LATICRETE Strata Heat User Manual

Construction Solutions

Wire

Globally Proven

Installation Manual

0804 Series

Technical Helpline

+1-203-393-0010 ext 1235

IMPORTANT!

Please read this manual before attempting to install the STRATA_HEAT™ Wire

LIFETIME

Warranty

1

*

Table of Contents

Quick Install Guide �������������������������������������������������������������������������������������4-5

Components Required for Installation ���������������������������������������������������������������6

Do’s & Don’ts �������������������������������������������������������������������������������������������7-8

Step 1 - Electrical Supply ������������������������������������������������������������������������9-11

Step 2 - Subfloor Considerations ������������������������������������������������������������12-13

Step 3 - Lay STRATA_HEAT™ Mat �����������������������������������������������������������14-15

Step 4 - Layout Planning �����������������������������������������������������������������������16-19

Step 5 - Install STRATA_HEAT Wire ���������������������������������������������������������20-21

Step 6 - Tiled Floor Covering�����������������������������������������������������������������������22

Step 7 - Lay the Floor Covering ��������������������������������������������������������������23-24

Step 8 - Connect the Thermostat �����������������������������������������������������������������25

Troubleshooting �������������������������������������������������������������������������������������26-27

Performance Troubleshooting �������������������������������������������������������������������28-29

How to Test the STRATA_HEAT Wire and Floor Sensors �������������������������������������30

Layout Plan ������������������������������������������������������������������������������������������������31

Control Card �����������������������������������������������������������������������������������������������32

Warranty ���������������������������������������������������������������������������������������������������33

Technical Specifications ���������������������������������������������������������������������������34-35

Subfloor Considerations -Spacing Strips ���������������������������������������������������� 36-37

Alternate Installation - Installing Using Spacing Strips ��������������������������������� 38-39

2

WARNING

Your STRATA_HEAT™ Radiant Floor Heating system has been designed so that

installation is quick and straight forward, but as with all electrical systems, certain

procedures must be strictly followed� Please ensure that you have the correct

STRATA_HEAT Wire for the area you wish to heat�

LATICRETE, accepts no liability, expressed or implied, for any loss or consequential damage

suffered as a result of installations which in any way contravene the instructions that follow�

It is important that before, during and after installation that all requirements are met and

understood� If the instructions are followed, you should have no problems� If you require

help at any stage, please contact LATICRETE Technical Services�

You may also find a copy of this manual, STRATA_HEAT Wire Installation Manual,

and other helpful information on our website:

www.laticrete.com

3

Quick Install Guide - The full installation instructions in this manual must be followed�

