LaserVision VP415 Service Manual

~@[fWO©@

~@[fWO©@

LaserVision ROM disc drive

VP415/001os1as

Service

LaserVision

ervice Manual

The VP415 is a professional Video Disc Drive for use

computerized audiovisual systems, involving a high

degree of interactivity.

The Drive

optical video discs, according to the LaserVision system

(PAL standard) and it has the capacity to handle

LV-ROM (LaserVision Read Only Memory) interactive

discs.

is

suitable for playback

of

pre-recorded

in

L\fRDM

The differences between /00, /05 and/35 are only related

to the ornamental plate

mainscord.

Version /00

= LV-ROM Disc Drive with Euro mainscord.

= BBC Domesday version with

/05

mainscord

/35

= /00 with

on

the front panel and to the

GB

mainscord

GB

Contents:

Chapter 1

Chapter 2 Remarks

Caution

"Use of controls or adjustments

procedures other than those specified here

in

hazardous ratliation exposure".

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified

used.

Technical data

Controls, indicators, connections

Connector pinning

Warnings

Modification levels

Adjustments

Demounting instructions

Service hints

Service tools

List of used symbols

Connections of semiconductors

or

performance

in

may result

of

be

Chapter 3 Module- and connector

Chapter 4 Survey

Chapter 5 Exploded view drawings

Chapter 6 Repair method

Chapter 7 Circuit description

Chapter 8 Service Information

Signal listing

Wiring diagram

Blockdiagram Control routes

Blockdiagram AUDIO/VIDEO signal path

Blockdiagram Servo

of

modules

Modules A to Z

- Circuit diagram

PCB

-

- Adjustments

- Electrical parts

Remote control

List

List

lay-out

of

mechanical parts

of

electrical parts

lay-out

DocumentationTechnique Service Dokumentation Documentazione di Servizio Huolte-Ohje Manual

Subject to modification

CS

@)

7 814

4822 726 14282

Printed

in

The Netherlands

c Copyright reserved

de

Servicio Manual de

Service

Published

Consumer

Servic;;io

by

Electronics

Technical data

Controls, indicators, connections

Connector pinning

Chapter 1

Remarks

Warnings

Modification levels

Adjustments

Demounting instructions

Service hints

Service tools

List of used symbols

Connections

Module-

of

semiconductors

and connector

lay-out

Signal listing

Wiring diagram

Blockdiagram Control routes

Blockdiagram

AUDIO/VIDEO signal path

Blockdiagram Servo

Chapter 2

Chapter 3

of

Survey

Modules

modules

A to Z

- Circuit diagram

- PCB

lay-out

- Adjustments

- Electrical parts

Remote control

Exploded view drawings

List of mechanical parts

List of electrical parts

Repair method

Circuit description

Chapter 4

Chapter 5

Chapter 6

Chapter 7

Service Information

Chapter 8

Technical data

Controls, indicators, connections

Connector pinning

Chapter 1

TECHNICAL DATA

LASERVISION DISC

Disc diameter

Disc thickness

Disc speed

Maximum capacity

(30

cm

- 12" disc)

Max. playingtime

Average track pitch

LASERVISION DISC DRIVE VP415

General

Front loading motor-powered disc-tray

startup time <13s

unload time (time

between Eject

command

and disc out

SSL (solid state laser)

Laser type AIGaAs semiconductor

Wavelength 780

Aperture 0.5

Output of laser 3 - 5

of

player) <15s

30

cm

(12")

or

20

cm

2.7

mm

(0.1")

CAV disc: 1500 r.p.m.

CLV disc: 1500-570 r.p.

CAV disc: 54000 pictures per side

LV-ROM disc

(max.) user data per side

(in

place of audio)

CAV disc:

CLV disc: 1 hour per side

1.6-1.8

nm

mW

36

minutes per side

µm

(8")

(CAV):

m.

324 Mbyte

Signal-to-noise ratio

Timebase instability

Audio

Audio input (cinch)

Audio output (cinch)

Audio output

(Euroconnector

pins 1

&

3)

Audio bandwidth

Signal-to noise ratio

Channel separation

Genlock

Sync input (BNC) 0.3-2.0 Vpp 75Q, loop-though

Sync input

Sync output (BNC) 2.0 Vpp

Genlock lock-in time

(DIN

40 dB typ. unweighted

(disc dependent)

50

dB typ. weighted

(disc dependent)

less than 1

3 Vpp (load 47

650 mV r.m.s. into 1 k

(max. deviation)

650

40-20

;;,,

50 dB typ. weighted

(disc dependent)

better than

(wavefrom acc. to CCIR

standards)

pin

4)

line freq.

field freq.

freq., interlaced, with

equalising pulses, negative-going,

logic

5s

Ons

mV

r.m.s. into 1 k

OOO

Hz

55

15

50

0:0-1

V,

75

n,

(normal play)

k)

dB

625

Hz

Hz

locked to line

logic 1 :2.2-4.2 V

negative-going

± 100 ppm

or

without

Random access time

Instant jump up to

On-board

programming

Program retention with

no mains supply at least 1 week

Mains voltage 220-240 V (

Mains frequence

Power consumption

Electrical safety acc.

operational conditions

Rei. humidity 20-80%

storage conditions

Rei. humidity 10-95%

Dimensions

disc-tray open

Weight

TV

system

Video

CVBS input (BNC) 1 V into

CVBS output (BNC) 1 V into

CVBS output

(Euroconnector pin

RGB

output

(Euroconnector)

R (pin

15)

G (pin 11)

B (pin

Video bandwidth

7)

CAV:

max. 3s

CLV: max. 15s

reverse) within vertical interval time

Up

number segments

50

frames (forward or

to 16 picture number/chapter

± 10%) a.c.

50

to

60

60

10

-40

420x 160x400mm

420x160x740mm

15

625/50 PAL

19)

1 V into 75 n

0.7

0.7 v into

0.7 v into

RGB

CVBS: 3 MHz

Hz

W approx.

to

IEC

70

°C

(approx.)

75

75

75

75

75

: 5 MHz

65

n,

Q

to 35 °C

to

kg

v into

n

n

n

(-3dB)

(~1

s average)

(~5

s average)

loop-through

(-3

dB), encoded

Video mixer

RGB mixing/keying modes:

Player RGB only

Computer output RGB only

Mixed mode: player 62%, computer 38%

Key mode: player 100%, computer 100%

Enhanced mode: Player 57%/100%

LV-ROM

User data capacity Max. 324 Mbyte per disc side

User data per frame 6 kbyte

User data transfer rate

from disc 150 kbyte/s (depending on

Data integrity

rate)

Internal C.P.

System

U.

computer)

(error

~1Q-16

4X6 kbyte cache memory for user

data

compatible with floppy disc and

hard disc systems

CS

7 816

CONTROLS, INDICATORS AND CONNECTIONS

-----

-----

/

EJECT

D

---------

c;;I

STANDBY

~ONISTANOBY

EJE~T PAUSE REPl.AY

-

CJ

c:::::J c:::::J

ROEAT

AUOOI

ea

0

AUDIO AUOIO

IN

AUOl02

ea

OUT

~,

l

,'.'.'.'.'.

CAV

ea ea

SCSI•

'.'.'.J

\\

CLV

11

CONn!Ol

"'"""'

c:,

121314

<100

•••••0•0••••<1••

.......

CJ

SYNC

......

)

OUT

.......

••••• ••

.......

SYNC

IN

15

--

c

Cl

a:]

Cl

Cl

EJ

NUSE

CJ

a

Cl

6

Cl

Cl

Cl

Cl

CORR

CJ

GOnJ

~

4SEARCHt>

~

<I

STILL

t>

~

(I

PU.Y

t>

E:::::::::::I

c=J

'""

"""

CJ

CJ

0-ClEAR-Q

CJ

CJ

""''

~

0

STAIIITIAEPU.T

~

I AUOIQ 2

CJ

CJ

<I

FAST

t>

~

<ISU'.11Nt>

~

-

SPUO

CJ

CJ

+

1

2 3

4

5

16

Front

EJECT button

STANDBY indicator

ON/STANDBY button

EJECrindicator

PAUSE indicator

REPLAY ini:licator

REPEAT indicator

AlJDIO 1 indicator

AUDIO 2 indicator

CAV

indicator

CLV indicator

REMOTE CONTROL indicator

6

7 8

Rear

. ,

1 ON/OFF switch

2 MAINS lead socket

3 REPLAY on/of switch

RC

4

5 WIRED

IA/EURO switch

RC

socket

6 RS232C socket

7 BAUD

8 AUDIO

9 AUDIO OUT

RATE

IN

(1

dip switches

&2)

(1

10 A/V EUROCONNECTOR

11

H-SHIFT control [for Genlock]

12 CVBS OUT socket

13

SYNC OUT socket

14 CVBS

15

16

17

18

IN

socket

SYNC

IN

RGB

SCSI

sockets

(TTL)

