Page 1

OPERATING INSTRUCTIONS

CHIPPER

LS 150 T

Orig. version: 08.2016

Page 2

2

Foreword

Thank you very much that you have just purchased our product, the chipper

LS 150 T. Our company has been engaged in production of equipment for wood residues

crushing and disposal for many years and has gained considerable experiences in this field.

Quality of our small and also powerful machines is proven in 40 countries of Europe and Asia

we export to.

Permanent innovation of the Laski s.r.o. manufacturing assortment was crowned by the Gold

Medal for our complex family of shredding and chipping equipment KDO and LS at the

occasion of the International Trade Fair.

Grand Prix Techagro 1998

Grand Prix Silva Regina 2002

Grand Prix Silva Regina 2008

This manual brings important instructions for users, i.e. instructions for putting the machine

into operation, work safety and operating experiences. You will learn how to carry out

maintenance, repairs and servicing and who is authorised for doing checks and other actions

on the machine.

Your local dealer will give you this manual with instructions for operation and maintenance

while taking this new machine over. Make sure, if you understand everything. If not, do not

hesitate and contact your dealer and ask him for explanation. It is very important for you and

your work safety to understand all instructions given in this manual.

The firm Laski spol. s r.o. does not bear any responsibility for any claims resulting from

disobedience to the instructions given in this manual.

This operation manual includes also work safety instructions in various parts of the text. If

there is any work safety rule or instruction in general description, then this instruction is

indicated with the following symbol:

Page 3

3

Contents

FOREWORD ........................................................................................................... 2

CONTENTS ............................................................................................................. 3

PRODUCT IDENTIFICATION ........................................................................... 5

WORK SAFETY INSTRUCTIONS ..................................................................... 8

UTILISATION ......................................................................................................... 8

NOT ALLOWED USE .............................................................................................. 8

GENERALLY .......................................................................................................... 8

WORK SAFETY SYMBOLS .................................................................................... 14

TRANSPORT OF PRODUCT/HANDLING ................................................................. 15

PRECAUTIONS IN DESIGN .................................................................................... 16

CONTROLS .......................................................................................................... 18

USE ........................................................................................................................ 19

TRANSPORT SAFETY ........................................................................................... 19

STORAGE ............................................................................................................. 21

BEFORE PUTTING INTO OPERATION .................................................................... 21

COUPLING TO TRACTORS .................................................................................... 23

PUTTING INTO OPERATION .................................................................................. 24

CHIPPING ............................................................................................................ 25

PUTTING OUT OF OPERATION .............................................................................. 29

EMERGENCY SITUATIONS ................................................................................... 29

TECHNICAL DESCRIPTION ........................................................................... 30

Chipping Device ............................................................................................. 30

Frame ............................................................................................................. 31

Technical Parameters..................................................................................... 31

MAINTENANCE ................................................................................................. 32

Lubrication ................................................................ ................................ ..... 32

Blade Grinding ............................................................................................... 33

Chipping Adjustment ...................................................................................... 35

NOSTRESS System – Speed Regulation ......................................................... 36

NOSTRESS SYSTEM PROTECTION AGAINST OVERVOLTAGE ............................... 37

Maintenance Intervals .................................................................................... 38

Checking, Oil Exchange ................................................................................. 39

Page 4

4

FAILURES AND TROUBLESHOOTING .................................................................... 39

WASTE DISPOSAL ............................................................................................... 41

USE OF THE CHIPPER EQUIPPED WITH A HITCH ..................................................... 41

WARRANTY ........................................................................................................ 44

SERVICE REPORT ............................................................................................ 46

Page 5

5

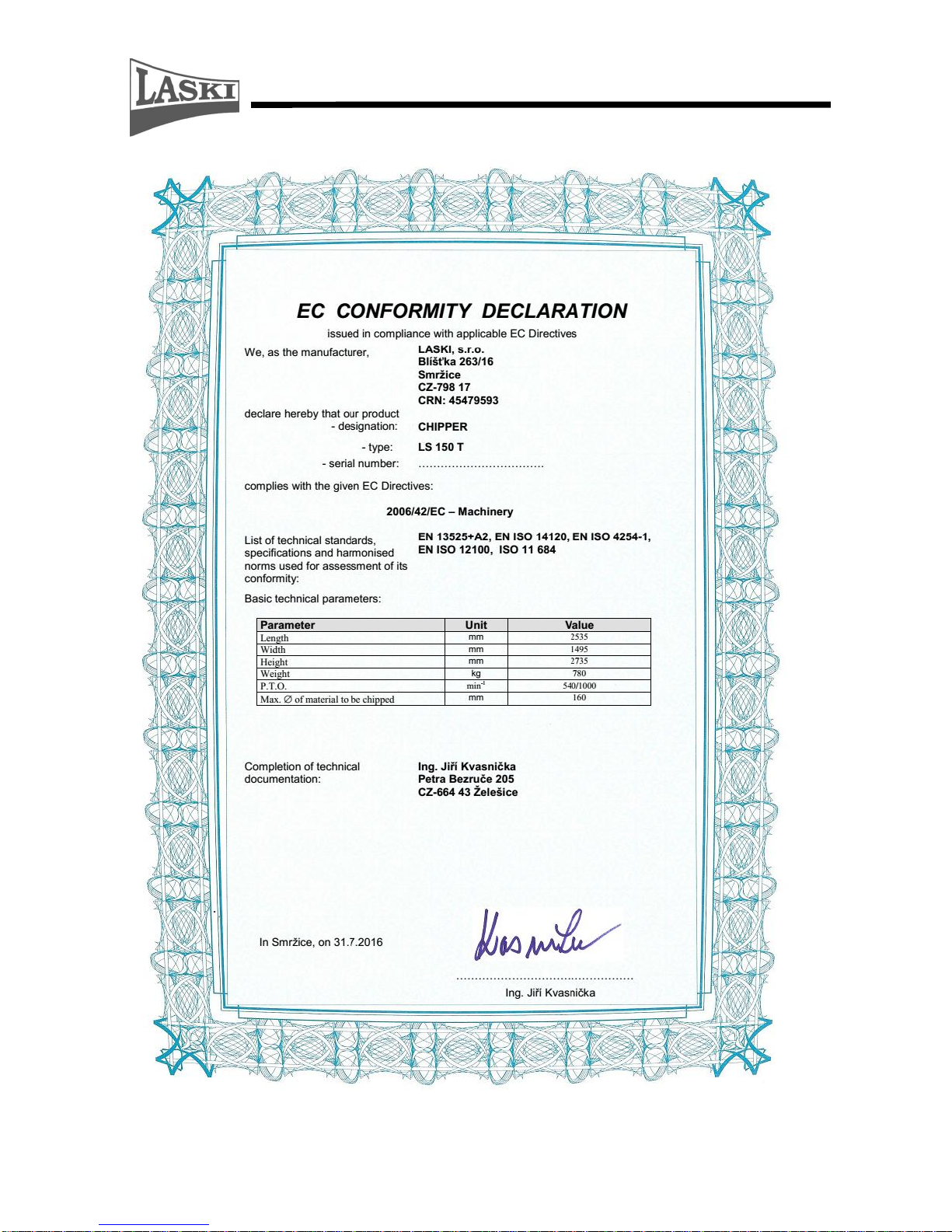

Page 6

6

Page 7

7

Product Identification

Our product is identified with its serial number stamped in its type plate on the frame. Upon

take-over of the product we recommend you to fill required data in the following form

concerning the given product and your dealer.

Type of product:

…………………………………………………….

Serial number of product:

……………………………………………………..

Dealer's address:

……………………………………………………..

Address of authorised service:

……………………………………………………..

Date of delivery:

……………………………………………………..

Warranty expiration date:

……………………………………………………..

Interruption of warranty period:

……………………………………………………..

This type plate includes:

- manufacturer's

data

- type

- serial number

- weight of machine

Page 8

8

Work Safety Instructions

Utilisation

This chipper, being coupled with a tractor three-point hitch, is designed for

disposal of wood waste, twigs, barks, branch-wood and other above-ground

biomass or for manufacture of chips from aforesaid materials and also for disposal

of redundant timber, such as sticks, deals, pickets etc. The chipper can dispose all

these materials with diameter up to 160 mm or flat boards and plates with thickness

up to 60 mm. These wooden pieces must be free of metal, glass and other similar

objects. While working, the chipper must be relatively levelled.

The chipper should be controlled and operated by two attendants who in turns load

materials to be chipped in a loading chute.

Not Allowed Use

The chipper is not allowed to be used for disposal of aforesaid materials with

foreign matters and objects, such as metal, steel binding bands, glass cullet, stony

debris, ceramics etc.

It is not allowed to use the chipper in the presence of unauthorised persons who

may stand or move in direction of discharge ducting. At work in residential zones

use the machine in accordance with regulations of the local authorities to avoid

disturbing of local inhabitants (noise level). It is not allowed to use the chipper, if

its loading chute height above the ground is less than 600 mm and if its cardan

shaft is deformed or damaged.

Generally

- This machine is allowed to be operated only by attendants who are over 18 yrs

old, physically and mentally capable and demonstrably instructed with its

operation.

- One of two attendants at least (a tractor driver) should have a respective

driver's license, group "T".

- This machine can be operated by two persons only.

- Any training course for attending personnel should include also practical

operation under supervision of an experienced person or your dealer and

necessary work safety instructions.

- Before working learn all functions of individual controls and safety elements

(safety frame) and carry out functional checks before any use. Check

especially loading of materials, i.e. the controller frame. By pushing the

Page 9

9

concerned controller in infeed direction this machine must stop loading

materials and by its next pushing the loading rolls should turn back while

being under permanent pressure (pushing). The controller frame have to be

advanced in front of the hinged loading chute edge so that the attendant stops

the loading rolls, or let them turn back, at pushing by using parts other than

hands (e.g. shoulder, elbow, hip, legs etc.).

- It is strictly forbidden to change or to set the controller frame so that the STOP

position is under the loading chute edge.

10

- To stop loading it is also possible to press the STOP button under the loading

chute.

- It is forbidden to tighten the fixing nuts on the safety frame with intend to

increase its resistance against unwished switching off. Required force for

switching control should remain on values preset by the manufacturer, i.e. up

to 80 N in the lower horizontal frame part.

- Any removal of safety elements and guards from the machine and any further

operation without them are strictly forbidden.

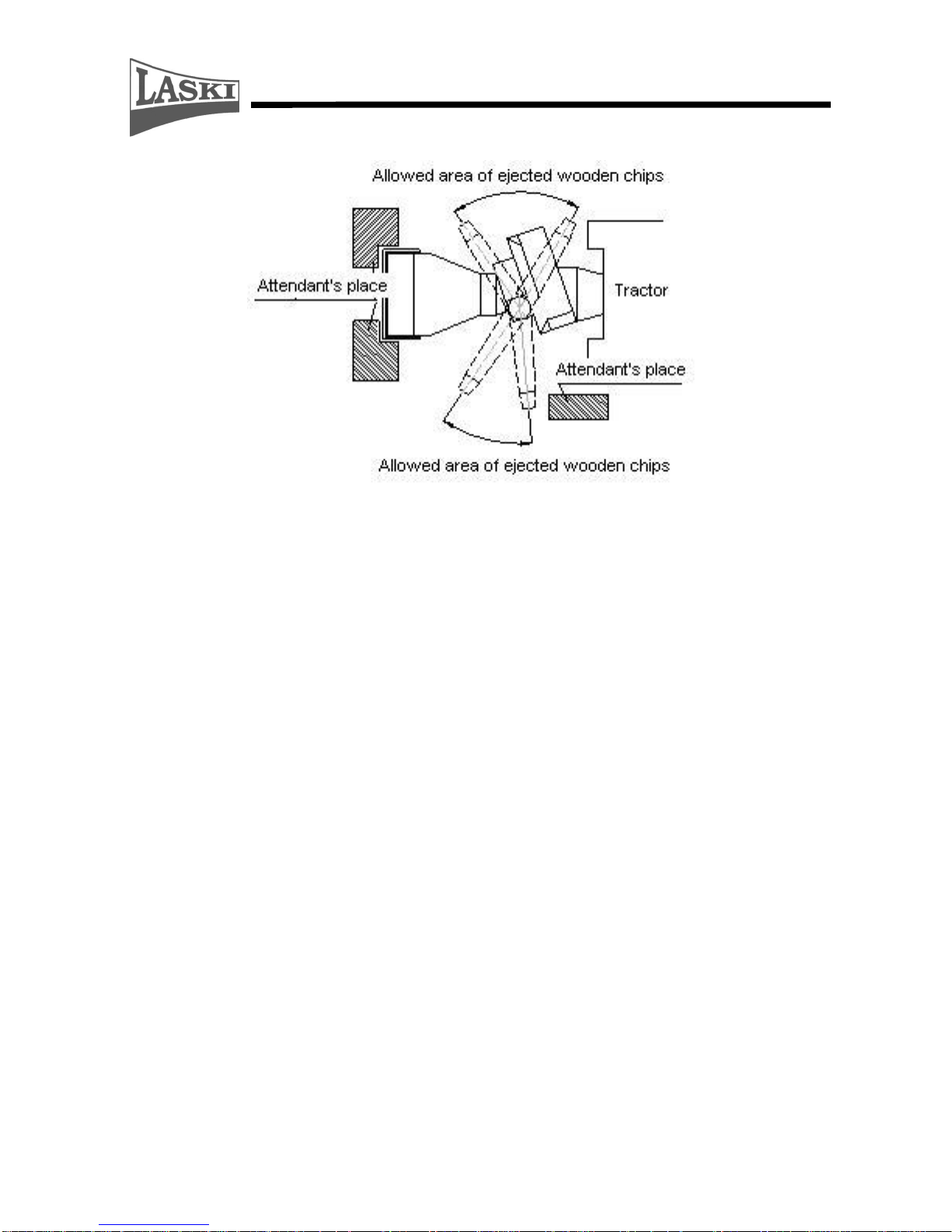

- While chipping it is not allowed to enter the area of ejected flying wooden

chips.

- The end piece of the discharge duct (its upper turnable part) can be set only in

angles, see following figure. Never direct it toward the attendant's place!!

