Lattice Semiconductor Corporation ISPLSI8600V-90LB492, ISPLSI8600V-90LB272, ISPLSI8600V-60LB492, ISPLSI8600V-60LB272, ISPLSI8600V-125LB492 Datasheet

...

®

ispLSI

8600V

3.3V In-System Programmable

SuperBIG™ High Density PLD

Features

• SuperBIG HIGH DENSITY IN-SYSTEM

PROGRAMMABLE LOGIC

— 3.3V Power Supply

— 32,000 PLD Gates/600 Macrocells

— 192-264 I/O Pins Supporting 3.3V/2.5V I/O

— 864 Registers

— High-Speed Global and Big Fast Megablock (BFM)

Interconnect

— Wide 20-Macrocell Generic Logic Block (GLB) for

High Performance

— Wide Input Gating (44 Inputs per GLB) for Fast

Counters, State Machines, Address Decoders, Etc.

— PCB-Efficient Ball Grid Array (BGA) Package

Options

2

• HIGH-PERFORMANCE E

—

fmax = 125 MHz Maximum Operating Frequency

tpd = 8.5 ns Propagation Delay

—

— Electrically Erasable and Reprogrammable

— Non-Volatile

— Programmable Speed/Power Logic Path

Optimization

• IN-SYSTEM PROGRAMMABLE

— Increased Manufacturing Yields, Reduced Time-to-

Market and Improved Product Quality

— Reprogram Soldered Devices for Faster Debugging

• 100% IEEE 1149.1 BOUNDARY SCAN TESTABLE AND

3.3V IN-SYSTEM PROGRAMMABLE

• ARCHITECTURE FEATURES

— Enhanced Pin-Locking Architecture, Symmetrical

Generic Logic Blocks Connected by Hierarchical

Big Fast Megablock and Global Routing Planes

— Product Term Sharing Array Supports up to 28

Product Terms per Macrocell Output

— Macrocells Support Concurrent Combinatorial and

Registered Functions

— Embedded Tristate Bus Can Be Used as an Internal

Tristate Bus or as an Extension of an External

Tristate Bus

— Macrocell and I/O Registers Feature Multiple Control

Options, Including Set, Reset and Clock Enable

— I/O Pins Support Programmable Bus Hold, Pull-Up,

Open-Drain and Slew Rate Options

— Separate VCCIO Power Supply to Support 3.3V or

2.5V Input/Output Logic Levels

— I/O Cell Register Programmable as Input Register for

Fast Setup Time or Output Register for Fast Clock to

Output Time

CMOS® TECHNOLOGY

• ispDesignEXPERT™ – LOGIC COMPILER AND COMPLETE ISP DEVICE DESIGN SYSTEMS FROM HDL

SYNTHESIS THROUGH IN-SYSTEM PROGRAMMING

— Superior Quality of Results

— Tightly Integrated with Leading CAE Vendor Tools

— Productivity Enhancing Timing Analyzer, Explore

Tools, Timing Simulator and ispANALYZER™

— PC and UNIX Platforms

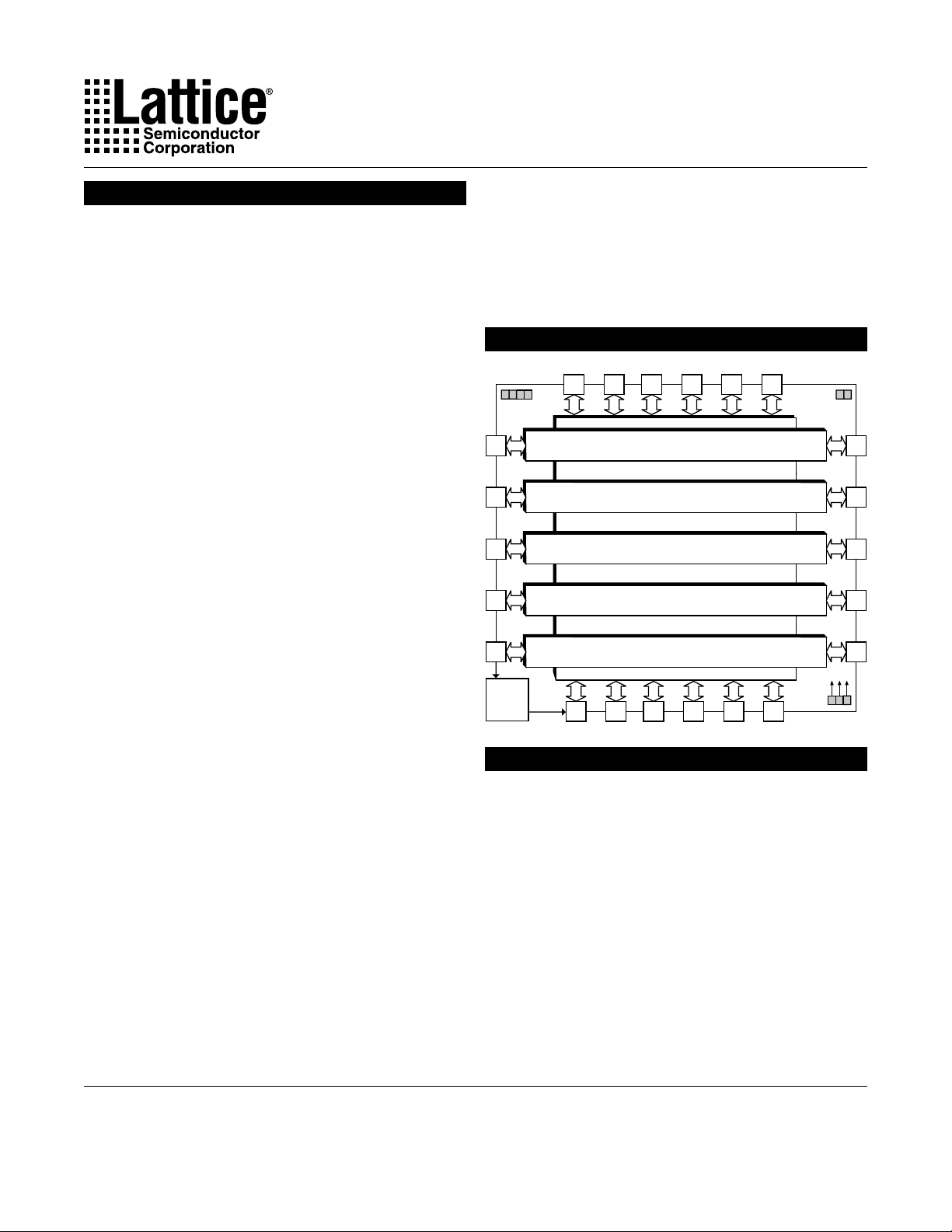

Functional Block Diagram

12

I/O

12

I/O

12

I/O

12

I/O

12

I/O

Boundary

Scan

12

I/O

12

I/O

12

12

I/O

Big Fast Megablock 0

Big Fast Megablock 1

Big Fast Megablock 2

Global Routing Plane

Big Fast Megablock 3

Big Fast Megablock 4

12

I/O

I/O

12

I/O

12

I/O12I/O12I/O

12

I/O12I/O12I/O

8600v block

12

I/O

12

I/O

12

I/O

12

I/O

12

I/O

ispLSI 8000V Family Description

The ispLSI 8000V Family of Register-Intensive, 3.3V

SuperBIG In-System Programmable Logic Devices is

based on Big Fast Megablocks of 120 registered macrocells and a Global Routing Plane (GRP) structure

interconnecting the Big Fast Megablocks. Each Big Fast

Megablock contains 120 registered macrocells arranged

in six groups of 20, a group of 20 being referred to as a

Generic Logic Block, or GLB. Within the Big Fast

Megablock, a Big Fast Megablock Routing Pool (BRP)

interconnects the six GLBs to each other and to 24 Big

Fast Megablock I/O cells with optional I/O registers. The

Global Routing Plane which interconnects the Big Fast

Megablocks has additional global I/Os with optional I/O

registers. The 192-I/O version contains 72 Big Fast

Megablock I/O and 120 global I/O, while the 264-I/O

Copyright © 2000 Lattice Semiconductor Corp. All brand or product names are trademarks or registered trademarks of their respective holders. The specifications and information herein are subject

to change without notice.

LATTICE SEMICONDUCTOR CORP., 5555 Northeast Moore Ct., Hillsboro, Oregon 97124, U.S.A.

Tel. (503) 268-8000; 1-800-LATTICE; FAX (503) 268-8556; http://www.latticesemi.com

