. 78

7.12.1 Program example ............................................................................................................................ 78

7.12.2 Selecting and starting the program (Start, Hold, Stop) ................................................................... 80

7.12.3 Interrupting, continuing or terminating the program (Hold, Continue, Stop) ................................... 81

7.12.4 Creating or modifying a program (Edit) ........................................................................................... 82

7.12.5 Defining the number of program loops (Loops) .............................................................................. 86

7.12.6 Viewing the program sequence as a graph (Graph) ....................................................................... 86

7.12.7 Obtaining information on a program (Info) ...................................................................................... 87

7.12.8 Optimization of the Programmer ..................................................................................................... 88

7.13 RAMP FUNCTION ............................................................................................................................... 89

7.14 TIMER FUNCTION / TIMER (COMMAND) ................................................................................................ 90

7.15 CONTROL AND CONTROL PARAMETERS .............................................................................................. 91

7.15.1 Setting instructions for bypass ........................................................................................................ 92

7.15.2 Configuration examples .................................................................................................................. 93

7.15.3 Internal control variable (integral measurement probe) .................................................................. 94

7.15.3.1 Procedure for setting the control parameters for internal control ............................................ 95

7.15.3.2 Table with control parameters and pump lev el for internal control .......................................... 95

7.15.4 External control variable (External measurement probe) ............................................................... 96

7.15.4.1 Procedure for setting the control parameters for external control ........................................... 97

7.15.4.2 Well-proven settings for control parameters and pu m p level for external control ................... 99

7.15.5 Internal and external control parameter sets .................................................................................. 99

7.15.6 Self Adaption ................................................................................................................................. 101

7.15.7 Limiting the heating and cooling power ......................................................................................... 103

7.15.7.1 Actuating signal limit .............................................................................................................. 103

7.15.7.2 Dynamic limitation of heating power ...................................................................................... 103

7.15.7.3 Dynamic control of heating power ......................................................................................... 104

7.16 ALARMS, WARNINGS AND ERRORS .................................................................................................. 105

7.16.1 Overtemperature protection and checking .................................................................................... 105

7.16.2 Low-level alarm and low-level checking ........................................................................................ 106

7.16.3 High-level settings ......................................................................................................................... 107

7.16.4 High-level warning or alarm .......................................................................................................... 108

7.16.5 Pump-motor supervision: Overload or blockage ........................................................................... 109

YAWE0028 / 24/06/2016 Contents 5

Integral XT

7.16.6 Pump-motor supervision: Dry running ........................................................................................... 109

7.17 RS232/RS485 INTERFACE (ONLY COMMAND REMOTE CONTROL OR MODULE) ................................... 110

7.17.1 Connecting cables and interface test RS232 ................................................................................. 110

7.17.2 Protocol RS232 .............................................................................................................................. 110

7.17.3 Connecting cable RS485 ............................................................................................................... 111

7.17.4 Protocol RS485 .............................................................................................................................. 111

7.17.5 Write commands (Data commands to the thermostat) .................................................................. 112

7.17.6 Read commands (Data requested from the thermostat) ............................................................... 113

7.17.7 Error messages .............................................................................................................................. 115

7.17.8 Driver-software for LABVIEW® ...................................................................................................... 115

8 INTERFACE MODULES ............................................................................................................... 116

8.1 INSTALLING OF MODULES .................................................................................................................. 116

8.2 MENU STRUCTURE FOR ALL MODULES ............................................................................................... 118

8.3 SERIAL INTERFACES RS232/485 ...................................................................................................... 119

8.4 ANALOGUE MODULE ......................................................................................................................... 119

8.5 CONTACT MODULE ........................................................................................................................... 121

8.5.1 Contact module LRZ 915 with three inputs and three outputs ...................................................... 121

8.5.2 Namur-Contact module LRZ 914 with only one input and one output ........................................... 122

9 MAINTENANCE ............................................................................................................................ 123

9.1 CLEANING ....................................................................................................................................... 123

9.1.1 Cleaning the surface of the device ................................................................................................ 123

9.1.2 Cleaning the hydraulic circuit ......................................................................................................... 123

9.1.3 Draining the water-cooled condenser ............................................................................................ 123

9.2 DEVICE STATUS ............................................................................................................................... 123

9.2.1 Interrogating the device type.......................................................................................................... 123

9.2.2 Software version ............................................................................................................................ 124

9.2.3 Serial numbers ............................................................................................................................... 124

9.2.4 Device data .................................................................................................................................... 124

9.2.5 Fault memory (Command remote control) ..................................................................................... 125

9.2.6 Operating info ................................................................................................................................ 125

9.2.7 Heater Info ..................................................................................................................................... 126

9.3 SERVICING AND REPAIR .................................................................................................................... 127

9.3.1 Service intervals ............................................................................................................................. 127

9.3.2 Cleaning the condenser ................................................................................................................. 128

9.3.2.1 Air-cooled condenser .............................................................................................................. 128

9.3.2.2 Water-cooled condenser......................................................................................................... 128

9.3.2.2.1 Cleaning the dirt trap ........................................................................................................... 128

9.3.2.2.2 Decalcifying the water cooling circuit .................................................................................. 129

9.3.3 Fuses ............................................................................................................................................. 130

9.3.4 Testing the heat transfer liquid ...................................................................................................... 137

9.3.5 Repair information .......................................................................................................................... 137

9.4 REMEDYING FAULTS ......................................................................................................................... 138

9.5 SERVICE, ORDERING REPLACEMENT PARTS AND RATING LABEL ........................................................... 142

9.6 DISPOSAL INFORMATION ................................................................................................................... 143

9.6.1 Disposal of the refrigerant .............................................................................................................. 143

9.6.2 Disposal of the packaging .............................................................................................................. 143

10 ACCESSORIES ............................................................................................................................ 144

11 TECHNICAL DATA ....................................................................................................................... 148

12 INDEX ............................................................................................................................................ 160

CONFIRMATION………………………………………………………………………………………...163

6 Contents YAWE0028 / 24/06/2016

Integral XT

Explanation of signs:

1 Safety information

According to Paragraph 14 of the operational safety decree (BetrSichV)1, the device is a system which

requires supervision. (Classification according to the Pressure Equipment Directive 97/ 23 / EC: Category I). Before being put into operation, the system must be subjected to inspection for siting, for ascertaining that the device is in order and for correct functioning. A certificate must be issued regarding this

inspection, documenting the extent and the result of the inspection.

1

The national regulations of the respective country in which the system is sited must be followed.

Danger: This sign is used where there may be injury to person-

nel if a recommendation is not followed accurately or is

disregarded.

Note: Here special attention is drawn to some aspect. May

include reference to danger.

Reference Refers to other information in different sections.

