Page 1

iCE40 Ultra™ Mobile Development Platform User Guide

EB90 Version 1.1, June 2015

Page 2

iCE40 Ultra Mobile Development Platform User Guide

Introduction

This platform is designed to develop and demonstrate various mobile applications using the iCE40 Ultra device.

The board is in the form factor of a bar phone featuring various sensors and connectivity to external mobile software development platforms.

Kit Contents

The following items are included in the development kit:

• Main Board – The main board is mounted in lower plastic enclosures.

• Key Set – The key set includes keys A, B, C, and Custom. Key A is installed on the main unit by default.

• DragonBoard Interface Module

• Interconnecting Cables – The cables include USB mini-B cable, DragonBoard interface ribbon cable, and +5 V

supply flywire.

Variants

The unit is built in two variants with different sets of RGB LED and IR LED parts.

Variant A includes the following parts on the board:

• RGB LED used at D12: AEBMT-RGBZ by Advanced Optoelectronics Technology

• IR LED used at D7: SFH 4645 by Osram Opto Semiconductors

Variant B includes the following parts on the board:

• RGB LED used at D13: APTF1616SEEZGQBDC by Kingbright

• IR LED used at D7: VSMB2948SL by Vishay Semiconductor

The variants can be distinguished through the populated status of D12 and D13.

• Variant A: D12 is populated and D13 is not populated

• Variant B: D12 is not populated and D13 is populated

2

Page 3

iCE40 Ultra Mobile Development Platform User Guide

MAX44008 (I2C)

RGB ALS

APP PROCESSOR (SPI)

(10 pin CONN)

3.3v

BMP180 (I2C)

Pressure

IR LED (TX)

HIGH POWER

WHITE LED

JUMPER SEL

POOL-B I2C

POOL-A I2C

POWER SUPPLIES

(from USB / Battery)

FT2232H

SPI CONFIG FLASH (SPI)

USB

CHEETAH CONN

LSM330DLC (I2C)

Accel. & Gyro

HALL SENSOR

THESE CONNECTIONS VIA INTERCONNECT

[40 pin FPC connector]

TMD27711 (I2C)

Proximity & ALS #2

Key-socket selection

FINGERPRINT SENSOR I2S MIC#2

SPI

Li-ion BatteryCHARGER

Key-socket selection

RGB LED

I2S MIC#1 SMA CONN

CURRENT MEASURE

CURRENT

MEASURE

BLE Module

IR RX

LSM303DLHC (I2C)

Magentometer

SHT20 (I2C)

Humidity &Temp.

TMD27711 (I2C)

Proximity & ALS #1

POOL-B I2C

POOL-B I2C

3.3V

3.3V

SMA CONN

Operated together

Optional

CONFIG SPI & BANK 1

BANK 2

BANK 0

iCE5LP4KSWG36

SPI

UART

Demo Board Architecture

Figure 1 shows the demo board architecture. The different I2C sensors are split up and wired on two separate I2C

buses as Pool A and Pool B. The other sensors that are not I2C are either wired separately or are connected

instead of Pool B and other resources on the board. Changes to connectivity are user controllable and achieved by

means of changing the keys – a method to replace using multiple jumpers to re-route wiring to different resources.

Figure 1. Block Diagram

3

Page 4

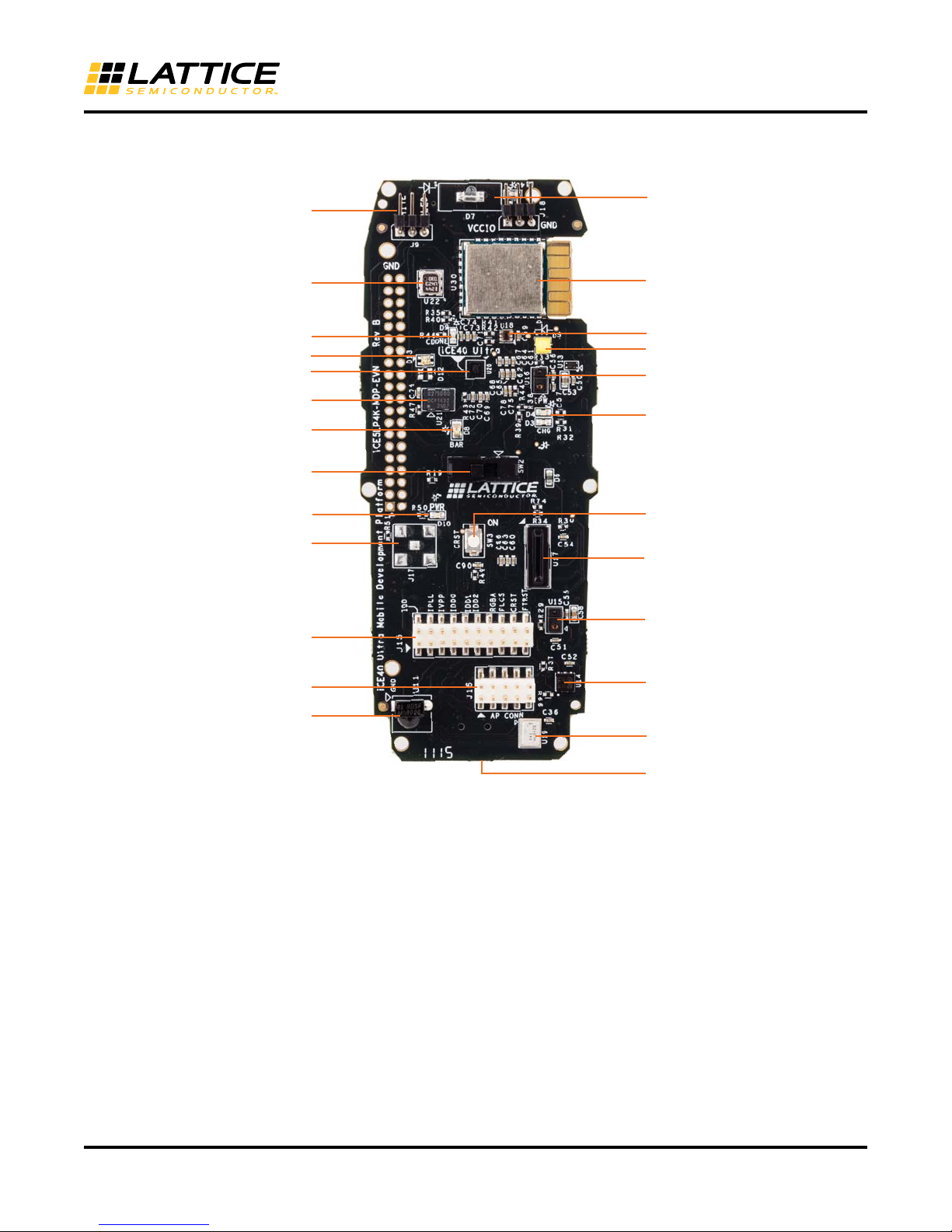

Figure 2. Top View of Main Unit

iCE40 Ultra Mobile Development Platform User Guide

Jumper selection between

IR and White High Power LEDs

BMP180

Pressure Sensor

CDONE LED

RGB LED

iCE40 Ultra

27 MHz

Oscillator

Barcode LED

(Red)

Power Switch

Power LED

SMA Footprint

J15 (Jumper

Pool Header)

IR LED (Emitter)

BLE Module

MAX4408 RGB ALS Sensor

High Power White LED

TMD2711 Proximity Sensor

External Power and

Charging Status Indicator

CRST Button

FPC1080A Fingerprint Sensor

TMD2711 Proximity Sensor

AP Connector

IR Rx (TSMP58000)

SHT20 Humidity Sensor

ADMP441 I2S Mic

USB Port

4

Page 5

Figure 3. Bottom View of Main Unit

ADMP441 I2S Mic

LSM303DLHC

Magnetometer Sensor

LSM330DLC

Accelerometer and

Gyroscope Sensor

iCE40 Ultra Mobile Development Platform User Guide

Key Socket

Battery

Connector

FTDI FT2232H

M25P80

SPI Flash

USB Port

5

Page 6

iCE40 Ultra Mobile Development Platform User Guide

Features

• Supports BLE (Bluetooth Low Energy) module

• Supports OTA (Over-The-Air) configuration of FPGA

• Form factor similar to mobile phone

Sensor list

The following table lists the different sensors used on the board.

