Page 1

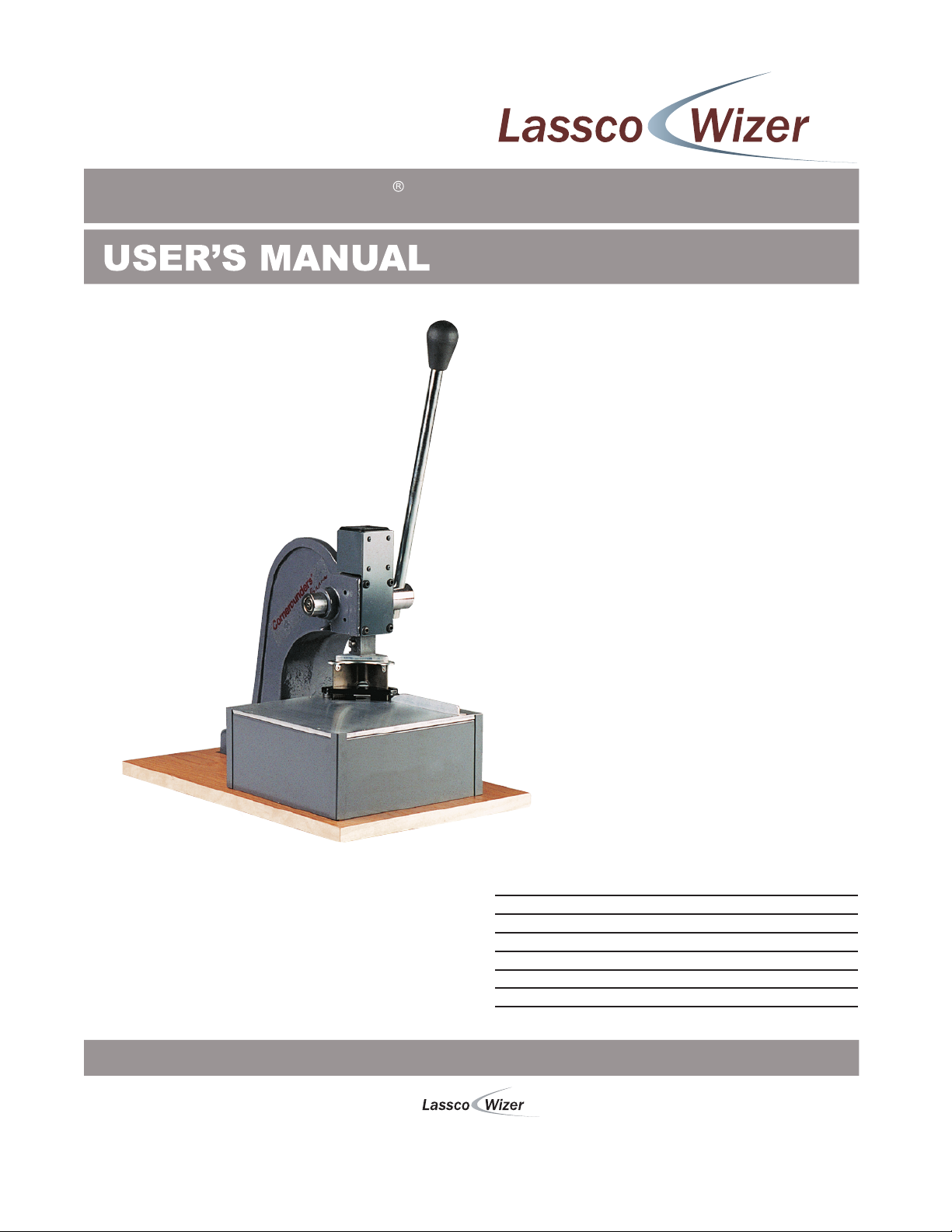

CR-60 Cornerounder

ProSource Packaging, Inc.

14911 Stuebner Airline

Houston, TX 77069

800-203-0233

www.Machine-Solution.com

Suite A

Before operating this equipment, please read these

instructions completely and keep these operating

instructions for future reference.

485 Hague Street, Rochester, NY 14606 U.S.A.

Tel: 585-436-1934 Fax: 585-464-8665

www.lasscowizer.com info@lasscowizer.com

Serial Number:

Date of Purchase:

Dealer:

Address:

Telephone Number:

Page 2

Introduction

Introduction

Thank you for your purchase of the CR-60 Cornerounder .

