Spinnit FMM 2 Manual Paper Drill

R

-

USER’S MANUAL

Before operating this equipment, please read these

instructions completely and keep these operating

instructions for future reference.

485 Hague Street, Rochester, NY 14606 U.S.A.

Tel: 585-436-1934 Fax: 585-464-8665

www.lasscowizer.com info@lasscowizer.com

Serial Number:

Date of Purchase:

Dealer:

Address:

Telephone Number:

Table Of Contents

1 - Introduction

1 - Introduction

1.1

Your New FMM-2 Paper Drill................

1.2

Shipping Damage Inspection...............

2 - Safety

2.1

Safety Instructions................................

2.2

Warning Labels.....................................

2.3

Grounding Instructions.........................

3 - Setting Up Your Machine

3.1

Loose Items Inventory..........................

3.2

Accessories Warning............................

3.3

Uncrating and Removing From the

Pallet....................................................

3.4

Installing the Leveling Feet..................

3.5

Attaching the Paper Side Stops...........

3.6

Attaching the Chip Bag........................

3.7

Electrical Instructions...........................

4 - Operation

4.1

Protective Guard..................................

4.2

Drill Bit Removal and Installation.........

4.3

Leveling the Drill Bits............................

4.4

Adjusting the Table Height...................

4.5

Adjusting the Back-Gauge Assembly...

4.6

Adjusting the Distance Between

Holes....................................................

4.7

Adjusting the Stop Collars....................

4.8

Multi-hole Set-up..................................

4.9

Traversing the Table.............................

4.10

Drilling Procedures...............................

4.11

Tips on Drilling......................................

Page 01

Page 01

Page 02

Page 03

Page 04

Page 05

Page 05

Page 06

Page 06

Page 07

Page 07

Page 07

Page 08

Page 08

Page 09

Page 10

Page 10

Page 11

Page 11

Page 12

Page 12

Page 13

Page 13

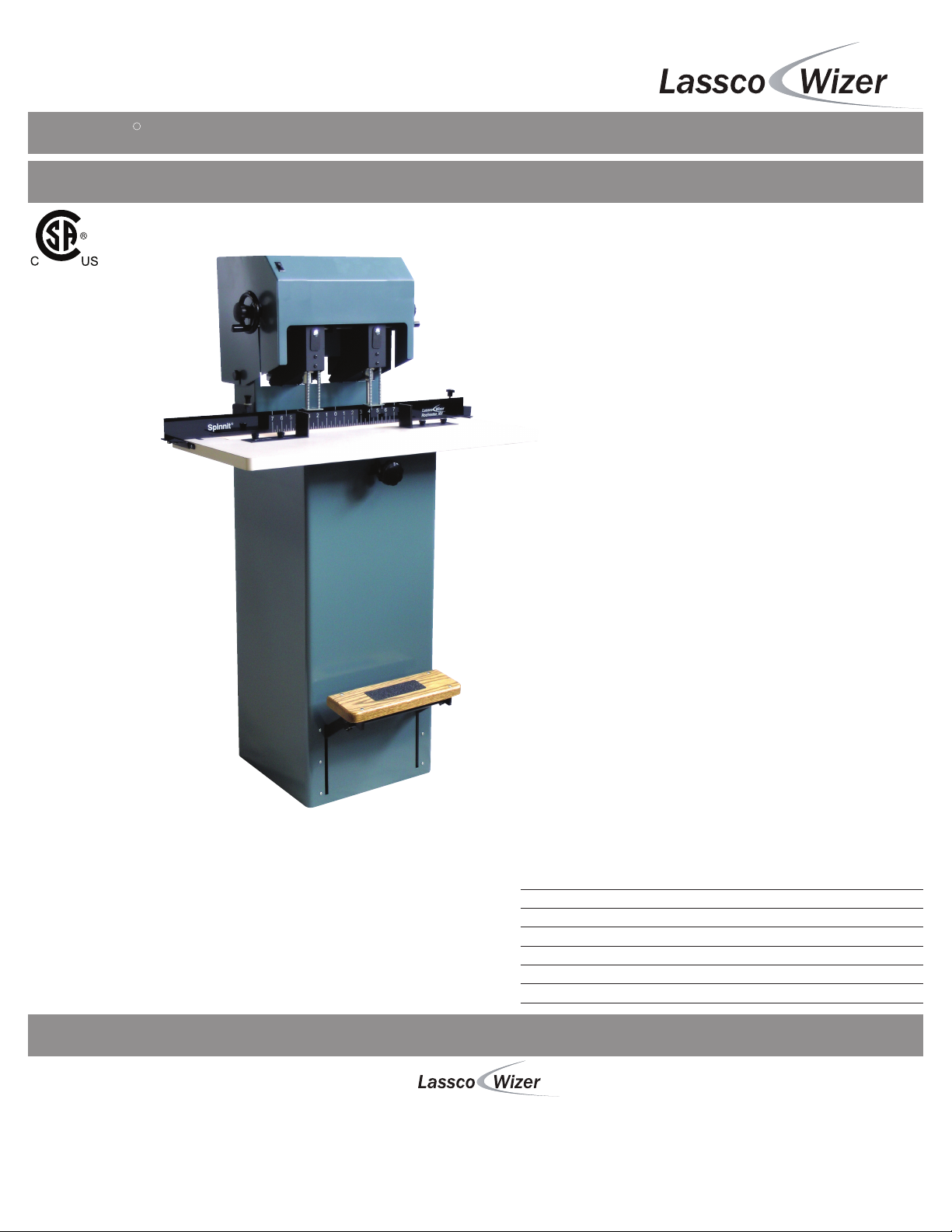

1.1 - Your New FMM-2 Paper Drill

Thank you for your purchase of the Spinnit FMM-2

Paper Drill.

We ask that you take a moment to fill in the serial

number and other information on the front cover of the

manual. Please keep this manual as a reference for

future use.

For parts and service, please contact the Lassco-Wizer

Dealer from whom you purchased the machine. If you

require assistance in locating a Lassco-Wizer Dealer

please contact our customer service department at 585436-1934. Please have the model of your machine and

the serial number when you call.

If you wish to write to us, send correspondence to:

Lassco-Wizer

Attn: Customer Service

485 Hague Street

Rochester, NY 14606

R

1.2 - Shipping Damage Inspection

Remove the machine from the carton and inspect for

any shipping damage. If any damage is present, report

the damage to the carrier immediately; failure to do so

may void any warranties.

5 - Maintenance

5.1

Safety....................................................

5.2

Annual Lubrication................................

5.3

Inspecting the Flex Drive......................

6 - Trouble Shooting Guide

6.1

Determining the Cause and Correction

to Certain Problems..............................

7 - Parts Diagrams

7.1

Side View.............................................

7.2

Head Assembly.....................................

7.3

Spindle and Chuck Assembly...............

7.4

Rear View.............................................

7.5

Parts List..............................................

