La Spaziale S1 Vivaldi II Owner's Manual

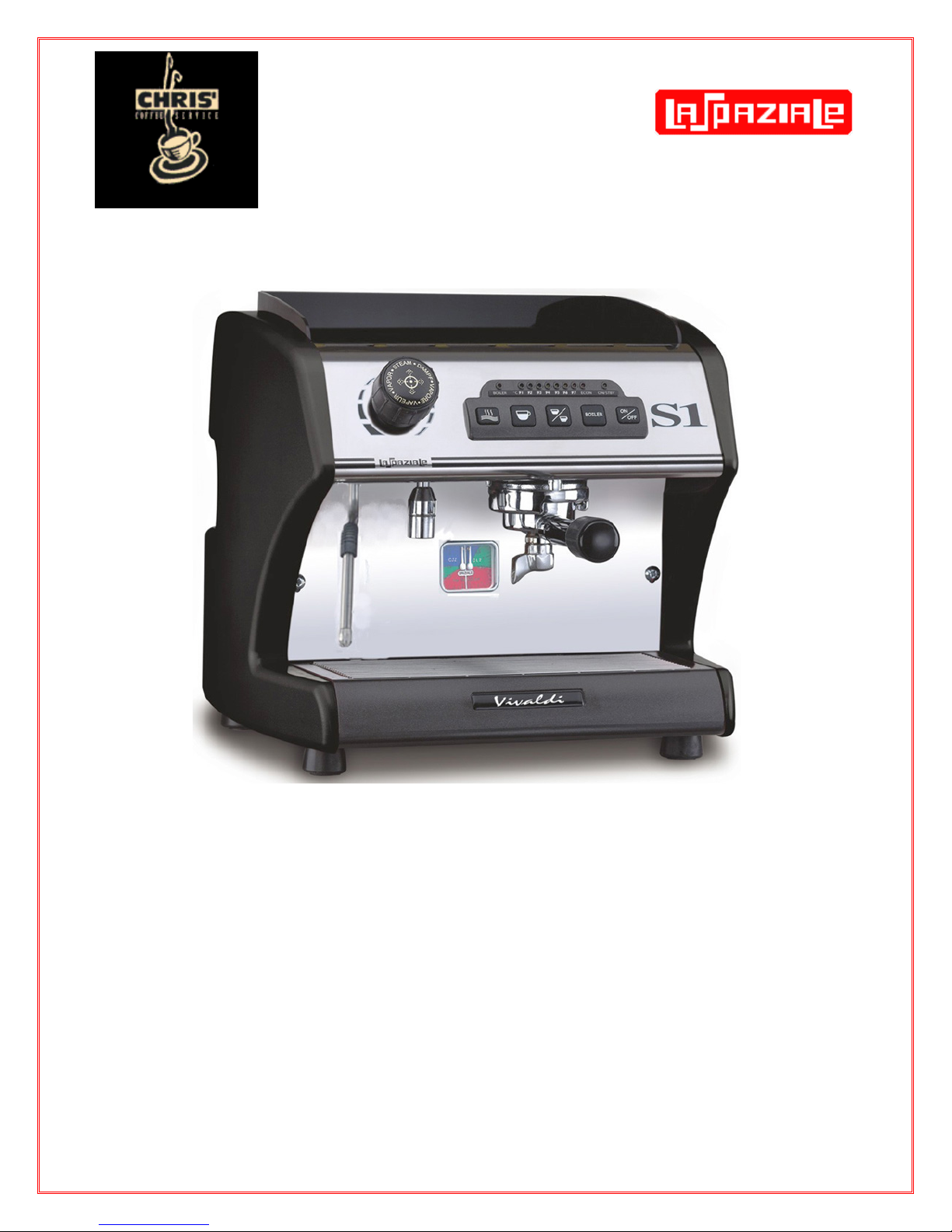

La Spaziale S1 Vivaldi II

Double Boiler Espresso Machine

Owner’s Manual

(Covers VII’s with and w/o Enhanced Temperature Offset and Programmable Preinfusion)

Added Information on adjusting steam pressure

10/11/2015

S1 Vivaldi II Owner’s Manual

Page 1

Table of Contents

1! Feature Overview ..................................................................................................... 3!

2! Reference Photos ..................................................................................................... 3!

