■

■

■

■

■

■

■

■

®

ispPAC-POWR1220AT8

In-System Programmable Power Supply

Monitoring, Sequencing and Margining Controller

August 2007 Data Sheet DS1015

Features

Monitor, Control, and Margin Multiple

Power Supplies

• Simultaneously monitors up to 12 power

supplies

• Provides up to 20 output control signals

• Provides up to eight analog outputs for

margining/trimming power supply voltages

• Programmable digital and analog circuitry

Power Supply Margin and Trim Functions

• Trim and margin up to eight power supplies

• Dynamic voltage control through I

• Four hardware selectable voltage profiles

• Independent Digital Closed-Loop Trim function

for each output

Embedded PLD for Sequence Control

• 48-macrocell CPLD implements both state

machines and combinatorial logic functions

Embedded Programmable Timers

• Four independent timers

• 32µs to 2 second intervals for timing sequences

Analog Input Monitoring

• 12 independent analog monitor inputs

• Differential inputs for remote ground sense

• Two programmable threshold comparators per

analog input

• Hardware window comparison

• 10-bit ADC for I

2

C monitoring

High-Voltage FET Drivers

• Power supply ramp up/down control

• Programmable current and voltage output

• Independently configurable for FET control or

digital output

2-Wire (I

• Comparator status monitor

• ADC readout

• Direct control of inputs and outputs

• Power sequence control

• Dynamic trimming/margining control

2

C/SMBus™ Compatible) Interface

2

C

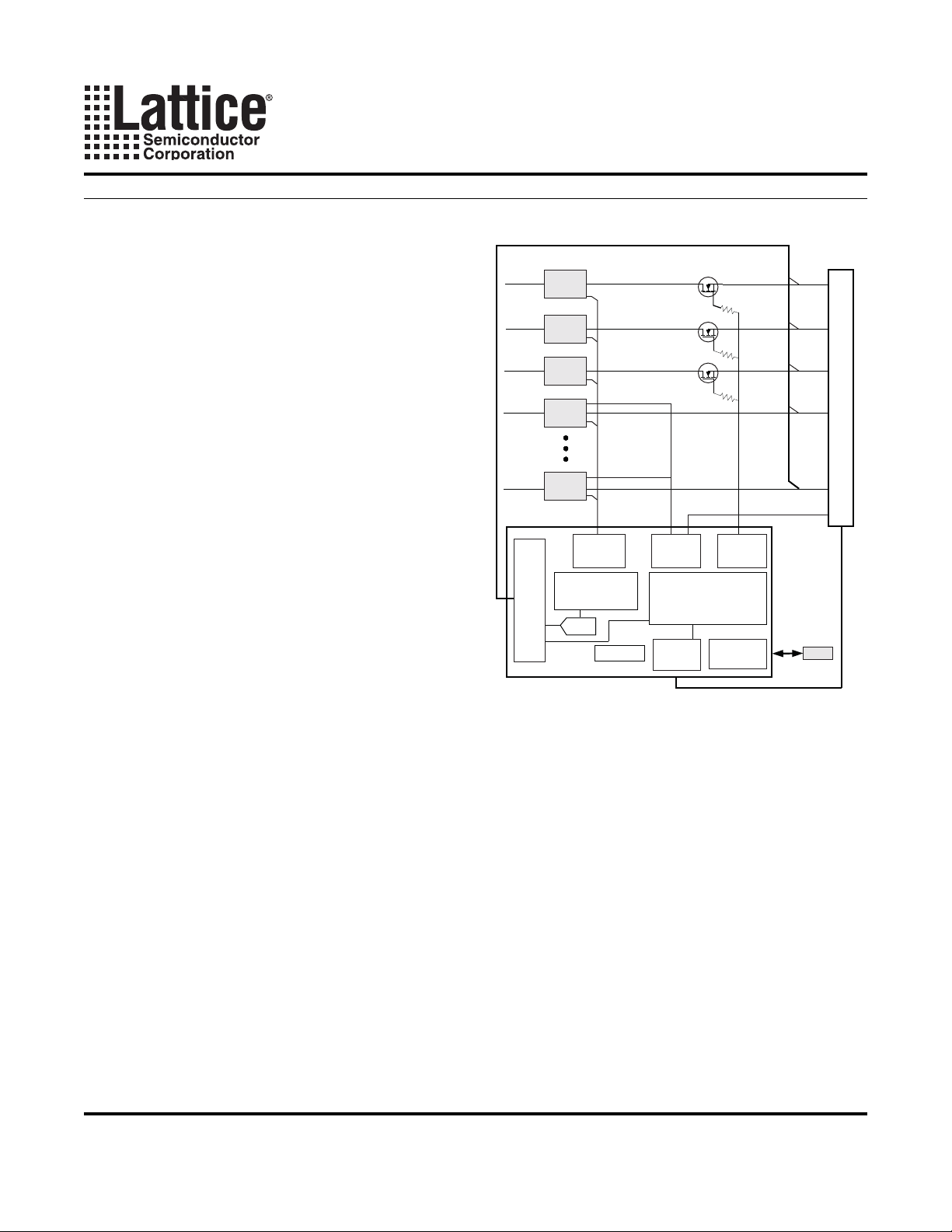

Application Block Diagram

Primary

Supply

Primary

Supply

Primary

Supply

Primary

Supply

Primary

Supply

3.3V

2.5V

1.8V

POL#1

POL#N

Power Supply

Margin/Trim

Control Block

ADC

12 Analog Inputs

and Voltage Monitors

ispPAC-POWR1220AT8

8 Analog

Trim

Outputs

4 Timers

n

igraM/

m

ir

T

Enables

16 Digital

Outputs

48 Macrocells

6 Digital

Inputs

Other Control/Supervisory

Signals

4 MOSFET

Drivers

CPLD

83 Inputs

2

C

I

Interface

I

Bus

2

Voltage

C

itry

u

Other Board Circ

Monitoring

CPU

Digital Monitoring

Description

Lattice’s Power Manager II ispPAC-POWR1220AT8 is a

general-purpose power-supply monitor, sequence and

margin controller, incorporating both in-system programmable logic and in-system programmable analog

functions implemented in non-volatile E

nology. The ispPAC-POWR1220AT8 device provides 12

independent analog input channels to monitor up to 12

power supply test points. Each of these input channels

offers a differential input to support remote ground

sensing, and has two independently programmable

comparators to support both high/low and in-bounds/

out-of-bounds (window-compare) monitor functions. Six

general-purpose digital inputs are also provided for miscellaneous control functions.

2

CMOS

®

tech-

3.3V Operation, Wide Supply Range 2.8V to

3.96V

• In-system programmable through JTAG

• Industrial temperature range: -40°C to +85°C

• 100-pin TQFP package, lead-free option

© 2007 Lattice Semiconductor Corp. All Lattice trademarks, registered trademarks, patents, and disclaimers are as listed at www.latticesemi.com/legal. All other

brand or product names are trademarks or registered trademarks of their respective holders. The specifications and information herein are subject to change without

notice.

www.latticesemi.com

The ispPAC-POWR1220AT8 provides 20 open-drain

digital outputs that can be used for controlling DC-DC

converters, low-drop-out regulators (LDOs) and optocouplers, as well as for supervisory and general-purpose logic interface functions. Four of these outputs

1

DS1015_01.4

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

(HVOUT1-HVOUT4) may be configured as high-voltage MOSFET drivers. In high-voltage mode these outputs can

provide up to 10V for driving the gates of n-channel MOSFETs so that they can be used as high-side power

switches controlling the supplies with a programmable ramp rate for both ramp up and ramp down.

The ispPAC-POWR1220AT8 incorporates a 48-macrocell CPLD that can be used to implement complex state

machine sequencing for the control of multiple power supplies as well as combinatorial logic functions. The status

of all of the comparators on the analog input channels as well as the general purpose digital inputs are used as

inputs by the CPLD array, and all digital outputs may be controlled by the CPLD. Four independently programmable

timers can create delays and time-outs ranging from 32µs to 2 seconds. The CPLD is programmed using LogiBuilder™, an easy-to-learn language integrated into the PAC-Designer

monitor the status of any of the analog input channel comparators or the digital inputs.

In addition to the sequence control functions, the ispPAC-POWR1220AT8 incorporates eight DACs for generating

trimming voltage to control the output voltage of a DC-DC converter. The trimming voltage can be set to four hardware selectable preset values (voltage profiles) or can be dynamically loaded in to the DAC through the I

Additionally, each power supply output voltage can be maintained typically within 0.5% tolerance across various

load conditions using the Digital Closed Loop Control mode. The operating voltage profile can either be selected

using external hardware pins or through the PLD outputs.

The on-chip 10-bit A/D converter can both be used to monitor the V

implementing digital closed loop mode for maintaining the output voltage of all power supplies controlled by the

monitoring and trimming section of the ispPAC-POWR1220AT8 device.

2

The I

C bus/SMBus interface allows an external microcontroller to measure the voltages connected to the V

inputs, read back the status of each of the V

comparator and PLD outputs, control logic signals IN2 to IN5, con-

MON

trol the output pins, and load the DACs for the generation of the trimming voltage of the external DC-DC converter.

®

software. Control sequences are written to

voltage through the I

MON

2

C bus as well as for

2

C bus.

MON

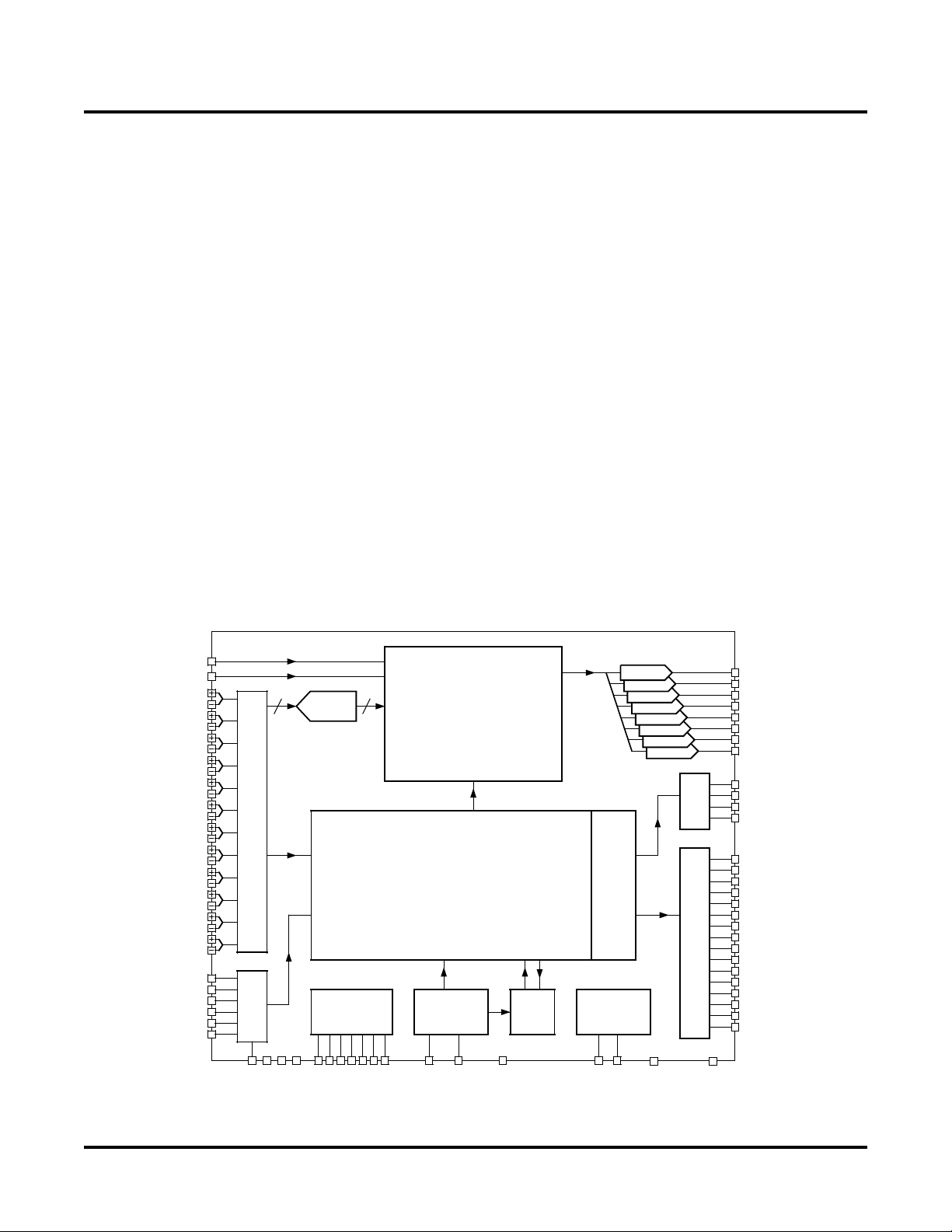

Figure 1. ispPAC-POWR1220AT8 Block Diagram

VPS0

VPS1

VMON1+

VMON1GS

VMON2+

VMON2GS

VMON3+

VMON3GS

VMON4+

VMON4GS

VMON5+

VMON5GS

VMON6+

VMON6GS

VMON7+

VMON7GS

VMON8+

VMON8GS

VMON9+

VMON9GS

VMON10+

VMON10GS

VMON11+

VMON11GS

VMON12+

VMON12GS

IN1

IN2

IN3

IN4

IN5

IN6

A

N

D

V

O

L

T

A

E G

N O M

I

T

O

R

S

6

I

N

D

P

I

G

I

T

T U

A

S

L

VCCINP

1

2

A

N

A

L

O

G

I

N

P

S T U

VCCD (3)

VCCA

V

C

C

P

R

O

G

ADC

JTAG LOGIC

V

T

T

T

C

C

D

K

C

O

S M

J

OSCILLATOR

S

A

T

E

D

T

D

L

I

T

I

D

I

MARGIN/TRIM

CONTROL LOGIC

CPLD

48 MACROCELLS

83 INPUTS

CLOCK

P

M

L

C

L

C D

K

L

K

R

T E S E

b

TIMERS

(4)

VOLTAGE OUTPUT

DACS (8)

DAC

DAC

DAC

DAC

DAC

O

U

T

P

U

P

T

O

R

O

O

L

U

T

G N I

I2C

INTERFACE

S

S

C

L

GNDA (2)

D

A

DAC

DAC

DAC

TRIM1

TRIM2

TRIM3

TRIM4

TRIM5

TRIM6

TRIM7

TRIM8

D

R

I

V

R E

S

G I D

T I

L A

O

T U

P

U

T

S

4

F

E

T

1

6

O

P

E

N

D

R

I A

N

GNDD (6)

