COD. 79101EN.00

11/2013

BIOSELF

MULTIFUEL BOILER

USER AND INSTALLATION MANUAL

COD. 79101EN.00

11/2013

2

COD. 79101EN.00

11/2013

3

LASIAN Tecnología del Calor, S.L.

g

ives thanks for trust in us

¡THANKS FOR PURCHASING THIS PRODUCT!

COD. 79101EN.00

11/2013

4

COD. 79101EN.00

11/2013

5

DECLARATION OF CONFORMITY

In compliance with the requirements of the COUNCIL OF THE EUROPEAN UNION

The Company LASIAN Tecnología del Calor, S.L.

with C.I.F. B50141894, and registered address at:

Políg. Ind. Las Norias, parcela nº 7 - 50450 MUEL (Zaragoza) - SPAIN

Manufacturer of boilers for production of heating and A.C.S,

brand: LASIAN

In its different models:

BIOSELF 18 kW

BIOSELF 24 kW

WE HEREBY DECLARE, under our sole responsibility, that the above mentioned products are

manufactured in accordance with the following directives and standards:

98/37 CE

2006/95 CE

89/336/ CEE

Real Decreto 1027/2007

UNE - EN 303-5

Muel, 20th March 2013

The characteristics and manufacture date on each unit are indicated in the technical documentation that accompanies each

boiler.

COD. 79101EN.00

11/2013

6

Users of this boiler must read and understand this entire manual. The manual and all the documentation provided

must be kept during all the life-cycle of the boiler in an easily accessible place.

Care of the manual and how to consult it

Take care of this manual and keep it in an easily accessible place.

Should the manual be misplaced or ruined, request a copy from your installer or directly from the manufacturer

giving the identification details of the product.

“Bold text” requires particular attention.

Text in “italics” is used to draw your attention to other paragraphs in this manual or any additional explanation.

SYMBOLS USED IN THE MANUAL

SYMBOL MEANING: EXPLANATION, ADVICE, NOTES

ATTENTION!

Carefully read and understand the relative message. Failure to comply with

what is written can cause serious damage to the boiler and put the user’s

safety at risk.

OPERATING SEQUENCES

Sequence of buttons to be pressed to access the menus or make adjustments.

INFORMATION

Important information for a good performance of the boiler. Failure to comply

with these provisions will compromise the use and performance of the boiler.

COD. 79101EN.00

11/2013

7

INDEX

1. IMPORTANT INSTRUCTIONS ................................................................................................................................9

2. TECHNICAL DATA.................................................................................................................................................10

3. FUEL.......................................................................................................................................................................12

4. INSTALLATION ......................................................................................................................................................13

4.1 GENERAL NOTES...........................................................................................................................................13

4.2 UNPACKING ....................................................................................................................................................13

4.3 DOMESTIC FIRE PREVENTION.....................................................................................................................13

4.4 MINIMUM SAFETY DISTANCE.......................................................................................................................14

4.5 FLOOR PROTECTION ....................................................................................................................................15

4.6 DUCT OR CHIMNEY .......................................................................................................................................16

4.7 FLUE DUCT OUTLET ......................................................................................................................................17

4.7.1 GENERAL NOTES ...................................................................................................................................17

4.7.2 PIPES AND MAXIMUM USABLE LENGTHS ...........................................................................................17

4.7.3 HOLE IN FLUE DUCT PIPE .....................................................................................................................18

4.7.4 USE OF A TRADITIONAL TYPE CHIMNEY ............................................................................................18

4.8. USE OF EXTERNAL CHIMNEY .....................................................................................................................19

4.9 EXTERNAL CHIMNEY.....................................................................................................................................19

4.10 FRESH AIR INTAKE ......................................................................................................................................21

4.11 MINIMUM DISTANCES FRESH AIR INTAKE ...............................................................................................21

5. CONNECTIONS .....................................................................................................................................................22

5.1 ELECTRICAL CONNECTION..........................................................................................................................22

5.2 HYDRAULIC CONNECTION ...........................................................................................................................22

6. USE ........................................................................................................................................................................23

6.1 WARNINGS......................................................................................................................................................23

6.2 CONTROL BEFORE IGNITION.......................................................................................................................23

6.3 LOADING THE PELLETS ................................................................................................................................24

6.4 IGNITION OF THE BOILER.............................................................................................................................24

6.5 CLEANING .......................................................................................................................................................24

6.6 LOAD................................................................................................................................................................24

6.7 PAUSE .............................................................................................................................................................24

6.8 WAITING FOR THE FLAME ............................................................................................................................24

6.9 FLAME STABILIZATION..................................................................................................................................24

6.10 IN OPERATION..............................................................................................................................................24

6.11 SHUTDOWN ..................................................................................................................................................25

6.12 NOT WORKING .............................................................................................................................................25

6.13 STANDBY ......................................................................................................................................................25

6.14 PROTECTION CONTROL OF THE BOILER OFF OR IN STANDBY............................................................25

6.15 WATER PUMP CONTROL.............................................................................................................................25

7. CONTROL PANEL INSTRUCTIONS .....................................................................................................................26

7.1 START-UP SCREEN .......................................................................................................................................26

COD. 79101EN.00

11/2013

8

7.2 PROGRAMS MENU.........................................................................................................................................27

7.3 BOILER TEMPERATURE PROGRAMMING...................................................................................................27

7.4 DATE AND TIME ADJUSTMENT ....................................................................................................................27

7.5 PROGRAMMED START-UP AND SHUTDOWN.............................................................................................28

7.6 FUEL ................................................................................................................................................................32

7.7 PRESSURE H

2

O..............................................................................................................................................32

7.8 ALARM DESCRIPTIONS.................................................................................................................................33

7.9 SAFETY TEMPERATURE LIMITER AND ROOM THERMOSTAT.................................................................34

8. WARNINGS AND MAINTENANCE ........................................................................................................................35

8.1 DOOR OPENING .............................................................................................................................................35

8.2 DISPOSAL OF ASHES ....................................................................................................................................35

8.3 BRAZIER CLEANING ......................................................................................................................................35

8.4 ASH PAN CLEANING ......................................................................................................................................35

8.5 COMBUSTION CHAMBER CLEANING ..........................................................................................................36

8.6 HEAT EXCHANGER CLEANING ....................................................................................................................36

8.7 SMOKE CHAMBER CLEANING......................................................................................................................37

8.8 UNLOAD INSTALLATION CLEANING ............................................................................................................37

8.9 PEEPHOLE GLASS BREAKAGE ....................................................................................................................37

8.10 ORDINARY AND EXTRAORDINARY MAINTENANCE ................................................................................37

* WARRANTY CONDITIONS

COD. 79101EN.00

11/2013

9

1. IMPORTANT INSTRUCTIONS

This instruction manual has been prepared by the manufacturer and it is an essential part of the product. Should

the boiler be sold or transferred, it should always be accompanied by the manual as it contains information that is

necessary for the buyer and all persons involved in the installation, maintenance and use of the product.

Carefully read and understand the instructions and technical information contained in this manual before

proceeding with the installation, use and maintenance of the product. Familiarization of the instructions in this

manual ensures the safety of people and a longer life performance of the product.

The manufacturer disclaims any liability for damage caused by failure to read the rules and instructions for

installation, use and maintenance listed in the book of instructions, unauthorized product modification or use of

non-original spares.

Installation and use of the product should be in accordance with the manufacturer's instructions, obeying European,

national and local regulations.

Installation, electrical connection, maintenance and repairs must be performed only by a qualified, authorized

person and with a proper knowledge of the product.

The product should not be installed near wooden walls or combustible material. For a proper installation it is

necessary to consult the chapter "Safety distance". Check the flatness of the floor where the product will be

installed. Use of appropriate gloves is advised when handling coated parts to avoid leaving traces that are difficult

to remove in the first cleaning. The assembly of the boiler should be carried by at least two people.

Connect the boiler to the mains only after connecting the chimney. The power cable must be accessible after the

installation of the boiler. To start the boiler refer to chapter "FUEL". Never use liquid fuels to start the boiler.

Provide sufficient ventilation during the installation. In case of malfunction, the fuel supply will be interrupted.

Restart the product only after having the cause of the problem solved. Stop using the product in case of failure or

malfunction. Do not lift the grating which lies inside the fuel hopper. Any accumulation of unburned fuel in the

burner resulting from misfire must be removed before ignition.

While the boiler is working, it is recommended not to touch the hottest parts like handle, door and chimney. Pay

attention to keep anyone not involved in the installation away from the boiler. Inform persons in the vicinity of the

boiler of the necessary precautions while the product and possible products are working. In case of problems or

misunderstandings of the instructions, contact the installer. Do not place non heat-resistant objects on the boiler or

within the prescribed minimum safety radius of the boiler.

