Lattner Boiler Company HW, LW Installation Maintenance And Service Manual

INSTALLATION, MAINTENANCE,

1

AND SERVICE MANUAL

INDEX

General Information Page 1

Installation Page 2

Typical Piping Diagram Page 2

Operation & Controls Page 3

Construction Page 3

Start Up Page 4

Maintenance Page 4

Element Replacement Page 5

Troubleshooting

Literature Index

Page 6

Page 7

ELECTRIC HOT WATER BOILERS

(LW, HW)

Vessel Construction – All vessels registered with the

National Board of Boiler and Pressure Vessel Inspectors;

Data reports are furnished. Comply with Section IV, ASME

Code, stamped with “H”. Maximum design temperature and

pressure is 250 degrees F and 160 psi if model “LW” boiler.

Vessels above 250 degrees F and/or above 160 psi are

designed to ASME Section I or Section VII and are

stamped “S” or “U”; model number designation is “HW”.

Heating Elements – Removable, incoloy sheathed electric

heating elements are mounted in 150 lb. ASME blind

flanges with plated steel compression fittings. Complete

flange assembly is inserted horizontally into vessel and

bolted in place.

GENERAL INFORMATION

UL Listing – Under file No. E30432 up to 600 volts.

Enclosure – Heavy gauge steel control panel and steel

vessel enclosure are attached to a steel frame, mounted on

a 4” channel base. All surfaces are protected against

corrosion with durable baked finish.

Insulation – Minimum 4” fiberglass on all sides. Minimizes

heat loss from vessel and keeps enclosure temperature

cooler.

INSTALLATION

2

1. Before installing unit, refer to job plans and

specifications for complete description of service and

accessories to be included.

2. If unit is not to be placed in immediate service, protect

from job site dust and debris with drop cloth or other

means. Do not cover ventilation louvers while unit is in

operation.

3. Unit should be installed in accordance with ASME

standards, NEC, and local codes.

4. Be certain unit is installed on a level, noncombustible

surface. Lifting lugs, welded directly to the pressure

vessel are provided.

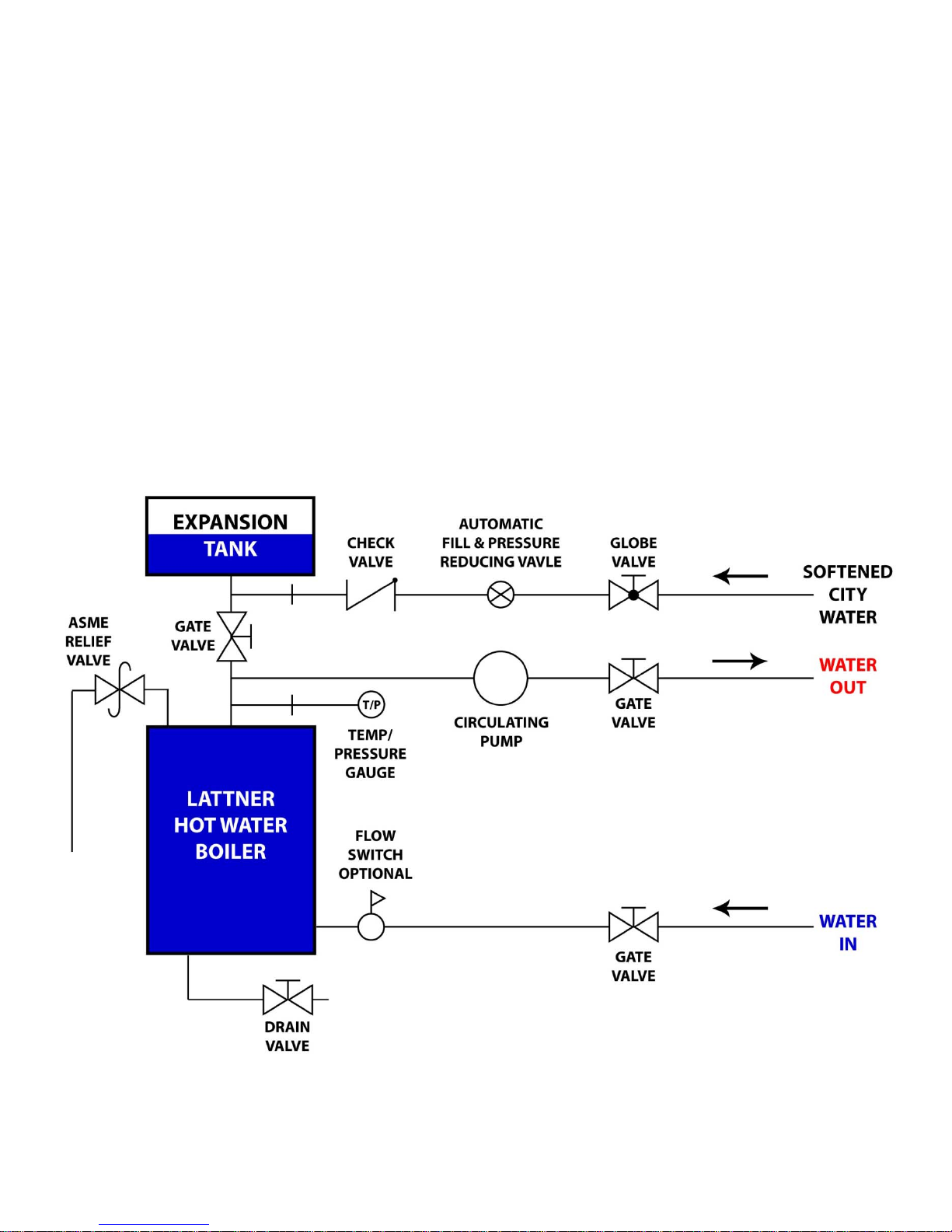

TYPICAL PIPING DIAGRAM

5. Required access (see certified print for exact

dimensions):

Front – 36” minimum

Rear – 12” minimum

Top – 36” minimum

Element removal – 64” minimum

Side opposite element flange – 12” minimum

6. Install drain and relief valves.

7. Make water inlet and outlet piping connections.

8. Wire supply conductors to main supply terminal lugs in

control panel. The unit has been prewired internally at

the factory. Refer to wiring diagram furnished with

boiler for complete details. Check all terminations for

tightness.

Loading...

Loading...