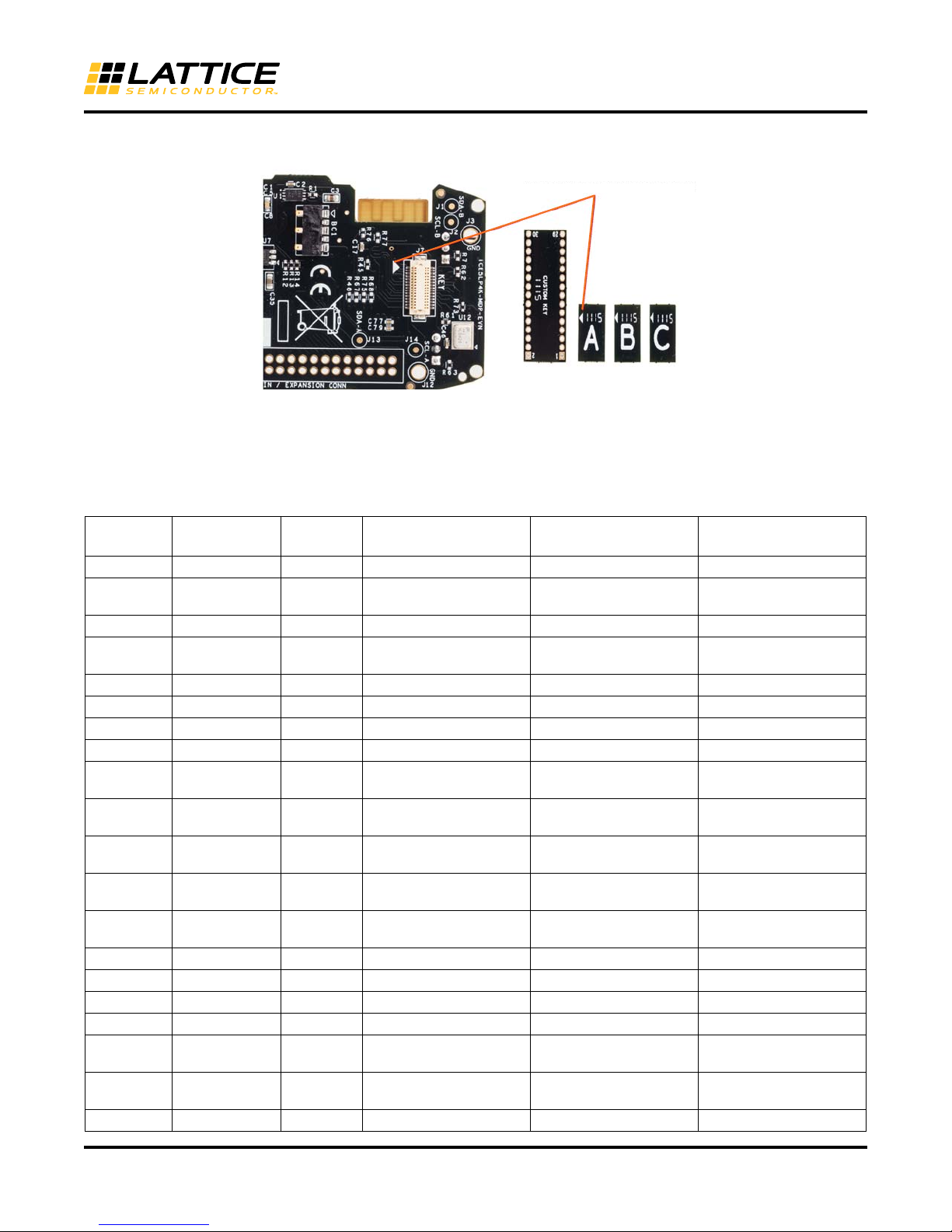

Table 1. Sensor List

Number Sensor Function Interface Sensor Part Number Manufacturer

1 RGB LED (Variant 1) Direct AEBMT-RGBZ AOT

2 RGB LED (Variant 2) Direct APTF1616SEEZGQBDC Kingbright

3 High Current IR Tx LED

(Variant A)

4 High Current IR Tx LED

(Variant B)

5 High Current Visible LED Direct XBDA WT-00-0000-

6 IR Rx Direct TSMP58000 Vishay Semiconductor

7 Proximity Sensor

(Two numbers)

8 RGB Light Sensor I2C MAX44008 Maxim-IC

9 Temperature Sensor I2C BMP180 (integrated) Bosch

10 Barometric Pressure I2C BMP180 Bosch

11 Accelerometer I2C LSM330DLC

12 Gyroscope I2C

13 Magnetometer I2C LSM303DLHC ST Micro

14 Humidity I2C SHT20 Sensirion

15 Hall Direct BU52051NV X-TR Rohm Semiconductor

16 Fingerprint SPI FPC1080A Fingerprints

17 MEMS Mic (Two numbers) I2S ADMP441 Invensense

Direct SFH4645 Osram Opto

Direct VSMB2948SL Vishay Semiconductor

Cree Inc.

00000LCE3

I2C TMD27711 A MS-TA OS USA Inc

ST Micro

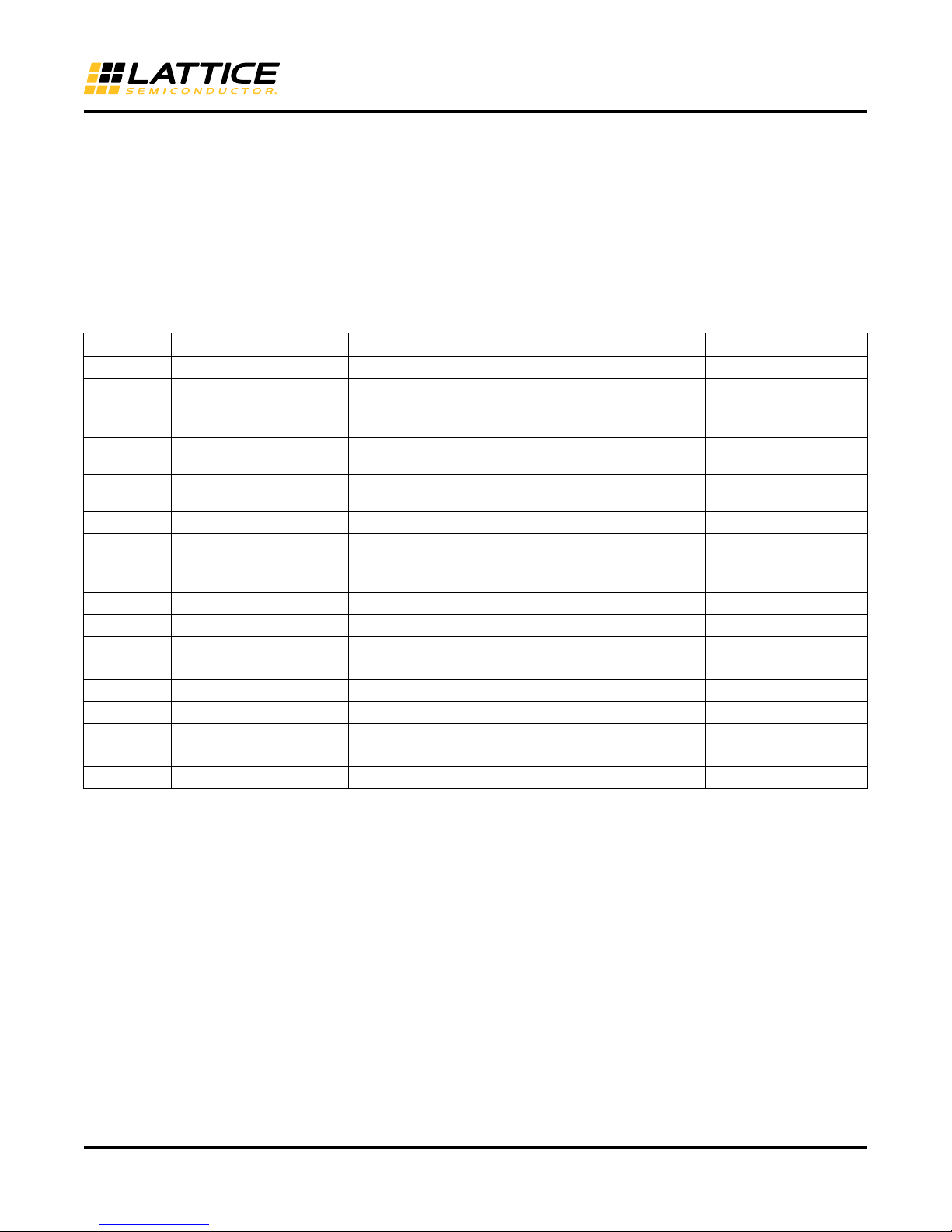

Key-socket Arrangement

Three predefined keys and one user defined key is provided to allow the user to change the wiring of the board

between different sensor sets as described in Table 2. The table also denotes pin assignments to the iCE40 Ultra

FPGA on the board. While selecting and inserting a particular key of choice, ensure that you align the aligning

arrow on the key and on the main PCB. The keys are mechanically delicate, and hence, you must be careful while

inserting and removing the keys. Figure 4 shows the four keys and socket on the main board.

6

Page 7

iCE40 Ultra Mobile Development Platform User Guide

Orient the direction of the key

using these arrows

Figure 4. Key-socket Arrangement

Pin assignments iCE40 Ultra FPGA

Table 2 lists the complete pin assignments for the iCE40 Ultra FPGA for the different keys and other hard wired

peripherals on the board

Table 2. Pin Assignment

Pin

Number Pin Name Bank

A4 VCCIO_0 Bank 0 3V3 3V3 3V3

B5 IOT_46B_G0 Bank 0 Not used / Optional ext

A6 RGB2 Bank 0 BLED (RGB LED) BLED (RGB LED) I2S_CE1 (Microphone 1)

B6 RGB1 Bank 0 GLED (RGB LED) GLED (RGB LED) I2S_SCK1 (Microphone

C6 RGB0 Bank 0 RLED (RGB LED) RLED (RGB LED) I2S_SD1 (Microphone 1)

A2 IRLED Bank 0 HPLED (IRLED or VLED) HPLED (IRLED or VLED HPLED (IRLED or VLED

A1 VSSIO_LED Bank 0 GNDGNDGND

C3 SPI_VCCIO1 Bank 1 3V3 3V3 3V3

D1 IOB_33B_SI_M

OSI_SPI1

F2 IOB_32A_SO_

MISO_SPI1

E1 IOB_34A_SCK_

SCK_SPI1

F1 IOB_35B_SS_

MCSNO_SPI1

E4 IOB_12A_G4_C

DONE

D3 CRESET_B Bank 1 CRESET CRESET CRESET

B2 IOB_31B Bank 1 HALL_OUT/BMP_XCLR HALL_OUT/BMP_XCLR HALL_OUT/BMP_XCLR

C1 IOB_30A Bank 1 PoolA_Sensor_SDA PoolA_Sensor_SDA PoolA_Sensor_SDA

E2 IOB_29B Bank 1 Pool_Sensor_SCL Pool_Sensor_SCL Pool_Sensor_SCL

D2 IOB_27B Bank 1 CLK_STNDBY#

B1 IOB_26A Bank 1 FP_RSTn

E3 IOB_20A Bank 1 UART_TX (BLE) UART_TX (BLE) UART_TX (BLE)

