Laserscale BL57-RE Instruction Manual

Scale Unit / Maßstabseinheit

BL57-RE

Read all the instructions in the manual carefully before use and strictly follow them.

Keep the manual for future references.

Lesen Sie die ganze Anleitung vor dem Betrieb aufmerksam durch und folgen Sie beim

Betrieb des Geräts den Anweisungen. Bewahren Sie diese Bedienungsanleitung zum

späteren Nachlesen griffbereit auf.

LASERSCALE / LASERSCALE

Instruction Manual / Bedienungsanleitung

BL57-RE

Safety Precautions

Magnescale Co., Ltd. products are designed in full consideration of safety. However, improper

handling during operation or installation is dangerous and may lead to fire, electric shock or

other accidents resulting in serious injury or death. In addition, these actions may also worsen

machine performance.

Therefore, be sure to observe the following safety precautions in order to prevent these types of

accidents, and to read these “Safety Precautions” before operating, installing, maintaining, inspecting, repairing or otherwise working on this unit.

Warning indication meanings

The following indications are used throughout this manual, and their contents should be understood before reading the text.

Warning

Failure to observe these precautions may lead to fire, electric shock or other accidents resulting

in serious injury or death.

Caution

Failure to observe these precautions may lead to electric shock or other accidents resulting in

injury or damage to surrounding objects.

Symbols requiring attention

CAUTION ELECTRICAL

Symbols prohibiting actions

DO NOT

DISASSEMBLE

Symbols specifying actions

UNPLUG-

GING

SHOCK

FINGER JAM

LASER BEAM

BL57-RE

(E) (1)

Warning

• Do not use this unit with voltages other than the specified supply voltages as this may

result in fire or electric shock.

• Do not perform installation work with wet hands as this may result in electric shock.

• Do not disassemble or modify the unit as this may result in injury or damage the

internal circuits.

• This device is a class 1 laser product using a semiconductor laser with wavelength of

790 nm that is outside the visible range. The maximum output of the laser is 6 mW

(class 3B).

• Although the laser beams emitted from the head interior are invisible to the eye, they

are hazardous to the human body. Therefore, never disassemble the scale unit, or try

to look into it from the sealed section of the scale unit. Also, never insert foreign objects into the sealed section of the scale unit.

CLASS 1 LASER PRODUCT

Caution

LASERSCHUTZKLASSE 1 PRODUKT

TO EN 60825

• Be sure to check the machine and device conditions to ensure work safety before

working on the machine.

• Be sure to cut off the power supply and other sources of drive power before working

on the machine. Failure to do so may result in fire or accidents.

• When turning on the power supply or other sources of drive power to operate the

machine, take care not to catch your fingers in peripheral machines and devices.

(2) (E)

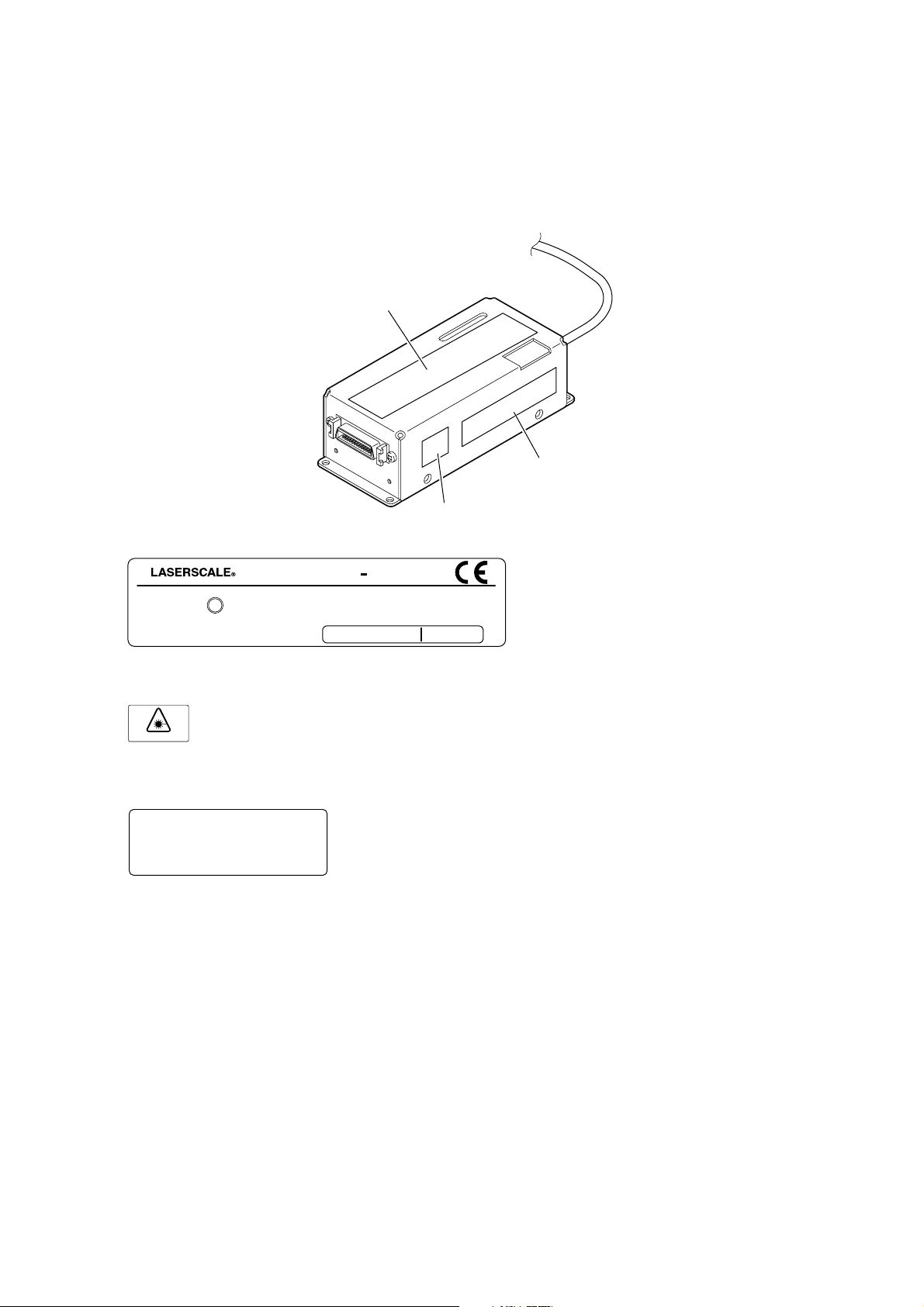

BL57-RE

CAUTION

5V

Magnescale Co

CT COCO

ES WIWI

TH

21

CFR

J

BLE

OF

E.

Use of controls or adjustments or perfomance of procedures other than those specified herein may result in hazardous radiation exposure.

q

e

w

q Specification/DHHS label

CERTIF I CA T ION

PR OD UCT

A PP L I CACABLE

J

POPOWE R R SUSUPP LY : DC

Magnescale Co

., Ltd.

w Laser Danger label

See Manual

e FCC label

THIS CLASS A DIGITAL DEVICE COMPLIES WITH PART 15 OF THE FCC

RULES AND THE CANADIAN ICES-003.

OPERATION IS SUBJECT TO THE FOLLOWING TWO CONDITIONS: (1) THIS

DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE. AND (2) THIS DEVICE

MUST ACCEPT ANY INTERFERENCE RECEIVED. INCLUDING INTERFERENCE

THAT MAY CAUSE UNDESIRED OPERATION.

CET APPAREIL NUMERIQUE DE LA CLASSE A EST CONFORME A LA NORME

NMB-003 DU CANADA.

MP L I ES

AT T D AT E E OF

3-188-177-22

BL57

TH

D HH S S R ULULE S S 21

+

5V

MA NU F A CT U RE.

CFR

S UB CH A PTPTE R

MADADE E I N N JAPAPAN

BL57-RE

(E) (3)

Operating Precautions

• An antistatic cap is attached to the connector plug of the interface unit. Do not remove this cap until you are

ready to connect the peripherals.

After removing the static electricity proof cap, take care not to touch the connector pins as this might cause

malfunctions.

• Be sure to make all connections of the interface unit connector and the peripherals before switching the power on.

Never insert or pull out the connector when the power switch is on.

• Do not pull at the cable forcibly or bend it excessively. (Bending radius (inside) Static: 10 mm or more, immobile)

• Use the BL57-RE approximately 30 minutes after power is supplied to the unit, when the temperature of the

detector head reaches a stable state.

• The BL57-RE is a precision measuring instrument. Handle it with extreme care so that no excessive shock is

applied to it. For transport, be sure to pack it in the same way as it was packed at the time of purchase. Be sure

to always attach the antistatic cap to the connector.

Notes on installation

Take careful note of the following points when installing the scale unit to prevent noise and electromagnetic interference from other equipment.

• Do not pass the head cable and connection cable through the same duct as the power line.

• Install in a location that is at least 0.5 meters separated from sources of high voltage and large currents and

large power relays.

• Do not use the cable connecting the detector head to the interface unit in a location where it is likely to be

repeatedly subjected to a bending force (cable bear, etc.). In such a case, bend the cable connected to the

output connector on the interface unit.

Notes on attachment location

• Attach the scale in a location as near as possible to the workpiece and measurement object of the machine.

• Use this product in an environment with an ambient temperature of 0 to 40 °C.

Do not attach it to a location that is exposed to direct sunlight or warm air or near sources of heat such as motors.

This could adversely affect the accuracy.

• If using a water-soluble cutting fluid or other substances, ensure that there is adequate protection so that it does

not adhere to the scale.

• Never place objects on top of the attached scale, rest your elbows or feet on the scale when using it, or apply an

excessive amount of pressure to the scale.

Notes on storage

• Do not store in locations with high temperatures or high humidity.

This could have an adverse effect on scale performance. Store in a location that is as dry as possible.

General Precautions

When using Magnescale Co., Ltd. products, observe the following general precautions along with those given

specifically in this manual to ensure proper use of the products.

• Before and during operations, be sure to check that our products function properly.

• Provide adequate safety measures to prevent damages in case our products should develop malfunctions.

• Use outside indicated specifications or purposes and modification of our products will void any warranty of the

functions and performance as specified of our products.

• When using our products in combination with other equipment, the functions and performance as noted in this

manual may not be attained, depending upon operating environmental conditions. Make full study of the compatibility in advance.

(4) (E)

BL57-RE

[For U.S.A. and Canada]

THIS CLASS A DIGITAL DEVICE COMPLIES WITH

PART15 OF THE FCC RULES AND THE CANADIAN

ICES-003. OPERATION IS SUBJECT TO THE

FOLLOWING TWO CONDITIONS.

(1) THIS DEVICE MAY NOT CAUSE HARMFUL

INTERFERENCE, AND

(2) THIS DEVICE MUST ACCEPT ANY

INTERFERENCE RECEIVED, INCLUDING

INTERFERENCE THAT

MAY CAUSE UNDERSIGNED OPERATION.

CET APPAREIL NUMERIQUE DE LA CLASSE A

EST CONFORME A LA NORME NMB-003 DU

CANADA.