Do not open the door during operation, or start the boiler if the peephole glass is broken.

For terms, limits and exclusions refer to the warranty certificate supplied with the product. The manufacturer may

make changes deemed appropriate to the boiler documentation without notice, to pursue a policy of constant

development and constant renewal of the product.

This document is property of the manufacturer and can not be transferred in whole or in part to any third party

without the written consent of the company. All rights

reserved.

DIRECTIVES AND STANDARDS

All our products are manufactured according to the following directives:

89/366 CEE

2004/108 CE

2006/95 CE

89/106 CEE

All our products are manufactured according to the following standards:

EN 60335-1; EN 60335-2-102;

EN 61000-3-2; EN 61000-3-3;

EN 50366; EN 55014-1; 55014-2

EN 303-5

COD. 79101EN.00

11/2013

10

2. TECHNICAL DATA

The technical label indicates data and performance of the appliance.

The handling, removal or lack of technical label hinders any installation and maintenance, since it is not possible

to identify the product. In case of damage, request a duplicate of it to the service center. Given the importance of

the label, we recommend installing the boiler respecting the distances so that it is always visible.

MODEL

BIOSELF 18 kW BIOSELF 24 kW

Nominal thermal output

min./max.

kW

6,2 - 18

8,5 - 24

Nominal thermal output to

water

kW

16

20

Efficiency %

>92 >89

Consumption hourly

min./max.

kg/h

1,3 – 3,7

1,9 - 5,1

Tank capacity

kg

95 95

Electric absorment in work

W

50 - 150

50 - 150

Flue duct Ø

80 mm 80 mm

Weight

kg

177 182

Dimensions

LxBxH 550x700x1450 550x700x1450

COD. 79101EN.00

11/2013

11

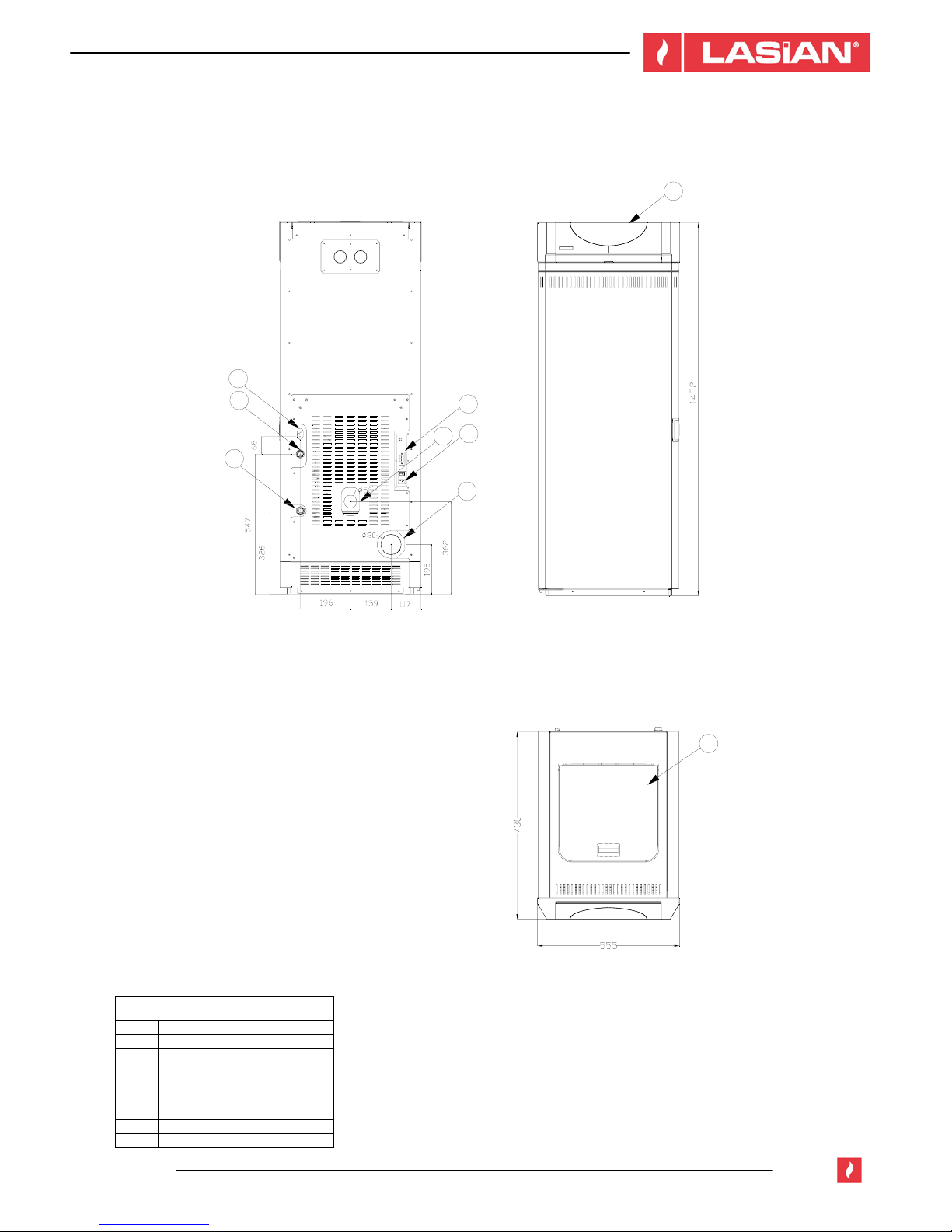

DIMENSIONS AND COMPONENTS MODELS BIOSELF 18 / 24 kW

BIOSELF 18 / 24 kW

2

1

7

6

4

5

3

9

8

COMPONENTS

1 Control panel

2 Ø 80 Flue duct

3 Safety valve

4 ¾ male discharge

5 ¾ male return

6 Air intake

7 Electrical outlet

8 Hopper lid

9 Room thermostat connection

COD. 79101EN.00

11/2013

12

3. FUEL

The multi-fuel boiler is designed to burn fuels derived from solid biomass:

Wood pellet: is a fuel made from compacted sawdust extracted from the remains of the production and processing

of dried natural wood; the compactness of the product is guaranteed over time by a natural substance contained in

the wood: the lignin. The typical form resembling small cylinders is achieved by wire drawing.

On the market there are various types of pellet with quality and features that change depending on the kind of

production and type of wood materials used.

Solid biomass: biomass is a type of fuel recovered and produced directly or indirectly from the disposal of

industrial processing, from substances such as olive, almond, hazelnut, rape or pruning cuts, or from the disposal

during wood processing or the remains. These fuels are materials such as shredded vegetables including olive pits,

almonds or hazelnut shells; other types are the pellet boiler and pellet olive of a diameter of 6 or 8 mm. etc. This

LASIAN boiler has an ash cleaning system that allows these fuels to be used in the devices, choosing the specific

program that is already recorded for the fuel we use:

FUEL PROGRAMS:

Combustible 1 DIN PLUS

Combustible 2 PELLET QUALITY MEDIUM

Combustible 3 PELLET QUALITY LOW

Combustible 4 OLIVE PITS

Combustible 5 SHREDDED ALMOND SHELL

The importation of these programs can be found in chapter 8 Operation of the control panel, in the

paragraph 8.6.

ATTENTION!

The boiler is provided with two burners, one for the pellets and shredded almond shell

combustion (which is factory assembled) and another specific burner for olive pits combustion.

When you select the program “Combustible 4” for burning olive pits, the pellet burner must be

replaced by the olive pits burner, which has smaller holes.

The following types of fuel are excluded for its use; splinters - wood chunks - branches in

general.

Because the characteristics and fuel quality influence significantly in the autonomy, performance and

proper operation of the boiler, it is advised to:

AVOID the use of fuel containing powder of mixed sawdust, resins or chemical, additional or binder substances.

AVOID the use of wet fuel.

The choice of unsuitable fuel causes:

- brazier and smoke exhaust dust jam,

- increase in fuel consumption,

- decrease in performance,

- does not guarantee the normal operation of the boiler,

- glass dirt,

- production of unburned granules.

The presence of moisture in the fuel increases the volume of the capsules and breaks them causing:

- malfunctions of the load system,

- bad combustion.

Fuel must be stored in a dry place and special attention must be paid to the handling of the sacks in order to avoid

grinding them and form sawdust.

In order to use a fuel with size and calorific characteristics calorific different to the ones specified, it could be

necessary to modify the operating parameters of the boiler. Should that be your case, contact an authorized service

center.

COD. 79101EN.00

11/2013

13

The use of fuel not according to the manufacturer's instructions can damage the boiler and

compromise its performance, resulting in the invalidation of the warranty and in the end of the

liability of the manufacturer on the product.