1.1 General safety information

A process thermostat is used to heat, cool and circulate heat transfer liquids as specified. Hazards arise

from this due to high or low temperatures, excess pressures, fire and the general hazards due to the

application of electrical energy.

The user is largely protected by the application of the relevant standards.

Further hazard sources can arise from the type of material for which the temperature is to be stabilized,

e.g. by the exceeding or undercutting certain temperature thresholds or by the fracture of the container

and reaction with the heat transfer liquid.

It is not possible to include all possibilities. They remain essentially subject to the judgment and responsibility of the operator.

The devices may only be used as intended, that is as described in this operating manual. This includes

operation by instructed specialist personnel.

The devices are not designed for use in medical applications in accordance with DIN EN 60601-1 or

IEC 601-1.

Use restriction

Classification in accordance with EMC requirements

On the EMC standard DIN EN 61326-1:

Devices in Emissions Class A can only be operated on power grids that are n ot con-

nected to residential areas!

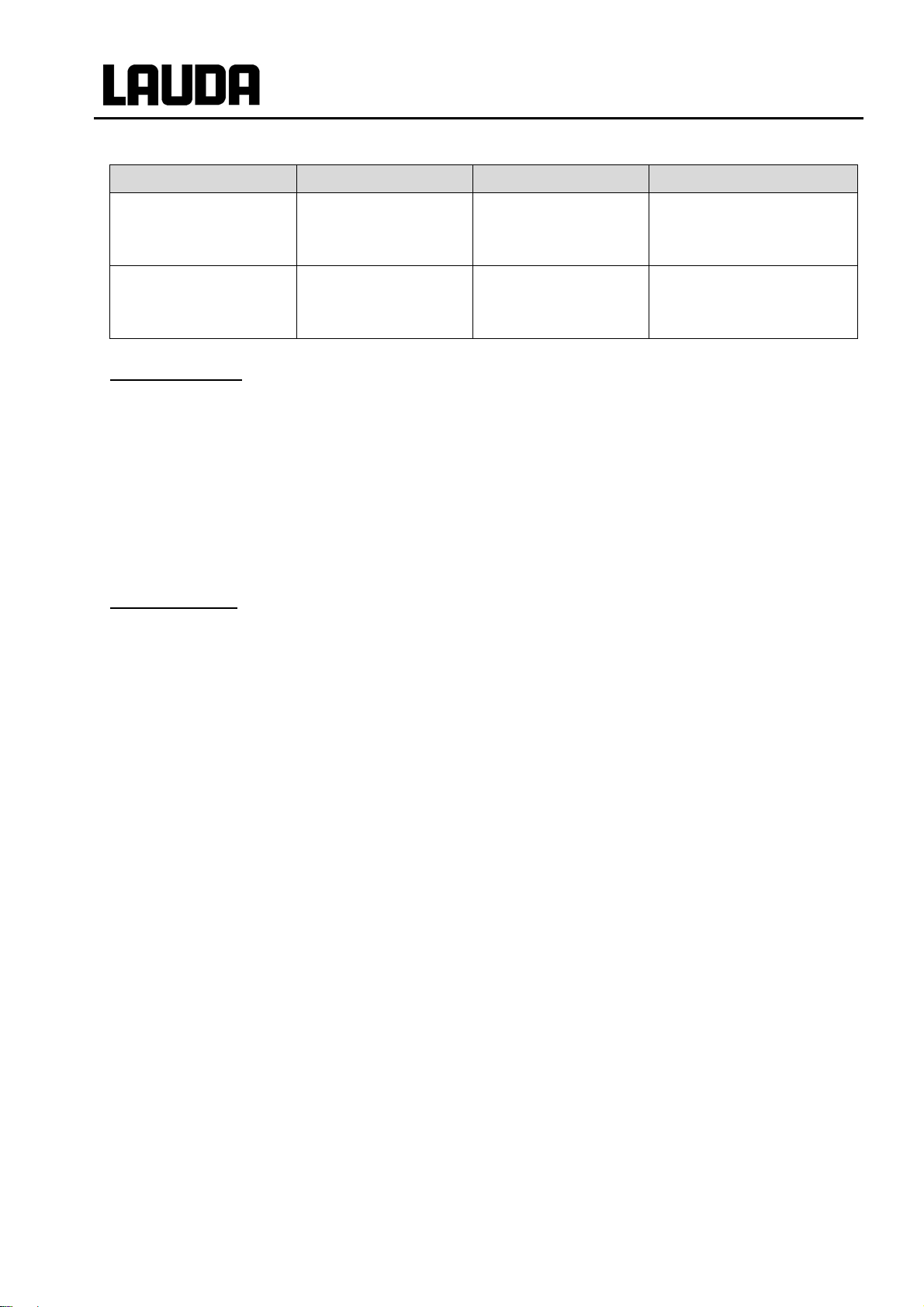

Device Immunity Emissions class Customer power supply

Integral XT high-

temperature ther-

mostat

YAWE0028/ 11/11/2016 Safety information 7

Type 2 in accordance

with

DIN EN 61326-1

Emissions Class B

in accordance with

CISPR 11

Worldwide

No limitation

Integral XT

Device Immunity Emissions class Customer power supply

Integral XT process

thermostat

single-phase and triple-

phase devices

Integral XT process

thermostat

single-phase and triple-

phase devices

Valid for the USA:

Instructions for Class A digital devices

“This equipment has been tested and found to comply with the limits for Class A digital device, pursuant to

Part 15 of the FCC (Federal Communication Commission) Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.”

“This device complies with Part 15 of the FCC (Federal Communication Commission) Rules. Operation is

subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.”

Valid for Canada:

“This Class A digital apparatus complies with Canadian ICES-003” (ICES = Interference Causing Equipment

Standards).

« Cet appareil numérique de la Classe A est conforme à la norme NMB-003 du Canada ».

Type 2 in accordance

with

DIN EN 61326-1

Type 2 in accordance

with

DIN EN 61326-1

Emissions Class B

in accordance with

CISPR 11

Emissions Class B

in accordance with

CISPR 11

Domestic connection value

Rest of the world (outside

Only for EU

≥ 100 A

EU)

No limitation

1.2 Other safety information

Check the device carefully for shipping damage before putting into operation. The device should not

be put into operation if shipping damage has been found.

Only connect equipment to PE grounded mains so ckets.

At higher operating temperatures, parts of the device (e.g. connection, drain points) can take on sur-

face temperatures of over 70 °C. Be careful when touching the device Danger of burns.

After a mains failure or after switching off the device, the device surfaces can further heat up briefly.

Use suitable hoses ( 6.2).

Check the hoses from time to time for any material fatigue. Hot liquid can e scape due to hose fracture

and become a danger to personnel and materials.

Heat transfer hoses and other hot parts must not come into contact with the mains cable.