IN

address dip switches

SCSI socket

17

sockets

&2)

sockets

socket

10

e

--

18

Remote control functions

- Play forward/reverse

- Still frame/step forward/reverse

- Audio 1 /2 on/off

- Picture number/time display on/off

- Chapter number display on/off

- Programme display on/off

- Search forward/reverse

or

- Goto (Picture

Chapter number)

- Input correction

- Digits 0-9 entry

- Fast forward/reverse

- Slow forward/reverse (1/100 to normal speed)

- Fast/slow rate

+/-

- Clear memory

- Enter

- Standby

- Pause

- Start/Repeat

- Next

(20

times normal speed)

(3,

10,20 x normal speed)

CS 7 817

A/V

Euroconnector

Pin signal

1 audio

2 not connected

3 audio

4 audio earth

5 blue earth

6 not connected

7 blue

8 player status (player in standby: 2

9 green earth

1 O not connected

11

12 not connected

13 red earth

14 earth

15 red

16 fast blanking: 2.5 V into 75 n (RGB status)

17 CVBS earth

18 RGB status earth

19 CVBS

20

21

RGB

6-pole female connector, 270 degrees

pin

1 Red signal

2 Green signal

3 Blue signal

4 Composite sync

5 Ground

6

(logic 0:0

than

pulses, negative going.)

out

(right) 650 mV rms/1 k

out

(left) 650 mV rms/1 k

out

700 mV/75 n

player on : 12

green

out

out

out

using RGB)

not

connected

socket earth

(TIL)

IN

Not

connected

-1

V,

+/-

100 pm, interlaced, with

V)

700 mV/75 n

700 mV

/75

1 V/75 n (also ects as sync

socket

(DIN)

logic 1 :2.2.

n

-4.2

V,

out

V.

Sync instability better

or

without equalising

when

SCSI interface

A computer interface in accordance with SCSI

standards. The player is fitted with a 50-pole

unshielded connector consisting

25 male pins on 100 mil centres.

Single-ended cable pin assignments:

pin signal

2

-08(0)

4

-08(1)

6

-08(2)

8

-08(3)

10

-08(4)

12

-08(5)

14

-08(6)

16

-08(7)

18 -DB(P)

20 GROUND

22 GROUND

24 GROUND

26 *TERMPWR

supply)

28 GROUND

30

GROUND

32 -ATN

34 GROUND

36 -BSY

38

-ACK

40 -RST

42 -MSG

44

-SEL

46 -C/D

48 -REQ

-1/0

50

Notes

All odd pins except pin 25 are connected

Pin 25 should be left open, but may be connected

to

ground.

(not connected

of

two

to

rows

of

internal

to

ground.

power

RS232-C interface

Serial computer interface, in accordance with international

communication standards.

Full duplex

8 data bits, 1 stop bit, no parity

Data transmission speed may be set

1200/2400/4800/9600 baud according

the

two

baud rate dip switches (numbers 1 and

rear

of

the player.

Baud rate

1200

2400

4800

9600

The player is fitted with a 25-pole female 0-connector with

the following pin connections :

pin

2 (TxD)

3 (RxD)

5 (CTS)

7 (GND)

9

10

20 (DTR)

switch 1

UP

UP

DOWN

DOWN

signal

transmitted data from player

to

computer

received data from computer

to

clear

player indicating the computer is ready

receive data

transmit)

logic ground

+12 V/100

-12

V/10

data terminal ready: a signal from player

to

computer indicating that player is

ready

to

for

data)

switch 2

UP

DOWN

UP

DOWN

send: a signal from computer

(;;;:..+3

mA

mA

receive data

to

to

the positions

2)

to

player

V means O.K.

(;;;:..+3

V means O.K.

at

of

the

to

to

to

A minus sign indicates active low.

Maximum cable length is 6 m.

of

, Address dip switches at rear

position = OFF. Switches 1-4 and switch 8 should be

OFF. Switches 5-7 determine the SCSI bus address

of

the player as follows:

address switch 5 switch 6 switch 7

0

1 OFF OFF

2

3

4

5

6

7

(Factory setting: address

Termination according

If you have more than one device connected

computer via the SCSI bus, the SCSI bus termination in

the player has

For details see* note in diagram

Module Wb.

OFF OFF OFF

OFF

OFF

ON

ON

ON

ON

to

be altered.

ON

ON

OFF OFF

OFF

ON

ON

to

player. Dip switch in up

ON

OFF

ON

ON

OFF

ON

0)

SCSI: 330 n TO

n

too

220

of

LV-ROM Interface

+5

V

v

to

the

CS 7 828

host

Remarks

Warnings

Modification levels

Adjustments

Demounting instructions

Service hints

Service tools

List of used symbols

Chapter 2

Connections

of

semiconductors

REMARKS

3.

Repair

on

modules

1. Care of the disc drive

The disc drive requires no special maintenance.

It is, however, recommended to clean the objective

lens from time to time with a piece

in

alcohol.

2.

Set-up

The set is composed

Z).

have also been classified per module.

a)

Of

given, with the incoming signals drawn as much as

possible

signals at the right-hand side. Each incoming and

outgoing signal has a unique name, the meaning

which can be read

If a signal enters

place via a connector (e.g.

82) and via a letter indication in the line. This

indication mentions

connected.

If the letter indication in the line is the same as the

module on which the signal is present, the signal

remains on the module mentioned and, naturally, no

connector is drawn.

b) Oscillograms and voltages in the circuit diagrams

- The oscillograms in the diagrams have been

- The DC voltages have been measured with a

c) PCS layouts

Most modules

doublesided copper pattern and plated-through holes.

For each module a PCB layout is drawn, consisting

a drawing

side (chip side) with corresponding copper pattern.

d) Parts lists

e) Service code numbers

of the Service Manual

of

The circuit diagrams, PCB layouts and parts lists

various modules (A through

Circuit diagrams

each module a functional circuit diagram has been

at

the left-hand side and the outgoing

in

the Signal listing.

or

leaves the module, this takes

682

to

which module the line is

measured with a

Timebase PM3214. The set has been connected

a monitor by means

Video : still picture, picture number 5530

Audio

Audio

Digital Multimeter PM2524, still picture, picture

number 5530, unless stated otherwise.

For each module an electrical parts list is given,

stating the service code numbers

electrical components that have been applied on

the module.

The code numbers

(ICs, transistors, diodes, standard resistors , etc.)

have been placed on a collective list in Chapter

(EBU colour bar, 75% saturation)

1:

normal play, picture numbers 6200 - 6500,

1 kHz modulation

2:

normal play, picture numbers 6500 - 6900,

1 kHz modulation

of

dual-beam

of

a SCART cable

in

the set have been equipped with

the component side and

of

the standard components

of

In this Service Manual service code numbers for

the modules have

consult you parts supplier .

not

been mentioned. Please

of

wadding, dipped

= pin 6

scope with Delayed

of

connector

of

the soldering

of

the specific

the modules

of

5.

to

of

To

enable repair/adjustment on modules use can be

made

of

survey can be found sub Service Tools

extension PCBs

or

extension cables. A

in

this chapter.

4. Hidden switches

On

Analog 1/0 module U two switches have been

applied, hidden for the user.

The function

SK1

SK2 : ENCODED CVBS

Please consult the circuit diagram

module U for more details on these switches.

of

these switches is :

: +

11 V or

connector.

Factory adjustment is RC5 at pin 8 (switch

pressed out).

signal on CVBS OUT connector BNC3. The

factory adjustment is ENCODED (switch

pressed out).

RC5

signal at pin 8

of

the Euro

or

NOT ENCODED CVBS

of

Analog 1/0

5. The optical deck

The optical deck

various critical components and at the production

department adjusted by complicated alignment

equipment.

For the time being repair

of

the Laser Detection Unit by a service technician is

not allowed.

If a failure analysis reveals that the Deck Electronics

or

LDU

are defective, the entire deck should be

submitted for repair to the production centre via the

Central Repair Procedure

Centre. Please inquire at your parts supplier's for this

procedure.

Repairs on the slide drive assy and the Automatic Tilt

Control (ATC) assy are possible. See the List

mechanical parts

in

the disc drive is composed

of

the Deck Electronics and

of

the Concern Service

for

the correct code numbers.

of

6. Coding of items

The coding

of

the PCB's can differ from the coding

the circuit diagrams (exept supply module

PCB's, a letter/number coding has been used (e.g. R1,

C1) and in the diagram a 4 number coding (e.g.

3001,2001

between both coding systems.

Circuit diagram

4 number coding

2 001

T-Citem

Lcomponent

of

component items in the service printing

of

).

The table below shows the conversion

Service printing on PCB

letter/number coding

C1

nbr

nbr

:

1

= Unit, battery

= capacitor

2

= resistor

3

= coil, trafo , cristal

5

= diode

6

= transistor, IC

7

TLitem

Lcomponent

=U

=C

=R

= S,L,K

=D

= T,TS,1,IC

the items in

T).