4. INSTALLATION

4.1 GENERAL NOTES

Do not install the boiler in bedrooms, locations with bath or shower and in places where there is another heating

unit devoid of an adequate airflow (chimney, stove, etc.), outside exposed to the atmospheric agents or in wet

areas.

The installation of the boiler must be in a location that allows a safe and easy use and a simple maintenance. This

place must also be equipped with an electrical outlet with a regulatory earth connection.

The external air intake must meet the requirements of paragraphs 4.10 and 4.11.

ATTENTION!

Ensure that the plug for the electrical connection is accessible after the boiler

installation.

4.2 UNPACKING

Unpack the product carefully so it does not get damaged or scratched. Remove from the tank of the boiler, the

accessory and home box possible pieces of polystyrene or cardboard used to block the removable parts, etc.

Also keep out of reach of children parts of the packaging (plastic bags, polystyrene, etc.) that could be potentially

dangerous and dispose according to the existing laws.

4.3 DOMESTIC FIRE PREVENTION

- The installation and use of the boiler must comply with the manufacturer's instructions and local siting

regulations.

- Always consult the instructions given in this manual for a correct use of the boiler and the electronic devices

connected to it.

- When a chimney crosses a wall or ceiling it is necessary to perform particular operations (protection, thermal

insulation, distance of heat sensitive materials, etc.)

- The chimney connection pipe should never cross a combustible surface.

- Do not connect this boiler to another smoke duct already used by another device.

- It is recommended to keep out of the heat source area and at least at one meter all flammable or combustible

items such as wooden beams, furniture, curtains, flammable liquids, etc...

- In the event that there are flammable or heat sensitive coatings in the surrounding space, a protective layer of

insulating and not combustible material must be placed. If the floor is made of combustible material, fireproof

material protections projected 15 cm laterally and 30 cm from the front must be placed.

- For further information refer to local regulations.

- If the flue should catch fire, be equiped with a suitable systems for suffocating the flames or request help from

the fire service.

COD. 79101EN.00

11/2013

14

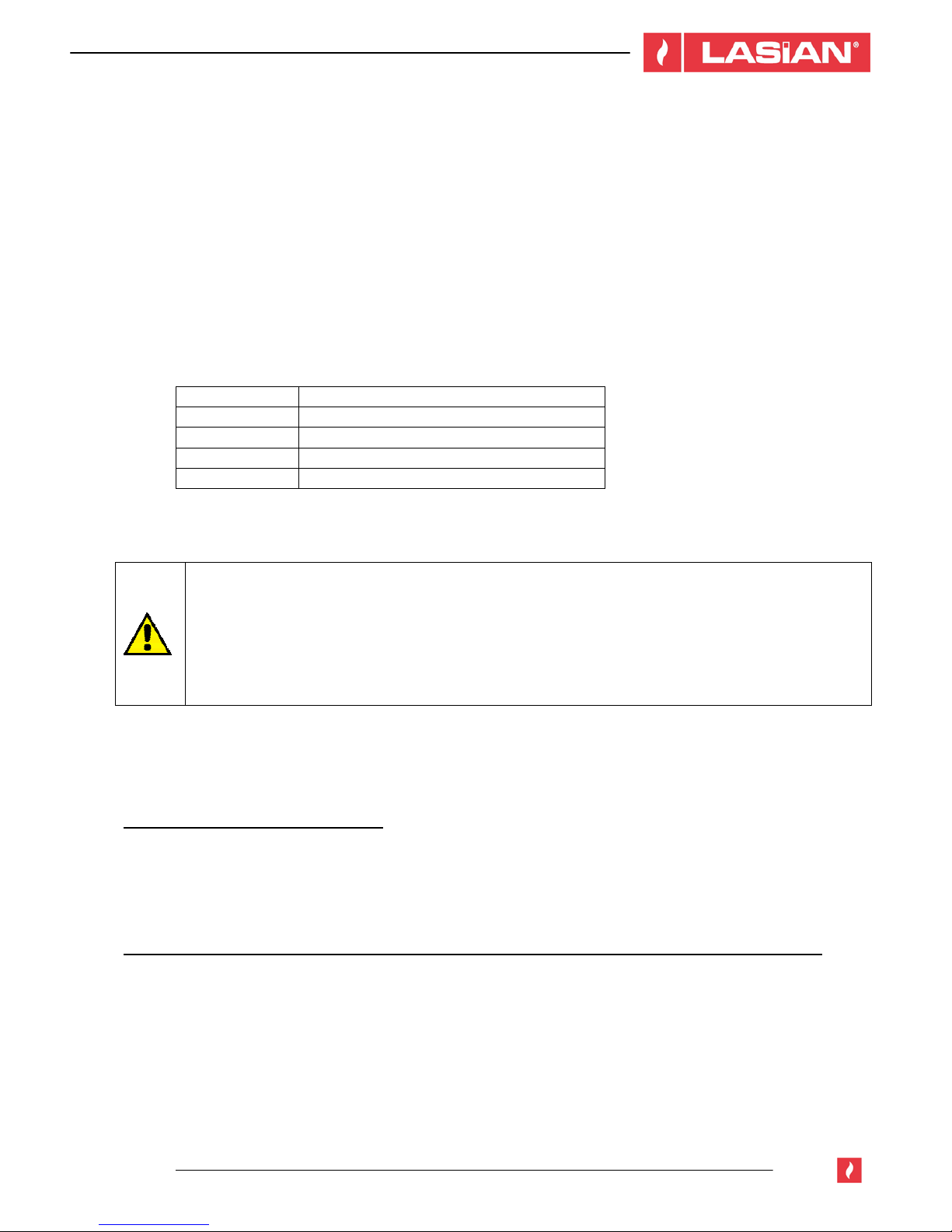

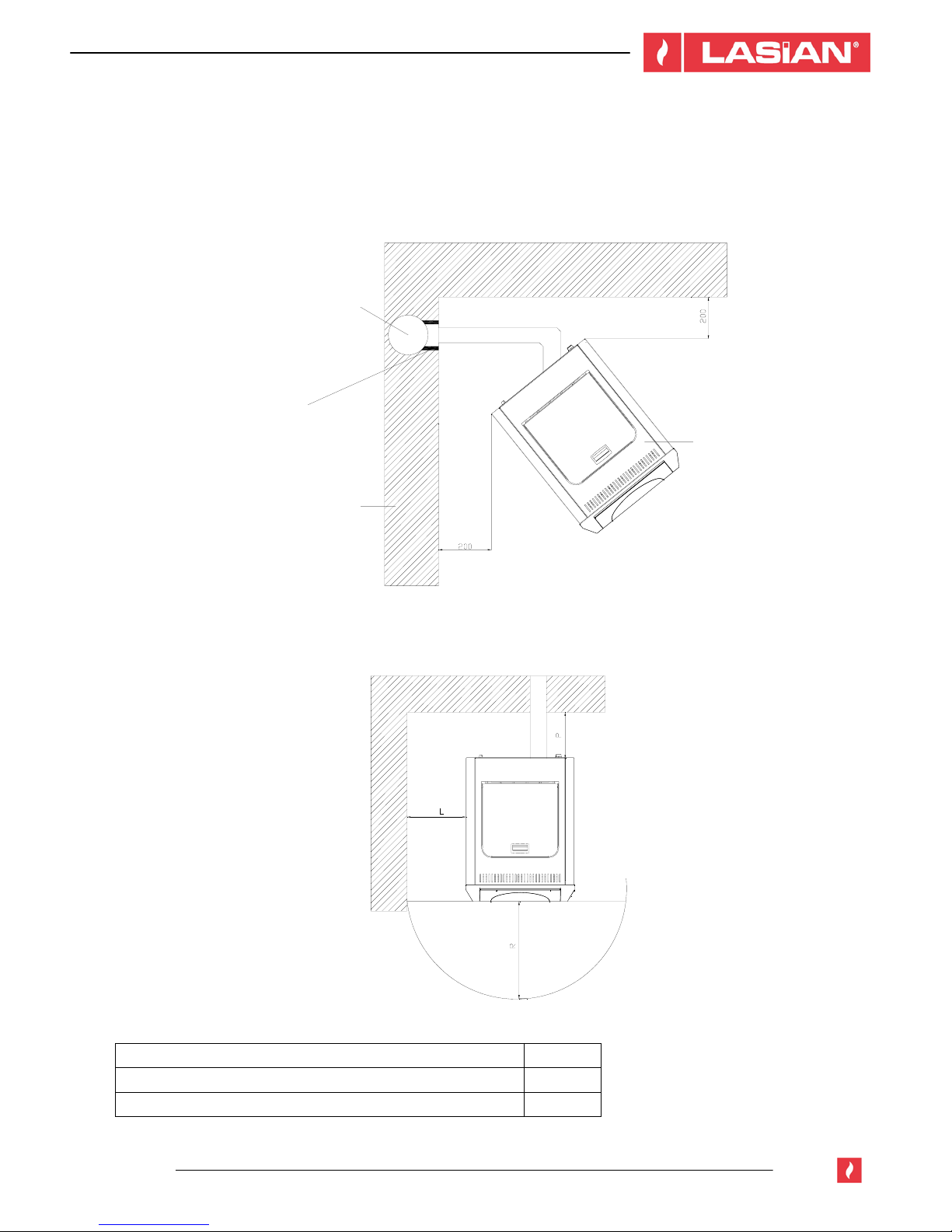

4.4 MINIMUM SAFETY DISTANCE

The following figures show the minimum safety distance that must always be guaranteed.