July 2000

8600v_03 1

Specifications ispLSI 8600V

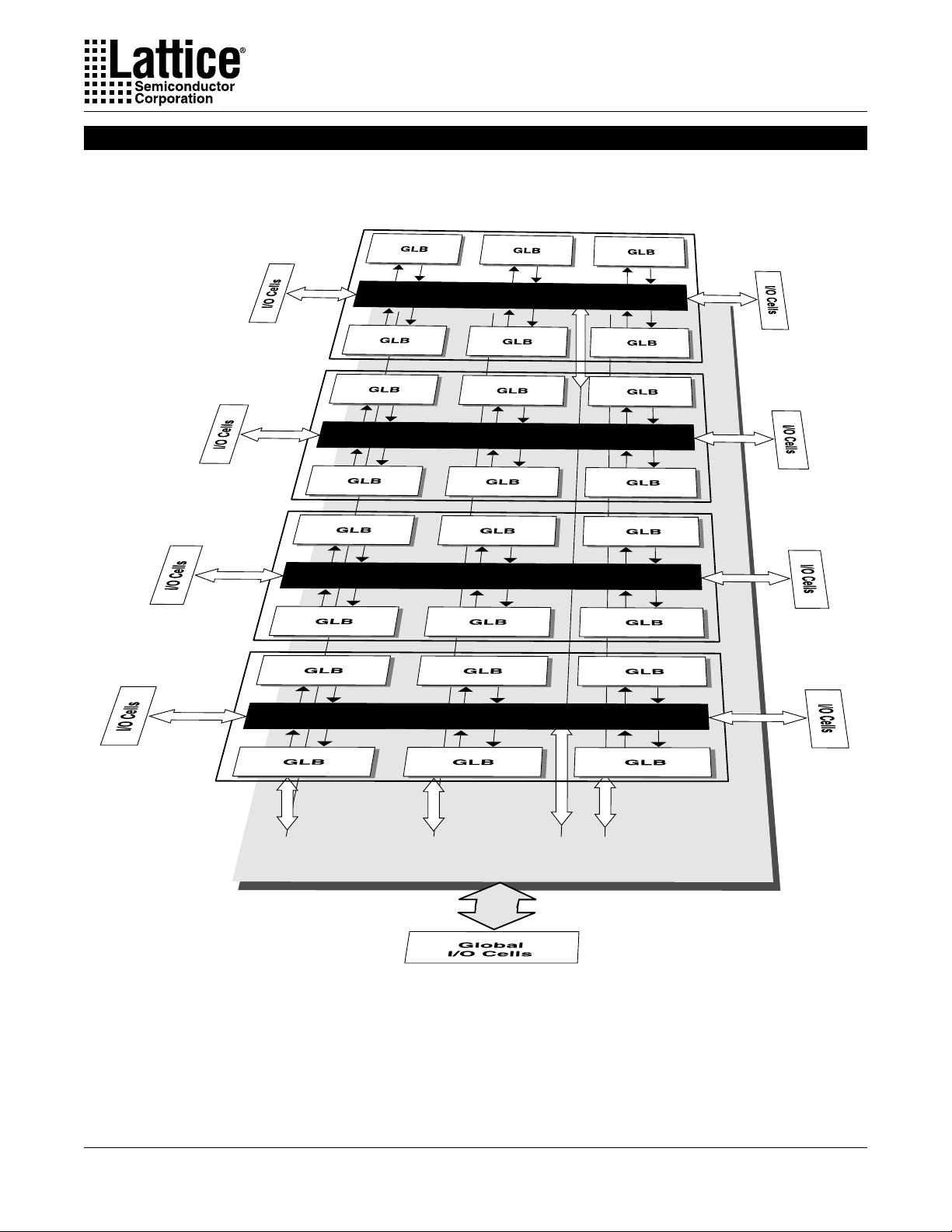

Functional Block Diagram

Figure 1. ispLSI 8600V Functional Block Diagram (Perspective)

Big Fast Megablock Routing Pool (BRP)

Big Fast Megablock Routing Pool (BRP)

Big Fast Megablock Routing Pool (BRP)

Big Fast Megablock Routing Pool (BRP)

Global Routing Plane (GRP) with Tristate Bus Lines

2

ispLSI 8000V Family Description (Continued)

Specifications ispLSI 8600V

version contains 120 Big Fast Megablock I/O and 144

global I/O.