Page 10

10

- While working the chipper should rest on the ground.

- Keep this machine beyond children's and unauthorised person's reach. Avoid

their attendance while chipping.

- When using the chipper without any container or closed bin, keep anybody

beyond the area where chips are being thrown.

- When using the chipper with such a bin, never look inside if the chipper is still

working.

- When leaving the machine take always the switch key out of ignition.

- Every operator of this machine is fully responsible for any injury or damage

caused to the third persons within the operating reach of the machine.

- At work in residential zones use the machine in accordance with regulations of

the local authorities to avoid disturbing of local inhabitants (noise, flying

chips).

- Warning !!! Be aware of ejected particles. They have substantial kinetic

energy. If the loaded wooden material contains not allowed parts, such as

metal, sand, glass etc., then such objects can reach a longer distance than

wooden chips. Direct the discharge duct to regulate its ejecting as needed.

- Instructions for use of the cardan shaft operation and the trailing tractor are an

integral part of this manual and should be always respected.

- While coupling the chipper to a tractor do not stand between its towing bar

and a tractor. Do not stand behind a towing tractor while backing. Ask other

person to help you with coupling.

- First it is necessary to couple the cardan shaft to the chipper input shaft, then

the lower linkage, the upper drawbar of the three-point hitch and finally the

tractor PTO shaft.

Page 11

11

While chipping the operator is obliged:

to use only such a chipper which is in optimal operating condition, not

damaged through transport, storage of from previous operation,

to check functions of all controls and safety elements, particularly the

controller frame, before putting the chipper into operation,

to avoid disturbing of other people with noise, exhaust fumes or ejected flying

particles (at windy weather),

to keep traffic rules and local regulations when going or working on or nearby

public roads,

to turn the machine off if the discharge duct is clogged.

Clean the duct at standstill only. For cleaning use only suitable hooks or bars

to release pressed materials. After repeated putting the chipper into operation

let the machine run idle in the chipping mode to empty the whole discharge

ducting. If proper cleaning is required, then take always the switch key out of

ignition before removing its hoods.

When working never lean over the loading chute and never push wooden

materials with your hand or leg only. Use always a wooden stock or a bar to

push materials between the loading rolls.

While working wear always personal protective equipment - protecting shield

or goggles, protective gloves, working shoes and working cloth properly

buttoned. Avoid wearing free parts, such as ties, scarves and shawls, belts etc.

In case of longer hairs use always a proper head piece. Otherwise, such a

person is not allowed to operate this machine.

In case of two attendants it is necessary to make simple signals clear before

working and to appoint one who will manage the work.

If any object, not allowed to be chipped, falls down into the loading chute, do

not try to pull it out with your hand. It is very hazardous for your health and

operational safety. Turn always the machine off.

- Keep traffic lights and work safety symbols in proper order.

- Check materials to be loaded and remove all undesirable objects. If you see

such particles in ejected chips, stop working immediately.

- This manual describes problems and faults which could occur at work and

which may be remedied by an instructed person. In case of other problems and

faults do not hesitate and contact the manufacturer. He is always ready to help

you.

- Never do any technical changes or any actions which are neither given in this

manual nor allowed by the manufacturer. The machine, not correctly installed

or adjusted, may run without problems now but in the future it could damage

Page 12

12

any of important parts. Pay regular attention to all joints and bolts. Keep them

properly tightened.

- Do not put any objects or tools on the machine.

- The manufacturer does not bear responsibility for any damages or injures

caused to the third persons or to other equipment resulted from disobedience

to instructions given in this manual.

- When handing the machine over to another person make sure if all controls,

guards and other safety elements are complete and fully functional.

- Never remove guards and other safety elements. They serve for your safety.

- Keep the given intervals for checks of bolted joints.

- Always after work clean all parts of the machine properly. Pay your attention

especially to any oil spots or fuel leakage. Clean any oily spots.

- Some parts of the machine can be hot while in operation. Avoid any settling of

flammable chipped materials on such parts or close to fuel tank, hydraulic oil

tank and exhaust manifold. Stop working if such deposits exceed 1 mm.

- Any servicing can be done only if the machine was put out of operation, its

battery was disconnected and the cardan shaft was uncoupled. If the chipper is

still coupled to the three-point hitch, block the tractor (wheels) against

unwanted motion.

- Do not use petrol as a cleaning agent.

- Keep open fire away while filling the tank.

- Keep the machine beyond reach of open fire.

- Some parts of the machine run warm, such as hydraulic elements, belts and

pulleys. Do not touch them when the engine is still running or having been just

stopped.

- Do not let the engine running in high speed unreasonably.

- Do not start the machine in confined or ill-ventilated spaces.

- Combustion gases outgoing from a tractor are toxic!

- Do not use the machine under conditions of low visibility, especially at foggy

weather on public roads.

- Do not use the machine without prior reading this manual.

- Do not carry out any repairs that are specified for authorised services only.

- Do not carry out any repair where its solution exceeds your experiences.

- It is strictly forbidden to work with the chipping device damaged (out-of-

balance, vibrations while running).

- While servicing the chipping device, or in the vicinity thereof, it should be

always blocked against unwilling motion (with its safety pin inserted).

Page 13

13

Before transport on public roads:

Set the machine in the transport position, i.e. with its discharge duck tilted

backwards and locked against motion. Be aware that traffic lights must remain

visible.

Couple the chipper to a towing vehicle properly and check proper pin

coupling.

Plug and check traffic lights of the chipper.

If necessary, remove all mud, especially from tires, before coming to a public

road.

Transport on public roads

When going on roads the chipper must be lifted at least 25-30 cm above the

ground.

Any transport on public roads is allowed only with the PTO shaft turned off

and the discharge duck tilted.

Any transport of persons or of any load on the machine is not allowed.

Never exceed max. allowed transport speed.

While putting the coupled chipper aside block the tractor wheels against

unwilling motion by means of scotch blocks.

Pay attention to handling performance on roads. Cornering, turning, braking

make new demands on driving.

Adjust driving speed to ambient conditions, especially at turning, obstacle

crossing, exits to plots etc.

This machine is approved to transport on public roads. Some restrictions are

given in your registration papers. Take these papers always with you.

Before coupling to a tractor check up the allowed weight limit in the tractor

hitch and compare it with the weight of your chipper. If a load on the tractor

front axle is less than 20% total weight, any coupling to a tractor is forbidden.

Note: Be aware that traffic rules and regulations in different countries may differ.

Page 14

14

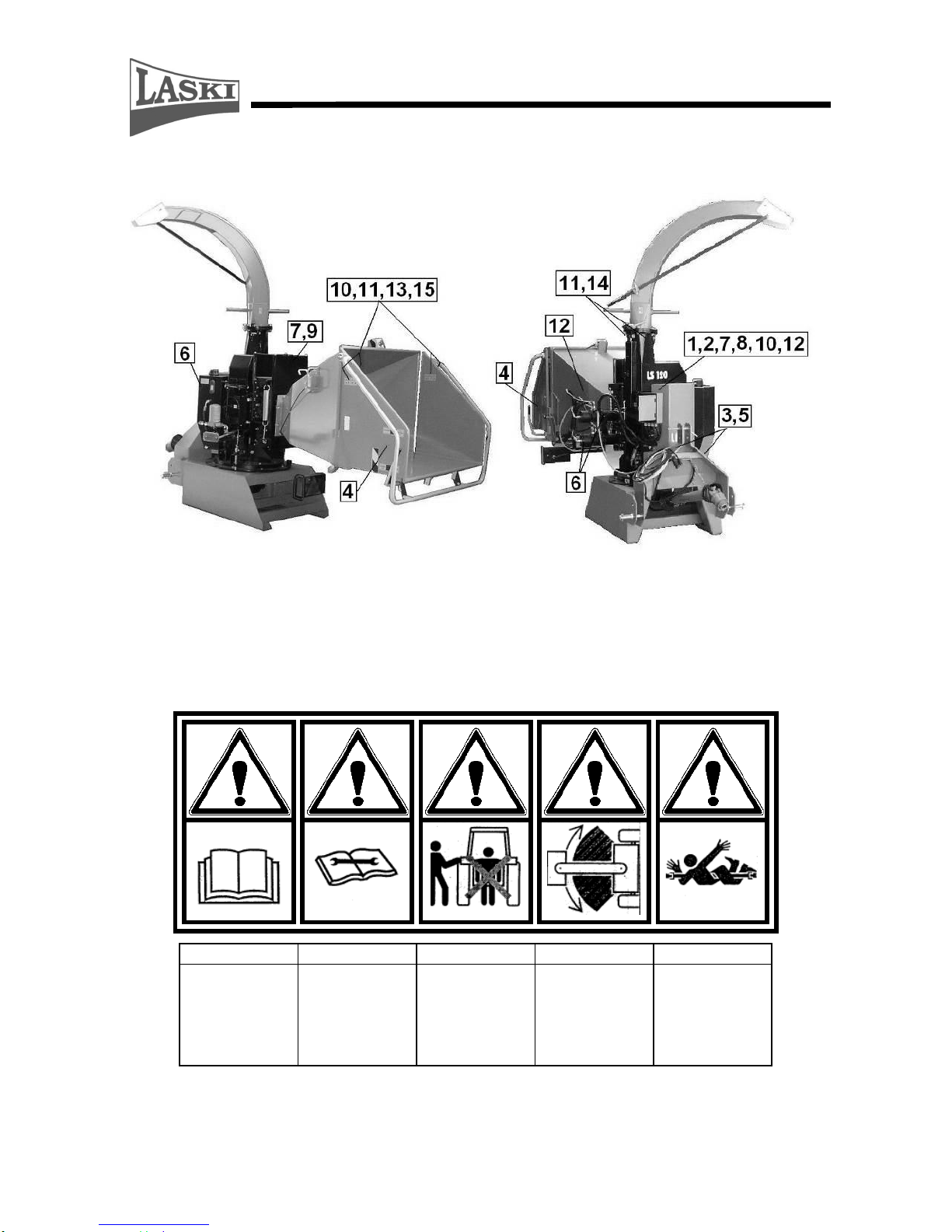

Work Safety Symbols

This article introduces work safety symbols (pictographs) used on this machine.

Under the given pos. number there is their location on the machine. These work

safety symbols warn the operator against risks connected with the machine use.

Your respect to the symbol meanings is a precondition for your work safety.

1 2 3 4 5

Read this operating

manual before use.

Always follow the

manual while

maintaining,

servicing or repairing

the machine and take

always the switch

key out of ignition.

Do not stand

between tractor and

equipment while

coupling.

Warning! It swings

out while turning.

Warning! Rotating

parts - accident risk.

Page 15

15

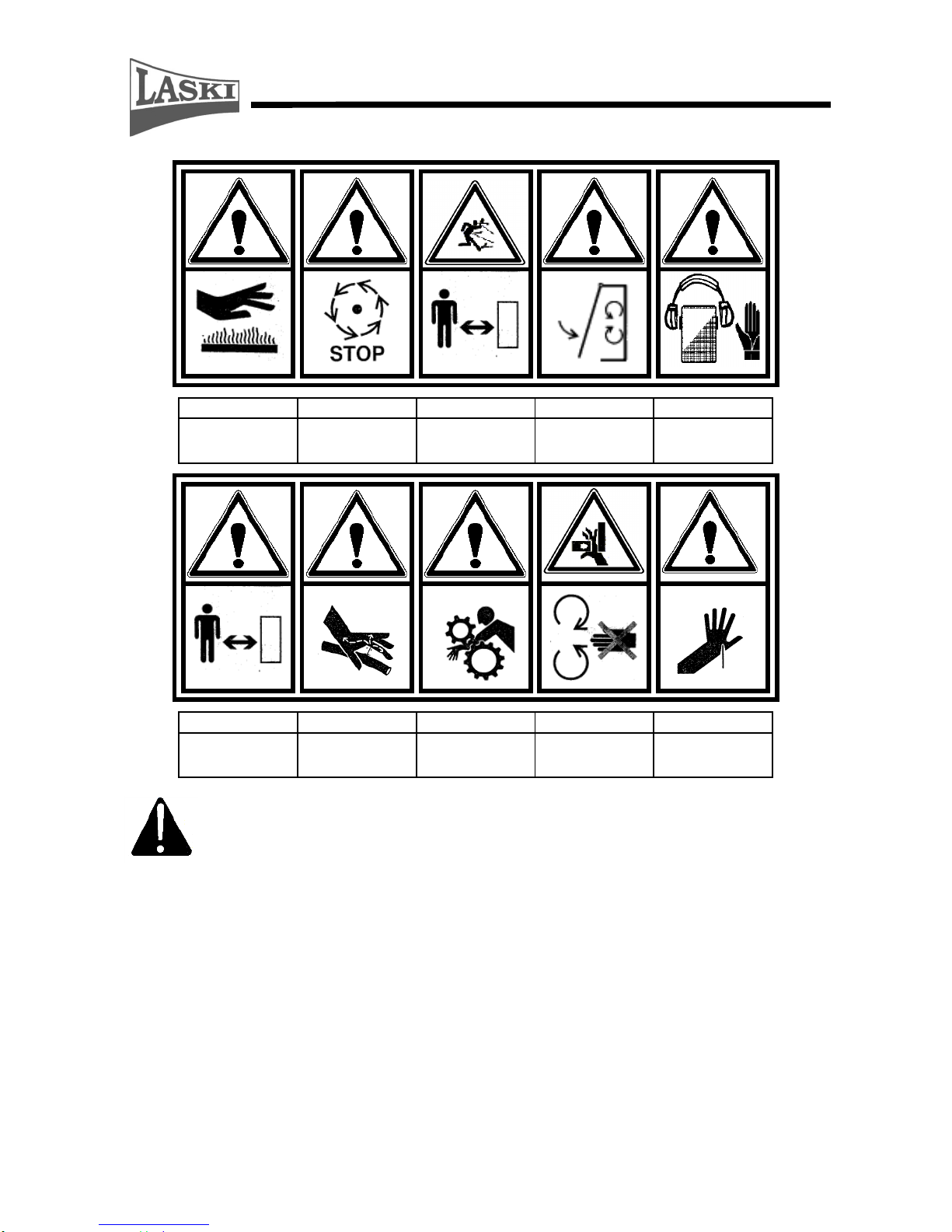

6 7 8 9 10

Warning! Hot parts.