HVOUT1

HVOUT2

HVOUT3

HVOUT4

OUT5/SMBA

OUT6

OUT7

OUT8

OUT9

OUT10

OUT11

OUT12

OUT13

OUT14

OUT15

OUT16

OUT17

OUT18

OUT19

OUT20

2

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

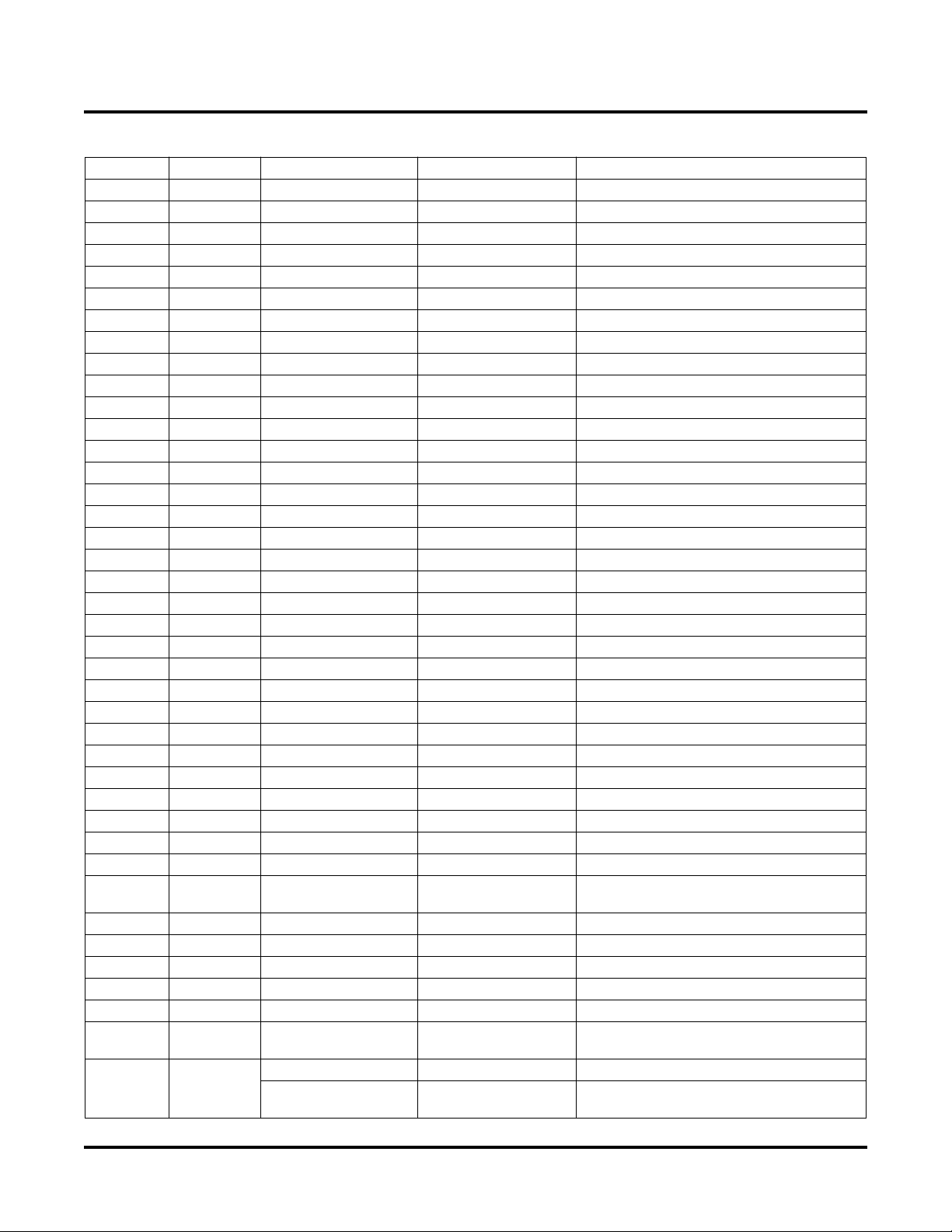

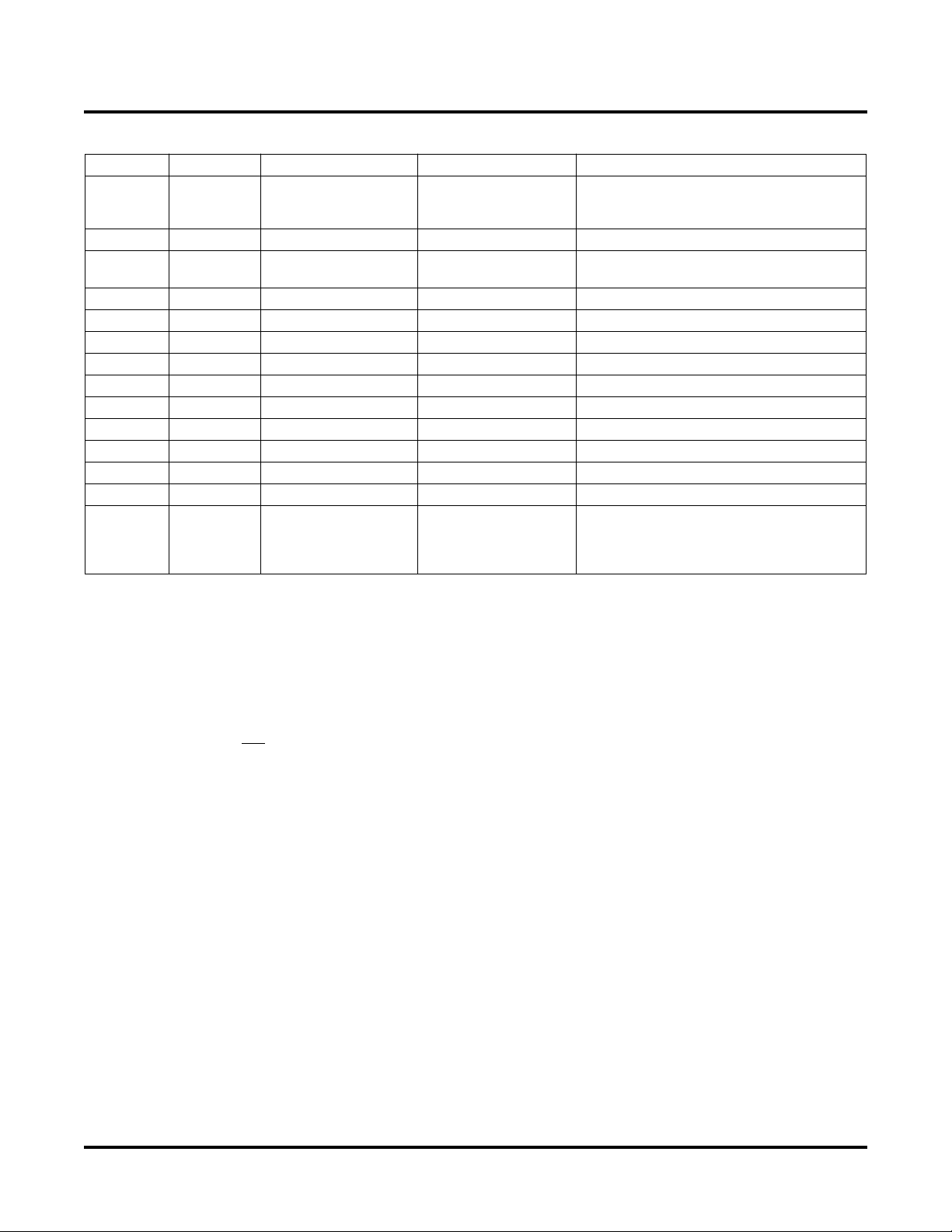

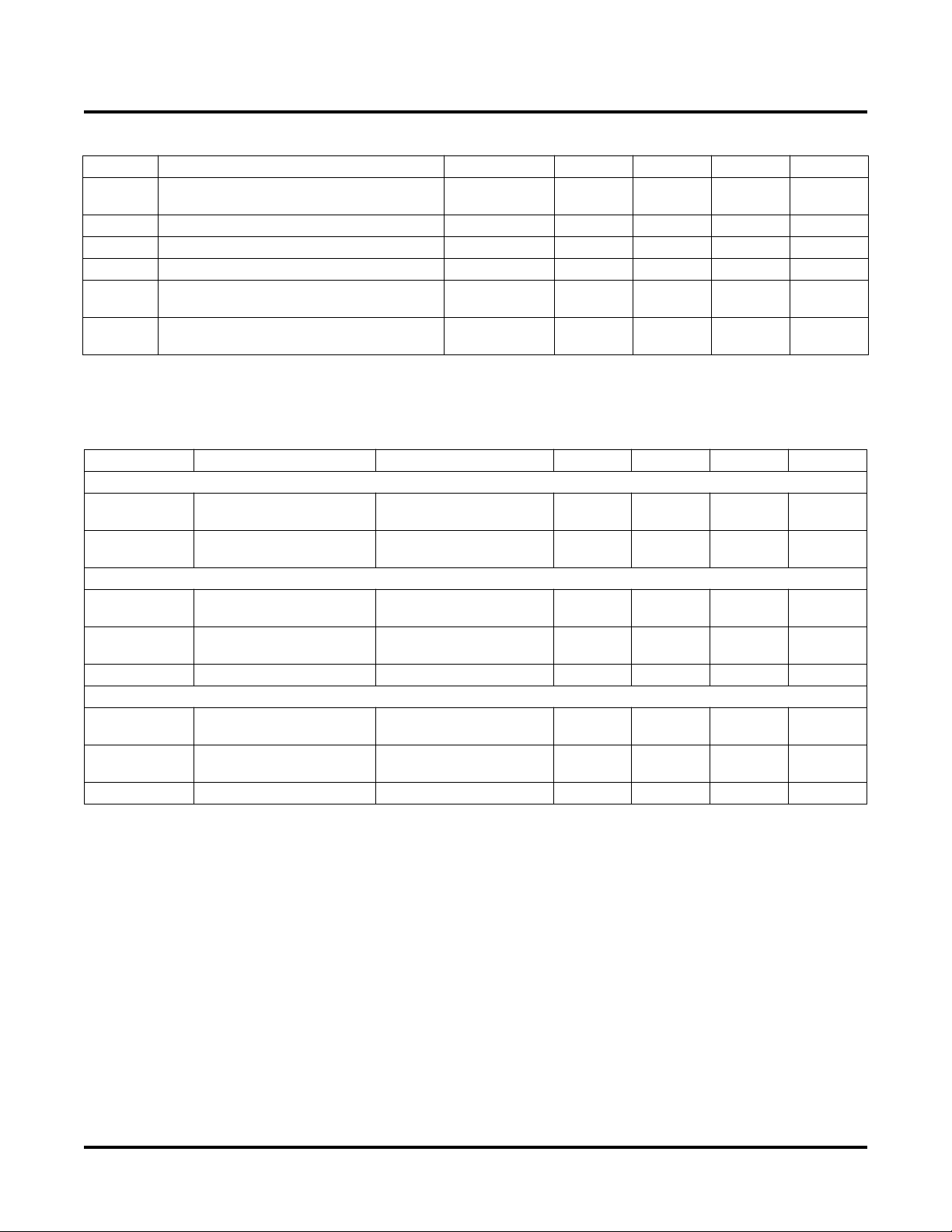

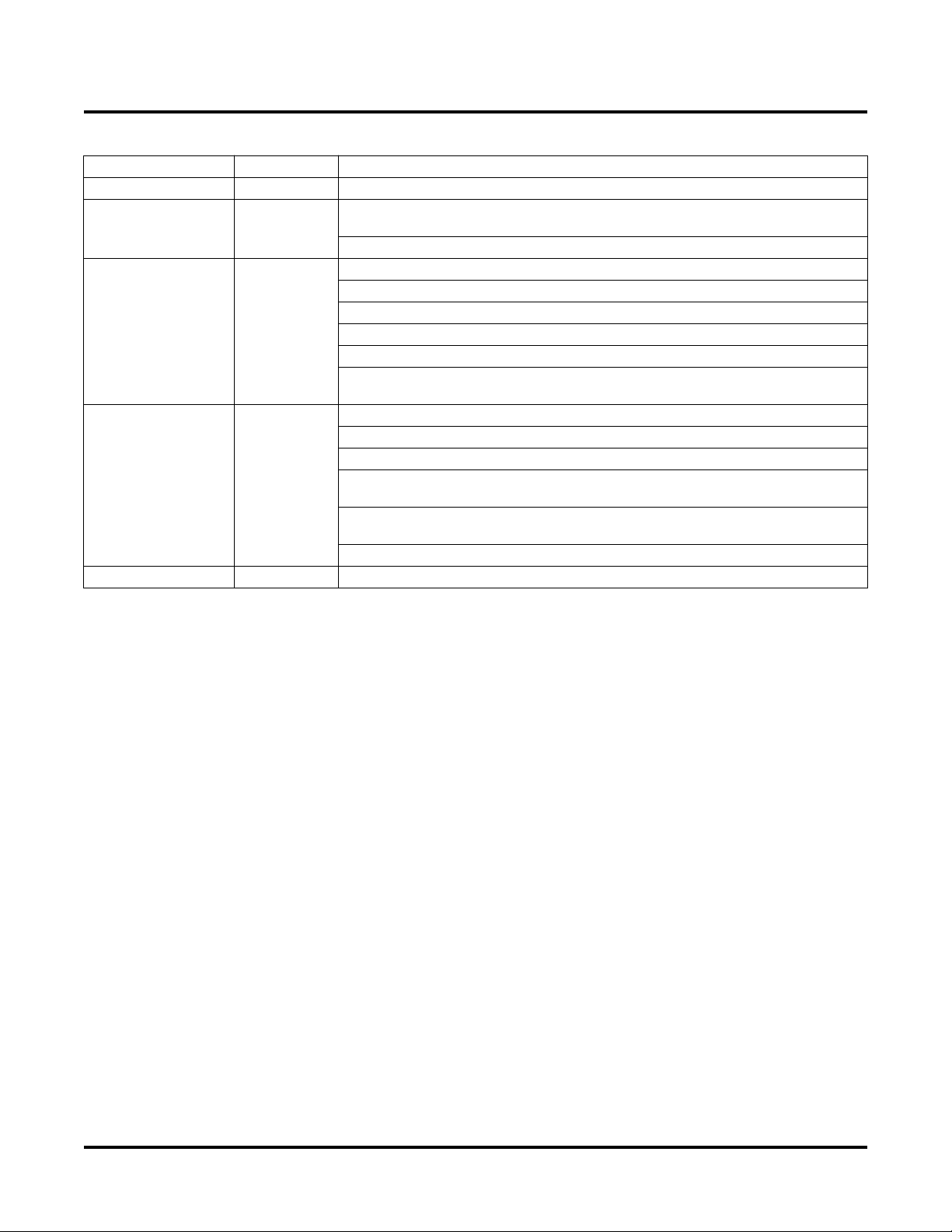

Pin Descriptions

Number Name Pin Type Voltage Range Description

89 VPS0 Digital Input VCCD Trim Select Input 0 Registered by MCLK

90 VPS1 Digital Input VCCD Trim Select Input 1 Registered by MCLK

97 IN1

1IN2

2IN3

4IN4

6IN5

7IN6

2

3

3

3

3

3

Digital Input VCCINP

Digital Input VCCINP

Digital Input VCCINP

Digital Input VCCINP

Digital Input VCCINP

Digital Input VCCINP

47 VMON1 Analog Input -0.3V to 5.75V

46 VMON1GS Analog Input -0.2V to 0.3V

50 VMON2 Analog Input -0.3V to 5.75V

48 VMON2GS Analog Input -0.2V to 0.3V

52 VMON3 Analog Input -0.3V to 5.75V

51 VMON3GS Analog Input -0.2V to 0.3V

54 VMON4 Analog Input -0.3V to 5.75V

53 VMON4GS Analog Input -0.2V to 0.3V

56 VMON5 Analog Input -0.3V to 5.75V

55 VMON5GS Analog Input -0.2V to 0.3V

58 VMON6 Analog Input -0.3V to 5.75V

57 VMON6GS Analog Input -0.2V to 0.3V

62 VMON7 Analog Input -0.3V to 5.75V

61 VMON7GS Analog Input -0.2V to 0.3V

64 VMON8 Analog Input -0.3V to 5.75V

63 VMON8GS Analog Input -0.2V to 0.3V

66 VMON9 Analog Input -0.3V to 5.75V

65 VMON9GS Analog Input -0.2V to 0.3V

68 VMON10 Analog Input -0.3V to 5.75V

67 VMON10GS Analog Input -0.2V to 0.3V

70 VMON11 Analog Input -0.3V to 5.75V

69 VMON11GS Analog Input -0.2V to 0.3V

72 VMON12 Analog Input -0.3V to 5.75V

71 VMON12GS Analog Input -0.2V to 0.3V

3, 22, 36,

43, 88, 98

45, 87 GNDA

13, 38, 94 VCCD

60 VCCA

GNDD

8

8

7

7

Ground Ground Digital Ground

Ground Ground Analog Ground

Power 2.8V to 3.96V Core VCC, Main Power Supply

Power 2.8V to 3.96V Analog Power Supply

5 VCCINP Power 2.25V to 3.6VVCC for IN[1:6] Inputs

33 VCCJ Power 2.25V to 3.6VVCC for JTAG Logic Interface Pins

39 VCCPROG Power 3.0V to 3.6V

6

0V to 10V Open-Drain Output 1

12.5µA to 100µA Source

100µA to 3000µA Sink

86 HVOUT1

Open Drain Output

Current Source/Sink

1

1

1

1

1

1

4

5

4

5

4

5

4

5

4

5

4

5

4

5

4

5

4

5

4

5

4

5

4

5

PLD Logic Input 1 Registered by MCLK

PLD Logic Input 2 Registered by MCLK

PLD Logic Input 3 Registered by MCLK

PLD Logic Input 4 Registered by MCLK

PLD Logic Input 5 Registered by MCLK

PLD Logic Input 6 Registered by MCLK

Voltage Monitor 1 Input

Voltage Monitor 1 Ground Sense

Voltage Monitor 2 Input

Voltage Monitor 2 Ground Sense

Voltage Monitor 3 Input

Voltage Monitor 3 Ground Sense

Voltage Monitor 4 Input

Voltage Monitor 4 Ground Sense

Voltage Monitor 5 Input

Voltage Monitor 5 Ground Sense

Voltage Monitor 6 Input

Voltage Monitor 6 Ground Sense

Voltage Monitor 7 Input

Voltage Monitor 7 Ground Sense

Voltage Monitor 8 Input

Voltage Monitor 8 Ground Sense

Voltage Monitor 9 Input

Voltage Monitor 9 Ground Sense

Voltage Monitor 10 Input

Voltage Monitor 10 Ground Sense

Voltage Monitor 11 Input

Voltage Monitor 11 Ground Sense

Voltage Monitor 12 Input

Voltage Monitor 12 Ground Sense

VCC for E

Not Powered by V

2

Programming when the Device is

CCD

or V

CCA

High-voltage FET Gate Driver 1

3

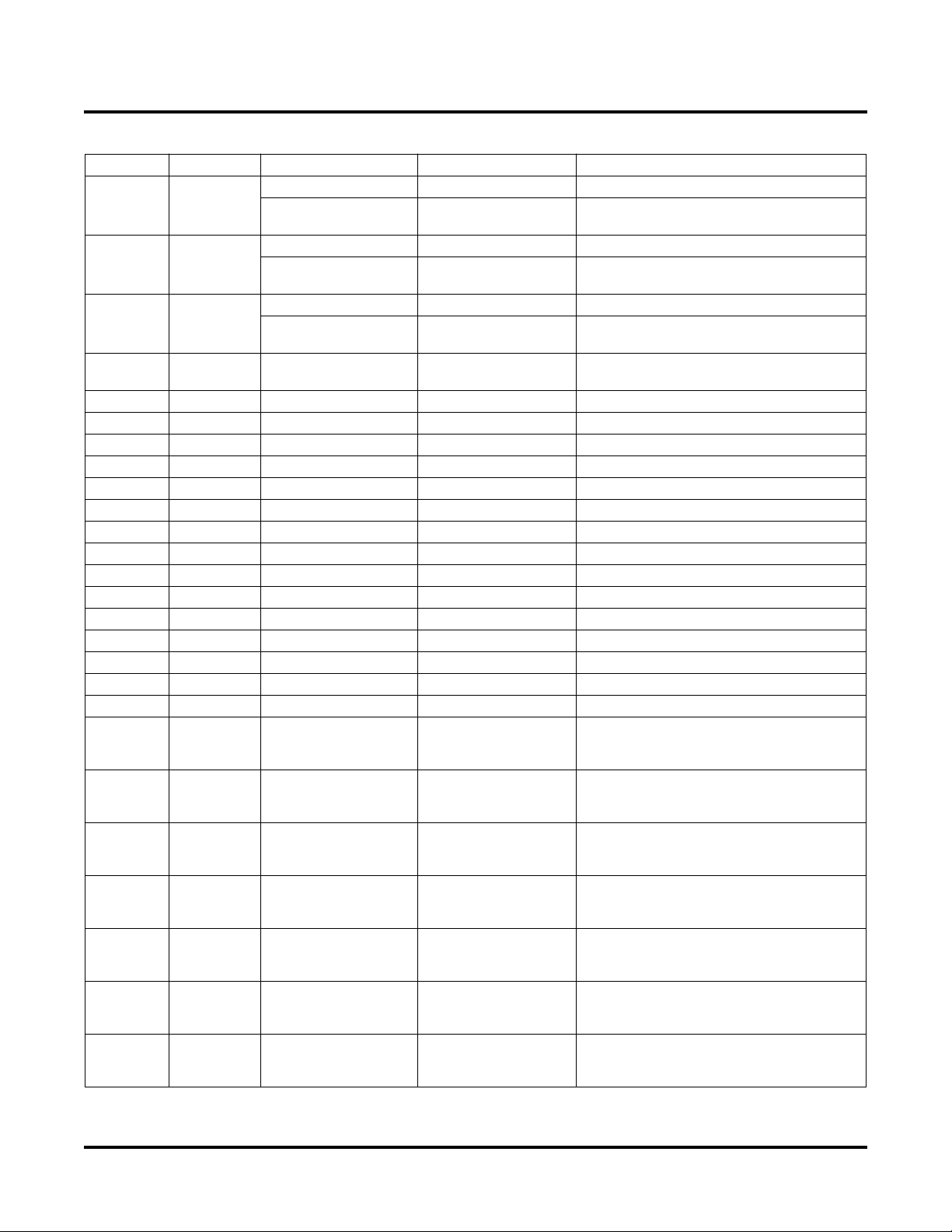

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

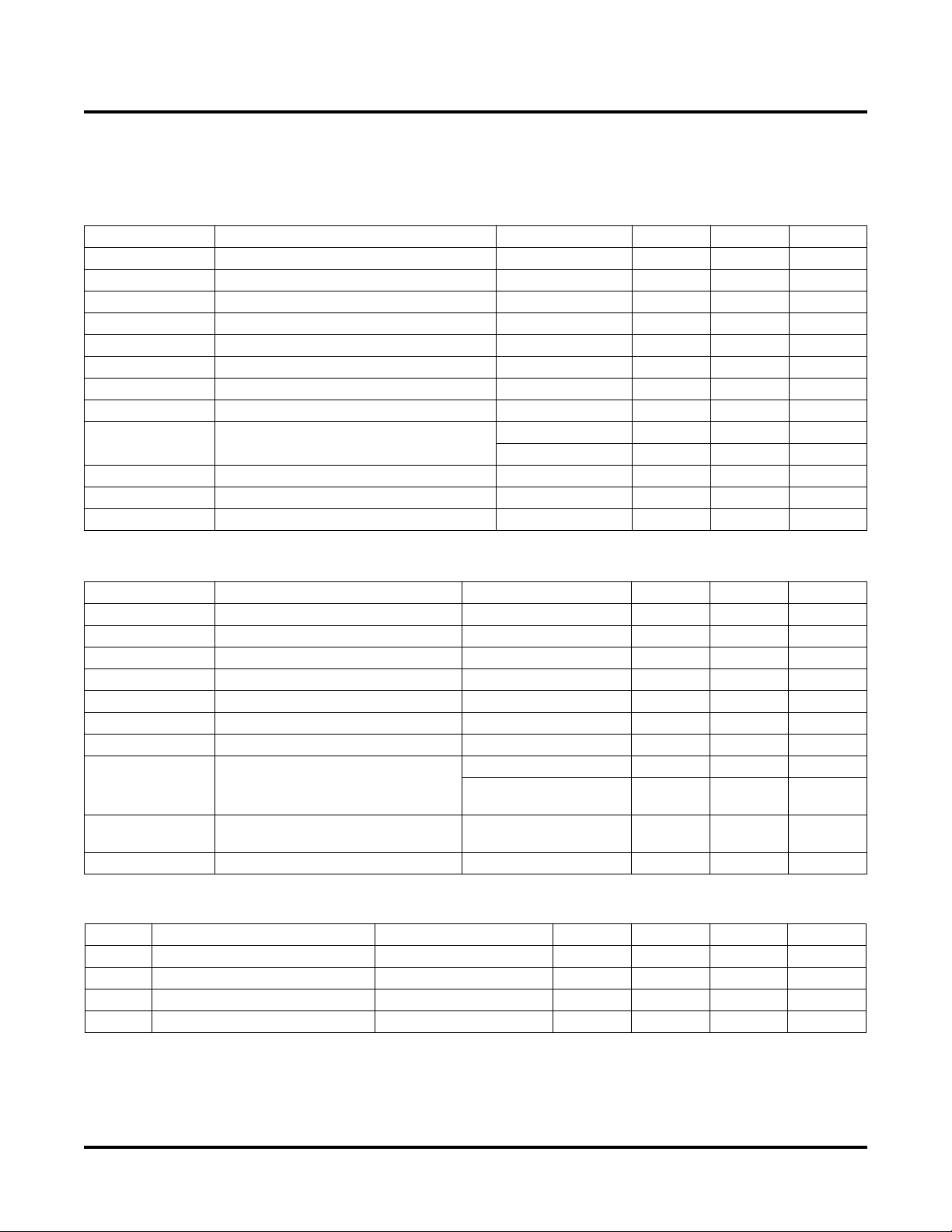

Pin Descriptions (Cont.)

Number Name Pin Type Voltage Range Description

Open Drain Output

85 HVOUT2

Current Source/Sink

Open Drain Output

42 HVOUT3

Current Source/Sink

Open Drain Output

40 HVOUT4

Current Source/Sink

8 OUT5_SMBA Open Drain Output

9 OUT6 Open Drain Output

10 OUT7 Open Drain Output

11 OUT8 Open Drain Output

12 OUT9 Open Drain Output

14 OUT10 Open Drain Output

15 OUT11 Open Drain Output

16 OUT12 Open Drain Output

17 OUT13 Open Drain Output

18 OUT14 Open Drain Output

19 OUT15 Open Drain Output

20 OUT16 Open Drain Output

21 OUT17 Open Drain Output

23 OUT18 Open Drain Output

24 OUT19 Open Drain Output

25 OUT20 Open Drain Output

84 TRIM1 Analog Output

83 TRIM2 Analog Output

82 TRIM3 Analog Output

80 TRIM4 Analog Output

79 TRIM5 Analog Output

75 TRIM6 Analog Output

74 TRIM7 Analog Output

6

0V to 10V Open-Drain Output 2

12.5µA to 100µA Source

100µA to 3000µA Sink

6

0V to 10V Open-Drain Output 3

12.5µA to 100µA Source

100µA to 3000µA Sink

6

0V to 10V Open-Drain Output 4

12.5µA to 100µA Source

100µA to 3000µA Sink

6

0V to 5.5V

6

0V to 5.5V Open-Drain Output 6

6

0V to 5.5V Open-Drain Output 7

6

0V to 5.5V Open-Drain Output 8

6

0V to 5.5V Open-Drain Output 9

6

0V to 5.5V Open-Drain Output 10

6

0V to 5.5V Open-Drain Output 11

6

0V to 5.5V Open-Drain Output 12

6

0V to 5.5V Open-Drain Output 13

6

0V to 5.5V Open-Drain Output 14

6

0V to 5.5V Open-Drain Output 15

6

0V to 5.5V Open-Drain Output 16

6

0V to 5.5V Open-Drain Output 17

6

0V to 5.5V Open-Drain Output 18

6

0V to 5.5V Open-Drain Output 19

6

0V to 5.5V Open-Drain Output 20

High-voltage FET Gate Driver 2

High-voltage FET Gate Driver 3

High-voltage FET Gate Driver 4

Open-Drain Output 5, (SMBUS Alert Active

Low)

-320mV to +320mV

from Programmable

Trim DAC Output 1

DAC Offset

-320mV to +320mV

from Programmable

Trim DAC Output 2

DAC Offset

-320mV to +320mV

from Programmable

Trim DAC Output 3

DAC Offset

-320mV to +320mV

from Programmable

Trim DAC Output 4

DAC Offset

-320mV to +320mV

from Programmable

Trim DAC Output 5

DAC Offset

-320mV to +320mV

from Programmable

Trim DAC Output 6

DAC Offset

-320mV to +320mV

from Programmable

Trim DAC Output 7

DAC Offset

4

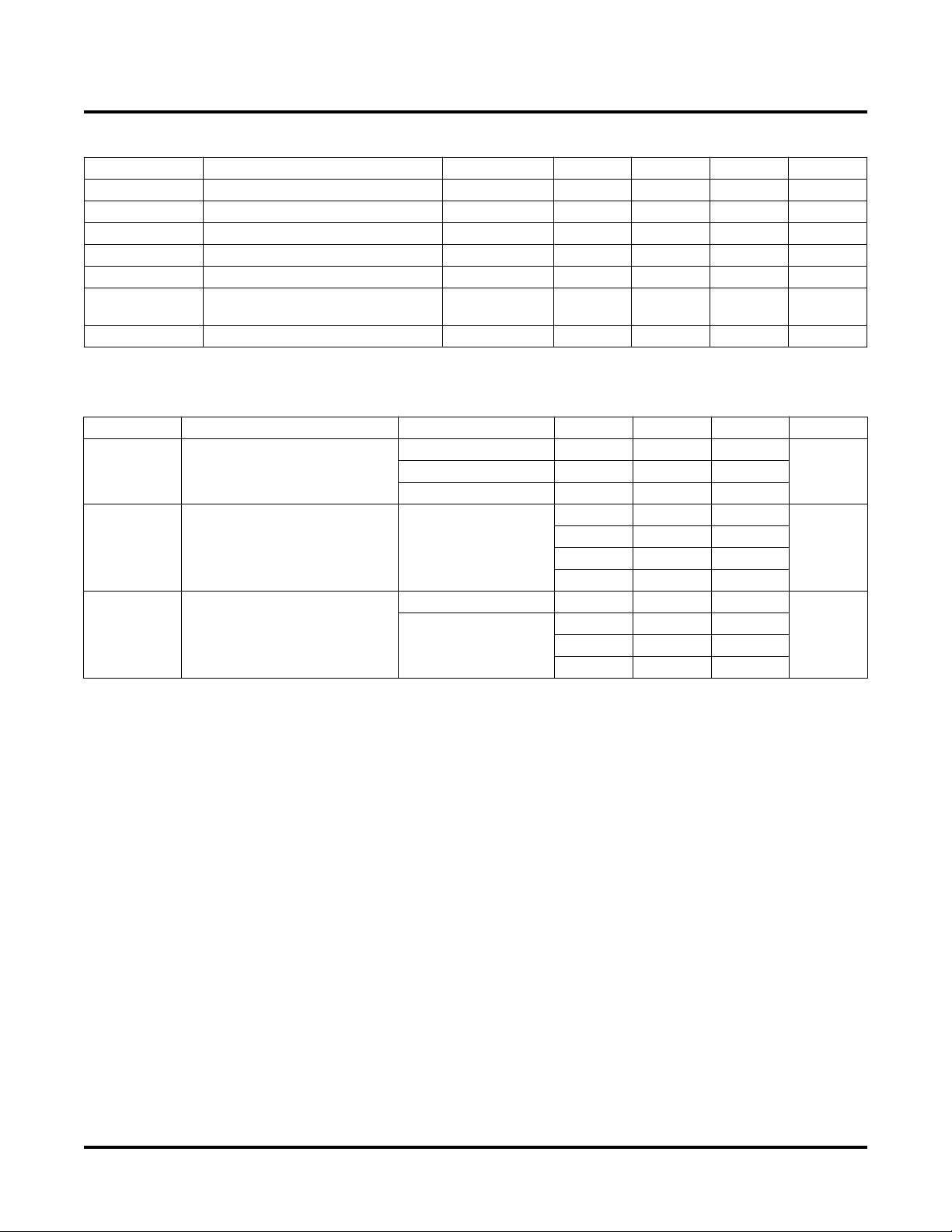

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Pin Descriptions (Cont.)