The following actions may start the thermostat unintentionally from the standby mode: Previously ac-

tivated timer mode ( 7.14), "Start" command via interfaces ( 8).

Withdraw the mains plug before cleaning, servicing, repairing or moving the thermostat.

Have repairs carried out only by speciali sts. The device may only be service d by trained specialist

personnel.

Keep to service and maintenance intervals ( 9.2.6).

Observe the permissible storage and operating temperatures ( 11).

The device should not be subjected to fire; otherwise there is the danger of an explosion.

The device may only be operated with its housing in place.

Do not site the device in areas where there are aggressive media.

Only site the device on a level surface.

8 Safety information YAWE0028 / 11/11/2016

Integral XT

Do not put any heavy parts on the device.

The operating personnel must wear suitable protective equipment.

Do not operate the device when leaks have been found; ventilate the siting room immediately.

With pressure sensitive loads (e.g. glass apparatus) with a maxim um permissible operating pressure

below the maximum pressure of the pump (3.5 bars for water, with XT 1850 W 7.0 bars with water),

the hoses of the load must be routed such that kinking or squashing is not possible. In addition, a

separate safety valve must be installed to protect against faulty operation ( 7.9.4, 7.9.5 and page

34).

When selecting the heat transfer liquid, observe the permissible temperature range.

Heat transfer liquids from LAUDA are recommended which have been tested for use with the device

( 6.2).

Always set the over temperature cut-off point immediately according to the heat transfer liqui d used

when filling ( 7.16.1).

If required, the heat transfer liquid should be checked for fitness for use (e.g. when changing the

method of operation), or half-yearly. Further use of the heat transfer liquid is only permissible if the inspection indicates this ( 9.3.1 and 9.3.4).

Keep the cover of the filling point closed during operation.

Under certain operating conditions (degassing, rapid heating phases), the temperature may increase

in the expansion vessel. In extreme cases, the outflow temperature of the device is reached. If heat

transfer liquids are heated beyond a certain temperature (25 °C under the fire poi nt of the heat transfer liquid), then sources of ignition must be kept away from the filling opening and overflow (and at the

aeration point of the expansion tank). In such cases, a nitrogen overlay of the expansion vessel is

recommended (cover XT with connection for nitrogen overlay LWZ 072).

Degas carefully (slowly) ( 7.6.3).

It is essential to avoid gas cushions in the load sy stem. This can be done by reducing the pump pow-

er by one or two levels and checking that the level indication of the device does not increase.

If an overflow catchments container is connected, it must be suitable (including the connecting hose)

for the maximum operating temperature. The connection hose must be securely fitted.

The overflow must not be closed.

Draining / drain mode is only permissible with an established temperature range ( 7.7).

During operation the draina ge openings must be closed with plugs (standard accessories).

On changing the heat transfer liquid, thoroughly clean the device a nd completely drain it. It is recom-

mended that the device is rinsed with the new heat transfer liquid ( 7.8).

It is essential to prevent the ingress of secondary liquids (e.g. via a customer's defective heat ex-

changer).

Only water-cooled devices:

The return hose of the water cooling m ust be securely fixed on the outlet port in order to prevent the

hose sliding off uncontrollably, also during pressure surges.

The return hose of the water cooling m ust be fixed on the outlet port that hot cooling water cannot

splash out.

It is essential to prevent kinking or squashing of the return hose for the water cooling. Excessive

pressure can cause the cooling water hoses to tear and hot water to escape.

To prevent damages by a leakage of the cooling water system it’s recommended to use a leak-wate r

detector with shut-off valve (Aqua Stop).

YAWE0028/ 11/11/2016 Safety information 9

Floor-standing device

°C

°C

2 Brief operating instructions

These brief instructions shall give you the possibilit y to operate the unit quickly.

For safe operation of the unit, it is absolutel y necessary to read carefully all the instruc-

tions and safety notes!

1. Set up the device or complete the configuration as required (þ 6.1).

The device should never be tilted or stood upside down!

Note the connection of the hose joints (þ 6.2).

2. Pay attention to pressure sensitive loads (e.g. glass apparatus) with a maximum permi ssible operating pressure (þ 7.9.4).

3. Only operate the Integral XT when flow through t he external load is possible.

4. Open any shut-off valves in the external loads.

5. Compare the details on the rating label with the m ains voltage.

Three-phase device: Ensure a clockwise phase sequence.

Only XT 1850 W Order No. LWP 732 and XT 1590 W Order No. LWP 742:

Check the switch position [400 V; 3/PE; 50 Hz or 440-480 V; 3/PE; 60 H z] for presence of

mains voltage and frequency. An incorrect setti ng does not result in any damage, but an

error message occurs

correctly set switch to the correct voltage and f requency values. The switch is fitted on the

back of the unit at the top left, behind the cover panel (þ 2.3).

Error 367 (þ 9.4). With the unit switched off, set the in-

Integral XT

6. Only connect device to a socket having a safety earth conductor.

7. Switch on the device by the main fuse-switch on the front panel ("ON =

Bench-top device

8. In the display you see either the current outflow temperature , e.g.:

or if the device has not yet been filled:

Act. val. outflow temp.

02%32

Fill device

FiLL

l").

10 Brief operating instructions YAWE0028 / 24/06/2016

Integral XT

F or Fill

If instead, a warning or error message is displayed, then refer to Section 7.16.

9. Fill device with heat transfer liquid and follow Section 7.6.

Use suitable heat transfer liquid (þ 6.2).

The devices are rated for operation with non-flamm able and flammable liquids according to

DIN EN 61010-2-010.

Water is not permissible!!

10. Set the over temperature cut-off point with

(þ 7.16.1).

2.1 Menu structure: Master

25.32

This shows the actual

value of outflow temperature or actual value of

external temperature.

Fill

Filling mode, superimposed as required.

according to the heat transfer liquid used

SEt

Set setpoint

Section 7.9.1.

Pu

Pump power

Section 7.9.3.

LE

Level indication

Section 7.5.

P

Pump pressure

Section 7.9.4.

Con

Control Int/Ext

Section 7.9.5.

Filling mode

Section 7.6.

unFill

Draining

Section 7.7.

YAWE0028 / 24/06/2016 Brief operating instructions 11

Menu

Display

Sounds Command

Language

Master mode

Autostart

Current consumpt.

Pump

Settings

Graph

Programmer

Interfaces 1

Limits

Pump Level

Pressure control

Start Fill mode

Start Unfill mode

Start unfill heat exch.