Warning! Turning

part is running out.

Warning! Ejected

objects hazard. Keep

away.

Warning! Close all

guards before

starting the machine.

Wear personal

protective

equipment.

11

12

13

14

15

Keep safety distance.

Warning! Risk of

high-pressure liquid

leakage

Warning! Rotating

rolls. Pull-in hazard.

Warning! Hazard of

extremity injury by

rotating part

Warning! Accident

risk.

The user is obliged to keep all the work safety symbols legible, clear and

undamaged. In case of any damage or illegibility ask your local dealer or

an authorised service for a new relevant pictograph.

Transport of Product/Handling

- This product is delivered completely mounted and fitted on a wooden pallet.

- While handling the chipper you may use a lift truck.

- After coupling to a tractor any further handling is possible only according to

tractor technical parameters. The chipper should not bring any negative

impacts on tractor stability.

- Uncouple and put the chipper aside always on compact, flat and sufficiently

bearing surface only.

- Any work with the chipper is supposed on slopes with gradient up to 8o

only

.

Page 16

16

Precautions in Design

This product is equipped with hoods and covers protecting rotary and hot parts

against touching. Protective covers are usually fixed, bolted down on framing.

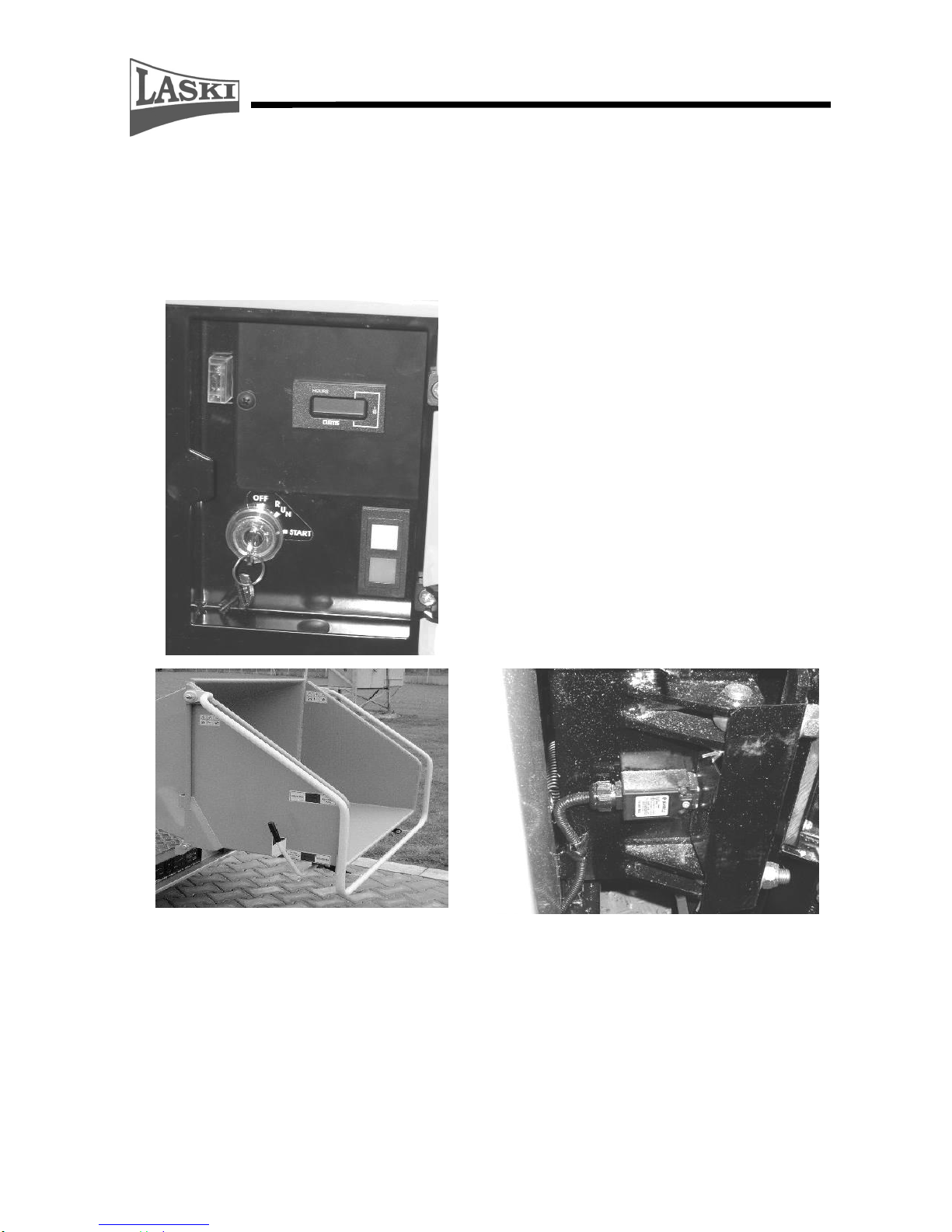

Ignition box for starting, completed

with a removable switch key. Any

confusion with another ignition keys is

not possible. Turn the key in the RUN

position and the orange LED lights on,

i.e. the electric installation of the

machine is in its standby mode being

correctly connected to a towing tractor.

For correct function of the loading rolls

it is necessary to activate the safety

circuit by turning the key in the START

position. The green LED lights up, i.e.

the safety circuit is activated. After any

interruption of the safety circuit it is

necessary to activate it again.

Safety frame for material loading

serves as an actuator for the loading rolls

control, i.e. their stopping or reversing.

Once being pushed the chipper stops

loading motion immediately, the next

pushing brings reverse turning of loading

rolls.

Dangerous space behind the loading

rolls is protected with a hinged cover

and by a terminal switch which blocks

the drive if the cover remains opened.

Once opened the driving hydromotor

stops immediately. This cover is locked

with two bolts that should be properly

tightened.

Page 17

17

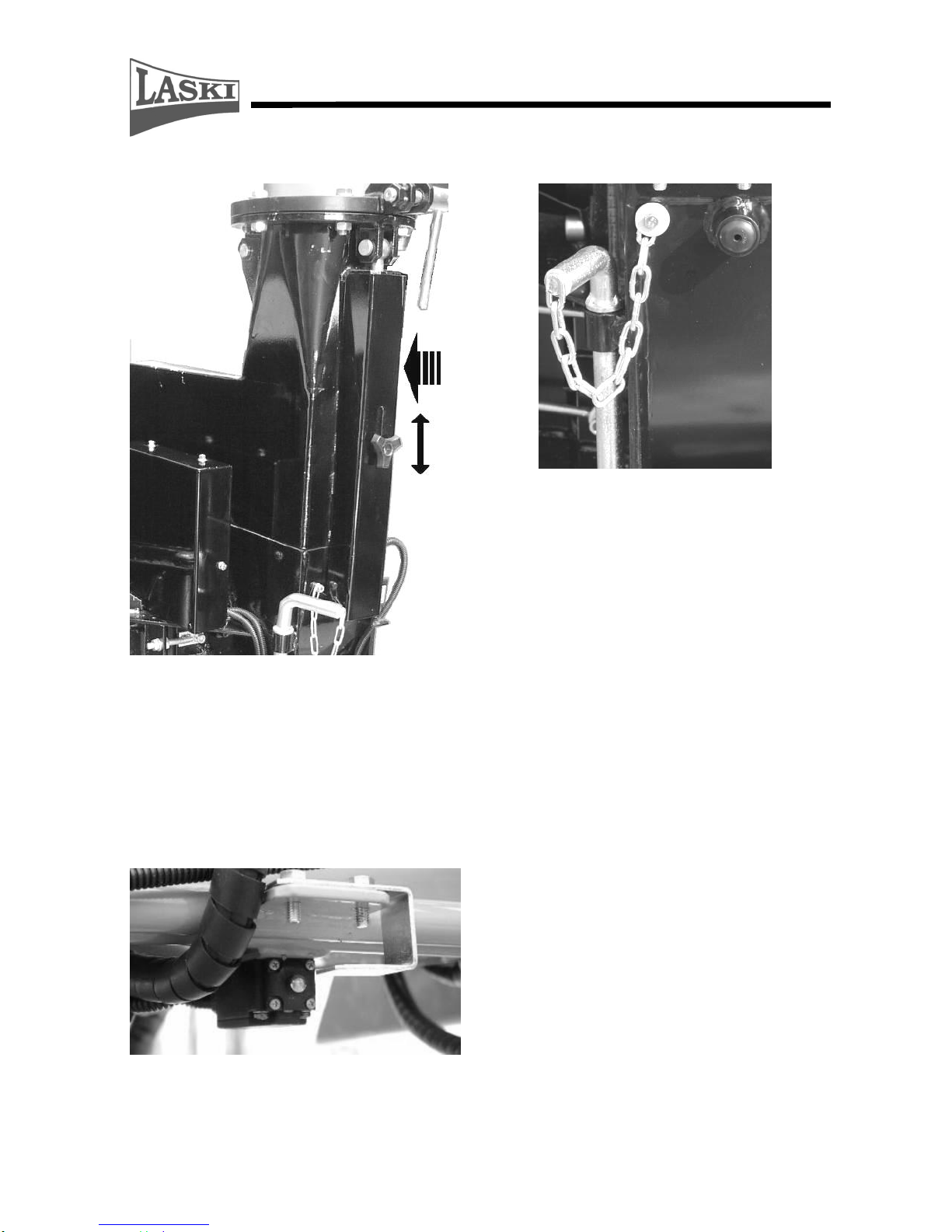

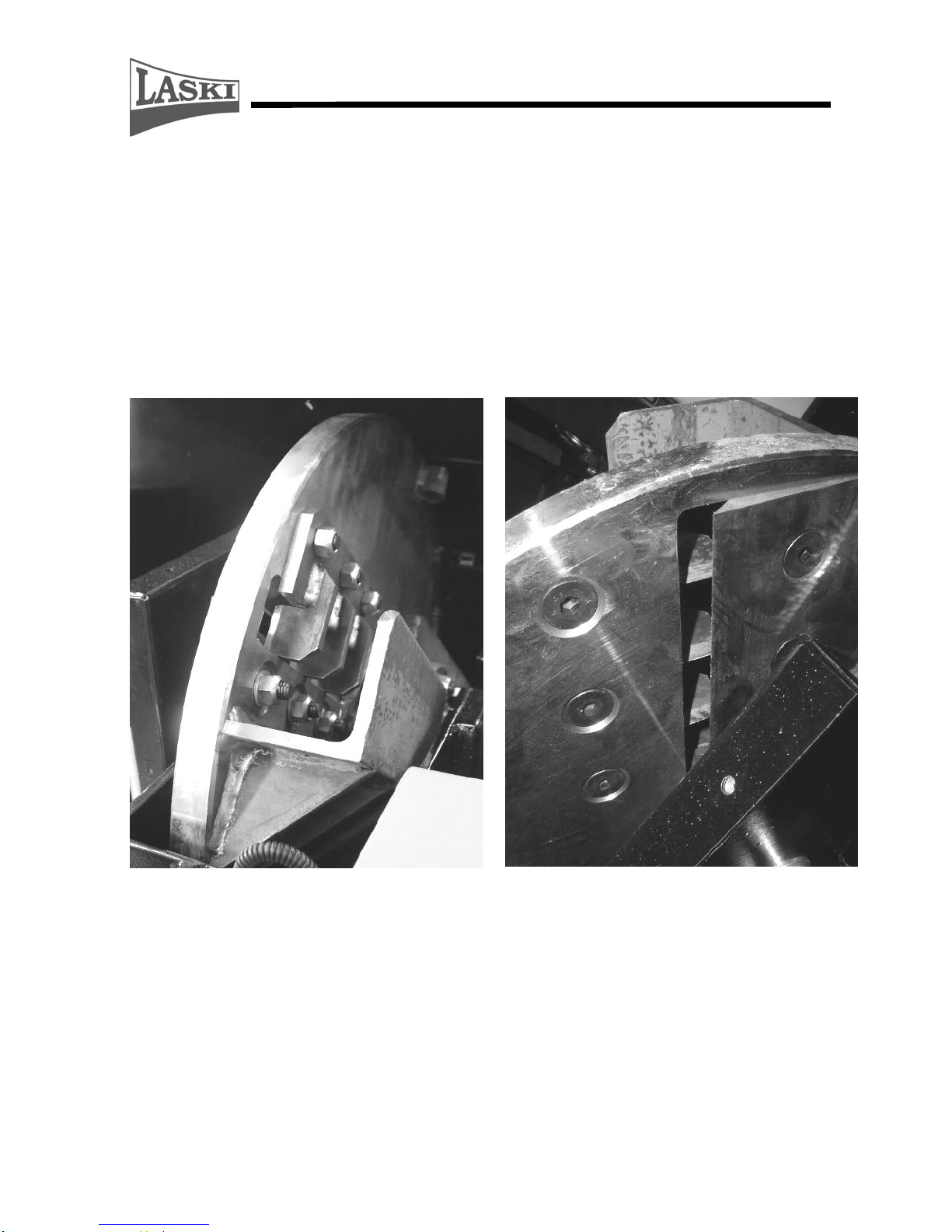

Dangerous space of the chipping wheel

is secured by a terminal switch. To swing

the discharge duck away or to open the

upper half of the chipping wheel guard it

is necessary to unlock the guard and

move it in the arrow direction, see figure.

It is not possible to set the loading rolls

in motion if the guard remains opened.

Safety pin of the chipping device

rotor serves for rotor blocking at

blades exchange and servicing. The pin

is chained on the machine side. A hole

for pin inserting is covered with a

rubber stopper. The chipping device is

blocked if the pin is inserted into a bush

on the rotor.

Terminal switch of a hinged part of the

loading chute turns the driving engine

off if the chute is tilted.