Number Name Pin Type Voltage Range Description

73 TRIM8 Analog Output

91 RESETb

9

Digital I/O 0V to 3.96V Device Reset (Active Low)

95 PLDCLK Digital Output 0V to 3.96V

96 MCLK Digital I/O 0V to 3.96V 8MHz Clock I/O (Tristate), CMOS Drive

34 TDO Digital Output 0V to 5.5V JTAG Test Data Out

37 TCK Digital Input 0V to 5.5V JTAG Test Clock Input

28 TMS Digital Input 0V to 5.5V JTAG Test Mode Select

31 TDI Digital Input 0V to 5.5V JTAG Test Data In, TDISEL pin = 1

30 ATDI Digital Input 0V to 5.5V JTAG Test Data In (Alternate), TDISEL Pin = 0

32 TDISEL Digital Input 0V to 5.5V Select TDI/ATDI Input

92 SCL Digital Input 0V to 5.5V I

93 SDA Digital I/O 0V to 5.5V I

44, 59 RESERVED Reserved - Do Not Connect

26, 27, 29,

35, 41, 49,

76, 77, 78,

NC No Internal Connection

81, 99, 100

1. [IN1...IN6] are inputs to the PLD. The thresholds for these pins are referenced by the voltage on VCCINP.

2. IN1 pin can also be controlled through JTAG interface.

3. [IN2..IN6] can also be controlled through I

4. The VMON inputs can be biased independently from VCCA. Unused VMONs should be tied to GNDD.

5. The VMONGS inputs are the ground sense line for each given VMON pin. The VMON input pins along with the VMONGS ground sense

pins implement a differential pair for each voltage monitor to allow remote sense at the load. VMONGS lines must be connected and are

not to exceed -0.2V - +0.3V in reference to the GNDA pin.

6. Open-drain outputs require an external pull-up resistor to a supply.

7. VCCD and VCCA pins must be connected together on the circuit board.

8. GNDA and GNDD pins must be connected together on the circuit board.

9. The RESETb pin should only

be used for cascading two or more ispPAC-POWR1220AT8 devices.

2

C/SMBus interface.

-320mV to +320mV

from Programmable

DAC Offset

Trim DAC Output 8

250kHz PLD Clock Output (Tristate), CMOS

Output

2

C Serial Clock Input

2

C Serial Data, Bi-directional Pin

5

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Absolute Maximum Ratings

Absolute maximum ratings are shown in the table below. Stresses beyond those listed may cause permanent damage to the device. Functional operation of the device at these or any other conditions beyond those indicated in the

recommended operating conditions of this specification is not implied.

Symbol Parameter Conditions Min. Max. Units

V

CCD

V

CCA

V

CCINP

V

CCJ

V

CCPROG

V

IN

V

MON+

V

MONGS

V

TRI

I

SINKMAXTOTAL

T

S

T

A

Core supply -0.5 4.5 V

Analog supply -0.5 4.5 V

Digital input supply (IN[1:6]) -0.5 6 V

JTAG logic supply -0.5 6 V

2

E

programming supply -0.5 4 V

Digital input voltage (all digital I/O pins) -0.5 6 V

V

input voltage -0.5 6 V

MON

V

input voltage ground sense -0.5 6 V

MON

Voltage applied to tri-stated pins

HVOUT[1:4] -0.5 11 V

OUT[5:20] -0.5 6 V

Maximum sink current on any output 23 mA

Storage temperature -65 150

Ambient temperature -65 125

o

C

o

C

Recommended Operating Conditions

Symbol Parameter Conditions Min. Max. Units

V

CCD,

V

CCINP

V

CCJ

V

CCPROG

V

IN

V

MON

V

MONGS

V

CCA

Core supply voltage at pin 2.8 3.96 V

Digital input supply for IN[1:6] at pin 2.25 5.5 V

JTAG logic supply voltage at pin 2.25 3.6 V

E2 programming supply at pin During E2 programming 3.0 3.6 V

Input voltage at digital input pins -0.3 5.5 V

Input voltage at V

Input voltage at V

pins -0.3 5.9 V

MON

pins -0.2 0.3 V

MONGS

OUT[5:20] pins -0.3 5.5 V

V

OUT

T

APROG

T

A

Open-drain output voltage

Ambient temperature during

programming

HVOUT[1:4] pins in opendrain mode

-0.3 10.4 V

-40 85

Ambient temperature Power applied -40 85

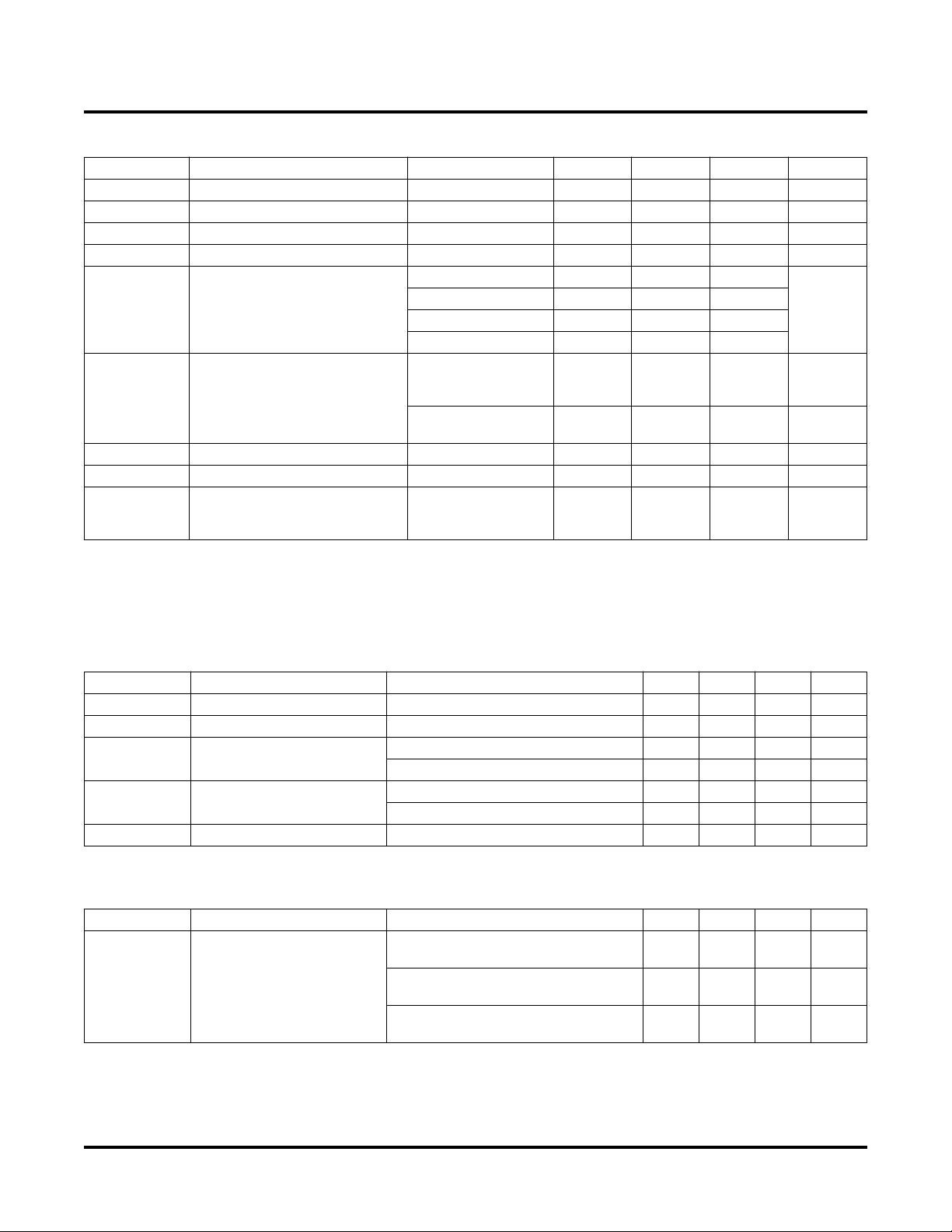

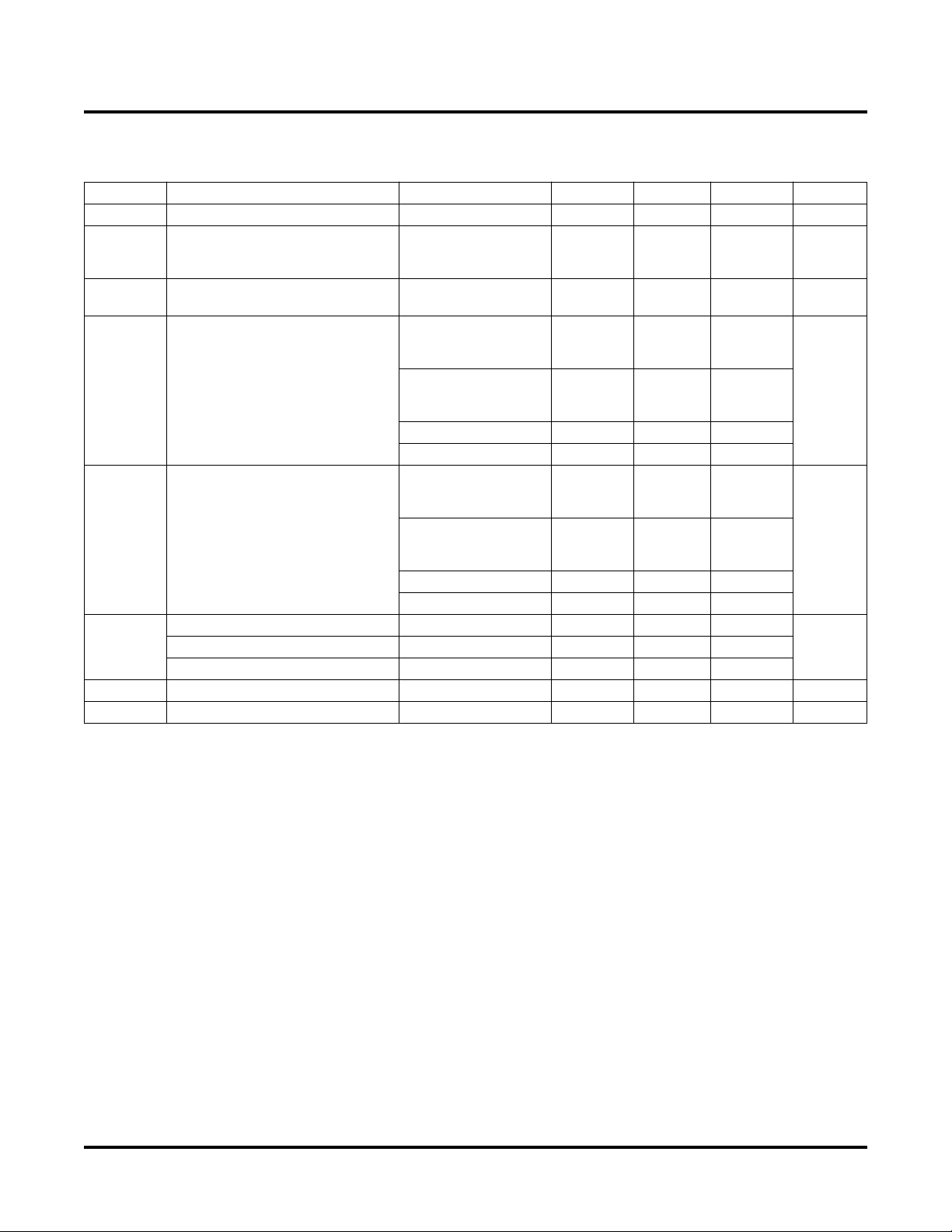

Analog Specifications

Symbol Parameter Conditions Min. Typ. Max. Units

1

I

CC

I

CCINP

I

CCJ

I

CCPROG

1. Includes currents on V

Supply current 40 mA

Supply current 5mA

Supply current 1mA

Supply current During programming cycle 40 mA

CCD

and V

CCA

supplies.

o

C

o

C

6

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Voltage Monitors

Symbol Parameter Conditions Min. Typ. Max. Units

R

IN

C

IN

V

Range Programmable trip-point range 0.075 5.734 V

MON

Sense Near-ground sense threshold 70 75 80 mV

V

Z

Accuracy Absolute accuracy of any trip-point

V

MON

HYST

Input resistance 55 65 75 kΩ

Input capacitance 8 pF

1

Hysteresis of any trip-point (relative to

setting)

0.2 0.7 %

1%

CMR Common mode rejection 60 dB

1. Guaranteed by characterization across V

range, operating temperature, process.

CCA

High Voltage FET Drivers

Symbol Parameter Conditions Min. Typ. Max. Units

10V setting 9.6 10 10.4

V

PP

I

OUTSRC

I

OUTSINK

Gate driver output voltage

Gate driver source current

(HIGH state)

Gate driver sink current

(LOW state)

6V setting 5.8 6 6.2

12.5

Four settings in

software

25

50

100

FAST OFF mode 2000 3000

100

Controlled ramp

settings

250

500

V8V setting 7.7 8 8.3

µA

µA

7

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Margin/Trim DAC Output Characteristics

Symbol Parameter Conditions Min Typ Max Units

Resolution 8(7+sign) bits

FSR Full scale range +/-320 mV

LSB LSB step size 2.5 mV

I

OUT

BPZ

TS

C_LOAD Maximum load capacitance 50 pF

T

UPDATEM

TOSE

1. To 1% of set value with 50pf load connected to trim pins.

2. Total time required to update a single TRIMx output value by setting the associated DAC through the I2C port.

3. This is the total resultant error in the trimmed power supply output voltage referred to any DAC code due to the DAC’s INL, DNL, gain, output impedance, offset error and bipolar offset error across the industrial temperature range and the ispPAC-POWR1200AT8 operating V

and V

CCD

Output source/sink current -200 200 µA

Offset 1 0.6

Bipolar zero output voltage

(code=80h)

Offset 2 0.8

Offset 3 1.0

Offset 4 1.25

DAC code changed

TrimCell output voltage settling

1

time

Update time through I2C port

Total open loop supply voltage

3

error

ranges.

from 80H to FFH or

80H to 00H

Single DAC code

change

2

MCLK = 8MHz 260 µs

256 µs

Full scale DAC corresponds to ±5% supply

-1% +1% V/V

voltage variation

2.5 ms

V

CCA

ADC Characteristics

Symbol Parameter Conditions Min. Typ. Max. Units

ADC Resolution 10 Bits

T

CONVERT

V

IN

ADC Step Size LSB

Eattenuator Error Due to Attenuator Programmable Attenuator = 3 +/- 0.1 %

1. Maximum voltage is limited by V

ADC Error Budget Across Entire Operating Temperature Range

Symbol Parameter Conditions Min. Typ. Max. Units

TADC Error

1. Total error, guaranteed by characterization, includes INL, DNL, Gain, Offset, and PSR specs of the ADC.

Conversion Time Time from I2C Request 200 µs

Input range Full Scale

Programmable Attenuator = 1 0 2.048 V

Programmable Attenuator = 3 0 5.9

1

Programmable Attenuator = 1 2 mV

Programmable Attenuator = 3 6 mV

pin (theoretical maximum is 6.144V).

MONX

Total Measurement Error at

Any Voltage

1

Measurement Range 600 mV - 2.048V,

VMONxGS > -100mV, Attenuator =1

Measurement Range 600 mV - 2.048V,

VMONxGS > -200mV, Attenuator =1

Measurement Range 0 - 2.048V,

VMONxGS > -200mV, Attenuator =1

-8 +/-4 8 mV

+/-6 mV

+/-10 mV

V

8

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Power-On Reset

Symbol Parameter Conditions Min. Typ. Max. Units

T

GOOD

V

TL

V

TH

V

T

T

POR

C

L

1. Corresponds to VCCA and VCCD supply voltages.

Power-on reset to valid VMON comparator

output

Threshold below which RESETb is LOW

Threshold above which RESETb is HIGH

Threshold above which RESETb is valid

Minimum duration dropout required to trigger

RESETb

Capacitive load on RESETb for master/slave

operation

1

1

1

2.5 ms

2.3 V

2.7 V

0.8 V

15µs

200 pF

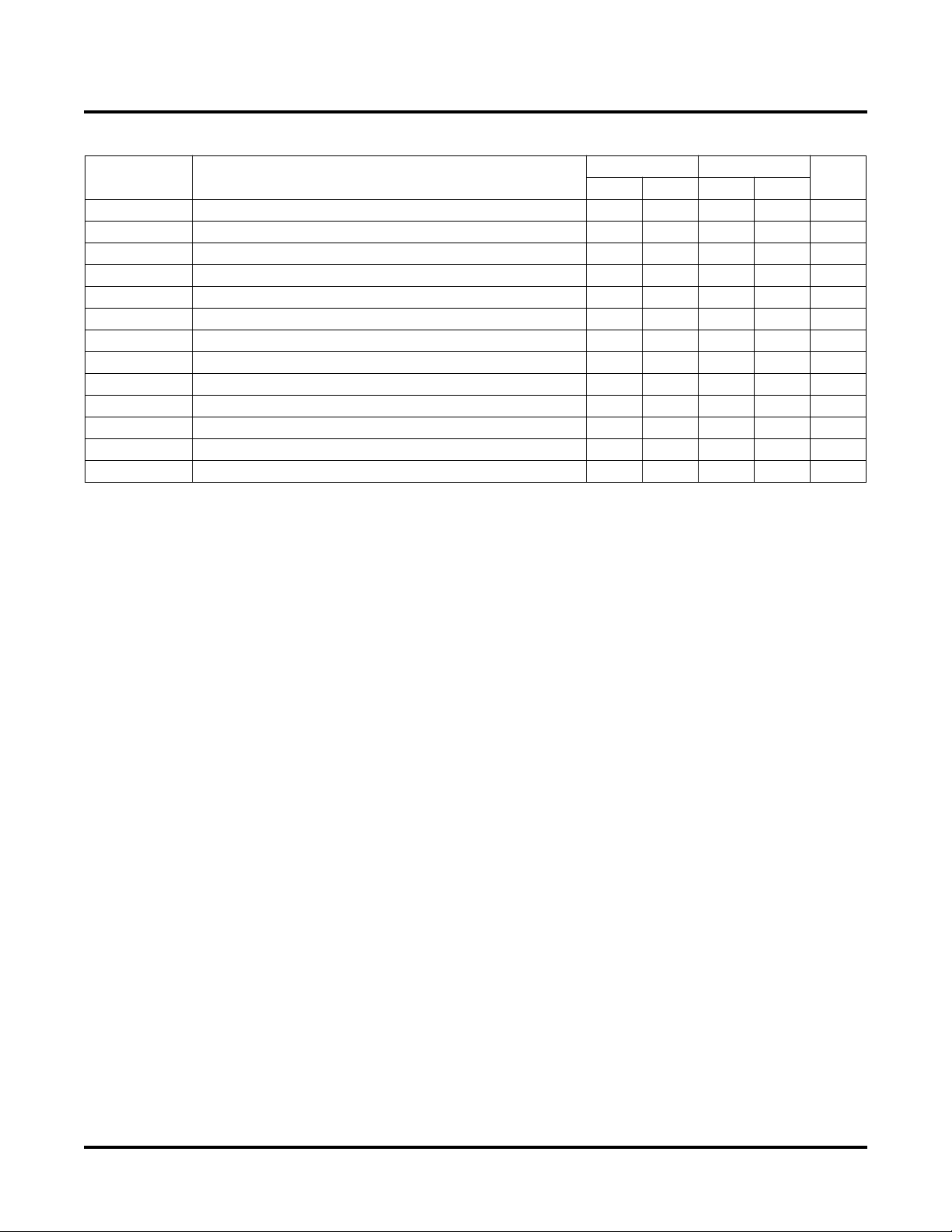

AC/Transient Characteristics

Over Recommended Operating Conditions

Symbol Parameter Conditions Min. Typ. Max. Units

Voltage Monitors

t

PD16

t

PD64

Propagation delay input to

output glitch filter OFF

Propagation delay input to

output glitch filter ON

Oscillators

f

CLK

f

CLKEXT

f

PLDCLK

Internal master clock

frequency (MCLK)

Externally applied master

clock (MCLK)

PLDCLK output frequency f

Timers

Timeout Range

Resolution

Range of programmable

timers (128 steps)

Spacing between available

adjacent timer intervals

Accuracy Timer accuracy f

7.6 8 8.4 MHz

7.2 8.8 MHz

= 8MHz 250 kHz

CLK

f

= 8MHz 0.032 1966 ms

CLK

= 8MHz -6.67 -12.5 %

CLK

16 µs

64 µs

13 %

9

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Digital Specifications

Over Recommended Operating Conditions

Symbol Parameter Conditions Min. Typ. Max. Units

I

IL,IIH

I

OH-HVOUT

I

PU

V

IL

V

IH

V

OL

V

OH

I

SINKTOTAL

1. VPS[0:1], SCL, SDA referenced to V

Input leakage, no pull-up/pull-down +/-10 µA

HVOUT[1:4] in open

Output leakage current

drain mode and pulled

35 60 µA

up to 10V

Input pull-up current (TMS, TDI,

TDISEL, ATDI, MCLK)

70 µA

VPS[0:1], TDI, TMS,

ATDI, TDISEL, 3.3V

0.8

supply

Voltage input, logic low

1

VPS[0:1], TDI, TMS,

ATDI, TDISEL, 2.5V

0.7

V

supply

SCL, SDA 30% V

IN[1:6] 30% V

CCD

CCINP

VPS[0:1], TDI, TMS,

ATDI, TDISEL, 3.3V

2.0

supply

Voltage input, logic high

1

VPS[0:1], TDI, TMS,

ATDI, TDISEL, 2.5V

1.7

V

supply

HVOUT[1:4] (open drain mode), I

TDO,MCLK,PLDCLK I

TDO, MCLK, PLDCLK I

SCL, SDA 70% V

IN[1:6] 70% V

= 10mA 0.8

SINK

= 20mA 0.8

SINK

= 4mA 0.4

SINK

= 4mA V

SRC

CCD

CCINP

V

CCD

V

CCINP

- 0.4 V

CCD

VOUT[5:20] I

All digital outputs 130 mA

; IN[1:6] referenced to V

CCD

; TDO, TDI, TMS, ATDI, TDISEL referenced to V

CCINP

CCJ

.