On

nbr

of

the

letter:

CS 7 818

WARNINGS

1.

Laser radiation

The Laser Detection Unit (LDU)

in

the optical deck has

been equipped with a semiconductor laser. This laser

emits

invisible light which

is

focussed on the disc

the objective.

If the objective would

be

removed

in

case of repair,

the laser light exits from the objective aperture. Avoid

looking directly into the laser beam, as this might

cause permanent injury to the eye.

2.

Replacement of modules

Before replacing a module upon repair, first the mains

switch should

be

switched off. This should

be

done to

prevent damage to the circuits on the modules.

3. Service position of the set

If measurements or repair require that the set

placed on its side

done when a

and

the front loader has been removed. If a disc with

a larger diameter

6"

test disc

is

(90°·

position), this may only

is

played

used

(8"

or

12"),

on

the optical deck

the risk that the

is

be

disc will come loose from the turntable (motor)

cause injury to people

in

the vicinity will

be

too great.

Also ensure that the disc is always locked on the

turntable by the magnetic disc clamping piece (see

service tools).

by

and

In

the above-mentioned 90° position of the set not

signals will

be

present according to specification.

Adjustments and checks for correct functioning are

therefore only allowed

in

the horizontal position of the

set.

4. The 6" test disc

The

6"

test disc may only

be

played when the front

loader has been removed. With mounted front loader

playback of

8"

and 12" discs

is

possible.

all

MODIFICATION LEVELS

In

the entire set various modification levels have been

indicated.

1. Modification level of the set

The modification level of the set can

rear of the cabinet.

a) Change code on the type number plate

Under the type number a letter and digit code

which looks as follows :

IA

HI

O

216

4

311

7 I '-.

production change week

centre code

The change code

centre.

b) Modification level on yellow sticker

On

a yellow sticker a TM code is marked,

indicating the modification level,

TM

4 7 10

5 8

1

6 9

2.

Modification level of the module

number

is

preceded by the production

13 16

11

14 17

12 15 18

be

found at the

0 1 2 3

\:

serial number

in

this case TM3.

is

41

given

The modification level

Control EPROMs can also

an

external computer. To achieve this

command "?=" should

the directions for use, chapter F-CODE COMMANDS

: Revision level request).

The feedback

software revision.

Digit 1

Digit 2

Digit 3

Digit 4

Digit 5

The modification level of the Drive software will then

be

e.g.

software e.g. 1.4 (digit 4 . digit

The relation with the modification level

number

Drive

Control

Each time a change takes place

modification level will by raised

A survey of the modification levels of the set, the

modules and the software can

Information, chapter

of

= 0

= major level drive

= minor level drive

= major level control

= minor level control

1.5 (digit 2 . digit

is

as

follows:

mod. level progr.

3104 103 6803.4

3104 103 6804.4

of

the software

be

be

sent to the disc drive (see

the disc drive

3)

and

number

8.

in

the Drive and

retrieved

is a 5-digit

of the Control

5).

by

be

by

means of

an

F-code

code of the

in

the program

mod. level software

revision

1.5

1.4

in

the software, the

one.

found

in

the Service

In

the circuit diagram: top right, under the name of the

module (e.g.

On

the PCB:

side

~OO....,mJ........-4..-1

( e.g.

The modification level is marked then.

3. Modification level of the software

On

various modules EPROMs have been applied, that

have been programmed (see survey below).

module

Drive

Proc

Control (S)

*CPU (W)

*CPU (W)

*CPU (W)

*CPU (W)

*= only for VP415

The program number of the software has been

applied

The modification level

of the program number (behind the dot).

MOD

LEVEL

in

the service printing at the component

s..-1s..-11..-ls

......

19

.......

!o!).

item number

(R)

7204

7202

7201

7224

7247

7248

on

a sticker on the EPROM.

CONTROL

LV DOS

LV DOS

of

the software

3).

name

DRIVE

SYNC

DESCR.

in

the EPROMs

program number

3104 103 6803.4

3104 103 6804.4

3104 103 6808.0

3104 103 6807.0

3104 103 6805.2

#1

#2

3104 103 6806.2

is

the last digit

r,~ 7

R?O

ADJUSTMENTS

1. General

For

each module an adjustment procedure is given

components that are replaced during repair.

If

an entire module is replaced, in principle adjustment

should not take place, with the exception

K,

module

module

Module K : in case

VIDEO DO CORR module L and ANALOG 1/0

U.

(video ampl.)

of

replacement, adjust R3043

of

HF PROC

for

Module L : in case

Module U : in case

Module B : in case

When module

check the CVBS OUT signal (NOT ENCODED) on BNC3

for

correct amplitude and correct VITS signals MBI and

MBIV. The CVBS OUT signal is described

1

of

Ananlog 1/0 module

The VITS signals are described in adjustment 2

D.O. Corr. module

For amplitude adjustments see Fig

The adjustments take place without connection

computer (video overlay)

stated otherwise.

2. Required

To

perform the adjustments the following equipment is

required:

- Test disc 6"

-

Dual-beam

If available: - vector scope

- Scope probes with 1:10 attenuator, preferable

FET probes

- BNC

of

replacement, adjust R3050 (MTF)

of

replacement, adjust R3305

gain) and R3315

R3315 on Analog 1/0 module

H,

of

K, L or

(B-Y

gain).

replacement, adjust R3305 and

Z is replaced,

U.

it

is advisable

L.

2.1

or

external video source, unless

or

8"

scope with Delayed Timebase

-

dual-beam

X-deflection

PM3226P)

or

probes with a capacitance < 3pF.

75n

terminator (4822 263 60037).

or

scope with

via

8-channel

U.

in

adjustment

of

of

(R-Y

to

Video

a

(e.g.

CS 7

821

=-~-

I

rn

VIDEO ADJUSTMENTS

·~

-~·.,.

I

=i_J

IJll

.,,

~

..

...

I

:ij

llrm

~

GAIN

402

1001

802

60

2

CS

N

CS

- S/NS

S-CS

- EXT

MTF

R3050

MTF

3L2

OEM-

S

YNC

BOTTOM

411111~L

ELECTRONIC

TI

MEBASE

CORRECTION

TO GENL

BK

REFERENCE

SYNC.

GEN

ERA

TOR

MODULE

OCK

~

SOURC

FI

RAMP-EN

TXT

- WH

TXT

- WV

REFV

REFH

CBL

CS

REF

CLP

H/2

BF

L___

E

D

COLOUR BURST

SPECIAL BUR

CV-TB

M

TO

ETBC

MODULE

501

401

203

103

70

1

80

1

90

1

102

60

1

302

202

ST

- C

[]

CV-EXT

9C

2

SCI

9CI

CV/

CS

CV-f

/i B

8C2

P-CLP

SYNC BOTTOM

IOCI

VBL

3AI

!

~

Al

RGB

SC

3BI

L COLOUR BURST

AUDI

AUD2

DE

CODI

NG

EXT AUD

EXT AUD2

RGB

MATR

IX

SYNC BOTTOM

AUD1

0N

A

eves

SWITCH

BPCLP

) MI

4

VPO

VIDEO

Y5

XER

TXT-WH

3Y5

VP!

U020N

INS-TXT

ADDER

7Y2

IY

3Y

2Y5

VP2

TXT

2

2

CS

-WV

R MIX

G- MIX

8 MIX

5/NS

NS

NOT SK2

ENC

ENC

IU3

3U3

5U3

9U3

CS

7U3

(ONLY

EN

eves

I

Al- E/i

A2-E/i

10

2B3

3A3

4B3

ANALOG

4a

U1

1

au1

4CU1

lcUl

8a

U1

LUM

83

9aU

1

R

17

aU1

G

1

7c

U1

B

18aU1

CBL

1

oau

1

REFH

1

0cU

1

G

-

-

-

~

~

1/

0

Ua

1u2 9YI

3U2

5U2

7U2

9U2

COMPUTER

RGB

3aU1

A- SYNT

1

2i:tU

1 12cUI

BF

H/2

G

7YI

5YI 5Y2

CBL

3YI

REFH

!YI

CS

i

l

C

>--r<

>--r<

VP41

Uc

Ub

Ua

5)

~

(75o TERMINATED)

19

cU1

cs

s,NS

SaUI

NS

11

cu1

L

COLOU

R BURST

19

eves

15

G

CS

PAS

02477

T 08

715

Fi

g.

21

CS 7 822

DEMOUNTING INSTRUCTIONS

1

~

PUSHING OUT

* short size

DEMOUNTING UPPERCASET AND FRONTLOADER

THE

·····@

DISC TRAY

~

~

' ---

------

-----=-----

···-

... _o_~----.

_

Ji>

1

---------

screws dot marked

DEMOUNTING DI

MOUNTING

~

--

1

g'

DIS

"'-

2

a.-..