Page 18

18

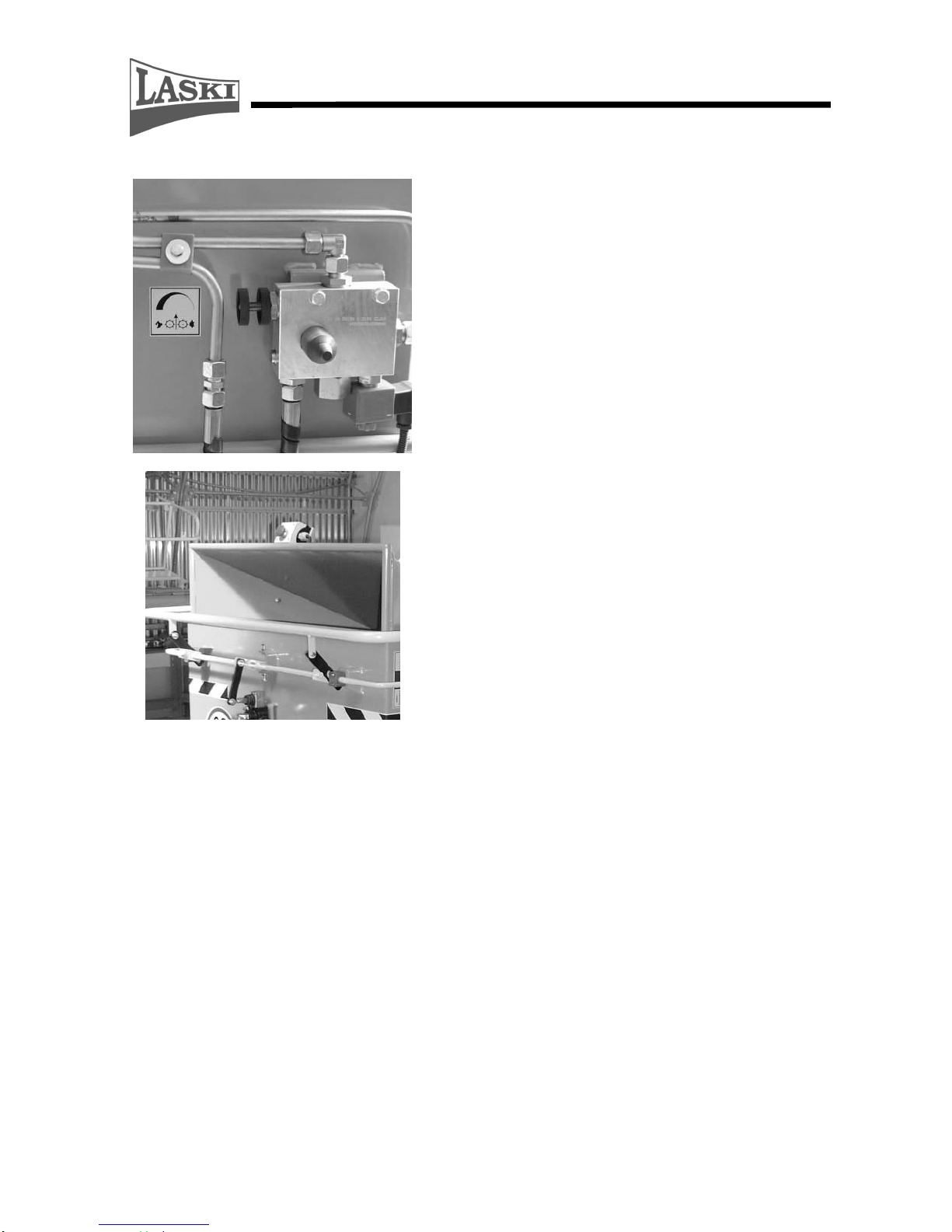

Emergency STOP button blocks

loading immediately – similar function

as that of the safety frame.

Controls

Ignition box – used for supply and control of the

safety circuit.

CAUTION: Despite the fact that this machine is not

equipped with any driving engine, its ignition key,

analogously to engine starting, must be set in the

START position and afterwards in the RUN position.

The "S" key serves for control of the running hours

counter (daily, total).

Safety frame for material loading with following

positions:

As seen from the attendant's place:

position for MATERIAL LOADING, middle position for

ENERGENCY STOP, by pushing and under

permanent pressure for REVERSE RUN.

This lever controls loading start, stopping and

reversing

Page 19

19

Controller of loading speed - installed under

a hinged part of the loading chute

Change of loading roll speed

Speed regulation in range from 0 to 40 m/min

Emergency STOP button blocks loading

immediately – similar function as that of the

safety frame.

Use

Transport Safety

- For transport the chipper should be coupled to a tractor and locked properly in

its hitch.

- Avoid any side swinging of the chipper and set the lower drawbar tighteners

accordingly.

- Set up the upper drawbar so that the chipper is aligned.

- Plug traffic lights (seven-pole plug socket).

- Checks before drive:

lights

machine for completeness

depositing of cardan shaft (if not coupled)

locking of turnable parts in transport position

depositing and locking of discharge duct

Page 20

20

locking of hinged part of loading chute in transport position

fitting of triangular symbol for slowly vehicles on framing

- It is strictly forbidden to transport the chipper with the PTO shaft on.

- It is not allowed to transport any objects or loads on the chipper.

- Never couple another machine or implement to the chipper.

- Keep side marker lights clean.

- Avoid any damage of side marker lights.

- If necessary, remove all mud and other deposits before coming to a public

road.

- Putting the chipper aside block the tractor against unwilling motion by means

of scotch blocks and mark it as a transport obstacle.

- While going on public roads, keep all traffic rules not to endanger other road

users.

- While working along public roads, keep direction of ejected chips away from

other road users and avoid any road fouling.

- In case of any fault repair the machine always off the road.

- While repairing, avoid any site fouling with oil products, dirty rags etc.

Transport position

Hinged part of loading chute up and locked, discharge duct locked

against turning.

Page 21

21

Storage

Store the chipper always in a dry shelter to protect it against weather effects.

- During storage keep the switch key separately.

- Keep the stored machine beyond unauthorised persons reach.

- Before storage clean all parts of the machine. For cleaning use pressure water.

Should the water be in the chipping device space, wipe it off and let it dry.

- Clean especially oily spots.

- Exchange all damaged or worn parts. Use always original spare parts. For

spare parts contact your dealer or authorised services.

- Do not apply any grease or similar agents on elastic hydraulic hoses.

- Always put the machine aside on a flat and solid floor or on a wooden pallet

for further handling.

- Do not put any objects or tools on the machine.

Before Putting into Operation

- Before the first putting into operation check up the machine for contingent

damages and completeness after its transport and storage.

- Check tightening of bolted joints, especially guards,

grids and completeness of other parts.

- Check movability of turnable parts (loading chute,

discharge duct etc.).

- Check work safety labels for completeness and

legibility. Replace any damaged and illegible label, if

necessary.

- Grease bearings and sliding parts.

- Check the hydraulic oil level (level indicator) and refill

if necessary. The oil level must be between both marks

(MIN and MAX).

- Do not try to repair the machine if it is beyond your

competence. Any servicing, especially of rotating

parts, should be carried out by authorised persons only.

- Check conditions of blades. Replace them if worn or damaged.

- The chipping wheel can be optionally completed with a breaker. According to

the material to be chipped install/remove a breaker on/from the chipping

wheel.

- For replacement use always original spare parts. Parts, such as rotors and

blades, must be balanced properly.

- All blades should be replaced always at the same time as a set. Pay special

attention to their fixing bolts. Replace them if worn or damaged.

Page 22

22

- Avoid spillage at filling hydraulic oil. Use always a proper filling funnel. If

any oil is spilled or overflowed then wipe off the spots immediately.

- Do not use petrol or similar inflammable matters as a cleaning agent.

- It is strictly forbidden to do any technical changes on the machine without any

prior approval of the manufacturer in writing.

- If any adjustment is required, do it always at standstill only. Remember

blocking the wheels against unwilling motion.

- Check conditions and proper tightening of V-belts.

- It is strictly forbidden to start the chipper with removed hoods and guards.

This chipper can be optionally equipped with an optional breaker which is to be

installed close to the blade output opening in order to break transversely cut wood

slices. It is not included in a standard delivery.

RECOMMENDATION:

The breaker should not be used for small and short wooden pieces, leaved or

coniferous branch wood (with low weight) which may bring fouling due to

shortage of woody mass. To clean the fouled ducting just put some more woody

materials inside the loading chute.

Page 23

23

Coupling to Tractors

This chipper can be coupled to a tractor which is equipped with a three-point hitch,

category I or II and a PTO shaft. This hitch coupling can be done from outside by

means of locking pins, Ø 27 mm for the category II or Ø 22 mm for the category I.

The chipper is height-adjustable (according to tractor tires size) when inserting

pins in other holes, see following figure.

The lower drawbar of the three-point

hitch can be coupled to a pin Ø 27 mm

from outside. The white arrow shows

a coupling point where the lower

drawbar is to be hinged. In both cases

the locking pin must be properly

locked.

Height adjustment by means of a hinge

pin

Page 24

24

When coupling the chipper to a tractor just let the lower drawbars go down in a

similar height as the coupling pins are. Go back slowly with the tractor to the

chipper hinge.

While coupling the chipper no person is allowed to stand between the

chipper and the tractor

Lock the lower drawbars by means of locking pins in the chipper

hinge. Make sure that the pins/drawbars are locked properly.

Connect power supply by means of a plug and a socket used for a service lamp

Putting into Operation

Before start check if the loading chute and the discharge duct are free of

any materials. Direct the discharge duct out of possible motion of other

persons or prevent other persons to enter the working area. At work

proceed always very carefully.

- Let the three-point hitch go down on the ground.

- Swing away the hinged part of the loading chute and lock it.

- Swing away the discharge duct and lock it by a locking nut.

- Set the guard under the discharge duct in the upper position and lock it by a

locking nut.

- Set the safety lever in the central STOP position to block the loading rolls.

- Close all guards (if opened).

- Turn the PTO shaft on and let it running at slightly increased speed, as rated

for 540 rpm shaft speeds.

As soon as the PTO shaft starts turning, the chipping wheel and V-belts

are set in motion. Keep away from these rotating parts.

- Set the control lever in the position for LOADING.

- Set the switch key in the START position and then release the key in the

position for RUN. Now the loading rolls start turning.

- Having turned the chipping device on wait for speed stabilization. With that

you may soever increase or reduce the tractor PTO shaft speed.

- CAUTION !!! As soon as the PTO shaft is ON, the tractor hydraulic

circuit is under pressure and the loading rolls start turning according to

actual setting of the safety frame or of the control lever.

- CAUTION !!! As soon as the PTO shaft is ON then chips from previous

operation may be ejected from the discharge duct.

Page 25

25

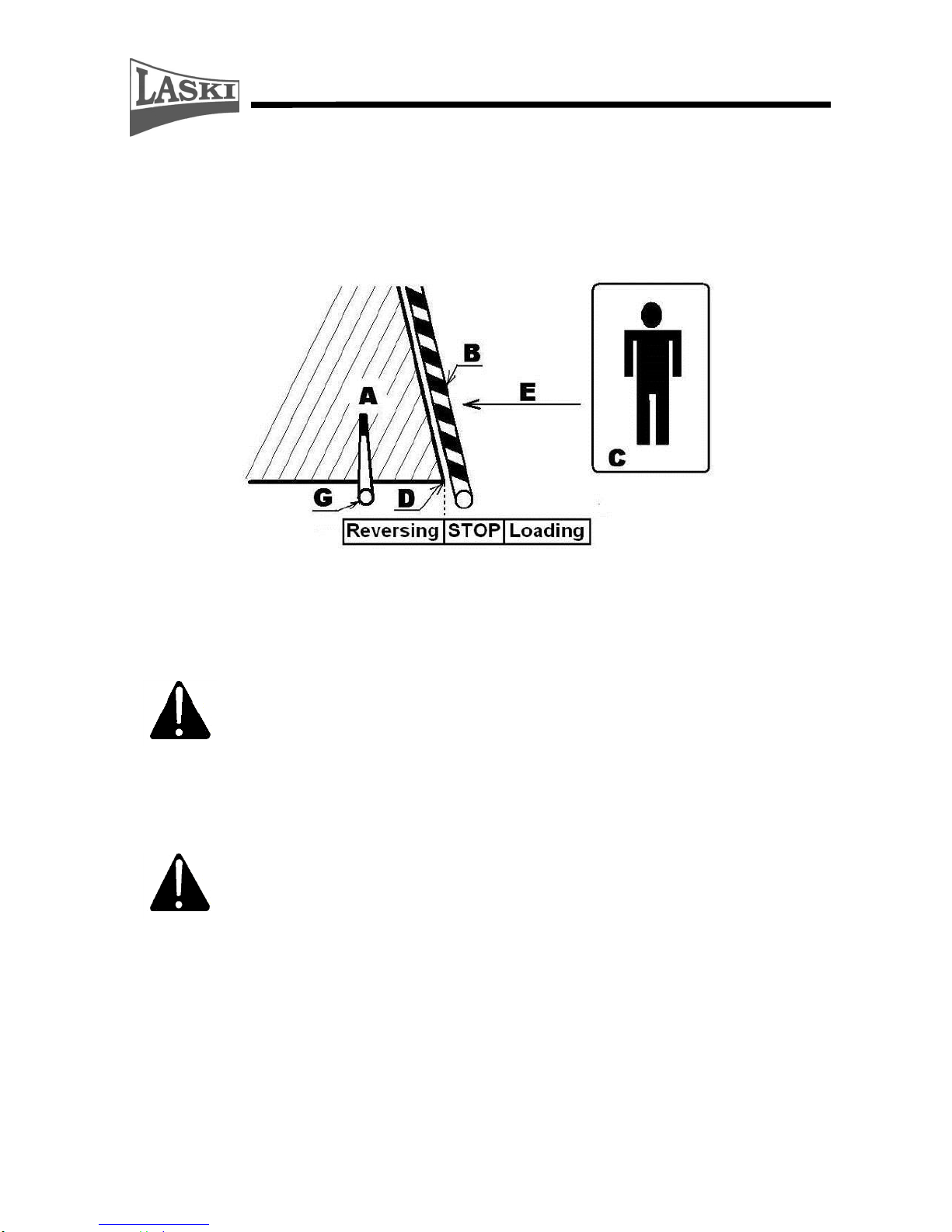

- Carry out a functional check of the safety frame of the loading chute. Set the

lever in the infeed position and the loading rolls start turning (loading). By

first pushing the frame the rolls should stop loading immediately

(EMERGENCY STOP), the next pushing behind the chute edge (D) brings

their reverse turning.