BL57-RE

(E) (5)

(6) (E)

BL57-RE

Contents

1. Overview ......................................................................... 1-1

1-1. Introduction .................................................................................................. 1-1

1-2. Main Features ............................................................................................... 1-1

1-3. Series Models ............................................................................................... 1-2

2. Names and Functions of Parts ..................................... 2-1

3. Mounting and Adjustment ............................................. 3-1

3-1. Mounting Precautions .................................................................................. 3-1

3-1-1. When Mounting .......................................................................... 3-1

3-1-2. Mounting Direction .....................................................................3-2

3-1-3. Mounting Requirements .............................................................. 3-2

3-2. Mounting Surface Preparations .................................................................... 3-3

3-3. Scale Mounting ............................................................................................ 3-5

3-4. Detector Head Mounting .............................................................................. 3-9

3-5. Signal Adjustment ...................................................................................... 3-10

3-5-1. Signal Adjustment Preparations ................................................ 3-10

3-5-2. Azimuth Adjustment ................................................................. 3-11

3-6. Completion of Mounting and Adjustment.................................................. 3-13

4. Interface Unit .................................................................. 4-1

4-1. Removing and Attaching the Interface Unit Cover ...................................... 4-1

4-2. Installing the Interface Unit .........................................................................4-1

4-3. Names of LEDs ............................................................................................ 4-2

4-4. MODE Switch ..............................................................................................4-3

4-4-1. Detailed Description of MODE Switches ................................... 4-4

4-5. Changing the Settings .................................................................................. 4-5

4-5-1. Changing the Direction ............................................................... 4-5

4-5-2. Changing the Resolution ............................................................. 4-5

4-5-3. Setting the Reference Point Output Signal Width .......................4-5

4-5-4. Adjusting the Reference Point .................................................... 4-6

4-5-5. Setting the Reference Point Output and Reference Point

Detection Direction ..................................................................... 4-7

4-5-6. Setting the Alarm Reset Mode .................................................... 4-8

5. Scale Signal Output ....................................................... 5-1

5-1. A/B Signal and Alarm Output Specifications

(For output formats F and G) ....................................................................... 5-1

5-2. Analog Output Specifications (For output format H) .................................. 5-2

6. Input/Output Connectors............................................... 6-1

6-1. Connectors.................................................................................................... 6-1

6-2. Connection Specifications ............................................................................6-3

6-2-1. A/B Signal Output Type ..............................................................6-3

6-2-2. Analog Output Type .................................................................... 6-5

6-2-3. Output Cable Length (For analog output only) ........................... 6-6

BL57-RE

7. Main Specifications........................................................ 7-1

(E) i

8. Dimensions ..................................................................... 8-1

8-1. Neoceram Models ........................................................................................ 8-1

8-2. Soda Lime Glass Models ............................................................................. 8-2

9. Trouble Prevention ......................................................... 9-1

ii (E)

BL57-RE

1. Overview

1-1. Introduction

The BL57-RE series is an open-type LASERSCALE with integrated detector containing a built-in reference

point. The interface unit is supplied with DC power at +5 V ±5 % for output of A/B and Z signals, or analog

and reference point signals.

1-2. Main Features

■ Resolution: A/B signal output type : 0.1/0.05, 0.02/0.01 µm

Analog output type : 0.4 µm

■ Head signal cycle of 0.4 µm allows the interpolation error to be disregarded

■ Optical integrated circuits employing the latest semiconductor technology are used to achieve a compact

and low-energy design

■ Theoretically not affected by changes in temperature, air pressure, or by atmospheric fluctuations and

uses low-expansion glass for enhanced measurement stability

■ Maximum speed: 3,000 mm/s (analog output)

BL57-RE

(E) 1-1

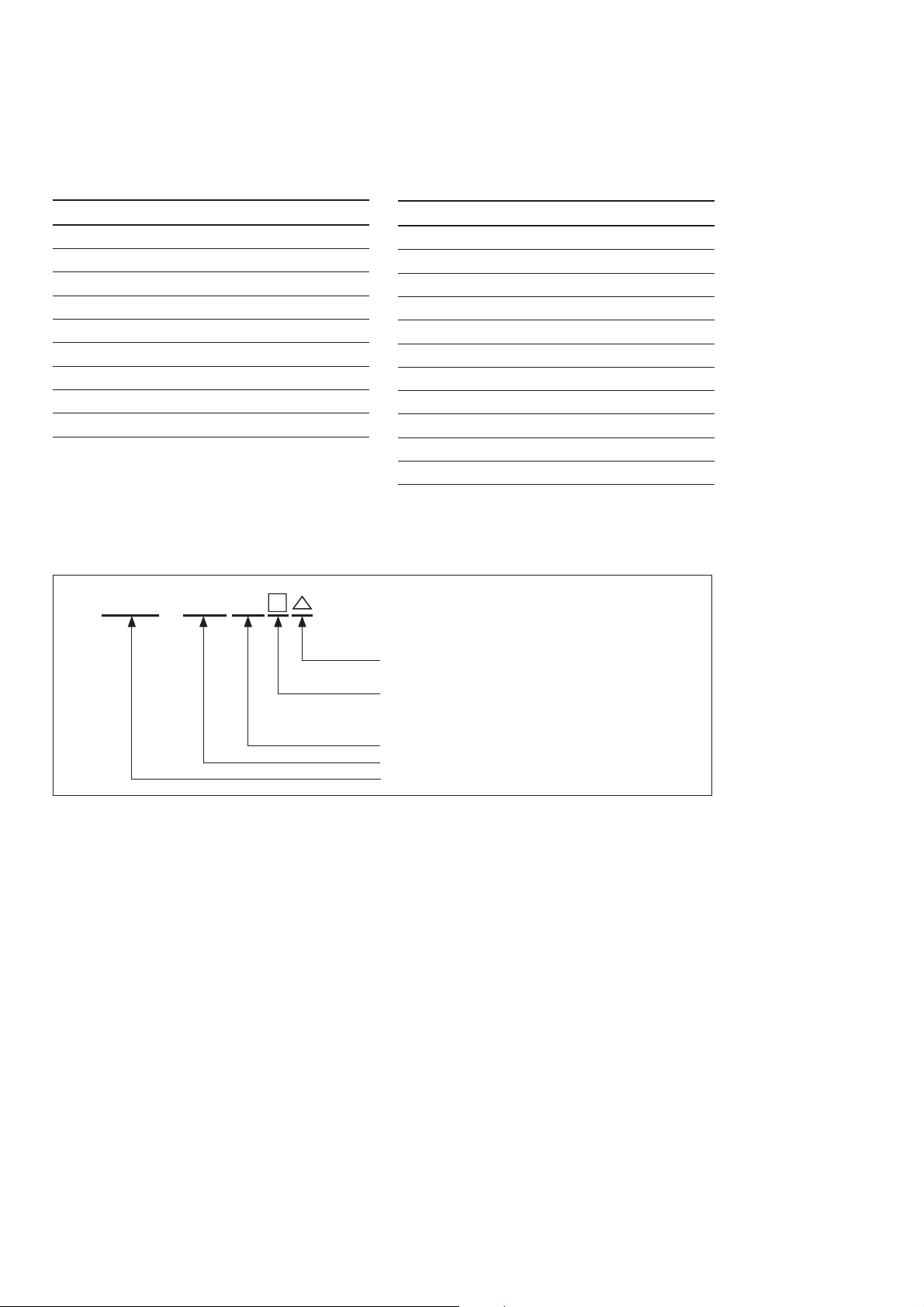

1-3. Series Models

Neoceram models Soda lime glass models

Model name Measuring length

BL57-003RE∗C 30 mm

BL57-006RE∗C 60 mm

BL57-011RE∗C 110 mm

BL57-016RE∗C 160 mm

BL57-021RE∗C 210 mm

BL57-026RE∗C 260 mm

BL57-031RE∗C 310 mm

BL57-036RE∗C 360 mm

BL57-041RE∗C 410 mm

Note:It is possible to use a special specification unit that

has a measuring length of between 420 and 660 mm.

Table 1-1

BL57−

***

RE

Model name Measuring length

BL57-006RE∗B 60 mm

BL57-016RE∗B 160 mm

BL57-026RE∗B 260 mm

BL57-036RE∗B 360 mm

BL57-046RE∗B 460 mm

BL57-056RE∗B 560 mm

BL57-066RE∗B 660 mm

BL57-076RE∗B 760 mm

BL57-086RE∗B 860 mm

BL57-096RE∗B 960 mm

BL57-106RE∗B 1060 mm

Note: It is possible to use a special specification unit that has

a measuring length of between 1070 and 1360 mm.

Scale material C : Neoceram

B: Soda lime glass

Output format F : A/B signal output (0.1/0.05 µm)

G: A/B signal output (0.02/0.01 µm)

H: Analog output (0.4 µm)

Open type (with reference point)

Measuring length (cm)

Model

Fig. 1-1

Examples

• BL57-026REGC : Neoceram 260 mm, Open type with reference point, A/B signal output (0.02/0.01 µm)

• BL57-006REFB : Soda lime glass 60 mm, Open type with reference point, A/B signal output (0.1/

0.05 µm)

• BL57-026REHB : Soda lime glass 260 mm, Open type with reference point, Analog output (0.4 µm)

1-2 (E)

BL57-RE

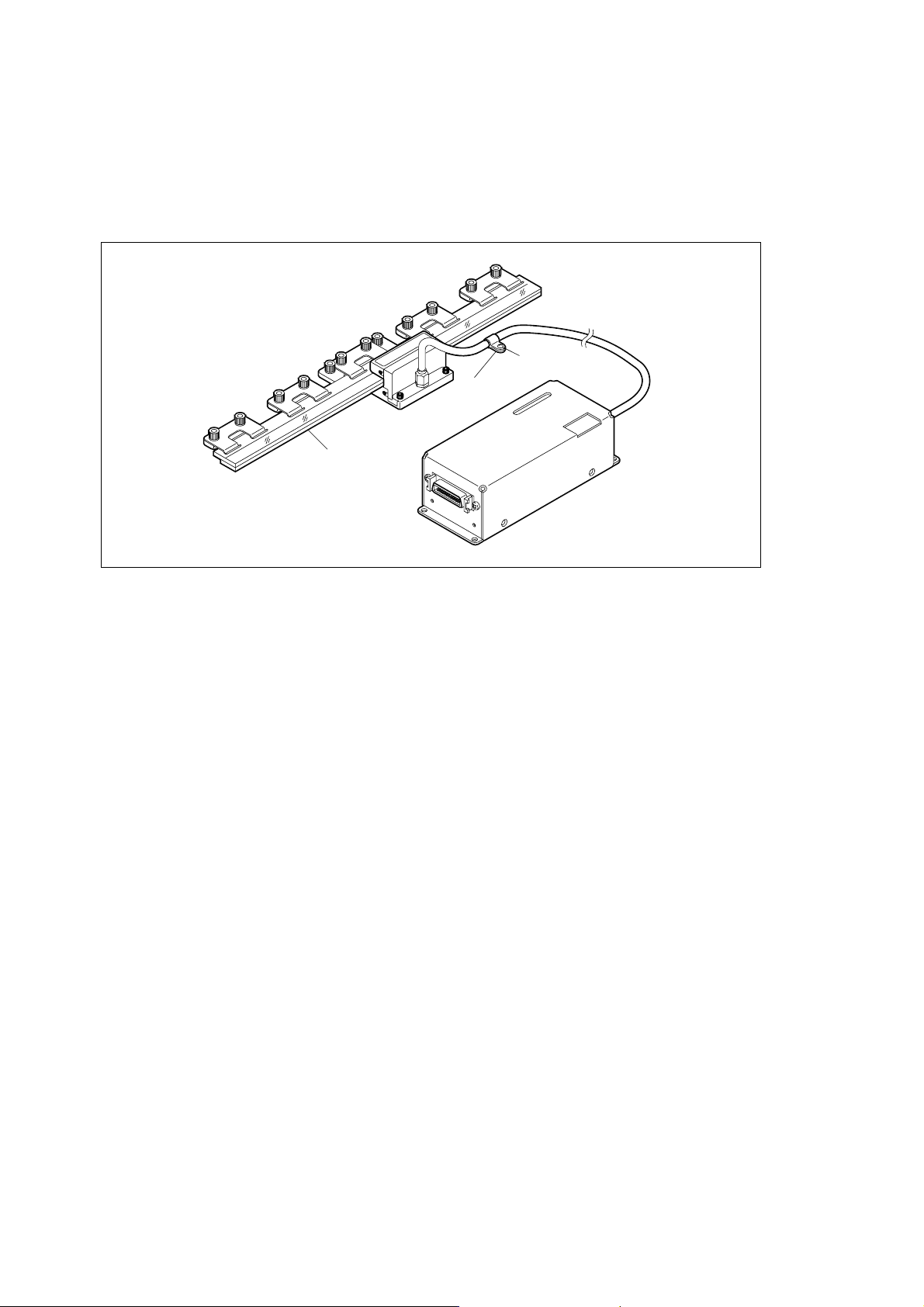

2. Names and Functions of Parts

Reference plate

Mounting screw

Plain washer

Scale clamp

Spacer

Scale

Head cable

Pan-head screw

Cable clamp

Detector

head

Interface unit

Fig. 2-1

BL57-RE

(E) 2-1

2-2 (E)

BL57-RE

3. Mounting and Adjustment

Follow the procedure below. (For details refer to the corresponding pages.)