Aux. Pump OFF

Calibration

Works settings

Resolution

Device status

Display data

Basic settings

Set time

Set data

Timer 1

Timer 2

Program 1

Program 2

Program 3

Program 4

Program 5

Ramp function

prog.Optimization

Serial Command

serial Master 2/

Profibus

Analog interfaces

Smart Cool 4

Control parameters

Control para. sets

Tv manual/auto

Correction limitation

Self Adaption

Control variable

Control parameters

Controller outp. limit

dynamic heat limit

HT Cooler min. Temp 3

Brightness

intern Pt100

extern Pt100

Device type

Software Version

Serial numbers

Device data

Operating info

Heater Info

Status

Time

Time unit

internal

Analog interface

extern serial

Calibration

Default

Alarm

Basic window

Standard window

Super window

Edit

Default

T il (min)

T ih (max)

Tn

Tv (auto)

Td (auto)

Kpe

Tve (auto)

Tde (auto)

Xpf

Prop_E(a)

off

Status

Loops

Graph

Start / Stop

Hold / continue

Modify

Erase

Show chart

Offset source

Setpoint offset

Automatic

Status

Setpoint

Identification

Actual Parameters

All Modules

Master

Command

Cool

Pump

Other connected

modules

Deutsch

Français

Español

All default

Only control par. int.

Only control par. ext.

Only miscellaneous

Settings

Mode

Displayed value

Legend

Sample Time

Time axis

Time base

Limits

off

automatic

none

Warning

Alarm

Mode

RS485 address

all default

max. Cool

max. Heat

off

on

on

Start

Set value

1 (þ 8.2)

2

no menu in Command

3

only HT-Devices

4

not at XT 4 H, XT 8 H

2.2 Menu structure: Command

Max. Press.[bar] 1,0

Integral XT

Display

Clock

Control

Overlevel handling

Format of date

Switching contact

on

Errorstore

Sounds Master

Temp. scale

Edit

Contrast

Warning

English

Warn.+ Heater off

Xp

12 Brief operating instructions YAWE0028 / 24/06/2016

Info

external Pt100

Setpoint offset

HT Cooler Mode 3

End

Temp. Change

Baud rate

Tne

Manual

external Pt100

Integral XT

2.3 View of the device and connections

Integral XT 150

1 2

3

4

6 5

1 Main switch

2 Filling point for heat transfer liquid

3 Interface section

4 Mains cable

5 Drain point M16 x 1

6 Drain tap

Refer to page 19 for an illustrated side view of connections and taps.

YAWE0028 / 24/06/2016 Brief operating instructions 13

Integral XT

Integral XT 250 W

1 2

3

4

6 5

Refer to page 19 for an illustrated side view of connections and taps.

14 Brief operating instructions YAWE0028 / 24/06/2016

Integral XT

3

Integral XT 350 HW and XT 950 W(S)

1 2

4

YAWE0028 / 24/06/2016 Brief operating instructions 15

Refer to page 20 for an illustrated side view of connections and taps.

Integral XT

3

Refer to page 20 for an illustrated side view of connections and taps.

Integral XT 280, XT 750 (S) und XT 750 H(S)

1 2

4

16 Brief operating instructions YAWE0028 / 24/06/2016

Integral XT

3

Refer to page 20 for an illustrated side view of connections and taps.

Integral XT 490 W, XT 1590 W, XT 1590 WS, XT 1850 W, XT 1850 WS

1 2

4

YAWE0028 / 24/06/2016 Brief operating instructions 17

Integral XT

Rear view

XT 150/ XT 250 W from XT 280

1

2

1 Overflow and venting for the equalizing container (all units)

2 Switch for setting mains voltage and frequency (þ 2 and 9.4) (only XT 1850 W Order No. LWP 732;

XT 1590 W Order No. LWP 742).

Interface section

Two LiBus sockets for the Command remote control (standard) and LiBus accessories, socket for external Pt100 temperature probe (resistance thermometer to DIN EN 60751) (accessory), two slots for LiBus

interface modules (accessories).

18 Brief operating instructions YAWE0028 / 24/06/2016

Integral XT

Side view of connections (with XT 250 W as example)

1

2

3

4

1 Exit cooling water connection R3/4” (only water cooled devices W).

2 Entrance cooling water connection R3/4” (only water cooled devices W).

3 Pump connector outflow M30 x 1.5 (to the consumer).

4 Pump connector return M30 x 1.5 (from the consumer).

YAWE0028 / 24/06/2016 Brief operating instructions 19

Integral XT

Side view of connections and taps (with XT 350 HW as example)

1 Pump connector outflow M30 x 1.5 (to the consumer) (XT 1850 W(S): M38 x 1.5).

devices W)

1

2

3

4

5

6

7

8

2 Pump connector return M30 x 1.5 (from the consumer) (XT 1850 W(S): M38 x 1.5).

3 Drain point M16 x1 with drain tap: expansion vessel.

4 Drain point M16 x1 with drain tap: main emptying.

5 Drain point M16 x1 with drain tap: HT-cooler (only devices with temperature range up to 300 °C.)

6 Drain point M16 x1 with drain tap: cooling unit.

7 Exit cooling water, connection R3/4” (XT 1590 W(S), XT 1850 W(S): R1”) (only water cooled devices

W)

8 Entrance cooling water, connection R3/4” (XT 1590 W(S), XT 1850 W(S): R1”) (only water cooled

20 Brief operating instructions YAWE0028 / 24/06/2016

Integral XT

Graphical display,

Cursor key

pump are switched off.

Yellow standby LED

3 Controls and functional elements

Control element: Master

Mains on

(green LED)

Control element:

Command remote control

Indication of an error message

(red LED flashes)

Control with ext. temperature

probe (green LED lights)

EXT

The temperature of the external

source is shown in the display

(EXT lights green)

Cooling active (blue LED lights)

Heating active (yellow LED lights)

Selection and entry keys

Overtemperature cut-off point

Check or set T

here in the normal window display of the v al ues:

• Actual tempe rat ure T

of the internal outflow temperature

out

probe

• Setpoint tem perat ure T

• Actual tempe rat ure T

set

of the external load temperature

ext

probe

• Level in the e xpansion vessel

• Pump level

• Outflow pressure

max

YAWE0028 / 24/06/2016 Controls and functional elements 21

RS232 socket

(concealed on the back of Command)

Enter key

Decimal point or "-" sign

Escape key for quitting a window

without making any changes

Standby key brings the thermostat into the waiting mode. Heating, refrigeration machine and

5 softkey duo-keys, the respective function of which is shown in

the display

4 Device description

4.1 Environmental conditions

The operation of the thermostats is only all owed under the following conditions as specified in

EN 61010-2-010:2003 and EN 61010-1:2001:

− Indoor use.

− Altitude up to 2000 m above sea level.

− Foundation must be dense, even, non-slippery and non-flammable.

− Keep clear distance (þ 6.1).

− Ambient temperature range (þ 11).

Use only within this range for an undisturbed op eration.

− Mains supply voltage fluctuations (þ 11).