Legend:

A - loading chute, B - safety frame, C - attendant's place, D - loading chute edge,

E - infeed direction, G - control lever

- The safety frame must be always adjusted so that the

EMERGENCY STOP must be activated before the point D –

loading chute edge.

- Do not leave the machine unattended.

Chipping

- The chipper is powered by a tractor combustion engine. Do not

start it in confined or ill-ventilated spaces or under conditions of

low visibility.

- While chipping the chipper must always be properly coupled to a

tractor.

- It is not allowed to use the cardan shaft with its damaged guard. This guard

must be properly locked against turning. Check up locks on the sliding shaft.

- Set the discharge duct in required direction. The discharge duct cannot be

directed to the attendant's place, see following figure.

Page 26

26

- When loading materials and during operation of the chipper the attendant

should always stand in the attendant's place, see fig.

- Having turned the chipping device on wait for speed stabilization. With that

you may soever increase or reduce the tractor PTO shaft speed. For correct

chipping functions it is necessary if the tractor PTO shaft speed is 540

rpm(1000 rpm).

- Wooden chips can be gathered in bulk or into a container located on a towing

vehicle.

- While discharging into a container, pay your attention to ejecting to avoid

ejecting chips back out off the container.

- Before going to another working place it is necessary to turn the PTO shaft off

and wait for total stopping of the cardan shaft. Before going lift up the chipper

above the ground by means of the three-point hitch and tractor hydraulics.

- Do not load materials with parts of metal, glass, ceramics and other similar

objects.

- Do not chip or load materials while driving.

- Having put materials in the loading chute/between loading rolls, release the

loaded material immediately and keep a certain distance from the chute.

- When working, never lean over the loading chute and never pull out wooden

materials, already loaded, from the chute.

- Do not load materials with diameters exceeding 150 mm.

- If loaded materials are spreading with risks of catch holding of attendant's

dress being drawn in the loading chute then it is necessary to prepare such

materials accordingly (trimming, cutting).

- Pay special attention to thorny materials, such as acacia and roses, which may

easily catch your sleeves.

Page 27

27

- Be careful while loading since materials may unexpectedly move in unwished

directions.

- In case of two attendants it is necessary to make simple signals clear before

working. During operation it is not easy to make any agreements because of

operating noise.

- Observe the working area. If any person, children or animals approach while

chipping, then stop working immediately.

- Be aware that there is a certain time period required between loading, chipping

and final ejection of chips.

- As far as possible load the chipper evenly, adapt loading speed accordingly

and keep continuous chipping.

- While loading, stand aside the loading chute.

- When loading short materials, throw them in the chute and push them forward

between the loading rolls by means of a wooden rod or another branch.

- Never use metal objects. They could cause serious damage of the loading rolls

and blades.

- When finishing the work, first wait for emptying of the loading chute.

- Lengths of materials to be loaded should not exceed 3 meters.

Recommendations:

Do chipping at rated PTO shaft speed only, i.e. at

sufficient power of the chipping wheel for ejecting chips.

Being loaded short and fine materials may deposit or clog

the space behind the loading rolls in front of the chipping

wheel. To avoid such problems and clogging put

occasionally also some longer branches.

To prolong service life of blades never put any materials

with parts of impurities, such as of metal, glass, ceramics

and other similar objects.

Optimal sharp blades reduce operating costs of the

loading and chipping equipment (reduced wear of the

chipping device).

If loaded material is free of any impurities then a grinding

interval for blades may last several months or several

hundreds m3 of loaded materials.

Page 28

28

Blunt blades are evident on chipped edges which are not

clean but broken.

The optionally used breaker for crushing brings increased

costs for energy consumption.

The breaker should not be used for small and short

wooden pieces, leaved or coniferous branch wood (with

low weight) which may bring fouling due to shortage of

woody mass.

The chipper is optionally equipped with its speed regulation and the NOSTRESS

system intended particularly for tractors with power less than 30 HP.

This regulator reduces material feeding upon contingent overloading (PTO shaft

speed dropping).

The chipping wheel speed is set by the manufacturer to 1450 rpm to turn the rolls

off and to 1500 rpm to turn the rolls on again.

Recommendations!!

Should the loading rolls be frequently turned off while chipping,

it means that there is too much material loaded and the chipping

device is overloaded. To avoid this overloading:

reduce volume of material to be loaded, or

reduce infeed speed of the loading rolls

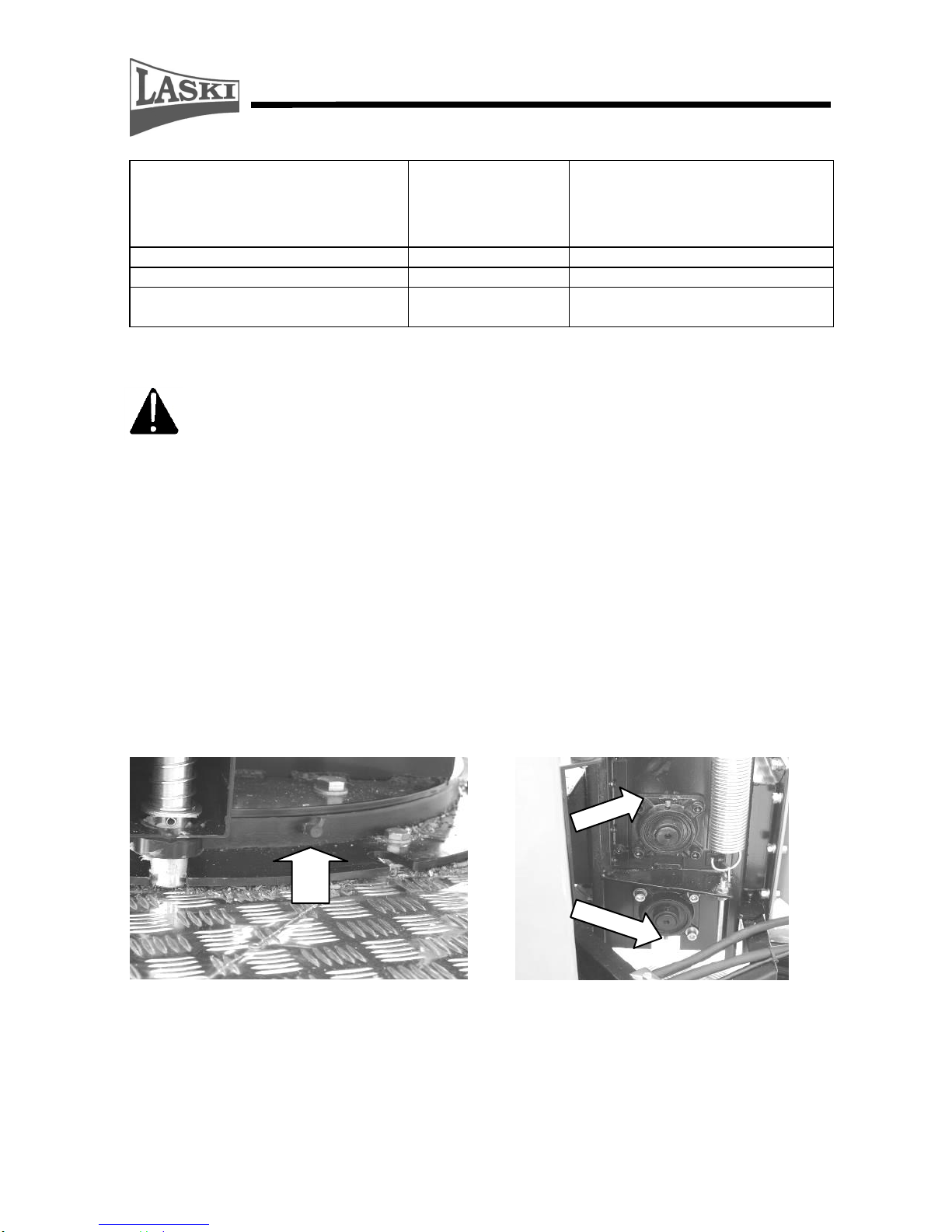

The loading rolls infeed speed can be reduced by the regulating screw (see arrow

on following figure) under the hinged part of the loading chute. To change the

infeed speed, just turn the regulating screw accordingly.

Page 29

29

Putting out of Operation

If you want to stop chipping:

- In case of loaded material wait for emptying of the loading chute.

- Wait for emptying of the discharge duct.

- Turn the tractor PTO shaft off.

Warning! The cardan shaft is equipped with a freewheel clutch. When

turned off, the rotor of the chipping device runs out – approximately 120

sec.

- Regardless of this running out, turn the switch key in the STOP position.

Emergency Situations

Put the chipper out of operation immediately in

following cases:

- If any person or animal approaches under 20 m while chipping, then stop

working immediately.

- If any breakage, damage or disengagement occurs, stop chipping immediately.

- If you heard any strange noise or vibrations or felt a strange smell while

chipping, then turn off the machine immediately and contact your dealer or

directly the manufacturer.

- In case of fire or breakdown, stop chipping immediately.

- In case of fire use foam extinguishers only.

- If you cannot damp the fire down yourself, call for a fire brigade.

- If an attending person gets caught by rotating parts or loaded materials, stop

the loading rolls by pushing the safety frame (STOP position). Stop working

and go on only if the attending person is uninjured and fully concentrated.

- If the discharge duct gets clogged, stop loading immediately and reverse the

loading rolls by pushing the control lever in the REVERSE position. Turn the

PTO shaft off and while having all rotary parts stopped (after about 120 sec)

use an elastic rod and try to release the clogged material in the end piece of the

discharge duct. Having released the clogged material, try to turn on the PTO

shaft again. If it is not successful, remove the upper hood part and try to

remove all materials by hand (the chipping wheel must be blocked properly

while removing materials).

Page 30

30

Technical Description

This machine consists of following main parts:

- chipping device

- loading chute

- loading rolls

- chipping wheel

- discharge duct

- frame

Chipping Device

Loading chute

The loading chute is made of welded steel plates consisting of two parts: fixed

and hinged one. The hinged part serves as an extension of the chute with a safety

frame and is protected by a terminal switch. This frame, if pushed by an attending

person or branchy materials being caught, turns the loading rolls off. The chute

itself, shaped as a square pyramid, is decreased in width toward the loading rolls

and in this way loaded materials are pressed together.

Loading rolls

These rolls take over loaded materials and move them to the chipping wheel. Their

speed can be regulated according to the given sort of material and expected results

– chips. The top roll is ribbed and the bottom one smooth. These rolls enable

loading materials and also pulling them out at reverse turning, if necessary

(chipping wheel overloading). The top roll is height-adjustable according to the

given material. The rolls are powered by a hydraulic motor. This infeed device is

equipped also with speed regulation based on chipping wheel speed sensing. Its

evaluation and following switching is controlled by a logical unit in the driving

part.

Chipping wheel

It is a steel disc serving also as a flywheel for absorption of shocks while chipping.

This wheel is put in ball bearings; a drive pulley is fitted on its shaft. The wheel is

equipped with two blades for cutting of loaded materials. Vanes welded on its rear

side serve for ejecting chips in the discharge duct. This chipping wheel can be

optionally completed with a breaker which is to be installed close to the blade

output opening in order to break transversely cut wood slices, e.g. for further

mechanical processing or heating.

Page 31

31

The chipping wheel is installed in a rigid frame and protected by a steel plate. Its

protective shield consists of two parts and particular parts are bolted together. By

safety reasons the upper part is protected with a terminal switch for turning the

drive off if the shield was opened or got loose.

Discharge duct

This duct continuously extends the chipping wheel shielding and serves for

directing the ejected chips. The duct is turnable and its end piece (tilting gate)

serves also for setting the range of ejected chips.

Frame

This rigid frame is equipped with three-point hitching for coupling to a tractor.

In the lower part of the frame there is a gearbox with an input shaft. The chipper

itself is fitted on a swivel base.

Technical Parameters

Parameter

Unit

Value

Overall length/transport length

mm

2535/2135

Overall width/transport width

mm

1495/1490

Overall height/transport height

mm

2735/2025

Weight

kg

780

Chipping device:

Chipping wheel – diameter

mm

560

- number of blades

-

2

- number of breakers

-

2

- rate of cutting

m.s

-1

42

Max diameter disposed materials

mm 160

Chipping wheel drive

-

3 x belts B 17 x 1422 La

Loading device:

Infeed hole size

mm

290 x 220

Number of loading rolls

-

2

Diameter of rolls

mm

190

Feeding speed

m.s-1

12 - 40

Drive

-

hydrostatic

Loading roll speed for turning-off

min

-1

1525

Loading roll speed for turning-on

min-1

1550

Speed regulation

-

NOSTRESS

Loading chute:

Feeding profile

mm

920 x 800

Drive:

Type

-

tractor PTO shaft

PTO shaft speed

min-1

540 (1000)

Shaft - six-spline

Hydraulic oil:

-

OH HV 46

Page 32

32

ISO VG 46, ISO 6743/4 typ HV

CETOP RP 91 H Category HV

DIN 51 524 část 3-HVLP

Poclain P00552-13P

Capacity of hydraulic oil tank:

l

15

Gear Oil -

SAE 80W/90, API GL-4

Recommended amount of gearbox

l

1,5 + 1,5

Maintenance

- Any servicing of the chipper should be carried out by authorised

persons only.

- Check up the machine for completeness and its general condition.

- Any maintenance and servicing on the machine can be done at standstill only,

i.e. the PTO shaft off, the switch key being pulled out from the ignition box,

tractor wheels blocked against unwished motion.

- While servicing the chipper should be lowered on the ground.

- Pay special attention to all safety elements.

- Check up V-belts for tightness and wear.

- Keep regular intervals for lubrication of bearings.

- Check up condition of blades and chipping wheel vanes regularly.

- Check up hydraulic hoses for wear. Replace them if necessary or every five

years.