10

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

I2C Port Characteristics

100KHz 400KHz

Symbol Definition

F

I2C

T

SU;STA

T

HD;STA

T

SU;DAT

T

SU;STO

T

HD;DAT

T

LOW

T

HIGH

T

F

T

R

T

TIMEOUT

T

POR

T

BUF

1. If F

is less than 50kHz, then the ADC DONE status bit is not guaranteed to be set after a valid conversion request is completed. In this

I2C

case, waiting for the T

readout. When F

I2C clock/data rate 100

After start 4.7 0.6 us

After start 4 0.6 us

Data setup 250 100 ns

Stop setup 4 0.6 us

Data hold; SCL= Vih_min = 2.1V 0.3 3.45 0.3 0.9 us

Clock low period 4.7 1.3 us

Clock high period 4 0.6 us

Fall time; 2.25V to 0.65V 300 300 ns

Rise time; 0.65V to 2.25V 1000 300 ns

Detect clock low timeout 25 35 25 35 ms

Device must be operational after power-on reset 500 500 ms

Bus free time between stop and start condition 4.7 1.3 us

CONVERT

is greater than 50kHz, ADC conversion complete is ensured by waiting for the DONE status bit.

I2C

minimum time after a convert request is made is the only way to guarantee a valid conversion is ready for

1

400

UnitsMin. Max. Min. Max.

1

KHz

11

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

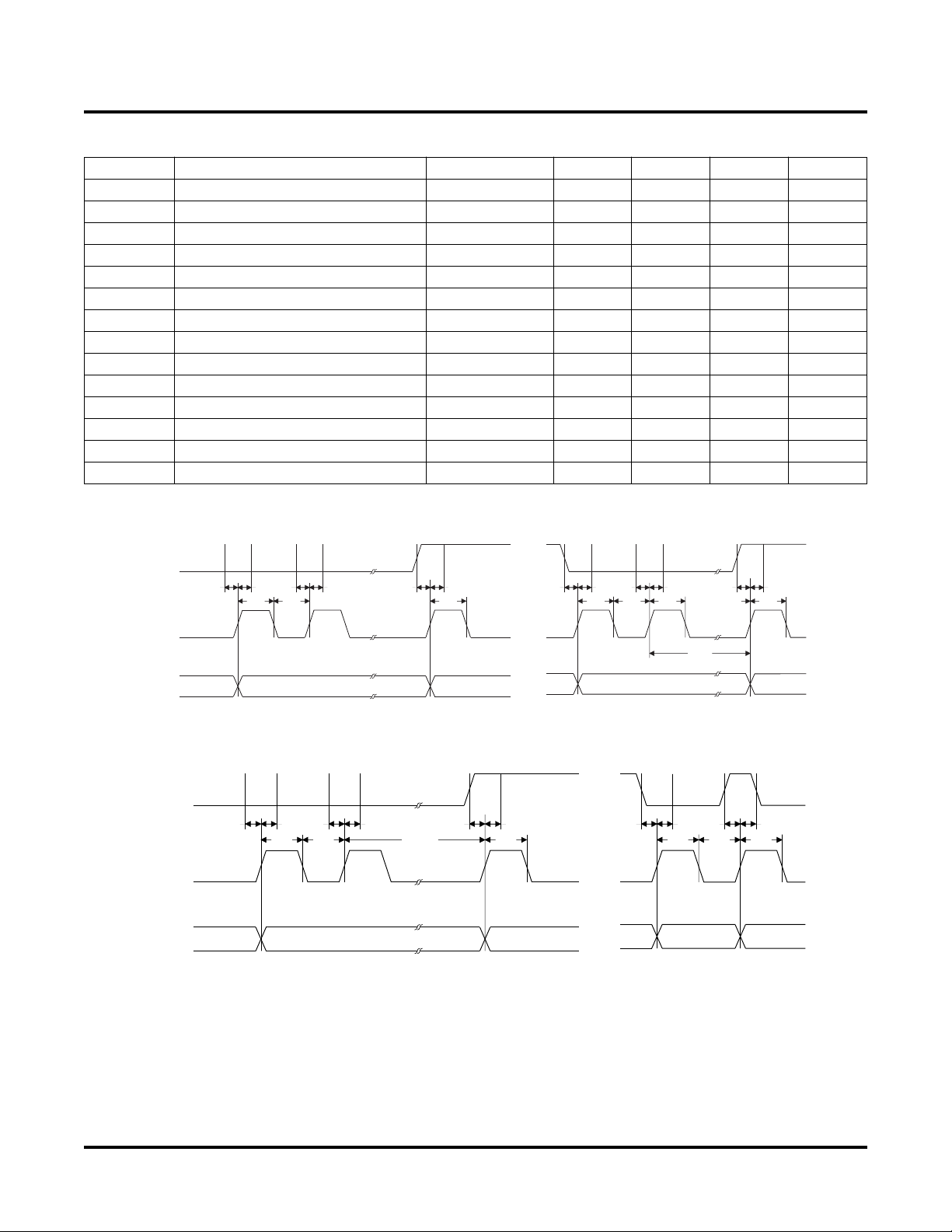

Timing for JTAG Operations

Symbol Parameter Conditions Min. Typ. Max. Units

t

ISPEN

t

ISPDIS

t

HVDIS

t

HVDIS

t

CEN

t

CDIS

t

SU1

t

H

t

CKH

t

CKL

f

MAX

t

CO

t

PWV

t

PWP

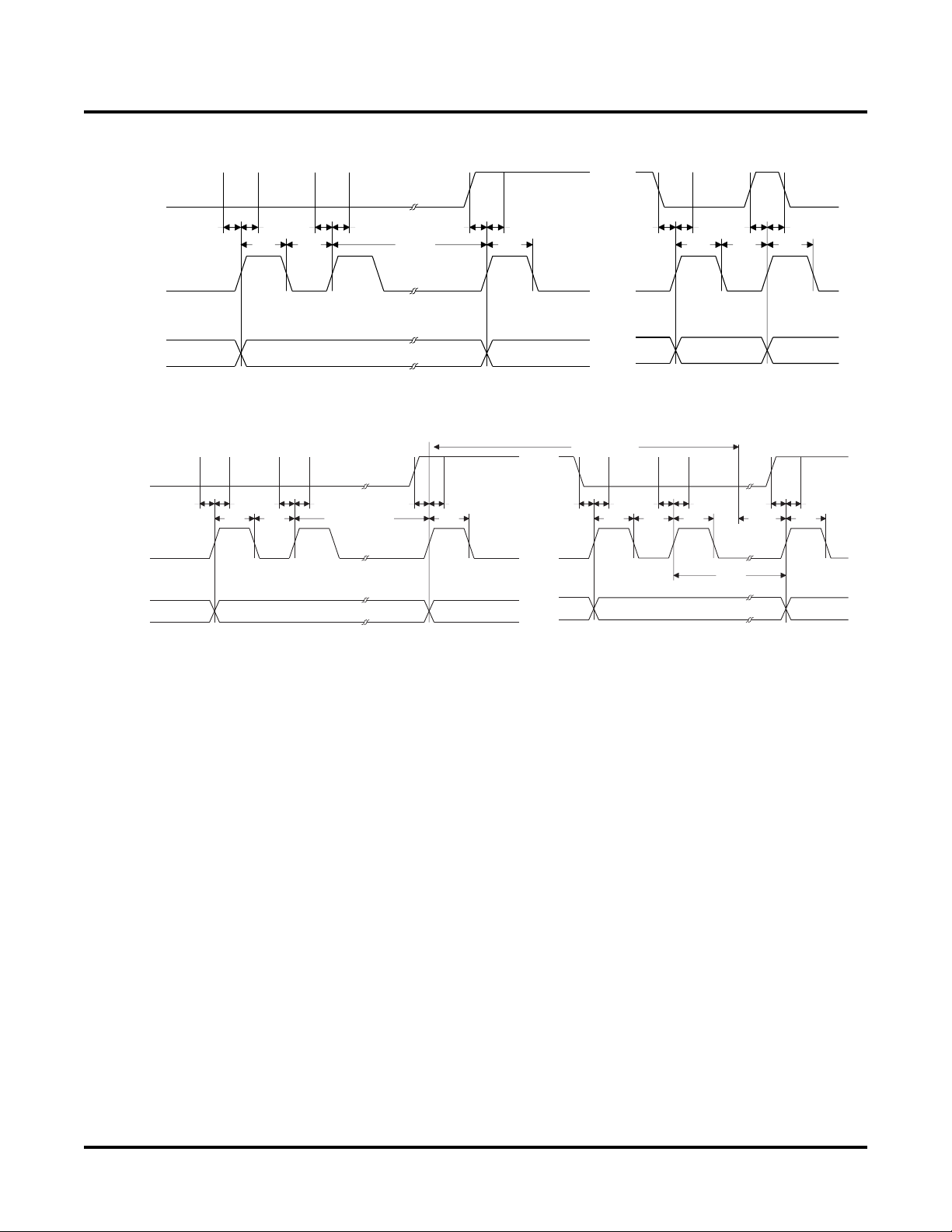

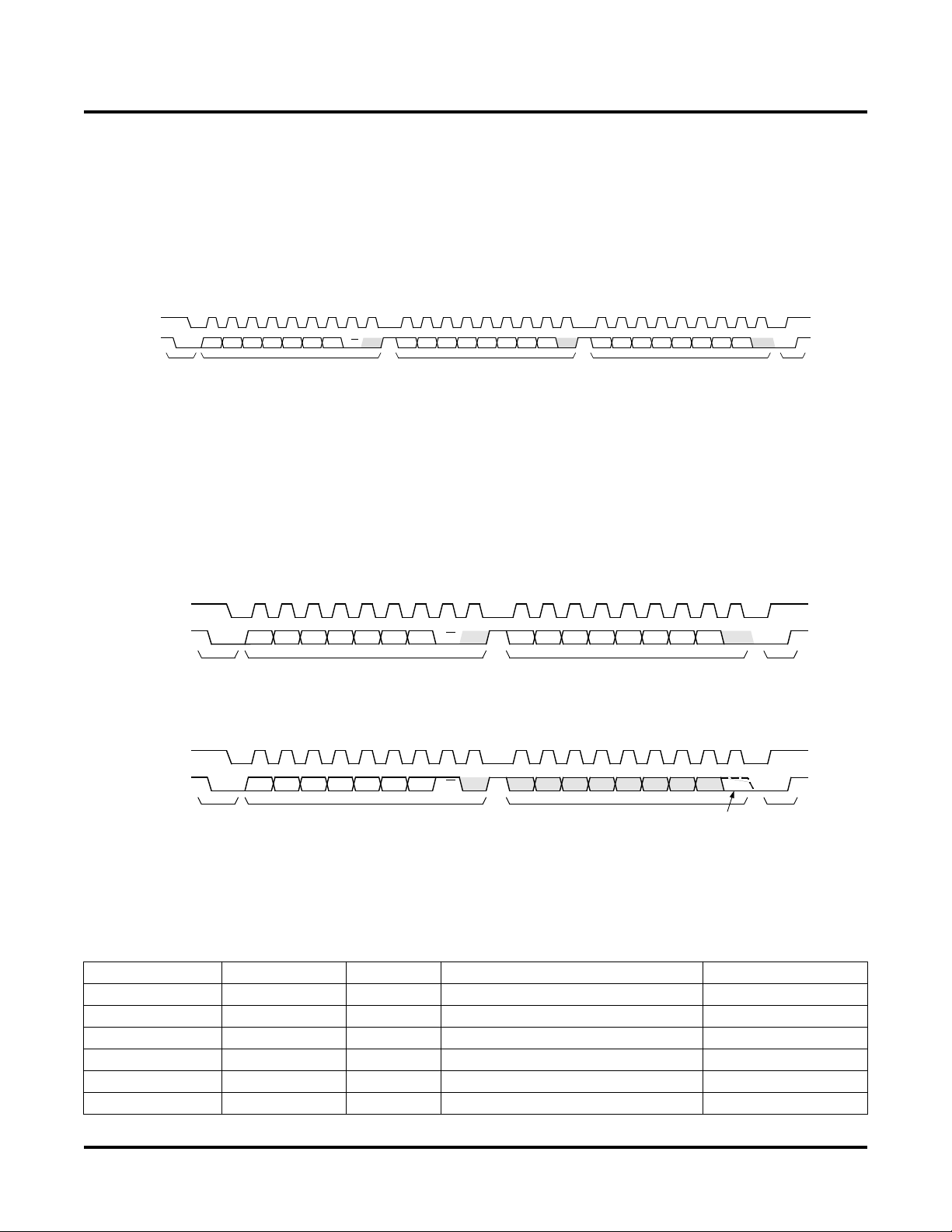

Figure 2. Erase (User Erase or Erase All) Timing Diagram

Program enable delay time 10 — — µs

Program disable delay time 30 — — µs

High voltage discharge time, program 30 — — µs

High voltage discharge time, erase 200 — — µs

Falling edge of TCK to TDO active — — 15 ns

Falling edge of TCK to TDO disable — — 15 ns

Setup time 5 — — ns

Hold time 10 — — ns

TCK clock pulse width, high 20 — — ns

TCK clock pulse width, low 20 — — ns

Maximum TCK clock frequency — — 25 MHz

Falling edge of TCK to valid output — — 15 ns

Verify pulse width 30 — — µs

Programming pulse width 20 — — ms

VIH

TMS

VIL

t

SU1

VIH

TCK

VIL

Update-IR Run-Test/Idle (Erase) Select-DR Scan

State

t

t

SU1

H

t

CKH tGKL

t

H

Figure 3. Programming Timing Diagram

VIH

TMS

VIL

TCK

State

t

SU1

VIH

VIL

Update-IR Run-Test/Idle (Program) Select-DR Scan

t

t

SU1

H

t

t

CKL

CKH

CKH

t

SU1

t

SU2

t

t

SU1

H

t

CKL

t

H

t

CKH

t

H

t

CKH

t

SU1

t

H

t

H

t

CKH

t

SU1

t

PWP

t

t

SU1

Instruction, then clock to the Run-Test/Idle state

Clock to Shift-IR state and shift in the Discharge

t

H

CKH

t

t

SU1

H

t

t

CKH

GKL

Run-Test/Idle (Discharge)

t

SU1

t

H

t

CKH

Specified by the Data Sheet

t

Update-IR

Clock to Shift-IR state and shift in the next

Instruction, which will stop the discharge process

12

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Figure 4. Verify Timing Diagram

VIH

TMS

VIL

t

H

t

CKH

TCK

VIH

VIL

t

t

SU1

t

H

SU1

t

t

CKH

CKL

t

H

t

SU1

t

PWV

t

H

t

CKH

t

SU1

t

t

H

SU1

t

t

CKH

CKL

State

Update-IR Run-Test/Idle (Program) Select-DR Scan

Update-IR

Clock to Shift-IR state and shift in the next Instruction

Figure 5. Discharge Timing Diagram

t

(Actual)

t

SU1

Clock to Shift-IR state and shift in the Verify

Instruction, then clock to the Run-Test/Idle state

HVDIS

t

t

H

SU1

t

t

CKH

CKL

Run-Test/Idle (Verify)

t

H

t

CKH

Specified by the Data Sheet

t

SU1

t

PWV

Actual

t

PWV

t

H

t

CKH

TMS

TCK

State

VIH

VIL

t

H

VIH

VIL

t

t

SU1

t

H

SU1

t

CKH tCKL

Update-IR Run-Test/Idle (Erase or Program)

t

SU1

t

PWP

t

H

t

CKH

Select-DR Scan

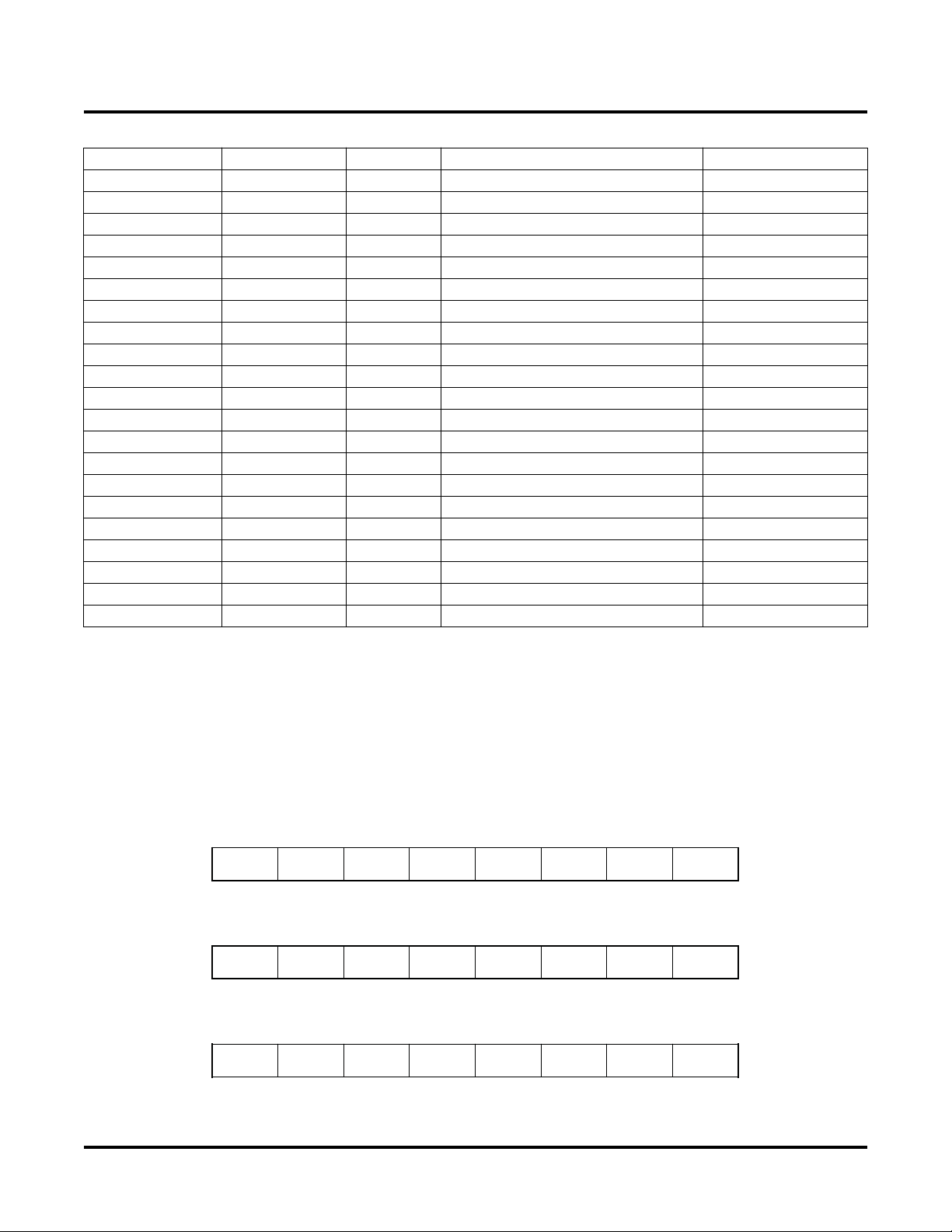

Theory of Operation

Analog Monitor Inputs

The ispPAC-POWR1220AT8 provides 12 independently programmable voltage monitor input circuits as shown in

Figure 6. Two individually programmable trip-point comparators are connected to an analog monitoring input. Each

comparator reference has 368 programmable trip points over the range of 0.664V to 5.734V. Additionally, a 75mV

‘zero-detect’ threshold is selectable which allows the voltage monitors to determine if a monitored signal has

dropped to ground level. This feature is especially useful for determining if a power supply’s output has decayed to

a substantially inactive condition after it has been switched off.