Outputs from the GLBs in a Big Fast Megablock can drive

both the Big Fast Megablock Routing Pool within the Big

Fast Megablock and the Global Routing Plane between

the Big Fast Megablocks. Switching resources are provided to allow signals in the Global Routing Plane to drive

any or all the Big Fast Megablocks in the device. This

mechanism allows fast, efficient connections, both within

the Big Fast Megablocks and between them.

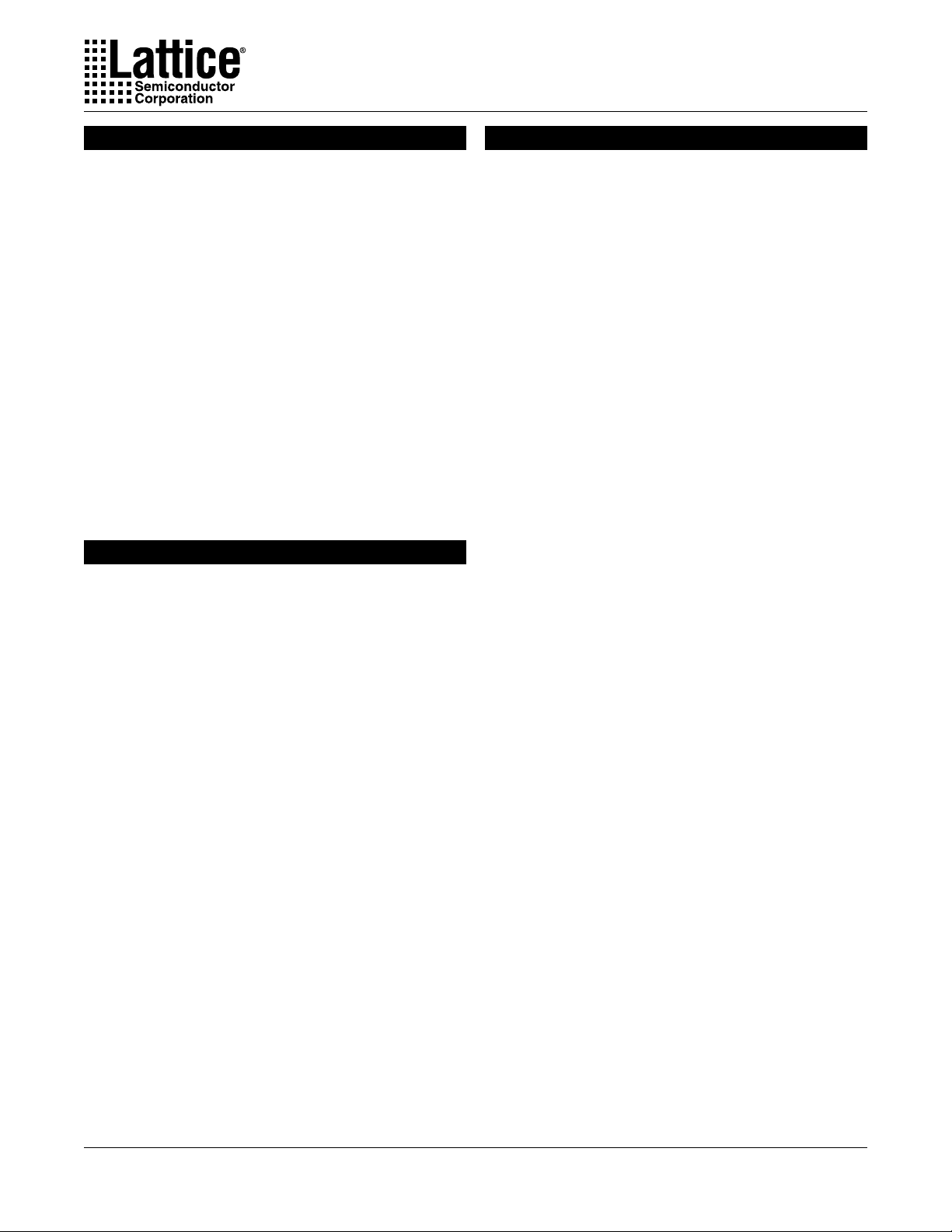

Each GLB contains 20 macrocells and a fully populated,

programmable AND-array with 82 logic product terms.