Lubrication

Grease cups of chipping wheel

Lubrication every 40 running hrs

(LTA 3EP MOL Lition)

Grease cups of loading rolls

Lubrication every 40 running hrs

(LTA 3EP MOL Lition)

Page 33

33

Grease cups of loading roll slides

(LTA 3EP MOL Lition)

Grease cups of swivel base

(LTA 3EP MOL Lition)

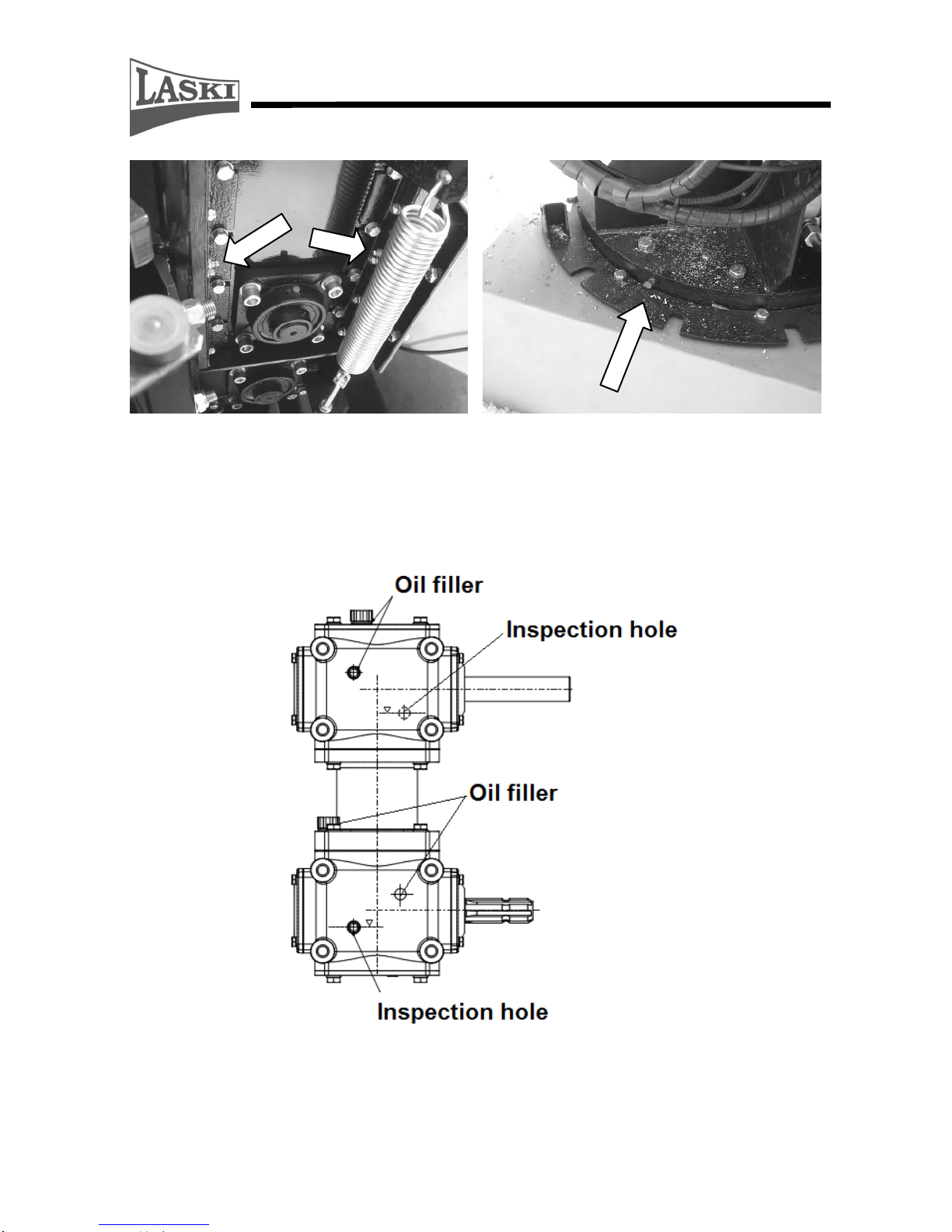

Oil change in gearboxes

Gearbox oil - SAE 80W/90, API GL-4

Oil charge – 1,5l per 1 gearbox, in total 3l oil

Oil change after 2500 working hours or 5 years

Page 34

34

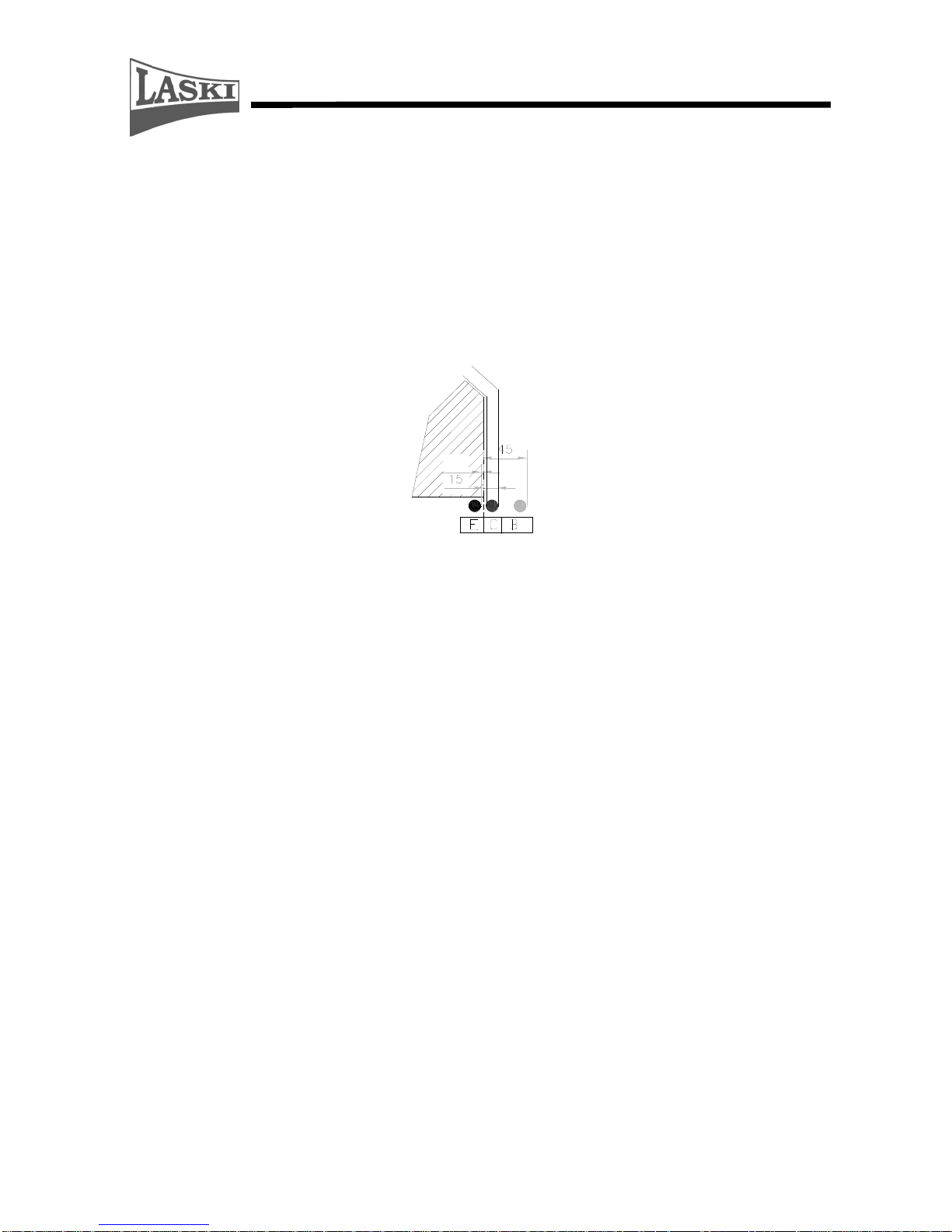

Blade Grinding

Blades, fitted on the chipping wheel, are double-sided, i.e. reversible if one side is

blunt.

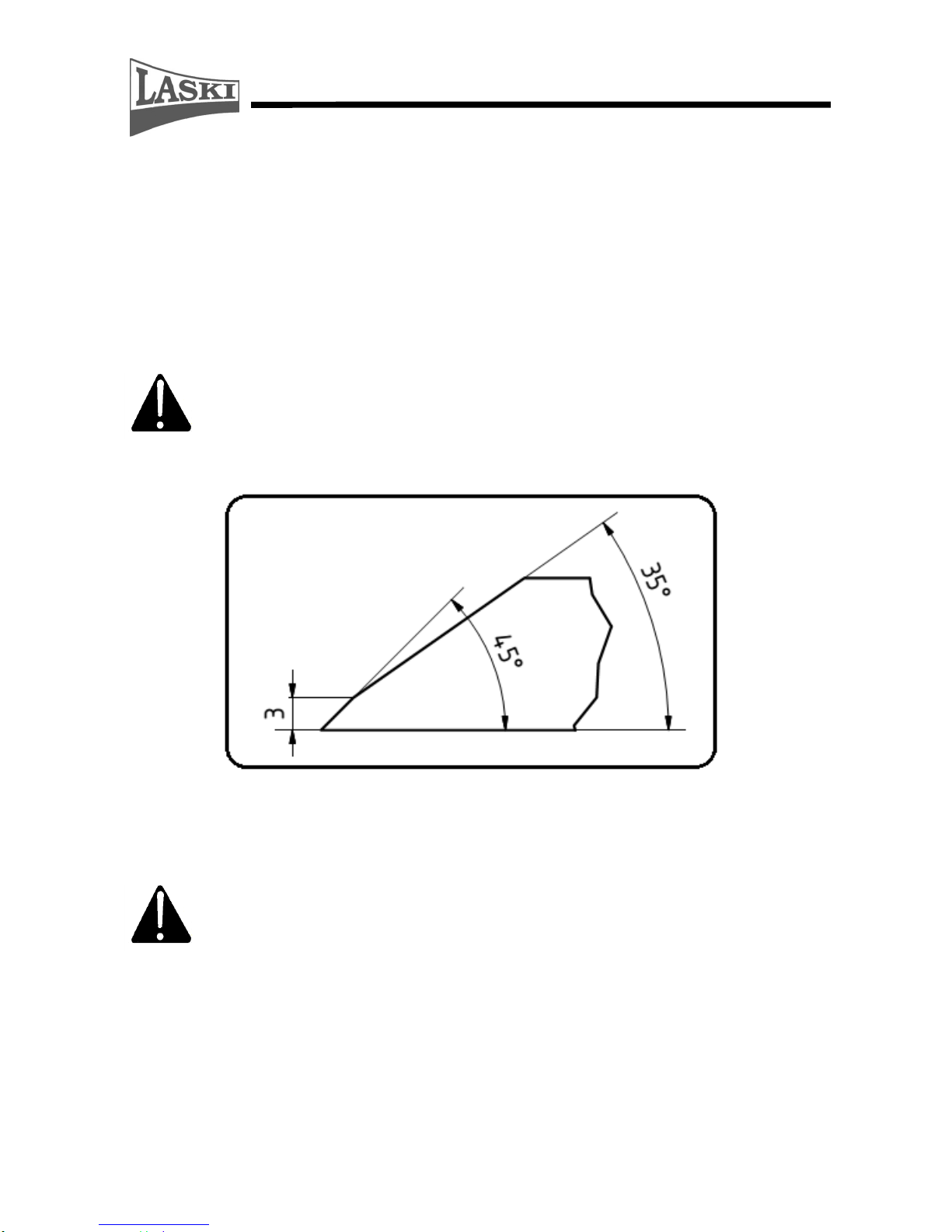

Blades edge regrinding requires high demands for keeping cutting edge shape.

While grinding it is necessary to keep its optimal geometry, see following figure.

Proper shapes prolong blade service life.

While regrinding it is necessary to keep the same weight of particular

blades because of balance of their rotating mass. For grinding use

always a grinder with its magnetic table and a special jig.

Detailed geometry of blade edge

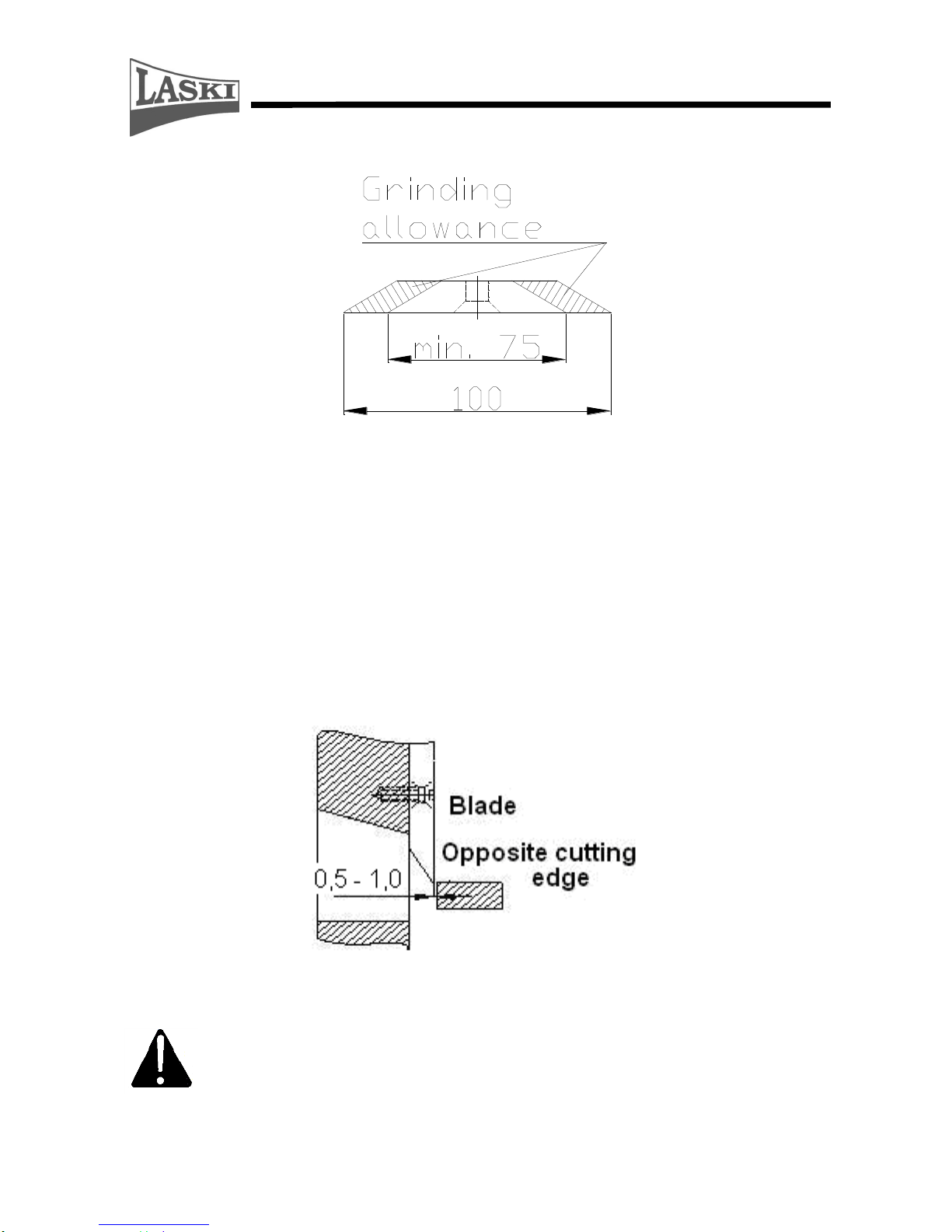

Grind every blade only up to minimum distance from edge to its fixing

bolt. i.e. 37,5 mm. This distance on a new blade is 100 mm, see

following figure.