3-1. Mounting Precautions....................................................................................................................... 3-1

3-1-1. When Mounting .................................................................................................................... 3-1

3-1-2. Mounting Direction ............................................................................................................... 3-2

3-1-3. Mounting Requirements ........................................................................................................ 3-2

3-2. Mounting Surface Preparations ........................................................................................................ 3-3

3-3. Scale Mounting................................................................................................................................. 3-5

3-4. Detector Head Mounting .................................................................................................................. 3-9

3-5. Signal Adjustment .......................................................................................................................... 3-10

3-5-1. Signal Adjustment Preparations .......................................................................................... 3-10

3-5-2. Azimuth Adjustment ........................................................................................................... 3-11

3-6. Completion of Mounting and Adjustment ...................................................................................... 3-13

3-1. Mounting Precautions

3-1-1. When Mounting

• The scale and the detector head are adjusted to each other. If using more than one scale unit, be sure that

the scale-head combinations have matching serial numbers.

• Consider the mounting position (Abbe error) and the environmental conditions (temperature, humidity,

vibration and dust) thoroughly.

• Do not lead the head cable through the same duct with the power cable. Also, do not bundle the head cable

and power cable together using a tie.

• Install in a location that is at least 0.5 meters separated from sources of high voltage and large currents

and large power relays.

• Do not use the cable connecting the detector head to the interface unit in a location where it is likely to be

repeatedly subjected to a bending force (cable bear, etc.). In such a case, bend the cable connected to the

output connector on the interface unit.

• Use this product in an environment with an ambient temperature of 0 to 40 °C.

Do not attach it to a location that is exposed to direct sunlight or warm air or near sources of heat such as

motors. This could adversely affect the accuracy.

• If using a water-soluble cutting fluid or other substances, ensure that there is adequate protection so that

it does not adhere to the scale.

• Set the maximum travel of the machine’s moving part shorter than that of the scale.

Scale’s max. travel = measuring length +10 mm/0.39" (5 mm/0.20" per each side)

(If the scale’s max. travel is exceeded, the scale unit signals will not be output and an error will occur.)

• For the scale unit, scale signal adjustment is necessary after mounting. When mounting the scale to the

machine, make sure that there is enough space for the adjustment. (See pages 3-3 to 3-13.)

• When mounting and adjusting the detector head, do not touch the surface of the head cover indicated by

the arrows in the drawing below.

BL57-RE

Fig. 3-1

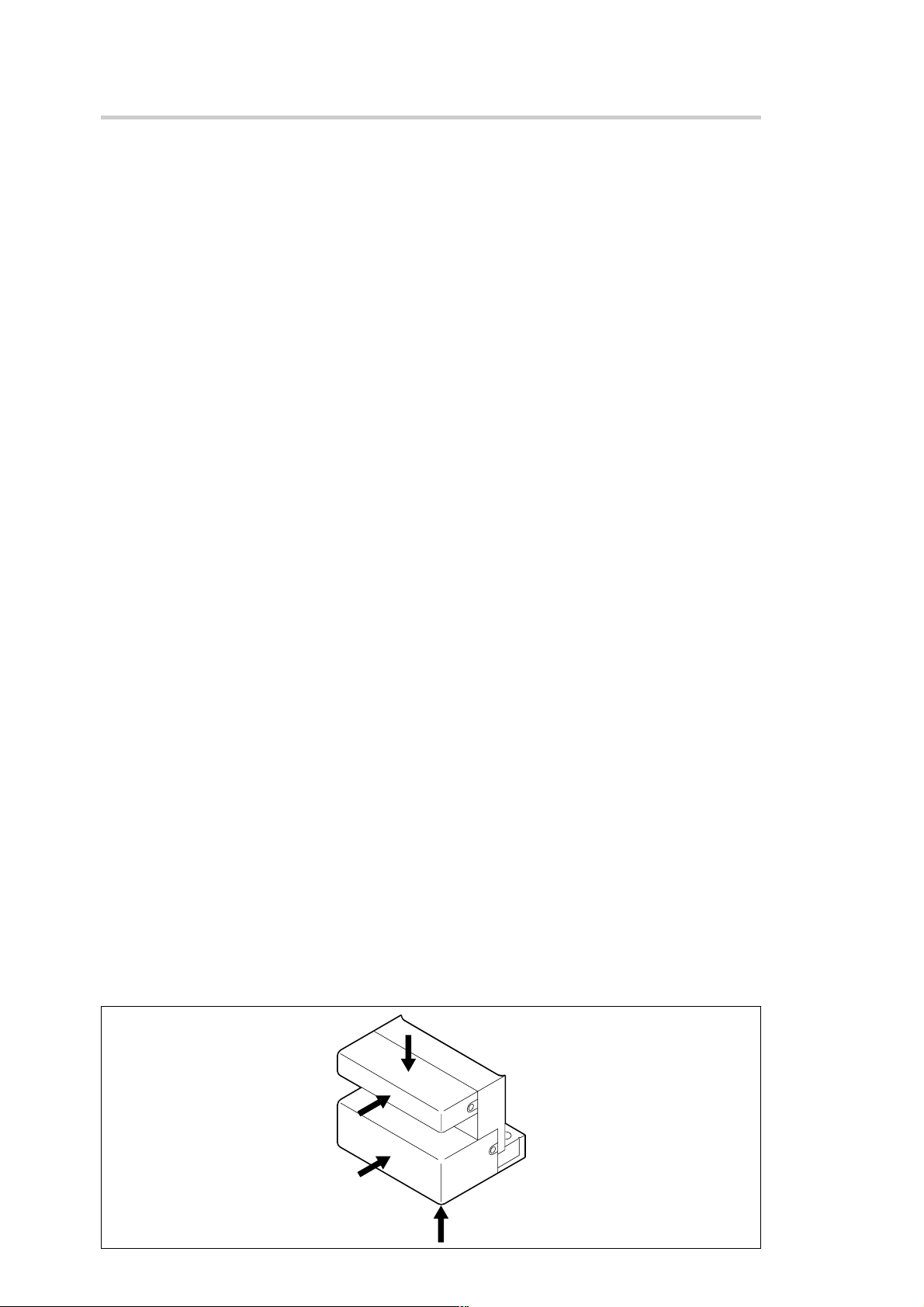

(E) 3-1

3-1-2. Mounting Direction

Mounting can be performed in the vertical or horizontal direction.

The mounting direction shown in the figure is recommended when mounting in the horizontal direction.

Upside

or

Downside

Fig. 3-2

3-1-3. Mounting Requirements

Measuring Instruments

• Electrical micrometer or lever type dial gauge ......................................................................................(1)

(one that can measure to an accuracy of 2 µm)

• Dial gauge stand .....................................................................................................................................(1)

• Oscilloscope ...........................................................................................................................................(1)

Capable of 2-quadrant X-Y display

Input sensitivity : DC 0.1 V/DIV

X-Y frequency band : 1 MHz or more

Tools

• Hex. wrenches: 3 mm.............................................................................................................................(1)

• Philips screwdriver No. 1 .......................................................................................................................(1)

• Philips screwdriver No. 0 .......................................................................................................................(1)

Miscellaneous

• Accessories ...................................................................................................................................... (1 set)

• Gauze ................................................................................................................................ (Small amount)

• Alcohol .............................................................................................................................. (Small amount)

3-2 (E)