Bank 1 ICE_SI/FLSH_MOSI ICE_SI/FLSH_MOSI ICE_SI/FLSH_MOSI

Bank 1 ICE_SO/FLSH_MISO ICE_SO/FLSH_MISO ICE_SO/FLSH_MISO

Bank 1 FLSH_SCLK FLSH_SCLK FLSH_SCLK

Bank 1 FLSH_CS FLSH_CS FLSH_CS

Bank 1 CDONE CDONE CDONE

Pin Assignment for

Default Key A

SMA clock

(Osc. Standby)

(Fingerprint reset)

Pin Assignment for

Key B

Not used / Optional ext

SMA clock

CLK_STNDBY#

(Osc. Standby)

FP_RSTn

(Fingerprint reset)

Pin Assignment for

Key C

I2S_WS1 (Microphone 1

(DP R51))

1)

CLK_STNDBY#

(Osc. Standby)

FP_RSTn (

Fingerprint reset)

7

Page 8

iCE40 Ultra Mobile Development Platform User Guide

Pin

Number Pin Name Bank

F3 IOB_16A Bank 1 UART_RX (BLE) UART_RX (BLE) UART_RX (BLE)

B4 IOB_10A Bank 1 PROC_INTR PROC_INTR PROC_INTR

C2 IOB_25B_G3 Bank 1 PROC_CS PROC_CS PROC_CS

F4 IOB_11B_G5 Bank 1 CLK (27 MHz) CLK (27 MHz) CLK (27 MHz)

C4 VCCIO_2 Bank 2 3V3 3V3 3V3

E5 IOB_7B Bank 2 BAR_LED FP_INTR (Fingerprint) S_LR2 (Microphone 2)

F5 IOB_6A Bank 2 IR_IN (IR Rx) IR_IN (IR Rx) I2S_LR1

D5 IOB_5B_MCSN

0_SPI2

D6 IOB_4A_SCK_

SPI2

E6 IOB_3B_G6_M

OSI_SPI2

F6 IOB_2A_MISO_

SPI2

D4 VPP_2V5 Power 2V5 2V5 2V5

B3 VCCPLL Power 1V2 1V2 1V2

A5 VCC Power 1V2 1V2 1V2

C5 GND1 Power GNDGNDGND

A3 GND2 Power GNDGNDGND

Bank 2 Spare GPIO on Exp

Bank 2 PoolB_Sensor_SCL FP_SCK (Fingerprint) I2S_SD2

Bank 2 PoolB_Sensor_SDA FP_MOSI (Fingerprint) ISS_SCK2

Bank 2 Spare GPIO on Exp

Pin Assignment for

Default Key A

Header p.16

Header p.20

Pin Assignment for

Key B

FP_CS (Fingerprint) I2S_WS2

FP_MISO (Fingerprint) I2S_CE2

Pin Assignment for

Key C

(Microphone 1)

(Microphone 2)

(Microphone 2)

(Microphone 2)

(Microphone 2)

External Interfacing

The board can be interface to external systems by one of two methods:

• SPI based application processor interface via J16 (AP Conn)

• BLE wireless module

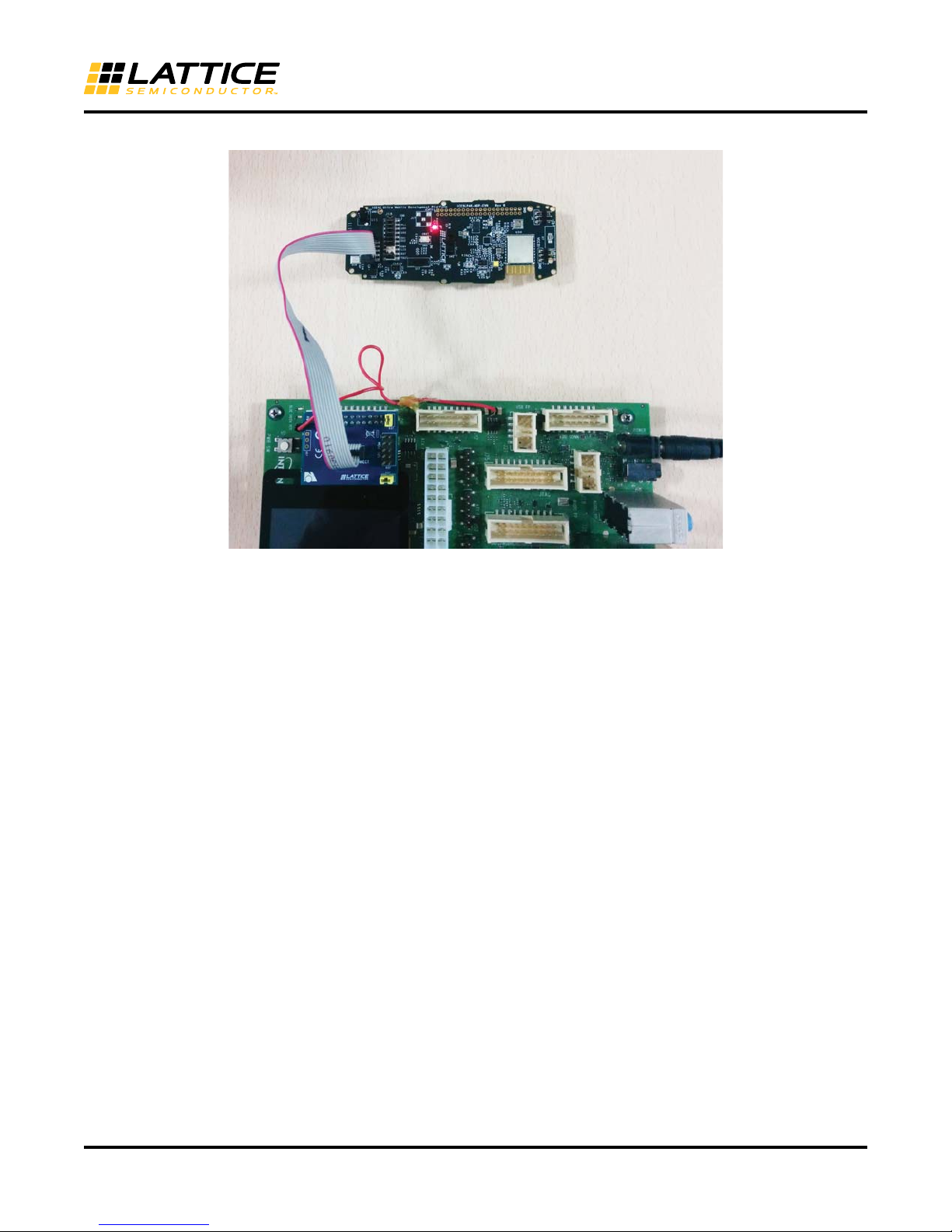

For DragonBoard based SPI based application processor interfacing, a DragonBoard interfacing module and a

connecting ribbon cable are required (provided). Figure 5 shows the interfacing module, connecting cable, and

method to power the module from the DragonBoard.

A BLE module provides a feature on the board for wireless interfacing using Bluetooth Low energy version 4.

8

Page 9

iCE40 Ultra Mobile Development Platform User Guide

Figure 5. Data and 5 V Wiring from DragonBoard to DB Interface Module

Clocking

The board features an onboard 27 MHz oscillator. When an external clock is required, the SMA footprint can be

populated with a suitable SMA SMD connector (such as Molex part # 732511350). You must depopulate R51 on

the board.

Daisy Chain Interconnect / Expansion Connector

Daisy chain interconnect to the iCE FPGA by means of a connecting cable between two boards is possible via J10

on the main board. Refer to the schematics for the pin assignments of J10. All the pins of the FPGA are accessible

on this connector – and hence also forms a convenient way to tap into, or expand from any pin on the FPGA.

Basic Usage Procedures

Powering the Board

The board may be powered using one of three following methods:

• USB cable: USB A to mini B cable (supplied) connected to a PC may be used to power the board

• +5 V supplied to the DragonBoard interface module used to power the board through the provided ribbon cable.

The +5 V can be tapped from the DragonBoard as indicated in the Figure 5.

• Internal rechargeable battery not supplied with the kit. It must be procured separately. An example is the Nokia

BL-5C Lithium-ion battery shown in Figure 7.

Charging the Battery

The battery is charged when USB power is applied. Glowing of the green LED D3 (CHG) indicates the charging of

the battery. Glowing of the green LED D4 (EPW) indicates that an external charging power (USB) is applied. Glowing D3 indicates that charging is in progress. If D3 does not glow and D4 (EPW) glows, it means that charging is

complete.

9

Page 10

iCE40 Ultra Mobile Development Platform User Guide

Figure 6. USB Socket Located on the Lower Side

Figure 7. Nokia BL-5C Li-ion Battery Mounted Inside Back-cover of the Main Unit

Configuring the FPGA

The iCE40 Ultra can be configured using one of two methods:

• By programming the on-board SPI Flash U3 (ST Micro's M25P80)

• By directly configuring the FPGA using a processor to configure via iCE40 Ultra's SPI

Configuration by Programming SPI Flash

The SPI Flash (M25P80) can be programmed using the on-board FTDI's FT2232H (USB-SPI FIFO) via USB and

Lattice Diamond

To program the SPI Flash via USB and Lattice Diamond

1. Apply a jumper to FLCS on jumper pool header J15.

2. Connect the USB cable to the demo board.

3. Download the bitstream in SPI Flash (M25P80) using Lattice Diamond Programmer. To download the bitstream:

®

Programmer.

Programmer:

a. Open Diamond Programmer version 3.2 or above and select Create a new blank project as shown in

Figure 8.

10

Page 11

iCE40 Ultra Mobile Development Platform User Guide

Figure 8. Diamond Programmer Getting Started Dialog Box

b. The Diamond Programmer main interface opens, as shown in Figure 9.

Figure 9. Diamond Programmer Main Interface

c. Select iCE5LP in Device Family and iCE5LP4K in Device, as shown in Figure 10.

11

Page 12

Figure 10. Device Selection

iCE40 Ultra Mobile Development Platform User Guide

d. Double-click Fast Program and choose the desired *.bin file.

e. In the Device properties dialog box, select the program to be used in programming the device and click

OK, as shown in Figure 11.