2

·

SC

TRAY

C T

RAY

'-.._

Oo

Oo

Oo

0

4~

~

~

a

ASSY

REMOVING SPEEDNUT

ASS

Y

g'

3

screws dot marked

DEMOUNTING OPTICAL DECK

CS

7 823

~o

~

r1

.[..,,)

Oo

0060000

:,0

~~~~~~

O~

r • ~ O

o J 1

DEMOUNTING ANALOG 1/0 MODULE U

. . -

.

~~~

~~~

ij-~o

Oo0 Oo

Oo

006o00

oo

O(lo

l

0

o

~~~J

-·

0

6oo

ooo

0

00

3

0

01

.,

..

@

- I • ,

T

•

_J.·

ON

LY

FOR

VP415:

DEMOUNTING SANDWICH

PART

EVA.00317

T28/710

SERVICE HINTS

WARNING

ESD

,.

~

All ICs and many other semi-conductors are

to

susceptible

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are connected

with the same potential as the mass

wrist wrap with resistance.

Keep components and tools also at th is potential.

The photodiodes and the laser are more sensitive

electrostatic discharges than MOS IC's.

Careless handling during servicing may reduce life

expectacy drastically.

For this reason care should be taken that

servicing the potentials

equal to that

Chip components {SMD)

Chip components have been applied in the set. For

the insertion and removal

figure below.

electrostatic discharges (ESD).

of

the

of

the tools and yourself are

of

the screening

of

the set

of

chip components see the

set

dur

via a

ing

to

SOLDER

c:B:j~CO

CHIP

COMPO

GLUE

GENERAL

NENT

. SO

I

LD

ER

P

P.C.B.

PERT

RACK

~~~~E~\,,

e.g.

WELLER~~-:'.'.

R TIP PT-H7

SOLDE

SOLDERING

SOLDER WICK

48

22

321 40042

SOLDER

SOLD

ERING

IR

ON

~

~

SOLDERING

IRON

DISMOUNTING

VACUU

~4822