Page 14

Page 14

Page 16

Page 17

Page 20

Page 21

Page 22

Page 23

Page 24

Page 01

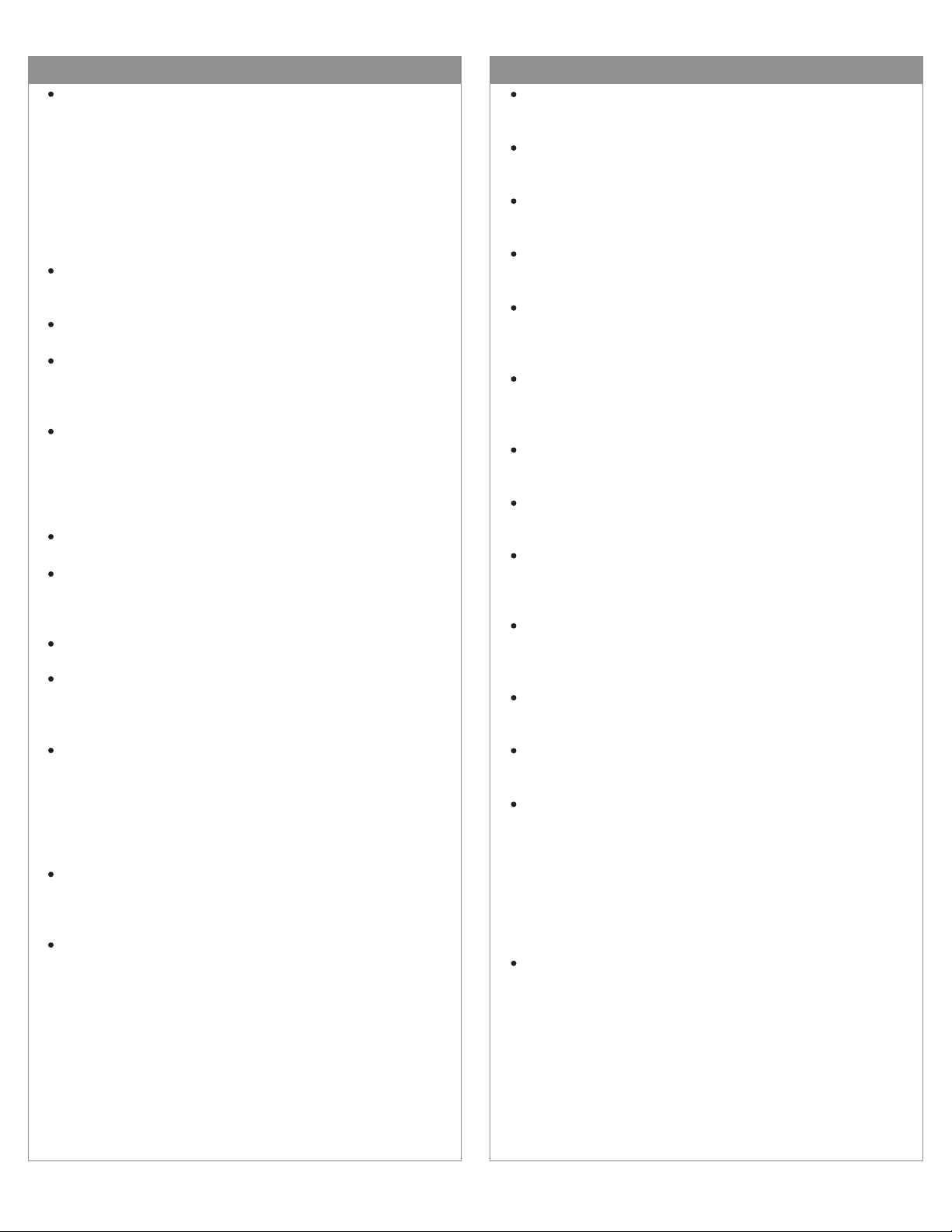

2 - Safety

2.1 - Safety Instructions

All operators must read and understand the Users

Manual including all safety instructions before using this

equipment. Failure to fully understand the safety

instructions can result in personal injury. If after reading the

manual you are still uncertain about use, please

contact the dealer from whom you purchased the

machine for assistance. If you need contact information for

a Service Technician nearest you please call

585-436-1934.

SAFETY OF THIS EQUIPMENT IS THE RESPONSIBILITY

OF THE USER(S).

Please read and follow all warning labels on your machine.

INDUSTRIAL AND IN-PLANT USE ONLY. This equipment

is for use in industrial and in-plant areas only and must be

operated by trained and qualified personnel.

WEAR PROPER APPAREL. Do not wear loose

clothing , gloves, neckties, rings, bracelets, or other jewelry

which may get caught in moving parts. Non slip footwear

is recommended. Wear protective hair covering to contain

long hair.

Keep hands clear while operating machine.

ALWAYS USE SAFETY GLASSES. Also use face or dust

mask if drilling operation is dusty. Everyday eyeglasses only

have impact resistant lenses, they are NOT safety glasses.

KEEP GUARDS IN PLACE and in working order.

Always disconnect the power before servicing this machine.

Service should only be performed by a QUALIFIED TECH

NICIAN.

KEEP CHILDREN AWAY. All visitors should be kept a safe

distance from the work area.

MAKE WORKSHOP KID-PROOF with padlocks or master

switches.

DON’T FORCE MACHINE. It will do the job better and safer

at the rate for which it was designed.

USE RIGHT MACHINE. Don’t force tool or attachment to

do a job for which it was not designed.

MAINTAIN MACHINE WITH CARE. Keep tools sharp and

clean for best and safest performance. Follow instructions

for lubricating and changing accessories.

REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting wrenches

are removed from machine before turning it on.

KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

DISCONNECT MACHINE before servicing; when changing

accessories, such as drill bits, drill blocks, and the like.

REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure the power switch is in the off position before

plugging in.

USE RECOMMENDED ACCESSORIES. Consult the us

er’s manual for recommended accessories. The use of im

proper accessories may cause risk of injury to persons.

-

NEVER STAND ON MACHINE. Serious injury could occur

if the machine is tipped.

-

-

Always turn the machine to off mode and wait for the drills

to stop spinning before installing or removing drill bits. Keep

hands away from drills when operating. PLEASE NOTE

THAT THE DRILL BITS MAY BE HOT AFTER USE. PRO

CEDE WITH CAUTION WHEN CHANGING THE DRILL

BITS.

DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use

this machine in damp or wet locations, or expose it to rain.

Keep work area well lighted.

THIS MACHINE IS DESIGNED FOR ONE PERSON OP

ERATION. Never operate the machine with more than one

person.

DON’T OVERREACH. Keep proper footing and balance at

all times.

-

-

CHECK DAMAGED PARTS. Before further use of the ma

chine, a guard or other part that is damaged should be care

fully checked to determine that it will operate properly and

perform its intended function--check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation.

A guard or other part that is damaged should be properly

repair or replaced.

NEVER LEAVE MACHINE RUNNING UNATTENDED.

TURN POWER OFF. Don’t leave machine until it comes to

a complete stop.

-

-

Page 02

2 - Safety

2.2 - Warning Labels

English French

WARNING: DO NOT EXPOSE TO RAIN

OR USE IN DAMP LOCATIONS.