BL57-RE

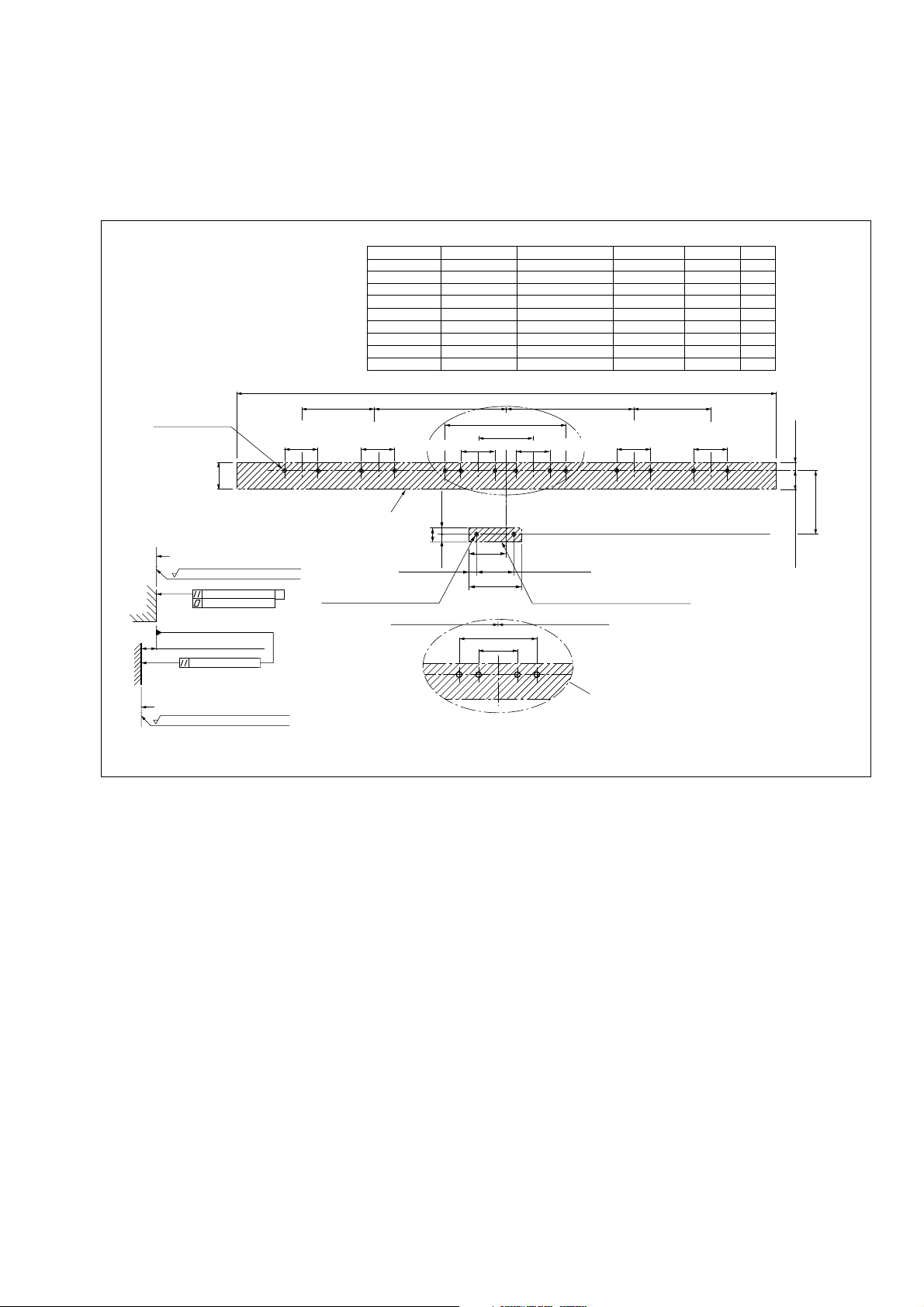

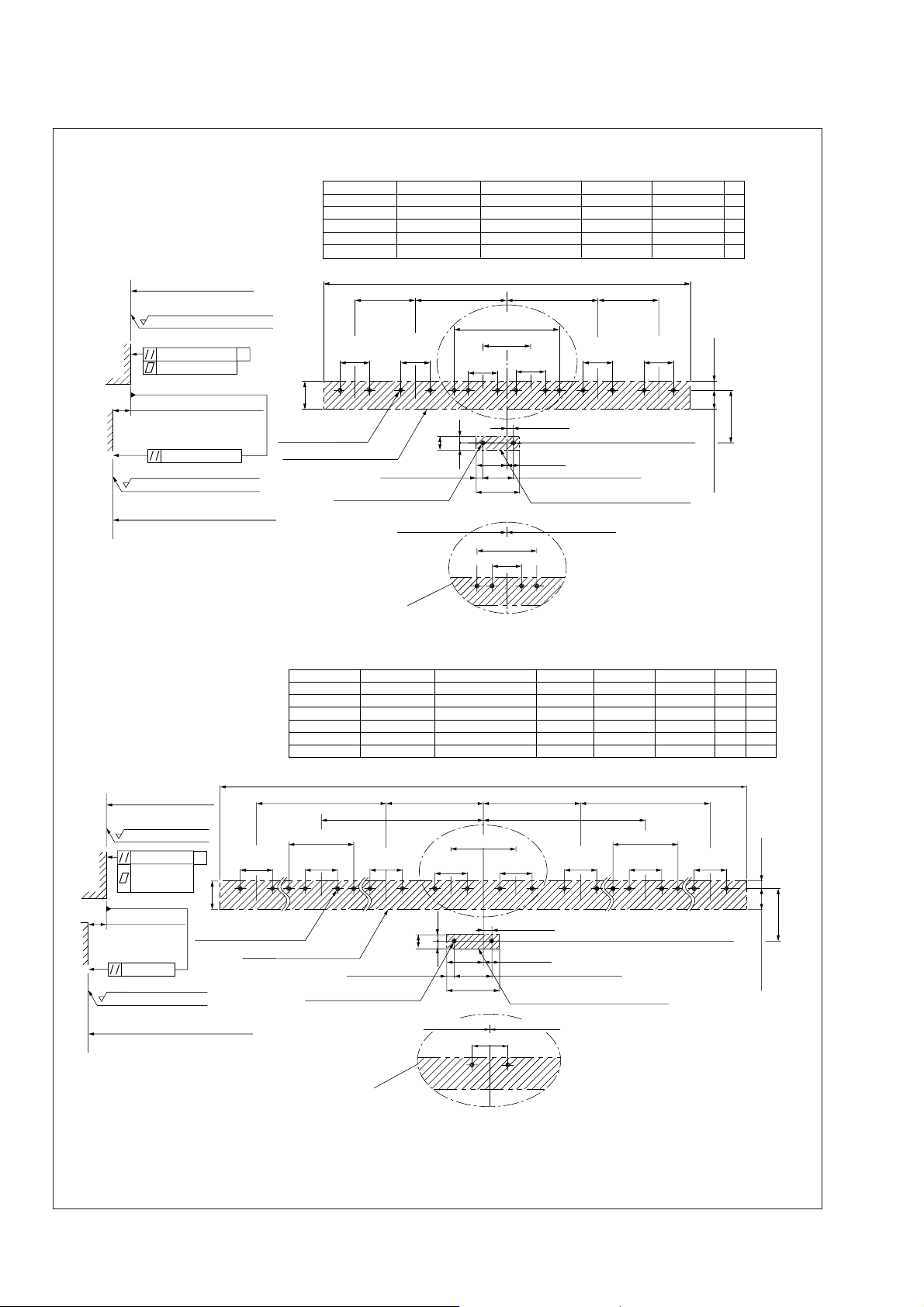

3-2. Mounting Surface Preparations

1. Check the mounting surface range (the shaded sections in the figure) and accuracy.

2. Check the accuracy of the mounting screw coordinates.

Neoceram models

depth: 6 (0.236")

P-M4

19.5 (0.768")

Scale mounting surface

Rmax = 6.3S (250 µinch)

0.01 (0.00039")

0.01 (0.00039")

18.4 ±0.2 (0.724" ±0.008")

0.02 (0.00079")

Detector head mounting surface

Rmax = 12.5S (500 µinch)

25 ±0.2

(0.984" ±0.008")

(0.984" ±0.008")

Scale mounting surface

M

2-M4 depth: 10 (0.394")

Model

BL57-003RE*C

BL57-006RE

BL57-011RE

BL57-016RE

BL57-021RE

BL57-026RE

BL57-031RE

BL57-036RE

BL57-041RE

25 ±0.2

L2

Measuring length

30 (1.181")

60 (2.362")

C

*

110 (4.331")

C

*

160 (6.299")

C

*

210 (8.268")

C

*

260 (10.236")

C

*

310 (12.205")

C

*

360 (14.173")

C

*

410 (16.142")

C

*

L1

66 (2.598") or more

96 (3.780") or more

146 (5.748") or more

196 (7.717") or more

246 (9.685") or more

296 (11.654") or more

346 (13.622") or more

396 (15.591") or more

446 (17.559") or more

L2

–

–

50 (1.969")

75 (2.953")

100 (3.937")

120 (4.724")

120 (4.724")

75 (2.953")

100 (3.937")

L1

L2 ±1 (0.039") L2 ±1 (0.039")L3 ±1 (0.039") L3 ±1 (0.039")

±

0.3 (3.465" ±0.012")

88

40 ±0.2 (1.575" ±0.008")

25 ±0.2 (0.984" ±0.008") 25 ±0.2 (0.984" ±0.008")

5

(0.197")

(10.5)

(5.5)

(0.217")

±

1 (0.039")

(0.413")

5.5

(1.102")

(0.217")

28

38

(1.496")

27 ±0.2

(1.063" ±0.008")

Detector head mounting surface

L2 ±1 (0.039")

25 ±0.2

(0.984" ±0.008")

(0.984" ±0.008")

50 ±0.3 (1.969" ±0.012 ")

25 ±0.2 (0.984" ±0.008")

For BL57-003RE*C, 011RE*C, 016RE*C,

C, 036RE*C, 041RE*C

021RE

*

L3

–

–

–

–

–

–

–

75 (2.953")

100 (3.937")

25 ±0.2

P

4

6

8

8

8

10

10

12

12

6 (0.236")

42.7 ±0.2

0.2

0.008")

±

±

(1.681" ±0.008")

13.5

(0.531"

Note: “M” refers to the machine guide.

Fig. 3-3

Unit: mm (inch)

BL57-RE

(E) 3-3

Soda lime glass models

Scale mounting surface

Rmax = 6.3S (250 µinch)

(Note 1)

0.01 (0.00039")

M

0.01 (0.00039")

16.4 ±0.2 (0.646" ±0.008")

0.02 (0.00079")

Rmax = 12.5S (500 µinch)

Detector head mounting surface

For BL57-016RE∗B, 036RE∗B

Model

BL57-006RE∗B

BL57-016RE∗B

BL57-026RE∗B

BL57-036RE∗B

BL57-046RE∗B

25 ±0.2

(0.984" ±0.008")

22 (0.866")

P-M4 depth: 6 (0.236")

Scale mounting surface

2-M4 depth: 10 (0.394")

Measuring length

60 (2.362")

160 (6.299")

260 (10.236")

360 (14.173")

460 (18.110")

25 ±0.2

(0.984" ±0.008")

(10.5)

(5.5) (0.217")

96 (3.780") or more

196 (7.717") or more

296 (11.654") or more

396 (15.591") or more

496 (19.528") or more

L1

88 ±0.3 (3.465" ±0.012")

40 ±0.2 (1.575" ±0.008")

25 ±0.2

(0.984" ±0.008")

5

(0.197")

(0.413")

5.5

(0.217")

28

(1.102")

38

(1.496")

50 ±0.3 (1.969" ±0.012")

25 ±0.2 (0.984" ±0.008")

L1

L2 ±1 (0.039")L2 ±1 (0.039")

L2

–

75 (2.953")

120 (4.724")

75 (2.953")

120 (4.724")

±

L3

25 ±0.2

25 ±0.2

(0.984" ±0.008")

(0.984" ±0.008")

4.5 (0.177")

10 (0.394")

27 ±0.2 (1.063" ±0.008")

Detector head mounting surface

L2 ±1 (0.039")L2 ±1 (0.039")

75 (2.953")

75 (2.953")

1 (0.039") L3 ±1 (0.039")

25 ±0.2

(0.984" ±0.008")

L3

P

–

6

–

8

–

10

12

14

(5)

(0.197")

0.2

0.008")

±

±

44.2

0.008")

±

(1.740"

16 ±0.2

(0.630"

Unit: mm (inch)

Scale mounting surface

Rmax = 6.3S (250 µinch)

0.1 (0.0039")

M

0.02 (0.00079")/

50 ±0.3 (1.969" ±0.012") 50 ±0.3 (1.969" ±0.012")

25 ±0.2

(0.984" ±0.008")

200 (7.874")

(Note 2)

16.4 ±0.2

(0.646" ±0.008")

22 (0.866")

P-M4 depth: 6 (0.236")

Scale mounting surface

0.02 (0.00079")

Rmax = 12.5S (500 µinch)

Detector head mounting surface

For BL57-066RE∗B, 096RE∗B, 106RE∗B

Model

BL57-056RE∗B

BL57-066RE∗B

BL57-076RE∗B

BL57-086RE∗B

BL57-096RE∗B

BL57-106RE∗B

Measuring length

560 (22.047")

660 (25.984")

760 (29.921")

860 (33.858")

960 (37.795")

1060 (41.732")

L1

596 (23.465") or more

696 (27.402") or more

796 (31.339") or more

896 (35.276") or more

996 (39.213") or more

1096 (43.150") or more

L2

100 (3.937")

75 (2.953")

100 (3.937")

100 (3.937")

75 (2.953")

75 (2.953")

L3

175 (6.890")

225 (8.858")

250 (9.843")

250 (9.843")

300 (11.811")

300 (11.811")

75 (2.953")

75 (2.953")

75 (2.953")

75 (2.953")

75 (2.953")

75 (2.953")

L1

NA × L4 ±1 (0.039") NA × L4 ±1 (0.039")

L2 ±1 (0.039") L2 ±1 (0.039")

L3 ±1 (0.039")L3 ±1 (0.039")

25 ±0.2

(0.984" ±0.008")

25 0.2

(0.984" ±0.008")

(5.5) (0.217")

2-M4 depth: 10 (0.394")

50 (1.969")

25 ±0.2

(0.984" ±0.008")

5

(0.197")

5.5

(0.217")

28

(1.102")

38

(1.496")

(10.5) (0.413")

25 ±0.2

(0.984" ±0.008")

25 ±0.2

(0.984" ±0.008")

4.5 (0.177")

10 (0.394")

27 ±0.2 (1.063" ±0.008")

Detector head mounting surface

25 ±0.2

(0.984" ±0.008")

L2 ±1 (0.039")L2 ±1 (0.039")

25 ±0.2 (0.984" ±0.008")

NA

L4

(0.984" ±0.008")

2

3

3

4

5

6

25 ±0.2

Unit: mm (inch)

16

18

20

24

26

30

16 ±0.2

P

(6)

(0.236")

44.2 ±0.2

(0.630" ±0.008")

(1.740" ±0.008")

3-4 (E)

Note 1: “M” refers to the machine guide.

Note 2: The flatness of the scale mounting surface must be within 0.02 over the range of 7 (width) × 200 (length) mm.