3! Document Scope – Caveats and Clarifications ........................................................ 5!

4! Basic Machine Operation ......................................................................................... 5!

4.1! 15A or 20 Amp Operation .................................................................................. 5!

4.2! Optional On/Off Timer Accessory – Overview and WARNING ........................ 7!

4.3! Initial Installation Before Connecting Power ...................................................... 8!

4.4! Turning On and Heating the Machine ............................................................... 9!

4.5! Espresso Brewing ............................................................................................. 9!

4.6! Volumetric Dose Programming ....................................................................... 10!

4.7! Hot Water Delivery .......................................................................................... 10!

4.8! Steam Delivery ................................................................................................ 10!

4.9! Economy / Boiler Operational Modes .............................................................. 11!

4.10! V1/VII Mode Switch ......................................................................................... 12!

4.11!Espresso Group Water Temperature Regulation

......................................... 12!

4.11.1! Standard Temperature Adjustment .......................................................... 12!

4.11.2! Offset Temperature Adjustment ............................................................... 13!

4.11.3! Steam Pressure Adjustment .................................................................... 15!

4.11.4! Extreme Temperature Set Function ......................................................... 16!

4.12! Programmable Preinfusion .............................................................................. 17!

5! Alarm Handling ....................................................................................................... 18!

5.1! Coffee Group Water Dosing System Failure ................................................... 18!

5.2! Coffee Group Temperature Detection System Failure .................................... 18!

5.3! Steam Boiler Temperature Detection System Failure ..................................... 18!

5.4! Damaged Group Heating Element Triac (SSR) .............................................. 18!

5.5! Damaged Boiler Heating Element Triac (SSR) ............................................... 19!

5.6! Boiler Automatic Refill System Failure ............................................................ 19!

6! Connection Diagrams ............................................................................................. 20!

6.1! Electrical Connection Diagram ........................................................................ 20!

6.2! Control Board Connection Diagram ................................................................ 21!

6.3! Triac Board Connection Diagram .................................................................... 21!

6.4! Control Panel Connection Diagram ................................................................. 22!

6.5! Wiring Diagram Definitions .............................................................................. 22!

7! VII Water Flow Diagram ......................................................................................... 23!

8! Adjustments and Maintenance ............................................................................... 24!

8.1! External VII Surface Cleaning ......................................................................... 24!

8.2! Routine Group Cleaning .................................................................................. 24!

8.3! Group Pressure Test and Adjustment ............................................................ 25!

8.4! Expansion Valve Release Adjustment ............................................................ 26!

9! Optional Accessories .............................................................................................. 27!

10! Other LaSpaziale VII Resources ............................................................................ 30!

S1 Vivaldi II Owner’s Manual

Page 2

11! Quick Setting Guide ................................................................................................ 31!

S1 Vivaldi II Owner’s Manual

Page 3

1 Feature Overview

! Dual Boiler

! Steam Boiler 2.5 liter

! Steam Boiler Element 1250 Watts

! Group Boiler .45 liter

! Group Boiler Element 800 Watts

! Direct Plumbed

! Rotary Pump

! Volumetric Dosing Adjustable Through Touch Pad

! Group Temperature Indicated by lamp Display

! Group Temperature Adjustable in 1°C Increments Through Touch Pad

! New and Upgraded machines since 7/1/2008 include Extended Temperature Offset

Adjustment and Programmable Preinfusion

! Electronic Boiler Refill

! Built in Safety Thermostat

! Semi Automatic Hot Water Delivery

! Manual Steam Valve

! Fault Diagnosis Alarms

! Combined Boiler and Group Pressure Gauge

! Two Complete Portafilter handles - Single and Double Baskets

! Extra shower screens, removal wrench, cleaning brush, tamper

! Includes rubber back flush disk

! OPTIONAL Pre Infusion Chamber

! OPTIONAL 7 Day Programmable Timer

! OPTIONAL No Burn Steam Arm

! OPTIONAL longer La Spaziale steam arm

! OPTIONAL Drain Kit

! Color Black, Silver, or Red

! 110 volt

! Available in either 15 amp or 20 amp

! ETL Sanitation Listed (Conforms to ANSI/NSF STD 4)