Figure 11. Device Properties Dialog Box

12

Page 13

e. Verify that the operation is completed successfully. In the main interface, INFO: Operation: successful

is displayed in the Output pane.

Figure 12. Verifying Operation

iCE40 Ultra Mobile Development Platform User Guide

Alternatively, the SPI Flash can be programmed using Totalphase's Aardvark or Cheetah. Flash Center GUI flash

programming utility can be hooked up to the J29 (SPI PGM) header on the DragonBoard interfacing module.

To program the SPI Flash using Aardvark/Cheetah:

1. Apply a jumper on FLCS located on jumper pool header J15.

2. Ensure that the ribbon cable is connected between J16 (AP CONN) on main board and J26 (AP Interconnect)

on the DragonBoard interfacing module.

3. Remove shunt on J20 (PGM) header on the DragonBoard interfacing module.

4. Connect Aardvark / Cheetah to the J29 (SPI PGM) header on the DragonBoard interfacing module and its USB

to the PC/Laptop running the Flash Center GUI utility.

5. While operating the CRST button or applying the jumper on CRST of J15 (on the main board), use the Flash

Center GUI and appropriate bitmap to program the M25P80 SPI Flash.

6. After programming, remove the shunts on CRST and PGM.

Direct Configuration by a Processor (Processor Configuration)

The iCE40 Ultra FPGA can be configured directly without using an external SPI Flash. This can be done by the

application processor interfacing with the iCE40 Ultra SPI lines. While using this method appropriate software and

Android Application is required.

To configure the hardware:

1. Remove the jumper shunt on FLCS located on J15 (jumper pool header).

2. Apply a jumper shunt on FTRST located on J15 (jumper pool header).

3. Remove the jumper shunt on CRST located on J15 (jumper shunt header).

13

Page 14

iCE40 Ultra Mobile Development Platform User Guide

4. Using the ribbon cable provided, connect the main PCB and the DragonBoard through the DragonBoard inter-

facing module.

5. Run the appropriate software / application to configure iCE40 Ultra directly from the DragonBoard processor.

Current Measurements

FPGA currents are measured by inserting ammeters in series with the respective current paths. This is achieved by

means of removing the jumper shunts on the pooled jumper header J15, and replacing those by ammeters. Note

the legends printed across each of the jumpers on the PCB and the corresponding wiring in the schematics around

region of J15 to make the desired measurements. Current measurements for the high power LED (IR or white) can

be done at J9 (LED selecting 3 pin jumper). Note that RGB LED current measurements on J15 (jumper pool

header) is for the common Anode limb of the LED and not individual RGB circuits; Thus appropriate drive must be

made to measure individual RG

Technical Support Assistance

Submit a technical support case via www.latticesemi.com/techsupport

Revision History

Date Version Change Summary

June 2015 1.1 General update in multiple sections.

Updated Appendix A. Schematic Diagrams section.

Added Appendix B. Bill of Materials section.

June 2014 01.0 Initial release.

© 2015 Lattice Semiconductor Corp. All Lattice trademarks, registered trademarks, patents, and disclaimers are as

listed at www.latticesemi.com/legal. All other brand or product names are trademarks or registered trademarks of

their respective holders. The specifications and information herein are subject to change without notice.

14

Page 15

iCE40 Ultra Mobile Development Platform User Guide

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

PRESSURE SENSOR

LATTICE SEMICONDUCTOR CORPORATION CONFIDENTIAL

Notes:

- Gyro and Accelerometer interfaces are both set to I2C

- I2C address LSB for both Gyro and Accelerometer is '1'

- SPI for both Gyro and Accelerometer is disabled

R

O

SNES LLA

H

ROS

N

ES RETEM

O

REL

E

CCA & EP

O

C

S

O

R

YG

RGB ALS SENSOR

PROXIMITY SENSOR-2

iCE5LP Mobile Development Platform Rev B

DEFAULT VCCIO1 IS SET TO 3.3V

poolA_sensor_SCL

poolA_sensor_SDA

poolA_sensor_SDA

poolA_sensor_SCL

poolA_sensor_SDA

poolA_sensor_SCL

Hall_out

poolA_sensor_SDA

poolA_sensor_SCL

VCCIO1

VCCIO1

VCCIO1

VCC3V3

VCCIO1

VCCIO1

VCCIO1

VCCIO1

poolA_sensor_SDA [Pg7]

poolA_sensor_SCL [Pg7]

Hall_out [Pg7]

Title

veRrebmuN tnemucoDeziS

t

ee

h

S

:

e

taD

of

04130-973-2

0

1

Pool-A I2C Sensors

B

210

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD

of

04130-973-2

0

1

Pool-A I2C Sensors

B

210

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD

of

04130-973-2

0

1

Pool-A I2C Sensors

B

210

Wednesday, April 22, 2015

R9

DNP

C25

0.1u

J14

ASCL

1

J13

ASDA

1

C79

1u

C57

1u

U18

MAX44008

VDD

1

GND

2

A0

3

INT4SCL5SDA

6

U22

BMP180

NC1

1

VDD

2

VDDIO

3

NC4

4

SCL

5

SDA

6

GND

7

R8

10k

U13

BU52051NVX

OUT

1

GND

2

NC3VDD

4

TPAD

5

C14

0.1u

U5

LSM330DLC

RES0

2

GND0

1

RES8

14

RES7

13

RES6

12

RES5

11

RES4

10

VDD0

7

CAP15DEN_G16DRDY_G/INT2_G

17

INT1_G18INT2_A19INT1_A

20

VDD_IO_0

21

CS_G

22

CS_A

23

SCL_A/G

24

VDD_IO_1

25

SDO_G

26

RES13RES2

4

RES3

5

GND1

6

VDD1

8

VDD2

9

SDO_A

27

SDA_A/G

28

C56

1u

R42

4k7

R3310k

C11

10u

TMD27711

U16

VDD1GND

3

LEDA

4

SCL

2

LEDK

5

LDR

6

INT

7

SDA

8

C16

10n

R41

4k7

C53

10u

C50

0.1u

C77

0.1u

C59

1u

Appendix A. Schematic Diagrams

Figure 13. Pool-A I2C Sensors

15

Page 16

iCE40 Ultra Mobile Development Platform User Guide

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

Humidity, Temperature Sensor

IR RX MODULE

CLOCK OSCILLATOR

LATTICE SEMICONDUCTOR CORPORATION CONFIDENTIAL

PROXIMITY SENSOR-1COMPASS SENSOR

iCE5LP Mobile Development Platform Rev B

DEFAULT VCCIO2 IS SET TO 3.3V

poolB_sensor_SDA

poolB_sensor_SCL

poolB_sensor_SCL

poolB_sensor_SDA

GND

poolB_sensor_SCL

poolB_sensor_SDA

VCCIO2

VCCIO2

VCCIO2

VCCIO2

VCC3V3

VCCIO2

VCCIO2

poolB_sensor_SDA [Pg7]

poolB_sensor_SCL [Pg7]

IR_IN [Pg7]

clk [Pg7]

clk_stndby# [Pg7]

Title

v

e

RrebmuN

tnemucoD

e

ziS

te

eh

S:e

taD

of

04130-973-2

0

1

Pool-B I2C Sensors, IR Rx & Clocking

B

310

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

Pool-B I2C Sensors, IR Rx & Clocking

B

310

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

Pool-B I2C Sensors, IR Rx & Clocking

B

310

Wednesday, April 22, 2015

R2910k

ASFLMB-27.000MHZ-LC-T

U21

GND2VDD

4

STDBY#

1

OUT

3

R3

4k7

C5

1u

C55

1u

C76

0.1u

C1

0.1u

TMD27711

U15

VDD1GND3LEDA

4

SCL

2

LEDK

5

LDR

6

INT

7

SDA

8

R5

4k7

C49

4.7u

C58

10u

U14

SHT20

SDA

1

VSS

2

NC13NC2

4

VDD

5

SCL

6

PAD

7

C52

0.1u

U11

TSMP58000

VDD

3

OUT

1

GND

2

J2

BSCL

1

C6

0.1u

R43

10k

J1

BSDA

1

R22

100

C8

0.22u

C15

4.7u

LSM303DLHC

U4

C1

6

RES110RES211SETP12SETC

13

SCL

2

SDA

3

INT24INT1

5

DRDY

9

VDDIO

1

VDD

14

GND

7

NC

8

C51

1u

Figure 14. Pool-B I2C Sensors, IR Rx and Clocking

16

Page 17

Figure 15. Interconnects

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

To jumper pool

Default: Shunt

Note position of pin#1

in reference board

SPI CONFIGURATION / FLASH

iCE5LP Mobile Development Platform Rev B

LATTICE SEMICONDUCTOR CORPORATION CONFIDENTIAL

SEEED BLE MODULE

AP INTERCONNECT

flsh_sclk

flsh_csproc_intr

proc_cs

CRSTb

ice_SOice_SI

flsh_mosi ice_SI

flsh_miso

ice_SO

flsh_sclk

flsh_miso

UART_TX

UART_RX

DRGN5V

VCCIO1

VCC3V3

VCC3V3

VCC3V3

ice_SO [Pg4,7]

proc_cs [Pg7]

flsh_cs [Pg4,5,7]

ice_SI[Pg4,7]

flsh_sclk[Pg4,5,7]

proc_intr

[Pg7]

CRSTb[Pg4,5,7]

flsh_miso [Pg5]

M25P80_CSn[Pg7]

flsh_mosi[Pg5]

UART_TX

[Pg7]

UART_RX

[Pg7]

CDONE [Pg5,7]

CRSTb[Pg4,5,7]

ice_SI[Pg4,7]

ice_SO[Pg4,7]

flsh_cs[Pg4,5,7]

flsh_sclk[Pg4,5,7]

SWCLK

[Pg7]

SWDIO[Pg7]