We ask that you take a moment to fill in the serial number and other information

on the front cover of this manual. Please keep this manual as a reference for

future use.

Note:

Only the Table Assemblies are serialized. Please keep records of all the Table

Assemblies you may have purchased. The CR-60 arbor press does not contain a

serial number itself.

For parts and service please contact the Lassco-Wizer Dealer from whom you

purchased the machine. If you require assistance in locating a Lassco-Wizer

Dealer please contact our customer service department at 585-436-1934. Please

have the model of your machine and the serial number when you call.

If you wish to write to us please contact us at:

Shipping Damage Inspection

Remove the machine from the carton and inspect for any shipping damage. If any

damage is present, report the damage to the carrier immediately. Failure to do so

may void any warranties.

Lassco-Wizer

485 Hague Street

Rochester, NY 14606

Page 01

Page 3

Introduction

Safety Instructions

All operators must read and understand the Users Manual and all other safety instructions before using this equipment. Failure to fully understand the safety instructions can

result in personal injury. If after reading the manual you are still uncertain about use,

please contact the dealer from whom you purchased the machine for assistance. If you

need contact information for a Service Technician nearest you please call 585-436-1934.

Safety of this equipment is the responsibility of the users.

This machine is designed for one person operation. Never operate the machine with

more than one person.

Do not place fingers under the Knives on the Table Assembly. Do not remove the safety

guard on the Table Assembly.

Capacity

Commercial Grade Mild Steel......................................................0.035inch thick (0.89mm)

Soft Aluminum..............................................................................0.080inch thick (2.03mm)

Note:

Note:

Exceeding the recommended capacity for this unit voids all warranties.

Use of the Table Assembly without the use of the CR-60 arbor press voids all warranties.

Loose Item Inventory

Remove and inspect the following items:

Press Handle

5/64” Hex Key M3 Hex Key M4 Hex Key

Items not to scale

Page 02

Page 4

Setting Up Your Machine

Attaching the Press Handle

Insert the Press Handle into the hub of the press and tighten the setscrew onto the Press

Handle with a M4 Hex Key until the Press Handle is secure.

Press Handle

Hub

M4 Hex Key

Page 03

Page 5

Operating Instructions

Rounding The Corners

To put a Radius on the corner of your product:

1.

With the Press Handle in the up position as shown, slide the product to be cut along the guide until

it comes to rest against the inside edge of the Outer Knife.

2.

Hold the product in place firmly with one hand.

Note:

Note:

Make sure to keep fingers away from the Knives.

3.

Pull down on the handle so that the Outer Knife cuts through the product.

A quick snapping motion near the end of the cut will improve the quality of the cut.

4.

Raise the Press Handle to the up position and slide the product out from under the Outer Knife.

Press Handle

Outer Knife

Note:

Note:

Radius Disk Knife

Inspect the quality of the cut. The radius on the product should come to an almost perfect blend

against the straight edges. The edges of the cut may have a small burr. This burr should not be

excessive. If this burr is excessive, the Outer Knife may need adjusting, sharpening, or

replacement. (See Page 06)

Applying a small amount of light machine oil to your product before cutting and occasionally

applying some light machine oil to the blade on the Table Assembly will prolong the life of the

blade.

Page 04

Page 6

Operating Instructions

Changing The Table Assembly

To remove the Table Assembly...

1.

Rotate the Press Handle to its full upright position so that the Chrome Knob is disengaged from

the Rack Support Plate.

2.

Using a 5/8” Wrench (not provided) loosen, but do not remove the 7/16”-20 x 1” Hex Head Table

Mount Bolt.

3.

Remove the Table Assembly from the Wooden Base.

4.

Attach the new Table Assembly making sure the notch on the Bottom Plate fits into

the 7/16”-20 x 1” Hex Head Table Mount Bolt. Make sure the 7/16” Flat Washer

is on the topside of the Bottom Plate.

5.

Tighten down the 7/16”-20 x 1” Hex Head Table Mount Bolt and pull down

on the Press Handle to engage the Rack Support Plate. Make sure

the Rack Support Plate is coming straight down onto the

Chrome Knob. Adjust the Table Assembly as needed

to obtain proper alignment with the Rack Support

Plate.