The GLB has 44 inputs from the Big Fast Megablock

Routing Pool which are available in both true and complement form for every product term. Up to 20 of these inputs

can be switched to provide local feedback into the GLB

for logic functions that require it. The 80 general-purpose

product terms can be grouped into 20 sets of four and

sent into a Product Term Sharing Array (PTSA) which

allows sharing up to a maximum of 28 product terms for

a single function. Alternatively, the PTSA can be bypassed for functions of four product terms or less.

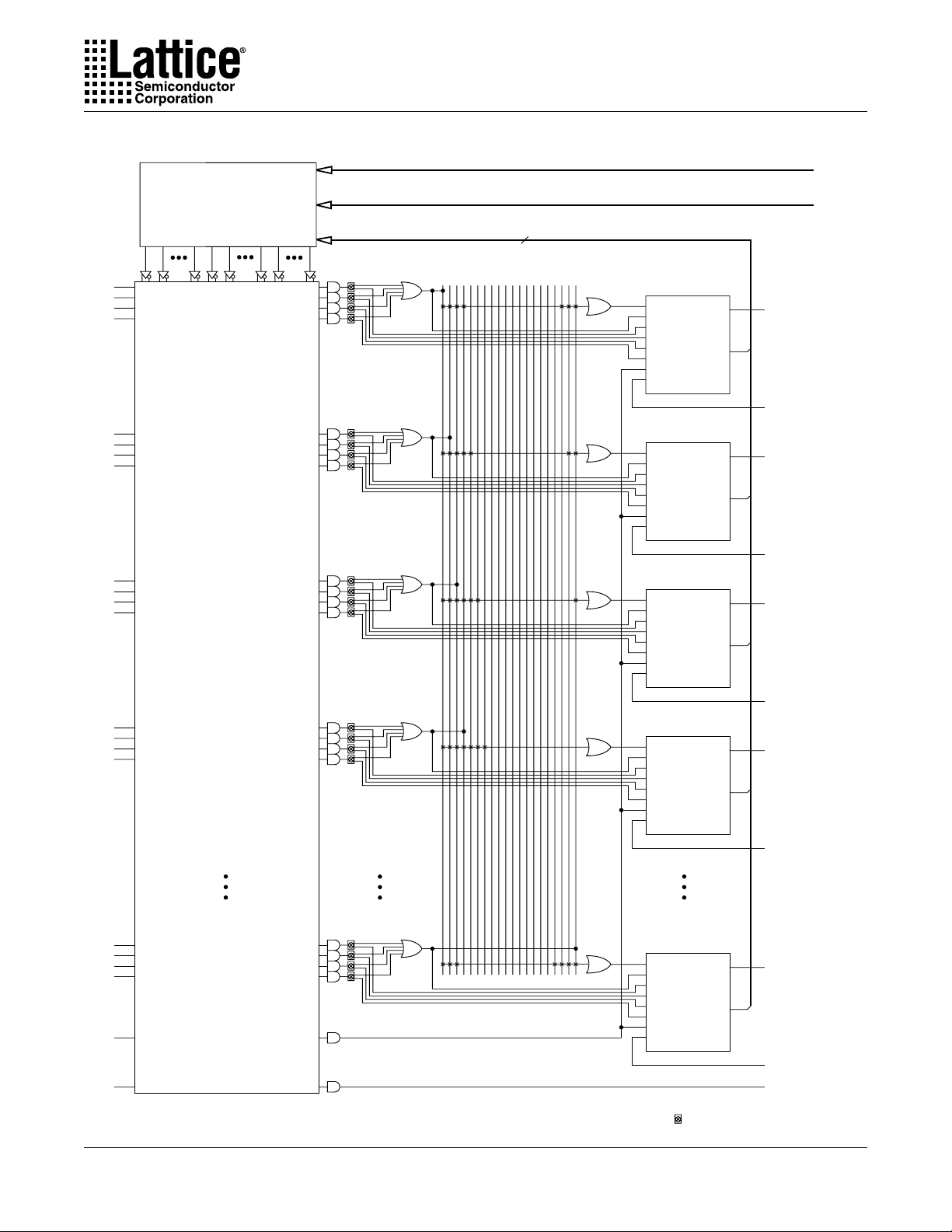

The 20 registered macrocells in the GLB are driven by the

20 outputs from the PTSA or the PTSA bypass. Each

macrocell contains a programmable XOR gate, a programmable register/latch/toggle flip-flop and the

necessary clocks and control logic to allow combinatorial

or registered operation. Each macrocell has two outputs,

one output can be fed back inside the GLB to the ANDarray, while the other output drives both the Big Fast

Megablock Routing Pool and the Global Routing Plane.

This dual output capability from the macrocell allows

efficient use of the hardware resources. One output can

be a registered function for example, while the other

output can be an unrelated combinatorial function.

Macrocell registers can be clocked from one of several

global, local or product term clocks available on the

device. A global, local and product term clock enable is

also provided, eliminating the need to gate the clock to

the macrocell registers. Reset and preset for the macrocell

register is provided from both global and product term

signals. The polarity of all of these control signals is

selectable on an individual macrocell basis. The macrocell register can be programmed to operate as a D-type

register, a D-type flow-through latch or a T-type flip flop.