Title

v

e

RrebmuN

tnemucoDeziS

t

e

eh

S

:

e

taD

of

04130-973-2

0

1

INTERCONNECTS

B

410

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

INTERCONNECTS

B

410

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

INTERCONNECTS

B

410

Wednesday, April 22, 2015

R2

10k

R13

0

R68

0

DNP

R12

0

R78

820

J16

AP INTERCONNECT

2

4

6

8

10

1

3

579

D14

RED

Manufacturer = Osram

PART_NUMBER = LS L29K-G1J2-1-Z

DNP

12

R37 0

R35

0

R6

10k

R67

0

DNP

R7

10k

J18

BLE PROG SEL

1

2

3

R76

0

DNP

R45

0

DNP

R48

0

DNP

M25P80

U3

SDI5SCK

6

WP3CS

1

SDO

2

HOLD

7

8

VCC

4

GND

R77

0

DNP

C9

0.1u

C17

0.1u

U30

SeeedBLE

GND1SWCLK

2

SWDIO

3

VCC

4

p12

6

p135p117p9

9

p8

10

p7

11

p6

12

p5

13

p4

14

p3

15

p2

16

p1

17

p0

18

p2920p2821p25

22

p2423p23

24

p17

25

p18

26

GND

27

p10

8

p30

19

R4

10k

R75

0

DNP

R40

0

iCE40 Ultra Mobile Development Platform User Guide

17

Page 18

Figure 16. USB Programming and Power

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

LATTICE SEMICONDUCTOR CORPORATION CONFIDENTIAL

iCE5LP Mobile Development Platform Rev B

FTDI PROGRAMMER

USB - POWER & PROGRAMMING

USB_DM

GND

FT_CRST

EP_CS

FT_CRST

GND

EP_DI

GND

EP_CLK

EP_CS

GND

FT_DI

FT_DI

FT_SK

FT_SK

FT_CS

EP_DI

FT_DO

FT_CS

EP_CLK

GND

USB_DP

GND

FT_DO

GND

GND

USB_DP

USB_DM

FT_CDONE

FT_CDONE

VCC3V3

VCC3V3

VCC3V3

FTVCOR

VCC3V3

FTVCOR

VCC3V3

FTVCOR

FTVCOR

VCC3V3

VCC3V3

VCC3V3

USB5V

CRSTb[Pg4,7]

flsh_miso

[Pg4]

flsh_sclk[Pg4,7]

flsh_cs[Pg4,7]

flsh_mosi

[Pg4]

CDONE

[Pg4,7]

FTRSTn[Pg7]

Title

veR

r

eb

muN

t

ne

mucoD

e

z

i

S

te

eh

S:etaD

of

04130-973-2

0

1

USB Programming & Power

B

510

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

USB Programming & Power

B

510

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

USB Programming & Power

B

510

Wednesday, April 22, 2015

R250 C13

0.1u

C37

27p

C48

0.1u

C30

4.7u

C22

0.1u

C47

0.1u

Y1

12MHz

R210

R23

470

5V D- D+ ID G

USB PWR

J5

1

2

3

4

S2

5

S1

S3

S4

R201k

R16 10

C23

27p

C21

10u

R11

10k

R260

C20

0.1u

L3

600 ohm, 500 mA

R280

R270

L1

600 ohm, 500 mA

R18

12k

93LC56BT-I/OT

U6

GND

2

VCC

6

DO

1

DI

3

CLK

4

CS

5

C29

0.1u

L2

600 ohm, 500 mA

C18

47u

C19

0.1u

R24

0

U9

FT2232H

Gnd_11OSCI2OSCO3VPHY4Gnd_75REF

6

DM

7

DP8VPLL

9

AGnd

10

Gnd11VCORE_112TEST13RESET#14Gnd_215ADBUS0

16

ADBUS1

17

ADBUS2

18

ADBUS3

19

VCCIO

20

ADBUS4

21

ADBUS5

22

ADBUS6

23

ADBUS7

24

Gnd_3

25

ACBUS0

26

ACBUS1

27

ACBUS2

28

ACBUS3

29

ACBUS4

30

VCCIO_3

31

ACBUS5

32

ACBUS633ACBUS7

34

Gnd_4

35

SUSPEND#

36

VCORE

37

BDBUS038BDBUS139BDBUS240BDBUS3

41

VCCIO_2

42

BDBUS443BDBUS544BDBUS645BDBUS7

46

Gnd_5

47

BCBUS0

48

VREGOUT

49

VREGIN

50

Gnd_6

51

BCBUS1

52

BCBUS2

53

BCBUS3

54

BCBUS4

55

VCCIO_1

56

BCBUS5

57

BCBUS6

58

BCBUS7

59

PWREN#

60

EEDATA

61

EECLK

62

EECS

63

VCORE_3

64

R102k2

C44

0.1u

C24

0.1u

R17 10

C38

0.1u

C43

4.7u

iCE40 Ultra Mobile Development Platform User Guide

18

Page 19

iCE40 Ultra Mobile Development Platform User Guide

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

LATTICE SEMICONDUCTOR CORPORATION CONFIDENTIAL

FINGERPRINT SENSOR

I2S MICROPHONES - 2

iCE5LP Mobile Development Platform Rev B

FP_CS

I2S_SD1

I2S_SD2

VCCIO0

VCCIO2

VCC1V8

VCCIO2

VCCIO2

VCCIO2

I2S_LR1 [Pg7]

I2S_WS1 [Pg7]

I2S_SD1 [Pg7]

I2S_SCK1 [Pg7]

I2S_CE1 [Pg7]

I2S_CE2 [Pg7]

FP_MISO [Pg7]

FP_CS [Pg7]

FP_INTR [Pg7]

FP_SCK [Pg7]

FP_MOSI [Pg7]

I2S_LR2 [Pg7]

I2S_WS2 [Pg7]

I2S_SD2 [Pg7]

I2S_SCK2 [Pg7]

FP_RSTn[Pg7]

Title

veR

re

b

muN

tn

e

mucoD

e

z

i

S

te

eh

S:etaD

of

04130-973-2

0

1

I2S MIC, FINGERPRINT SENSORS and MICRO SD

B

610

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

I2S MIC, FINGERPRINT SENSORS and MICRO SD

B

610

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

I2S MIC, FINGERPRINT SENSORS and MICRO SD

B

610

Wednesday, April 22, 2015

R62

10k

R66

100k

R73

100k

R63

10k

D6

TVS/VAR

C66

0.1u

U19

ADMP441

SCK

1

SD

2

WS

3

LR

4

GND

5

GND1

6

VDD7CE

8

GND2

9

C60

0.1u

FPC1080A

U17

DR11DR213DR317DR429TXOUT120TXOUT221ANATEST18ANATEST29TEST410TEST316TEST215TEST1

32

SPICLK

24

MISO26MOSI

25

CSN

6

RSTN

5

IRQ

4

VDD1

3

VDD2

19

VDDA

11

VDDIO

27

GND5

31

GND6

30

GND7

2

GND8

7

GND9

12

GND10

14

GND1

18

GND2

22

GND3

23

GND4

28

R30

100

C63

0.1u

R61

10k

U12

ADMP441

SCK

1

SD

2

WS

3

LR

4

GND

5

GND16VDD7CE8GND2

9

C36

0.1u

R34

10k

C54

0.1u

C46

0.1u

Figure 17. I2S MIC, Fingerprint Sensors and Micro SD

19

Page 20

iCE40 Ultra Mobile Development Platform User Guide

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

500mA track

500mA track

500mA track500mA track

Default: Shunt 1,2 (for IR LED)

All 500mA traces

All 500mA traces

Note:

Place close

to DUT

LATTICE SEMICONDUCTOR CORPORATION CONFIDENTIAL

iCE5LP Mobile Development Platform Rev B

IR, RGB and HI-POWER LEDs

DAISY CHAIN INTERCONNECT

100mA track

De-populate when using SMA CLK

KEY & SOCKET HEADER

OPTIONAL SMA CLOCK

DNP

JUMPER POOL HEADER

100mA track100mA track

DONE CRST

ALTERNATE RGB LED

Note:

Place close

to DUT

Note:

Place close

to DUT

500mA track

500mA track

CRSTb

VCC_A5

RLED

RGB_Anode

GLED

BLED

IRLEDVLED

VLED

HPLED

IRLED

GPIO_B2

Hall_out

CDONE

SMA_CLK

GPIO_B5

BAR_LED

VCC_A5

VCCPLL_B3

VPP2V5_D4

SPIVCCIO1_C3

VCCIO0_A4

VCCIO2_C4

RGB_Anode

GPIO_A6

BLED

GPIO_B6

GLED

GPIO_C6

RLED

GPIO_D6

poolB_sensor_SCL

GPIO_D5

GPIO_E6 poolB_sensor_SDA

GPIO_E5 BAR_LED

GPIO_F6

GPIO_F5

IR_IN

flsh_cs

CRSTb

GPIO_E5

GPIO_B6

GPIO_B1

SPIVCCIO1_C3

VCCIO0_A4

GPIO_D6

GPIO_F5

poolA_sensor_SDA

proc_cs

VCC_A5

GPIO_B2

GPIO_E6

GPIO_A6

HPLED

UART_TX

GPIO_D2

flsh_cs

CRSTb

UART_RX

VCCPLL_B3

GPIO_F6

GPIO_C6

ice_SO

poolA_sensor_SCL

proc_intr

GPIO_D5

CDONE

flsh_sclk

VCCIO2_C4

CLK_F4

ice_SI

GPIO_B5

VPP2V5_D4

GND GND

GPIO_D6

BLED

GLED

RGB_Anode

RLED

SPIVCCIO1_C3

GPIO_B1

VCCPLL_B3

GND

GND

VCCIO2_C4

GPIO_B6

HPLED

GPIO_C6

GPIO_B2

poolA_sensor_SCL

poolA_sensor_SDA

VPP2V5_D4

CDONE

flsh_cs

flsh_sclk

ice_SO

ice_SI

CRSTb

GPIO_E5

GPIO_F5

GPIO_D5

proc_cs

proc_intr

GPIO_D6

GPIO_D2

GPIO_E6

CLK_F4

GPIO_F6

GPIO_B5

GPIO_A6

VCCIO0_A4

VCCIO1

VCC3V3HP

VCC3V3HP

VCCIO1

VCC1V2

VCC2V5

VCCIO1

VCCIO0

VCCIO2

VCC3V3HP

VCC3V3

flsh_cs

[Pg4,5]