Press

Handle

Note:

Rack Support Plate

Chrome Knob

Table Assembly

When your machine is shipped, two Shipping Tabs are

placed under the Table Assembly to help prevent

movement and shipping damage. These tabs have no

further function and can be removed if necessary.

Bottom Plate

7/16” Flat Washer

7/16”-20 x 1” Hex Head

Table Mount Bolt

Shipping Tabs

Page 05

Page 7

Maintenance

Adjusting the Outer Knife

Note:

Note:

It is important to keep the Outer Knife in proper alignment or it

can be pressed down at an incorrect angle causing unnecessary stress on the knife. This can cause the Outer Knife to dull

quicker and/or break.

Remove the Table Assembly from the CR-60 Arbor Press

before adjusting the Outer Knife (See Page 05).

The Outer Knife should be perpendicular (90 ) to the surface

of the Table Assembly. Loosen the Cam Adjustment Screws

on the Cams using the 5/64” Hex Key provided. Rotate the

Cams as needed so that they hold the Outer Knife in proper

alignment.

If the Cam is rotated too tight, the Outer Knife will stick in

the down position when you attempt to operate.

Cam Adjustment Screw

Replacing The Outer Knife

Due to the fact that the Outer Knife is an expendable item, it

will be necessary to replace it over time. Replace the Outer

Knife if...

Table Assembly Top View

5/64” Hex Key

Cam

Outer Knife

Chrome Knob

Outer Knife

1.

Note:

2.

1.

2.

3.

4.

5.

You have adjusted the Outer Knife alignment and it is still

leaving an excessive burr.

Sharpening service is available through Lassco-Wizer.

Please contact us for further information.

Your Outer Knife has cracked or broken

To replace the Outer Knife...

Remove the Table Assembly from the CR-60 Arbor

Press (See Page 05).

Loosen the Cam Adjustment Screws and rotate the

Cams so that they are not aserting pressure on the

Outer Knife.

While pulling up on the Chrome Knob, press in the

Knife Support Plate which should release the Outer

Knife from the Casting.

Replace the new Outer Knife by by inserting it into

the Casting.

Press down on the Knife Support Plate until the

Outer Knife snaps into position.

Chrome Knob

Outer Knife

6.

Adjust the Cams so that the Outer Knife is

perpendicular to the surface of the Table Assembly.

Knife Support Plate

Page 06

Page 8

Trouble Shooting Guide

Problem Cause Correction

Excessive burrs appear on

the edge of the product

being cut.

The Outer Knife does not

return to the upright position

during operation.

Debris is wedged between the

Outer Knife and the Disk Knife

Outer Knife is out of adjusment. Adjust per the Maintenance

Outer Knife is dull. Sharpen or replace the Outer

Debris is wedged between the

Outer Knife and the Disk Knife

The Cams are adjusted too tight

against the Outer Knife.

The Knife Return Springs are

worn out.

Remove obstruction.

portion of this manual.

Knife. (See Maintenance)

Remove obstruction.

Loosen the Cam Adjustment

Screws and rotate the Cams until

they are properly adjusted.

(See Maintenance)

Replace the Knife Return

Springs. (Always replace both

even though one may not be

worn completely)

Page 07

Page 9

Parts Diagrams

CR-60 Arbor Press

Rack Shroud (60-04A)

Rack Shroud

Top (60-05)

Press

Handle

(60-08)

Wooden Base (60-02)

Rack (60-06)

Rack Support Plate (60-07)

Arbor Press (60-01)

7/16” Flat Washer

7/16”-20 x 1” Hex Head

Table Mount Bolt

Page 08

Page 10

Parts Diagrams

Table Assembly

Front View

Top View

Table

Disk Knife

*Please note your Table Assembly may look slightly different depending on the size.

Chrome Knob

Outer Knife

Cam

Safety Guard

Side Guide

Welded Wraparound

Table

Side Guide

6/32 x 1/4 Button Head Screw

Rear View

Cam Adjustment Screw

Chrome Knob

Side Guide

Outer Knife

Cam

Outer Knife

10/32 x 1/2 Flat Head Screw

Disk Knife

Bottom Mounting Plate

Table

Cam

Welded Wraparound

Knife Return Spring

Flat Pressure Spring

Knife Support

Casting

Bottom Mounting Plate

Page 09

Loading...

Loading...