− Maximum relative humidity (þ 11).

− Transient over voltage according to Installation Categories (Over voltage Categories) II.

Integral XT

− Pollution degree: 2.

4.2 Types of devices

Process thermostats

The type designation of the Integral XT Process Thermostat consists of the numerical figures for the

cooling power (in kW at 20 °C, mathematically roun ded) and the minimum temperature (rounded,

without arithmetical sign). The identifying let ter "H" stands for devices with a maximum operati ng temperature of 300 °C or "W" stands for water-cooled variants.

Examples: XT 750 is a device with approx. 7 kW cooling power, approx. -50 °C lowest temperature

and 220 °C highest temperature.

XT 350 HW is a device with approx. 3 kW cooling po wer, approx. -50 °C lowest tempera ture, 300 °C highest temperature and wat er cooling.

High-temperature thermostats

The type designation of the Integral XT High-temperature thermostat consists of the numerical fi gures

for the heating power (in kW, starting from 230 V devices, mathematically rounded) and an identifying

letter. The identifying letter "H" stands for high-temperature thermostats and "W" stands for watercooled variants.

High-temperature thermostats with cooling wate r connection (type W) always require a cooling water

supply, even if they are only used in heating mode.

Precise figures can be taken from the Technical Data (þ 11).

22 Device description YAWE0028 / 24/06/2016

Integral XT

herefore be optimally matched to the respe ct i ve task: High pump pressure when, for

Alternative to eight power levels, operati on with closed loop pressure control is available f or supplying

processes (loads) with a maximum permissible pres sure rating e.g. pressure sensitive glass reactors.

which is used for displaying the measurements a nd setting values as well as the operating states. The

4.3 Hydraulic circuit and Vario pump

The hydraulic circuit in the unit partly consi st s of a pipe system through which the temperature stabilizing liquid flows under pressure.

The main components are:

All devices are equipped with an eight-level, herm etically sealed (magnetically coupled) pump. T he

pump power can t

example, long hoses lead to external loads.

pipe system,

equalizing tank (with no flow),

pump,

heater and

heat exchanger.

On the right side of the device outflow and return connection pieces are fitted for external loads.

In the heating range the pump operates up to cinematic viscosities of 200°mm²/s. In normal op erat i on

50°mm²/s should not be exceeded. From 30°mm²/s the temperature control is optimum.

The device pump connections are fitted with t hreaded connections M30 x 1.5 or M38 x 1.5 according

to DIN 3863.

Pump characteristics (þ 11).

4.4 Substances / materials

All parts coming into contact with the medi a l i quid are made of high quality material suitable f or the

operating temperature. Non-rusting stainless st eel is used almost exclusively. To a slight extent

brass/copper is used where the media temperature i s 200 °C maximum. Sealing materials: Graphite,

copper, PTFE, FKM, polymer seals.

4.5 Temperature display, control and safety circuit

The devices are fitted with a removable command operating console with back-lit graphical display

entry of the set value and other settings occurs using menu guidance via context sensitive cursor and

"soft" keys.

A Pt100 temperature probe measures the outf l ow t emperature in the device. A high resolving A/D

converter processes the measurement. Further measurement processing occurs via a special control

algorithm for driving the heating power actuator and the special cooling system with further me asurement transducers.

An external Pt100 can be connected via a socket (10S) for measuring an external temperature. This

value can be displayed and if required, used as the controlled variable when the external controll er

(master) is switched on. In this way the system c ontrol is based on the external measurement and not

on the outflow temperature.

YAWE0028 / 24/06/2016 Device description 23

Integral XT

The safety system conforms to DIN EN 61010-2-010. A dual-channel system is used in which two micro-controllers monitor one another. Apa rt from the outflow temperature or temperature probe, there is

a second safety temperature probe (Pt100) for t he safety circuit for switching off due to excessive

temperature and for monitoring the outflow tem perature probe. This fulfills the requirements of

DIN EN 61010-2-010. The over temperature switch-off point is displayed by pre ssing the key

the Master.

Changing the over temperature cut-off point: (þ 7.16.1).

The level in the expansion vessel is acquired by the SelfCheck Assistant in 15 levels. If the minimum

level is undercut, the pump, heating and refrigerating machine are switched off. The behavior in the

case of an excessive level can be set (þ 7.16). Dif ferent reactions can be chosen depending on the

thermostatic medium.

With low level, over temperature or other alarm s t he S el fCheck Assistant switches the heater off on all

poles. The pump and the refrigerating machine are also switched off.

This fault switch-off remains, i.e. once the fault has been rectifi ed the alarm must be released with the

reset key

Other device functions are described in the corresponding sections and in Section 7 (Starting up).

.

4.6 Programmer and ramp function

The units are equipped with a programmer function which enables five temperature/time programs to be

saved. Each program consists of a number of temperature/time segments. These also include details of

how often the program is to be executed. Up to 150 segments can be distributed amongst the fiv e programs (þ 7.12).

With the ramp function a rate of change can be direct l y entered in °C/unit time.

on

4.7 Interfaces

As standard, the device is fitted with the foll owing sockets:

• One socket (10S), for an external Pt100 temperature sen sor.

• Two sockets (70S), for the Command remote control and for LiBus Components.

• An RS232/RS485 interface (65S) at the back of the Command remote control.

24 Device description YAWE0028 / 24/06/2016

Integral XT

When the fault circuit trips, the refrigerating unit is also switched off.

4.8 Interface modules (accessories)

Other interface modules can be inserted into two slots (refer to Section 8).

The following modules are currently available:

1. RS232/485 Interface Module (Order No. LRZ 913) with 9-pole SUB-D socket. Electrically isolated through optocouplers. Command set l argel y compatible with the ECO, Ecoline, Proline, Integral XT and Integral T Series. The RS2323 interf ace can be directly connected to the PC with a

cable wired 1:1 straight through (Order No. EK S 037).

Further details can be found in section 0 and 8.3.

2. Analog Module (Order No. LRZ 912) with two inputs and two outputs on 6-pole DIN socket. The

inputs and outputs can be set independently as 4 – 20 mA, 0 – 20 mA or 0 – 10 V interface.

Further details can be found in section 8.4.

3. Contact Module (Order No. LRZ 915) on 15-pole SUB-D socket. With three relay contact out-

puts (changeover, max. 30 V / 0.2A) and three binary inputs fo r control via external voltage-free

contacts. Plug 15-pole, Order No. EQM 030 and plug case Order No. EQG 017.

Further details can be found in section 8.5.1.

4. Contact Module (Order No. LRZ 914) with connect or to NAMUR NE28. Functionality as

LRZ 915, but only one output and one input on each o f two DIN sockets. Coupling socket 3-pole,

LAUDA Order No. EQD 047 and coupling plug 3-pole, LAUDA Order No. EQS 048.