INSTALLATION IN ANGLE (mm)

INSTALLATION TO WALL (mm)

Safety distance of the flammable material mm

minimum distance air from flammable posterior wall P = 400

minimum distance air from flammable side wall L = 400

front distance of flammable material R = 1000

Chimmey

Passing pipe

insulation

Walls

Boiler

COD. 79101EN.00

11/2013

15

DISTANCE FROM FALSE CEILINGS OR

FLAMMABLE CEILINGS (mm)

DISTANCE FROM THE FLUE DUCT OF

FLAMMABLE WALLS INSTALLATION (mm)

4.5 FLOOR PROTECTION

In case of heat sensitive or flammable floors is necessary to use a floor protection, eg: Steel sheet, marble or tiles.

Whatever type of protection is chosen, it must protrude at least 300 mm from the front, and at least 150 mm from

the sides of the boiler, support the weight of the boiler and have a thickness of at least 2 mm fig. 6 and 7.

Fig. 6

Fig. 7

2 mm protection

Floor

Boiler

Protection

COD. 79101EN.00

11/2013

16

4.6 DUCT OR CHIMNEY

Each appliance must have a vertical duct or chimney to expel outside the fumes produced by combustion.

Flue duct must meet the following requirements:

Do not connect to any other fireplace, boiler, boiler or any kind of extractor (fig. 1)

It must be adequately separated from combustible or flammable materials by a cavity wall or an insulating material.

The inner section should be uniform, preferably circular: square or rectangular sections must have rounded edges

with a radius of at least 20 mm; regular bends without discontinuities, deviations from the axis no greater than 45°

(Fig. 2).

Each appliance must have its flue duct with a section equal to or greater than the diameter of the flue outlet duct of

the boiler and a height of not less than that declared (See table in paragraph 4.7.2).

Two boilers, fireplace and a boiler, an oven and a wood boiler, etc. should never be used in the same environment

since the draw of one may damage the other. Collective type ventilation ducts cannot be used either as they could

cause a vacuum in the environment of installation, even if installed in adjoining or communicating rooms.

It is forbidden to perform fixed or mobile openings in the chimney to connect a different appliance.

It is advisable that the flue is equipped with a solid material collection chamber and possible condensations

beneath the mouth of the duct to be easily opened and inspected from the door hermetically.

COD. 79101EN.00

11/2013

17

4.7 FLUE DUCT OUTLET

4.7.1 GENERAL NOTES

ATTENTION!

The use of various fuels distinguishes this boiler from the others. The draw of the smoke is

forced thanks to an extractor that keeps the combustion chamber in depression and all the

discharge pipes under a slight pressure. It is required to verify that this extractor is installed

correctly and completely tight and firm, both for performance and safety.

The exhaust duct must be built by specialized staff or companies, as indicated in this manual. Always carry out the

unloading installation so that periodic cleaning is assured without having to dismantle any part.

Pipes should ALWAYS be sealed with silicone, not cement-based, which retains their strength and elasticity at high

temperatures, 250 ° C, and should be fixed with a Ø3, 9mm. self-tapping screw.

- Do not install dampers or valves that could block the passage of flue gas.

- Do not connect to a flueway where other appliances (boilers, extractor hoods, etc.) discharge fumes or vapours.

4.7.2 PIPES AND MAXIMUM USABLE LENGTHS

Pipes of painted aluminium-clad steel (minimum thickness of 1.5 mm), stainless steel (Aisi 316) or enameled steel

(minimum thickness of 0.5 mm) with a nominal diameter of 80 mm can be used; for pipes which run inside the flue

the maximum diameter is 150 mm.

Hoses are admitted if they meet the specifications set by law (stainless steel with a smooth inner wall) and malefemale connectors must have a minimum length of 50 mm.

The diameter of the pipes depends on the type of installation; the boiler was designed to take Ø80 mm pipes, as

shown in the specifications of the model chosen, and in some cases and models it is necessary to use Ø100 mm

double-walled pipes.

TYPE OF INSTALLATION WITH Ø 80 mm PIPE

WITH DOUBLE-WALLED

Ø 100 mm PIPE

Minimum length 1.5 m 2m

Maximum length (with three 90° bends) 4.5 m 8m

For installations more than 1200m above the sea - required

Maximum number of bends 3 4

Length of horizontal sections with minimum

5% gradient

2m 2m

NOTE: Losses in pressure associated with a 90 ° bend can be compared to those incurred by one meter of pipe;

an inspectable union-tee can be considered equivalent to a 90 ° bend.

Tee

Ø80>Ø100 connection

Sealing plug

Direction of cleaning

Direction of cleaning

Direction of

cleaning

Tee

Tee

Tee

Max. 2m (min 5%)

COD. 79101EN.00

11/2013

18

4.7.3 HOLE IN FLUE DUCT PIPE

Once the boiler location is established, it is necessary to make the hole for the flue duct pipe. This varies

depending on the type of installation, diameter of the unloading pipe and type of wall or ceiling that it is going to

pass through.

The insulating barrier must be mineral-based (rock wool, ceramic fiber) with a nominal density greater than 80

kg/m

3

.

Diameter flue duct pipe [mm]

Ø80

Up to 24 kW

Ø 100

From 28 kW

Insulation

thickness [mm]

Diameter holes to be done [mm]

Wall in flammable wood or with

flammable parts

100 280 300

Wall or ceiling in cement 50 180 200

Wall or ceiling in brick 30 140 160

4.7.4 USE OF A TRADITIONAL TYPE CHIMNEY

If you wish to use an existing chimney it is strongly recommended that you have it checked by a professional

chimneysweep to ensure that it is completely airtight. The reason for this is that the smoke, because it is slightly

pressurized, can infiltrate any cracks in the flue and escape into living spaces.

If upon inspection you find that the chimney is not completely sound, it is recommended that you insert piping made

of new material.

If the existing chimney is wide enough, we recommend a pipe with a maximum diameter of 150 mm; it is also

recommended that you insulate the chimney flue. Fig. 1 and 2 represent the solutions to be adopted if you want to

use an existing chimney.

Fig. 1

Fig. 2

COD. 79101EN.00

11/2013

19

4.8. USE OF EXTERNAL CHIMNEY

An external flue can be used provided it complies with the following requirements:

• Use only insulated double-walled

stainless steel pipes fixed to the

building.

• There must be an inspection opening at

the base of the flue to permit periodic

checks and maintenance.

• The chimney must be fitted with a down-

draught cowl ensuring compliance with

the safety distance from the edge of the

building as outlined in paragraph 4.9.

• The drawing represents the solution

adopted to use an exteral chimney.

4.9 EXTERNAL CHIMNEY

The flue duct must be equipped, in its upper part, with an appliance called chimney, which facilitates the discharge

of combustion gases outdoors.

The external chimney must comply with the following requisites:

- To have an internal section equivalent to the flue pipe.

- To have a useful outlet section of not less than twice of the flue pipe section.

- The chimney which emerges from the ridge or that remains in contact with the outside (e.g. the case of an

open roof) must be covered with brick elements and perfectly insulated. They must be built in such a way to

prevent the penetration of rain, snow or foreign matter, and in the event of winds from all directions and angle,

discharge of the combustion products is assured (chimney stack with down-draught cowl).

- The external chimney must be installed to ensure the adequate dispersion and dilution of the combustion

products outside the reflux area. This area has different sizes and shapes depending on the angle of inclination

of the roof, and it is therefore necessary to adopt the minimum heights shown in Fig 1 and Fig 2.

- The chimney must be a windproof type and surpass the ridge height like in fig.1 and fig.2.

- Any building or other obstacles that exceed the chimney height cannot be near the chimney itself (Fig. 1).

- Never cover the chimney with nets.

Inspection

Fresh air intake with nonclosable grille

COD. 79101EN.00

11/2013

20

Fig. 1

Fig. 2

Pitch of the roof

[°]

Horizontal width of reflux

area from ridge axis A[m]

Minimum height of

outlet from roof

Hmin =Z+0.50m

Height of reflux area Z

[m]

15 1.85 1.00 0.50

30 1.50 1.30 0.80

45 1.30 2.00 1.50

60 1.20 2.60 2.10

Surpass

COD. 79101EN.00

11/2013

21

4.10 FRESH AIR INTAKE

- The boiler must have the necessary air to ensure a trouble-free and correct performance of the combustion, as

well as a good environment.