~~~~~'=

ON~

IR

E~~~'==~:'.:~~

e.g. A

PA~EZ

HEA

TIN

~~~EATI

I 4

SOLDERING IRON

WI

CK~

PRECAUTIONS

M PISTON

395

10082

~ ~ = ~

OR

=~

ER

S B

NG

CLEA

NIN

G

~

MOUNTING

A

A

SOLDER

0 0.5 - 0.8 mm

.PRESSURE

+

SOLDERING TIME SOLDER

< 3 sec/side 0 0.5 - 0.8 mm

PR

ESSURE

+

C

EXAMPLES

(#

SOLDERING

0$"

B

SERVICE PACKAGE

M

~

""~

~

27 012C

12

CS 7 824

SERVICE TOOLS

REPAIR SET 4822 310 31198

CONTAINING:

TEST DISC

6"

4822 397 30156

TEST DISC 12" 4822 397 30119

TEST DISC

8"

4822 397 30118

2x

---

EXTENDER PRINT 64P (7949.1)

4822 263 70208

_,,

_::...._

___

TORX SCREW DRIVER SET

4822 395 50145

1x

EXT. CABLE 12P (7955.

4822

321

22269

0)

----

4"';:

:...:.;;;:=

--

EXT. ASSY 6P

4822

321

22268

~.,........- 2xEXT. ASSY 10P (7950.1)

2x

4822

321

22267

2x

.

---

COUPLING PIECE 10P (7953.2)

4822 267 50704

2x

COUPLING PIECE 6P (7952.2)

4822 267 40712

(7951.1)

"'-

1x

COUPLING PIECE 12P (7954.2)

4822 267 50705

~

1x

COUPLING PIECE

VID MIX (7957.2)

4822 267 50707

1x

•

.

DISC CLAMPING PIECE

4822 532 60775

/ PIN 3 AND 4 INTERCONNECTED

~

1x

·- FRONTLOADER SIMULATION

4822 267 50706

CS 7 825

41

832

A

APPLICATION OF SERVICE TOOLS

.----

__.---

TEST DISC

DISC CLAMPING PIECE

6"

TEST DISC

6"

:.._.------

--

---

EXTENSION OF MOTOR MODULE

COUPLING PIECE 12P

EXT.

CABLE12P

FRONT LOADER

SIMULATION

EXTENDER PRINT 64P

~;;,,,-:;

;:.__

EXT. ASSY 6P

~

=----

EXTENSION OF MODULE (FLEX)

EXT.ASSY10P

----

EXTENDER PRINT 64P

I

EXTENSION OF DRIVE/CONTROL MODULE

COUPLING PIECE

VID MIX

EXT. ASSY 6P

EXT. ASSY 10P

EXTENSION OF MODULE (STEADY)

ONLY VP415

SHORT CIRCUITING OF VID MIX SIGNALS

41

833

CS 7 826

B

LIST OF USED SYMBOLS

Safety resistor

Veiligheidsweerstand

Sicherheitswiderstand

Resistance de

,;;;

0.2 W

(CR16) > 270 kO - 10%

33

W < 1 MO -

0.

(SFR25) > 1

,;;; 1 MO -5%

0.5 W

(CR37) > 1

W · \1R25 -

0.33

0.5 W,;;; 1 MO -

(CR52) > 1

1 W

,;;;

(CR68) > 1.6 MO - 10%

0.5 W High voltage resistor

(VR37) Hoogspanningsweerstand

Safety capacitor

Vei I igheidscondensator

Sicherheitskondensator

Condensateur de

......

~

--u--

D~

--n--

a =2.5 V

b =

c =6.3 V

d = 10 V

e = 16 V

=25

f

Ceramic plate capacitor

Keramische plaatcondensator

Keramischer Platten-Kondensator

Condensateur ceramique plaquette

Metalized polyester flat film capacitor

Gemetalliseerde polyester condensator

l

Metallisierter Polyester-Flachkondensator

Condensateur plat

metallisee

Miniature electrolytic capacitor

Miniatuur electrolytische condensator

Miniatur-Elektrolytkondensator

Condensateur electrolytique miniature

g =

4V

V

h =

=100 V

j

=125 V

I

m =150 V

q =200 V

securite

220 kO -

1.6 MO -

Hochspannungswiderstand

Resistance haute tension

MO

MO

MO

5%

5%

- 10%

- 10%

1%

5%

- 10%

5%

securite

a feuille de polyester

=

250

350V

500

V

V

40

63

V

V

r

s =

u = 400 V

v =

w = 630 V

x =1000 V

y =1600 V

Sawtooth pulse converter

Zaagtand-puls omzetter

Siigezahn

Convertisseur d'impulsions en dents de scie

Pulse-code modulation (6-unit binary

Puls

lmpulscode-Modulation

Modulation

Puls-duration modulation

_ft_

@-

ill

ill

-0

0

~

ID

z

ID

8

=@}-

Pulslengte modulatie

lmpulsliinge-Modulation

Modulation

Sync separator

Sync scheider

Sync-Trenner

Separateur

FM

FM

FM

Detecteur

Phase

Fasediscriminator

Phasenvergleich

Discriminateur de phase

Detector

Detector

Detektor

Detecteur

Level detector

Niveau detector

Niveau-Detektor

Detecteur de niveau

Phase-changing network

Faseverschuiver

Phasenverschiebung

Circuit

Rejection

Bandsperfilter

Bandsperrefilter

z

Filtre de suppression

· Bandpass

Band-doorlatend filter

Bandpassfilter

Filtre passe-bande

Low-pass

Laag-doorlatend filter

Tiefpassfilter

Filtre passe-bas

Mixer stage

Mengtrap

Mischstufe

Etage melangeur

lmpulsumformer

code

modulatie (6 bits code)

code d'impulsions (code 6 bits)

de duree

sync

detector

detector

-Detektor

FM

discriminator

de

dephasage

filter

filter

filter

(6

Bits-code)

d'impulsion

co

High-pass

Hoog-doorla~end filter

Hochpassfi

Filtre passe

HF generat

l:l

e)

-EJ-

J

l_

HF generat

HF-Generat

Generateur HF

Sawtooth generator

Zaagtandgenerator

Siigezahngenerator

Generateur en dents de scie

Square wave generator

Pulsgenerat

Rechteckgenerator

Generateur d'impulsions

rectangulaires

Delay element

Vertragingselement

Verzogerungselement

Element

Limiter

Begrenzer

Begrenzer

Limiteur

Positive-going step

Positieve flank

Ubergang von tief zu hoch

Fonction

Negative-going step

Negatieve flank

Ubergang von hoch zu

Fonction

Emitter

Emitter volger

Emitter fol

Emetteur suiveur

Automatically controlled

Automatisch gestuurde versterker

Automatisch gesteuerter Verstiirker

Ampl

Mixer

Mengtrap

Mischstufe

Etage melangeur

filt

er

lt

er

-haut

or

or

or

or

a retard

de

palier en sens positif

de

palier en sens negat

follower

ger

ifi

cateur

a commande automatique

stage

function

function

tief

amplifier

-D-

if

D

G

0

Amplifier

Versterker

Verstiirker

t>-

Ampli

Differential amplifier

Verschi lversterker

Differentialverstiirker

Ampli differential

Amplifier

Versterker met open uitgang

Verstiirker

Ampli a sortie ouverte

with open

mit

output

offenem ausgang

D-

-CT

fi

Electronic

Electronische schakelaar

Elektronische Schaller

Commutateur

switch

electronique

fi

Electronic switch

Electronische schakelaar

Elektronischer Schalter

Commutateur

electronique

Common

Gemeenschappel

Gemeinschaftlicher Kontrolleblock

Bloc de

SRG

Q

()

G

CE

00

'lnvertor

Invert

Inverter

lnvertisseur

Or

Of-poort

Oder

Porte ou

Norgate

"Nor"

No

"

Porte

And gate

En-poort

Und Gatter

Porte Et

Nandgate

"Nand"

"Nand"

Porte "

Buf

Buffer

Puffer

Tampon

Inverting

lnverterende

lnvertierender

Tampon invertisseur

Buffer with open

Buf

Puffer mit offenem ausgang

Tampon

contro

l block

ijk

controleblok

contro

le commun

Shift

regis

Schuit

Schieberegister

Registre

Output

Uitgang

Ausgang

Sortie

Open collector out

Open kolle

Offenen

Sortie collecteur ouvert

Command input

Kommando

Kommando

Entree

Chip

Chip

Chip

Entree

Bidirectional

Tweezijdig gevoelig

Doppelseitig e

Bidirect

er

gate

r"

Non-ou

ter

register

a deca lage

ktor

Kollektor ausgang

ingang

eingang

ord

res

enable in

enable ingang

enable eingang