Fig. 3-4

BL57-RE

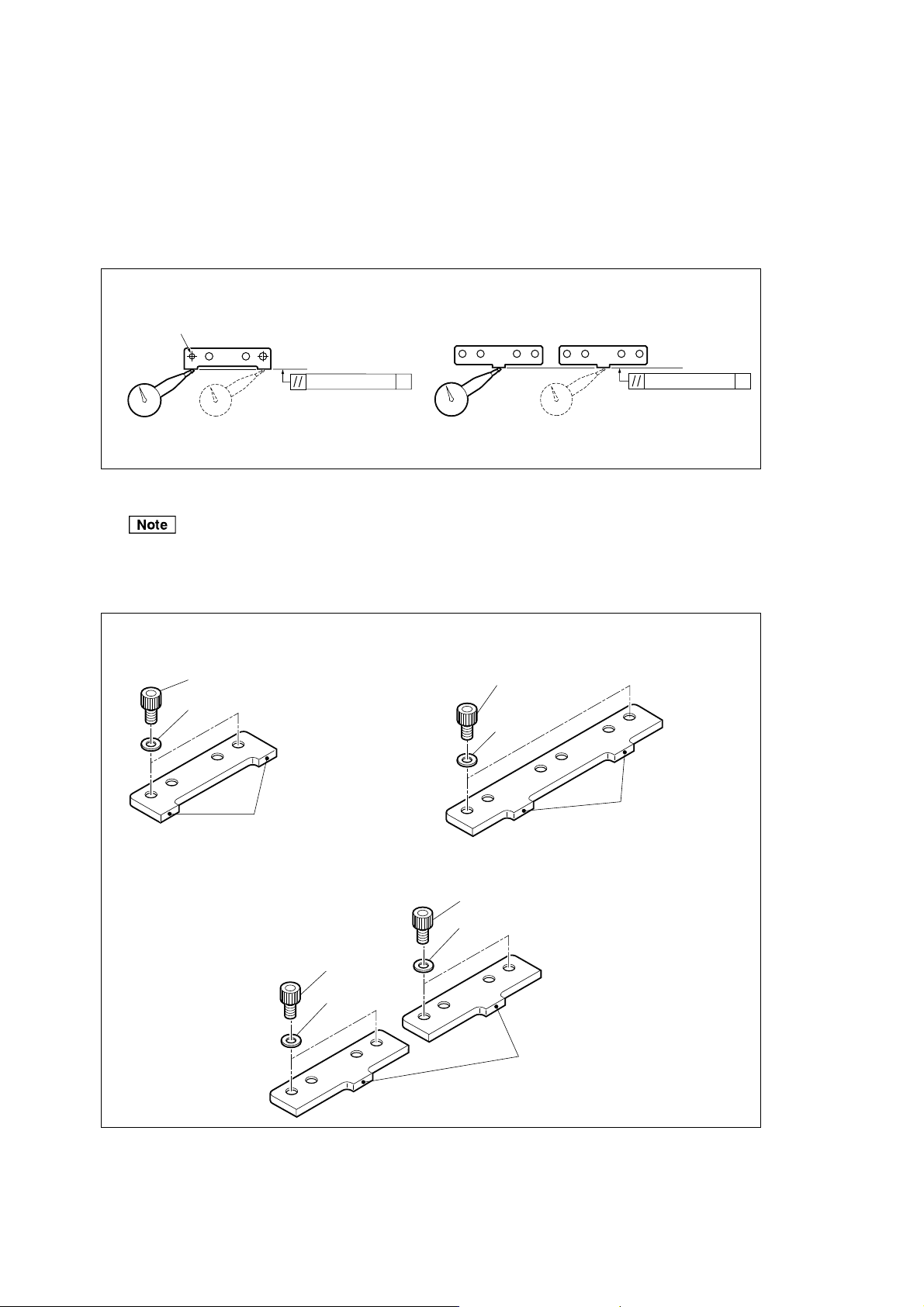

3-3. Scale Mounting

1 Check that there is no dust or other foreign substances on the mounting surface, and mount the reference

plate parallel to the machine guide as shown in the figure. (Fastening torque: 1.4 N · m)

The reference hole is located on the left, as shown in the figure. Adjust at the right side while observing

the parallelism with the lever type dial gauge.

BL57-003RE to 046RE BL57-056RE to 106RE

+

Reference ø4 0

0.05

0.01 (0.00039")

M

Fig. 3-5

0.1 (0.0039")

Note: “M” refers to the machine guide.

M

The scale is pressed against the reference plate for parallelism when mounting. The reference plate is

vital to accurate scale mounting. Be sure to always use the supplied screw and mount it exactly as

described in the specifications.

BL57-003RE, 011RE, 016RE, BL57-006RE, 026RE, 031RE, 046RE

021RE, 036RE, 041RE

M4 × 8

Plain washer (nominal 4)

Reference abutment

surface

M4 × 8

Plain washer

(nominal 4)

Reference abutment

surface

BL57-RE

BL57-056RE, 066RE, 076RE, 086RE, 096RE, 106RE

M4 × 8

Plain washer (nominal 4)

M4

×

8

Plain washer

(nominal 4)

Reference abutment

surface

Fig. 3-6

(E) 3-5

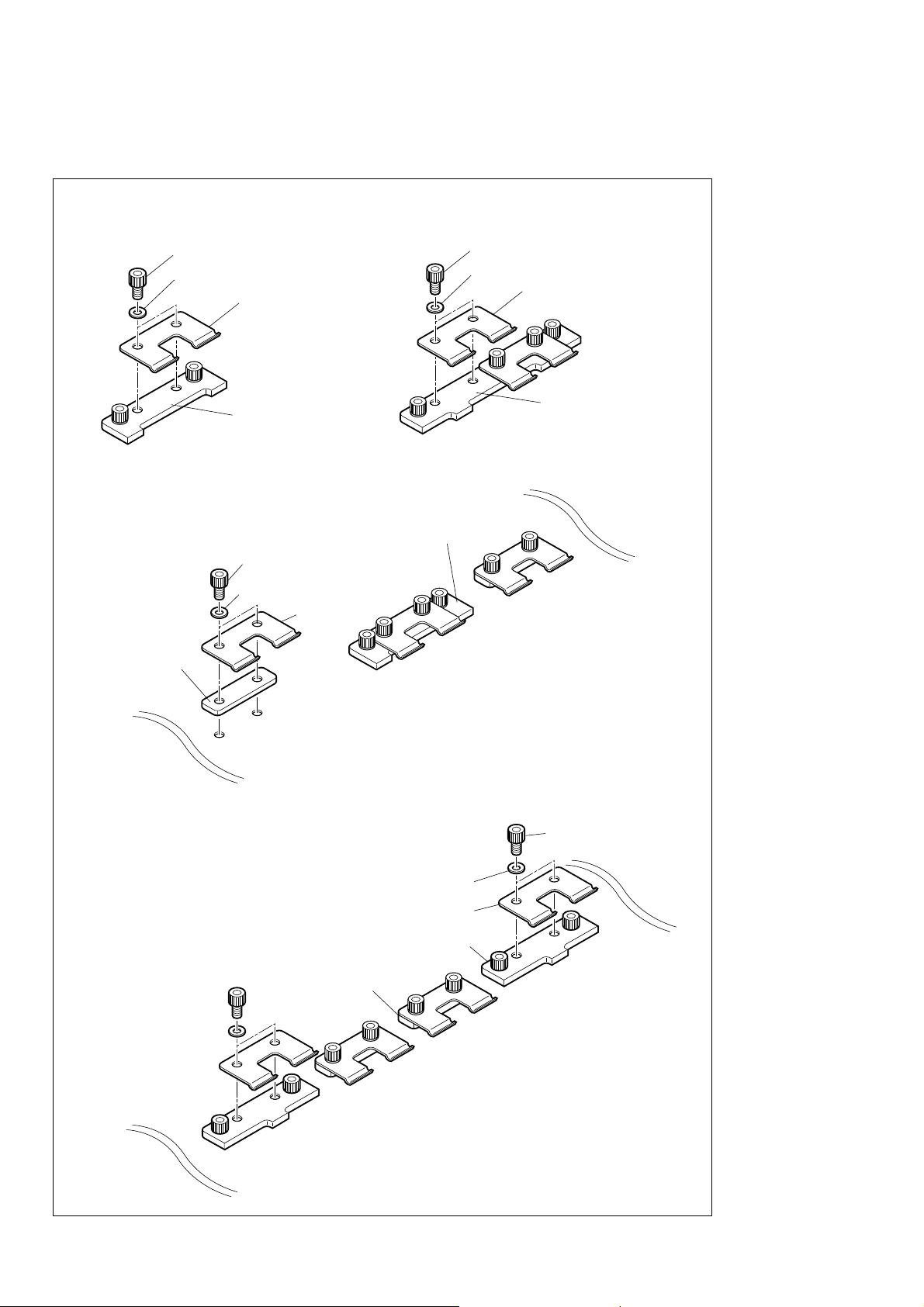

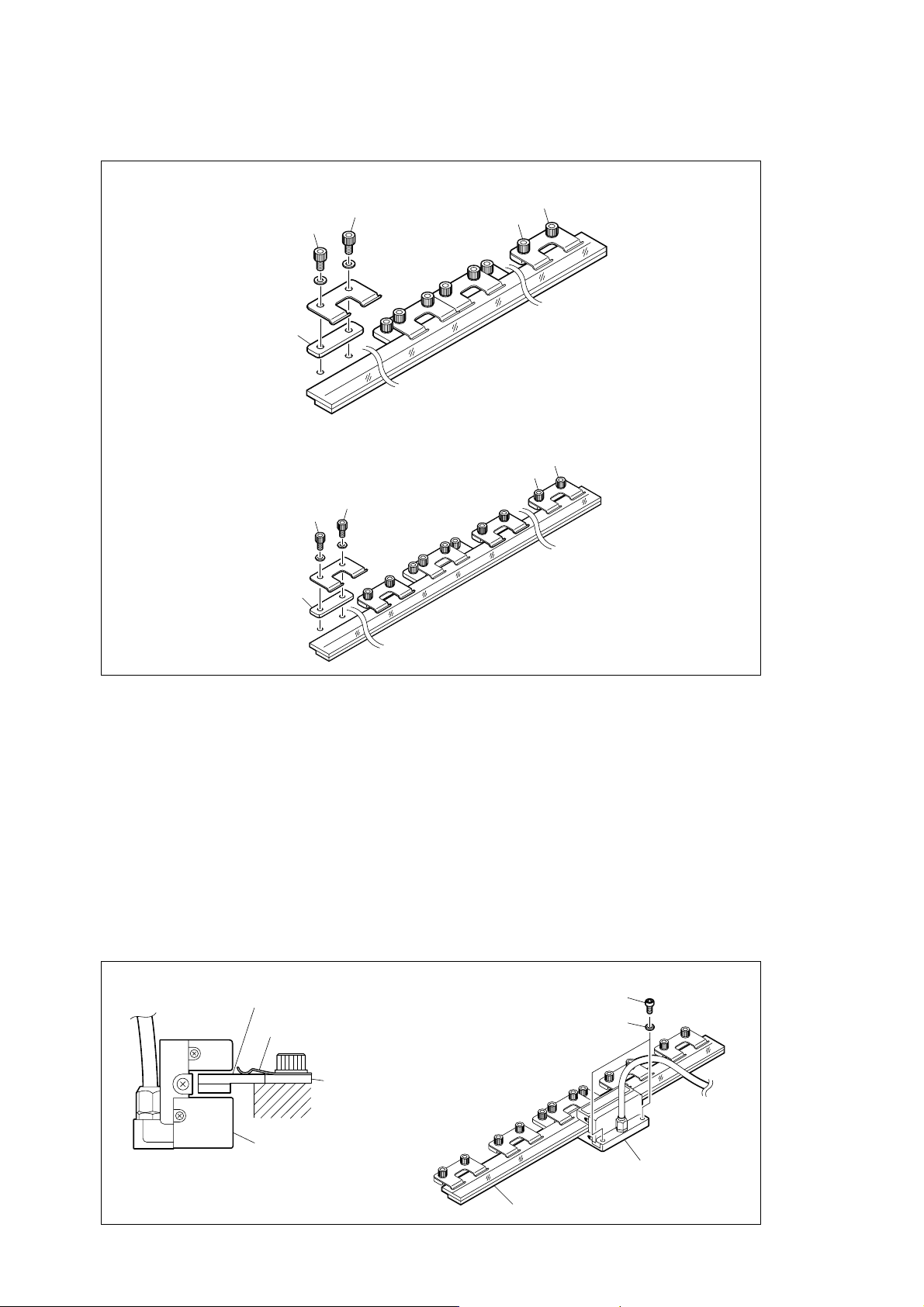

2 Attach the scale clamps loosely (1 or 2 full turns looser than the semi-tightened position) by using the

mounting screws, as shown in the figure.

BL57-003RE BL57-006RE, 026RE, 031RE, 046RE

M4 × 8

Plain washer (nominal 4)

Reference plate

Spacer

Scale clamp

BL57-011RE, 016RE, 021RE, 036RE, 041RE

Reference plate

× 8

M4

Plain washer (nominal 4)

Scale clamp

M4 × 8

Plain washer (nominal 4)

Scale clamp

Reference plate

3-6 (E)

BL57-056RE, 066RE, 076RE, 086RE, 096RE, 106RE

Plain washer (nominal 4)

Scale clamp

Reference plate

Spacer

Fig. 3-7

M4

×

8

BL57-RE

3 Check the mounting surface and the datum surface of the scale for dust and dirt. If the surfaces are dirty,

wipe them clean with gauze moistened with alcohol.