! c ETL us Listed (Conforms to UL STD 197 Certified to CAN/CSA STD C22.2 NO. 109

2 Reference Photos

These numbered photos will be referenced throughout the document; i.e. (13)

S1 Vivaldi II Owner’s Manual

Page 4

FIGURE 1 – Indicator Lights and Control Buttons

S1 Vivaldi II Owner’s Manual

Page 5

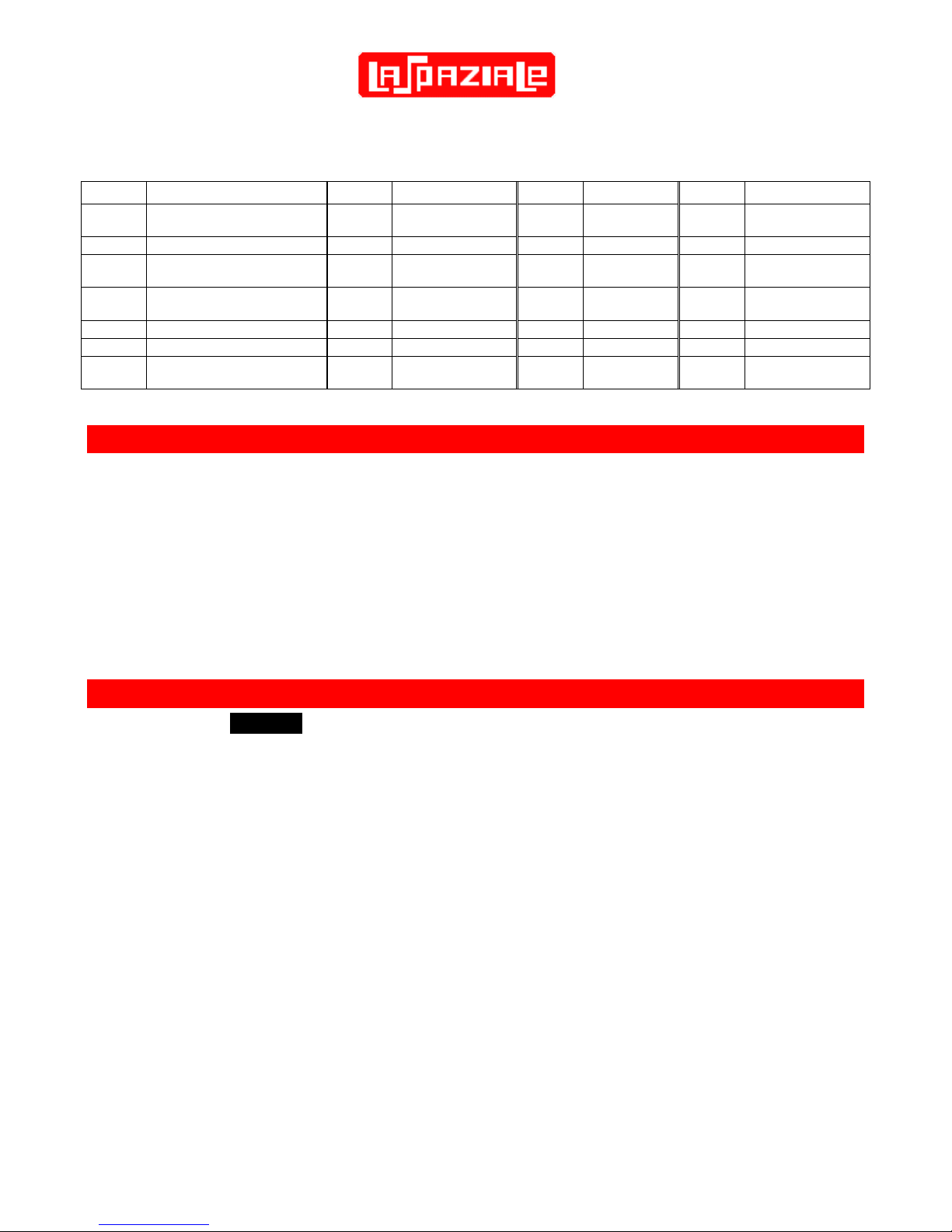

Label

Function

Label

Function

Label

Function

Label

Function

1

Drip Tray

8

Cup Warming

Tray

15

92°C Lamp

22

On/Standby

Lamp

2

Steam Arm

9

Control Panel

16

93°C Lamp

23

Hot Water Button

3

Rubber Feet

10

Group

17

94°C Lamp

24

Single Cup

Button

4

Steam/Group Pressure

Gauge

11

Portafilter Handle

18

95°C Lamp

25

Double Cup

Button

5

Side Panels

12

Drip Tray Grate

19

96°C Lamp

26

Boiler Button

6

Steam Knob

13

Boiler Lamp

20

97°C Lamp

27

On/Off Button

7

Splash Panel

14

91°C Lamp

21

ECON

Lamp

28

Hot Water Outlet

3 Document Scope – Caveats and Clarifications

This manual includes material that both duplicates and enhances the official LaSpaziale S1

Vivaldi II Instruction Manual in key areas. However, it does not duplicate the detailed and

very important information covering machine certifications or ratings nor does it repeat all the

warning and safety information contained on the “lawyer” pages. That information, as

contained in LaSpaziale Instruction Manual, is considered included in this document by

reference.

This document solely covers the S1 Vivaldi II plus options available and supported by Chris

Coffee Service and/or other vendors supplied by Chris Coffee Service through its exclusive

distribution agreements with La Spaziale S.p.A.

4 Basic Machine Operation

(BOLD = lamps, Reverse = buttons, numbers in parentheses reference to above table)

4.1 15A or 20 Amp Operation

Please read this section first, especially if you purchased the 20A version of the

LaSpaziale VII Mini but do not currently have an available 20A outlet.

The LaSpaziale VII is available in 15A and 20A versions. In actuality, they are both identical

machines. There is an internal switch that selects the operating mode and they have

different power cords installed. The power cord is the easiest way to tell which version you

have. The 15A VII has a standard 3-prong AC plug with two parallel blades and a round

ground pin. The 20A VII has a 3-prong plug with two perpendicular blades and a round

ground pin. The 20A version therefore requires a 20A circuit which has a special 20A outlet