Further details can be found in section 8.5.2.

5. Profibus (LAUDA Order No. LRZ 917).

Further details can be found in the operating inst ructions YAAE0020 of the Profibus Modules.

4.9 Refrigerating unit

The refrigerating machine mainly consists of one or two fully hermetically sealed compressors. The dissipation of the condensation and motor heat takes place via a fan-ventilated laminated condenser.

Here, fresh air is drawn in at the front of the unit, heated towards the back and output at the side. To

ensure proper air circulation the ventilation slots must not be restricted. (þ 6.1).

The condenser must be cleaned regularly to prevent soiling (þ 9.3.2.1). The SelfCheck Assistant outputs a warning signal when the condenser is soil ed.

On water cooled devices the heat dissipation takes place via a plate-type heat exchanger or a bundle

tubing heat exchanger using cooling water. Regular cleaning is also required here depending on the

water contamination

(þ 9.3.2.2).

The compressors are equipped with over temperature cutouts which respond to the compressor temperature and the compressor current consumption. In addition the refrigerating system is ba cked up by

a pressure control device against over pressure. The refrigerating unit is normally switched in aut om at ically, but can be switched manually via the operat i ng menu (þ 2.2).

YAWE0028 / 24/06/2016 Device description 25

down!

• Closely inspect the device for transport damage prior

5 Unpacking

Falling down / tipping over of the device

• Do not tip the refrigerator and never place it upside

− If the device is overthrown or overturned on the shipping, log the fall and contact also the

+

5.1 After unpacking

LAUDA Service Constant Temperature Equipment. (þ 9.5)

− To repack the unit carefully and properly, it is necessary to store the origi nal package!

Integral XT

Damage to property

Transport damage

Electric shock

to commissioning!

• Never operate a device that has sustained transport

damage!

After unpacking, firstly check the device and acc essories for any damage in transit. If contrary to expectations the unit is found to be damaged, the ship pi ng company must be immediately informed so t hat

verification can take place.

Please also inform the LAUDA Service Constant Temperature E quipment (Contact þ 9.5).

5.2 Standard accessories:

Quantity Article Article no.

1 x Operating Instructions for all devices YAWE0028

each 1 x

each 3 x

each 4 x

Plug and union nut

(for M16 x 1)

Plug and union nut

(for M16 x 1)

Plug and union nut

(for M16 x 1)

for bench-top devices

for floor-standing devices

for floor-standing devices with HT cooler

(H)

HKN 065

HKM 032

HKN 065

HKM 032

HKN 065

HKM 032

2 x

2 x

2 x Screw cap M30 x 1.5 (plastic) XT 150, ..., XT 1590 W(S) EZV 101

2 x Screw cap M38 x 1.5 (plastic) XT 1850 W, XT 1850 WS EZV 129

26 Unpacking YAWE0028 / 24/06/2016

Threaded hose coupling

Nipple ½“; Nut R¾“

Threaded hose coupling

Nipple ¾“; Nut R1“

for all water-cooled devices (W) except

XT 1590 W(S) and XT 1850 W(S)

XT 1850 W(S), XT 1850 W(S) EOA 053

EOA 001

Integral XT

5.3 Unpacking and packing with original transport packaging material

5.3.1 Sector of application

From Integral XT 280 up to and including XT 1850 WS. There are two different sizes of transport palettes, one for middle chassis (XT 280 / 350 / 550 / 750 / 950) and one for big (XT 490 / 1590 / 1850)

chassis.

5.3.2 Background

For the customer to allow a properly packaging, e.g. for further transport or return transport to LAUDA.

5.3.3 Supposition

You need a crane with two textile slings or lashings; or a fork lifter with adjustable fork.

5.3.4 Unpacking the device

To unpack the device with crane or fork lifter see the o rder “Packing and unpacking order Integral XT”.

Art. No. YVW 0001.

5.3.5 Packing for shipping with original transport packaging material

5.3.5.1 Overview

Cardboard box

Outer cardboard box

Large distance cardboard

Small distance cardboard

YAWE0028 / 24/06/2016 Unpacking 27

Integral XT

Transportation board

Front side of

the device

Pallet

Recess on the pallet for the cooling water in

and out connections.

Pallet with transportation board in place.

Front side of

the device

5.3.5.2 Packing the device

Align the wheels on the device length.

28 Unpacking YAWE0028 / 24/06/2016

Integral XT

Move transportation board underneath. The long er

part of the board with end-to-end bar to the front side

of the XT unit.

Place transportation strips under both sides of the

transportation board. Do not use chains!

Lift the XT unit up and move it over the pallet. Take

care for good position between the fixtures of the pallet and take care for the cooling water connections.

Recess on the pallet is giving space for the cooling

water connections.

YAWE0028 / 24/06/2016 Unpacking 29

Integral XT

Slip over the outer cardboard box. It is fixed by transportation board and pallet.

Place the operating instructions of Integr al XT device

on top of the device.

First bring in the small distance cardboard (þ

5.3.5.1). The two beads shall be on the front and rear

side of the unit.

30 Unpacking YAWE0028 / 24/06/2016

Integral XT

Then place the large distance cardboard 90° rotated

to the small distance cardboard.

Close the outer cardboard box with retaining cli ps and

adhesive tape.

YAWE0028 / 24/06/2016 Unpacking 31

Integral XT

Secure the outer cardboard box twice on its larger

and once on its smaller side.

Stick on labels, markings and shock sensors!

This unpacking instruction has to be placed prominent

in a transparent plastic bag.

32 Unpacking YAWE0028 / 24/06/2016

Integral XT

• Do not tip the refrigerator and never place it upside

down.

[D]

[D]

[C]

[C]

[D]

6 Preparations

Falling down / falling over of the device on inclined plane

Crushing of the hands and feet

• Only posit i on the device on level surfaces and not

6.1 Assembly and siting

close to table edges.

Falling down / tipping over of the device

Damage to property

/ table edge

− Site the unit on a flat surface.

− The unit must not be put into operation if its temperature during

storage or transport has dropped below the dew point.

Wait for about one hour.

− The device should never be tilted or stood upside down.

− Do not cover the ventilation openings.

− Leave free space on all sides (þ 11).

− Plug the bus connector of the Command remote control into

the 70S socket and secure it.

Further T-adaptors are available as accessories E K S 073.

− Check that the drain tap [D] is closed (position 0),

and that the sealing cap on the drain is fully tightened. Tighten

the sealing cap only slightly with the open-ended wrench (AF

19). (There are one to four drain taps depending on the device).

− Check that with water-cooled (optional) devices the cooling

water inlet and the cooling water outlet [C] are correct and

firmly connected.