Mounting surface

Datum surface

Fig. 3-8

4 Insert the scale between the scale clamp and the mounting surface while pressing the datum surface of

the scale (see Fig. 3-6) lightly against the reference abutment surface (Note). Gradually and alternately

tighten screws A and B of the scale clamp indicated in the figure. (Use only the left-side scale clamp for

clamps with two screws, and use the center scale clamp for clamps with three screws.) (Final fastening

torque: 1.4 N · m)

BL57-003RE BL57-006RE, 026RE, 031RE, 046RE

B

A

B

A

BL57-011RE, 016RE, 021RE, 036RE, 041RE

B

A

BL57-056RE, 066RE, 076RE, 086RE, 096RE, 106RE

B

A

B

A

BL57-RE

Fig. 3-9

(E) 3-7

When pressing the scale against the datum surface, lightly press two points on the edge of the scale surface

opposite the datum surface with your fingers with a force of 9.8 N or less as shown in Fig. 3-10 on the left.

If the middle part of the scale is pressed with a force of 4.9 N or more as shown in Fig. 3-10 on the right, or

if the scale is installed with deformation, the specified accuracy cannot be achieved. (This also applies to the

following procedures. If it appears that the scale has been bent by force, loosen the scale clamp and mount it

again properly.)

BL57-003RE to 046RE

CORRECT WRONG

BL57-056RE to 106RE

CORRECT WRONG

Fig. 3-10

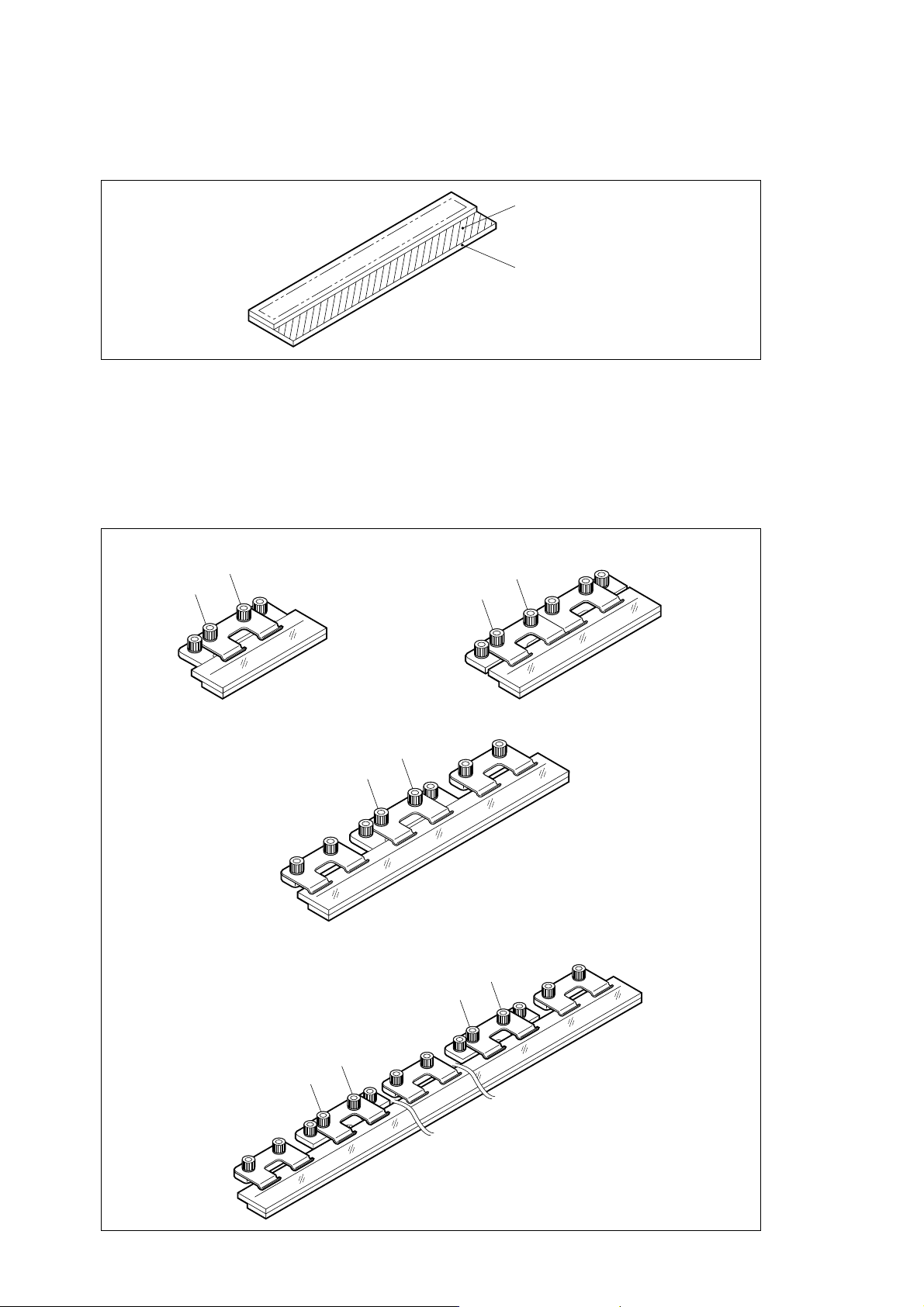

5 Leave the scale in the condition of Fig. 3-9 for one hour or more until the scale temperature stabilizes.

6 Secure the remaining scale clamps by gradually and alternately tightening screws A and B. (Use only

the right-side scale clamp for clamps with two screws, and use the right-side and the left-side scale

clamps for clamps with three screws.) (Final fastening torque: 1.4 N · m)

BL57-006RE, 026RE, 031RE, 046RE BL57-011RE, 016RE, 021RE, 036RE, 041RE,

B

A

056RE, 066RE, 076RE, 086RE, 096RE, 106RE

B

A

B

A

Fig. 3-11

3-8 (E)

BL57-RE

7 Fasten scale clamps on both ends of the scale with the same torque. (Final fastening torque: 1.4 N · m)

BL57-026RE, 031RE, 046RE

B

A

Spacer

BL57-016RE, 036RE, 041RE, 056RE, 066RE, 076RE, 086RE, 096RE, 106RE

B

A

B

A

B

A

Spacer

Fig. 3-12

8 Check the surface of the scale for oil and dust. If the surface is dirty, wipe it clean with gauze moistened

with alcohol. Be sure to wipe off oil and dust on the surface thoroughly.

3-4. Detector Head Mounting

1 Move the machine table and adjust the mounting position of the detector head to roughly the center of

the scale.

2 Use the supplied mounting screws to semi-tighten the detector head.

Detector head mounting screw

(M4

×

Scale

Scale clamp

12 hex. socket-head cap screw)

Plain washer (nominal 4)

BL57-RE

Reference

plate

Detector head

Detector head

Scale

Fig. 3-13

(E) 3-9

3-5. Signal Adjustment

3-5-1. Signal Adjustment Preparations

Check that the interface unit is turned off.

Refer to section 4-1 for removing and attaching the cover of the interface unit.

1

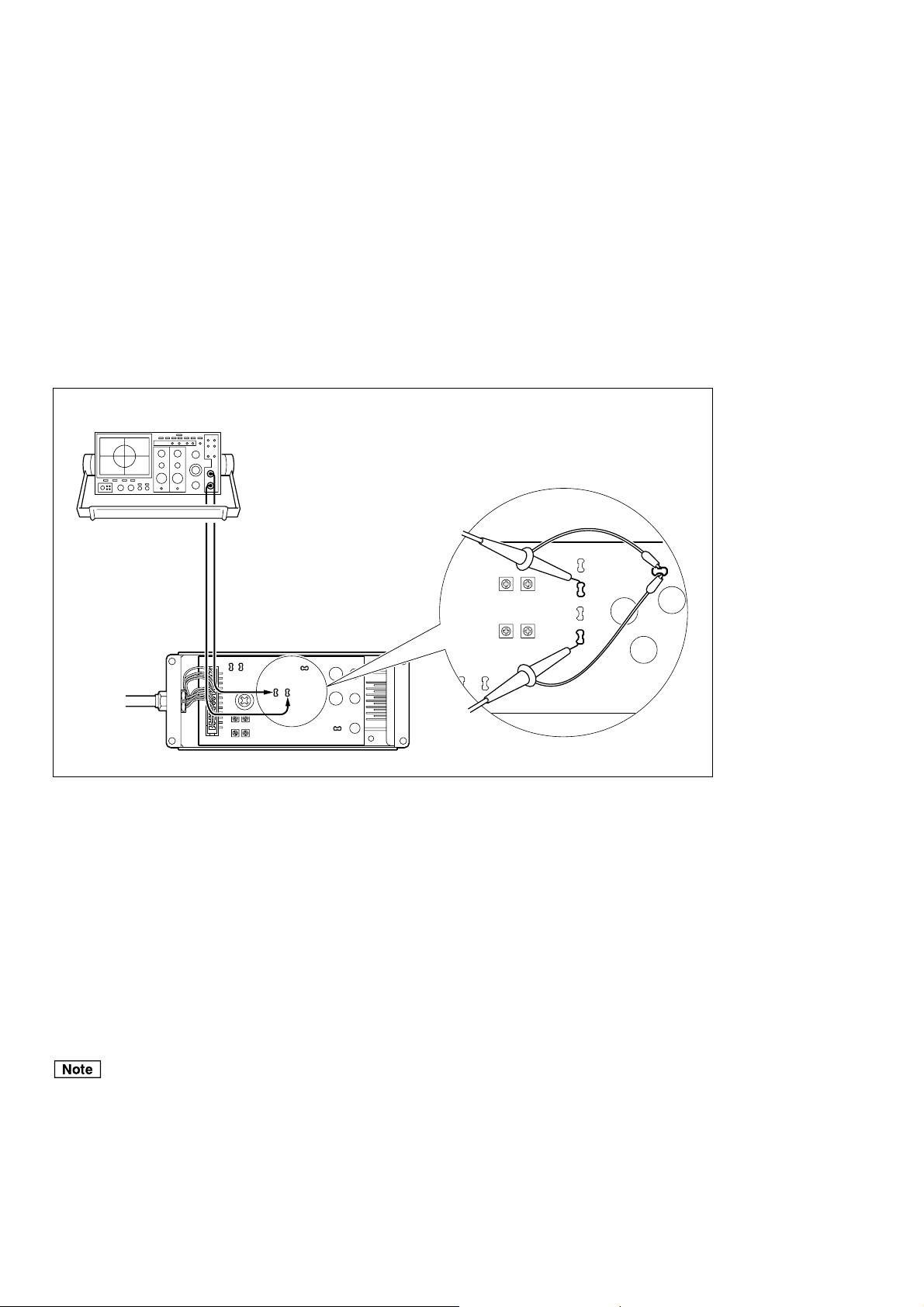

1 Connect the CH1 probe of the oscilloscope to the check pins

1 Output format F, G or H : TP3 (SIN) and TP8 (GND)

∗

2 Connect the CH2 probe of the oscilloscope to the check pins

2 Output format F, G or H : TP2 (COS) and TP8 (GND)

∗

∗

of the interface unit.

2

∗

of the interface unit.

Oscilloscope

CH1CH2

Probe

TP9

TP10

(LD)

(

)

APC

TP7

(

)

AGND

TP5

(

)

COS

TP1

(

)

SIN

TP8

(

DGND

Interface unit

3 Set the TIME/DIV switch to the X-Y mode.

)

Fig. 3-14

Signal adjustment

section-detailed view

Output format F, G, H

CH1

TP3

TP2

TP901

CH2

TP6

TP8

TP5

4 Set the deviation sensitivity (VOLTS/DIV) of CH1 and CH2 to 0.5 V/DIV.

5 Set the input coupling switches of CH1 and CH2 of the oscilloscope to GND, and adjust the position of

the oscilloscope so that the signal appears at the bottom left of the screen.