AVERTISSEMENT: NE PAS EXPOSER

À LA PLUIE ET NE PAS UTILISER DANS

LES EMPLACEMENTS HUMIDES

Page 03

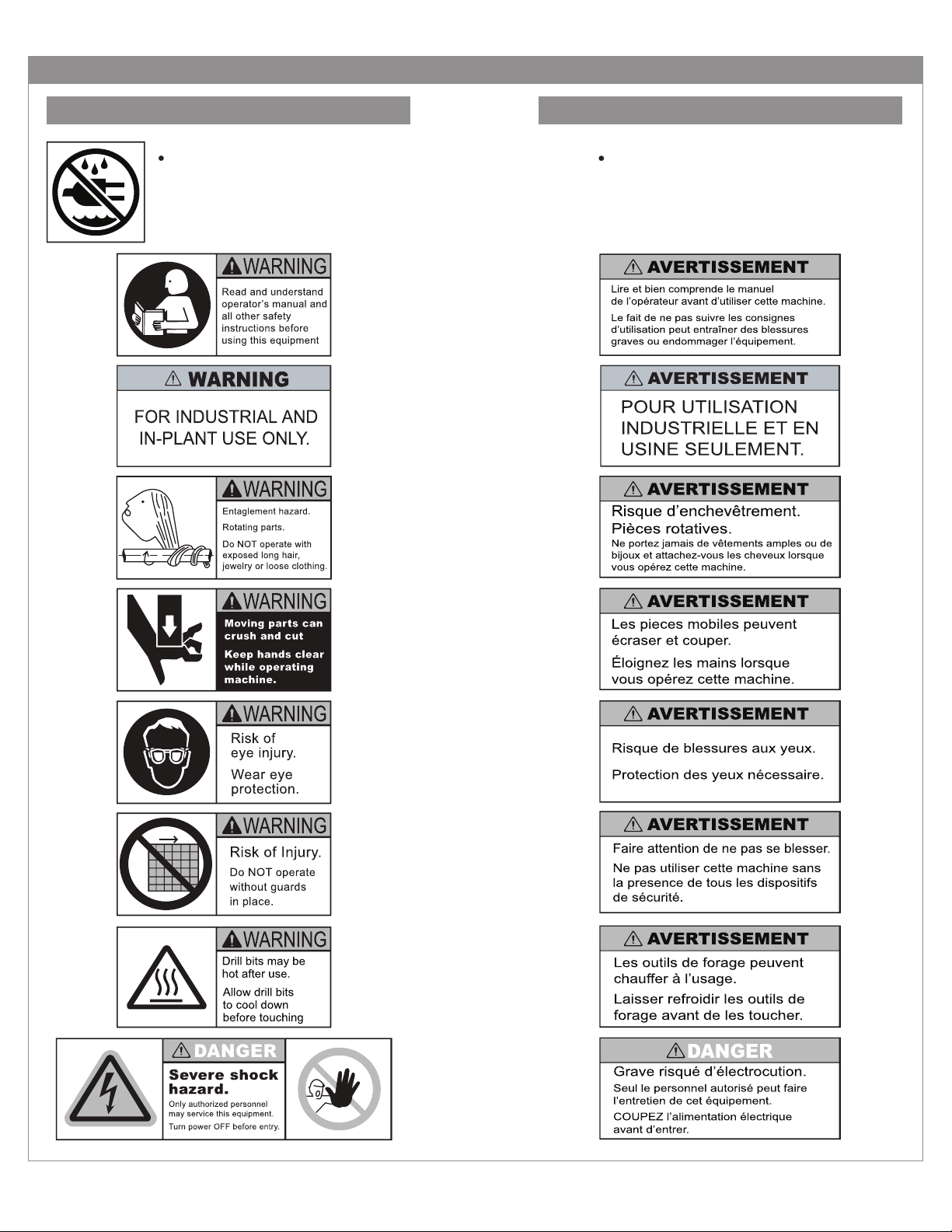

2.3 - Grounding Instructions

METAL SCREW

GROUNDING

PIN

COVER OF GROUNDED

OUTLET BOX

Diagram 2-10

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not fit the outlet, have the proper outlet installed by a QUALI

-

FIED ELECTRICIAN.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The conductor

with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding

conductor to a live terminal. Check with a QUALIFIED ELECTRICIAN or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the tool is properly grounded. Use only 3-wire

extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the machine’s plug.

This machine is intended for use on a circuit that has an outlet that looks like the one illustrated in diagram 2-10.

The machine has a grounding plug that looks like the plug illustrated in diagram 2-10. Make sure the machine is

connected to an outlet having the same configuration as the plug. No adapter is available or should be used with

this machine. If the machine must be reconnected for use on a different type of electric circuit, the reconnection

should be made by qualified service personnel; and after reconnection, the tool should comply with all local codes

and ordinances.

Page 04

3 - Setting Up Your Machine

3.1 - Loose Items Inventory

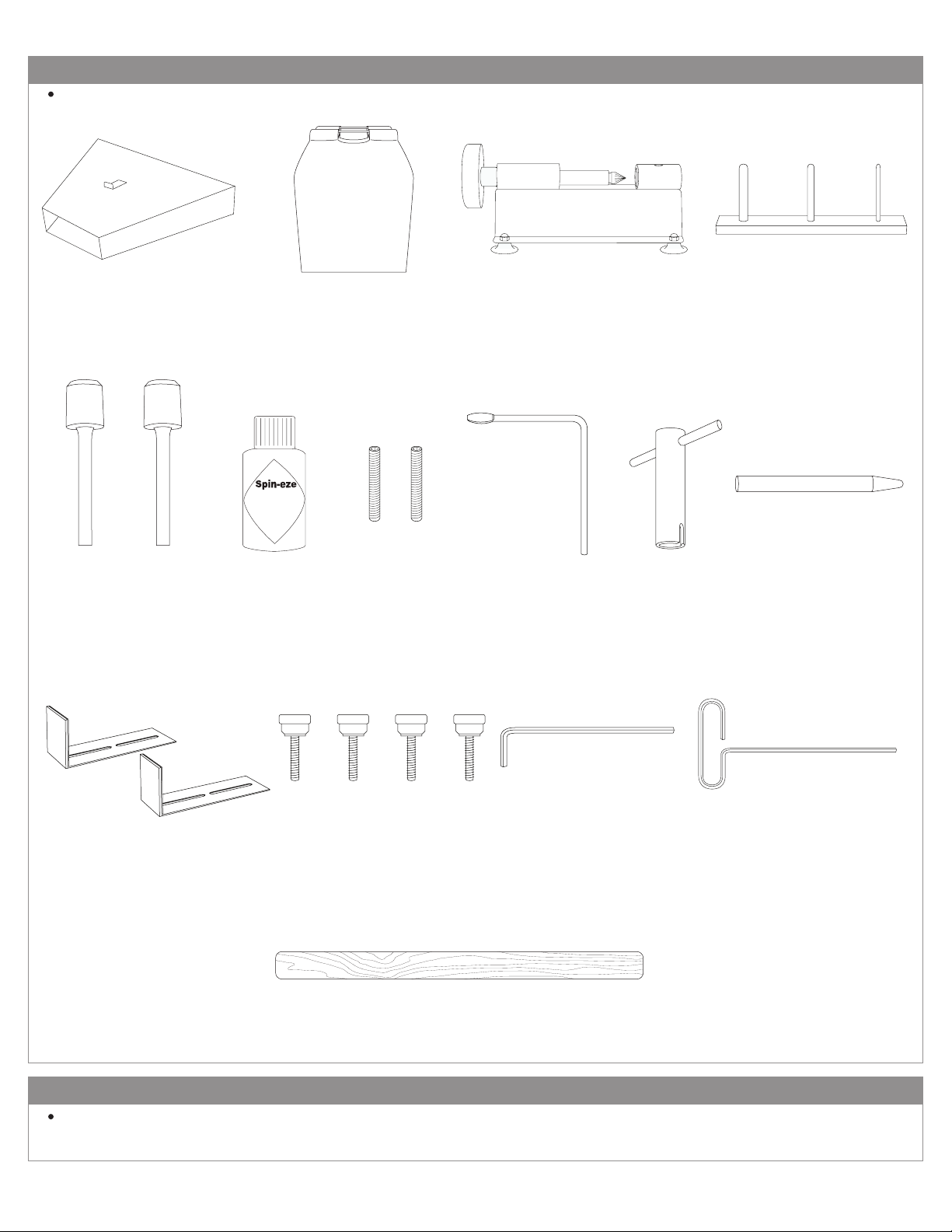

Please remove and inspect the following items:

(This item may be installed)

Chute (1)

Hollow Drill Bits (2)

(these items may be installed)

Assembly (1)

SPIN-EZE: Drill Bit

Lubricant (1)

Short Set

Screws (2)

MS-1: Drill Sharpener (1)FMM6-651A: Master Chip

EBM-32: Chuck Re-

lease Key (1)

FMM9-957A: Spindle

Rotation Tool (1)

CC-2: Chip Clearer (1)FMM6-652A: Chip Bag

EBM-41: Sharpening

Stone (1)

FM4-4006: Paper Side

Stops (2)

FM4-4007: Side Stop

Screws (4)

FM4-4001: 25” Drill Strip (1)

(this item comes installed)

HEX-332: Hex Wrench

3/32” (1)

HEX-732-T: Hex Wrench

7/32” T Style (1)

3.2 - Accessories Warning

USE RECOMMENDED ACCESSORIES. Only use accessories approved by a Lassco-Wizer. The use of improper accessories may cause risk of injury to persons.

Page 05

3 - Setting Up Your Machine

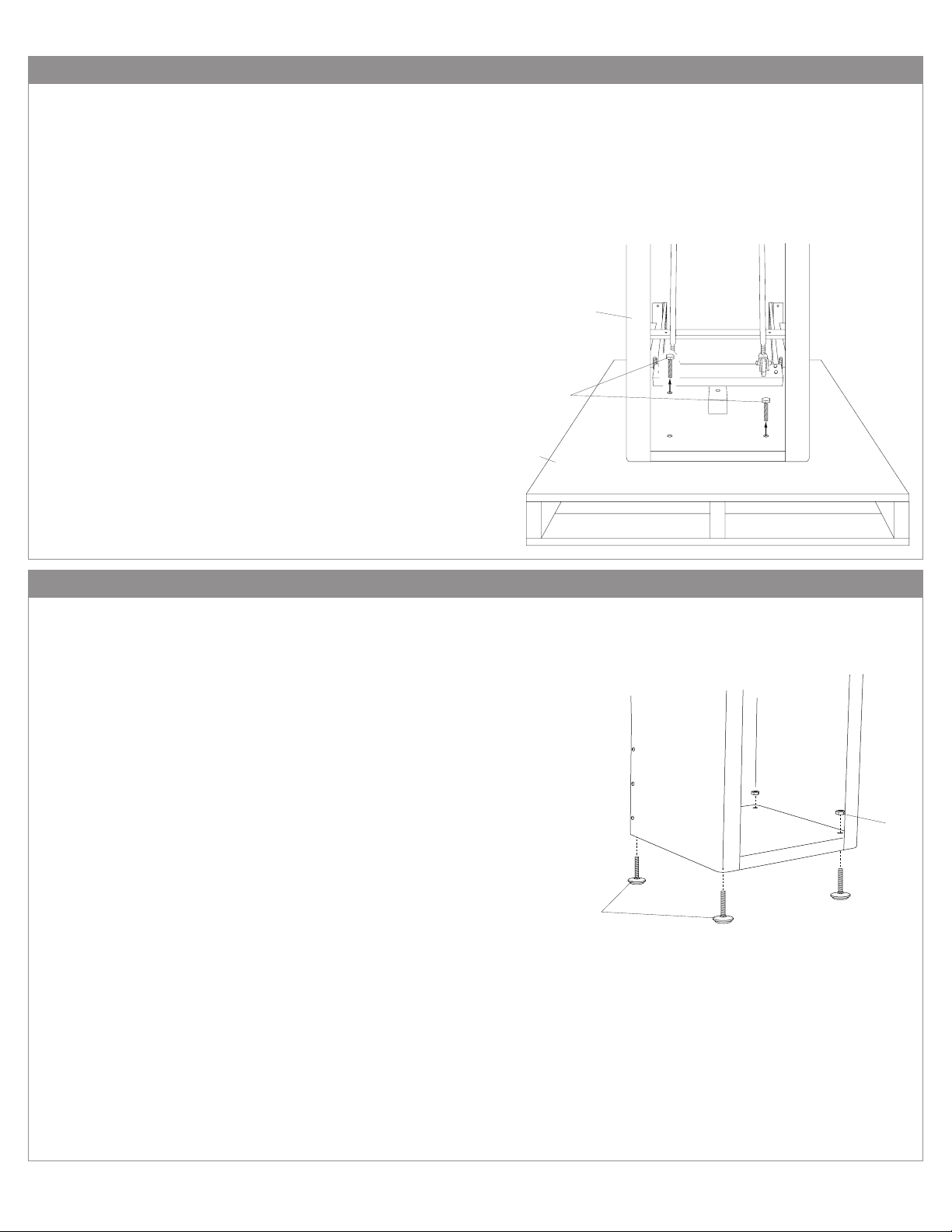

Wooden Pallet

FMM-3

5/16” Bolts

Leveling Feet

Base of the Machine

Nut

3.3 - Uncrating and Removing From the Pallet

3.3.1

3.3.2

3.3.3

3.3.4

Remove the wooden framing around the outside box.

Remove the box up and over the machine.

Remove the two (2) 5/16” bolts which are securing the machine to

the pallet: access through the rear of the machine using a 5/16”

wrench (not provided) as shown in diagram 3-10. Discard the two

(2) 5/16” bolts.

Remove the FMM-2 from the pallet carefully “stepping” it off the

edge. DO NOT drop the machine. DO NOT lift by the table. Two

people may be needed to remove the machine from the pallet

safely.

Diagram 3-10

3.4 - Installing the Leveling Feet

3.4.1

3.4.2

3.4.3

Set the machine down in its desired location and determine if the

machine is level, making sure that it does NOT rock in any direction. If it does, determine which Leveling Feet need to be adjusted

and whether they need to be adjusted up or down.

If adjustment is needed, start by loosening the four (4) nuts which

are accessed through the rear of the machine.

Next adjust the four (4) Leveling Feet by screwing them clockwise

to raise the or counter-clockwise to lower. After each adjustment

set the machine down completely to verify that the machine no

longer rocks. Continue adjustment as needed until the machine

sits securely in place. Tighten the four (4) nuts down to secure the

position of the Leveling Feet.