Hall_out[Pg2]

CDONE[Pg4,5]

poolB_sensor_SDA[Pg3]

poolB_sensor_SCL[Pg3]

poolA_sensor_SDA[Pg2]

poolA_sensor_SCL[Pg2]

IR_IN[Pg3]

flsh_sclk[Pg4,5]

ice_SI

[Pg4]

proc_intr

[Pg4]

CRSTb[Pg4,5]

ice_SO

[Pg4]

proc_cs

[Pg4]

I2S_WS1 [Pg6]

FTRSTn [Pg5]

I2S_CE1

[Pg6]

I2S_SCK1 [Pg6]

I2S_SD1

[Pg6]

FP_SCK [Pg6]

I2S_SD2[Pg6] FP_CS [Pg6]

I2S_WS2 [Pg6]

FP_MOSI [Pg6]

I2S_SCK2[Pg6]

FP_INTR [Pg6]

I2S_LR2[Pg6]

FP_MISO [Pg6]

I2S_CE2[Pg6]

I2S_LR1 [Pg6]

M25P80_CSn [Pg4]

clk_stndby#[Pg3]

FP_RSTn[Pg6]

SWCLK

[Pg4]

SWDIO[Pg4]

UART_TXPg[4]

UART_RX

Pg[4]

clk

Pg[3]

Title

veRreb

m

uN tne

m

uco

D

eziS

te

eh

S:etaD

of

04130-973-2

0

1

iCE5LP4KSWG36 FPGA & LEDs

B

710

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

iCE5LP4KSWG36 FPGA & LEDs

B

710

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

iCE5LP4KSWG36 FPGA & LEDs

B

710

Wednesday, April 22, 2015

J7

KEY

2

468

1012141618

20

22

242628

30

1

3

57911131517

19

21

232527

29

3132

C70

10n

C71

10n

C65

10n

D5

VIS

1

K

2

A

3

3

J9

HP LED SEL

1

2

3

C72

1u

R38

2k2

C64

10n

C67

1u

C78

0.1u

J10

CON40A

1 2

3

4

5 6

7 8

9

101112

13 14

151617

18

19 20

21 22

23 24

25 26

27 28

29 30

31

32

33

34

35 36

37

38

39 40

J17

SMA

A

1

Sh12Sh2

3

Sh3

4

Sh4

5

C75

10n

R470

DNP

D8

BAR

D13

APTF1616SEEZGQBDC

A

1

R2G

3

B

4

R44

100

C90

0.1u

J15

A3-20PA-2SV(71)

1

3

5

7911

13

151719

2

4

6

8

101214

16

18

20

C62

1u

R14

150

R46

2k2

R740

R390

R49

10k

C61

0.1u

C69

0.1u

C73

0.1u

R51

0

C68

0.1u

Bank 0

Bank 2

CONFIG SPI & Bank 1

iCE5LP4KSWG36

iCE5LP4KSWG36

U20

IOB_2A_MISO_SPI2

F6

IOB_3B_G6_MOSI_SPI2

E6

IOB_4A_SCK_SPI2

D6

IOB_5B_MCSN0_SPI2

D5

IOB_6A

F5

IOB_7B

E5

IOB_29B

E2

IOB_30A

C1

IOB_31B

B2

IOB_32A_SO_MISO_SPI1

F2

IOB_33B_SI_MOSI_SPI1

D1

SPI_VCCIO1

C3

IOB_10A

B4

IOB_11B_G5

F4

CRESET_B

D3

IOB_16A

F3

IOB_20AE3IOB_25B_G3

C2

IOB_26A

B1

IOB_27B

D2

IOB_34A_SCK_SCK_SPI1

E1

IOB_35B_SS_MCSNO_SPI1

F1

VCCPLL

B3

IOT_46B_G0

B5

RGB2A6RGB1B6RGB0

C6

GND2

A3

GND1

C5

VCC

A5

VCCIO_0

A4

VCCIO_2

C4

VPP_2V5

D4

IOB_12A_G4_CDONE

E4

IRLED

A2

VSSIO_LED

A1

SW3

PB

D9

LED

C74

1u

D12

RGB

Green

1

Red2Anode

3

Blue

4

D7

IR

Figure 18. iCE5LP4KSWG36 FPGA and LEDs

20

Page 21

Figure 19. Power Supplies

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

spread across board, easy access

Default: 3V3

LDO REGULATORS

CHARGER

3

V3 :

tl

uaf

eD

3

V3 :

tl

ua

feD

YELLOW

GREEN

s

e

ca

r

t Am0

0

5secart Am

0

05

500mA traces

iCE5LP Mobile Development Platform Rev B

LATTICE SEMICONDUCTOR CORPORATION CONFIDENTIAL

POWER SOURCE SELECTOR

PWR

VCC3V3

VCC2V5

VCC3V3

VCC2V5

VCC1V8 VCC1V8

LDO_CE_VDC

LDO_CE_VDC

VCCIO0

VDC

VCC1V2

VCC1V8

VCCIO1

VCC3V3

VCCIO2

VCC1V8

VCC2V5

VCC2V5

VCC3V3

VDC

VCC3V3

USB5V

VBAT

VCC3V3HP

VDC

VBAT

VDC

VDC

USB5V

DRGN5V

Title

v

e

RrebmuN

tnemucoD

e

ziS

tee

h

S:e

t

a

D

of

04130-973-2

0

1

Power Supplies

B

810

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

Power Supplies

B

810

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

Power Supplies

B

810

Wednesday, April 22, 2015

BC1

Bat connector

VIN1GND

3

NC25NC1

4

NTC

2

MH16MH2

7

R59DNP

AP7312-1218FM-7

U10

1.8VO

5

1.8EN

3

1.2EN

2

1.2VO

6

VIN

1

GND

4

EPAD

7

C2

1u

R60DNP

J11

GND

1

D1

PMEG2010AEH

C3

2.2u

R580

J12

GND

1

C4

10u

C35

10u

R31

1k

R1

5k6

C26

0.1u

C40

10u

C28

0.1u

C42

10u

C45

10u

C7

10u

R32

1k

U1 MC34673AEPR2

VIN1nPPR

2

nCHG

3

nEN

4

BAT

8

ISET

7

nFAST

6

GND

5

EPAD

9

C31

10u

C41

10u

D10

LED

U7

LTC4411

In

1

Gnd

2

Ctl

3

Stat

4

Out

5

R520

U8

XC6222B331MR-G

Vin

1

Vss

2

CE

3

NC

4

Vout

5

J3

GND

1

D4

LED

R50

1k

R53DNP

C33

0.1u

C12

0.1u

D2

PMEG2010AEH

R54DNP

U2

MIC5335-SJYMT

VIN

1

GND

2

2V5EN

3

3V3EN

4

2V5VO

5

3V3VO

6

PAD

7

D3

LED

SW2

PWR

C34

10u

R550

R19

1k

C10

47u

R56DNP

C39

0.1u

C32

0.1u

R57DNP

C27

10u

iCE40 Ultra Mobile Development Platform User Guide

21

Page 22

Figure 20. Keys (4 Different PCB Modules)

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

KEY-A (DEFAULT) KEY-B (GETS FP ILO PoolB)

KEY-C (GETS I2S MICs ILO PoolB, IR Rx, RGB)

KEY-D (CUSTOM KEY)

iCE5LP Mobile Development Platform Rev B

LATTICE SEMICONDUCTOR CORPORATION CONFIDENTIAL

Title

v

e

RrebmuN

tnemucoD

e

ziS

tee

h

S:e

t

a

D

of

04130-973-2

0

1

KEYS (4 different PCB modules)

B

910

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

KEYS (4 different PCB modules)

B

910

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

04130-973-2

0

1

KEYS (4 different PCB modules)

B

910

Wednesday, April 22, 2015

J23

CON15

123456789101112131415

J4

DF12B(3.0)-30DP-0.5V(86)

246

8

101214161820222426

28

30

135791113151719212325

27

29

3132

J6

DF12B(3.0)-30DP-0.5V(86)

246

8

10

1214161820

22

24

262830

135791113151719212325

27

29

3132

J8

DF12B(3.0)-30DP-0.5V(86)

2

468

10

121416

182022

242628

30

1357911131517192123252729

3132

J21

DF12B(3.0)-30DP-0.5V(86)