The 20 outputs from the GLB can drive both the Big Fast

Megablock Routing Pool within the Big Fast Megablock

and the Global Routing Plane between the Big Fast

Megablocks. The Big Fast Megablock Routing Pool contains general purpose tracks which interconnect the six

GLBs within the Big Fast Megablock and dedicated

tracks for the signals from the Big Fast Megablock I/O

cells. The Global Routing Plane contains general purpose tracks that interconnect the Big Fast Megablocks

and also carry the signals from the I/Os connected to the

Global Routing Plane.

Control signals for the I/O cell registers are generated

using an extra product term within each GLB, or using

dedicated input pins. Each GLB has two extra product

terms beyond the 80 available for the macrocell logic.

The first additional product term is used as an optional

shared product term clock for all the macrocells within the

GLB. The second additional product term is then routed

to an I/O Control Bus using a separate routing structure

from the Big Fast Megablock Routing Pool and Global

Routing Plane. Use of a separate control bus routing

structure allows the I/O registers to have many control

signals with no impact on the interconnection of the GLBs

and Big Fast Megablocks. The I/O Control Bus is split into

four quadrants, each servicing the I/O cell control requirements for one edge of the device. Signals in the

control bus can be independently selected by any or all

I/O cells to act as clock, clock enable, output enable,

reset or preset.

Each Big Fast Megablock has 24 I/O cells. The Global

Routing Pool has 144 I/O cells. Each I/O cell can be

configured as a combinatorial input, combinatorial output, registered input, registered output or bidirectional

I/O. I/O cell registers can be clocked from one of several

global, local or product term clocks which are selected

from the I/O control bus. A global and product term clock

enable is also provided, eliminating the need for the user

to gate the clock to the I/O cell registers. Reset and preset

for the I/O cell register is provided from both global and

product term signals. The polarity of all of these control

signals is selectable on an individual I/O cell basis. The

I/O cell register can be programmed to operate as a Dtype register or a D-type latch.

The input thresholds are fixed at levels which comply with

both 3.3V and 2.5V interfaces. The output driver can

source 4mA and sink 8mA (3.3V output supply). The

output drivers have a separate VCCIO power supply

which is independent of the main VCC supply for the

device. This feature allows the output drivers to run from

either 3.3V or 2.5V while the device logic is always

3

Specifications ispLSI 8600V

ispLSI 8000V Family Description (Continued)

powered from 3.3V. The output drivers also provide

individually programmable edge rates and open drain

capability. A programmable pullup resistor is provided to

tie off unused inputs and a programmable bus-hold latch

is available to hold tristate outputs in their last valid state

until the bus is driven again by another device.

The ispLSI 8000V Family features 3.3V, non-volatile insystem programmability for both the logic and the

interconnect structures, providing the means to develop

truly reconfigurable systems. Programming is achieved

through the industry standard IEEE 1149.1-compliant

Boundary Scan interface using the JTAG protocol. Boundary Scan test is also supported through the same interface.

An enhanced, multiple cell security scheme is provided

that prevents reading of the JEDEC programming file

when secured. After the device has been secured using

this mechanism, the only way to clear the security is to

execute a bulk-erase instruction.

ispLSI 8600V Description

The ispLSI 8600V device has five Big Fast Megablocks

for a total of 5 x 120 = 600 macrocells.

Each Big Fast Megablock has a total of 24 I/O cells and

the Global Routing Plane has a total of 144 I/O cells. This

gives (5 x 24) + 144 = 264 I/Os for the full I/O version,

while the partial I/O version contains 72 BFM I/O + 120

Global I/O = 192 I/Os.

The total registers in the device is the sum of macrocells

plus I/O cells, 600 + 264 = 864 registers.

Embedded Tristate Bus

There is a 108-line embedded internal tristate bus as part

of the Global Routing Plane (GRP), enabling multiple

GLBs to drive the same tracks. This bus can be partitioned into various bus widths such as twelve 9-line

buses, six 18-line buses or three 36-line buses. The

GLBs can dynamically share a subset of the Global

Routing Plane tracks. This feature eliminates the need to

convert tristate buses to wide multiplexers on the programmable device. Up to 18 macrocells per GLB can

participate in driving the embedded tristate bus. The

remaining two macrocells per GLB are used to generate

the internal tristate driver control signals on each data

byte (with parity). The embedded tristate bus can also be

configured as an extension of an external tristate bus

using the bidirectional capability of the I/O cells connected to the Global Routing Plane. The Global Routing

Plane I/Os 0-8 and 15-23 from each group (I/OGx as

defined in the I/O Pin Location Table) can connect to the

internal tristate bus as well as the unidirectional/nontristate global routing channels. I/Os 9-14 connect only to

the global routing channel.

The embedded tristate bus has internal bus hold and

arbitration features in order to make the function more

“user friendly”. The bus hold feature keeps the internal

bus at the previously driven logic state when the bus is

not driven to eliminate bus float. The bus arbitration is

performed on a “first come, first served” priority. In other

words, once a logic block drives the bus, other logic

blocks cannot drive the bus until the first releases the bus.

This arbitration feature prevents internal bus contention

when there is an overlap between two bus enable signals. Typically, it takes about 3ns to resolve one bus

signal coming off the bus to another bus signal driving the

bus. The arbitration feature, combined with the predictability of the CPLD, makes the embedded tristate bus the

most practical for real world bus implementation.