13

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

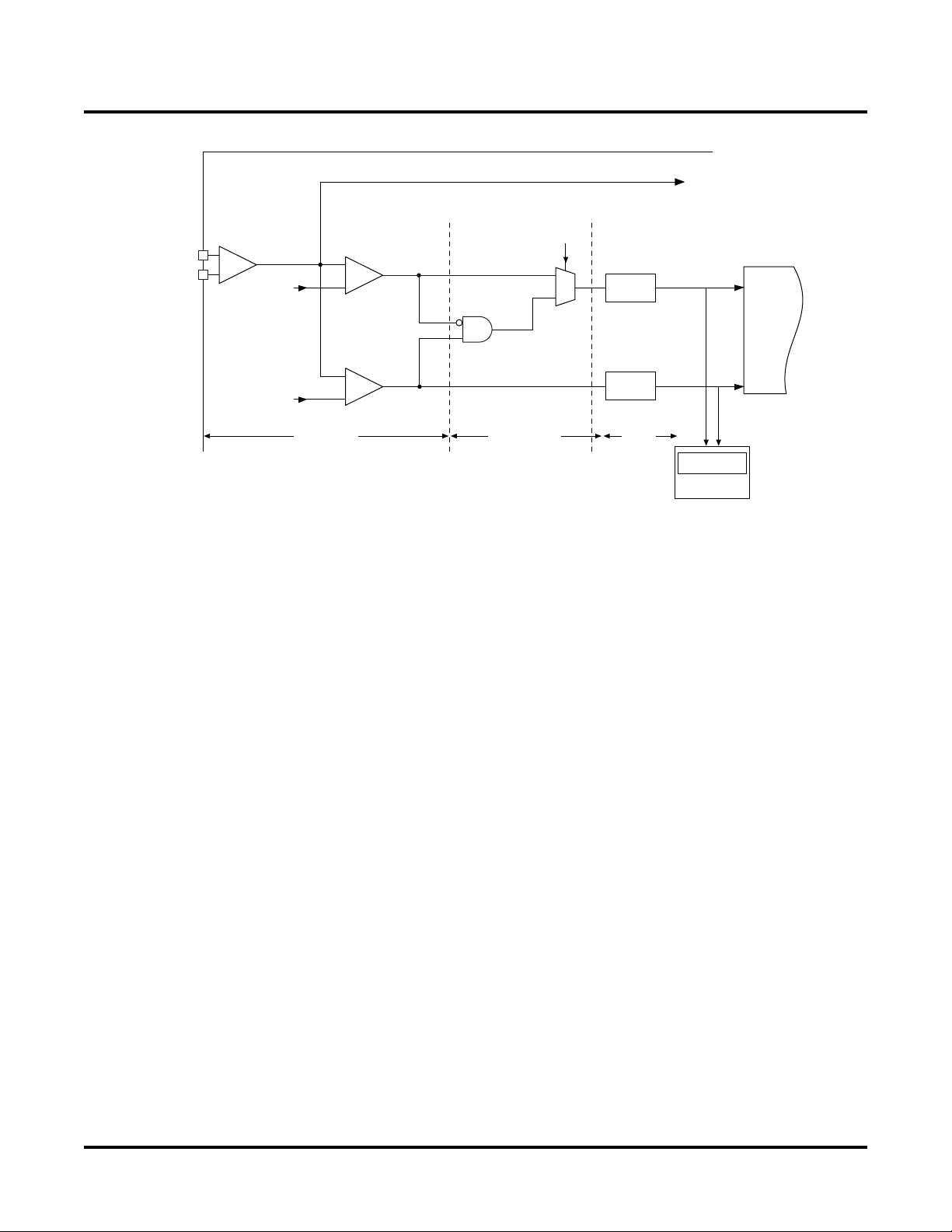

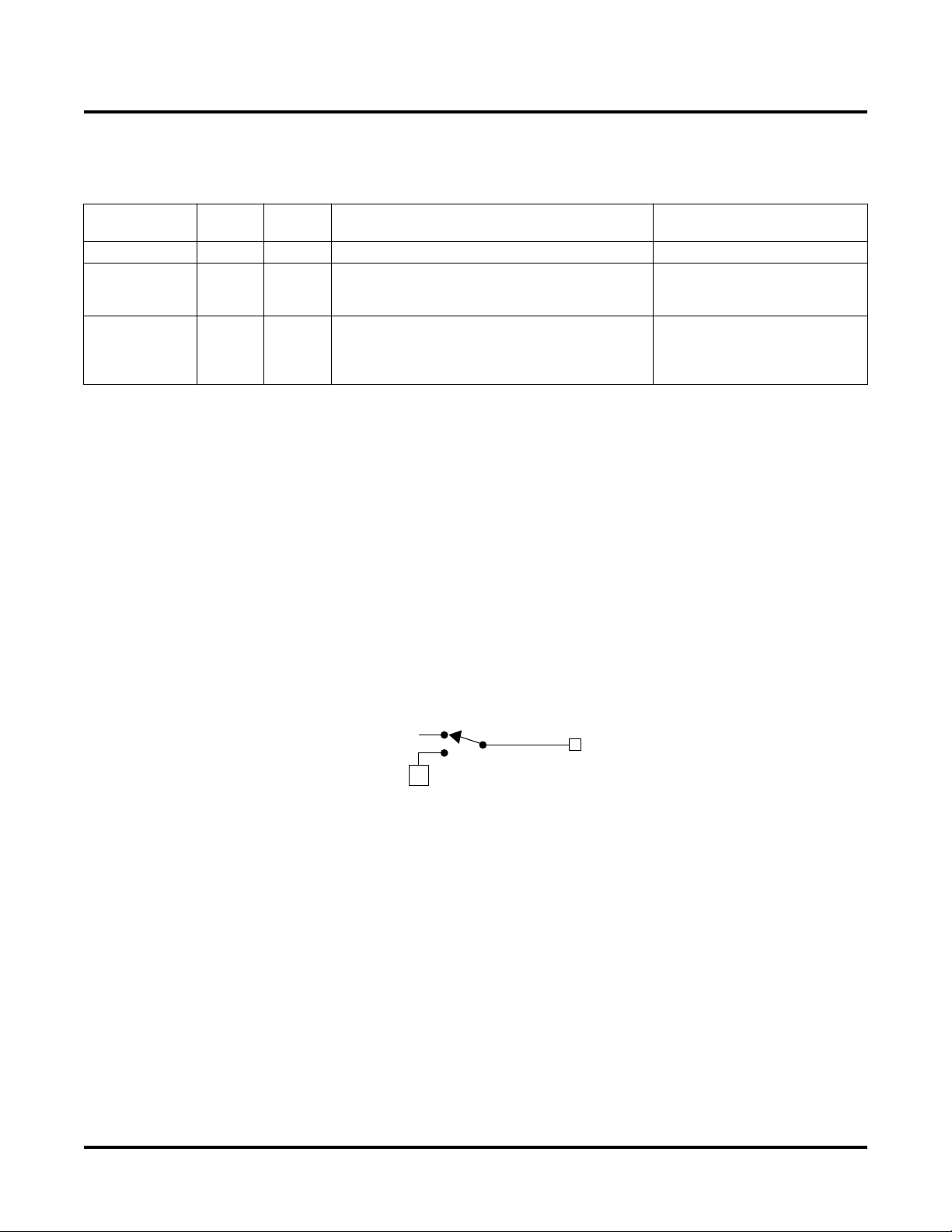

Figure 6. ispPAC-POWR1220AT8 Voltage Monitors

ispPAC-POWR1220AT8

To ADC

Comp A/Window

Select

Window Control

MUX

Glitch

Filter

Glitch

Filter

Filtering

VMONxA

Logic

Signal

VMONxB

Logic

Signal

VMONx Status

I2C Interface

Unit

PLD

Array

VMONx

VMONxGS

Differential

Input Buffer x

Trip Point A

Trip Point B

Comp A

+

–

Comp B

+

–

Analog Input

Figure 6 shows the functional block diagram of one of the 12 voltage monitor inputs - ‘x’ (where x = 1...12). Each

voltage monitor can be divided into three sections: Analog Input, Window Control, and Filtering. The first section

provides a differential input buffer to monitor the power supply voltage through VMONx+ (to sense the positive ter-

minal of the supply) and VMONxGS (to sense the power supply ground). Differential voltage sensing minimizes

inaccuracies in voltage measurement with ADC and monitor thresholds due to the potential difference between the

ispPAC-POWR1220AT8 device ground and the ground potential at the sensed node on the circuit board.

The voltage output of the differential input buffer is monitored by two individually programmable trip-point comparators, shown as CompA and CompB. Table 1 shows all 368 trip points spanning the range 0.664V to 5.734V to

which a comparator’s threshold can be set.

Each comparator outputs a HIGH signal to the PLD array if the voltage at its positive terminal is greater than its programmed trip point setting, otherwise it outputs a LOW signal.

A hysteresis of approximately 1% of the setpoint is provided by the comparators to reduce false triggering as a

result of input noise. The hysteresis provided by the voltage monitor is a function of the input divider setting. Table 3

lists the typical hysteresis versus voltage monitor trip-point.

AGOOD Logic Signal

All the VMON comparators auto-calibrate immediately after a power-on reset event. During this time, the digital

glitch filters are also initialized. This process completion is signalled by an internally generated logic signal:

AGOOD. All logic using the VMON comparator logic signals must wait for the AGOOD signal to become active.

Programmable Over-Voltage and Under-Voltage Thresholds

Figure 7 (a) shows the power supply ramp-up and ramp-down voltage waveforms. Because of hysteresis, the comparator outputs change state at different thresholds depending on the direction of excursion of the monitored power

supply.

14

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

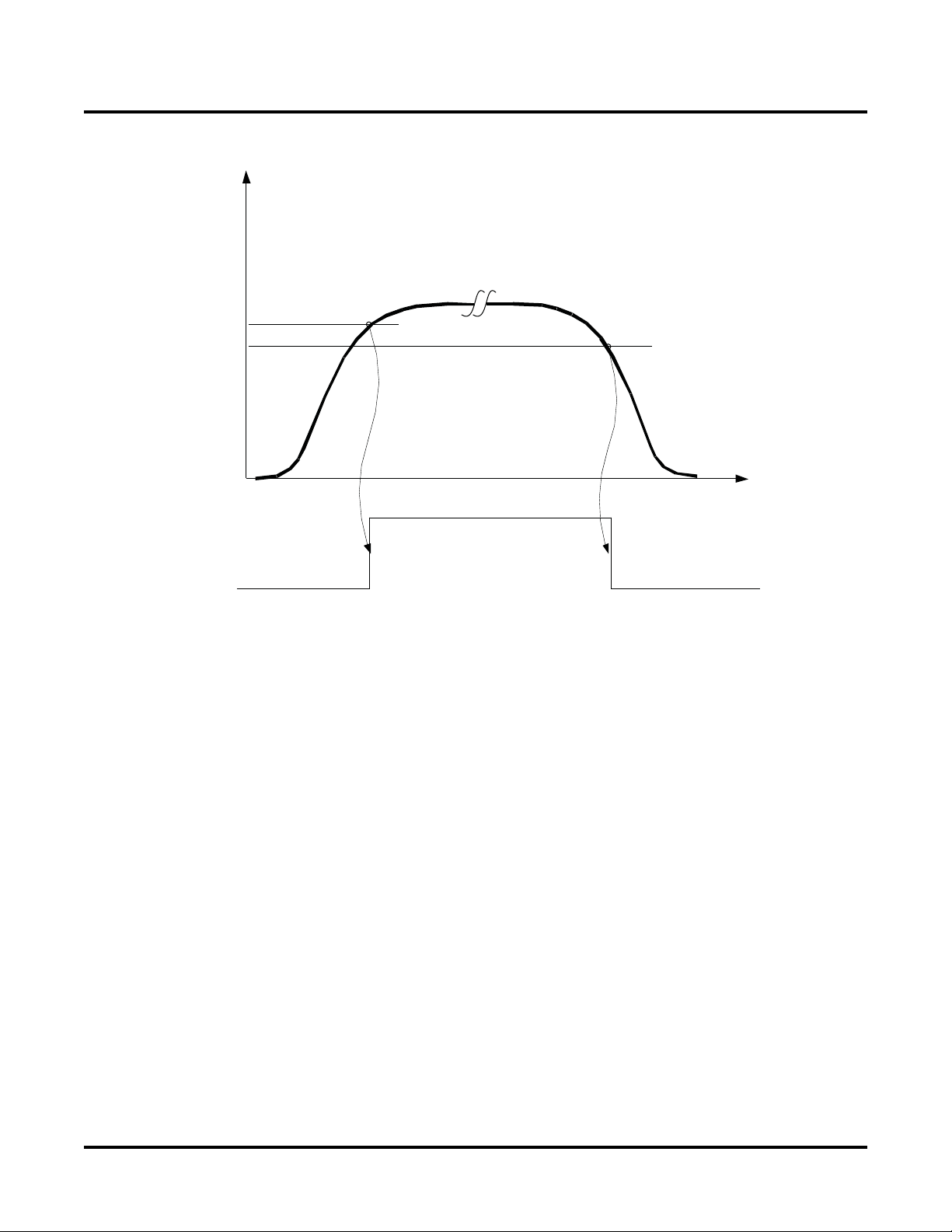

Figure 7. (a) Power Supply Voltage Ramp-up and Ramp-down Waveform and the Resulting Comparator

Output, (b) Corresponding to Upper and Lower Trip Points

UTP

LTP

(a)

Monitored Power Supply Votlage

(b)

Comparator Logic Output

During power supply ramp-up the comparator output changes from logic 0 to 1 when the power supply voltage

crosses the upper trip point (UTP). During ramp down the comparator output changes from logic state 1 to 0 when

the power supply voltage crosses the lower trip point (LTP). To monitor for over voltage fault conditions, the UTP

should be used. To monitor under-voltage fault conditions, the LTP should be used.

Tables 1 and 2 show both the under-voltage and over-voltage trip points, which are automatically selected in software depending on whether the user is monitoring for an over-voltage condition or an under-voltage condition.

15

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

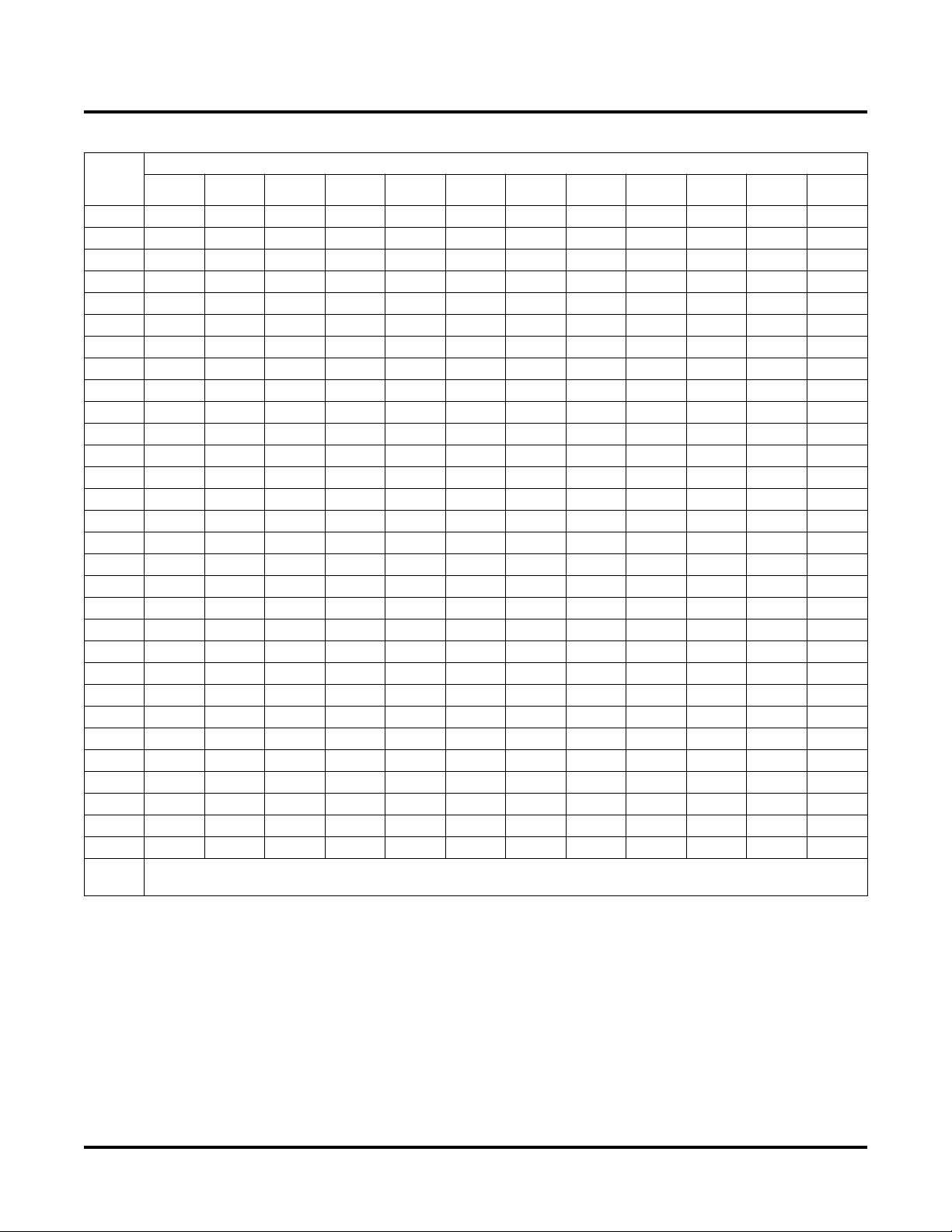

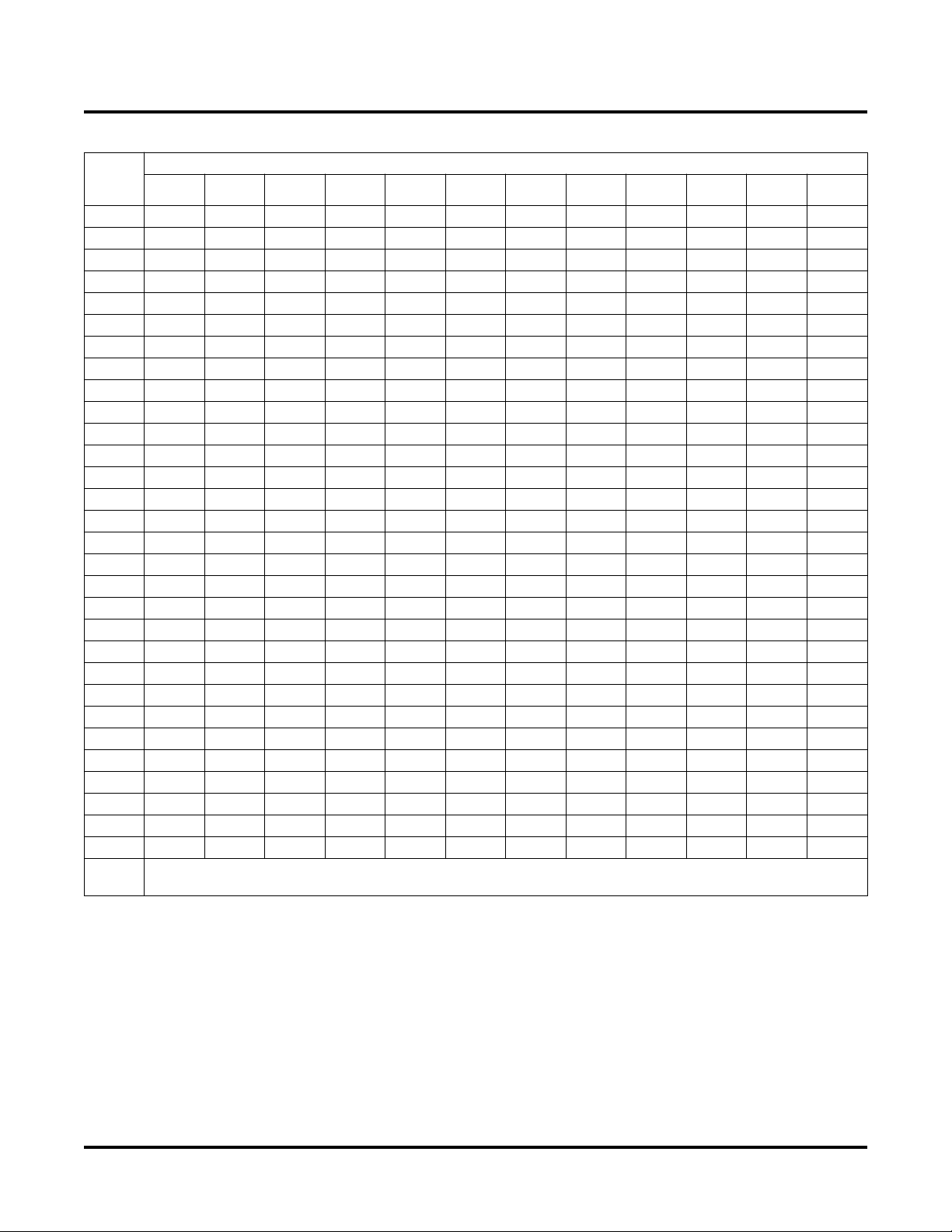

Table 1. Trip Point Table Used For Over-Voltage Detection

Fine

Range

Setting

1 0.790 0.941 1.120 1.333 1.580 1.885 2.244 2.665 3.156 3.758 4.818 5.734

2 0.786 0.936 1.114 1.326 1.571 1.874 2.232 2.650 3.139 3.738 4.792 5.703

3 0.782 0.930 1.108 1.319 1.563 1.864 2.220 2.636 3.123 3.718 4.766 5.674

4 0.778 0.926 1.102 1.312 1.554 1.854 2.209 2.622 3.106 3.698 4.741 5.643

5 0.773 0.921 1.096 1.305 1.546 1.844 2.197 2.607 3.089 3.678 4.715 5.612

6 0.769 0.916 1.090 1.298 1.537 1.834 2.185 2.593 3.072 3.657 4.689 5.581

7 0.765 0.911 1.084 1.290 1.529 1.825 2.173 2.579 3.056 3.637 4.663 5.550

8 0.761 0.906 1.078 1.283 1.520 1.815 2.161 2.565 3.039 3.618 4.638 5.520

9 0.756 0.901 1.072 1.276 1.512 1.805 2.149 2.550 3.022 3.598 4.612 5.489

10 0.752 0.896 1.066 1.269 1.503 1.795 2.137 2.536 3.005 3.578 4.586 5.459

11 0.748 0.891 1.060 1.262 1.495 1.785 2.125 2.522 2.988 3.558 4.561 5.428

12 0.744 0.886 1.054 1.255 1.486 1.774 2.113 2.507 2.971 3.537 4.535 5.397

13 0.739 0.881 1.048 1.248 1.478 1.764 2.101 2.493 2.954 3.517 4.509 5.366

14 0.735 0.876 1.042 1.240 1.470 1.754 2.089 2.479 2.937 3.497 4.483 5.336

15 0.731 0.871 1.036 1.233 1.461 1.744 2.077 2.465 2.920 3.477 4.457 5.305

16 0.727 0.866 1.030 1.226 1.453 1.734 2.064 2.450 2.903 3.457 4.431 5.274

17 0.723 0.861 1.024 1.219 1.444 1.724 2.052 2.436 2.886 3.437 4.406 5.244

18 0.718 0.856 1.018 1.212 1.436 1.714 2.040 2.422 2.869 3.416 4.380 5.213

19 0.714 0.851 1.012 1.205 1.427 1.704 2.028 2.407 2.852 3.396 4.355 5.183

20 0.710 0.846 1.006 1.198 1.419 1.694 2.016 2.393 2.836 3.376 4.329 5.152

21 0.706 0.841 1.000 1.190 1.410 1.684 2.004 2.379 2.819 3.356 4.303 5.121

22 0.701 0.836 0.994 1.183 1.402 1.673 1.992 2.365 2.802 3.336 4.277 5.090

23 0.697 0.831 0.988 1.176 1.393 1.663 1.980 2.350 2.785 3.316 4.251 5.059

24 0.693 0.826 0.982 1.169 1.385 1.653 1.968 2.337 2.768 3.296 4.225 5.030

25 0.689 0.821 0.976 1.162 1.376 1.643 1.956 2.323 2.752 3.276 4.199 4.999

26 0.684 0.816 0.970 1.155 1.369 1.633 1.944 2.309 2.735 3.256 4.174 4.968

27 0.680 0.810 0.964 1.148 1.361 1.623 1.932 2.294 2.718 3.236 4.149 4.937

28 0.676 0.805 0.958 1.140 1.352 1.613 1.920 2.280 2.701 3.216 4.123 4.906

29 0.672 0.800 0.952 1.133 1.344 1.603 1.908 2.266 2.684 3.196 4.097 4.876

30 0.668 0.795 0.946 1.126 — 1.593 1.896 2.251 — 3.176 4.071 4.845

Low-V

Sense

123456789101112

Coarse Range Setting

75mV

16

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Table 2. Trip Point Table Used For Under-Voltage Detection