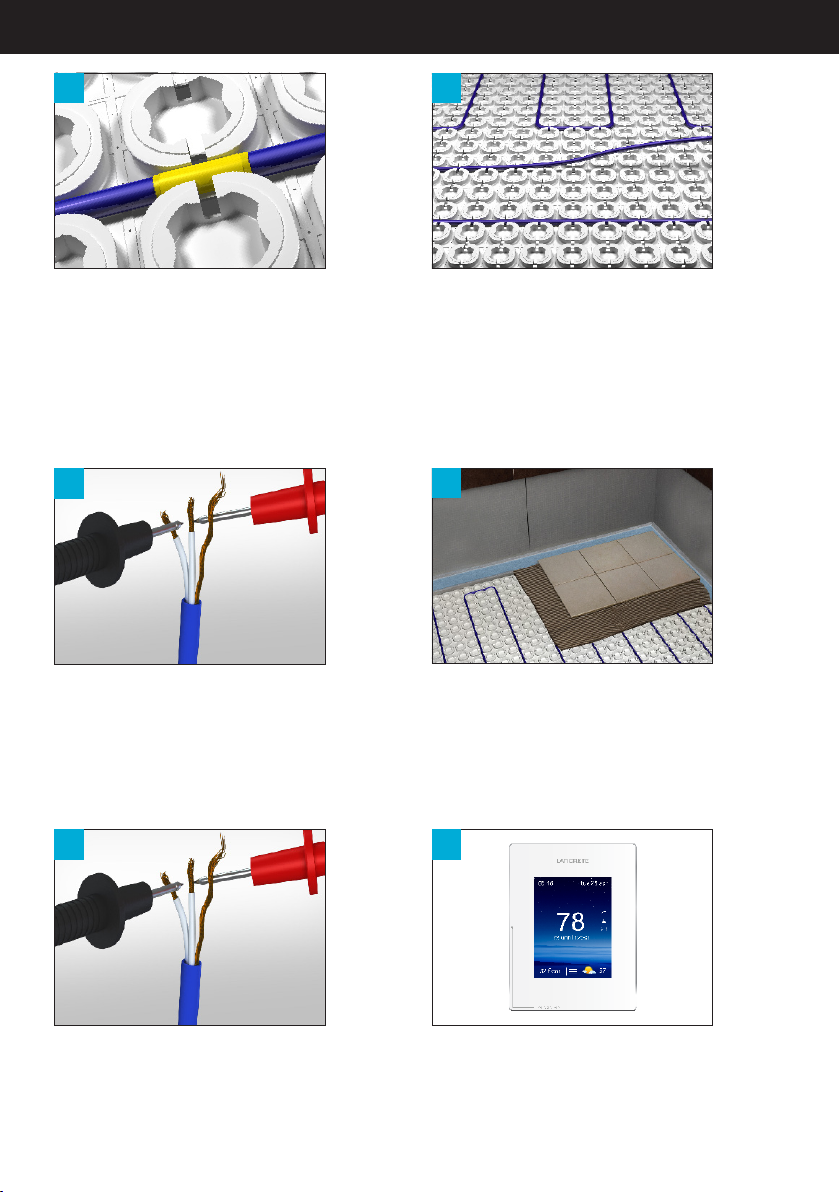

1

Make electrical provisions for the STRATA_HEAT™ Wire�

A deep, 4" x 4" x 2 ¾" (100 x 100 x 70 mm) UL/cUL

certified double-gang box with a mud plate should be

provided by the electrician for the thermostat connections�

The power leads must be protected where they leave the

floor by a suitable approved conduit where required

by electrical code�

3

2

Ensure the subfloor is smooth, dry and free from dust�

4

We recommend installing 1/4" (6 mm)

HYDRO BAN® Board for optimum performance�

5 6

Cut the STRATA_HEAT Mat to size and press into the adhesive

bed using a float or roller, removing any air pockets�

Lay additional sheets as above ensuring that the

pegs are aligned�

4

Where required, install perimeter strip around the

perimeter of the room�

Apply a thin-set layer to the substrate using a 1/4" x 1/4"

(6 x 6 mm) square notch trowel�

Test the resistance of the STRATA_HEAT Wire ensuring it is

within the range set out in the Reference Resistance Band

table on Page 34�

7

8

STRATA_HEAT Wire is manufactured so that there is a

spliceless connection where the heating cable meets the

coldtail� This connection is marked with tape and

MUST be installed within the STRATA_HEAT

Mat and covered with adhesive and not exposed� Ensure this connection is installed straight in the

STRATA_HEAT Mat and not bent around a peg�

9

Test the resistance of the STRATA_HEAT Wire after

installation and check against the previous value to

ensure no damage has occurred�

Install the STRATA_HEAT™ Wire at the chosen spacing�

Maintain a minimum 3 peg (2 3/8" / 60 mm) spacing

for UL Compliance� Install the floor sensor centrally

between two runs of the heater wires� For the termination joint, channel a groove in the STRATA_HEAT Mat,