6 Set the input coupling switches of CH1 and CH2 of the oscilloscope to DC.

7 Turn the interface unit’s power on.

Be sure that the interface unit is turned off before attaching or removing the probe of the oscilloscope.

3-10 (E)

BL57-RE

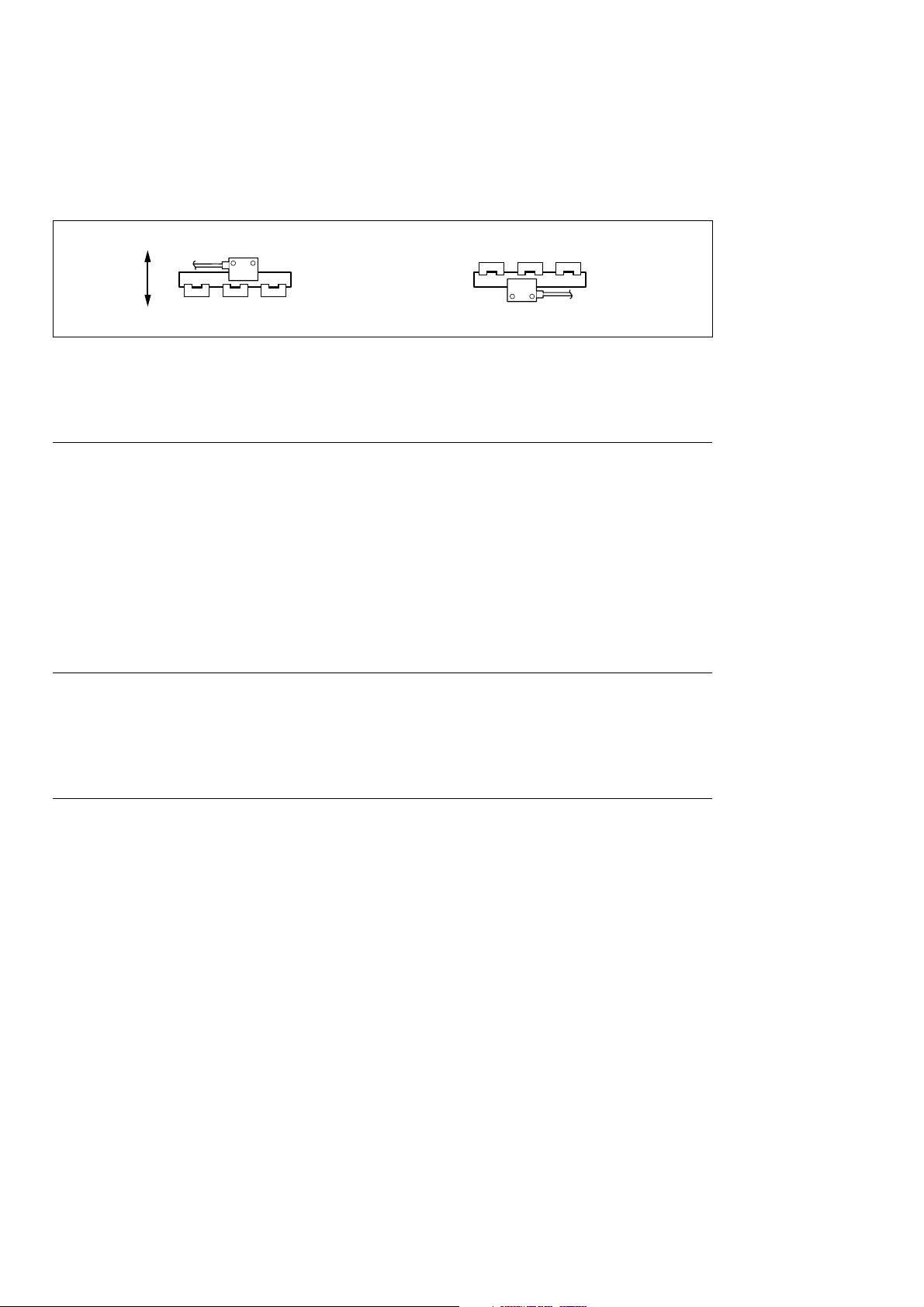

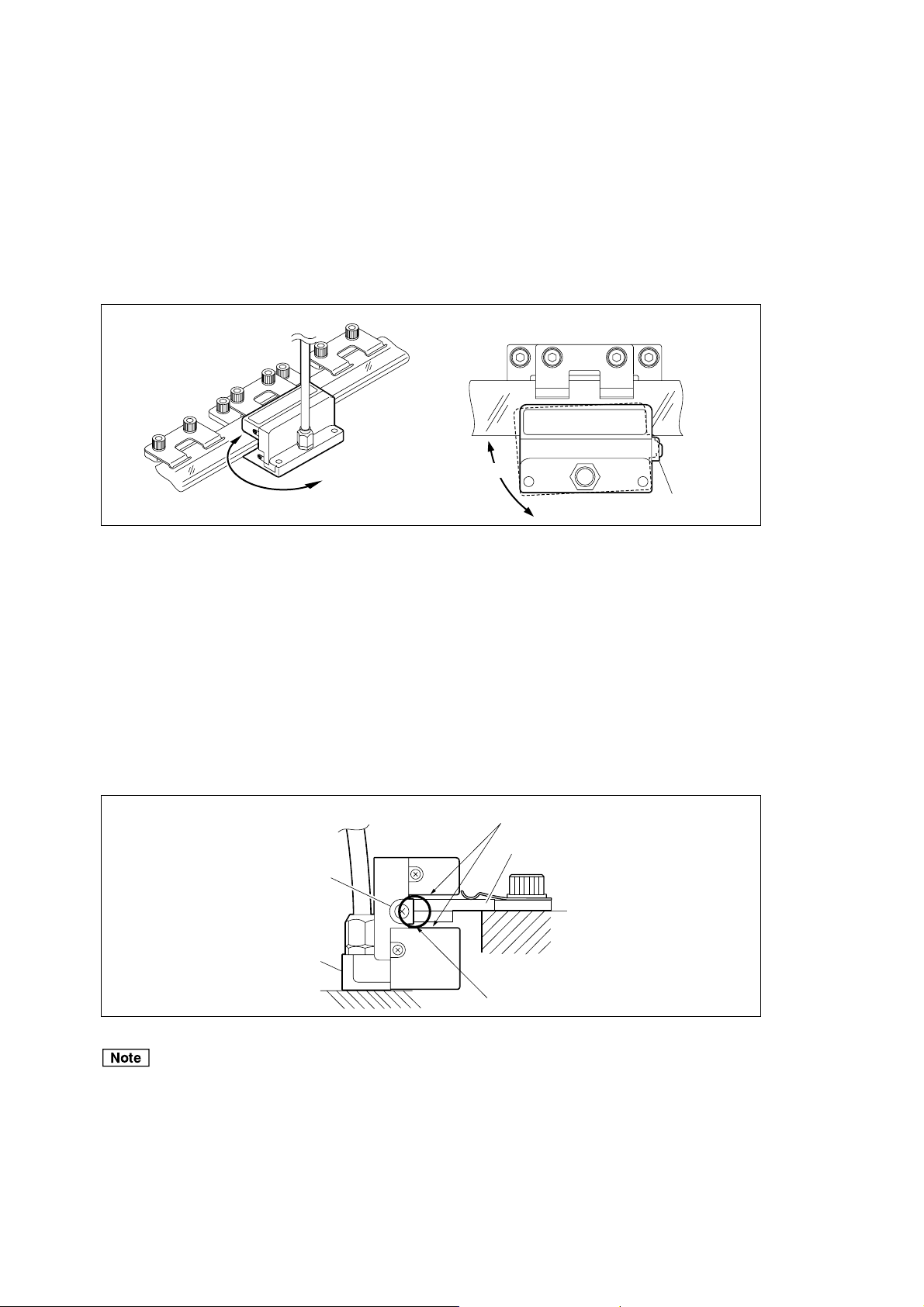

3-5-2. Azimuth Adjustment

The direction shown in the figure below is referred to as the azimuth direction. A stable output signal within

the range of the specified values can be obtained by adjusting the detector head direction.

<Specified values>

A/B signal output type ...... Output format F : Amplitude 0.7 Vp-p to 1.3 Vp-p

Output format G : Amplitude 0.8 Vp-p to 1.2 Vp-p

Analog output type ........... Output format H : Amplitude 0.6 Vp-p to 1.1 Vp-p

Azimuth direction

Azimuth direction

Fig. 3-15

Stopper

1 Loosen the detector head mounting screws, and then bring the stopper directly against the scale bottom

surface.

2 Rotate the detector head about the stopper in the azimuth direction as shown in Fig. 3-15 to find the

location where the Lissajous’ figure has the maximum amplitude.

3 Alternately tighten the two detector head mounting screws little by little at the detector head position

with the maximum amplitude of the Lissajous’ figure. (Fastening torque: 1.4 N · m)

4 Check that there is no interference between the scale and detector head.

Check for interference

Scale

Stopper

Detector head

Bring directly against

Fig. 3-16

Do not move the machine device with the stopper attached to detector head because this may result in

breakage of the detector head or the scale.

BL57-RE

(E) 3-11

5 Remove the stopper from the detector head.

Do not move the machine device with

the stopper attached to detector

head because this may result in

breakage of the detector head or the

scale.

Stopper

Fig. 3-17

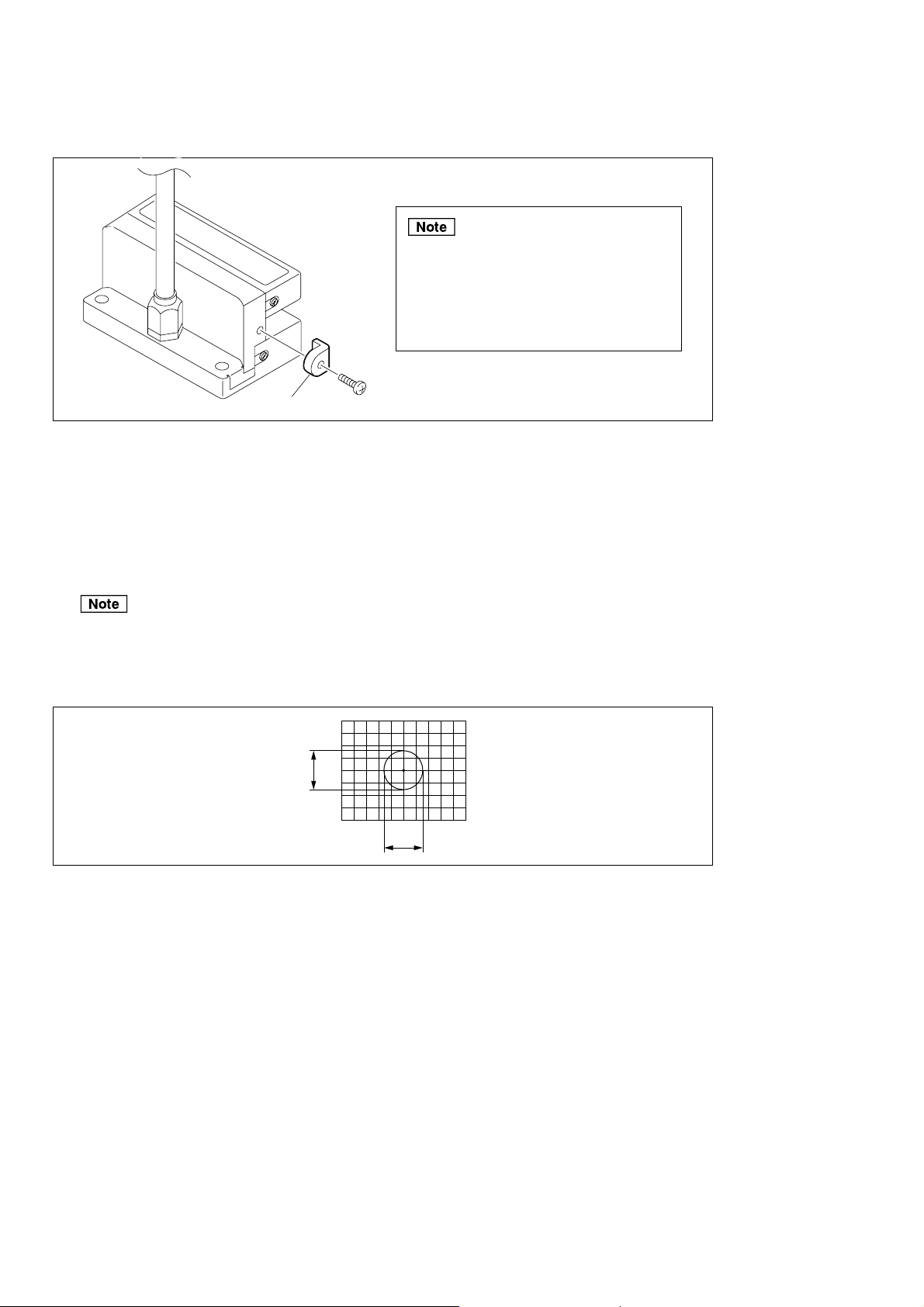

6 Move the scale, and make sure that the amplitudes A and B (see Fig. 3-18) of the Lissajous’ figure are

within the range of the specified values over the entire length.