Fine

Range

Setting

1 0.786 0.936 1.114 1.326 1.571 1.874 2.232 2.650 3.139 3.738 4.792 5.703

2 0.782 0.930 1.108 1.319 1.563 1.864 2.220 2.636 3.123 3.718 4.766 5.674

3 0.778 0.926 1.102 1.312 1.554 1.854 2.209 2.622 3.106 3.698 4.741 5.643

4 0.773 0.921 1.096 1.305 1.546 1.844 2.197 2.607 3.089 3.678 4.715 5.612

5 0.769 0.916 1.090 1.298 1.537 1.834 2.185 2.593 3.072 3.657 4.689 5.581

6 0.765 0.911 1.084 1.290 1.529 1.825 2.173 2.579 3.056 3.637 4.663 5.550

7 0.761 0.906 1.078 1.283 1.520 1.815 2.161 2.565 3.039 3.618 4.638 5.520

8 0.756 0.901 1.072 1.276 1.512 1.805 2.149 2.550 3.022 3.598 4.612 5.489

9 0.752 0.896 1.066 1.269 1.503 1.795 2.137 2.536 3.005 3.578 4.586 5.459

10 0.748 0.891 1.060 1.262 1.495 1.785 2.125 2.522 2.988 3.558 4.561 5.428

11 0.744 0.886 1.054 1.255 1.486 1.774 2.113 2.507 2.971 3.537 4.535 5.397

12 0.739 0.881 1.048 1.248 1.478 1.764 2.101 2.493 2.954 3.517 4.509 5.366

13 0.735 0.876 1.042 1.240 1.470 1.754 2.089 2.479 2.937 3.497 4.483 5.336

14 0.731 0.871 1.036 1.233 1.461 1.744 2.077 2.465 2.920 3.477 4.457 5.305

15 0.727 0.866 1.030 1.226 1.453 1.734 2.064 2.450 2.903 3.457 4.431 5.274

16 0.723 0.861 1.024 1.219 1.444 1.724 2.052 2.436 2.886 3.437 4.406 5.244

17 0.718 0.856 1.018 1.212 1.436 1.714 2.040 2.422 2.869 3.416 4.380 5.213

18 0.714 0.851 1.012 1.205 1.427 1.704 2.028 2.407 2.852 3.396 4.355 5.183

19 0.710 0.846 1.006 1.198 1.419 1.694 2.016 2.393 2.836 3.376 4.329 5.152

20 0.706 0.841 1.000 1.190 1.410 1.684 2.004 2.379 2.819 3.356 4.303 5.121

21 0.701 0.836 0.994 1.183 1.402 1.673 1.992 2.365 2.802 3.336 4.277 5.090

22 0.697 0.831 0.988 1.176 1.393 1.663 1.980 2.350 2.785 3.316 4.251 5.059

23 0.693 0.826 0.982 1.169 1.385 1.653 1.968 2.337 2.768 3.296 4.225 5.030

24 0.689 0.821 0.976 1.162 1.376 1.643 1.956 2.323 2.752 3.276 4.199 4.999

25 0.684 0.816 0.970 1.155 1.369 1.633 1.944 2.309 2.735 3.256 4.174 4.968

26 0.680 0.810 0.964 1.148 1.361 1.623 1.932 2.294 2.718 3.236 4.149 4.937

27 0.676 0.805 0.958 1.140 1.352 1.613 1.920 2.280 2.701 3.216 4.123 4.906

28 0.672 0.800 0.952 1.133 1.344 1.603 1.908 2.266 2.684 3.196 4.097 4.876

29 0.668 0.795 0.946 1.126 1.335 1.593 1.896 2.251 2.667 3.176 4.071 4.845

30 0.664 0.790 0.940 1.119 — 1.583 1.884 2.236 — 3.156 4.045 4.815

Low-V

Sense

123456789101112

Coarse Range Setting

75mV

17

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Table 3. Comparator Hysteresis vs. Trip-Point

Trip-point Range (V)

Hysteresis (mV)Low Limit High Limit

0.664 0.79 8

0.79 0.941 10

0.94 1.12 12

1.119 1.333 14

1.326 1.58 17

1.583 1.885 20

1.884 2.244 24

2.236 2.665 28

2.65 3.156 34

3.156 3.758 40

4.045 4.818 51

4.815 5.734 61

75 mV 0 (Disabled)

The window control section of the voltage monitor circuit is an AND gate (with inputs: an inverted COMPA “ANDed”

with COMPB signal) and a multiplexer that supports the ability to develop a ‘window’ function without using any of

the PLD’s resources. Through the use of the multiplexer, voltage monitor’s ‘A’ output may be set to report either the

status of the ‘A’ comparator, or the window function of both comparator outputs. The voltage monitor’s ‘A’ output

indicates whether the input signal is between or outside the two comparator thresholds. Important: This windowing

function is only valid in cases where the threshold of the ‘A’ comparator is set to a value higher than that of the ‘B’

comparator. Table 4 shows the operation of window function logic.

Table 4. Voltage Monitor Windowing Logic

Input Voltage Comp A Comp B

< Trip-point B < Trip-point A 0 0 0 Outside window, low

V

IN

Trip-point B < V

Trip-point B < Trip-point A < V

< Trip-point A 0 1 1 Inside window

IN

IN

1 1 0 Outside window, high

Window

(B and Not A) Comment

Note that when the ‘A’ output of the voltage monitor circuit is set to windowing mode, the ‘B’ output continues to

monitor the output of the ‘B’ comparator. This can be useful in that the ‘B’ output can be used to augment the windowing function by determining if the input is above or below the windowing range.

The third section in the ispPAC-POWR1220AT8’s input voltage monitor is a digital filter. When enabled, the comparator output will be delayed by a filter time constant of 64 µS, and is especially useful for reducing the possibility of

false triggering from noise that may be present on the voltages being monitored. When the filter is disabled, the

comparator output will be delayed by 16µS. In both cases, enabled or disabled, the filters also provide synchronization of the input signals to the PLD clock. This synchronous sampling feature effectively eliminates the possibility of

race conditions from occurring in any subsequent logic that is implemented in the ispPAC-POWR1220AT8’s internal PLD logic.

2

The comparator status can be read from the I

C interface. For details on the I2C interface, please refer to the I2C/

SMBUS Interface section of this data sheet.

18

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

VMON Voltage Measurement with the On-chip Analog to Digital Converter (ADC)

The ispPAC-POWR1220 has an on-chip analog to digital converter that can be used for measuring the voltages at

the VMON inputs. The ADC is also used in closed loop trimming of DC-DC converters. Close loop trimming is covered later in this document.

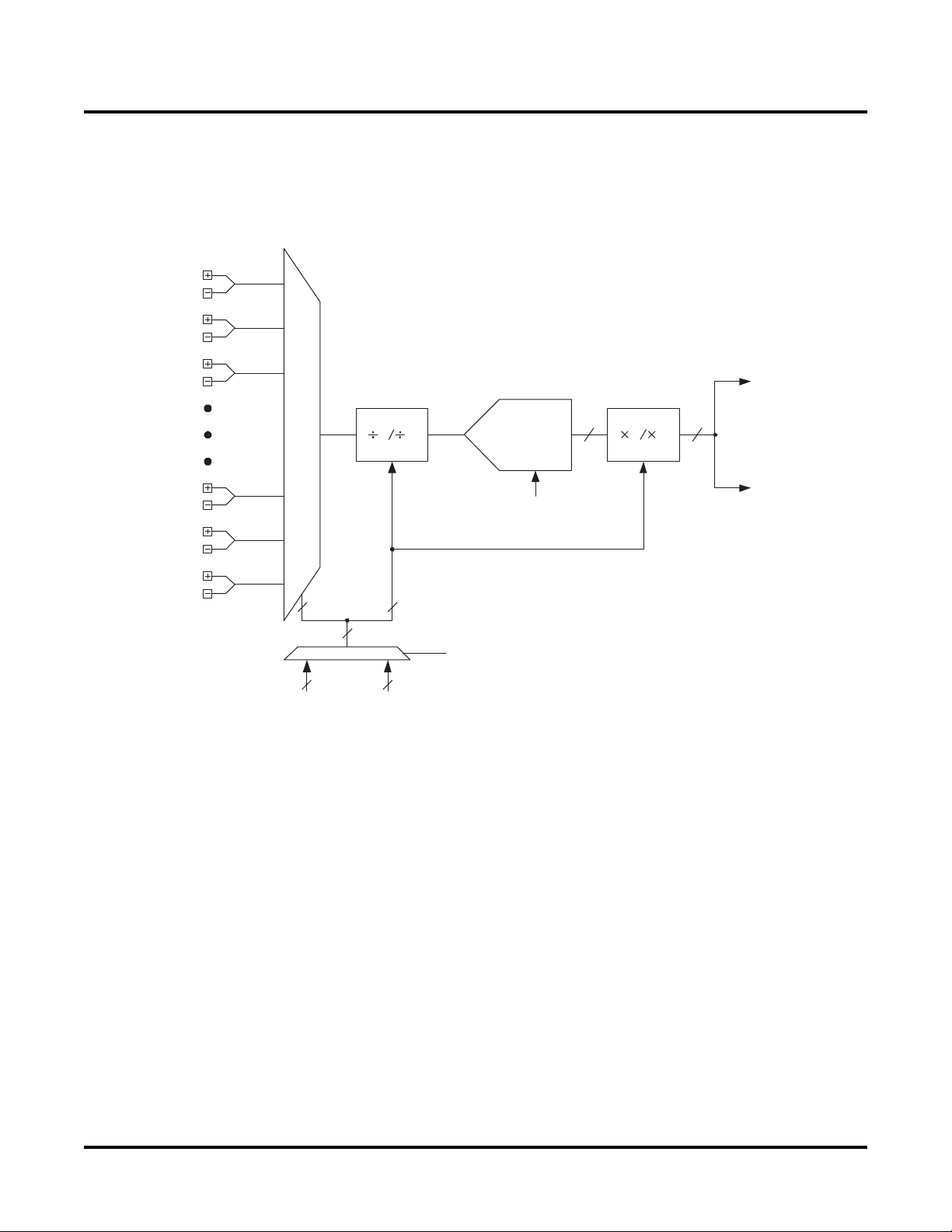

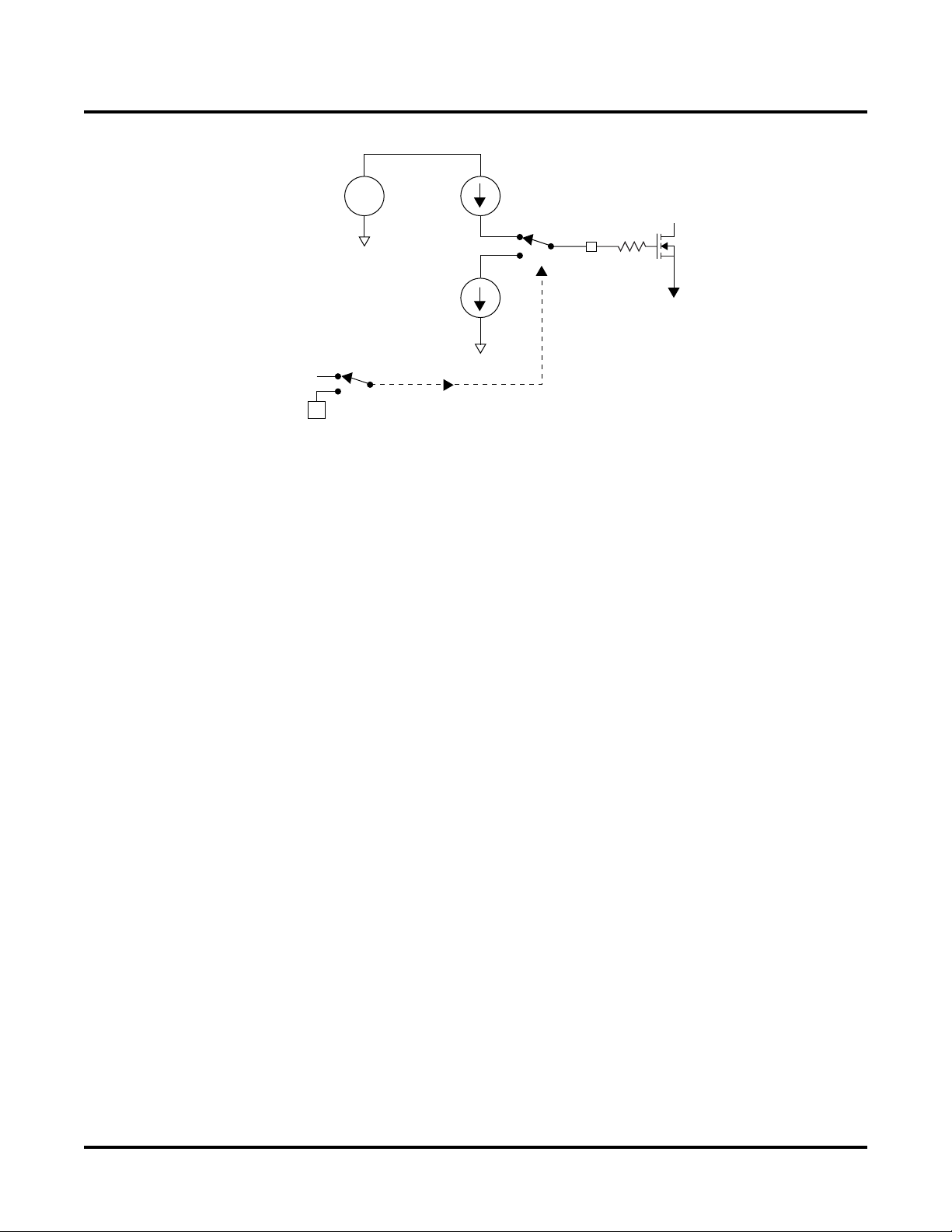

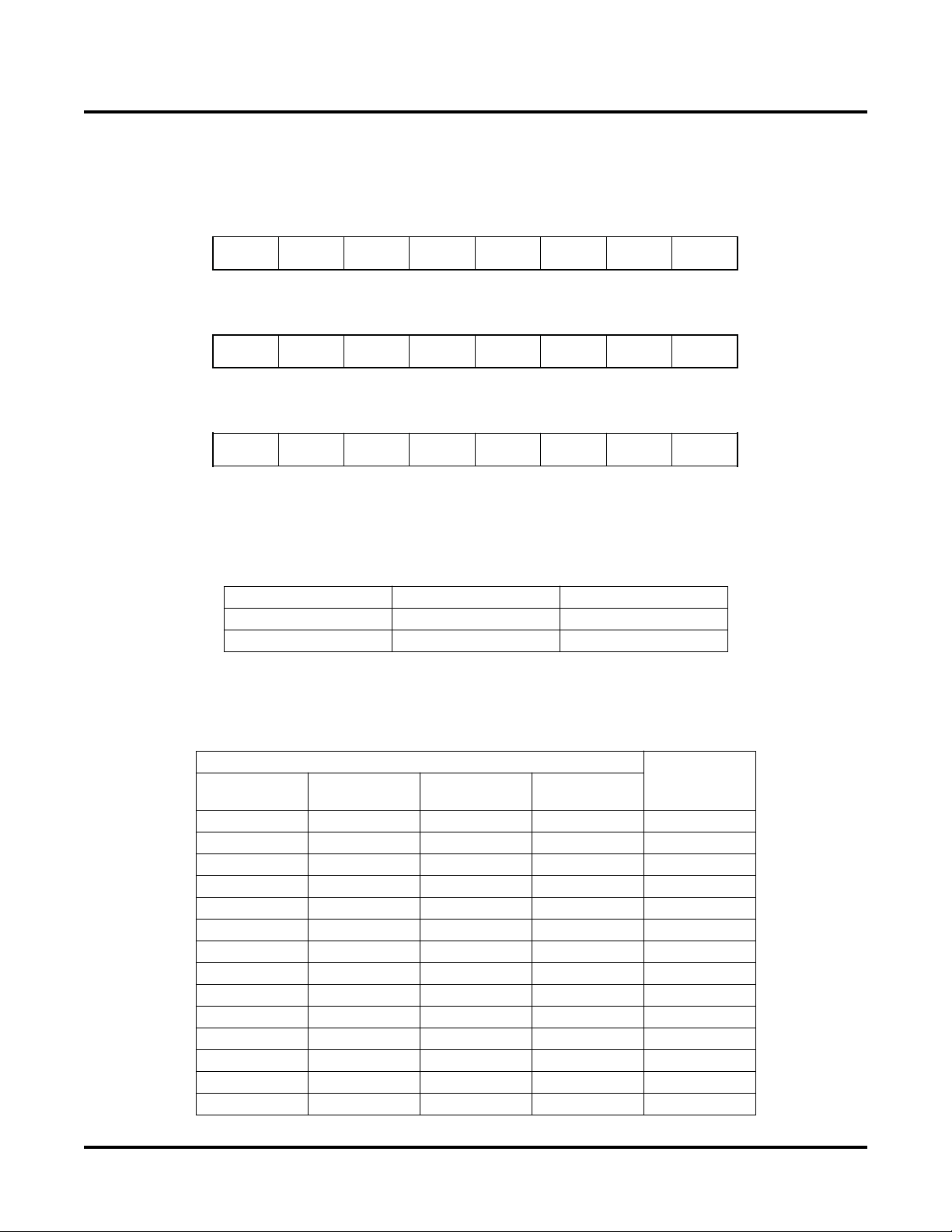

Figure 8. ADC Monitoring VMON1 to VMON12

VMON1

VMON2

VMON3

VMON12

VDDA

VDDINP

ADC

MUX

4

5 5

From Closed

Loop Trim

Circuit

Programmable

Analog

Attenuator

3 1

1

5

From I2C

ADC MUX

Register

ADC

Internal

VREF-

2.048V

Internal

Control Signal

Programmable

Multiplier

10

Digital

31

To Closed

Loop Trim

Circuit

12

2

C

To I

Readout

Register

Figure 8 shows the ADC circuit arrangement within the ispPAC-POWR1220AT8 device. The ADC can measure all

analog input voltages through the multiplexer, ADC MUX. The programmable attenuator between the ADC mux and

the ADC can be configured as divided-by-3 or divided-by-1 (no attenuation). The divided-by-3 setting is used to

measure voltages from 0V to 6V range and divided-by-1 setting is used to measure the voltages from 0V to 2V

range.

A microcontroller can place a request for any VMON voltage measurement at any time through the I2C bus. Upon

the receipt of an I2C command, the ADC will be connected to the I2C selected VMON through the ADC MUX. The

ADC output is then latched into the I2C readout registers.

Calculation

The algorithm to convert the ADC code to the corresponding voltage takes into consideration the attenuation bit

value. In other words, if the attenuation bit is set, then the 10-bit ADC result is automatically multiplied by 3 to calculate the actual voltage at that V

input. Thus, the I2C readout register is 12 bits instead of 10 bits. The following

MON

formula can always be used to calculate the actual voltage from the ADC code.