enabling the joint to fit flush with the top of the mat�

DO NOT tape over the termination joint�

10

Lay the tiles over the STRATA_HEAT Mat and Wire� The

STRATA_HEAT Wire, including spliceless connection and

termination joint, must be completely encased by the tile

adhesive and not exposed� Use PERMACOLOR or

SPECTRALOCK grout when grouting

11 12

Test the resistance of the heating cable after tiling

and check against previous values to ensure no

damage has occurred�

Connect your STRATA_HEAT Thermostat�

5

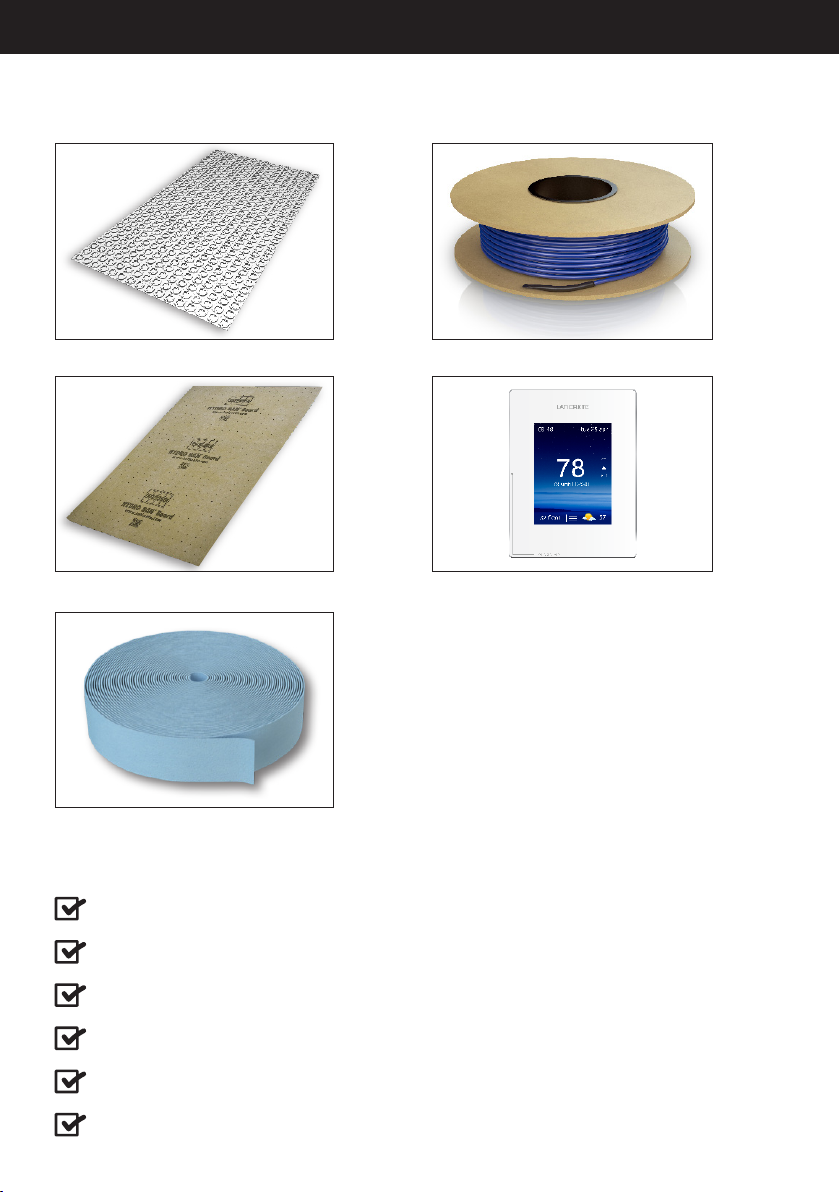

Components Required for Installation

Components available from LATICRETE

STRATA_HEAT™ Mat

SKU: 9450-0014-2

1/4" (6 mm) HYDRO BAN® Board for insulation

Perimeter Strip (Optional)

STRATA_HEAT Wire

STRATA_HEAT Thermostat and Floor Sensor

Additional components needed as part of your heating installation:

Digital Multi-meter required for testing the resistance of the heater and floor sensor�

Electrical tape to secure the floor sensor�

UL/cUL certified electrical housing, back boxes and junction boxes�

UL/cUL certified electrical trunking/conduit for housing the power leads�

UL/cUL certified electrical conduit for housing the power leads�

LATICRETE® Tile Adhesive and Grout�

6

Do’s & Don’ts

DO’S

DO Ensure that tile adhesive used is compatible with

underfloor heating and suitable for application

with non porous materials such as the

STRATA_HEAT™ Mat.

DO Maintain a spacing that produces no more than

16 W/ft2 (162 W/m2) of heat input into

the floor.

DO Make sure all electrical work is done by qualified

persons in accordance with local building and

electrical codes, the National Electrical Code

(NEC), especially article 424, Part V of the NEC,

ANSI/NFPA 70, for the US and Canadian Electrical

Code, Part 1, for Canada.

DO Check the resistance of the STRATA_HEAT Wire

before, during, and after installation to ensure

that no damage has occurred. A tolerance of

+/- 5% is allowed.

DO Make sure the STRATA_HEAT Wire is connected

to a UL/cUL certified GFCI controller or breaker

where required by code.

DO Plan the heating system layout and installation so

that any drilling after tiling (e.g. for fixtures such

as vanity units, tubs) will not damage the wiring.

Remember to keep a copy for future reference.

DO Ensure that the STRATA_HEAT Wire is separated

at least 8" (20.3 cm) from other heat sources

such as baseboard heating, heating vents,

lights and chimneys.

DO Ensure that the minimum free bending radius of

the STRATA_HEAT Wire is no less than 1" (25 mm).

DO Ensure that each tile is solidly bedded in tile

adhesive, with no gaps or voids beneath.

DO Make sure that the STRATA_HEAT Wire, including

spliceless connection and termination joint

are positioned under the final floor finish and

completely embedded in thin-set/adhesive.

DO Install the floor probe for the STRATA_HEAT

Thermostat. It should be installed centrally

between two STRATA_HEAT Wire runs. Ensure

that the sensor does not touch or cross over the

STRATA_HEAT Wire.

DO Ensure that you have electrical provisions to run

the STRATA_HEAT Wiring at 120VAC /or 240VAC

depending on the system being installed.

