Operating and maintenance manual

150515

ELECTRONICS WATER SOFTENERS

Balugani S.r.l. - Divisione Trattamento Acqua

via Iacobella ,11 – Villanova di Denore – Ferrara (FE)-Italy

tel.+39 0532 427485 – fax. +39 0532 427487

www.baluganisrl.it

Technical specifications

Operating temperature: min. 5°C – max 50°C

Operating pressure min 1,8 bar - max 5 bar

Power supply: 230v/50Hz (230V\12Vcc by electrical transformer supplied)

MODEL

Average Capacity

(with input water hardness = 40°F)

BAV5

450 LITERS

BAV8

650 LITERS

BAV10

800 LITERS

BAV12

1200 LITERS

WARNINGS:

Automatic BAV softener family have electronic head that provides a system of regeneration of the

resins in volume, which is preferable to the chronometric system because the software in the

microprocessor of our electronic volumetric controller enables the start-up of the resin regeneration

only when necessary, or only when a certain volume of water has passed through the resin..

The technology of these electronic controllers is internationally patented and certified according to the

requirements of "CE", "RoHS" and NSF.

In a low water comsumption state, the water softener will regenerate the resin every 3 days (this is

programmable data).

Operating Conditions

BAV WATER SOFTENERS MUST BE USED FOR ALREADY DRINKING WATER TREATMENT ONLY;

SHOULD NOT BE USED FOR OTHER USES, TAMPERED OR MODIFIED.

ANY OTHER USE MUST BE CONSIDERED IMPROPER AND POTENTIALLY DANGEROUS.

THE PRODUCER CAN NOT BE HELD RESPONSIBLE FOR ANY DAMAGE DUE TO MISUSE AND

UNREASONABLE USE.

THE WATER SOFTENER MUST NOT BE USED TO TREAT DIFFERENT LIQUIDS THAN WATER.

USE PURE SALT TABS ONLY INTO THE BRINE TANK.

ALWAYS CHECK THAT THE ELECTRICAL CONNECTION IS COMPATIBLE WITH ELECTRICAL DATA

DEVICE TO BE CONNECTED.

IS FORBIDDEN WASH THE WATER SOFETENER BY JETS OF WATER.

IS FORBIDDEN REMOVE THE WATER SOFTENER CONTROL VALVE PROTECTIONS.

FOR ANY DEVICE REPAIRS, REFER TO AUTHORIZED SERVICE CENTER.