Voltage at the VMONx Pins

VMON = ADC code (12 bits1, converted to decimal) * 2mV

1

Note: ADC_VALUE_HIGH (8 bits), ADC_VALUE_LOW (4 bits) read from I2C/SMBUS interface

19

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

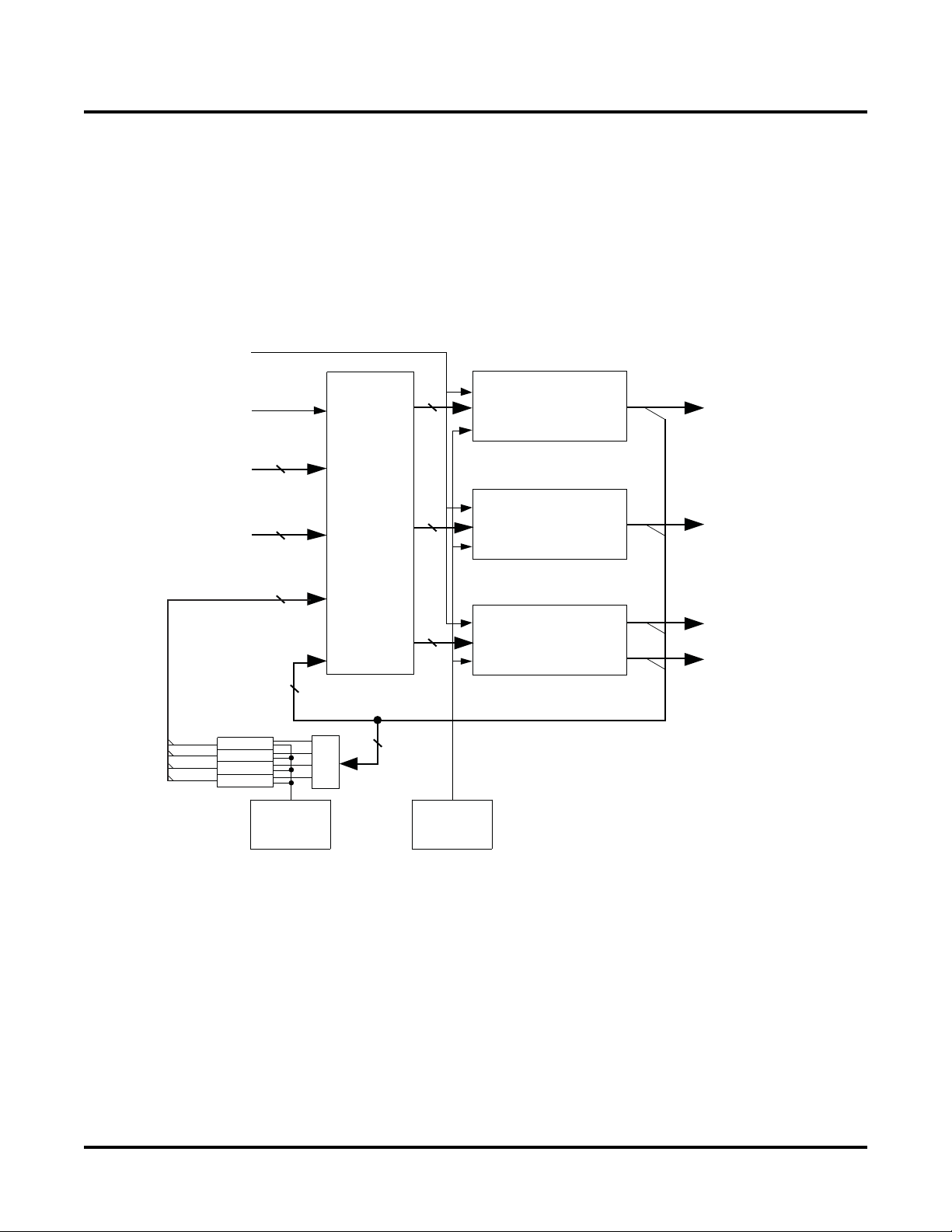

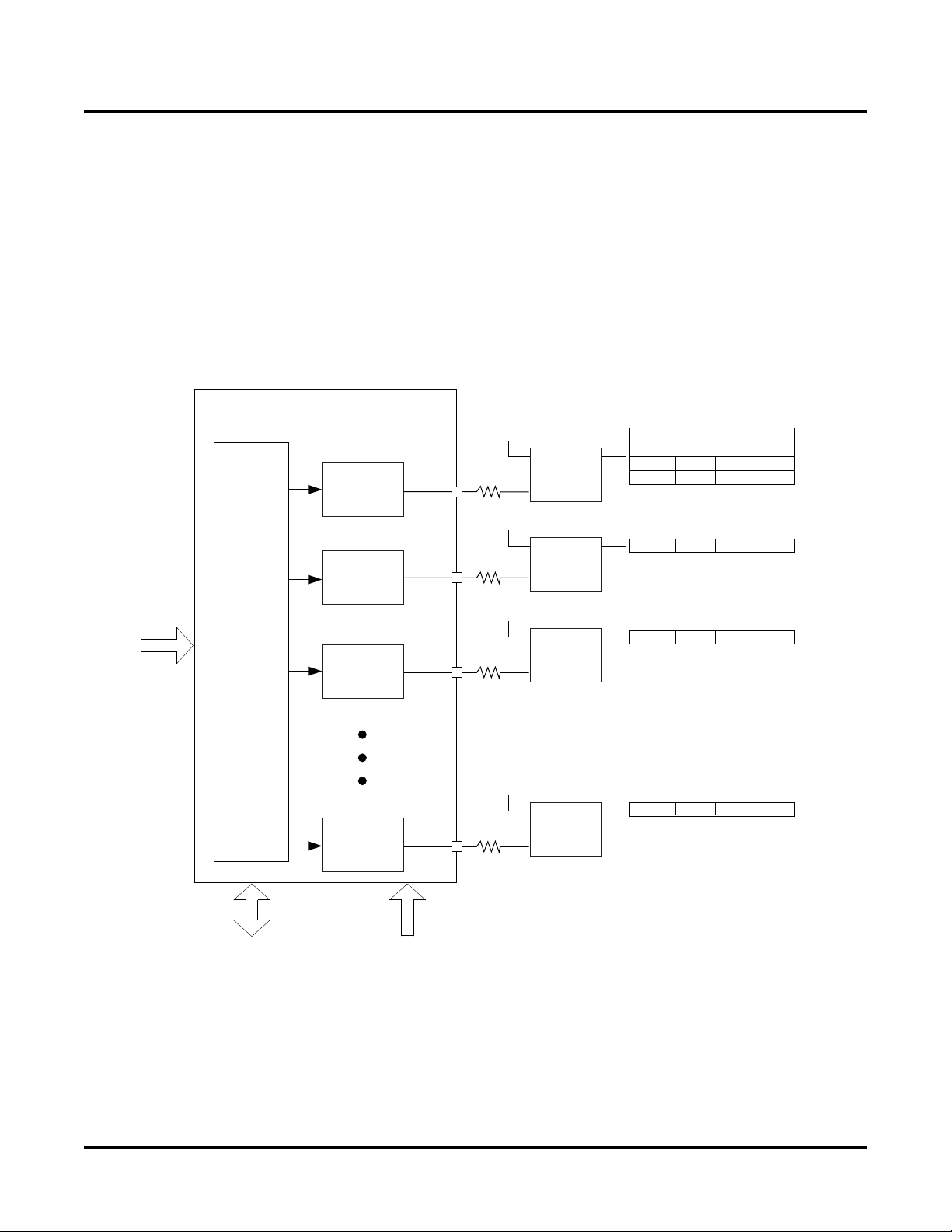

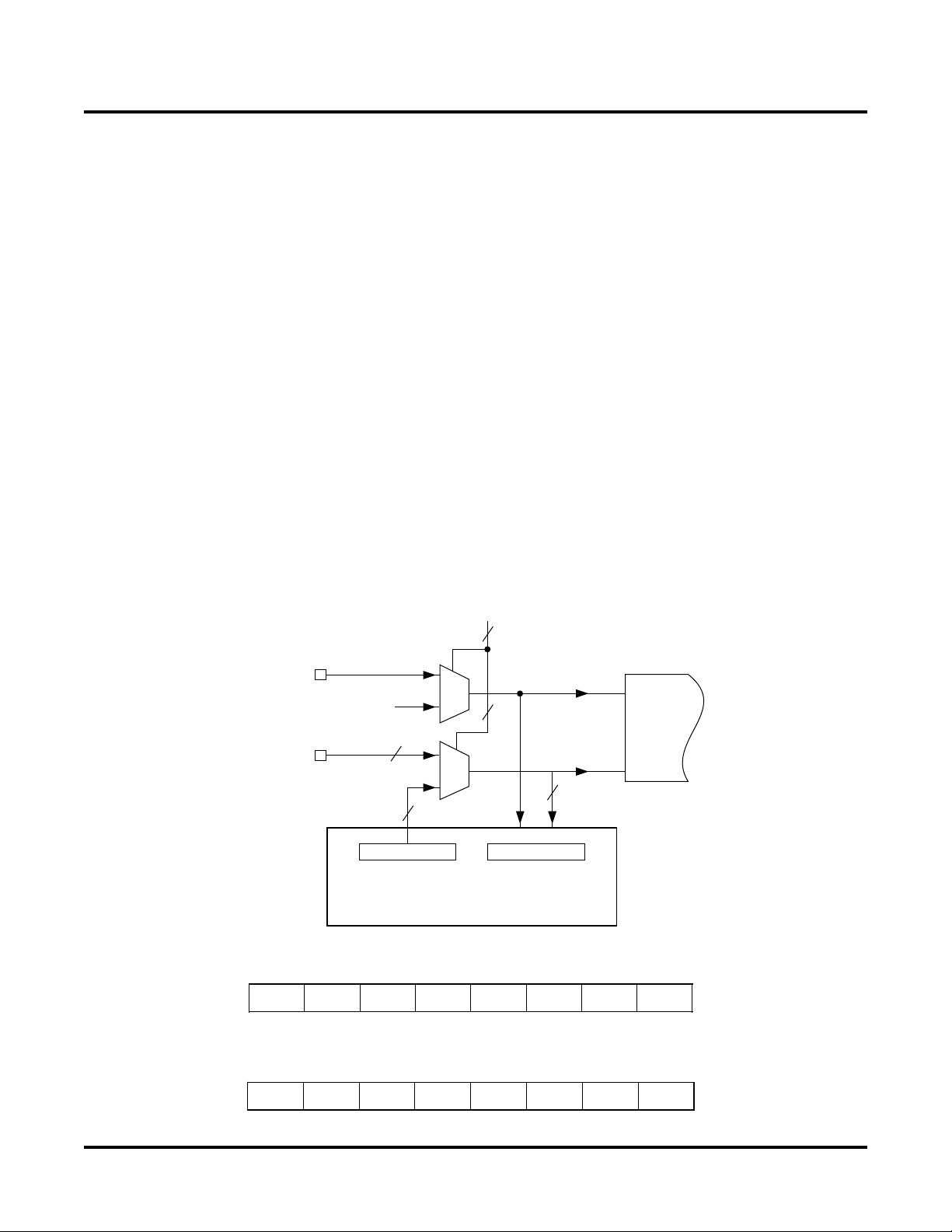

PLD Block

Figure 9 shows the ispPAC-POWR1220AT8 PLD architecture, which is derived from the Lattice's ispMACH™ 4000

CPLD. The PLD architecture allows the flexibility in designing various state machines and control functions used for

power supply management. The AND array has 83 inputs and generates 243 product terms. These 243 product

terms are divided into three groups of 81 for each of the generic logic blocks, GLB1, GLB2, and GLB3. Each GLB

is made up of 16 macrocells. In total, there are 48 macrocells in the ispPAC-POWR1220AT8 device. The output signals of the ispPAC-POWR1220AT8 device are derived from GLBs as shown in Figure 9. Additionally, the GLB3

generates the timer control and trimming block controls.

Figure 9. ispPAC-POWR1220AT8 PLD Architecture

Global Reset

(Resetb pin)

GLB1

AGOOD

IN[1:6]

Generic Logic Block

81

6

16 Macrocell

81 PT

HVOUT[1..4],

OUT[5..8]

VMON[1-12]

Output

Feedback

Timer0

Timer1

Timer2

Timer3

Timer Clock

AND Array

83 Inputs

IRP

243 PT

14

24

4

48

81

81

PLD Clock

GLB2

Generic Logic Block

16 Macrocell

81 PT

GLB3

Generic Logic Block

16 Macrocell

81 PT

OUT[9..16]

OUT[17..20]

PLD_CLT_EN,

PLD_VPS[0:1]

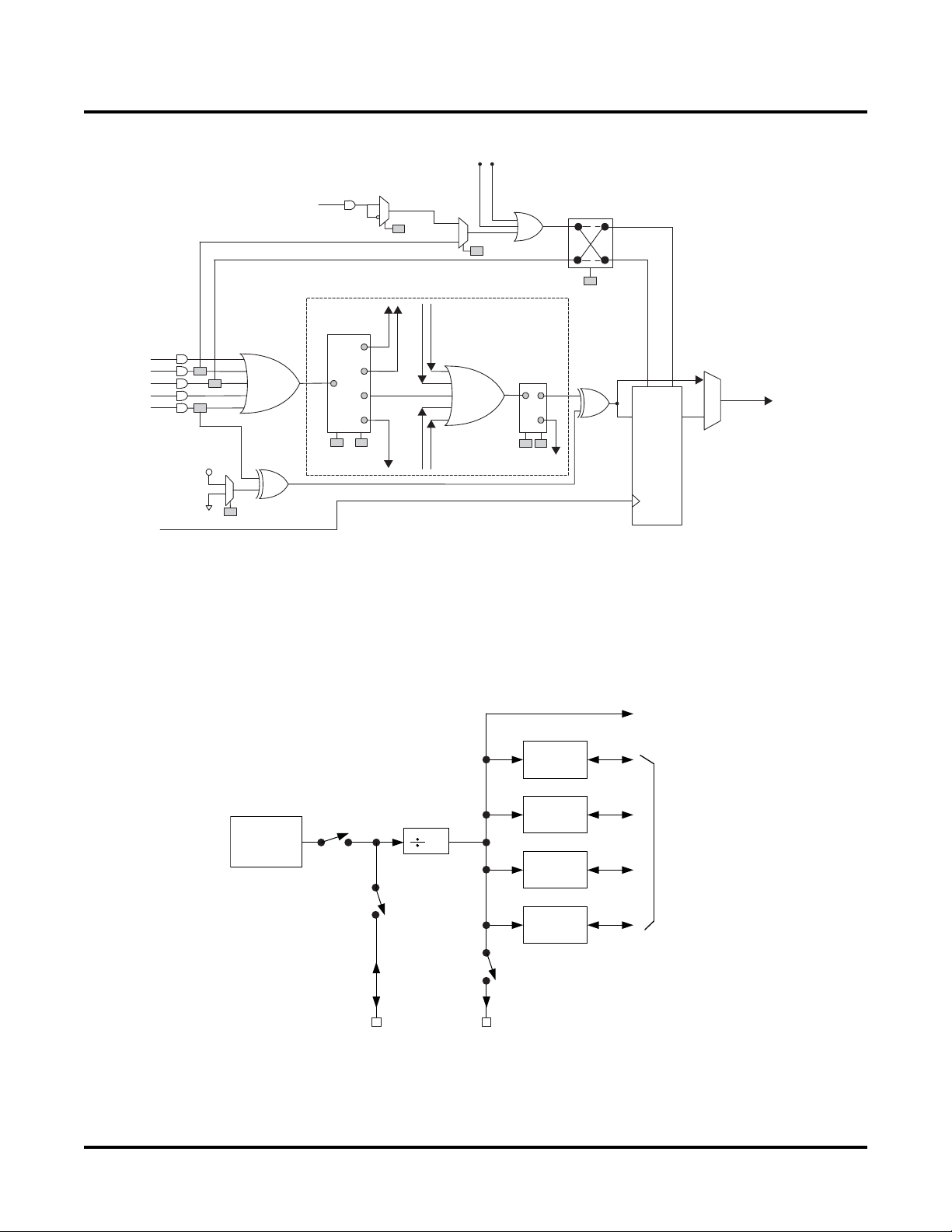

Macrocell Architecture

The macrocell shown in Figure 10 is the heart of the PLD. The basic macrocell has five product terms that feed the

OR gate and the flip-flop. The flip-flop in each macrocell is independently configured. It can be programmed to

function as a D-Type or T-Type flip-flop. Combinatorial functions are realized by bypassing the flip-flop. The polarity

control and XOR gates provide additional flexibility for logic synthesis. The flip-flop’s clock is driven from the common PLD clock that is generated by dividing the 8 MHz master clock by 32. The macrocell also supports asynchronous reset and preset functions, derived from either product terms, the global reset input, or the power-on reset

signal. The resources within the macrocells share routing and contain a product term allocation array. The product

term allocation array greatly expands the PLD’s ability to implement complex logical functions by allowing logic to

be shared between adjacent blocks and distributing the product terms to allow for wider decode functions.

20

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

C

Figure 10. ispPAC-POWR1220AT8 Macrocell Block Diagram

Global Reset Power On Reset

Global Polarity Fuse for

Init Product Term

Product Term Allocation

RP

D/T Q

CLK

Macrocell flip-flop provides

D, T, or combinatorial

output with polarity

To ORP

PT4

PT3

PT2

PT1

PT0

Block Init Product Term

Polarity

Clock

Clock and Timer Functions

Figure 11 shows a block diagram of the ispPAC-POWR1220AT8’s internal clock and timer systems. The master

clock operates at a fixed frequency of 8MHz, from which a fixed 250kHz PLD clock is derived.

Figure 11. Clock and Timer System

lock

PLD

Timer 0

Internal

Oscillator

8MHz

SW0

32

SW1

MCLK PLDCLK

SW2

Timer 1

To/From

PLD

Timer 2

Timer 3

The internal oscillator runs at a fixed frequency of 8 MHz. This signal is used as a source for the PLD and timer

clocks. It is also used for clocking the comparator outputs and clocking the digital filters in the voltage monitor cir-

21

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

cuits, ADC and trim circuits. The ispPAC-POWR1220AT8 can be programmed to operate in three modes: Master

mode, Standalone mode and Slave mode. Table 5 summarizes the operating modes of ispPAC-POWR1220AT8.

Table 5. ispPAC-POWR1220AT8 Operating Modes

Timer

Operating Mode SW0 SW1 Condition Comments

Standalone Closed Open When only one ispPAC-POWR1220AT8 is used. MCLK pin tristated

Master Closed Closed

Slave Open Closed

When more than one ispPAC-POWR1220AT8 is

used in a board, one of them should be configured

to operate in this mode.

When more than one ispPAC-POWR1220AT8s is

used in a board. Other than the master, the rest of

the ispPAC-POWR1220AT8s should be programmed as slaves.

MCLK pin outputs 8MHz clock

MCLK pin is input

A divide-by-32 prescaler divides the internal 8MHz oscillator (or external clock, if selected) down to 250kHz for the

PLD clock and for the programmable timers. This PLD clock may be made available on the PLDCLK pin by closing

SW2. Each of the four timers provides independent timeout intervals ranging from 32µs to 1.96 seconds in 128

steps.

Digital Outputs

The ispPAC-POWR1220AT8 provides 20 digital outputs, HVOUT[1:4] and OUT[5:20]. Outputs OUT[5:20] are permanently configured as open drain to provide a high degree of flexibility when interfacing to logic signals, LEDs,

opto-couplers, and power supply control inputs. The HVOUT[1:4] pins can be configured as either high voltage FET

drivers or open drain outputs. Each of these outputs may be controlled either from the PLD or from the I2C bus. The

determination whether a given output is under PLD or I2C control may be made on a pin-by-pin basis (see

Figure 12). For further details on controlling the outputs through I2C, please see the I2C/SMBUS Interface section of

this data sheet.

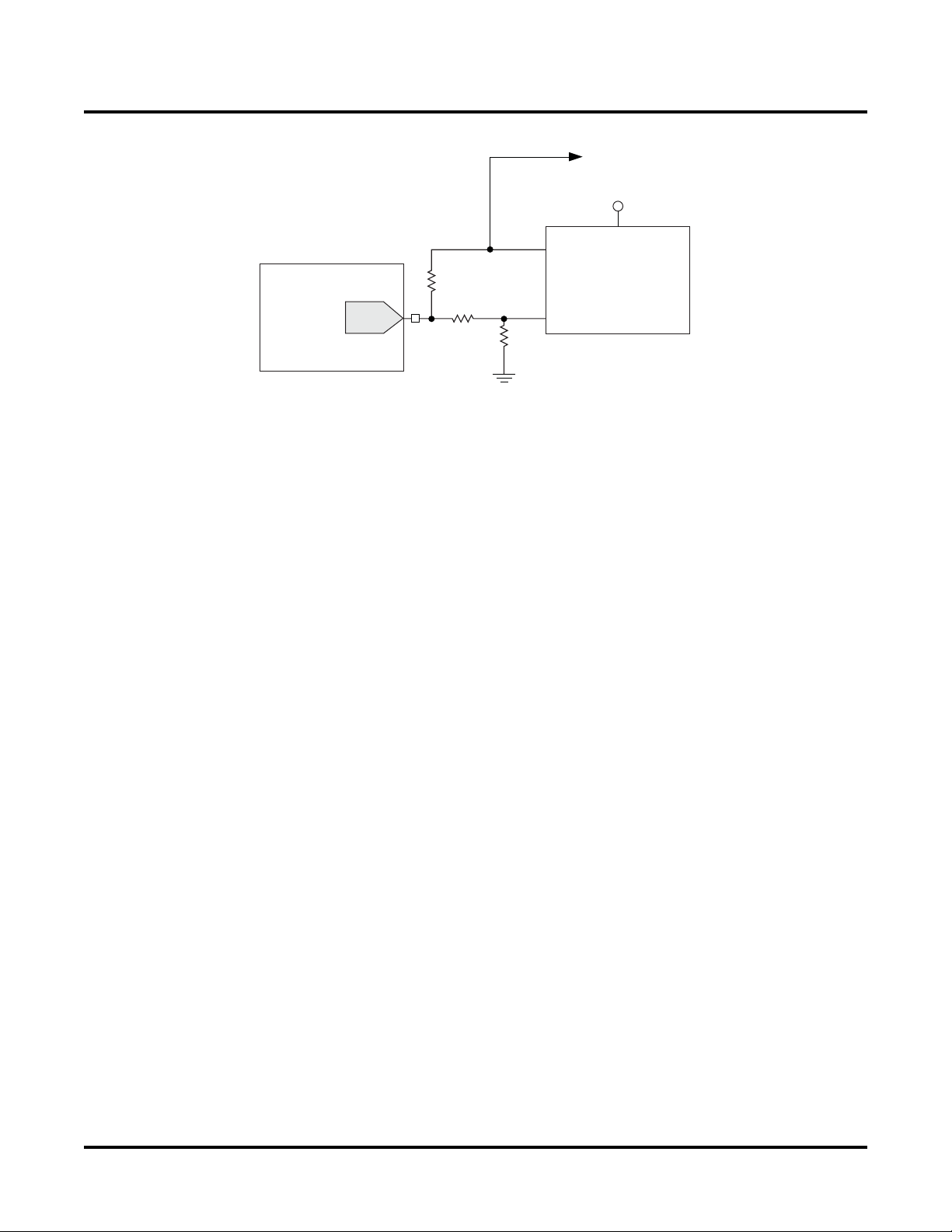

Figure 12. Digital Output Pin Configuration

Digital Control

from PLD

Digital Control

2

C Register

from I

OUTx

Pin

High-Voltage Outputs

In addition to being usable as digital open-drain outputs, the ispPAC-POWR1220AT8’s HVOUT1-HVOUT4 output

pins can be programmed to operate as high-voltage FET drivers. Figure 13 shows the details of the HVOUT gate

drivers. Each of these outputs may be controlled from the PLD or from the I2C bus (see Figure 13). For further

details on controlling the outputs through I2C, please see the I2C/SMBUS Interface section of this data sheet.