DO Check the wattage and voltage of the

STRATA_HEAT Wire to ensure you have the

correct system for your application.

DO Ensure any parallel runs of cold tail and sensor

wire are kept separated within the wall, using

UL/cUL certified conduit where required.

DO Make sure that the system is fully grounded

following the wiring instructions provided.

DO Use a separate STRATA_HEAT Wire for the

shower area.

DO Indicate which circuits supply power to the

STRATA_HEAT Wire on the circuit breaker. Attach

the product labels for each STRATA_HEAT Wire to

the circuit breaker, for future reference.

DO Ensure the subfloor is fully cured and stable

before commencing installation of the

STRATA_HEAT Wire.

7

Do’s & Don’ts

DONT’S

DON’T Install parallel runs of STRATA_HEAT

closer than 3" (76.2 mm) at any time if

using wire spacing strips or 2 3/8" (61 mm)

if using STRATA_HEAT Mat. Refer to the

Layout Planning page for further guidance.

™

Wire

DON’T Cross the STRATA_HEAT Wire over another

run, over coldtails or the floor sensor. This

will cause overheating and will damage the

STRATA_HEAT Wire.

DON’T Cut or shorten the STRATA_HEAT Wire at

any time.

DON’T Install the STRATA_HEAT Wire with staples or

other metal fixings that can cause damage.

DON’T Store tiles, sharp or heavy objects on top of

the STRATA_HEAT Wire

DON’T Install STRATA_HEAT Wire below

5°F (-15°C).

DON’T Attempt to bypass the GFCI if it trips and

cannot be reset during normal operation.

Consult a qualified electrician or call the

technical helpline for further assistance.

DON’T Install the STRATA_HEAT Wire under

permanent fixtures or in closets.

DON’T Cover the spliceless connection or

termination joint with tape. This may

cause air pockets resulting in the

joints overheating.

DON’T Install the STRATA_HEAT Wire beyond the

room or area in which they originate.

DON’T Attempt to repair the STRATA_HEAT Wire

if it is damaged. Call the technical helpline

for further instructions.

DON’T Allow the Thermostat to exceed the

maximum temperature for your final

floor finish. Always check the maximum

temperatures allowed with the floor

covering manufacturer.

DON’T Switch on the installed STRATA_HEAT Wire

until tile adhesive has fully cured, check

adhesive manufacturer’s instructions.

3 days at 70°F (21°C).

DON’T Install the cold leads closer than 2" (50 mm)

from the STRATA_HEAT Wire. Damage to

supply conductor insulation may occur.

DON’T Install the STRATA_HEAT Wire closer than

2" (50 mm) from the wall, partitions, and

any permanently fixed objects.

DON’T Commence installation on a screed that has

not been fully cured.

WARNING: “RISK OF ELECTRIC SHOCK AND FIRE”�

DAMAGE TO SUPPLY CONDUCTOR INSULATION MAY OCCUR IF CONDUCTORS ARE ROUTED LESS

THAN 2" (50 MM) FROM THIS HEATING PRODUCT� CAUTION: A UL/cUL CERTIFIED GROUND

FAULT PROTECTION DEVICE MUST BE USED WITH THE STRATA_HEAT™ WIRE�

ATTENTION : This product must be protected by grounding�

8

Step 1 - Electrical Supply

Thermostat

Spliceless Connection installed in mat,

Termination Joint recessed into the mat

and subfloor� Coldtail connected

to the thermostat

Floor Sensor 12" (300 mm) into

heated area� Floor sensor connected

to thermostat�

The installation of electrical systems presents risks of fire and electrical shock which can result in personal injury� All electrical

connections should be carried out by a qualified electrician in accordance with the National Electrical Code and all local Codes�

For installations in Canada, refer to relevant sections in the CEC�

The STRATA_HEAT™ Wire MUST be connected to the electrical system through a UL/cUL certified Ground Fault Circuit Interrupter

(“GFCI”)� If you are not using a thermostat, such as a STRATA_HEAT Thermostat with an integral GFCI, ensure that the branch

circuit supplying your STRATA_HEAT Wire is GFCI protected� If possible, use a dedicated GFCI protected circuit to supply each

heated zone� This requirement is critical to the safe operation of the STRATA_HEAT Wire�

For smaller areas, you may be able to utilize an existing circuit� In most cases, however, you will need a separate dedicated

circuit to power the STRATA_HEAT Wire�

NOTE: The power leads must be protected where they leave the floor by a suitable UL/cUL certified conduit

NOTE: A UL/cUL certified junction box is required if more than two STRATA_HEAT Wires are being installed�

NOTE: When conducting an insulation resistance test on the supply to the STRATA_HEAT Thermostat, the thermostat and

STRATA_HEAT Wire must be isolated or disconnected�

9

Step 1 - Electrical Supply

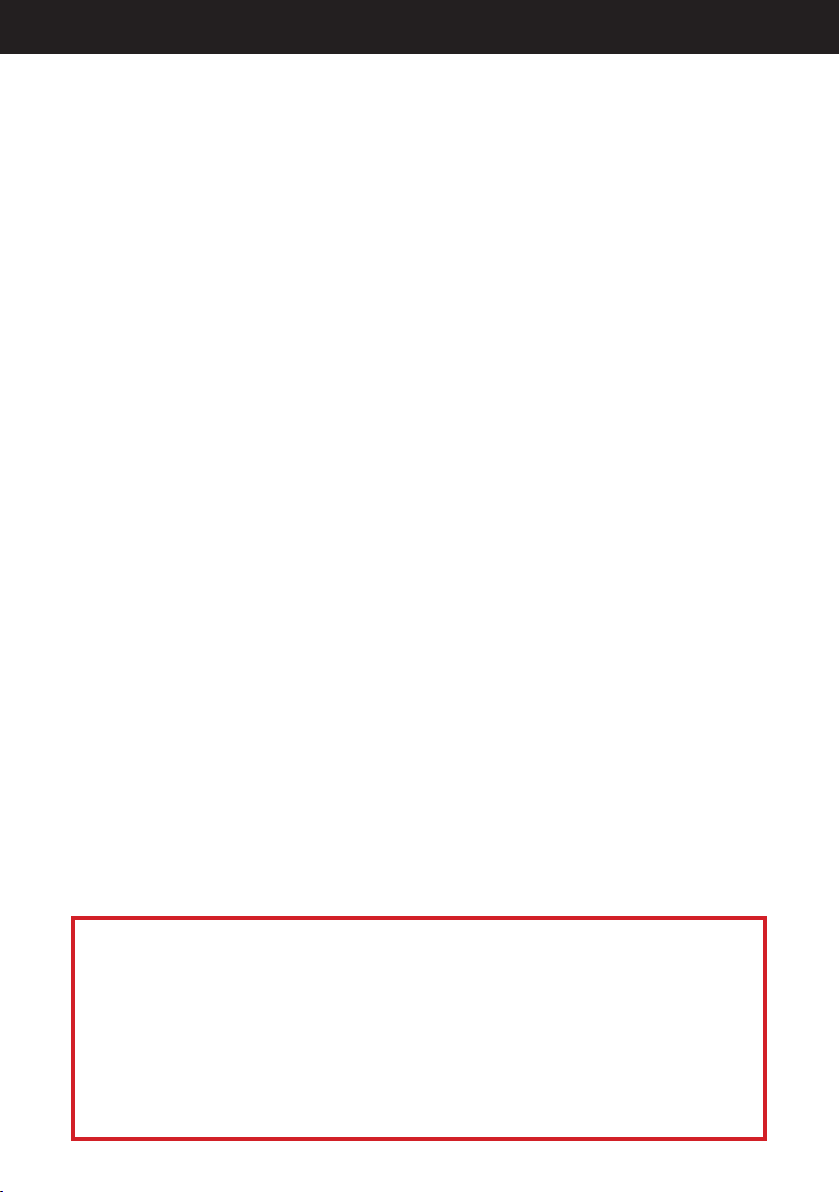

Typical Wiring Diagram 120V

Typical Wiring for STRATA_HEAT™ Thermostat

Dedicated 120V Circuit CSA/CEC or NEC

Ground (green/bare)

Breaker

Box

Live (hot)

Neutral

Control

(black)

Control

(red)

Top two

terminals

not used

Control

1

(back)

2

Load

(black)

Load

(red)

Sensor Wire

(No Polarity)

Heater(s)

(ground braid)

Heater(s)

(black)

Heater(s)

(yellow)

NOTE: All electrical work performed by a qualified electrician in accordance with local building and electrical codes and the Canadian Electrical Code,

part 1 in Canada or the National Electrical Code in the USA, especially Article 424 of NEC, ANSI/NFPA70 and Section 62 of CEC.

™

Thermostat and Relay

Load

(black)

Relay

110 120V

(Relay

provided by

installer)

Heater(s)

(ground braid)

Heater(s)

(black)

Heater(s)

(yellow)

Dedicated 120V Circuit CSA/CEC or NEC

Ground

Live (hot)

Breaker

Box

Neutral

Typical Wiring for STRATA_HEAT

Control

(black)

Control

(red)

Undertile

Heater(s)

Sensor

Undertile

Heater(s)

Load

Control

1

(back)

2

(red)

Sensor Wire

(No Polarity)

Sensor

NOTE: All electrical work performed by a qualified electrician in accordance with local building and electrical codes and the Canadian Electrical Code,

part 1 in Canada or the National Electrical Code in the USA, especially Article 424 of NEC, ANSI/NFPA70 and Section 62 of CEC.