YAWE0028 / 24/06/2016 Preparations 33

Integral XT

Connection of the load

Watercooled High-temperature thermostats:

Always connect cooling water

Cooling water connection is not established

Equipment damage

(lasting damage to the high temperature valve)

• The Hi gh-temperature thermostat has to be connect-

− Connection of closed loads only!

ed to the cooling water supply!

+

− In order that gas and vapor bubbles can be driven out of the system and undi sturbed

operation is possible, the external load must be connected according to the sketch.

The outflow is connected to the external load point located at the bottom and the return line must be connected to the external l oad point located at the top so that liquid

passes through the load from the bottom t o the top.

Vent valve

Fitting instructions for the connections to the load

Ball-type nipples and olives:

− The sealing surfaces of tapers and ball-type nipples/ olives must not be damaged (dropping on

− Contamination on the sealing surfaces (taper and ball-type nipple/ olive) must be carefully re-

− Place the ball-type nipple/ olive vertically onto the cone (support the hose, etc. when tightening).

− The ball-type nipple/ olive must not turn when tightening the union nut (if necessary, apply a lit-

− Tighten the union nut only slightly with an open-ended wrench and counter with a second

34 Preparations YAWE0028 / 24/06/2016

hard floors etc.).

moved before fitting.

tle grease or oil between the ball-type nipple/ olive and the union nut.

wrench on the connection nozzle.

Integral XT

Olives:

− Push a hose onto the hose olive. Secure hoses against slippage with the aid of hose clips etc.

General notes:

− Always ensure the largest possible passages in the external circuit . For a hose cross-section

− Only operate the Integral XT when flow through the external load i s possible.

− Open any shut-off valves in the external loads.

− Depending on the configuration of the load circuit, a venting valve can significantly simplify the

− Reactors for steam heating are not suitable as external loads, be cause they generally have an

− If external control is to be used, provide a Pt100 probe in the external l oad.

that is too small à Temperature gradients occu r between the device and external load due to

low volume flow.

venting process. The venting valve should be posit i oned at the highest point of the hydraulic circuit (þ see the drawing on page 34).

area through which flow does not pass and in which vapor cushions can form.

− Pay attention to pressure sensitive loads (e.g. glass apparatus) with a maximum

permissible operating pressure (þ 7.9.4).

− Check whether the hoses for external loads h ave been mounted.

+

Connection of the cooling water

Note that the following conditions apply for the connection of the cooling water supply:

Cooling water pressure (feed - outlet) maximum 10 bar overpressure

Differential pressure (feed - outlet) minimum 3.0 bar

− With outflow temperatures over 70 °C the sup pl i ed self-adhesive label (EZB

260) should be applied on the device at an easily v i sible poi nt.

− Do not carry out technical changes on the device!

− The unit can be safely operated up to an ambient temperature of 40 °C.

− An increased ambient temperature (above the reference tempe rature of 20 °C) re-

duces the cooling capacity and the minimum t em perature that can be achieved.

− With loads situated at a higher level and with the pump stopped and air se epi ng into

the thermostatic circuit (for example a not completely closed or defective venting

valve), then even with enclosed circuits, the external volume c an run empty.

à Danger that the process thermostat will overflow!

− Install a dirt trap if the complete heat transfer system on the customer side is not

guaranteed to be dirt free.

Cooling water temperature 10 to 15 °C recommended ,

10 to 30 °C admissible (with power restrictions)

Cooling water quantity see Technical Data (þ 11)

Cooling water hose for connection to the

device

YAWE0028 / 24/06/2016 Preparations 35

minimum 13 mm (up to XT 950 W)

minimum 19 mm (XT 1590 W(S), XT 1850 W(S))

Safety data sheets for heat transfer liquids can be ordere d i f requi red.

Certain requirements are placed on the cooling wat er with regard to purity. Depending on the cooling wa-

not covered by our guarantee.

6.2 Heat transfer liquids, cooling water and hoses

Filling, venting and degassing of heat transfer liquids (þ 7.6).

Testing of the heat transfer liquid (þ 9.3.4).

a) Approved heat transfer liquids

Integral XT

LAUDA

designation

Ultra 350 30 – 350

Kryo 30 À -20 – 90

Kryo 70 -70 – 220 Silicone oil 5 43 at -60 °C > 162 LZB 127 LZB 227 LZB 327

Kryo 90 -90 – 140 Silicone oil 1.76 15 at -70 °C

+

Tempera-

ture range

from °C

to °C

À The proportion of water reduces with longer working at high temperatures à Mixture be-

comes flammable (flash point 128 °C). à Check the mixing ratio using a hydrometer.

− When choosing the heat transfer liquid it must be noted that at t he l ower limit of the temperature range a worsening of the properties is to be expected due to the increasing viscosity.

Therefore only fully exploit temperature r anges when required.

− The working ranges of the heat transfer liquids and hoses are general figures which can be

tightened due to the operating temperature range of the devices.

Chem.

designation

Synthetic

heat transfer

liquid

Monoeth-

ylene

glycol/ water

Viscosity

(kin)

mm²/s

at 20 °C

47 28 at 30 °C > 240 LZB 107 LZB 207 LZB 307

4 35 at -20 °C -- LZB 109 LZB 209 LZB 309

Viscosity

temperature

at

mm²/s °C 5 L 10 L 20 L

(kin)

Fire

point

/ 56

Packing drum

Order number

LZB 128 LZB 228 LZB 328

− With silicone rubber, silicone oils lead to substantial swelling. à Never use silicone oil with

silicone hoses.

− EPDM hose is not suitable for Ultra 350 and not suitable for mineral oils.

b) Cooling water

ter contamination, a suitable method of purif i cat i on and/or treatment of the water must be employed. The

condenser and the complete cooling water circuit can become blocked, damaged and leaky due to unsuitable cooling water. Extensive consequential dam age may arise on the whole cooling circuit. The co oli ng

water quality depends on local conditions. If a fault or damage occurs due to unsuitable water quali ty, it is

36 Preparations YAWE0028 / 24/06/2016

Integral XT

• Free chlorine (e.g. from disinfectants) and water containing chlorine lead to pitting in the cooling water

• Putrid water is not suitable.

Follow the information for cleaning and decalcif ying the cooling water circuit (þ 9.3.2.2).

Important: Danger of corrosion of the cooling water circuit due to water of unsuitable quality.

circuit.

• Distilled, deionized or demineralized water is unsuitable due to its corrosiv e properties and leads to

corrosion in the cooling water circuit .

• Seawater is unsuitable due to its corrosive properties and leads to corrosio n i n the cooling water circuit.

• Water containing iron or iron particles leads to rust formation in the cooling water circuit.

• Due to the high lime content hard water is not suitable for cooling and leads to c alcification in the cool-

ing water circuit.

• Cooling water with suspended matter is not suitable.