22

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Figure 13. Basic Function Diagram for an Output in High Voltage MOSFET Gate Driver Mode

Charge Pump

(6 to 10V)

+

-

I

SOURCE

(12.5 to 100 µA)

HVOUTx

Input

Supply

Pin

Digital Control

from PLD

from I

(100 to 500 µA)

+Fast Turn-off

Digital Control

2

C Register

I

SINK

(3000µA)

Load

Figure 13 shows the HVOUT circuitry when programmed as a FET driver. In this mode the output either sources

current from a charge pump or sinks current. The maximum voltage that the output level at the pin will rise to is also

programmable between 6V and 10V. The maximum voltage levels that are required depend on the gate-to-source

threshold of the FET being driven and the power supply voltage being switched. The maximum voltage level needs

to be sufficient to bias the gate-to-source threshold on and also accommodate the load voltage at the FET’s

source, since the source pin of the FET to provide a wide range of ramp rates is tied to the supply of the target

board. When the HVOUT pin is sourcing current, charging a FET gate, the source current is programmable

between 12.5µA and 100µA. When the driver is turned to the off state, the driver will sink current to ground, and

this sink current is also programmable between 3000µA and 100µA to control the turn-off rate.

Programmable Output Voltage Levels for HVOUT1- HVOUT4

There are three selectable steps for the output voltage of the FET drivers when in FET driver mode. The voltage

that the pin is capable of driving to can be programmed from 6V to 10V in 2V steps.

Controlling Power Supply Output Voltage by Margin/ Trim Block

One of the key features of the ispPAC-POWR1220AT8 is its ability to make adjustments to the power supplies that

it may also be monitoring and/or sequencing. This is accomplished through the Trim and Margin Block of the

device. The Trim and Margin Block can adjust voltages of up to eight different power supplies through TrimCells as

shown in Figure 14. The DC-DC blocks in the figure represent virtually any type of DC power supply that has a trim

or voltage adjustment input. This can be an off-the-shelf unit or custom circuit designed around a switching regulator IC.

The interface between the ispPAC-POWR1220AT8 and the DC power supply is represented by a single resistor

(R1 to R8) to simplify the diagram. Each of these resistors represents a resistor network.

Other control signals driving the Margin/Trim Block are:

• VPS [1:0] – Control signals from device pins common to all eight TrimCells, which are used to select the

active voltage profile for all TrimCells together.

• PLD_VPS[1:0] – Voltage profile selection signals generated by the PLD. These signals can be used instead

of the VPS signals from the pins.

• ADC input – Used to determine the trimmed DC-DC converter voltage.

• PLD_CLT_EN – Only from PLD, used to enable closed loop trimming of all TrimCells together.

Next to each DC-DC converter, four voltages are shown. These voltages correspond to the operating voltage profile

of the Margin/Trim Block.

23

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

When the VPS[1:0] = 00, representing Voltage Profile 0: (Voltage Profile 0 is recommended to be used for the nor-

mal circuit operation)

The output voltage of the DC-DC converter controlled by the Trim 1 pin of the ispPAC-POWR1220AT8 will be 1V

and that TrimCell is operating in closed loop trim mode. At the same time, the DC-DC converters controlled by Trim

2, Trim 3 and Trim 8 pins output 1.2V, 1.5V and 3.3V respectively.

When the VPS[1:0] = 01, representing Voltage Profile 1 being active:

The DC-DC output voltage controlled by Trim 1, 2, 3, and 8 pins will be 1.05V, 1.26V, 1.57V, and 3.46V. These sup-

ply voltages correspond to 5% above their respective normal operating voltage (also called as margin high).

Similarly, when VPS[1:0] = 11, all DC-DC converters are margined low by 5%.

Figure 14. ispPAC-POWR1220AT8 Trim and Margin Block

ispPAC-POWR1220AT8

VPS[0:1]

Margin/Trim Block

(Closed Loop)

C Interface Control

2

Digital Closed Loop

and I

TrimCell

#1

TrimCell

#2

(I2C Update)

TrimCell

#3

(I2C Update)

Trim 1

Trim 2

Trim 3

R1*

R2*

R3*

V

IN

DC-DC

Trim-in

V

IN

DC-DC Output Voltage

Controlled by Profiles

0123

1V (CLT) 1.05V 0.97V 0.95V

1.2V (I2C) 1.26V 1.16V 1.14V

DC-DC

Trim-in

V

IN

2

1.5V (I

C) 1.57V 1.45V 1.42V

DC-DC

Trim-in

V

IN

3.3V (EE) 3.46V 3.20V 3.13V

DC-DC

Trim-in

Input From ADC Mux

Read – 10-bit ADC Code

TrimCell

#8

(Register 0)

Trim 8

PLD Control Signals

PLD_CLT_EN,

R8*

*Indicates resistor network

PLD_VPS[0:1]

There are eight TrimCells in the ispPAC-POWR1220AT8 device, enabling simultaneous control of up to eight individual power supplies. Each TrimCell can generate up to four trimming voltages to control the output voltage of the

DC-DC converter.

24

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Figure 15. TrimCell Driving a Typical DC-DC Converter

V

OUT

V

IN

V

OUT

R

3

R

TrimCell

#N

DAC

1

R

2

Trim

Figure 15 shows the resistor network between the TrimCell #N in the ispPAC-POWR1220AT8 and the DC-DC converter. The values of these resistors depend on the type of DC-DC converter used and its operating voltage range.

The method to calculate the values of the resistors R1, R2, and R3 are described in a separate application note.

Voltage Profile Control

The Margin / Trim Block of ispPAC-POWR1220AT8 consists of eight TrimCells. Because all eight TrimCells in the

Margin / Trim Block are controlled by two common voltage profile control signals, they all operate at the same voltage profile. These common voltage profile control signals are derived from a Control Multiplexer. One set of voltage

profile control inputs to the control multiplexer is from a pair of device pins: VPS0, VPS1. The second set of voltage

profile control inputs is from the PLD: PLD_VPS0, PLD_VPS1. The selection between the two sets of voltage profile control signals is programmable and is stored in the E2CMOS memory.

DC-DC

Converter

25

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Figure 16. Voltage Profile Control

ispPAC-POWR1220AT8

Margin/Trim Block

VPS0

VPS1

PLD Control Signals

PLD_VPS[0:1]

TrimCell

Trim 1

#1

TrimCell

Trim 2

#2

TrimCell

INT/EXT

SELECT

2

CMOS)

(E

2

CTRL

MUX

2

Common Voltage Profile Control Signals

2

#3

TrimCell

#4

TrimCell

Trim 3

Trim 4

Trim 5

#5

TrimCell

Trim 6

#6

TrimCell

Trim 7

#7

Common Voltage Profile Control Signals

TrimCell

Trim 8

#8

TrimCell Architecture

The TrimCell block diagram is shown in Figure 17. The 8-bit DAC at the output provides the trimming voltage

required to set the output voltage of a programmable supply. Each TrimCell can be operated in any one of the four

voltage profiles. In each voltage profile the output trimming voltage can be set to a preset value. There are six 8-bit

registers in each TrimCell that, depending on the operational mode, set the DAC value. Of these, four DAC values

(DAC Register 0 to DAC Register 3) are stored in the E2CMOS memory while the remaining register contents are

stored in volatile registers. Two multiplexers (Mode Mux and Profile Mux) control the routing of the code to the DAC.

The Profile Mux can be controlled by common TrimCell voltage profile control signals.

26

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Figure 17. ispPAC-POWR1220AT8 Output TrimCell

TRIMCELL ARCHITECTURE

VOLTAGE

PROFILE 3

VOLTAGE

PROFILE 2

VOLTAGE

PROFILE 1

VOLTAGE

PROFILE 0

DAC REGISTER 3

2

(E

CMOS)

DAC REGISTER 2

2

(E

CMOS)

DAC REGISTER 1

2

(E

CMOS)

DAC REGISTER 0

2

(E

CMOS)

DAC REGISTER

2

(I

C)

CLOSED LOOP

TRIM REGISTER

FROM CLOSED LOOP

TRIM CIRCUIT

8

8

8

8

8

8

VOLTAGE PROFILE 0

MODE

MUX

MODE SELECT

(E2CMOS)

11

10

01

00

8

COMMON TrimCell

VOLTAGE PROFILE

CONTROL

PROFILE

MUX

2

8

DAC

TRIMx

Figure 14 shows four power supply voltages next to each DC-DC converter. When the Profile MUX is set to Voltage

Profile 3, the DC supply controlled by Trim 1 will be at 0.95V, the DC supply controlled by Trim 2 will be at 1.14V,

1.43V for Trim 3 and 3.14V for Trim 8. When Voltage Profile 0 is selected, Trim 1 will set the supply to 1V, Trim 2 and

Trim 3 will be set by the values that have been loaded using I2C at 1.2 and 1.5V, and Trim 8 will be set to 3.3V.

The following table summarizes the voltage profile selection and the corresponding DAC output trimming voltage.

The voltage profile selection is common to all eight TrimCells.

Table 6. TrimCell Voltage Profile and Operating Modes

PLD_VPS[1:0]

or VPS[1:0] Selected Voltage Profile Selected Mode

11 Voltage Profile 3 — DAC Register 3 (E

10 Voltage Profile 2 — DAC Register 2 (E

01 Voltage Profile 1 — DAC Register 1 (E

DAC Register 0 Select DAC Register 0 (E

00 Voltage Profile 0

DAC Register I

2

C Select DAC Register (I2C)

Digital Closed Loop Trim Closed Loop Trim Register

Trimming Voltage

is Controlled by

2

CMOS)

2

CMOS)

2

CMOS)

2

CMOS)

TrimCell Operation in Voltage Profiles 1, 2 and 3: The output trimming voltage is determined by the code stored

in the DAC Registers 1, 2, and 3 corresponding to the selected Voltage Profile.

TrimCell Operation in Voltage Profile 0: The Voltage Profile 0 has three operating modes. They are DAC Register

0 Select mode, DAC Register I

2

C Select mode and Closed Loop Trim mode. The mode selection is stored in the

E2CMOS configuration memory. Each of the eight TrimCells can be independently set to different operating modes

during Voltage Profile 0 mode of operation.

2

DAC Register 0 Select Mode: The contents of DAC register 0 are stored in the on-chip E

CMOS memory. When

Voltage Profile 0 is selected, the DAC will be loaded with the value stored in DAC Register 0.

DAC Register I2C Select Mode: This mode is used if the power management arrangement requires an external

microcontroller to control the DC-DC converter output voltage. The microcontroller updates the contents of the DAC

27

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Register I2C on the fly to set the trimming voltage to a desired value. The DAC Register I2C is a volatile register and

is reset to 80H (DAC at Bipolar zero) upon power-on. The external microcontroller writes the correct DAC code in

this DAC Register I2C before enabling the programmable power supply.

Digital Closed Loop Trim Mode

Closed loop trim mode operation can be used when tight control over the DC-DC converter output voltage at a

desired value is required. The closed loop trim mechanism operates by comparing the measured output voltage of

the DC-DC converter with the internally stored voltage setpoint. The difference between the setpoint and the actual

DC-DC converter voltage generates an error voltage. This error voltage adjusts the DC-DC converter output voltage toward the setpoint. This operation iterates until the setpoint and the DC-DC converter voltage are equal.

Figure 18 shows the closed loop trim operation of a TrimCell. At regular intervals (as determined by the Update

Rate Control register) the ispPAC-POWR1220AT8 device initiates the closed loop power supply voltage correction

cycle through the following blocks:

• Non-volatile Setpoint register stores the desired output voltage

• On-chip ADC is used to measure the voltage of the DC-DC converter

• Three-state comparator is used to compare the measured voltage from the ADC with the Setpoint register contents. The output of the three state comparator can be one of the following:

• +1 if the setpoint voltage is greater than the DC-DC converter voltage

• -1 if the setpoint voltage is less than the DC-DC converter voltage

• 0 if the setpoint voltage is equal to the DC-DC converter voltage

• Channel polarity control determines the polarity of the error signal

• Closed loop trim register is used to compute and store the DAC code corresponding to the error voltage.

The contents of the Closed Loop Trim will be incremented or decremented depending on the channel polarity and the three-state comparator output. If the three-state comparator output is 0, the closed loop trim register contents are left unchanged.

• The DAC in the TrimCell is used to generate the analog error voltage that adjusts the attached DC-DC con-

verter output voltage.

Figure 18. Digital Closed Loop Trim Operation

SETPOINT

2

(E

CMOS)

Three-State

DIGITAL

COMPARE

(+1/0/-1)

POWR1220AT8

CHANNEL

POLARITY

2

CMOS)

(E

+/-1

UPDATE

RATE

CONTROL

PLD_CLT_EN

2

CMOS Registers

E

DAC Register 3

DAC Register 2

DAC Register 1

DAC Register 0

DAC Register I

Closed Loop

Trim Register

2

C

Profile 0 Mode

Control (E

TRIM CELL

DAC

Profile Control

(Pins/ PLD)

2

CMOS)

ADC

TRIMx

VMONx

TRIMIN

DC-DC

CONVERTER

VOUT

GND

The closed loop trim cycle interval is programmable and is set by the update rate control register. The following

table lists the programmable update interval that can be selected by the update rate register.

28

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Table 7. Output DAC Update Rate in Digital Closed Loop Mode

Update Rate

Control Value

00 580 µs

01 1.15 ms

10 9.22 ms

11 18.5 ms

Update

Interval

There is a one-to-one relationship between the selected TrimCell and the corresponding VMON input for the closed

loop operation. For example, if TrimCell 3 is used to control the power supply in the closed loop trim mode, VMON3

must be used to monitor its output power supply voltage.

The closed loop operation can only be started by activating the internally generated PLD signal, called

PLD_CLT_EN, in PAC-Designer software. The selection of Voltage Profile 0, however, can be either through the

pins VPS0, VPS1 or through the PLD signals PLDVPS0 and PLDVPS1.

Closed Loop Start-up Behavior

The contents of the closed loop register, upon power-up, will contain a value 80h (Bipolar-zero) value. The DAC

output voltage will be equal to the programmed Offset voltage. Usually under this condition, the power supply output will be close to its nominal voltage. If the power supply trimming should start after reaching its desired output

2

voltage, the corresponding DAC code can be loaded into the closed loop trim register through I

C (same address

as the DAC register I2C mode) before activating the PLD_CLT_EN signal.

Details of the Digital to Analog Converter (DAC)

Each trim cell has an 8-bit bipolar DAC to set the trimming voltage (Figure 19). The full-scale output voltage of the

DAC is +/- 320 mV. A code of 80H results in the DAC output set at its bi-polar zero value.

The voltage output from the DAC is added to a programmable offset value and the resultant voltage is then applied

to the trim output pin. The offset voltage is typically selected to be approximately equal to the DC-DC converter

open circuit trim node voltage. This results in maximizing the DC-DC converter output voltage range.

The programmed offset value can be set to 0.6V, 0.8V, 1.0V or 1.25V. This value selection is stored in E2CMOS

memory and cannot be changed dynamically.

29

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Figure 19. Offset Voltage is Added to DAC Output Voltage to Derive Trim Pad Voltage

TRIMCELL X

From

Trim Registers

8 TRIMx

(-320mV to +320mV)

DAC

7 bits + Sign

Pad

Offset

(0.6V,0.8V,1.0V,1.25V)

E2CMOS

RESETb Signal, RESET Command via JTAG or I2C

Activating the RESETb signal (Logic 0 applied to the RESETb pin) or issuing a reset instruction via JTAG or I2C will

force the outputs to the following states independent of how these outputs have been configured in the PINS window:

• OUT5-20 will go high-impedance.

•HVOUT pins programmed for open drain operation will go high-impedance.

•HVOUT pins programmed for FET driver mode operation will pull down.

At the conclusion of the RESET event, these outputs will go to the states defined by the PINS window, and if a

sequence has been programmed into the device, it will be re-started at the first step. The analog calibration will be

re-done and consequently, the VMONs, ADCs, and DACs will not be operational until 2.5 milliseconds (max.) after

the conclusion of the RESET event.

CAUTION: Activating the RESETb signal or issuing a RESET command through I2C or JTAG during the ispPACPOWR1220AT8 device operation, results in the device aborting all operations and returning to the power-on reset

state. The status of the power supplies which are being enabled by the ispPAC-POWR1220AT8 will be determined

by the state of the outputs shown above.

I2C/SMBUS Interface

I2C and SMBus are low-speed serial interface protocols designed to enable communications among a number of

devices on a circuit board. The ispPAC-POWR1220AT8 supports a 7-bit addressing of the I2C communications protocol, as well as SMBTimeout and SMBAlert features of the SMBus, enabling it to easily integrated into many types

of modern power management systems. Figure 20 shows a typical I2C configuration, in which one or more ispPACPOWR1220AT8s are slaved to a supervisory microcontroller. SDA is used to carry data signals, while SCL provides a synchronous clock signal. The SMBAlert line is only present in SMBus systems. The 7-bit I2C address of

the POWR1220AT8 is fully programmable through the JTAG port.

30

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

Figure 20. ispPAC-POWR1220AT8 in I

V+

SDA

SCL

INTERRUPT

MICROPROCESSOR

2

C MASTER)

(I

2

C/SMBUS System

SDA/SMDAT (DATA)

SCL/SMCLK (CLOCK)

SMBALERT

SDA SDA

POWR1220AT8

2

C SLAVE)

(I

OUT5/

SCL SCL

SMBA

POWR1220AT8

2

C SLAVE)

(I

OUT5/

SMBA

To Other

2

I

C

Devices

In both the I2C and SMBus protocols, the bus is controlled by a single MASTER device at any given time. This master device generates the SCL clock signal and coordinates all data transfers to and from a number of slave devices.

The ispPAC-POWR1220AT8 is configured as a slave device, and cannot independently coordinate data transfers.

Each slave device on a given I2C bus is assigned a unique address. The ispPAC-POWR1220AT8 implements the 7bit addressing portion of the standard. Any 7-bit address can be assigned to the ispPAC-POWR1220AT8 device by

programming through JTAG. When selecting a device address, one should note that several addresses are

reserved by the I2C and/or SMBus standards, and should not be assigned to ispPAC-POWR1220AT8 devices to

assure bus compatibility. Table 8 lists these reserved addresses.

Table 8. I

2C/SMBus Reserved Slave Device Addresses

Address R/W bit I2C function Description SMBus Function

0000 000 0 General Call Address General Call Address

0000 000 1 Start Byte Start Byte

0000 001 x CBUS Address CBUS Address

0000 010 x Reserved Reserved

0000 011 x Reserved Reserved

0000 1xx x HS-mode master code HS-mode master code

0001 000 x NA SMBus Host

0001 100 x NA SMBus Alert Response Address

0101 000 x NA Reserved for ACCESS.bus

0110 111 x NA Reserved for ACCESS.bus

1100 001 x NA SMBus Device Default Address

1111 0xx x 10-bit addressing 10-bit addressing

1111 1xx x Reserved Reserved

The ispPAC-POWR1220AT8’s I2C/SMBus interface allows data to be both written to and read from the device. A

data write transaction (Figure 21) consists of the following operations:

1. Start the bus transaction

2. Transmit the device address (7 bits) along with a low write bit

3. Transmit the address of the register to be written to (8 bits)

4. Transmit the data to be written (8 bits)

5. Stop the bus transaction

31

Lattice Semiconductor ispPAC-POWR1220AT8 Data Sheet

To start the transaction, the master device holds the SCL line high while pulling SDA low. Address and data bits are

then transferred on each successive SCL pulse, in three consecutive byte frames of 9 SCL pulses. Address and

data are transferred on the first 8 SCL clocks in each frame, while an acknowledge signal is asserted by the slave

device on the 9th clock in each frame. Both data and addresses are transferred in a most-significant-bit-first format.

The first frame contains the 7-bit device address, with bit 8 held low to indicate a write operation. The second frame

contains the register address to which data will be written, and the final frame contains the actual data to be written. Note that the SDA signal is only allowed to change when the SCL is low, as raising SDA when SCL is high signals the end of the transaction.

Figure 21. I

2C Write Operation

SCL

SDA

123456789

A6 A5 A4 A3 A2 A1 A0 R7 R6 R5 R4 R3 R2 R1 R0

START

R/W

123456789 123456789

D7 D6 D5 D4 D3 D2 D1 D0

Note: Shaded Bits Asserted by Slave

ACKACKACK

STOPDEVICE ADDRESS (7 BITS) REGISTER ADDRESS (8 BITS) WRITE DATA (8 BITS)

Reading a data byte from the ispPAC-POWR1220AT8 requires two separate bus transactions (Figure 22). The first

transaction writes the register address from which a data byte is to be read. Note that since no data is being written

to the device, the transaction is concluded after the second byte frame. The second transaction performs the actual

read. The first frame contains the 7-bit device address with the R/W bit held High. In the second frame the ispPACPOWR1220AT8 asserts data out on the bus in response to the SCL signal. Note that the acknowledge signal in the