10

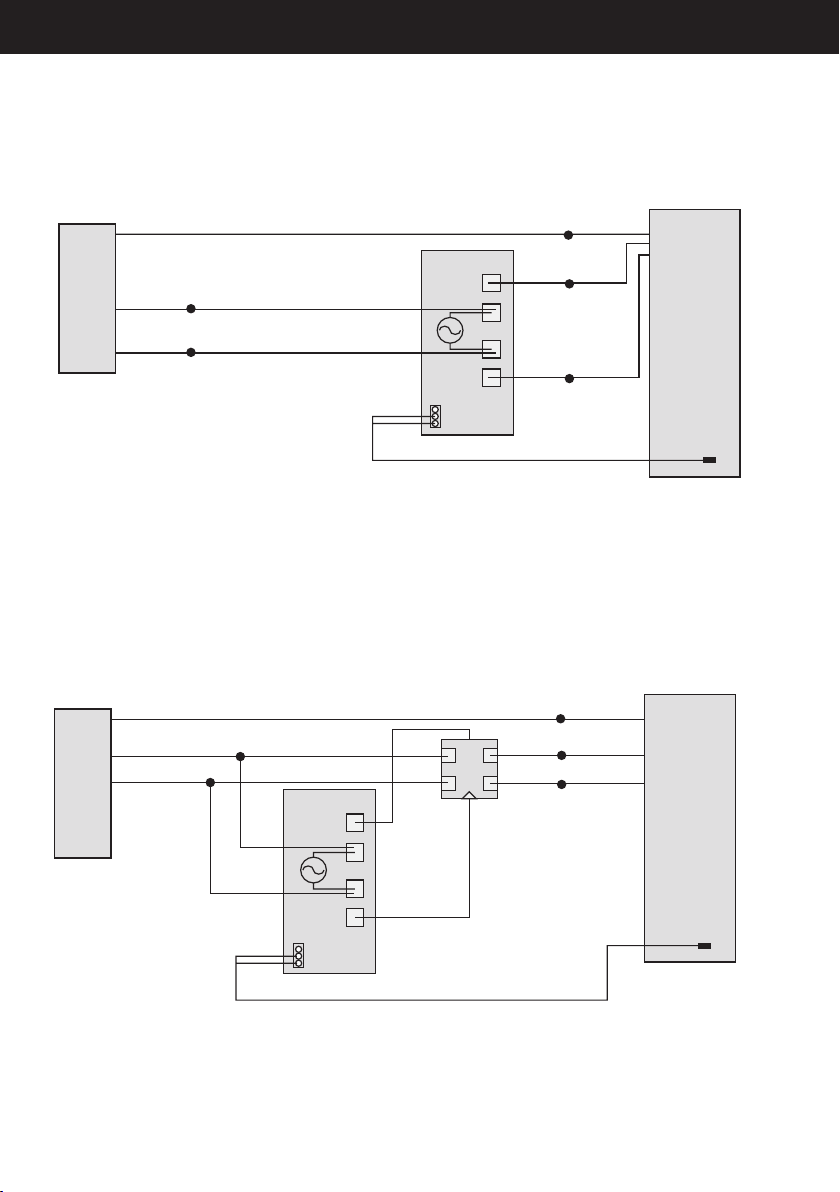

Step 1 - Electrical Supply

Typical Wiring Diagram 240V

Typical Wiring for STRATA_HEAT™ Thermostat

Dedicated 240V Circuit CSA/CEC or NEC

Ground (green/bare)

Breaker

Box

Live (hot)

Live (hot)

Control

(black)

Control

(red)

Top two

terminals

not used

Control

1

(back)

2

Load

(black)

Load

(red)

Sensor Wire

(No Polarity)

Heater(s)

(ground braid)

Heater(s)

(black)

Heater(s)

(red)

NOTE: All electrical work performed by a qualified electrician in accordance with local building and electrical codes and the Canadian Electrical Code,

part 1 in Canada or the National Electrical Code in the USA, especially Article 424, Part V of the NEC ANSI/NFPA 70. Undertile heaters are to be

installed in parallel across the load terminals of the thermostat or contactor and must not exceed their rated load.