4

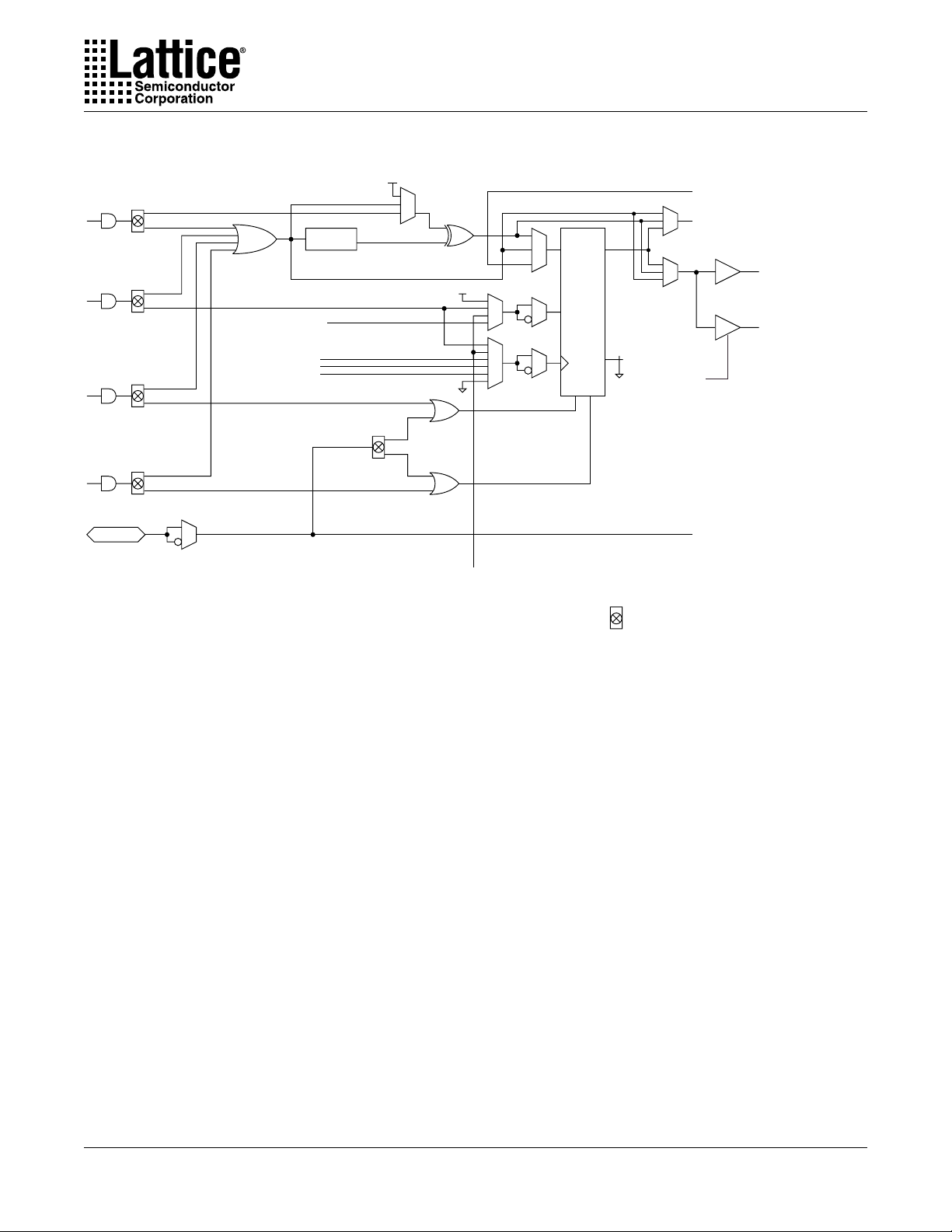

Figure 2. ispLSI 8000V GLB Overview

I/O Big Fast Megablock Input Tracks

Specifications ispLSI 8600V

PT 0

PT 1

PT 2

PT 3

PT 4

PT 5

PT 6

PT 7

PT 8

PT 9

PT 10

PT 11

AND Array Input

0

Fully Populated

Routing

AND Array

General Purpose Big Fast Megablock Input Tracks

Feedback Inputs

43

Product Term

Sharing Array

20

Macrocell 0

From PTSA

PTSA Bypass

Single PT

PT Clock

PT Preset

PT Reset

Shared PT Clock

Bus Input

Macrocell 1

From PTSA

PTSA Bypass

Single PT

PT Clock

PT Preset

PT Reset

Shared PT Clock

Bus Input

Macrocell 2

From PTSA

PTSA Bypass

Single PT

PT Clock

PT Preset

PT Reset

Shared PT Clock

Bus Input

0

1

2

To Interconnect

From Tristate

Bus Track

To Interconnect

From Tristate

Bus Track

To Interconnect

PT 12

PT 13

PT 14

PT 15

PT 76

PT 77

PT 78

PT 79

PT 80

PT 81

Macrocell 3

From PTSA

PTSA Bypass

Single PT

PT Clock

PT Preset

PT Reset

Shared PT Clock

Bus Input

Macrocell 19

From PTSA

PTSA Bypass

Single PT

PT Clock

PT Preset

PT Reset

Shared PT Clock

Bus Input

Function Selector (E2 Cell Controlled)Note: Macrocells 9 and 10 do not support Tristate Bus Feedback.