Diagram 3-20

Page 06

3 - Setting Up Your Machine

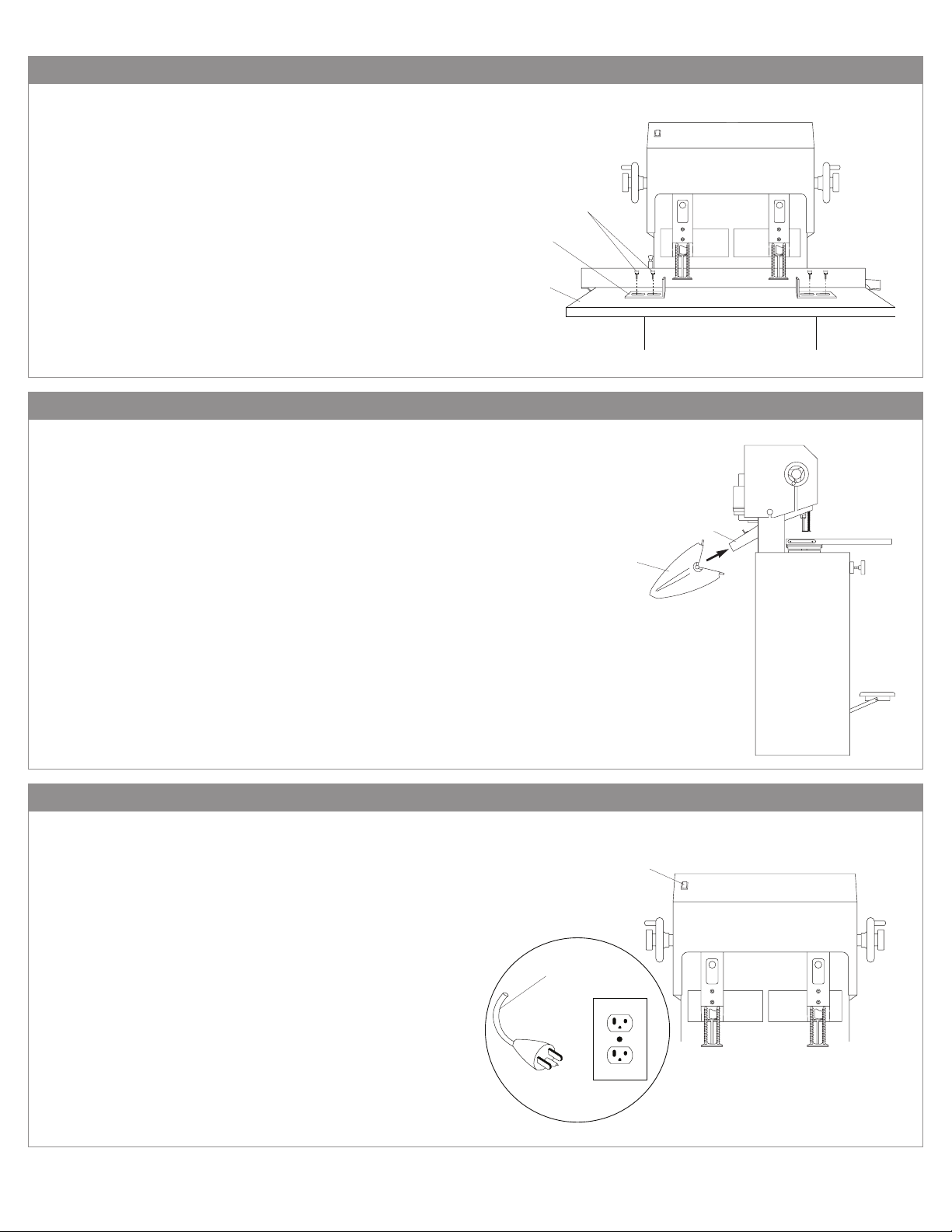

Master Chip Chute

Chip Bag

Table

Paper Side Stop

Side Stop Screws

Rocker Switch

Power Cord

3.5 - Attaching the Paper Side Stops

3.5.1

Attach the Paper Side Stops (FM4-4006) using two (2) Side Stop

Screws (FM4-4007) each. Position the Paper Side Stop as de

sired and tighten down with light pressure.

3.6 - Attaching the Chip Bag

3.6.1

Attach the Chip Bag (FMM6-652A) to the machine by stretching

the mouth of the bag over the Master Chip Chute and hooking

the aluminum bar onto the bracket located on the top flat portion

of the master chip chute as shown. Please note that you must

empty this bag as needed to avoid clogging.

-

Diagram 3-30

Diagram 3-50

3.7 - Electrical Instructions

3.7.1

3.7.2

Your FMM-2 comes with an electrical cord containing the plug to

fit into a standard grounded 115V outlet. This machine has a full

load draw of 11 Amps.

Making sure that nothing is interfering with the drill bits, plug the

cord set into a grounded 115V outlet. To turn the machine on,

press the Rocker Switch on the front of the shroud.

Diagram 3-60

Page 07

4 - Operation

Chip Chute

Chuck

Hole Guard

Drill Bit

Chip Chute

Chuc

k

Hole Guard

Drill Bit

Chuck Release Key

Tab

4.1 - Protective Guard

4.1.1

Your FMM-2 comes with a protective guard installed. DO NOT

operate this machine without the guard in place.

Diagram 4-10

4.1.2

Please note that when you are performing certain operations such

as removing and installing drill bits, you will need to move the

guard out of the way. Making sure the power to the machine is

disconnected or locked-out, push the guard up and hold in place

while performing necessary operations or maintenance. The pro

tective guard should not be removed during operation.

4.2 - Drill Bit Removal and Installation

CAUTION: DRILL BITS MAY BE HOT AFTER USE. ALLOW DRILL BITS TO COOL

DOWN BEFORE TOUCHING.

BEFORE REMOVING OR INSTALLING THE DRILL BITS, DISCONNECT OR

LOCK-OUT THE POWER SUPPLY.

4.2.1

4.2.2

Remove the hole guard which is attached to the chuck. This is

done by grasping the tab and sliding the guard off.

Using the Chuck Release Key (EBM-32), insert the tapered end

facing down into the chuck hole. With a clockwise motion turn the

Chuck Release Key 45 degrees. The drill bit will slide out of the

spindle. It is recommended that you hold onto the drill bit so that

it does not drop out of the spindle damaging the tip. Place the

hole guard back onto the chuck to protect debris from clogging

the spindle.

-

Diagram 4-20

4.2.3

4.2.4

4.2.5

To install a drill bit, grasp the drill bit and being

careful to keep it straight, press it up into the Chuck.

Seat the drill bit by using a stack of scrap paper. Set the scrap

on the table as shown. Step on the foot pedal slowly raising the

table toward the drill bit. Put light pressure on the hollow drill bit

seating it firmly in place.

Remove the scrap paper and turn the machine on to check the

concentricity of the bit. If the bit is not concentric, remove it and

repeat steps 4.2.1 through 4.2.4 until it is concentric.

Diagram 4-30

Page 08

4 - Operation

Access Guard

1/8” Hex Wrench

Access Guard Screw

7/32 Hex Wrench

Insert Retainer

Screw

Chuck

Table

Card Stock

Spindle Rotation Tool

Access Cover

Pressure Foot

Table

4.3 - Leveling the Drill Bits

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

We recommend using a piece of card stock on the

Table when leveling the drill bits to avoid drilling into

the drill strip. This will lengthen the life of your drill bits

and keep them sharper.

Remove one (1) of the two (2) Access Guard Screws

using the 1/8” Hex Wrench (HEX-18). Swing the Ac

cess Guard as shown in diagram 4-40 to gain access

to the motor shaft.

Insert the Spindle Rotation Tool (FMM9-957A) into the

end of the motor shaft through the opening in the top

of the machine shroud until the notch in the Spindle

Rotation Tool fits into the keyway securely.

Swing the access cover located on the front of the

heads to one side allowing access to the spindle and

chuck.