which accepts the 20A plug.

Most modern kitchens have 20A circuits. However, they often do not use 20A outlets

because multiple outlets may be on the same 20A circuit. If you have a 20A circuit with a

20A outlet this most likely means that outlet has its own dedicated 20A circuit and is safe to

use with the VII. A 20A circuit with normal 15A outlets probably means that multiple kitchen

outlets are on the one 20A circuit. Often this means the refrigerator outlet. 20A VII owners

should contact their electrician if unsure how to proceed.

S1 Vivaldi II Owner’s Manual

Page 6

The internal switch which places the VII in 15A mode does so by never allowing the group

boiler and the steam boiler to operate at the same time. When the thermostats for both

boilers try to turn on at the same time, the group boiler always has precedence, and then the

steam boiler operates in sequential fashion. A number of 15A VII owners note that they see

little operational effect when running in this mode.

The 20A VII allows both boilers to operate simultaneously. HOWEVER, it is possible to place

the 20A VII into 15A mode without removing the covers from the machine and flipping the

internal mode switch. This is called ECONOMY mode and is described later in this manual.

As a temporary solution, Economy mode is a great option for those that really want the 20A

machine but that do not currently have a 20A circuit. However, this will require swapping out

your standard 15A outlet with a 20A outlet. These are readily available from most hardware

stores. For a more temporary solution there is an alternative such as this adapter cable

available from Chris Coffee Service:

http://www.chriscoffee.com/products/home/espressoaccs/20t015adaptorplug. It is also

available elsewhere or you can make your own with a quick trip to your local hardware store.

Locating/Changing the 15A / 20A Mode Switch

1. The Vivaldi VII must be unplugged and allowed to cool down first.

2. Remove any cups from the cup warming tray (7)

3. Remove the single screw in the front middle of the cup warming tray (7) as shown in

the photo below

S1 Vivaldi II Owner’s Manual

Page 7

4. From the front of the machine look down into the top of the machine. In the right rear

of the machine you will see a toggle switch with its positions labeled 15 and 20. Reach

down with the same screwdriver you used to remove the cup warming tray and flip the

switch to the desired position.