chip

validation

ional

A B X

0 0 0

0 1 1

1 0 1

1 1 1

A B X

0 0 1

0 1 0

1 0 0

1 1 a

x

0 0 0

1

0 1 0

1 0 0

1 1 1

. X

1]

0 0 1

0 1 1

buffer

puffer

output

1 0 1

1 1 0

Non-Et"

fer

buffer

fer met open uitgang

a sortie ouverte

put

uitgang.

put

mpf

indlich

CS 7 827

Module- and connector

lay-out

Signal listing

Wiring diagram

Blockdiagram Control routes

Blockdiagram AUDIO/VIDEO signal path

Blockdiagram Servo

Chapter 3

MODULE

AND

CONNECTOR LAY

OUT

1

D

3

10

I-

1

-

Al C2

10

~o

83

1

II-

10

I-

1

82

I-

1

@]

@

A{

cj

0

a:

Cl.

0

i5

::J

<{

1

6

cj

0

§

a:

Cl.

[D

l')

0

w

a:

0

10

6

>

I-

-

,B·I

-

1

I-

1

C3

@]

Cl

6

U

1

10

I-

~~

a:

::J

0

Cf)

LL

w

a:

10

-

-

1

PLAYER

'----------

I

ANALOG 1/0 (ill

1

~·

10

32

03

02

01

E2 El

' I I•

, 1

U3

10 1 11

Ul

10

I

D

I

suD

11

, I

RIV

E

•

Gl

Hl

11

110

[I]

,I

NI

=:!

~ 1

I'

E

i------11

j 10

F2

I 10 GEN

I

1 1

MOTOR+SEQUENCE 0

LOCK

ETBC

B

,o

ETBC C

DISPL.+KEYB.

@]

[E]

[TI

~

~D

~D

.;

ZZ6

zz1

6

U

1

~

~~

10

1

-

Jl

G

F3

12

0

cj

0

a:

Cl.

10

Cf)

::J

(.)

0

lL

lL

I

6

J

1

1 1

1 1

L{

6

·2

1

-

L2

-

10

B

a:

a:

0

(.)

0

0

0

w

0

>

F1

10

I

G2

,L-=:J.

H2

1

U

I-

-.

10

6

1

10

[II

...J

<{

i5

<{

a:

M2

Ml

1 ,

~

cj

0

a:

Cl.

w

>

a:

0

~

JJ

I-

JJ

a C

32

a C

32

R2

Rl

01

B

S1

...J

0

a:

f-

z

0

(.)

32

u

'-

DECK

ELE

CTRONI

CS

@

B

>-

...J

Cl.

Cl.

::J

Cf)

II

0

"~

Wl

1

,o ~

Xl

1

3

1

6

U:

2

1-

10

T1

-

1

E2

M

12

F3

1

In

z5

,o

u

Oo,

1

I

10

12

, 1 I 10

I

NNI

IR

.~EC.

\J

1

-

I

\

FR

ONT - LOADER

'

\

PRS01711

TD8

711

FRONTLOADER

\

0

'\

D

3

--,

P2

1

CS 7 829

ALPHABETICAL SIGNAL LISTING

-(8-Y)

-(R-Y)

+12 Switched + 12V

+12SB +12V standby supply

+5

+5SB +5V standby supply

0-RPM

-12

-12SB

2-PPR

Colour difference

Colour difference

8-Y

R-Y

DLCF Data left CIM to FIL

OLEN

DO-INH

DR

Switched +5V

DRCF

DTR

OV

0 RPM status

Switched

-12V

-12\/

standby supply DTR 2 DTR

= 0 RPM DTR 3

DTR 1 DTR

2 pulses per revolution pos.pulses DUMP

400Hz PAL PAL switching signal DUMP-ON

-5SB

80-FH

A1-E/I

A2-E/I

ALE

A-SYNT

ATN

AUD1

-5V

standby supply EJECT

80 times horizontal freq.

Audio 1 internal/external +12V =

Audio 2 internal/external +12V =

ext

ext

Address latch enable

Synthesised audio

Attention

on/off

+12V = on EXT AUD 2

OV

= active

Audio 1

ELCF

ERCF

ER-DIS

EXT AUD 1 External audio 1

FAS-REL

FI

AUD1+2 Audio 1 + audio 2 FOCACT

AUD10N

AUD2

AUD20N

Audio 1 on/off +12V = on

Audio 2 FOC-ER Focus error

Audio 2 on/off +12V = on

B Blue video signal

BF Burst flag pos.pulses

8-MIX

BP-CLP

BRA

BAB Baudrate select B

8-TTL

Blue video signal from mixer FSDE

Bypass clamp pos.pulses FSEC

Baudrate select A

OV

OV

/ +5V

/ +5V

Blue video signal TTL level

BURST-ER Burst error signal

CBL

CLCF

Composite blanking pos.pulses

Bit clock CIM

to

FIL

CLOE Bit clock DEMOD to ERCO HALL

CLEC Bit clock ERCO

CLOX

LV-ROM

CLP Clamp pulse

CL-RAD

CL-VID

CLV-TC

COMM1 Commutation coil 1 +5V = on HALL

COMM2 Commutation coil 2

COMM3 Commutation coil 3

COMM4 Commutation coil 4

CP-1

CP-2

CS

CS

1-8

CS-EXT

CS-REF

CS-S/NS

Clipped radial

Clipped video

CL V trackcross +5V = active

Course pulse 1

Course pulse 2

Composite sync HOR. BL.

Chip select 1 up

External comp. sync input

Composite sync reference pos.pulses

Standard/non standard CS

to

CIM

decoder master clock

to

8

pos.pulses

-12V

/ +12V HALL AV+ » signals from HALL elements

OV

/ +12V

+5V = on

+5V = on

+5V = on

OV

= active

OV

= active HMANCH

select +5V = standard

CS-TTL

CTS

CTS1

Comp. sync TTL level

Clear

to

send (RS232)

CTS

FOC-EN

FOC-IND

FPI

FRLOCK

G Green video signal

GLC

GL-CL

G-MIX

G-TTL

H/2

C-

HALL

8HALL C+

HALL

B+

HALL

A-

HALL A+ »

CVHFATBC

HF-AUD

HF-OUT 1 HF

HF-OUT

HW-TEST

INS-TXT

IRQ

IR-REC

LA

LA-STA

LOI

LED1

CTS2 CTS LED2

CTS3

CV/CS

CVBSIN

CVBS Composite video/burst/sync LPWM

CTS

CVBS/Comp. Sync select

External CVBS input signal

+12V = CVBS

CVBS OUT CVBS output signal

CVBS2

CVBS-INT

CV-OEM CVBS demodulated

Disc CVBS without special burst

Internal CVBS

CV-DOC CVBS dropout corrected

CV-E/1

CV-EXT

CV-TBC

CV-TBM

CX-OFF

DADE

DA-DUMP

DAEC Data ERCO to CIM

OAK

DAV

DB/STAT

OEM-BK

DEMV Demodulated vert. pulse

CVBS external/internal select

External CVBS

CVBS time base corrected

CVBS time base measurement

ex

on/off

Data DEMOD

to

ERCO

Data disc dump

S-bus

data acknowledge

S-bus

data available

Databit/status text insert

Demodulator burst key pos.pulses

+ 12V = external

+12V =

off

OV

= busy PWM

LMOT-L

LMOT-R

LPO Line pulse out

LUM Luminance

MCES Motor control error signal

MCO

MCO-EN

MEM-SU

M-LOCK

MOTC

MOTS

MOTA

MTF Motional transfer function

NPL

NS-CS

NS-VID

OBF

OBS

01

01,2

Q2

P-bus

data line enable

Dropout protection inhibit

Disc reflection

to

Data right CIM

FIL

+5V = active 03,4 Common 3,4 (Red)

03

+ 12V = active

+5V = refl

04

R Red video signal

RADACT Radial actuator drive signal STB Strobe

Stepping motor coil 3 (Yellow) SPI Slide position indication

Stepping motor coil 4 (Grey) SSDE

SP-POS

ST-ST

Spot position

Symbol sy

Start-stop

Data terminal ready (RS232) RAD-ER Radial error STBY Standby command

DTR

RAD-FS Radial filter select

RAMP-EN Ramp enable pos.pulses

RC5

Dump

on/off

Data dump

on/off

Eject button

Error flag left

Error flag right

Error display

switch

OV

= dump on

+12V = on

OV

= active RC5-SCART

OV

= active

IN(B)

RC5

RC5-INT RC5 from

RC5-0UT

RCIR

RD

ADEN

External audio 2 RD-STRT

Phase relation REF-CLP Clamp

Field identification

Focus actuator drive signal

Focus enable

+ 12V = enable REPLAY Replay switch on/

REFH

REFV

RESI

In

focus indication

Focus position indication

Frame lock

Frame sync DEMOD to ERCO

Frame sync ERCO

to

CIM

Genlock clock (4.5MHz)

Genlock clock (4.5MHz)

Green video signal from mixer

Green video signal TTL level

PAL 8kHz pulse

))

))

))

))

OV = in

focus

-12V = in

position

RESI

RESO

1

1

+5V = in lock RESUPI Reset

RGB-:STA RGB status signal SCART

. RLS

A-MIX

A-TTL

RXD

RXD1

RXD2

RXD3 RXD

SC

SCANLS

SCL IIC bus clock

SCLT

SCSI Small computer system

»

SD

»

HF

audio timebase corrected

HF

audio

2