Turn the Spindle Rotation Tool by hand until the insert

retainer screw can be seen in the opening.

Stepping slowly on the foot pedal, raise the table so

that it meets the bottom of the pressure foot assem

bly.

Diagram 4-40

-

Diagram 4-50

-

4.3.7

4.3.8

4.3.9

4.3.10

4.3.11

4.3.12

Using the 7/32” Hex Wrench (HEX-732-T), loosen

the insert retainer screw approximately one half turn

(loosening too much may cause the insert retainer

screw to come out completely). Retighten the insert

retainer screw until it is snug but not tight; this will al

low you to raise or lower the chuck without too much

play. Hold onto the Spindle Rotation Tool to prevent

the belts from turning. Lower the height of the Chuck

by turning it counter-clockwise. Raise the height of

the Chuck by turning it clockwise.

When the drill bit is just touching the drill strip, re-tight

en the insert retainer screw. This may require you to

turn the Spindle Rotation Tool until the Insert Retainer

Screw is again accessable through the opening.

Lower the table by slowly releasing pressure on the

foot pedal.

Repeat steps 4.3.4 through 4.3.9 on the remaing Drill

Bits so that they are all level with each other.

REMOVE THE SPINDLE ROTATION TOOL FROM

THE MOTOR SHAFT. Leaving this attached can

cause injury to the user as it can fly out of the machine

upon startup.

Replace all the Access covers and Access Guards so

that they cover the motor shaft opening and the re

tainer screw openings.

-

Diagram 4-60

-

Diagram 4-70

-

Page 09

4 - Operation

Table

Internal Side View

Vertical Stop

Adjustment

Foot Treadle

Lock Knob

Clamp Knob

Back Gauge

Ta

ble

Back Gauge Scale

Back Gauge Scale

Back Gauge Scale

Drill Strip

Drill Strip

Hollow Drill Bits

4.4 - Adjusting the Table Height

4.4.1

4.4.2

4.4.3

After you level the drill bits you may need to adjust your table

height. Test drill through a stack of scrap approximately the same

height as that you will be drilling. If the drill bits drill into the Drill

Strip or if the drill bits fail to penetrate through the bottom sheet of

scrap you will need to adjust the table height. If you are using the

card stock under your scrap (recommended) then you should just

be lightly scoring the card stock when the table is in its full upright

position. If your bits are drilling correctly move onto section 4.4.

If your drill bits fail to penetrate through the scrap: Loosen the

Lock Knob of the Vertical Stop Adjustment Assembly and rotate

the large knob counterclockwise allowing the table to travel high

er. Tighten down the Lock Knob when it is positioned correctly.

If you are drilling into the Drill Strip: Loosen the Lock Knob of

the Vertical Stop Adjustment Assembly and rotate the large knob

clockwise allowing the table to travel lower. Tighten down the

Lock Knob when it is positioned correctly.

Diagram 4-80

-

4.5 - Adjusting the Back-Gauge Assembly

4.5.1

4.5.2

4.5.3

4.5.4

4.5.5

Adjust the Back-gauge so that it is the correct distance from the

edge of the product to the center of the hole to be drilled by per

forming the following:

Loosen the Clamp Knob on the right side of the Back-gauge.

Using the two (2) Scales embedded in the rear corners of the

table, align the front edge of the Back-gauge with the desired dis

tance.

Zero (0) on these scales align with the center of the hollow drill

bits.

Tighten down the Clamp Knob when the Back-gauge

is positioned as desired.

-

-

Diagram 4-90

Page 10

4 - Operation

3/32” Hex Wrench

Pedestal

Short Set Screw

Stop Collar Rod

Stop Collar

Pedestal Pin

3/32” Hex Wrench

Pedestal

Pedestal Pin

Stop Collar Rod

Stop Collar

Long Set Screw

Hand Wheel

Lock Knob

Hand Wheel

Shroud

4.6 - Adjusting the Distance Between Heads

4.6.1

To adjust the spindles to a desired spacing, loosen the Hand

Wheel Lock Knob. Turn the Hand Wheel to move the spindle

farther away from the center or to move the spindle closer to the

center. Please note that the direction you turn the Hand Wheel

depends on the side of the machine. Use the Back-gauge Scale

as a guide. When the spindle is at its desired location tighten the

Hand Wheel Lock Knob by turning clockwise. Repeat with the

second spindle.

4.6.2

When drilling fewer than two (2) holes simply remove undesired

drill bits.

4.7 - Adjusting the Stop Collars

4.7.1

4.7.2

The stop collars, located on the Stop Rod at the left rear of the

Table, are used to either create a stationary table mode of opera

tion or a traversing mode. Your machine comes set up in stationary mode.

For traversing table operations follow steps 4.7.3 through 4.7.5.

Refer to diagram 4-110.

Diagram 4-100

Diagram 4-110

-

4.7.3

4.7.4

4.7.5

4.7.6

4.7.7

4.7.8

4.7.9

Install the shorter Set Screws included with the machine into the

Stop Collars. Make sure all the Stop Collars are installed with the

shorter Set Screws keeping them loose enough to allow the Stop

Collars to slide into the desired positions.

Set the Stop Collars using the method explained in section 4.8.

When the Collars are positioned as desired, tighten down the

short Set Screws locking them in place using the provided Hex

Wrench (HEX-332).

For stationary table operations follow steps 4.7.7 through 4.7.9.

Refer to diagram 4-120.

Align the table so that zero (0) on the Back-gauge is aligned with

the center drill bit.

Install two longer Set Screws included with the machine into the

adjacent Stop Collars.

Tighten, with the provided Hex Wrench (HEX-332), the longer Set

Screws into the Stop Collars so that a Set Screw rests against

each side of the Pedestal preventing movement of the Table.

Diagram 4-120

Page 11

4 - Operation

Ruler (not provided)

Pedestal Pin

Table

Pedestal Pin Knob

Locking Pins

Pedestal

4.8 - Multi-hole Set-Up

4.8.1

4.8.2

4.8.3

4.8.4

4.8.5

4.8.6

If a hole pattern includes more than three (3) holes, you will need to adjust the Stop Collars to the desired spacing.

The Stop Collars are adjusted as descibed in section 4.7. To set the distance between the stop collars, follow steps

4.8.2 through 4.8.5.

Locate the product on the Table and adjust the Paper Side Stops to trap the material allowing no lateral movement.

Move the Table to align zero (0) on the Back-gauge Scale with the center drill bit.

Loosen the Stop Collars and position the first one against the Pedestal Pin marking the beginning position of the

Table and tighten in place.

The right side of this Stop Collar now indicates the center of the product to be drilled. Place the remaining Stop

Collars as desired by measuring with a Ruler (not provided) to the desired positions and tighten them down. Always

measure from the right side of the Stop Collar to the right side of the next Stop Collar as shown.

Diagram 4-130

Due to the width of the Stop Collars, the shortest travel between holes is 3/8”. Almost any center-to-center distance

can be drilled, but requires variations of table travel and lateral head adjustments.

4.9 - Traversing the Table

4.9.1

4.9.2

When all the Stop Collars are positioned as desired return the

Table to its original position. When traversing the Table during

drilling (see section 4.10), move the Table to the left until the Ped

estal Pin “clicks” over the next Stop Collar. Pull the table back

to the right and hold it there to assure contact between the Stop

Collar and the Pedestal Pin. Refer to diagram 4-140. Continue

drilling and repeat as needed.