- Make sure the room where the boiler is installed has adequate ventilation, and if not, install an air supply duct

from the outside with a recommended minimum section of 100 cm².

- The fresh air intake must be communicated directly with the environment of the installation of the boiler, placed

so that it avoids to get obstructed, and it is protected with a permanent grid or another suitable guard provided

it does not reduce the minimum section.

- The air flow can also be obtained from an adjacent room to the place of the installation, provided this air flows

freely through permanent apertures that cannot be closed, and communicate with the outside.

- The adjacent room must not be used as a garage, store for combustible materials or for activities with a risk of

fire.

4.11 MINIMUM DISTANCES FRESH AIR INTAKE

The combustion air intake cannot be connected to any air distribution duct or to the air intake placed in the

wall.

These distances must be respected to prevent the combustion air being released from another source; for example

opening of a window can take the fresh air causing the lack of it to the boiler.

Air intake must be placed at least:

1.5 m Under

1.5 m Horizontally far from

0.3 m Above

Doors, windows, flue duct,

cameras, etc.

1.5 m Far from Flue duct

COD. 79101EN.00

11/2013

22

5. CONNECTIONS

5.1 ELECTRICAL CONNECTION

The system must be suitable for the electrical power of the boiler.

The boiler is supplied with a power cable that needs to be connected to

a 230V 50Hz outlet.

The connection of the outlet to the back of the boiler is shown in the

figure.

Ensure that the main switch of the boiler is at 0, and then connect the power cord first behind the boiler and then

into an electrical outlet on the wall. The main switch located on the back wall will be activated only when the boiler

is lit; otherwise, it is advisable to remove the cable from the boiler.

Maximum electrical absorption while ignition (6 min) 490 Wat

Electrical absorption (Wat) 120 Wat

Voltage and supply frequency 230 V / 50Hz

By law, the installation requires an earth connection and residual-current circuit breaker (RCCB). Make sure the

power cord, in its definitive position, does not make contact with hot parts.

5.2 HYDRAULIC CONNECTION

For the connection of the input water, output water, unloading and filling pipes, use long

flexible tubes of at least 70 cm to facilitate the movement of the boiler for maintenance.

INDICATIVE HYDRAULIC SCHEME

From the aqueduct to

water reintegration

Output water heating installalation

Input water heating installation

Closing flange

Non-returning valve

Pressure reducing valve

COD. 79101EN.00

11/2013

23

6. USE

6.1 WARNINGS

- Do not use the appliance as an incinerator or in any other way different to the purpose it has been designed

for.

- Do not use liquid fuel.

- The appliance, especially the external surfaces, reaches high temperatures during operation; maneuver

carefully to avoid burns.

- Do not make any unauthorized modification to the appliance.

- Use only original spare parts recommended by the manufacturer.

- Try to familiarize yourself with the commands given by the panel or by the remote control.

- Try to incidentally memorize the boiler messages displayed on the screen.

- To prevent the escape of fumes, the combustion chamber must be kept closed, except during cleaning

operations, which are conducted with the boiler off.

- Do not remove the protective grille inside the tank.

- Do not touch the boiler with wet hands, as this is an electrical appliance. Always remove the power cord before

intervening in the unit.

- Incorrect installation or poor maintenance (non-compliant to what it was stated in this manual) may cause

damage to people, animals... In this case, Lasian will be exempt of any civil or criminal liability.

- If during the ignition phase, this does not occur and you notice a lot of smoke in the combustion chamber, turn

off the boiler and replace the fuel as the humidity could be too high. Remove any rest of fuel in the crucible

caused by misfire before restarting the boiler.

During the first ignition, it is important to increase the boiler temperature gradually avoiding

using the maximum power or overheating it.

The boiler is subject to expansion and contraction during the ignition and cooling phases. The

phenomenon is quite normal since the structure is made of steel and therefore should not be

considered a defect.

6.2 CONTROL BEFORE IGNITION

Make sure you have followed all the safety conditions seen before. Having read and understood the operating

instructions:

- Remove from the boiler anything that can get burned (instructions, labels, stickers).

- Check that the brazier is standing properly on its base.

Ensure that all doors and air intake of the combustion chamber and ash pan are closed properly to avoid drops in

performance and possible leakage of fumes during operation.

After a long inactivity, the remains of pellets will need to be removed from the tanks as they may

have absorbed some moisture, changing its original features and not being suitable for

combustion.

COD. 79101EN.00

11/2013

24

6.3 LOADING THE PELLETS

The load of fuel is made through the upper side of the boiler. Pour the pellet in the tank.

Never remove the protection grille inside the tank. During the load, prevent the sack of pellet

from contacting hot surfaces. Fill the tank only with the fuel that meets the aforementioned

specifications.

6.4 IGNITION OF THE BOILER

Press the button ON/OF during more than 3 seconds, the boiler will pass to mode on, on the screen will appear

the word “FIRE”.

Subphases “ON”:

The start phase is composed by 5 phases which occur in the following order: “CLEANING”, “LOAD”,

“PAUSE”, “WAITING FLAME” and “FLAME STABILIZATION”. These phases are described below.

6.5 CLEANING

Burner cleaning phase. The burner motor is working for a defined time and the fume motor at a defined speed.

6.6 LOAD

Continuous load of fuel into the burner, preheating of the resistor. The burner motor turns off, while the fume motor

continues running at the defined speed.

6.7 PAUSE

Loading auger still, fume motor at the defined speed and resistor on.

6.8 WAITING FOR THE FLAME

Waiting phase when the ignition must take place; the auger motor starts working again for a defined time. The

transition to the next phase is permitted when the fumes temperature exceeds the threshold and during the next 90

seconds there is an increase of 3 ° C of such temperature. If such increase does not occur in the first 90 seconds,

other records are made, always in intervals of 90 seconds, until it reaches an increase of at least 3 ° C; all within a

time limit defined by a parameter. If the waiting for the flame phase does not come to fruition, the alarm of " FAILED

IGNITION" will be activated. During this phase, the fume motor rotates at a defined speed.

6.9 FLAME STABILIZATION

Stabilization phase after the presence of the flame with an intermediate load of fuel. The fume motor, at a defined

speed, and the auger, at a defined speed, are active while the resistors for the ignition of the flame are off.

6.10 IN OPERATION

Phase of regular operation of the burner with a variation of the power from 1 to the maximum programmed in

function of the temperature of the boiler. The modulation of the operating conditions is made according to the

parameters.

During this phase 3 types of control take place:

Temp. Control. Maximum fumes: if the maximum temperature of the fumes is exceeded, the auger starts working

in regimen 1.

COD. 79101EN.00

11/2013

25

Temp. Control. Maintenance: if the fumes temperature falls below the maintenance temperature for more than 3

minutes, the current regimen of operation is increased to the next regimen.

Extinct of flame control: if the fume temperature decreases below the extinction of the flame temperature, flame

extinction alarm is activated.

6.11 SHUTDOWN

Timed shutdown phase subdivided into two subphases regulated by two parameters:

1) fume motor at maximum regimen and the auger off;

2) fume motor at maximum regimen and start-up of the burner motor.

If after this subphase the fumes temperature is still higher than the shutdown temperature programmed by the

parameter, the fume motor continues running while the burner motor shuts off.

NOTE: if you press the button ON / OFF during 3 seconds, the boiler is forced to pass from the TURN OFF state to

the OFF state.

6.12 NOT WORKING

NOTE: If at this stage the fumes temperature is higher than the initial temperature, the fume motor is activated.

During the ignition phase (load, pause, wait and flame stabilization), it is not possible to switch

off the boiler: you need to wait.

Similarly, if it is in the shutdown phase, the ignition cannot be forced again.

6.13 STANDBY

The boiler pass from the “ON” state to the “STANDBY” state in the following cases:

1) When the water temperature of the boiler is higher than the SET POINT temperature + the value of the

“OVERTCIMP” parameter;

2) When the "ROOM THERMOSTAT" has reached the required temperature.

The boiler returns to the “ON” state when the ROOM THERMOSTAT contact closes (the ignition will start when the

water temperature is lower than the SET POINT temperature, which is of 5 ºC).

6.14 PROTECTION CONTROL OF THE BOILER OFF OR IN STANDBY

If under these operating conditions is detected a boiler temperature higher than the protection temperature, the

pump starts working.

6.15 WATER PUMP CONTROL

If the water temperature of the boiler is lower than the “TEMP. ACC. POMPA” parameter, the pump does not run.