signal disc drive

HF signal sandwich

Horizontal sync

neg.pulses

0-7

SDA

SDAT

SEL Selection WR

SL-PWR Slide power low/high

SMF

OV

= low pass

RC5 input SCART STR2 Strobe 2

RC5 commands

IR

RC5

receiver SYNC OUT Sync output signal

commands SCART

RC5 output control

RC

input IR/SCART +5V =

IR

Read

S-bus

read enable TPI Track position

Read start pulse text insert

Horizontal reference

+5V = inactive indication(

pos.pulses TTM Turntable motor

Vertical reference pos.pulses

off

OV

= replay

Reserved input dipswitch

Reserved input drive

Reserved output drive TXD3 TXD

UPI

Radial loop switch

+OV

= closed

Red video signal from mixer

Red video signal TTL level (Error flag)

Recieved data (RS232)

RXD

RXD

Sandcastle pulse pos.pulses VMANCH

Scan loop

P-bus

clock

switch

OV

= active VOBN

interface

S-bus

data

IIC bus data WDOGRS

P-bus

data WINDOW

+5V = low

Switch mode frequency 17,6 kHz WREN

STBY-BUT

STR1

SYNC

Standby button command

Strobe 1

IN

External sync input signal

TANG-ER Tangential error

Ti

Tray inside

TILTOK Tilt in position

TLS

Tilt loop switch

TSP Terminal speed

TX/RX

Transmit/receive data

TXD Transmit data (RS232)

TXD1

TXD2

TXT-IW

TXD

TXD

Teletext insertion window

TXT-WH Teletext window

TXT-WV

UNEC

V/

C-TXT

VBL

VI-A/D

VI-DOP

Teletext window vertical pos.pulses

Unreliable data ERCO

Video/control text insert +5V = video text

Vertical blanking neg.pulses

Video analogue/digital +12V = analogue

Video dropout pulse

Vertical sync neg.pulses

Video background insertion

vow

VPO

VP1

VP2

VR

Video character insertion

Video mixer control 0

Video mixer control 1

Video mixer control 2

Vertical reference

Watchdog reset +5V = reset

S-bus

Write

WR-CLK

Write clock text insert +5V = inactive

S-bus

Horizontal blanking adjustment

Hardware test

TXT signal

for

insert

Interrupt request

RC5 from

Laser

Laser status

IR

on/off

receiver

OV

OV=

= off

on

Load index

LED drive

LED drive

Load motor left

Load motor right

+5V = on

+5V = on

Line pulse width modulated

Motor control output

MCO enable

Memory start up

Motor lock

))

» Motor drive signals

))

Normal play forward

+ 12V = active

+5V = active

+5V = active

Non standard composite sync

Non standard video indication

+12V = NSV

Output buffer full

Output burst switch NTSC

+ 12V = active

Pulse width modulated

Stepping motor coil 1 (Yellow)

Common 1,2 (Red)

Stepping motor coil 2 (Grey)

OV

nc

DEMOD

to

ERCO

switch OV = start

OV

OV

(16

bit word)

(8

bit word)

OV

OV

+5V = closed

+6/-6V)

on/off

-6V

+5V = on

OV

horizontal

to

pos.pulses

CIM

OV

+5V=

window

write enable

= inwards

= active

= standby

= inside

= in position

= on track

= receive

= active

active

f"C

·.7

0'ln

111!

SA>O'MCH

VDMIX(Y

l)

I

I'

II

111111

-t!-1i-1!-t!-1

5'NOW>CH

VOMIX(Y2)

I

11

!

1 1111111

LV

5'NOW>CH

ROM

DEqX4)

l

§

cwsw

.

:,,>;;l

·~

W

IRI

NG DIAGRAM

PLAYER I WDP I

~

I ; I

'

.,,

_

,,

.L

-

TI',

"9'

--

-i--------

-i---

------f----------------

~

;;-,

•=

=-s

l.

""'

+

ETBC

GJ

~

-+-

- C

-------------------'

FRONT

LOADER

CS 7 831

SCSI

BUS

WIRI

NG

DIAGRAM SANDWICH

I

WDSI

g

~

~

(/)

X X X

~-t~ --l ~

u z

W3

--l~--l~--1

ro

c.,

a:

RGB (TIL)

VI

DMI

X

[!]

IW4

CTS3 I DTR2 I

2W4

RXD3 I

rxo2

TX03

I RXD2 I

DTR3 I CTS2 I

.l

[TI

NPL

I

14

02

CPU+DATAGRABB

ER

~

3W4

4W4

5W

6W4

7W4

4

IW

2W2

3W2

4W2

SW2

6W2

!WI

2Wl

3WI

4WI

SW!

6WI

7WI

BWI

I I I I I I

2

+1

.l

-

5S8

.l

+

SSB

•5

.l

ELCF

ER

DLCF

STA I

CLCF

STR2

DRCF

2SB

CF

6X2

5X2

4X2

3X2

2X2

IX2

BXS

7X5

6X5

sxs

4XS

3X5

2XS

IXS

~~S~28

LV-

ROM

00

DEC

BX!

9Xl

3X4

2X4

IX!

2Xl

3XI

4XI

SXI

6XI

7XI

IX4

-

-

-

-

-

-

-

-

-

-

+

-

•5

+5SB

.l

-5SB

-12

-12SB

.l

,12

+12SB

PAS

T 08

00906

708

CS 7 832

BLOCKDIAGRAM CONTROL

ROUTES

s

C

s

I

C

111--1\

0

N

N

~

E

C

T

0

R

M

IXER

• MIXING

DATAGRABBER + CPU

SANDWI

~

MODES

VPO

VP1

VP2

NPL

CH

PART I DISC· DRIVE

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I COMMANDS SCAAT

I

I

I

~

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

RS232-2

PART

4

1\

v

CON

TROL

SCART-

RCS l

• REMOTE

• TEXT INSERT

VIDEO/CONTROL

CONTROL

f

v1C

-rxr

~

1

11

~

DECK

ELECTR

ONICS

.

•

S-BUS

~

LASER ON

TJLT

ON

LA

TLS

ANALOG 1/0

•

AUDIO SWITCHING

AUD

IO SWITCHI

~ } A-SYNT

PROCESSOR

DE

POS

ITION

CONTROL

TUS

NG

.

NS-VJO

r

VI-A/0

•

VIDEO

[R

• TIMING

FO

• MOTOR IN

•

•

BEEP

Al

-E/

A2-E/1 3

DRIVE

-

SPI

--

TILTOK

DR

--

LA-STA

.

SU

.

TI

LT

•

DISCAEFLECTION

.

LASER STA

4

2

1\

REFH

AEFV

--

0-APM

2-PPA

~

SWITCHING

cv1CS

CV-E

~,

AUO

AU020N

},

/1

,,5

"2

COMM-1.2.3.4

5

2

3

SL-PWR

CLV-TC

MEM-SU

ii

F

RLOC

•

READING

•

CORRECT

MOTOR

MANCHESTER

SPEED

CODE

HMANCH

VMAN

CL-VIO

K

2

FRLO

M-LOCK

CH

3

ION

cv1CS

cv-Efi

--

VOBN

vow

VBL

TIM

CK

AUDIO

PROC

ESSOR

•

AUDI

O SWITCHI

VI

DEO

PROCESSOR

• VIDEO SWI

TCH

• I

NDEX INSER

•

VER

T BLANKING INS

REF

ERENCE

SOURCE

SLIDE DRI

• DRI

VE

SLIDE MOTOR

MO

TOR

+

SEQ

UEN

CE

•

TUR

NT ABLE M

• CLV SEARCH

• MEMORY ON

GE

NLOCK

ETBC-C

NG

ING

T

VE

OTOR ON

~

~

ERT

l__[2_

~

~

~

~

LV-ROM

DECO

DER

r

L:_

R

s

2

3

2

C

0

N

N

E

C

T

I

0

I

R

I

I

I

I

I

I SDAT

I SCLT

I

I

l/1

I\

RS232-1

I\

v

• REMOTE

RCS

CONTROL COMM

P.

\J

ACS

ANDS

~

3

OLEN

•

LED

DRIVE

FRONT

LOADER

• TRAY DRIVE

l P

DISPLA

LMOT

L

MOT

Y +

2

ST

2

- A

L

KEYBOARD

- ST

TI

• TRAY INFORMATI

ON

• KE

YB0ARD SWI

--

EJECT

STBY-BUT

2

I

TCH

• 1N

FOCUS

l_:!_

---

FQC-

SP-POS

CL-RAD

-

INO

" 5

COMMAND

IJ

-

~

b._

PRS02172

T02/708

CS

7 833

FOC

US

FOC-EN

•

ENA

BLE

FOCUS DRIVE

S

CANLS

AAD-FS

RLS

2

CP-1

CP-2

RAD

IAL

SUPPLY

STBY

• ST ANOBY

HF-0UT2

TO LV-AOM

DECK

ELECTRONICS

DECODER

0

HF- OUT1

3K2

MTF

6L1

VIDEO

CORRECT

DROPOUT

ION

ELECTRONI

TIMEBASE

CORRECTION

C

2H1

BLOCKDIAGRAM AUDIO/VIDEO PATH

AU01

10A1

0N

A

3A1

1

A1

CV-TBC

AUDIO

PROCESSING

3C1

CVBS2

AUD1

AUD2

EXT

EX

AUD1

T AUD2

ANALOG 1/0

~au

,

CV-E/i-+-<-:>------~

29cU

1

B

P-CLP

-+---i<~---+

26cU1

AUD10N

3a

A-SYNT

AUD20N

U1

AUD2

O

UT

~

IODI

402

802

602

CS-S/

NS-CS

CS- EXT

3L2

OEM-BK

NS

SYNC

GENERATOR