From Tristate

Bus Track

To interconnect

3

From Tristate

Bus Track

To Interconnect

19

From Tristate Bus Track

To Output Control MUX

5

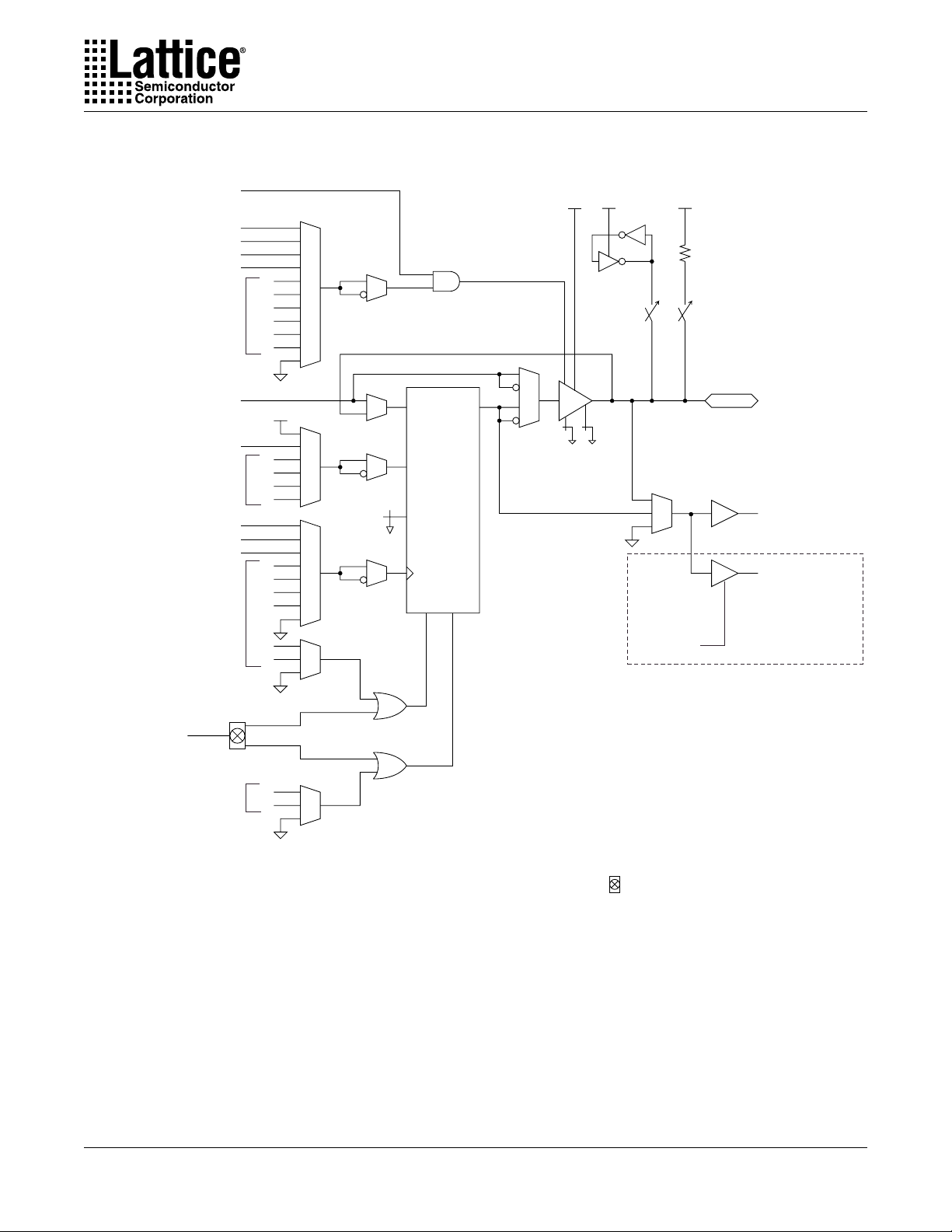

Figure 3. ispLSI 8000V Macrocell Overview

Single PT

PTSA

PTSA Bypass

PT Clock

Global Clock Enable

Global Clock 0

Global Clock 1

Global Clock 2

PT Reset

GRST

PT Preset

Specifications ispLSI 8600V

Bus Input From Tristate

Bus Track*

Feedback to AND Array

DQ

To Big Fast Megablock

or Global Interconnect

Clk En

RP

R/L

From Macrocell

9 or 10

To Specific

Global Tristate Bus*

Reset pin

Preset/Reset Input has Global Polarity Control

GRST

To All Macrocells and I/O Cells

From PT80

: Function Selector (E2 Cell Controlled)*Not available for Macrocells 9 and 10.

6

Figure 4. ispLSI 8000V I/O Cell

Specifications ispLSI 8600V

TOE

GLOBAL OE0

GLOBAL OE1

GLOBAL OE2

GLOBAL OE3

From Output

Control Bus

Multiplexed Output From

Big Fast Megablock or

Global Track

GLOBAL I/O CLOCK ENABLE

From Output

Control Bus

GLOBAL CLOCK0

GLOBAL CLOCK2

QUADRANT I/O CLOCK

From Output

Control Bus

DQ

CLKEN

R/L

R

P

VCCIO

Slew

Rate

VCCIO

Open

Drain

VCCIO

Big Fast Megablock I/O Pad

or Global I/O Pad

To Specific

Big Fast Megablock

or Global Tracks

To Specific

Global Tristate Bus

From Output

Control Bus

Global I/O Cell

Only

GRST

From Output

Control Bus

: Function Selector (E2 Cell Controlled)

7

Specifications ispLSI 8600V

Q

u

a

d

ra

n

t 0

, 1

6

-B

it W

id

e

O

u

tp

u

t C

o

n

tro

l B

u

s

(I/O

B

0

-B

4

<

0

-1

1

>

, Q

IO

C

L

K

0

)

Q

u

a

d

ra

n

t 2

, 1

6

-B

it W

id

e

O

u

tp

u

t C

o

n

tro

l B

u

s

(I/O

B

0

-B

4

<

1

2

-2

3

>

, Q

IO

C

L

K

2

)