246

8

10121416182022

242628

30

13579111315171921

232527

29

3132

J22

CON15

123456789

1011121314

15

iCE40 Ultra Mobile Development Platform User Guide

22

Page 23

iCE40 Ultra Mobile Development Platform User Guide

5

5

4

4

3

3

2

2

1

1

D

D

C

C

B

B

A A

DNP

MISO FOR iCE,

MOSI FOR FLASH

MISO FOR iCE,

MOSI FOR FLASH

DNP

iCE5LP Mobile Development Platform Rev B

LATTICE SEMICONDUCTOR CORPORATION CONFIDENTIAL

SPI_CS_1V8

INTRV_1V8

SPI_CLK_1V8

SPI_MOSI_1V8

SPI_MISO_1V8

SPI_CS

SPI_MISO

SPI_CLK

SPI_MOSI

VCC5VLT

INTRV

VCC5VLT

CReset1V8

GPIO_CS_1V8

CReset3V3

SPI_MOSI_1V8

VCCBVLT

SPI_CLK_1V8

SPI_MISO_1V8

SPI_MISO

SPI_MOSI

SPI_CLK

GPIO_PROC_CS

GPIO_PROC_CS

SPI_CLK SPI_MISO

SPI_MOSI

SPI_CS_1V8

CS

CS

GPIO_CS_1V8

CS

VLTOE

CReset1V8

VCCBVLT

SPI_CS_1V8

INTRV_1V8

CReset3V3

SPI_CS

SPICS3V3

INTRV

VLTOE

SPICS3V3

GPIO_PROC_CS

VCC1V8V

VCC3V3V

VCC1V8V

VCC1V8V

VCC3V3VVCC1V8V

VCC5VLT

VCC1V8V

VCC1V8V

VCC1V8V

Title

v

e

RrebmuN

tnemucoD

e

ziS

tee

h

S:e

t

a

D

of

0413

0

-B973-2

0

1

DragonBoard VLT Adapter module

B

10 10

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

0413

0

-B973-2

0

1

DragonBoard VLT Adapter module

B

10 10

Wednesday, April 22, 2015

Title

veRrebmuN tnemu

c

o

D

eziS

teehS

:etaD of

0413

0

-B973-2

0

1

DragonBoard VLT Adapter module

B

10 10

Wednesday, April 22, 2015

U23

74AVC4T774

DIR11DIR2

2

A1

3

A24A35A4

6

DIR3

7

DIR4

8

OE

9

GND

10

B411B3

12

B213B1

14

VCCB15VCCA

16

C84

0.1u

J20

PRGM

1

2

C89

0.1u

C88

0.1u

R64

0

J24

SPICS

1

2

C82

10u

R65

DNP

J26

10p 2mm

2

4

6

1

3

578910

C118

0.1u

R69

0

J29

Aardvark Header

SS2

1

GND1

2

SS3

3

NC2

4

MISO

5

NC1

6

SCLK

7

MOSI

8

SS1

9

GND2

10

C80

10u

C85

0.1u

R71 10k

U24

LD1117-3V3

GND

1

VOUT

2

VIN

3

4

TAB

C86

10u

TP10

+5V

1

R72

0

C119

0.1u

DNP

J27

24p 2p54mm

13579111315171921

23

246

8

10

121416

18

202224

U29

74AVC4T774

DIR11DIR2

2

A1

3

A24A3

5

A4

6

DIR37DIR4

8

OE

9

GND

10

B4

11

B312B2

13

B1

14

VCCB

15

VCCA

16

U25

LD1117-1V8

GND

1

VOUT

2

VIN

3

TAB

4

R70 10k

J28

1

2

3

C83

0.1u

C81

10u

U26

SN74AUP1G08DBVR

A1B

2

GND

3

Y

4

VCC

5

C87

0.1u

Figure 21. DragonBoard VLT Adapter Module

23

Page 24

iCE40 Ultra Mobile Development Platform User Guide

Appendix B. Bill of Materials

Item Reference Quantity Part PCB Footprint Comments Par t Num ber Manufacturer Description

1 BC1 1 Bat connector BATT_009155003

2 C1,C6,C9,C12,C13,C14,C17,

3 C2,C5,C51,C55,C56,C57,C59,

4 C3 1 2.2 u C0603 — CC0603ZRY5V6

5 C4,C11,C21,C27,C31,C35,C4

6 C7,C34,C41,C42,C80,C86 6 10 u C0603 — CL10X106MP8N

7 C8 1 0.22 u C0603 — CL10B224KO8N

8 C10,C18 2 47 u C3528 — TCJB476M010R

9 C15,C30,C43,C49 4 4.7 u C0603 — CC0603KRX5R6

10 C16,C64,C65,C70,C71,C75 6 10 n C0402 — CL05B103KO5N

11 C23,C37 2 27 p C0402 — CL05C270JB5N

12 C119 1 0.1 u C0402 DNP CL05A104MP5N

13 D1,D2 2 PMEG2010AEH SOD123F — PMEG2010AEH,

14 D3 1 LED led0603 — LG L29K-G2J1-

15 D4 1 LED led0603 — LY Q976-P1S2-36Osram Opto LED CHIPLED 587NM YLW 0603 SMD

C19,C20,C22,C24,C25,C26,

C28,C29,C32,C33,C36,C38,

C39,C44,C46,C47,C48,C50,

C52,C54,C60,C61,C63,C66,

C68,C69,C73,C76,C77,C78,

C83,C84,C85,C87,C88,C89,

C90,C118

C62,C67,C72,C74,C79

0,C45,C53,C58,C81,C82

45 0.1 u C0402 — CL05A104MP5N

12 1 u C0402 — CL05A105KP5N

12 10 u C0603 — CL10A106MQ8

301006

— 09155003301006AVX CONN BATTERY 3 POS RIGHT

NNC

NNC

BB225

NNNC

RNC

NNC

0070

BB475

CNC

NNC

NNC

115

24-Z

Samsung CAP CER 0.1UF 10V 20% X5R 0402

Samsung CAP CER 1UF 10V 10% X5R 0402

Ya g e o CAP CER 2.2UF 10V Y5V 0603

Samsung CAP CER 10UF 6.3V 20% X5R 0603

Samsung CAP CER 10UF 10V 20% X6S 0603

Samsung CAP CER 0.22UF 16V 10% X7R 0603

AVX CAP TANT 47UF 10V 20% 1210

Ya g e o CAP CER 4.7UF 10V 10% X5R 0603

Samsung CAP CER 10000PF 16V 10% X7R

Samsung CAP CER 27PF 50V 5% NP0 0402

Samsung CAP CER 0.1UF 10V 20% X5R 0402

NXP Semiconductor

Osram Opto LED SMARTLED GREEN 570NM

ANGLE

0402

DIODE SCHOTTKY 20V 1A SOD123F

0603

16 D5 1 VIS XBDAWT — XBDAWT-00-

17 D6 1 TVS/VAR R0603 — VC060330A650DPAVX VARISTOR 36.9V 30A 0603

18 D7 1 IR IRD — VSMB2948SL Vishay IR EMITTER HIGH SPEED 940NM

19 D8 1 BAR LED0805 — APT2012SRCPRVKingbright Corp LED 2X1.2MM 640NM RD WTR CLR

20 D9 1 LED led0603 — LG L29K-G2J1-

21 D10 1 LED led0603 — LS Q976-NR-1 Osram Opto LED CHIPLED 633NM RED 0603 SMD

22 D12 1 RGB RGBD DNP AEBMTRGBZ Custom —

23 D13 1 APTF1616SEEZ

24 D14 1 RED LED0603 DNP LS L29K-G1J2-

25 J1 1 BSDA TP_TH_40_24_S DNP PCB MDN —

26 J2 1 BSCL TP_TH_40_24_S DNP PCB MDN —

27 J3,J11,J12 3 GND TUR_TH DNP 1573-2 Keystone Elec-

28 J4,J6,J8,J21 4 DF12B(3.0)-

29 J5 1 USB PWR CONN_S5P1RMI

30 J7 1 KEY HIROSE_DF12B_30— DF12B(3.0)-

31 J9 1 HP LED SEL hdr1x3-40_2mm — NRPN031PARN-RCSullins Connec-

32 J10 1 CON40A hdr20x2_2mm DNP 0877582016 Molex Inc CONN HEADER 20POS 2MM VERT

33 J13 1 ASDA TP_TH_40_24_S DNP PCB MDN —

GQBDC

30DP-0.5V(86)

RGBOPT2 — APTF1616SEEZ

HIROSE_DF12B_

30_mirror

NIUSBB_MOLEX

000000000LCE3

24-Z

GQBDC

1-Z

— DF12B(3.0)-

30DP-0.5V(86)

— 67503-1020 Molex CONN RECEPT MINIUSB R/A 5POS

30DS-0.5V(86)

Cree Inc LED HIGH BRIGHTNESS

SMD

SMD

Osram Opto LED SMARTLED GREEN 570NM

KingbrightCorp LED RED/GREEN/BLUE WTR CLEAR

Osram LED SMARTLED GREEN 570NM

tronics

Hirose CONN HEADER 30POS 3MM SMD

Hirose CONN RCPT 30POS 3MM SMD

tor Solutions

0603

SMD

0603

TERMINAL TURRET DBL .082"L

0.5MM

SMD

0.5MM

CONN HEADER 2MM SINGLE R/A

3POS

GOLD

24

Page 25

iCE40 Ultra Mobile Development Platform User Guide

Item Reference Quantity Part PCB Footprint Comments Part Number Manufacturer Description

34 J14 1 ASCL TP_TH_40_24_S DNP PCB MDN —

35 J15 1 A3-20PA-

36 J16 1 AP INTERCON-

37 J17 1 SMA molex_0732511350DNP 732511350 Molex CONN SMA JACK STR 50 Ohm SMD

2SV(71)

NECT

hirose_10x2_2m

m

hirose_5x2_2mm — A3-10PA-

— A3-20PA-

2SV(71)

2SV(71)