If the water temperature of the boiler is higher than the “TEMP. ACC. POMPA” parameter, the pump starts working

according to the conditions below:

1) If the boiler is off, the pump is inactive.

2) If the boiler is on, the pump is working.

3) If boiler is on “STAND BY”:

a) The pump starts to work if there is a water demand of the “ROOM THERMOSTAT”;

b) The pump will not work if there is not a water demand.

COD. 79101EN.00

11/2013

26

7. CONTROL PANEL INSTRUCTIONS

7.1 START-UP SCREEN

When the boiler is on, after a few seconds from the ignition, the display shows the following information on the

screen:

* During the operation phase, the screen shows the power of the boiler from 1 to 6. Using ▲ and ▼ the

power of the boiler can be increased or decreased manually.

Current date

current time

Mon

Operation regimen

from 1 to 6 when the

boiler is on *

Boiler state

Room temperature

COD. 79101EN.00

11/2013

27

Temp. boiler

Hours

Ignition

Pressure H2O

Combustible

7.2 PROGRAMS MENU

From the main screen you can access to the menu programs by pressing the SET button; using ▲ and ▼

the following screens will be displayed sequentially, from where you can leave at any time by pressing the

button

.

Once the parameter has been chosen, you can display/modify pressing the SET key to go to the submenu

or exit by pressing they key ON/OFF.

7.3 BOILER TEMPERATURE PROGRAMMING

After pressing Set to access the menu, press SET again to enter the submenu Temp. boiler.

It allows you to select the maximun temperature for the water boiler: Use

▲ and ▼ to set the temperature.

The range goes from 10 °C to 80 °C. Press SET to confirm and save or

the

to exit without saving the modification.

7.4 DATE AND TIME ADJUSTMENT

After pressing Set to access the menu, press SET again to enter the submenu Hours.

It allows you to change the day of the week: use the keys ▲ and

▼ to modify the day; press SET to confirm and access the

screen hours, or with the key

to pass to the screen hours

without modifying the day of the week.

Day of

week Tue

E

SC

SET <- ->

E

SC

SET <- ->

E

SC

SET <- ->

E

SC

SET <- ->

E

SC

SET <- ->

boiler 22.5oC

Temperature H

2

O

A

ccording to the screen, the function

of the keys change.

ESC SET

<- ->

Temp. boiler

COD. 79101EN.00

11/2013

28

It allows you to reschedule the current time. With the keys ▼

and ▲ you can modify the time; press SET to confirm or the key

to exit without saving the modifications.

7.5 PROGRAMMED START-UP AND SHUTDOWN

After pressing Set to access the menu, press SET again to enter the submenu Ignition.

This function allows you to switch on/off the boiler with

scheduled times: thanks to the internal clock and buffer battery

(CR2032 3V), which keep date and time in memory even without

power. There are up to 16 programs available, and each of them

allows you to define the start-up and shutdown time, and the

day/days of the week affected by each programming.

To activate the time: use they keys ▲ and ▼, to activate and

deactivate the time, when it is active, the green led is on. Pressing

SET the command is confirmed, and with the key

you exit

without saving any modification. If you activate the timer, you

access automatically to the first screen of programs.

This screen on the left will appear if we activate the timer, from

which we can see and modify the programs:

- TimerXX: number of program

- mtwtfss: days of the week from Monday to Sunday

- on00:00: time of activation

- off00:00: time of shutdown

Below you can see an example of a weekly schedule:

Example:

From Monday to Friday, the boiler starts at 10 am until 2 pm, and then from 5 pm to 11 pm. On Saturday and

Sunday from 8 am to 8 pm.

Go to the screen "IGNITION" and after selecting the keys ▲ and ▼ "SI", press the key SET, to gain access to the

programs screen.

The text “Timer01” flashes to show which program is selected.

To change the program it is necessary to press SET and then

change the value with the keys ▲ and ▼. In this case we leave

“Timer01“.

To go to the next parameter, press the key ▲ and this time the list with the days of the week flashes.

Pressing the key SET, the list "mtwtfss" will stop flashing and only

the first day of the week will be flashing. Now we need to decide

whether we include it in the schedule (Timer 01) or not. To switch

the active day, press ▲ and the flashing moves to the following

day. Every time you press ▼, the active day changes from lower

case to capital letter (and vice versa). The remaining days in capital

letter will be included in the schedule “on/off” of this program.

Hours

11:08

Ignition

Trigger

Timer YES

Timer01 mtwtfss

on00:00 off00:00

Timer 01 mtwtfss

on00:00 off00:00

Timer 01 mtwtfss

on00:00 off00:00

COD. 79101EN.00

11/2013

29

As you can see, only the days from Monday to Friday are

capitalized. Once the days are selected, press SET

to confirm: now the text “MTWTFss” will start flashing again.

To go to the next parameter, press the key ▲. The text “on00:00”

will now flash.

Now we can choose the desired start-up time for program 1

“Timer 01”, pressing SET and the text “on00:00” will stop

flashing.

With ▲ and ▼ we can select 10:00 and press SET to confirm. The

text "on10:00" will flash again. To move to the next parameter,

press ▲, and this time the text "off00: 00" flashes.

Now we can choose the desired shutdown time for program 1

“Timer01”, pressing SET and the text “off00:00” will stop

flashing.

With the keys ▲ and ▼ you can select the time 14:00 and press

SET to confirm it. From now on the text “off 14:00” will start

flashing again.

Now we are going to set the afternoon program from Monday to

Friday. We will follow the same procedure used to set the morning

programming but using “Timer 02”.

To start, we need to press ▲ so that the text “Timer 01” flashes.

When “Timer01” is flashing, it indicates that the programming is in

selection.

To be able to move to another programming, you need to press

SET.

Timer 01 MTWTFss

on00:00 off00:00

Timer 01 MTWTFss

on00:00 off00:00

Timer 01 MTWTFss

on10:00 off00:00

Timer01 MTWTFss

on10:00 off00:00

Timer01 MTWTFss

On10:00 off14:00

Timer01 MTWTFss

On10:00 off14:00

COD. 79101EN.00

11/2013

30

The text “Timer01” stops flashing: We change the value with the

keys ▲ and ▼ until the text “Timer02” appears. You will see that

when choosing a new program, all the days of the week appear

deactivated, and the connection/disconnection time (on/off) are all in

00:00.

To go to the next parameter press ▲ and the list of days of the week

will start flashing.

When pressing SET, the list “mtwtfss” will stop flashing and only

the first day of the week will flash. Now we need to decide whether

we include it in the schedule (Timer02) or not.

To change the active day, press ▲, and the flashing pass to the

following day. Every time you press ▼ the active day pass from

lower case to capital letter (and vice versa). The days in capital

letter will be included in the schedule “on/off” of this program.

As you can see, only the days from Monday to Friday are in capital

letter. Once the days are selected, press SET to confirm: now the

text “MTWTFss” will start flashing.

To pass to the next parameter press ▲. Now the text “on00:00” is

flashing.

Now we can choose the desired start-up time for program 2

“Timer02”, pressing SET and the text “on00:00” will stop flashing

.

With the keys ▲ and ▼ we set the time at 17:00 and press SET to

confirm it. From now, the text “on17:00” will start flashing again.

To pass to the next parameter, press ▲. Now the text

“off00:00” flashes.

Now we can choose the desired shutdown time for program 2

“Timer02”, pressing SET and the text “off00:00” will stop

flashing.

With the keys ▲ and ▼ we can set the time at 23:00 and

press SET to confirm it. From now on, the text “off 23:0 0” will

start flashing again.

We still have to program the schedule for the weekend. It is the

same procedure followed in the previous program but using “Timer

03”.

Timer02 mtwtfss

on00:00 off00:00

Timer02 mtwtfss

on00:00 off00:00

Timer02 MTWTFss

on00:00 off00:00

Timer02 MTWTFss

on00:00 off00:00

Timer02 MTWTFss

On17:00 off00:00

On17:00 off00:00

Timer02 MTWTFss

Timer02 MTWTFss

On17:00 off23:00

COD. 79101EN.00

11/2013

31

To start, we press the key ▲ so that the text “Timer02” starts

flashing.

When “Timer02” is flashing, it indicates that the program is in

selection.

To change to other programs, it is necessary to press SET.

The text “Timer02” stops flashing: We change the value with the

keys ▲ and ▼ until the text “Timer03” appears. We will see that

when choosing a new program, all the days of the week appear

disabled and the times of connection/disconnection (on/off) will all be

in 00:00. To go to the next parameter press ▲ and the list of the

days of the week will start flashing.

When pressing SET the list “mtwtfss” will stop flashing and only

the first day of the week will flash. Now we need to decide whether

we include it in the program (Timer03) or not.