Page 35

35

Max. wear/grinding of cutting edge

Chipping Adjustment

Optimal operation of the chipping device requires proper setting of a clearance

between the blade and the opposite cutting edge. This distance should be set (see

following figure) and checked after fitting ground blades, then it grows with their

wear and chipped branches may be squeezed between the blade and the opposite

edge. It brings deterioration in quality of chipping.

Pay attention also to blades exchange. In such case set the given clearance bigger

to avoid damage of a new blade and its opposite cutting edge.

Recommendation: Check out conditions of blades every 40 operating hours.

Regrind blade edges if they are found blunt

Jointing elements (bolts and nuts) should be replaced together with

The blades exchange. Safety nuts should be used only once, since they

lose their self-locking properties if used repeatedly. The fixing bolts

should be tightened with torque of 100 Nm.

Page 36

36

NOSTRESS System – Speed Regulation

This system is intended for overload protection of

the combustion engine consisting of an electronic

control unit and a speed sensor installed on the

rotor shaft

No Stress ON – the machine chipping with

automatic regulation the infeed of the material (

there is no overload of the combustion engine

consisting)

No Stress OFF – this one use only when the No

Stress control unit is fail so that the Chipper does

without automatic regulation the infeed of the

materiál.

Control unit:

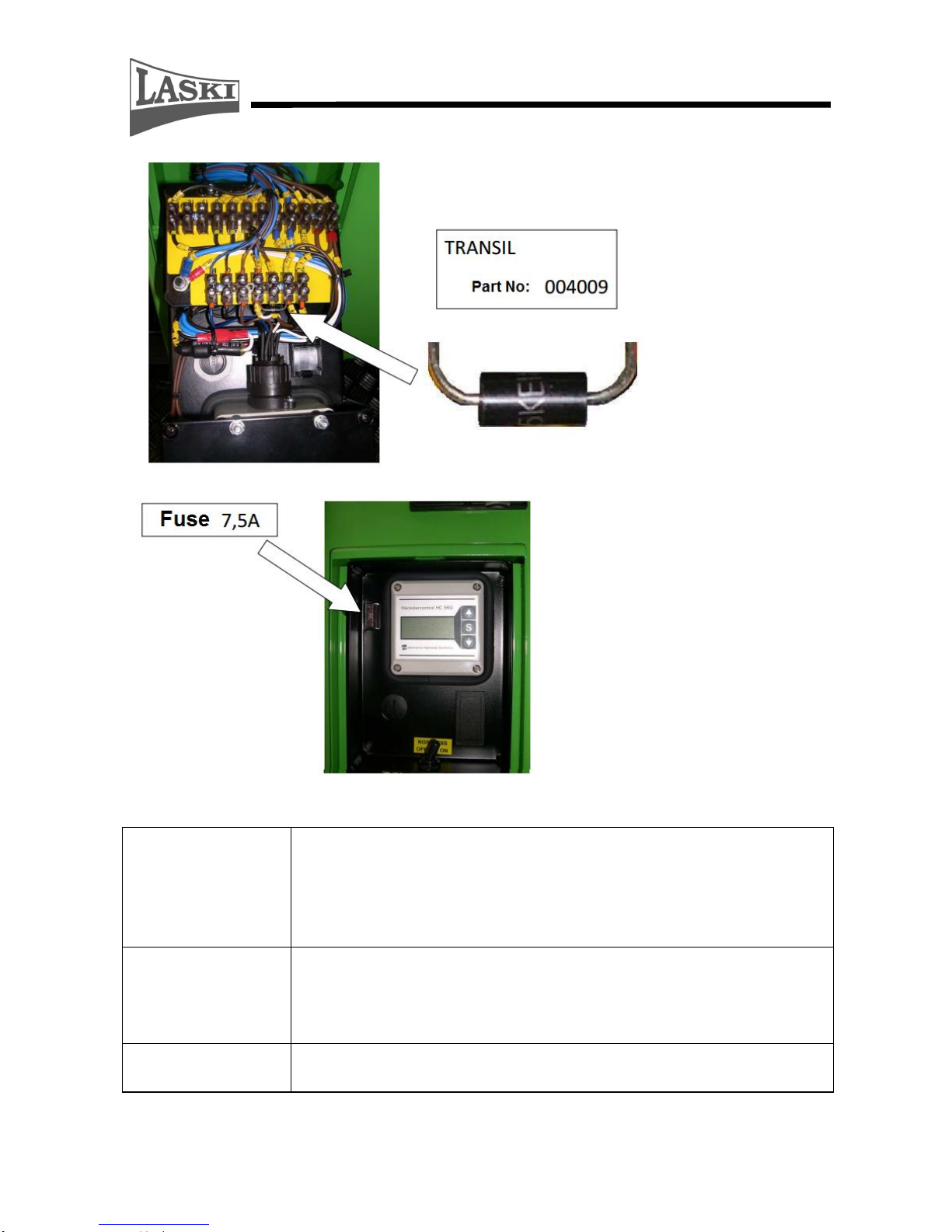

This control unit displays actual rotor speed values. When the rotor stops, the unit

displays a total number of running hours "th". To display a daily number of

running hours, just press the button "S". To reset this daily number, just press the

button "S" once to display a total number of running hours "th" and then press it

again and hold for total resetting. This control unit is protected by two fuses: 7,5 A

– installed just by the unit and 4 A – installed inside.

Right function of NOSTRESS system

This speed regulator reduces material feeding upon contingent overloading. The

chipping wheel speed is set by the manufacturer to 1525 rpm to turn the loading

rolls off and to 1550 rpm to turn the rolls on again. Actual rotor speed values are

displayed on the control unit.

Speed sensor:

This encapsulated sensor in fitted on a holder in a distance of 3,2 mm from the cam

lobe. In the rear part of the sensor sleeve there is an orange LED installed which

should be flashing in case of proper sensing.

The own setup (respectively check-up) of the speed sensor should

be done at standstill only.

Page 37

37

Location of sensor under hood

NOSTRESS system protection against overvoltage

Overvoltage occurrence in the electric installation blows the fuse and breaks the

TVS diode (Transient Voltage Suppressor / Transil) used to protect

sensitive NOSTRESS electronics against voltage spikes. Should the fuse (7,5 A) be

blown again, first replace the damaged TVS diode and then put a new fuse.

Page 38

38

Maintenance Intervals

Electric

Installation

Protect all wires against contact with oil products. Keep all

elements clean and avoid any damage of wires - short circuit

risk. All connections must have clean and proper contact

surfaces to avoid intermediate resistance at a wrong contact

point.

Hydraulic Oil

Change

Do the first oil change after the first 500 running hours or after

the first season. Next oil changes always after 1000 running

hours. It is recommended changing the filter element together

with the oil change.

Hydraulic Oil

Filter Change

We recommend changing the filter element together with the

oil change.

Page 39

39

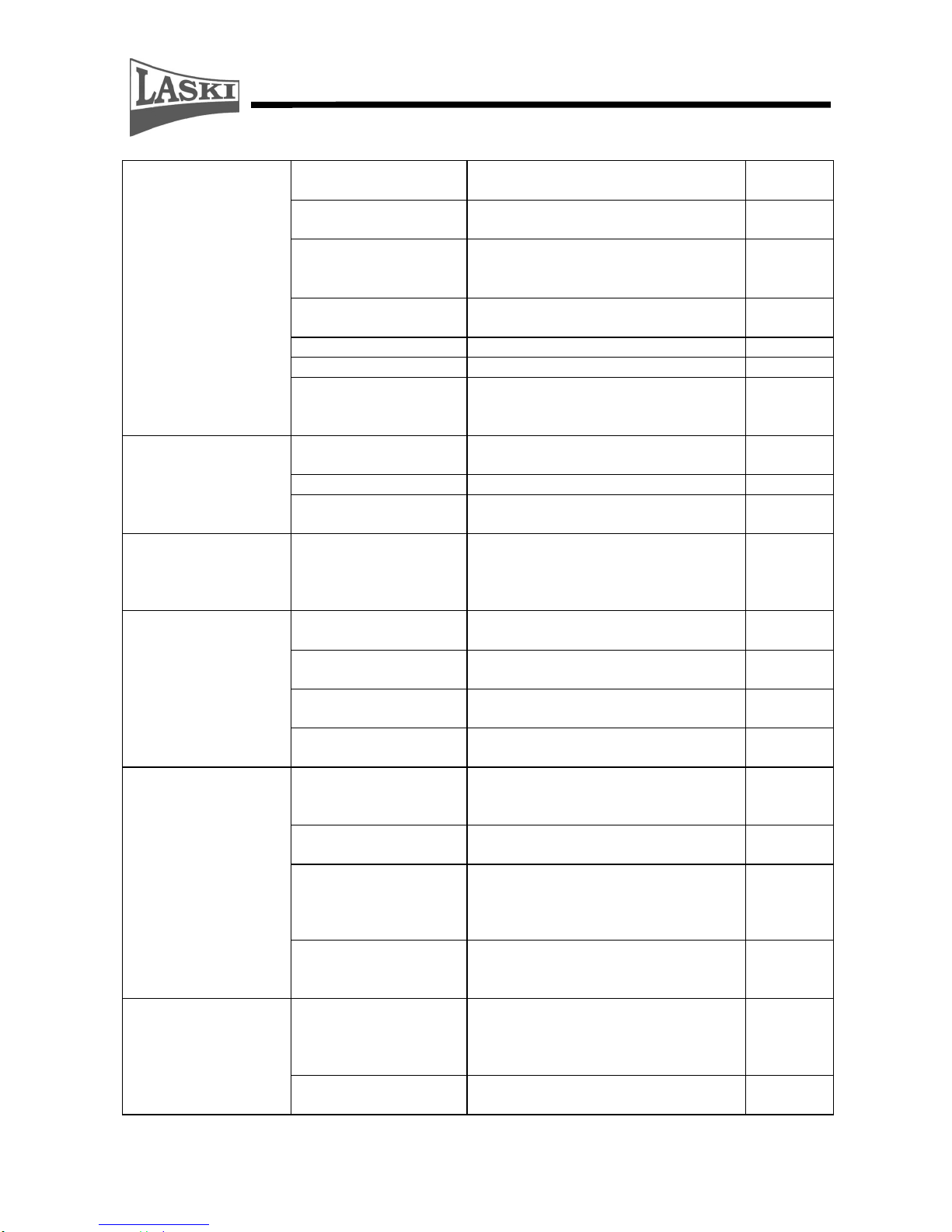

Checking, Oil Exchange

Operation

Component

Interval (hrs)

10

100

250

500

1000

2500

5000

Cleaning

Hydraulic oil tank

*

Hydraulic oil filter

*

Checking

Hydraulic oil in tank

*

Exchange

Hydraulic oil in circuit

*

Exchange

Oil gear

*

(5

years)