™

Thermostat and Relay

Contactor

Load

(black)

Heater(s)

(ground braid)

Heater(s)

240V

(Contactor

provided by

installer)

(black)

Heater(s)

(red)

Dedicated 240V Circuit CSA/CEC or NEC

Ground (green/bare)

Live (hot)

Breaker

Box

Live (hot)

Typical Wiring for STRATA_HEAT

Control

(black)

Control

(red)

Undertile

Heater(s)

Sensor

Undertile

Heater(s)

Top two

terminals

not used

Control

1

(back)

2

Load

(red)

Sensor

Sensor Wire

(No Polarity)

NOTE: All electrical work performed by a qualified electrician in accordance with local building and electrical codes and the Canadian Electrical Code,

part 1 in Canada or the National Electrical Code in the USA, especially Article 424, Part V of the NEC ANSI/NFPA 70. Undertile heaters are to be

installed in parallel across the load terminals of the thermostat or contactor and must not exceed their rated load.

NOTE: When installing the STRATA_HEAT™ Wire in kitchens or bathrooms it must be protected by a STRATA_HEAT Thermostat which contains a UL/cUL certified GFCI�

If the STRATA_HEAT Wire is switched by a separate contactor its supply must be GFCI protected� To prevent nuisance tripping a STRATA_HEAT Thermostat with integral GFCI

protection should not be supplied by a GFCI protected circuit�

11

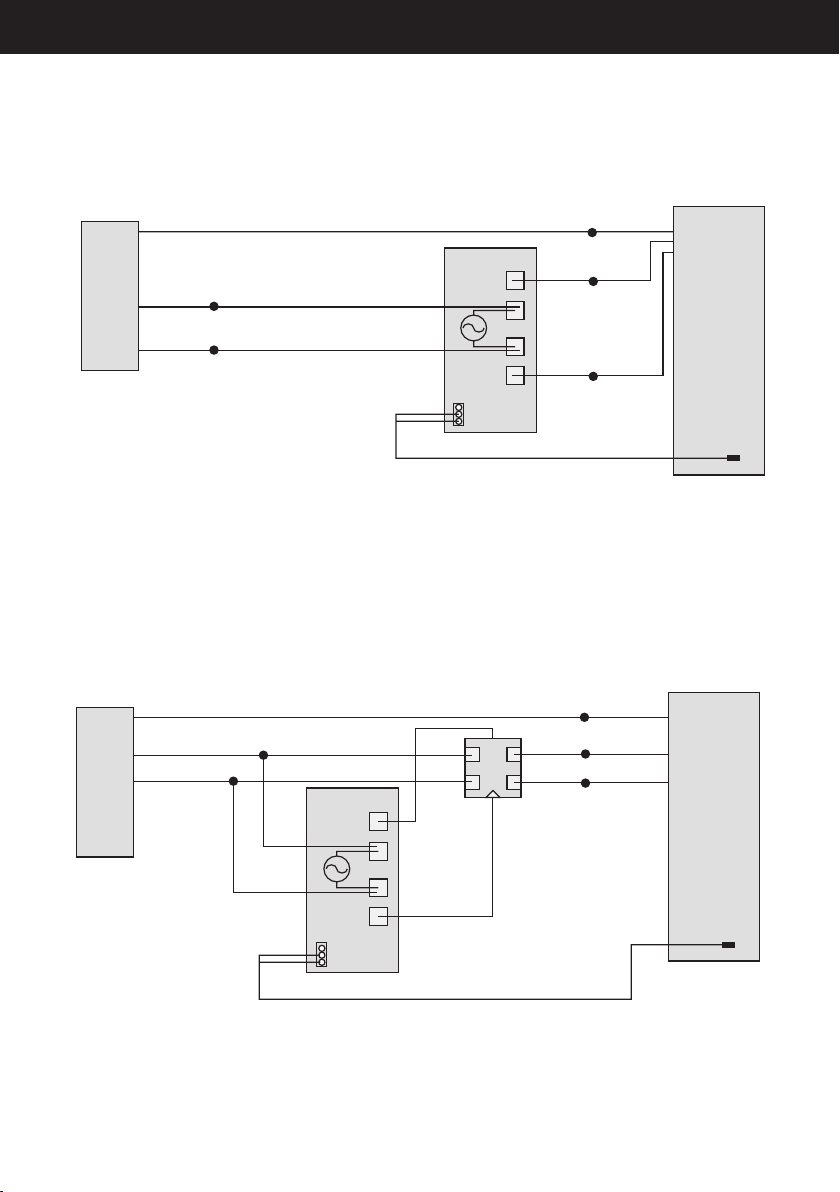

Step 2 - Subfloor Considerations

Subfloor Preparation

Subfloors previously covered in vinyl, cork or carpeting: all old flooring and glues must be removed�

Any materials on or within the subfloor must be suitable for supporting eUFH systems� If using temperature sensitive materials

beneath the eUFH system, such as damp proofing or tanking systems, contact the manufacturer for advice�

Concrete Subfloors

1

2

5

3

4

7

6

8

1

2

5

3

4

6

CONCRETE SUBFLOOR

(Recommended)

1 Floor Finish

2 ¼" (6 mm) Minimum thin-set

3 STRATA_HEAT™ Wire

4 STRATA_HEAT Mat

5 Thin-set layer applied with ¼" x ¼"

(6 mm x 6 mm) square notch trowel

6 HYDRO BAN® Board

7 Thin-set layer applied with ¼" x ¼"

(6 mm x 6 mm) square notch trowel

8 Subfloor

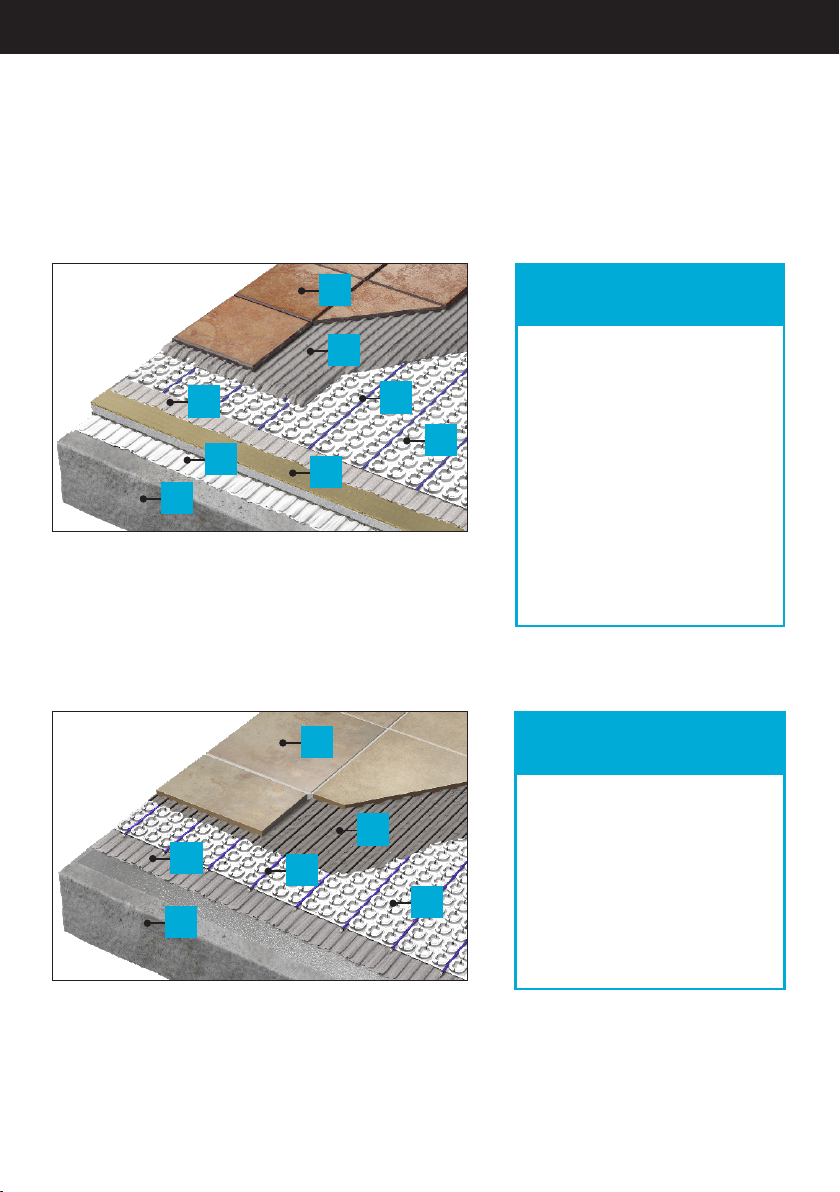

CONCRETE SUBFLOOR

1 Floor Finish

2 ¼" (6 mm) Minimum thin-set

3 STRATA_HEAT Wire

4 STRATA_HEAT Mat

5 Thin-set layer applied with ¼" x ¼"

(6 mm x 6 mm) square notch trowel

6 Subfloor

It is recommended that you use HYDRO BAN Boards beneath the STRATA_HEAT™ system for optimum performance� The

insulation will improve the systems response to heating demand, saving energy and reducing running costs�

Where expansion joints are present in the subfloor, these must be preserved up through all covering layers, including insulation

(where installed) and STRATA_HEAT system�

12

Loading...

Loading...