To change the active day, press ▲, and the flashing pass to the

following day. Every time you press ▼ the active day changes from

lower case to capital letter (and vice versa). The days in capital

letter will be included in the schedule “on/off” of this program.

As you can see, only the days Saturday and Sunday are in capital

letter. Once the days are selected, press SET to confirm: now the

text “mtwtfSS” will start flashing again.

To pass to the next parameter press ▲. Now the text “on00:00”

is flashing.

Now we can choose the desired startup time for program 3

“Timer03”, pressing SET and the text “on00:00” will stop

flashing. With ▲ and ▼ we can set the time at 08:00 and press

SET to confirm it. From now the text “on08:00” will flash again.

To pass to the next parameter press ▲. Now the text “off00:00”

is flashing.

Now we can choose the desired startup time for program 3

“Timer03”, pressing SET

and the text off00:00” will stop flashing.

Timer02 MTWTFss

On17:00 off23:00

Timer03 mtwtfss

on00:00 off00:00

Timer03 mtwtfss

Timer03 mtwtfSS

on00:00 off00:00

Timer03 mtwtfSS

on00:00 off00:00

Timer03 mtwtfSS

on08:00 off00:00

Timer03 mtwtfSS

on08:00 off00:00

on00:00 off00:00

COD. 79101EN.00

11/2013

32

With the keys ▲ and ▼ we can set the time at 20:00 and

press SET to confirm it. From now the text “off 20:00” will

start flashing again.

The schedule is finished, with only three timings the startup and shutdown time for all the week has been set.

Having 16 timers available, allows covering different time slots for each day and different days of the week.

Once the schedule is ready, press the key

.

7.6 FUEL

After pressing Set to go to the menu, press SET again to go to the submenu.

It allows you to select up to 5 types of fuel. From the settings menu

press the key ▲ until this screen appears. Then, press the key

SET and, after we select the corresponding number of fuel with

the keys ▲ and ▼. With the key SET we confirm the selection,

and with the key

we exit without saving the modification.

FUEL PROGRAMS:

Combustible 1 DIN PLUS

Combustible 2 PELLET QUALITY MEDIUM

Combustible 3 PELLET QUALITY LOW

Combustible 4 OLIVE PITS

Combustible 5 SHREDDED ALMOND SHELL

If the boiler is going to burn olive pits, the burner pellet must be replaced by the olive pits burner, which

has smaller holes.

7.7 PRESSURE H

2

O

After pressing Set to go to the menu, press SET again to go to the submenu Pressure H2O.

From the main menu you can access to the menu Pressure H

2

O

using the keys ▲ and ▼. To enter press SET and you will see

the water pressure of the installation. Press the key

to exit.

Timer03 mtwtfSS

on08:00 off20:00

Combustible 1

Pressure H

2

O

bar 01,4

ESC SET <- ->

COD. 79101EN.00

11/2013

33

7.8 ALARM DESCRIPTIONS

ALARM DESCRIPTION SOLUTION

Lack of fuel in the tank Load fuel and try to switch on the boiler again

Presence of fuel remains in the

burner

Clean the burner and try to switch on the boiler again

Lack of fuel in the burner

Empty the tank with a long neck vacuum cleaner and

check if any object that could block the good performance

of the auger has fallen

FAILED IGNITION

If the problem persists call a T.A.S. in your area

Lack of fuel in the tank Load fuel and switch on the boiler again

Fuel not appropriated for the

program

Check the settings of the fuel

Empty the tank with a long neck vacuum cleaner and

check if any object that could block the good performance

of the auger has fallen

Lack of fuel in the burner

Reset the manual thermostat. See paragraph 7.9

TURN OFF FIRE

If the problem persists, call a T.A.S. in your area

Cleaning of the heat exchanger. See paragraph 8.6

Cleaning of the exhaust duct. See paragraph 8.8

MAINTENANCE

ORDINARY

Appears after 300 hours of

operation

To cancel the message, with the boiler off press the button

during a few seconds

MAINTENANCE

EXTRAORDINARY

Appears after 1000 hours of

operation

General cleaning of the appliance and the exhaust duct

installation, contact the T.A.S of the area

Check the flue duct

Check the chimney

Reset the manual thermostat. See paragraph 7.9

PRESSOSTATO

Pressure switch aperture

If the problem persists, call a T.A.S. in your area

When the boiler has been turned off, switch off and then on

again the switch ON / OF

SYSTEM ERROR

Program error

If the problem persists, call a T.A.S. in your area

GAS PROBE

Fumes probe not connected

Contact a T.A.S. in your area

Check the flue duct

Check the chimney

Reset the manual thermostat. See paragraph 7.9

AUGER MOTOR 1

Loading auger stopped

Contact a T.A.S. in your area

MOTOR FLUE GAS

The fume motor spins too fast or

too slow

Contact a T.A.S. in your area

Reset the manual thermostat. See paragraph 7.9

TERMICO COCLEA

Boiler protection opening

Contact a T.A.S. in your area

SONDA CALDAIA

Boiler probe not connected or

damaged

Contact a T.A.S. in your area

COD. 79101EN.00

11/2013

34

Check the water pressure. See paragraph 7.7

LOW PRESSURE H2O

Water pressure sensor opening

If the problem persists, call a T.A.S. in your area

Check the water pressure. See paragraph 7.7

HIGH PRESSURE H2O

Water pressure sensor opening

If the problem persists, call a T.A.S. in your area

Reset the manual thermostat. See paragraph 7.9

TERMICO H2O

Water temperature too high, the

flame turns off

If the problem persists, call a T.A.S. in your area

CONT. OPERATION

Loading auger is working, but it

has to be sttoped

Contact a T.A.S. in your area

- Any alarm switches the boiler off.

- To cancel any of the alarms, press the key

during 3 seconds, wait another 3 seconds and press again the

key

during 3 seconds (except the mantenimiento extraordinario alarm, see paragrah 9.6).

7.9 SAFETY TEMPERATURE LIMITER AND ROOM THERMOSTAT

As you can see in Fig. 1, the safety temperature limiter is situated on the back of the boiler. To carry out the manual

reset of this one, unscrew the cap and press the red button. Return to screw the cap, and then, press the key

during 3 seconds, wait another 3 seconds and press again the key during 3 seconds.

Fig. 1

Just above the safety temperature limiter is situated the room thermostat connection (see Fig. 2). To connect,

remove the connector pressing both switches (black and red), press them again when the connector has been

removed, and connect the room thermostat electrical wiring to the two terminals.

Fig. 2

COD. 79101EN.00

11/2013

35

8. WARNINGS AND MAINTENANCE

All maintenance operations (cleaning, possible replacements, etc.) must be made with the fire off and when the

boiler is cold.

Before carrying out any cleaning or maintenance, preventively ensure that the boiler is unplugged from the mains

intervening in the general switch placed behind the boiler or disconnecting the power cable that feeds it.

A LACK OF CLEANING CAN JEOPARDIZE SAFETY

8.1 DOOR OPENING

Door must be closed while running. Door must only be opened when the boiler is off and cold to carry out the

maintenance and normal cleaning.

8.2 DISPOSAL OF ASHES

The ash pan must be emptied regularly to avoid the combustion waste getting to the brazier stand. Ashes must be

placed in a metal container with a tight-fitting lid. Until the ashes are completely extinguished, the closed container

must be placed over a non-flammable base or land and far away from flammable materials.

8.3 BRAZIER CLEANING

Never open the door of the boiler until the display shows the

message “OFF”

This boiler has an ash cleaning system but, due to the fuel quality,

some incrustations can be formed and they will hinder the good

performance of the boiler, so they must be removed.

With an ash vacuum, vacuum the ash accumulated inside the

chamber, remove the brazier and control that the holes in it are clear.

Release the holes of incrustations using a sharp-pointed tool.

The frequency of this operation is determined by the frequency of use

and the choice of fuel. It is also important to control the brazier stand

vacuuming the existing ashes.

For this type of cleaning it is necessary to have a machine to vacuum the ashes

Before switching on the boiler, check that the brazier is put back towards the pipe of the

ignition resistor.

8.4 ASH PAN CLEANING

Once a week, empty the ash tray placed at the button of the boiler.

You will find the ash pan when opening the door (see Fig. 1), pull the pan with the respective handle to take out it

(see Fig.3 and Fig.3). Once the ash pan is empty, reinsert it in its place.

COD. 79101EN.00

11/2013

36

Fig. 1 Fig. 2 Fig. 3

To remove the ashes, check paragraph 8.2.

8.5 COMBUSTION CHAMBER CLEANING

Periodically it is necessary to do the combustion chamber cleaning. With an ash vacuum, vacuum the ash

accumulated.