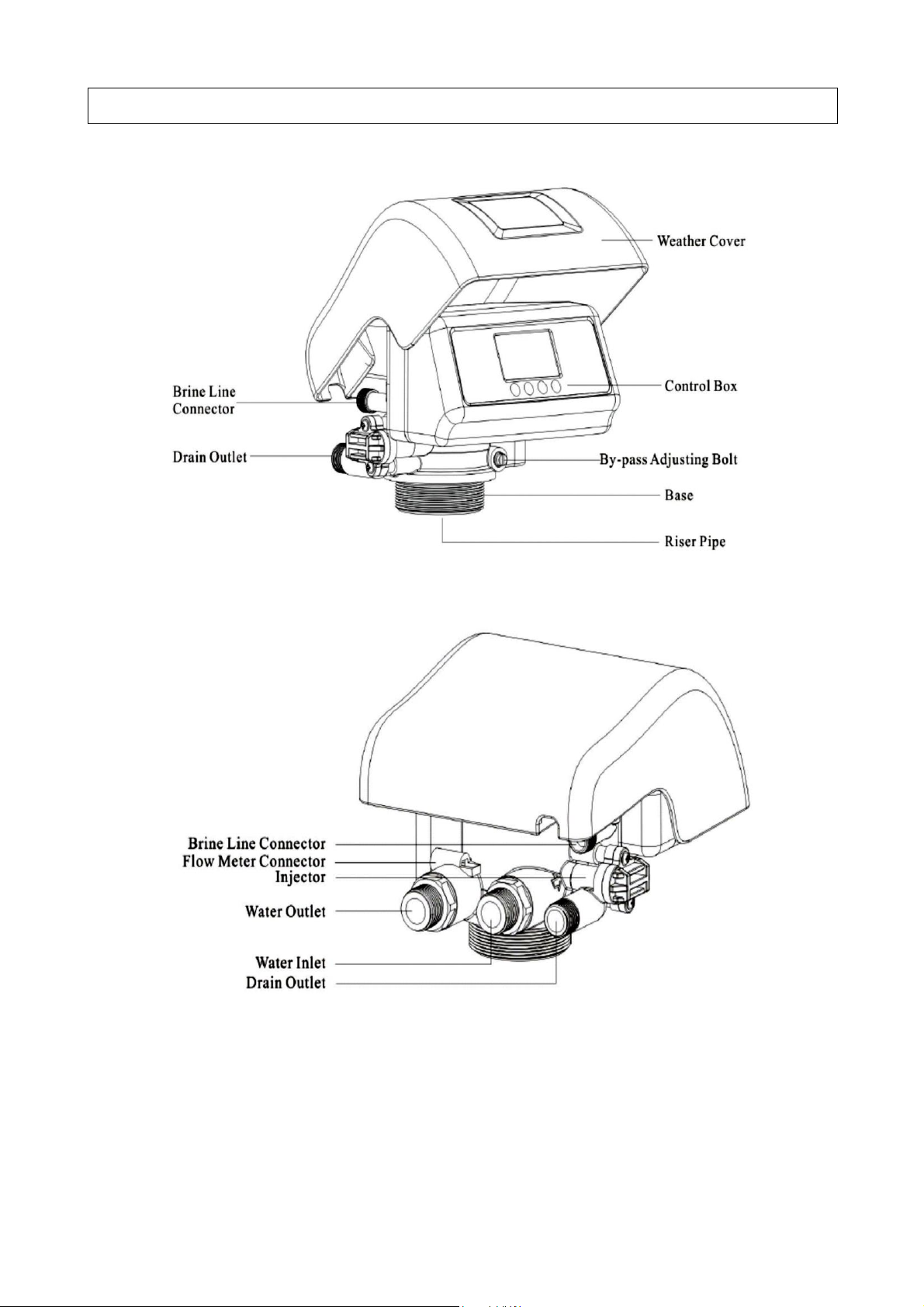

CONTROLLER DESCRIPTION

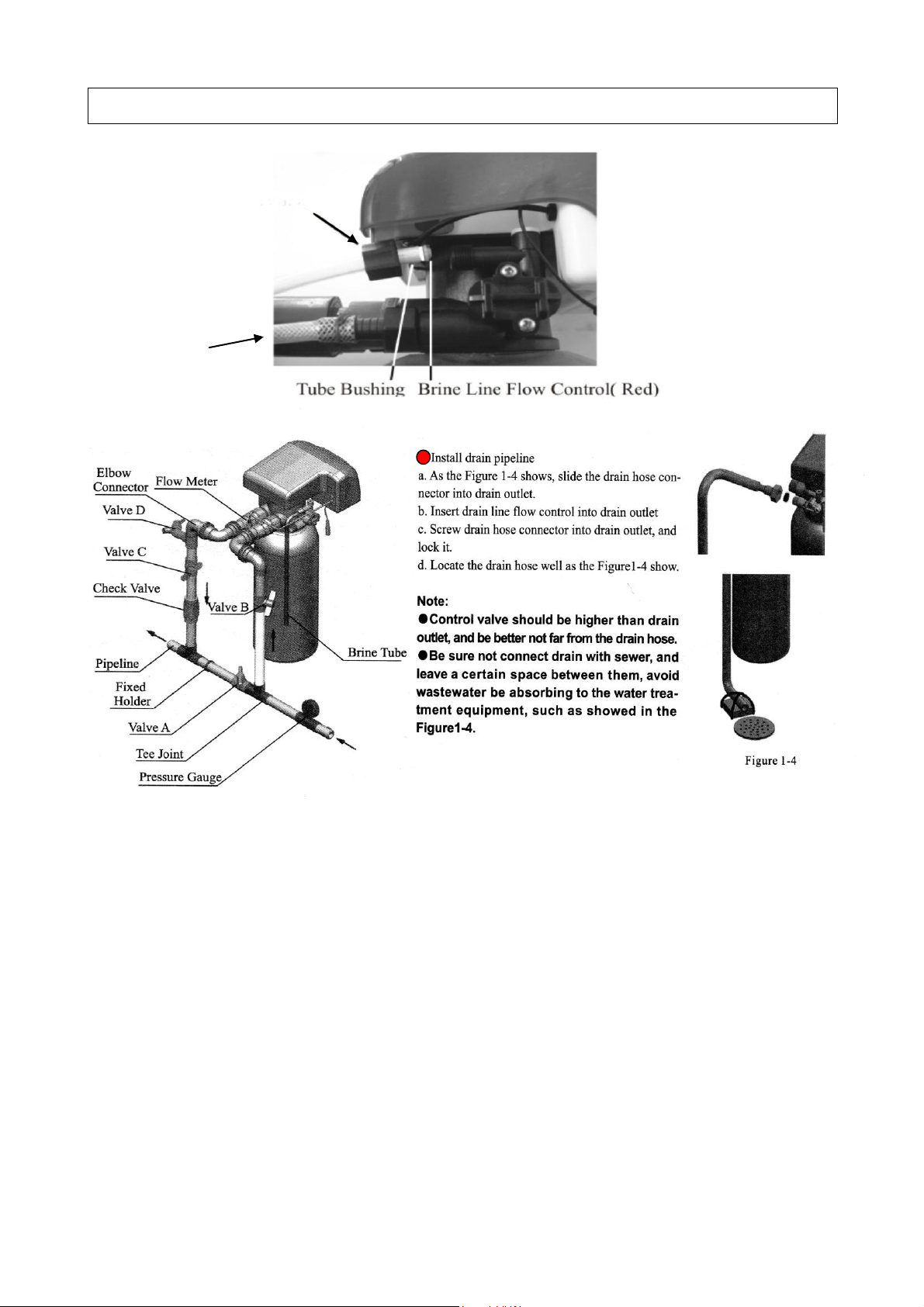

Connections and installation

Brine line

connector

DRAIN

The installation must be carried out as required by the regulations in force in the country

where the installation is performed by qualified and authorized personnel.

Incorrect installation can cause damage to the environment , people, animals and objects

for which the manufacturer declines all responsibility.

Please note that an optimal positioning of the softener will be useful when you make the

necessary routine maintenance , repairs in the field and the loading of salt in the container

of the brine.

The drain hose should be connected permanently to the appropriate hose ( see Image

above ) , verifying that the tube is of flexible type , of appropriate section and that there are

no bends along its length .

The drain hose must not be immersed in wells with standing water because it could cause

a backflow of water into the water sostener.

The excessive environmental heat or freezing can severely damage the water softener is

recommended that you place it in places with temperatures not lower than 2 ° C and no

higher than 50 degrees Celsius.

For optimal functionality of the water softener, minimum inlet water pressure must be 1,8

bar and maximum inlet water pressure must be 5 bar.

The softener BAV has been designed for the treatment of cold water and temperature limits

are : minimum 5 ° C and maximum 45 ° C.

START-UP

Periodic maintenance and inspections

After installation, you will have to proceed with the first water softener start-up.

1) Put water into the vat of salt (BAV5 = 2.5 Lt - BAV8 = 4LT - BAV10 5Lt - BAV12= 6Lt)

Later this will be done automatically by water softener after each regeneration of the resins.

2) Pour the salt (possibly pads) in the vat, until no longer than 3 \ 4 of the capacity of the

container.

3) Slowly open the tap which feeds the water softener and then open a tap of users

downstream of the softener in order to allow to free the pipes from the air and to perform a

sort of rinsing of the resins (3-5 minutes will be enough)