<Specified values>

A/B signal output type ..... Output format F : Amplitude 0.7 Vp-p to 1.3 Vp-p

Output format G: Amplitude 0.8 Vp-p to 1.2 Vp-p

Analog output type........... Output format H: Amplitude 0.6 Vp-p to 1.1 Vp-p

The center of the Lissajous’ figure is 2.5 V.

If the output of 1 Vp-p cannot be obtained even through repeated adjustment, recheck the mounting

surface accuracy of the scale and detector head (refer to pages 3-3 to 3-4), and check again that there is

no dirt on the scale’s surface.

Lissajous

A

B

Fig. 3-18

3-12 (E)

BL57-RE

3-6. Completion of Mounting and Adjustment

• Secure the cable with the supplied cable clamp and pan-head screw (M4 × 8).

• Before using the scale to perform measurements, allow the scale to set for about three hours after mount-

ing so that the secured parts can stabilize and the ambient temperature around the scale can stabilize.

Pan-head screw

(M4

×

Cable clamp

Scale

8)

Fig. 3-19

BL57-RE

(E) 3-13

3-14 (E)

BL57-RE

4. Interface Unit

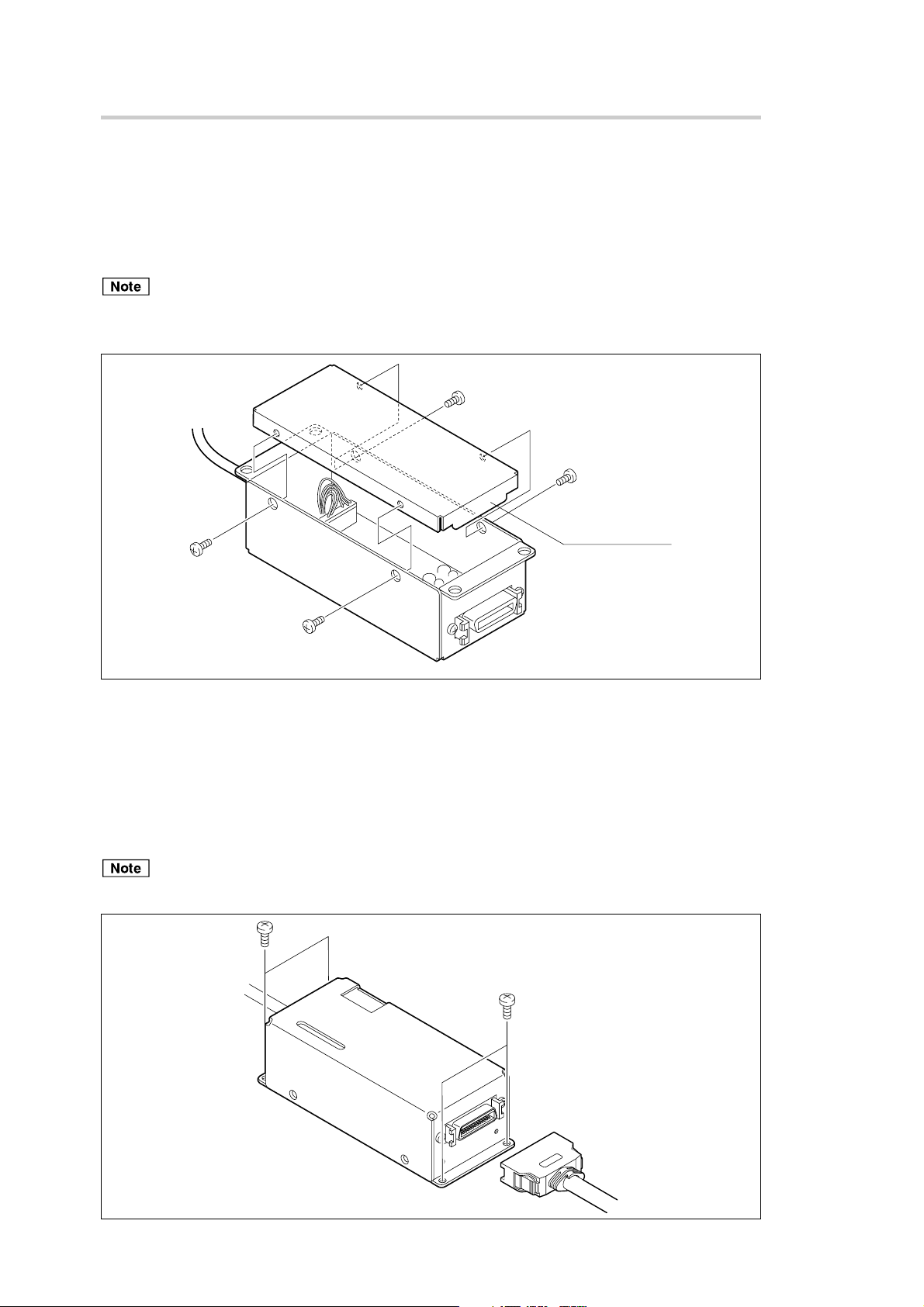

4-1. Removing and Attaching the Interface Unit Cover

To set or check the functions, remove the four screws, and then take off the interface unit cover.

When attaching the interface unit cover, place the cover so that the protruding surface is on the connector

side, and then retighten the removed screws in their original positions.

Tightening torque ......... 0.3 N · m

• Be careful not to lose the screws when you remove them.

• When attaching the interface unit cover, be sure that the protruding surface is on the connector side.

Protruding surface

Fig. 4-1

4-2. Installing the Interface Unit

Use the supplied screws to secure and attach the interface unit.

Firmly screw in the output connector.

Screw/Tightening torque ... M2.6 × 5: 4 pcs. / 0.8 N · m

Do not insert or remove the output connector while power is supplied to the interface unit.

BL57-RE

Fig. 4-2

(E) 4-1

5V

Magnescale Co

., Ltd.

CT COCO

ES WIWI

TH

21

CFR

J

BLE

OF

E.

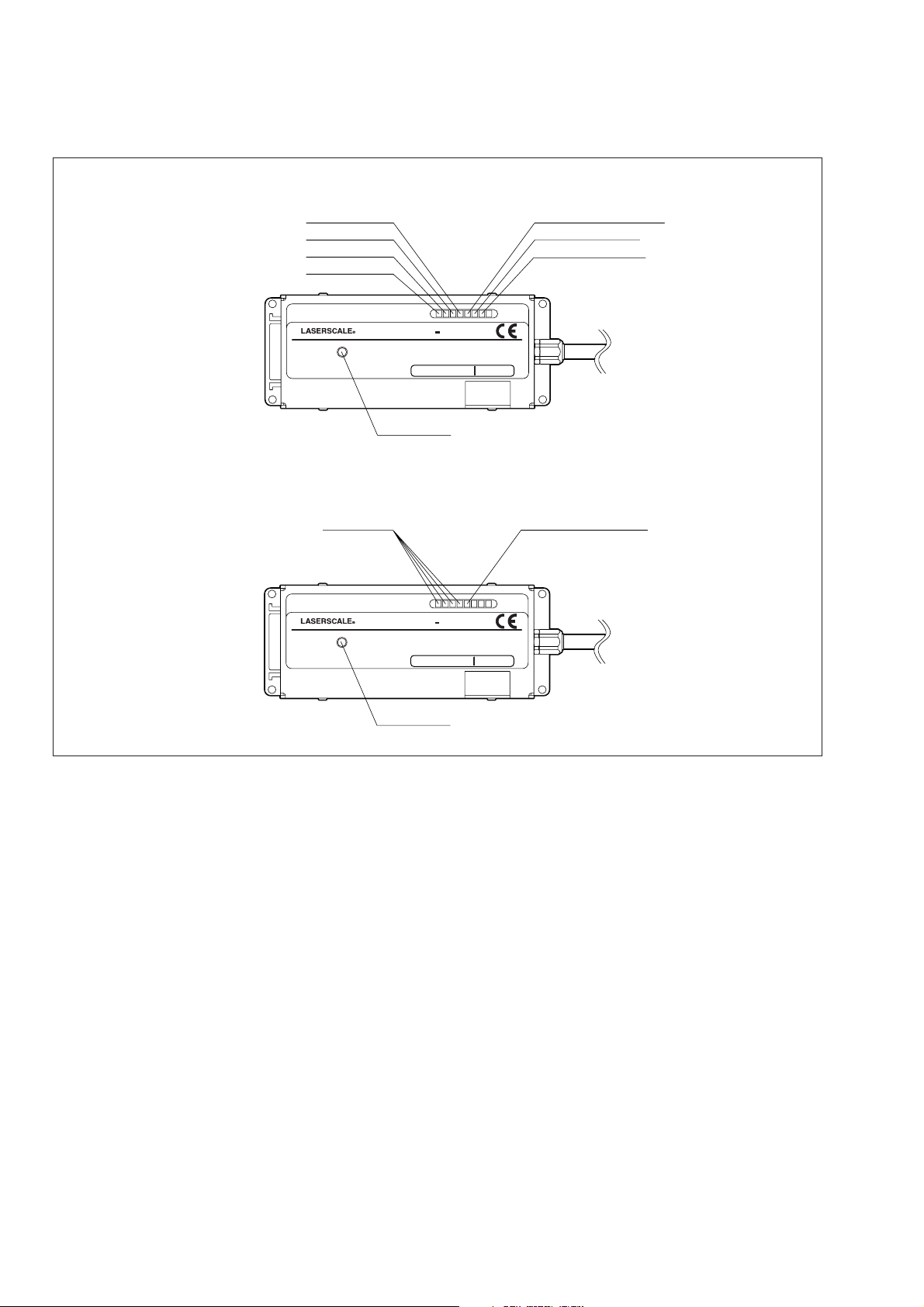

4-3. Names of LEDs

5V

Magnescale Co

., Ltd.

CT COCO

ES WIWI

TH

21

CFR

J

BLE

OF

E.

A/B signal output type: Output format F and G

Analog output type: Output format H

POS. lamp 1

POS. lamp 2

POS. lamp 3

POS. lamp 4

Magnescale Co

., Ltd.

POS. lamp

Magnescale Co

., Ltd.

CERTITIF I CAT IOION

MP L I ES

PR ODU CT

AP P L I CACABLE

J

POPOWER R SUSUPP LY : DC

Powe r lamp

CERTITIF I CAT ION

PR ODU CT

MP L I ES

AP P L I CACABLE

J

POPOWER R SUSUPP LY : DC

BL57

TH

AT T DA T E E OF

+

5V

BL57

TH

AT T DA T E E OF

+

5V

DH HS S RULULES S 21

MA NU F AC T UR E.

DH HS S RULULES S 21

MA NU F AC T UR E.

CFR

CFR

SU B CH APTPTER

MADADE E IN N JAPAPAN

Reference point lamp

SU B CH APTPTER

MADADE E IN N JAPAPAN

Reference point lamp

Level alarm lamp

Speed alarm lamp

Power lamp

Fig. 4-3

4-2 (E)

BL57-RE

Loading...

Loading...