To reverse the direction of the Table traverse, lift up on the Pedestal Pin Knob and turn it around. This will cause the angle of the

Pedestal Pin to reverse allowing the Table to travel back over the

Stop Collars. There are Locking Pins on the Pedestal Pin that fit

into a groove on the Pedestal keeping it locked into a

direction. Refer to diagram 4-150.

Diagram 4-140

-

Diagram 4-150

Page 12

4 - Operation

Product

Paper Side Stop

4.10 - Drilling Procedures

4.10.1

4.10.2

After all your adjustments are made as desired, position the Table

in its original position. Set the product to be drilled on the table

and make sure it is secure using the Paper Side Stops. To drill,

step down on the Foot Treadle raising the Table up to meet the

drill bits. Using one consistent smooth stroke, put pressure on

the Treadle so that the Table rises fully allowing the drill bits to

drill through the product. It is important you maintain a consistent

speed through the entire stack. It is also important you do not go

too slow or too fast. If you drill too slow you can burn the paper

leaving undesired marks. If you drill too fast, the drill bits will act

more like a punch and they will break.

Different product requires different speeds. It is always recom

mended to drill through a test stack of the product until the operator is confident of the required speed.

Diagram 4-160

-

4.11 - Tips on Drilling

4.11.1

4.11.2

4.11.3

4.11.4

Use a sharp drill bit at all times... Using the MS-1 drill bit sharpener, sharpen your drill bits regularly. Apply light pressure when sharpening. Too much pressure may cause flaring of the tip. (Once a drill bit has a flared tip, it becomes

defective.)

Sharpening Stone... Use to debur the outside cutting edge of the drill bits for better performance.

Lubricate drill bits occasionally... Use Drill-Ease or Spin-Eze. While the drill is running, simply touch the Drill-Ease

stick to the drill bit or brush on the Spin-Eze. Drill through scrap to remove any excess. This will allow for a smoother

cut.

Drill Strips...When drilling, a drill bit must stop slightly above the drill strip. Replace worn out drill strips regularly to

ensure proper drilling.

Page 13

5 - Maintenance

Lubricate

Pedestal

Lubricate Lubricate

Lubricate

Lubricate

Table Assembly

Slide

Lubricate

5.1 - Safety

ALWAYS DISCONNECT THE POWER BEFORE PERFORMING MAINTENANCE

ON THIS MACHINE. MAINTENANCE SHOULD ONLY BE PERFORMED BY A

QUALIFIED TECHNICIAN.

KEEP HANDS CLEAR WHILE PERFORMING MAINTENANCE ON THIS MACHINE.

MOVING PARTS CAN CRUSH AND CUT.

5.2 - Annual Lubrication

5.2.1

5.2.2

5.2.3

Lubricating your FMM-2 should be done at least once every 12

months; however, it may be necessary to lubricate certain parts

more often depending on use. Whenever a moveable or adjust

able part starts becoming difficult to move or adjust, it may be time

to lubricate.

Remove the Table by loosening the left end Stop Collar on the

Stop Bar Assembly and rotating the Table Traverse Stop down to

clear the Pedestal. Pull the Table to the right until the Table clears

the slide beneath the Table. Inspect the slide for build-up and

lubricate with light machine oil. Using the Foot Treadle raise the

Slide and Lubricate the bars underneath the Slide as shown. Re

place the Table in the same manner as it was removed and check

the Table traverse for free travel. Refer to diagram 5-10.

Lubricate the Stop Pin with light machine oil, work the pin up and

down and rotate it a few times for proper lubrication. Refer to

diagram 5-20.

-

Diagram 5-10

-

Diagram 5-20

5.2.4

Lubricate the pivot points, shown in the diagram 5-30, in the lower

back portion of the machine with light machine oil. Lubricate the

Treadle Pivot Assembly at the front of the machine in the same

manner.

Diagram 5-30

Page 14

5 - Maintenance

Lubricate

Push Rods

Rear View

Grease Points

Belt

Belt

Grease

Grease

Grease

Grease

5.2 - Annual Lubrication

5.2.5

5.2.6

5.2.7

Press down on the Foot Treadle to Raise the Table. Manually

holding the Table in place, slowly let up on the Foot Treadle so

that the Push Rods in the rear of the machine fall out of the Pin

Housings.

Lubricate the tips of the Push Rods and while holding up the Table

return the Push Rods into the Pin Housings. Release the Table so

that the Push Rods are locked in place.

Push down on the Foot Treadle to check for freedom of Travel.

Diagram 5-40

5.2.8

5.2.9

5.2.10

Making sure the machine is unplugged and after disconnecting the

electrical wiring to the Switch on the shroud, remove the shroud

by lifting straight up to clear the drive mechanism making sure the

Traverse Locks are disengaged.

Lubricate the two (2) Idler Pulleys with a good grade of grease. A

grease gun is required (not included). Rotate the belts by hand

to check the Idler Pulleys for wear. Some play between the Idler

Pulley Bearings and the Idler Pins comply with original specifica

tions and is not a problem. Refer to diagram 5-50.

Lubricate the Head Traverse Screws by applying light grease ei

ther by hand, or a small brush to the points indicated in diagram

5-60. Move the heads to both extremes to coat the complete

surface of the screws and inspect them for thread wear.

Diagram 5-50

-

-

Diagram 5-60

Page 15

5 - Maintenance

Grease

Grease

Grease

Grease

1/2”

Straight

Edge

Belt

Idler Pulley

Outside

Pulley

Belt Tension

Flex Drive

Pivot Assembly

Flex Drive

Pivot Assembly

Belt Adjustment Screw

Flex Drive

Pivot Assembly

Flex Drive

Pivot Assembly

5.2 - Annual Lubrication

5.2.10

5.3 - Inspecting the Flex Drive

5.3.1

Apply a light grease on the two (2) Traverse Rods either by hand

or with a small brush to the points indicated in diagram 5-70.

Crank both heads in and out to distribute the lubrication and to

check the head movement.

Inspecting the Flex Drive on your FMM-2 should be done at least

once every 12 months; however, it may be necessary to check

this more often if problems with the rotation of the spindles is no

ticed. Pelt shavings are normal for new adjusted belts, but contact a service technician if it becomes excessive.

Diagram 5-70

Diagram 5-80

-

5.3.2

5.3.3

5.3.4

Inspect the Belts for wear and the proper tension. The tension

should be adjusted to an approximate 1/2” gap between a straight

edge placed from the outside edge of the Idler Pulley to the out

side edge of the Outside Pulley with the pulleys located one behind the other. Depress the belt halfway between the two pulleys

and measure the distance between the straight edge and the belt

depression.

The belts can be adjusted by loosening the Lock Nut on the Belt

Adjustment Screw located on the front portion of the Flex Drive

Pivot Assembly and turning the screw clockwise to tighten the belt

and counterclockwise to loosen the belt. After the belt has been

properly adjusted, re-tighten the Lock Nut.

Visually check the Flex Drive Pivot Assembly for unusual wear.

Check the Pivot Assembly bolts and tighten if necessary.

-

Diagram 5-90

Diagram 5-100

5.3.5

Be sure the wiring is clear of all moving components and is prop

erly attached when replacing the Shroud.

-

Page 16

6 - Trouble Shooting Guide

Problem Cause Correction

Drill bit not concentric.