4) perform a visual inspection of all parts of the softener to exclude the presence of a water

leak.

Two or three times each year , must be performed the cleaning of the vat of brine for the

removal of sediment and foams which periodically may be formed by the salt deposits .

The resins contained in the blue tank have an average life of five years and after this period

must be replaced by qualified personnel.

To check the status of the resins , perform a test of the water hardness immediately after

the end of a regeneration .

If water were to be " hard" , this could be the signal of the exhaustion of the capacity of the

resins to perform the function of softening and you will have to proceed with the

replacement of the resins .

Regeneration of the resins takes place by means of hydro saline solution formed with the

dissolution of the salt in water, then it will be appropriate to keep under control often the

level of salt present in the vat and fill the brine tank in case the salt should be scarce.

For a correct functioning of the softener we recommend to use only the salt for water

softener system (pads).

If you have installed a filter before the softener , it must be cleaned regularly 3-4 times a

year and, if necessary , replace it with one with the same characteristics .

TIME SETTING

If the time displayed will be incorrect , you have to set the exact time , following

the steps below:

If you see the padlock symbol in the upper left, it means that the keypad is locked and to

unlock it you have to press the up / down keys simultaneously for a few seconds

When the padlock symbol will turn off , press MENU \CONFIRM (will appear SET 12 to 24

CLOCK)

Press the DOWN ARROW button , go to the item SET CLOCK and press

MENU \CONFIRM button

Use the up \ down keys to adjust the time and confirm by pressing MENU \ CONFIRM

To return to the service page , press MANUAL \ RETURN.

After a minute, the lock symbol will reappear and the panel will return to safety mode

CAUTION : ANY OTHER ELECTRONIC DEVICE PARAMETERS ARE ALREADY SET

BY OUR TECHNICAL SPECIALIST AND RECOMMENDED FOR MOST USERS .

ADDITIONAL SETTINGS ARE NOT REQUIRED BY THE USER.

Selection of language on display

The BAV display is multi-language.