Q

u

a

d

ra

n

t 1

, 1

6

-B

it W

id

e

O

u

tp

u

t C

o

n

tr

o

l B

u

s

(I/O

G

0

-G

5

<

1

2

-2

3

>

, Q

IO

C

L

K

1

)

Q

u

a

d

r

a

n

t 3

, 1

6

-B

it W

id

e

O

u

tp

u

t C

o

n

tro

l B

u

s

(I/O

G

0

-G

5

<

0

-

1

1

>

, Q

IO

C

L

K

3

)

G

L

B

G

e

n

e

ra

te

d

O

u

tp

u

t

C

o

n

tro

l

(se

e

F

ig

u

re

2

)

F

ro

m

P

T

8

1

OE Bus/8600V.eps

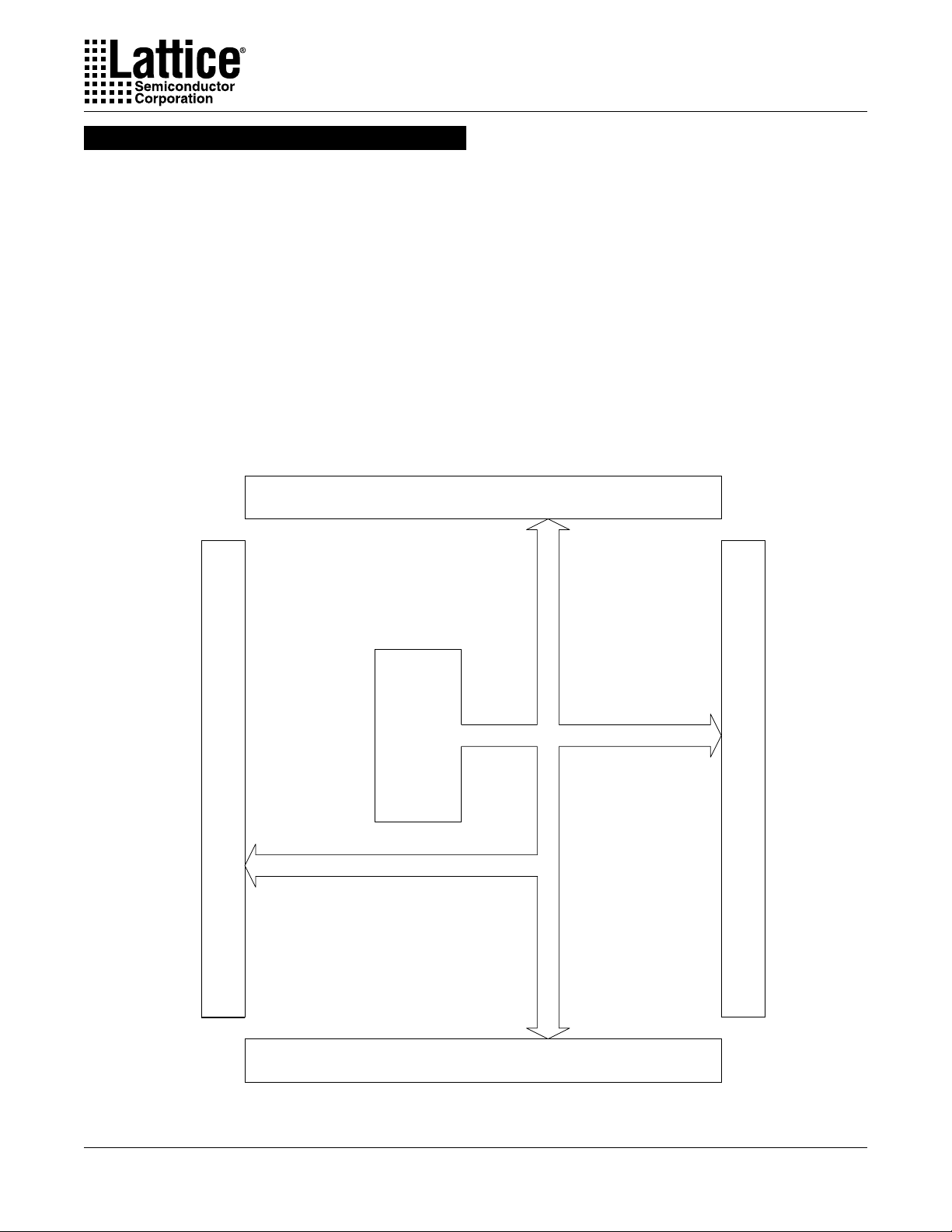

Output Control Organization

The Global OE signals and Test OE signal are driven

from the dedicated external control input pins.

In addition to the data input and output to the I/O cells,

each I/O cell can have up to six different I/O cell control

signals. In addition to the internal OE control, the five

control signals for each I/O cell consist of pin OE control,

clock enable, clock input, asynchronous preset and asynchronous reset. All of the I/O control signals can be driven

either from the dedicated external input pins or from the

internal control bus.

The output enable of each I/O cell can be driven by 21

different sources – 16 from the output control bus, four

from the Global OE pins and one from the Test OE pin.

The 16-bit wide output control buses are organized in four

different quadrants as shown in Figure 5. Since each

GLB is capable of generating the output control signals,

each of the output control bus signals can be driven from

a unique GLB. The 30 GLBs can generate a total of 30

unique I/O control signals. Referring to Figure 2, the GLB

generates its output control signal from control product

term (PT81).

Figure 5 also illustrates how the quadrant clocks are

routed to the appropriate quadrant I/O cells.

Figure 5. Output Control Bus and Quadrant Organization

8

Loading...

Loading...