Take out the front element (see Fig.1) and the two side elements of the combustion chamber (see Fig.2)

unscrewing the screw situated on the top of the frontal element, then disengage the three pieces. It is also

necessary to take out the cover situated just below the brazier (see Fig.3) unscrewing the screw that fixes it.

8.6 HEAT EXCHANGER CLEANING

Cleaning is fundamental for the good performance of the boiler. Therefore, it is essential to do it periodically.

Clean the ashes accumulated on the heat exchanger with an ash vacuum or brush, paying special attention to the

ashes accumulated between the stand brazier and the heat exchanger (see Fig.1).

COD. 79101EN.00

11/2013

37

Fig. 1

These actions can ONLY be done when the boiler is off and cold.

8.7 SMOKE CHAMBER CLEANING

Usually once a year (preferably at the beginning of the season), the extraordinary cleaning of the smoke chamber

must be performed to allow a correct operation of the boiler. The frequency of this operation depends on the type of

fuel used and the frequency of use. To perform this cleaning it is advisable to contact a Technical Assistance

Center.

8.8 UNLOAD INSTALLATION CLEANING

It is recommended to proceed with this maintenance in the extraordinary cleaning phase. We suggest doing this

cleaning at least monthly removing the plug connector and cleaning the ducts. It is necessary that at least the first

time this is carried out by qualified staff.

8.9 PEEPHOLE GLASS BREAKAGE

The boiler is provided with a 4 mm thick ceramic glass resistant to a thermal shock of 750 ° C. The glass can only

break due to a strong impact or misuse. Do not shake the door or hit the glass. If the glass breaks, avoid turning on

the boiler and replace the glass only with an original spare. For replacement, contact a Technical Assistance

Center.

8.10 ORDINARY AND EXTRAORDINARY MAINTENANCE

- Precise cleaning of the combustion chamber.

- Remove the refractory walls placed inside the combustion chamber.

- With an ash vacuum cleaner, vacuum the remains deposited on the walls.

- Reassemble all components of the combustion chamber and place them into their original position.

- Precise cleaning of the heat exchanger.

- Fume motor, disassembly and cleaning of the exhaust duct, new silicone where necessary.

- Inspection and testing of the sealing of the gaskets, replace them and apply silicone where necessary.

- Control of the electrical part and electronic components.

- Cleaning and control of the pipe.

- Control and possible replacement of parts subject to war: brazier, resistor, ash pan, etc.

COD. 79101EN.00

11/2013

38

COD. 79101EN.00

11/2013

39

BOILER

Manufacturer: LASIAN Tecnología del Calor, S.L.

This complementary sheet is completed by the installer and user N. 51806.0

IMPORTANT

Read carefully the content of this warranty sheet, should you have any doubt of interpretation consult your installer, seller or T.A.S. in your area. Fill in all required information on the warranty card and

keep always this sheet, as it will be necessary to show it to our T.A.S. so any repair or inspection can be performed under warranty.

Filling in the details of the warranty card, assumes that the user knows and accepts the terms and conditions of this Warranty Certificate.

VALIDITY

1- The length of the warranty is of two years for the boiler. For electronic and electric components and fans the duration of the warranty is one year. This warranty includes the material and labor

and displacement expenses.

2- To validate the warranty it is essential that the copy of the warranty card, which is accompanied, addressed to LASIAN Tecnología del Calor, S.L. is received by our After Sales Department

within 30 days from the installation of the equipment. Just a proof of purchase will not be accepted as a document to validate the warranty.

COVERAGE

1- The manufacturer warrants his product exclusively against anomalies caused by manufacturi ng defects, consisting of repair or replacement, "in sit u" or in the service facility, of the defective

parts.

2- The warranty does NOT cover:

. Parts that require change by wear and tear, even if it occurs before the end of the warranty validity term as the painting, cleaning auger, glass, vermiculite, brazier, igniter, ceramic parts.

. Variations in color in the painted or ceramic parts cannot therefore constitute reason for dispute, as they are natural characteristics of the material and use of the product .

. FAULTS CAUSED AS A RESULT OF AN IMPROPER INSTALLATION, NEGLIGENCE IN THE USE OF THE BOILER, LACK OF MAINTENANCE AND CLEANING, HANDLING BY

UNQUALIFIED STAFF, IMPROPER OPERATION CONDITIONS, OR DAMAGE CAUSED IN TRANSPORTATION, HANDLING AND STORAGE IN HOUSING OR PROPERTY DURING

INSTALLATION OF THE BOILER.

. LASIAN is not responsible for damage caused, directly or indirectly, to persons, animals or things, as a result of the failure to follow the instructions in the manual, especially in terms of

installation, use and maintenance of the boiler.

. Breakdown of electrical components or product performance failures that may have occurred by external agent s: storms, lightning, voltage variations or supply f ailure in the power supply, lack

of earth connection, eddy currents, electromagnetic waves, etc.

. Any intervention to adjust the product in relation to the type of fuel or type of installation

. Damage caused to the boiler by using non-original parts or subsequent interventions carried out by unauthorized agent.

. Interventions that may be required for water or fuel not having proper quality:

- Water with high calcareous index or chloride concentration greater than 300 mg / l.

- Damage caused by corrosion or normal deposits of the heating systems, in particular for products with integrated heating system for "water"

- Insufficient air input grilles for the combustion.

- BIOMASS BOILER OR SOLID FUELS

- Fuels with a moisture content above 20% of humidity.

3- Cases than INVALIDATE the warranty:

. Warranty conditions have not been complied with.

. The installation was not done in accordance with applicable rules and requirements described in the manual.

. Negligence of the customer due to lack of maintenance.

. Presence of components or electrical and / or hydraulic facilities that do not meet current standards.

. Damage resulting from atmospheric, chemical, hydraulic, electrochemical agents, improper use, modification or manipulation of the product, and / or other causes not originated f r om the

manufacture of the product.

. Not having a minimum of draw or chimney section as specified in the corresponding manual.

. Improper use of the boiler.

. To install and use the product the steps and instructions given in the manual supplied with the boiler must be followed.

WARRANTY CONDITIONS

1- Warranty will be voided if the start-up of the appliance is not done by the Technical Assistance Service or by a person professionally accredited and authorized by the manufacturer.

2- If during the startup of the boiler the T.A.S. detects any anomaly or defect in the installation, deficiency in the location (space, room ventilation, gas exhaust, etc..) , the T.A.S. will not be forced to

perform the startup until the defect has been corrected and, if deemed appropriate, charge displacement expenses.

3- After the startup, the T.A.S. (or authorized person or entity if applicable) will sign and stamp the warranty validating it. Th is "user" warranty sheet will be held by the same and will always be

available when intervention in the boiler is required under the warranty concept.

4- The manufacturer reserves the right to make product changes without notice, always maintaining the technical and essential service characteristics to fulfill the purpose for which it is intended.

5- The manufacturer assumes no responsibility for damages caused to persons or things from accidents that are not exclusively from the boiler itself as an individual unit and for manufacturing

defects.

6- In case of dispute, the customer waives their own jurisdiction and agrees to submit to the courts of Zaragoza or the designated by the manufacturer.

ADDITIONAL CLAUSES

If during normal use of the product defective parts or malfunctions are found, our Technical Assistance Service (T.A.S.) in the area will replace such parts for free.

Warranty is not extended for parts replacement, for the period of inefficiency compensation is not recognized.

USEFUL TIPS

Do not handle the inside of the boiler. If you doubt of its correct performance, please read carefully the instruction manual included with each appliance or consult your local Technical Service.

To maintain an optimal operation of the boiler or heating unit LASIAN, we recommend an annual review of the same by a member of our T.A.S. or an ent ity authorized by LASIAN Tecnologí a del Calor

S.L., which for convenience we recommend you to perform it at the end of the heating season.

LASIAN

Tecnología del Calor S.L.

MANUFACTURER WARRANTY

COD. 51631.0

COD. 79101EN.00

11/2013

40

COD. 79101EN.00

11/2013

DATE WORKING HOURS INTERVENTION

TAS

SIGNATURE

USER

SIGNATURE

COD. 79101EN.00

11/2013

42

DATE WORKING HOURS INTERVENTION

TAS

SIGNATURE

USER

SIGNATURE

COD. 79101EN.00

11/2013

43

DATE WORKING HOURS INTERVENTION

TAS

SIGNATURE

USER

SIGNATURE

COD. 79101EN.00

11/2013

44

The manufacturer assumes no responsibility for damages caused to persons or things from

accidents that are not exclusively from the boiler itself as an individual unit and for

manufacturing defects.

NOTE: The manufacturer reserves the right to make product changes without notice,

always maintaining the technical and essential service characteristics to fulfill the

purpose for which the boiler is intended.

Separate this product from other types of waste and

recycle it correctly to promote the sustainable reuse of material resources.

Technical Service:

Loading...

Loading...