4.2 Optional On/Off Timer Accessory – Overview and WARNING

The S1V2 has an optional On/Off Timer that can be purchased which provides the capability

for up to 3 On/Off cycles per day with a different program for all 7 days of the week, if so

desired. Each new machine has the cable needed to plug this timer into cable tied into place

just behind the front panel. More information including the installation manual can be found

here: http://s1cafe.com/s1v2/images/Vivaldi%20Timer%20Instructions.pdf

S1 Vivaldi II Owner’s Manual

Page 8

There is a switch labeled ON / OFF on top of the controller box adjacent to the 15A/20A

switch shown in the above photo. (The ON/OFF switch is hidden in the photo.) This switch

must be set to OFF if you do not have the Timer plugged in and it must be set to ON when

the timer is installed. Also, the state of this switch is only sensed when the power cable is

unplugged, then plugged back in. So if you need to change this switch you will need to

unplug the machine for at least 5 seconds after you do so.

WARNING: If you do NOT have the Timer installed but you have the switch set to ON, the

pump will not come on when you try to pull a shot.

4.3 Initial Installation Before Connecting Power

After removing the VII from its packing carton and setting it on the counter, check for

additional installation instructions that may be included. You should also have all the

accessories shown in the photo below including a rubber backflush disk (not shown).

Tip the VII on its side. Twist all four rubber feet (3) hand tight as they may vibrate loose

during shipping. While performing that task, use a screwdriver to ensure that the four screws

on the bottom (two on each side between the rubber feet) which fasten the two side panels

(5) to the chassis bottom are tight. These steps will help ensure the quietest possible

operation of your VII.

Be sure you connect the included water hose to the threaded water inlet on the bottom of the

machine. Proper connection is obvious since there is only one place it can attach. The

opposite end of the hose - which connects to the water supply - may require adapters from

your local hardware store depending on your specific situation. Contact your VII dealer for

advice if the solution isn’t obvious. Also, your VII dealer may request that you check that your

water hardness is below a certain level to ensure long life and trouble free operation.

S1 Vivaldi II Owner’s Manual

Page 9

Hardness test strips may be included for this purpose. If your water fails this test, contact

your VII dealer and discuss the available options.

Once water supply is properly attached, turned on, and the desired basket has been inserted

into one of the portafilter handles, attach the portafilter to the group. Be sure that the drip tray

is installed by sliding it into place at the bottom front of the machine.

4.4 Turning On and Heating the Machine

1) Insert the plug into the 110V AC socket, the On/STBY light (22) starts flashing. (Standby mode).

2) Press the ON / OFF (27) button and keep it pressed for about 3 seconds, the green

On/STBY light (22) changes from flashing to steady indicating the machine is ON. At

the same time the lights from (14) to (21) turn on steadily for about a second

(indicating power on test mode).

3) The light corresponding to the set temperature starts flashing to indicate that the group

is heating and the automatic boiler refill starts until the water level preset by the

manufacturer is reached.

4) Once the filling process is finished, the BOILER light (13) starts flashing to indicate

that the boiler is heating. However, after first switching on, the boiler doesn't work until

the group has reached the set temperature.

5) Fasten the portafilter handle (11) to the brewing group (10).

6) Wait until the set temperature is reached, by checking that the lights on the control

panel (9) gradually turn on as the temperature rises. The visualization starts as soon

as the temperature reaches 91°C (turning on of light 14) and continues until the

machine has reached its operating temperature (light from flashing to fixed).

7) When the group has reached the set temperature, the boiler heating starts (BOILER

light (13) flashing), once it reaches the set temperature the light becomes fixed.

8) Every time the group temperature or the boiler temperature drops under the set value,

the respective light starts flashing (heating phase) until the set temperature is reached.

9) The machine is now ready.

WARNING!!

To activate and deactivate the boiler mode press the BOILER (26) button. Every time you

turn on the machine, the boiler is in service.

When the boiler is turned off, it is impossible to use hot water for infusions or steam delivery.

The machine can also operate in the economy mode (see relative paragraph).

4.5 Espresso Brewing

1. Unfasten the portafilter handle (11) from the brewing group (10) and insert the filter for

one or Double Cups. Fill it with ground coffee (aprox 7g for a single or 14-15g for a

double), making sure not to leave coffee powder on the upper edge of the portafilter

handle (11), and press it with the suitable coffee tamper provided.

2. Firmly attach the portafilter handle (11) to the brewing group (10).

Loading...

Loading...