Hirose CONN HEADER 20POS 2MM GOLD

Hirose CONN HEADER 10POS 2MM GOLD

SMD

SMD

38 J18 1 BLE PROG SEL hdr1x3-40_2mm — NRPN031PARN-RCSullins Connec-

39 J20 1 PRGM HDR1X2-40 — 77311-801-02LF FCI CONN HEADER .100 SINGL STR

40 J22,J23 2 CON15 HDR1x15_2mm_THDNP PCB MDN —

41 J24 1 SPICS HDR1X2-40 — 77311-801-02LF FCI CONN HEADER .100 SINGL STR

42 J26 1 10p 2 mm hdr_5x2_2mm — 0877581016 Molex Inc CONN HEADER 10POS 2MM VERT

43 J27 1 24p 2p 54 mm hdr12x2_TH_2p5

44 J28 1 DNP hdr1x3-40 DNP 77311-801-03LF FCI CONN HEADER .100 SINGL STR

45 J29 1 Aardvark Header hdr5x2 — 77313-801-10LF FCI CONN HEADER .100 SINGL STR

46 L1,L2,L3 3 600 Ohm,

47 R1 1 5k6 R0402 — RC1005F562CS Samsung RES 5.6 kOhm 1/16W 1% 0402

48 R2,R4,R6,R7,R8,R11,R29,

49 R3,R5,R41,R42 4 4k7 R0402 — RC1005J472CS Samsung RES 4.7 kOhm 1/16W 5% 0402

50 R9 1 DNP R0402 DNP WR04X000PTL Walsin —

51 R10,R38,R46 3 2k2 R0402 — RC1005J222CS Samsung RES 2.2 kOhm 1/16W 5% 0402

52 R12,R13,R35,R40 4 0 R0402 — RC1005J000CS Samsung RES 0.0 Ohm 1/16W JUMP 0402

53 R14 1 150 R0402 — RMCF0402JT150RStackpole Elec-

54 R16,R17 2 10 R0402 — RC1005J100CS Samsung RES 10 Ohm 1/16W 5% 0402

55 R18 1 12k R0402 — RC1005F123CS Samsung RES 12 kOhm 1/16W 1% 0402

56 R19,R20,R31,R32,R50 5 1k R0402 — RC1005J102CS Samsung RES 1 kOhm 1/16W 5% 0402

57 R21,R24,R25,R26,R27,R28,

58 R22 1 100 R0603 — RC1608J101CS Samsung RES 100 Ohm 1/10W 5% 0603

59 R23 1 470 R0402 — RC1005J471CS Samsung RES 470 Ohm 1/16W 5% 0402

60 R30,R44 2 100 R0402 — RC1005J101CS Samsung RES 100 Ohm 1/16W 5% 0402

61 R45,R47,R48,R67,R68,R75,

62 R53,R54,R56,R57,R59,R60,

63 R66,R73 2 100k R0402 — RC1005J104CS Samsung RES 100 kOhm 1/16W 5% 0402

64 R78 1 820 R0402 — RC1005F821CS Samsung RES SMD 820 Ohm 1% 1/16W 0402

65 SW2 1 PWR EG1218O_switch — EG1218 E-Switch SWITCH SLIDE SPDT 30V.2A PC

66 SW3 1 PB 2psmd_eswitch — TL1015AF160QGE-Switch SWITCH TACTILE SPST-NO 0.05A

67 TP10 1 +5 V HDR1 — 77311-801-01LF FCI HEADER BERGSTIK

68 U1 1 MC34673AEPR28-UDFN — MC34673AEPR2Freescale Semi-

69 U2 1 MIC5335-

70 U3 1 M25P80 SOIC8-W — M25P80-

71 U4 1 LSM303DLHC LGA14_LSM303 — LSM303DLHC ST Micro ACCELEROMETER/MAGNETOME-

72 U5 1 LSM330DLC LGA-28 — LSM330DLC ST Micro ACCELEROMETER/MAGNETOME-

73 U6 1 93LC56BT-I/OT SOT23-6 — 93LC56BT-I/OT Microchip Tech-

R33,R34,R43,R49,R61,R62,

R63,R70,R71

R37,R39,R51,R52,R55,R58,

R64,R69,R72,R74

R76,R77

R65

16 10k R0402 — RC1005J103CS Samsung RES 10 kOhm 1/16W 5% 0402

16 0 R0402 — RC1005J000CS Samsung RES 0.0 Ohm 1/16W JUMP 0402

8 0 R0402 DNP RC1005J000CS Samsung RES 0.0 Ohm 1/16W JUMP 0402

7 DNP R0402 DNP RC1005J000CS Samsung RES 0.0 Ohm 1/16W JUMP 0402

500 mA

SJYMT

4_mirror

L0603 — MMZ1608R601A TDK Corp FERRITE CHIP 600 Ohm 500MA 0603

6TMLF — MIC5335-

— M20-7831242 Harwin Inc 12+12 DIL VERT SOCKET L/FREE

SJYMT

VMW6G

tor Solutions

tronics

conductor

Micrel IC REG LDO 3.3 V/2.5 V 0.3A 6TMLF

Numonyx/ST

Micro

nology

CONN HEADER 2MM SINGLE R/A

3POS

2POS

2POS

GOLD

3POS

10POS

RES 150 Ohm 1/16W 5% 0402

MNT

12V

IC SGL CELL BATTERY CHRGR 8UDFN

IC FLASH 8MBIT 75MHZ 8SO

TER 14LGA

TER 28LGA

IC EEPROM 2KBIT 2MHZ SOT23-6

25

Page 26

iCE40 Ultra Mobile Development Platform User Guide

Item Reference Quantity Part PCB Footprint Comments Part Number Manufacturer Description

74 U7 1 LT C4 4 11 TSOT23-5 — LTC4411ES5#T

75 U8 1 XC6222B331MR-GSOT25 — XC6222B331MR-GTorex Semicon-

76 U9 1 FT2232H LQFP64 — FT2232HL FTDI IC USB HS DUAL UART/FIFO 64-

77 U10 1 AP7312-

78 U11 1 TSMP58000 TSOPIRx3P — TSMP58000 Vishay 3 V PH.MODULE S.VIEW

79 U12,U19 2 ADMP441 ADMP441 — INMP441ACEZ Invensense Omnidirectional Microphone with bot-

80 U13 1 BU52051NVX SSON004X1216 — BU52051NVX ROHM Semicon-

81 U14 1 SHT20 DFN6 — SHT20 Sensirion Humidity and Temperature Sensor IC

82 U15,U16 2 TMD27711 DFNL8 — TMD27711 AMS-TAOS USA

83 U17 1 FPC1080A FPC1080A — FPC1080A Fingerprints Swip e Sensor Package

84 U18 1 MAX44008 OTDFN-6 — MAX44008EDT+ Maxim Inte-

85 U20 1 iCE5LP4KSWG3636WLCSP Customer

86 U21 1 ASFLMB-

87 U22 1 BMP180 BMP180 — BMP180 Bosch SENSOR PRESSURE ABS

88 U23,U29 2 74AVC4T774 16TSSOP — SN74AVC4T774

89 U24 1 LD1117-3V3 sot223_ns — LD1117S33CTR ST Micro IC REG LDO 3.3 V 0.8A SOT223

90 U25 1 LD1117-1V8 SOT223_NS — LD1117AS18 ST Micro IC REG LDO 1.8 V 1A SOT223

91 U26 1 SN74AUP1G08

92 U30 1 SeeedBLE SeeedBLE — 113050012 Seeed Low cost ARM cortex-m0 based mod-

93 Y1 1 12 MHz 5x3p2mm2p — ABM3-

94 iCE40 Ultra MDP BOARD PCB 1 ———305-PD-15-0056 PAC T RO N —

BAG and TAG

Item Reference Qty Par t PCB Footprint Comments PA R T_ NUMBER Manufacturer Description

1 Battery 1 Li-ion Battery Battery unit - BL-5C Nokia From Amazon or other Nokia vendor

2 Plastic Enclosure 1 Plastic enclosure Plastic Enclosure Customer

3 SPI cable assembly 1 SPI cable

4 Fasteners / screws 2 PCB-Plastic fas-

5 2 mm jumper shunts for J15 7 2 mm jumper

6 2 mm jumper shunts with grip

7 2.54 mm jumper shunt for J20 1 2.54 mm jumper

for J15 & J9, J18

3 2 mm jumper

1218FM-7

27.000MHZ-LCT

DBVR

assembly

tening screws

shunts for J16

shunts with grip

for J15 and J10

shunt for J21

AP7312_6DFN — AP7312-

Supplied

osc_5x3p2 — ASFLMB-

SOT23-5 DNP SN74AUP1G08

Supplied

SPI cable assembly

PCB-Plastic fastening screws

2 mm jumper

shunts for J17

2 mm jumper

shunts with grip

for J15 and J11

2.54 mm jumper

shunt for J22

Customer

Supplied

BAG and

BAG and

BAG and

BAG and

RMPBF

1218FM-7

iCE5LP4KSWG36CTR

27.000MHZ-LCT

PWR

DBVR

12.000MHZ-B2T

Enclosure / full

housing set used

for Nokia 1110 **

Custom made or

Samtech part #

TCSD-05-D-

06.00-01-N

SMPPS0003 -

TAG

#0 x 3/16 - Pan

Head Sheet

Metal Screws –

Phillips

SPN02SYBN-RCSullins 2 mm jumper shunts for J15

TAG

NPN02SXLN-RCSullins 2 mm jumper shunts with grip for J15 &

TAG

STC02SYAN Sullins 2.54 mm jumper shunt for J20

TAG

Linear Technology

ductor Ltd

Diodes Inc IC REG LDO 1.2 V/1.8 V 0.15A 6DFN

ductor

Inc

grated

Lattice Semiconductor

ABRACON OSC MEMS 27.000MHZ CMOS SMD

Texas Instruments

Texas Instruments

Abracon Corp CRYSTAL 12MHZ 18PF SMD

Nokia or OEM From ebay or other Nokia accessory

Custom made or

equivalent Samtec Inc

Micro Fasteners SMPPS0003 - #0 x 3/16 - Pan Head

IC OR CTRLR SRC SELECT TSOT235

IC REG LDO 3.3 V 0.7A SOT25

LQFP

tom port and I2S digital port

IC LATCH SENSOR BIPO CMOS

4SSON

IC PROXIMITY DETECTOR DGTL 8MOD

IC AMBIENT/PROXIMITY SENS TDFN

—

IC BUS TRANSCVR 4BIT DL

16TSSOP

IC GATE AND 1CH 2-INP SOT-23-5

ule for Bluetooth module

vendor ** see note in comments

2 mm pitch, dual row, 5x2 FRC / IDC

female terminated, 15 cms ribbon

cable

Sheet Metal Screws – Phillips

J9

8 Jumper / Flywire for DB +5 V 1 Jumper / Flywire

for DB + 5 V

4” Jumper / Flywire for DB +5 V

26

Customer

Supplied

— Custom made or

equivalent

One side bare wire (28 or 26 AWG),

one side female header (single socket,

for 2.54 pitch type header)

Page 27

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Lattice:

ICE5LP4K-MDP-EVN

Loading...

Loading...