• Untreated and unpurified river or cooling tower water is not suitable due to i ts microbiological content

(bacteria), which can become deposited in the cooling water circuit.

Suitable cooling water quality

pH – value 7.5 – 9.0

Sulfates [SO4 2-] < 70 mg/L

Hydrocarbonates [HCO3-]/ sulfates [SO4 2-] > 1.0

Total hardness 4.0 – 8.5 °dH

Hydrocarbonates [HCO3-] 70 – 300 mg/L

Conductivity 10 - 500 μs/cm

Chlorides (Cl-) < 50 mg/L

Sulfites [SO3 2-] < 1 mg/L

Free chlorine gas (Cl2) < 1 mg/L

Nitrates (NO3 -) < 100 mg/L

Ammonia (NH3) < 2 mg/L

Iron (Fe), dissolved < 0.2 mg/L

Manganese (Mn), dissolved < 0.1 mg/L

Aluminum (Al), dissolved < 0.2 mg/L

Free aggressive carbonic acid (CO2) < 5 mg/L

Hydrogen sulfide (H2S) < 0.05 mg/L

Algae growth Not permissible

Suspended matter Not permissible

Risk to the environment due to oil contamination of the cooling water circuit

With a leaky condenser there is the danger that refrigerating machine oil from the coolant cir cuit of the cooling thermostat can pass into the cooling water.

Follow all the legal requirements and the regulat i ons of the water supply utility which apply at t he poi nt of

use.

Water pollution due to leakage

To avoid pollution due to a leak in the cooling water sy st em it is recommended that a leakage-water detector

with a water cut-off is installed.

Servicing intervals

YAWE0028 / 24/06/2016 Preparations 37

Integral XT

c) Hoses

LZM 084

LZM 085

LZM 086

Note:

Metal hoses in non-rusting stainless steel with union nut M30 x 1.5 internal width 20 mm

Hose type Length (cm) Temperature range °C Field of application Order number

With special insulation

MXC 100S 100 -50 – 300

MXC 200S 200 -50 – 300 "

MXC 300S 300 -50 – 300 "

Metal hoses in non-rusting stainless steel with union nut M38 x 1.5 internal width 25 mm

MX2C 100S 100 -50 – 300 "

MX2C 200S 200 -50 – 300 "

MX2C 300S 300 -50 – 300 "

Torque specifications for the assembling

The threads of the pump connectors or the threads of the union nuts and the seat of the mother must be

moistened with a lubricating medium.

for cold and hot areas

for all heat transfer liquids

LZM 081

LZM 082

LZM 083

Catalogue number and

type designation

Maximum torque speci-

fication

Thread

Maximum permitted pres-

sure

LZM 081 / MXC 100S 70 Nm M30 x 1.5 max. 10 bar

LZM 082 / MXC 200S 70 Nm M30 x 1.5 max. 10 bar

LZM 083 / MXC 300S 70 Nm M30 x 1.5 max. 10 bar

When using metal hoses M16 x 1 with reduction (from M30 x 1.5 to M16 x 1), the following maximum

permitted pressures are valid, depending on the temperature

(Hoses LZM 040 – 049, LZM 052 – 055, LZM 069).

Temperature range Maximum permitted pressure

up to 20 °C 2.3 bar

up to 100 °C 1.9 bar

up to 300 °C 1.5 bar

.

38 Preparations YAWE0028 / 24/06/2016

Integral XT

+

7 Starting up

7.1 Mains connection

Compare the rating on the name-plate (þ 9.5) with the m ai ns voltage.

Only valid for the USA:

Instructions for Class A digital devices

“This equipment has been tested and found to comply with the limits for Class A digital device , pursuant

to Part 15 of the FCC (Federal Communication Commission) Rules. These limits are designed t o provide reasonable protection against harmf ul i nterference when the equipment is operated in a c om m ercial environment. This equipment generates, us es, and can radiate radio frequency energy and, if not

installed and used in accordance with the instru ct i on manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the i nterference at his own expense.”

“This device complies with Part 15 of the FCC (Federal Communication Commission) Rules. Operation

is subject to the following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may cause und esired operation.”

Only valid for Canada:

“This Class A digital apparatus complies wit h Canadian ICES-003” (ICES = Interference Causing

Equipment Standards).

« Cet appareil numérique de la Classe A est conforme à la norme NMB-003 du Canada ».

Three-phase device:

Ensure a clockwise phase sequence. If the devic e i s c onnected with the wrong direction of rotation, an

alarm signal is output.

7.2 Switching on

High-temperature thermostats with cooling wate r connection (type W) always require a cooling water supply, even if they are only used in heating mode.

Failure of the cooling water supply

(lasting damage to the high temperature valve)

• Note the beeps, warnings and alarms of the device!

(þ 9.4)

− Connect unit only to sockets with a protective earth conductor (P E ). No liability is

accepted for incorrect mains connections!

− Ensure that the unit is filled according to Section 6.2 and 7.6.

Equipment damage

YAWE0028 / 24/06/2016 Starting up 39

Integral XT

+

°C

EXT

°C

°C

°C

°C

Switch on the main switch on the front

panel:

− The green LED for "Mains ON" is lit,

Self-test

88(((

Act. val. outflow temp.

02%32

Fill mode

FiLL

Overtemp. cut-off.

90

− and the unit starts its self-test. All display segments and symbols

appear for about 1 s.

− Display of the current outflow temperature ,

− The pump starts provided "Standby" or "Manual start" (þ Section

7.10.2) has not been programmed,

− all values are accepted which were active before switch-off.

− If the device has not been filled, this display appears. Then contin-

ue with Section 7.6 Filling, venting and degassing.

Check or set over temperature cut-off point:

− The switching point is shown in the LED display on pressing the

key

− Change over temperature cut-off (þ 7.16.1).

− Top up with heat transfer liquid as required which is pumped out

due to filling up the external load.

.

LEUEL

Level alarm

− Display for

vessel has too little liquid.

− Red LED

LEUEL (low level) appears when the expansion

above the fault triangle flashes.

40 Starting up YAWE0028 / 24/06/2016

Integral XT

Pump Menu End T

set

T

fix

English

Display

− Find cause of fault (þ 9.4) and, where necessary, top up missing

liquid (þ 6.2).

− Press the Enter key.

− Also press the key if unit has been switched off in the fault state.

− No release is possible on Command remote control!

Command

English

Deutsch

Français

Español

Sounds Master

Sounds Command

Language

Deutsch

Français

Español

Master-Mode

Autostart

Current Consumpt.

Language

− If the Command remote control is being

switched on for the first time, the illustrated window appears automatically, enabling you to select the dialog language

with the appropriate soft key.

− The dialog language also can be changed

later via à Settings à Basic settings à

Language .