REFERENCE

.

TO GENLOCK

MODU

LE

[Q]

FI

RAMP- EN

TXT-WH

TXT- WV

REFV

REFH

CBL

CS-REF

CLP

H

/2

BF

SOURC

E

D

CV-TBM

TO

ETBC-C

MOD

ULE

501

40

203

103

70

601

901

102

601

302

202

IT]

CV-EXT 9C

2

9C

8C

CV/CS

1

1

1

1

CV-E

8C2

/1

BP-CLP

10C1

VBL

RGB

DECODIN

G

-(

R-Y

)

BaUl

LUM

1083

9aU1

SC

17aU1

2

83

G G

383

483

-

17cU1

B B

-

18aU1

CBL CBL

-

>--+--<

IO

aUl

REFH

>--+--<

10cU1

G

381

RGB

MATRIX

Ua

1U2 9Y1

3

U2

5U

2

7

U2

9U2

COMP

RGB

1

H/ 2

2au1

12cU1

BF

7Y1

5Y1

3Y1

AEF

H

1Y1

UTER

CS

I

NS-TXT

A

DDER

i-

ENC

eves

.....

---+-------+-<:

Uc

Ub

c

vas

19

CS 7 834

I\

e,---...;

-------

BLOCKDIAGRAM

SERVO

DISC

FOCUS

DRIVE

1Jl

FLS

Gl

l!_

5JI

FOC-ACT

3Z4

-

! !

DECK

PHOTO

DIODES

L_: J

HALL

"

6JI

7JI 2JI

/

RAO-ACT

---

---

---

---

D

~[HE

---...

C B

---...

D

ELEMENTS

Q)

-

FPI

FOG- ER 924

FOG-EN

FOC-IND

82

2M2

22aA2 I

2

4

RADIAL

DRIVE

)

1aA

2

)

t t

SERVO

PRE-AMP

RAD- ACT

624 224 724

-

TPI

3M2 6M2 w

,

_....1

L~

RLS

J

-

-

SM! 7MI 8MI

RLS CP-1

"'

Rl

u ~ v ~ v ~ v

&'

CP

N

"'.

DRIV

PROCESSOR

~

10M1

9MI

CL-RAD

- 2

E

I

I

I

I

I

RAO-ER

&'

%v

t

RAD

I

N

-u

SP

-PO

S

I

I

;;,

I

I

I

I

--------------

SLIDE

MOTO

R

N N

N

w w

M V ~ V

N U

SLIDE

MOTOR

DRIVE

_,,, _,,,

_,,, _,,,

:g

M

M

:>

:>

:>

0 0 0 0

"

"

"

u

u u

u

ii

ii

jv

~ v ~ v

PORT

EXP.

~ v ~!

u,

:>

" - - -

ii

0v

I

_,,,

~

a!

ir

;u

~

2F3

3F3

8F3

9F3

10F3

11F3

Sfl

6FI

7FI

[_§_

lB_

22a

RI CL

C

21

aRI

C

21c

RI

C

22cR

1

C

23cR

I

C

MO

COMPA

RATORS

MOTOR

DRIVE

V-TC

--

0-APM

MEM- SU

TTM

2-PPR

TOR+

SEOUENCE

,-;.--

,............_

-

,____

i----i----i----i-----

i--------i---------

~TACHO

START

/

STOP

SEQUE

NCE

COMMUTATION

CLOCK

CIRCU

IT

LINE

SPEED

ME

ASUREMENT

MEASUREMENT

L

SF!

MEM- SU

2-PPR

TIM

0-APM

~

PWM

V

I

MOTOR

I

CON

TROL

SMF

LPWM

GL-CL

LPO 4F2

TSP

lsrnuENCE

I CI

RCUI

T

l£

4Fl

TTM

!F

I

M

I

I

CLV-TC

MCO-EN

MCO

3Fl

Sf2

6F2

2FI

3F2

TTM

BG!

6GI

9GI

10

2-PPIR

TT

I

)

)

)

G1

)

PRS02

12

1 711

GE

N.

LOCK

100

~

CS 7 835

CONNECTIONS OF SEMICONDUCTORS

G1

SMO TOPVJEW

SOT-143

SMO TOPVIEW

SOT-23

VAA

T0-

92

VAR

.

T0-

18

T0-

72

G2

w

S D

VAR 1

VAA2 VAA3

C C G

0 0 0

8 E E 8 D S

BOTTOM VIEW

VAA

I

VA

A 2

G G 8 G 8 8 8

8

VAA

VA

3

CB

TOP VIEW

A4

VAA

1

VAA2

VAA

vAR

4

3

©

T0-39

SOT

SOT-82

SOT

SOT

-32(10-

-93

- 186

126

tB

)

G

SOT-143

SOT-186 8UT11F

SOT-23

VAR.1

SOT-23 VAR.3 8FR30

SOT-32 (T0-126)

SOT-82

8F992

8C807

8C817 8C369

8C847

8C848 8C376

8C849

8C858 8C547

8C859

8FS19 8C549

80135

80434

80435

80436

80437

80438

8UX86 8C848

8UW85

C

©

D

8C264 T0-92 VAR.4

~C327

8C337 T0-92

8C368

8C375 T0-92 VAR.2

8C546 T0-92 VAR.2

8C548 T0-92 VAR.2

8C556 T0-92

8C557 T0-92

8C558

8C639 T0-92

8C640

8C807 SOT-23

8C817

8C847 SOT-23

8C849 SOT-23

8C858

MOA

00636

TIO 716

T0-92 VAR.2

T0-92

T0-92

T0-92 VAR.2

T0-92 VAR.2

T0-92 VAR.2

T0-92

T0-92

SOT-23

SOT-23

SOT-23

SOT-93 8UW12 8C859 SOT-23

T0-18

T0-39

T0-72

T0-92

VAR

.1

8SV78

8SV80

8SW68

8S0213

8C368

80135

80434

80435

80436

80437

80438

8FR30 SOT-23

SOT-32 (T0-126)

SOT-32 (T0-126)

SOT-32 (T0-126)

SOT-32 (T0-126)

SOT-32 (T0-126)

SOT-32 (T0-126)

8C369 8FR54 T0-92 VAR.2

8C639

8FS19 SOT-23

8C640 8F256 T0-92 VAR.4

T0-92 VAR.2

8C327

8C337

8C375

8C376

8C546

8C547

8C548

8C549

8C556

8C557

8C558

8F450 T0-92

8F494 T0-92 VAR.3

8F992 SOT-143

8S0213 T0-72

8SV80

8SW68

8UT11F

T0-18

T0-39

SOT-186

8UW12 SOT-93

8UW85

8UX86

PH2369

SOT-82

SOT-32 (T0-126)

T0-92

8FR54

PH2369

T0-92

VAR

.3 8F450

8F494

T0-92 VAR.4 8C264

8F256

VAR

.2

VAR

.1

VAR

.1

VAR

.2

VAR

.2

VAR

.2

VAR.1

VAR

.1

VAR.1

VAR

VAR.1

VAR.1

VAR

VAR

VAR.1

VAR

VAR

VAR

.3

VAR

.2

.1

.1

.1

.3

.1

CS 8 121

Survey

of

modules

Modules A to Z

- Circuit diagram

-

PCB

lay-out

- Adjustments

- Electrical parts

Remote control

Chapter 4

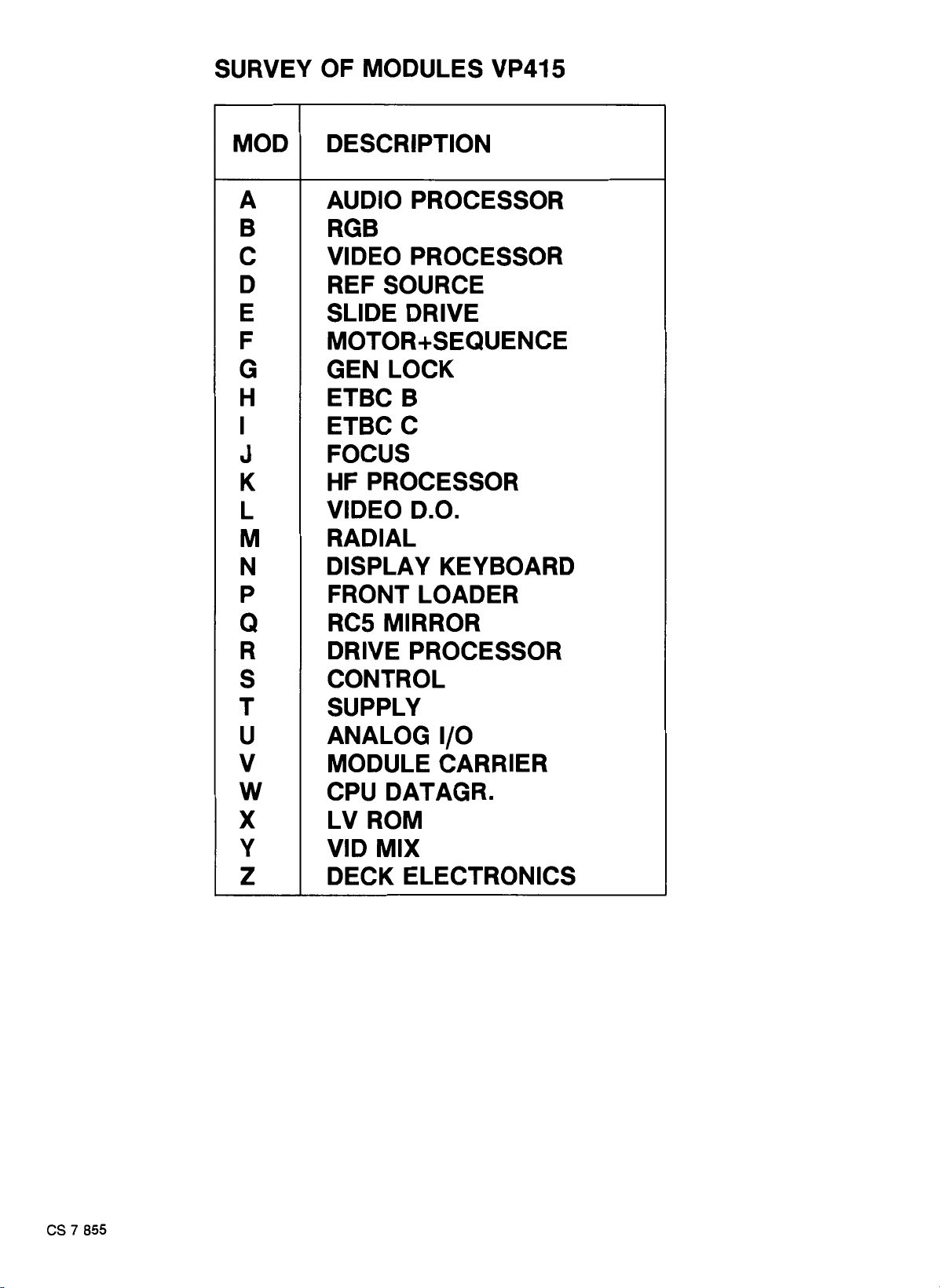

SURVEY OF MODULES VP415

MOD DESCRIPTION

A AUDIO PROCESSOR

B

C

D REF SOURCE

E SLIDE DRIVE

F

G

H

I

J

RGB

VIDEO PROCESSOR

MOTOR+SEQUENCE

GEN LOCK

ETBC B

ETBC C

FOCUS

K HF PROCESSOR

L

VIDEO D.O.

M RADIAL

N DISPLAY KEYBOARD

p

Q

R

s

FRONT LOADER

RCS

DRIVE PROCESSOR

CONTROL

MIRROR

T SUPPLY

u

ANALOG 1/0

V MODULE CARRIER

w CPU DATAGR.

X

y

z

LV

ROM

VID MIX

DECK ELECTRONICS

CS

7 855

=

=

-~

--

:

~

;j

.,

,.j

@(]

~

---

~J

~rJ

:---

...

MODULE CARRIER

tr,od level 1 )

[lJ

..

Ll

[lJ

ru·

-·

..

-·

[:l

LJ

0

0·

@]

--

ru

··

-·

.

.

ru

@]· ru@l·

--

-· -·

@]

.

.

Ll

·-

..:

El

i-j

i ::-l

:·-)

~~·-

~

. _ . _ 1

•• 1 .•...

···'

..

, . . . .• ,

'·"•

.••.

,,

...

,

,,

...

. . ,1 . . _.

·<!

...

:~

J~

i --:

l;J

D

El

i~

-· . .

~[§]

c::=J[,,J

[,,]:·,,,:

D

(fil

'

.,

, .

...

H

CS

7 836

.

AUDIO

PROC.

MODULE

(MOD LEVEL 2)

2004 B 6

2006 B 6

2007

A 3 2020 B 1 2034 A 2 2049 A 7 2066 A 3 2068 A 5 3003 A 1 3112 B 4 3114 A 4 5002 A 6

20

18 B 3

2021

A 7 2048 A 7 2065 A 3 2067 A 5 2069 A 2 3005 B 5 3113 A 4

2 3 4 5 6

5001

A 6 5003 A 6 5005 A 1 5007 A 7

5004

A 1 5006 A 1 5008 A 2 6002 A 7 6004 A 2 6107 B 1 6202 A 1

6001

B 6 6003 A 3

6102

8 5

6201

A 6 6203 A 4

ADJUSTMENTS

Required

Test

disc

Scope

Adjustment conditions

Load test disc

Normal play, picture no. 6200-6500 Audio

1,

6600-6900 Audio 2 (replay)

Audio modulation 1 kHz

Adjustments

1) R3003, R3005 (Audio demod)

- Measure the output voltage on

1A1

and

3A1

(AUD2 and

AUD1) with the scope.

- Adjust R3003 and R3005 until the output voltage is

1,8 Vpp.

Adjustment when item replaced:

replaced adjust

IC6201 R3005

IC6202 R3003

A

B

1001

B 3.

2010

1002

2001

2002 B 6 2013 B 6 2024 B 2

2003

2005

2008

2009

A

2011

B 3

B 6 2012 B 6 2023 B 2 2037

201

4

A 5

20

15

A 6

B 7 2016 B 1 2027 B 1

B 7

2017

2019 A 1

B 6

B 6

2022 B 2 2036 B 2 2053

B 6 2025

B 1

2026

A 1 2028 B 1

2

2030 B 6 2052

7

A

B 2

2039

B 1

2046 B 5

B 1 2047 B 1 2057 A 4

2050

2051

A 5

A 5

A 5

A 5

A 4

2054

A 4

2055

A 4 3001 B 6

2056

A 4

2058

A 5

2059

2 3

3

A 5 3007 B 6 · 3015 A 6 3023 B 6 3032

2060

2061

A 5

A 4

2062

A 4

2064

B 2

3002

B 5 3013 A 6

3004