(*) clean daily under special conditions

(**) clean every 4 – 5 hrs under extreme dusty conditions

(***) see recommended oils

(o) if clogging indicated

() first exchange

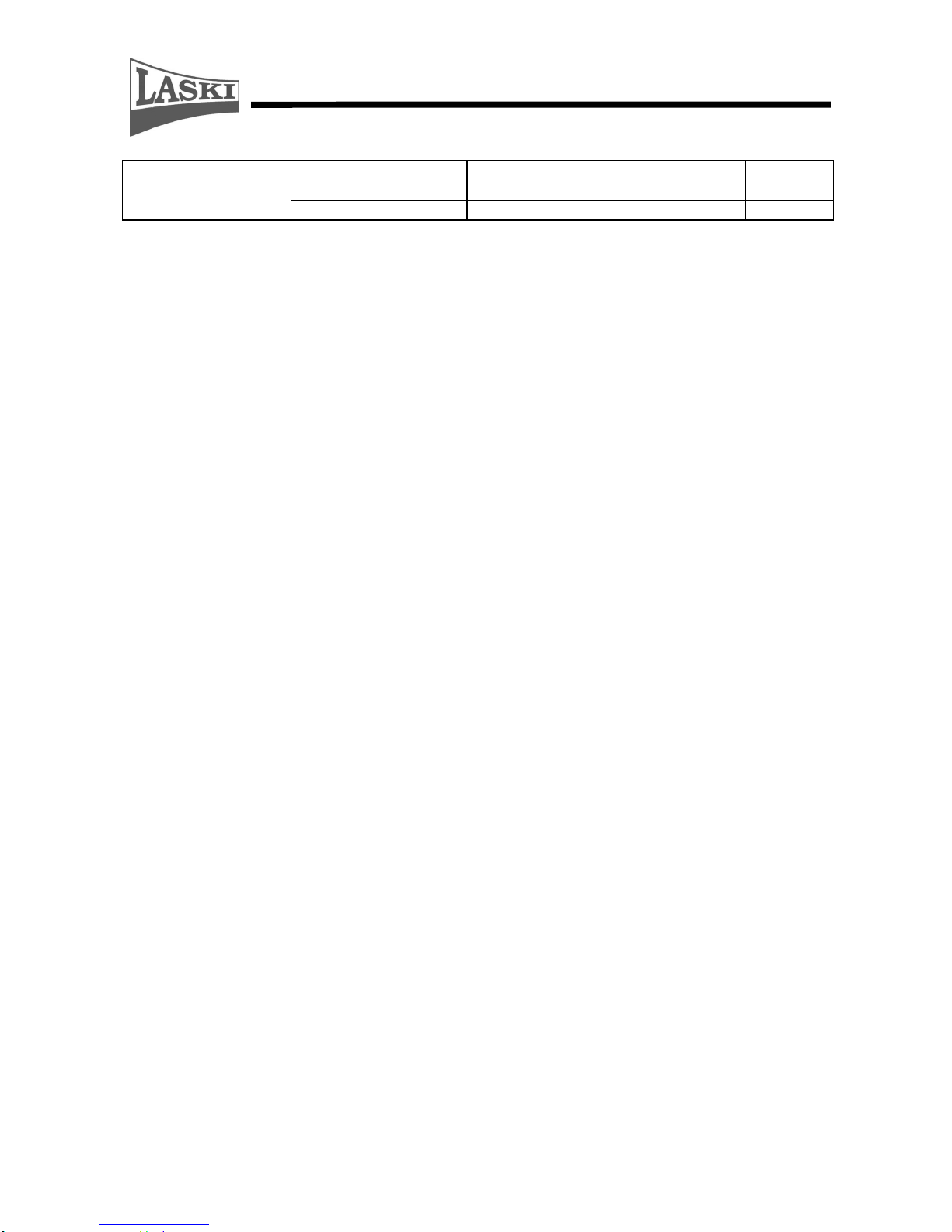

Failures and Troubleshooting

Failure

Cause

Remedy

Wrong chipping

or loading

Blunt blades

Remove and regrind blades. If worn,

replace them for new ones.

Worn opposite cutting

edge

Remove and regrind cutting edge; set

optimal clearance between blade and

opposite cutting edge

Malfunction of loading

rolls

See Problems with hydraulics

Wrong angle geometry

Regrind in accordance with detailed

figure of edge geometry

Damage/wear of

loading rolls

Replacement

Too small, dry or rotten

materials

Mix before loading

Breaker fouled

Load longer materials with higher

weight

Loading rolls do not

turn – rotor runs idle

Wrong setup of sensor for turning the

loading rolls on

service

Tractor engine

overloaded while

chipping

Wrong sensor setting

for min. speed

Switching-off speed is set too high

service

Blown fuse in

regulation circuit

Fuse replacement

Faulty control unit in

regulation circuit

Replacement

Faulty sensor – LED

does not burn

Replacement

Loading rolls do not

turn

Faulty electric

switchboard

Coil replacement

Page 40

40

Throttle valve closed

Check up manual speed regulation for

loading

Control lever in wrong

position

Press the lever in loading direction

Failure of NOSTRESS

system

Measure voltage on coil of

electromagnetic valve; it should be 0

at max. speed

Faulty coil of

electromagnetic valve

Coil replacement

Broken leads

Check up wiring for integrity

Faulty hydraulic pump

Pump replacement

Safety circuit not closed

Tilt rear part of the loading chute and

check up hood position protected with

terminal switch

Blades touch opposite

edge

Wrong setting of

clearance

Set distance to 0,5 – 1 mm

Loosen blade bolts

Tighten up fixing bolts

Clearance of chipping

wheel bearings

Tighten up fixing bolt of wheel on its

shaft

NOSTRESS system

out

of function

Blown fuse

Replacement of fuse 7,5 A

Faulty electronic

control unit

Replacement of fuse 4 A (inside

control unit)

Vibrations on discharge

ducting

Control unit replacement

Faulty speed sensor –

LED is not flashing

Check up wiring

Loading chute gets

clogged

Sensor replacement

Discharge duct gets

clogged

Too low speed of PTO

shaft

Stop loading and increase speed at

chipping. Min. working speed of PTO

shaft at chipping is 350 rpm

Discharge duct

deformed

Repair/replacement

Too small, dry or rotten

materials

Mix before loading

Loading rolls

overloaded with

material

Reduce loading roll speed

Bearings overheated

Insufficient lubrication

or wrong lubricant used

Lubrication and lubricants should be in

accordance with recommended

intervals and sorts (LTA 3EP MOL

Lition)

Too high speed of

chipping wheel

Optimal speed should not exceed 1900

rpm (PTO shaft: 620 rpm)

Page 41

41

Bearing loosened

Tighten up bearing housing bolts with

required torque

Bearing worn

Replacement

Waste Disposal

Any waste materials resulting from the machine operation should be disposed

in accordance with laws and regulations applicable in the given country.

Protect nature and water resources against used oil and filter elements.

Any parts of the machine should be disposed in accordance with laws and

regulations applicable in the given country.

Use of the chipper equipped with a hitch

The tractor-mounted chippers LS 150T can be optionally equipped also with a

hitch for towing of a trailer during chipping.

The hitch, mounted on the chipper rear, is intended solely for towing of a trailer

during chipping, i.e. for gathering of ejected wooden chips. It is forbidden to

couple a trailer to the chipper for its transport on public roads. This restriction can

be found also on a safety plate on the chipper.

Usage of a trailer coupled to the chipper can reduce running costs at chipping. It is

possible to displace the chipper to another site on short distances by means of one

towing tractor only, instead of two. The second tractor can be used only for

bringing of an empty trailer and removal of a loaded trailer.

For coupling of a trailer and its safety handling our chippers can be optionally

equipped with the hitch Rockinger, type 810B30, homologation

E1*89/173*2000/1*0296**00.

Besides the hitch on the machine rear there are also air-brake couplers for trailers

with two-line braking systems installed here: the red one as a filling line and the

yellow one as a control line. Both lines of the trailer braking system are to be

coupled through air hoses to the same couplers on the tractor rear.

On the machine rear there is also a 7-pin receptacle installed for the trailer lights

which should be interconnected through the corresponding plug on the machine

with the 7-pin receptacle on the tractor rear.

Page 42

42

Conditions for use of the hitch for towing of a trailer during chipping

1. The hitch, mounted on the chipper rear, is intended solely for towing of a

trailer during chipping, i.e. for gathering of ejected wooden chips.

2. It is forbidden to couple a trailer to the chipper for transport on public roads

3. While working on or nearby public roads the towing tractor must be equipped

with a beacon of orange colour for flashing and the chipper must be equipped

with 2 safety plates with red-white hatching, sight lights, reflector glasses and

a warning triangle for marking of slow-moving vehicles. The beacon on the

tractor cab must be turned on.

4. All the given lights, glasses and plates must be approved for transport on

public roads complying with applicable EU standards and local regulations. Be

aware that traffic rules and regulations in different countries may differ.

5. Max. permissible trailer gross weight is 8 000 kg.

6. Max. permissible vertical coupling load is 50 kg.

Page 43

43

7. Due to low permissible vertical coupling load it is forbidden to couple trailers,

resp. semi-trailers, with axles centrally mounted.

8. The trailer to be coupled must be in good technical condition and its brakes,

tyres and lights must by fully functional. The trailer must comply with

applicable EU standards and local regulations.

9. Min. drawbar length of the trailer must comply with legal requirements

applicable for tractor trailers. In case of doubts this length is to be checked

before the first use: the drawbar must not collide with the chipper in any

working position of the chipper or trailer.

10. While coupling, you must always interconnect both air-brake couplers and the

7-pin plug of the trailer with the tractor.

11. While chipping, the chipper should rest on the ground, the entire train must be

braked mechanically or blocked by means of scotch blocks. At work on hilly

terrain the trailer must be braked by means of its parking brake and in addition

to that its wheels must be blocked by scotch blocks.

12. The attendant is obliged to check efficiency of the braking system of the entire

train.

13. Set the loading chute so that it is accessible in any position of the coupled

trailer for material loading. When using a coupled trailer, you should direct the

discharge duct and its end piece to allow safe gathering of ejected chips in its

loading space.

14. While chipping in the vicinity of a road-side ditch or close to a terrain slope,

pay special attention to undulations of the ground to avoid any risk of slipping

or falling.

15. For displacement of the chipper to another site on short distances it is

necessary to set the loading chute in the tractor axis, to lift up the chipper

about 25 to 30 cm above the ground and to release the trailer brakes

respectively to remove the scotch blocks. For this displacement the trailer

Page 44

44

brakes and lights must be fully functional and the chipper engine must be

turned off.

16. If the chipper works in the same workplace for a longer time, it is necessary,

before its displacement, to check out safe coupling of the trailer, its air-brake

couplers and electric plug and to test their functionality.

17. At public road transport the tractor driver must keep all local regulations valid

for public roads. It is not allowed to exceed max. permissible speed of the

tractor or of the trailer.

18. Always before work with the trailer it is necessary to make checks of the hitch,

safe trailer coupling, interconnection of the tractor/trailer braking and

lightning systems and to keep them in proper technical condition.

Warranty

The manufacturer provides warranty on this product for a period as stated in the

enclosed Warranty Certificate. The given warranty period begins after delivery to

the customer.

This warranty covers all failures resulted from faulty assembly, manufacture and

used materials.

The manufacturer bears no responsibility for damages resulted from own user's

wrong usage, such as:

Usage by an unauthorised person.

Unauthorised changes, repairs and actions on the machine.

Usage of unoriginal spare parts or parts intended for other

models.

Disobedience to instructions for use.

Damage of the machine caused by faulty handling, maintenance

or overloading.

This warranty does not cover faults resulted from damages

caused by the user.

This warranty does not cover parts being subject to ordinary wear

and tear.

Page 45

45

This warranty does not cover any damage of machine caused by

usage of unoriginal spare parts.

This warranty does not cover consequences resulted from

weather effects.

Any warranty claims must be submitted in writing with papers concerning

acceptance for warranty or post-warranty repair.

Page 46

46

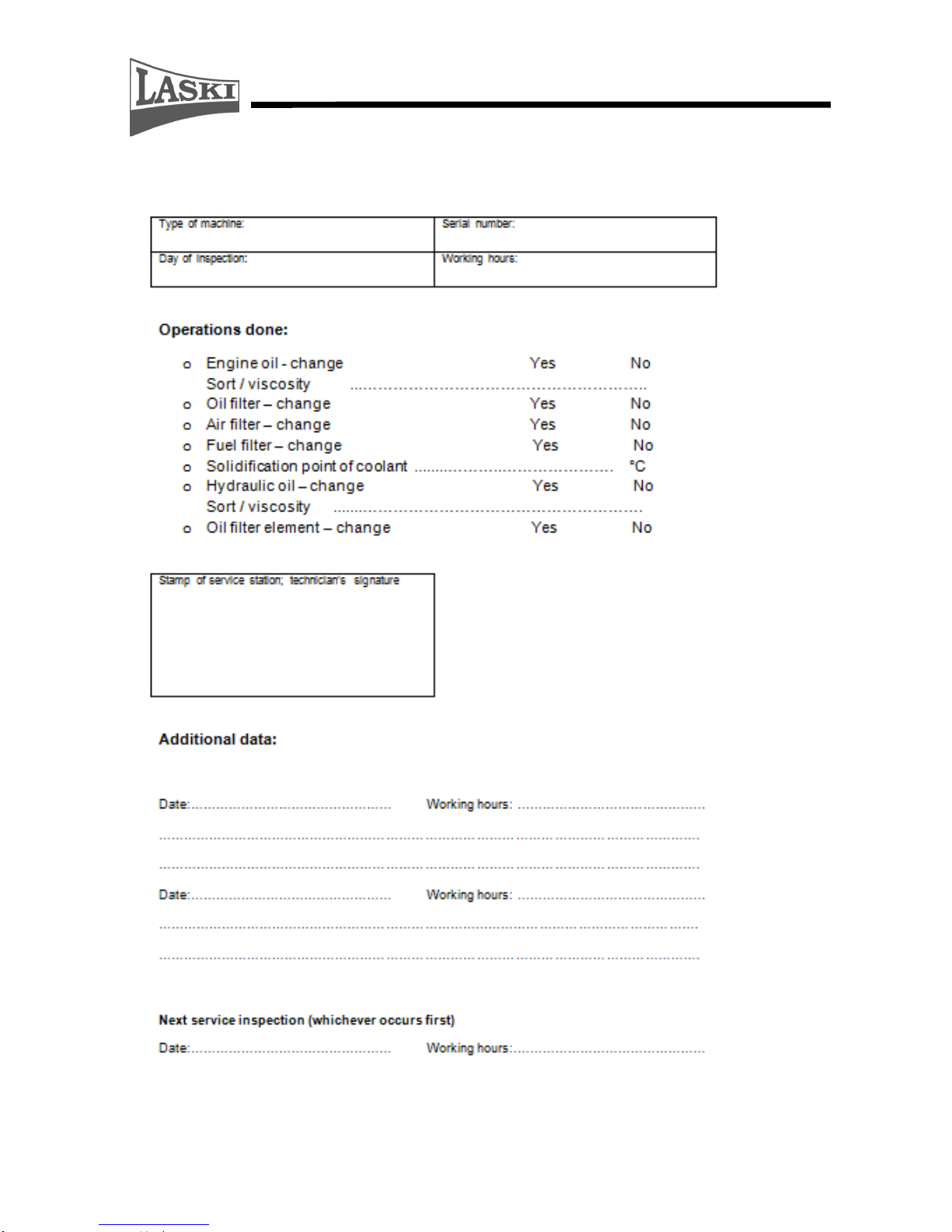

Service Report

Page 47

47

Service Report

Page 48

48

Service Report

Loading...

Loading...