Foreign material in chuck or in

drill plug.

Inspect and clean.

Drill bit is bent. Replace drill bit.

Drill bit not seated in chuck

properly.

Re-insert drill bit correctly.

(See Operating Instructions)

Chuck is not tight to spindle. Tighten set screw.

Drill bit not drilling. Drill bit plugged. Remove and clear chips. Check

for other foreign matter.

Drill bit dull. Sharpen drill bit.

Traverse table drags or skips

during operation.

Spring Plungers on the Slide

Plate are out of adjustment or

damaged.

Adjust or replace the Spring

Plungers.

Table lift system lifts

unevenly or is noisy.

Loose or missing pivot compo

nents in the Treadle Pivot

Assembly.

Tighten or replace as necessary.

Push Rods are bent. Replace

Bushings in the lift system are

dry or worn.

Lubricate or replace.

Push Rods out of adjustment. Adjust Push Rods to lift evenly.

Table traverse channel and/or

slide is dirty or needs lubrication.

Clean the channel and lubricate.

The Table is damaged. Repair or replace the Table.

In extreme conditions, the drill chuck and/or chip chute may

be plugged. Remove the drill bit, loosen the chip chute,

pull down, and clean. See Operating Instructions

Note:

In order to maintain smooth table operation, DO NOT sit

on, lean on, or force the table out of alignment.

Note:

If the raising mechanism is lifted without depressing the

Foot Treadle, the Push Rods will drop out of position and

must be re-installed in the Pushpins in order to operate the

Table.

Note:

6.1 - Determining the Cause and Correction to Certain Problems

Page 17

6 - Trouble Shooting Guide

Problem Cause Correction

Machine vibrates, wobbles,

resonates, etc.

The machine is not level on the

floor.

Use the leveling feet to make the

machine level on the floor. See

Setting Up Your Machine.

The drill bit(s) are drilling into

the drill strip or they are not

drilling through the bottom

sheet of the product you are

drilling.

Drill bit(s) are not adjusted

properly to the card stock/card

stock not used.

Adjust your drill bit(s) per Operat-

ing Instructions.

The outside Heads are

difficult to adjust.

The Lead Screw and/or T

raverse

Rods are dry or damaged.

Lubricate per Maintenance

schedule. Check for damaged or

worn components.

The drill bit(s) do not rotate

when the motor is turned on.

A

Drive Belt is broken on the

Flexible Drive System.

Replace the broken belt. See

Maintenance.

A

Drive Belt is loose on the

Flexible Drive System.

Ti

ghten the loose belt. See

Maintenance.

An Insert Retainer Screw is

hitting the inside of the Chuck

Housing.

Adjust the Chuck and tighten the

Insert Retainer Screw.

The Hand Wheel Lock is tightend

down in place.

Loosen the Hand Wheel Lock

enough so the Hand Wheel can

be turned.

An obstruction is between the

traversing heads.

Check and remove the obstruction.

The Chuck(s) were not tightened

after adjustment.

Re-adjust and tighten.

The Table Travel Stop is out of

adjustment.

Adjust to the proper Table Travel.

See Operating Instructions.

The machine is located directly

on a concrete floor.

Place a rubber mat or carpet

under the machine.

Drill bit(s) are not concentric. Re-install drill bit(s) until they are

concentric. See Operating

Instructions.

6.1 - Determining the Cause and Correction to Certain Problems

Page 18

6 - Trouble Shooting Guide

Problem Cause Correction

Uncommon metallic sounds

from under the shroud.

The Drive Pulley is loose. Adjust the Drive Pulley to the

proper height and tighten or

replace the Set Screw.

The Chuck cannot be

adjusted according to the

Operating Instructions.

The Chuck has been adjusted

too far down causing the adjust

-

ment threads to be disengaged.

Re-adjust to a lower position

which may require you to use

new hollow drill bits.

The Chuck has been rotated

while in the down position.

Push up on the Chuck and rotate

slowly while holding the Spindle

stationary until the Chuck returns

into a locked position.

The Needle Bearings on the Idler

Pulley(s) are not lubricated.

Lubricate the Needle Bearings as

needed.

The Chuck adjustment is designed for a 1/4” total movement up and down. Once you have sharpened the drill bit

down more than a 1/4” from its original length you must

replace it. Any drill bits that are longer than approx 2-1/4”

or shorter than approx 2” may cause Chuck adjustment

problems.

Note:

6.1 - Determining the Cause and Correction to Certain Problems

Page 19

7 - Parts Diagrams

7.1 - Side View

Page 20

7 - Parts Diagrams

7.2 - Head Assembly

Page 21

7 - Parts Diagrams

7.3 - Spindle and Chuck Assembly

Page 22

7 - Parts Diagrams

7.4 - Rear View

Page 23

7 - Parts Diagrams

FMM9-9534: Motor

FMM9-9513: Drive Belt

Grease Fitting

FMM8-8504: Hand Wheel

FMM8-8508: Hand Wheel Lock Knob

FMM9-9517: Shroud Locking Knob

FMM8-8503: Traverse Lead Screw

FMM8-8502: Traverse Rods

FMM5-5512: Access Cover

FMM5-5506: Housing

FMM2-9500: Left Pivot Channel

FMM2-9502: Right Pivot Channel

Misc: Hollow Drill Bit

FMM9-9506: Idler Pulley

FM6-600A: Pressure Foot Assembly

FMM8-8508: Traverse Stop

FMM9-9516: Cord Set

Cam Adjustment Screw (Belt Adjustment)

Chuck Release Hole

FMM9-9514: Pulley Bushing

FMM9-9505: Pulley

1/4 x 20 x 3/8 Socket Set Screw

FMM5-5503: Bearing Nut

FMM5-5501: Top Bearing

FMM5-5513: Spindle

FMM5-5502: Bottom Bearing

FMH-5517: Insert Retainer Screw

FMH-5515: Insert

N/A

N/A

FMH-5514: Chuck

FM7-70A: Back Gauge Assembly

FM7-7005: Backgauge Knob

FM7-7003: Clamp Bar

FM4-4003: Side Iron

FM4-4000: T

able

FM4-401A: Pedestal Stop Assembly

EBM-47: Stop Collar

FM4-4014: Stop Collar Rod

FM7-7002: Backgauge Clamping Bracket

FM3-3007: Pin Housing

FM3-304A: Vertical Table Travel Stop Assembly

FM2-2006: Push Rod

FM-42: Short Clevis

50-31: Clevis Pin

FM2-201A: Push Rod Angle Assembly

FM-37: Wear Strip

FM2-200A: Pivot Bar Assembly

FM2-2009: Treadle Bar

FM1-1006: Wood Stop

50-59: Leveling Feet

FM1-1000: Stand

FM2-2013: Foot Treadle

FM3-305A: Vertical Stop Adjustment Assembly

FM3-301A: Die Traverse Assembly

EBM2-1032: Pedestal Support Angle

FM3-3016: Slide Plate Support

FM3-3015: Slide Plate

FM4-4008: Traverse Channel

FM5-5006: On/Off Rocker Switch

FMM9-952A: Shroud Assembly

FM4-4016: Table Traverse Stop

FM-90: Guard Bracket

FM-93: Protective Guard

FM-95: Access Guard

FM-80: Junction Box

FM-86: Strain Relief

FM-82: 15 Amp Fuse

7.5 - Parts List

Page 24

Loading...

Loading...