To select the language you wont, follow these instructions :

1. Switch-off the power supply

2. Hold down the keys (press at the same time)

Then switch-on the power supply (still holding the key)

3. After 5 seconds, will appear the languages list

4. Release the two keys

5. using the arrows keys, scroll down to the language you want and confirm using

the key

Now your language is selected on display

How to adjust the output water hardness

Hardness Adjusting screw

The control valve of the automatic water softener BAV is equipped with a system for

adjusting the water hardness (water softener output)

Using a screwdriver on the adjustment screw indicated in the above picture , it is possible

to mix the output water treated (about zero French degrees), with the hard water , in order

to increase the treated water hardness degrees.

When the screw is completely screwed-in, the treated water will have zero degrees of

hardness.

If you unscrew the screw gradually, you will get more degrees of hardness.

The adjustment precision of the screw depends on the characteristics of the water to be

treated and it should be better use a kit for measuring the hardness of the water, easily

available on the market.

Please note that the automatic water softener BAV is usually set to zero degrees of

hardness.

--- SPARE PARTS ---

ITEM

DESCRIPTION

CODE

1,21,22,23,24,25,26,27,28,29,46,47,48

COMPLETE BAV VALVE BODY

CORVCBAV

2,3,4

VOLUME METERS

CONV

5,6

INPUT VALVE FITTING

RACIV 8 DRAIN FITTING

PORS

11,12,13,14,15,16,17,18

INJECTOR DEVICE

BLOEC

43,44,45

MOTOR

MOTC

32,33,41

VALVE PLASTIC BOX

SCAVC

34,35,36

ELECTRONIC SOFTWARE CARD

SCHSC

38,39

DISPLAY HOLDER

FROVC

37,40

DISPLAY

SCHDC

49

TRASFORMER 100-240\12Vcc

TRA22012V

30,31

DISK AND PHASE CARD

DSCHGF

49

--- SPARE PARTS ---

ITEM

DESCRIPTION

CODE

1,2,3,4,5,6,7,8

SAFETY FLOAT VALVE

GALBAVX

“VALBAV” CODE INCLUDES UNDER-VALVE ORING, RISER PIPE O-RING AND UNDER-VALVE

STRAINER

“PESRBAVx” includes riser pipe and filter (“x” is

the number at the end of water softener code example BAV”5” or BAV”8”)

Liability and warranty conditions

The automatic water softener referred to in this manual is covered by the warranty, as

required by applicable law ( the Consumer Code and the Civil Code) , starting from the

invoice date of the product.

The document to prove the date of purchase of the product must be kept for the entire

period of warranty coverage.

The warranty covers the replacement or free repair of the parts to be defective at the origin

due to manufacturing defects or otherwise affect the proper functioning of the softener.

La garanzia copre esclusivamente il prodotto o parte di esso e non verrà in ogni caso

estesa qualora si verifichino danni a terzi.

Are also not considered warranted defects due to neglect, misuse or improper

maintenance of the product, as well as incorrect installation or maintenance performed by

unqualified personnel .

The warranty excludes any worn parts whose defects are the result of normal wear and

tear of the product under normal conditions of use.

Are also excluded from the guarantee , the interventions concerning installation and

connection to electricity and water supply systems , and maintenance procedures

contained in this manual .

It is up to the buyer to perform the following checks:

a) upon receipt of the goods and before releasing signature release to the carrier, to make

the assessment of the gender and number of items which must be the same as indicated

on the transport document , also the assessment of the external conditions of the

packages,with special attention to signs of possible damage or tampering that may have

affected the quality and integrity of the product inside .

b) no later than eight (8) days from the date of delivery, the buyer will have to perform a

quality control of the products received .

The buyer will have to compare the order with the material received.

Dichiarazione di Conformità – Declaration of conformity

Our products meet the essential safety requirements of the directives applicable to the

product .

D.M. 07/02/2012 N.25 Rules concerning water treatment equipment (water for human

consumption)

D.M. 174/2004: rules relating to materials and objects that can be used in fixed

collection, treatment, supply and distribution of water intended for human

consumption (G.U. 17 July 2004 , n . 166)

LV DIRECTIVE:

2006\95 CE

EMC COMPATIBILITY:

2004\108 CE

RoHS

2011\65\CEE

MACHINERY DIRECTIVE 2006\42\CE

ACS (RESIN TANK)

HEALTH COMPLIANCE

Note: In accordance with the national regulations , the installation company must

issue the client with a statement of compliance outlining the systems made .

FERRARA, 08.01.2014

SPECIAL WASTE : Dispose of separately from normal waste and

enforce existing laws in the country where this product is disposed of

Loading...

Loading...